Patents

Literature

31results about How to "Improve opening force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

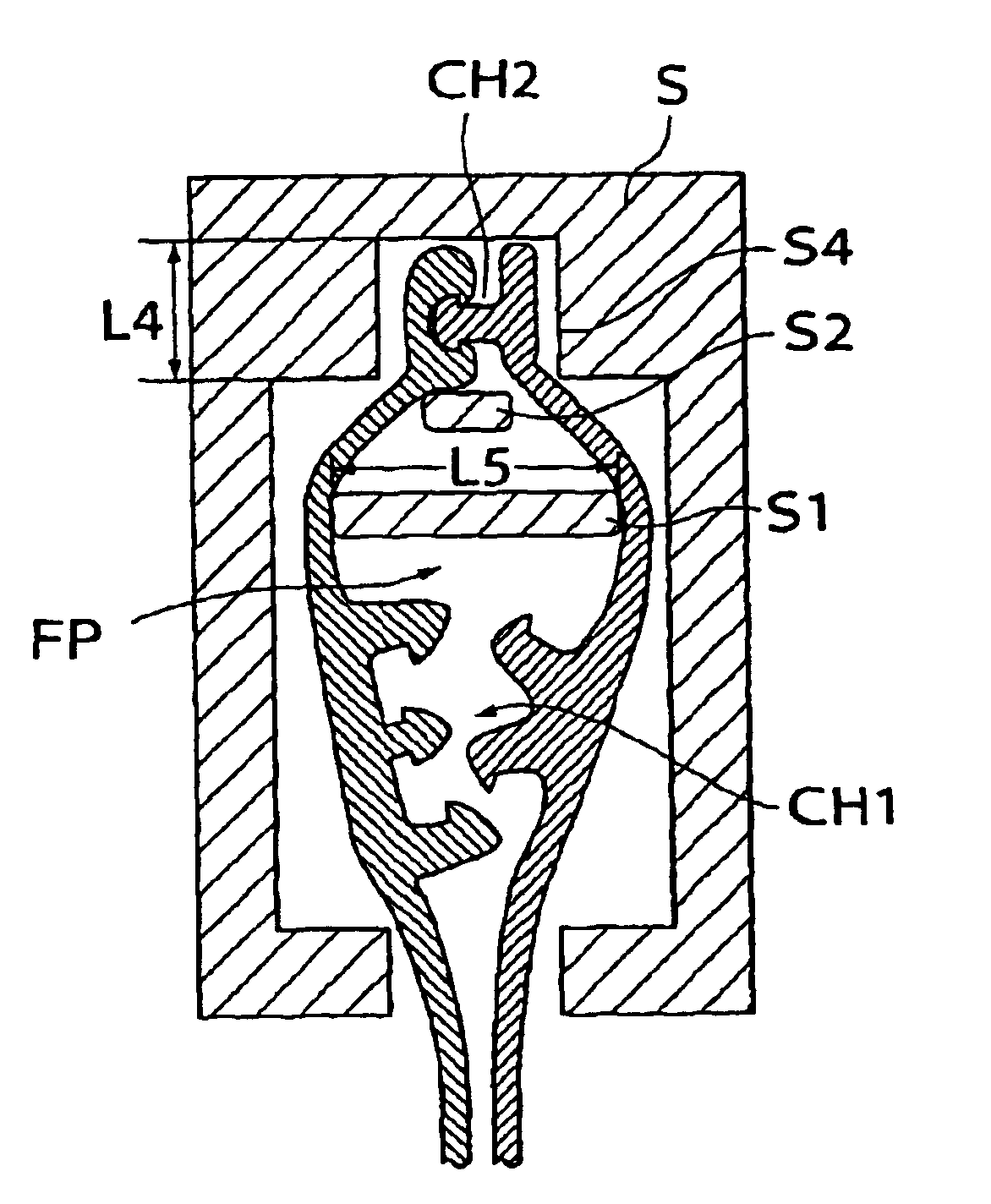

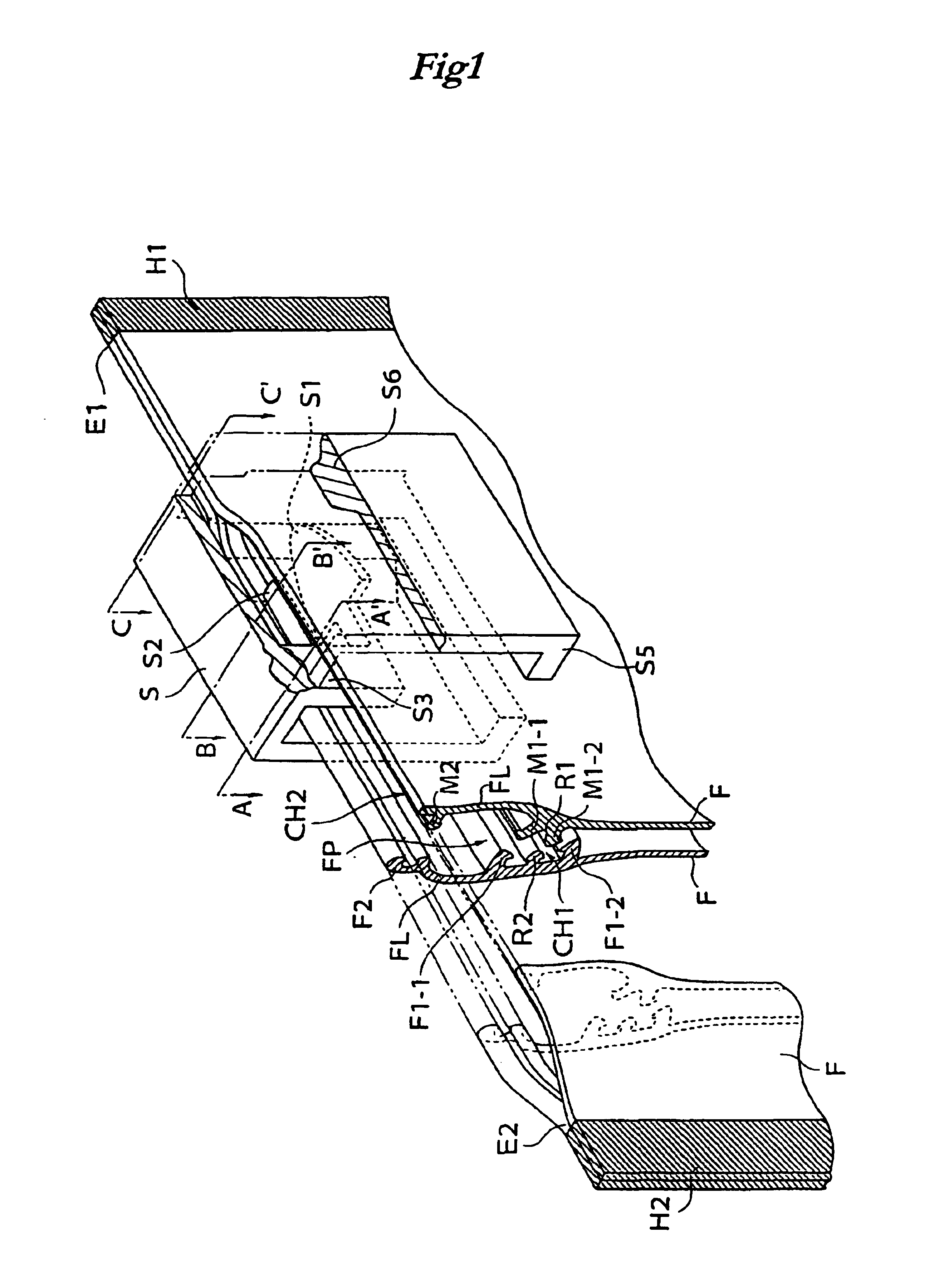

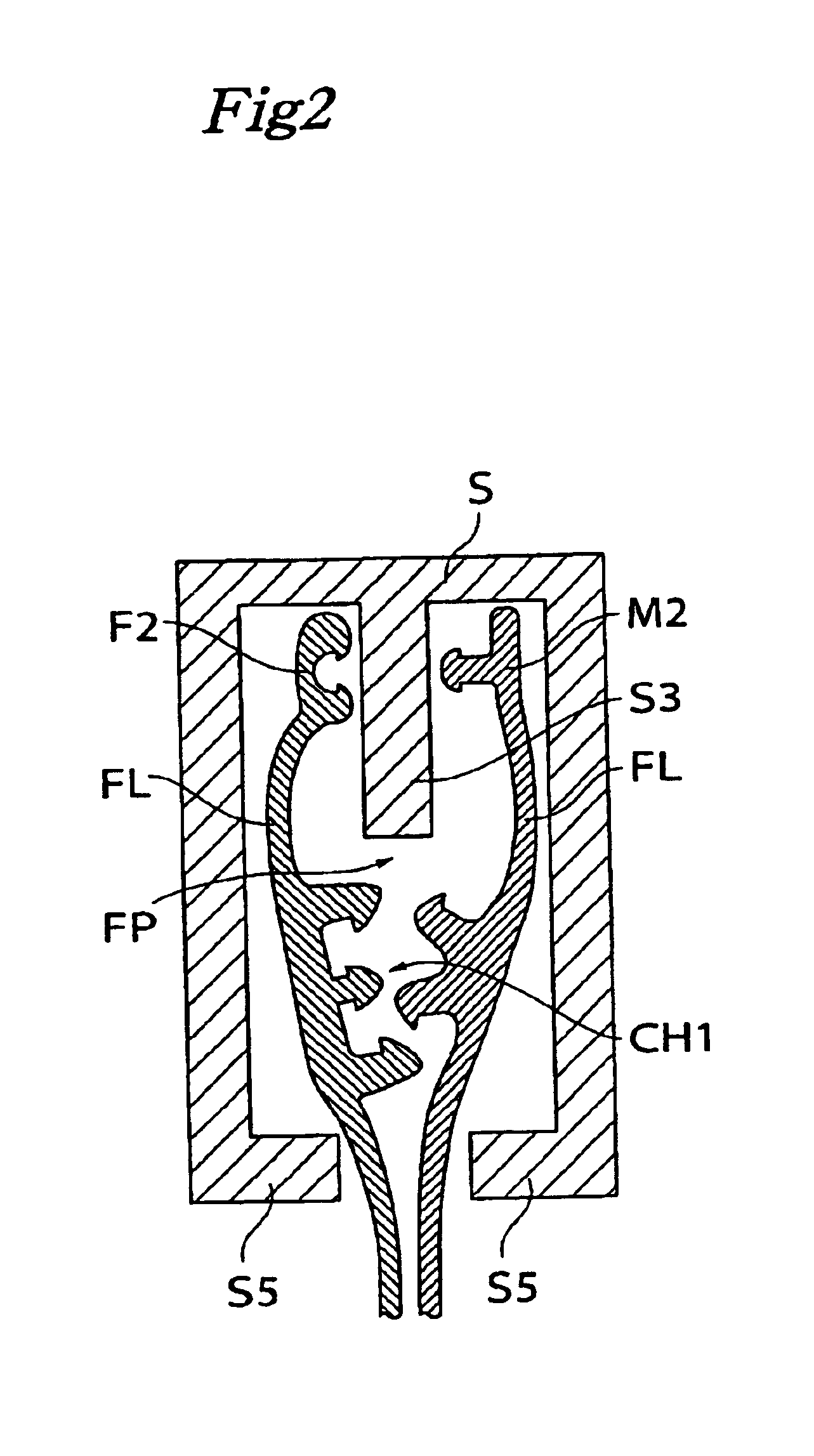

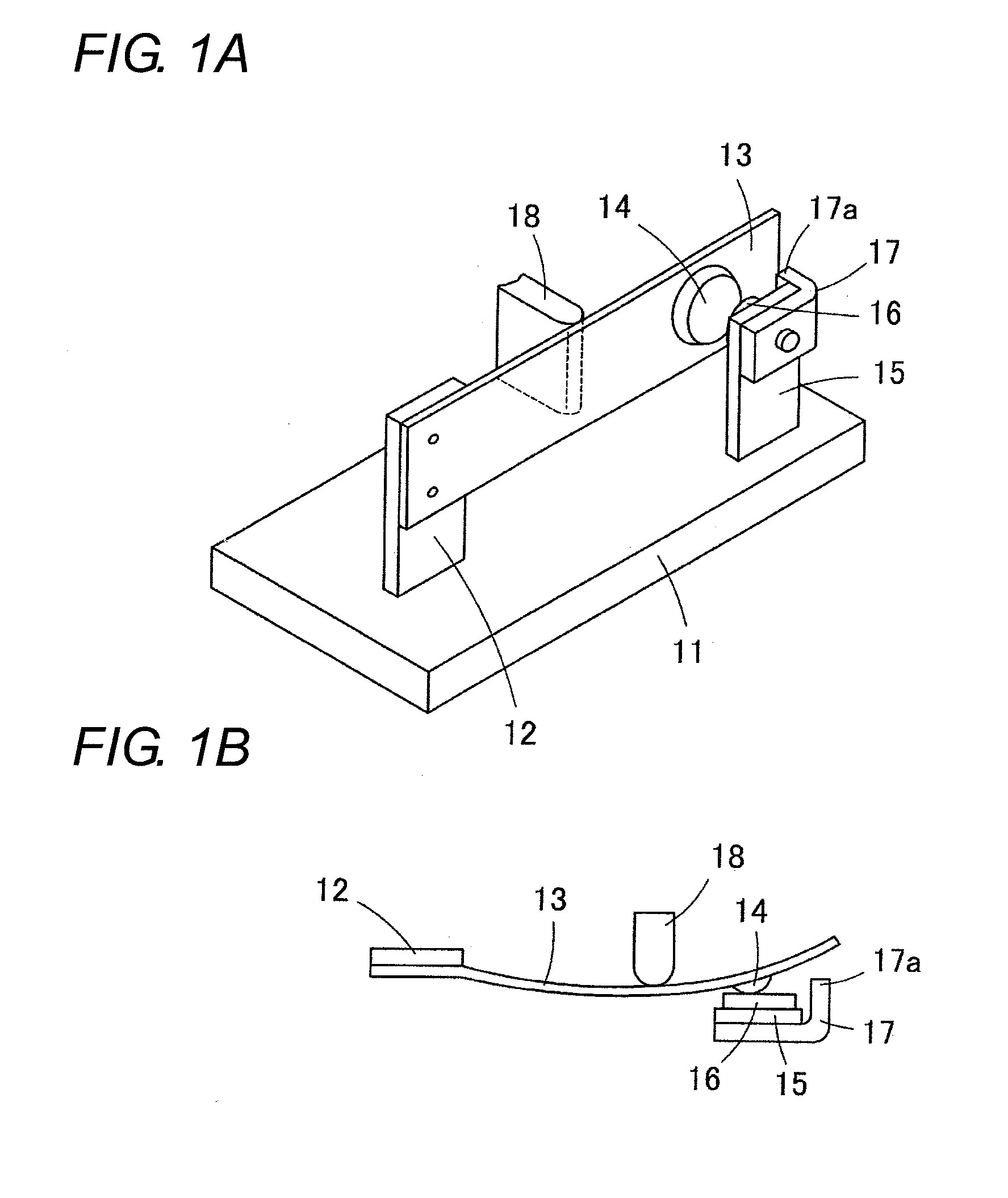

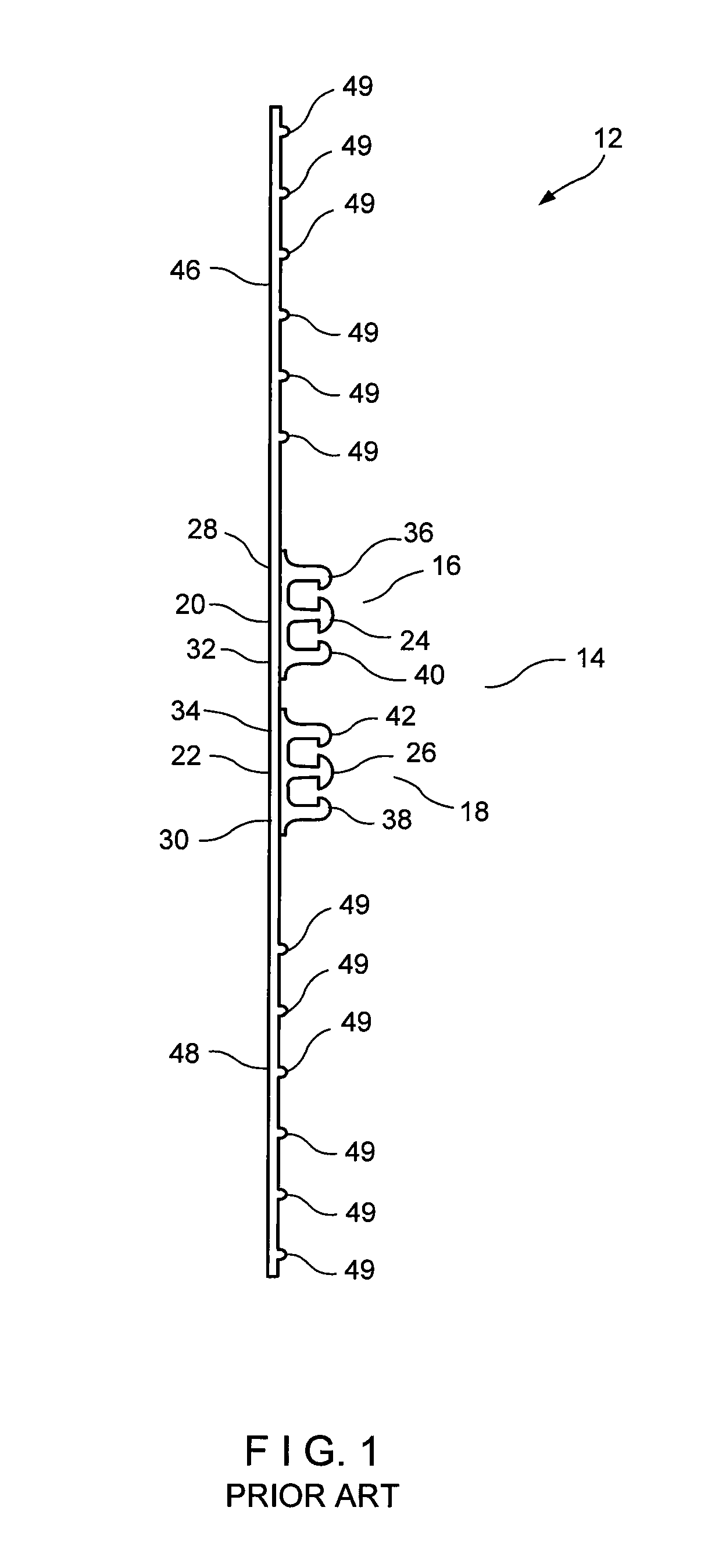

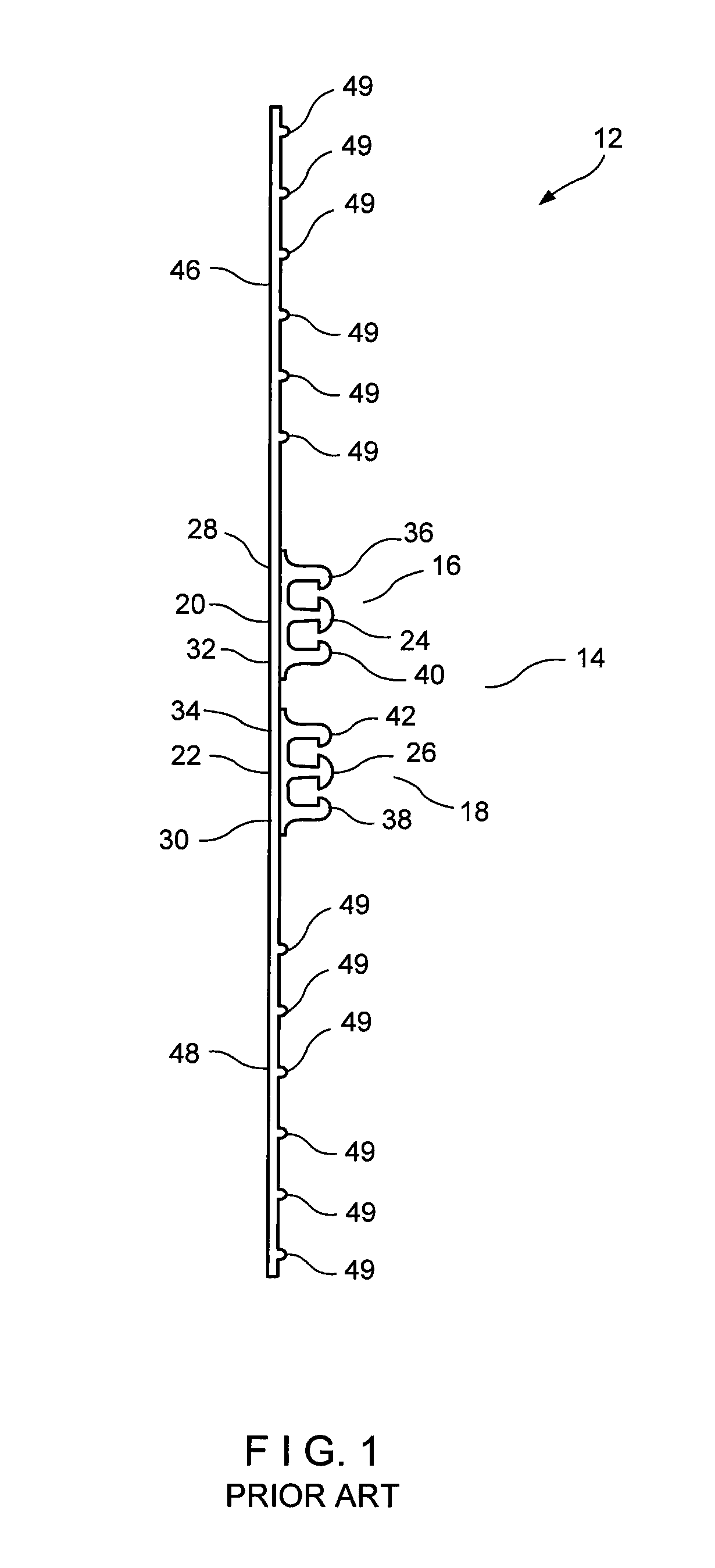

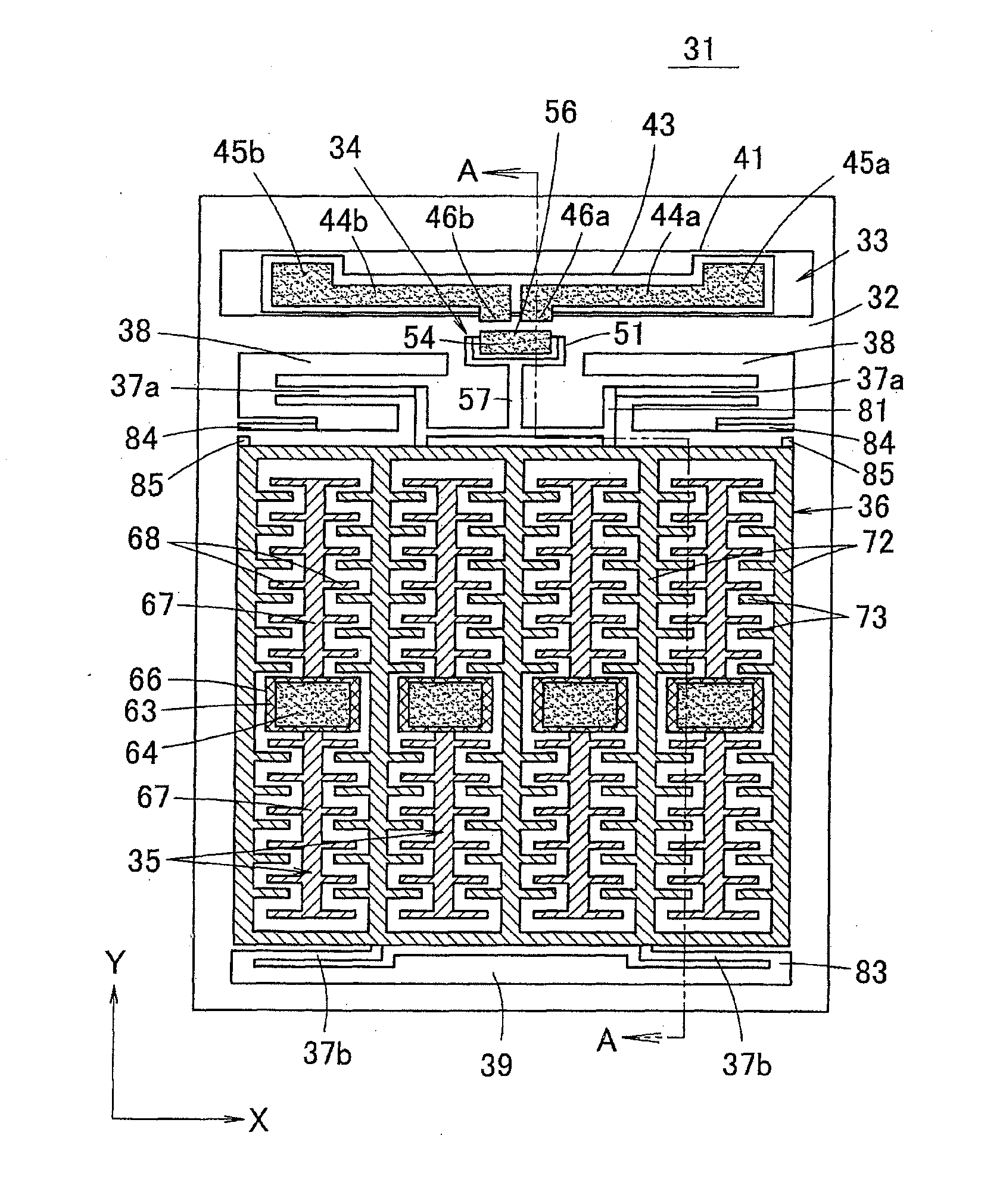

Plastic fastener with slider and bag body with plastic fastener

InactiveUS6915546B2Improve opening forceImpairing characteristicSnap fastenersSlide fastenersEngineeringFlange

A plastic zipper equipped with a slider, and a bag body equipped with the plastic zipper, the plastic zipper having a strong opening force despite its miniaturization. The hermetically sealing plastic zipper is equipped with a slider for opening and closing the zipper, and includes a pair of a male hook and a female hook, flanges on opening portion sides for each of the male and female hooks connectable at respective top end portions, and a wedged opening plate pressed into the inside of a closed plastic cylinder constituted of the connectable flange top end portions and extended to the zipper in an engaged state so that the zipper is firstly opened and after the zipper is opened, the top end portions of the flanges in a connected state are disconnected.

Owner:HIPACK

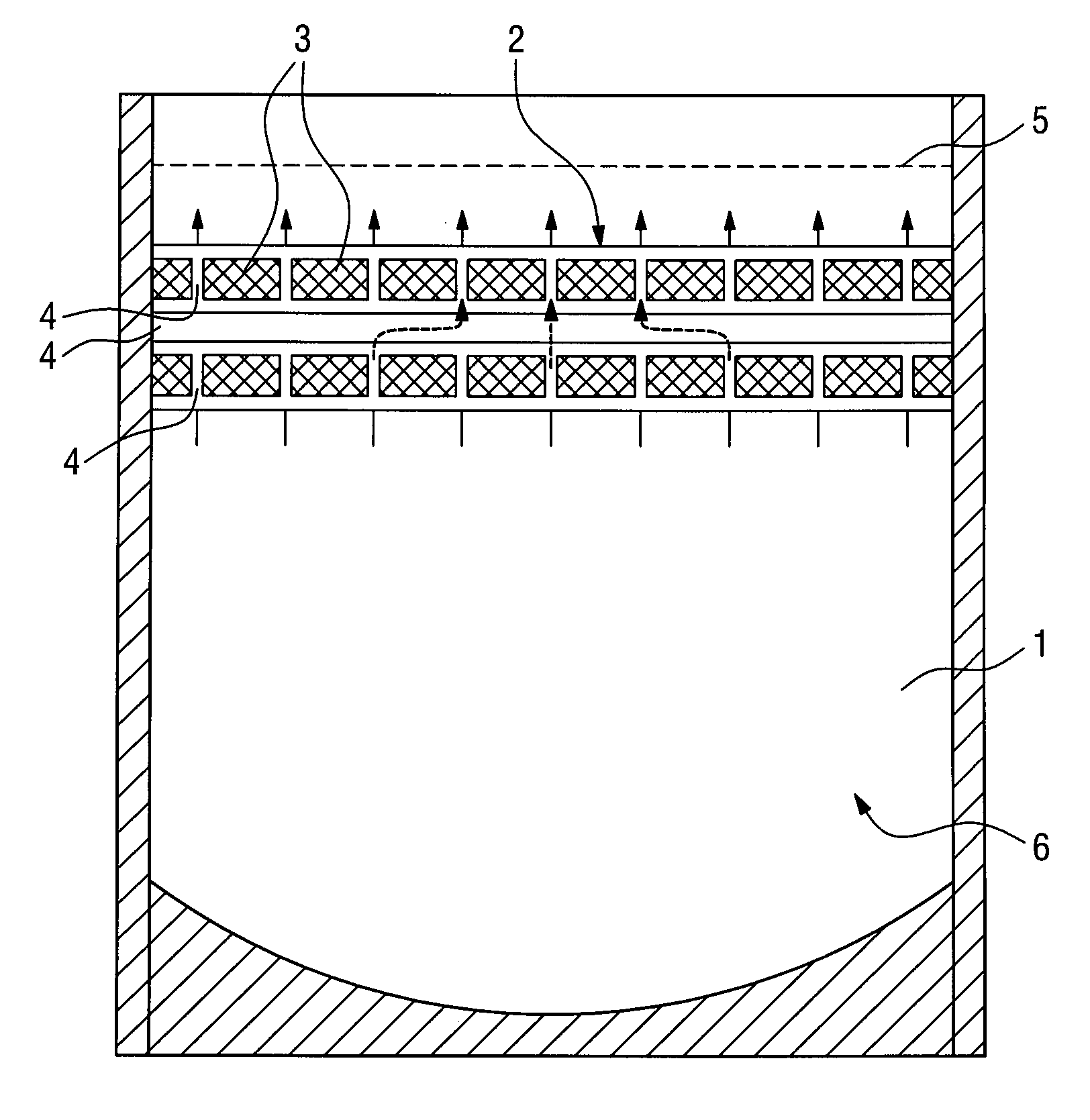

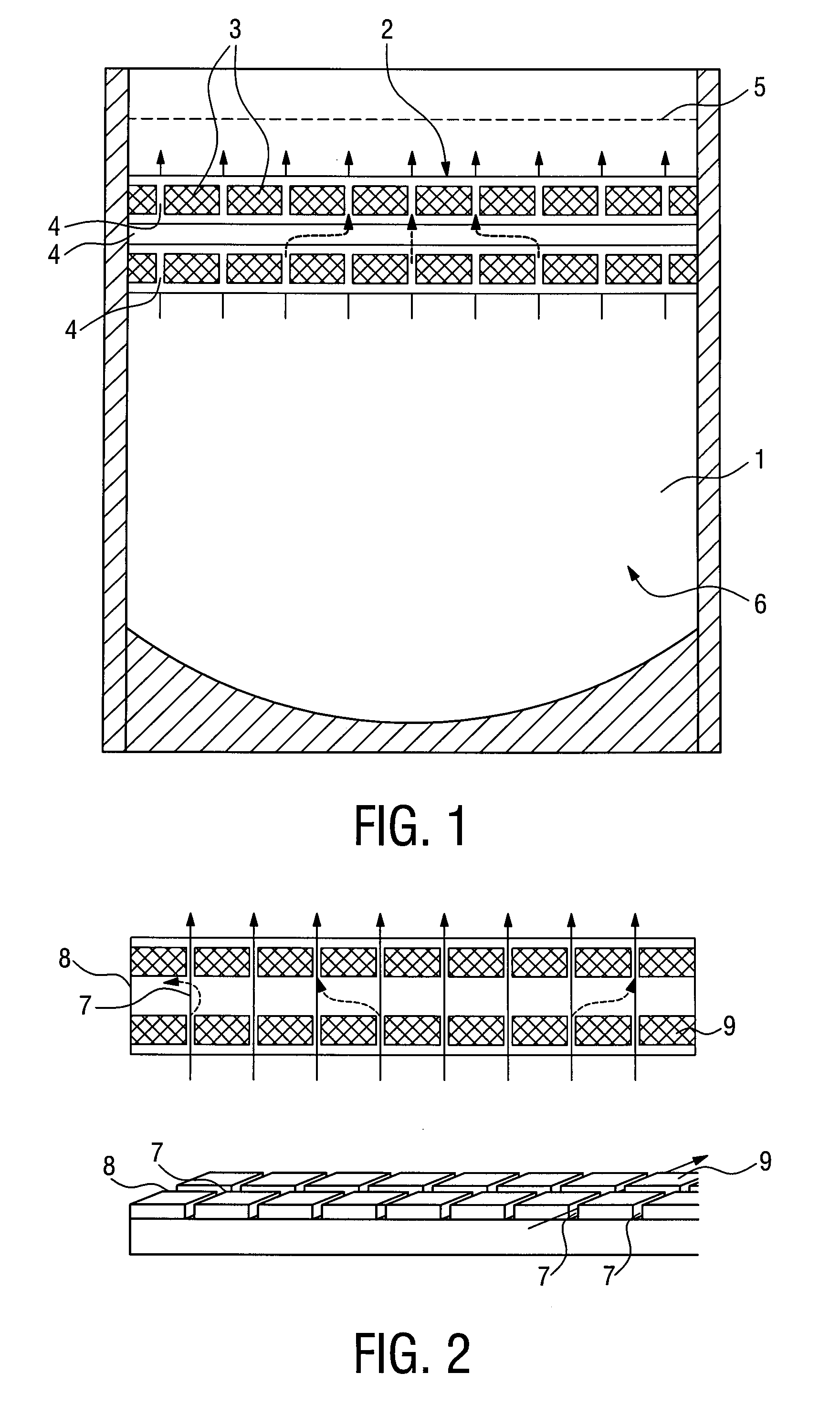

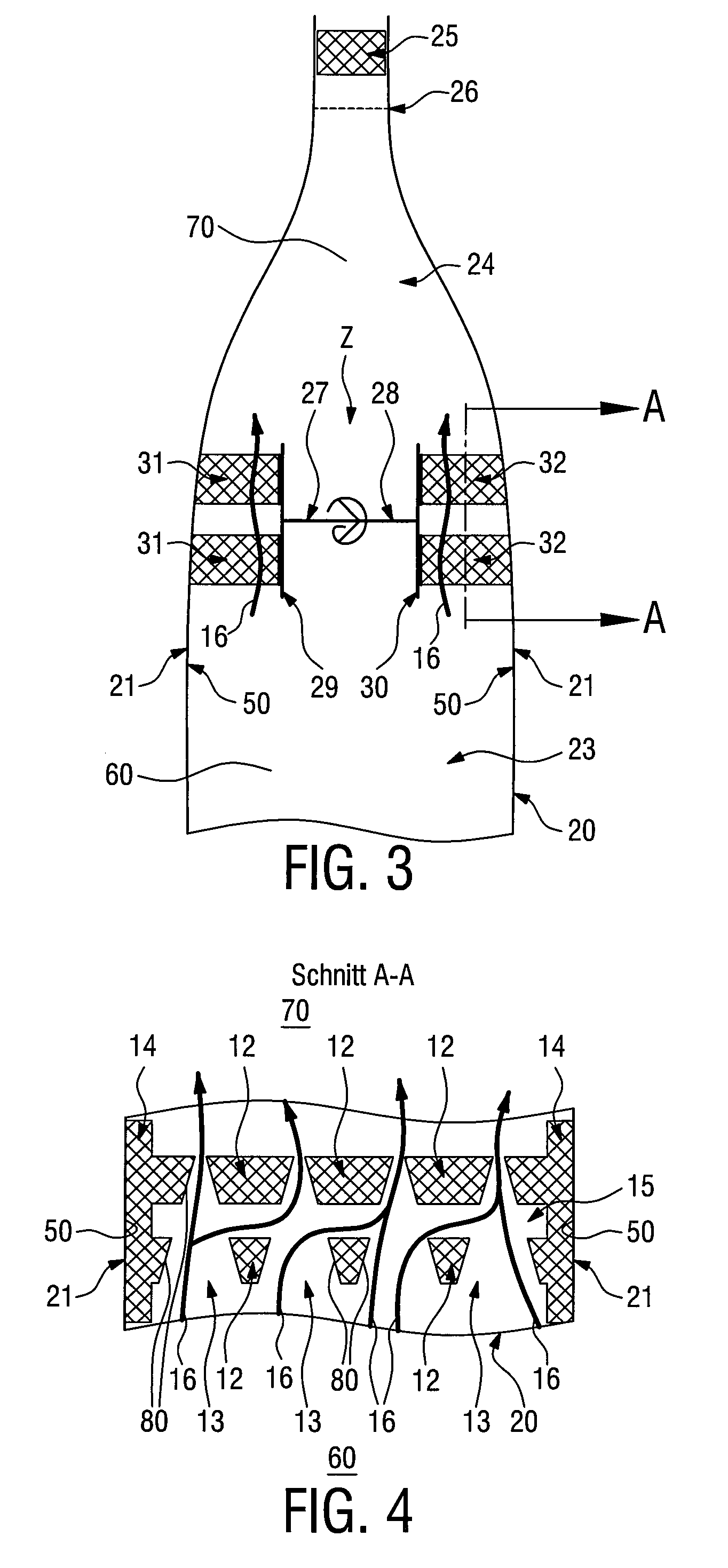

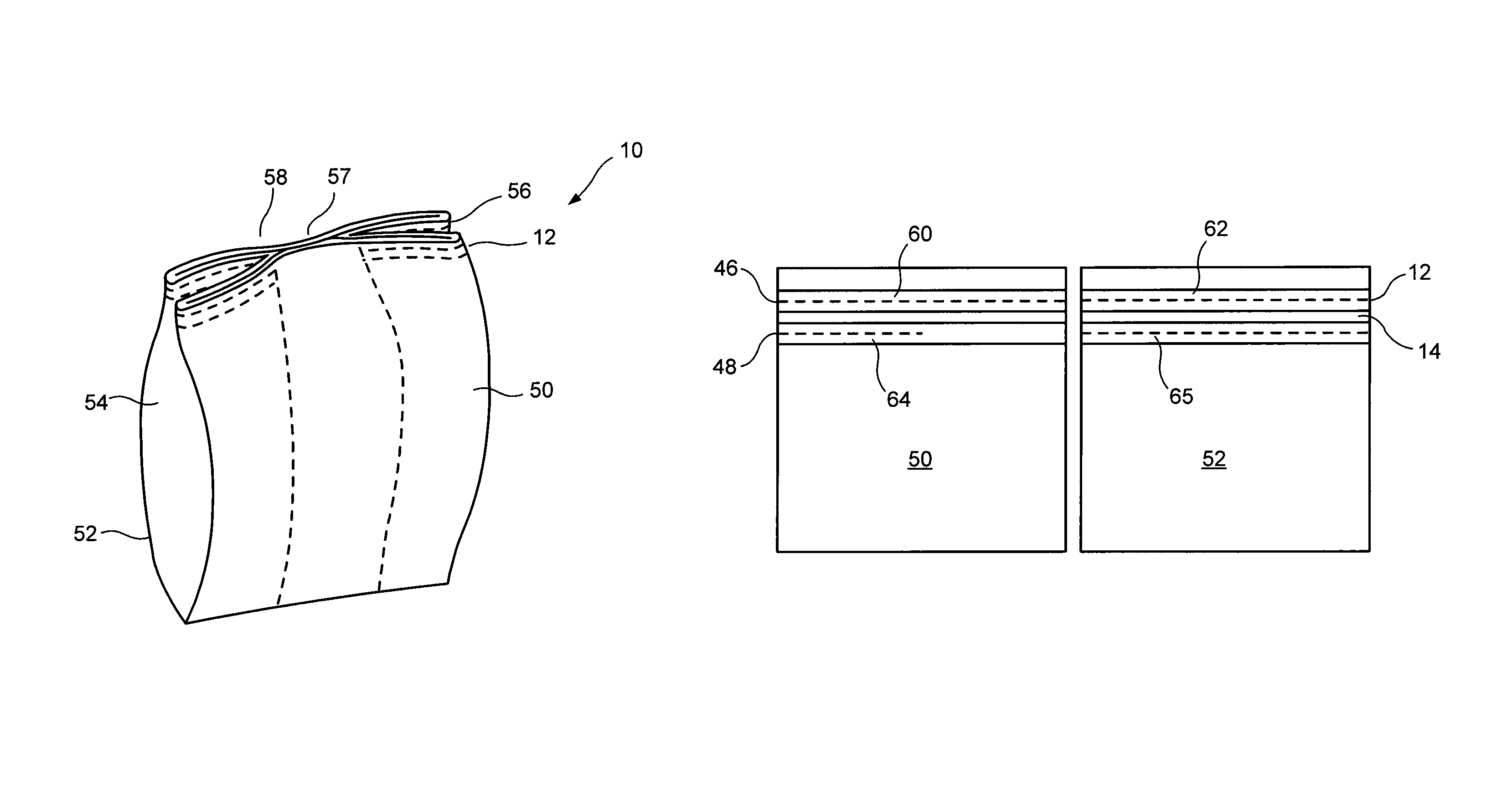

Microwavable bag with valve and method for the fabrication thereof

InactiveUS20110033134A1Strong toothed propertyHigh steam pressureEnvelopes/bags making machineryBagsEngineeringPlastic film

In a reclosable bag (20) a zipper (Z) is provided on the inner surfaces (50) of the plastic film and the two parts of the zipper (Z) are fixed on the opposite inner surfaces (50) of the bag (20), wherein the zipper (Z) is connected to the inner surface (50) of the plastic film in such a manner that between the welded regions (12, 14) between the zipper (Z) and the inner surface (50) of the plastic film, recesses (15, 13) are left free in the longitudinal direction of the zipper (Z) to form a seal-free longitudinal channel and in the transverse direction of the zipper (Z) to produce free air or steam passage openings at defined distances between the zipper (Z) and the inner surface (50), through which openings a passage of steam is possible, wherein ends of the openings facing the interior (60) of the bag (20) are larger than ends of the openings facing the exterior (70) of the bag (20).

Owner:MONDI GROUP

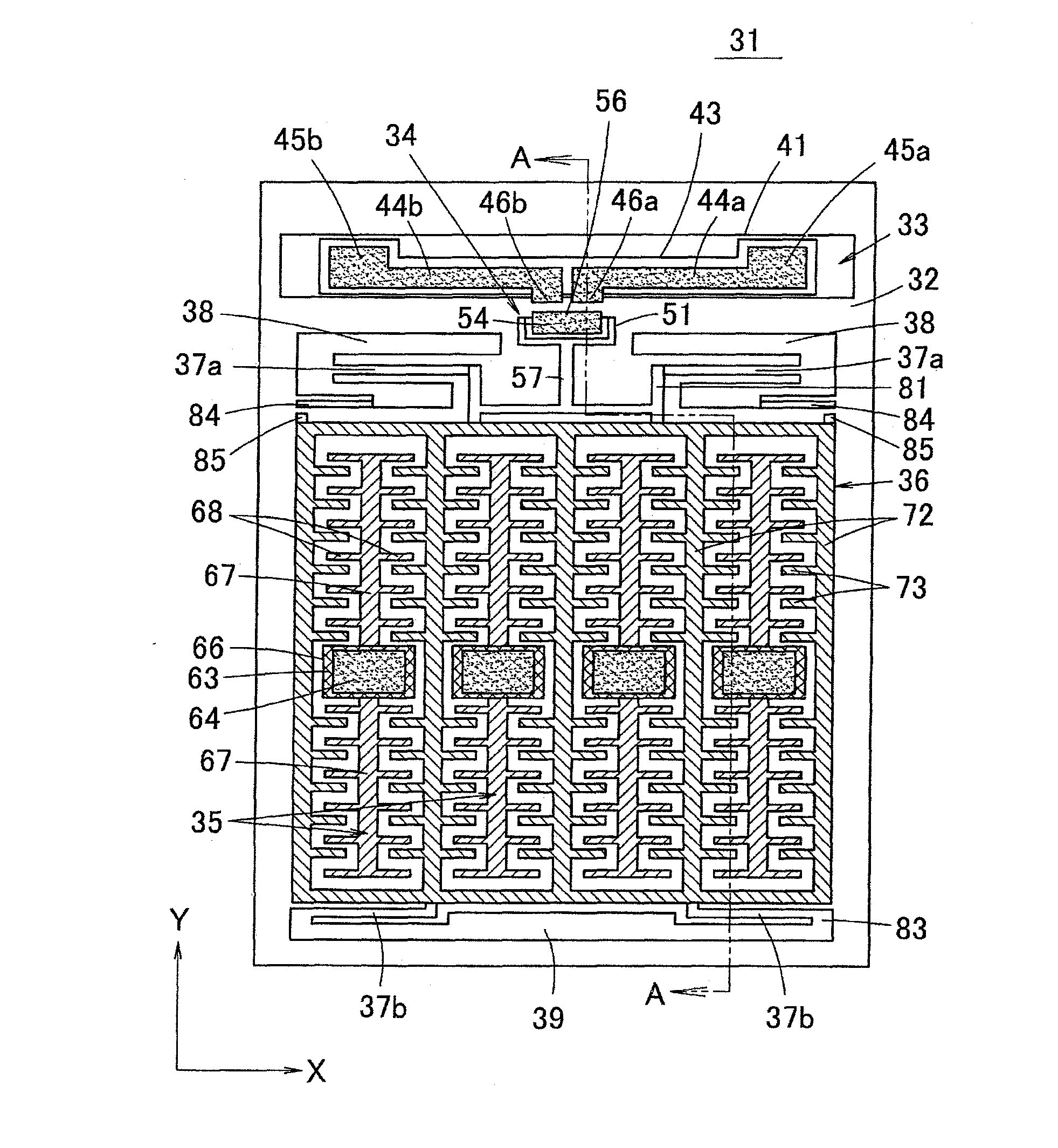

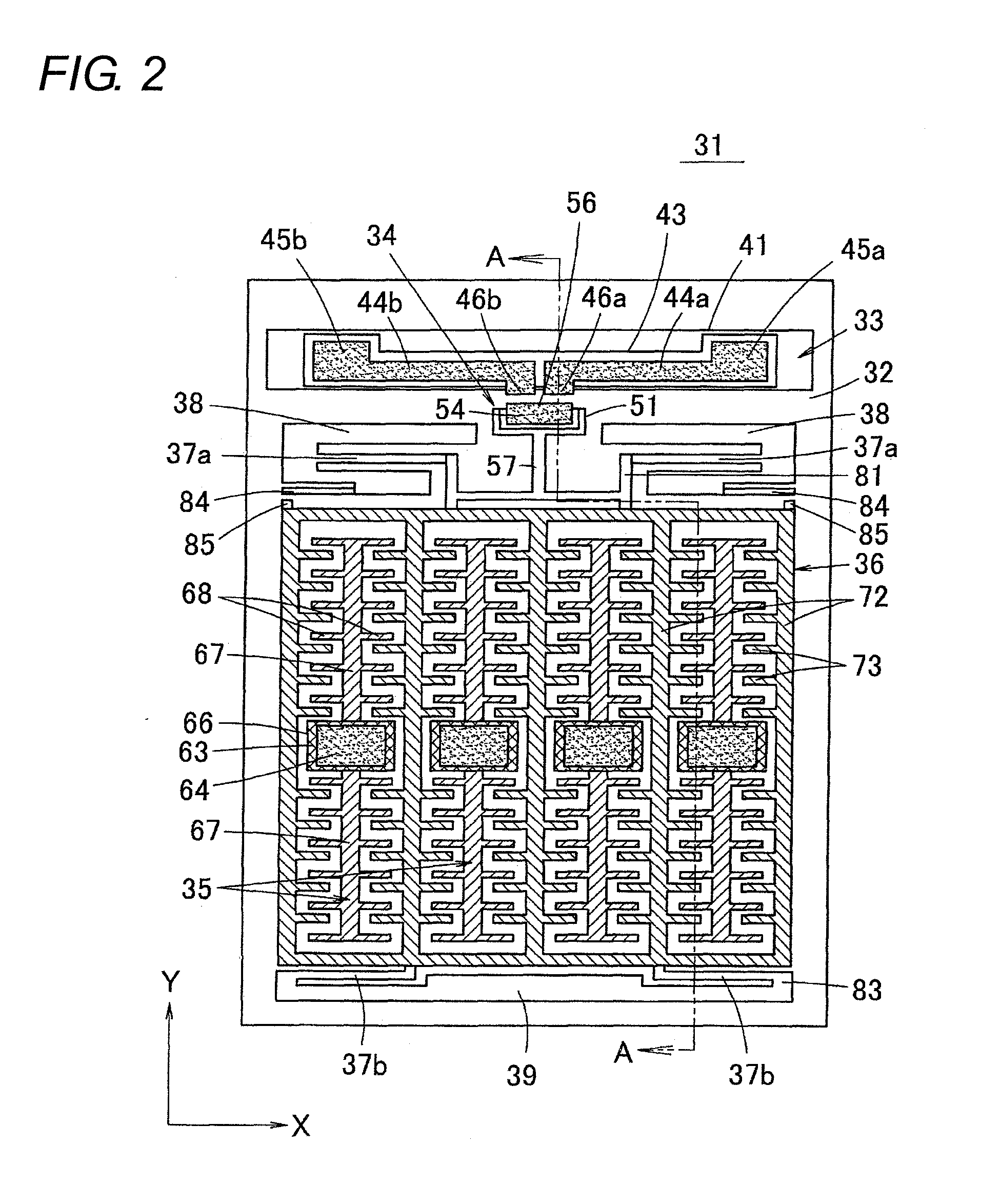

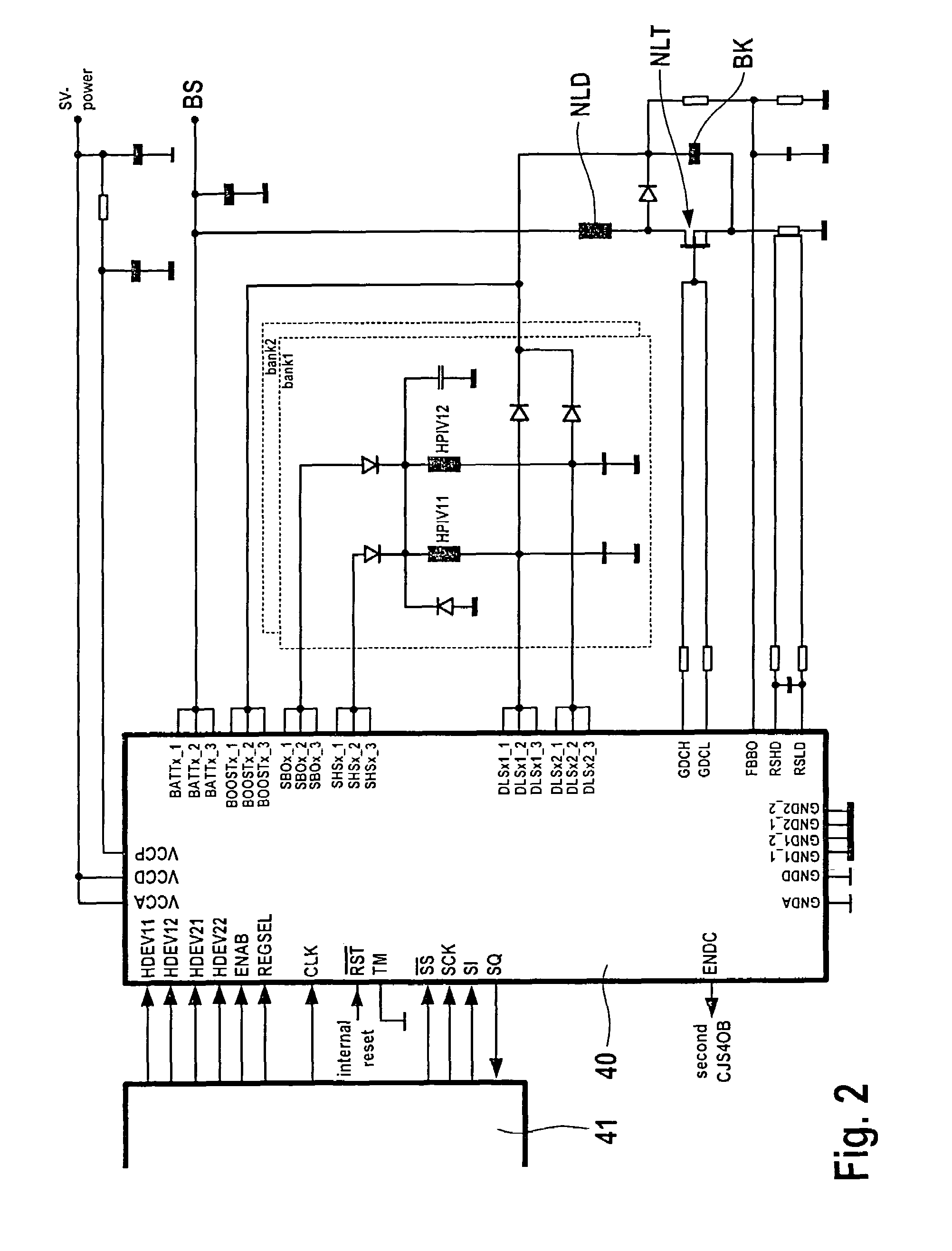

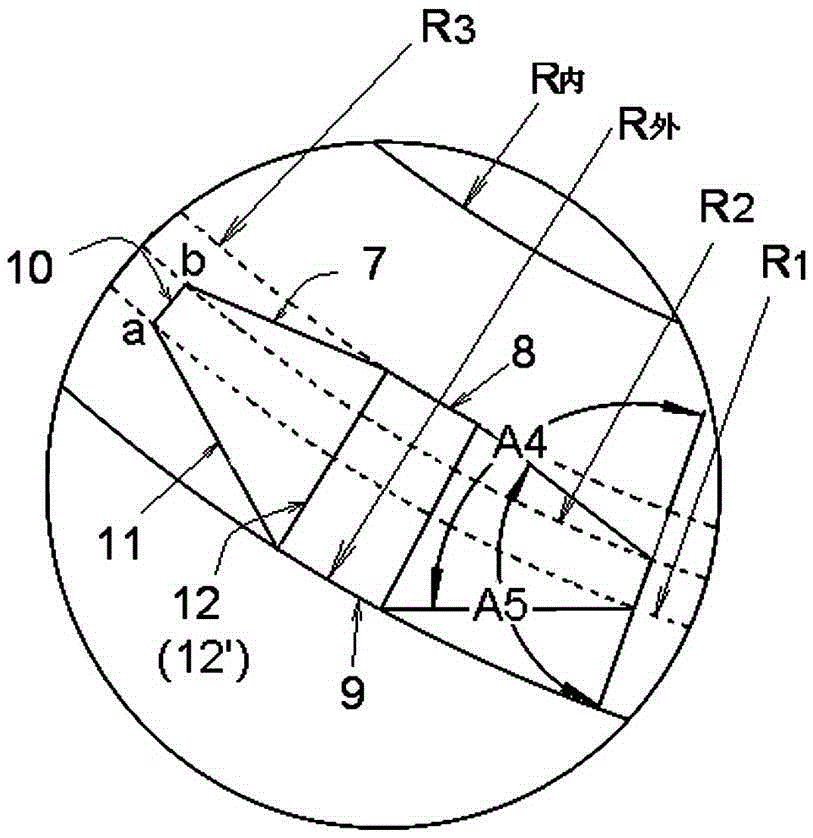

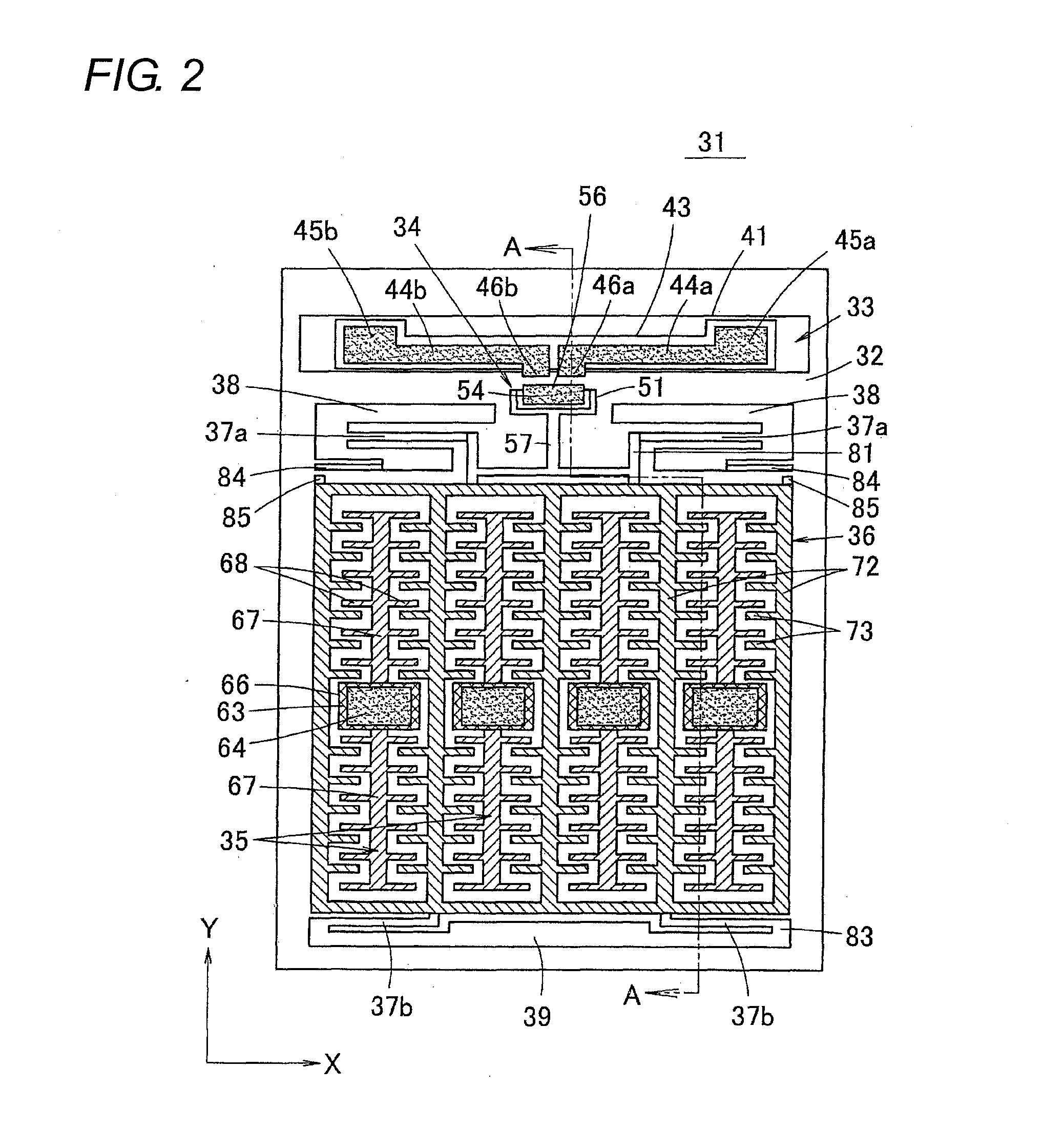

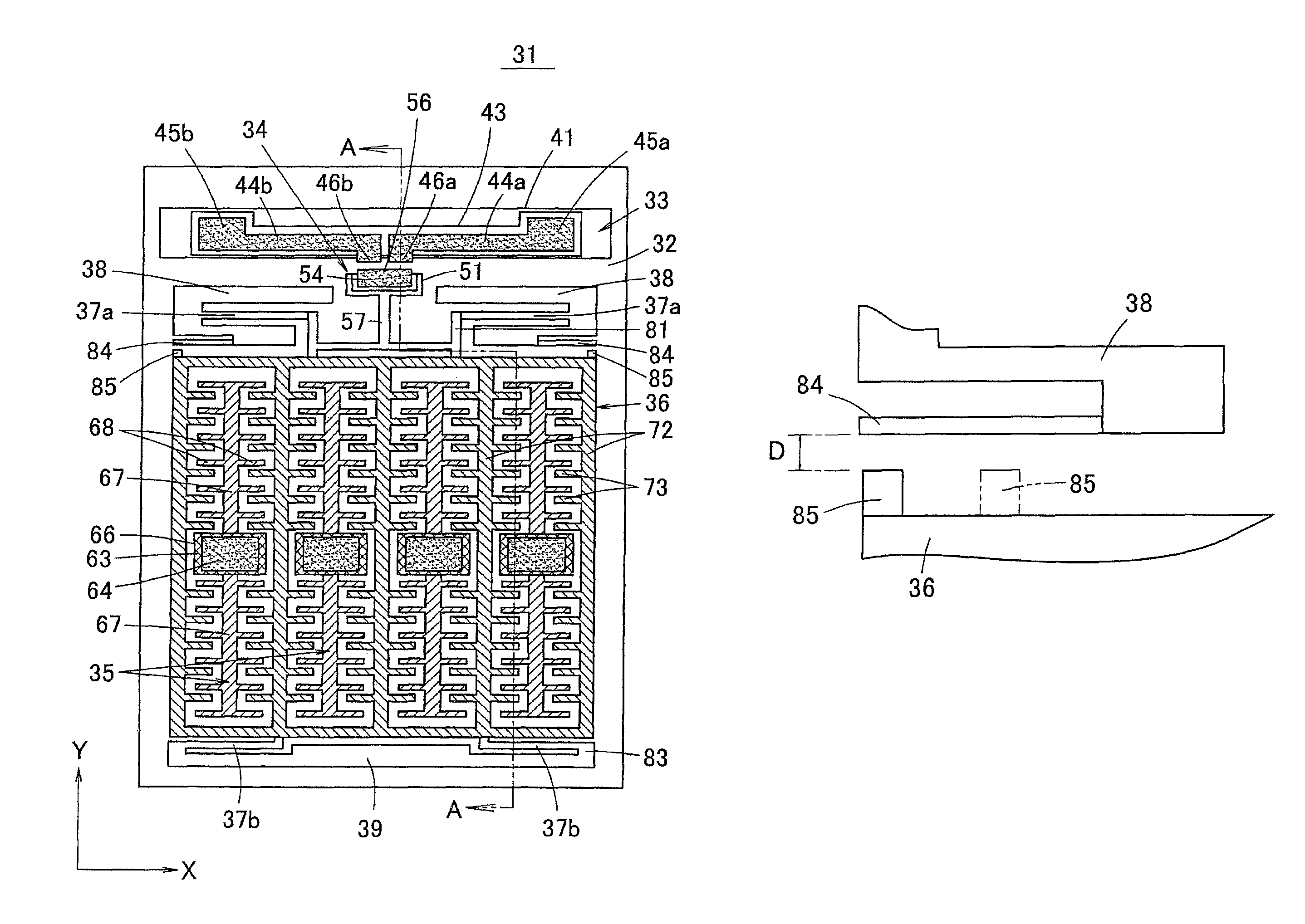

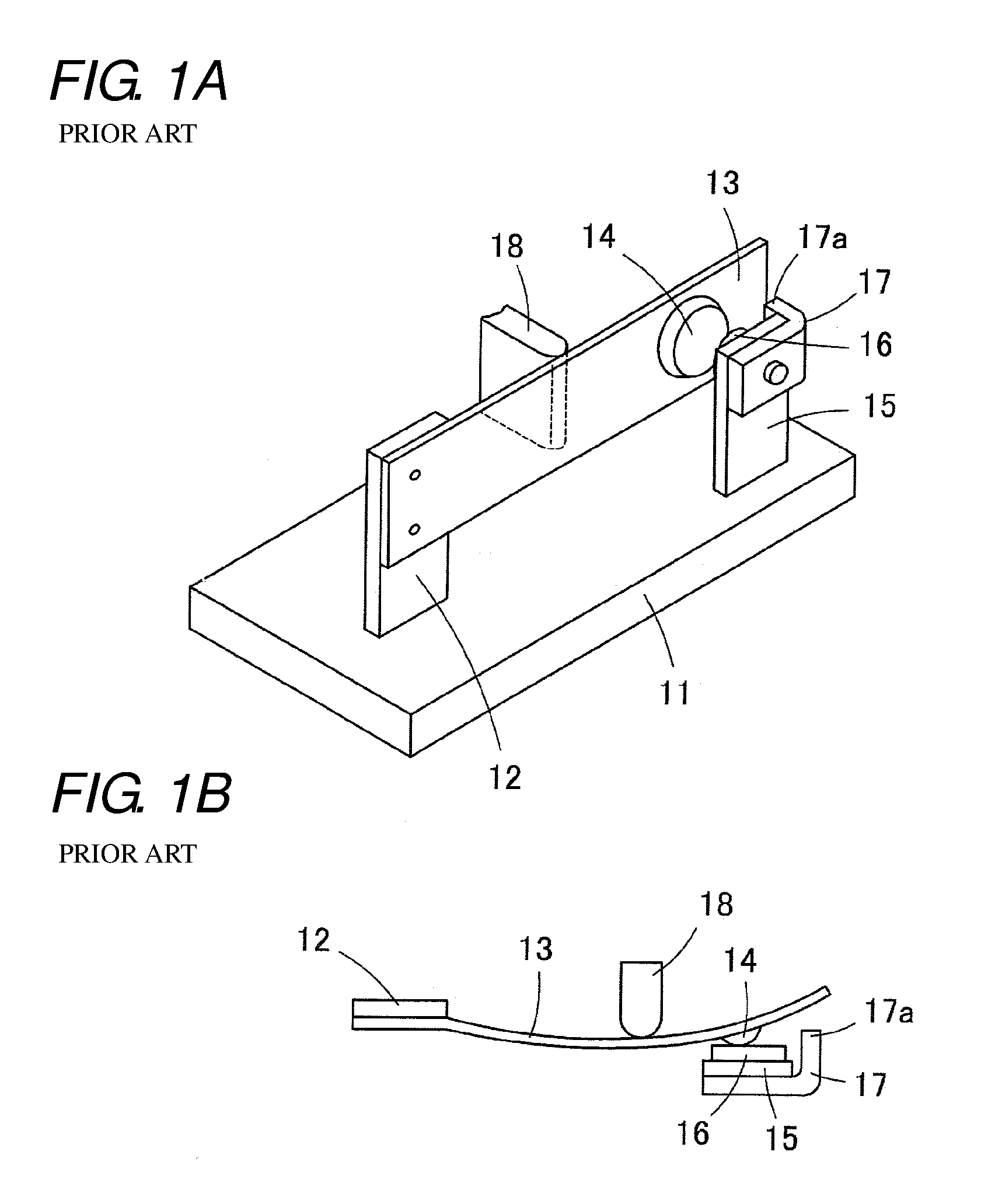

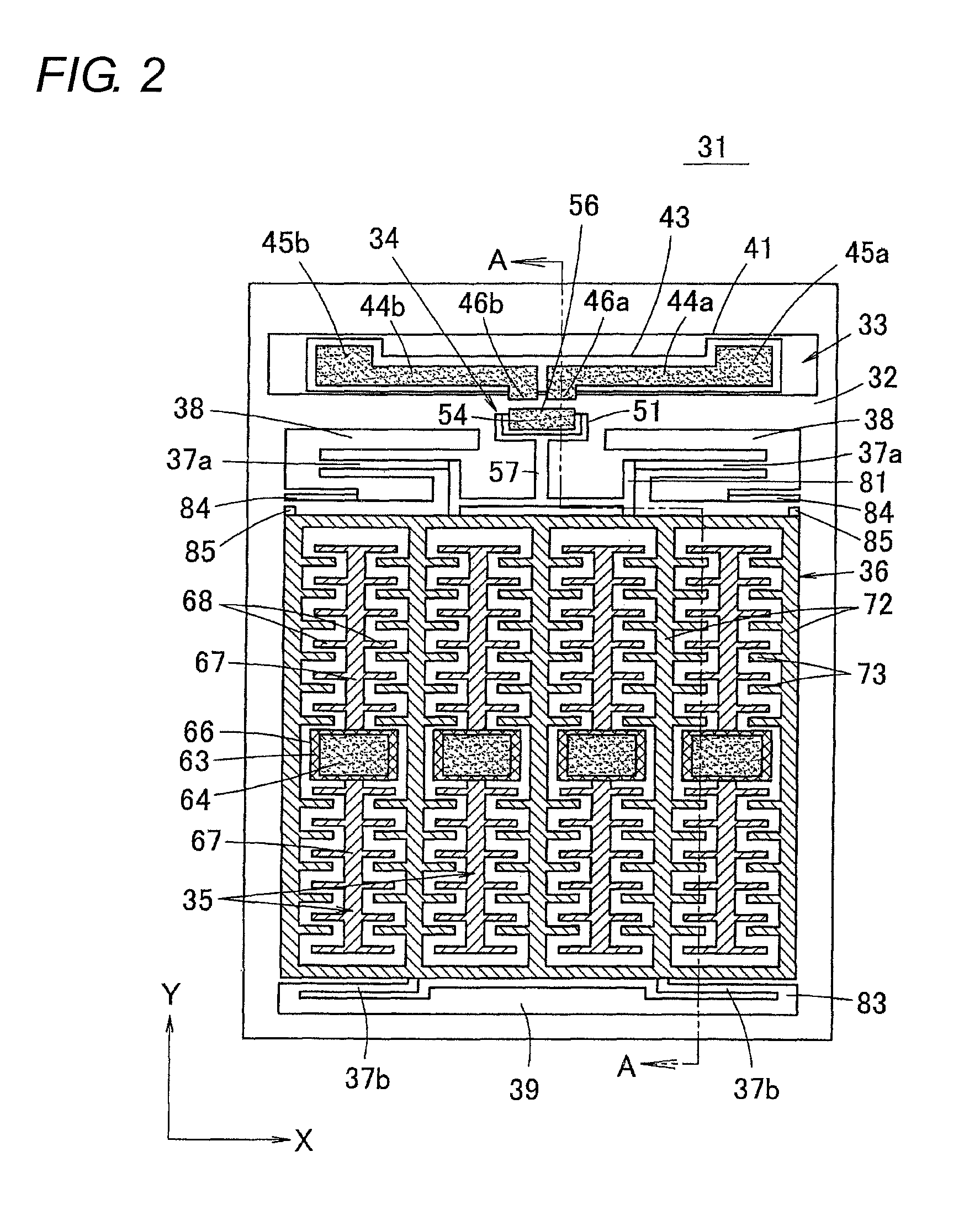

Electrostatic relay

InactiveUS20110220472A1Simple structureIncrease freedomEmergency actuatorsRelay terminal arrangementsElectrostatic actuatorEngineering

In an electrostatic relay in which a moving contact and a movable electrode are displaced in parallel with a base substrate, an opening force is increased when the movable electrode is separated from a fixed electrode, and a structure is simplified to enhance a degree of freedom of design. A fixed contact portion and a fixed electrode portion are fixed to the base substrate. The fixed electrode portion and a movable electrode portion constitute an electrostatic actuator that displaces the movable electrode portion and a moving contact portion. A movable spring provided in a spring supporting portion retains the movable electrode portion in a displaceable manner. A cantilever secondary spring is provided in the spring supporting portion, and a projection portion is provided in a front end face of the movable electrode portion. The secondary spring abuts on the projection portion while being not deformed until abutting on the projection portion, before the moving contact of the moving contact portion abuts on the fixed contact of the fixed contact portion when the moving contact portion and the movable electrode portion are displaced.

Owner:ORMON CORP

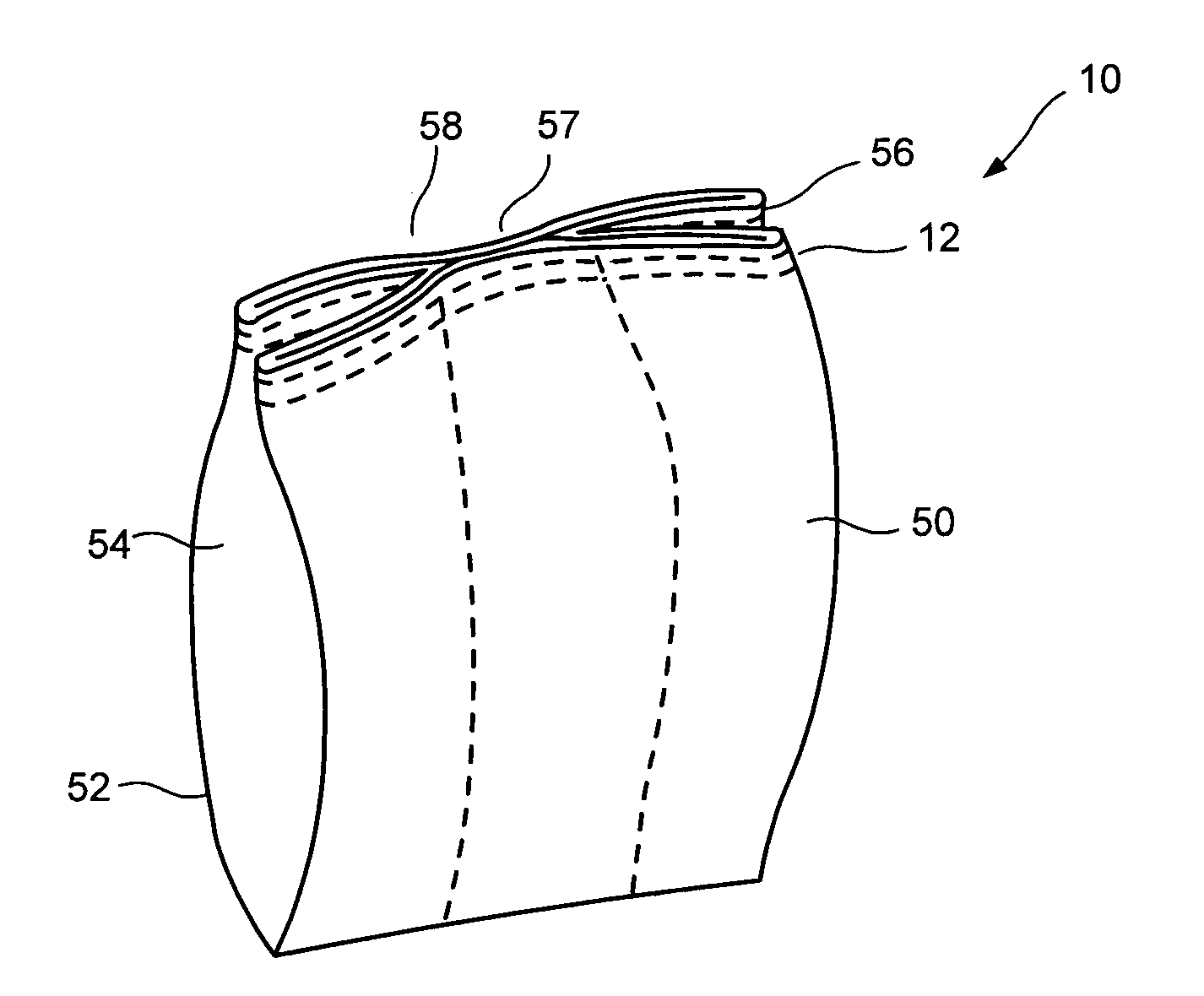

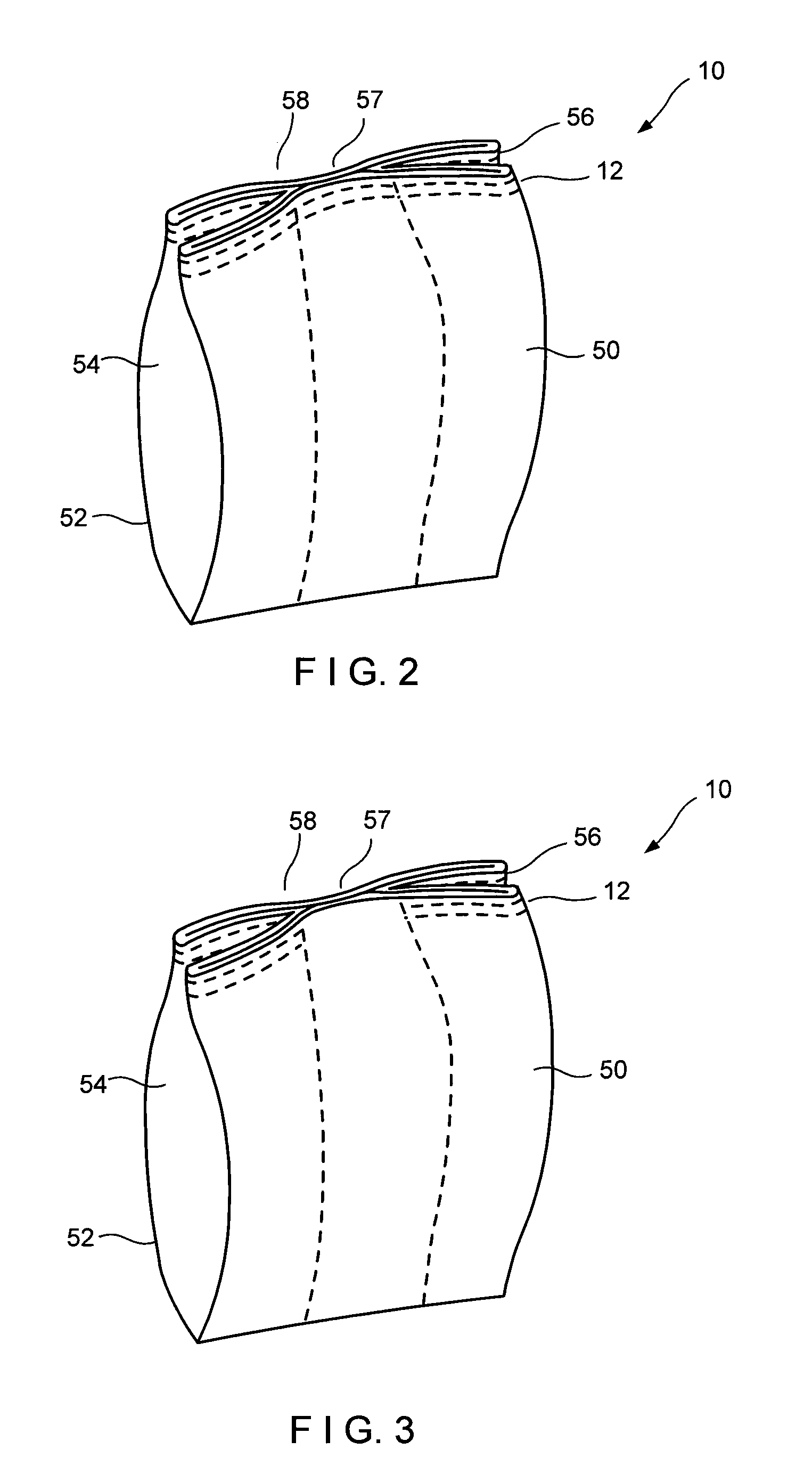

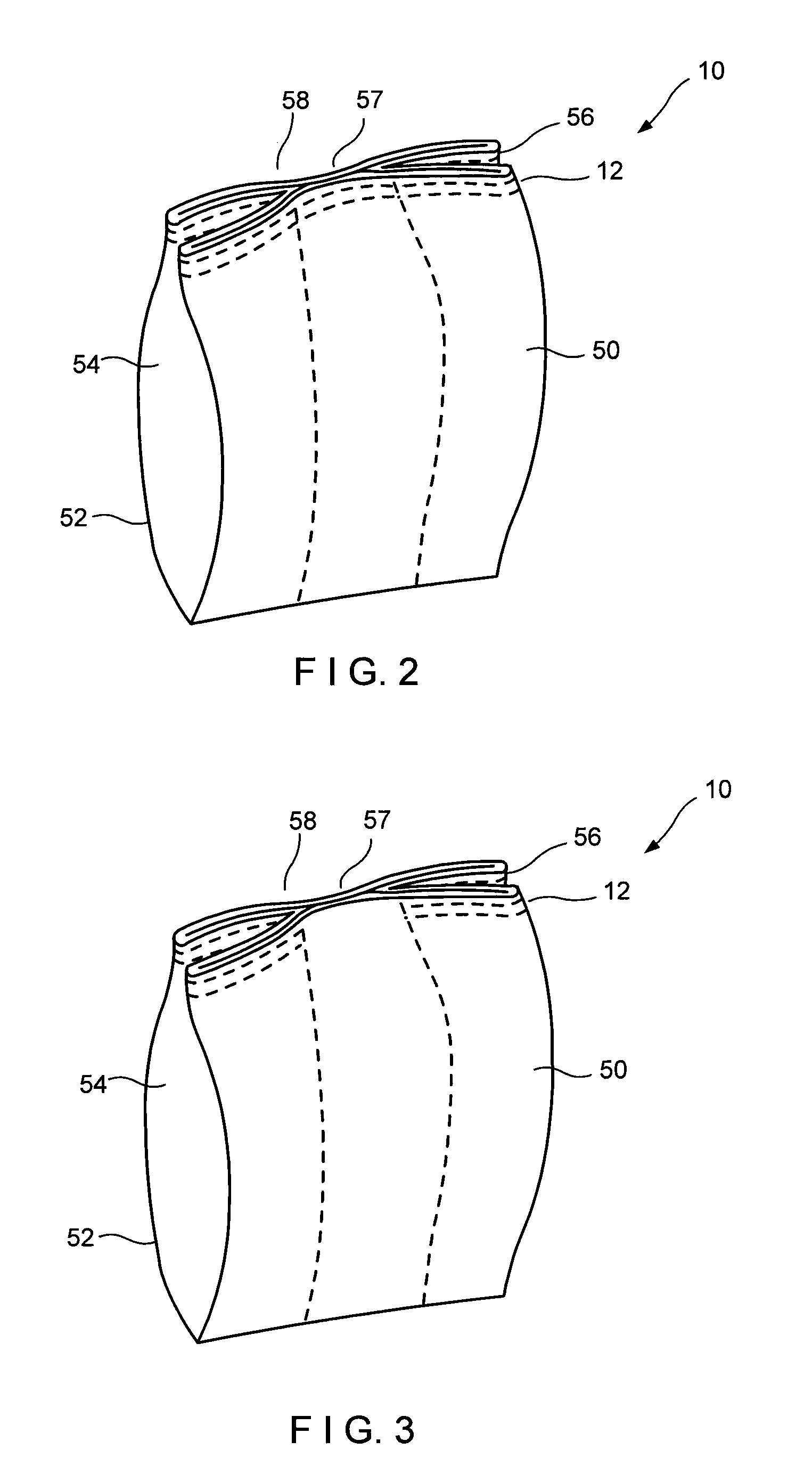

High burst package having a reclosable pour spout

The disclosure relates to a gusseted reclosable package with an internal unisex reclosure strip. The reclosure strip has upper and lower flanges, and a two or three-point connection, rather than a four-point connection, to the interior circumference of the package. This results in the package having a higher internal (product side) opening strength than the external (consumer side) opening strength, thereby allowing the package to be easily opened by the consumer while maintaining a high burst strength.

Owner:ILLINOIS TOOL WORKS INC

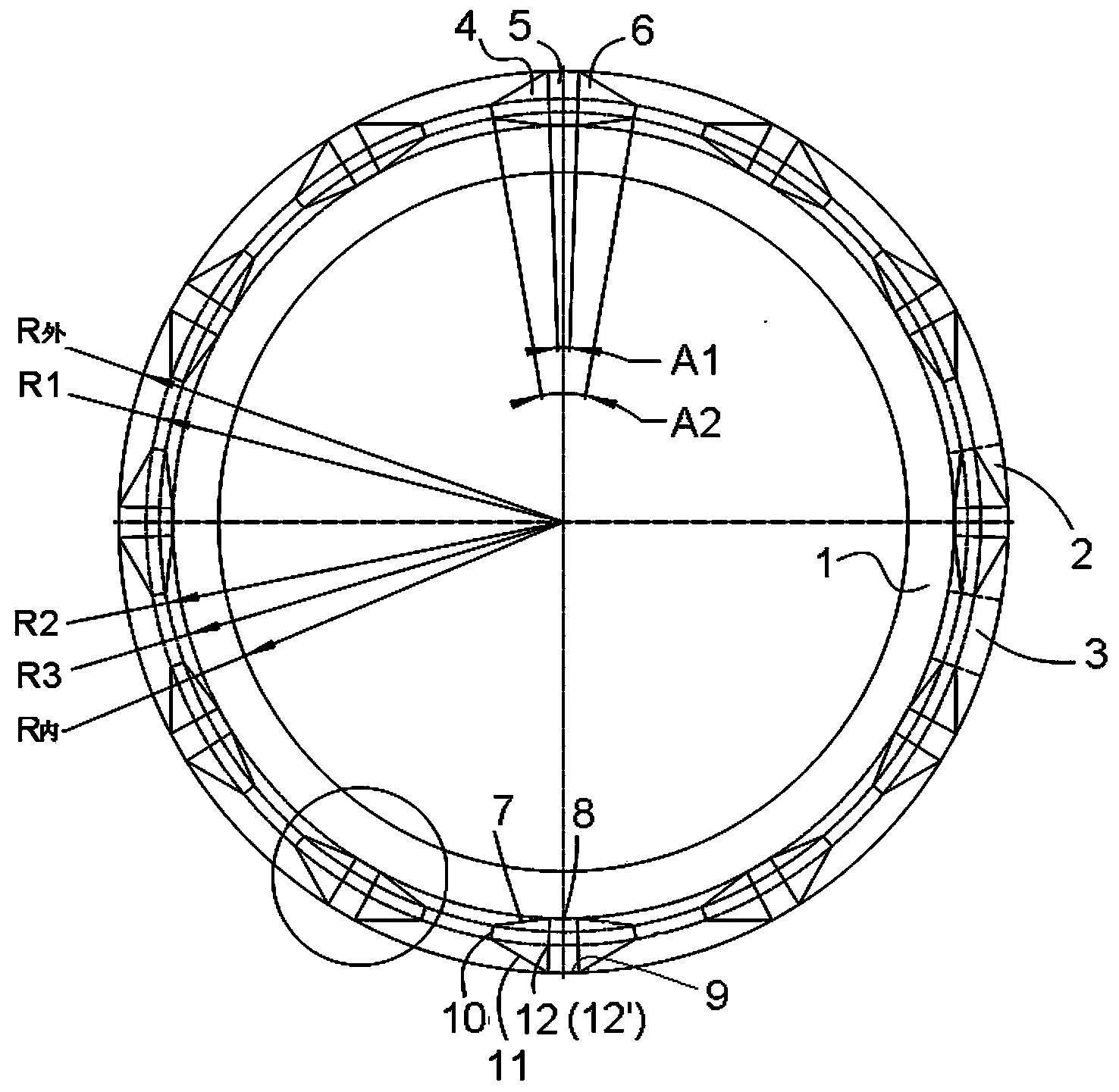

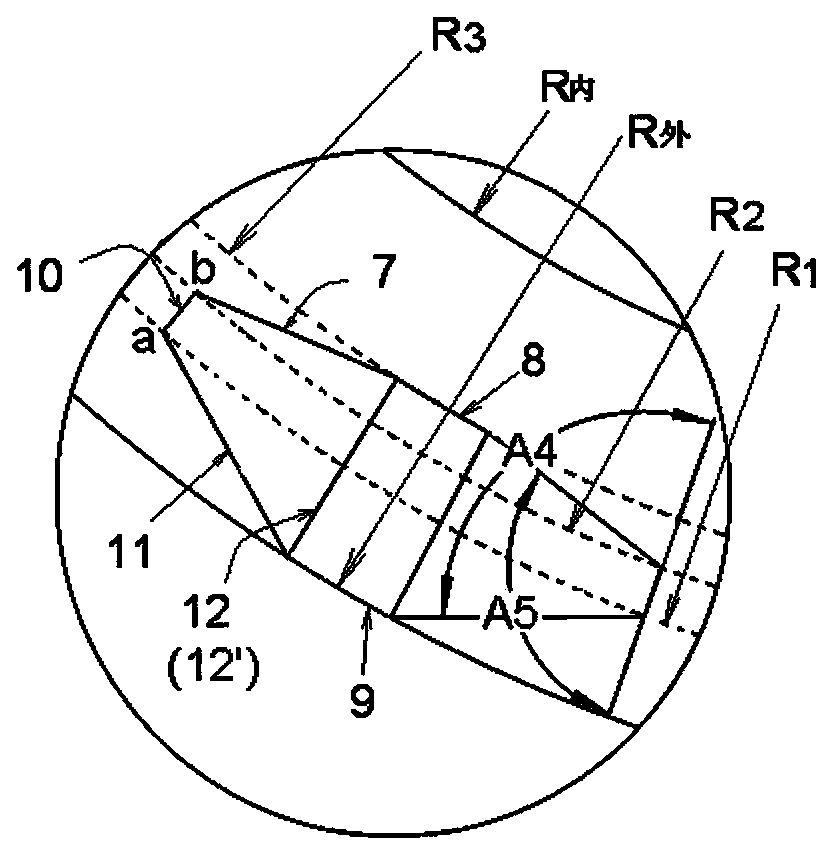

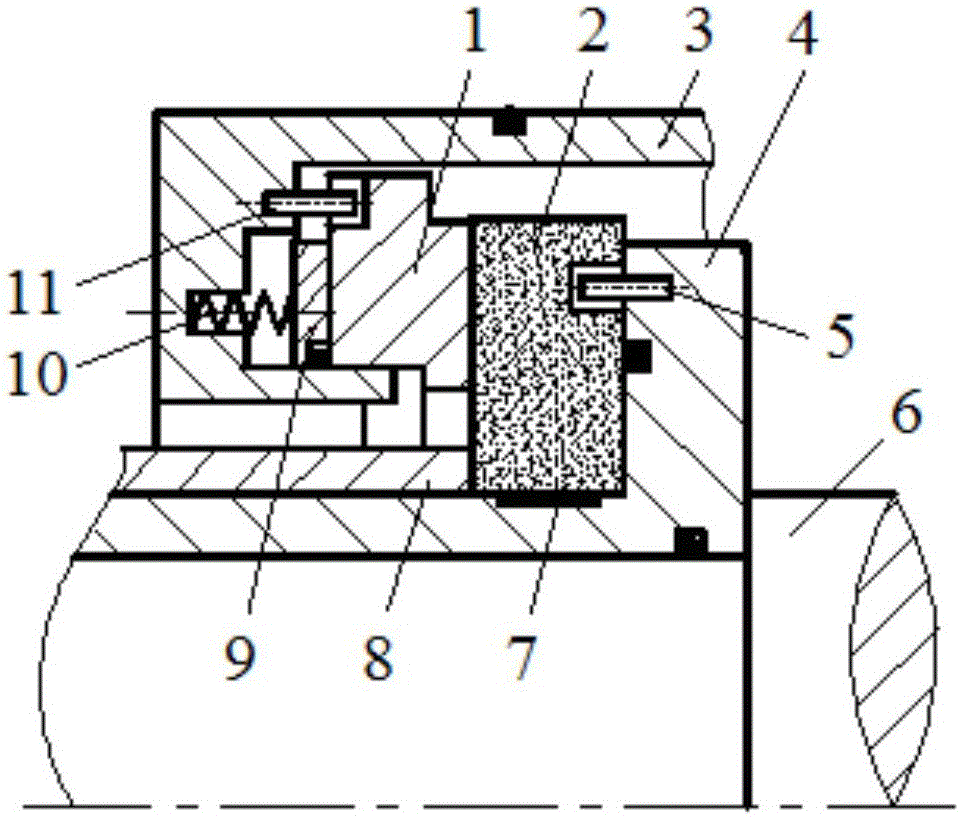

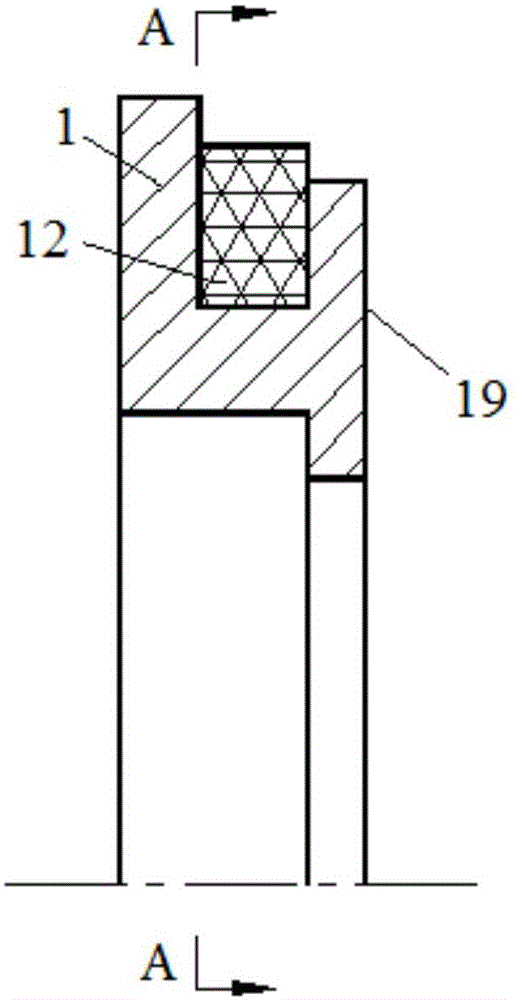

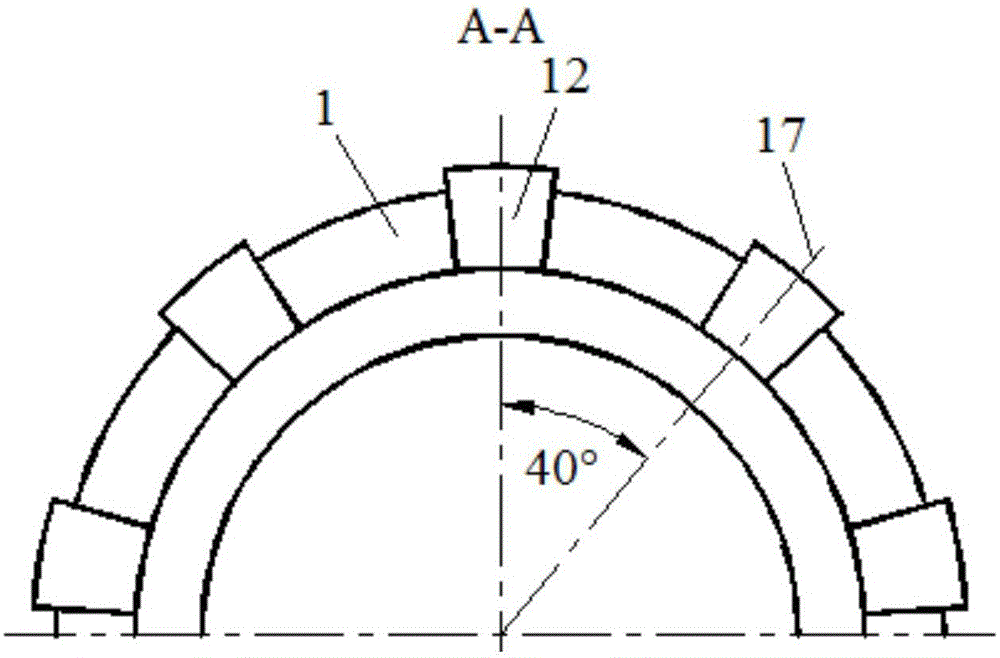

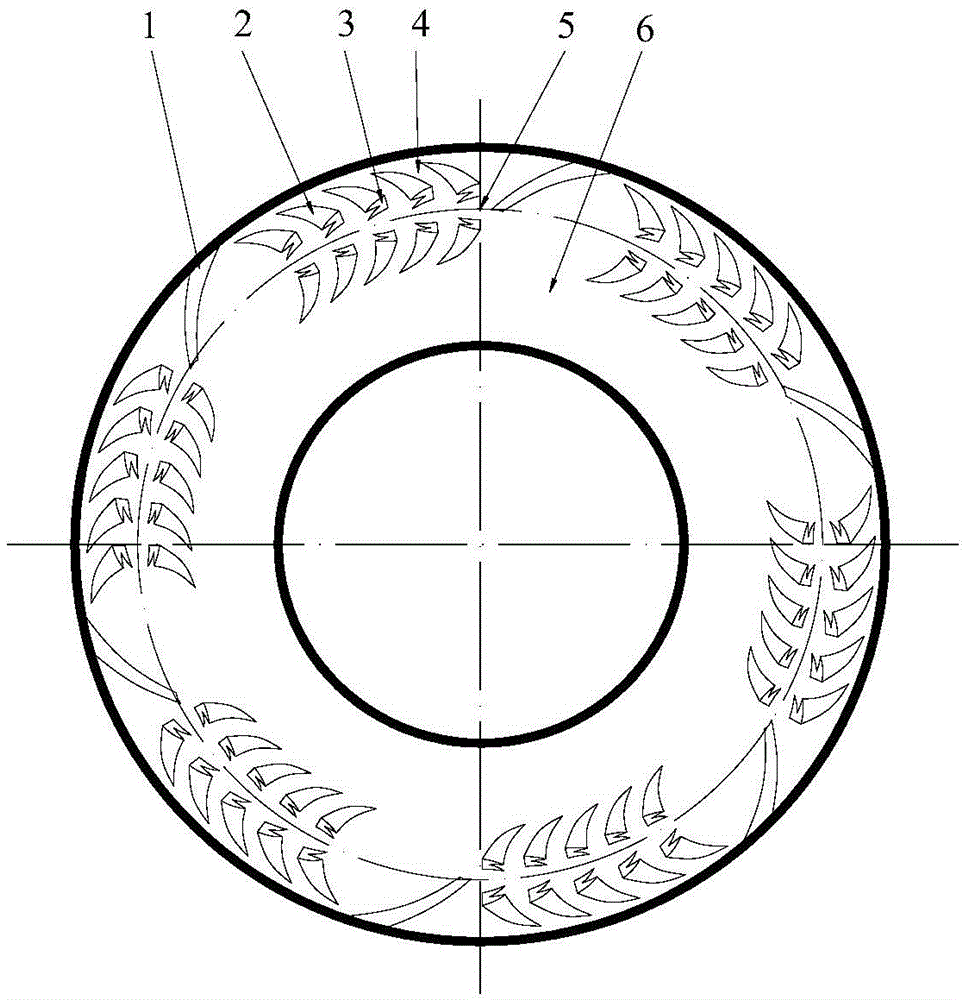

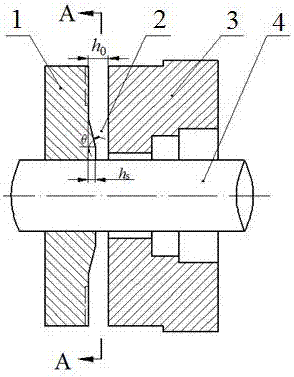

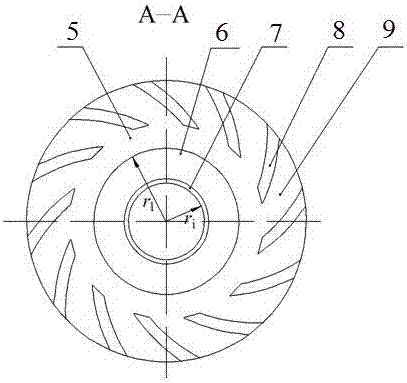

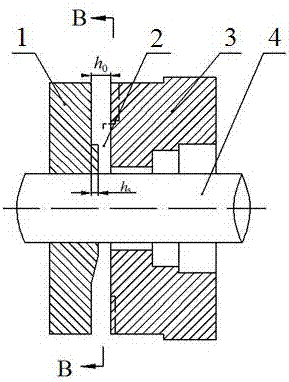

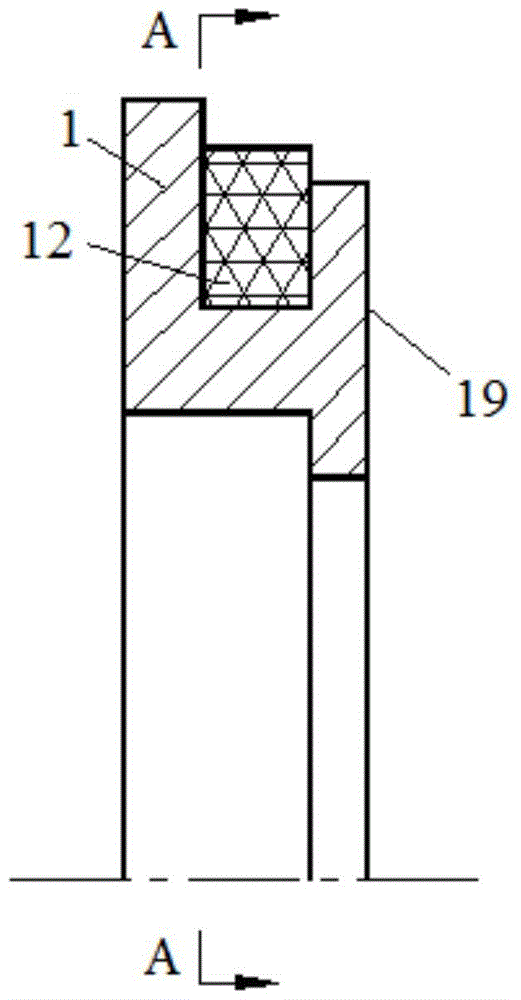

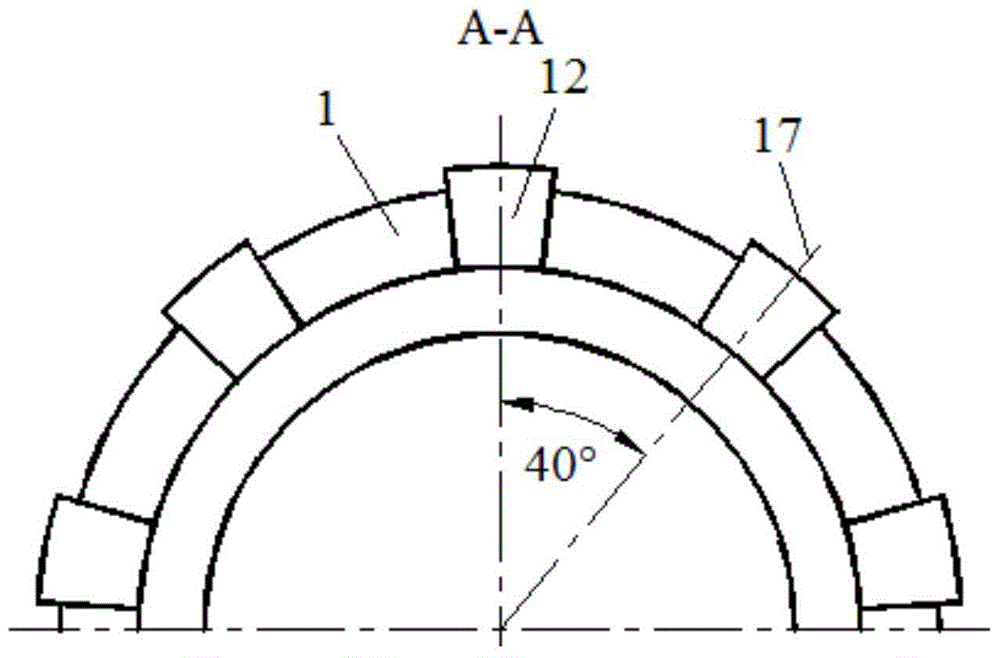

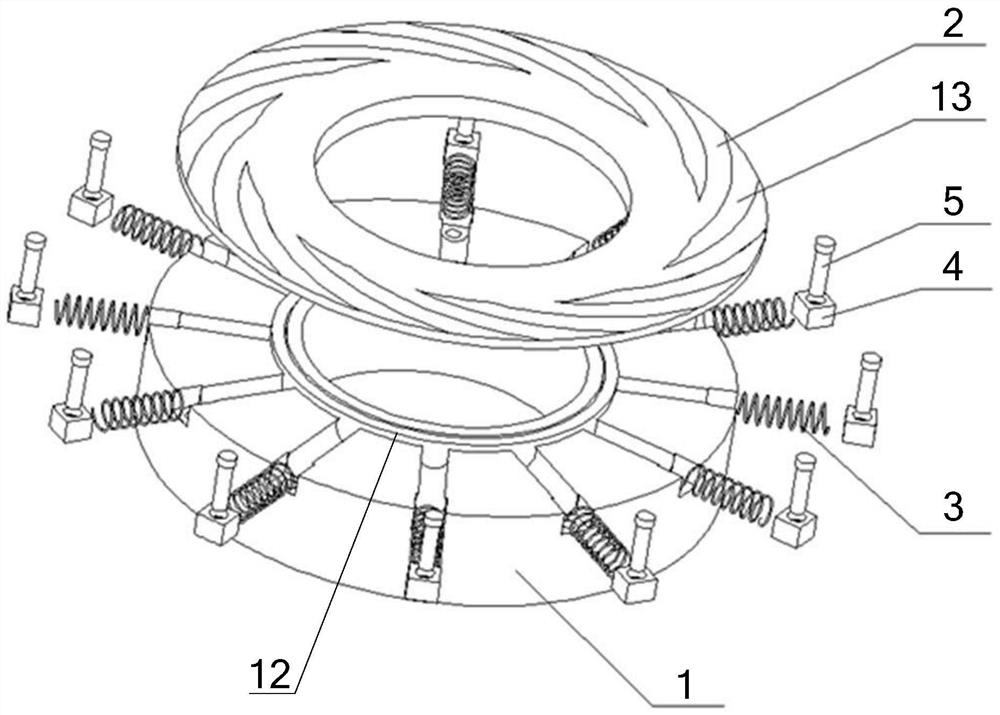

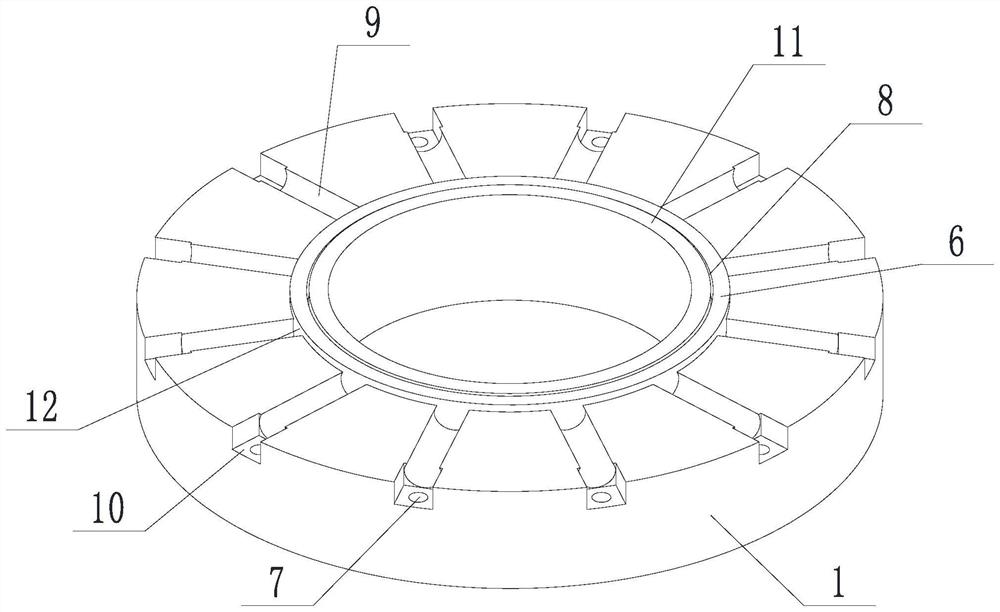

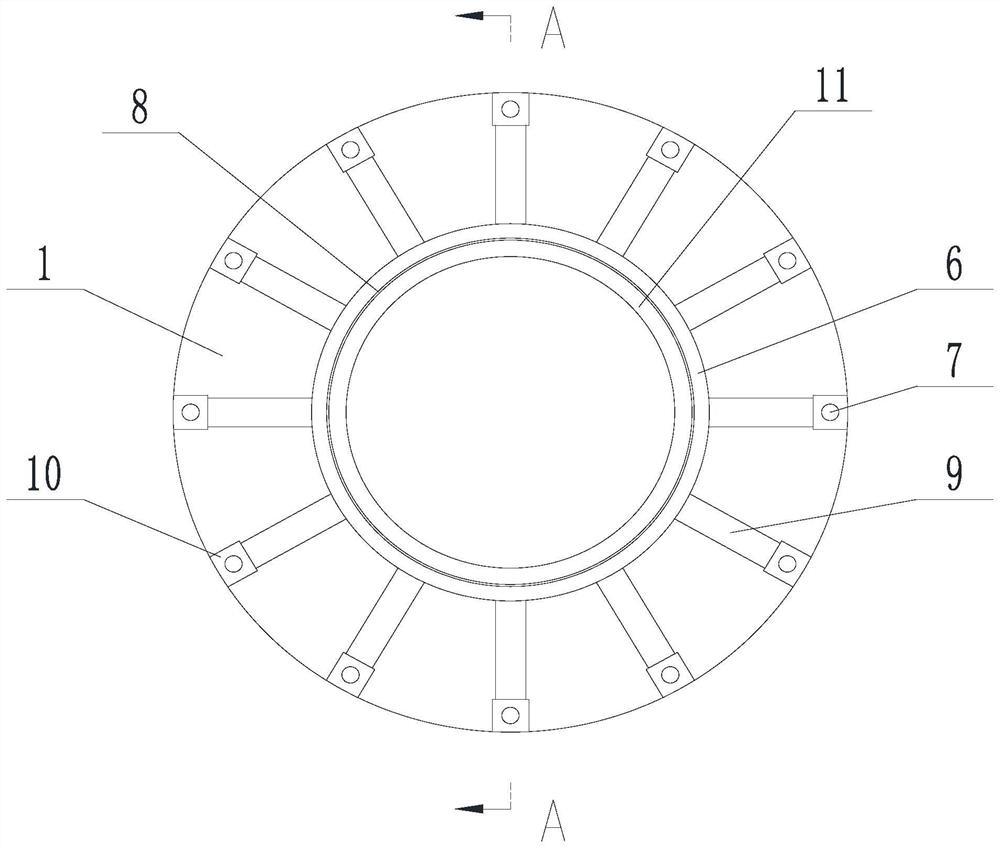

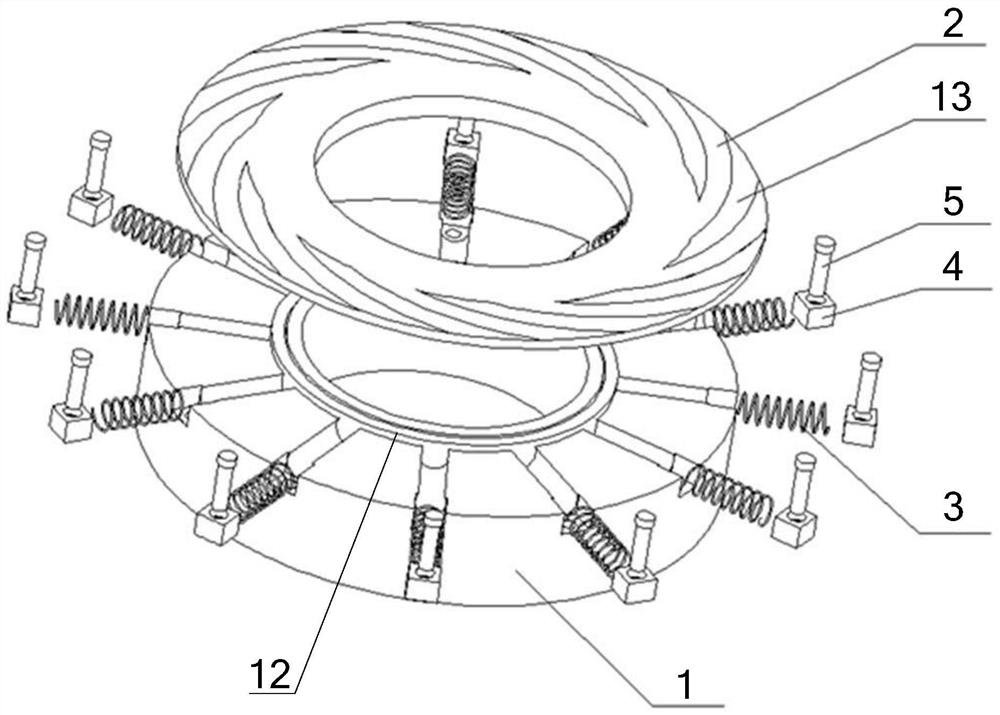

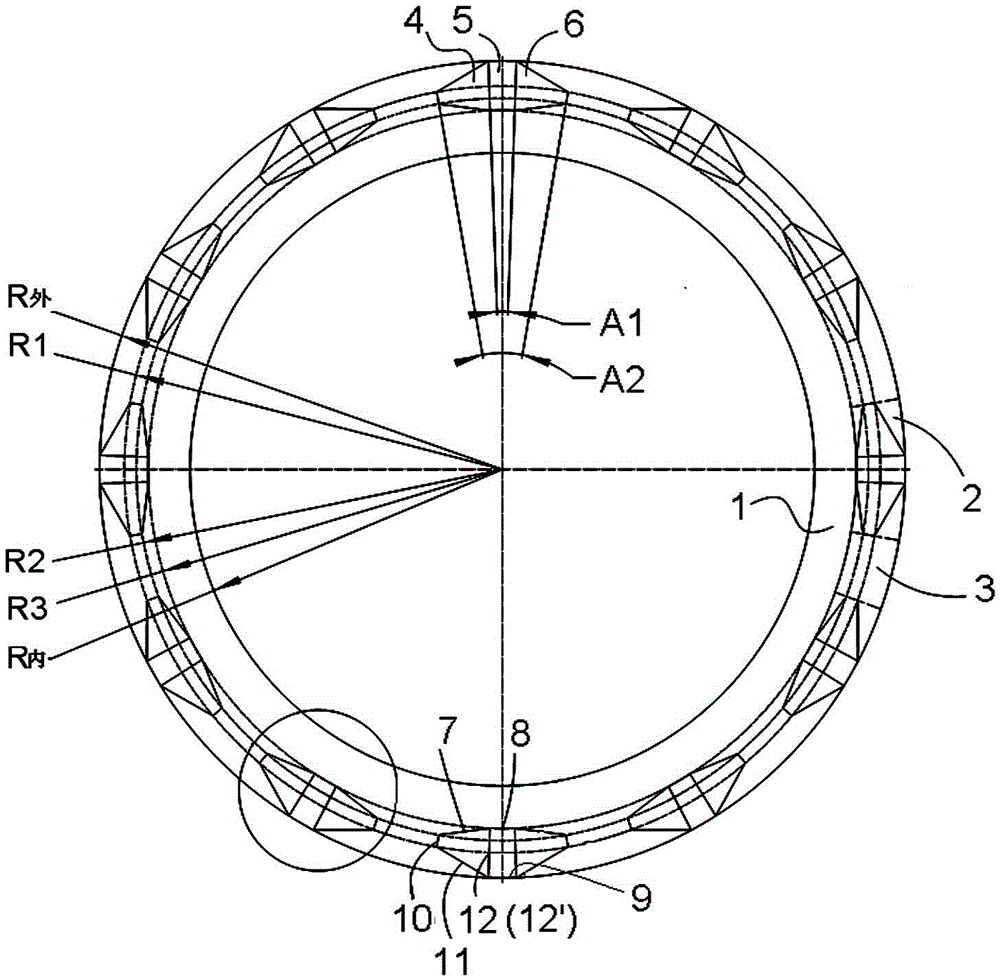

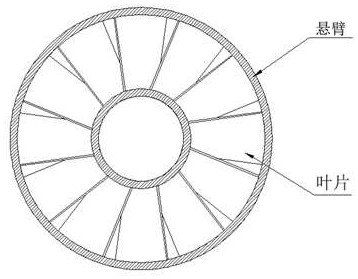

Non-contact mechanical seal ring with dual-rotating-direction hydrodynamic grooves

ActiveCN103453147AImprove opening forceImprove job stabilityEngine sealsEngineeringMechanical engineering

The invention provides a non-contact mechanical seal ring with dual-rotating-direction hydrodynamic grooves. Hydrodynamic groove structure units in same forms are arranged on the outer side of a seal end face circumferentially at equal intervals; the hydrodynamic groove structure unit is in a wing-shaped structure formed by a central groove and same wing grooves which are connected to two sides of the central groove respectively and which extend symmetrically in a converged manner; the central groove and two wall edges thereof are two radial extending segments of the seal end face respectively, the wall edge on the inner side is an arc concentric with the seal end face, and the central groove is formed in the circumferential wall of a seal ring body, long side edges of two sides of the wing grooves and short grooves at the converged-extending ends are two radial extending segments of the seal end face; the long side edges of two sides of the wing grooves fit and are connected with the side wall of the central groove where the same located. By the aid of the hydrodynamic groove structure, seal hydrodynamic effect can be improved, seal end face opening force is increased, thickness and strength of the fluid film between the seal end faces are increased, seal leakage is reduced, groove processing difficulty is reduced, and process requirements on seal parts processing and assembling are lowered.

Owner:SICHUAN SUNNY SEAL

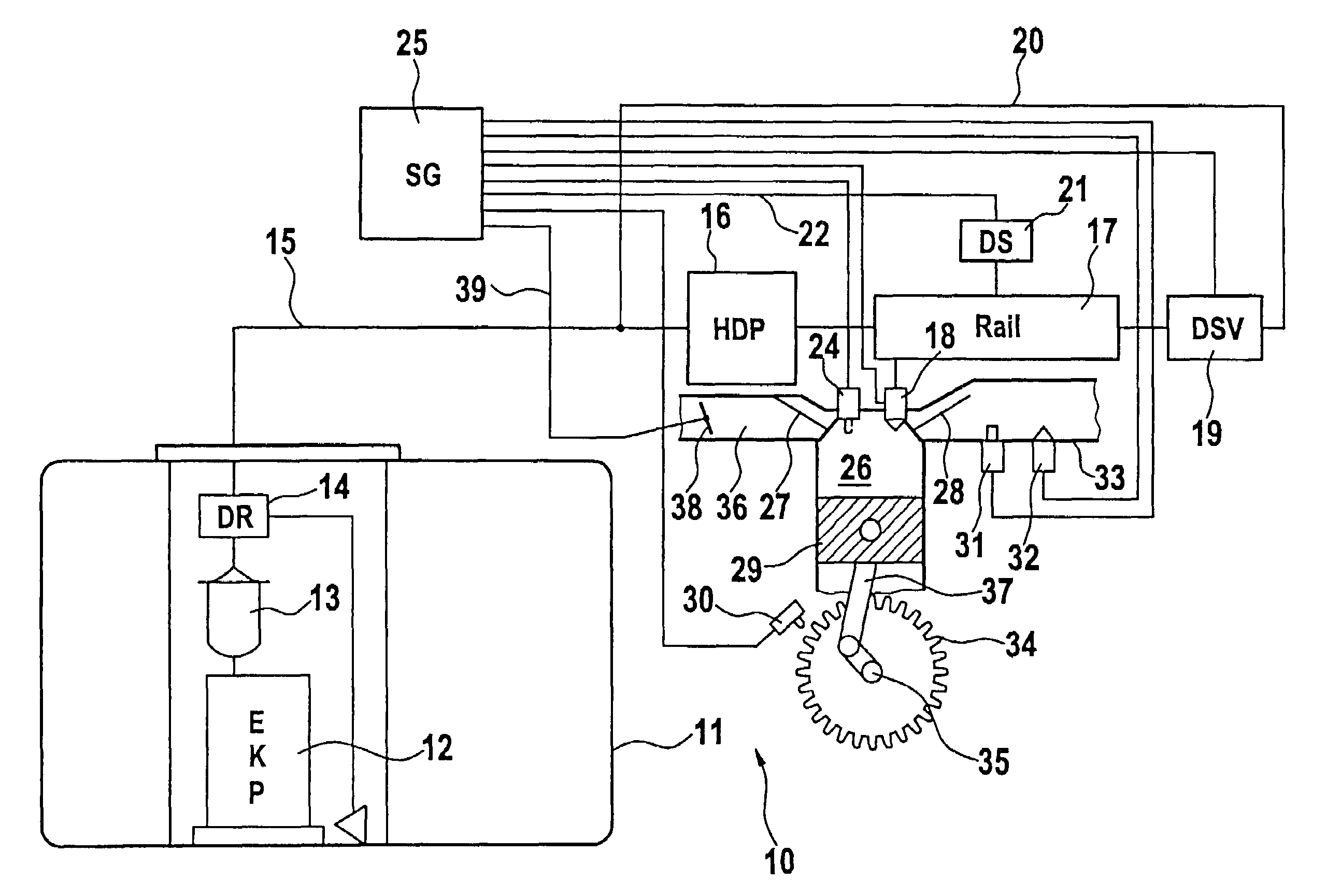

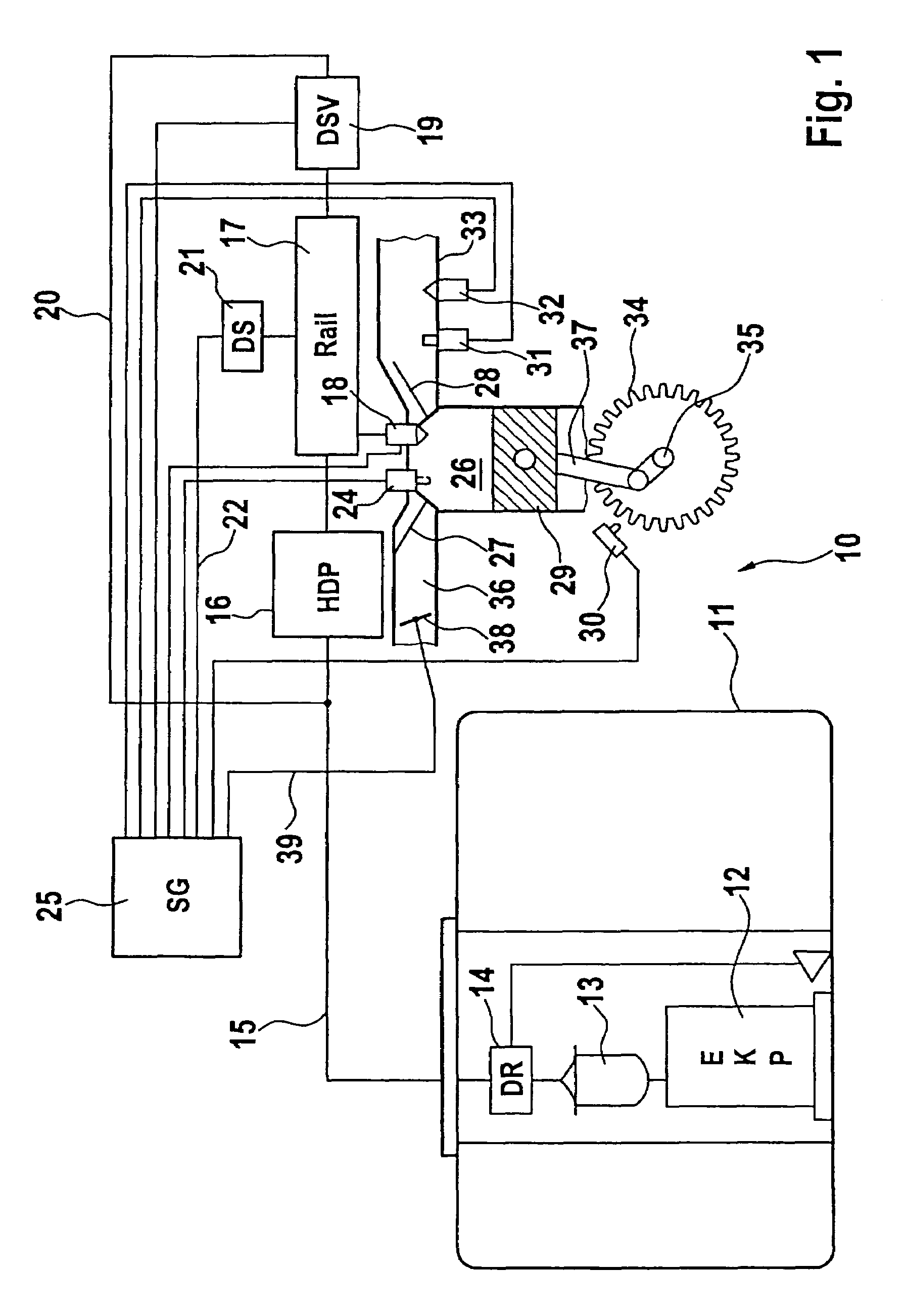

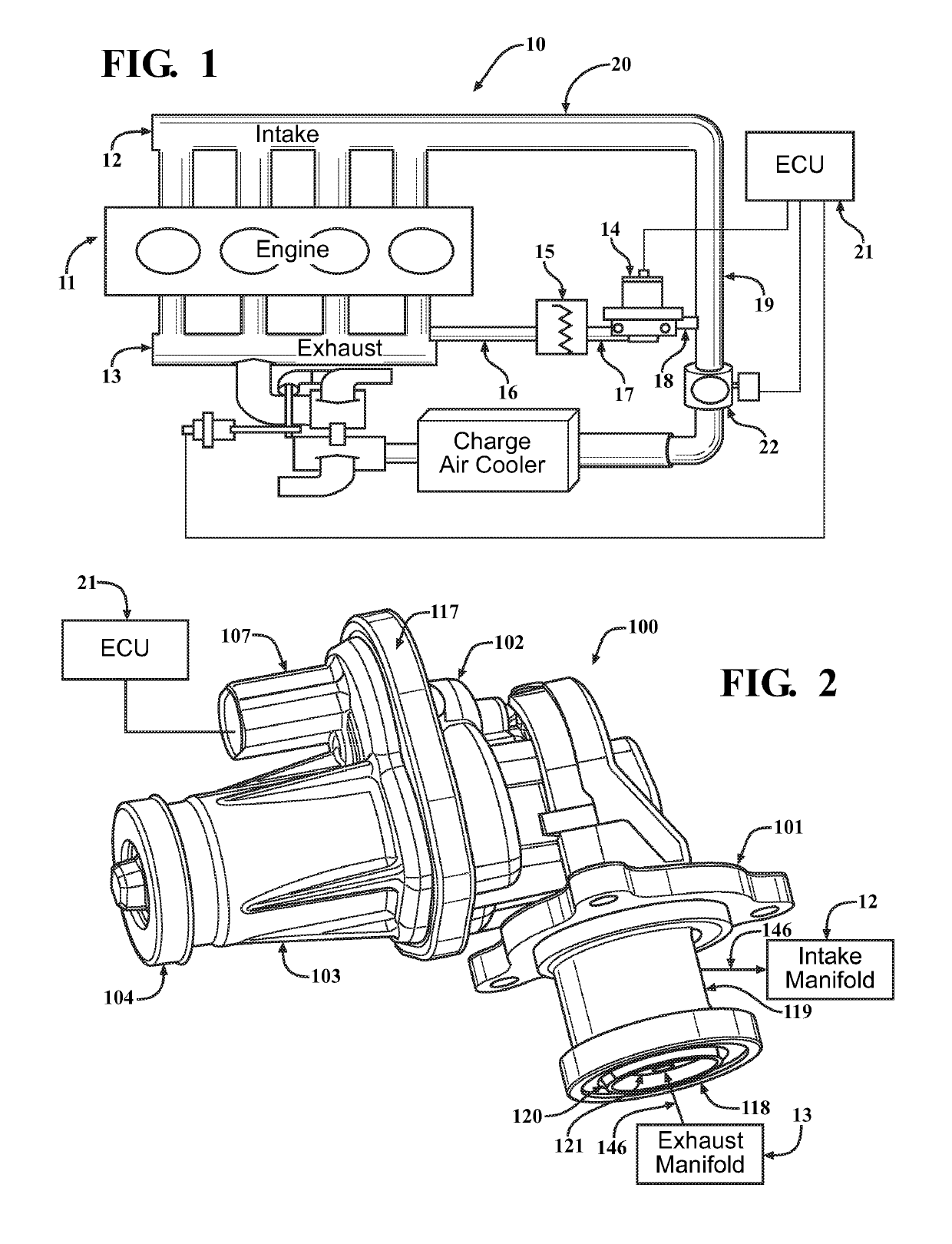

Method for operating an internal combustion engine

InactiveUS7497206B2High strengthIncrease cracking pressureElectrical controlFuel injection apparatusExternal combustion engineInternal combustion engine

Owner:ROBERT BOSCH GMBH

Mechanical seal device for end face seal ring with controllable bellows seal

ActiveCN105114626AImprove surface qualityEliminate or reduce the impactEngine sealsElectricityControl system

The invention relates to a mechanical seal device for an end face seal ring with controllable bellows seal. The mechanical seal device is provided with a moving ring and a non-rotating stationary ring, wherein the moving ring can synchronously rotate along with a rotating shaft, and the stationary ring is connected with a stationary ring base; the axial relative end faces of the moving ring and the stationary ring are the respective seal faces, and at least one seal face is in a plane structure. Electric heating structures keeping the distance with the seal faces are arranged in the circumferential direction of the stationary ring and / or the moving ring with the plane-structure seal surface at intervals, and the electric heating structures are connected with a control system. On the basis that the conventional end face bellows process is kept, the mechanical seal device can process the seal faces into high-precision planes and can obtain the high surface quality on the planes and the controllable bellows seal faces through heating control for the electric heating structures, therefore the influences on the seal effects caused by various factors can be effectively eliminated and avoided, the good hydrodynamic effect can be generated, and the ideal fluid film opening force and stiffness are obtained.

Owner:江苏光谷产业投资发展有限公司

Mechanical seal device with seal rings with controllable cone bevel seal end faces

The invention relates to a mechanical seal device with seal rings with controllable cone bevel seal end faces. The mechanical seal device is provided with a moving ring capable of synchronously rotating along with a rotary shaft and a non-rotating static ring connected with a static ring seat. Axially-opposite end faces between the moving ring and the static ring serve as respective seal faces. The seal face of at least one of the static ring and the moving ring is of a plane structure, and an annular electric heating structure concentric with the static ring and / or the moving ring is arranged at the position, spaced from the seal face, in the static ring and / or the moving ring and connected with a control system. On the basis of an existing end face processing technology, the seal faces can be processed into planes, the cone bevel structure seal faces with high surface quality and controllable cone angle sizes can be obtained on the planes through heating control over the annular electric heating structures, and therefore the influences of various factors on the seal effect can be effectively eliminated, a very good fluid hydrodynamic effect can be generated, and very ideal fluid film opening force and rigidity are obtained.

Owner:永嘉县环球机械密封件厂

High burst package having a reclosable pour spout

The disclosure relates to a gusseted reclosable package with an internal unisex reclosure strip. The reclosure strip has upper and lower flanges, and a two or three-point connection, rather than a four-point connection, to the interior circumference of the package. This results in the package having a higher internal (product side) opening strength than the external (consumer side) opening strength, thereby allowing the package to be easily opened by the consumer while maintaining a high burst strength.

Owner:ILLINOIS TOOL WORKS INC

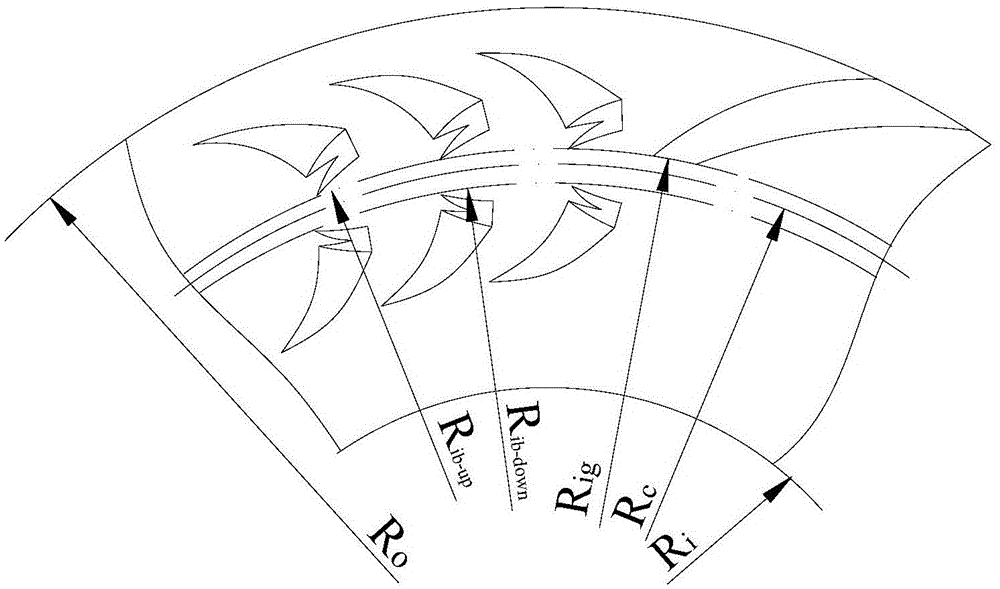

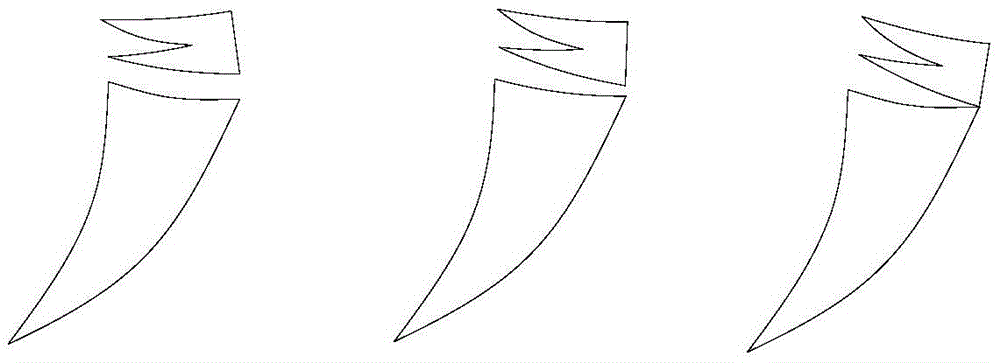

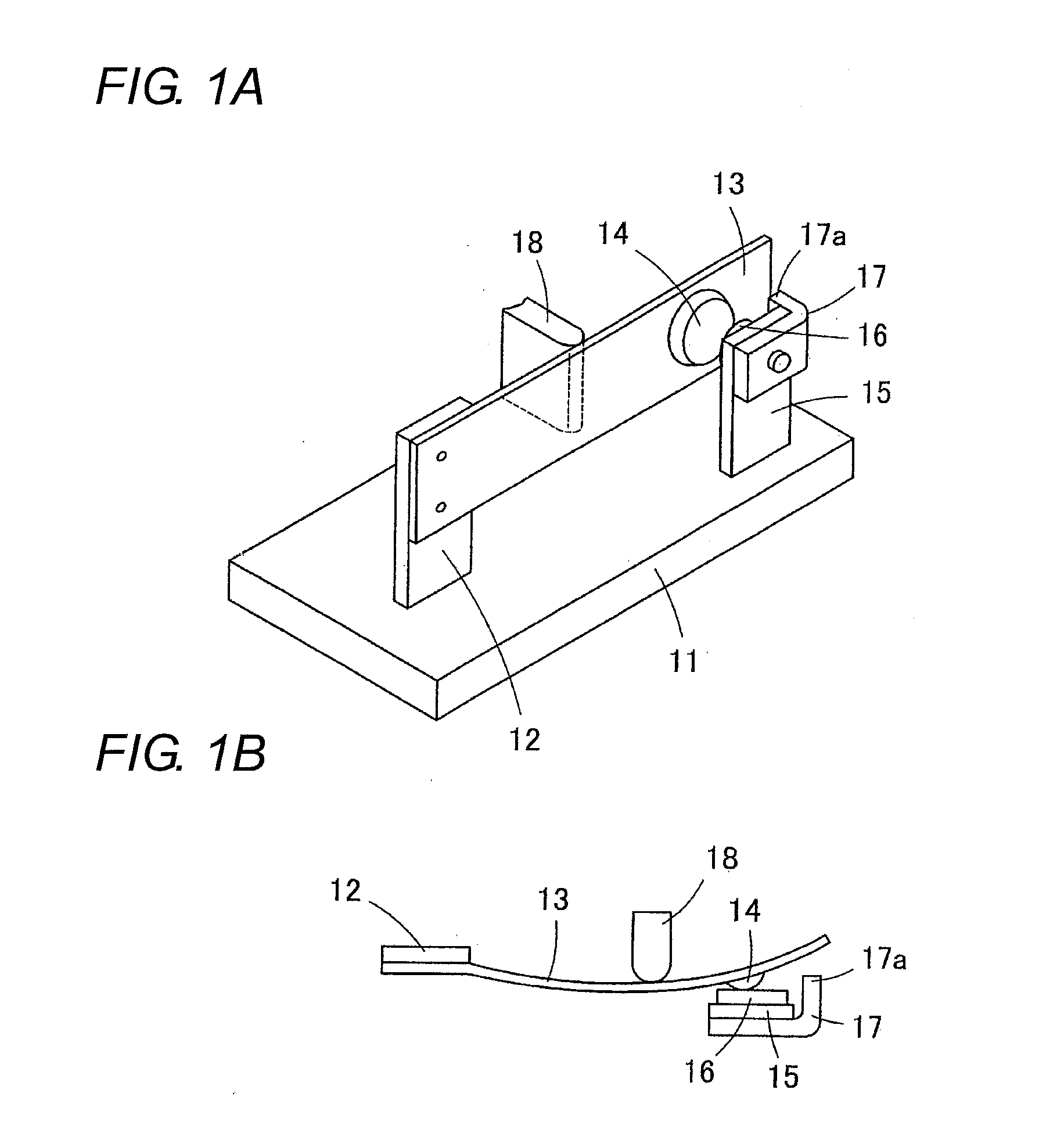

Gas-lubricated bird-wing-shaped groove end face seal structure

ActiveCN104265906BEnhance the dynamic pressure effectGood opening performanceEngine sealsGas lubricationMicrometer scale

A gas lubrication bird-wing-shape-imitation v groove end face sealing structure comprises two sealing rings with sealed end faces; the two sealing rings comprise a movable ring and a static ring; the end face of at least one of the movable ring and the static ring is provided with a plurality of bird-wing-shape-imitation v grooves; each bird-wing-shape-imitation v groove is composed of a tail-feather-shape-imitation v groove body and a flight-feather-shape-imitation v groove body; the tail-feather-shape-imitation v groove bodies are provided with swallow-tail-shaped furcal tails; the flight-feather-shape-imitation v groove bodies are roughly in a bull horn shape with the thick ends and the tail tip ends; the tail-feather-shape-imitation v groove bodies are transversely arranged at the thick ends of the flight-feather-shape-imitation v groove bodies; the thick segments of the flight-feather-shape-imitation v groove bodies and the thick ends of the tail-feather-shape-imitation v groove bodies are toward airflow; the bird-wing-shape-imitation v grooves are arranged to be bird-wing-shape-imitation v groove annular belts; secondary annular sealing dams are arranged between the bird-wing-shape-imitation v groove annular belts; annular main sealing dams are arranged on the low-pressure sides of the end faces; drainage grooves are arranged on the high-pressure sides of the end faces; the drainage grooves and the bird-wing-shape-imitation v grooves are shallow grooves of the micrometer scale; the depths of the flight-feather-shape-imitation v groove bodies are gradually decreased in the airflow direction. The sealing structure has the advantages of being good in stability and long in service life, and resisting abrasion.

Owner:ZHEJIANG UNIV OF TECH

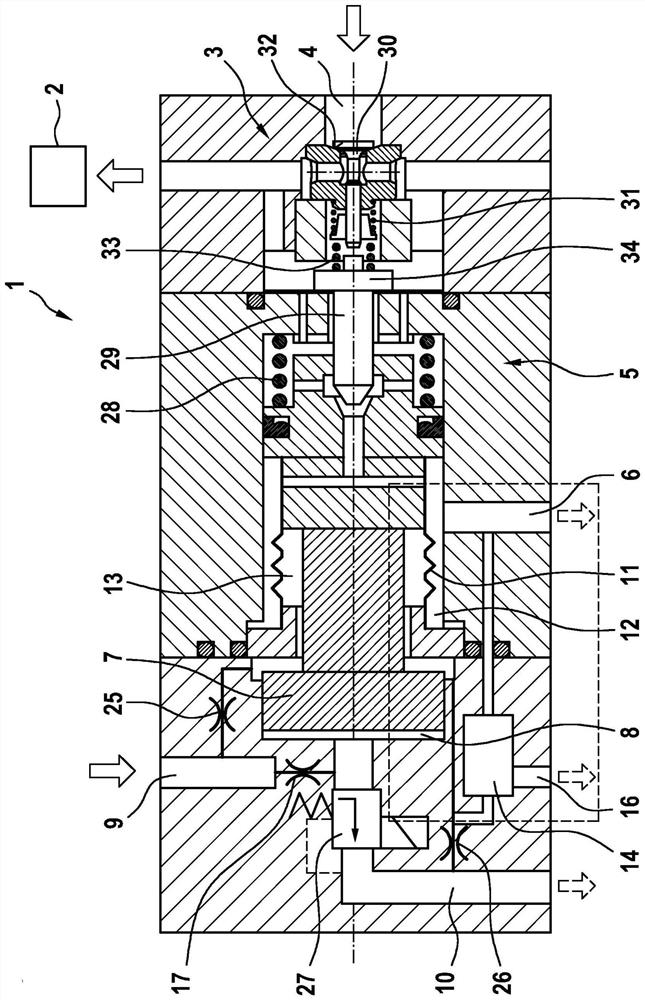

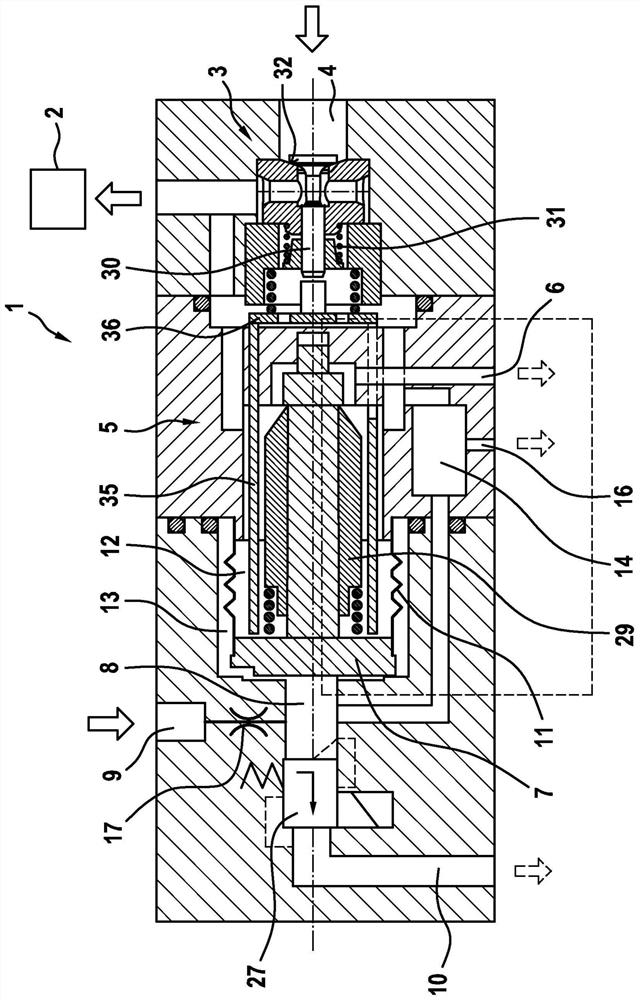

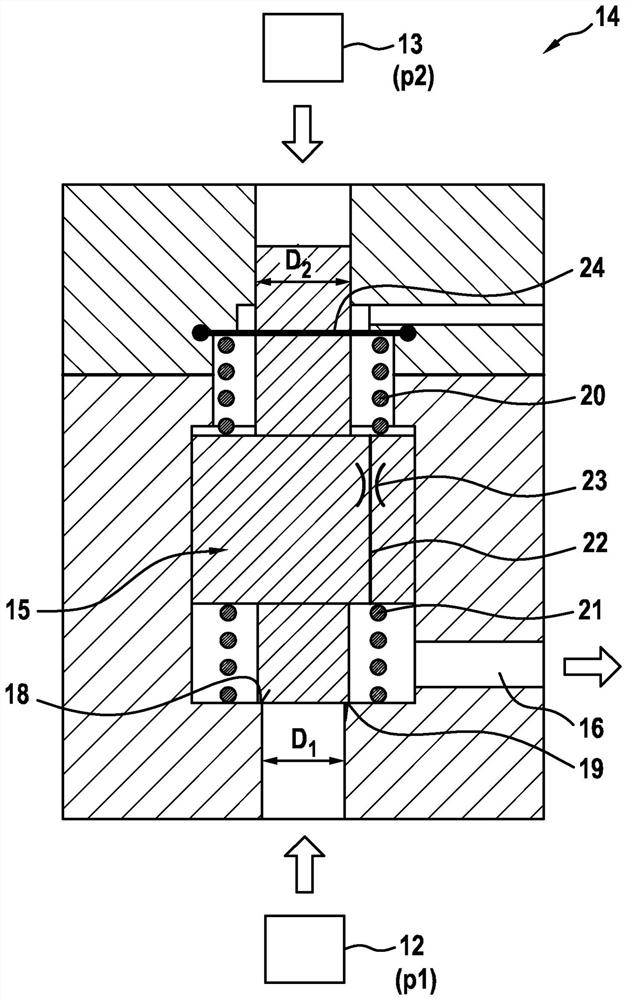

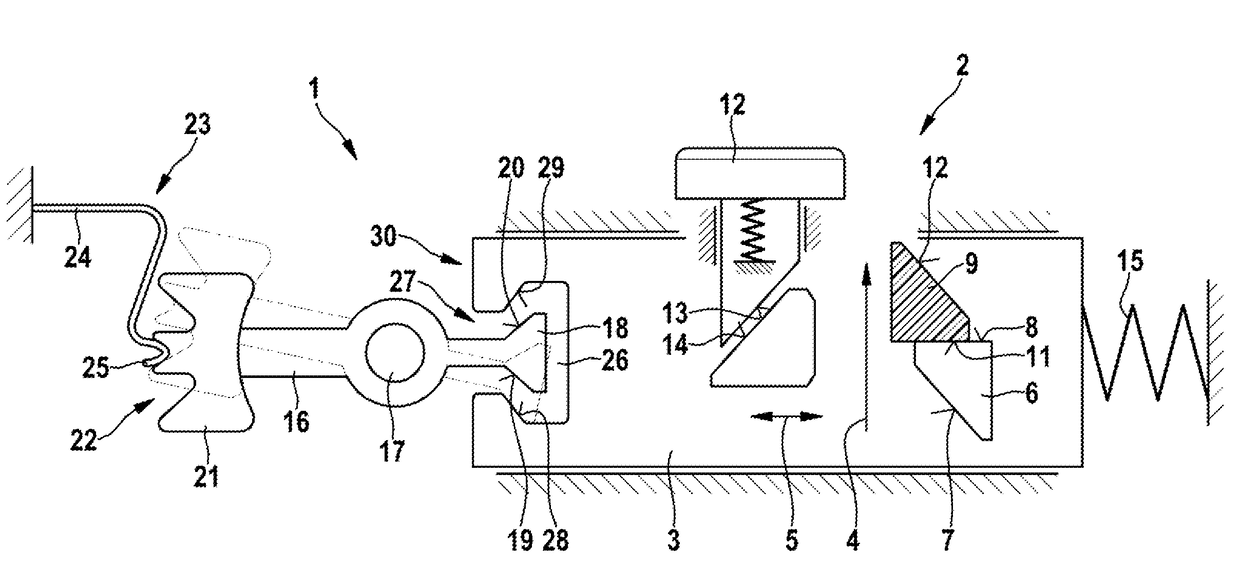

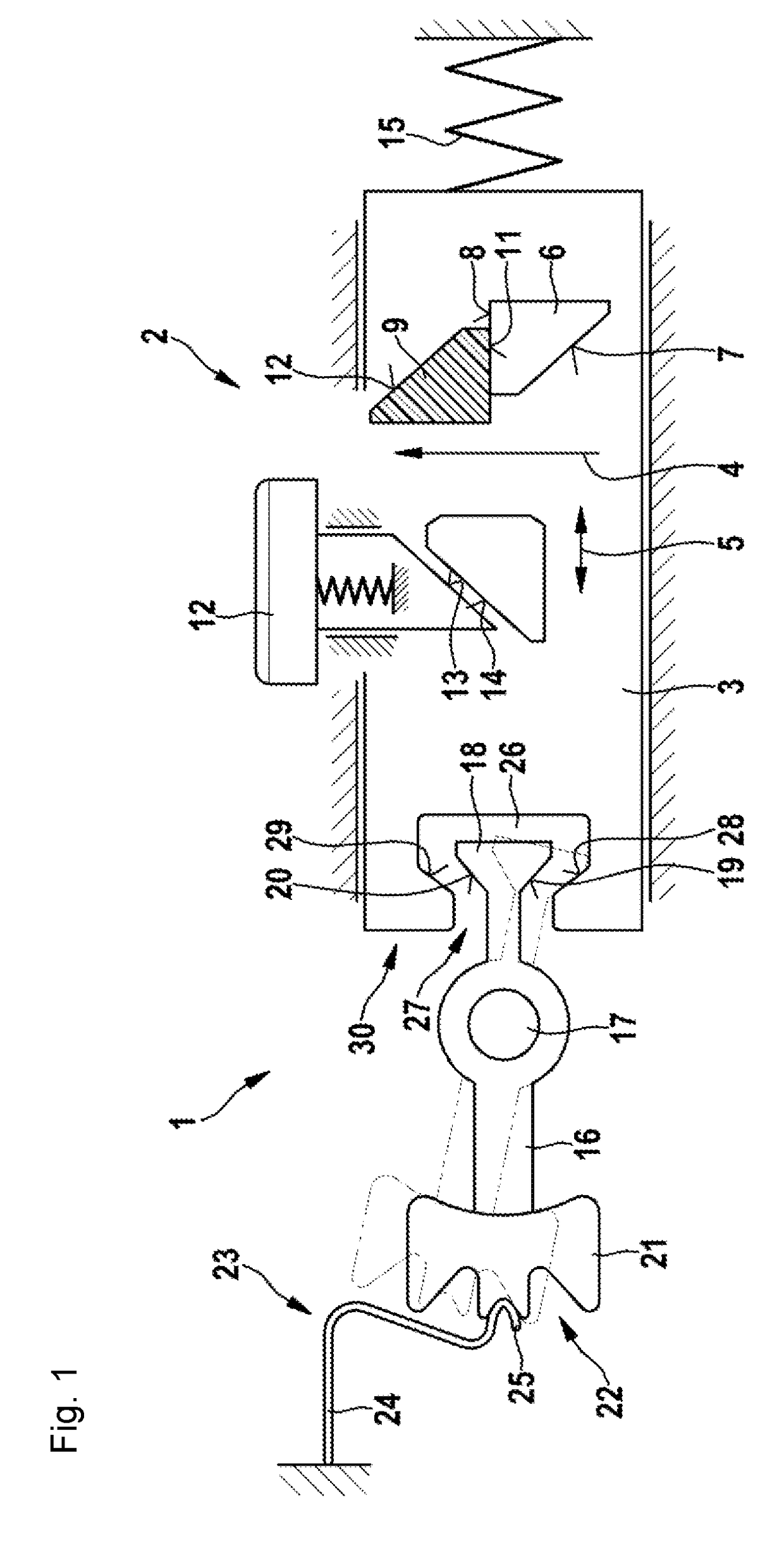

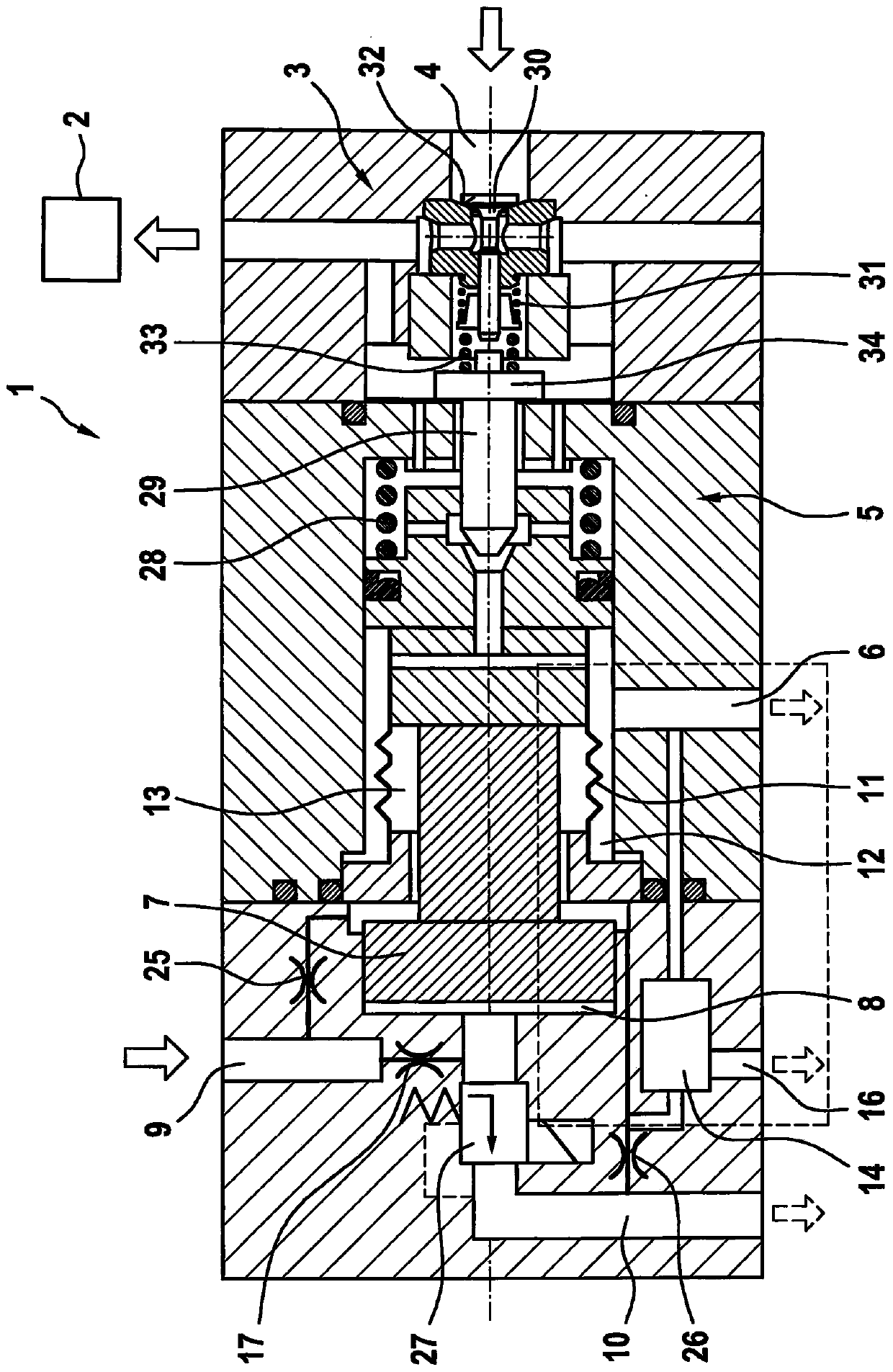

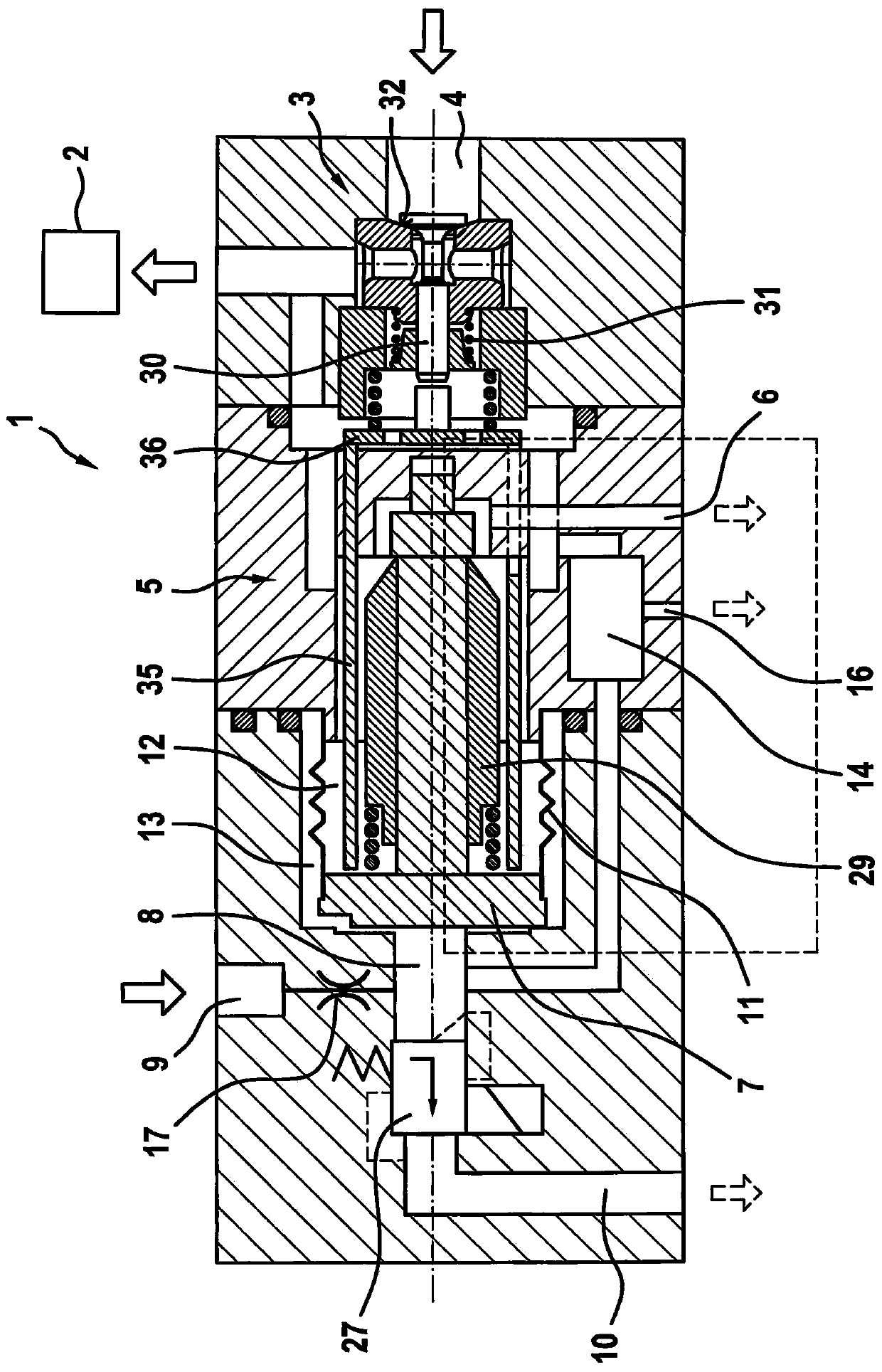

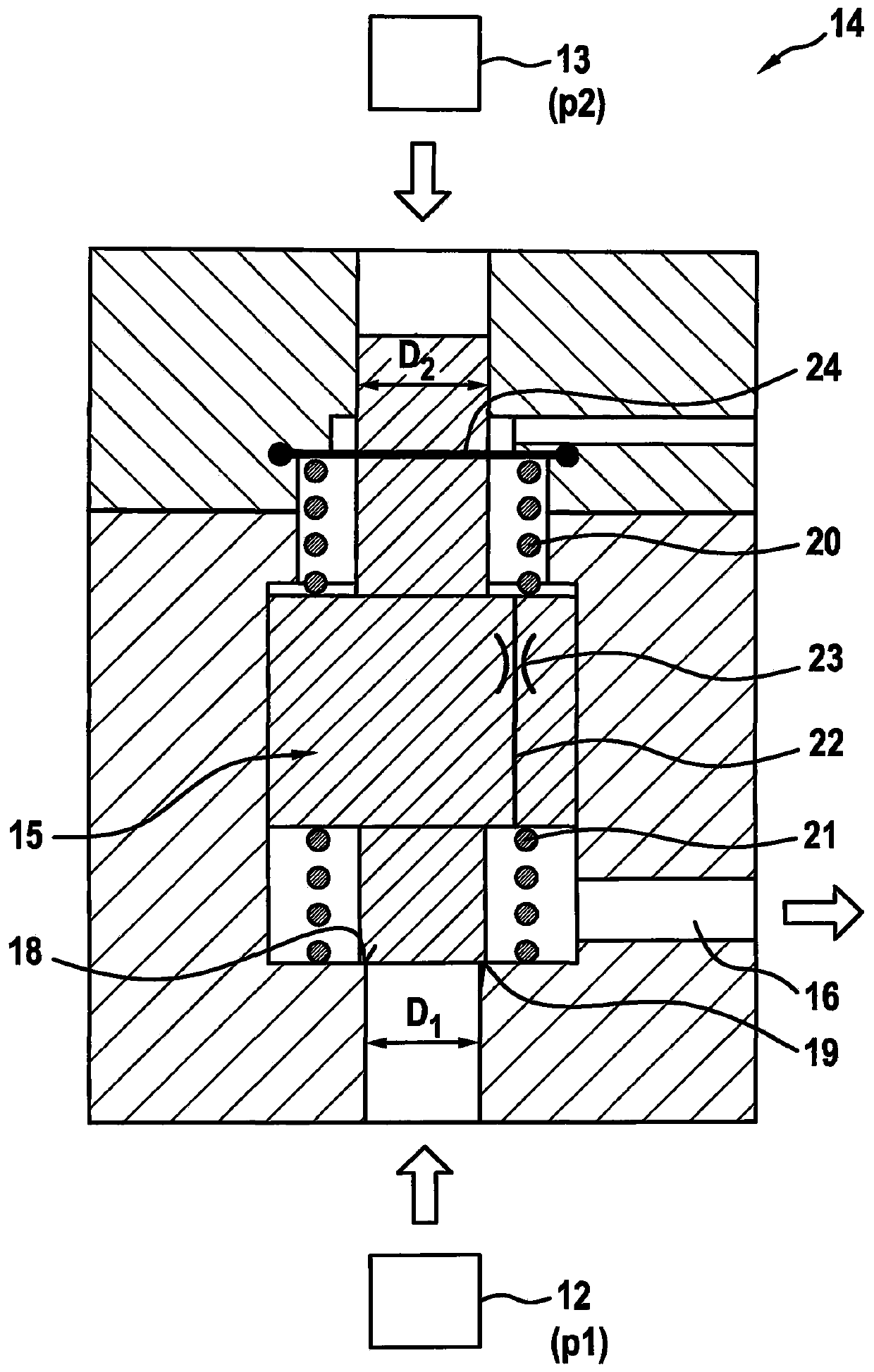

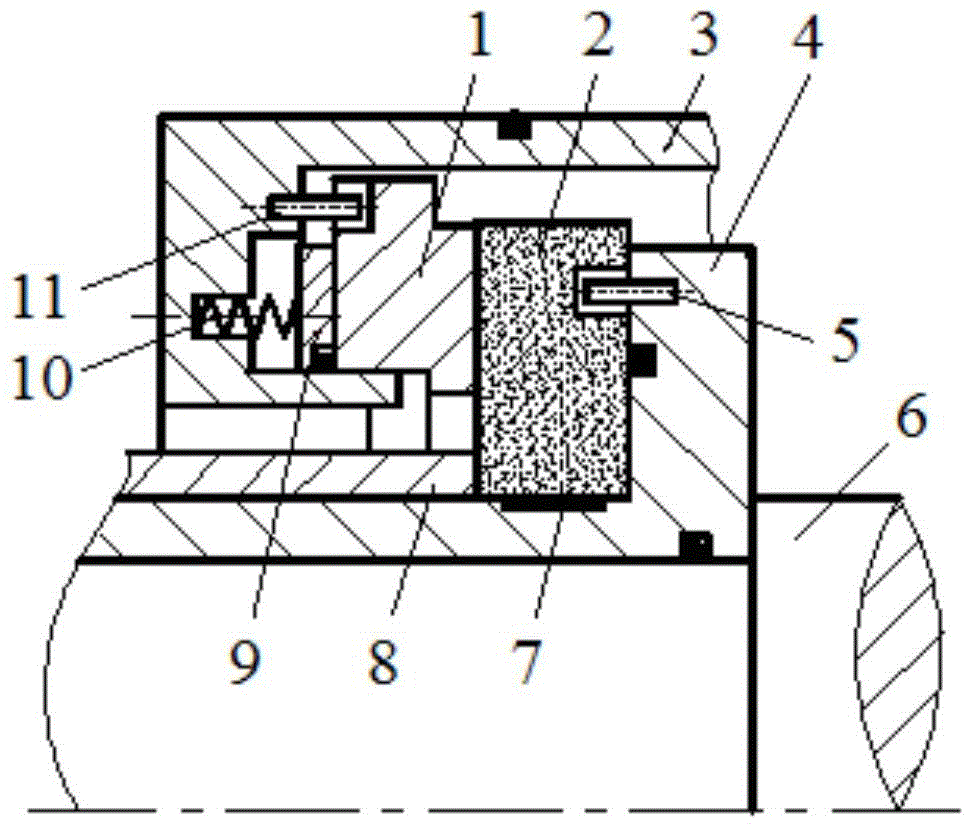

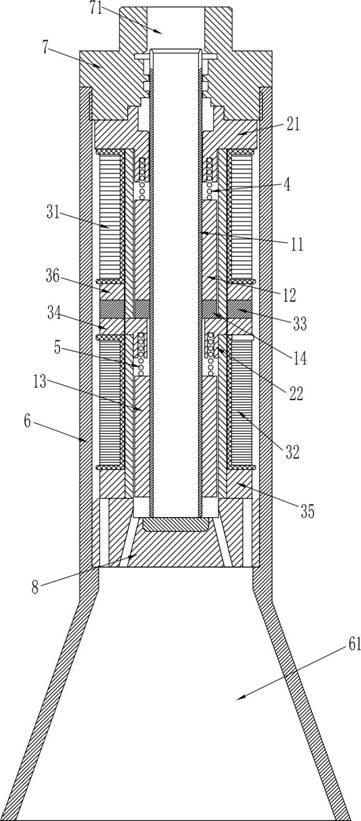

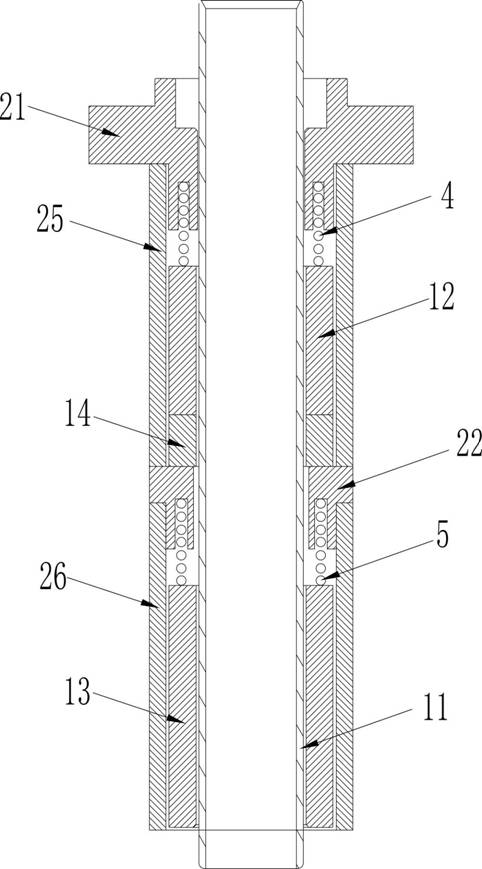

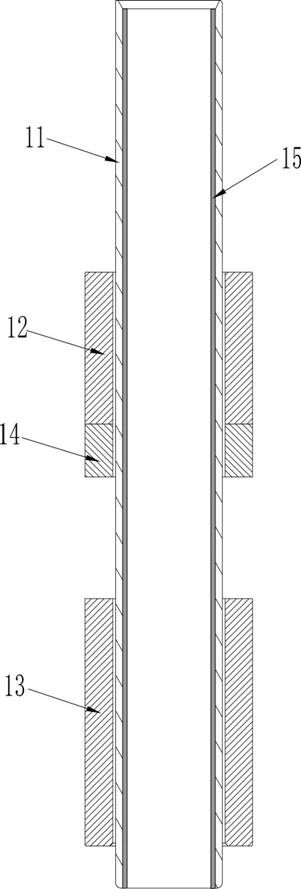

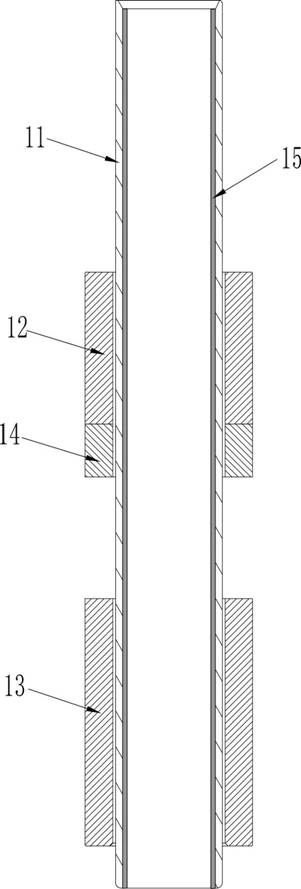

Valve assembly for controlling the gas pressure, fuel system comprising a valve assembly for controlling the gas pressure

InactiveCN112105809AReliable media separationRelieve pressureOperating means/releasing devices for valvesInternal combustion piston enginesReciprocating motionEngineering

The invention relates to a valve assembly (1) for controlling the gas pressure in a gas rail (2) of a fuel system for supplying an internal combustion engine with a gaseous fuel, in particular with natural gas, comprising a first valve (3) for connecting the gas rail (2) to a gas feed (4), a second valve (5) for connecting the gas rail (2) to a gas return (6), and a control piston (7) for actuating both valves (3, 5), wherein the control piston (7) delimits a control chamber (8), to which a hydraulic pressure medium can be applied by a pressure medium feed (9) and which can be depressurized via a pressure medium discharge (10), and further comprising a sealing element (11) which is designed as a corrugated or folding bellows and is arranged between a gas chamber (12) and a pressure mediumchamber (13) for media separation. The valve assembly is characterized by a pressure differential limiting valve (14) having a reciprocating piston (15) which, on the one hand, is acted upon by a pressure (p1) prevailing in the gas chamber (12) and which, on the other hand, is acted upon by a pressure (p2) prevailing in the pressure medium chamber (13), and which opens an additional gas return (16) when a predetermined pressure differential applied to the piston (15) is exceeded. The invention further relates to a fuel system comprising a valve assembly (1) according to the invention for controlling the gas pressure in a gas rail (2).

Owner:ROBERT BOSCH GMBH

Pumping-in type spiral groove dry gas seal structure with convergent type seal gap

The invention relates to a pumping-in type spiral groove dry gas seal structure with a convergent type seal gap. The pumping-in type spiral groove dry gas seal structure comprises two seal rings, a plurality of spiral grooves are uniformly formed in the external diameter side circumferential direction of the end face of any one of the two seal rings, and gas flows from the external diameter side to the internal diameter side in the radial direction; and a transitional face is machined on the position, close to the internal diameter, of the end face of any one seal ring to enable a seal gap between the two seal rings to form the convergent type seal gap in the flowing direction of the gas. According to the pumping-in type spiral groove dry gas seal structure with the convergent type seal gap, by reasonably designing parameters of the transitional face, the hydrodynamic effect generated by the spiral grooves and the hydrostatic effect generated by the convergent seal gap are utilized, and thus the seal opening capacity is improved. Meanwhile, the seal gap is designed into a convergent type, thus the seal leakage rate can be reduced to a certain extent, and the seal property is further improved.

Owner:KUNMING UNIV OF SCI & TECH

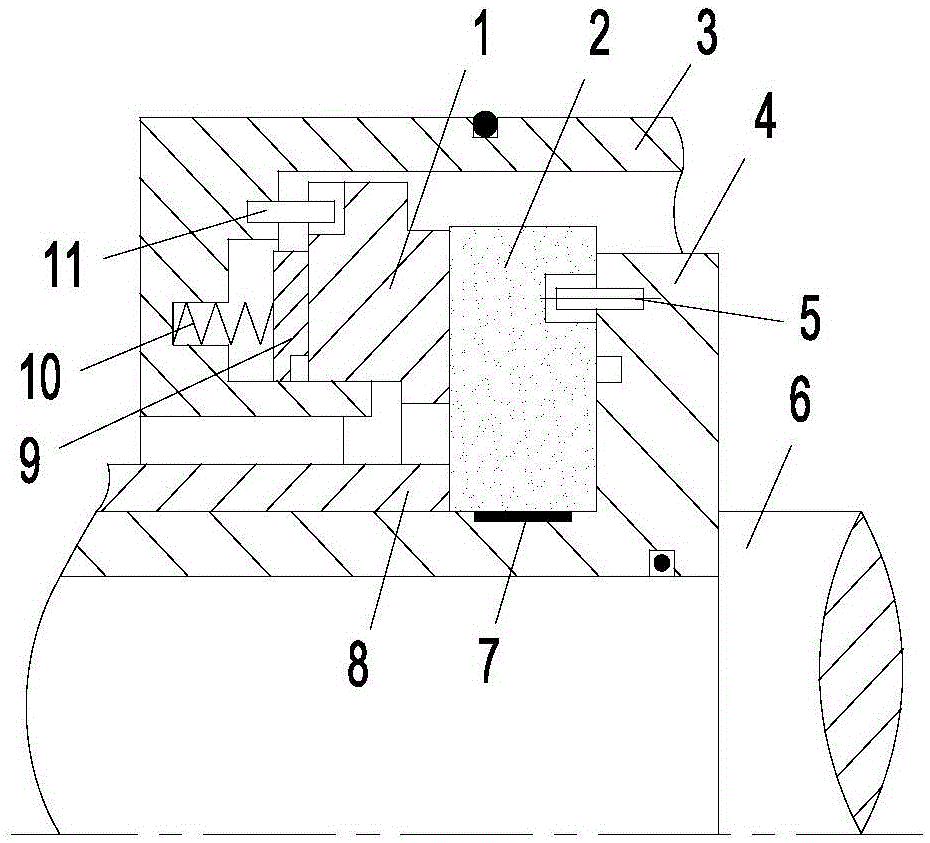

Receptacle comprising a safety locking mechanism for a vehicle

InactiveUS20170320644A1Improve opening forceAvoid elevationRemovable lids/coversLidsLocking mechanismEngineering

A receptacle including a safety locking mechanism in a motor vehicle. A lever is providing including a mass, which is held by a snap-fit device releasably in a non-deflected basic position or in a deflected locking position. In the deflected locking position, the lever, by way of a head, holds a closing element of a lock in a closed position. The lock can be opened in a non-deflected position of the lever. During opening, the lock restores the lever to the basic position, whereby the receptacle can be opened after an accident. The lever is deflected by accelerations that occur in the event of an accident.

Owner:FISCHER AUTOMOTIVE SYST

Valve assembly for controlling gas pressure, fuel system comprising valve assembly for controlling gas pressure

ActiveCN110469430AReliable media separationAchieve dampingInternal combustion piston enginesFuel supply apparatusPistonEngineering

The invention relates to a valve assembly for controlling the gas pressure in a gas rail of a fuel system for supplying an internal combustion engine with a gaseous fuel, in particular with natural gas, comprising a first valve for connecting the gas rail to a gas feed, a second valve for connecting the gas rail to a gas return, and a control piston for actuating both valves, wherein the control piston delimits a control chamber, to which a hydraulic pressure medium can be applied by a pressure medium feed and which can be depressurized via a pressure medium discharge, and further comprising asealing element which is designed as a corrugated or folding bellows and is arranged between a gas chamber and a pressure medium chamber for media separation. The valve assembly is characterized by apressure differential limiting valve having a reciprocating piston which, on the one hand, is acted upon by a pressure prevailing in the gas chamber and which, on the other hand, is acted upon by a pressure prevailing in the pressure medium chamber, and which opens an additional gas return when a predetermined pressure differential applied to the piston is exceeded. The invention further relatesto a fuel system comprising a valve assembly according to the invention for controlling the gas pressure in a gas rail.

Owner:ROBERT BOSCH GMBH

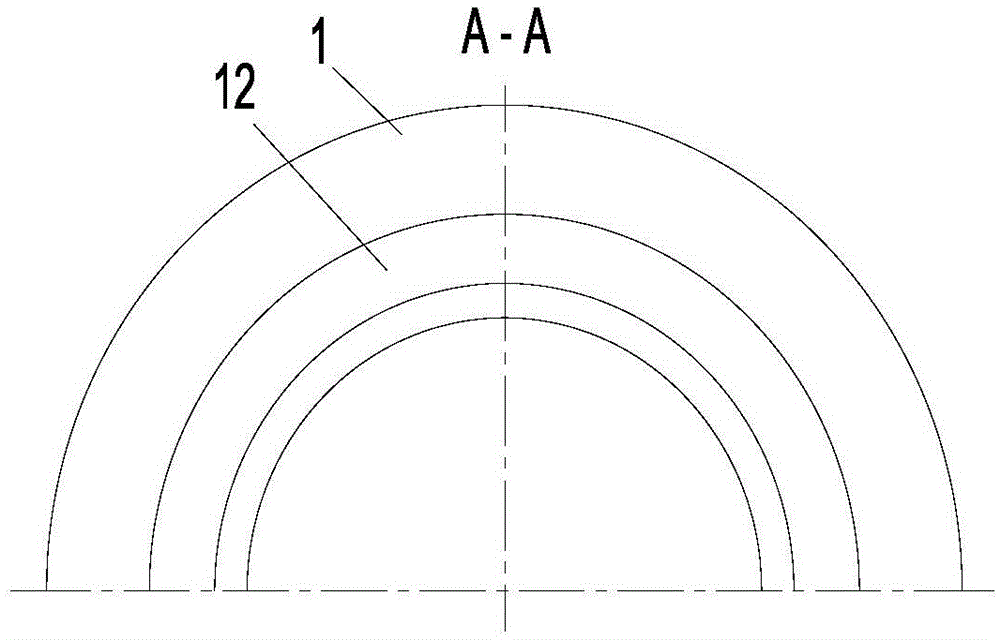

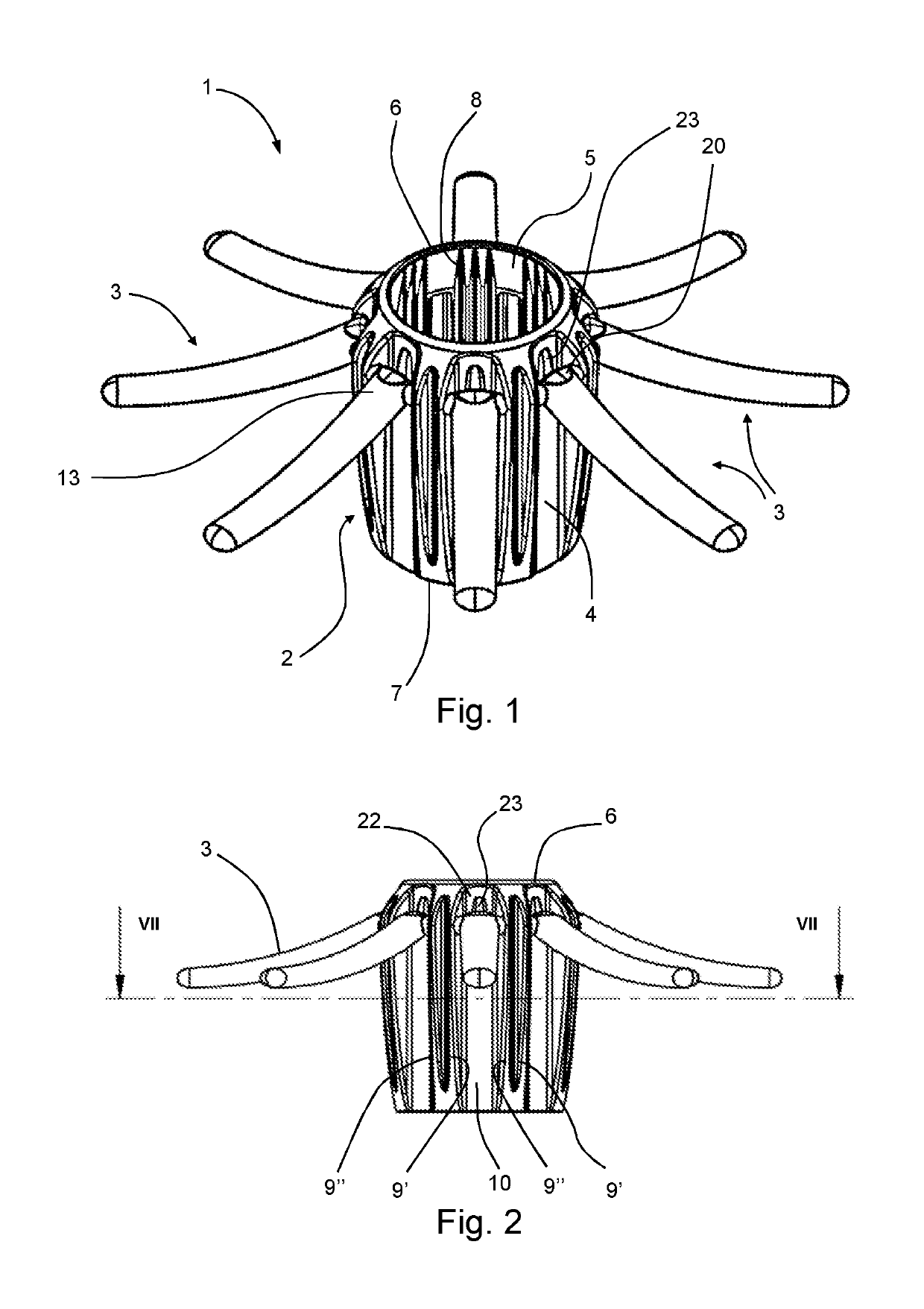

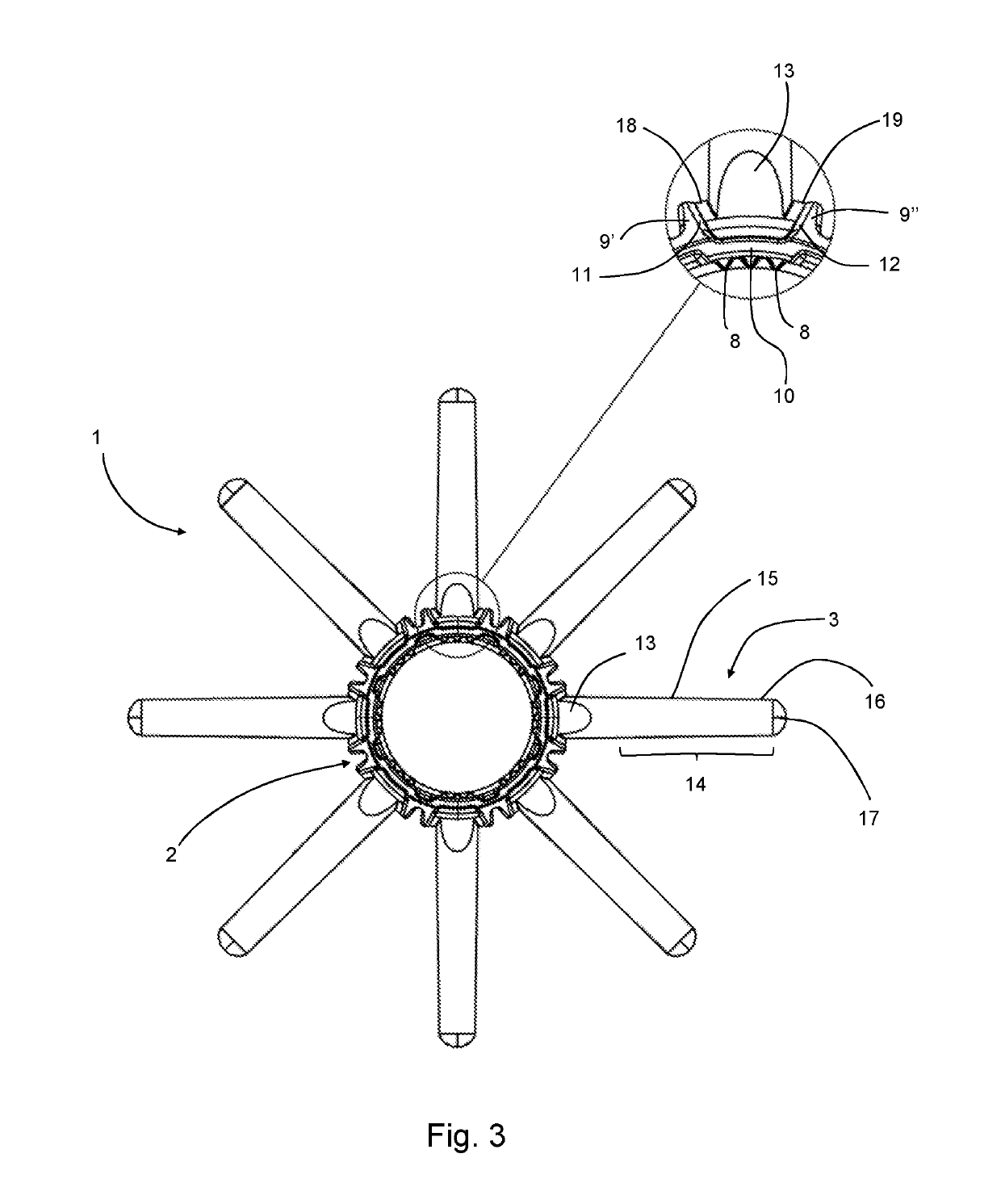

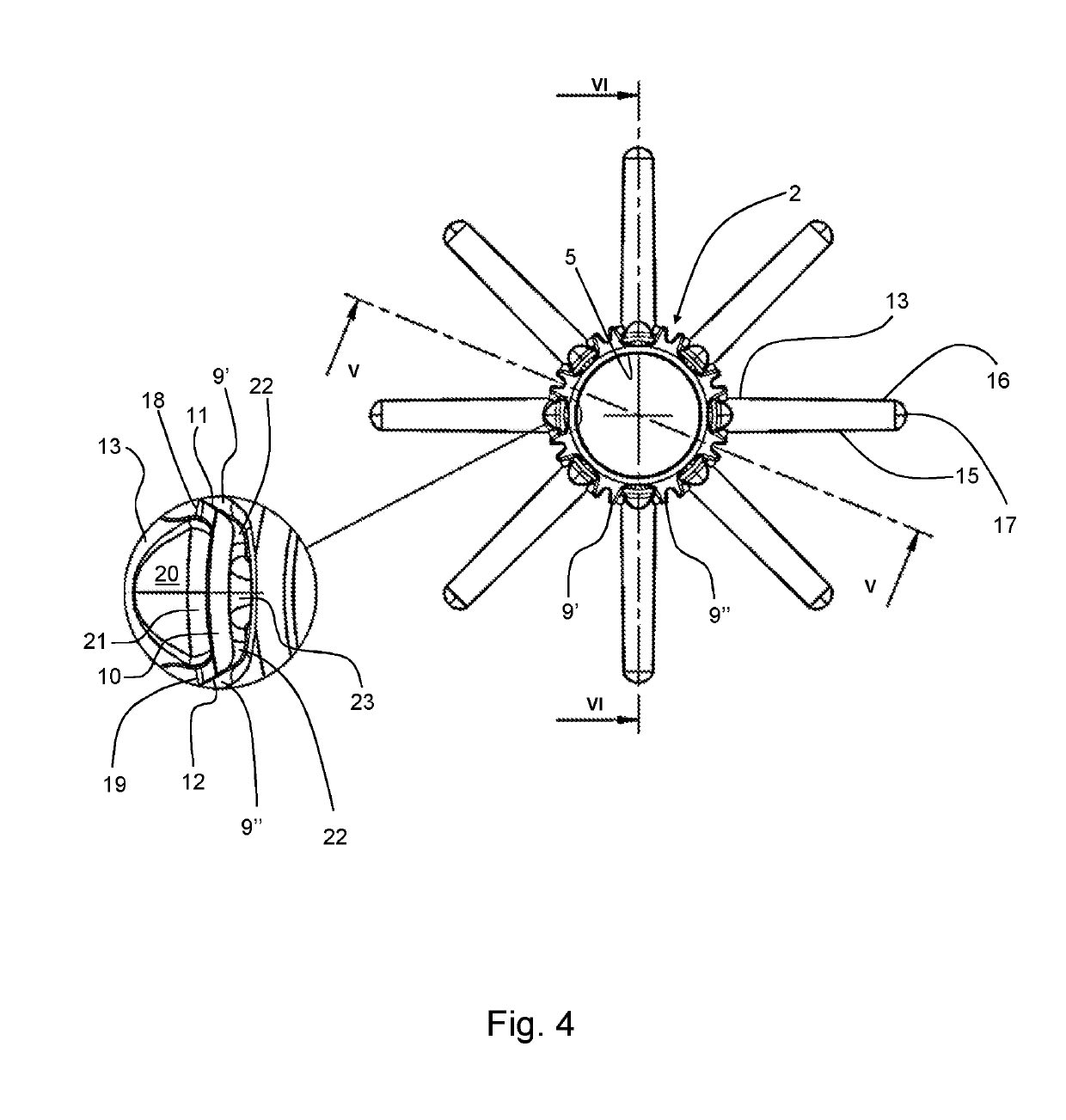

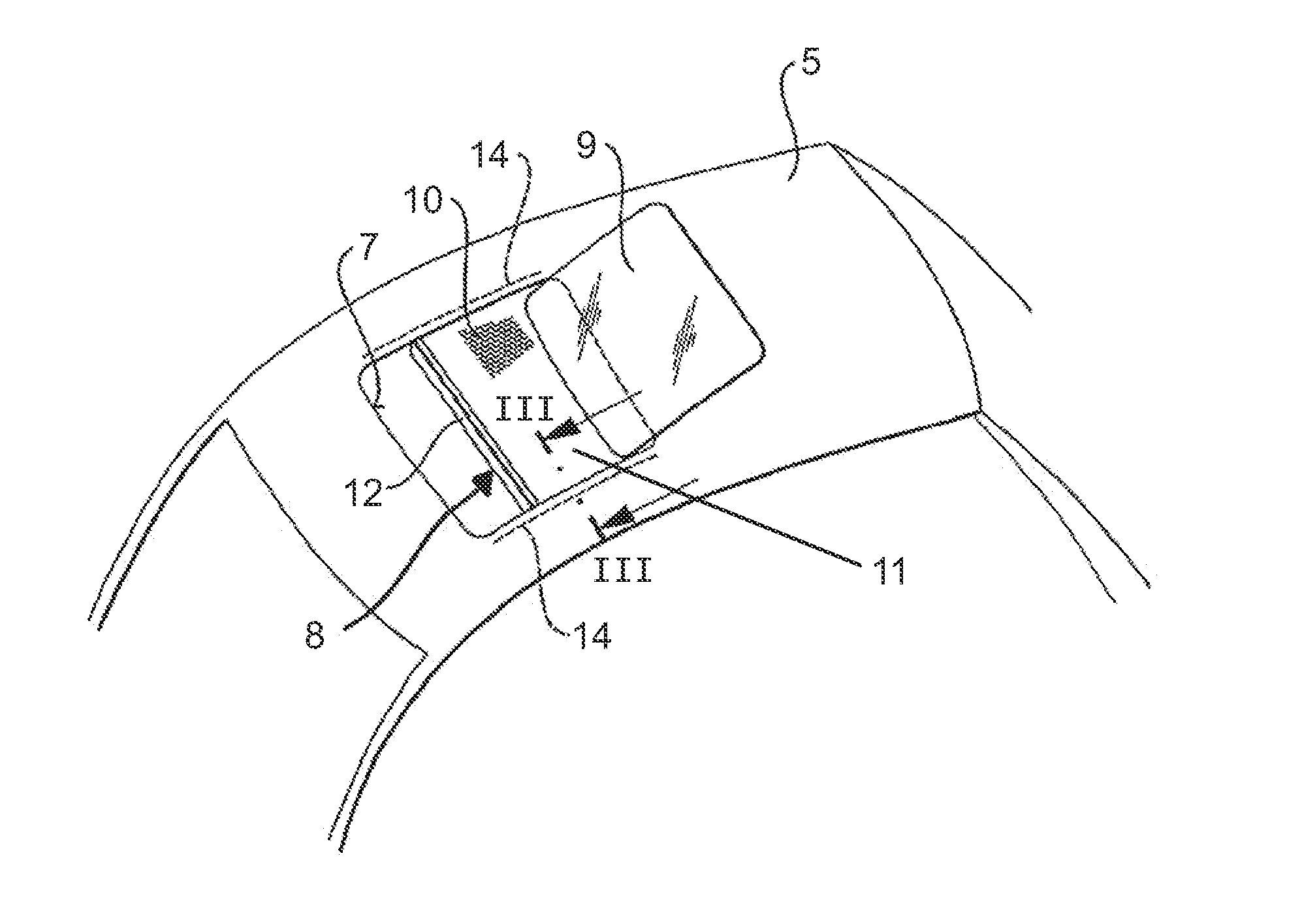

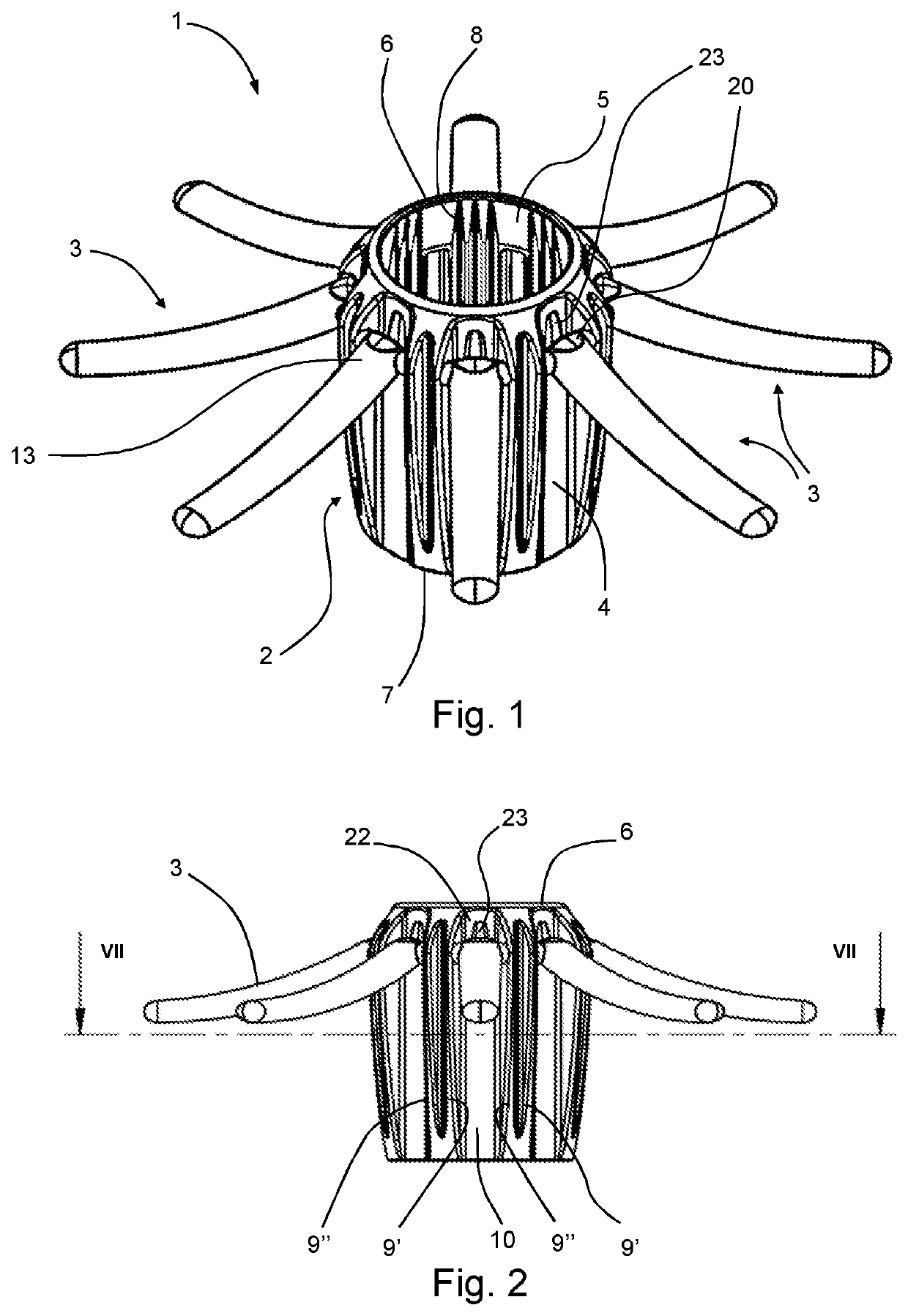

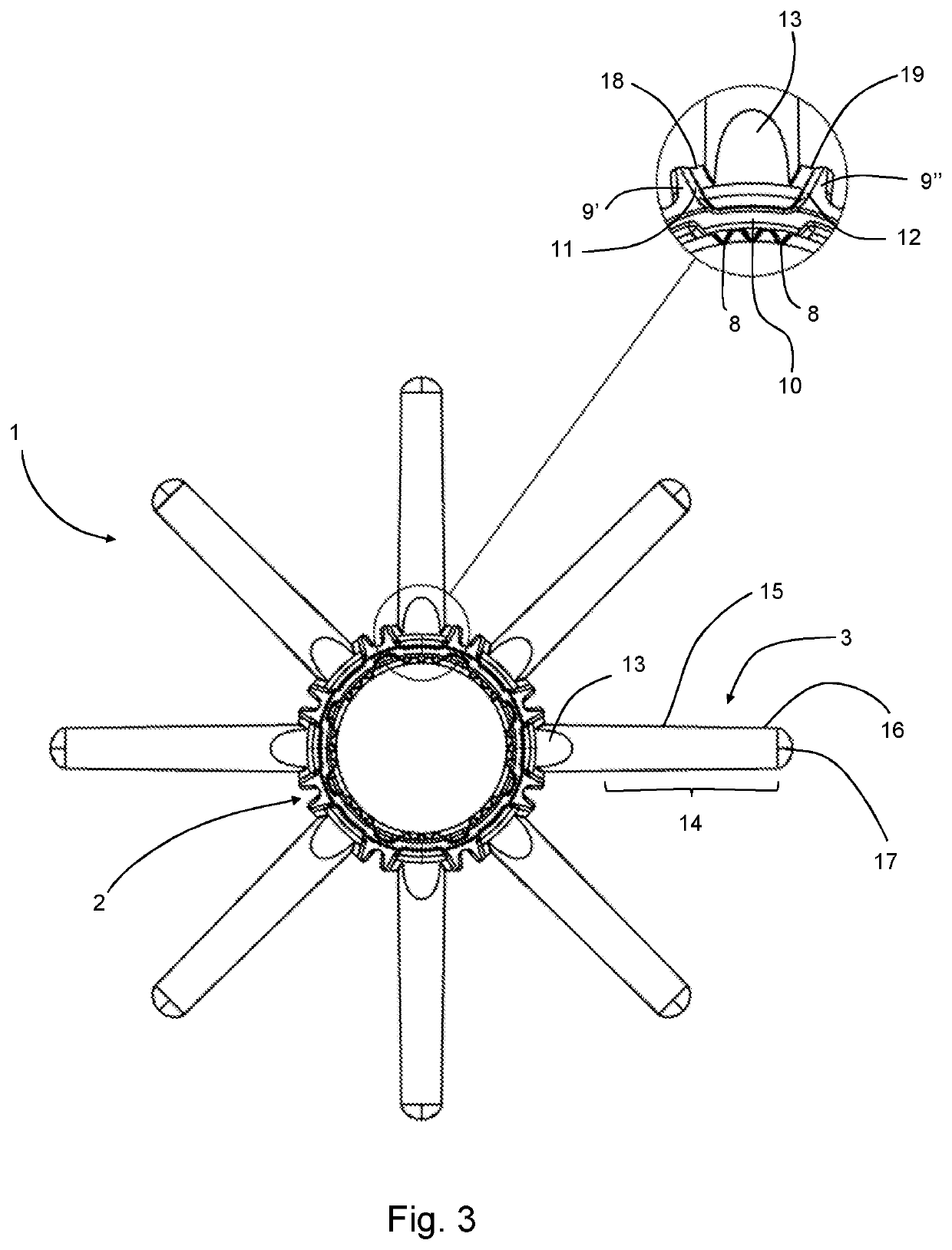

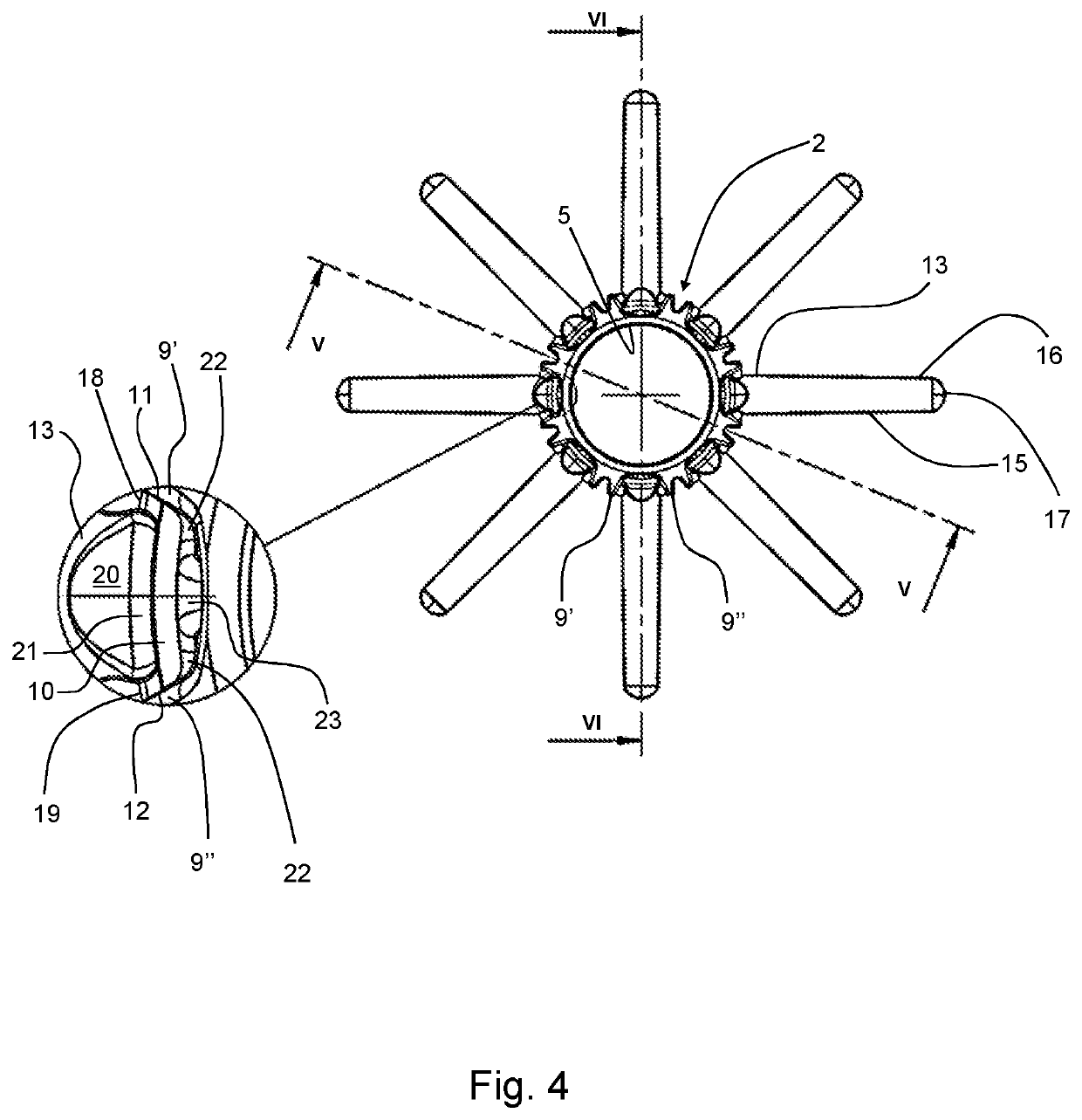

Medical Scope Accessory, Medical Scopes Comprising The Accessory, And Use Thereof

ActiveUS20190183328A1Hindering further pivoting movementFurther pivoting at the mountings is reduced or preventedSurgeryEndoscopesDetentBiomedical engineering

A cover (1) for a shaft of a medical scoping device comprises tubular member (2) arranged for application on the distal tip of the medical scoping device. The cover (1) comprises a plurality of projecting elements (3) spaced apart circumferentially around the tubular member (2), each projecting element having a base portion (13) and an arm portion (14). The projecting elements are pivotably mounted on the tubular member about a pivot axis. The base portion (13) comprises a detent (20), and the tubular member comprises a contact region, for example a protuberance (23), said contact region being located such that pivoting movement of the projecting element for moving the arm portion in a distal direction can effect impacting of the detent (20) on the contact region (23).

Owner:KEYMED MEDICAL & INDAL EQUIP

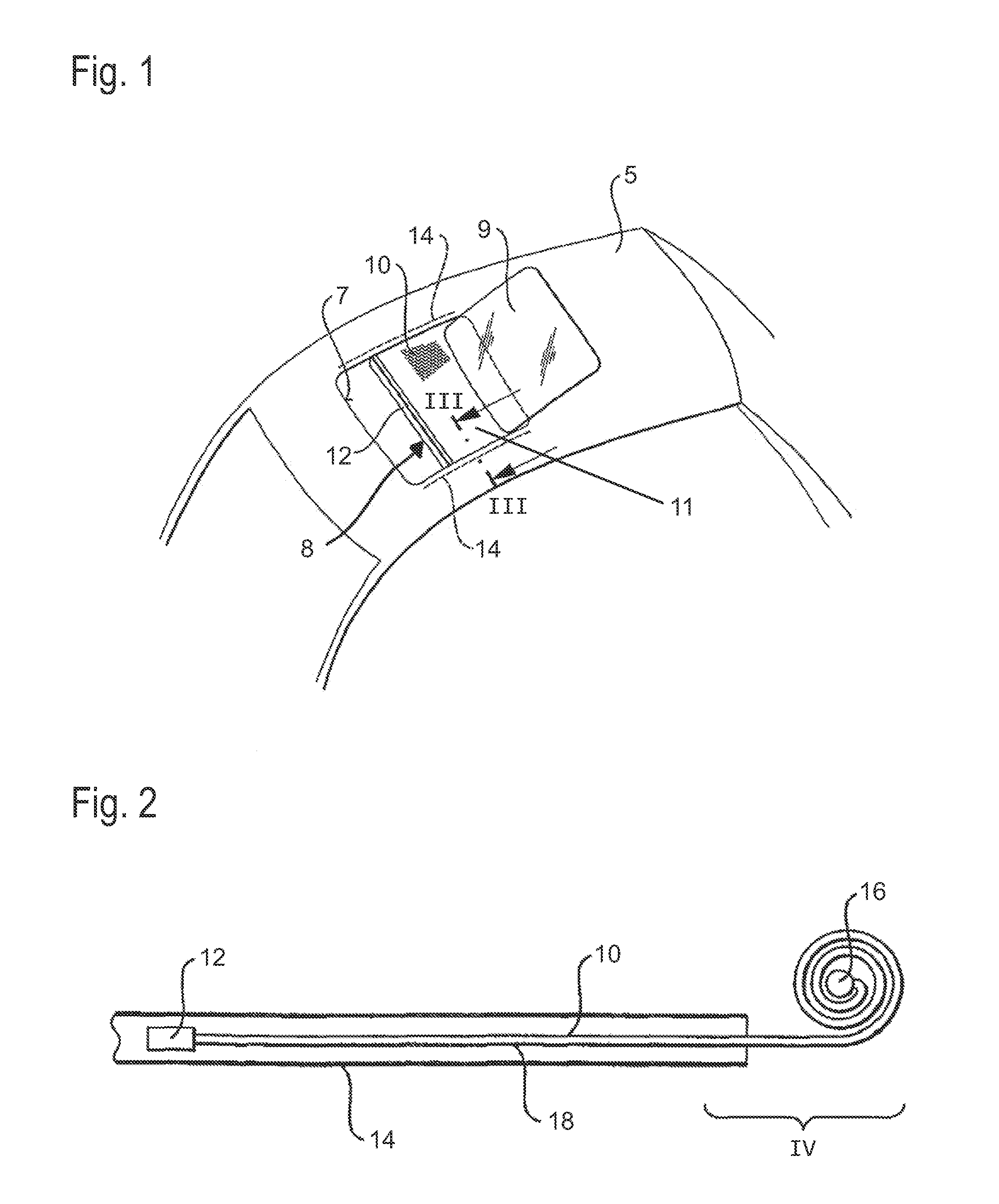

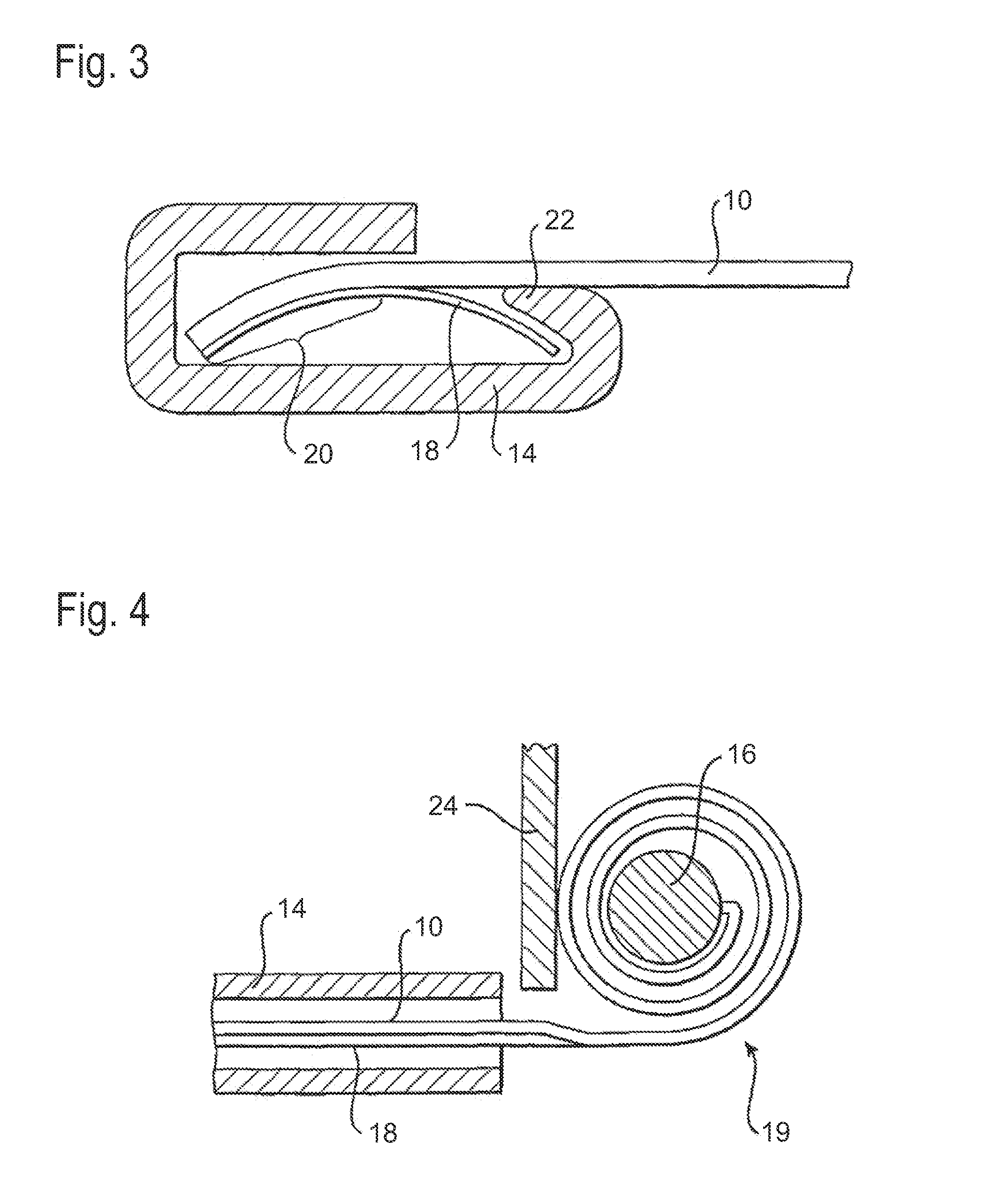

Roller blind system for a sliding roof

InactiveUS20150251526A1Increase frictionForce is smallScreensShutters/ movable grillesEngineeringMechanical engineering

A roller blind system for a sliding roof with at least one guide rail and with a roller blind with a roller blind fabric mounted on at least one guiding strip is provided, The guiding strip is sectionally guided in the guide rail and its end that is located outside the guide rail contracts to form a coil during a movement of the roller blind in opening direction, wherein at least one device for increasing the opening force of the roller blind is provided, which is designed and arranged such that the device produces an additional force at least in opening direction.

Owner:ROOF SYST GERMANY

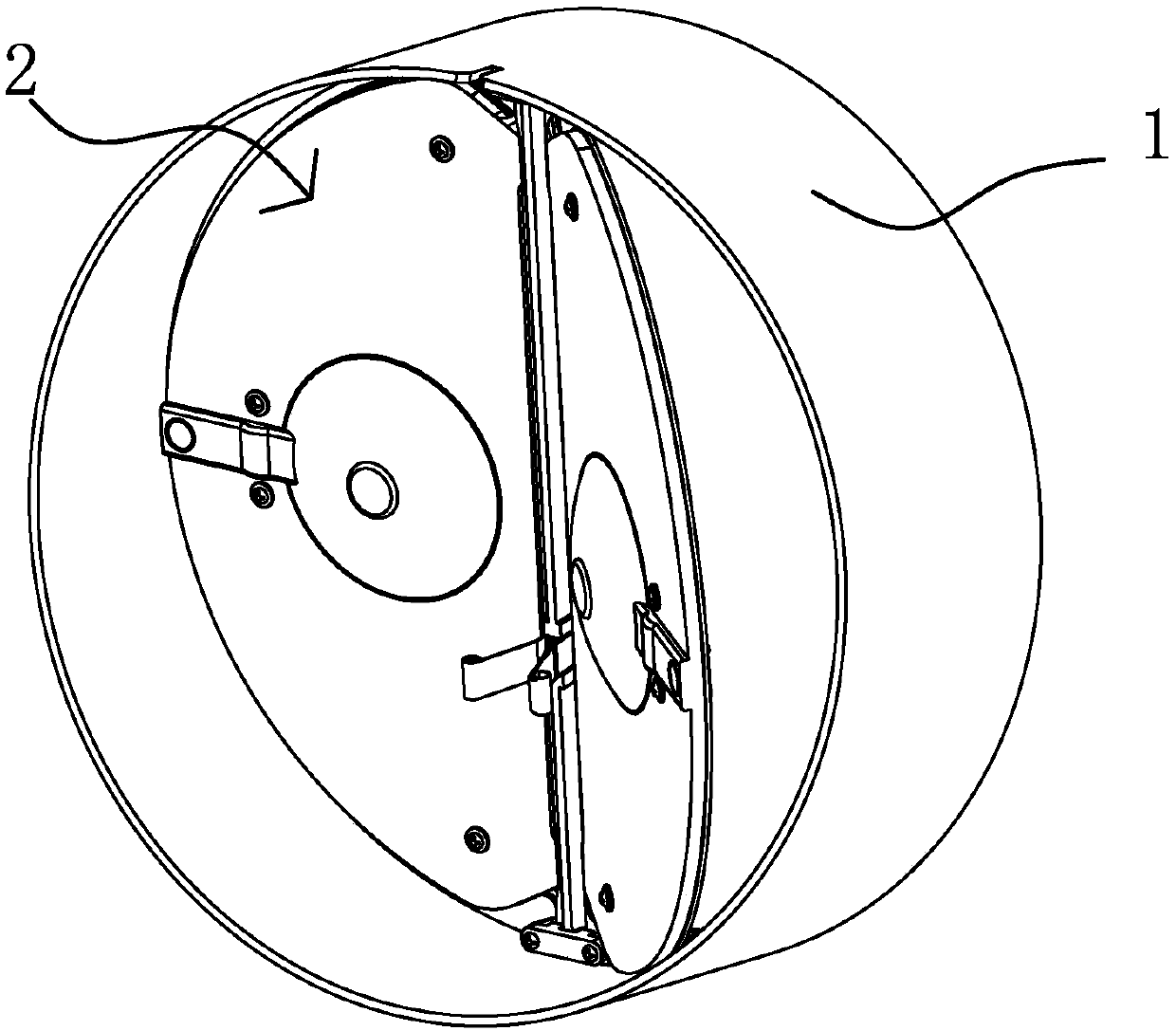

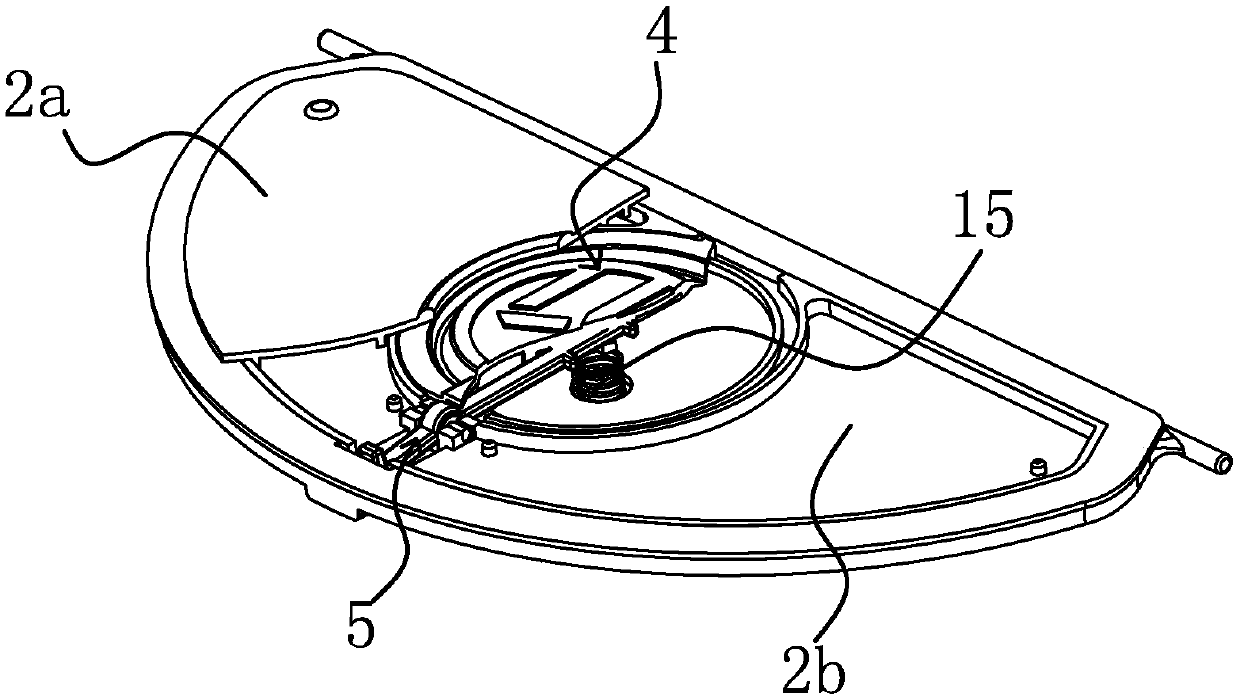

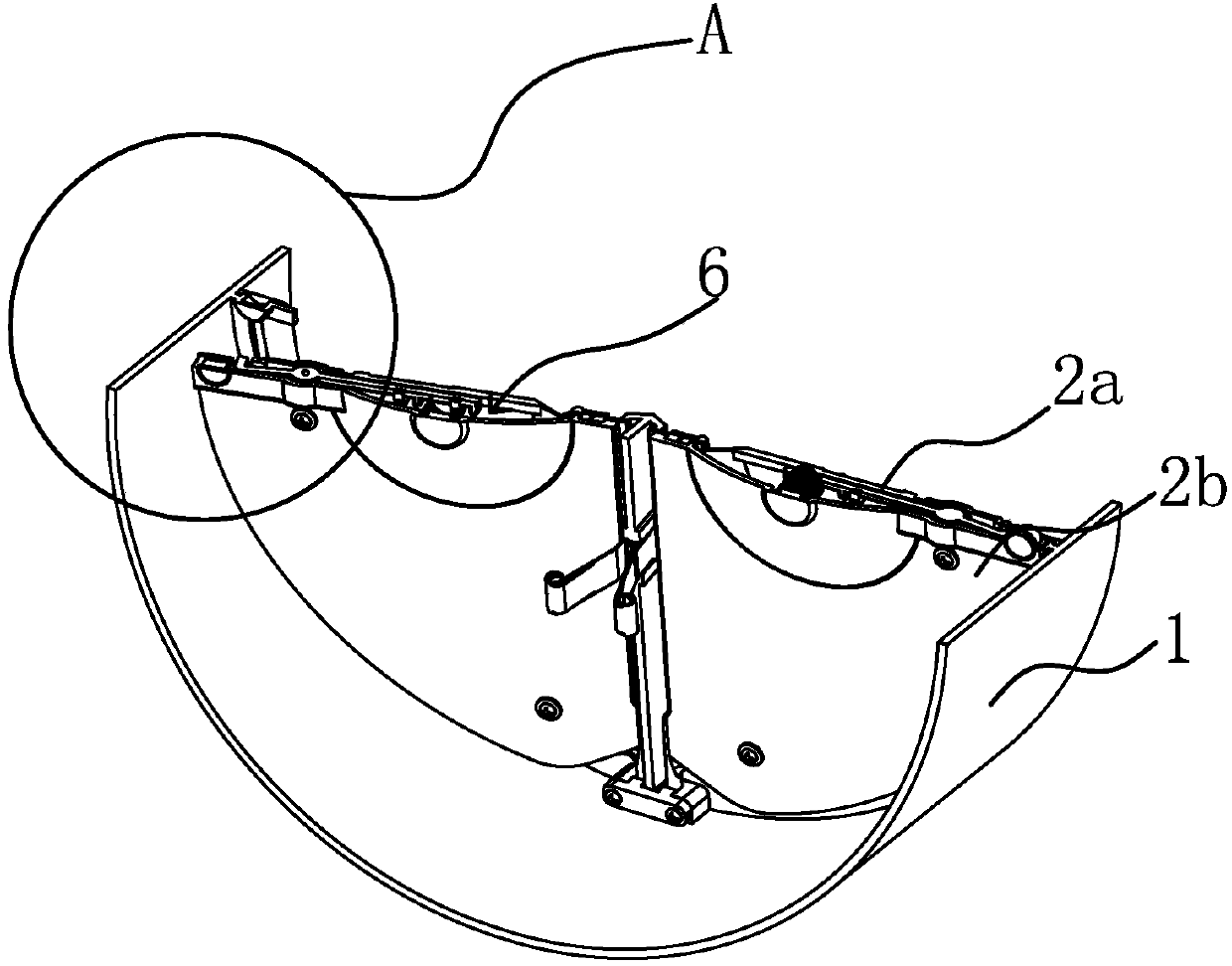

Auxiliary opening mechanism for flue check valve

The invention provides an auxiliary opening mechanism for a flue check valve, and belongs to the technical field of pipeline structures. The auxiliary opening mechanism solves the problem that valve plates cannot be opened after long-term use in the prior art. The auxiliary opening mechanism for the flue check valve comprises a shell and a plurality of valve plates; an annular sealing baffle edgeis arranged in the shell; the valve plates are hinged in the shell; the edges of the valve plates can be attached to or can be separated from the annular sealing baffle edge; and the shell is providedwith an air inlet end and an air outlet end. The auxiliary opening mechanism is characterized by comprising swing rods; an installation cavity is formed in each valve plate; the swing rods are arranged in the installation cavities in a swinging mode; openings I and openings II are formed in the sides, close to the air inlet end, of the valve plates; an elastic pad is arranged on each opening I; one ends of the swing rods make contact with the elastic pads; the openings II are formed in the edges of the valve plates; and when the elastic pads deform to drive one ends of the swing rods to swing, the other ends of the swing rods can penetrate out of the openings II to abut against the annular sealing baffle edge. The auxiliary opening mechanism has the advantage of enhancing the opening force of the valve plates.

Owner:MARSSENGER KITCHENWARE CO LTD

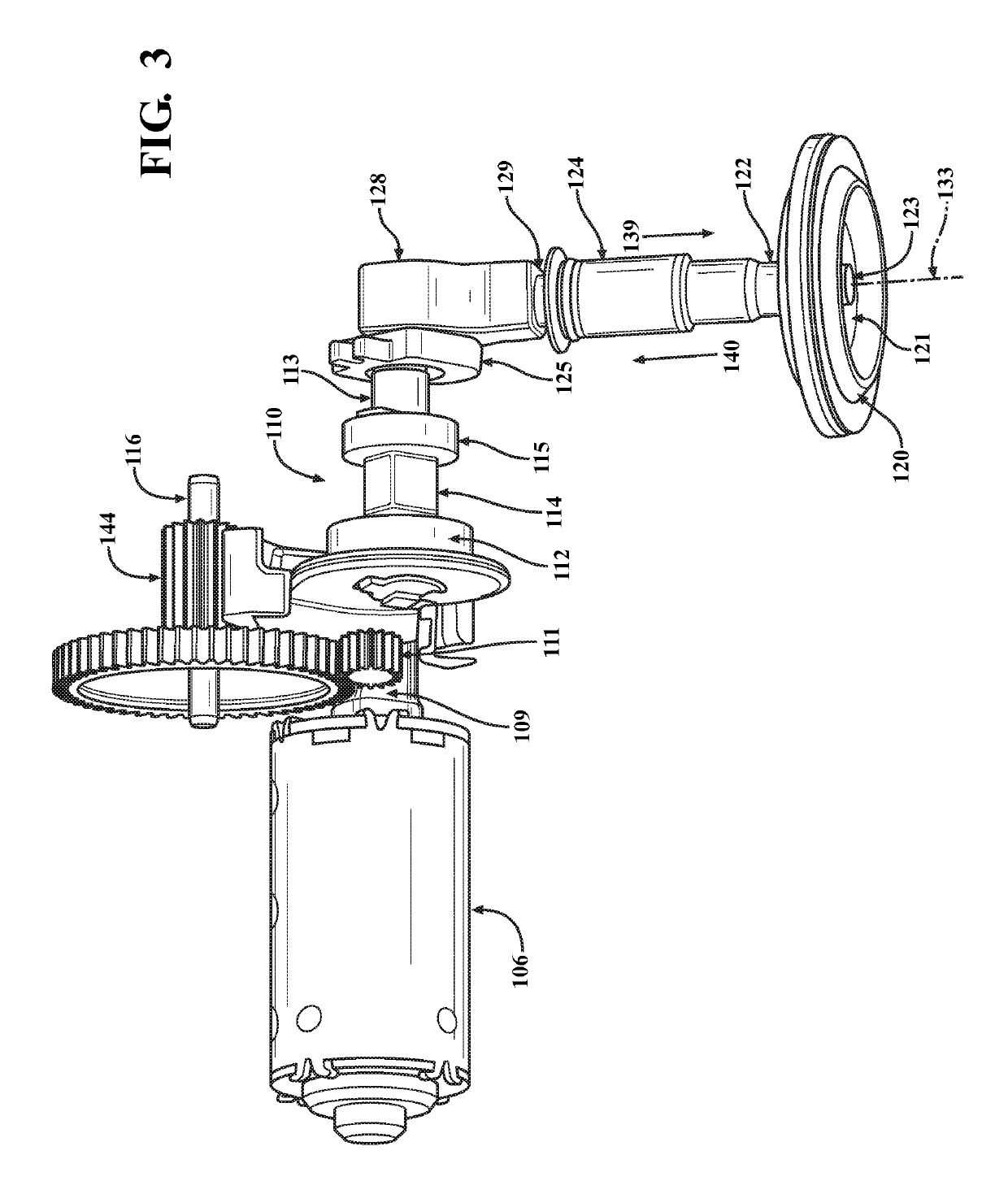

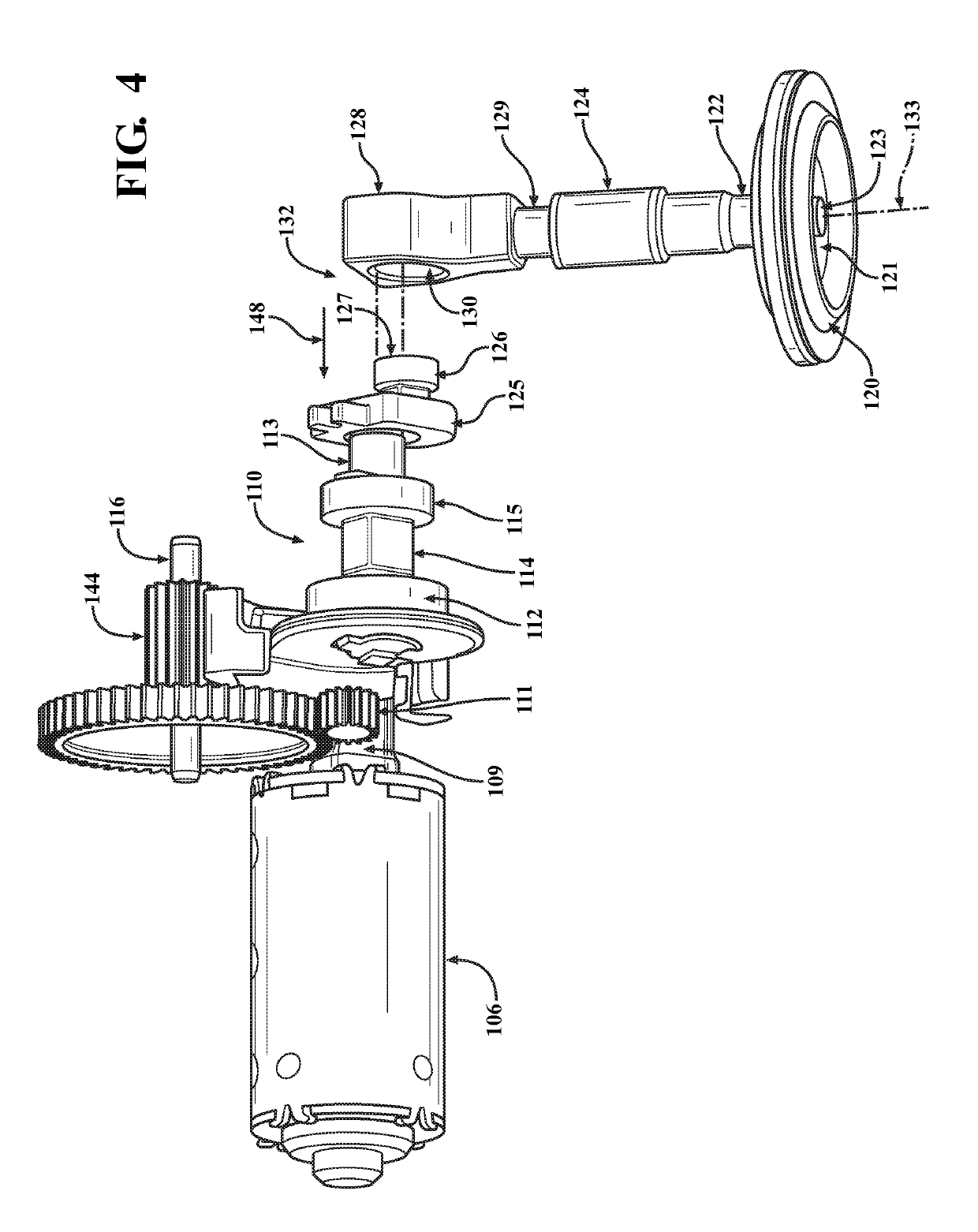

Split linkage mechanism for valve assembly

ActiveUS10473232B2Increase loadReduce trafficOperating means/releasing devices for valvesExhaust gas recirculationLinear motionRotational axis

A linkage mechanism for a valve assembly includes one of a slot and an engagement component operably coupled to at least one drive component and located eccentrically from a rotational axis of the at least one drive component, a link operably coupled to one end of a valve stem of a valve member and being moveable with the valve stem, the link having another one of a slot and an engagement component, and a rotatable lever coupled to at least one housing, the lever including one of a first slot and a first engagement component operably engaged with the one of the slot and the engagement component of the at least one drive component and one of a second slot and a second engagement component operably engaged with the one of the slot and the engagement component of the link, wherein rotation of the at least one drive component causes the lever to rotate to convert a rotational movement of the at least one drive component to a linear movement of the link such that the link, the valve stem, and the valve member are moved axially in a direction along a longitudinal axis of the valve stem.

Owner:BORGWARNER INC

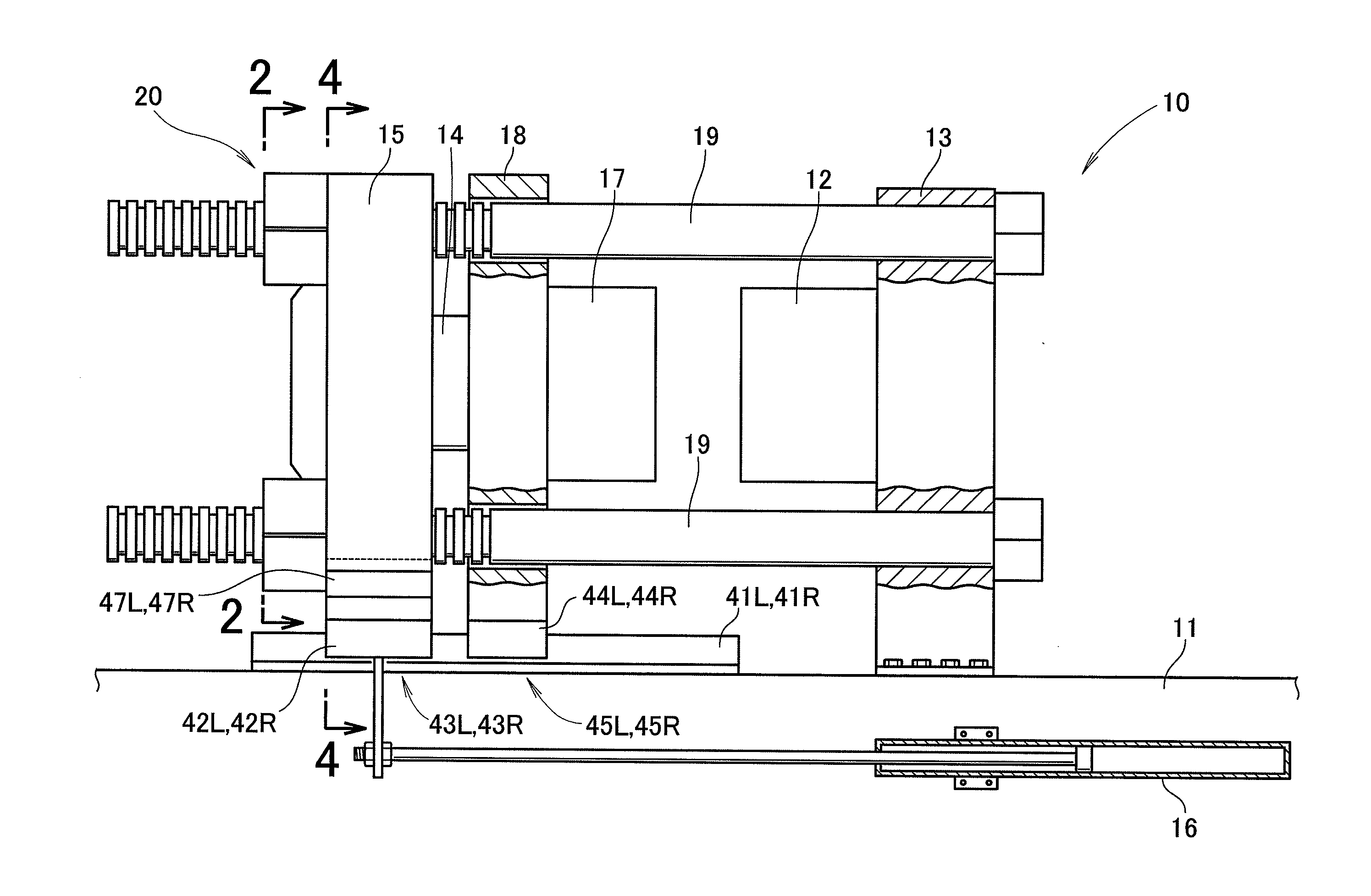

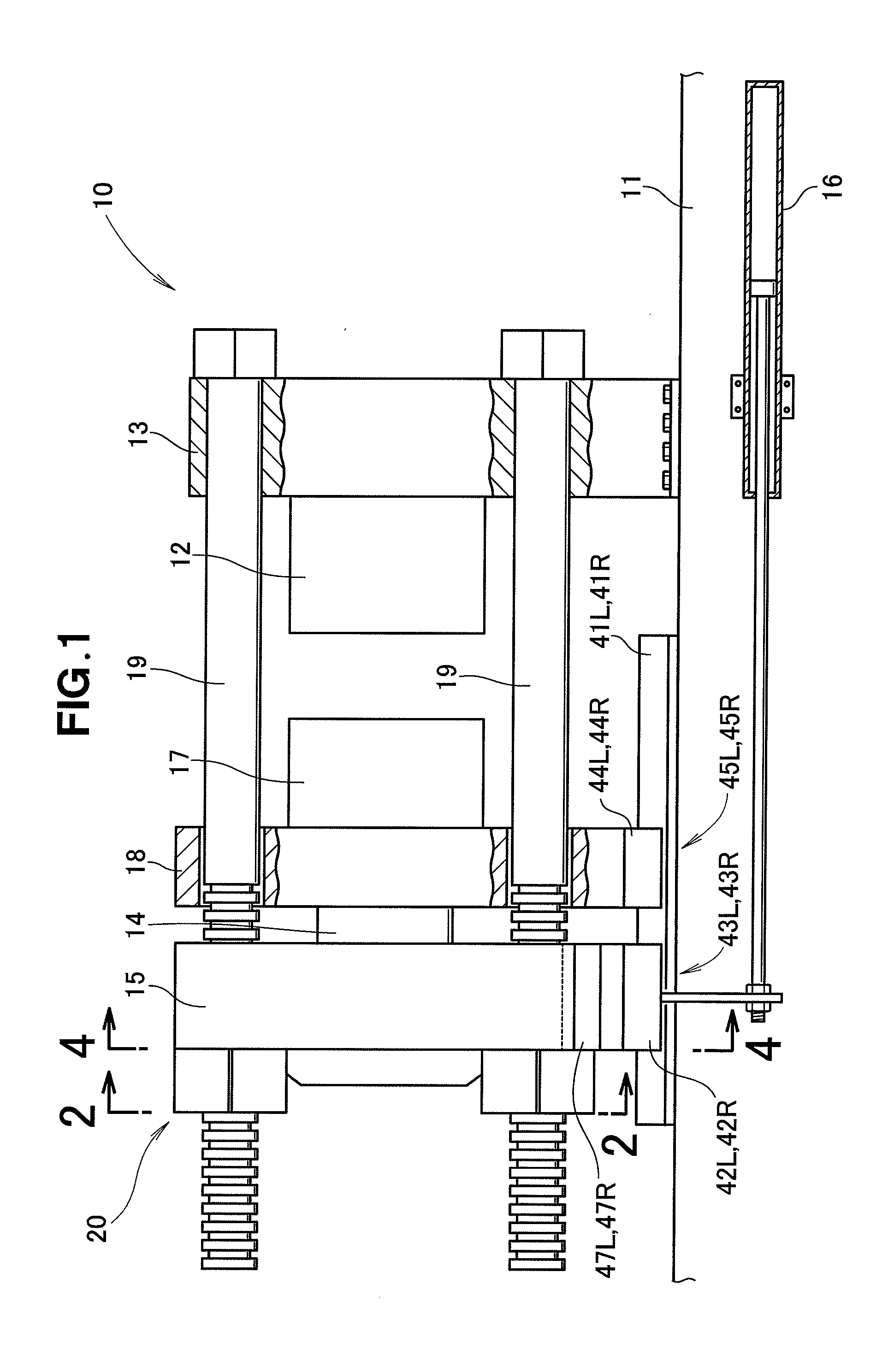

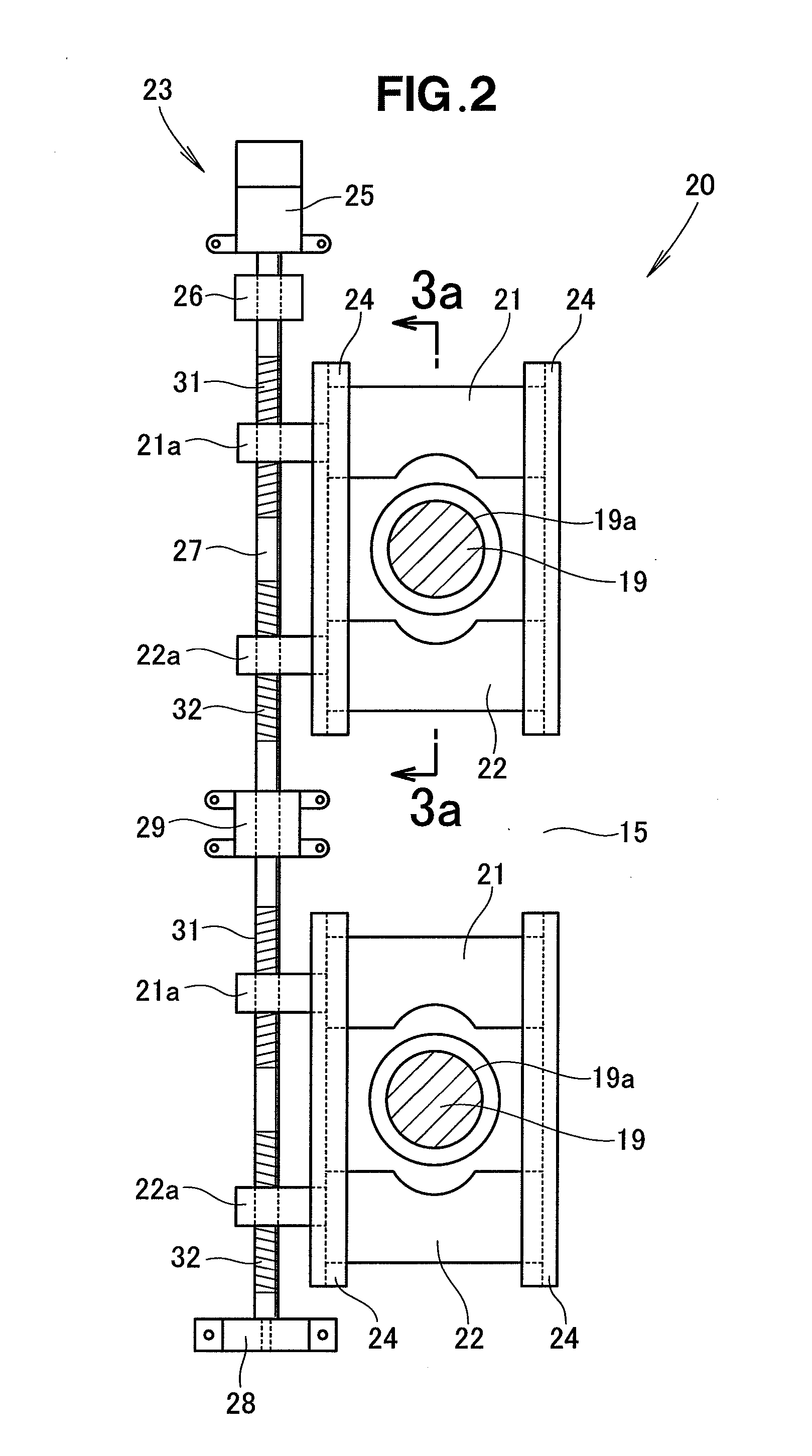

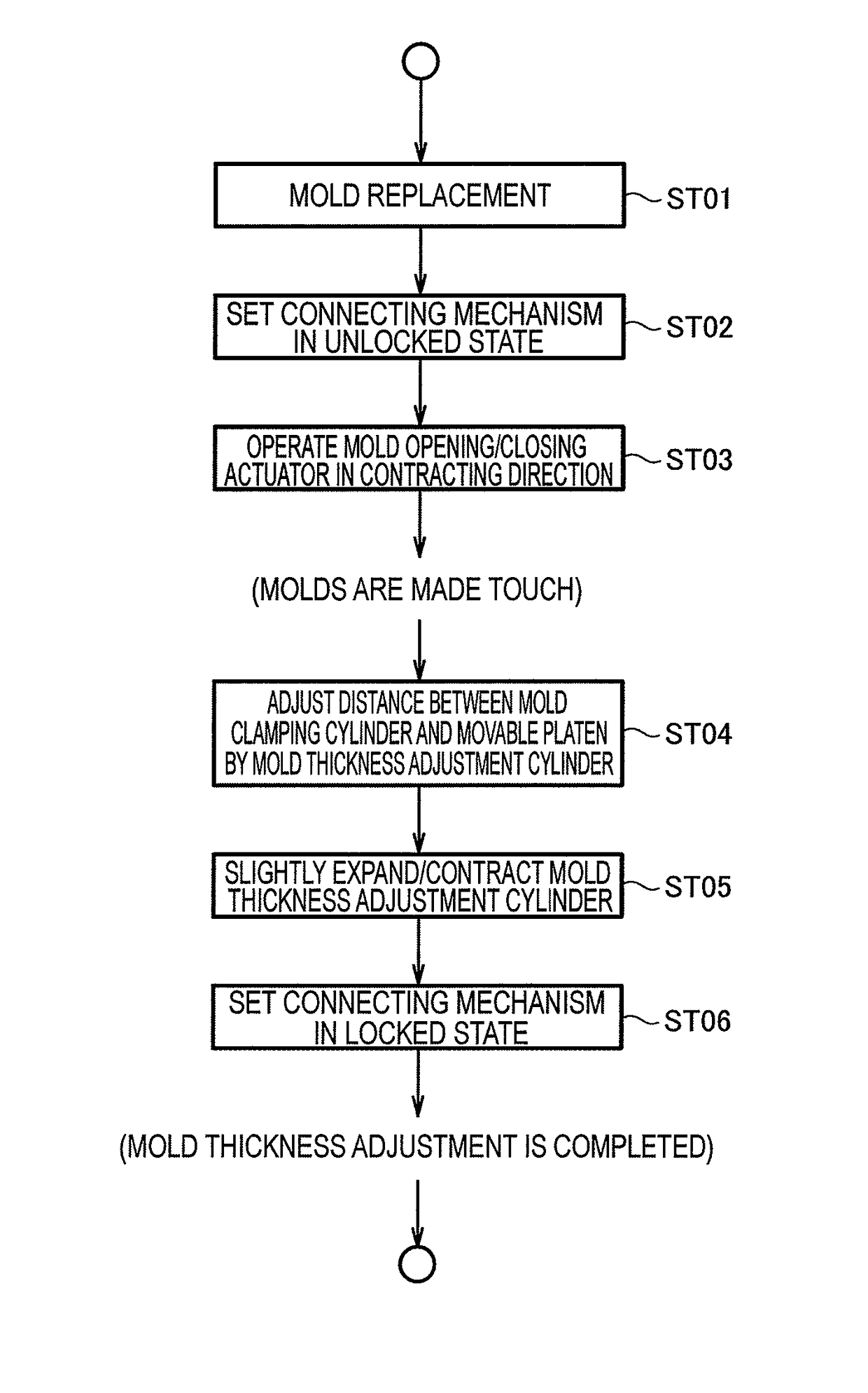

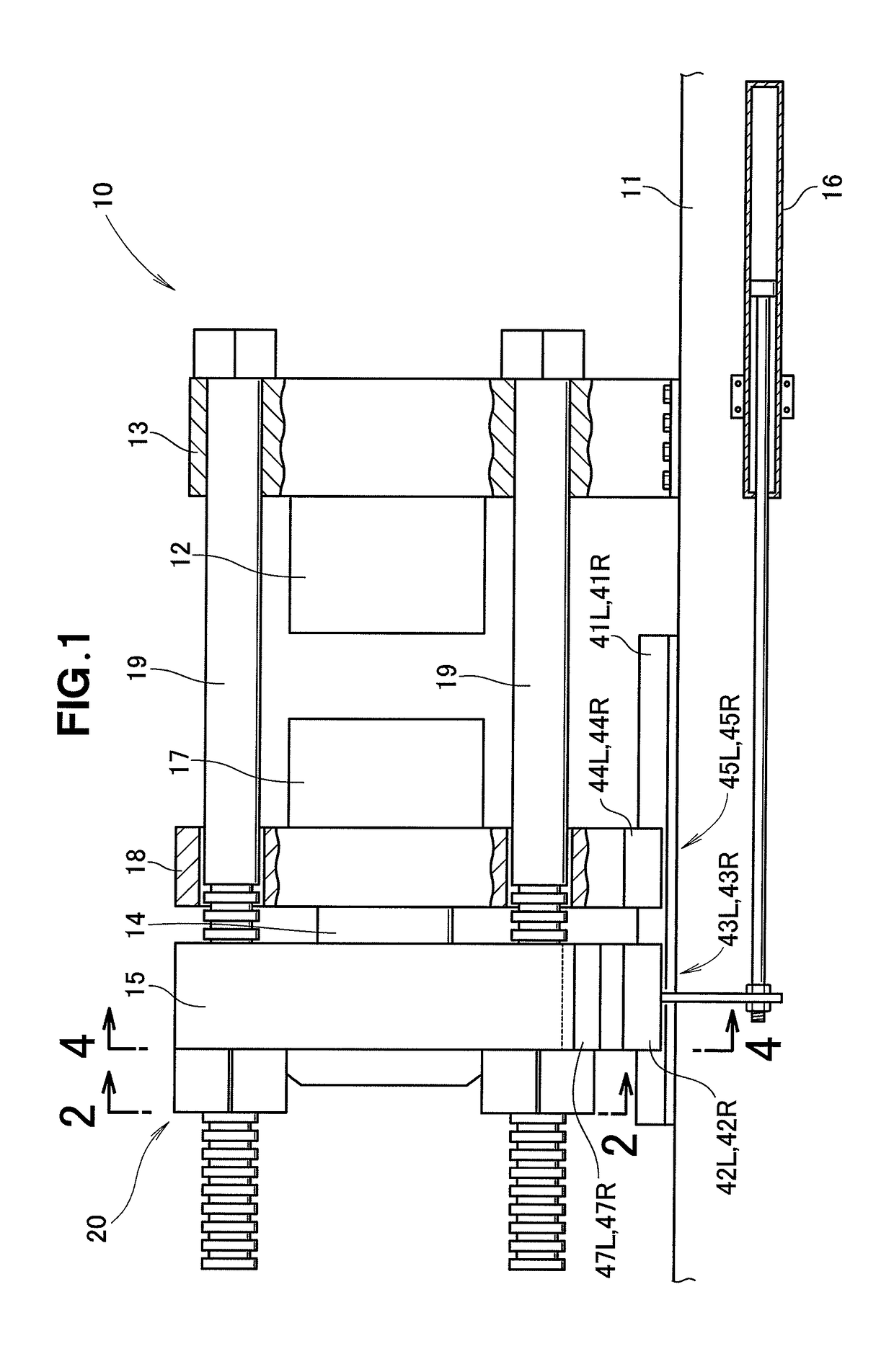

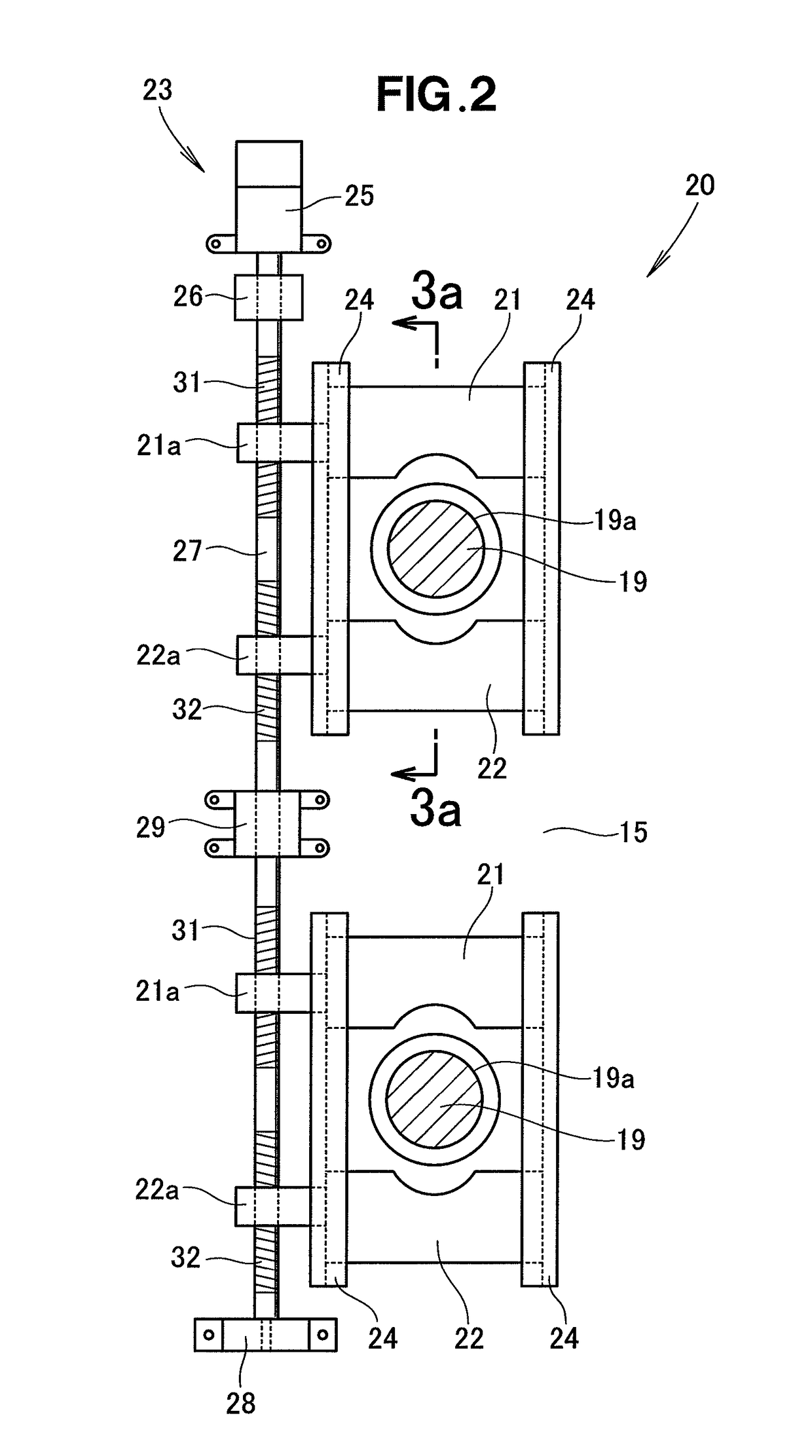

Mold clamping apparatus

A mold clamping apparatus includes a fixed platen, a mold clamping cylinder, a movable platen moved by the mold clamping cylinder toward the fixed platen, and a mold opening / closing actuator for moving the movable platen or the mold clamping cylinder. The mold clamping apparatus further includes a mold thickness adjustment cylinder provided between the mold clamping cylinder and the movable platen, the mold thickness adjustment cylinder being configured to generate an axial force larger than an axial force in an expanding direction of the mold opening / closing actuator and smaller than an axial force in a contracting direction of the mold clamping cylinder.

Owner:NISSEI PLASTIC IND CO LTD

Mechanical seal with controllable wave seal face seal ring

Owner:江苏光谷产业投资发展有限公司

Medical scope accessory, medical scopes comprising the accessory, and use thereof

ActiveUS11399712B2Hindering further pivoting movementFurther pivoting at the mountings is reduced or preventedSurgeryEndoscopesMechanical engineeringBiomedical engineering

A cover (1) for a shaft of a medical scoping device comprises tubular member (2) arranged for application on the distal tip of the medical scoping device. The cover (1) comprises a plurality of projecting elements (3) spaced apart circumferentially around the tubular member (2), each projecting element having a base portion (13) and an arm portion (14). The projecting elements are pivotably mounted on the tubular member about a pivot axis. The base portion (13) comprises a detent (20), and the tubular member comprises a contact region, for example a protuberance (23), said contact region being located such that pivoting movement of the projecting element for moving the arm portion in a distal direction can effect impacting of the detent (20) on the contact region (23).

Owner:KEYMED MEDICAL & INDAL EQUIP

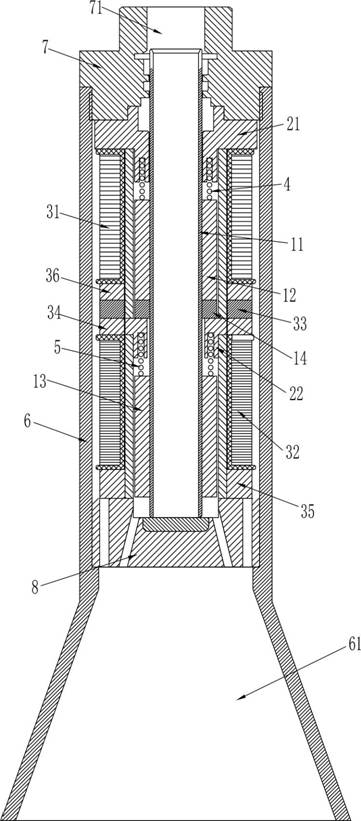

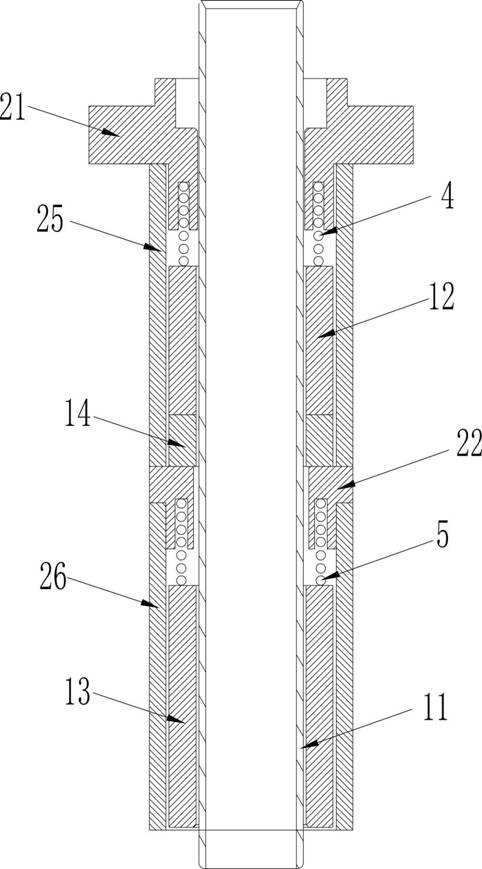

An ultra-high temperature, high pressure and large flow rapid response solenoid valve

ActiveCN114562592BOpen fastQuick responseOperating means/releasing devices for valvesThermal insulationSolenoid valveMagnetic isolation

The invention provides an ultra-high temperature, high pressure and large flow rapid response solenoid valve, which includes a movable valve core assembly, a magnetic isolation tube assembly and a coil assembly. The movable valve core assembly includes a center tube, an upper movable iron core and a lower movable iron core. A magnetic isolation ring is installed between the iron core and the lower movable iron core; the magnetic isolation tube assembly includes an upper fixed iron core arranged opposite to the upper movable iron core and a lower fixed iron core arranged opposite to the lower movable iron core; the coil assembly includes a The upper coil corresponding to the upper movable iron core, the lower coil corresponding to the lower movable iron core, and the first magnetic conductive plate and the second magnetic conductive plate arranged on both sides of the lower coil, and a magnetic isolation is installed between the upper coil and the lower coil. The lower end of the upper coil is provided with a third magnetic conductive plate, and the first magnetic conductive plate and the third magnetic conductive plate are respectively located on both sides of the magnetic isolation member; the invention provides an ultra-high temperature, high pressure and large flow rapid response solenoid valve, It overcomes the defects of the existing electromagnetic valve having a long opening and closing response time and being unsuitable for a high temperature and high pressure environment.

Owner:YUYAO SANLIXIN SOLENOID VALVE CO LTD

Mold clamping apparatus

A mold clamping apparatus includes a fixed platen, a mold clamping cylinder, a movable platen moved by the mold clamping cylinder toward the fixed platen, and a mold opening / closing actuator for moving the movable platen or the mold clamping cylinder. The mold clamping apparatus further includes a mold thickness adjustment cylinder provided between the mold clamping cylinder and the movable platen, the mold thickness adjustment cylinder being configured to generate an axial force larger than an axial force in an expanding direction of the mold opening / closing actuator and smaller than an axial force in a contracting direction of the mold clamping cylinder.

Owner:NISSEI PLASTIC IND CO LTD

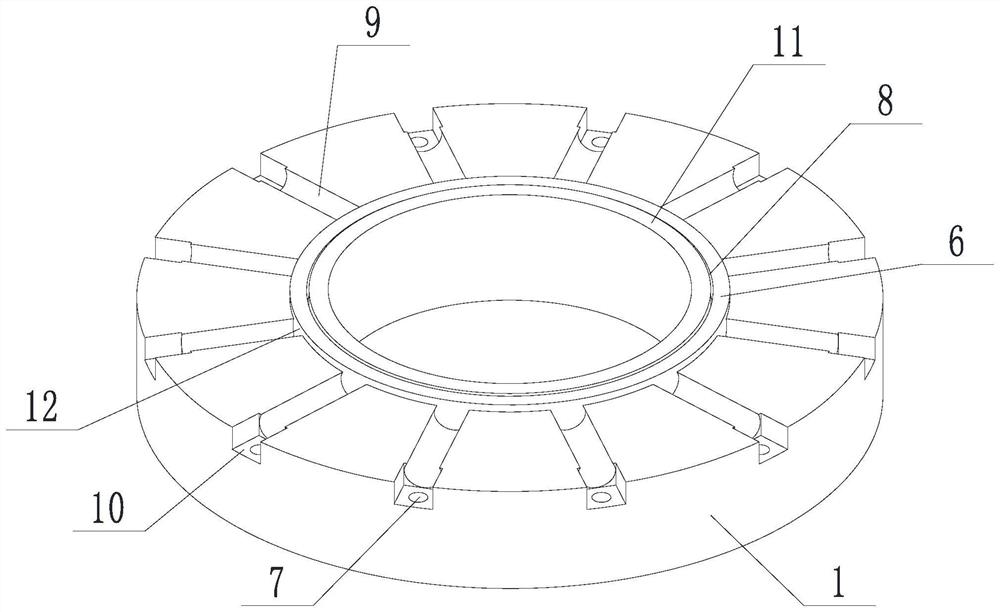

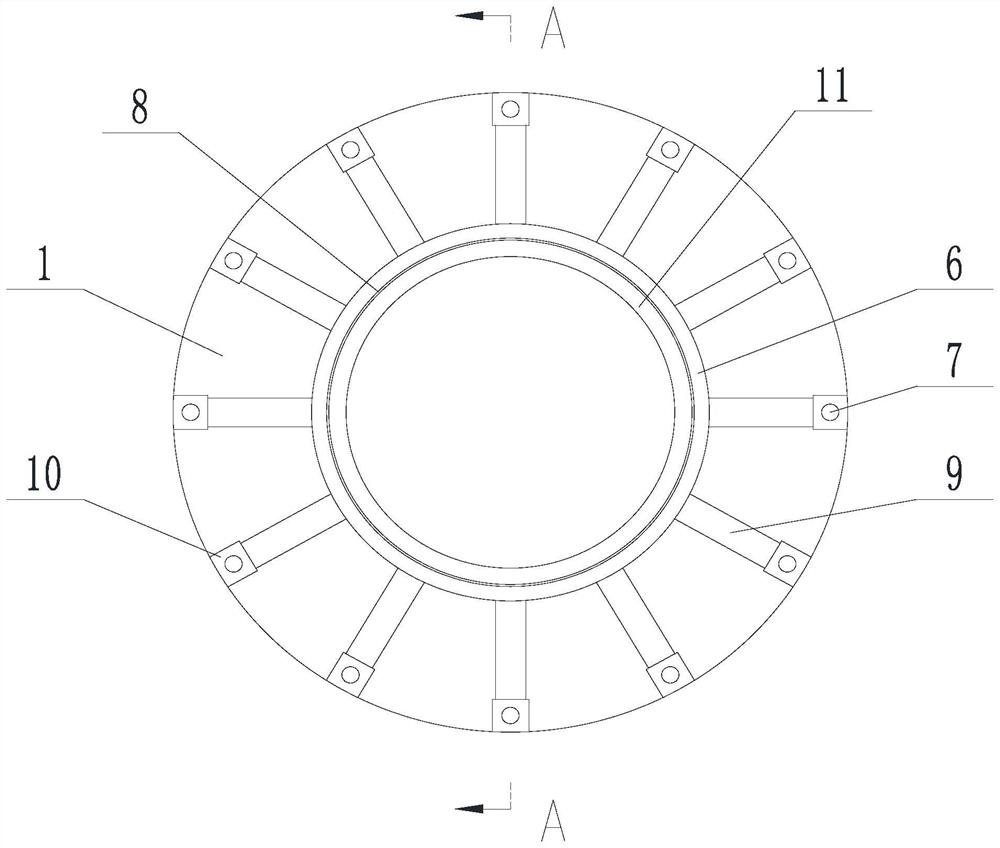

A dry gas seal structure with controllable end face stiffness

ActiveCN113202929BImprove adaptabilityImprove opening forceEngine sealsDry gas sealMechanical engineering

The invention discloses a dry gas sealing structure with controllable end face stiffness, which includes a moving ring and a static ring, the moving ring is a rigid end face, the static ring includes a static ring body, and a plurality of annular rings are embedded in the end face of the static ring body The evenly distributed elastic member also includes an annular flat foil assembled on the end surface of the static ring body, the flat foil is in contact with the elastic member, and a dynamic pressure groove is opened on the surface of the flat foil. The invention provides a dry gas seal structure with controllable end surface stiffness to solve the problems of weak self-adaptability and insufficient use effect in high-parameter service environments of rigid dry-gas seal technology in the prior art, and to realize improvement in high-parameter service The sealing effect in the environment and the purpose of the dynamic stability of the shafting.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Ultrahigh-temperature, high-pressure, large-flow and quick-response electromagnetic valve

ActiveCN114562592AOpen fastQuick responseOperating means/releasing devices for valvesValve members for heating/coolingEngineeringMechanical engineering

The invention provides an ultrahigh-temperature high-pressure large-flow quick response electromagnetic valve which comprises a movable valve element assembly, a magnetism isolating pipe assembly and a coil assembly, the movable valve element assembly comprises a center pipe, an upper movable iron core and a lower movable iron core, and a magnetism isolating ring is installed between the upper movable iron core and the lower movable iron core; the plunger tube assembly comprises an upper fixed iron core arranged opposite to the upper movable iron core and a lower fixed iron core arranged opposite to the lower movable iron core; the coil assembly comprises an upper coil corresponding to the upper movable iron core, a lower coil corresponding to the lower movable iron core, a first magnetic conductive plate and a second magnetic conductive plate, the first magnetic conductive plate and the second magnetic conductive plate are arranged on the two sides of the lower coil, a magnetic isolation piece is installed between the upper coil and the lower coil, and a third magnetic conductive plate is arranged at the lower end of the upper coil. The first magnetic conductive plate and the third magnetic conductive plate are located on the two sides of the magnetic isolation piece respectively. The ultrahigh-temperature, high-pressure, large-flow and quick-response electromagnetic valve overcomes the defects that an existing electromagnetic valve is long in opening and closing response time and not suitable for the high-temperature and high-pressure environment.

Owner:YUYAO SANLIXIN SOLENOID VALVE CO LTD

Dry gas sealing structure with controllable end face rigidity

The invention discloses a dry gas sealing structure with controllable end face rigidity. The dry gas sealing structure comprises a movable ring and a static ring. The movable ring has a rigid end face, the static ring comprises a static ring body, and a plurality of elastic pieces which are annularly and evenly distributed are embedded in the end face of the static ring body. The dry gas sealing structure further comprises an annular flat foil piece assembled on the end face of the static ring body, the flat foil piece makes contact with the elastic pieces, and the surface of the flat foil is provided with dynamic pressure grooves. According to the dry gas sealing structure with controllable end face rigidity, the problems that in the prior art, a rigid dry gas sealing technology is poor in self-adaptive capacity and poor in using effect in a high-parameter service environment is solved, and the purpose of improving the sealing effect and shafting dynamic stability in the high-parameter service environment is achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

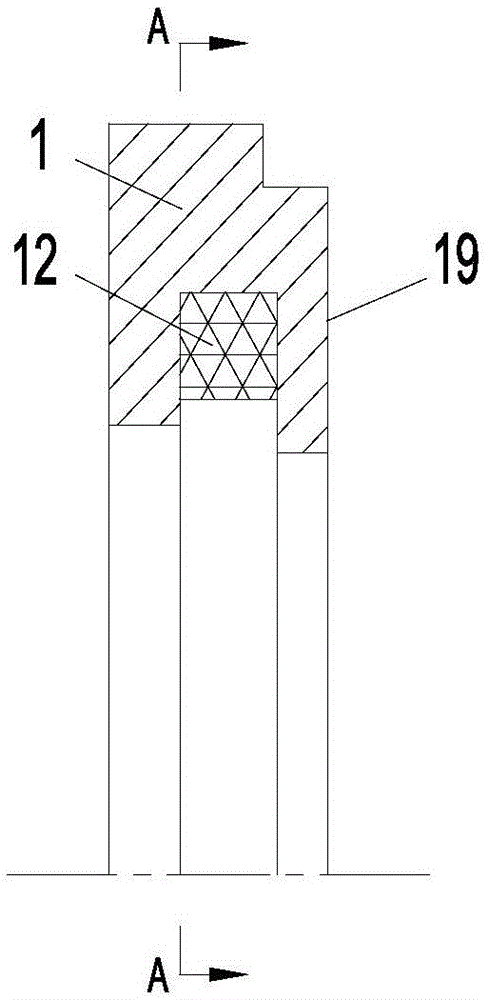

Non-contacting mechanical seal ring with bidirectional hydrodynamic grooves

ActiveCN103453147BImprove opening forceImprove job stabilityEngine sealsEngineeringMechanical engineering

For non-contact mechanical seal rings with bidirectional hydrodynamic pressure grooves, the same form of hydrodynamic pressure groove structural units are arranged at equal intervals along the circumference on the outer side of the sealing end face; the hydrodynamic pressure groove structural units are composed of central grooves The airfoil-shaped structure is composed of the same wing grooves respectively joined to the two sides of the circumference and symmetrically extended to the two sides; the two sides and the side walls of the central groove are respectively the two radial extensions of the sealing end face, and the inner wall It is an arc concentric with the sealing end face, and the central groove opens on the peripheral wall of the sealing ring; the long sides on both sides of the wing groove and the short groove side at the converging extension end are respectively two radial extensions of the sealing end face, and the length of the two wing grooves is The side edges are respectively notch portions joined with the side walls of the central groove on the side where they are located. The hydrodynamic pressure groove structure can improve the hydrodynamic pressure effect of the seal, increase the opening force of the seal end face, increase the fluid film thickness and film stiffness between the seal end faces, reduce the leakage of the seal, simplify the processing difficulty of the groove shape, and reduce the sealing parts. Process requirements for processing and assembly.

Owner:SICHUAN SUNNY SEAL

Electrostatic relay

ActiveUS20150170863A1Increase freedomImprove opening forceRelay terminal arrangementsEmergency actuatorsDegrees of freedomEngineering

In an electrostatic relay in which a moving contact and a movable electrode are displaced in parallel with a base substrate, an opening force is increased when the movable electrode is separated from a fixed electrode, and a structure is simplified to enhance a degree of freedom of design. A fixed contact portion and a fixed electrode portion are fixed to the base substrate. The fixed electrode portion and a movable electrode portion constitute an electrostatic actuator that displaces the movable electrode portion and a moving contact portion. A movable spring provided in a spring supporting portion retains the movable electrode portion in a displaceable manner. A cantilever secondary spring is provided in the spring supporting portion, and a projection portion is provided in a front end face of the movable electrode portion. The secondary spring abuts on the projection portion while being not deformed until abutting on the projection portion, before the moving contact of the moving contact portion abuts on the fixed contact of the fixed contact portion when the moving contact portion and the movable electrode portion are displaced.

Owner:ORMON CORP

Electrostatic relay

ActiveUS9508515B2Increase freedomImprove opening forceEmergency actuatorsRelay terminal arrangementsElectrostatic actuatorDegrees of freedom

In an electrostatic relay in which a moving contact and a movable electrode are displaced in parallel with a base substrate, an opening force is increased when the movable electrode is separated from a fixed electrode, and a structure is simplified to enhance a degree of freedom of design. A fixed contact portion and a fixed electrode portion are fixed to the base substrate. The fixed electrode portion and a movable electrode portion constitute an electrostatic actuator that displaces the movable electrode portion and a moving contact portion. A movable spring provided in a spring supporting portion retains the movable electrode portion in a displaceable manner. A cantilever secondary spring is provided in the spring supporting portion, and a projection portion is provided in a front end face of the movable electrode portion. The secondary spring abuts on the projection portion while being not deformed until abutting on the projection portion, before the moving contact of the moving contact portion abuts on the fixed contact of the fixed contact portion when the moving contact portion and the movable electrode portion are displaced.

Owner:OMRON CORP

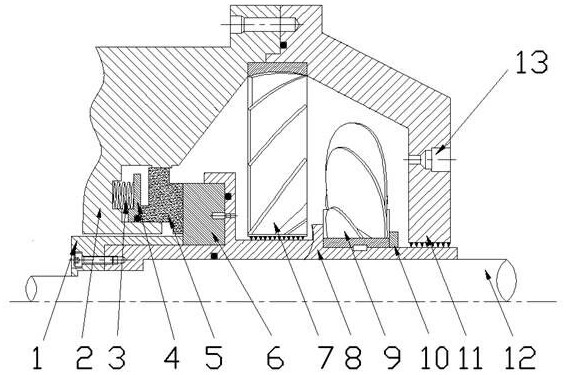

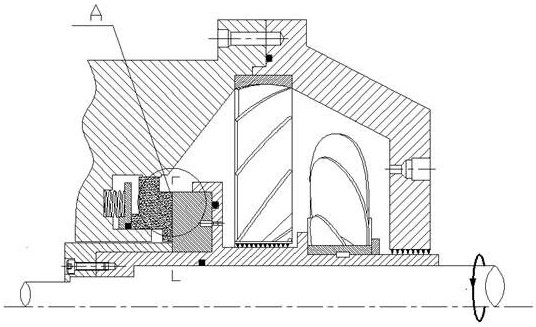

Impeller assembly for axial flow compressed air pressurization in shaft seal cavity and dry gas seal structure

PendingCN114718902AIncreased import pressureImproved air film stabilityEngine sealsPump componentsImpellerForming gas

The invention discloses an impeller assembly for axial flow compressed air pressurization in a shaft seal cavity. The impeller assembly comprises a static impeller and a flow guide impeller. The invention further discloses a dry gas sealing structure for axial flow compressed air pressurization in the shaft sealing cavity, and the dry gas sealing structure comprises the impeller assembly and further comprises an axial positioning ring, a sealing end cover, a working spring, a push ring, a static ring, a movable ring, a movable ring seat and a sealing chamber. After a gas sealing medium is guided and pressurized, the pressure of the gas sealing medium at the gas inlet of the movable ring is improved, the opening force and the gas film rigidity are also increased, and then the opening capacity and the external interference resistance of the gas film are improved; the formed gas film effectively overcomes the elastic force and fluid static pressure of the working spring, so that the contact probability between the two sealing rings is reduced, the frictional wear phenomenon is reduced, finally, the purposes of improving the dry gas sealing stability and prolonging the service life are achieved, and the dry gas sealing structure is particularly suitable for low-pressure and high-speed special working conditions.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com