Non-contacting mechanical seal ring with bidirectional hydrodynamic grooves

A mechanical seal, fluid dynamic pressure technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problem of low leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

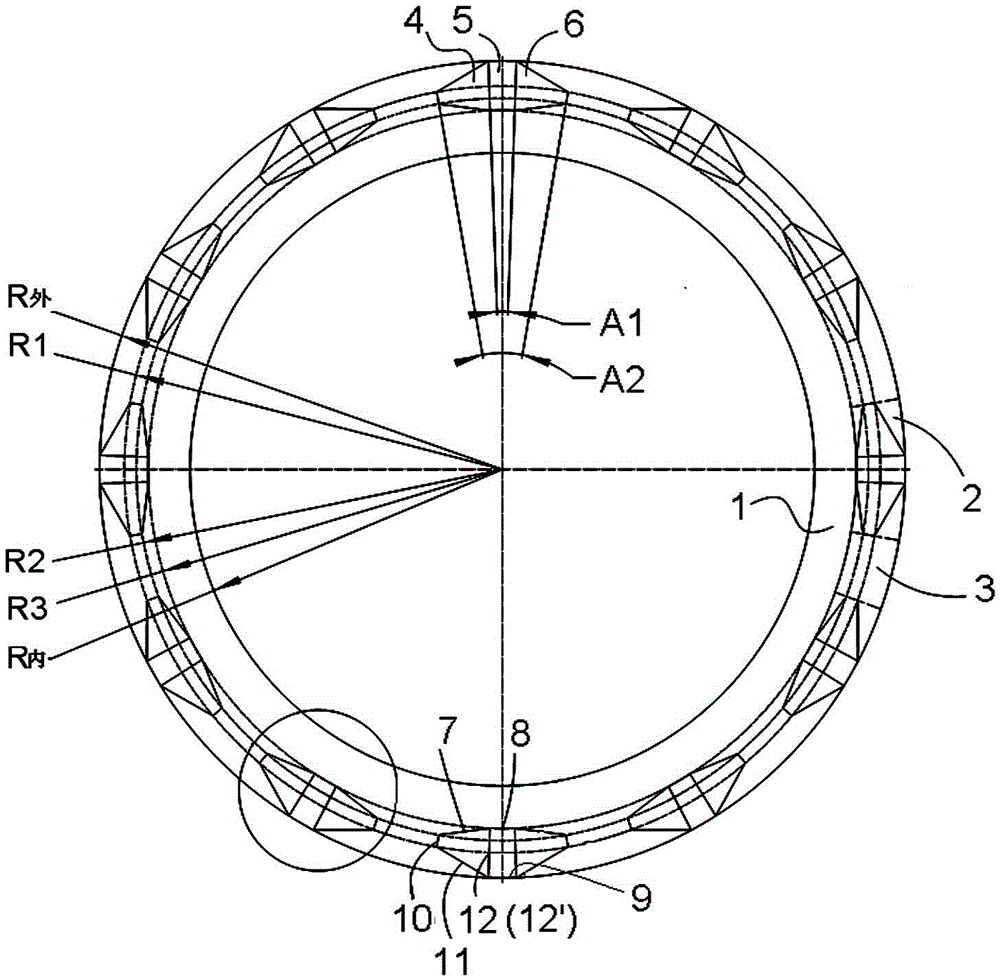

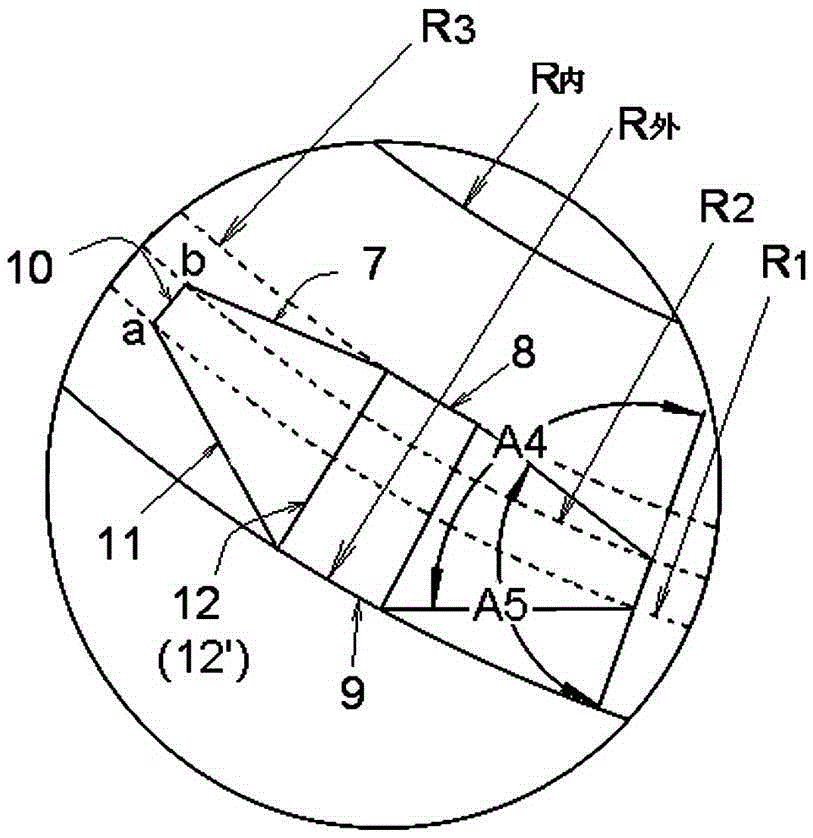

[0030] As shown in the figure, the non-contact mechanical seal ring with double-rotation hydrodynamic pressure grooves of the present invention, on the sealing end face with inner diameter R inner = 401.62mm and outer diameter R outer = 517.68mm, its R3 = 455.04mm The outer part is the sealing groove area 2, in which several ( figure 1 12) are the same type of fluid dynamic pressure groove structure units shown in , the interval between each fluid dynamic pressure groove structure unit is the sealing platform area 3, and the inner circumference of the sealing groove area 2 is a non-dynamic pressure groove structure Unit seal dam area 1. in:

[0031] ——Each hydrodynamic pressure groove structural unit is a “wing-shaped” structure composed of a central groove 5 and wing grooves 4, 6 of the same structure that join with it on both sides of its circumference and converge symmetrically to both sides The dynamic pressure groove group.

[0032] ——In the central groove 5, the two s...

Embodiment 2

[0038] In this example, the non-contact mechanical seal ring of the double-rotational hydrodynamic pressure groove is based on the structure of Embodiment 1, and the depth of the central groove 5 is changed from a constant depth to an arc-shaped inner wall edge 8 and a linear extension to the peripheral wall opening 9. The wedge-shaped groove, the peripheral wall opening 9 groove depth at the outer diameter is 24 microns, and the groove depth at the 8 ends of the arc-shaped inner wall is 5 microns equal to the wing groove depth. The dynamic pressure effect of the non-equal-depth wedge-shaped central groove is similar to that of Embodiment 1, but the static pressure opening effect is better, but the static pressure leakage also increases accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com