Patents

Literature

275 results about "Dry gas seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

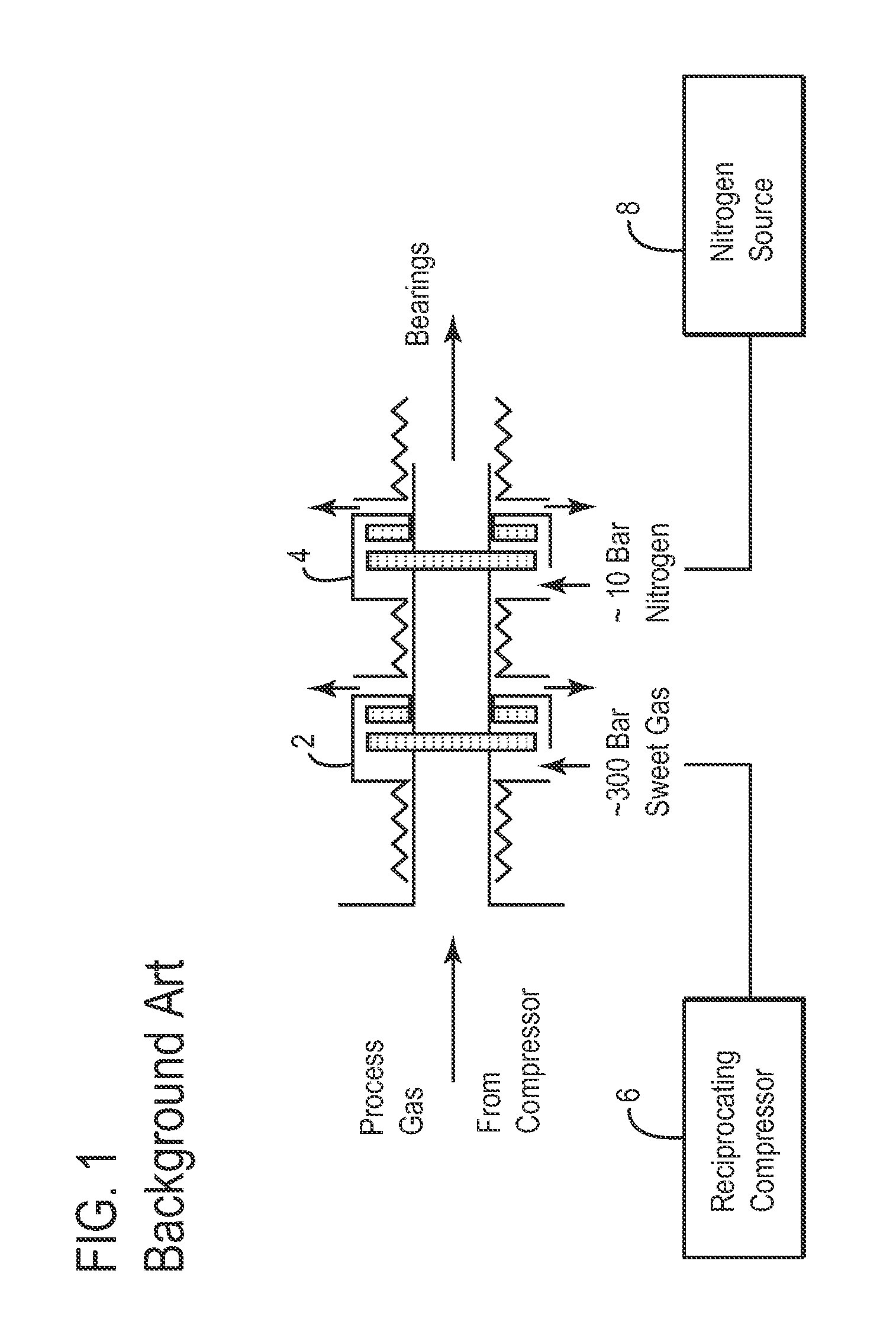

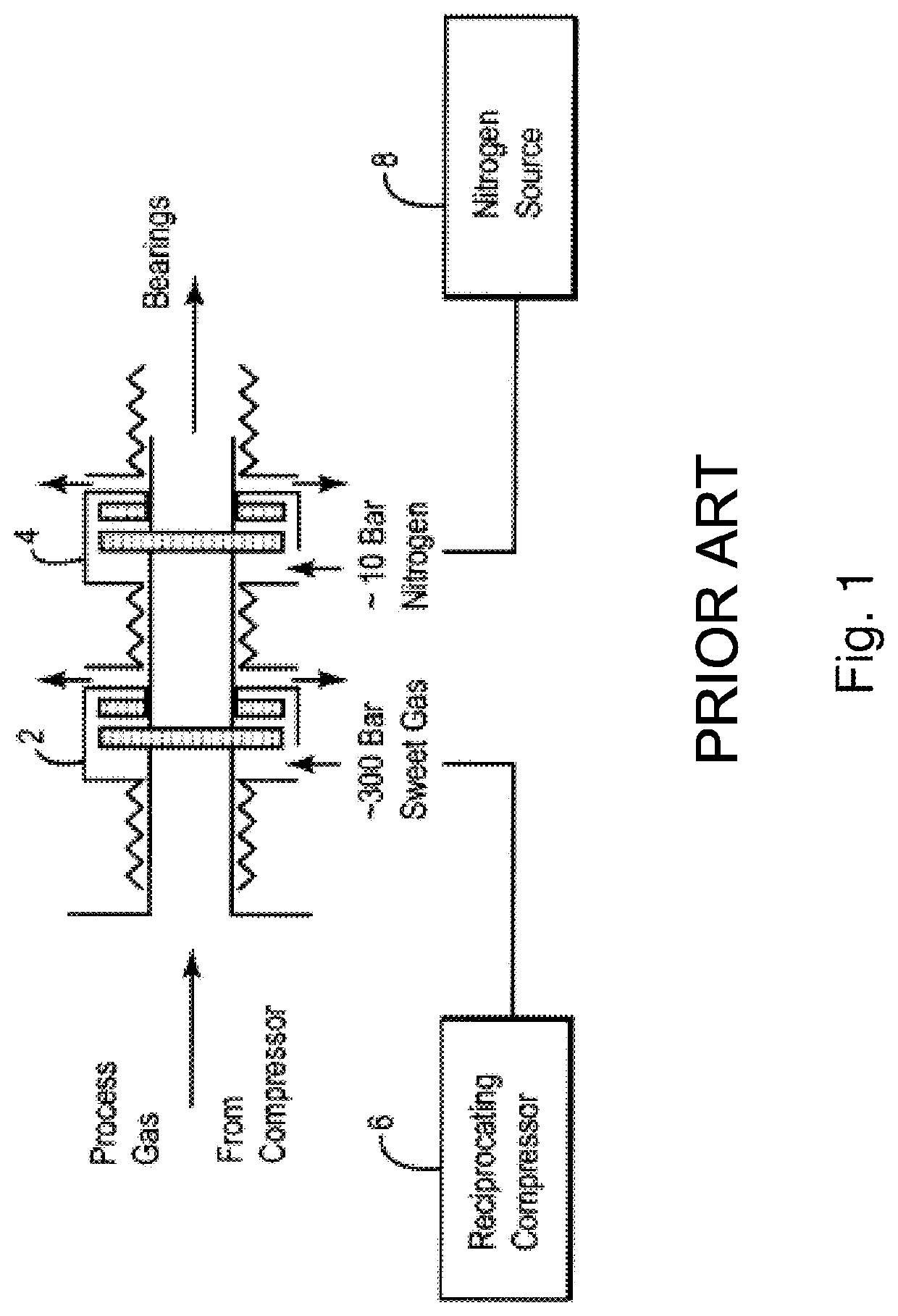

Dry gas seals are non-contacting, dry-running mechanical face seals that consist of a mating (rotating) ring and a primary (stationary) ring. When operating, lifting geometry in the rotating ring generates a fluid-dynamic lifting force causing the stationary ring to separate and create a gap between the two rings. Dry gas seals are mechanical seals but use other chemicals and functions so that they do not contaminate a process. These seals are typically used in a harsh working environment such as oil exploration, extraction and refining, petrochemical industries, gas transmission and chemical processing.

Method and Apparatus For Removal Of Oil From Utility Gas Stream

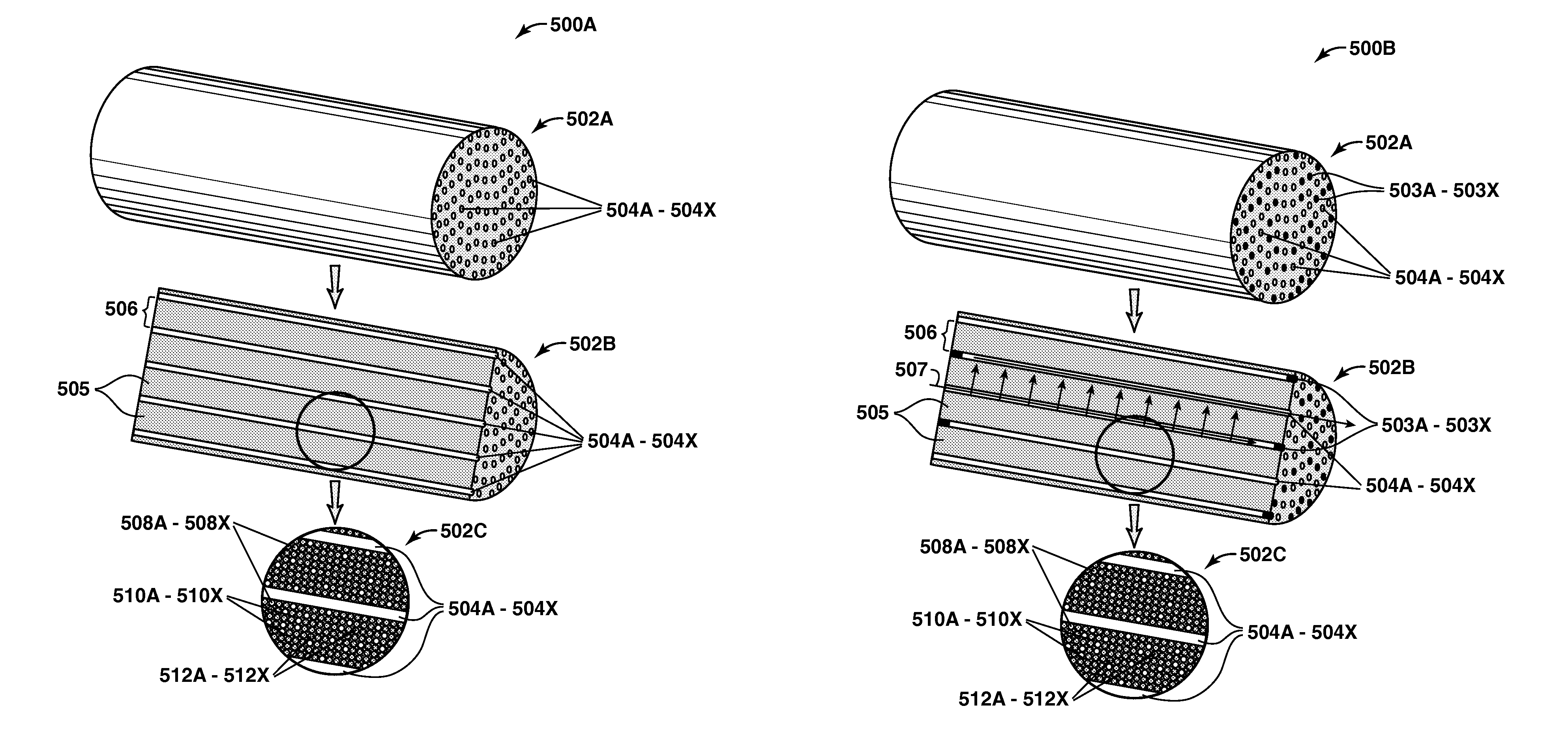

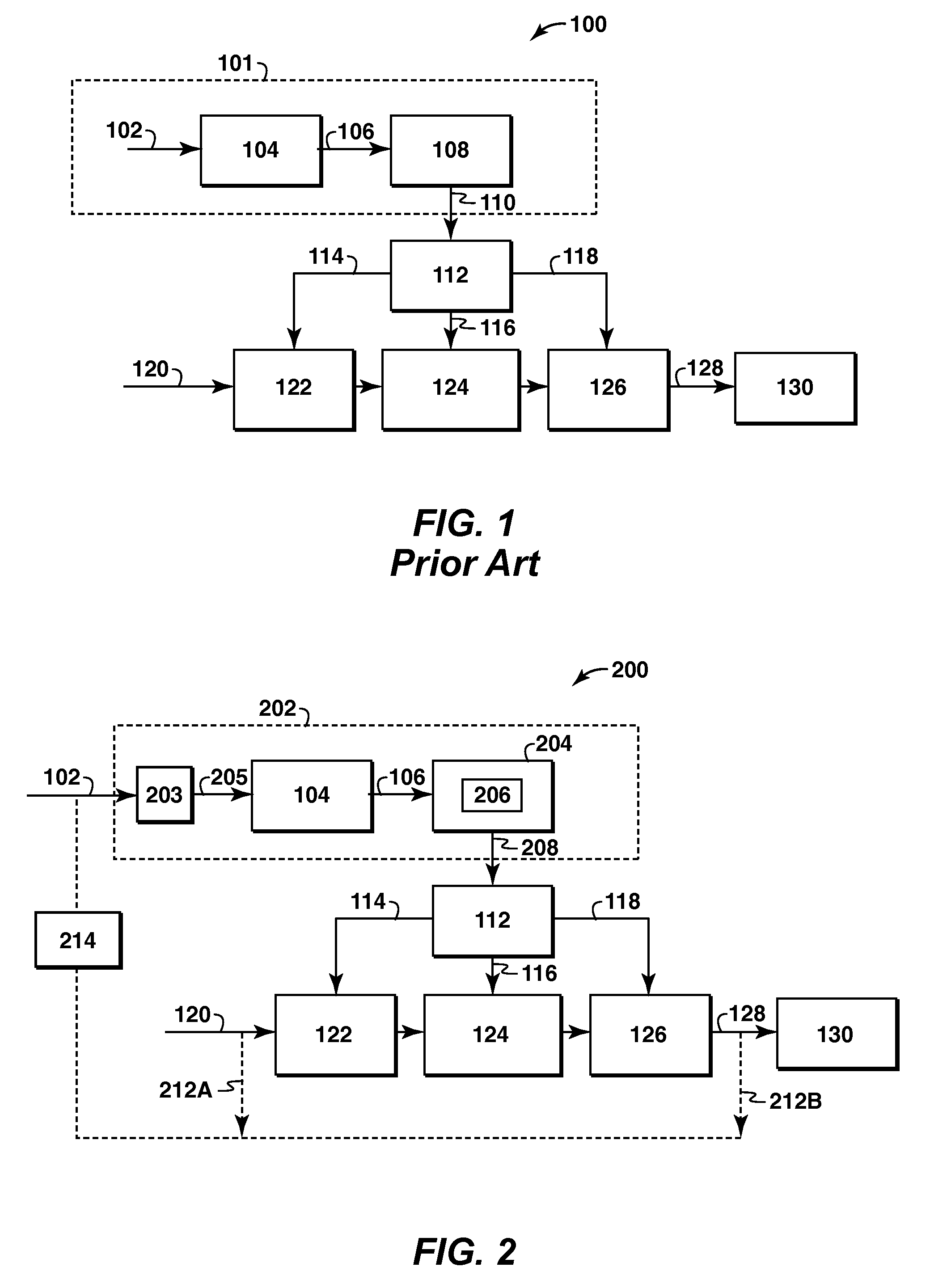

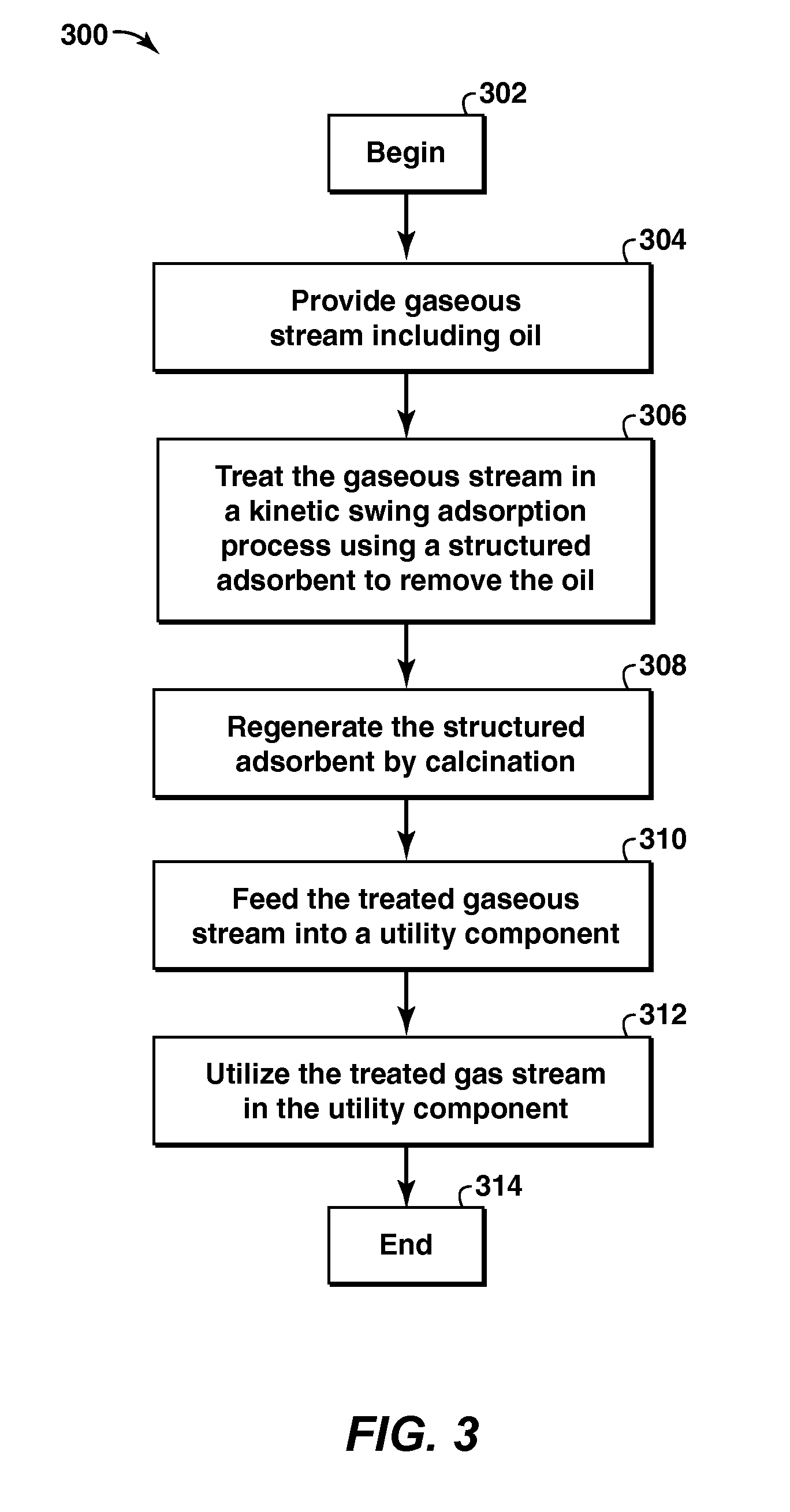

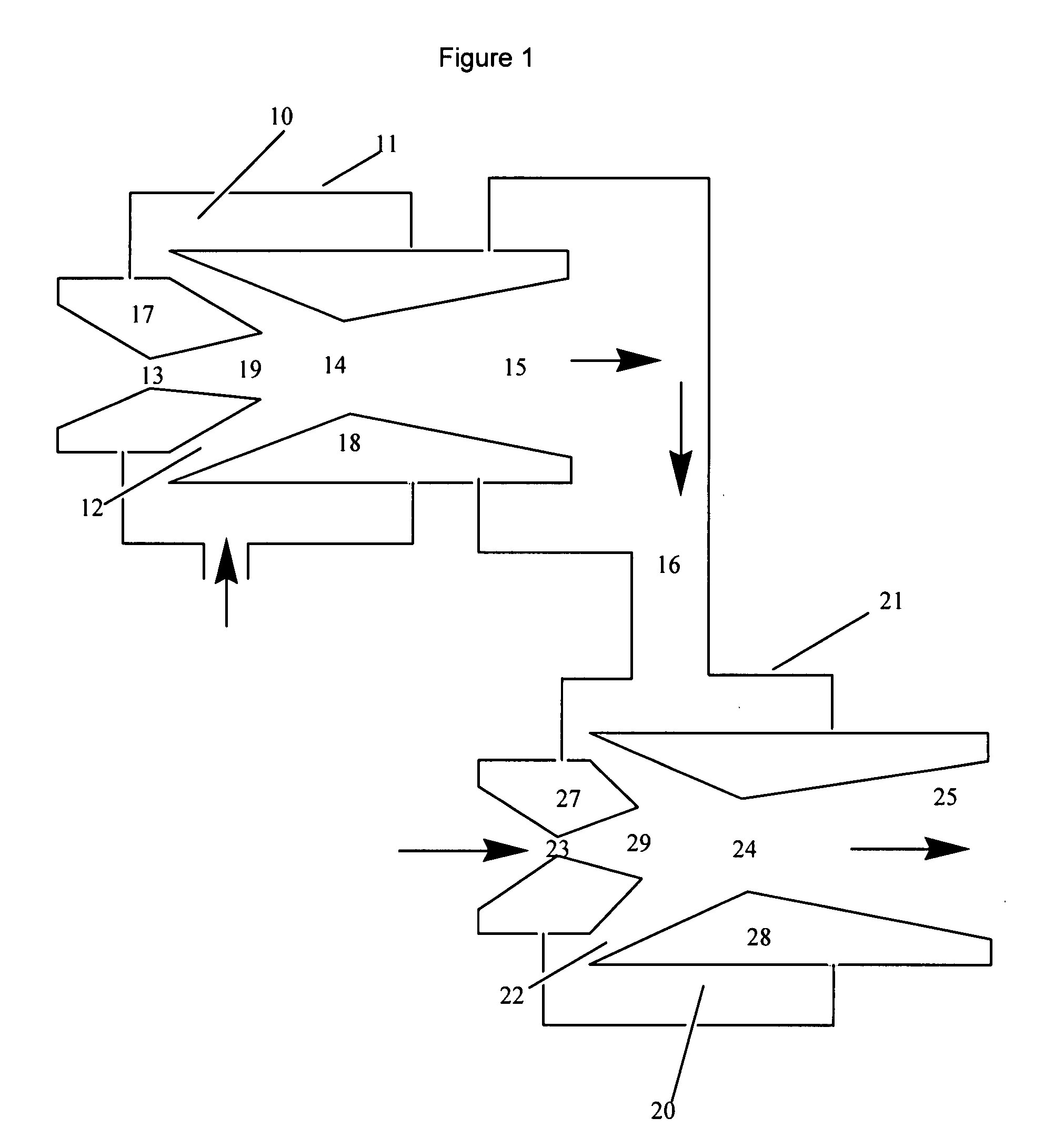

The present application is directed to a method and system for preparing gaseous utility streams from gaseous process streams, particularly, removing oil contamination from such streams prior to use in a dry gas seal. The methods and systems may include at least one kinetic swing adsorption process including pressure swing adsorption, temperature swing adsorption, calcination, and inert purge processes to treat gaseous streams for use in dry gas seals of rotating equipment such as compressors, turbines and pumps and other utilities. The adsorbent materials used include a high surface area solid structured microporous and mesoporous materials.

Owner:EXXONMOBIL UPSTREAM RES CO

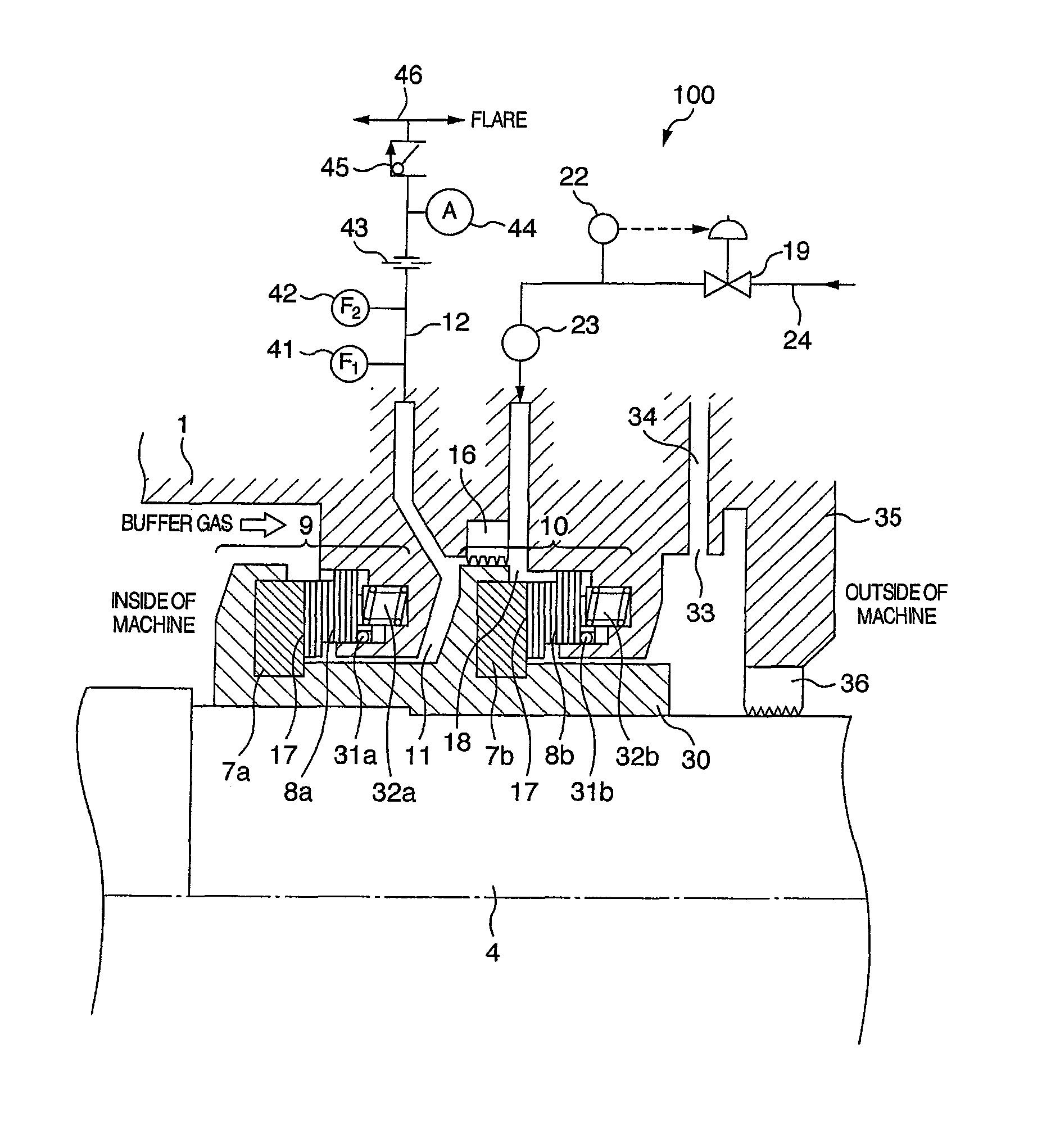

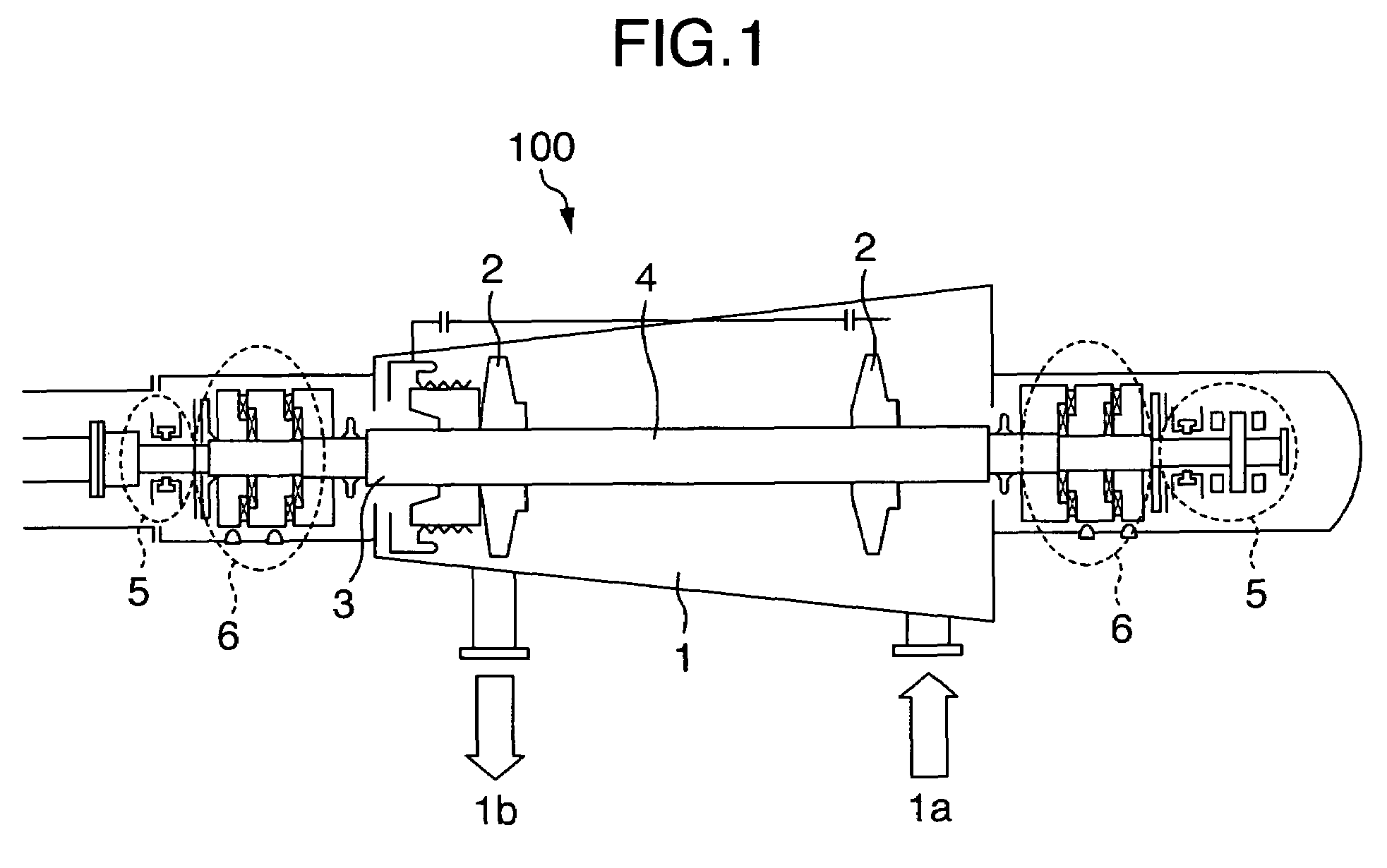

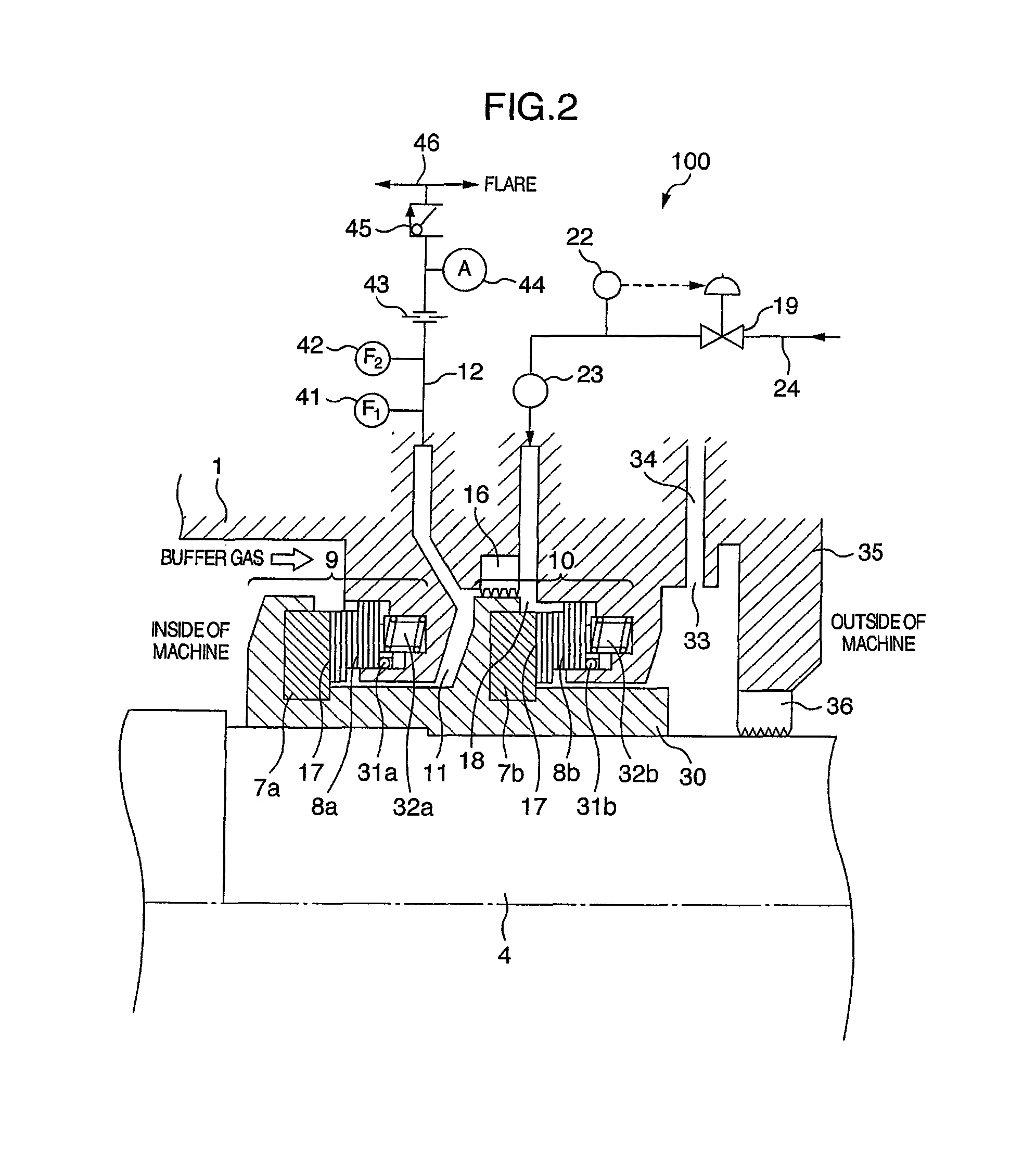

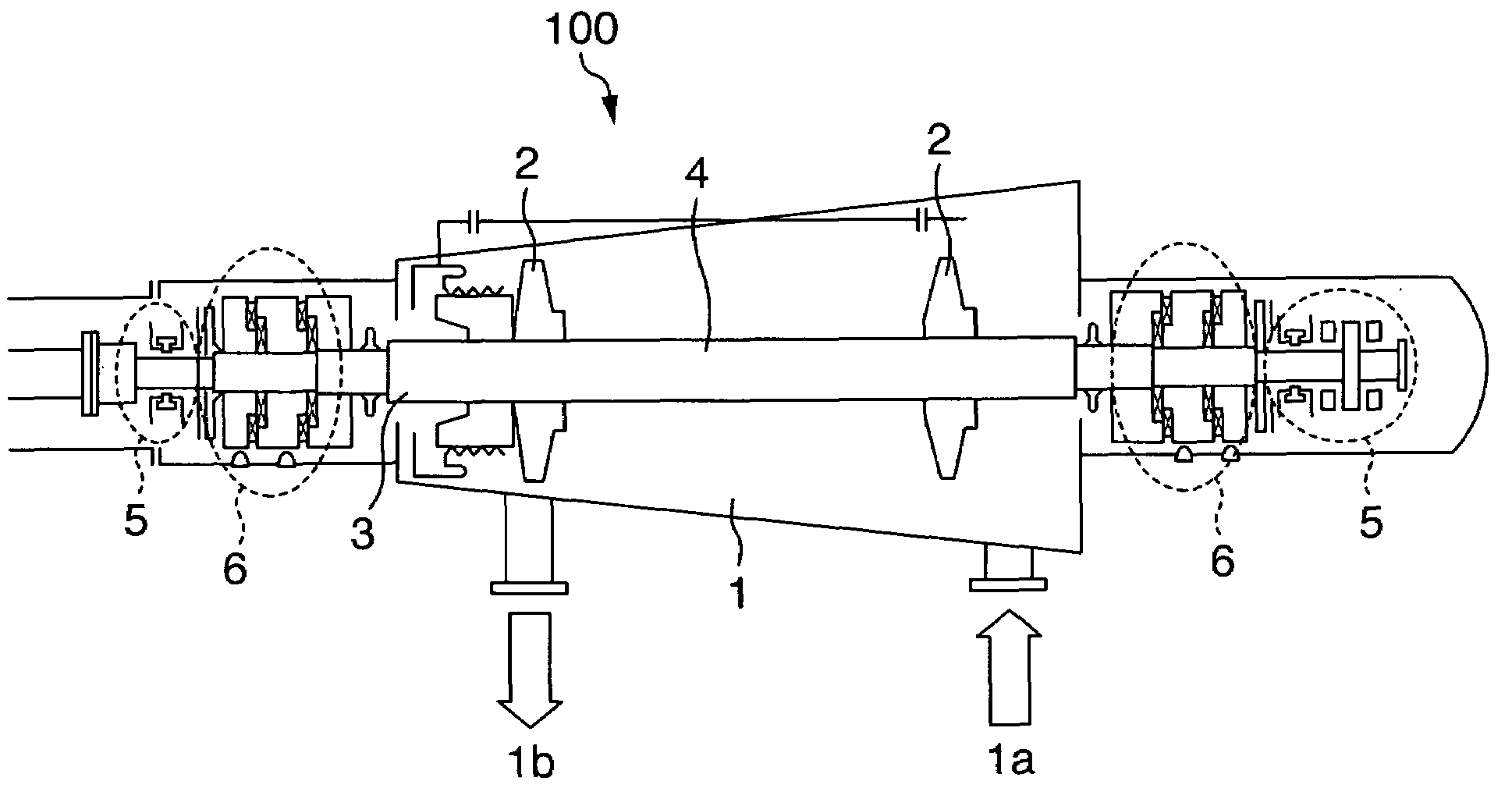

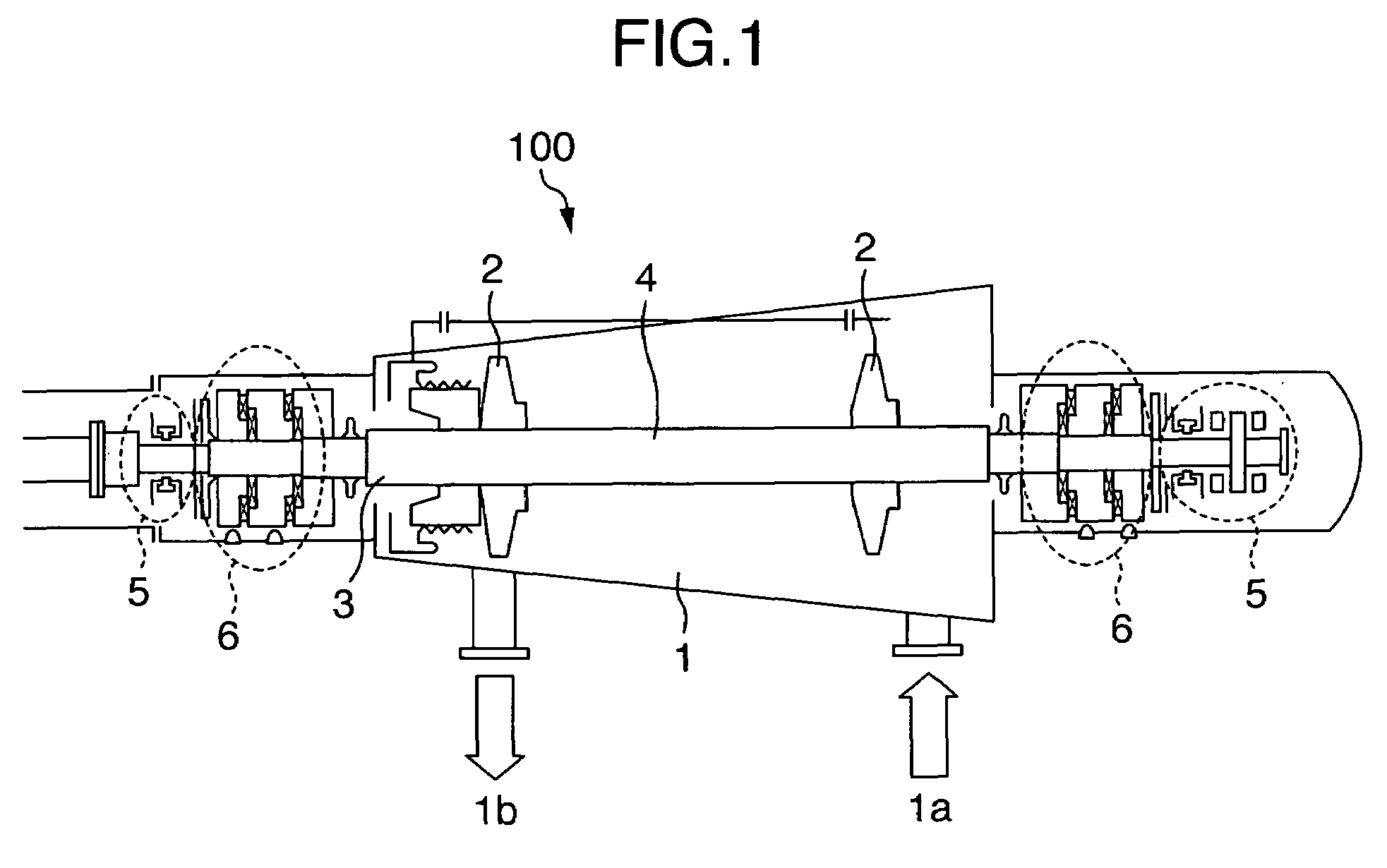

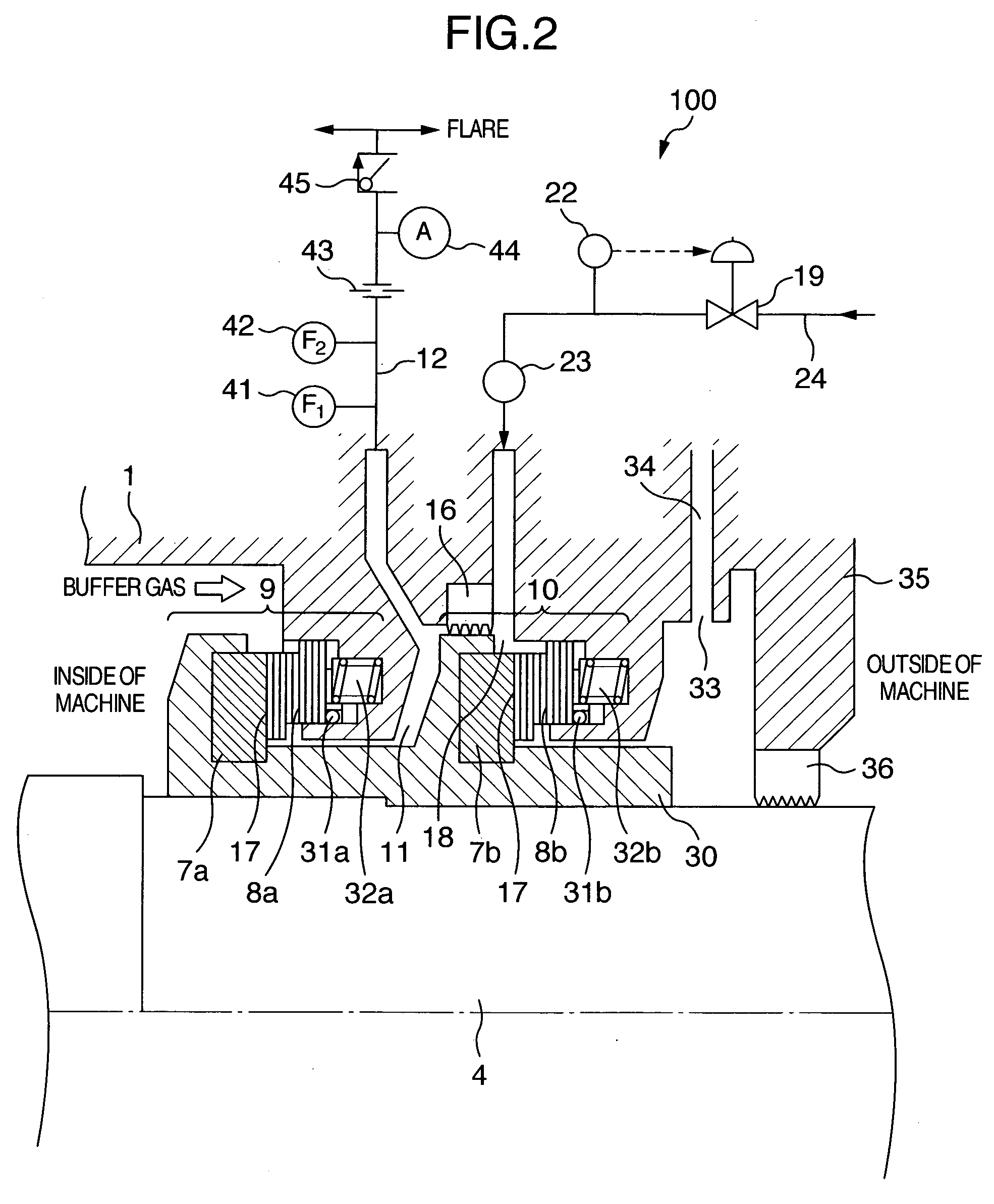

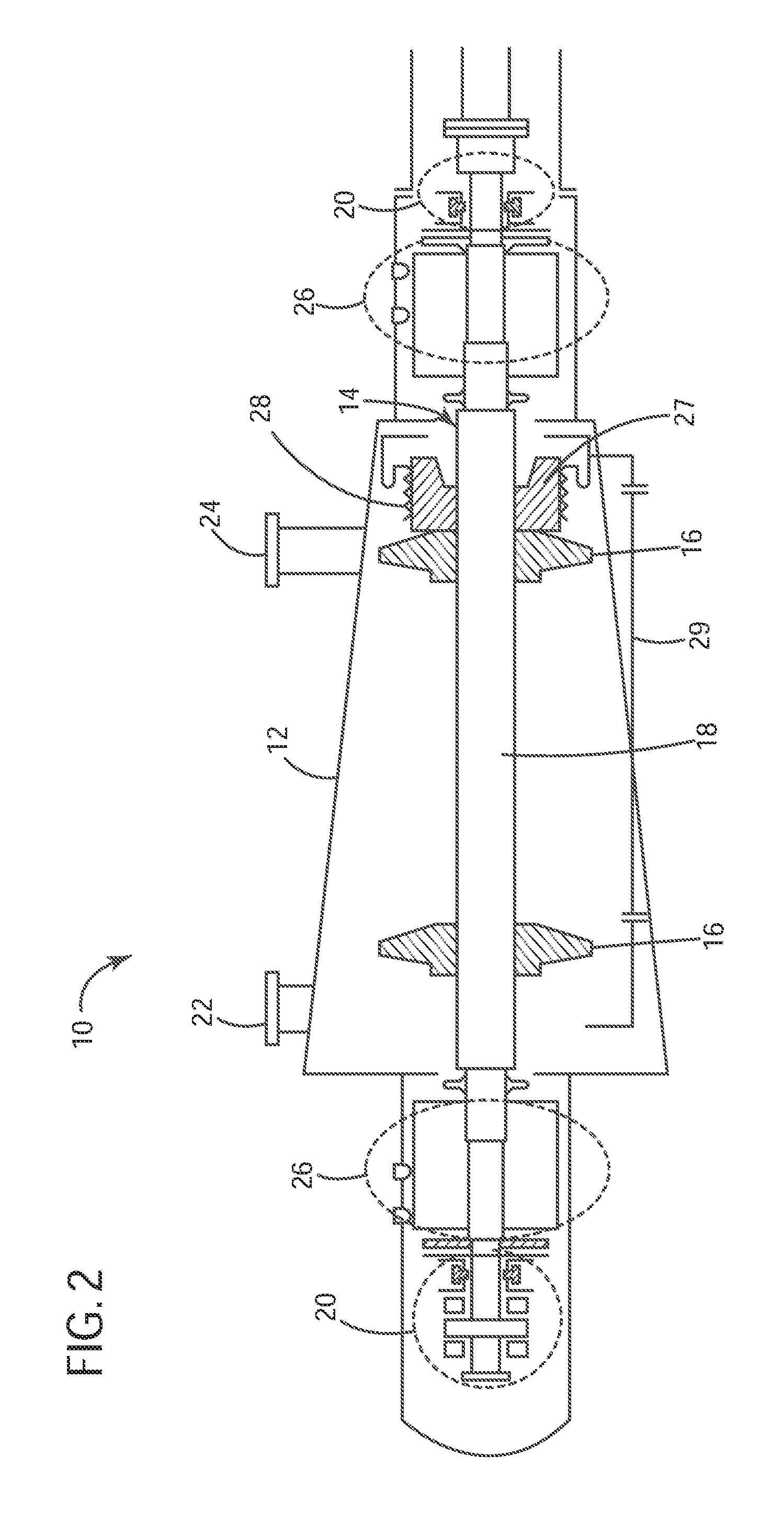

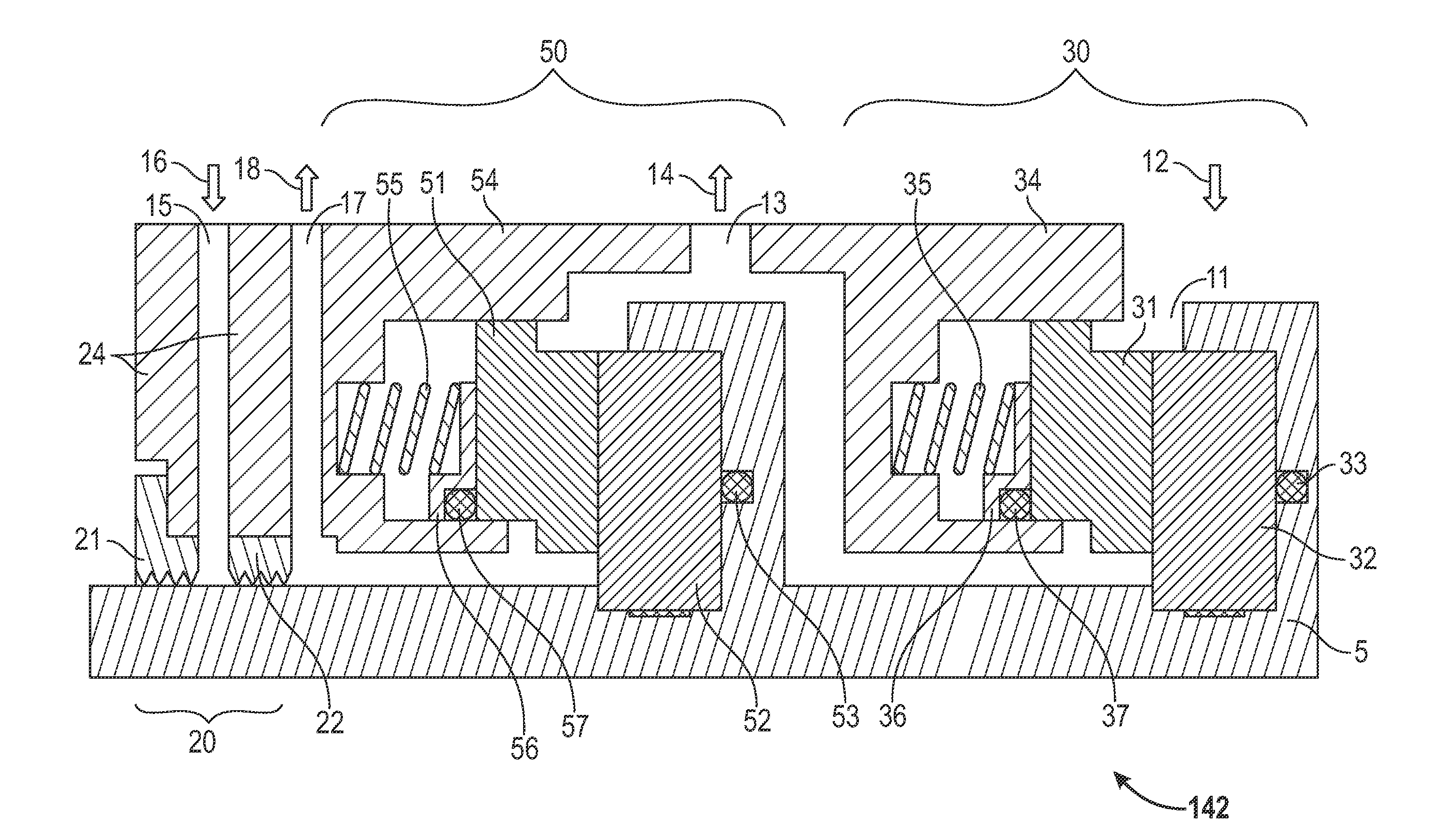

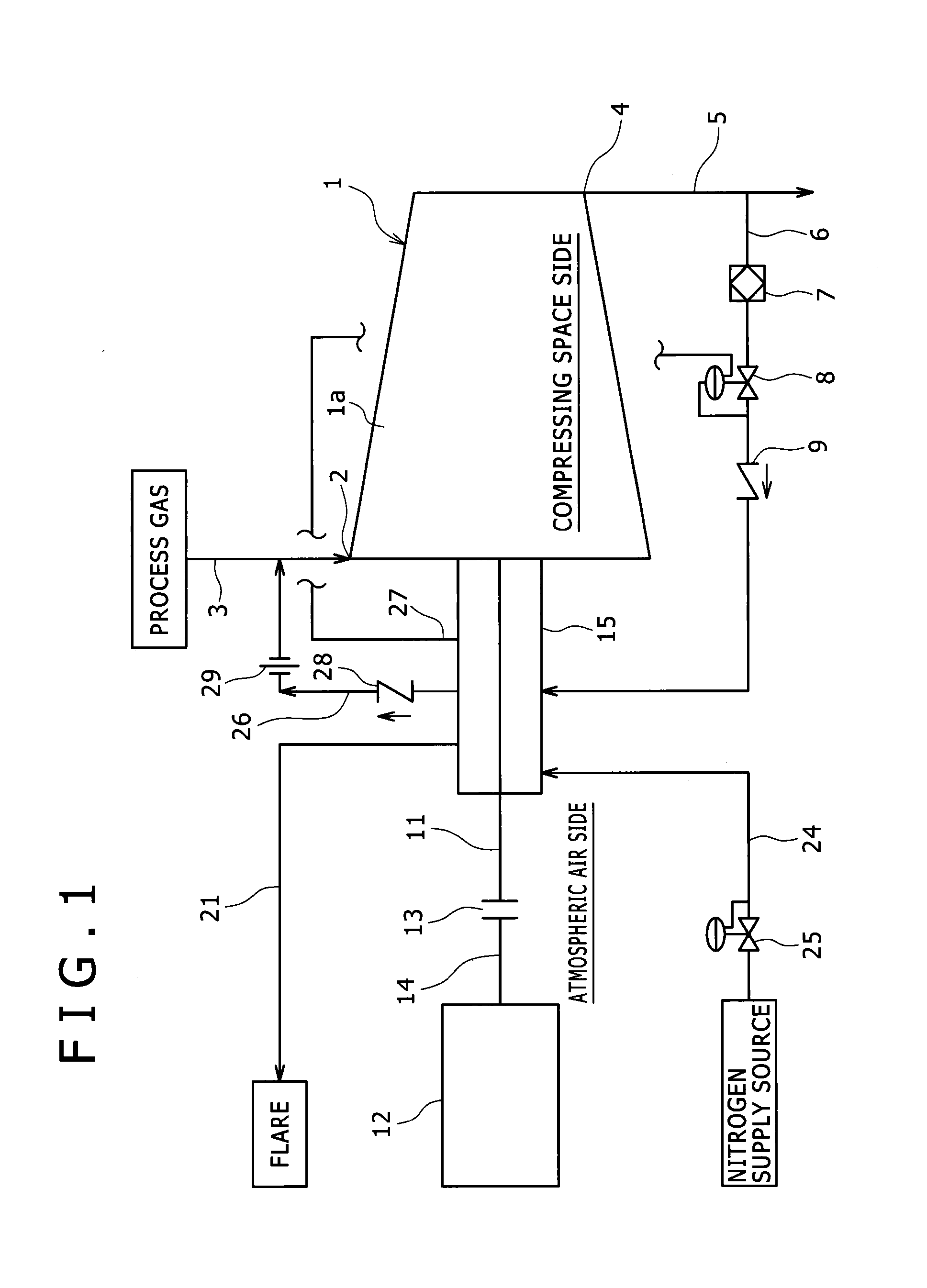

Centrifugal compressor and dry gas seal system for use in it

InactiveUS7854587B2Avoid unnecessary stopPrevent leakagePump componentsLeakage preventionDry gas sealProduct gas

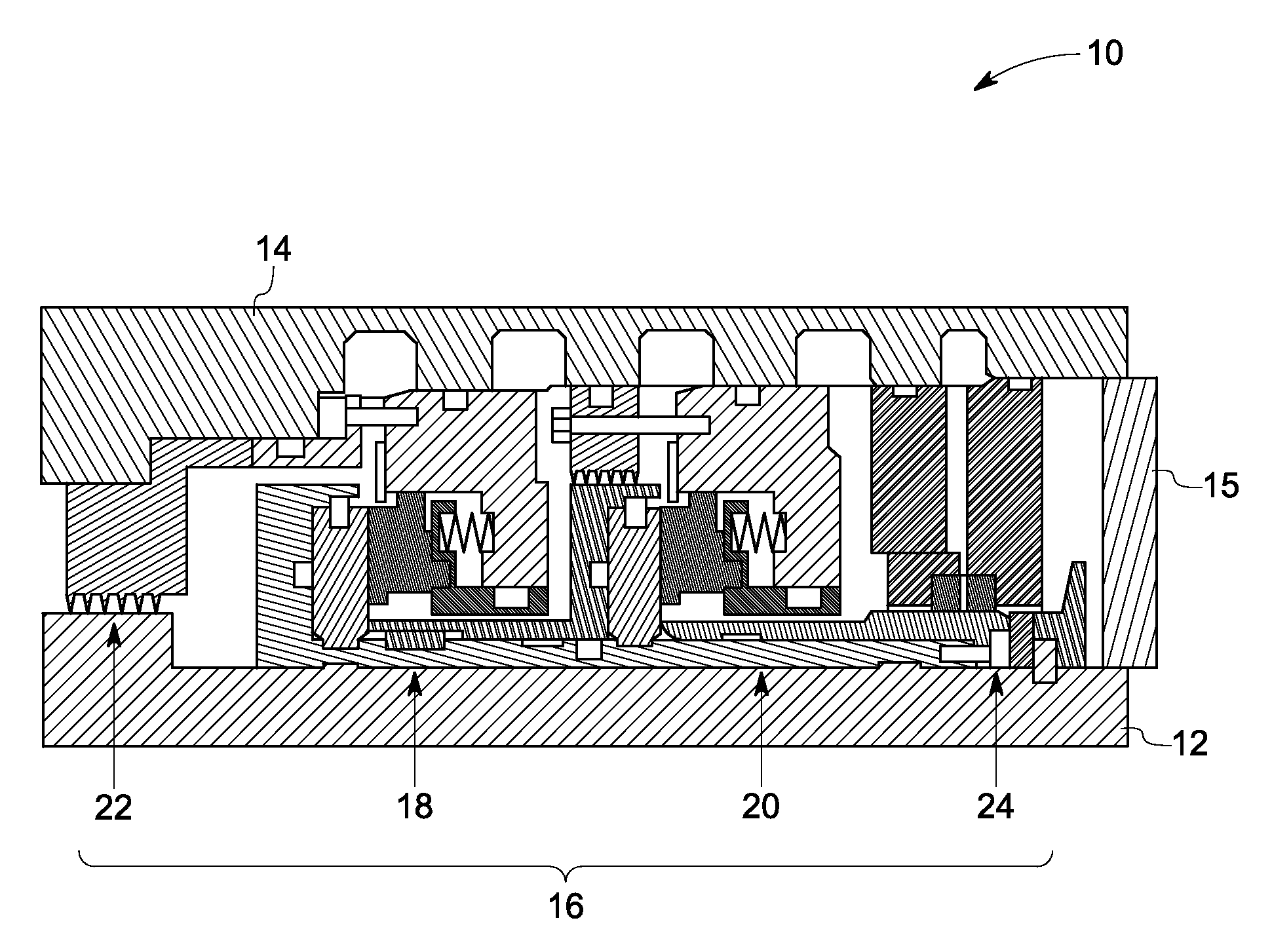

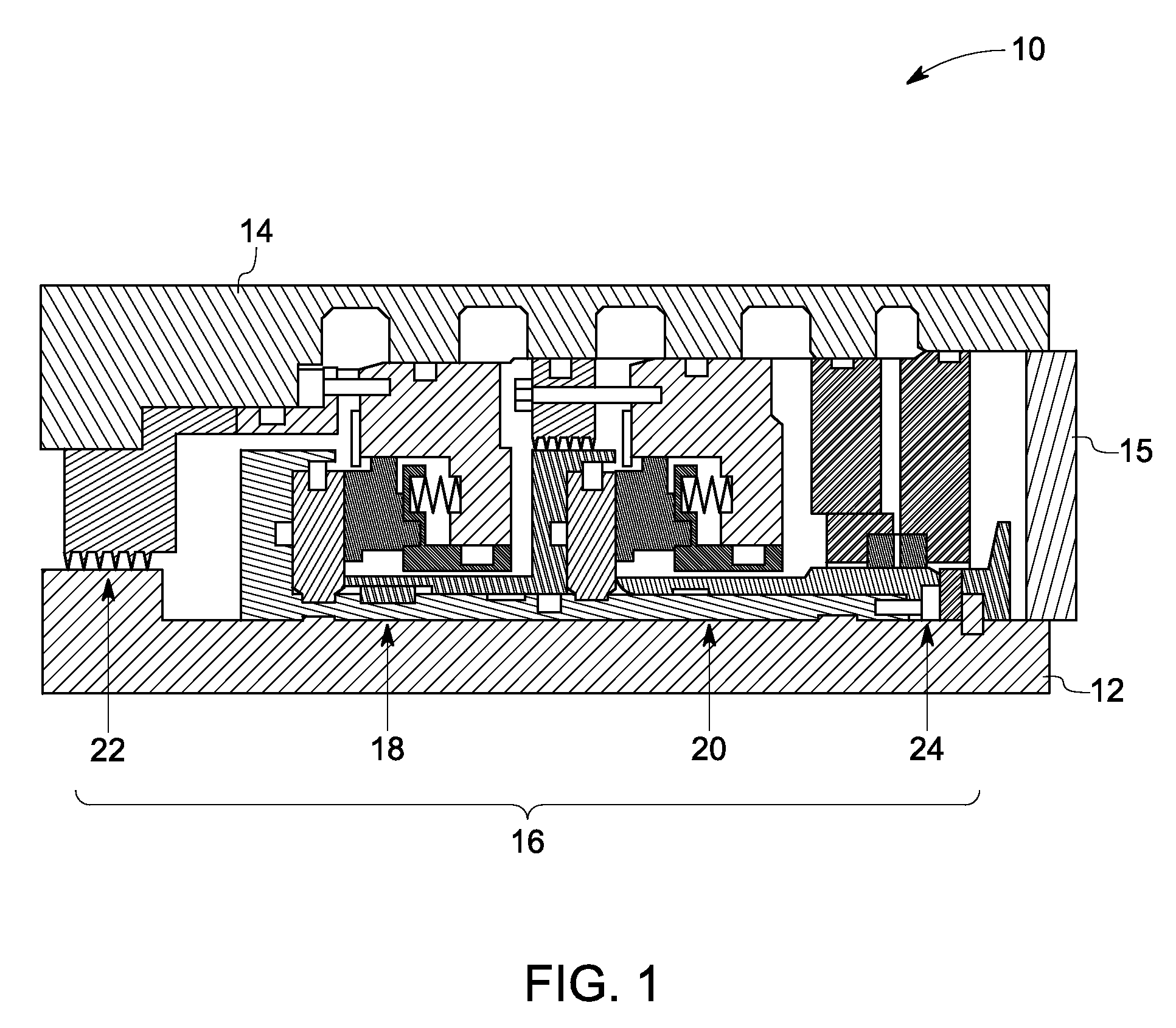

The present invention relates to a centrifugal compressor using a dry gas seal system for protecting seal means. A multistage centrifugal compressor has primary dry gas seal means for preventing leakage of working gas from a machine inner side, and secondary dry gas seal means for backing up the first dry gas seal means. A seal gas line for introducing the gas leaked from the first and second dry gas seal means to the outside of the machine is installed between the primary dry gas seal means and the secondary dry gas seal means. The gas seal line has an orifice and a check valve, and buffer means is installed between the orifice and the check valve.

Owner:HITACHI LTD

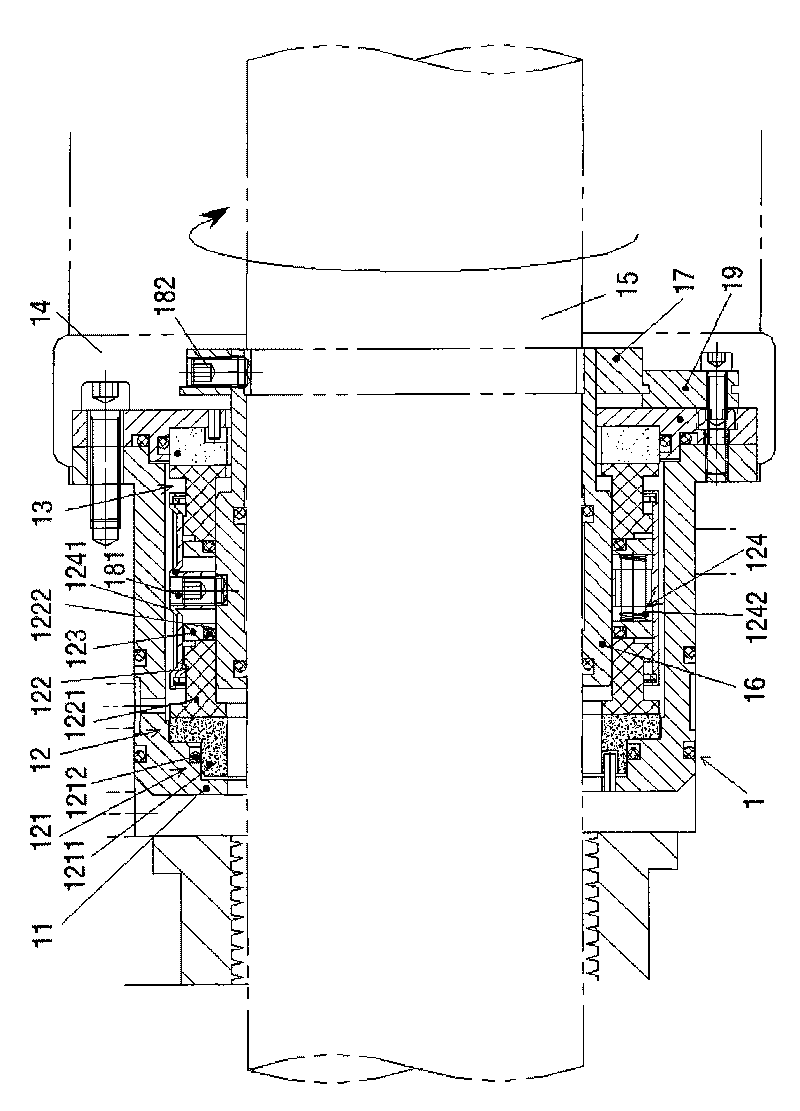

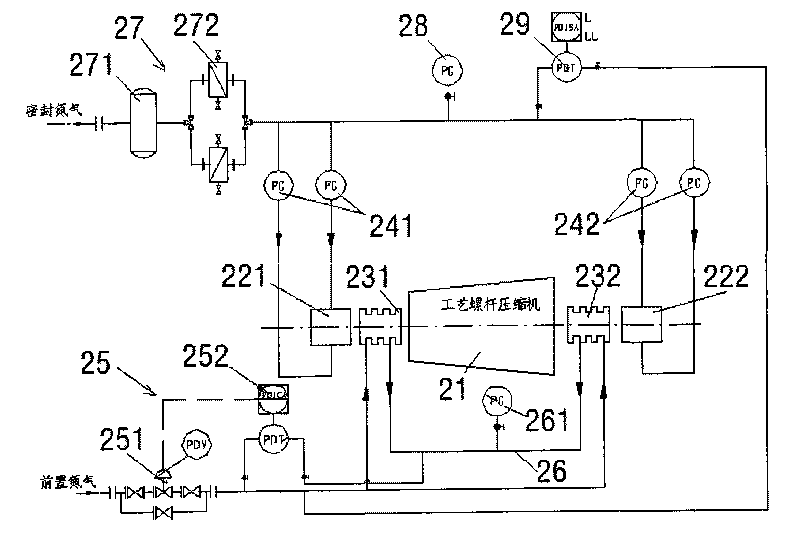

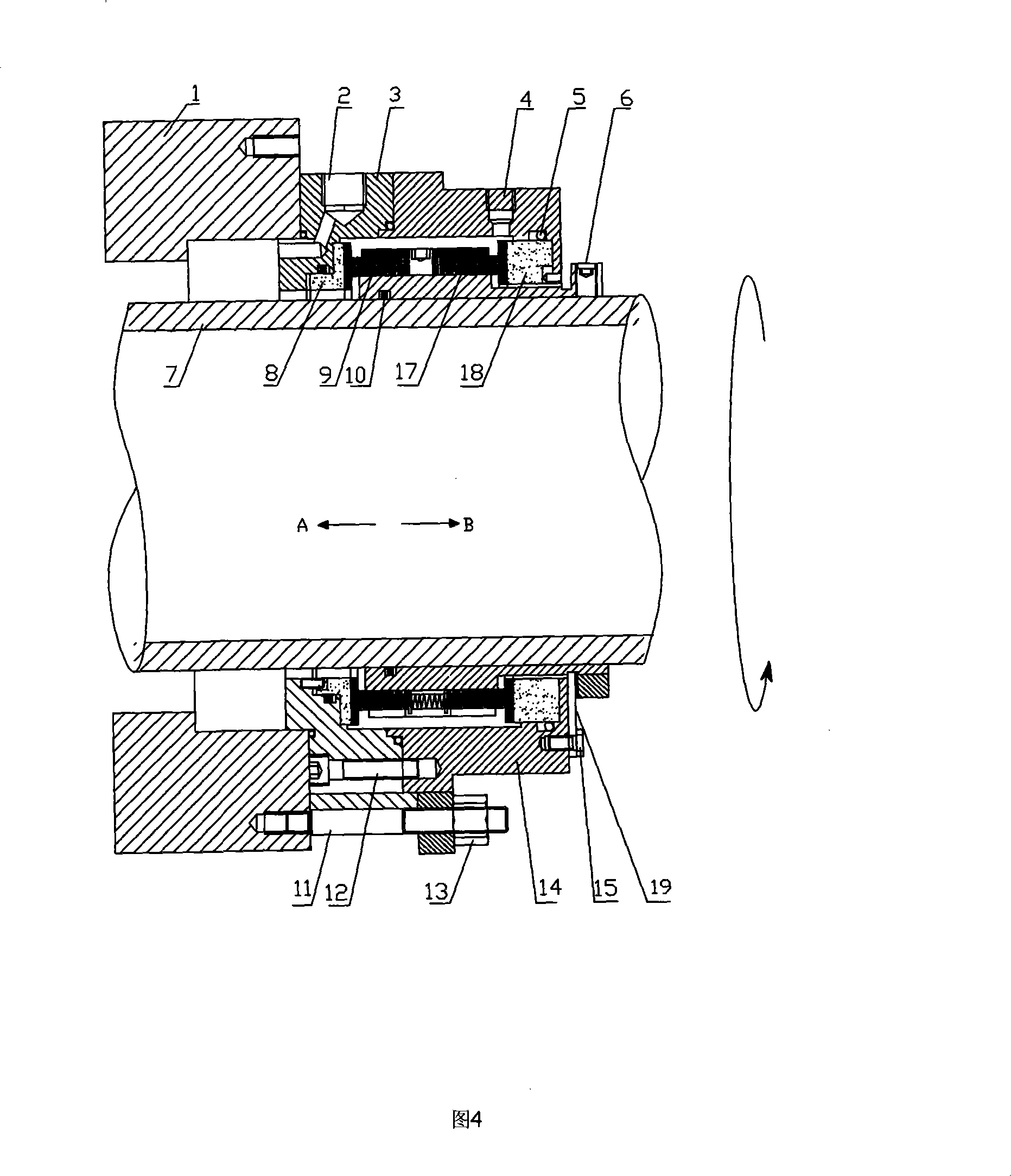

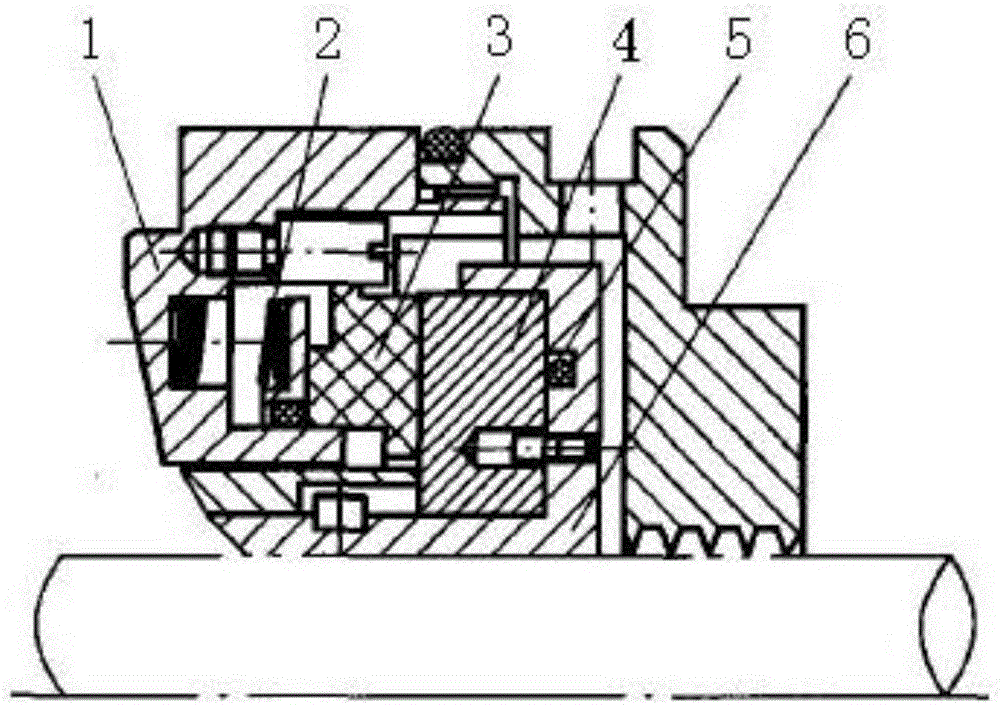

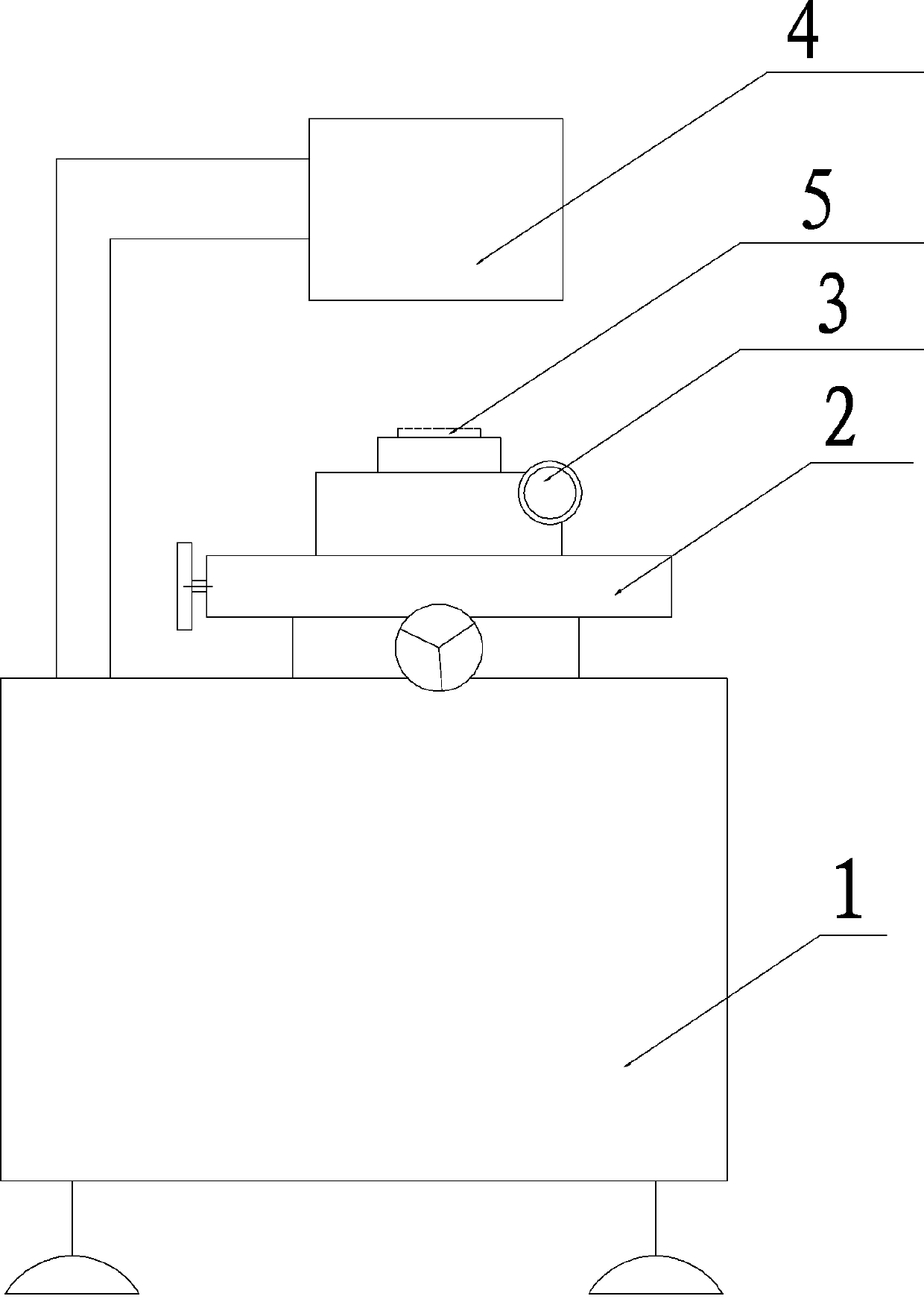

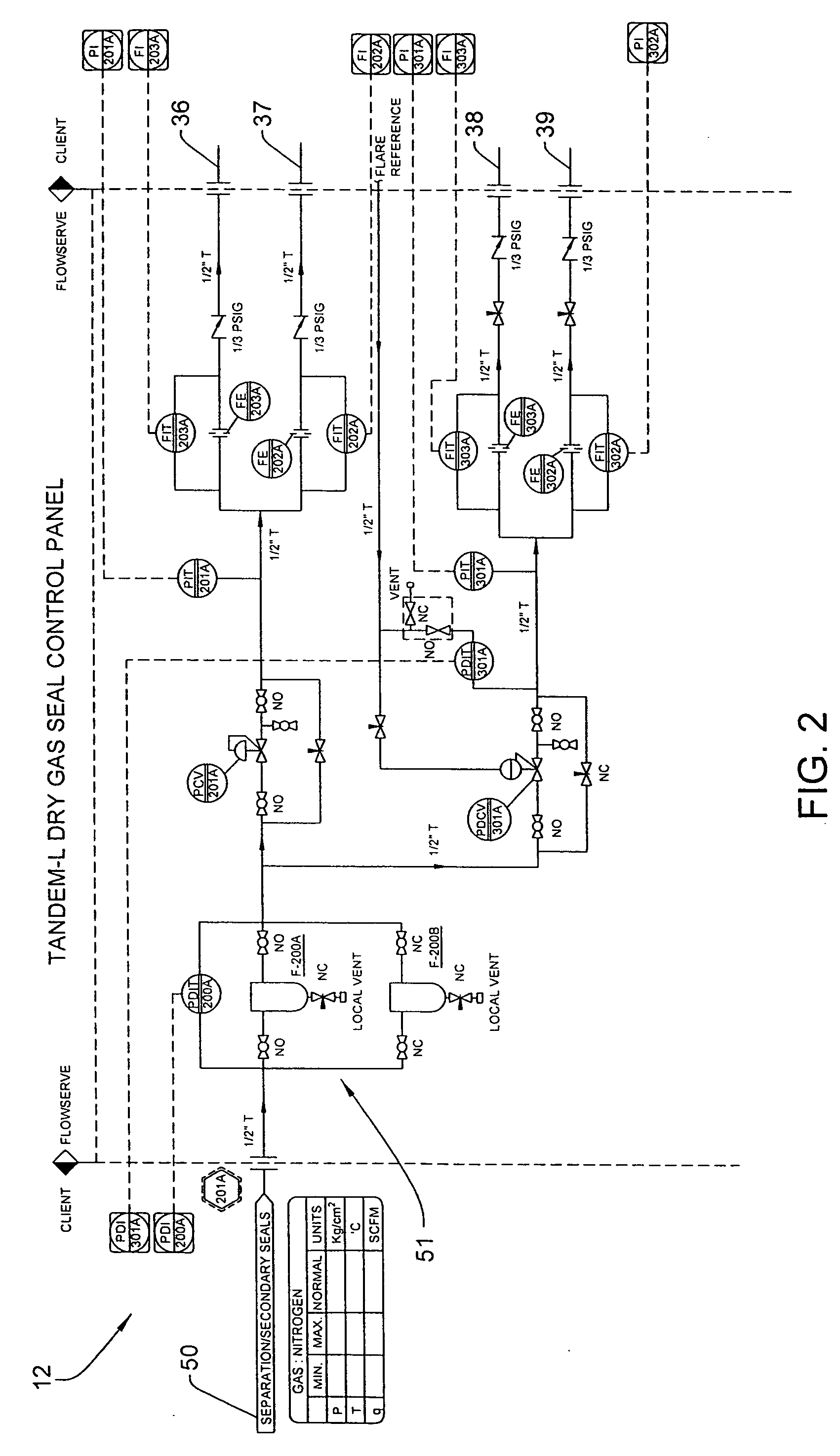

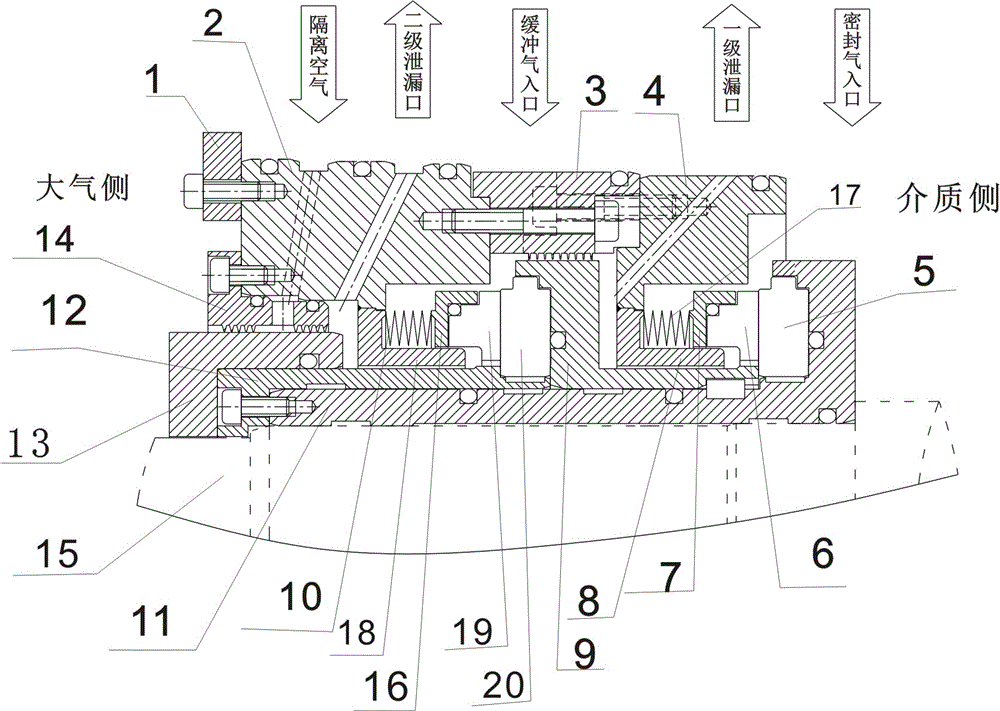

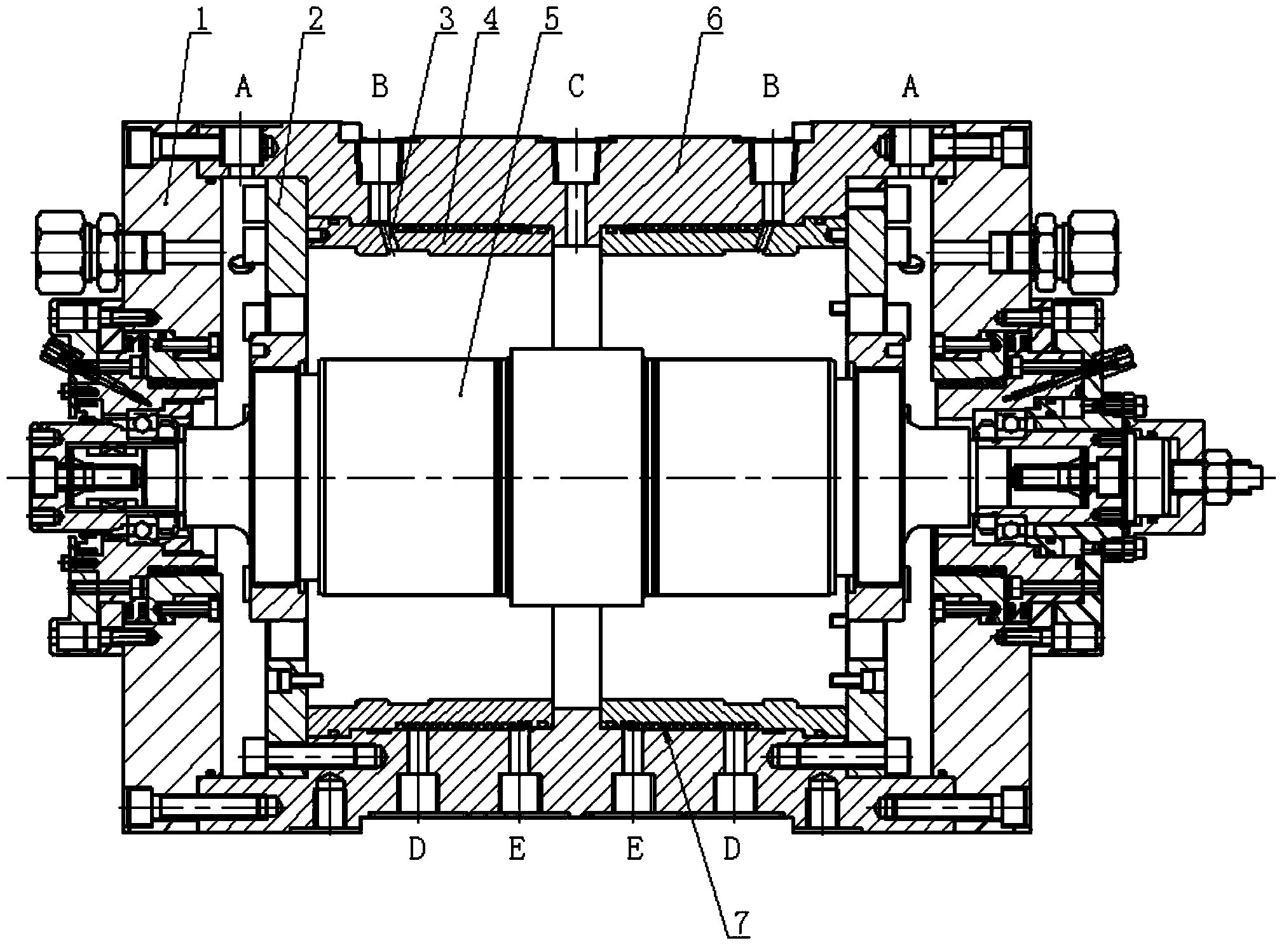

Dry gas sealing device for technical screw compressor and application system thereof

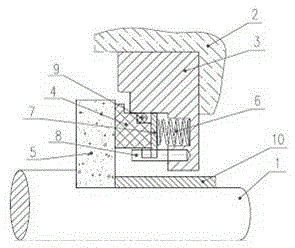

InactiveCN101713461AImprove performanceGuaranteed uptimeEngine sealsRotary piston pumpsNitrogenDry gas seal

The invention discloses a dry gas sealing device for a technical screw compressor and an application system thereof. The dry gas sealing device is characterized by comprising two sets of single sealing mechanisms with the same structure, wherein each set of single sealing mechanism comprises a static ring component, a moving ring component, a push ring and a spring component, wherein the static ring component is fixedly connected with a gland, and the moving ring component, the push ring and the spring component are fixedly connected with a shaft sleeve. The application system comprises a technical screw compressor, two dry gas sealing devices, two labyrinth sealing devices, two groups of gas flowmeters of sealed gas, a front-end gas input device and a sealed gas input device, wherein the two dry gas sealing devices and the two labyrinth sealing devices are symmetrically arranged at two ends of the shaft of the technical screw compressor. The invention also discloses an application method of the application system.The dry gas sealing device for the technical screw compressor of the invention has self adaptation and non-contact characteristics, can ensure reliable operation of dry gas sealing by matching the combined application system which has balancing cavity pressure relief, labyrinth seal obstruction, front-end nitrogen protection and dry gas sealing, and is especially suitable for high-pressure technical screw compressors with high rotary speed.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

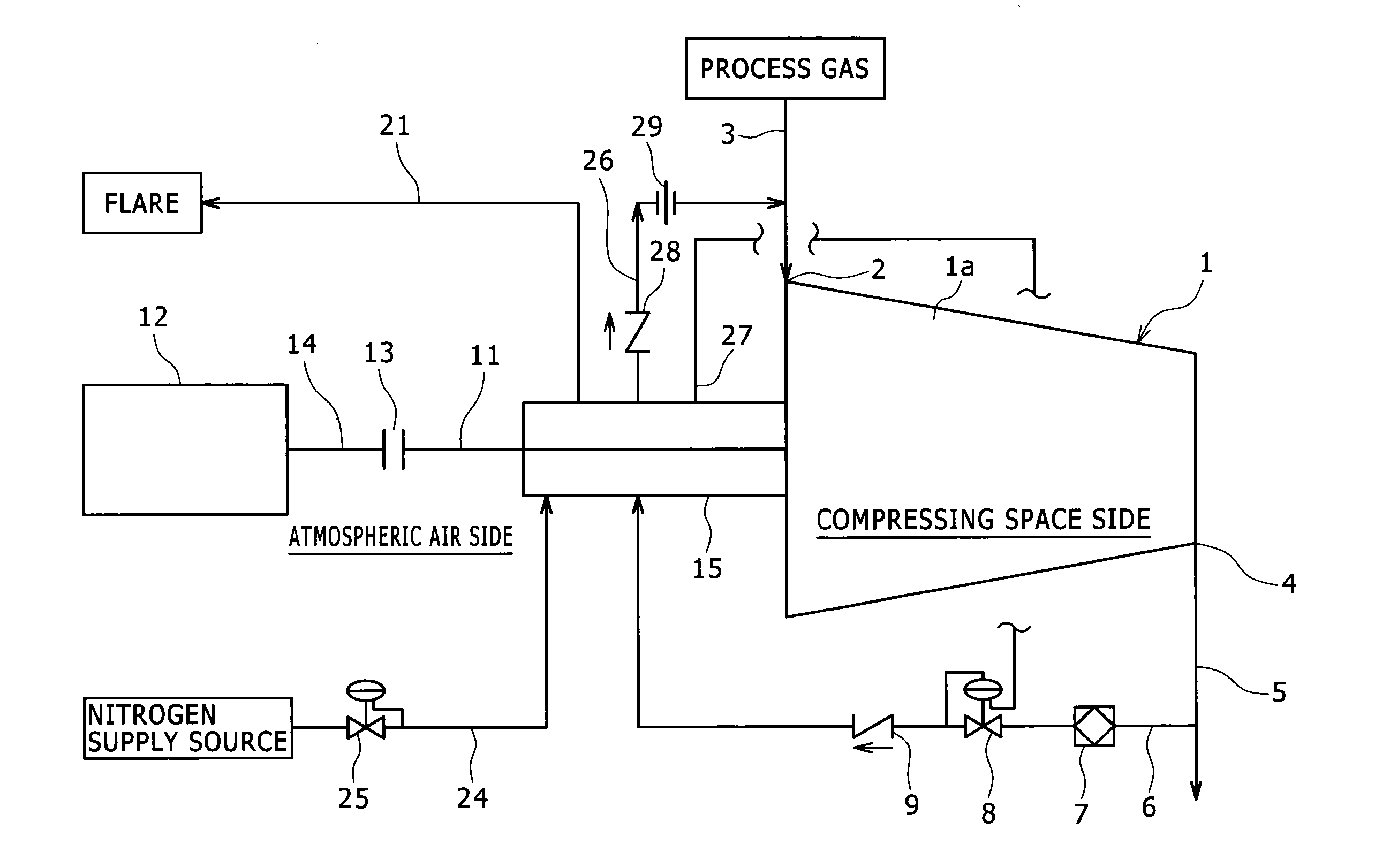

Centrifugal compressor and dry gas seal system for use in it

InactiveUS20070147988A1Avoid unnecessary stopPrevent leakagePump componentsLeakage preventionDry gas sealGas leak

The present invention relates to a centrifugal compressor using a dry gas seal system for protecting seal means. A multistage centrifugal compressor has primary dry gas seal means for preventing leakage of working gas from a machine inner side, and secondary dry gas seal means for backing up the first dry gas seal means. A seal gas line for introducing the gas leaked from the first and second dry gas seal means to the outside of the machine is installed between the primary dry gas seal means and the secondary dry gas seal means. The gas seal line has an orifice and a check valve, and buffer means is installed between the orifice and the check valve.

Owner:HITACHI LTD

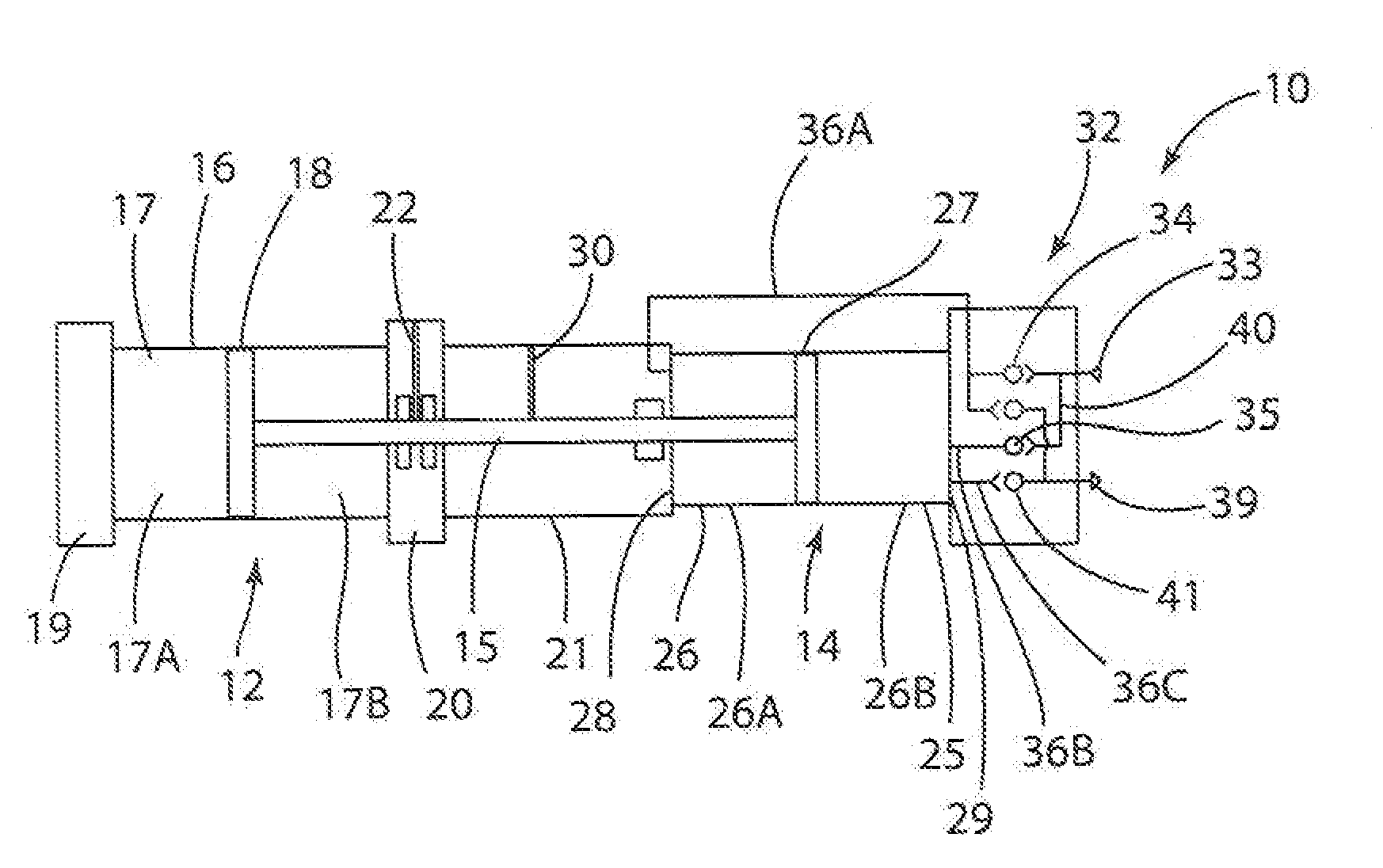

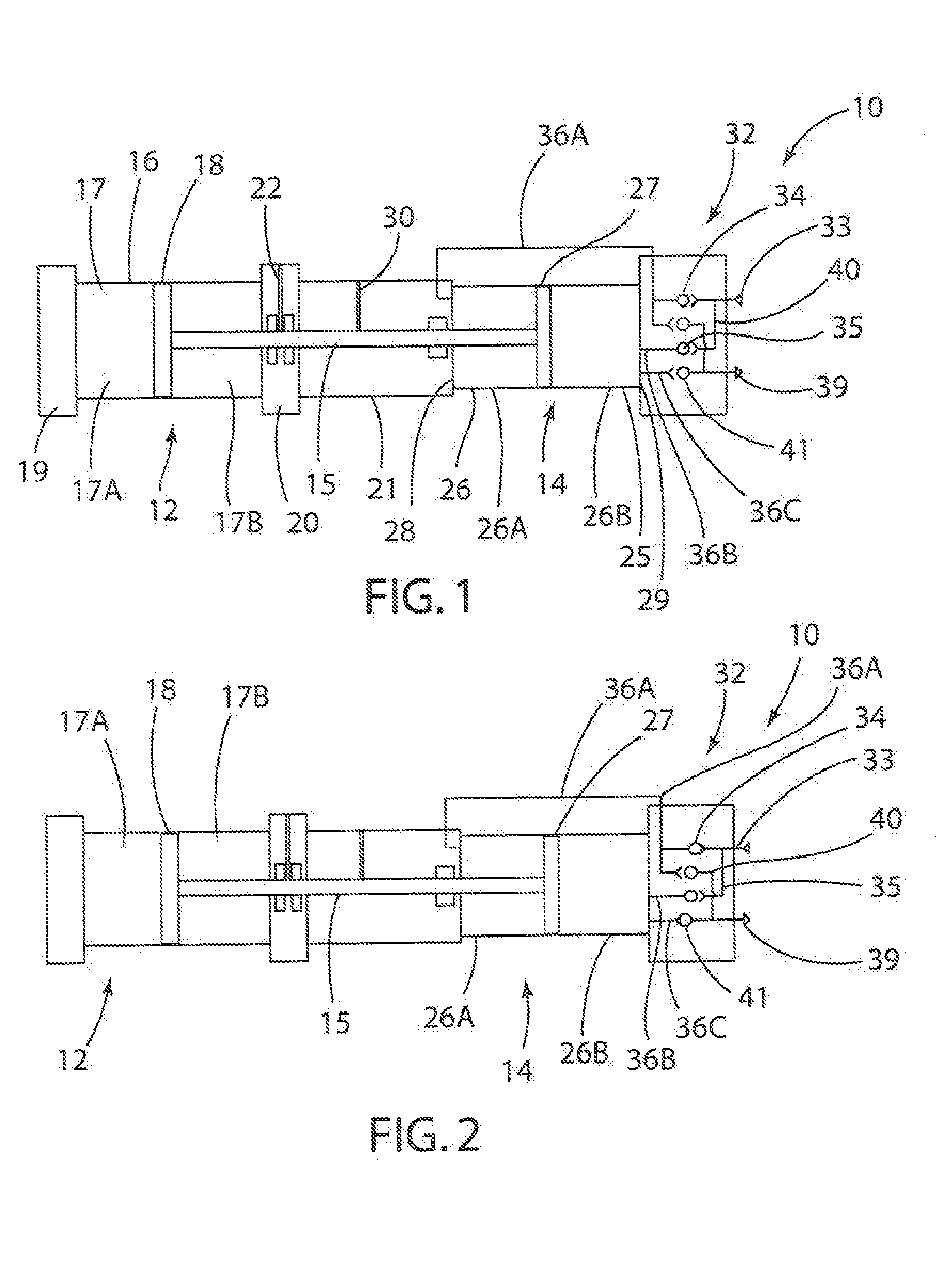

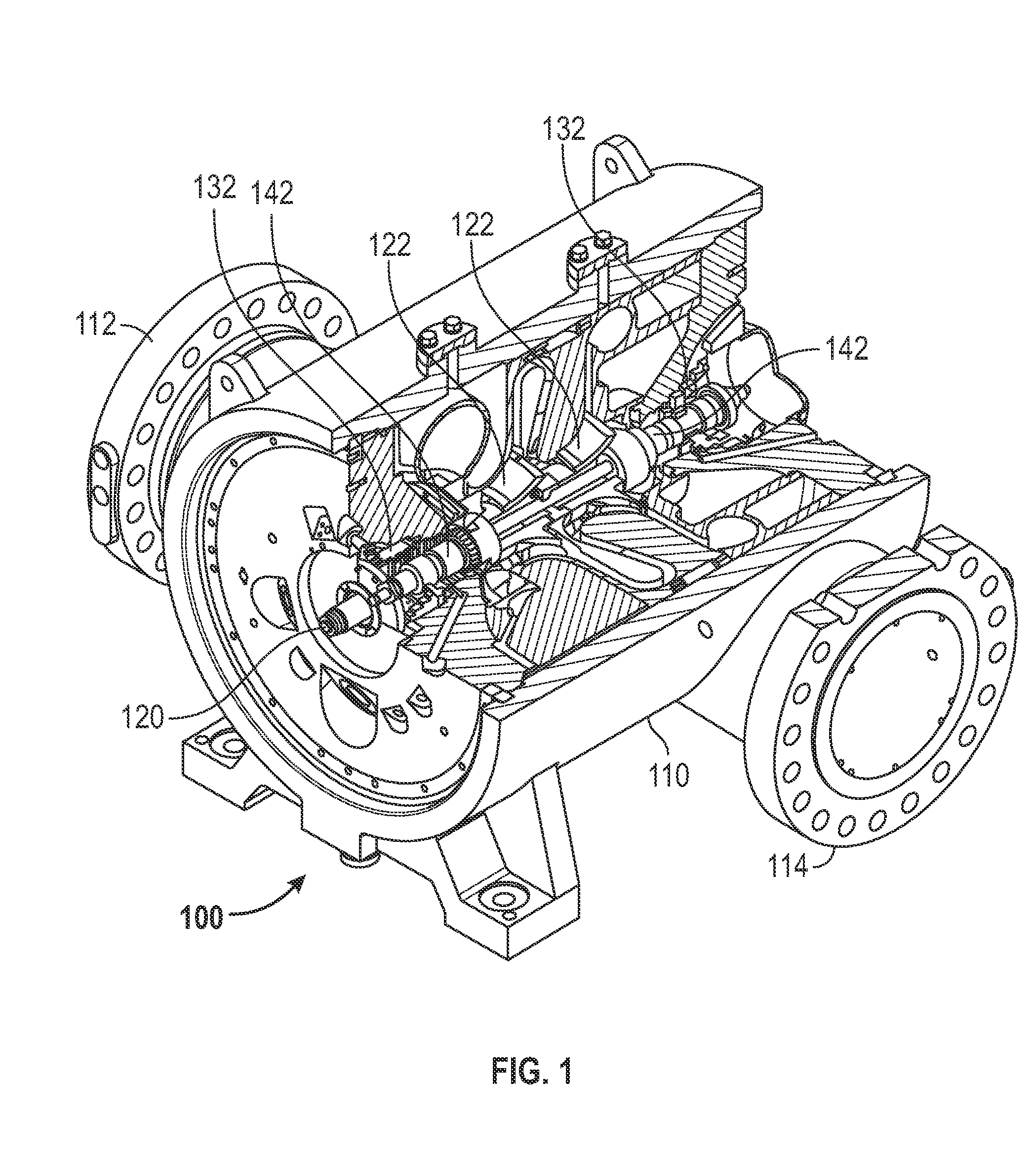

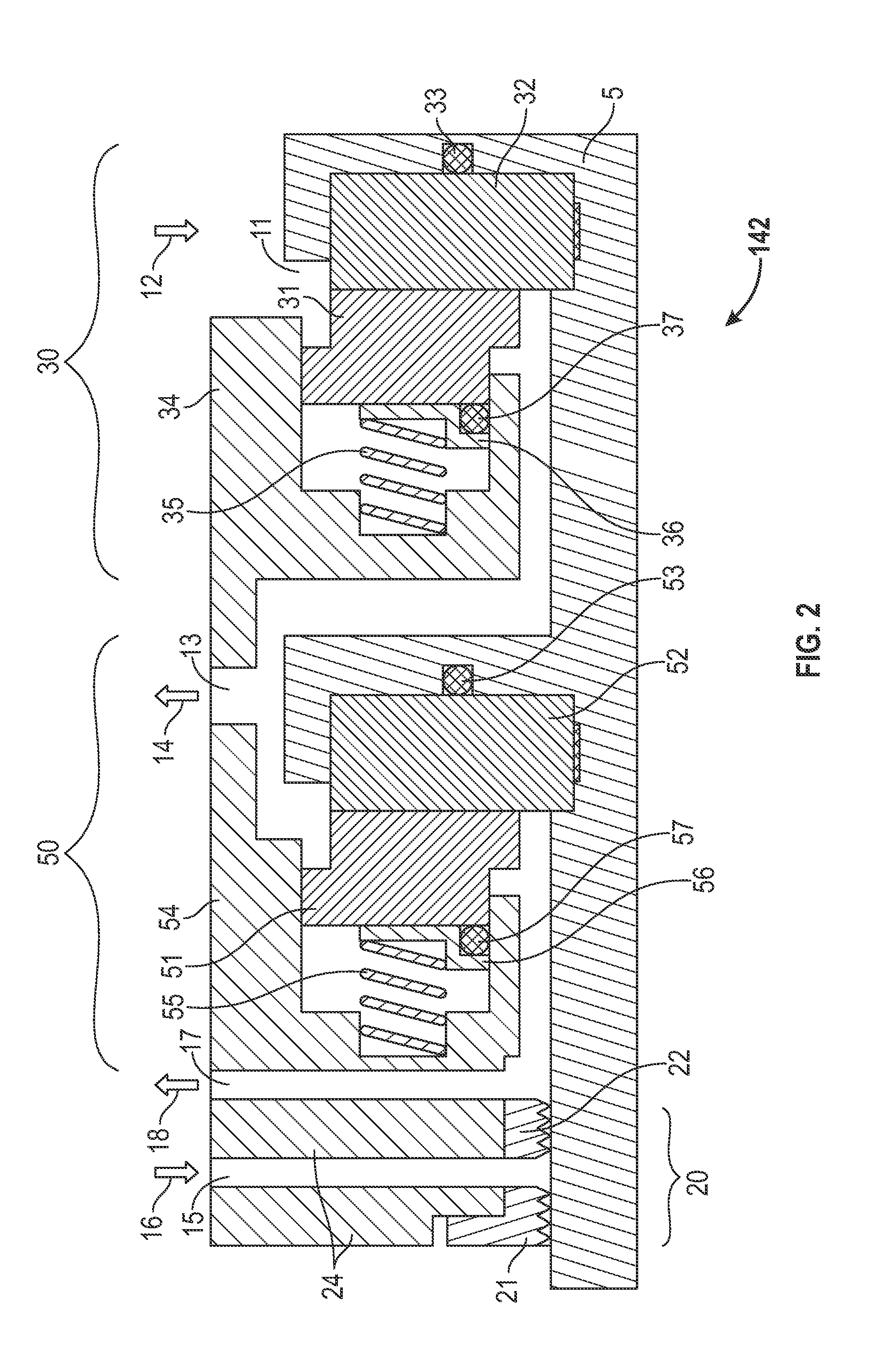

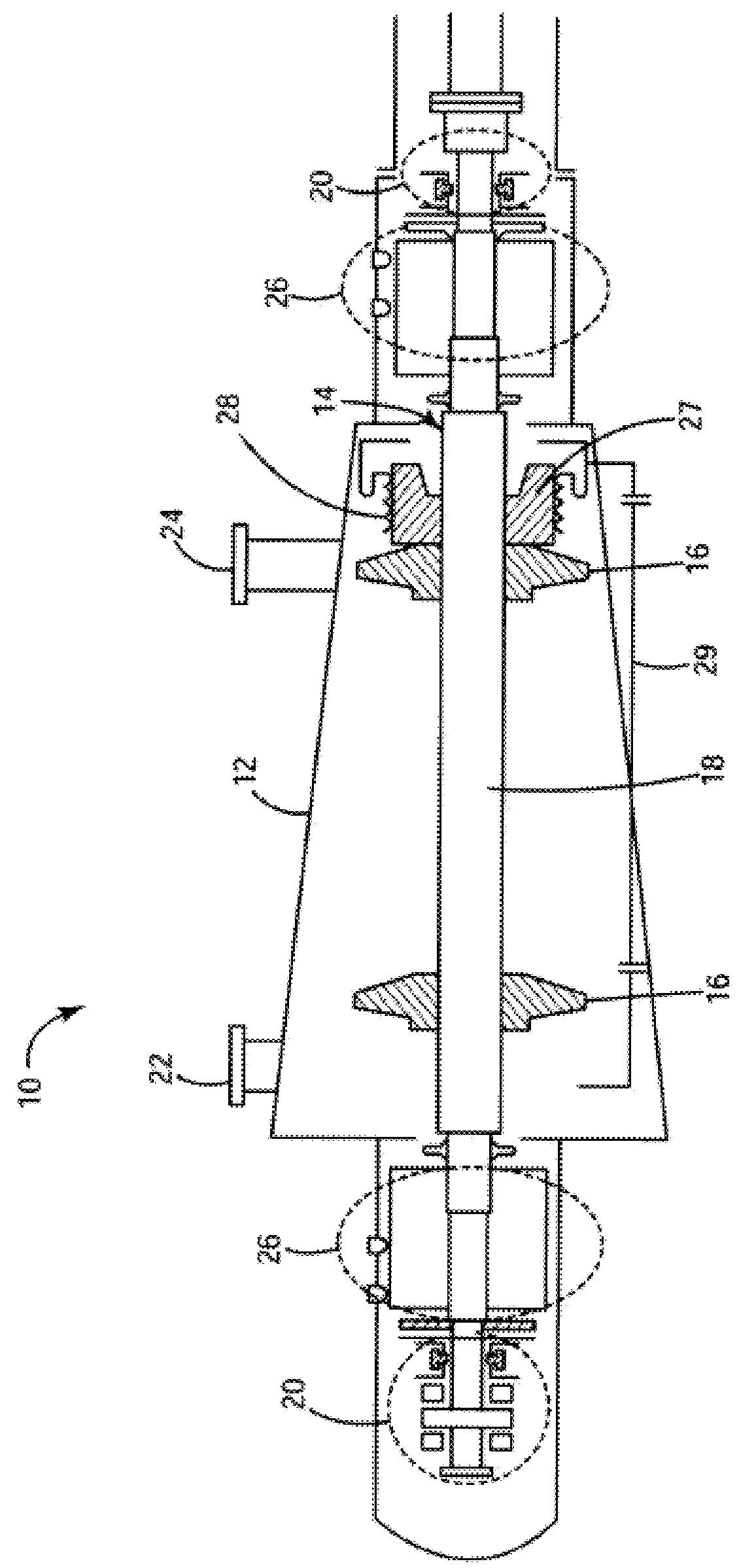

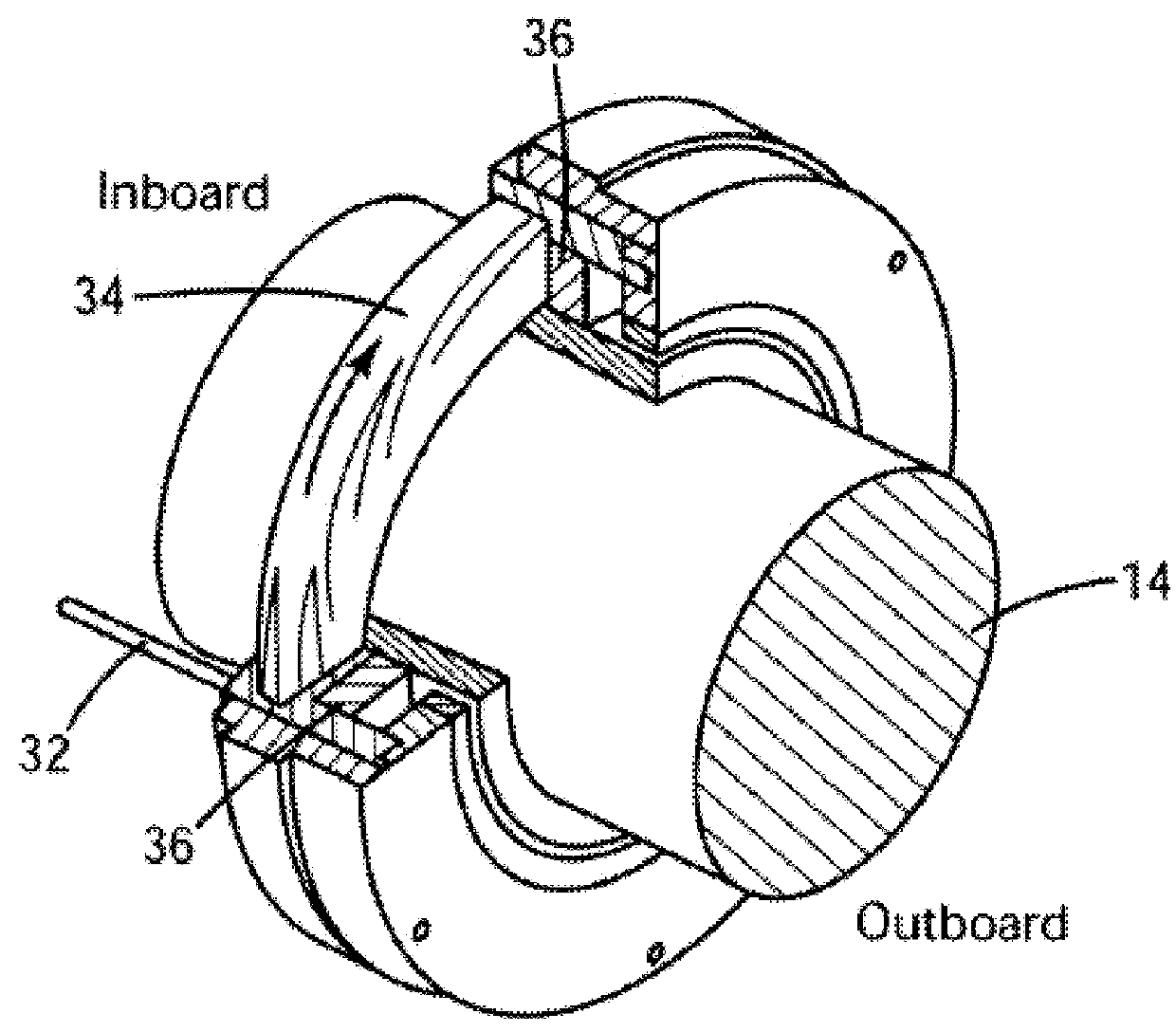

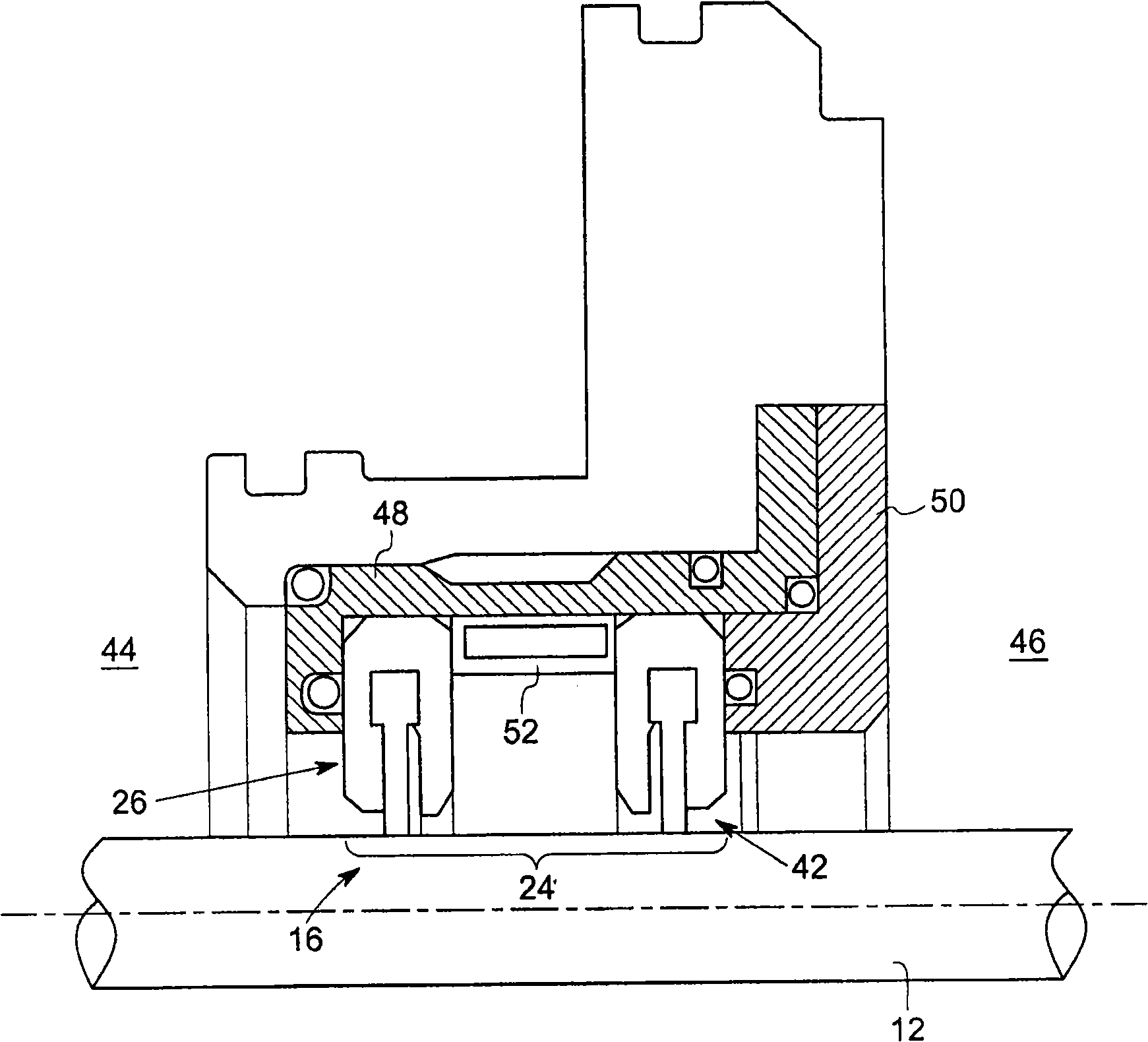

Barrier sealing system for centrifugal compressors

A rotary machine includes a machine rotor, a bearing coupled to the machine rotor, a machine stator, and a sealing device disposed between the machine rotor and the machine stator. The sealing device includes a dry gas seal and first and second seals disposed between the dry gas seal and the bearing. One or both of the first and second seals includes a brush seal or more specifically a brush seal including a plurality of non-metallic fibers.

Owner:NUOVO PIGNONE TECH SRL

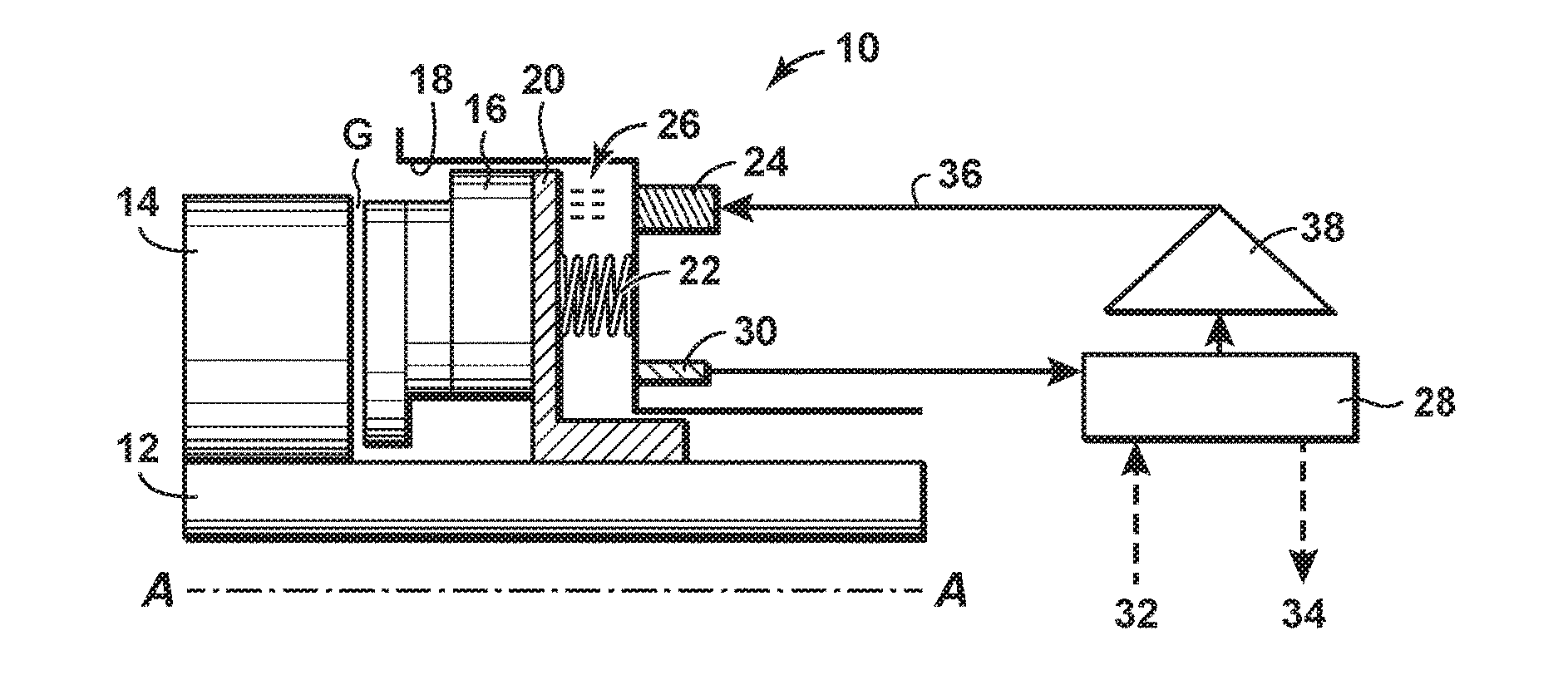

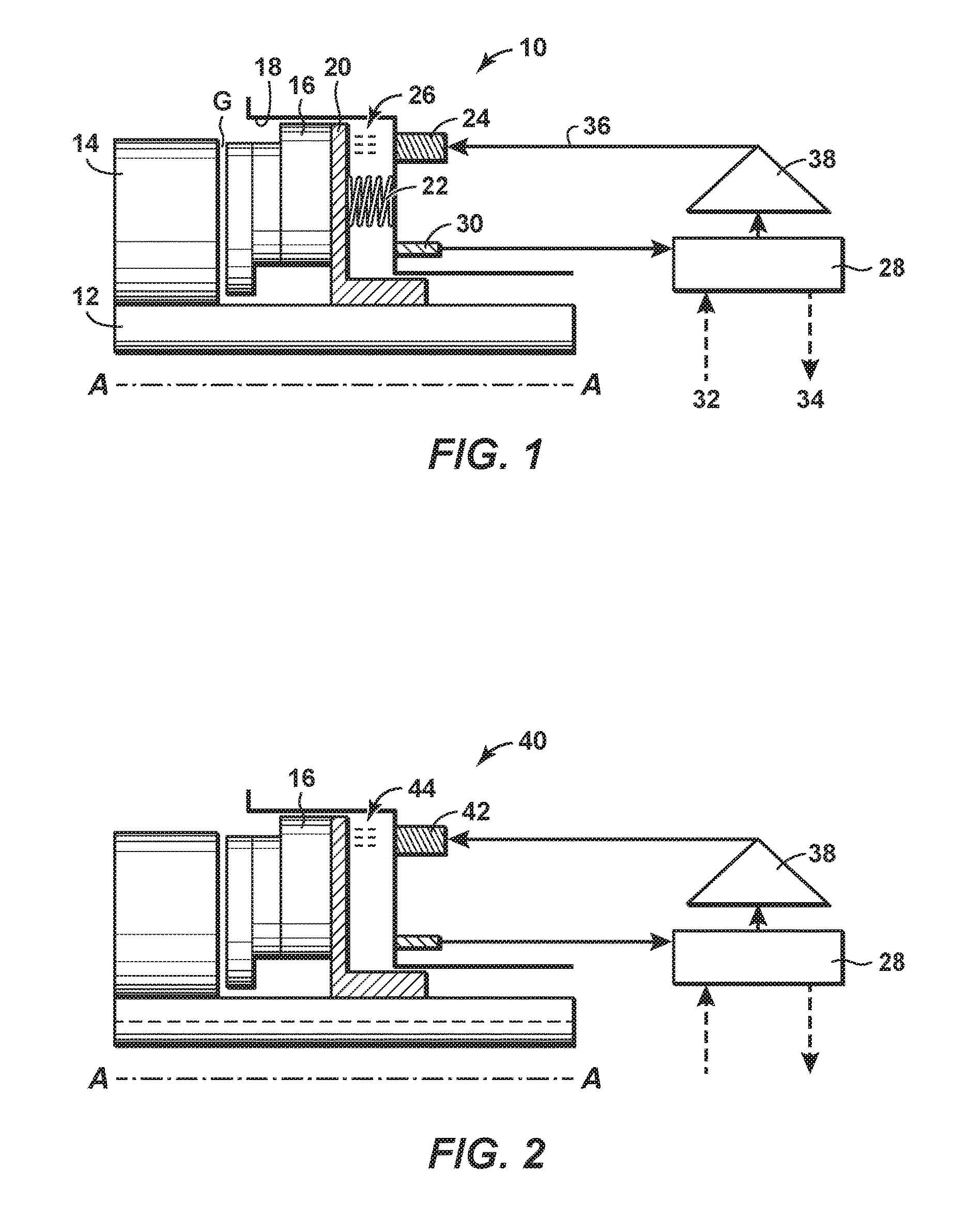

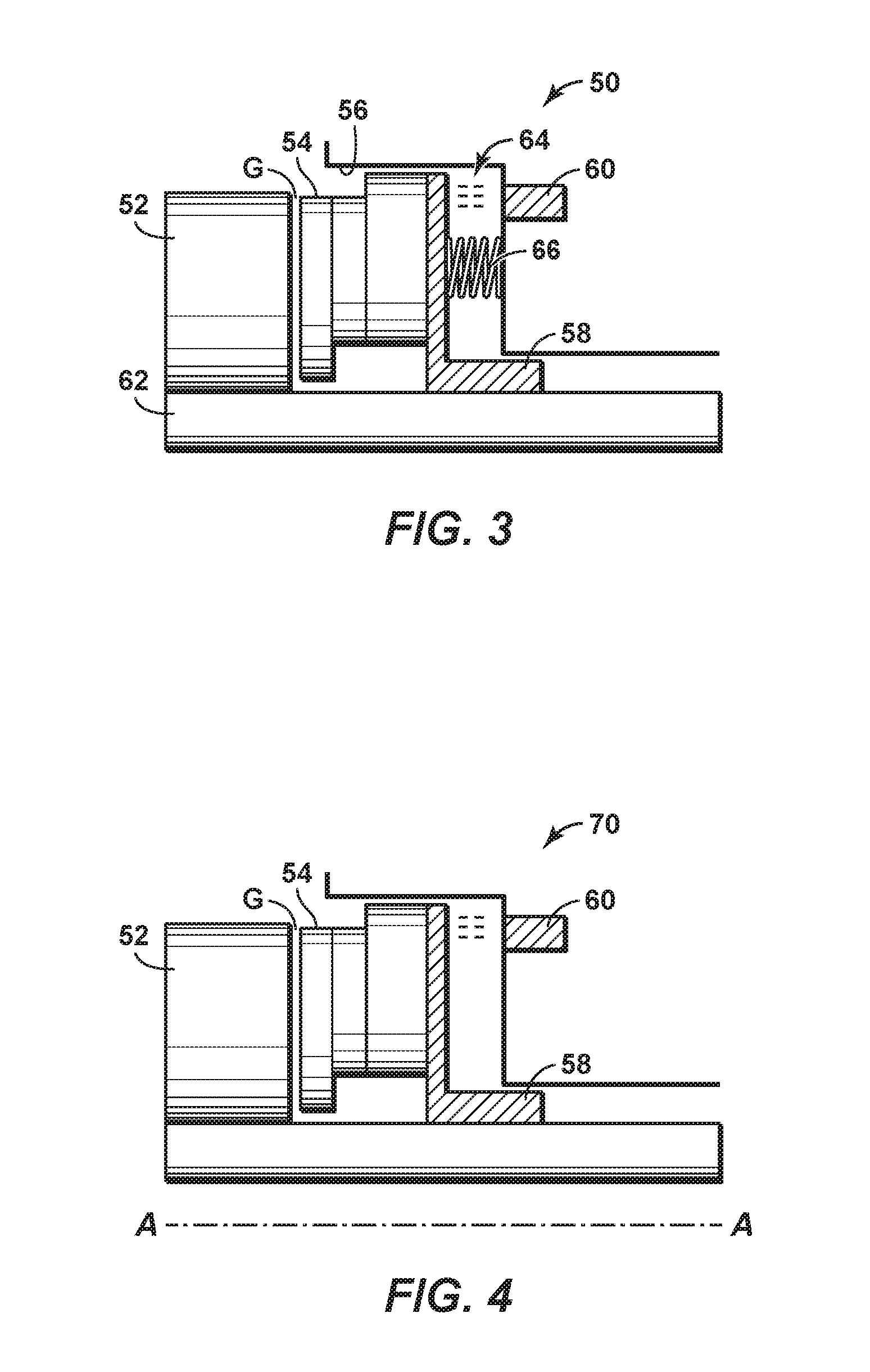

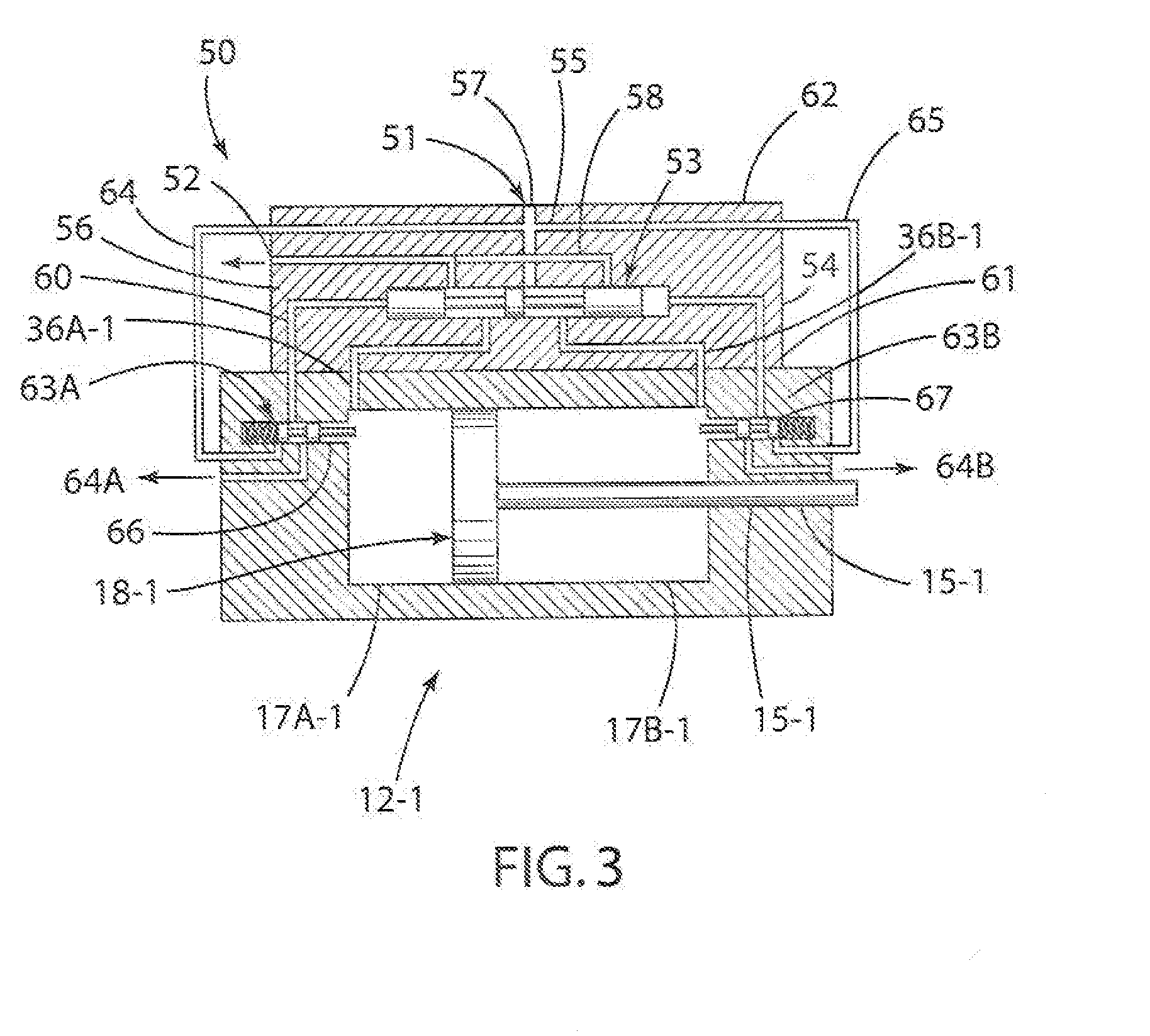

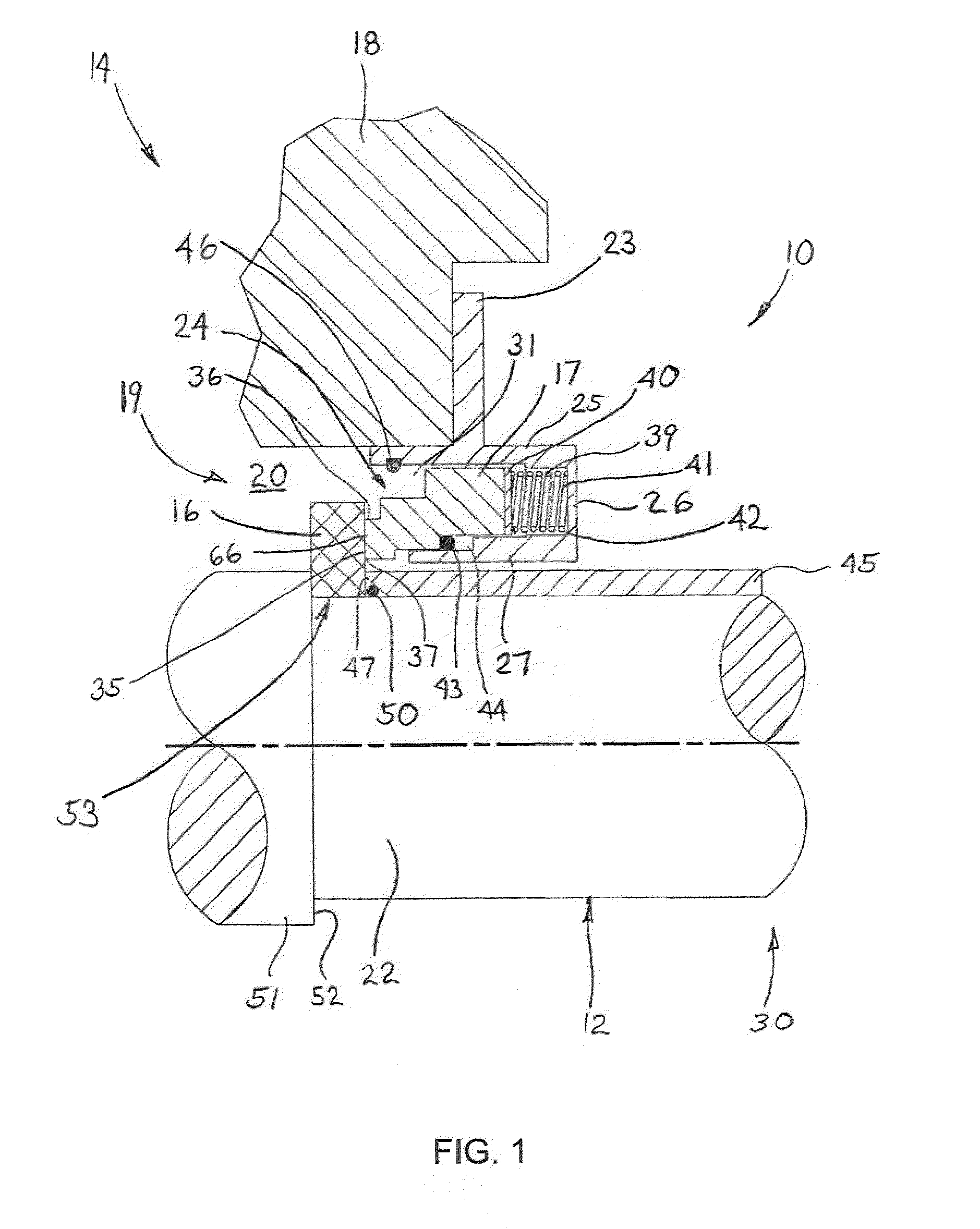

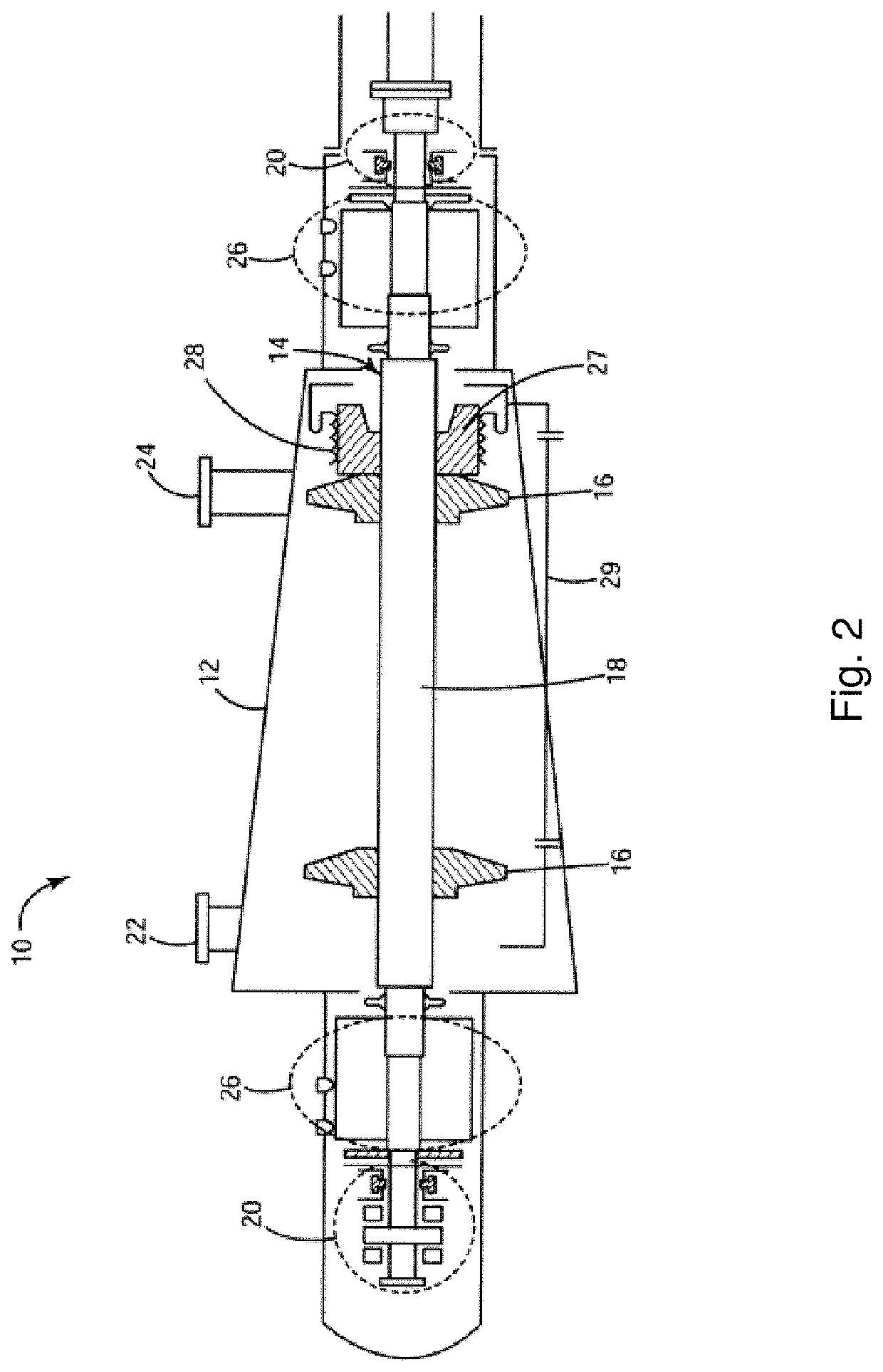

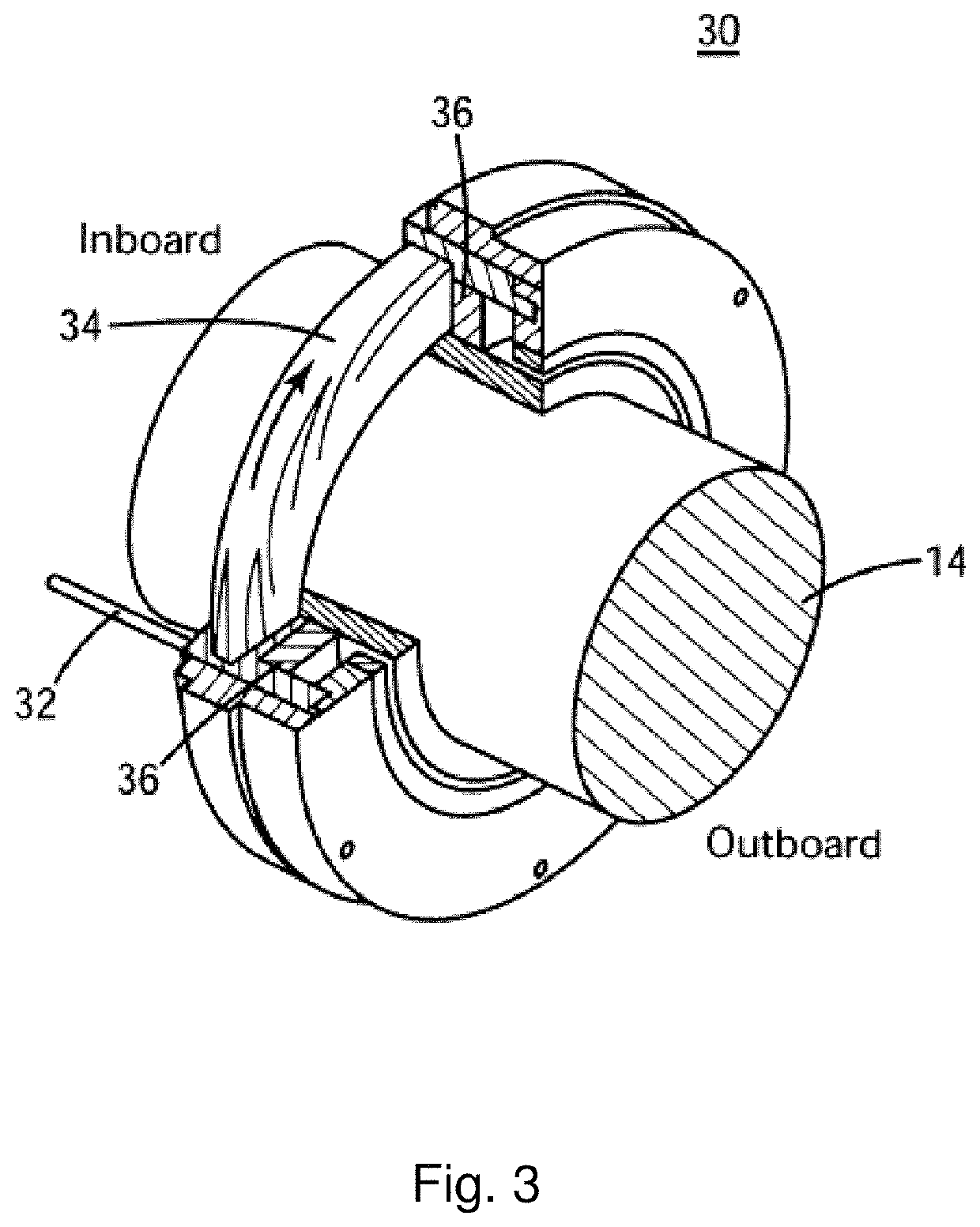

Device and Method for Magnetically Controlled Dry Gas Seal

A method to control an axial separation between a rotating ring and a stationary ring of a dry gas seal. The dry gas seal restricts leakage of a gas or other fluid to or from a rotating device. At least one property of the gas or other fluid is sensed. At least one of the axial separation between the rotating ring and the stationary ring, and a time rate of change of the axial separation, is sensed. A stiffness of a film between the rotating ring and the stationary ring is estimated. A field strength of at least one magnetic device is adjusted based on at least two of the sensed axial separation, the sensed time rate of change of the separation, and the estimated film stiffness. The axial separation between the rotating ring and the stationary ring is adjusted.

Owner:EXXONMOBIL UPSTREAM RES CO

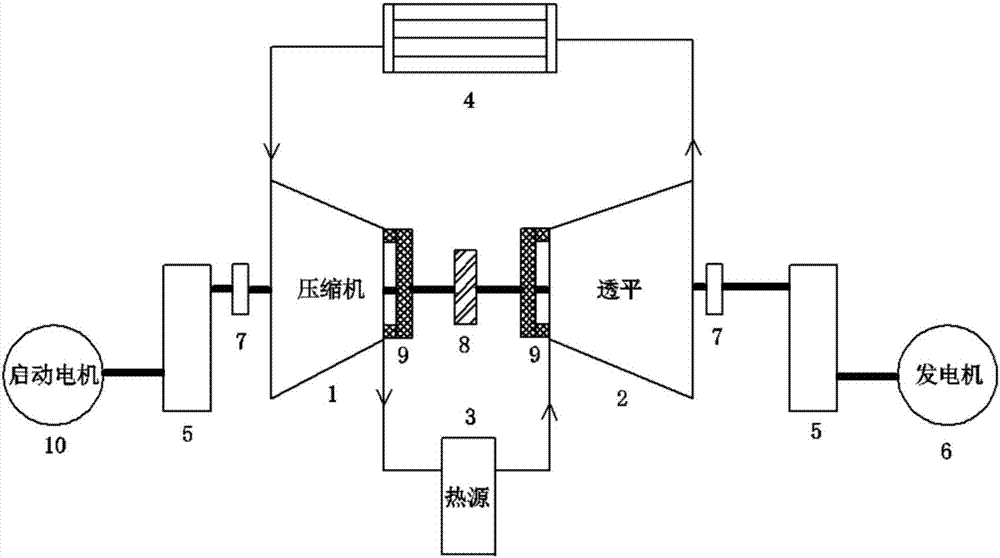

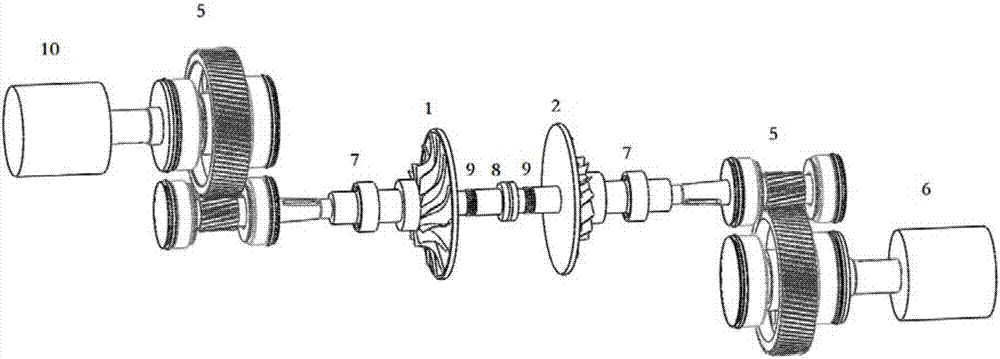

Supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure

InactiveCN107461227AViscosity of working mediumSmall working fluid viscositySteam engine plantsMotor driveElectric machine

The invention discloses a supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure. A supercritical carbon dioxide working medium sequentially flows through a centrifugal compressor to improve pressure and a heat source to improve temperature, and finally after output work in a radial-inward-flow turbine, the supercritical carbon dioxide working medium enters a cooler to be cooled and circulates to enter the centrifugal compressor again. A start motor drives the coaxial structure to start working through one gearbox, the coaxial structure is formed by the radial-inward-flow turbine and the centrifugal compressor through a rotor shaft, the centrifugal compressor is driven by one part of output work of the radial-inward-flow turbine, and the other part of output work of the radial-inward-flow turbine is output into a generator through the other gearbox. Radial bearings are arranged at the shaft ends of the two sides of the coaxial structure, a thrust bearing is arranged in the middle of the coaxial structure, and the type adapting to the corresponding rotary shaft rotating speed can be selected. Furthermore, the form of supercritical carbon dioxide dry gas seals is adopted in sealing parts. The supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure has the prominent beneficial effects of being simple and compact in structure, high in pneumatic efficiency, low in manufacturing cost and the like and has wide market prospects.

Owner:XI AN JIAOTONG UNIV

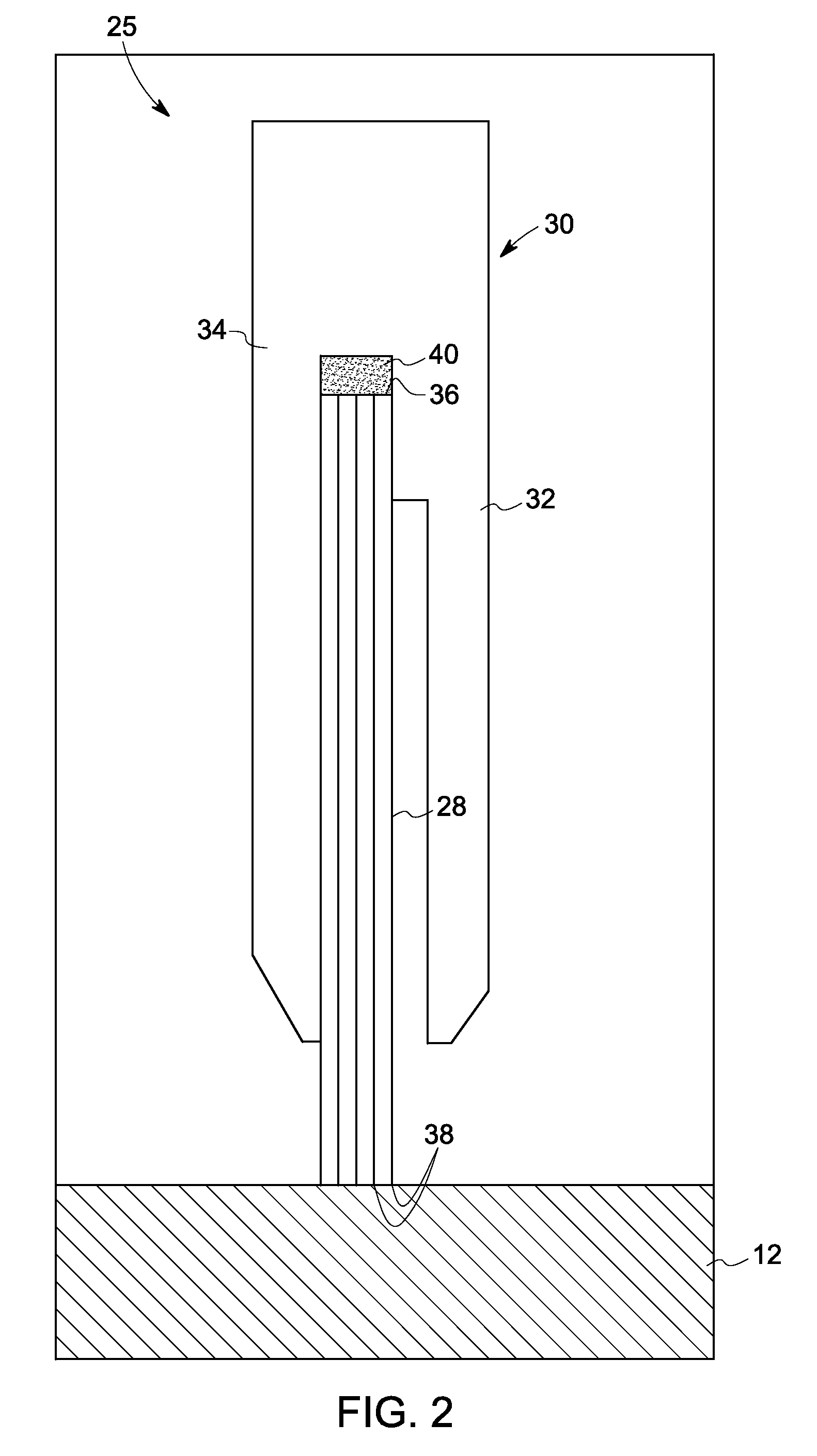

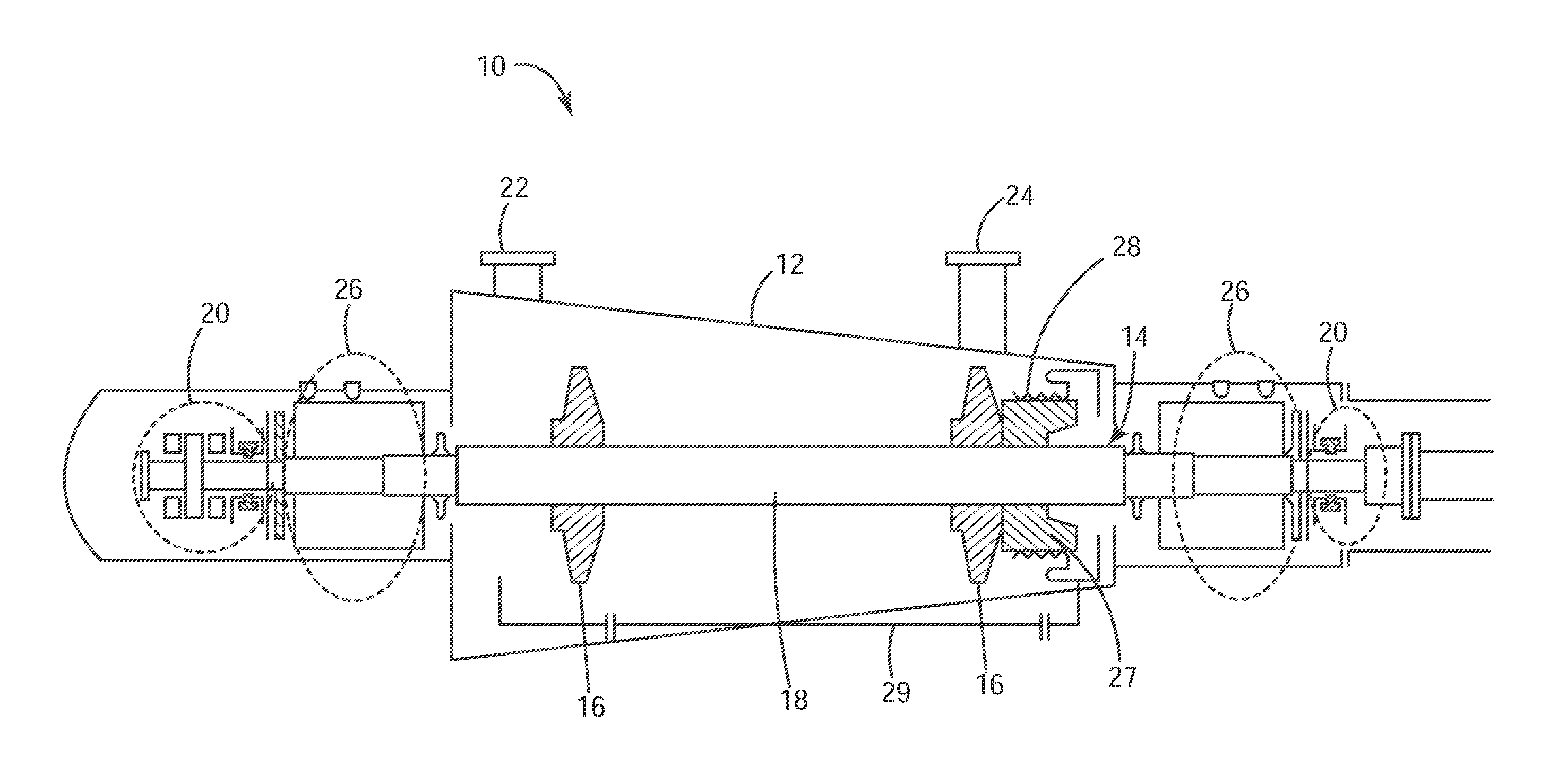

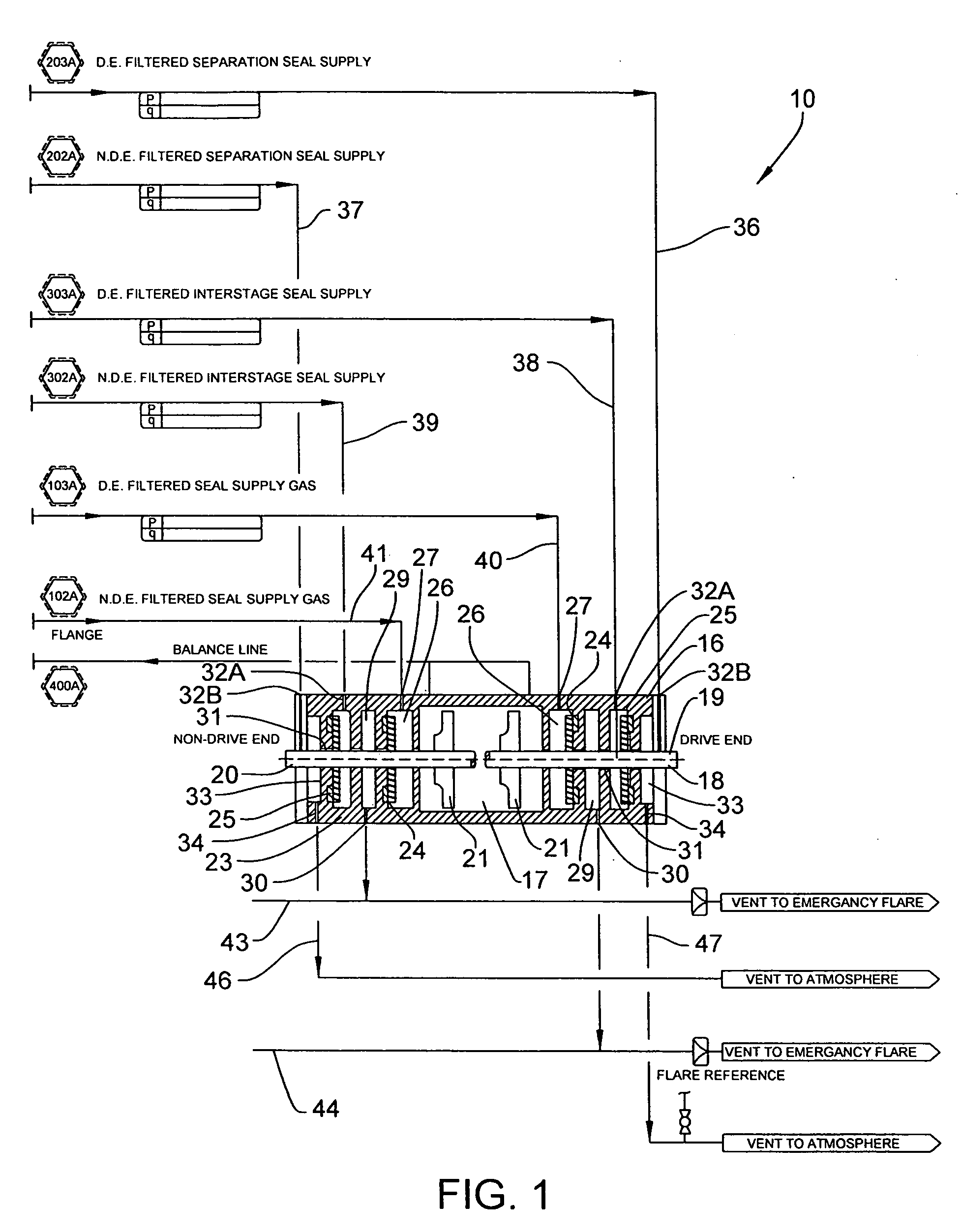

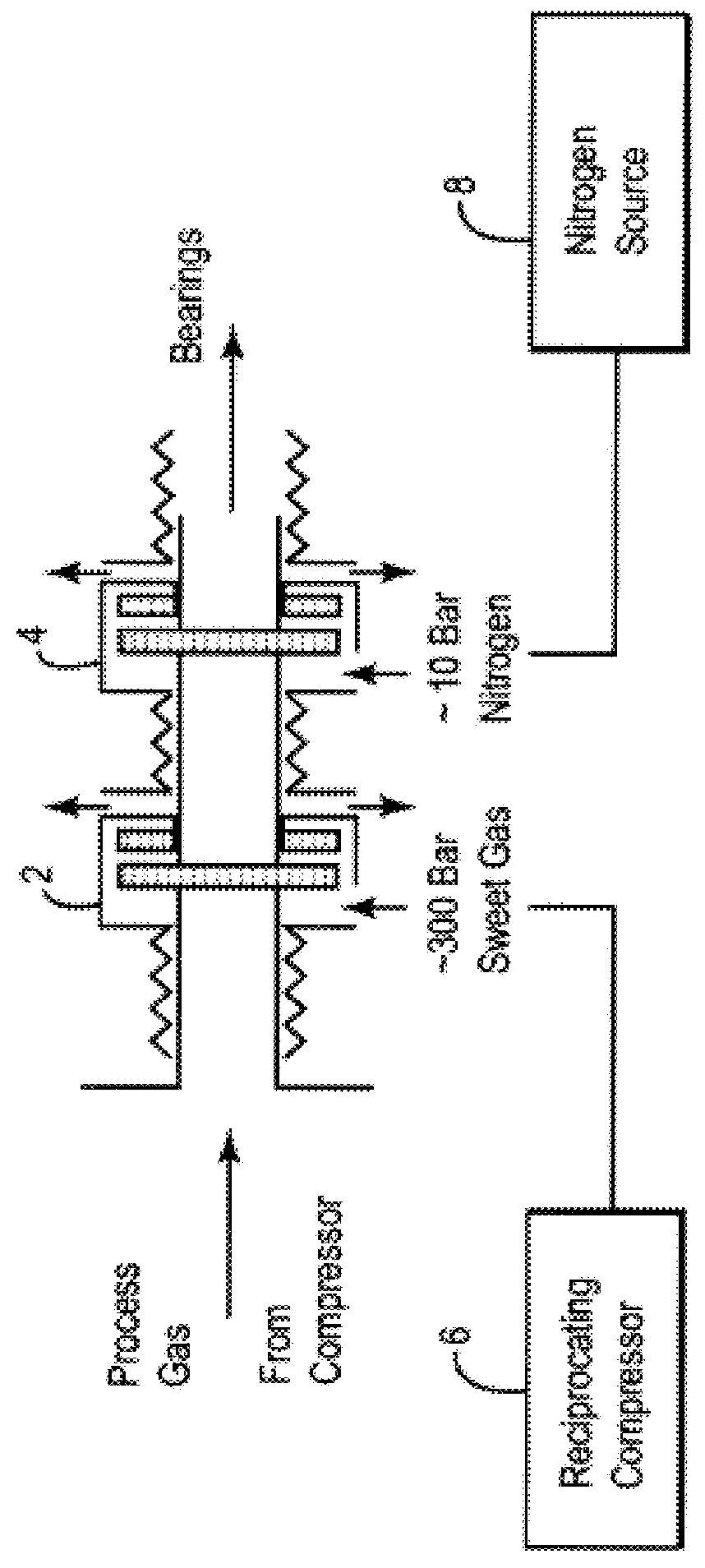

Fluid intensifier for a dry gas seal system

A gas supply system for a mechanical seal turns on the gas supply at a pressurized flow rate at the time of compressor case pressurization and remains on during compressor rotation until pressure is adequate. The gas supply system has an intensifier that includes a pair of mechanically inter-connected pneumatic pressure cylinders which comprise a drive cylinder that affects movement of a boost cylinder wherein the displacement of these mechanically interconnected pistons in the drive cylinder and boost cylinder intensifies the pressure being discharged by the boost cylinder and supplied as a barrier fluid to the mechanical seal. The intensifier uses a control valve and operating system which includes a fast-acting 5 / 2-way solenoid valve having a feedback loop connected to a control system which includes a micro-processor that controls valve actuation.

Owner:FLOWSERVE MANAGEMENT CO

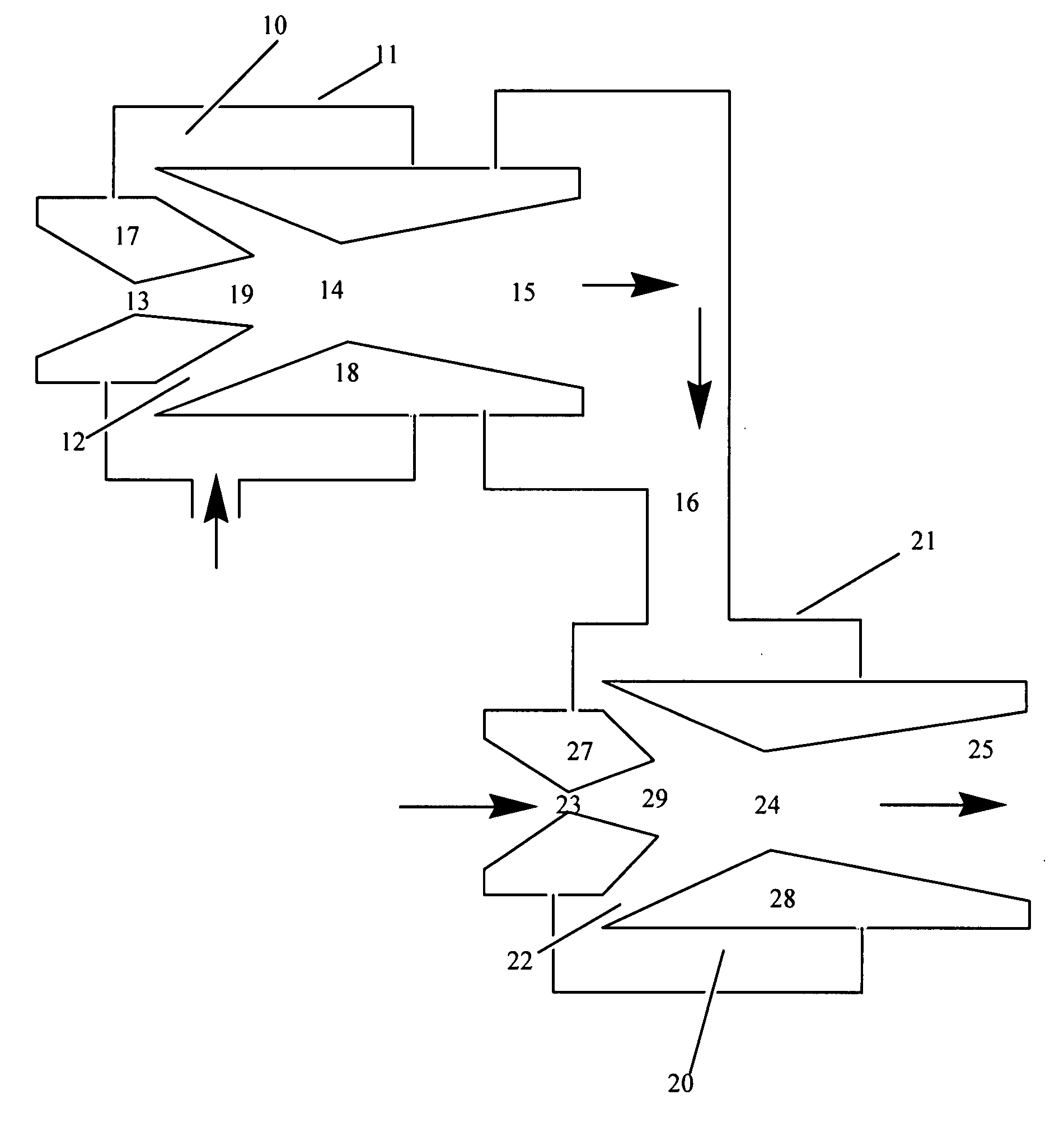

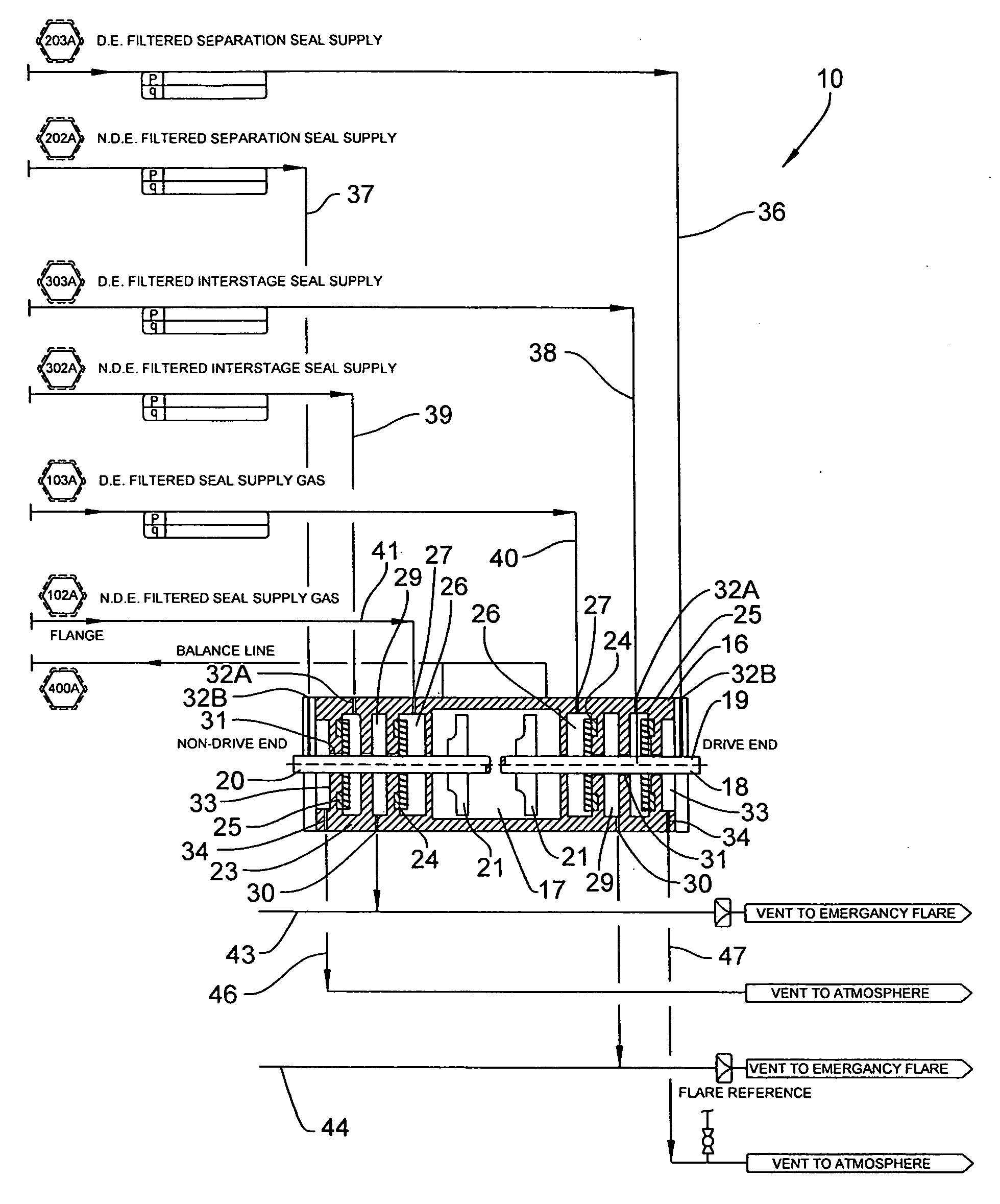

Low emission dry gas seal system for compressors

InactiveUS20130170961A1Easy to controlReduce complexityEngine sealsPump componentsAtmospheric airDry gas seal

Systems and methods according to these exemplary embodiments provide sealing mechanisms for centrifugal compressors. A sealing mechanism includes first, second and third dry gas seals arranged in series. Each seal receives its own sealing gas and has its own venting mechanism. Sealing gas pressures remain low enough that a dedicated compressor for supplying the sealing gases is not needed. Additionally, the risk of process gas being released into the atmosphere in case of seal failure is limited.

Owner:NUOVO PIGNONE SPA

Dry gas seal assembly

A seal assembly forms a barrier between a compressor's interior and exterior regions. The seals assembly includes a primary seal stage and a secondary seal stage. The primary seal stage is formed of materials chosen to effectively block flow of gas through the seal assembly. The secondary seal stage is formed of materials chosen to survive a failure of the primary seal stage.

Owner:SOLAR TURBINES

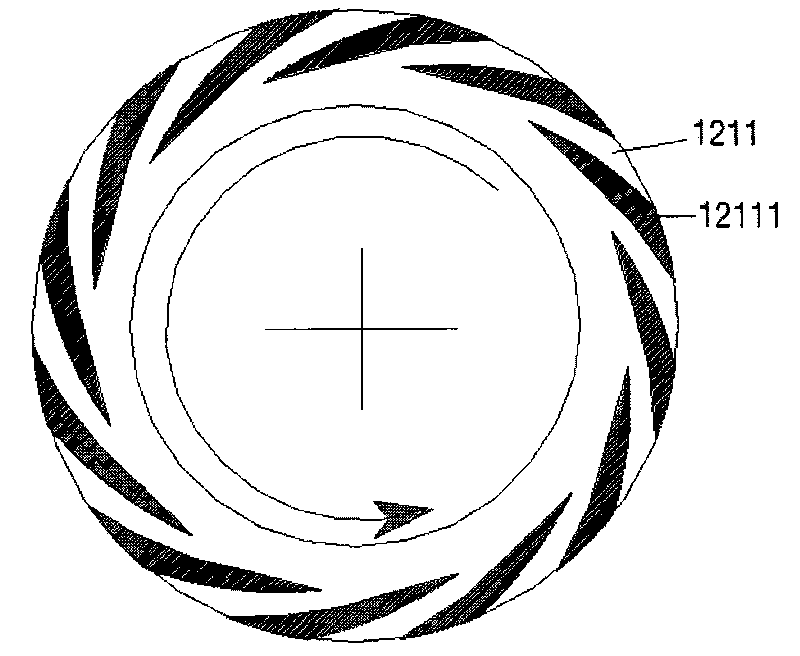

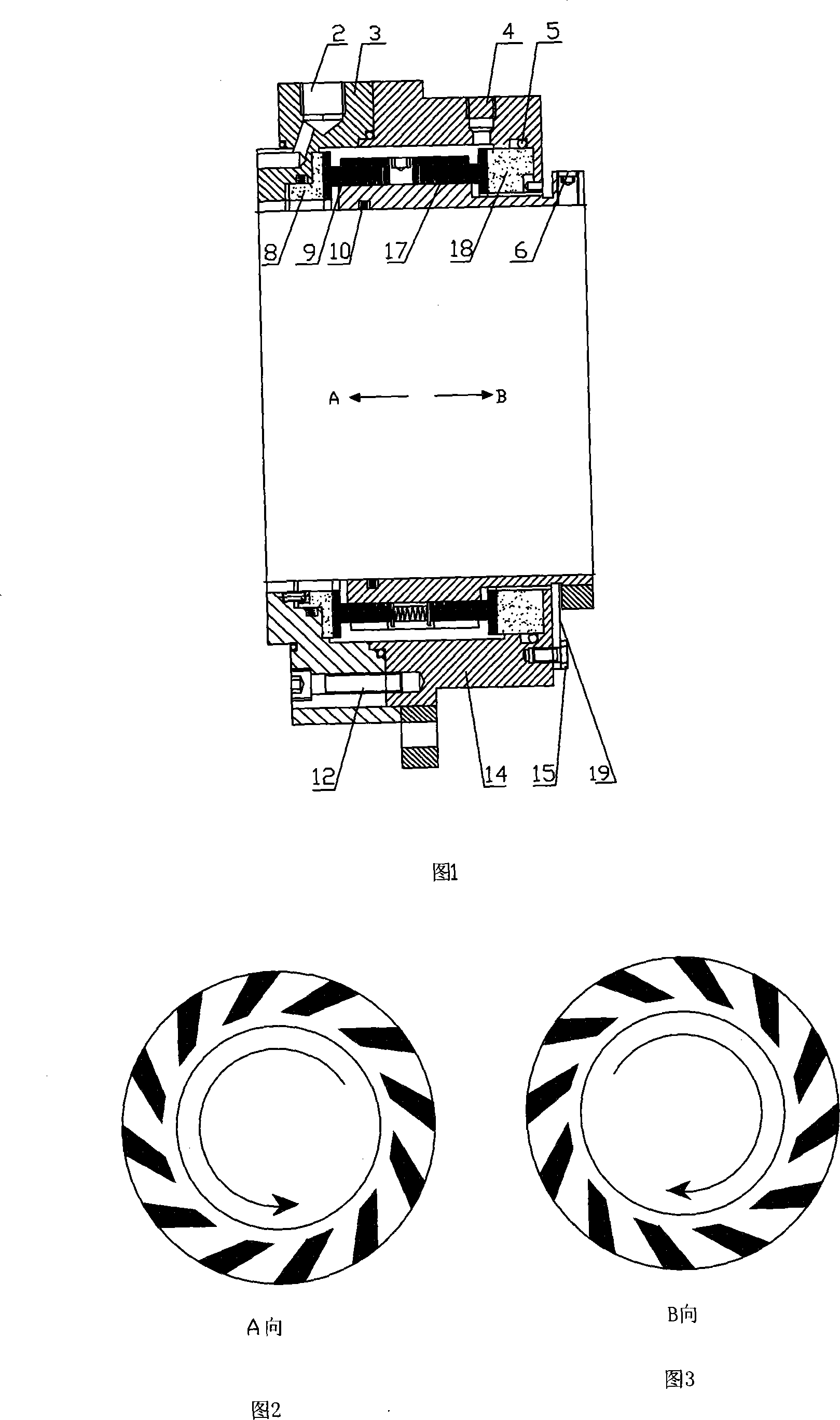

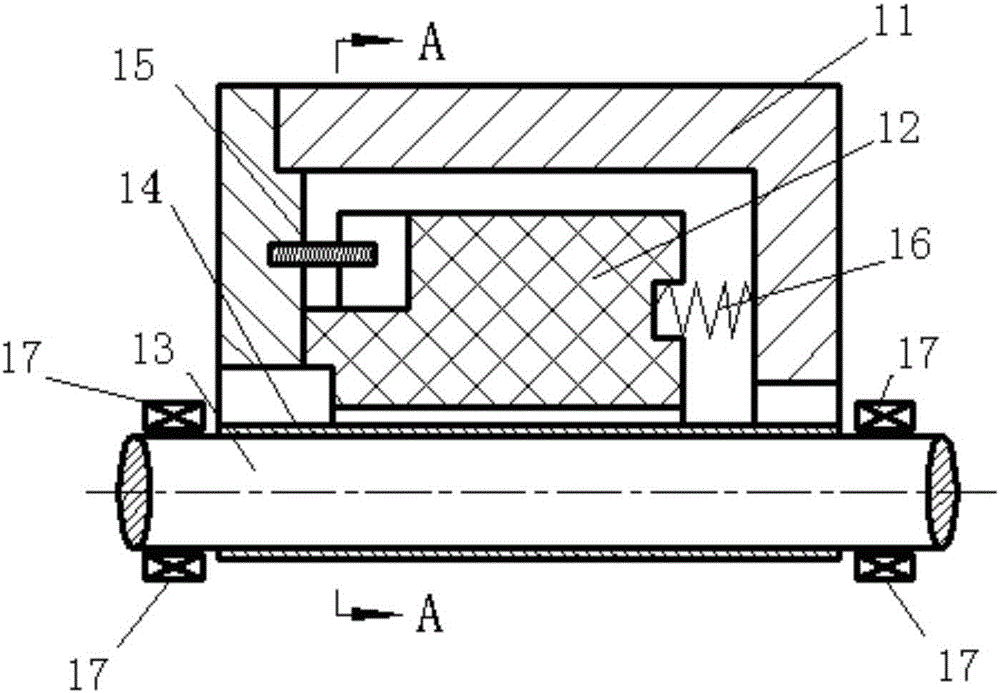

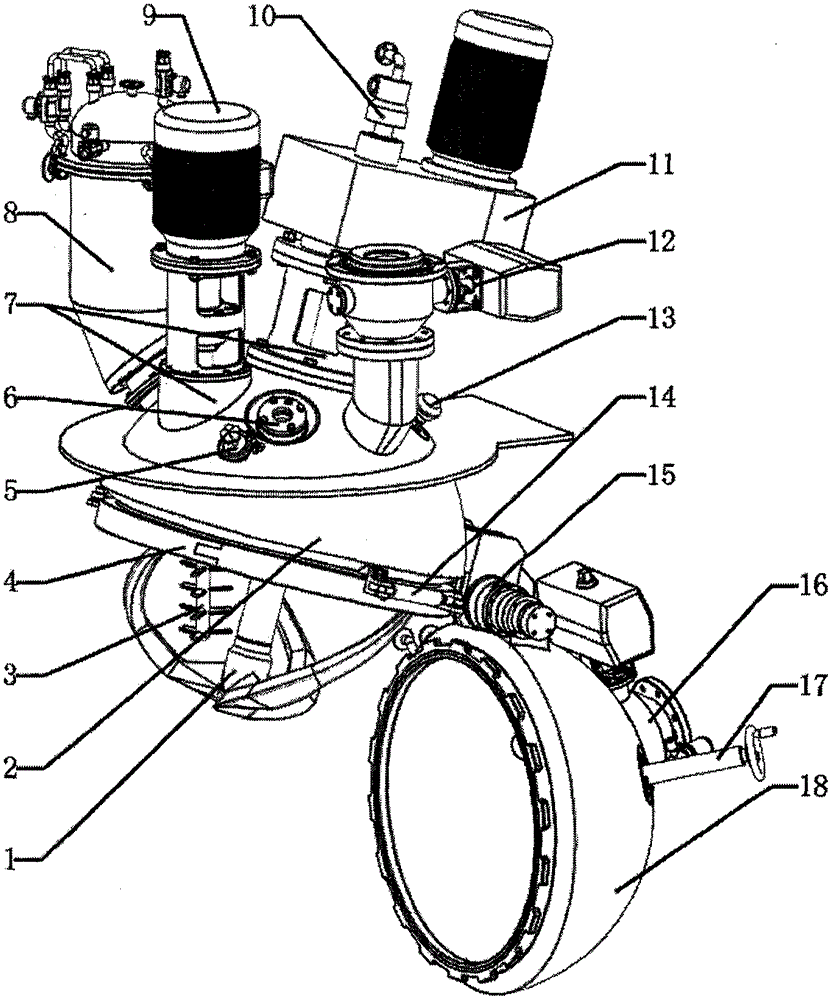

Dry gas sealing device for bidirectional rotary internal pressure pump

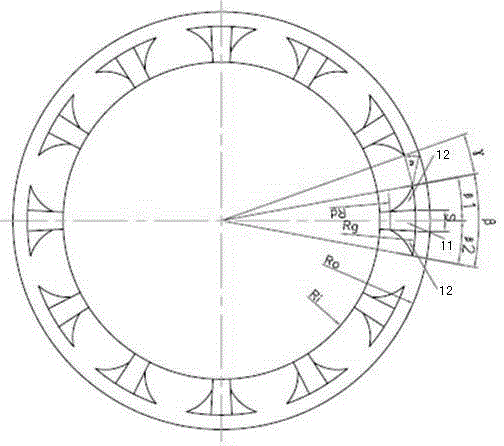

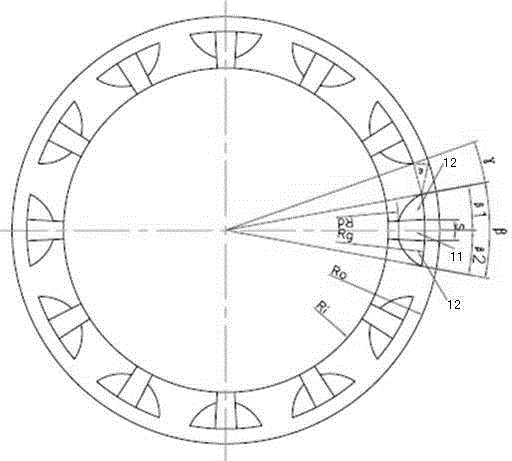

ActiveCN102619742ASimple structureCompact assemblyEngine sealsPositive displacement pump componentsInternal pressureRotary pump

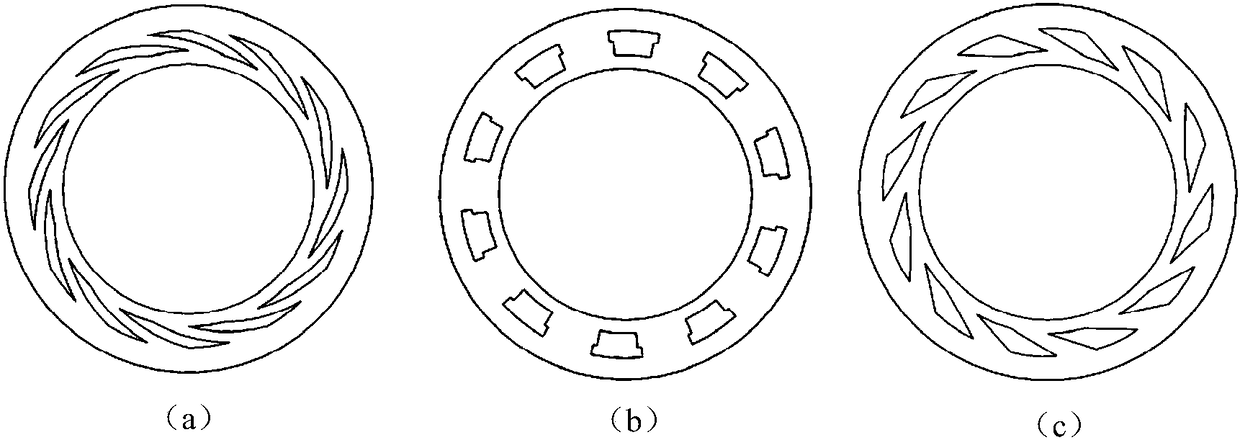

The invention discloses a dry gas sealing device for a bidirectional rotary internal pressure pump. The device comprises a rotating shaft, a shell, a sealed cavity, a static ring, a dynamic ring and an elastic element, wherein the rotating shaft penetrates through a hole of the sealed cavity; the dynamic ring is fixed on the rotating shaft through a fixing assembly; the sealing end faces of the static ring and the dynamic ring are jointed; the elastic element is positioned between the sealed cavity and a thrust ring; the thrust ring is attached to the back of the static ring; a sealing ring is arranged between the thrust ring and the static ring; a cylindrical pin is fixedly arranged on the sealed cavity; the sealed cavity is arranged in the shell; and groove groups are arranged on the sealing end face of the static ring or the dynamic ring and distributed in the circumferential direction, each groove group comprises a gas supply groove and dynamic pressure grooves, and the dynamic pressure grooves are distributed on the left and right sides of the gas supply groove. The device has the advantages of simple structure, compactness in assembly, good sealing property, strong bearing capacity, convenience in machining and manufacturing, capability of realizing bidirectional rotary sealing, wide application range and the like, and is particularly suitable for sealing various rotating shafts of solid-containing centrifugal pumps, screw pumps, rotary pumps and the like.

Owner:DALIAN HUAYANG SEALS

Mechanical face seal with a reverse trapezoidal face pattern

Owner:FLOWSERVE MANAGEMENT CO

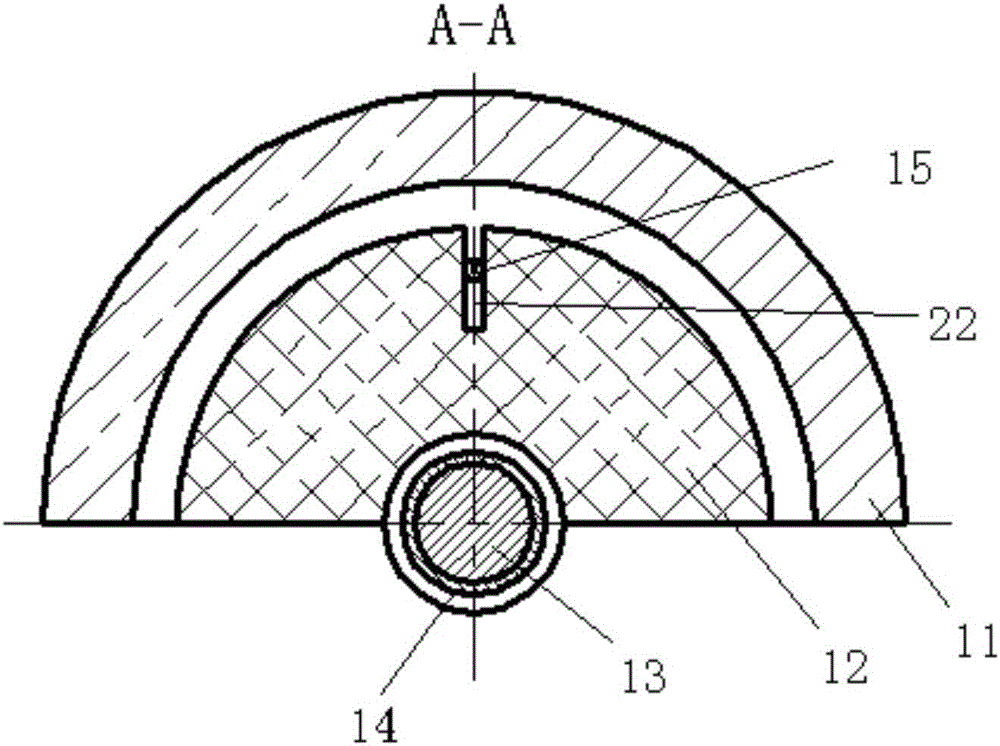

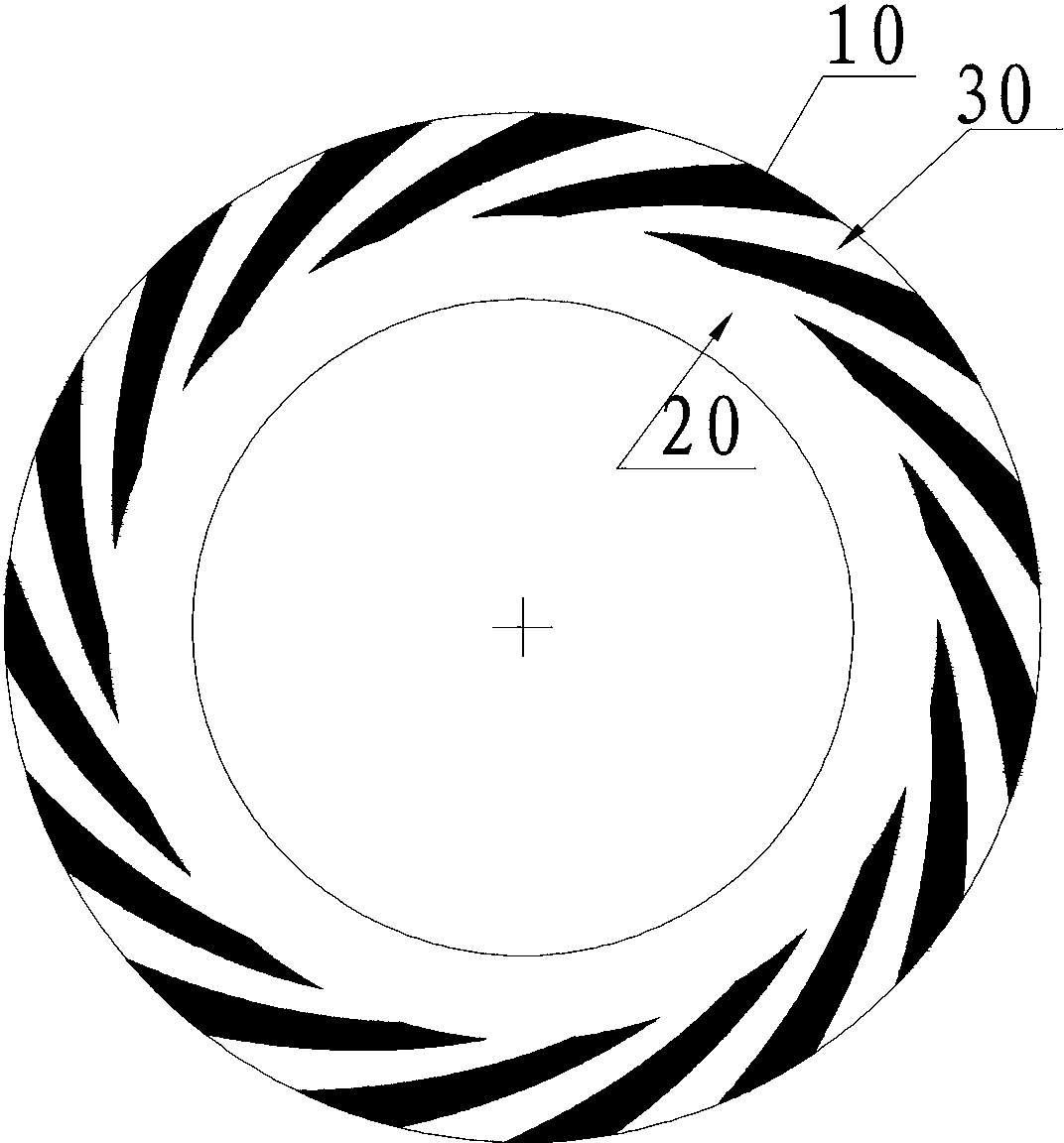

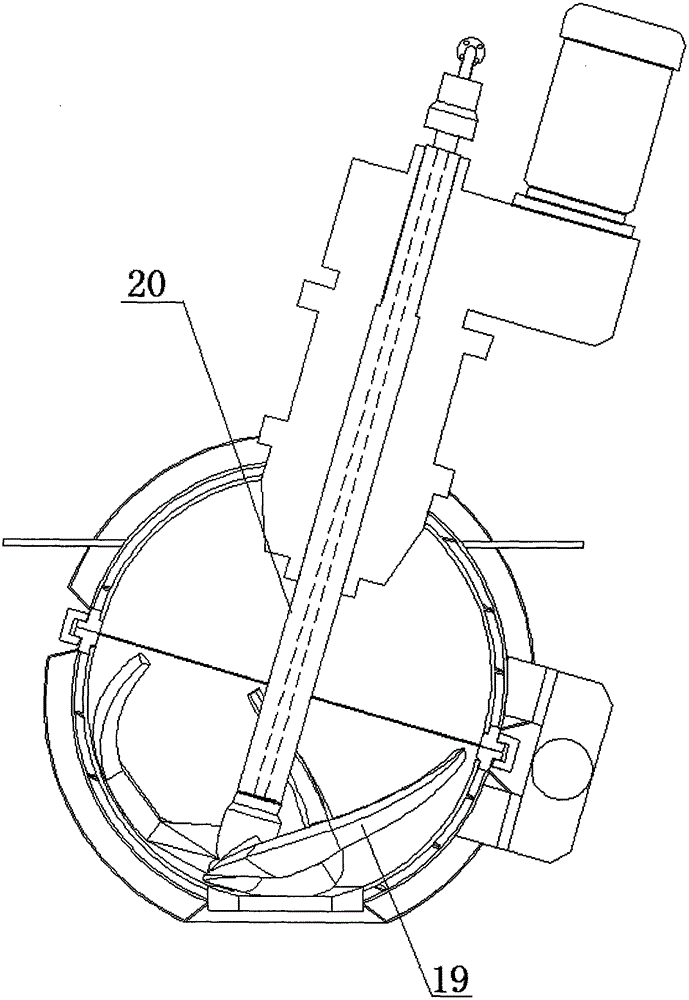

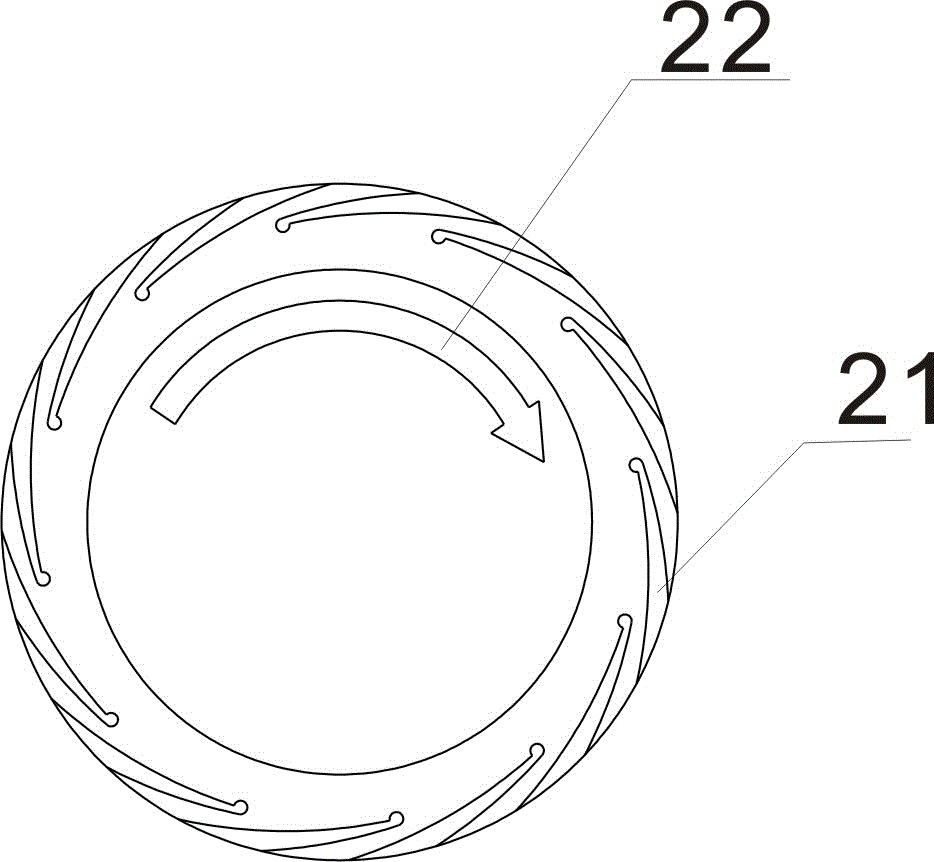

Phosphoric acid axial-flow pump dry gas sealing device

InactiveCN101158361AReduce dosageLow running costEngine sealsPump componentsAxial-flow pumpPhosphoric acid

The invention discloses a phosphoric acid bearing pump dry gas sealing device, comprising a dual-end sealing friction pair, a spring, a press plate component and a connecting bolt. The invention is characterized in that a gas sealing trough (19) is chiseled on a static ring; the rotation direction of a trough clearance (20) complies with the rotation direction of the pump. The dual-end sealing friction pair consists of a drive ring (3), a movable ring A(9), a fixed ring A(8), a movable ring B(17) and a fixed ring B(18); the fixed ring A(8) is fixed on the drive ring (3); an O-shaped sealing ring (5) is arranged between the fixed ring B(18) and the press plate component (14); the press plate component (14) is connected by a connecting bolt A(12) and a connecting bolt B(15); two ends of a spring (16) are connected with the movable ring A(9) and the movable ring B(17); an air outlet (2) and an air inlet (4) are both arranged on the press plate component (14). The invention has the advantages of long service life, simple troubleshooting, energy saving and consumption reduction, and low operation expense, without water entering the concentration system.

Owner:WENGFU (GRP) CO LTD

Dry gas seal device

InactiveCN105156687AEnhanced hydrodynamic effectImprove air film stiffnessEngine sealsDry gas sealEngineering

The invention belongs to the technical field of mechanical seals, and provides a dry gas seal device to solve the problems that when a current dry gas seal is applied to high-temperature large-amplitude vibration equipment, an auxiliary seal O-type ring of a compensation ring is likely to deform due to high temperature, and the compensation ring and an active ring are likely to rub. The dry gas seal device comprises a seal support, a pressure spring, a floating ring, a rotary shaft, a shaft sleeve and a locating pin. Bearings are arranged in the middle of the seal support, and the rotary shaft is assembled on the bearings. Spiral grooves, tables and dams are arranged on the outer wall of the shaft sleeve, and the shaft sleeve is arranged on the rotary shaft. The floating ring is located in the seal support and arranged on the shaft sleeve in a sleeving manner. One end of the floating ring and the seal support are circumferentially fixed through the locating pin, and the other end of the floating ring is connected with the pressure spring. The dry gas seal device is good in opening characteristic, high in gas film rigidity, stable in running and capable of adapting to shaft end seals of the high-temperature large-amplitude vibration equipment.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

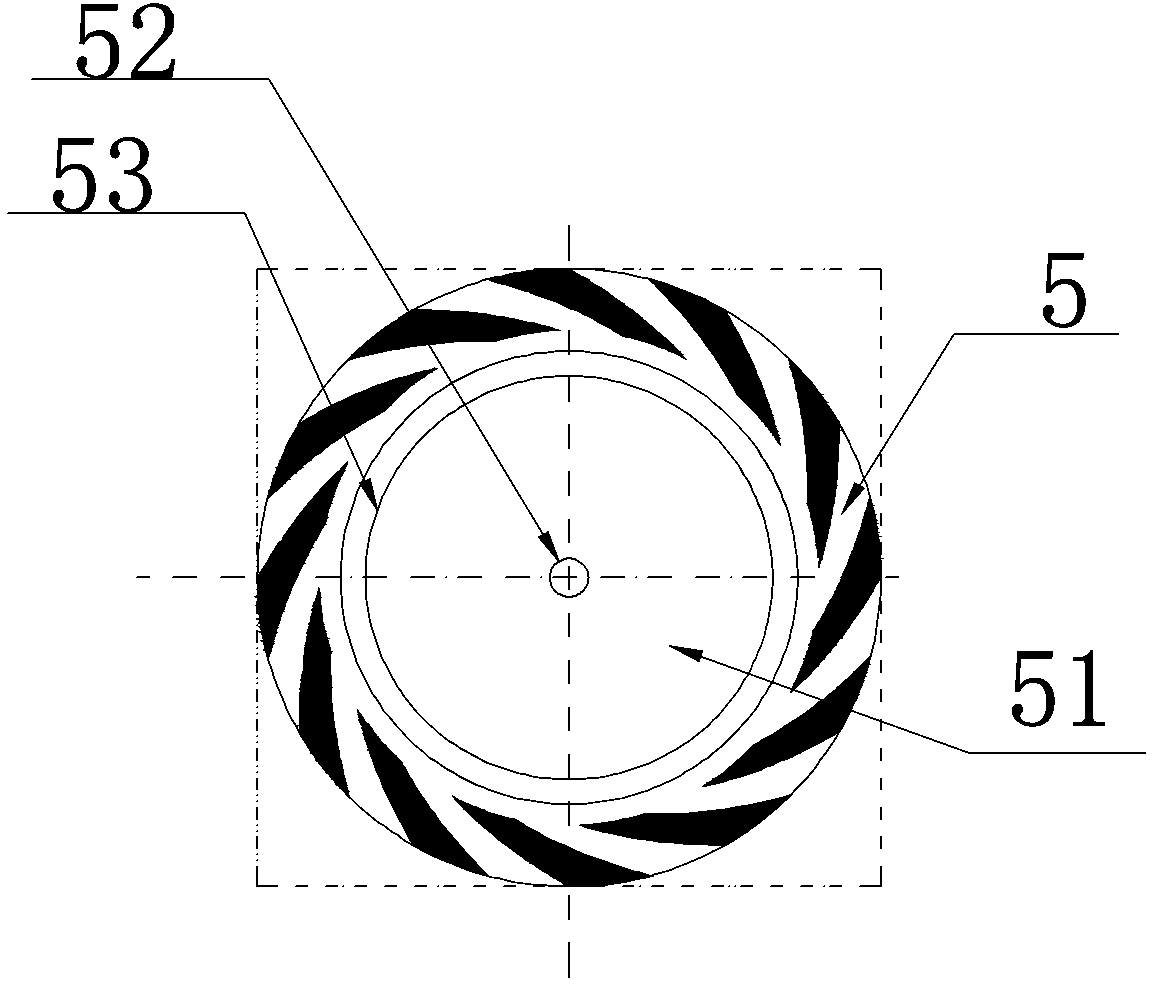

Laser grooving machining method of dry gas seal spiral groove

ActiveCN102990308AHigh speedNo mechanical deformationLaser beam welding apparatusMachined surfaceDry gas seal

The invention discloses a laser grooving machining method of a dry gas seal spiral groove, wherein a machining device is a 20W optical fiber marking machine. The machining method comprises the following steps of: (1) designing the shape of the dry gas seal spiral groove by special drawing software; (2) positioning, wherein a ring with outer diameter being is less than or equal to 100mm is positioned in a marking range, and a ring with outer diameter being more than 100mm is positioned by a groove-to-groove machining method; and (3) grooving which is implemented by selecting appropriate marking parameters of focal length, marking speed, effective vector step length, power, frequency and the like. The laser grooving method has the characteristics of having a wide application range, being applicable to machining surfaces of different materials and different shapes, ensuring no mechanical deformation of workpieces, no pollution, high speed, high accuracy, good repeatability, high automation degree, and the like, is used for machining logarithm spiral grooves, rectangular grooves and dual-trapezoid grooves, is especially suitable for machining shallow grooves, and has obvious effects of improving product quality and machining efficiency.

Owner:丹东市东升石化设备有限公司

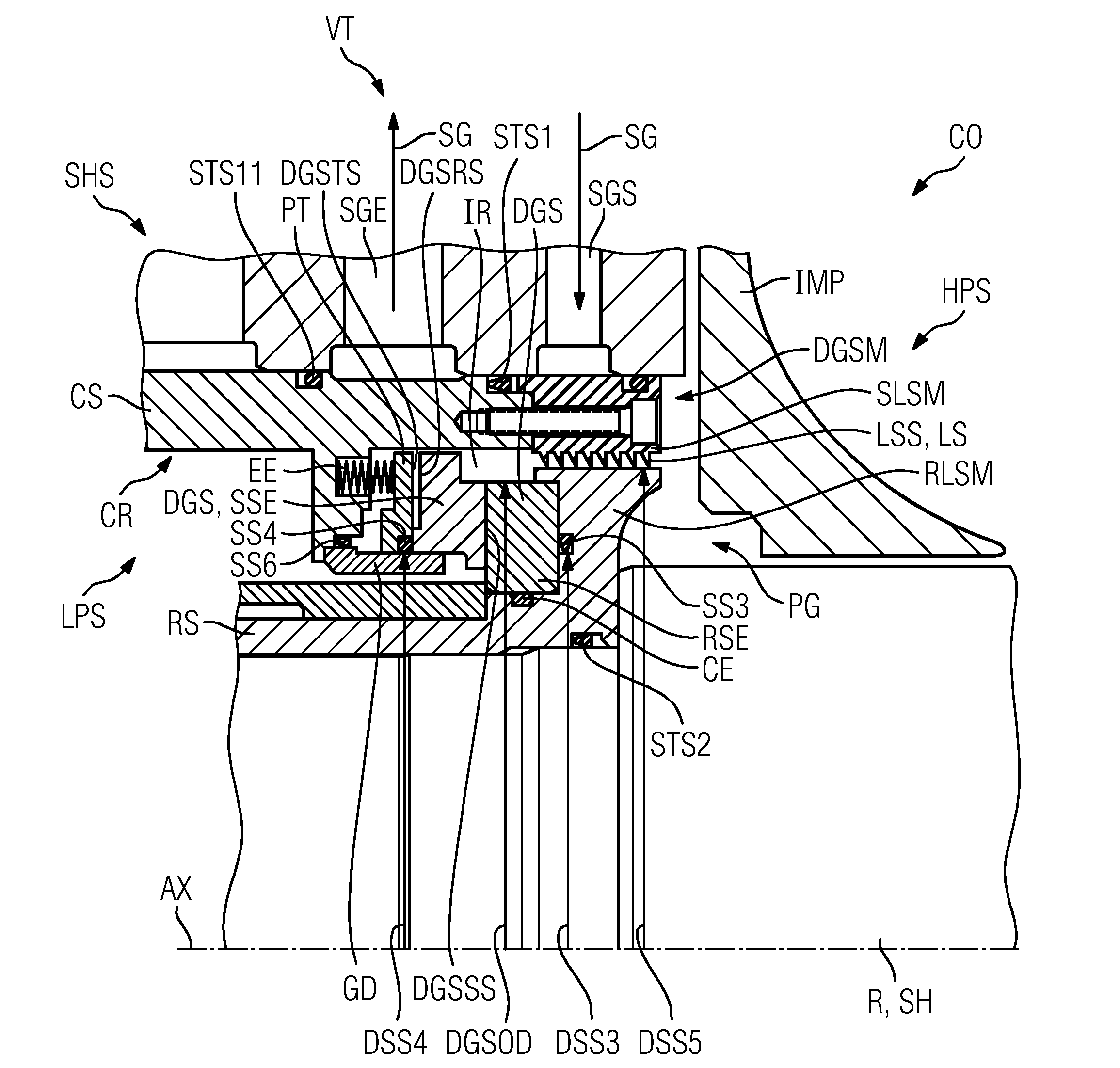

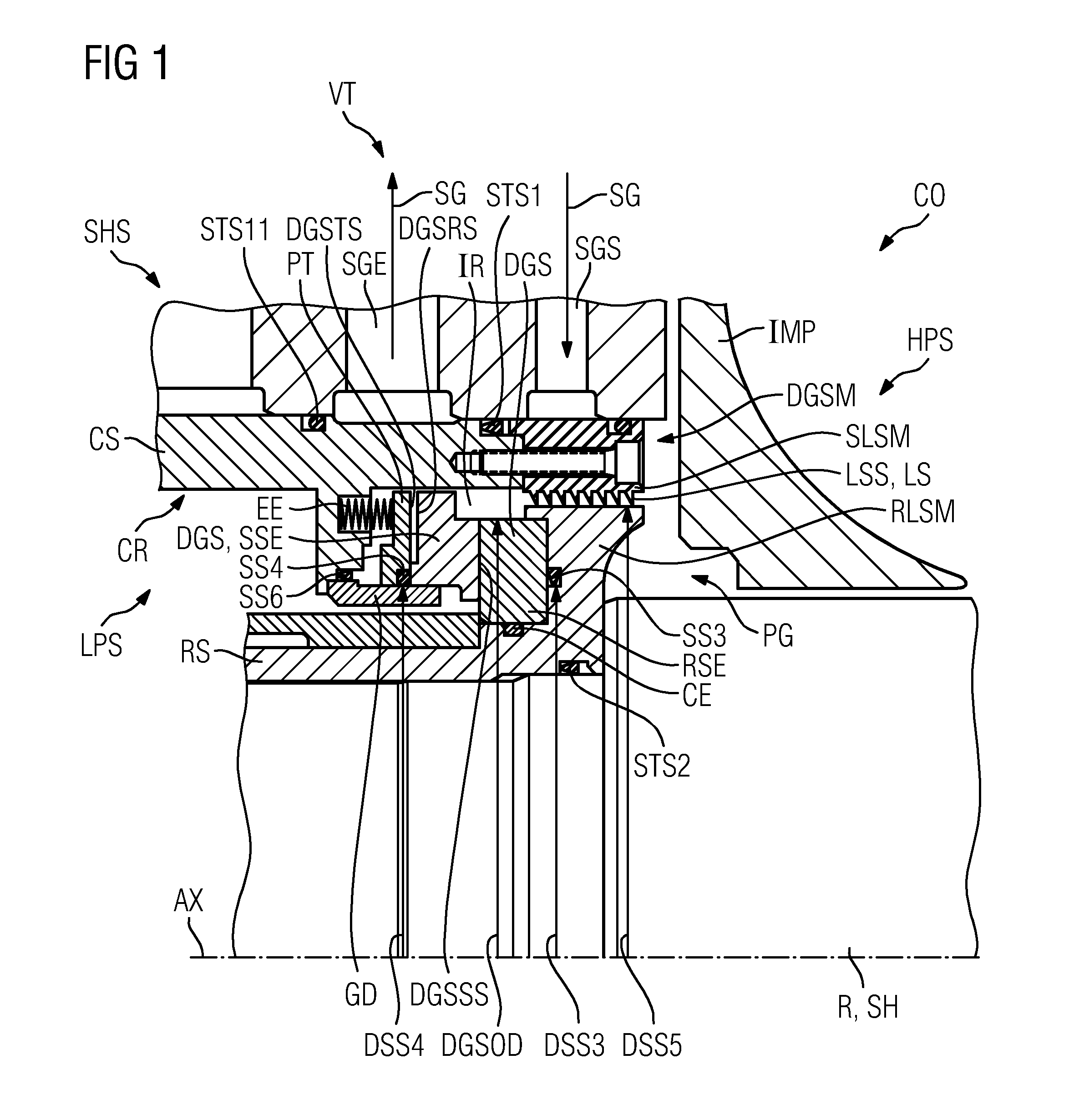

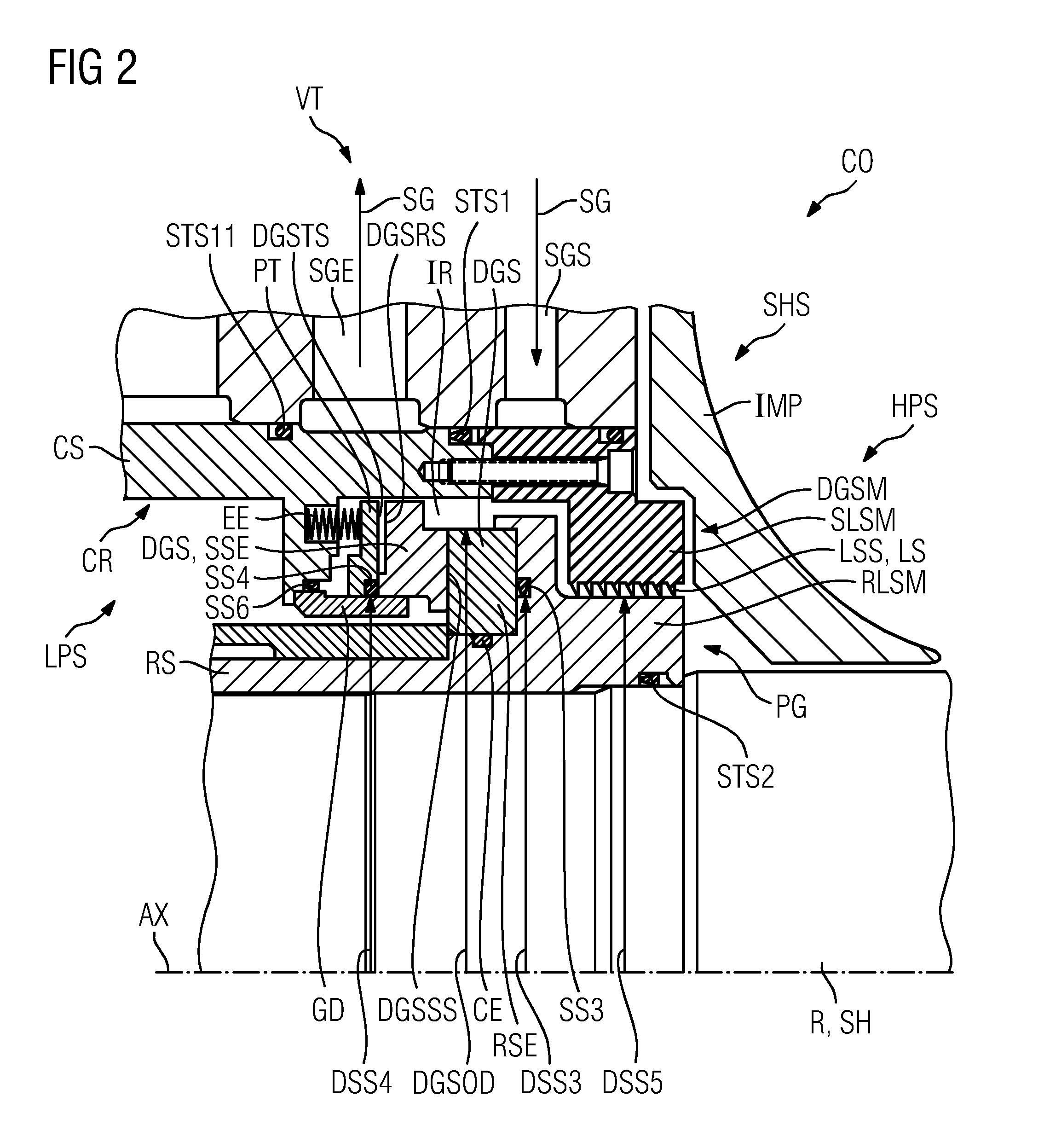

Shaft seal insert

InactiveUS20140030063A1Reduce complexityEasy to assembleEngine sealsPump componentsRotational axisDry gas seal

A shaft seal insert for the shaft seal of a turbomachine extending along a rotational axis includes:—a rotor part attachable on a shaft of a rotor,—a stator part insertable into a stator receiving area, and—a dry gas seal having a rotating seal element attached to the rotor part and a fixed seal element attached to the stator part to seal an intermediate space between the two seal elements, which lie opposite each other on a sealing surface extending radially and in the circumferential direction. A labyrinth seal is provided on a high-pressure side in a serial arrangement with the dry gas seal to seal the intermediate space, having a fixed and rotating labyrinth seal parts. The fixed labyrinth seal part is part of the stator part or is fixed thereto. The rotating labyrinth seal part is part of the rotor part or is fixed thereto.

Owner:SIEMENS AG

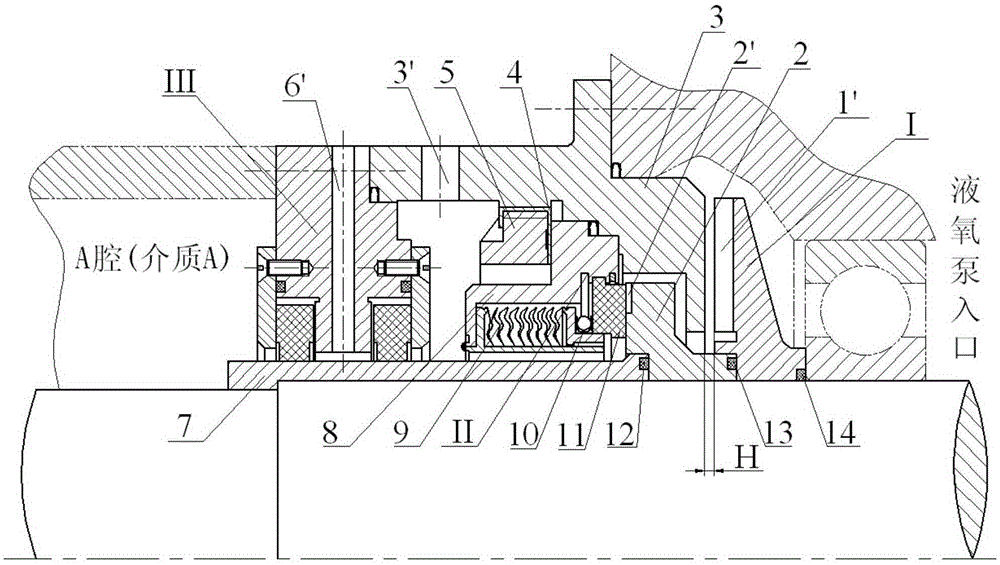

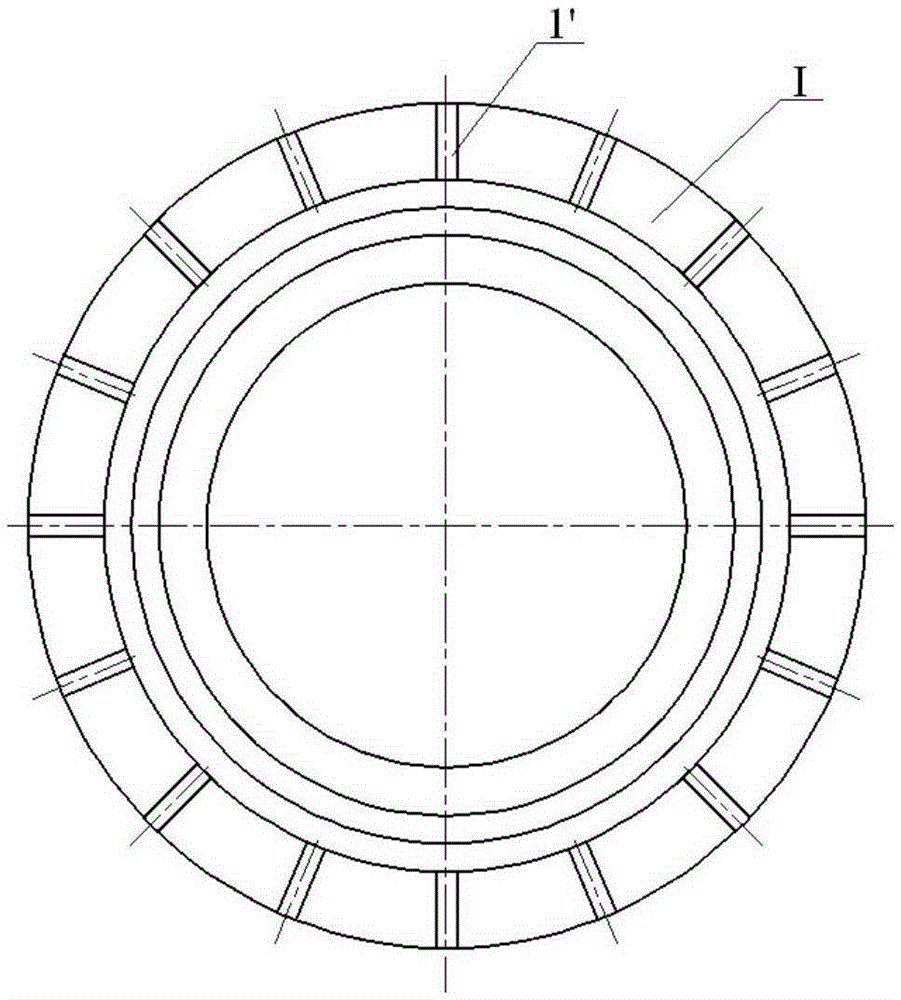

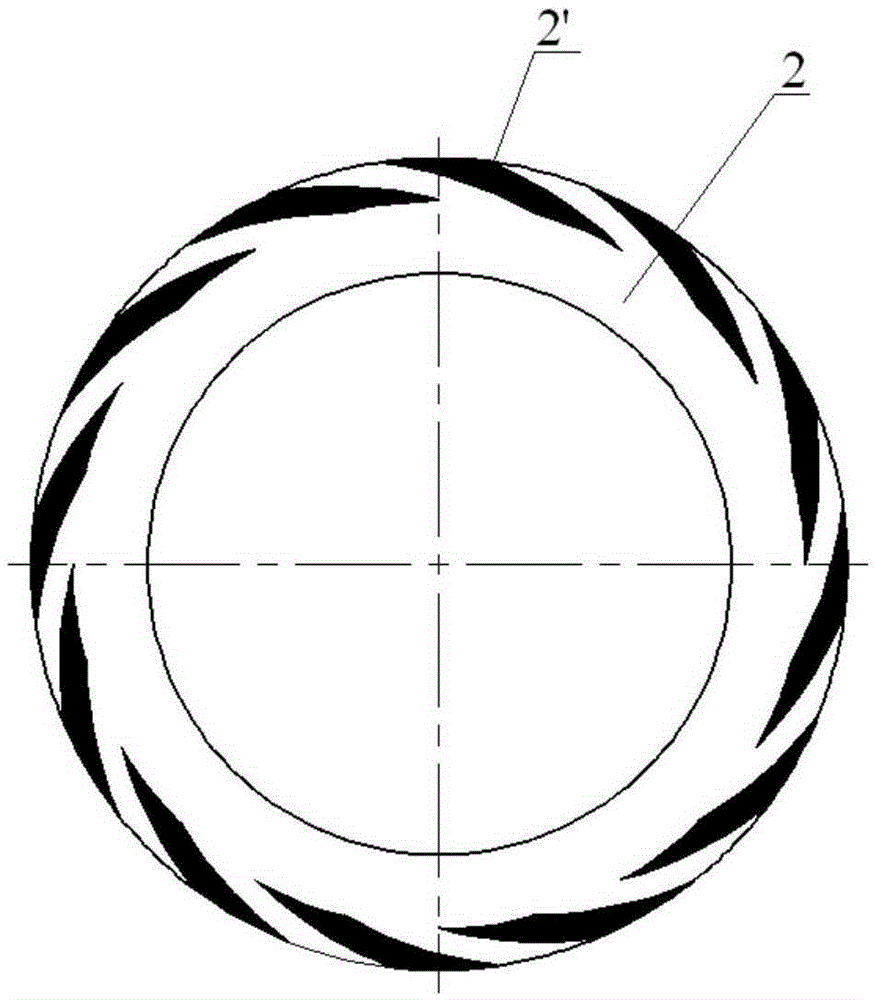

Combined type sealing device for liquid oxygen pump

The invention discloses a combined type sealing device for a liquid oxygen pump. The combined type sealing device comprises three non-contact seals sequentially arranged in a series-connected mode, namely the first-stage centrifugal seal, the second-stage dry gas seal and the third-stage floating ring seal. Blades of the first-stage centrifugal seal and dynamic pressure grooves of the second-stage dry gas seal are arranged in the same direction and turn the backs to the inlet of the liquid oxygen pump. A sealing cavity is formed among the second-stage dry gas seal, the third-stage floating ring seal and a sealed case, the sealed case is provided with a fluid channel, and the third-stage floating ring seal is provided with another fluid channel. The combined type sealing device well solves the problems that currently the seal faces of the liquid oxygen pump have wear-out failures or the leakage rate is large, and has the advantages of being long in service life and high in reliability.

Owner:XIAN AEROSPACE PROPULSION INST

Multifunctional spherical mixing, grinding and drying all-in-one machine

InactiveCN105617906AIncrease effective working volumeLarge effective working volumeDispersed particle filtrationTransportation and packagingDry gas sealSelf locking

The invention discloses a multifunctional spherical mixing, grinding and drying all-in-one machine, comprising a shell, a rotating hoop quick-opening device, a stirring paddle, a crushing cutter, a heating system, a dedusting filter, a CIP cleaning system, a charging valve, a discharging valve and a dry airtight sealing system; the shell is a spherical body; the stirring paddle and crushing cutter are arranged in the shell divided into an upper half sphere and a lower half sphere; the upper half sphere is provided with the CIP cleaning system, a blowback sight glass port, a speed reducer, the charging valve, the temperature sensor, the dry airtight sealing system and the dedusting filter; a motor is arranged at one side of the dedusting filter; the speed reducer is provided with a rotary joint; the lower half sphere is provided with a vacuum sampling valve. Materials are dried and mixed without dead angles due to the spherical design; the crushing cutter is added to prevent the product from forming hard blocks during drying and prevent water content from being locked in the product, the stirring paddle is obliquely mounted to conveniently overturn materials, and stirring has no dead angle; the sphere body is provided with the rotating hoop quick opening device and has self locking function, thus facilitating quick checking.

Owner:WUXI HAI CHANG MACHINERY

Dry gas seal

ActiveUS20180266265A1Increase productionImprove reliabilityEngine sealsPump componentsDry gas sealEngineering

A dry gas seal for sealing the shaft of a turbomachinery, provided with means for the continuous health monitoring of the dry gas seal comprising one or more sensors adapted to measure strains and / or loads induced to the primary ring of the dry gas seal and / or strains induced to one or more of the elastic elements coupled to the primary ring and / or adapted to measure displacements of the primary ring or of an element coupled to the primary ring, for an early detection of failure of the seal, thus enabling main failures early detection capability and proactive maintenance actions.

Owner:NUOVO PIGNONE TECH SRL

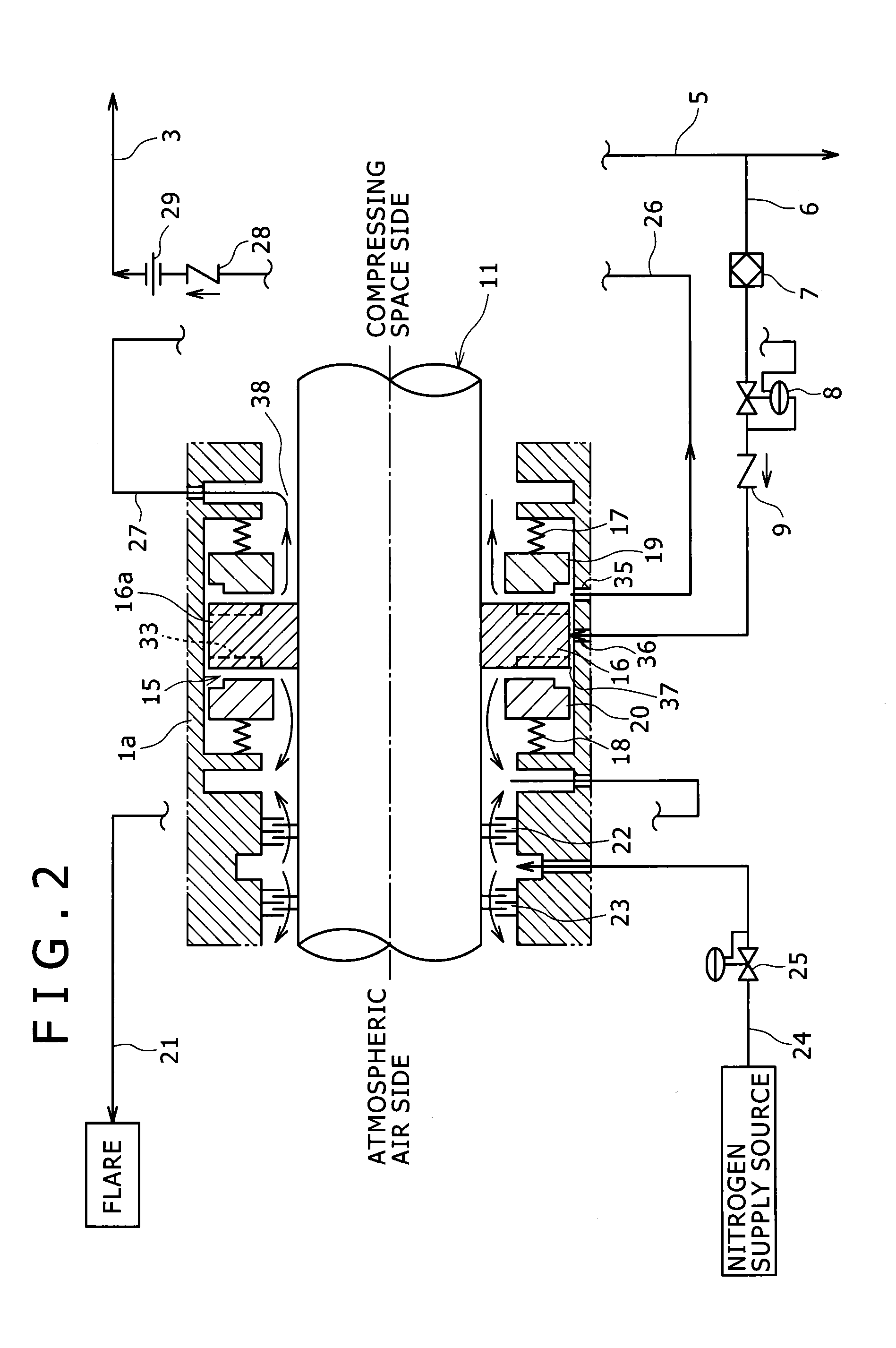

Compressor

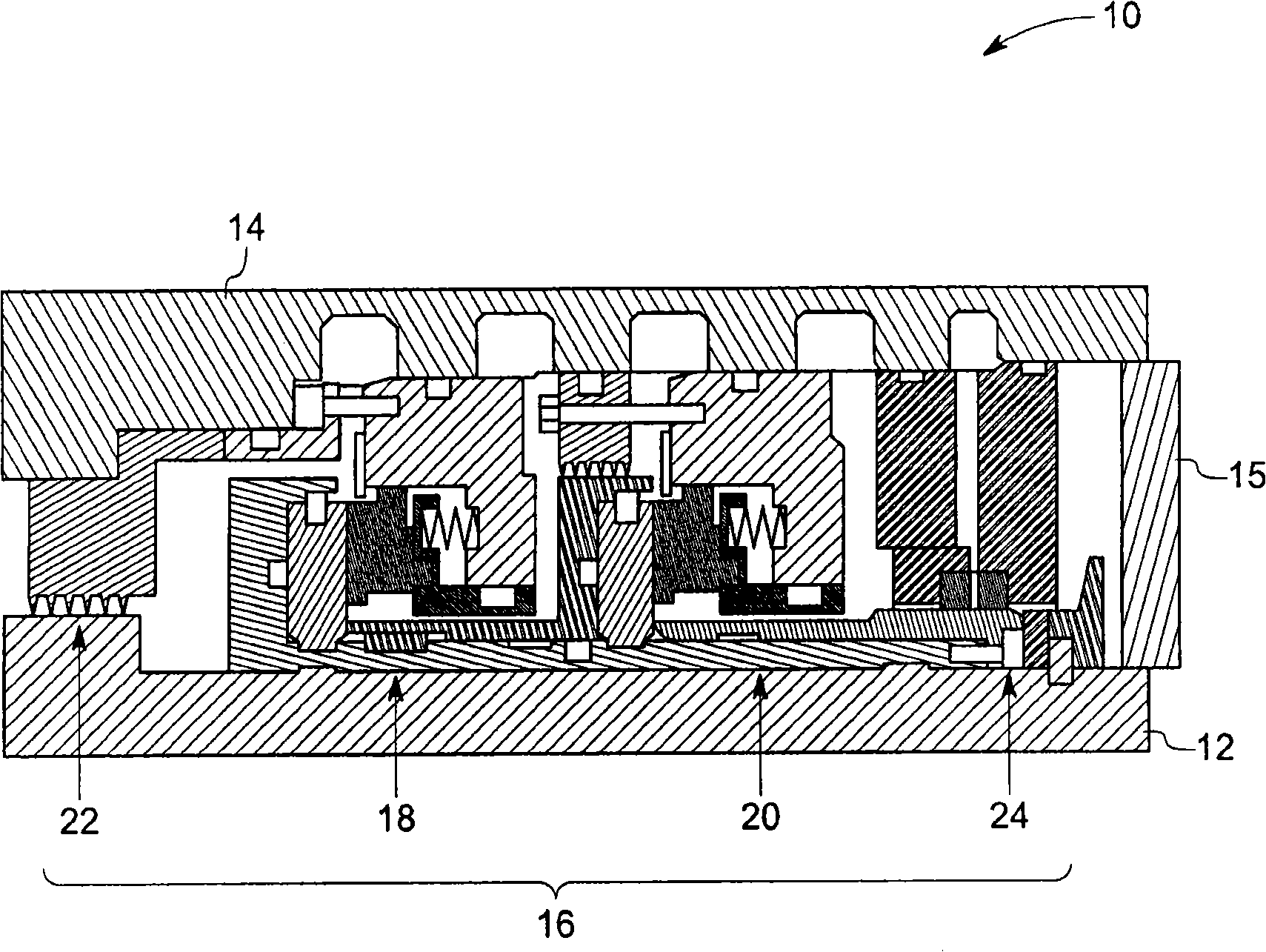

ActiveUS20130195649A1Liquefaction can be suppressedEasy dischargeEngine sealsPump componentsEdge surfaceDry gas seal

A sealing system is equipped with: a dry gas seal 15 having a rotating ring 16 positioned between a casing 1a and a rotor shaft 11 and around the circumference of the rotor shaft 11, and stationary rings 19, 20 provided on the casing 1a with elastic members 17, 18 interposed therebetween and so as to be capable of contacting the orthogonal edge surfaces of the rotating ring 16 that are substantially orthogonal to the rotor shaft 11; a sealing gas channel 6 having one end connected to a discharge channel 5, the other end connected so as to connect to a space 37 between the casing 1a and the outer perimeter surface 16a of the rotating ring 16 in the dry gas seal 15, and having a sealing gas regulating valve 8 provided therein; and a drain gas channel 26 having one end connected so as to connect to the space 37 via a through hole 35 formed in the casing 1a below the rotating ring 16, and the other end connected to an intake channel 3.

Owner:KOBE STEEL LTD

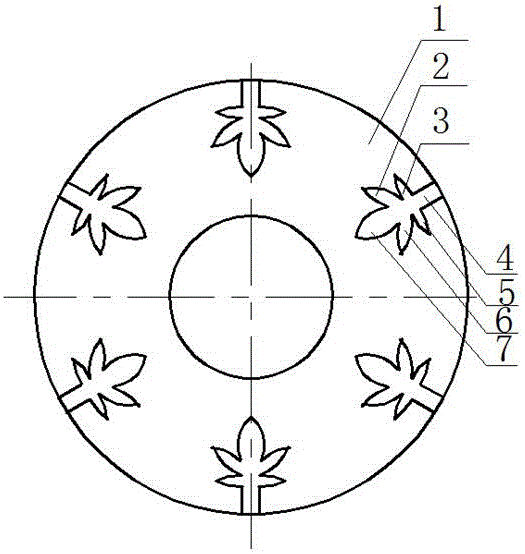

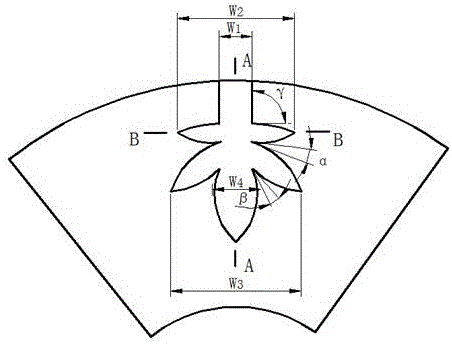

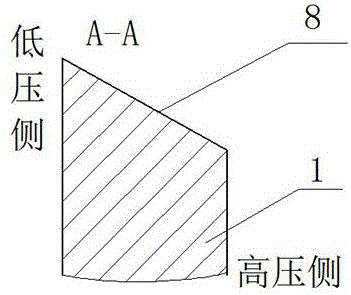

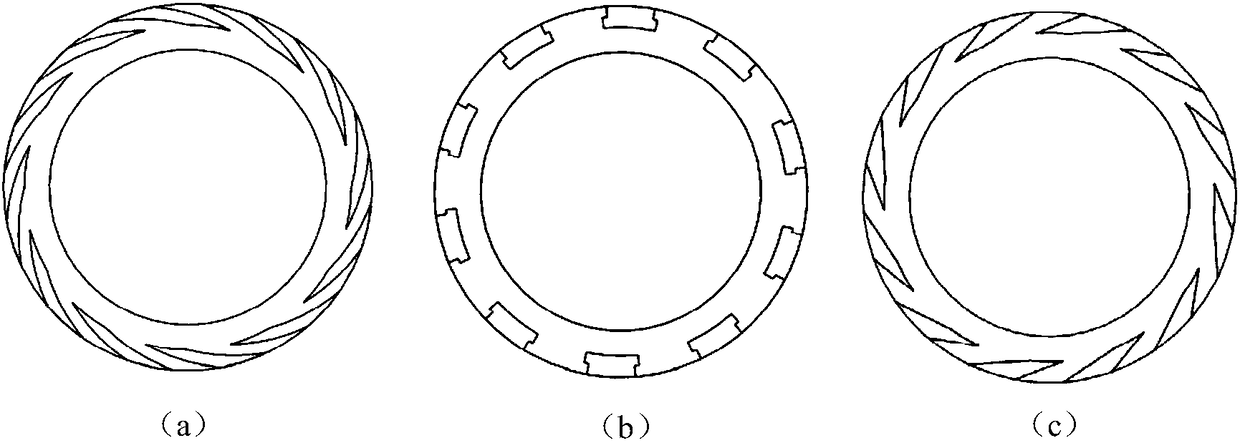

Mechanical seal ring with maple-leaf-like grooves

The invention relates to a mechanical seal ring with maple-leaf-like grooves. 2-50 maple-leaf-like grooves are circumferentially and evenly distributed in one end surface of the seal ring and are 1-100 mu m deep; each maple-leaf-like groove comprises a radial linear groove and five grooves, four of the five grooves are symmetrically distributed on two sides of the radial linear groove, another groove is connected with one end, close to the inner diameter of the seal ring, of the radial linear groove, and the radial linear groove is opened in the edge of the outer diameter of the seal ring; and the maple-leaf-like grooves are symmetric about the radial central axis. The seal ring is applicable to one-way rotation and two-way rotation machinery, is used for liquid sealing or dry gas sealing, can effectively reduce abrasions of seal end surfaces, has the relatively good flow guiding effect, the better opening force and the smaller leakage amount, has the better sealing effect and dynamic pressure performance, runs more stably and is wider in application range, and the cost is saved.

Owner:云南流体规划研究院有限公司

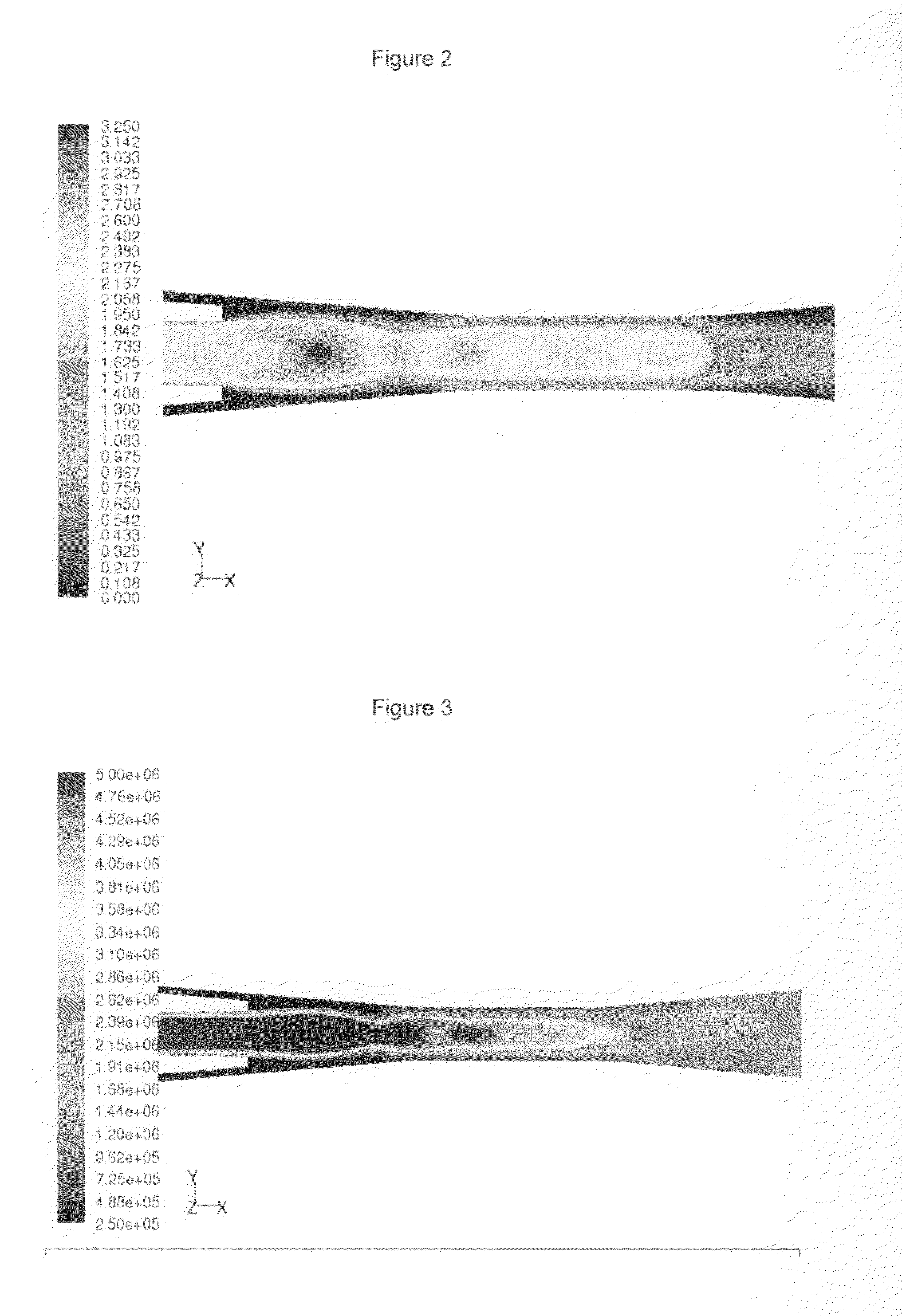

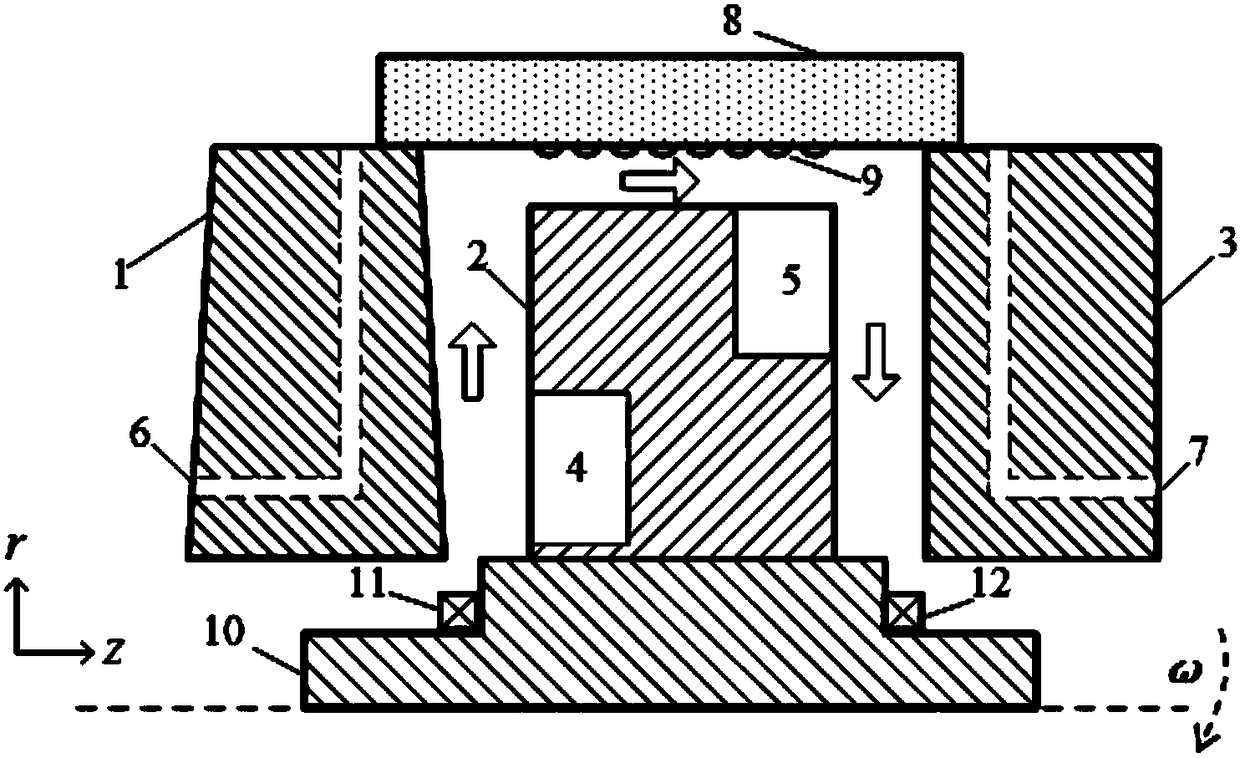

Dry gas sealing device suitable for supercritical working medium

The invention discloses a dry gas sealing device suitable for a supercritical working medium. Two-stage level dry gas seal is composed of a static ring-moving ring-static ring structure. The sealed supercritical working medium flows through, in the radial direction, a first-stage dry gas seal, and then flows through, in the radial direction, the flow channel between the moving ring and a cavity wall, and then flows through a second-stage dry gas seal. Divergent clearance is adopted in the first-stage dry gas seal, cooling channels are separately arranged on the two static rings, and a heat transfer enhancement structure is arranged on the cavity wall to reduce the end face temperature of a sealing ring. The sealed supercritical working medium is subjected to two-stage level dry gas seal, the leakage rate is greatly reduced, and the sealing performance is good. The dry gas sealing device suitable for the supercritical working medium has the remarkable advantages of reducing the temperature of the sealing ring, reducing the leakage rate and ensuring the sealing performance, and has broad market prospect.

Owner:XI AN JIAOTONG UNIV

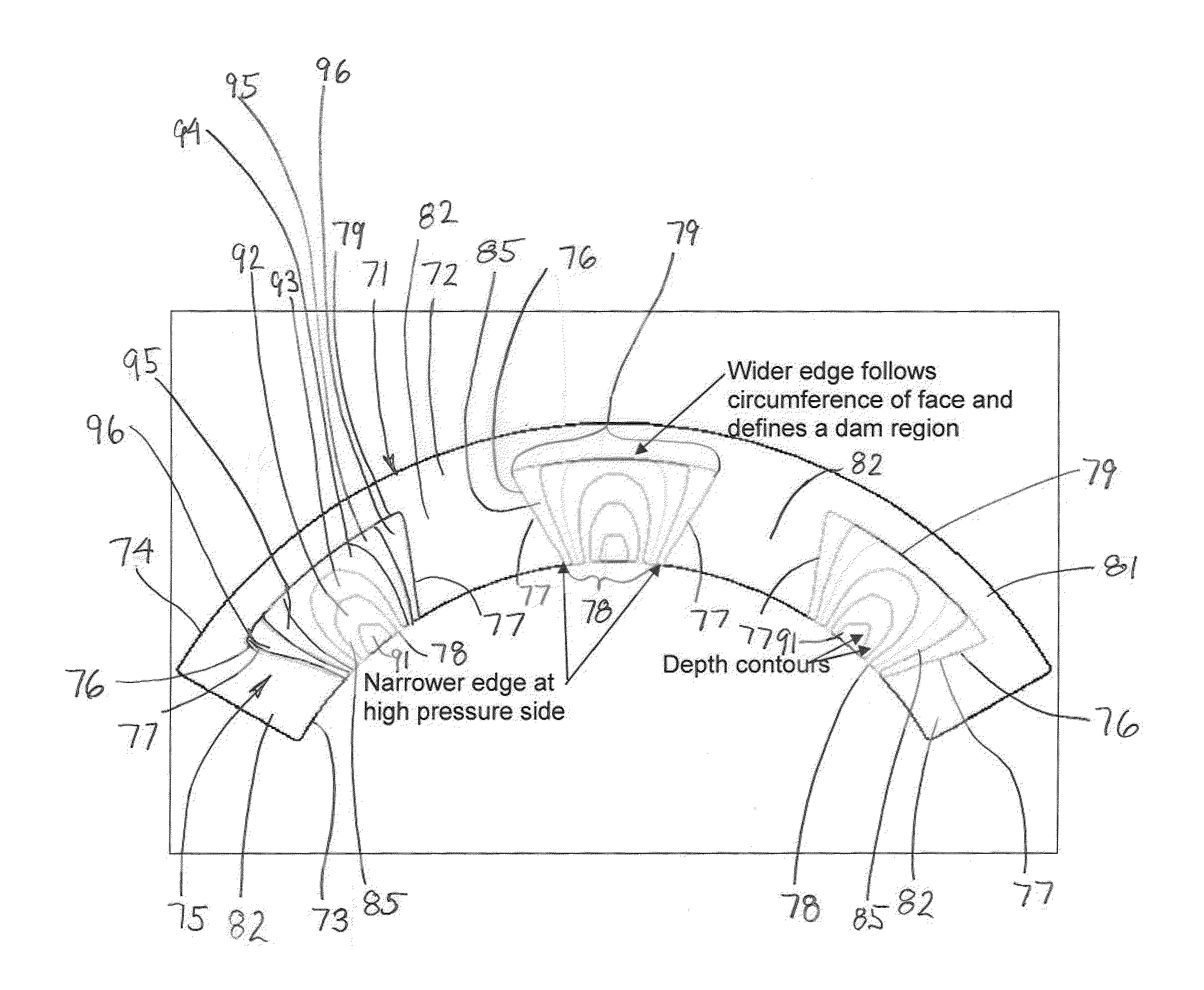

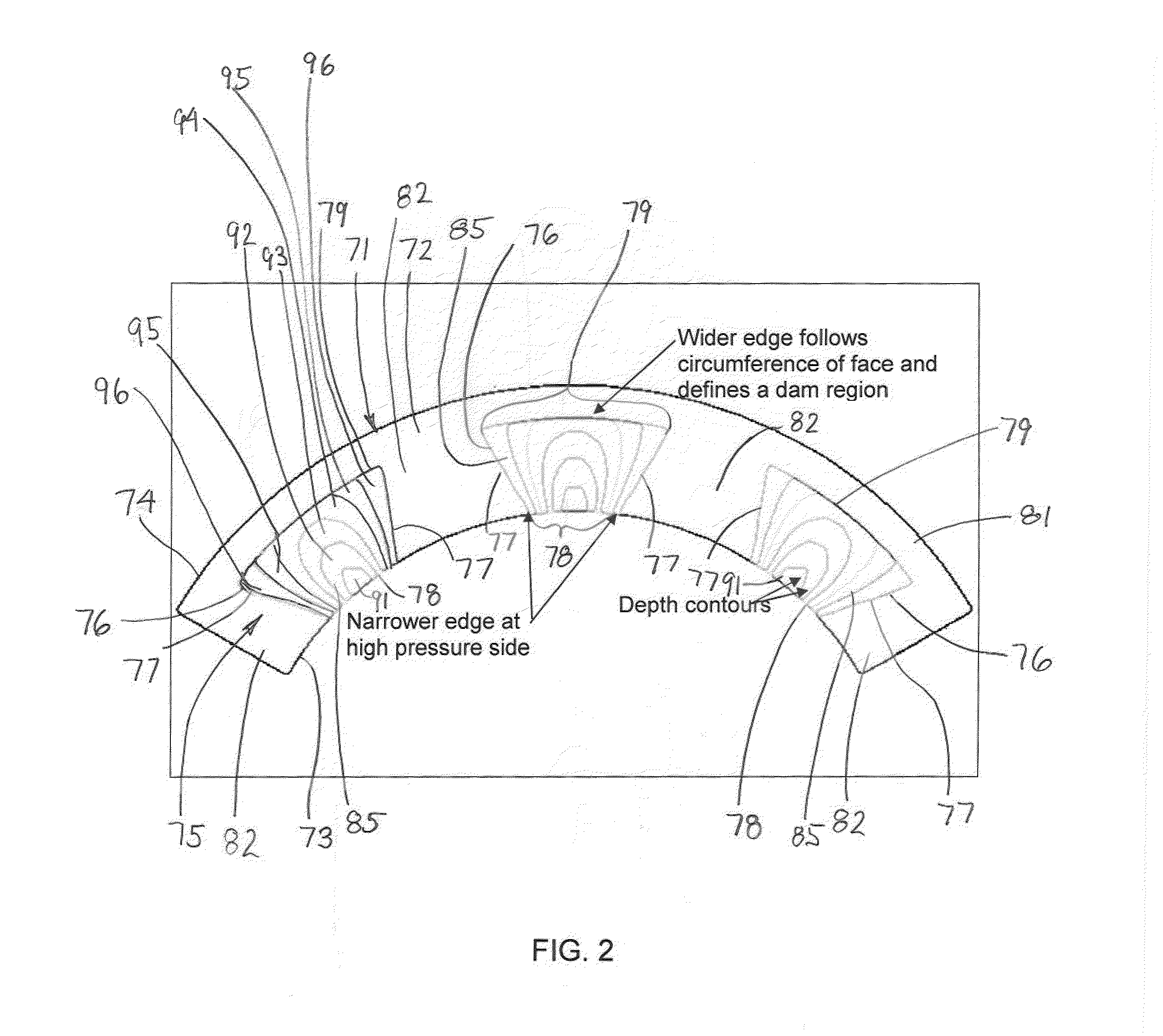

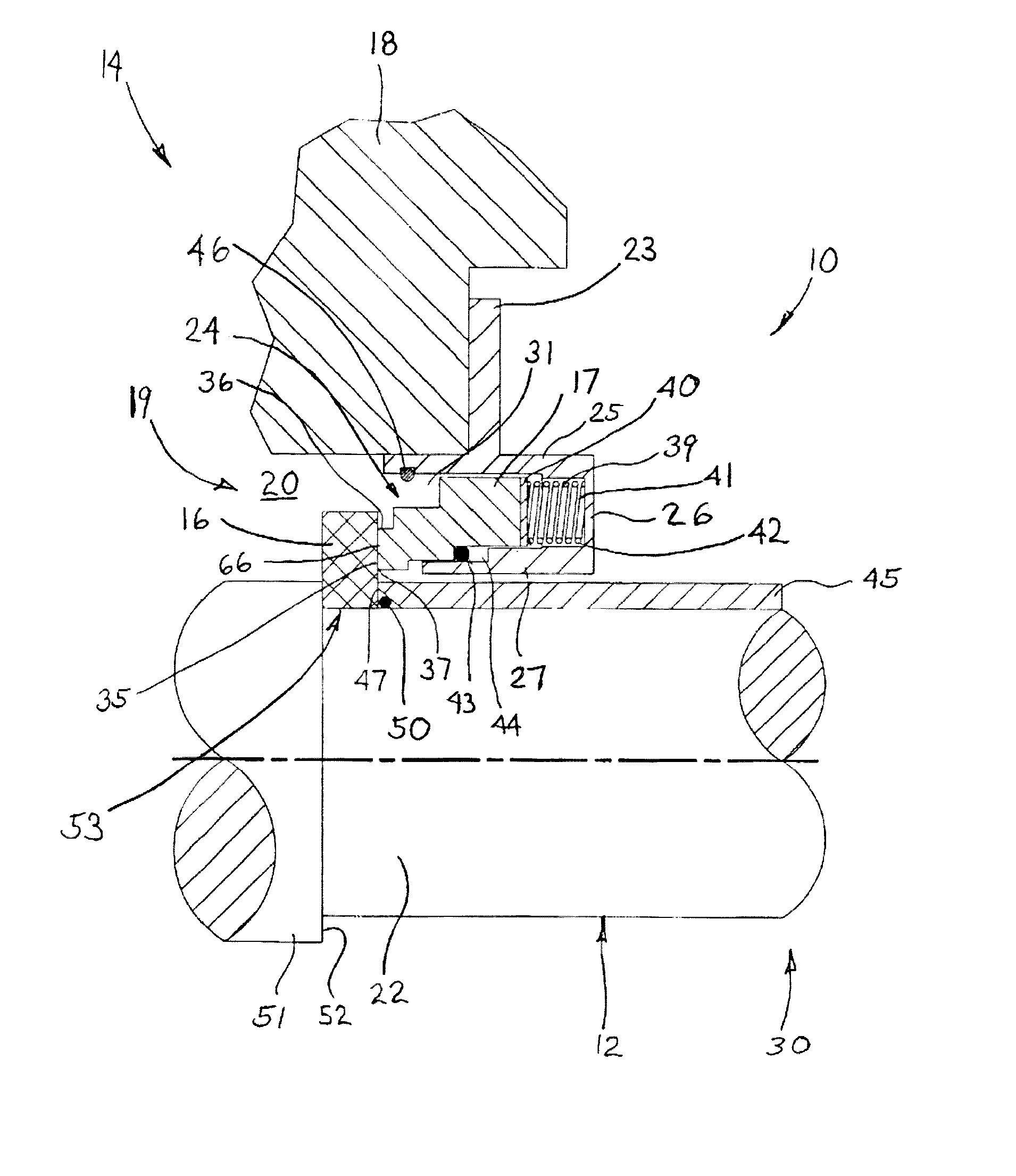

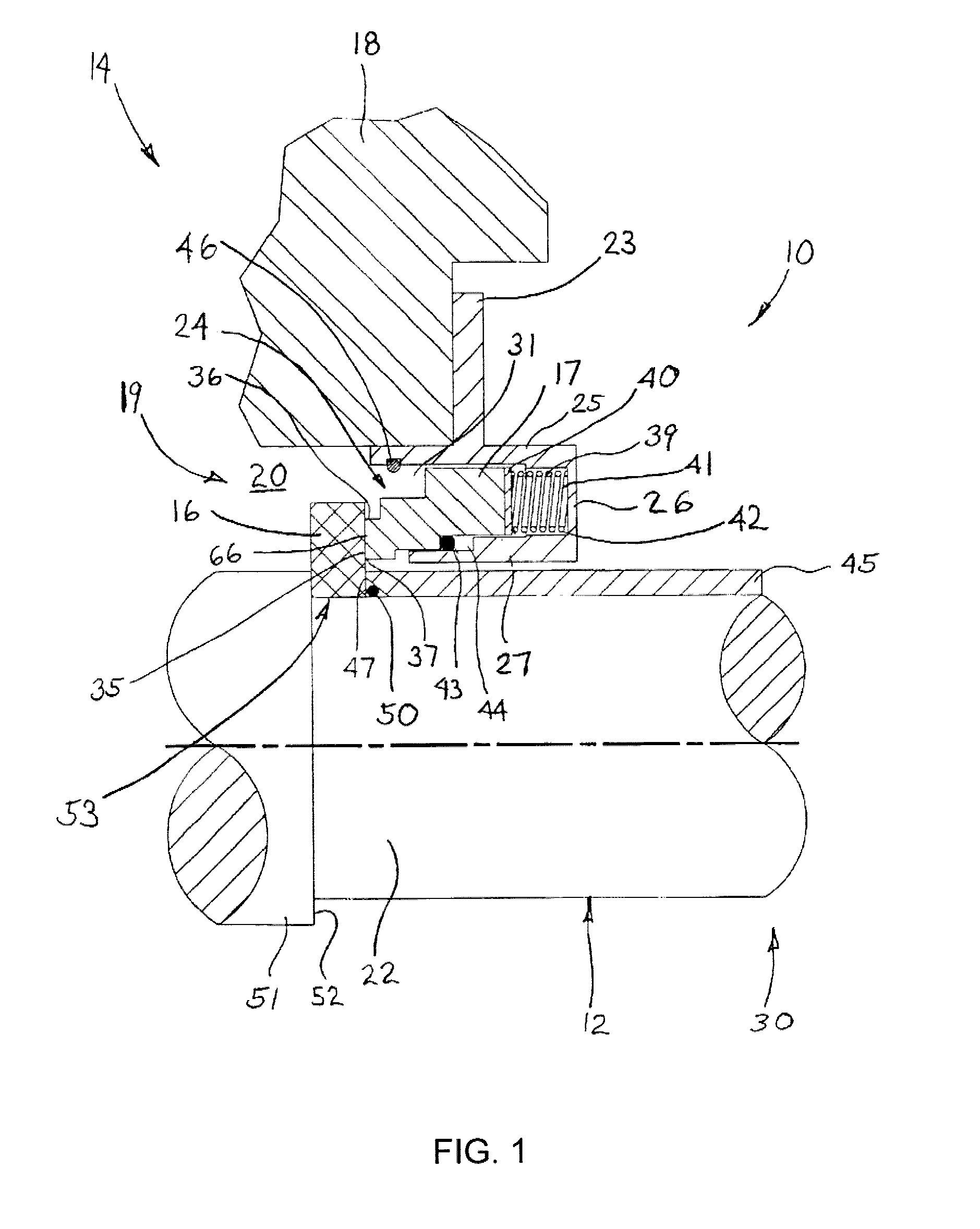

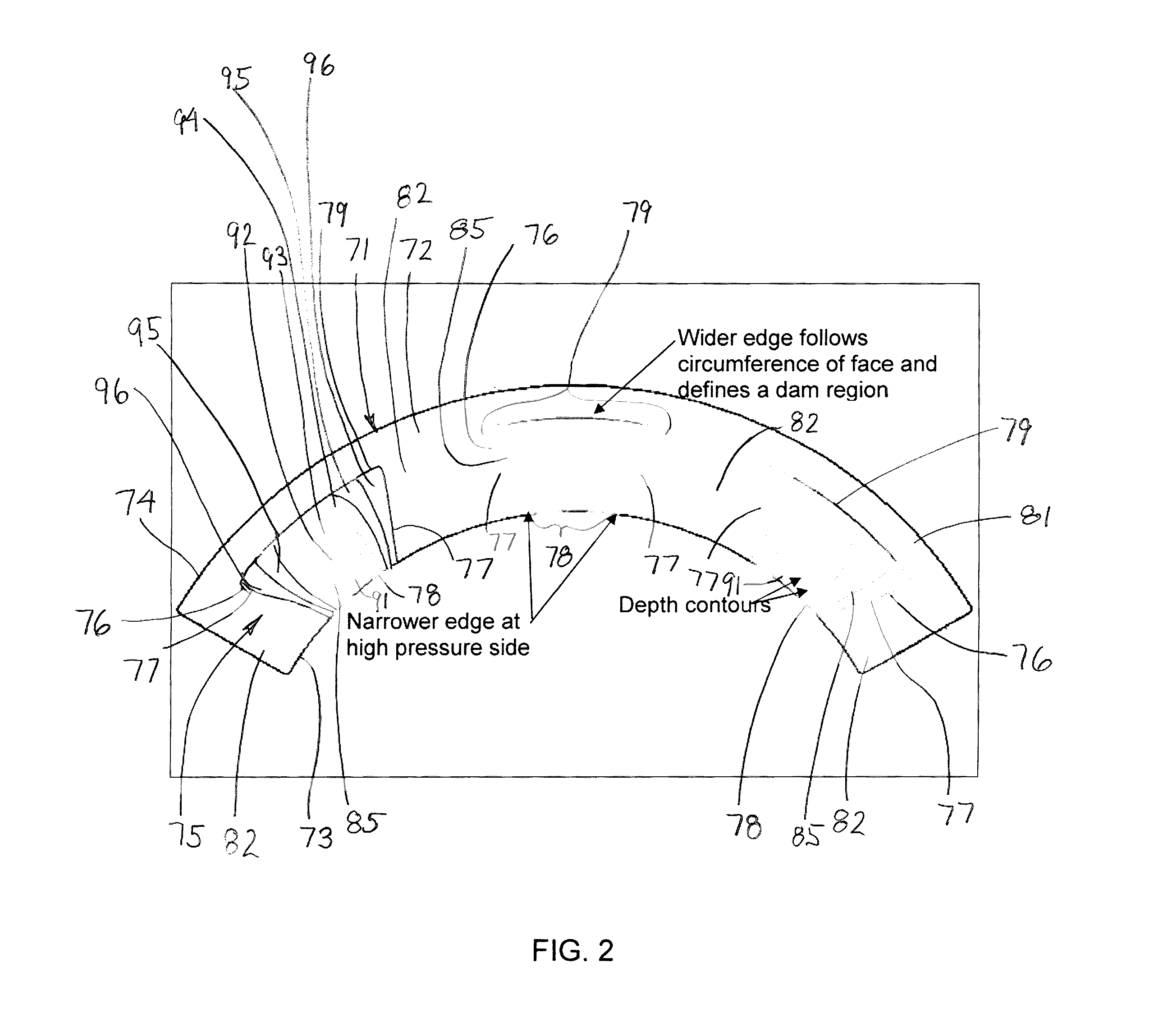

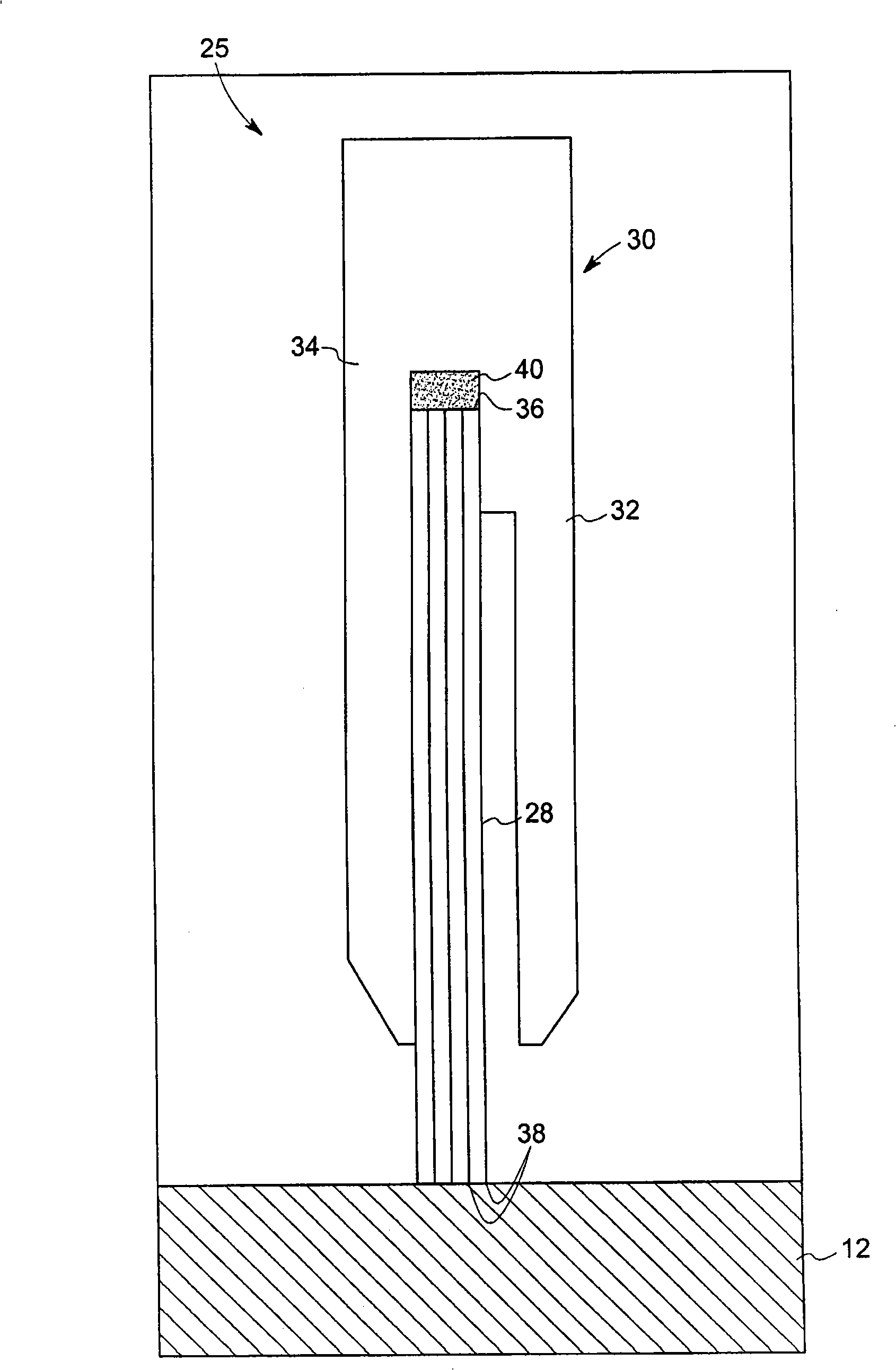

Mechanical face seal with a reverse trapezoidal face pattern

An improved mechanical face seal is provided which includes a pair of relatively rotatable seal rings having opposing seal faces. At least one of the seal faces includes a reverse trapezoidal face pattern having a sine wave depth profile wherein individual face features are circumferentially spaced over the seal face. The reverse trapezoidal face pattern serves to generate a hydrodynamic lift which provides a stable separation of the seal faces that permits formation of a fluid film between the seal faces. The individual trapezoidal grooves have a sinusoidal or similarly shaped depth profile wherein the trapezoid shape is arranged with the narrower edge communicating with the high pressure side of the seal, and the wider edge forms a circumferential dam region towards the low pressure side of the seal. Alternatively, the reverse trapezoidal face pattern may also be provided as a primary face pattern on a dry gas seal in combination with a secondary face pattern wherein the faces operate with a controlled gap under normal pressure conditions as well as when the pressure direction across the seal face is reversed.

Owner:FLOWSERVE MANAGEMENT CO

Corrugated pipe type dry gas seal device and seal method

The invention discloses a corrugated pipe type dry gas seal device and seal method. The corrugated pipe type dry gas seal device comprises a stationary component, a rotating component, a shaft, an inner corrugated pipe, an outer corrugated pipe and a casing, wherein the stationary component is fixed with the casing together through a positioning block; the rotating component is fixed to the shaft through a nut and rotates with the rotating of the shaft; and the inner corrugated pipe can perform the function of a spring but has a better effect than the spring. The corrugated pipe type dry gas seal device adopting the corrugated pipes works in various environments and cannot affect the rigidity of the corrugated pipes under the conditions of high temperature and strong corrosion. The corrugated pipe type dry gas seal device is reasonable in design, skillful in structure, great in seal effect, low in energy consumption, low in equipment investment, stable in running and low in accident occurring rate and nearly reaches no linkage at the shaft end.

Owner:成都化新密封有限公司 +1

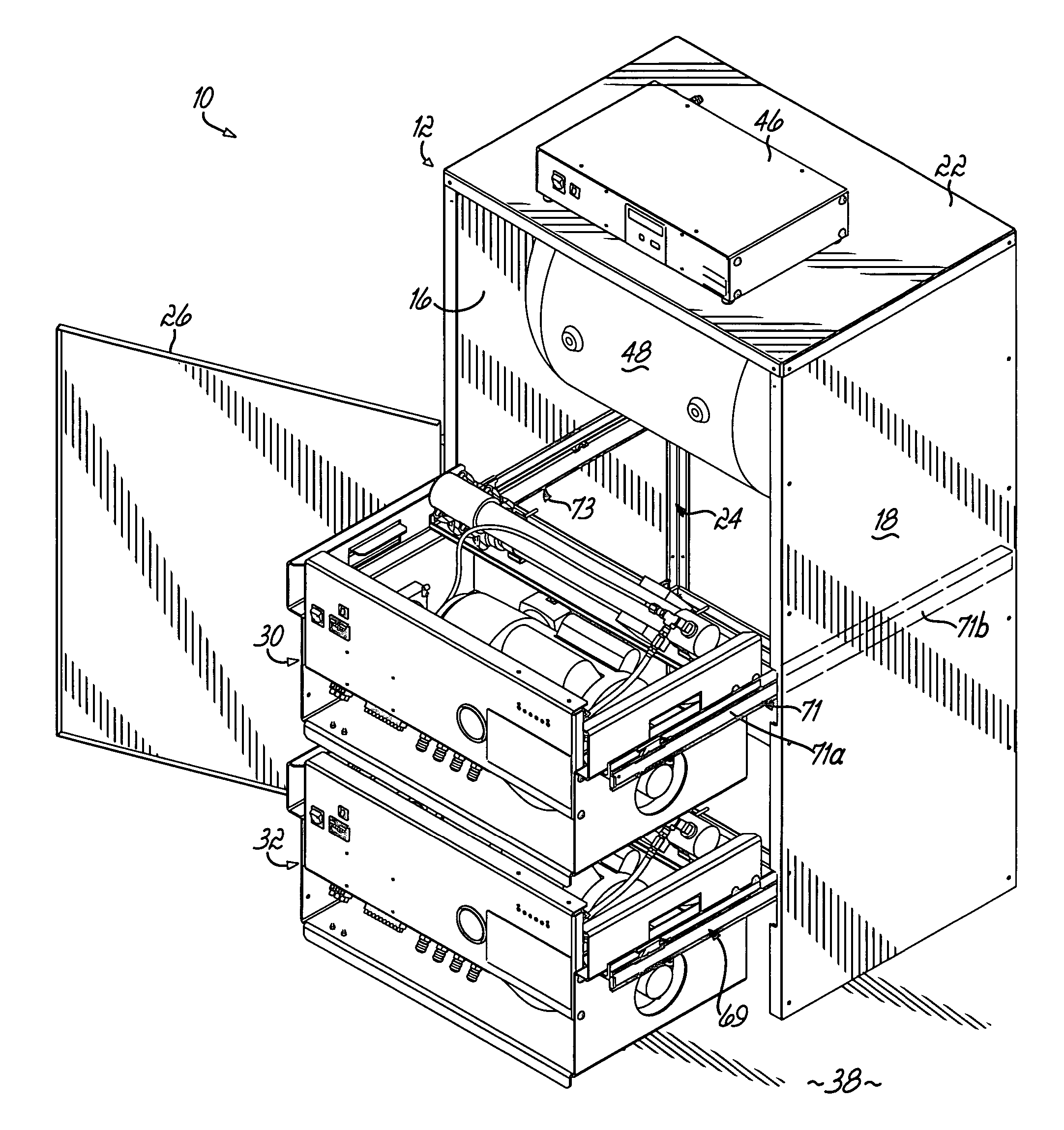

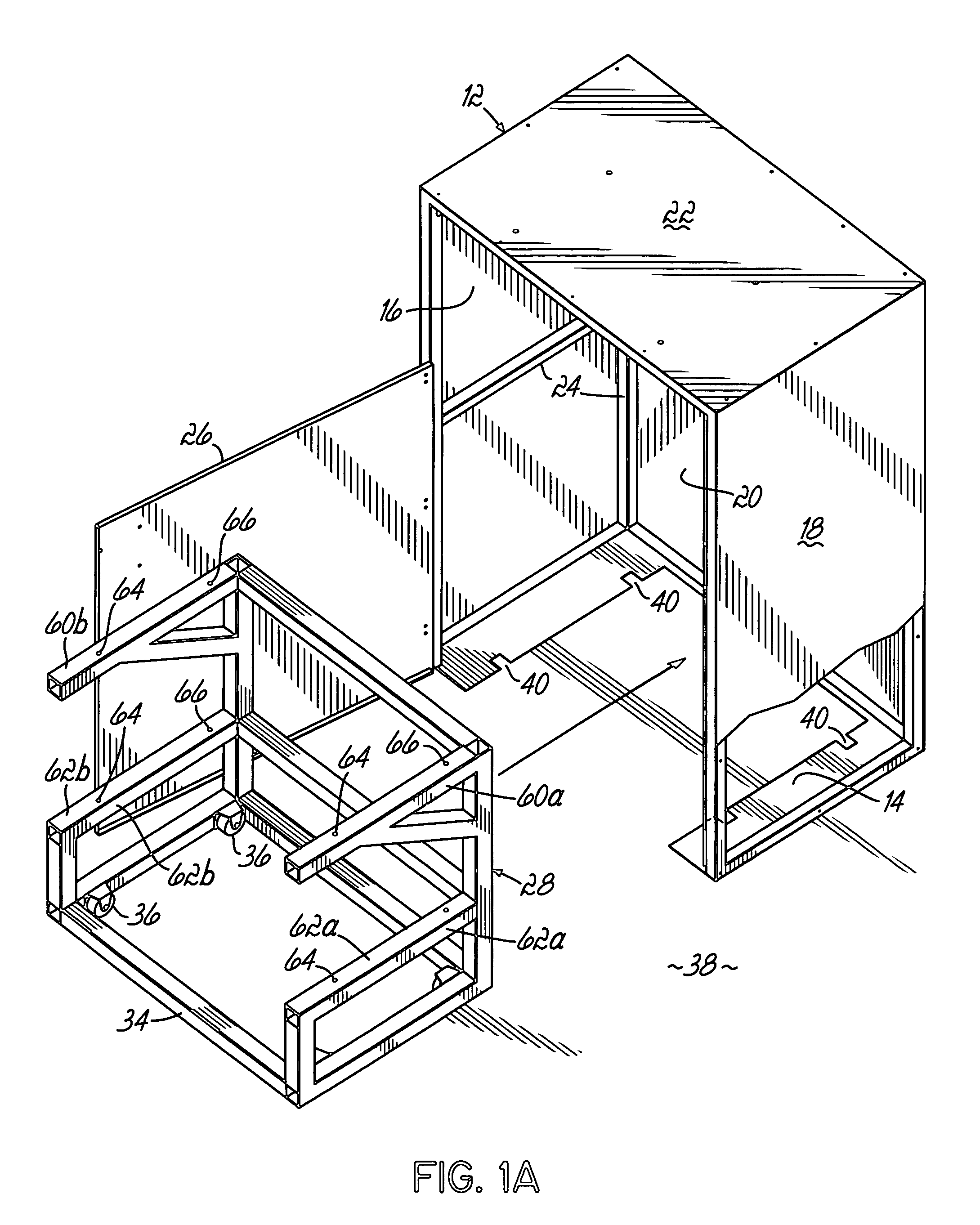

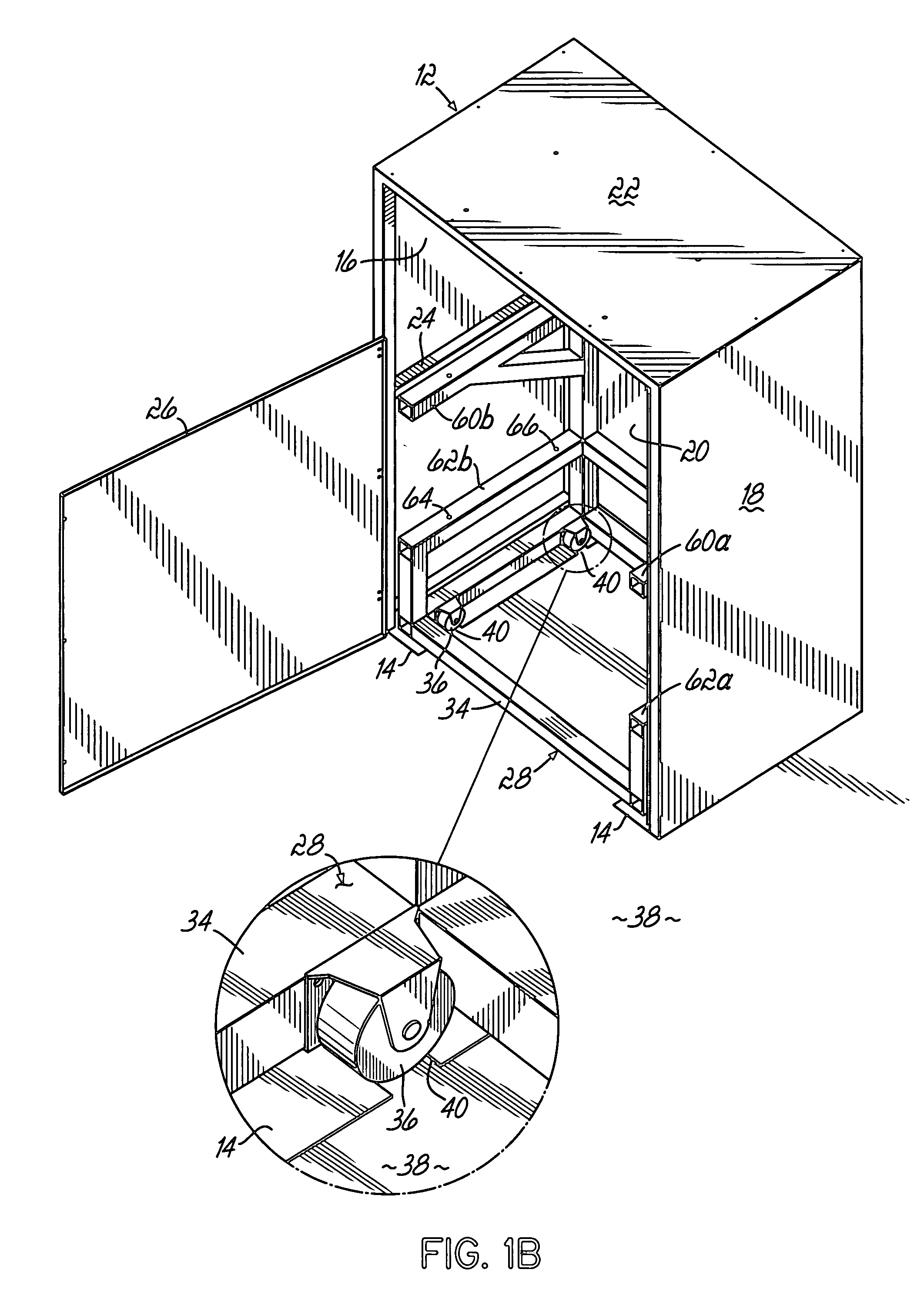

Dry gas production systems for pressurizing a space and methods of operating such systems to produce a dry gas stream

A dry gas production system for supplying dry gas to a pressurized space, such as an underground conduit or an aerial cable. The dry gas production system may include a modular enclosure that has a removable support to which multiple dry gas production modules are mounted. The support may be a mobile rack wheeled inside the enclosure and likewise removed from the enclosure while supporting the dry gas production modules. The dry gas production system may include multiple dry gas production modules that are operated as required to meet the dry gas demand for the pressurized space. The module compressor may include a variable frequency drive for driving the compressor motor at different speeds and may optionally include a mount with vibration isolation.

Owner:COMMSCOPE TECH LLC

Double-chamber structure of dry gas seal testing cavity

The invention relates to a double-chamber structure of a dry gas seal testing cavity. The double-chamber structure comprises chambers and a main shaft. Each chamber is of a cylindrical barrel structure, the two ends of each chamber are coaxially and symmetrically provided with two water sleeves, the two water sleeves and the chambers are fixedly arranged respectively, the main shaft is coaxially arranged in the two water sleeves, the two ends of the main shaft are movably arranged together with the chambers respectively through end covers, and dry gas seal components are arranged between the main shaft and the water sleeves respectively. The double-chamber structure can accommodate two dry gas seal components at the same time, so that work efficiency is effectively doubled, in addition, the dry gas seals in rotation can be quickly cooled through the water sleeves, a water inlet and a water return opening, the dry gas seals can be taken down right away after the testing is finished, and work efficiency is effectively improved.

Owner:TIANJIN NIBOT SEALS TECH

Barrier sealing system for centrifugal compressors

Owner:GENERAL ELECTRIC CO

Dry gas seal

ActiveUS10738641B2Increased reliability and availabilityIncrease productionEngine sealsPump componentsDry gas sealHealth surveillance

Owner:NUOVO PIGNONE TECH SRL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com