Patents

Literature

32results about How to "No mechanical deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

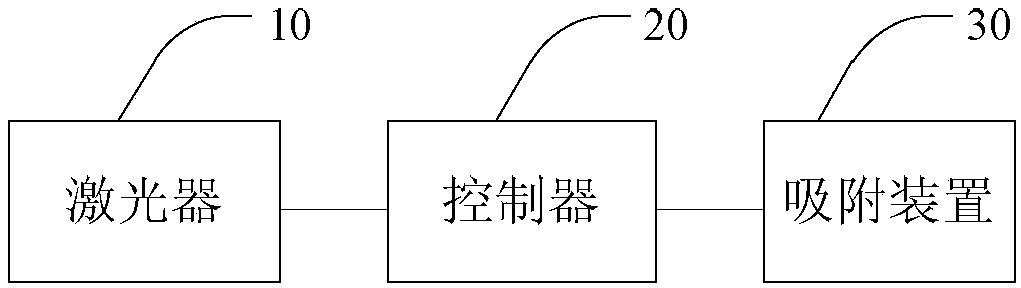

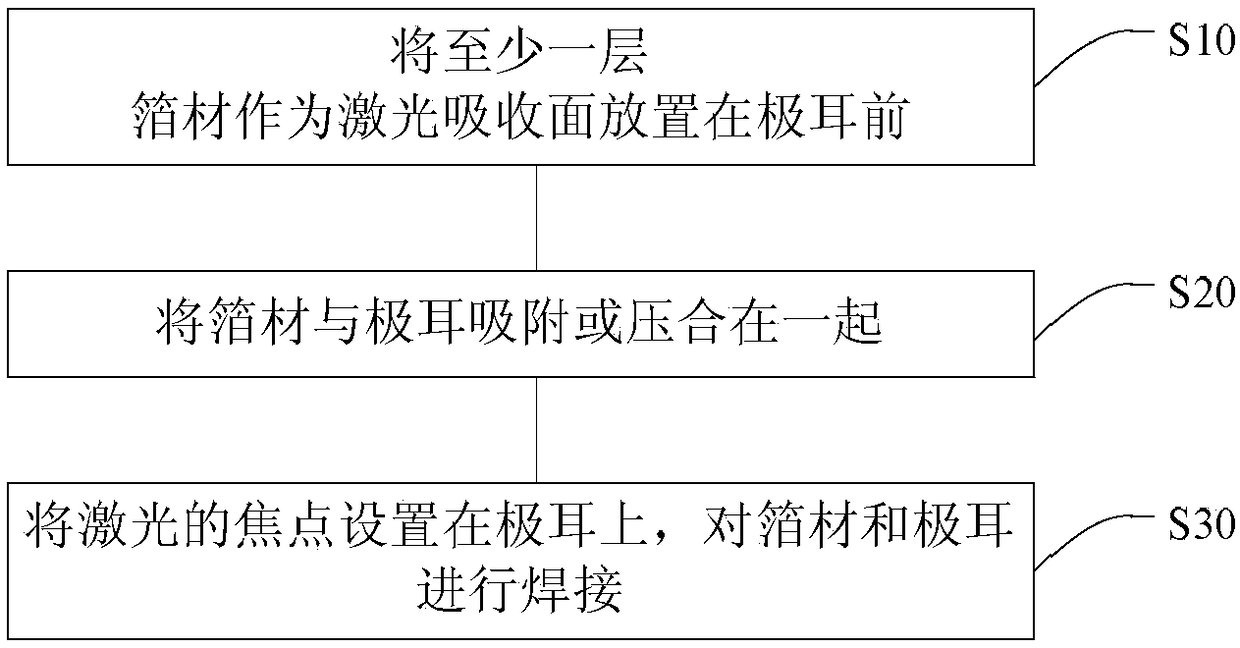

Method and device for laser-welding foil and lug

ActiveCN108465933AImprove brightness effectImprove directionalityCell component detailsLaser beam welding apparatusLaser processingContact type

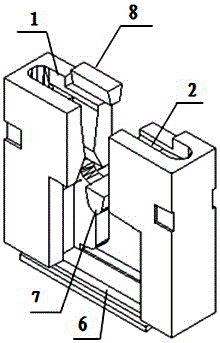

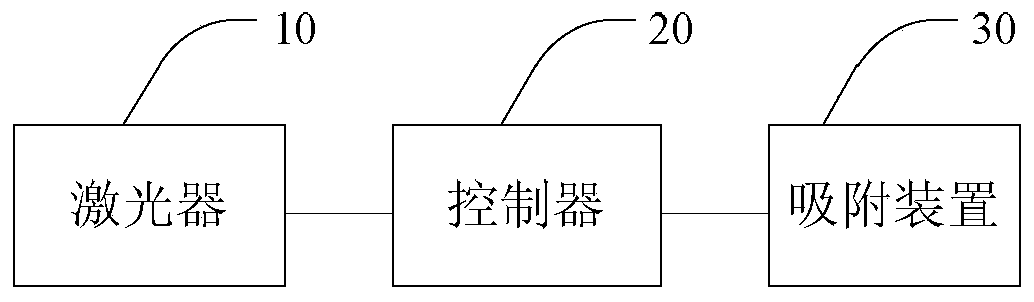

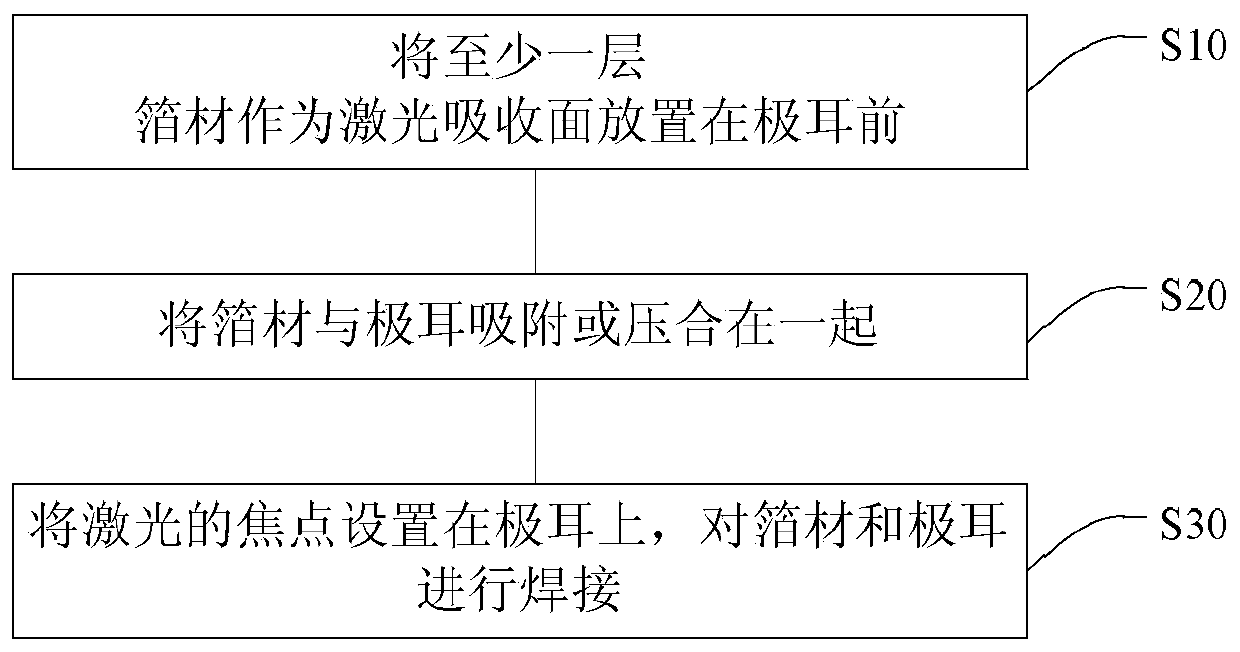

The invention discloses a method and device for laser-welding foil and a lug. The method comprises the following steps of taking at least one layer of the foil as a laser absorbing surface to put in front of the lug; adsorbing or pressing the foil and the lug together; arranging a laser focus on the lug; and welding the foil and the lug. The method adopts non-contact type laser welding to replaceconventional ultrasonic contact type welding, so that the foil and the lug are not affected by external force, and processing is stable. Laser processing efficiency is high, and multi-pulse light spots of laser can be adopted for process.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

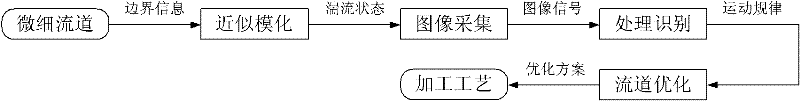

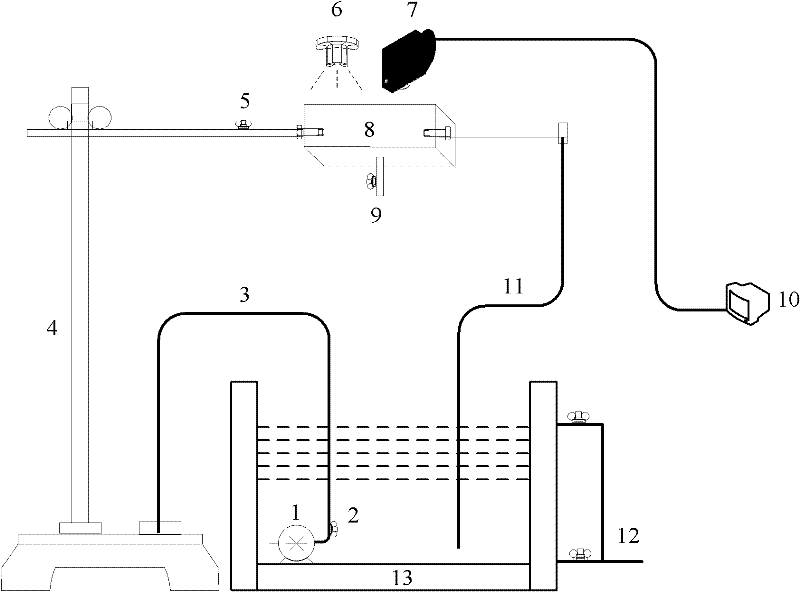

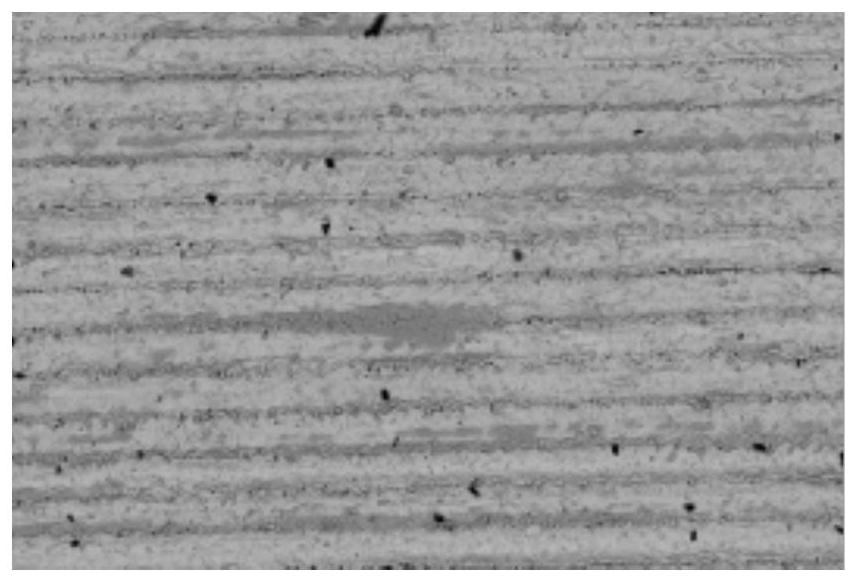

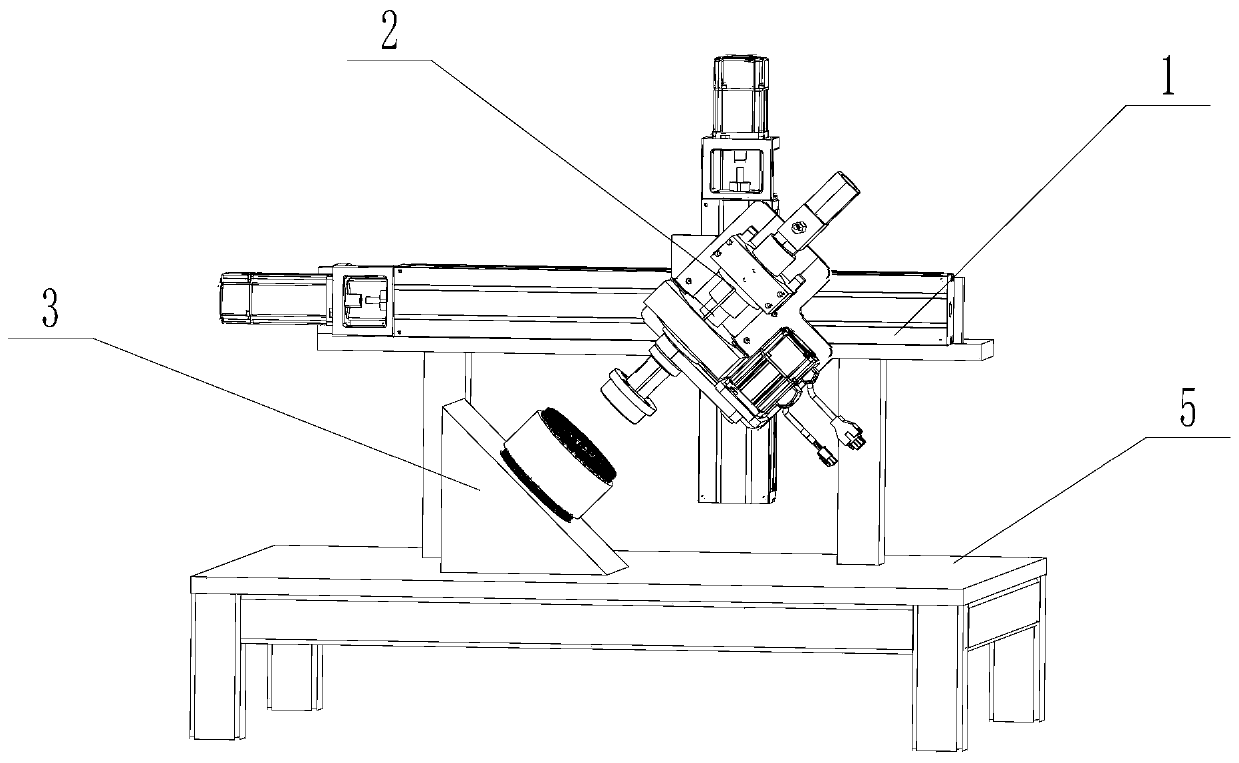

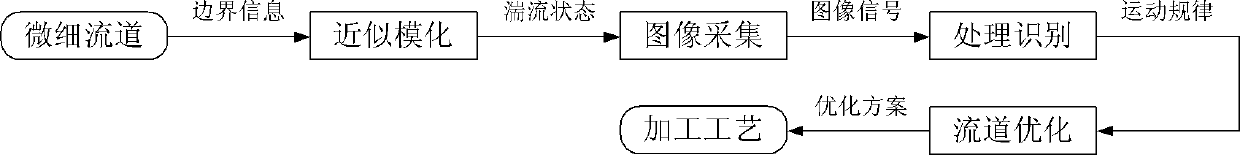

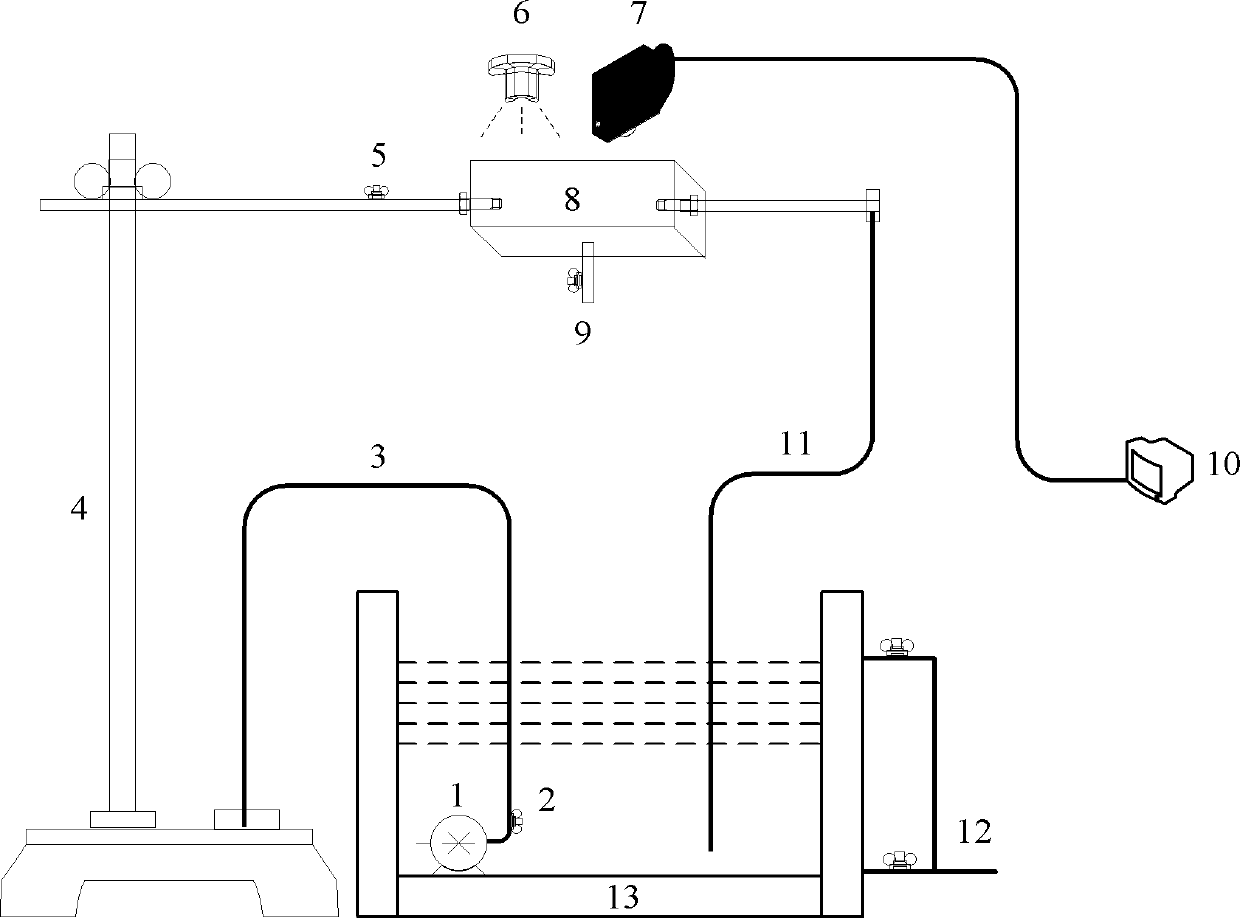

Observation method for fluid precision finishing of surfaces of micro-structures of molds

ActiveCN102528661ASimple and fast operationEffective filteringGrinding feed controlMicro structureParticle flow

An observation method for fluid precision finishing of surfaces of micro-structures of molds is based on a fluid flowing similar simulation method. A tiny mold structural surface is proportionally magnified, flowing states of sparse abrasive particle flows in tiny constraint flow channels are simulated, real-time image data in the flow channels are acquired and processed, and a distribution state, movement rules, typical flowing state characteristics and development trend of the sparse abrasive particle flows in environments of the tiny constraint flow channels are obtained; and experiments show that properties of forces stressed at various points in a flow channel model and properties of forces stressed at various corresponding points in a mold tiny constraint flow channel prototype are identical on the premise of meeting requirements of geometric similarity and kinematic similarity, the forces are proportional, a proportion constant keeps unchanged to optional corresponding points in two flow fields, and fluid dynamic properties of the two flow fields meet requirements of second law of flow similarity. The invention further provides an observation device for fluid precision finishing of surfaces of micro-structures of molds. The observation method and the observation device have the advantages that fluid finishing conditions and states for the surfaces of the micro-structures of molds can be well simulated, operation is simple, convenient and feasible, and universality is good.

Owner:ZHEJIANG UNIV OF TECH

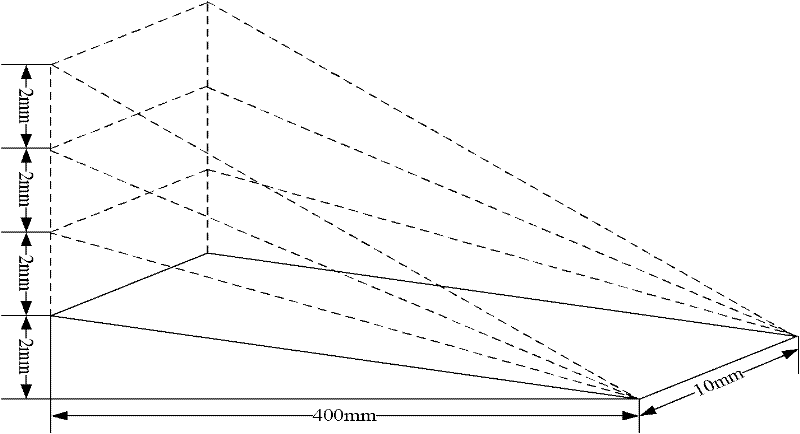

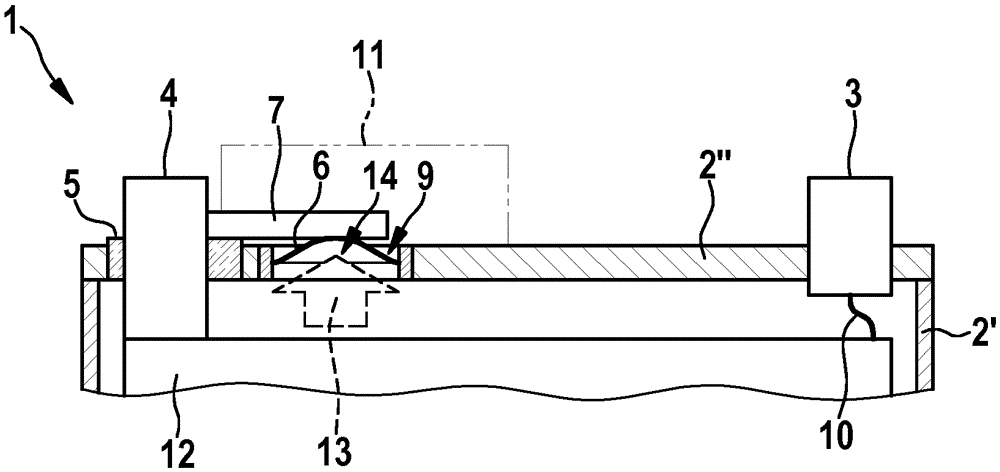

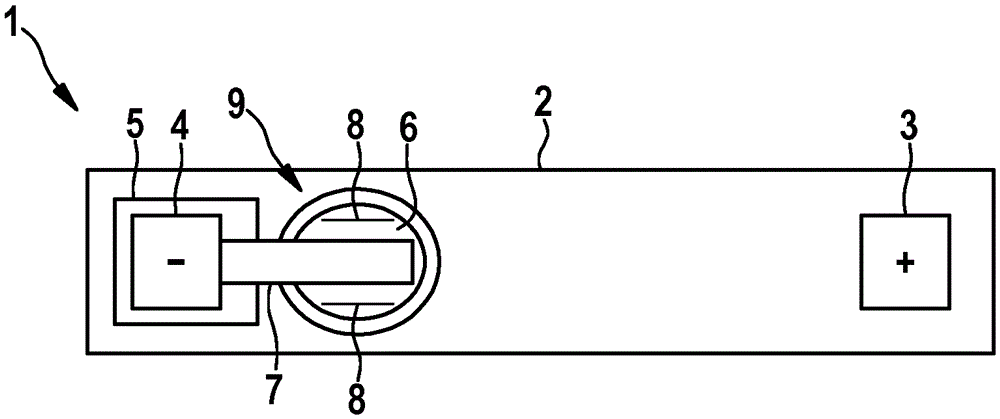

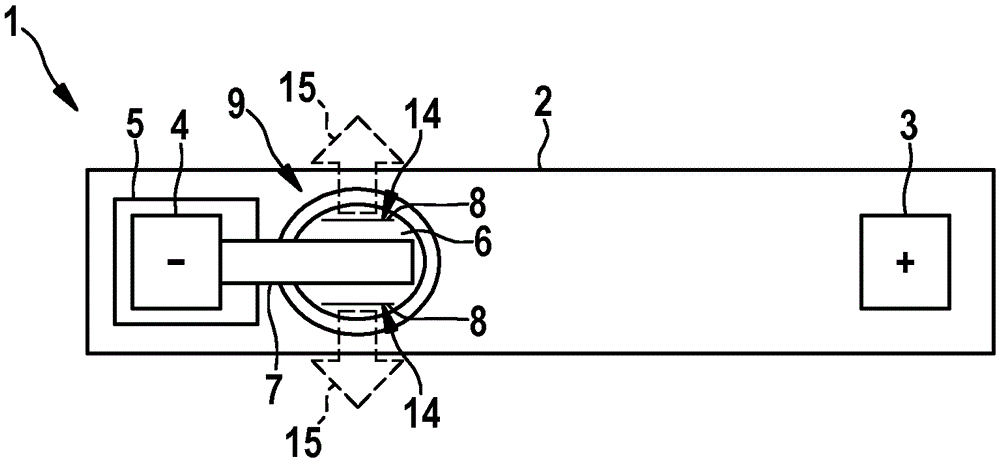

Battery cell with surge protector

InactiveCN105531849ALow costReduce areaCell component detailsBatteriesInternal pressureElectrical polarity

The invention relates to a battery cell (1) comprising a cell housing (2), a first electrode with a first polarity, a second electrode with a second polarity, and a surge protector for forming a short-circuit between the first electrode and the second electrode. The surge protector comprises a first contact element (6), which is inserted into an opening (9) of the cell housing (2) and which is connected to the first electrode in an electrically conductive manner, and a second contact element (7) at a distance from the first contact element (6), said second contact element being connected to the second electrode in an electrically conductive manner. The first contact element (6) is designed to contact the second contact element (7) in an electrically conductive manner in order to form a short-circuit between the first electrode and the second electrode if a cell housing internal pressure (13) exceeds a surrounding pressure by a first threshold. Furthermore, the first contact element (6) is designed to at least partly release the opening (9) of the cell housing (2) if a cell housing internal pressure (13) exceeds a surrounding pressure by a second threshold.

Owner:ROBERT BOSCH GMBH

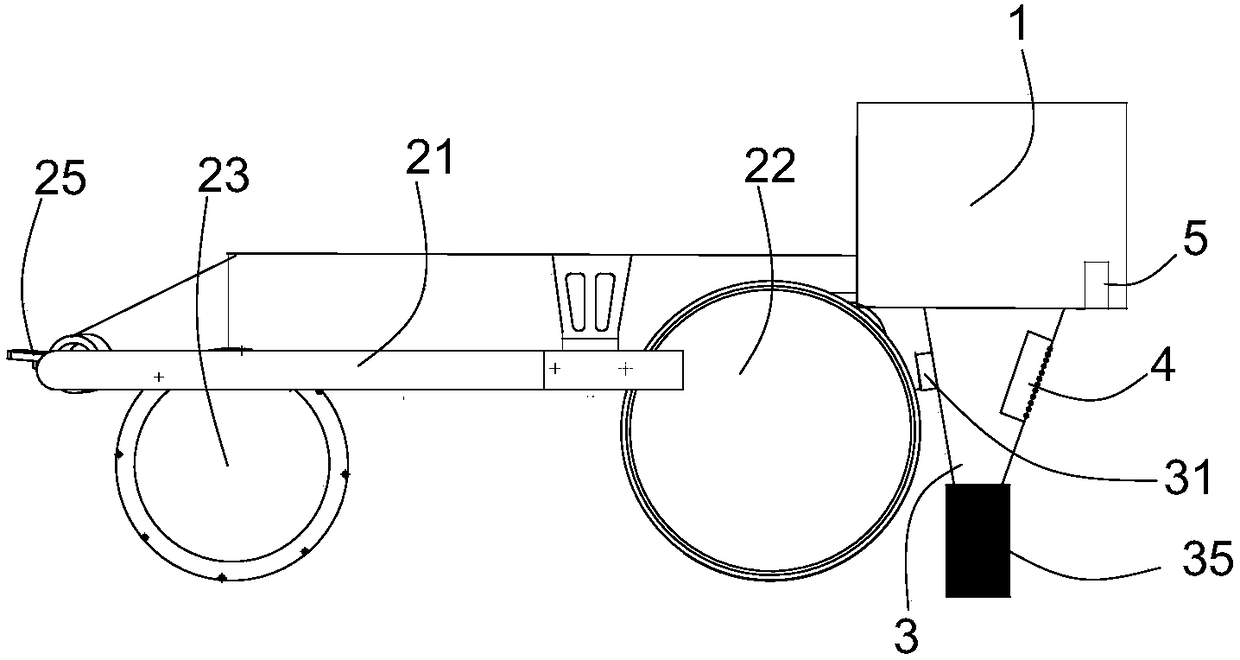

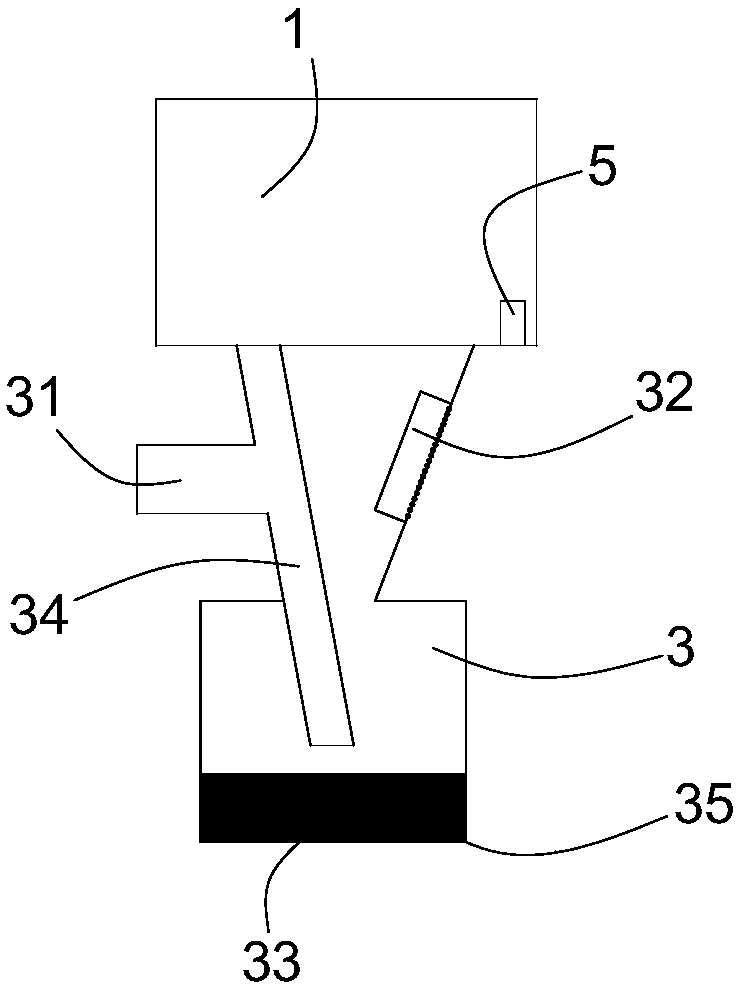

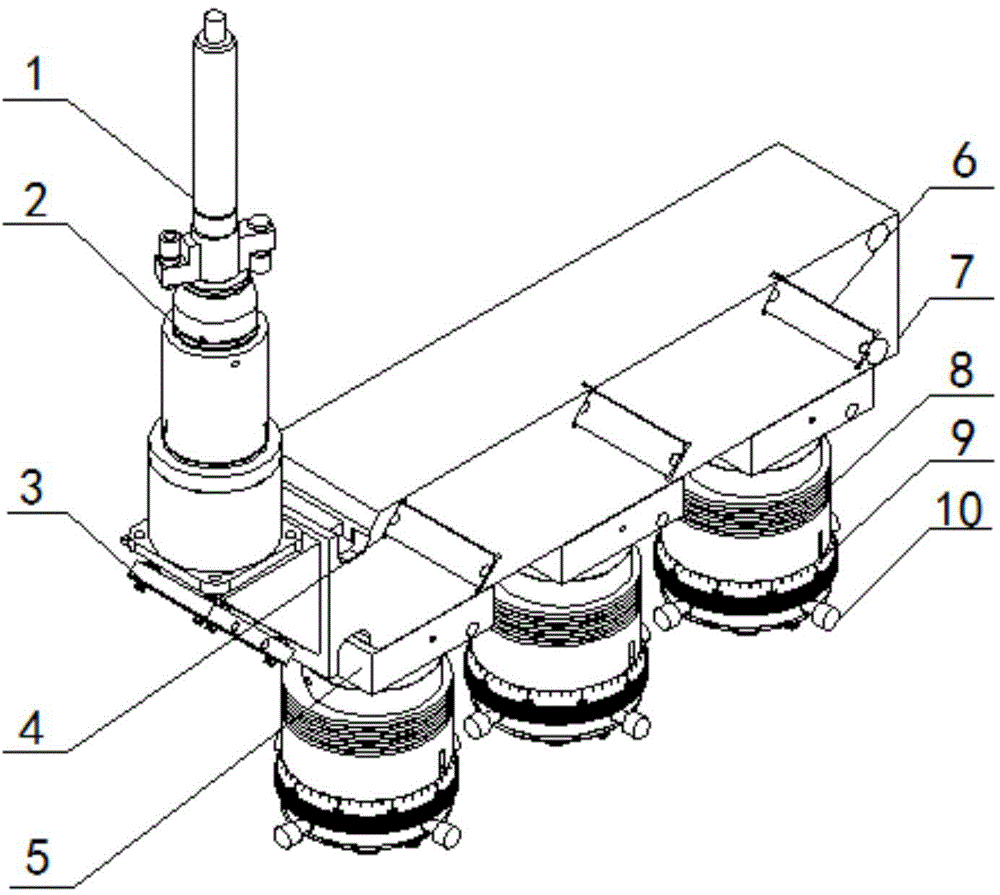

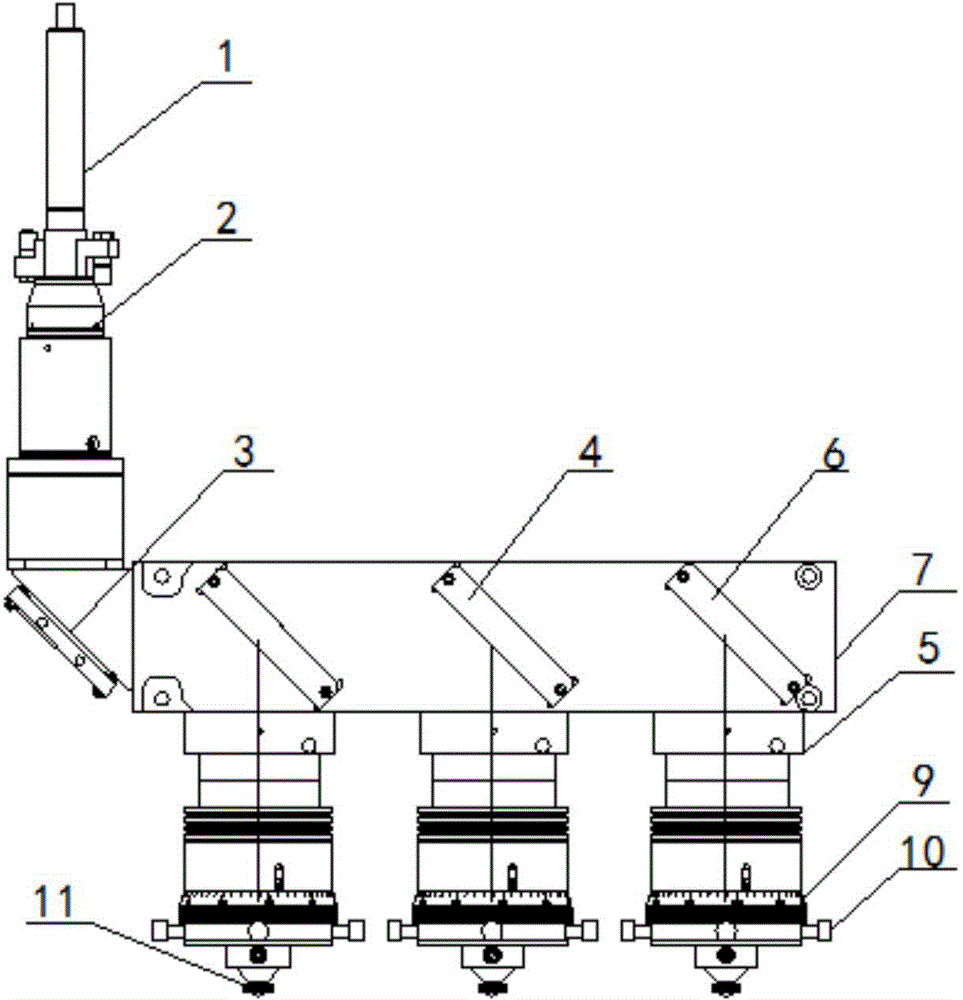

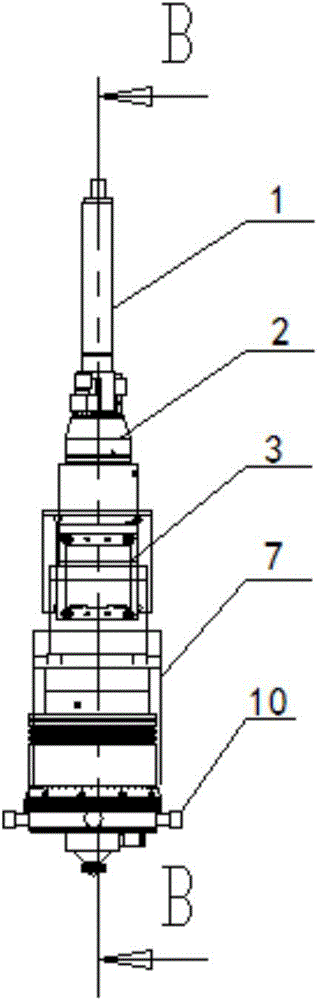

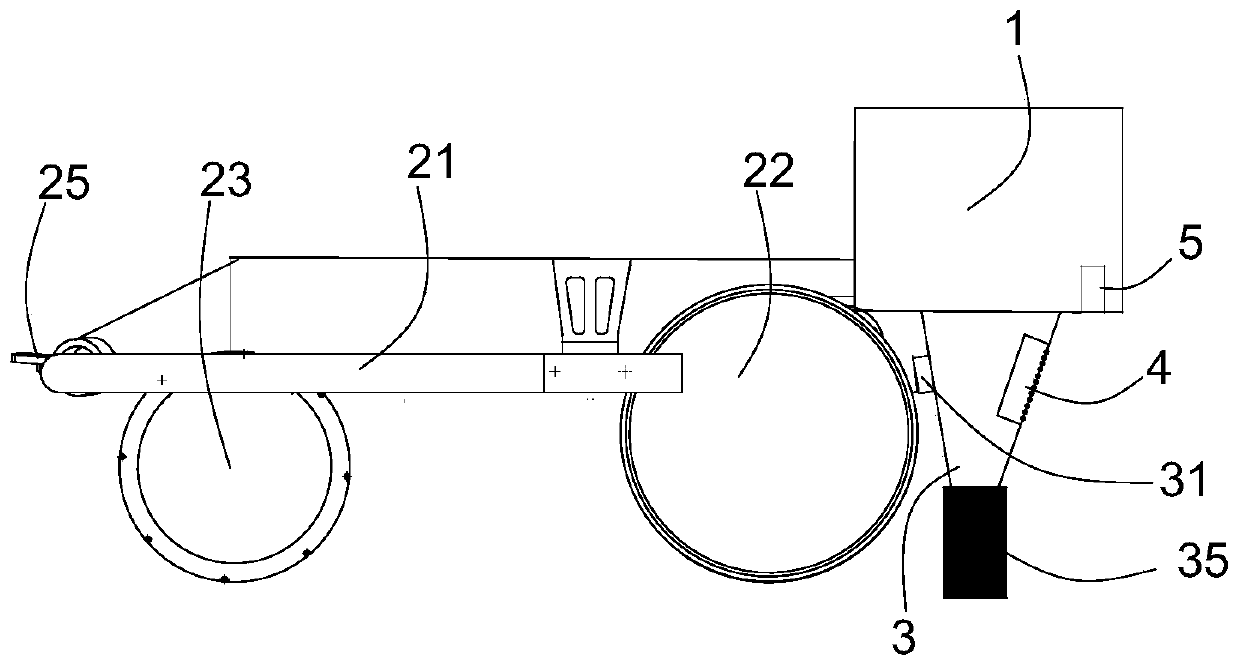

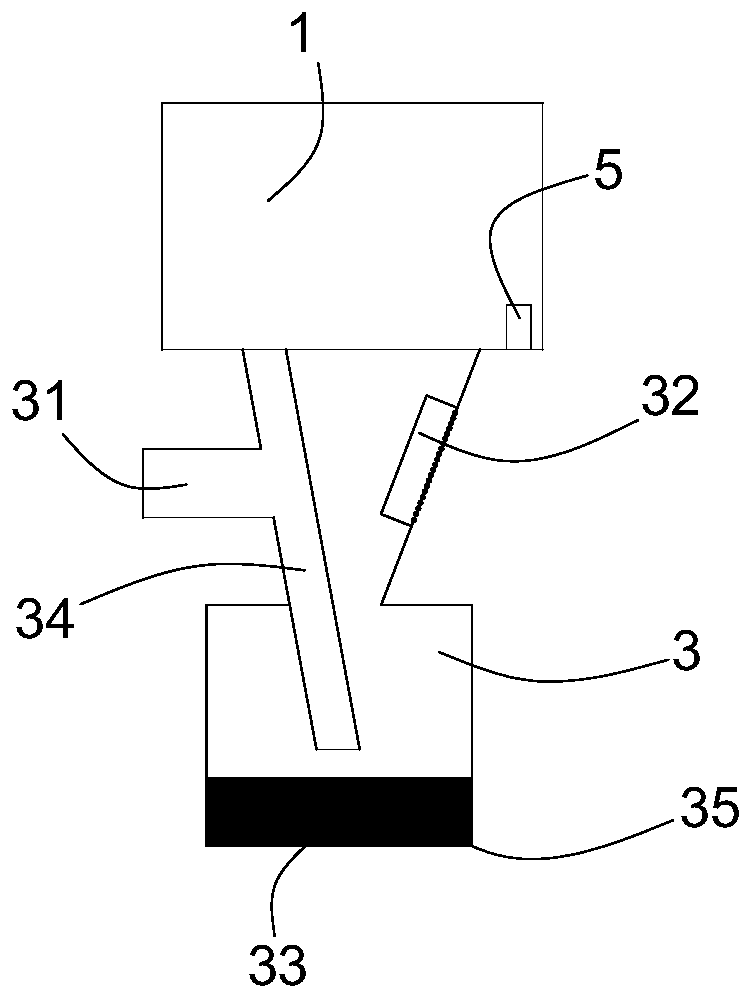

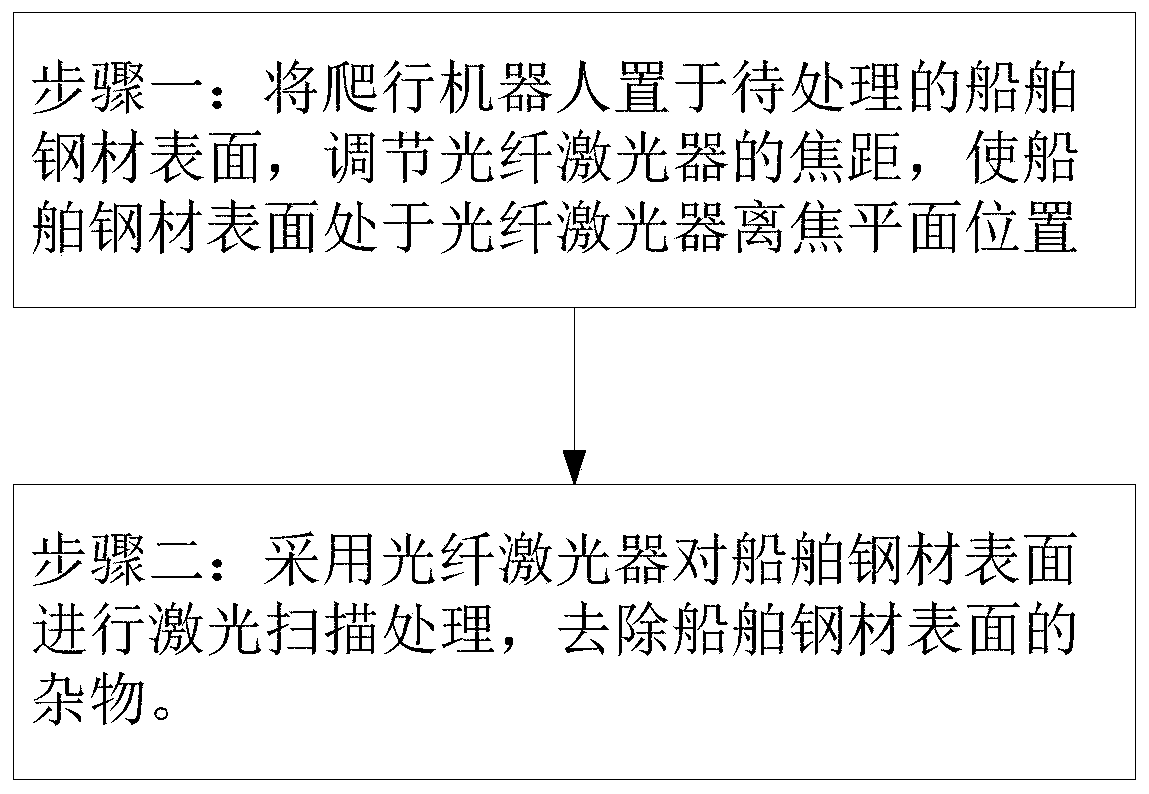

Crawling robot and marine steel surface pretreatment process

The invention provides a crawling robot and a marine steel surface pretreatment process. Fiber lasers are mounted on a vehicle body; the vehicle body is driven to move; laser cleaning is performed during moving; this mode is simple and efficient. The vehicle body has magnetic drive wheels so that the vehicle may travel in tight contact with the surface of a hull. The lasers mounted on the vehiclebody are kept evenly spaced from the surface of the hull. Fiber laser beams are used to perform laser scanning on the focal plane so that power density distribution is relatively uniform, and sundriesare cleaned without damaging steel base material. Compared with traditional grinding methods, the process employing noncontact processing has the advantages that laser processing causes no direct impact to marine steel so that no mechanical deformation occurs, laser processing precision is high so that the influence of human factors upon processing quality can be relieved, the processing efficiency is high, the quality is table and reliable, and the appearance is attractive.

Owner:WUHAN JINDUN LASER TECH CO LTD

Multi-end laser cutting head

InactiveCN104889564ACompact structureExtended service lifeLaser beam welding apparatusBeam splittingLight beam

The invention discloses a multi-end laser cutting head and belongs to the technical field of application of laser cutting machinery. The multi-end laser cutting head comprises a base, a collimating mirror is mounted on one side of the base, the top end of the collimating mirror is connected with a laser with a connector, a beam splitter and reflectors are arranged in the base, and the beam splitter is communicated with the inside of the collimating mirror. Cutting ends are mounted at the bottom of the base and nozzles are mounted at the bottom ends of the cutting ends. Focus lenses are arranged in the cutting ends and are connected with adjusting nuts on the side walls of the cutting ends, and a beam adjuster is arranged between the cutting ends and the base and is communicated with the beam splitter and the reflectors. The multi-end laser cutting head is added into a beam splitting system and a beam quality adjusting system, so that on the premise of the same cutting quality, efficiency is improved by several times, machining cost is greatly reduced, laser cutting kerf is narrow, workpiece deformation is small, operation efficiency is high, and the nozzles can well protect the focus lenses.

Owner:无锡信欧光电科技有限公司

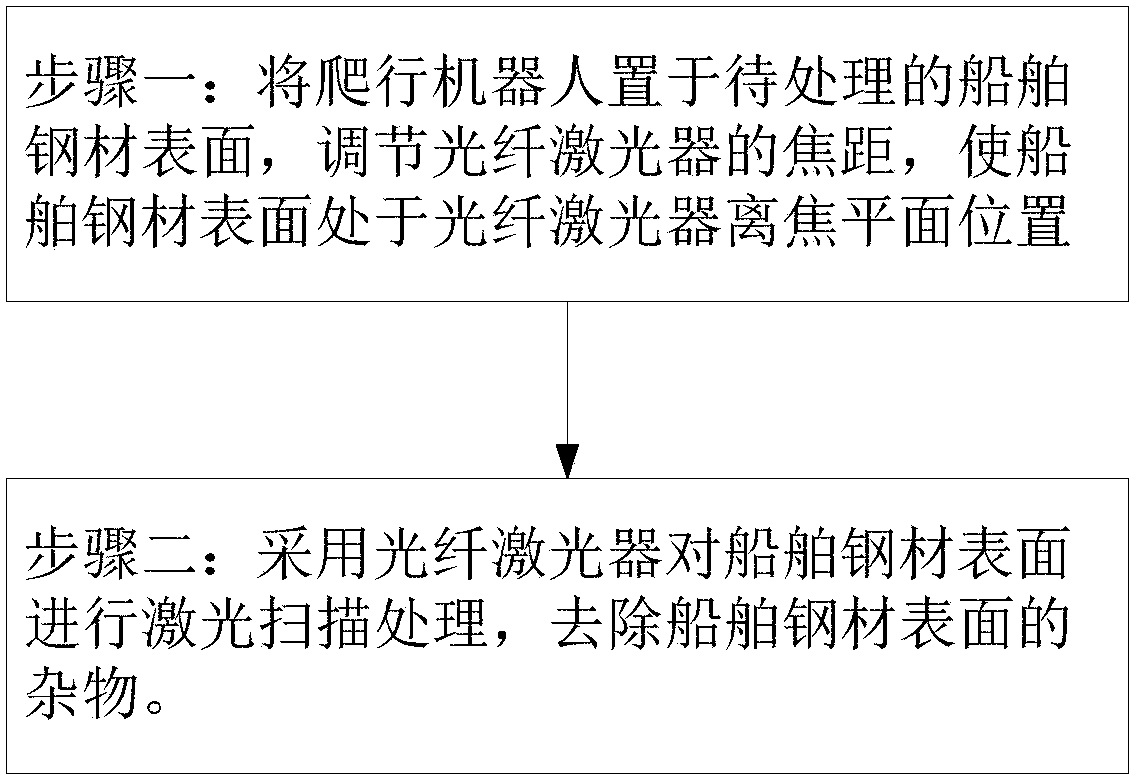

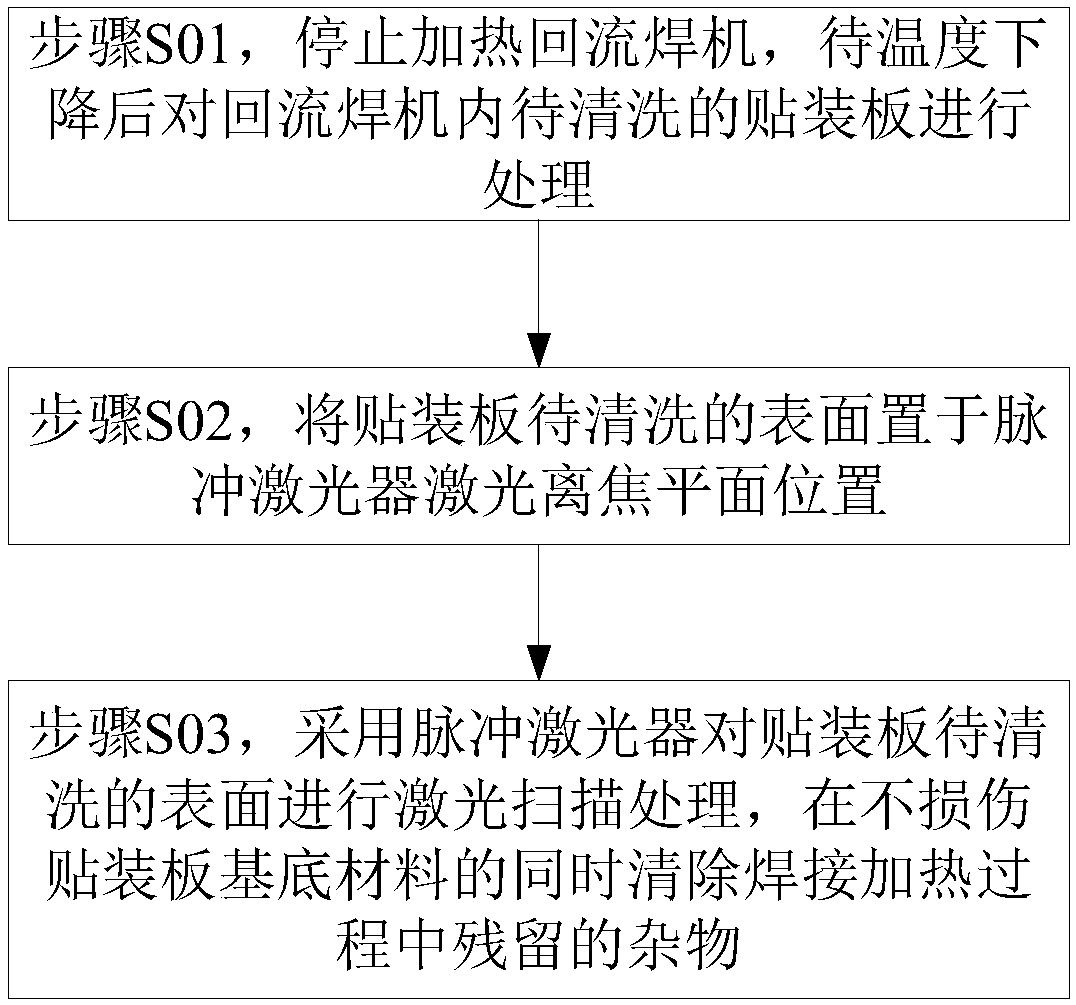

Laser cleaning process

InactiveCN108212947AWon't hurtWash thoroughlyPrinted circuitsCleaning processes and apparatusResistLaser processing

The invention provides a laser cleaning process. A pulse laser is used to perform laser scanning at a defocused plane position; residual solder balls, solder resist and other sundries during welding and heating are removed at the premise of not damaging base material of a surface-mounted board; noncontact processing is used; compared with traditional polishing methods, the laser cleaning process has the advantages that laser processing causes no direct impact on a surface-mounted board, and no mechanical deformation occurs. In addition, laser processing precision is high, only the surface to be cleaned is processed for the surface-mounted board, non-laser-irradiated parts are not or slightly affected, and the impact of human factors upon processing quality can be decreased; processing efficiency is high, the quality is stable and reliable, and the appearance is attractive.

Owner:WUHAN JINDUN LASER TECH CO LTD

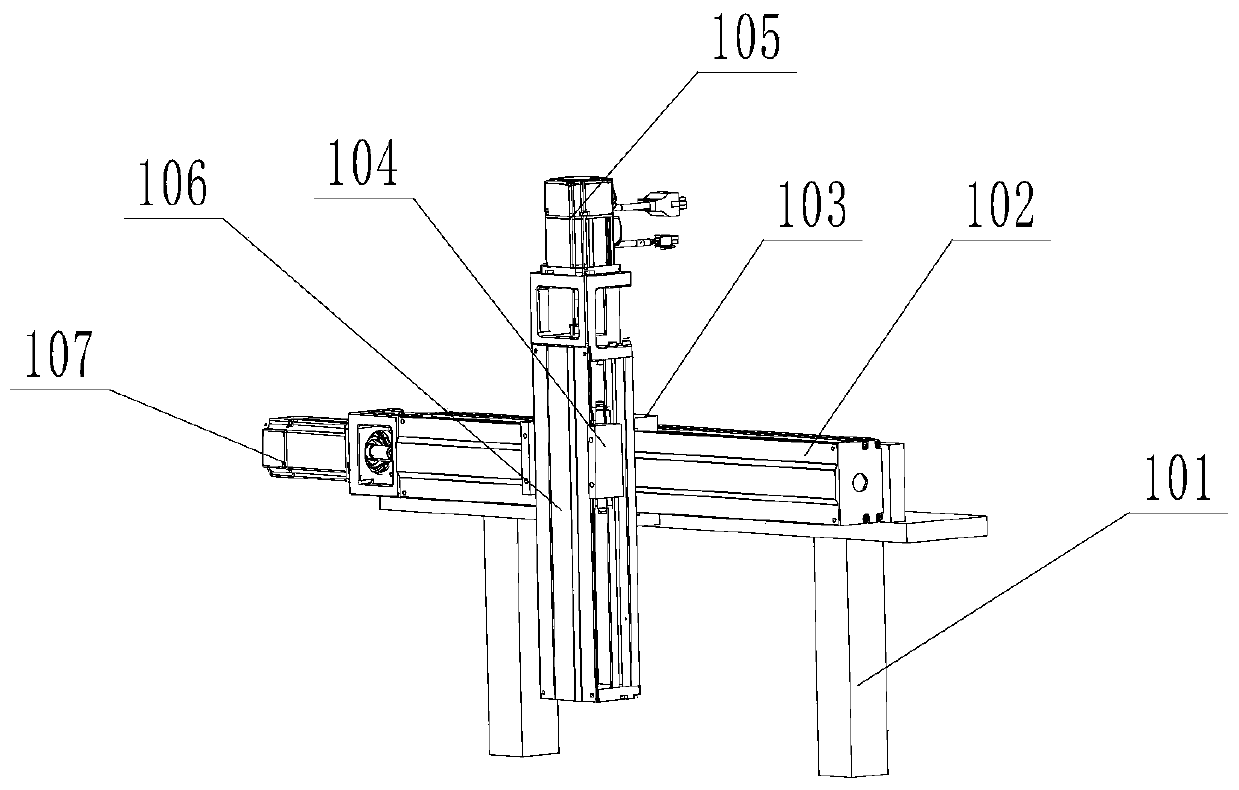

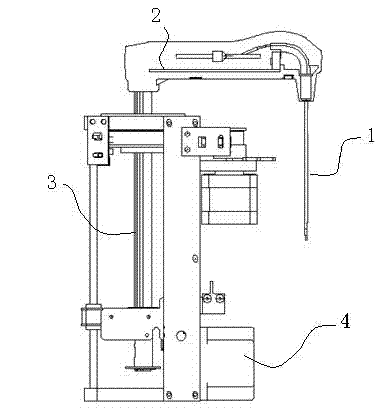

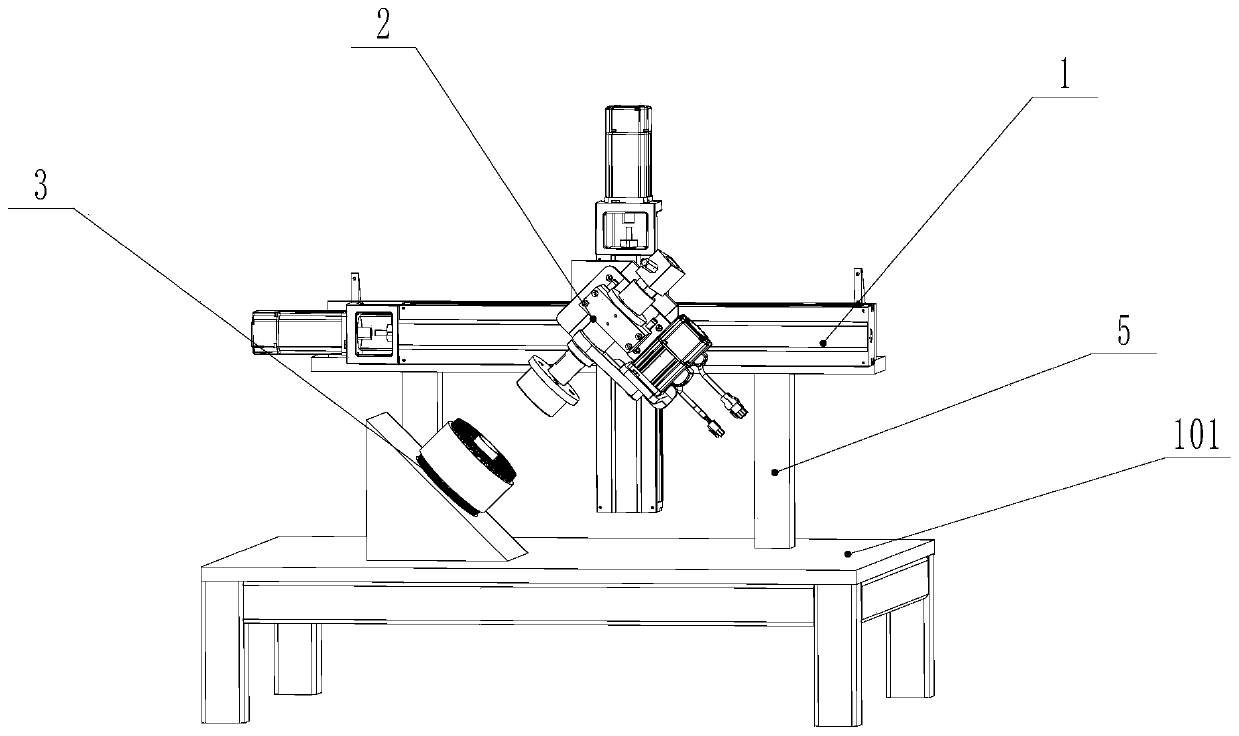

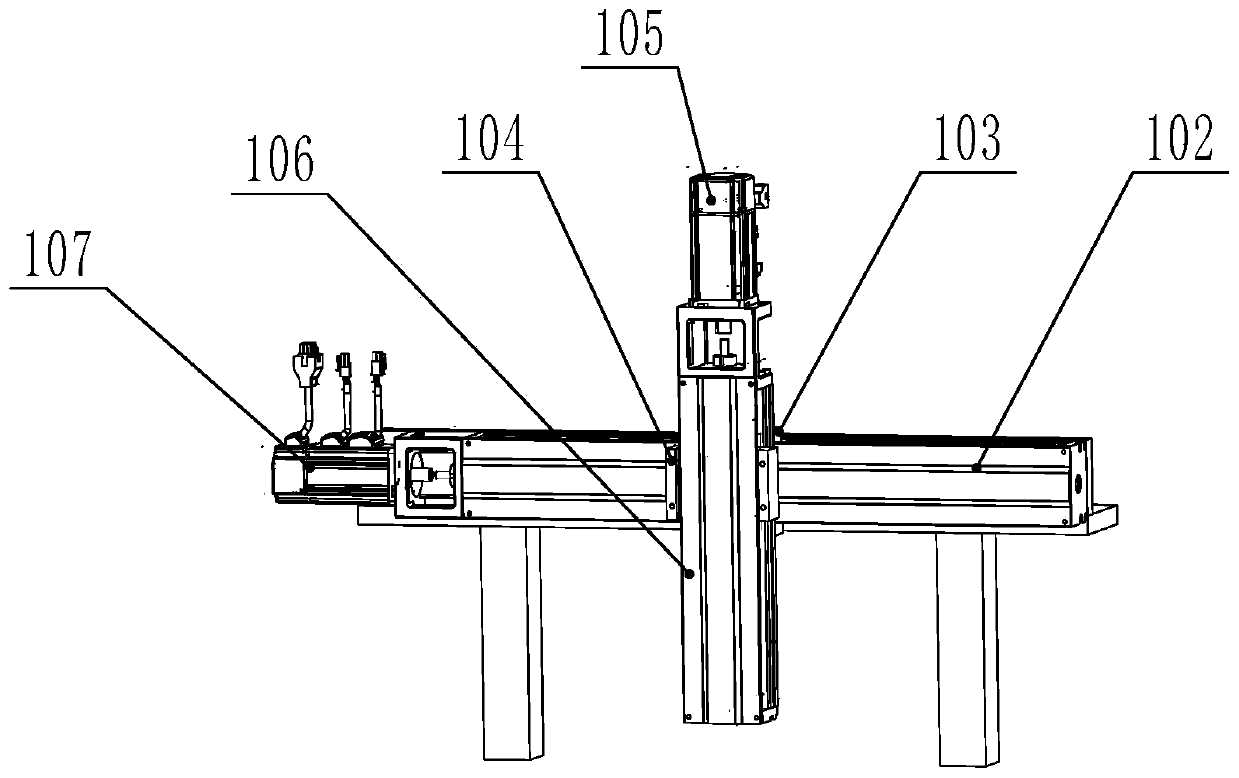

Corrugated cardboard cutting and pressing integrated machine

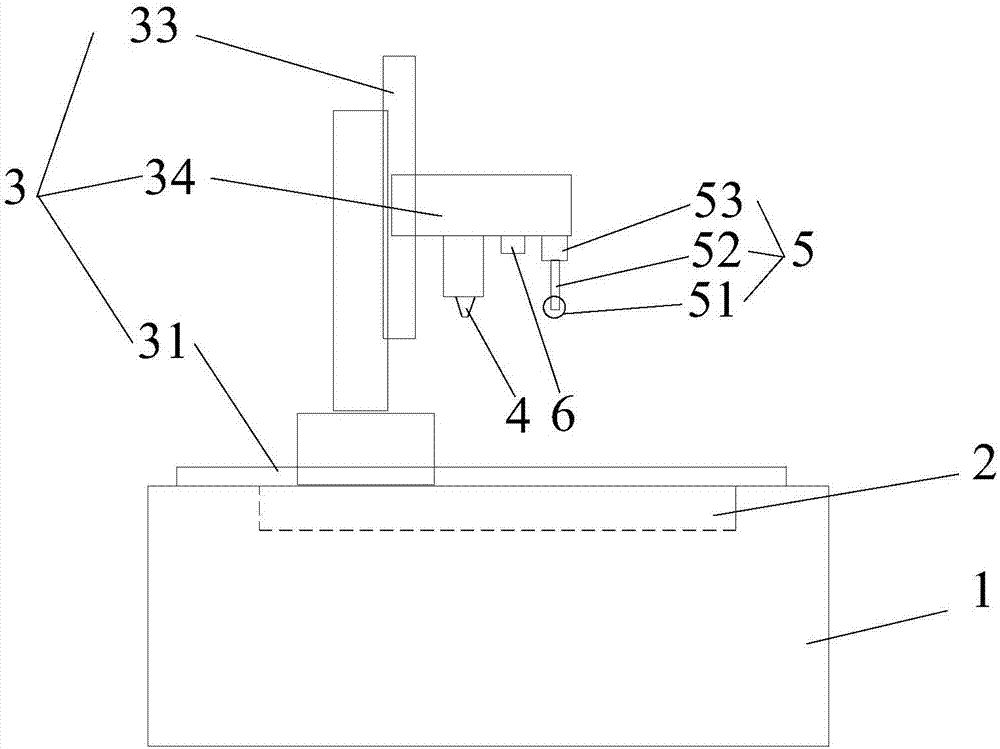

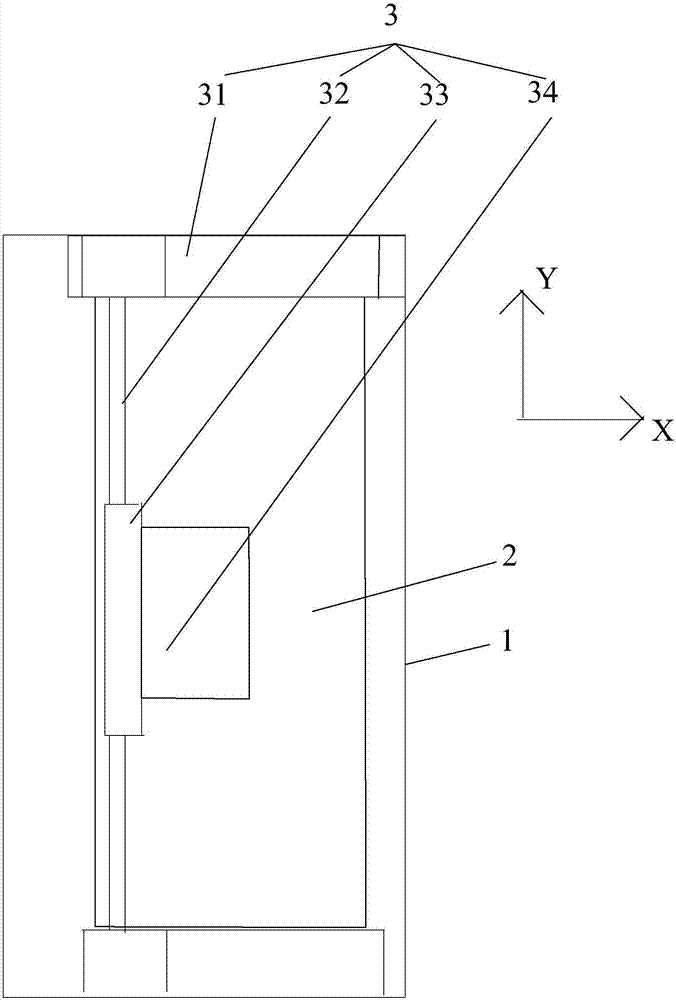

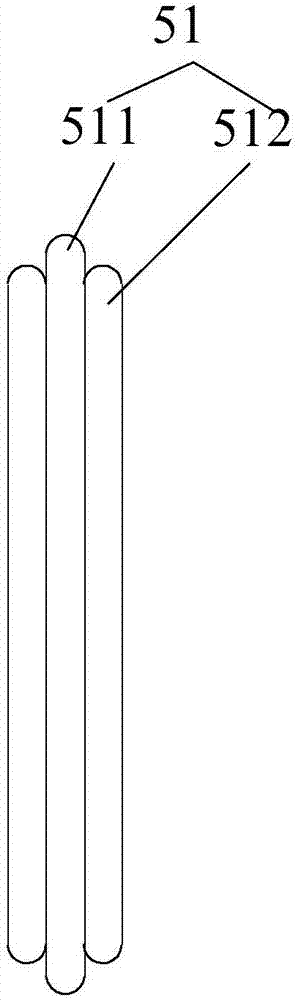

PendingCN106863902AReduce frictional resistanceHigh sensitivityBox making operationsPaper-makingCardboardEngineering

The invention discloses a corrugated cardboard cutting and pressing integrated machine comprising a rack, a workbench arranged on the rack and used for placing a corrugated cardboard, a three-dimensional displacement structure arranged on the rack, a laser cutting system used for emitting laser, an indentation wheel structure for indenting the corrugated cardboard and a control device; the laser cutting system, the indentation wheel structure and an image acquisition system are arranged above the workbench and are connected with the three-dimensional displacement structure; and the control device is connected with the three-dimensional displacement structure and is also connected with the laser cutting system and the indentation wheel structure, and the laser cutting system and the indentation wheel structure are driven by the three-dimensional displacement structure to displace. Due to the adoption of the structure, the corrugated cardboard cutting and pressing integrated machine is low in processing cost, short in period, high in cutting precision, precise in location, convenient to mount and debug, high in flexibility, free of jittering during starting and free of creeping phenomena during operating at low speed, so that the micro-feeding can be precisely controlled, and the corrugated cardboard cutting and pressing integrated machine has the advantages of motion stability, high driving efficiency, high precision and good synchronism.

Owner:昆明精研科技有限公司

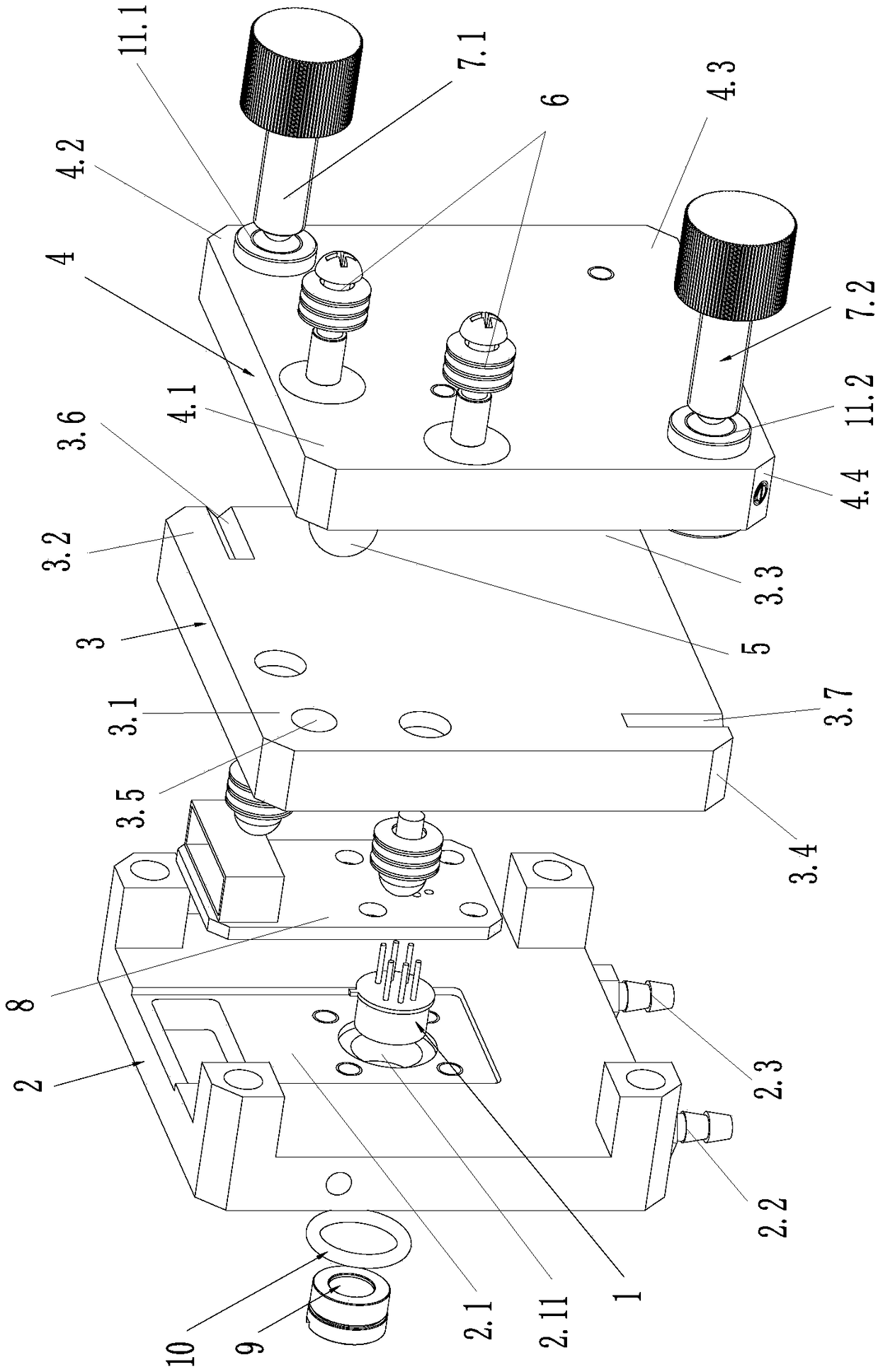

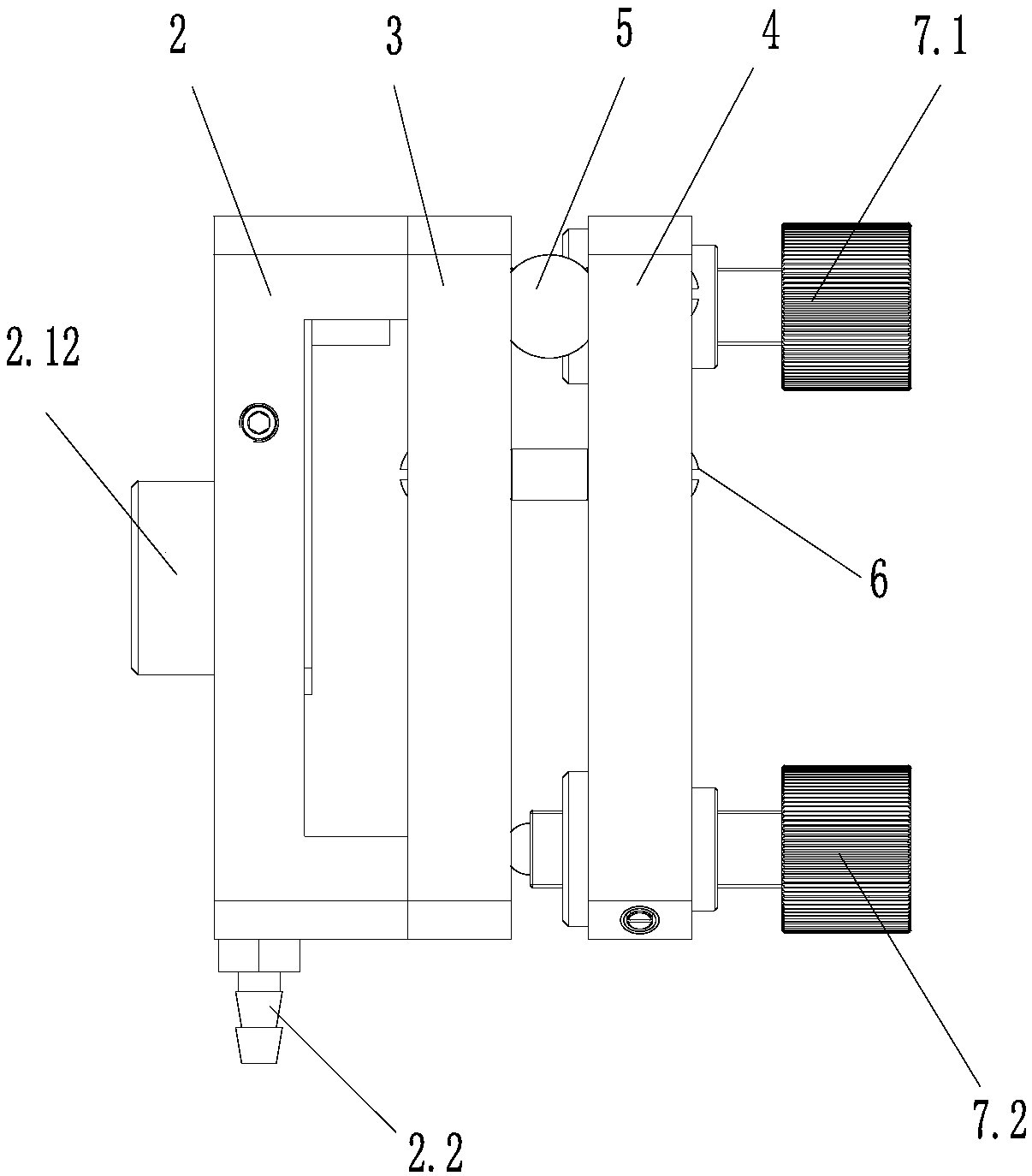

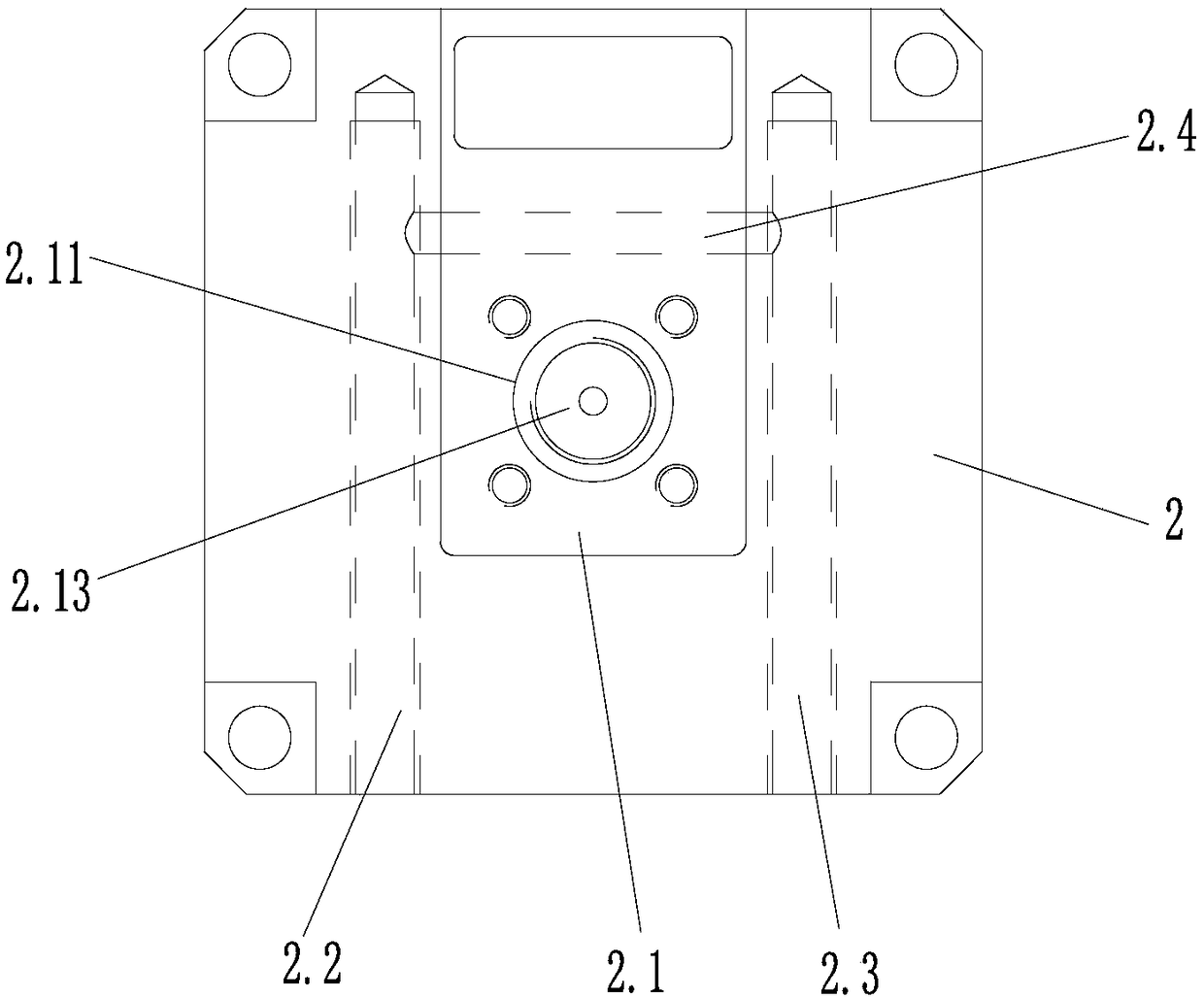

Laser beam multi-dimensional precision adjustment device integrating active heat dissipation structure

PendingCN108183384ASolve the adjustment blind spotGuaranteed stabilityLaser cooling arrangementsLight beamEngineering

The invention discloses a laser beam multi-dimension precise adjusting device integrating an active heat dissipation structure. The device includes a laser, a base with a self-heat dissipation function, a rotating seat for adjusting a laser spot position, and a fixing seat; a transverse sliding groove is formed at the second corner of the rotating seat; a first adjustment rotation rod is formed atthe second corner area of the fixing seat, wherein the first adjustment rotation rod abuts against the transverse sliding groove and is used for driving the rotating seat to rotate relative to the fixing seat with a ball adopted a rotation fulcrum, so that the laser spot can move leftwards and rightwards along a transverse direction; a vertical sliding groove is formed at the fourth corner of therotating seat; and a second adjustment rotation rod is formed at the fourth corner area of the fixing seat, wherein the second adjustment rotation rod abuts against the vertical sliding groove and isused for driving the rotating seat to rotate relative to the fixing seat with the ball adopted the rotation fulcrum, so that the laser spot can move up and down along a vertical direction. The laserbeam multi-dimension precise adjusting device integrating the active heat dissipation structure of the invention is compose of precise mechanical transmission devices on the basis of optical technologies. With the laser beam multi-dimension precise adjusting device integrating the active heat dissipation structure of the invention adopted, the installation, debugging and use of laser beams under any temperature and angle conditions can be realized.

Owner:武汉晟诺仪器科技有限公司

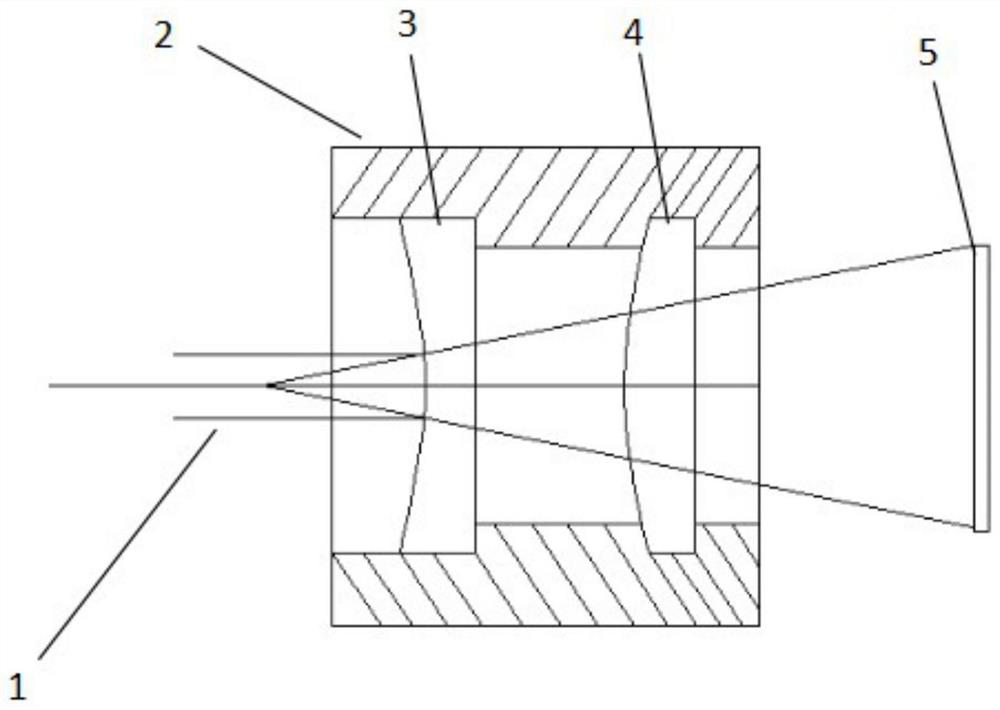

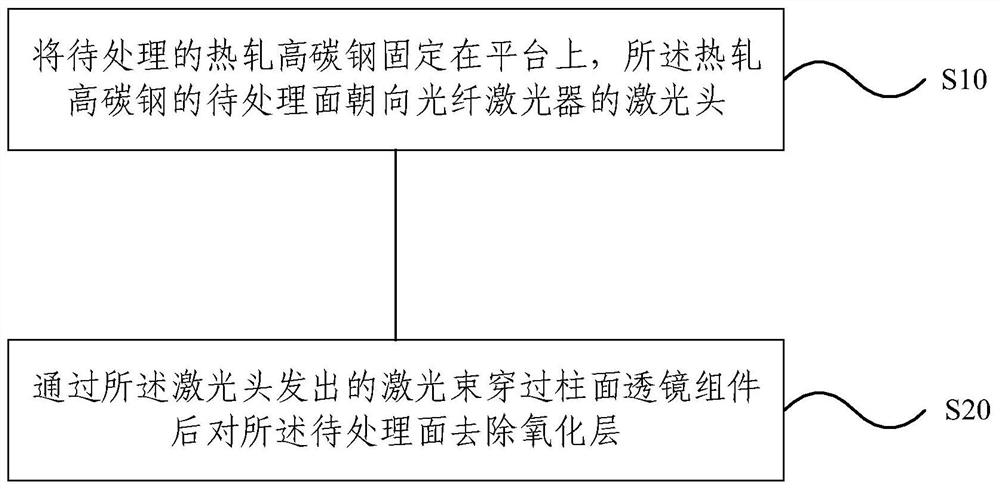

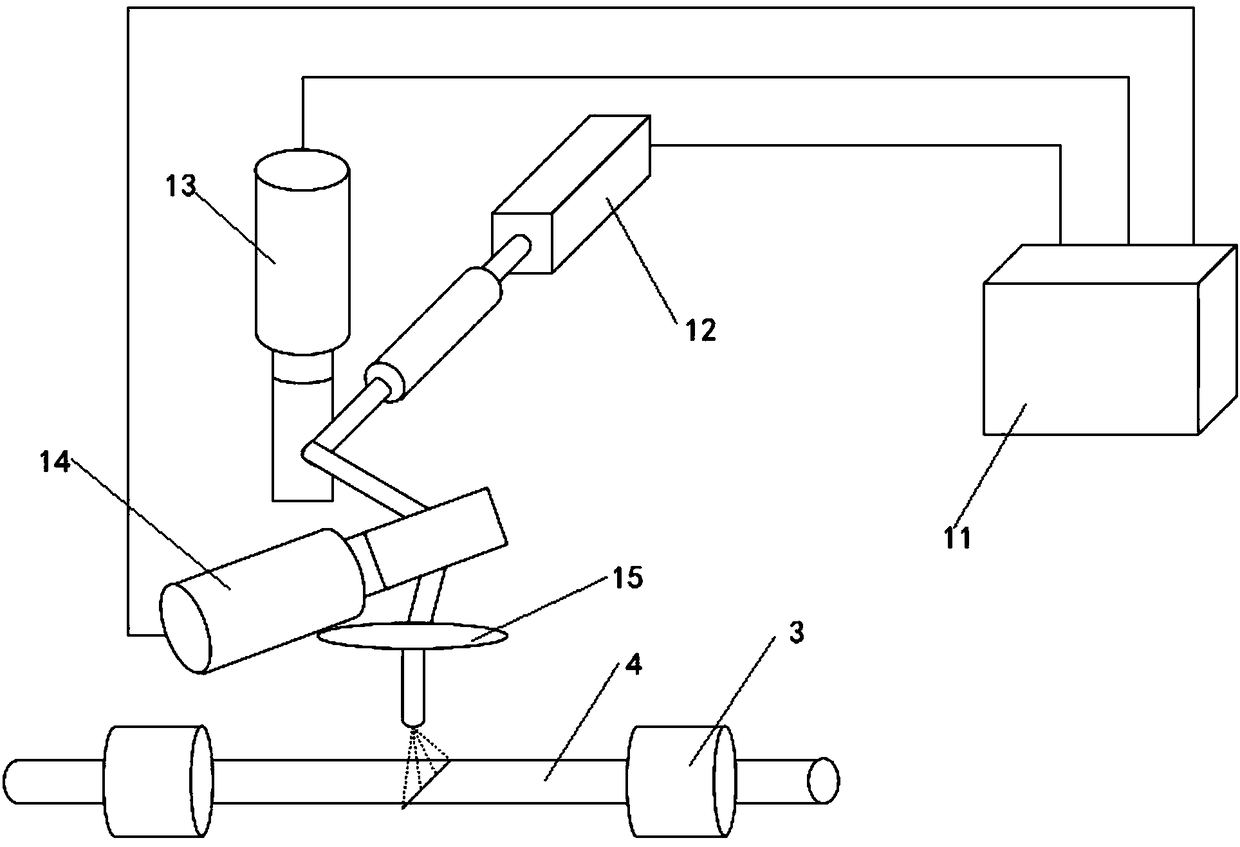

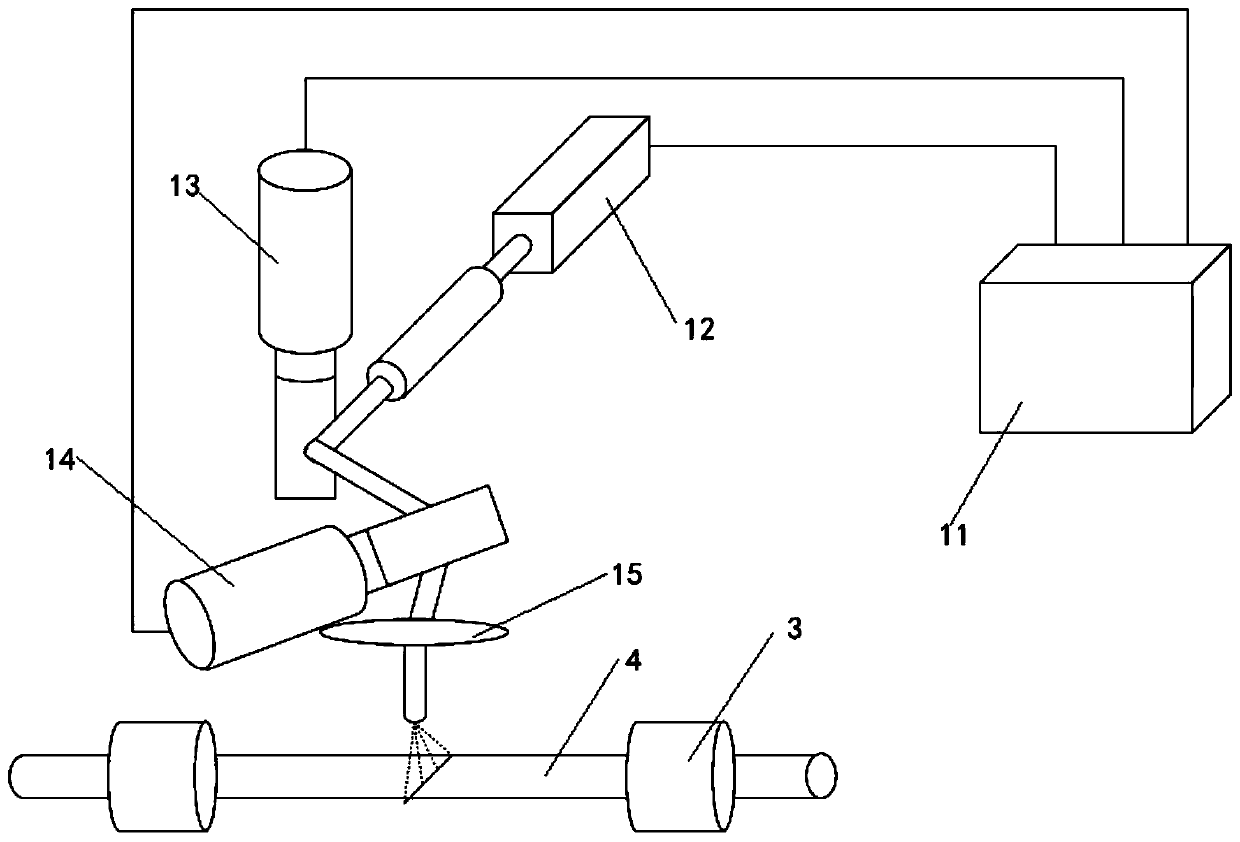

Laser cleaning device and method for oxide skin on surface of hot-rolled high-carbon steel

InactiveCN111992891AReduce collection and dischargeHigh precisionCleaning processes and apparatusLaser beam welding apparatusErbium lasersCarbon steel

An embodiment of the invention relates to the technical field of laser processing, and discloses a laser cleaning device and method for the oxide skin on the surface of hot-rolled high-carbon steel. The laser cleaning device for the oxide skin on the surface of the hot-rolled high-carbon steel comprises an optical fiber laser and a cylindrical lens assembly. The cylindrical lens assembly is used for changing the two-dimensional distribution of laser beams emitted by the optical fiber laser so as to adjust the energy density of the laser beams to a cleaning threshold value. According to the laser cleaning device for the oxide skin on the surface of the hot-rolled high-carbon steel, the fiber laser is used for cleaning the surface and removing the oxide skin on the surface of the hot-rolledhigh-carbon steel containing the compact oxide skin, and non-contact machining is achieved. Compared with a traditional grinding method, laser machining has no direct impact on a workpiece and does not generate mechanical deformation. Compared with an acid pickling mode, no pollution is caused, the discharging and collecting processes of chemical stains are reduced, the influence of human factorson the machining quality is reduced, the machining quality is stable and reliable, and the appearance is attractive.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

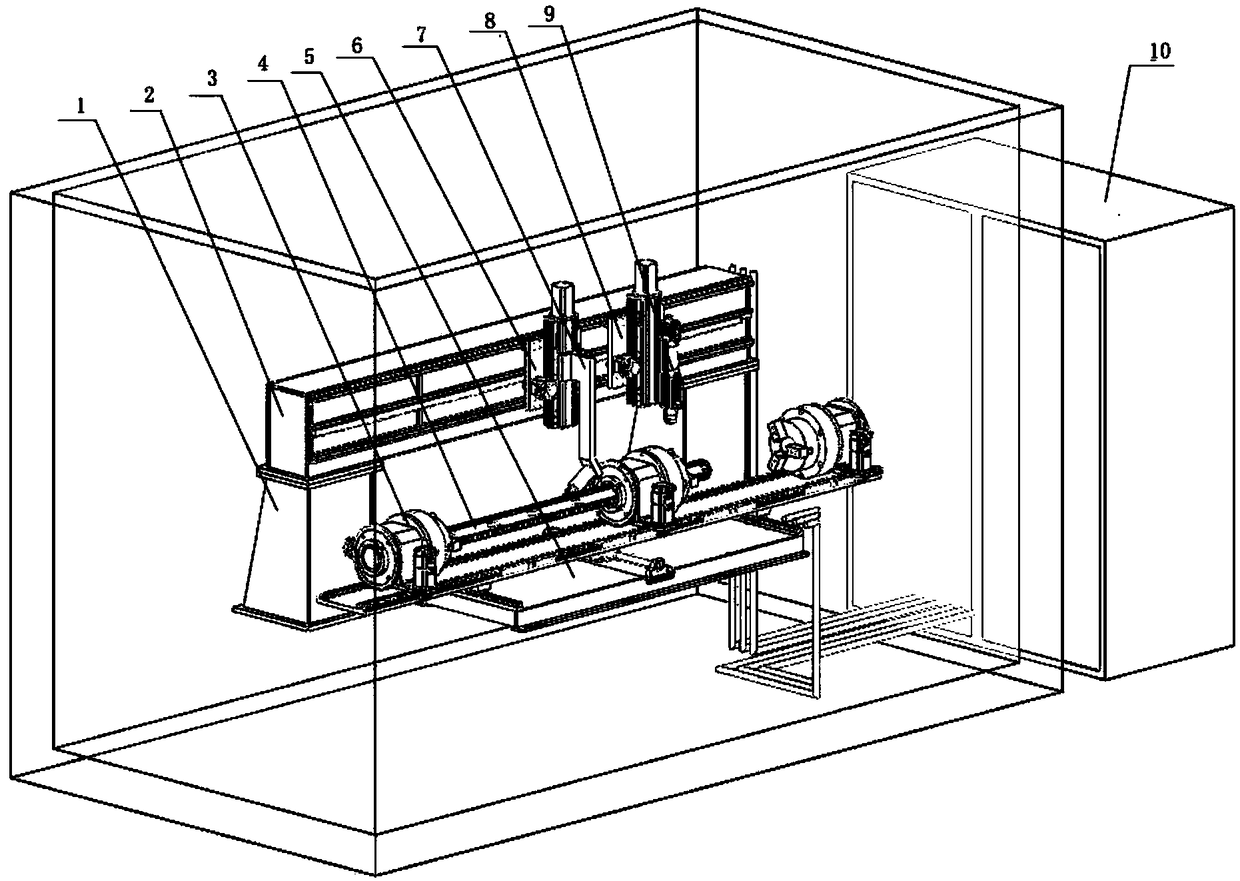

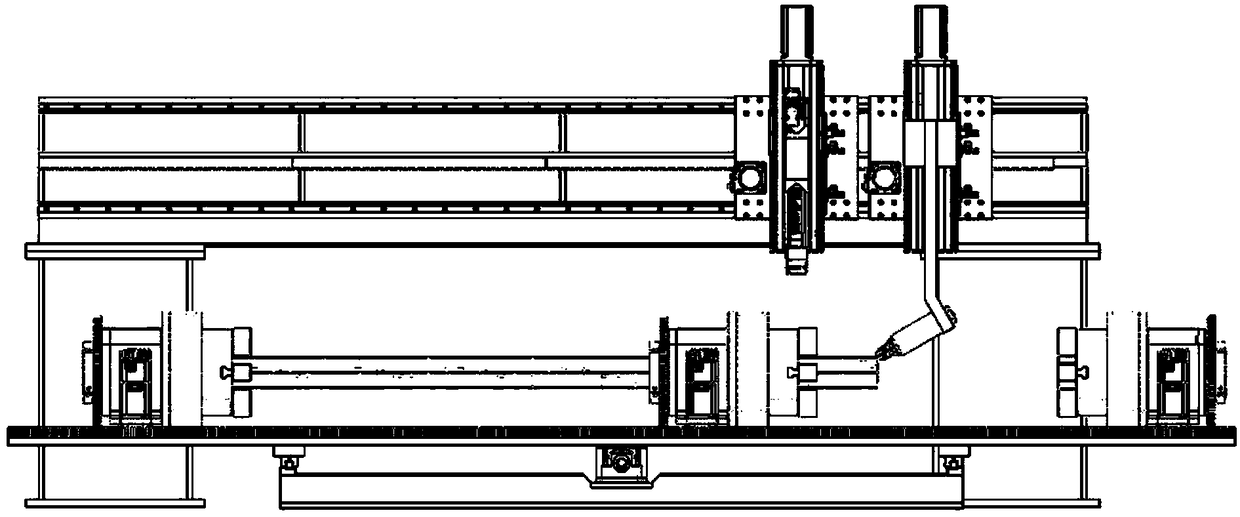

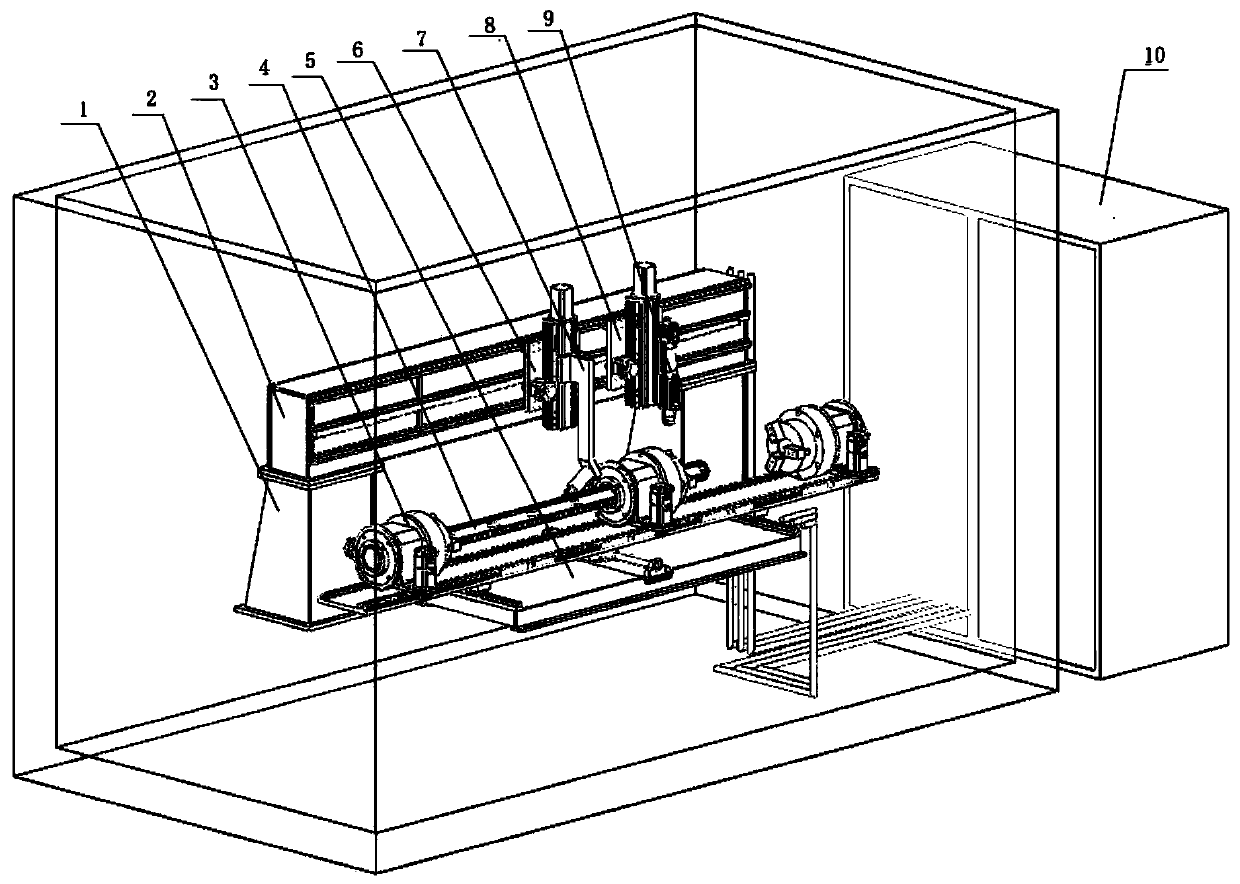

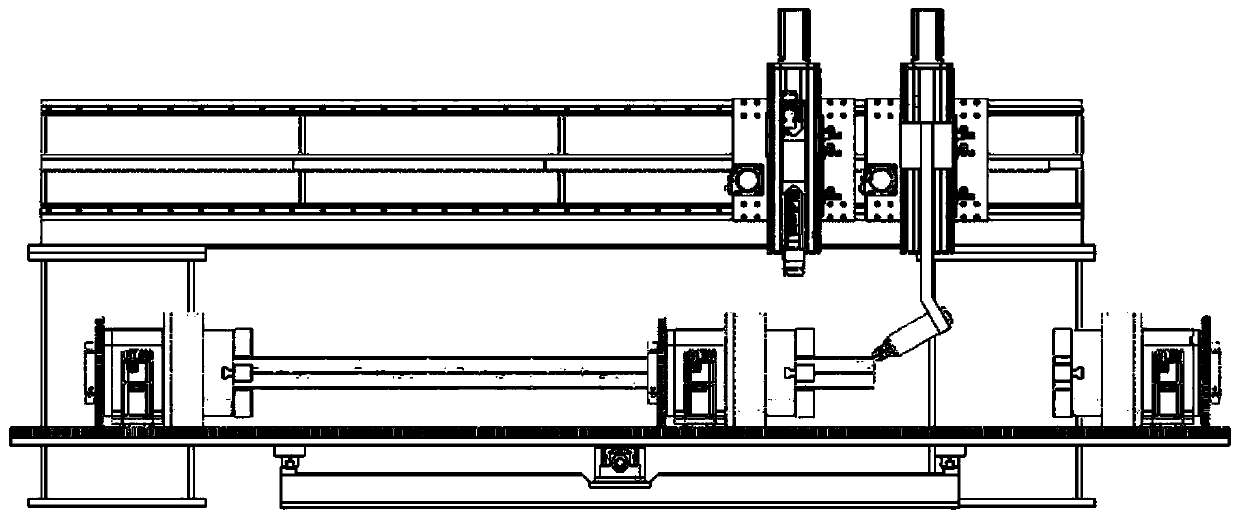

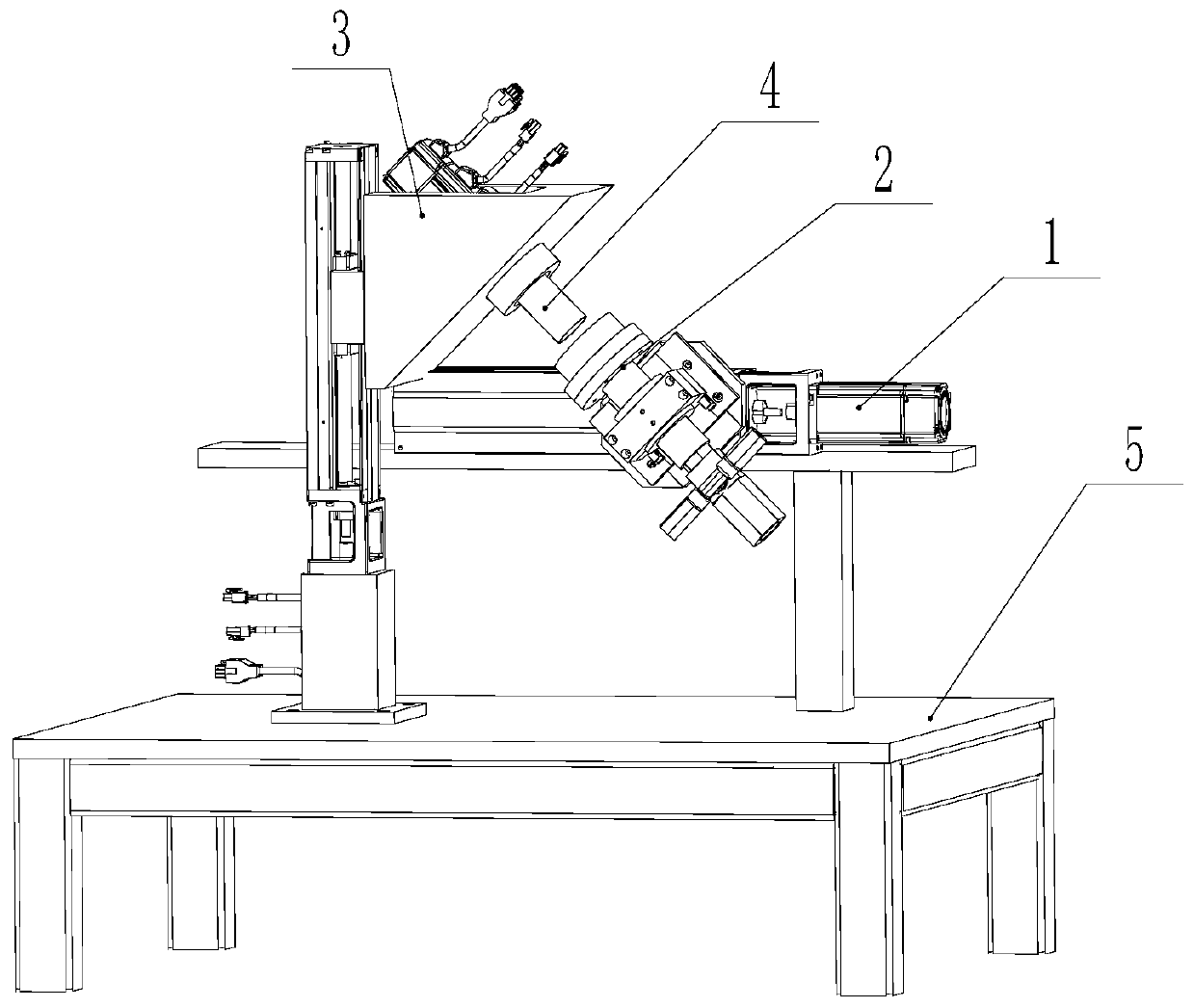

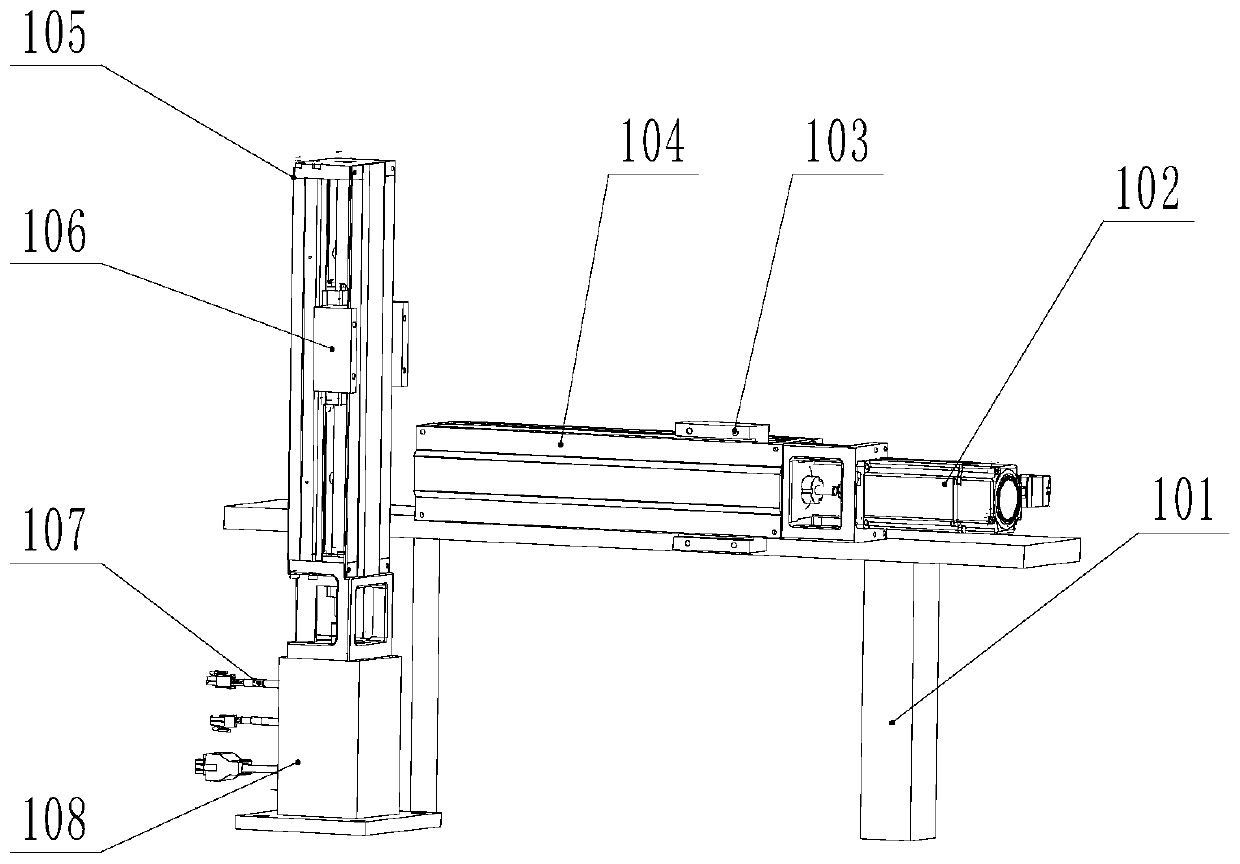

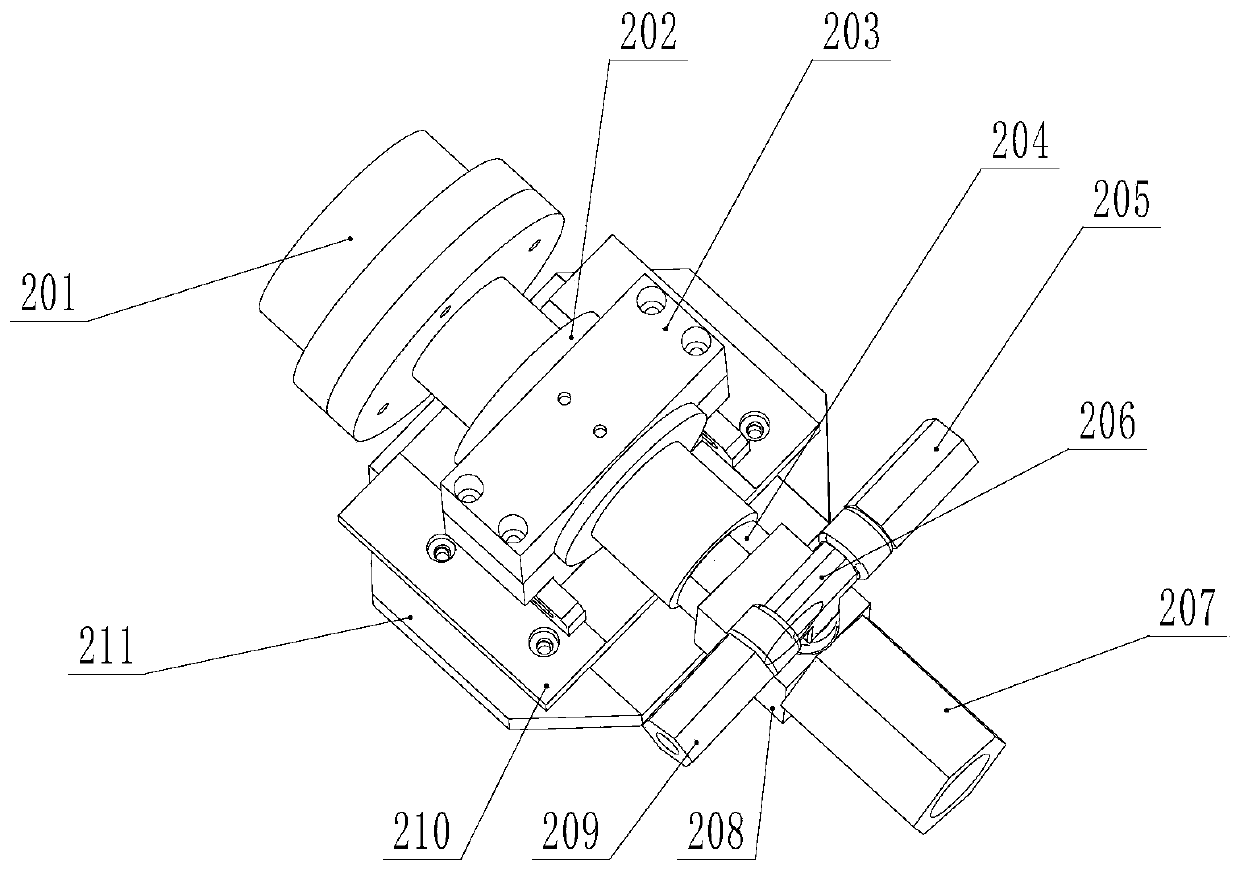

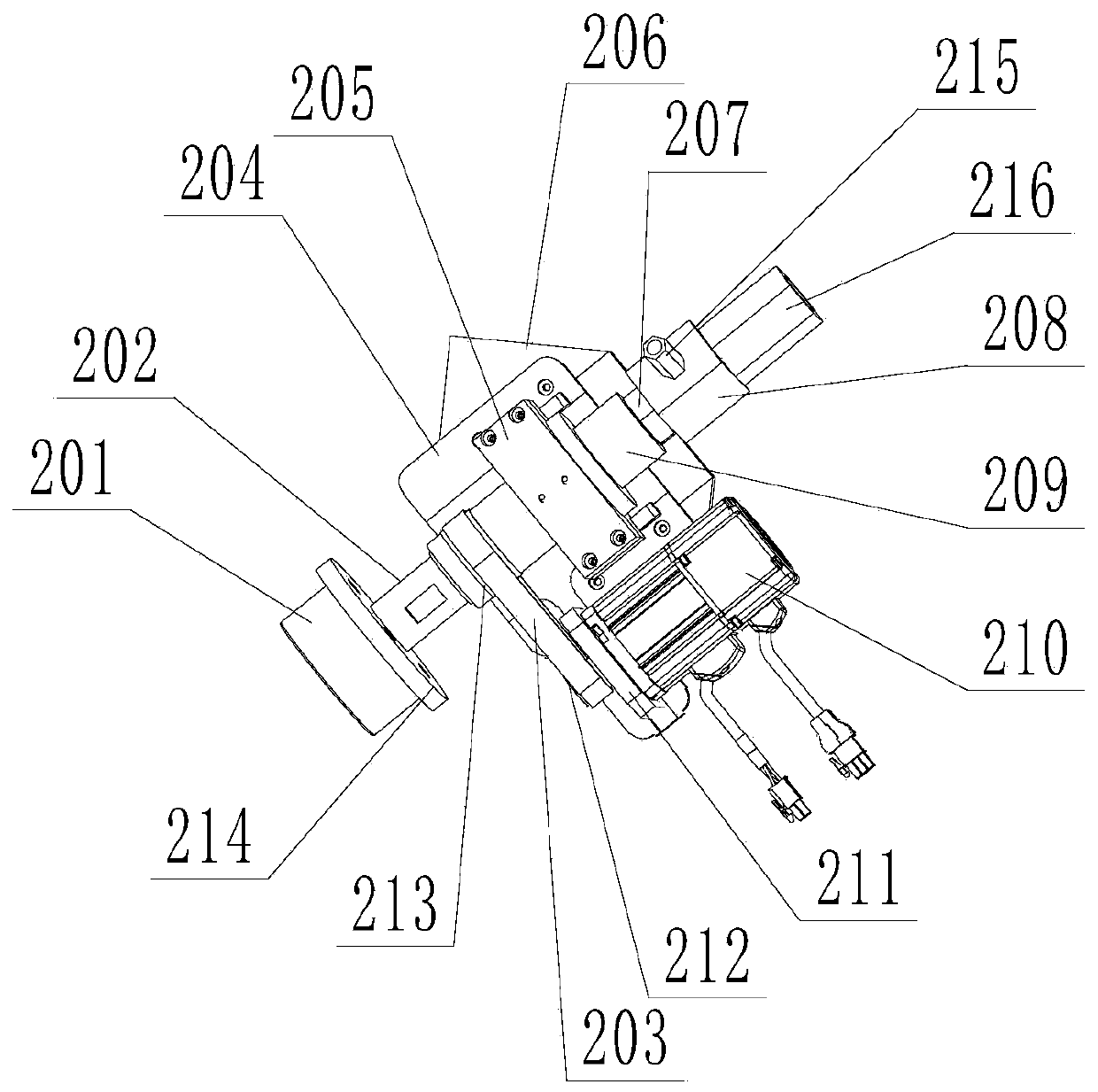

Laser disassembly equipment for externally-wrapped metal shell and application method thereof

ActiveCN108465943AImprove dismantling efficiencyAvoid meltingLaser beam welding apparatusLaser transmitterControl system

The invention discloses laser disassembly equipment for an externally-wrapped metal shell. The laser disassembly equipment comprises a control cabinet and an indoor equipment body; the control cabinetcomprises a laser emitter and a control system; the indoor equipment body comprises a movable cutting device and a clamping operation platform, wherein the movable cutting device and the clamping operation platform are arranged in the indoor equipment body and are supported by a lathe; a laser of the laser emitter adopts a pulse laser; the movable cutting device comprises a beam frame, a front slide carriage and a rear slide carriage, wherein the front slide carriage and the rear slide carriage are connected to the beam frame in a sliding mode; a laser cutting head arranged on the front slidecarriage is connected to the laser emitter; a cutting clamp is fixed to the rear slide carriage; the clamping operation platform comprises a sliding base, clamping head parts and a driving motor which are fixed to the lathe; and the clamping head parts are movably connected to the sliding base and is electrically connected to the driving motor. The laser disassembly equipment and the applicationmethod thereof have the advantages that a test workpiece is disassembled through a non-penetration type laser disassembly method, the cutting efficiency is high, the cutting quality is good, in addition, the laser disassembly depth is accurate and controllable, and the damage to internal materials can be prevented.

Owner:武汉翔明激光科技有限公司

Welding model and welding method of alloy steel turnout and trough type steel rail

PendingCN107175402AQuality improvementImprove performanceAlumino-thermic welding apparatusMaterials scienceAlloy steel

The invention discloses a welding model and welding method of an alloy steel turnout and a trough type steel rail. The welding model comprises a left sand mold and a right sand mold cooperating with the left sand mold. After being buckled, the left sand mold and the right sand mold are arranged on the two sides of a joint of the alloy steel turnout and the trough type steel rail. A bottom mold is arranged at the bottom of the left sand mold and the bottom of the right sand mold. The sand molds matched with the joint of the alloy steel turnout and the trough type steel rail, the bottom mold, a trough type plug block and a division block are arranged, and a closed thermit welding forming cavity is formed through cooperation between modules and manual filling and box sealing. The welding model cooperates with process methods and process parameters obtained through tests for the joint form, a casting system and the like for welding, a welding joint is stable in quality and good in performance, and various indexes meet the product performance requirement.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

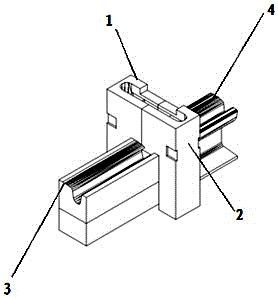

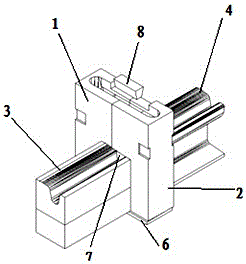

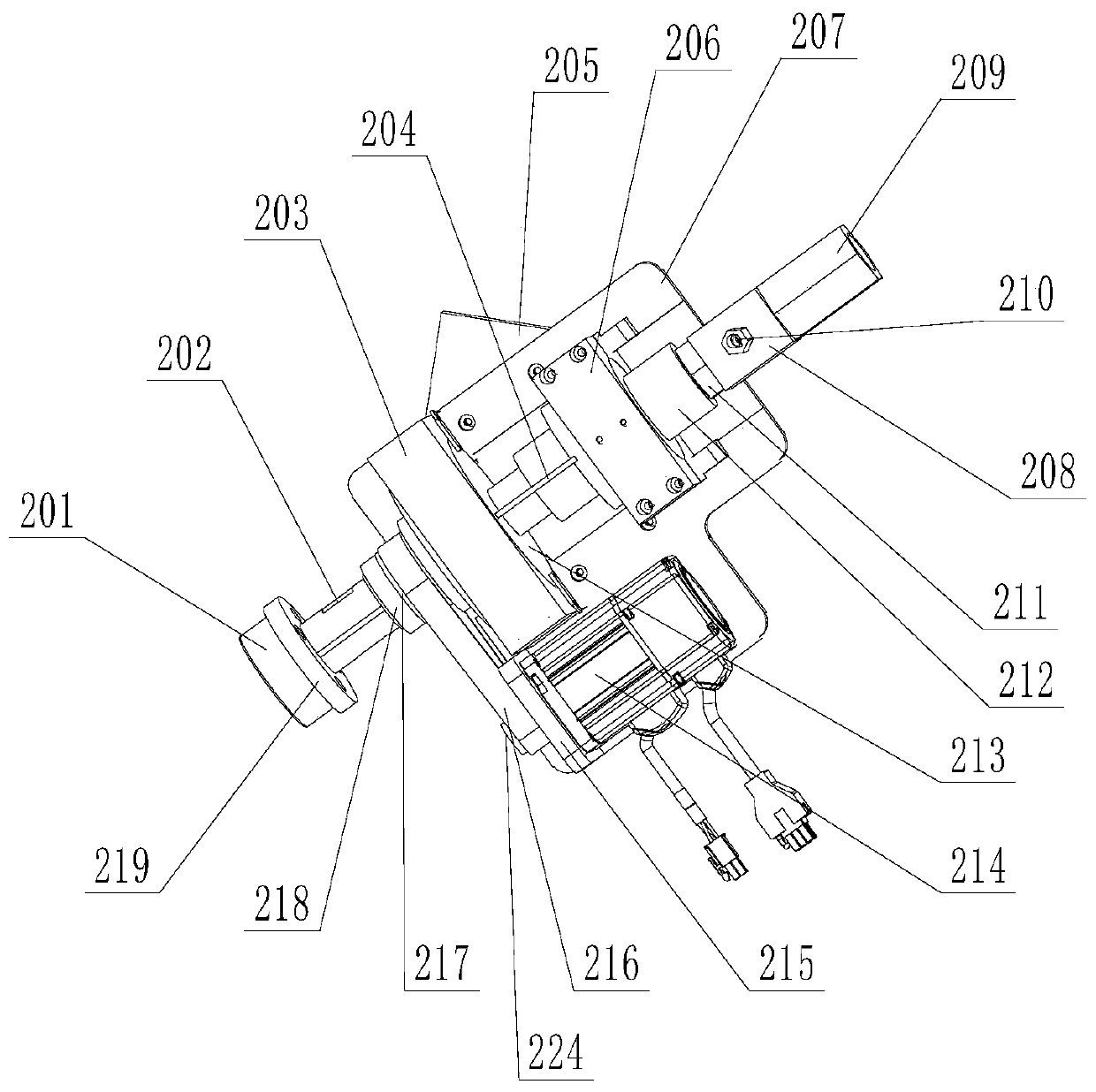

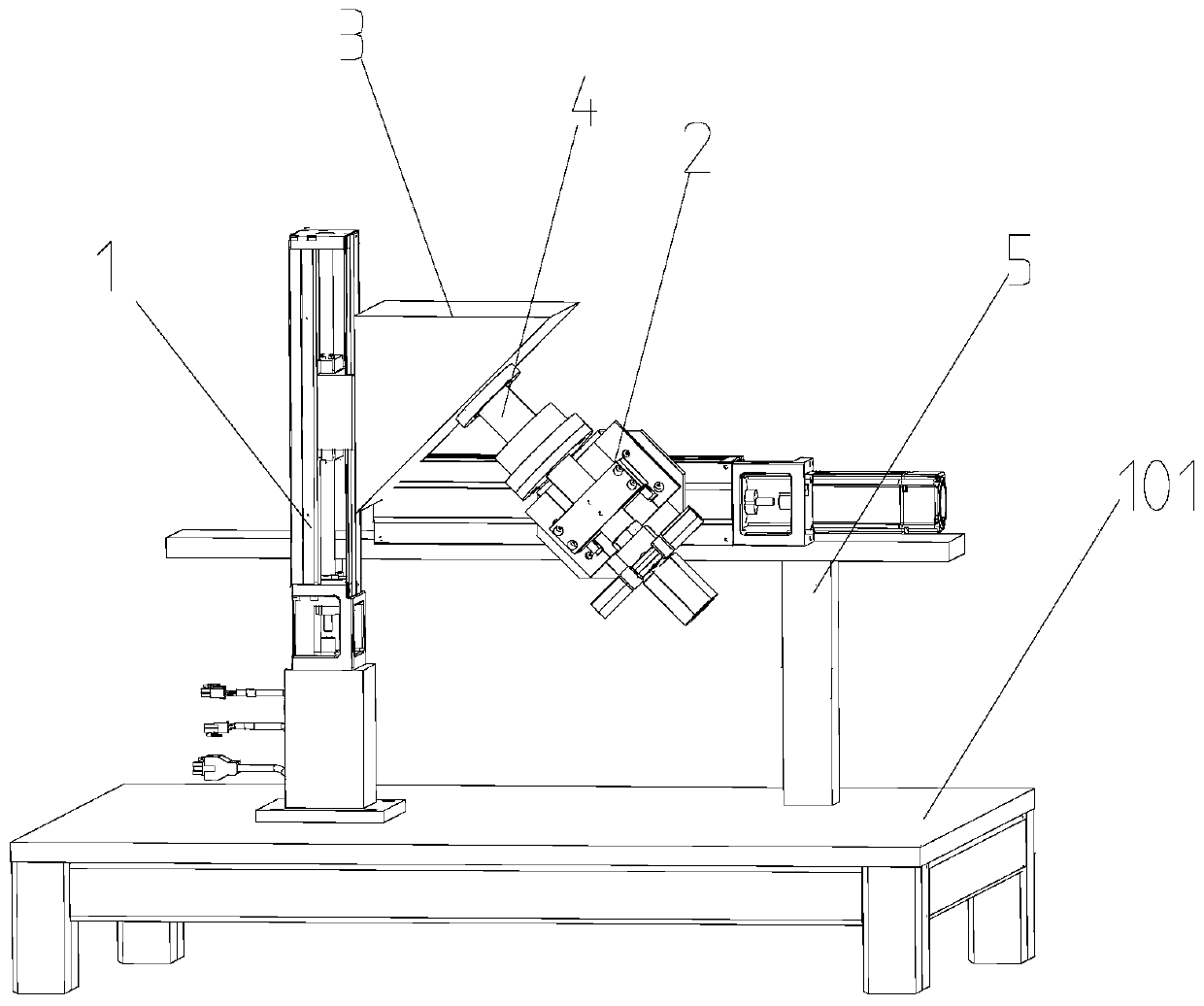

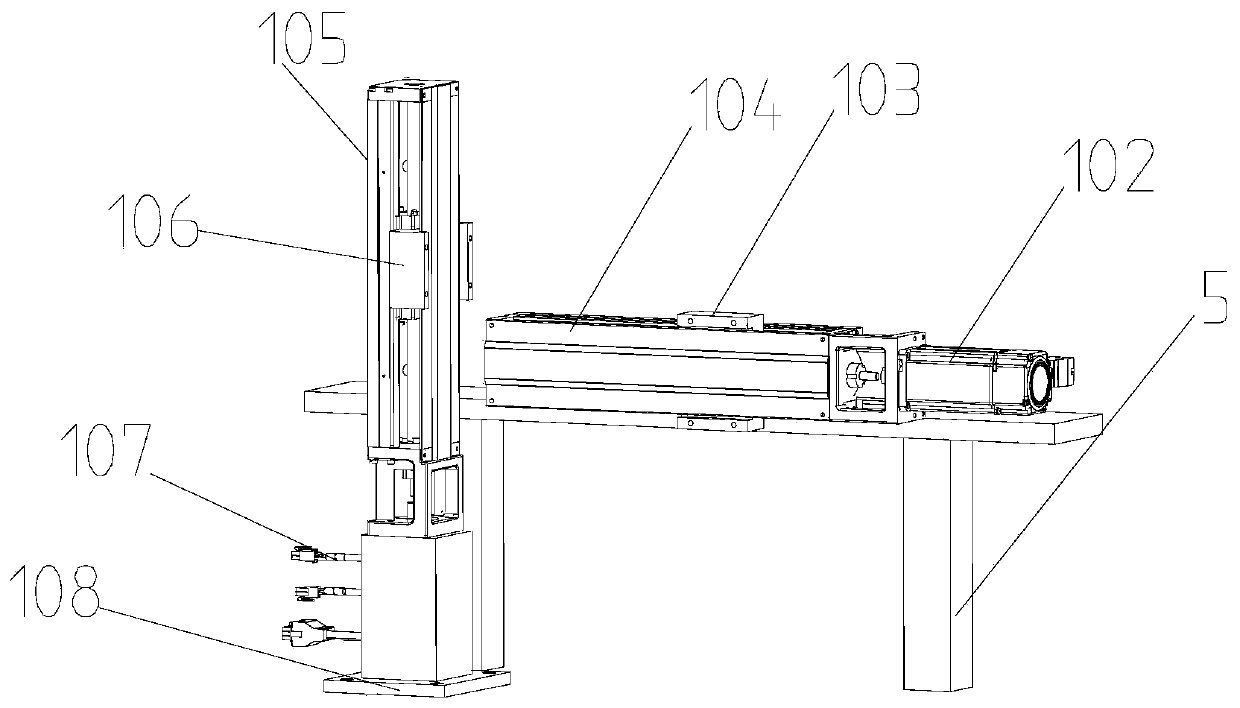

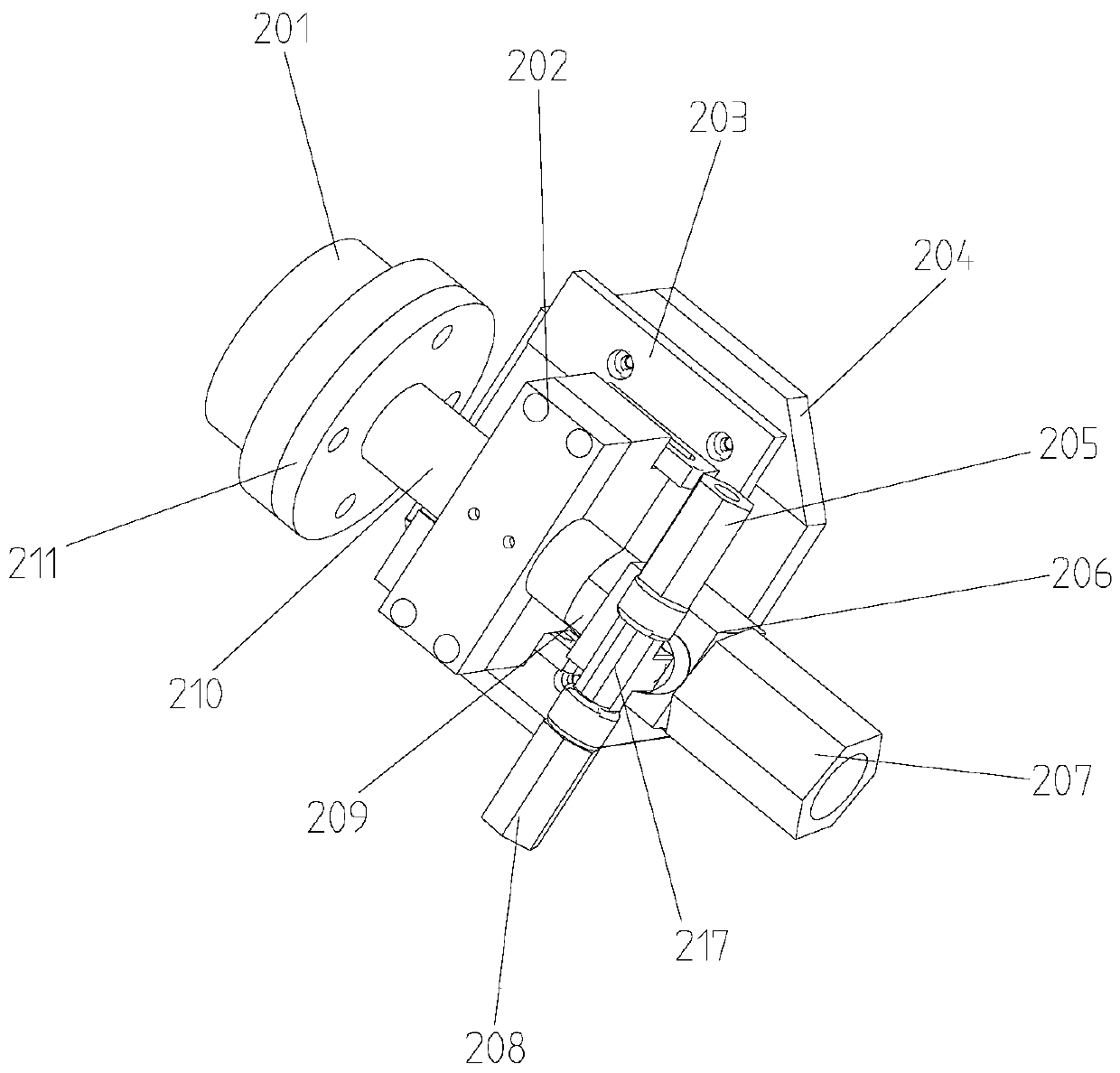

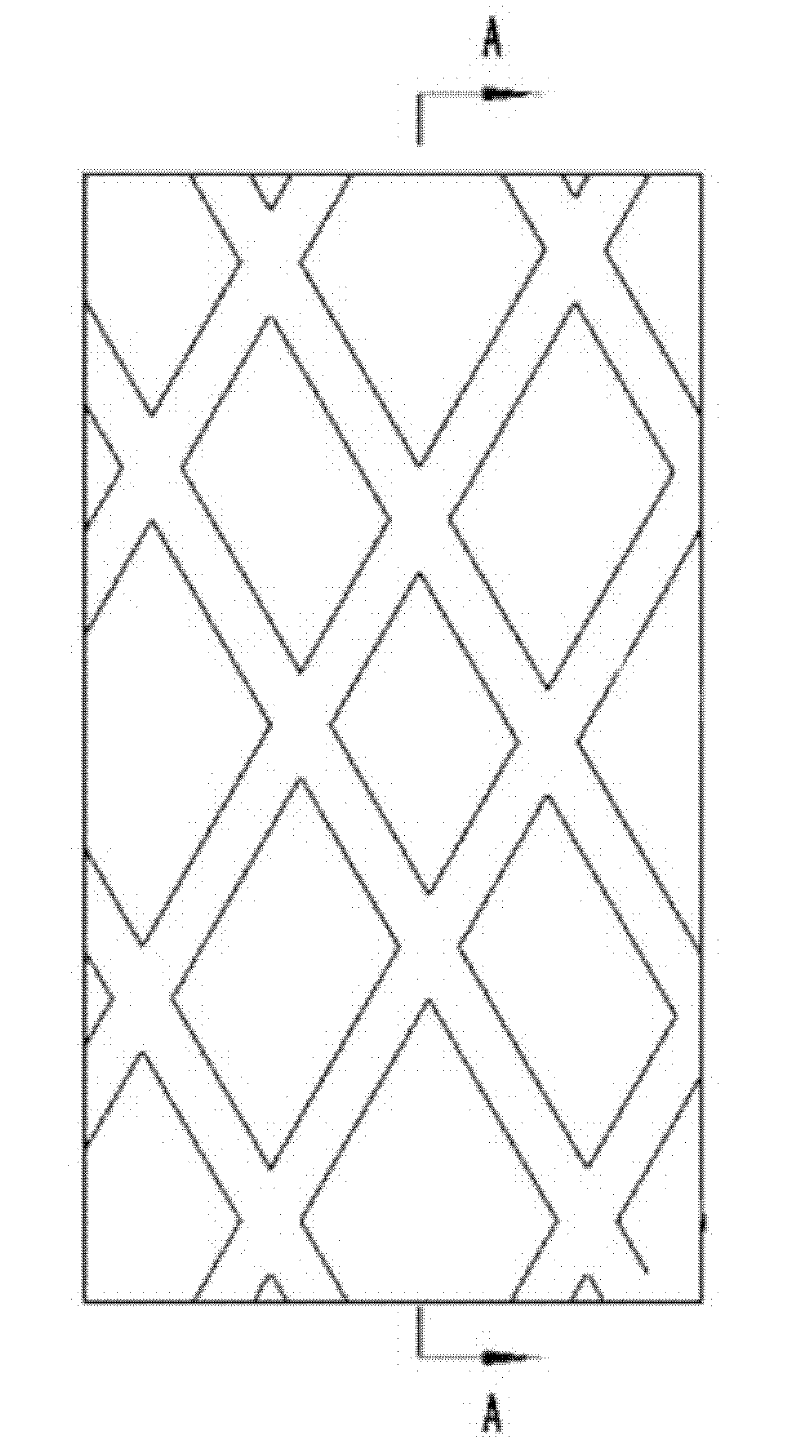

Negative-pressure polishing device and method for blind hole polishing for conductive workpieces

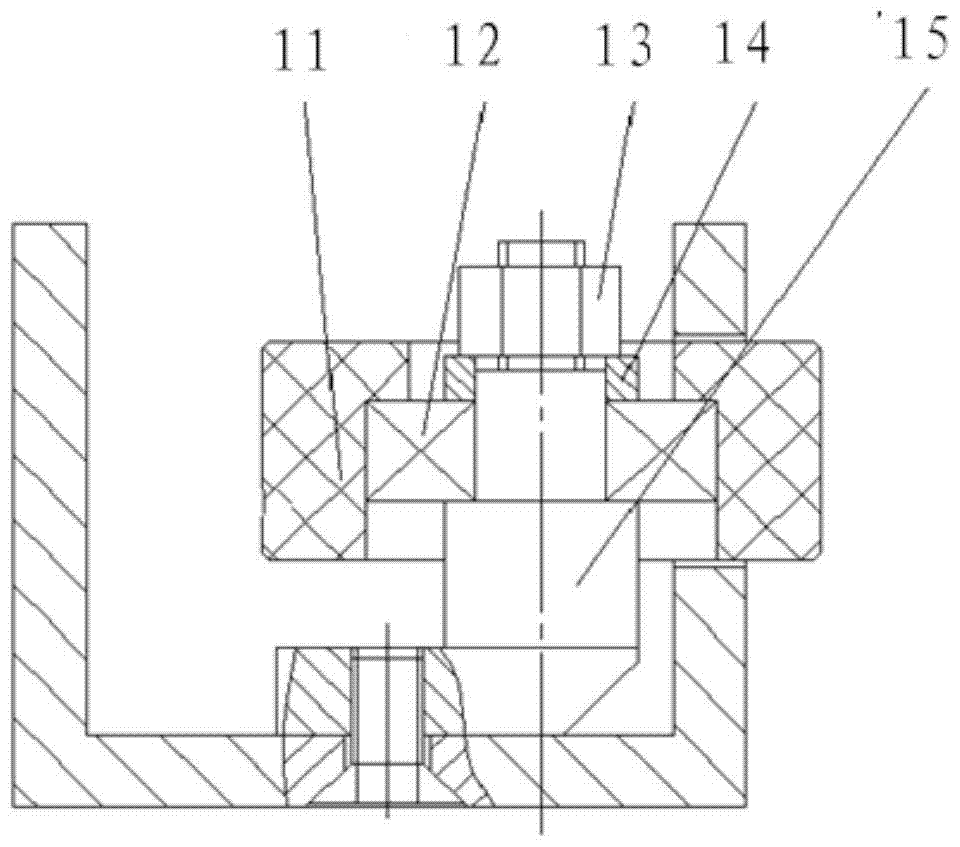

PendingCN110640614ASmooth entryNo mechanical deformationEdge grinding machinesGrinding carriagesParticle flowPolishing

The invention discloses a negative-pressure polishing device and method for blind hole polishing for conductive workpieces. The negative-pressure polishing device for blind hole polishing for the conductive workpieces comprises a workbench, a movable location device, a rotary flow channel device and a rotary magnetic field device, wherein the movable location device is installed on the workbench;the rotary flow channel device is installed on the movable location device; and the rotary magnetic field device is fixed to a part at the inclined lower part of the rotary flow channel device, of theworkbench. According to the negative-pressure polishing device and method for blind hole polishing for the conductive workpieces, blind hole of blind hole workpieces can be polished, and the blind holes of the workpieces to be polished are enabled to be in a negative-pressure state through air extraction, so that abrasive particle flow can much smoothly enters into the blind holes; the abrasive particle flow used in the negative-pressure polishing device and method is liquid metal abrasive particle flow, and metal particles in the liquid metal abrasive particle flow form good contact with thesurfaces of the workpieces to be machined under the action of a rotary magnetic field generated by a three-phase stator coil, micro-cutting is carried out, and mechanical deformation on the surfacesof the blind holes of the workpieces to be machined is avoided; and higher polishing efficiency and better effect are achieved, and the micro-cutting is carried out.

Owner:ZHEJIANG UNIV OF TECH

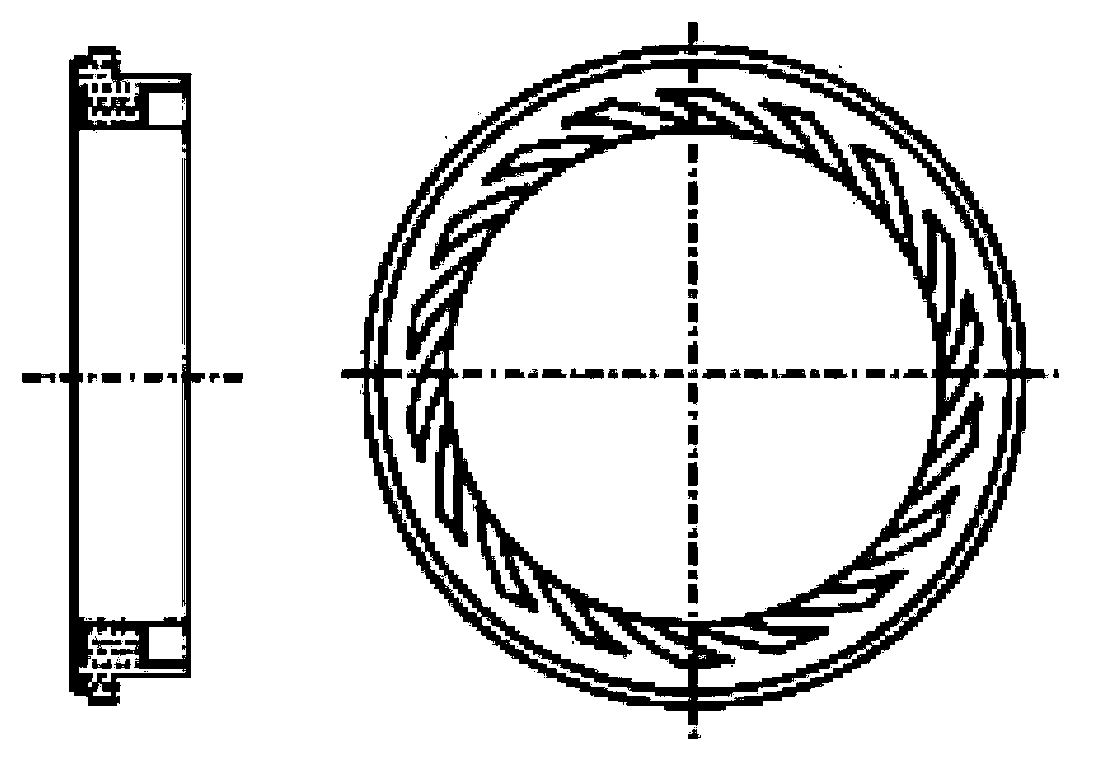

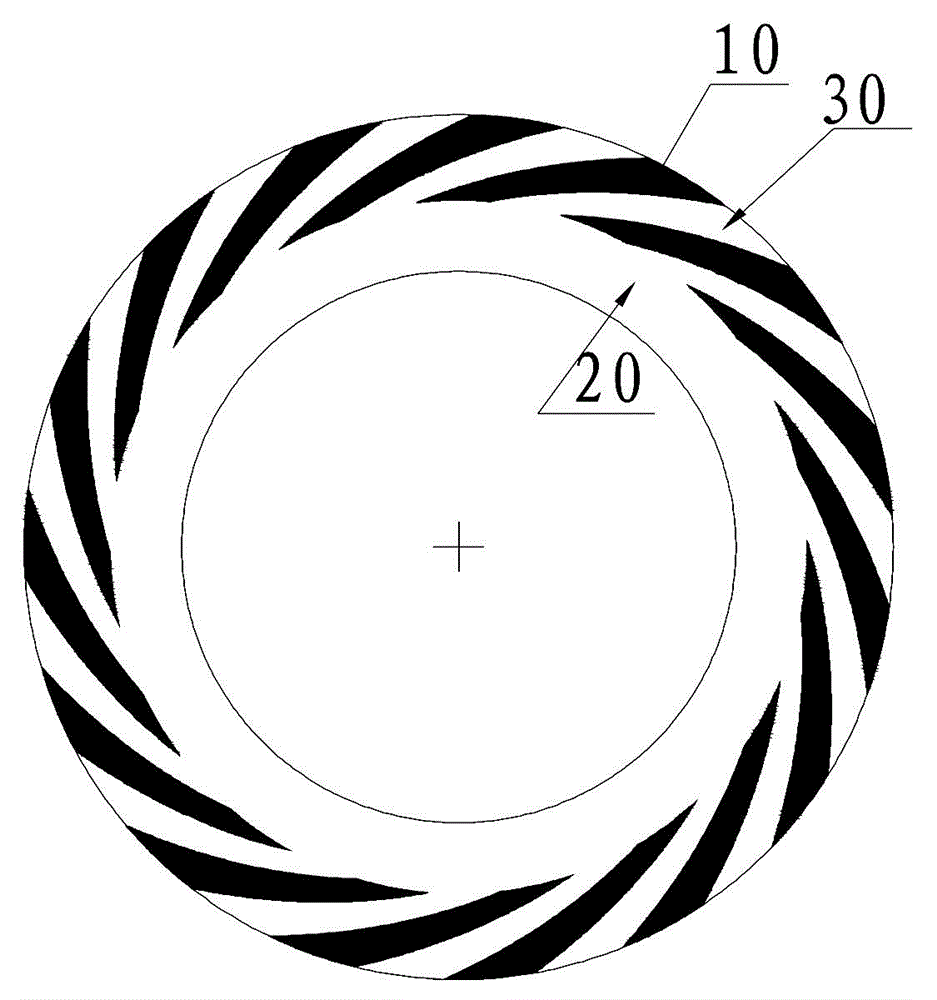

Silicon carbide friction pair used for non-contact mechanical seal and manufacturing method thereof

InactiveCN103671928AReduce intensityThe effect of uniform dischargeEngine sealsLaser processingCarbide

The invention relates to a silicone carbide friction pair used for a non-contact mechanical seal and a manufacturing method of the silicon carbide friction pair. Concave points or geometry-shaped grooves are evenly distributed in the friction end face of the silicon carbide friction pair used for the mechanical seal, and the depth of the groove can be evenly changed gradually. The concave points or the geometry-shaped grooves evenly distributed in the friction end face of the silicon carbide friction pair are manufactured through laser processing.

Owner:辽宁天泽产业集团机械制造有限公司

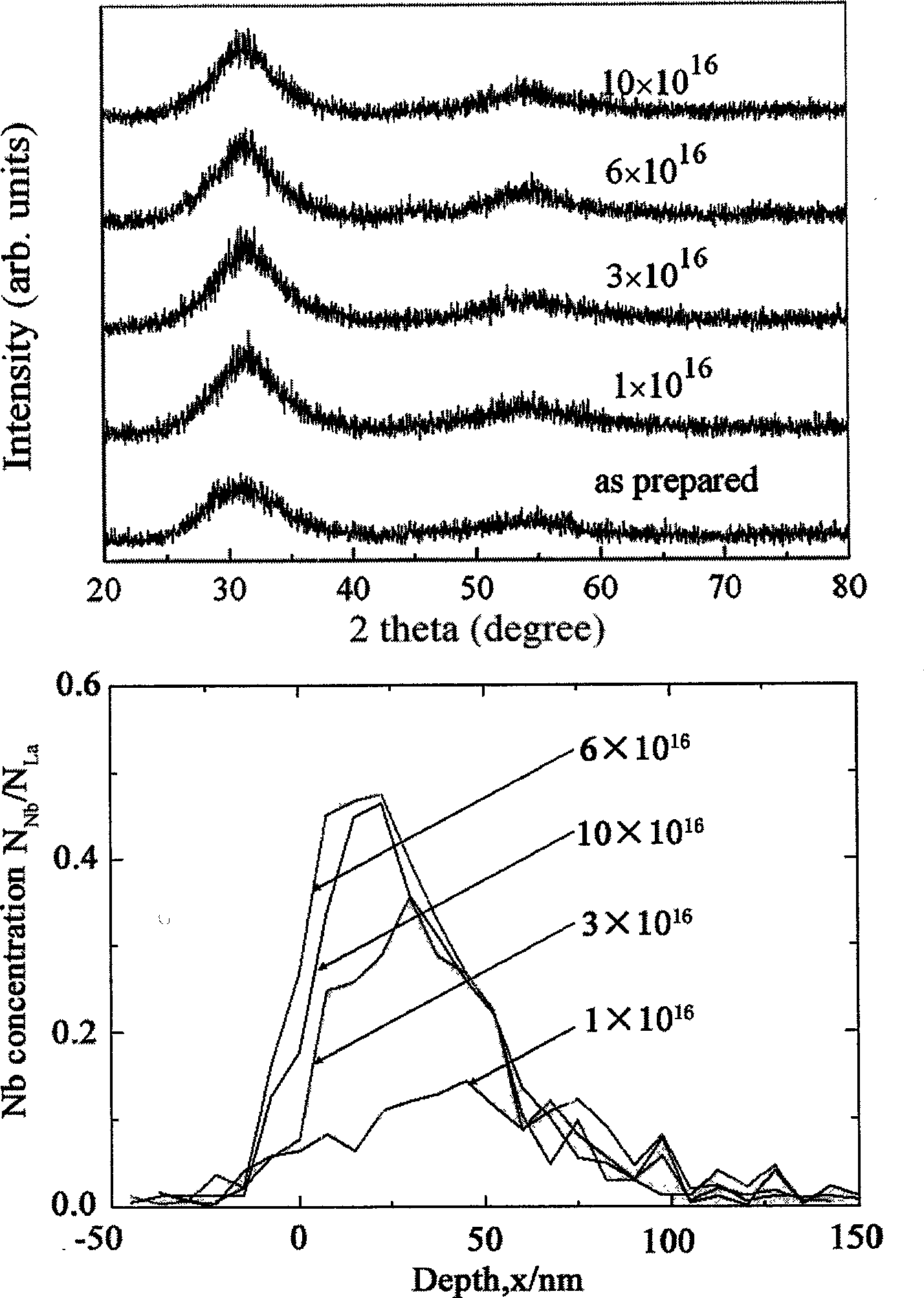

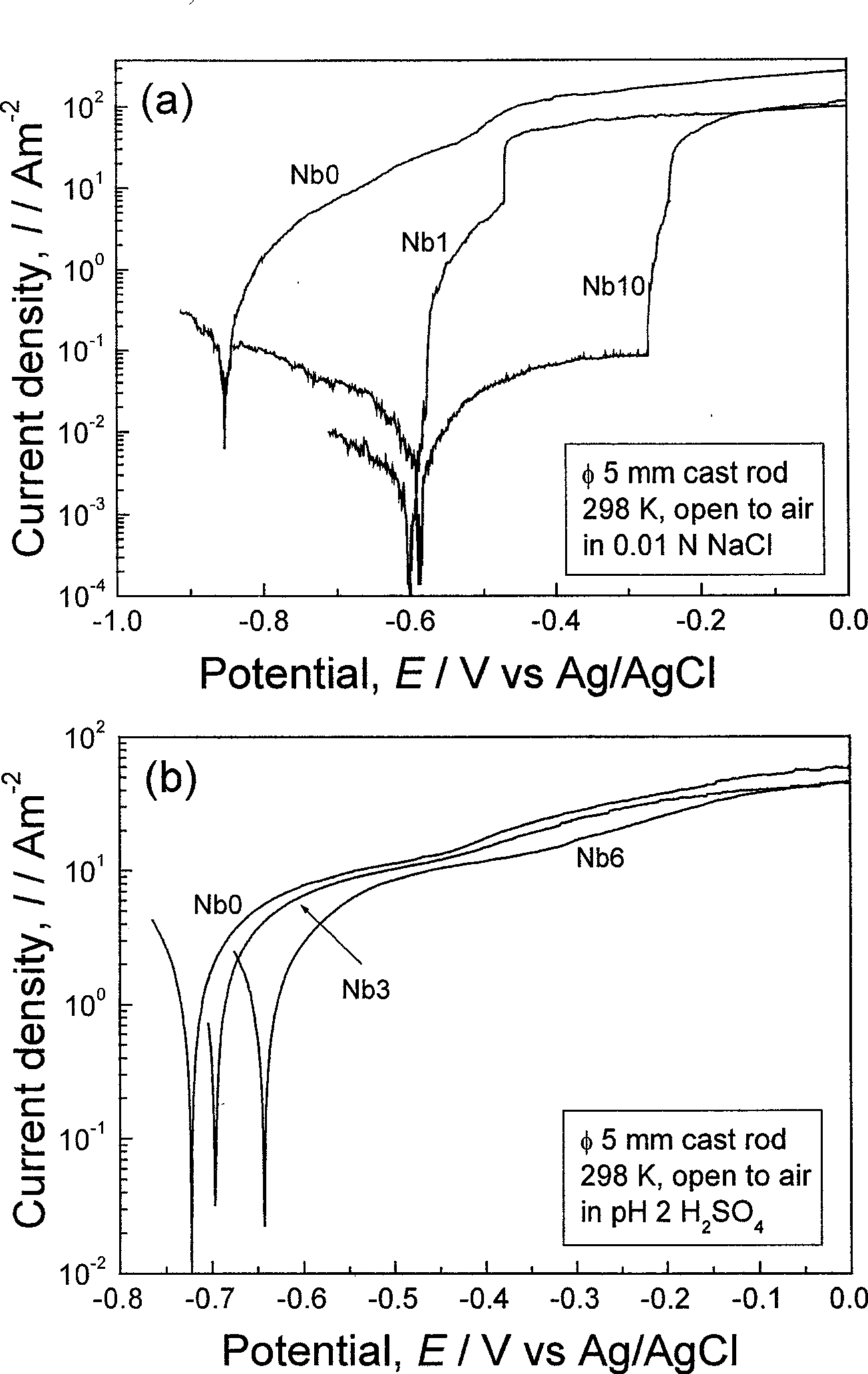

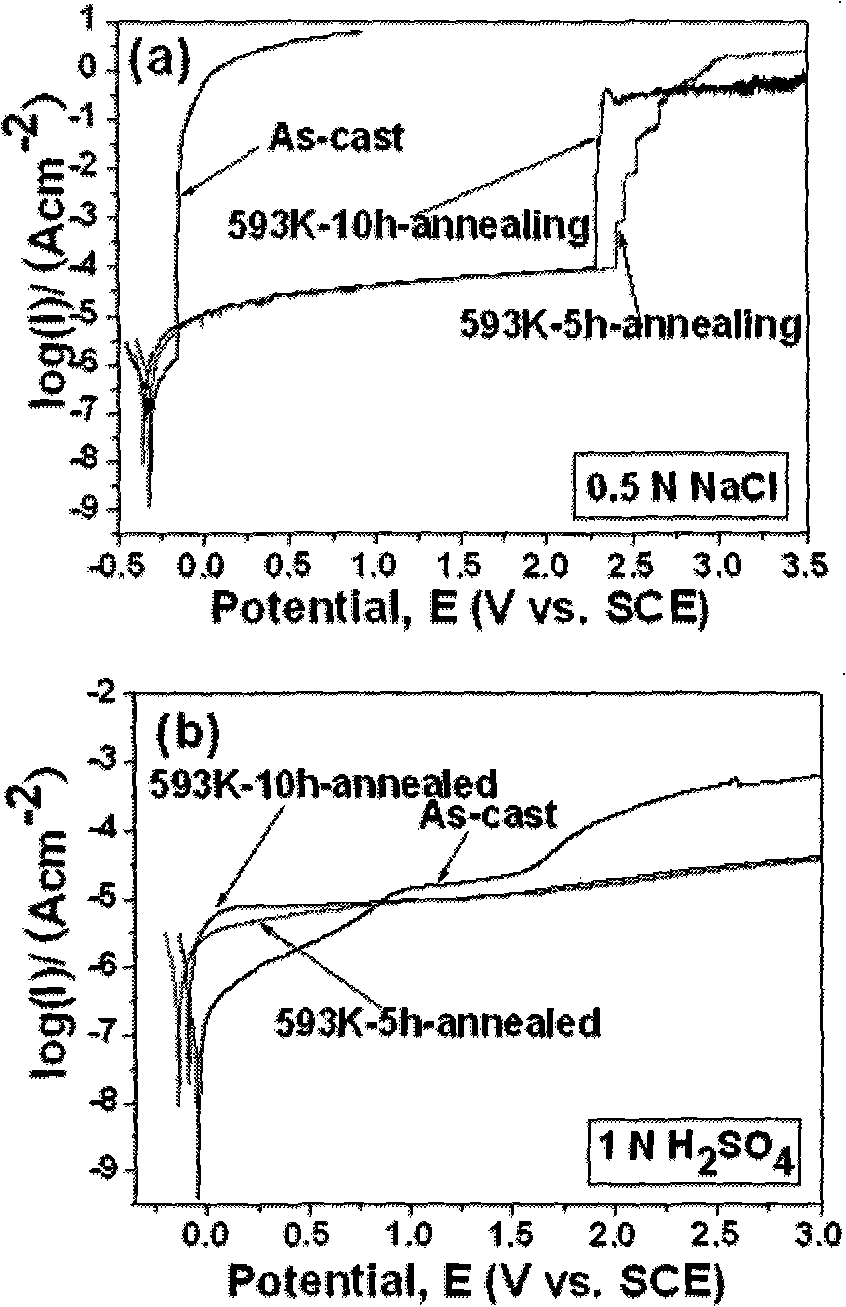

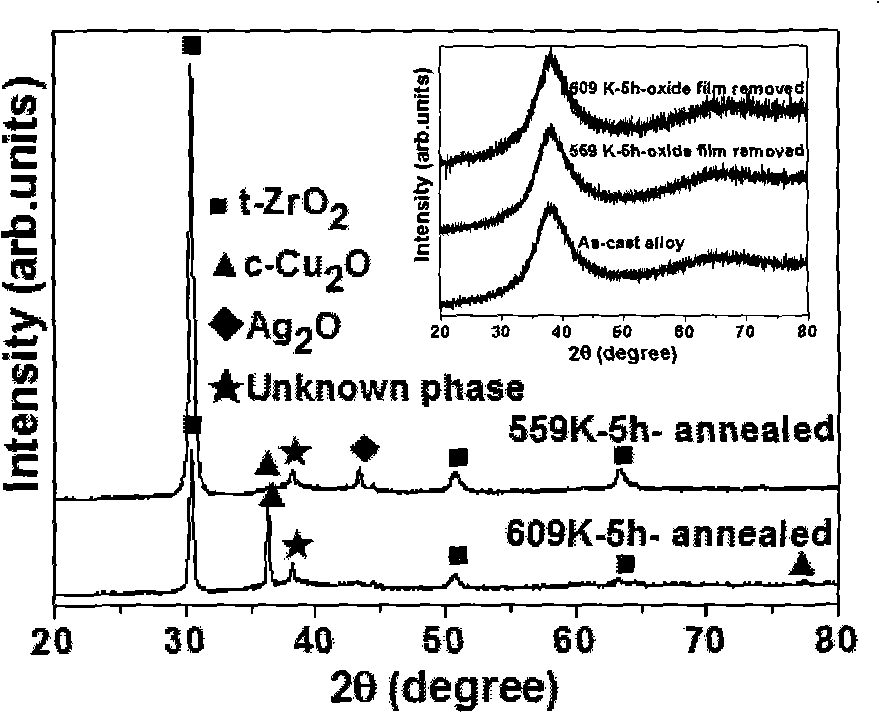

Ion implantation process to raise anticorrosion performance of lumpy amorphous alloy

InactiveCN100489152CImprove corrosion resistanceSuitable for finishingVacuum evaporation coatingSputtering coatingAlcoholVacuum chamber

Owner:ZHEJIANG UNIV

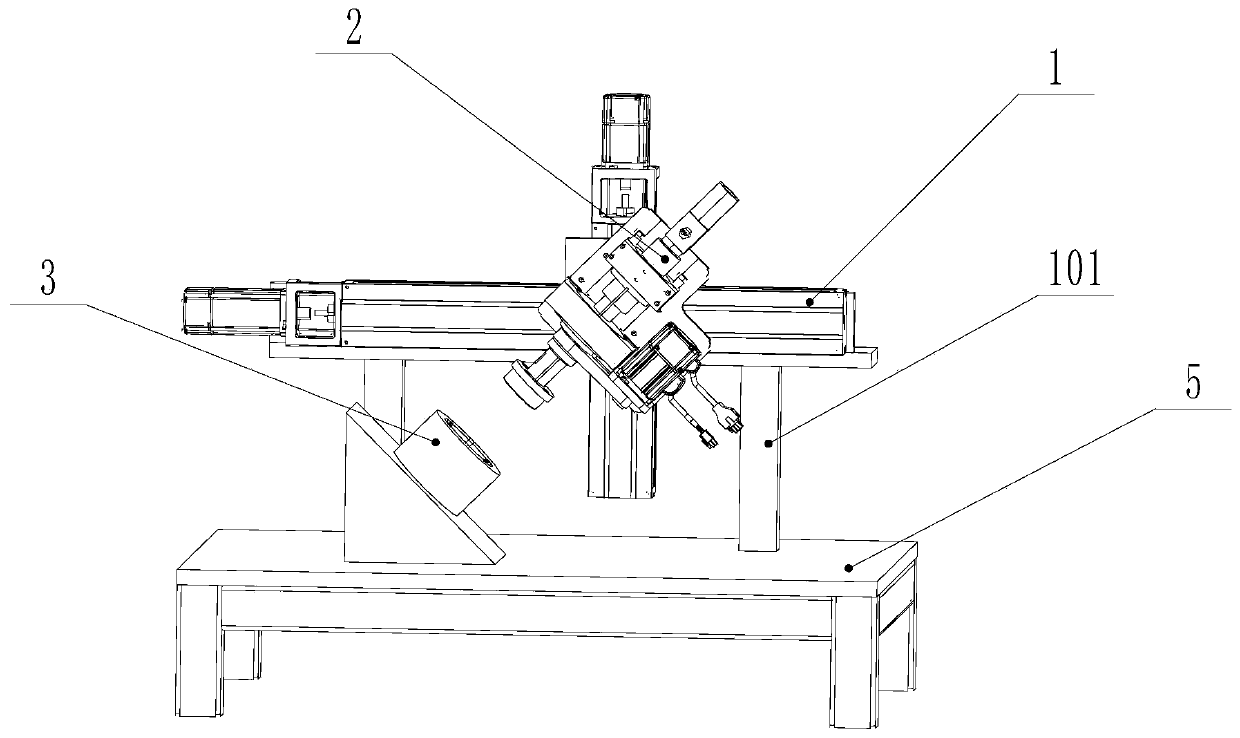

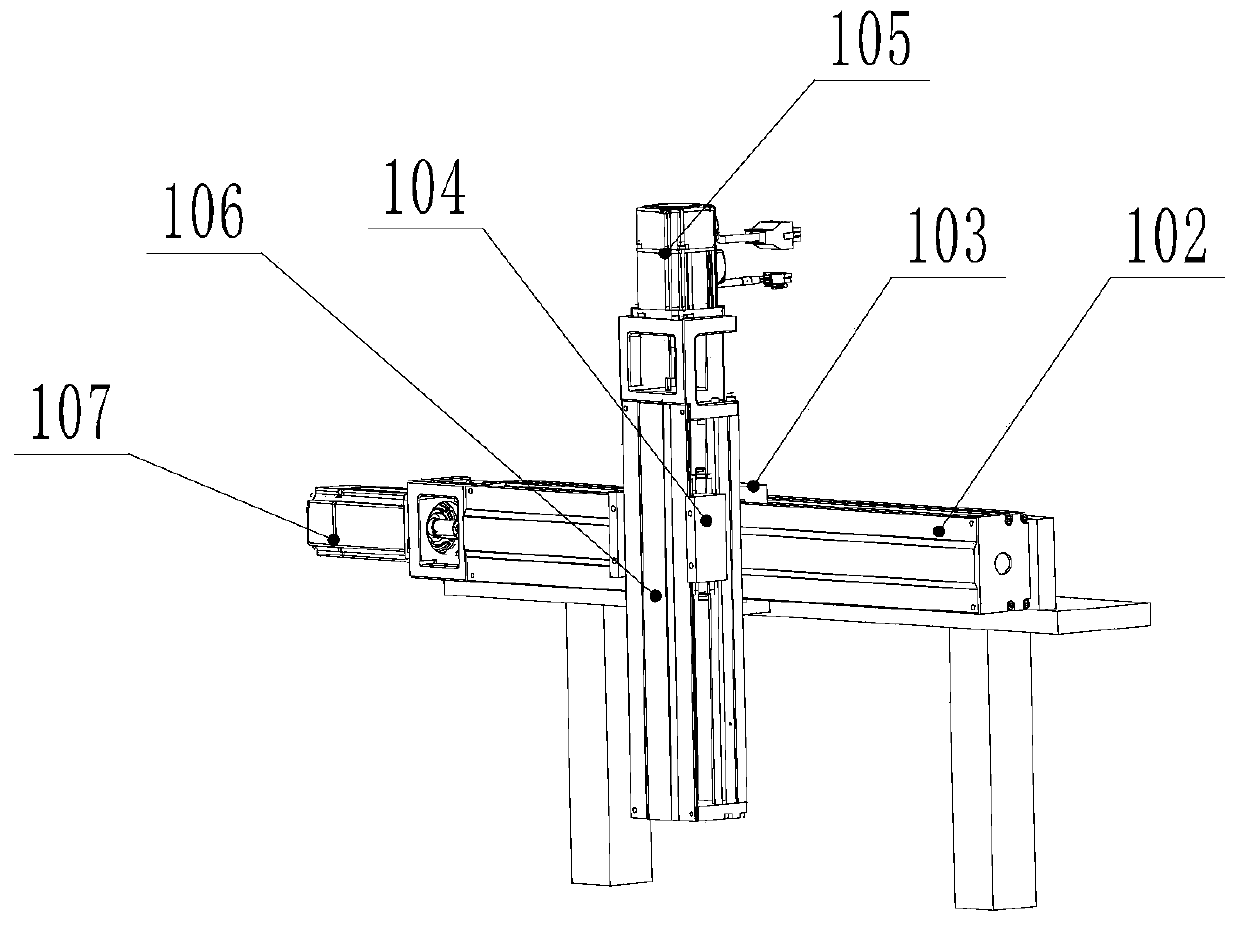

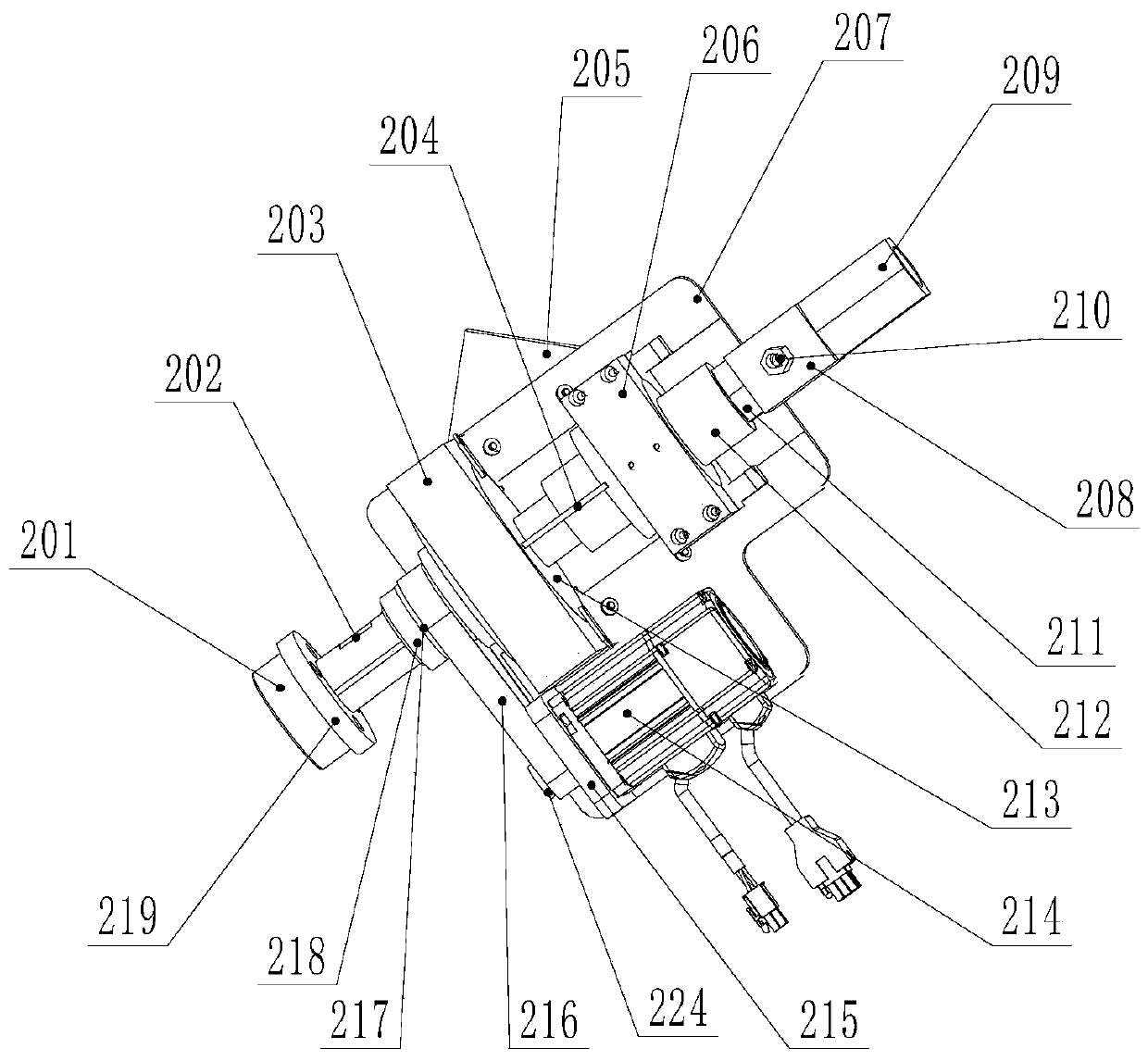

Compressed air exhausting polishing device and compressed air exhausting polishing method for polishing blind hole

PendingCN110605655ASmooth entryNo mechanical deformationEdge grinding machinesPolishing machinesParticle flowEngineering

The invention discloses a compressed air exhausting polishing device and a compressed air exhausting polishing method for polishing a blind hole. The compressed air exhausting polishing device comprises a movable positioning assembly, a runner assembly and a supporting and clamping assembly, wherein the movable positioning assembly comprises a worktable, a horizontal module mounting rack, a horizontal linear module, horizontal module driving motors, a vertical linear module and a vertical module driving motor; the supporting and clamping module comprises a supporting block, a secondary clamping head and a vertical mounting base; the runner assembly comprises a main clamping head, a hollow runner fixing seat, a runner fixing plate, a sliding rail connecting plate, an exhausting port one-wayvalve, a gas-liquid abrasive particle flow connector, an abrasive particle flow inlet valve, a compressed air port one-way valve, a runner connector, a hollow runner, a ring flange and a main clamping head O-shaped ring. The compressed air exhausting polishing device can polish blind holes of blind hole workpieces; and blind holes of to-be-polished workpieces are positioned in a negative pressurestate by exhausting air, so that abrasive particle flows can enter the blind holes more smoothly.

Owner:ZHEJIANG UNIV OF TECH

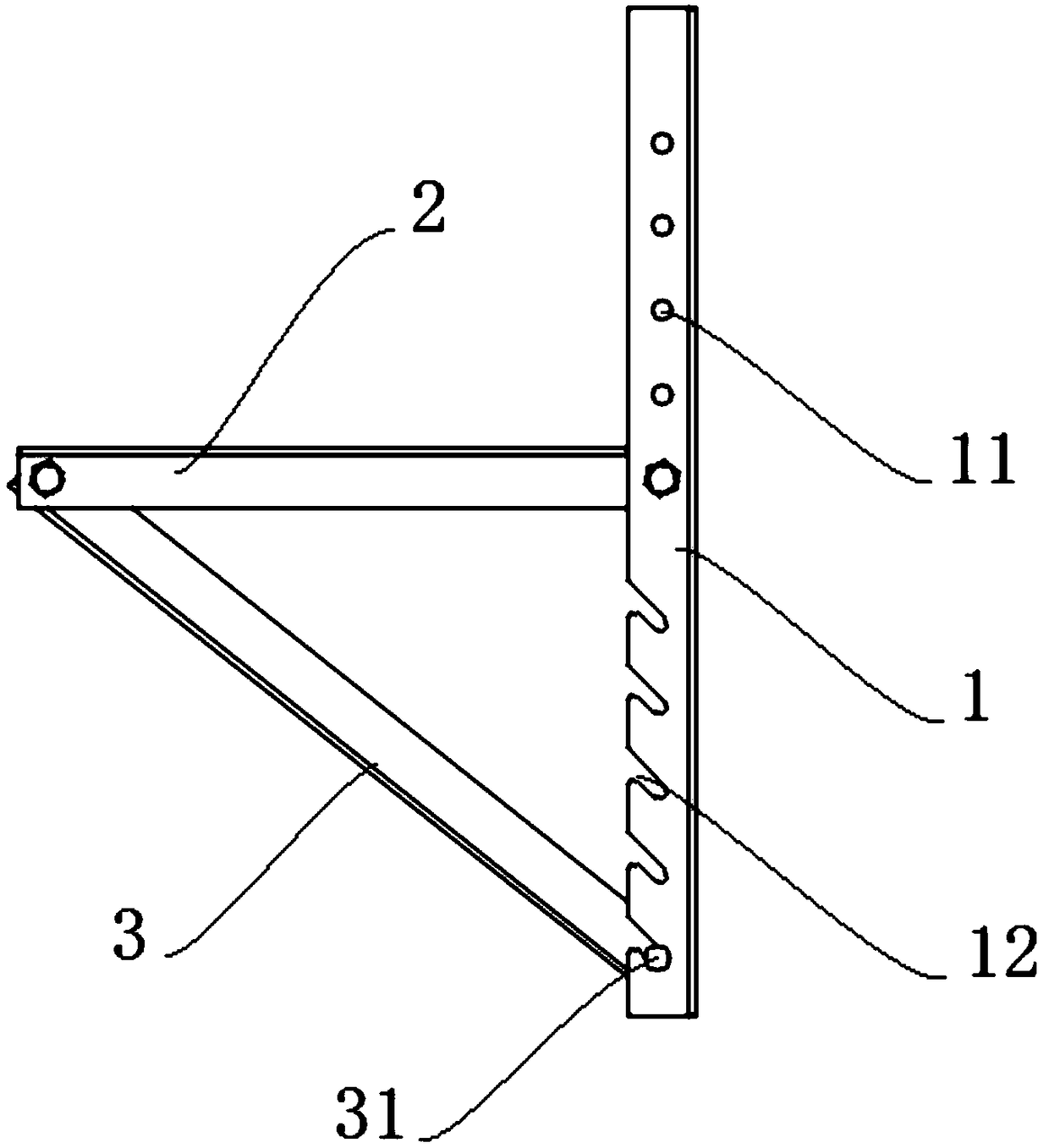

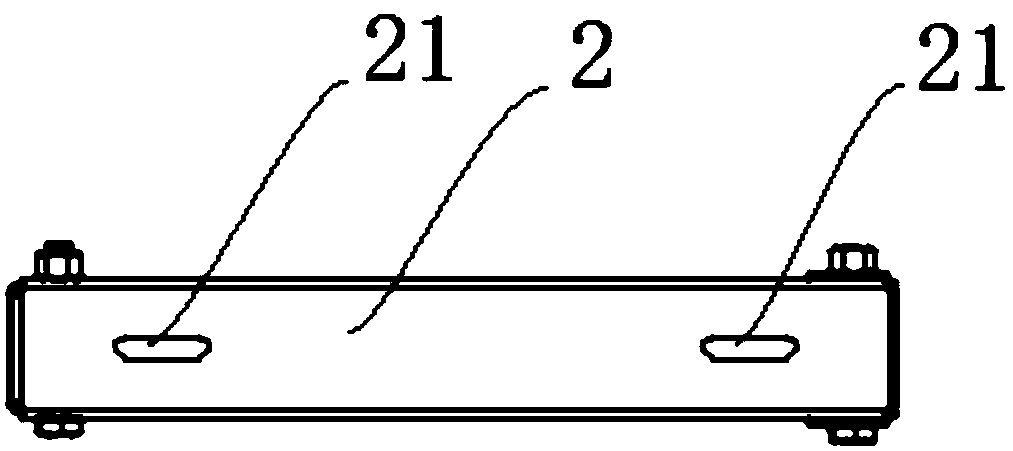

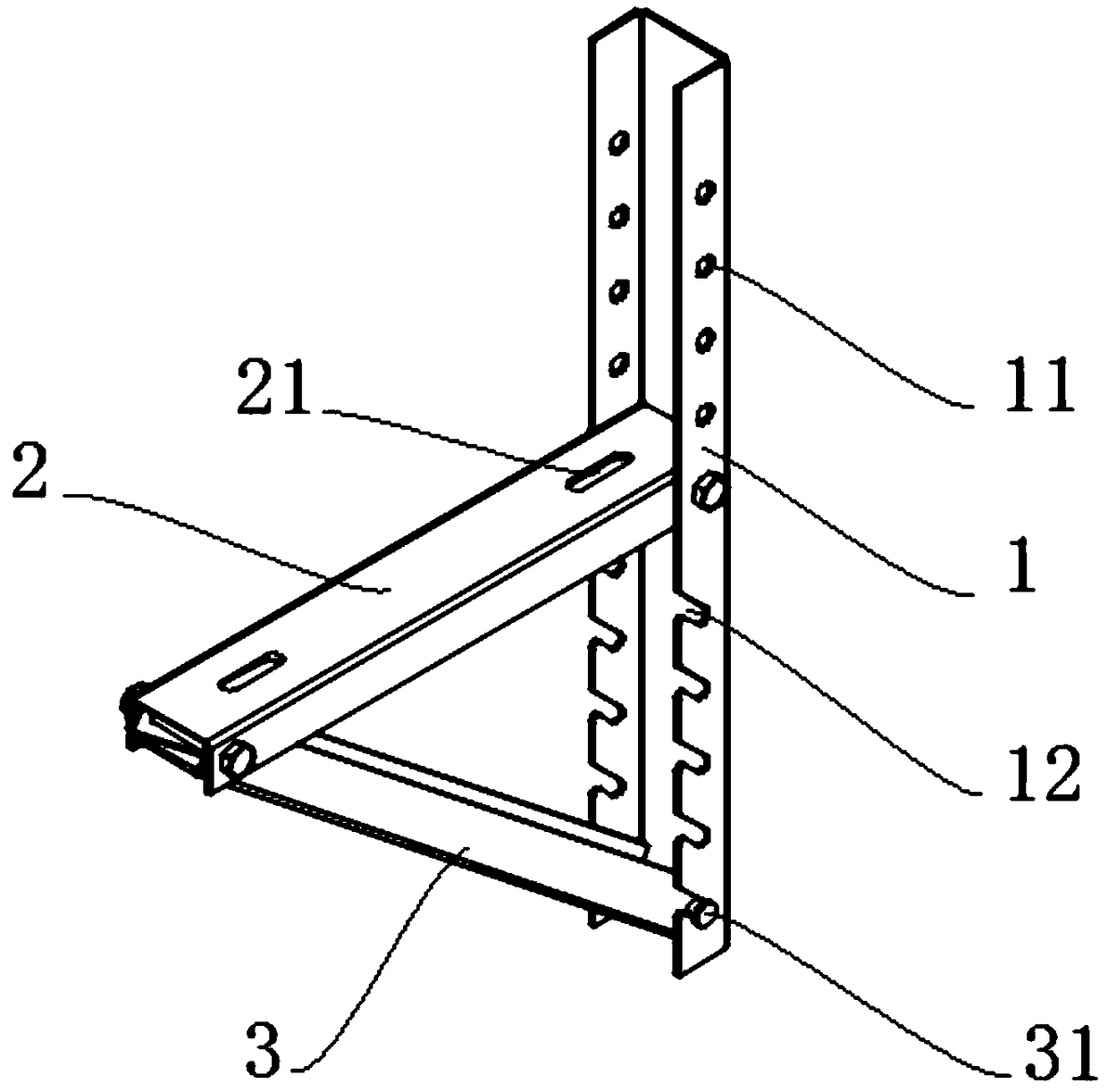

Mounting frame suitable for overloading type air conditioner external unit

InactiveCN108731130AStable structureNo mechanical deformationLighting and heating apparatusAir conditioning systemsEngineeringHeavy weight

The invention discloses a mounting frame suitable for an overloading type air conditioner external unit. The mounting frame includes a fixing frame; the fixing frame is of a [-shaped structure, the fixing frame is perpendicularly connected with a mounting frame body for mounting the air conditioner external unit, and the mounting frame body is of a [-shaped structure; mounting holes are formed inthe two side walls of the end of the mounting frame body, a plurality of mounting holes connected with the mounting frame body are evenly formed in the upper portion of the fixing frame body, a plurality of inserting grooves are formed in the lower portions of the fixing frame, the mounting holes in the fixing frame are connected with the mounting holes in the other end of the mounting frame bodythrough screws, and a supporting frame is further connected between the fixing frame and the mounting frame body; and a mounting hole connected with the other end of the mounting frame body through the bolts is formed in one end of the supporting frame, and a pin shaft matched with the inserting grooves of the fixing frame is arranged at the other end of the supporting frame. According to the mounting frame suitable for the overloading type air conditioner external unit, the groove steel material is used as the bearing structure of the mounting frame, the structure of the mounting frame adopting the material is firm, the heavy weight air conditioner external unit can be lifted, and the mechanical deformation of the mounting frame cannot take place during the longtime use.

Owner:四川原皓源环境工程有限公司

Observation method for fluid precision finishing of surfaces of micro-structures of molds

ActiveCN102528661BEffective filteringAvoid difficultiesGrinding feed controlMicro structureParticle flow

An observation method for fluid precision finishing of surfaces of micro-structures of molds is based on a fluid flowing similar simulation method. A tiny mold structural surface is proportionally magnified, flowing states of sparse abrasive particle flows in tiny constraint flow channels are simulated, real-time image data in the flow channels are acquired and processed, and a distribution state, movement rules, typical flowing state characteristics and development trend of the sparse abrasive particle flows in environments of the tiny constraint flow channels are obtained; and experiments show that properties of forces stressed at various points in a flow channel model and properties of forces stressed at various corresponding points in a mold tiny constraint flow channel prototype are identical on the premise of meeting requirements of geometric similarity and kinematic similarity, the forces are proportional, a proportion constant keeps unchanged to optional corresponding points in two flow fields, and fluid dynamic properties of the two flow fields meet requirements of second law of flow similarity. The invention further provides an observation device for fluid precision finishing of surfaces of micro-structures of molds. The observation method and the observation device have the advantages that fluid finishing conditions and states for the surfaces of the micro-structures of molds can be well simulated, operation is simple, convenient and feasible, and universality is good.

Owner:ZHEJIANG UNIV OF TECH

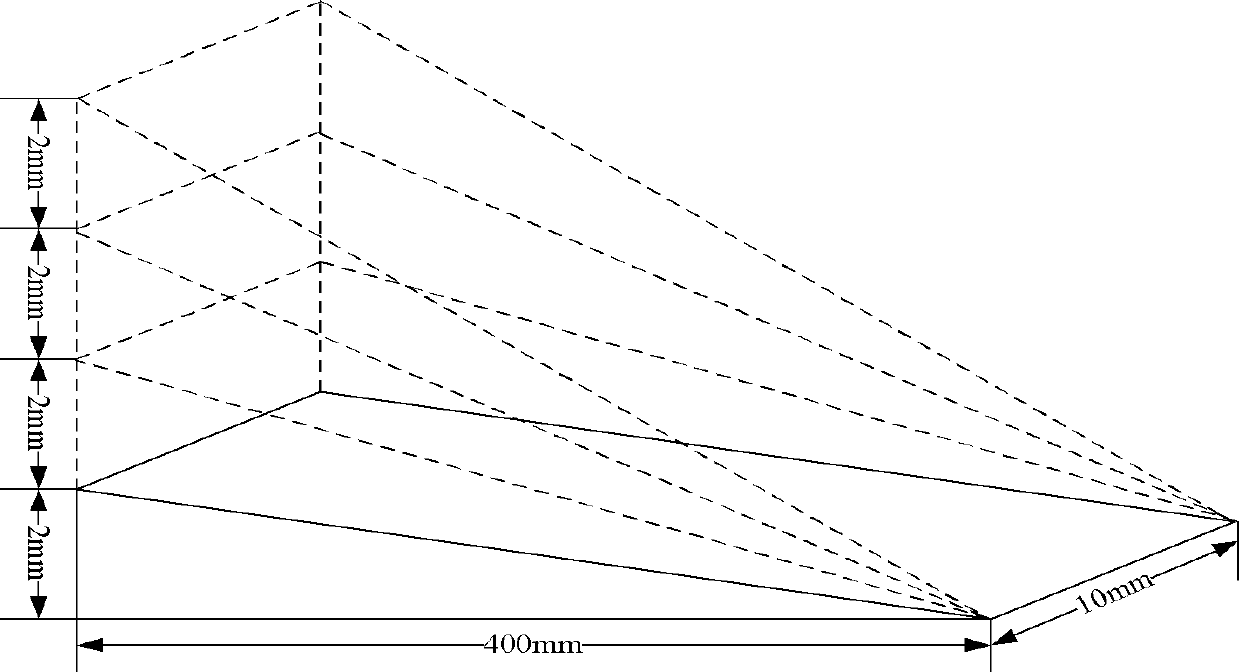

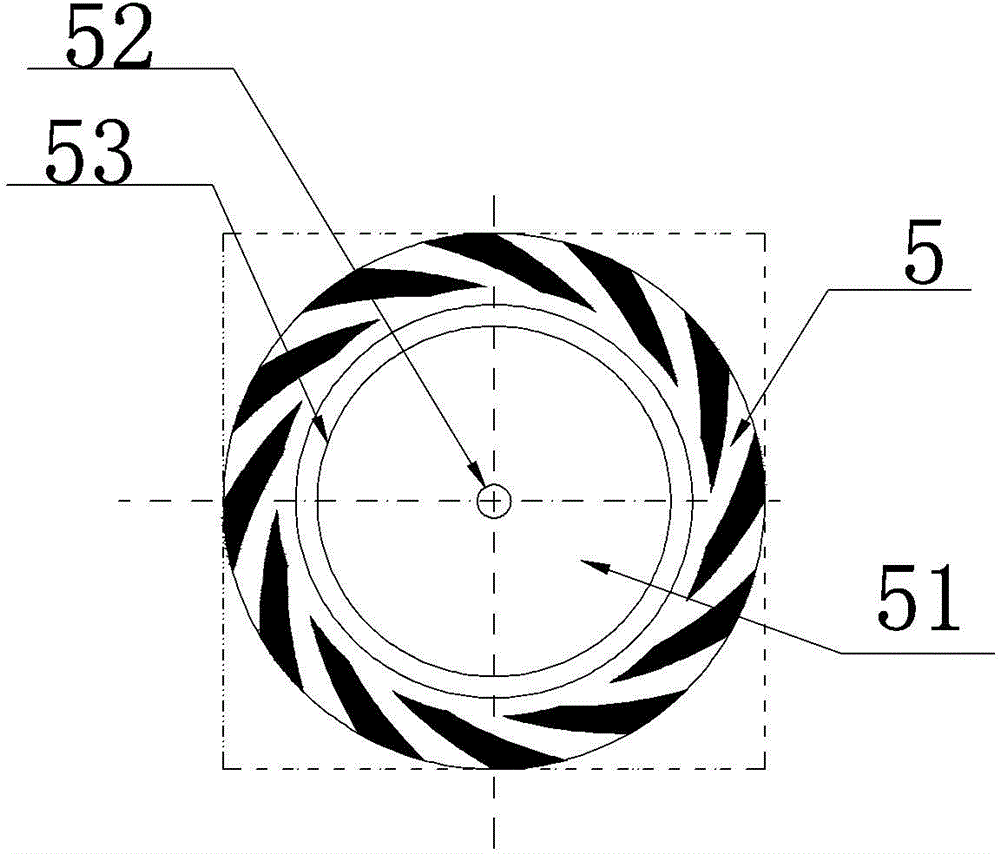

Laser grooving machining method of dry gas seal spiral groove

ActiveCN102990308BHigh speedNo mechanical deformationLaser beam welding apparatusMachined surfaceDry gas seal

The invention discloses a laser grooving machining method of a dry gas seal spiral groove, wherein a machining device is a 20W optical fiber marking machine. The machining method comprises the following steps of: (1) designing the shape of the dry gas seal spiral groove by special drawing software; (2) positioning, wherein a ring with outer diameter being is less than or equal to 100mm is positioned in a marking range, and a ring with outer diameter being more than 100mm is positioned by a groove-to-groove machining method; and (3) grooving which is implemented by selecting appropriate marking parameters of focal length, marking speed, effective vector step length, power, frequency and the like. The laser grooving method has the characteristics of having a wide application range, being applicable to machining surfaces of different materials and different shapes, ensuring no mechanical deformation of workpieces, no pollution, high speed, high accuracy, good repeatability, high automation degree, and the like, is used for machining logarithm spiral grooves, rectangular grooves and dual-trapezoid grooves, is especially suitable for machining shallow grooves, and has obvious effects of improving product quality and machining efficiency.

Owner:丹东市东升石化设备有限公司

Laser texturing method for plate welding machine box

InactiveCN102489881AReduce labor intensityNo mechanical deformationLaser beam welding apparatusEngineeringMaterials processing

A laser texturing method for a plate welding machine box belongs to the technical field of material processing engineering, and is high in processing efficiency and short in processing cycle. The laser texturing method includes the steps: firstly, coating a protective layer on the surface of a part; secondly, selecting laser parameters of a laser device according to the thickness of the protective layer, performing parameter test cutting on a process side of the part, judging that the parameters are qualified if the protective layer is completely cut through without exposing base materials, judging that the parameters are unqualified if the protective layer is completely cut through while base materials are exposed and scratched, decreasing laser power and performing test cutting again until finding qualified parameters at the moment, judging that the parameters are unqualified if the protective layer is incompletely cut through, and increasing the laser power and performing test cutting again until finding qualified parameters at the moment; and thirdly, performing formal cutting according to the determined laser parameters in test cutting.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method and device for laser welding foil and tab

ActiveCN108465933BImprove brightness effectImprove directionalityCell component detailsLaser beam welding apparatusLaser processingEngineering

The invention discloses a method and device for laser welding a foil and a tab. At least one layer of foil is placed in front of the tab as a laser absorbing surface; then the foil and the tab are adsorbed or pressed together; The focus of the laser is set on the tab, and the foil and the tab are welded. Non-contact laser welding is used to replace the traditional ultrasonic contact welding. The foil and tab are not affected by external forces, and the processing is stable. The efficiency of laser processing is high, and the multi-pulse spot processing of laser can be used.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Laser dismantling equipment with outer metal shell and its use method

ActiveCN108465943BImprove dismantling efficiencyAvoid meltingLaser beam welding apparatusLaser transmitterControl system

Owner:武汉翔明激光科技有限公司

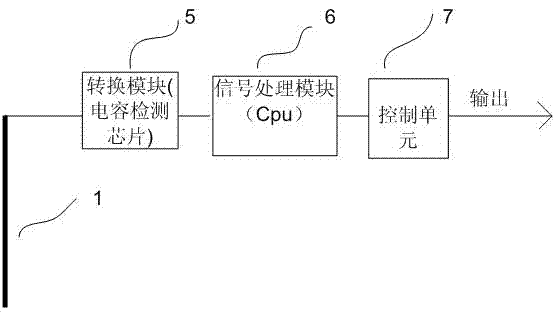

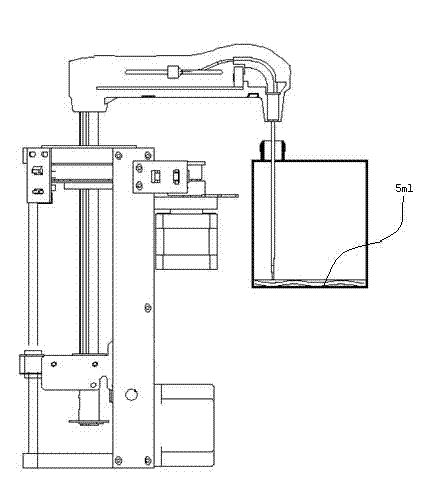

Device and method for remaining amount of reagent

ActiveCN102288260BImprove anti-interference abilityLower the thresholdLevel indicators by physical variable measurementCurrent voltageCharge and discharge

Owner:DIRUI MEDICAL TECH CO LTD

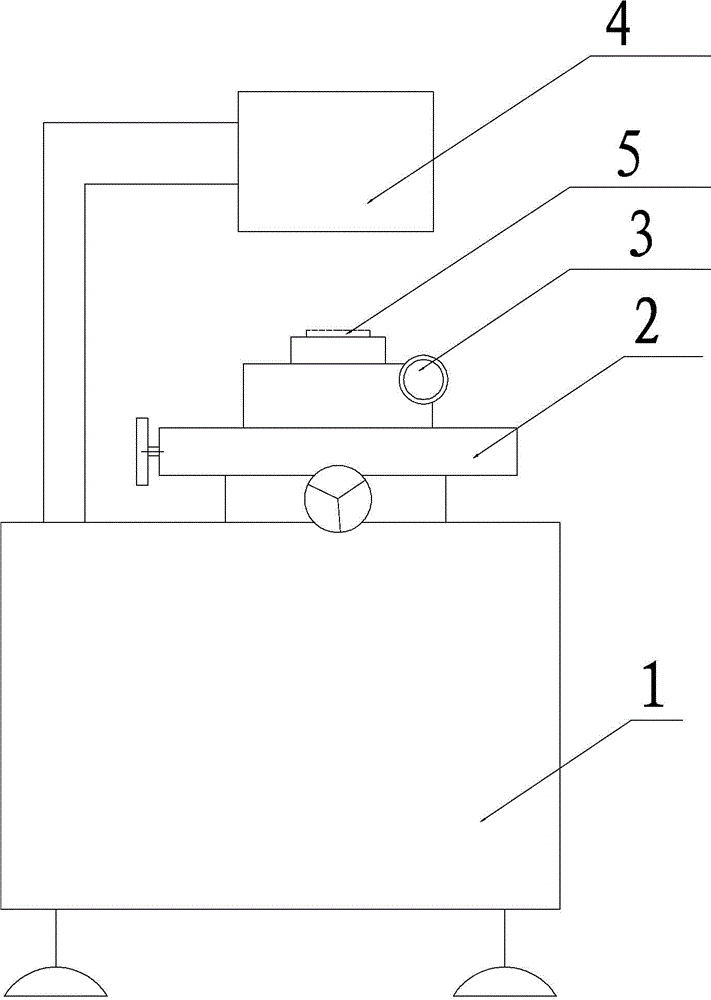

Device for conducting blind hole polishing of conductive workpiece by using liquid metal and method thereof

PendingCN110614543ASmooth entryNo mechanical deformationGrinding carriagesGrinding work supportsParticle flowMagnet

The invention discloses a device for conducting blind hole polishing of a conductive workpiece by using liquid metal and a method thereof. The device comprises a workbench, a moving positioning device, a rotating runner device and a rotating magnetic field device, wherein the moving positioning device is mounted on the workbench, the rotating runner device is mounted on the moving positioning device, and the rotating magnetic field device is fixed on the workbench obliquely below the rotating runner device. A blind hole of a blind hole type workpiece can be polished, and the blind hole of theto-be-polished workpiece is in a negative pressure state through air extraction, so that a abrasive particle flow can enter the blind hole more smoothly; and the abrasive particle flow used is a liquid metal abrasive particle flow, metal particles in the liquid metal abrasive particle flow can form good contact with the surface of the to-be-machined workpiece under the action of a rotating magnetic field generated by an annular permanent magnet, micro cutting is carried out, mechanical deformation is not generated on the surface of the blind hole of the to-be-machined workpiece, the polishingefficiency is faster, the effect is better, and micro cutting is carried out.

Owner:ZHEJIANG UNIV OF TECH

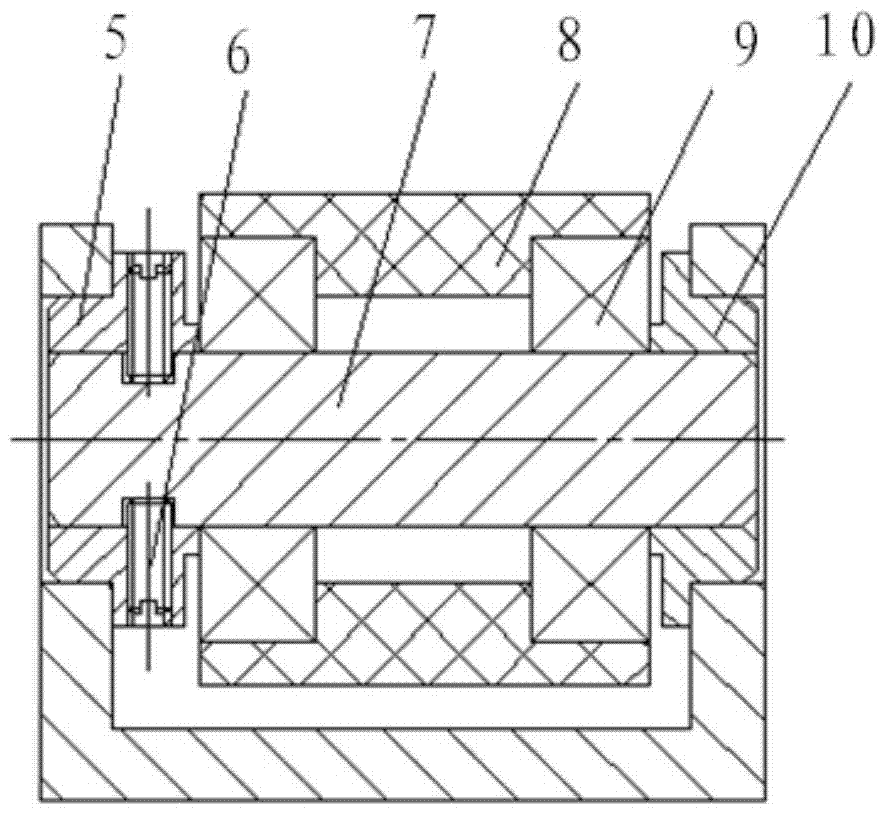

Immersion type cooling press bearing shell

InactiveCN101549567AHigh strengthImprove rigidityBearing componentsPressesContinuous/uninterruptedCooling effect

The present invention provides a immersion type cooling press bearing shell, the inner surface and two ends with flanges of the existing semicircular column shaped bearing shell will not be changed, the back of the bearing shell is provided with several cooling water tanks along the circumference or axial direction, and the tanks are connected to form a continuous water transfer tank, after assembling the bearing shell with corresponding bearing block, a closed, single and uninterrupted cooling water transfer channel will be obtained by matching a water outlet and a water inlet. A back reinforcing rod of the bearing shell is formed between two neighboring water tanks of the bearing shell. The outer surface of the bearing shell is provided with a water transfer cooling tank, thereby the cooling area of the bearing shell is larger, the external cylindrical surface and the reinforcing rod of the whole bearing shell are all immersed in the cooling water of the water transfer cooling channel, the cooling effect is good without heat distortion; secondly, the reinforcing rod reinforces the strength and the steel degree of the bearing shell, when reloading to operate, there is non mechanical deformation, thereby the service life of the bearing shell is prolonged, and the production cost is reduced.

Owner:方曙

Pretreatment process of crawling robot and ship steel surface

The invention provides a crawling robot and a marine steel surface pretreatment process. Fiber lasers are mounted on a vehicle body; the vehicle body is driven to move; laser cleaning is performed during moving; this mode is simple and efficient. The vehicle body has magnetic drive wheels so that the vehicle may travel in tight contact with the surface of a hull. The lasers mounted on the vehiclebody are kept evenly spaced from the surface of the hull. Fiber laser beams are used to perform laser scanning on the focal plane so that power density distribution is relatively uniform, and sundriesare cleaned without damaging steel base material. Compared with traditional grinding methods, the process employing noncontact processing has the advantages that laser processing causes no direct impact to marine steel so that no mechanical deformation occurs, laser processing precision is high so that the influence of human factors upon processing quality can be relieved, the processing efficiency is high, the quality is table and reliable, and the appearance is attractive.

Owner:WUHAN JINDUN LASER TECH CO LTD

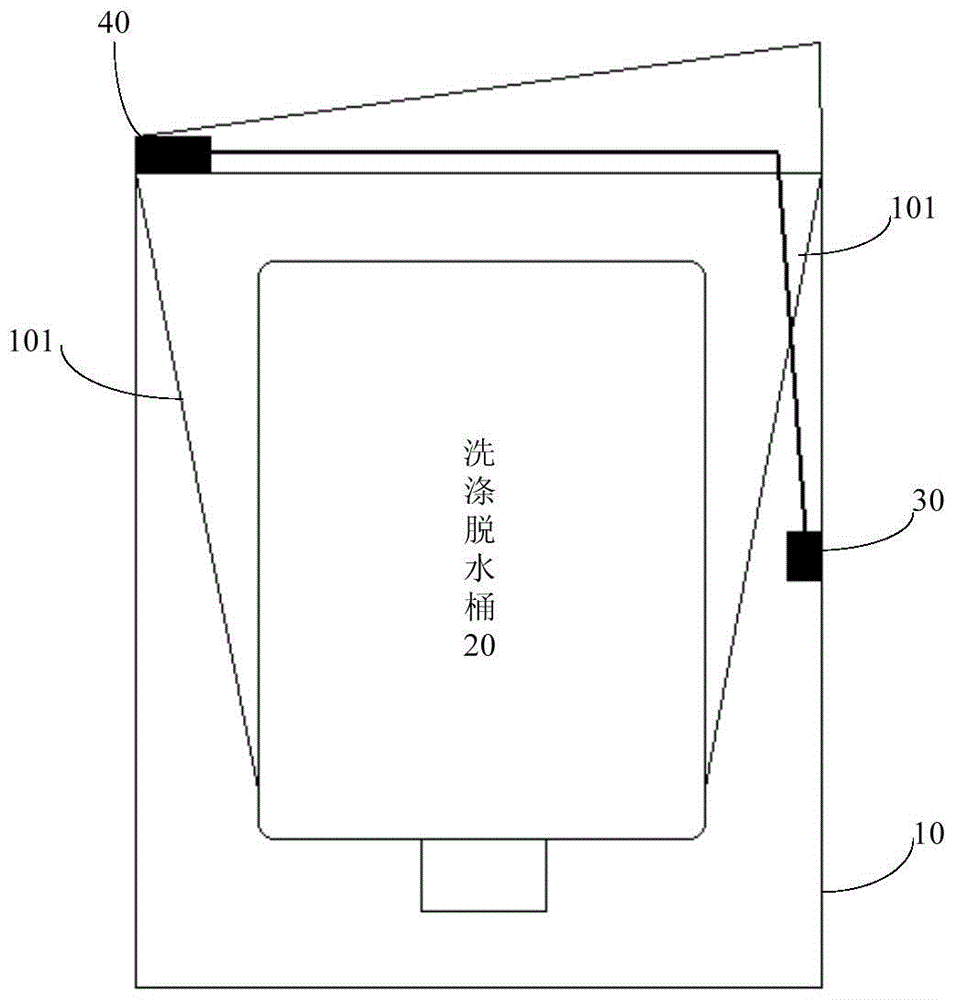

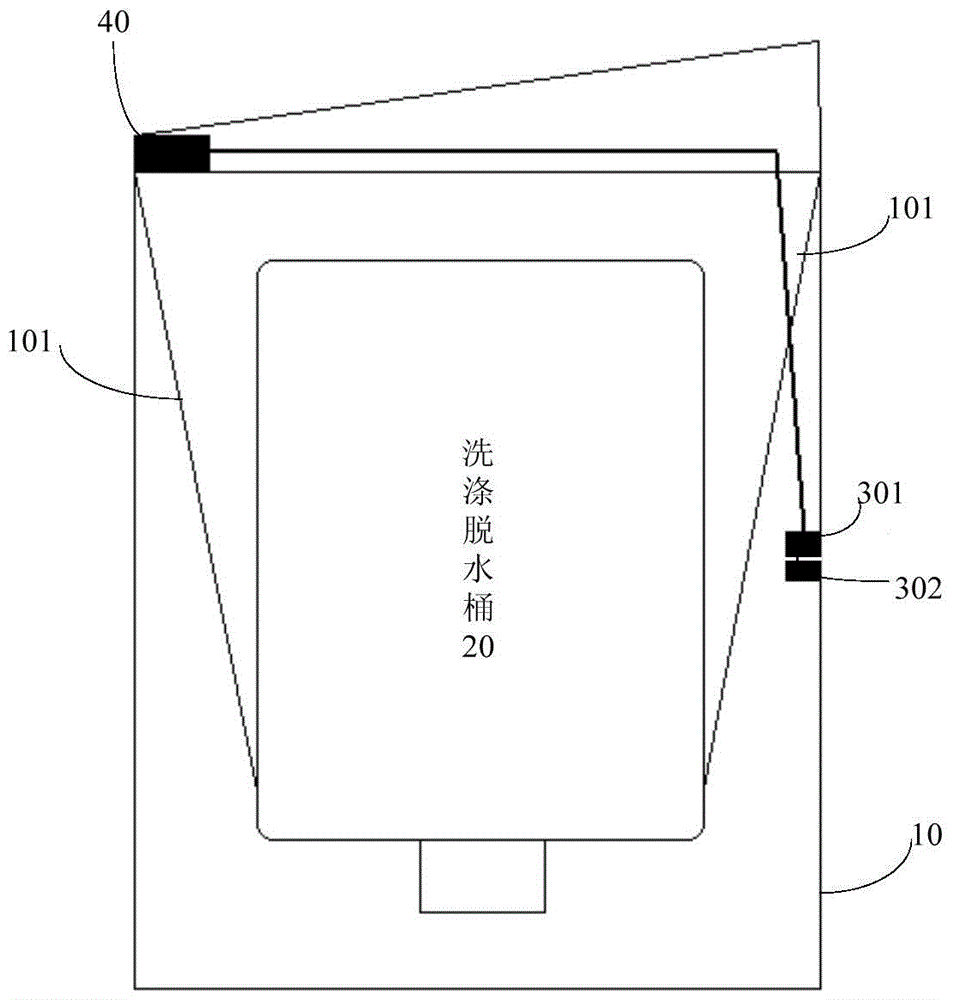

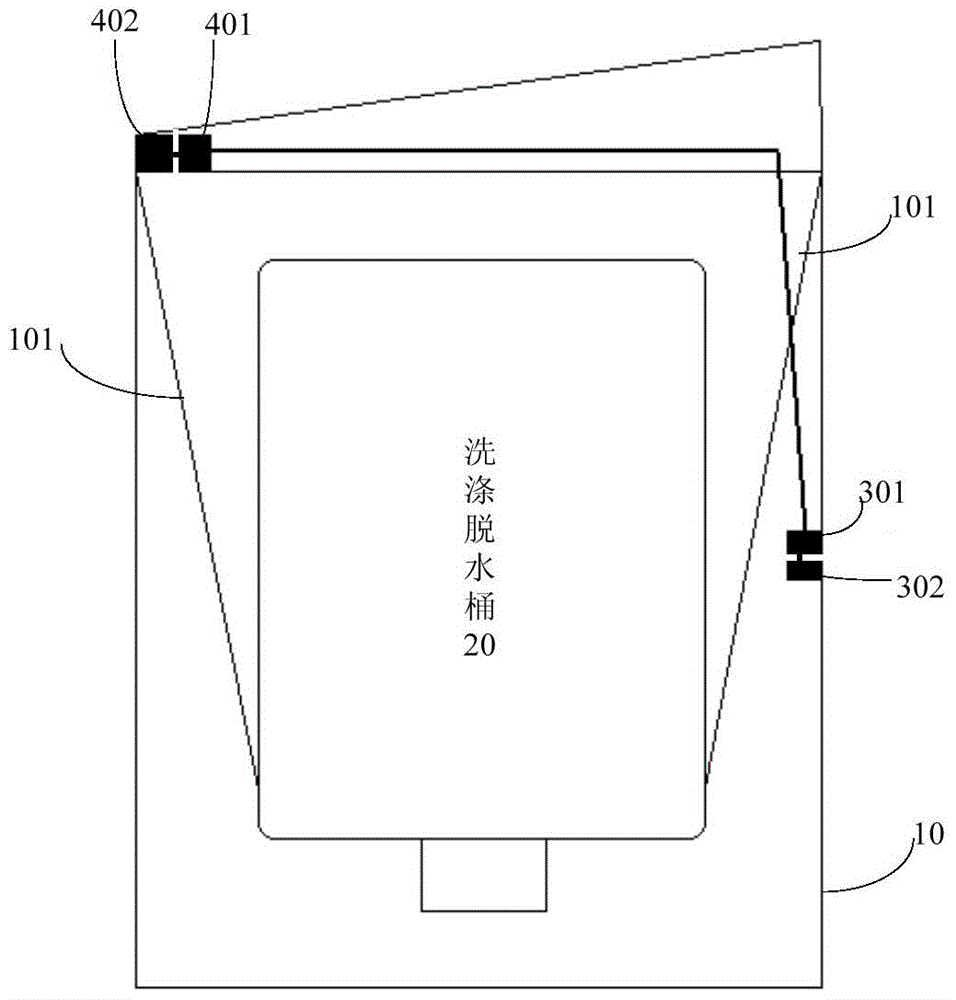

Washing machine and its detection method for unbalanced operation

ActiveCN104790167BNo mechanical deformationImprove reliabilityStatic/dynamic balance measurementOther washing machinesProcess engineeringElectronic component

The present invention provides a method for detecting an unbalanced washing machine and operation, wherein a washing machine comprising: a body casing with suspension member; dehydration washing tub, the washing tub by dewatering the suspension member is suspended inside the box; tank for detecting vibration frequency and the distance between the body and the casing of the washing-dehydrating tub detector, the detector is provided adjacent the inner side wall of the housing; a controller connected to the detector, in the washing machine during dehydration, according to the controller housing vibration frequency and the distance between the washing and dehydrating tub box determines whether the washing machine operating in an unbalanced state. Washing machine and method for detecting imbalance of the operation of the present invention, by determining whether the electronic components operating in an unbalanced state, determines high precision and high reliability of the washing machine, easy installation, not affect the misalignment, without causing mechanical deformation or wear.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

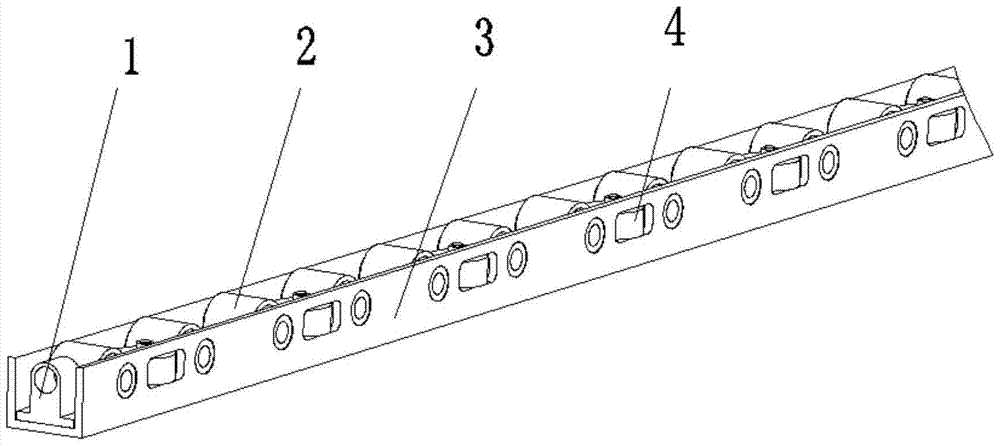

An installation support track for an underwater vehicle battery pack

InactiveCN105449136BGuaranteed uptimeNo bias phenomenonCell component detailsBatteriesEngineeringBattery pack

The invention discloses an installation and support rail for an underwater vehicle battery pack, which belongs to the technical field of underwater robots; it includes: a positioning hole seat, a support wheel, an installation base and a guide wheel; The two ends of the base plate; the two ends of the central axis of the support wheel are installed in the round holes of the two side plates of the installation base; the central axis of the guide wheel is fixed on the bottom plate of the installation base, wherein the outer peripheral surface of the guide wheel passes through Located in the same side hole of the installation base; the support wheels and guide wheels are arranged at intervals; the axis of the guide wheels is perpendicular to the bottom plate of the installation base, and the axis of the support wheels is perpendicular to the side plate of the installation base; the support wheels form the battery pack , Out of the running track of the shell of the underwater vehicle; the guide wheel is used to guide the unbiased movement of the battery pack; the track has good friction characteristics and high guiding precision, and the battery pack can be driven into and out of the water without bias by manpower aircraft hull.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

Rotary polishing device and method for blind hole polishing

PendingCN110614588ASmooth entryNo mechanical deformationAbrasive feedersAbrasive blasting machinesParticle flowInlet valve

The invention discloses a rotary polishing device and method for blind hole polishing. The rotary polishing device comprises a workbench, a movable positioning assembly, a flow pass assembly and a rotary clamping assembly. The movable positioning assembly comprises a horizontal module mounting rack, a horizontal straight line module, a horizontal module driving motor, a vertical straight line module and a vertical module driving motor. The rotary clamping assembly comprises a rotary motor, a motor mounting base, a bearing, a supporting block, an auxiliary clamping head and a vertical mountingbase. The flow pass assembly comprises a main clamping head, a rotary joint fixing base, a flow pass fixing plate, a sliding rail connecting plate, an extraction opening check valve, a gas-liquid abrasive particle flow joint, an abrasive particle flow inlet valve, an air pressure opening check valve, a flow pass joint, a flange-type rotating joint and a main clamping end O ring. By adoption of therotary polishing device and method for blind hole polishing, blind holes of blind hole type workpieces can be polished, the rotary motor can be used for driving the workpieces to be machined to rotate in the machining process, abrasive particle flow can impact the inner walls of the blind holes in a more unordered mode during machining, and machining efficiency of the blind holes is improved.

Owner:ZHEJIANG UNIV OF TECH

Polishing device and method for polishing blind hole of non-conductive workpiece

PendingCN110614542AFast polishing efficiencyGood effectGrinding carriagesGrinding work supportsParticle flowEngineering

The invention discloses a polishing device and method for polishing a blind hole of a non-conductive workpiece. The polishing device comprises a working table, a movable positioning device, a rotatingrunner device and a rotating magnetic field device, wherein the movable positioning device is arranged on the working table; the rotating runner device is arranged on the movable positioning device;the rotating magnetic field device is fixed onto the working table on the inclined downward part of the rotating runner device. According to the polishing device and method for polishing the blind hole of the non-conductive workpiece provided by the invention, the blind hole of a blind hole workpiece can be polished, and the blind hole of the workpiece to be polished is exhausted so as to be at anegative pressure state, so that an abrasive particle flow can smoothly enter the blind hole. According to the polishing device and method for polishing the blind hole of the non-conductive workpieceprovided by the invention, an orifice of the workpiece to be process is slantways upwards, the abrasive particle flow in the polishing process is gathered in the blind hole, and the adopted liquid metal abrasive particle flow produces turbulent flow under a rotating magnetic field, so that compared with traditional media such as water and oil, liquid metal has the characteristics of high density and good flow controllability.

Owner:ZHEJIANG UNIV OF TECH

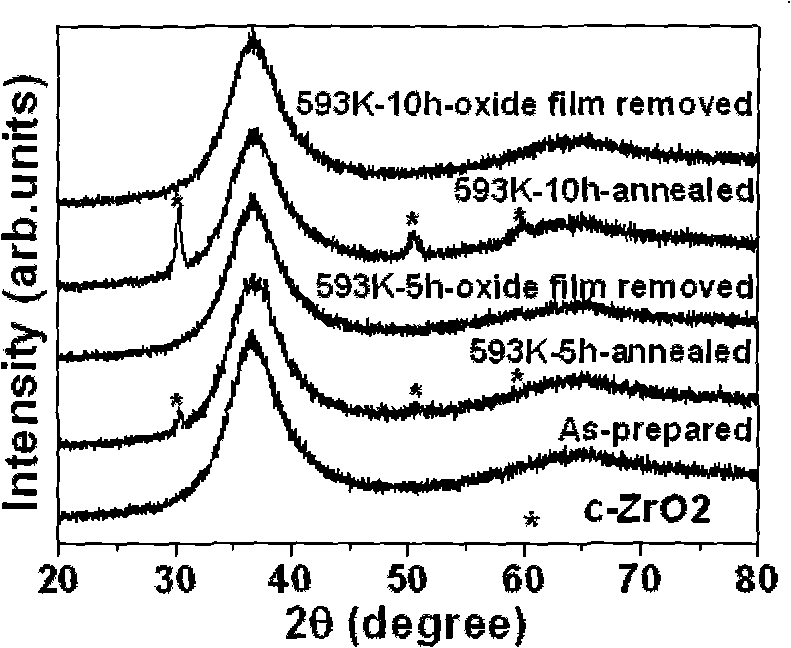

Method for improving corrosion performance of bulk amorphous alloy through oxidizing annealing in air atmosphere

The invention discloses a method for improving the corrosion performance of bulk amorphous alloy through oxidizing annealing in an air atmosphere. The method comprises the following steps: firstly, after polishing the surface of a bulk amorphous alloy, washing the surface of the bulk amorphous alloy with alcohol; secondly, placing the bulk amorphous alloy in a muffle furnace to heat the bulk amorphous alloy to between 286 and 336 DEG C at a speed of 10 DEG C / min; and thirdly, keeping the temperature constant for 5 to 10 hours to form a metallic oxide ceramic layer with high corrosion resistance on the surface of the bulk amorphous alloy. Compared with other common methods for improving the corrosion resistance of the bulk amorphous alloy, the technology has the advantages of greatly improving the corrosion resistance of the bulk amorphous alloy without influencing the glass forming ability of the alloy, along with simplicity, easy implementation and low cost. The process avoids changes in the original dimension and shape of a workpiece, ensures an excellent bonding force between a formed oxide layer and a substrate, and is applicable to the final processing of parts and products.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com