Observation method for fluid precision finishing of surfaces of micro-structures of molds

A technology of microstructure and observation device, applied in metal processing equipment, manufacturing tools, control of workpiece feed movement, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In conjunction with the accompanying drawings, the present invention will be described in detail below.

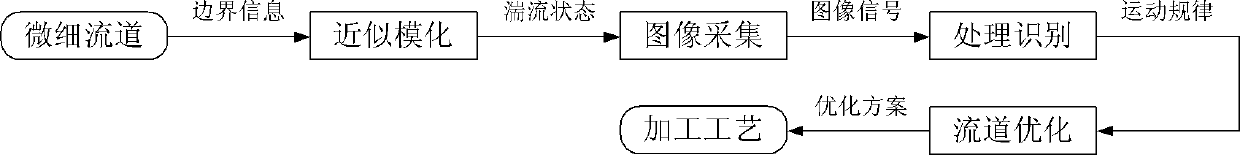

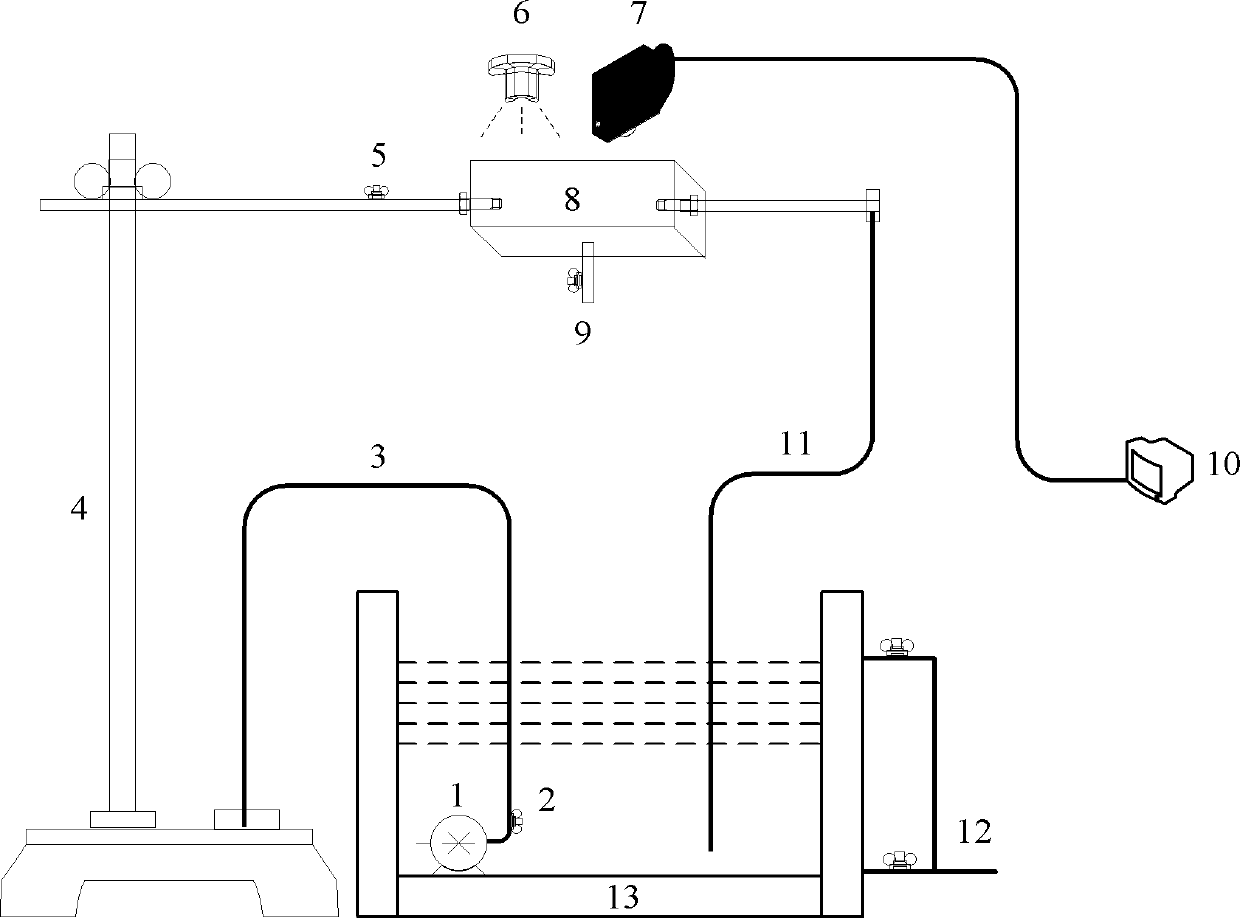

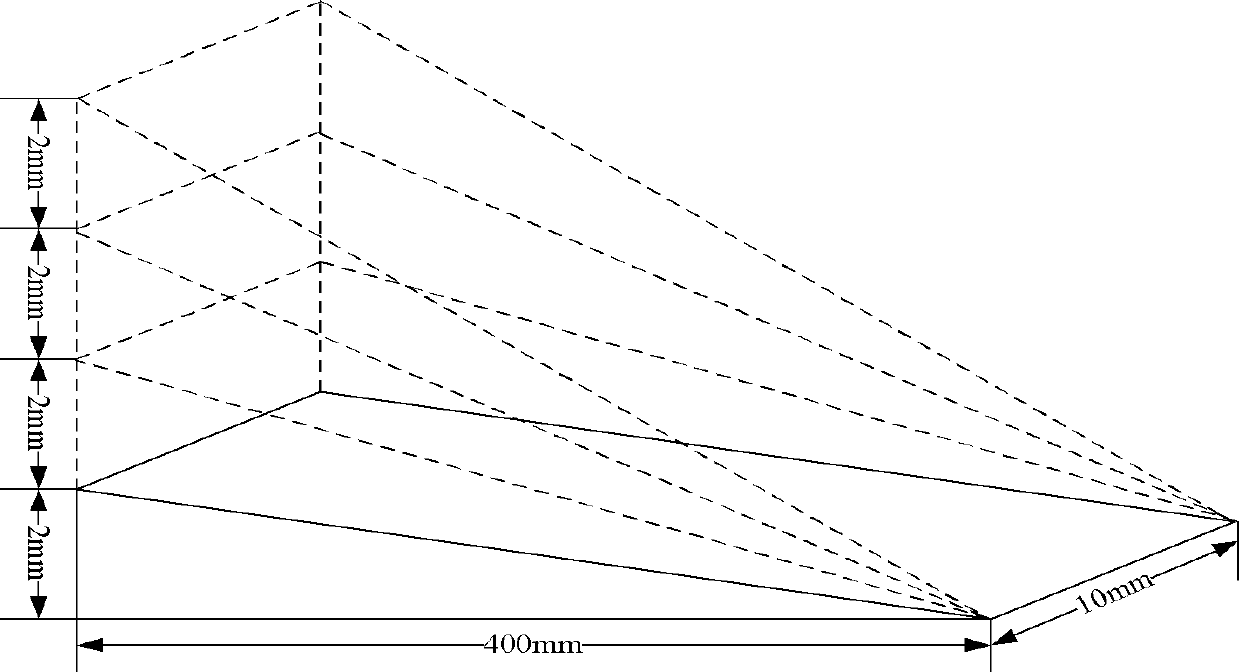

[0043] refer to Figure 1 to Figure 4 , an observation method for precision machining of mold microstructure surface fluid, its technical ideas are as attached figure 1 As shown, the specific implementation steps can be described as follows: Based on the similar modeling method of fluid flow, the structured surface of the micro-mold is enlarged in the same proportion as the boundary, and the flow state of the sparse abrasive flow in the micro-constrained flow channel is simulated. The real-time image data in the flow channel is processed and identified, and the distribution state, movement law, typical flow characteristics and development trend of the sparse abrasive flow in the micro-constrained flow channel environment are obtained. The technical basis provides experimental conditions for the research on the development of turbulent flow state in small flow chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com