Laser beam multi-dimensional precision adjustment device integrating active heat dissipation structure

A laser beam, active heat dissipation technology, applied in laser cooling devices, lasers, laser parts and other directions, can solve the problems of beam adjustment, interference, installation, equipment necrosis, inability to work, etc., and achieve reliable laser output. , to ensure stability and increase the effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific examples.

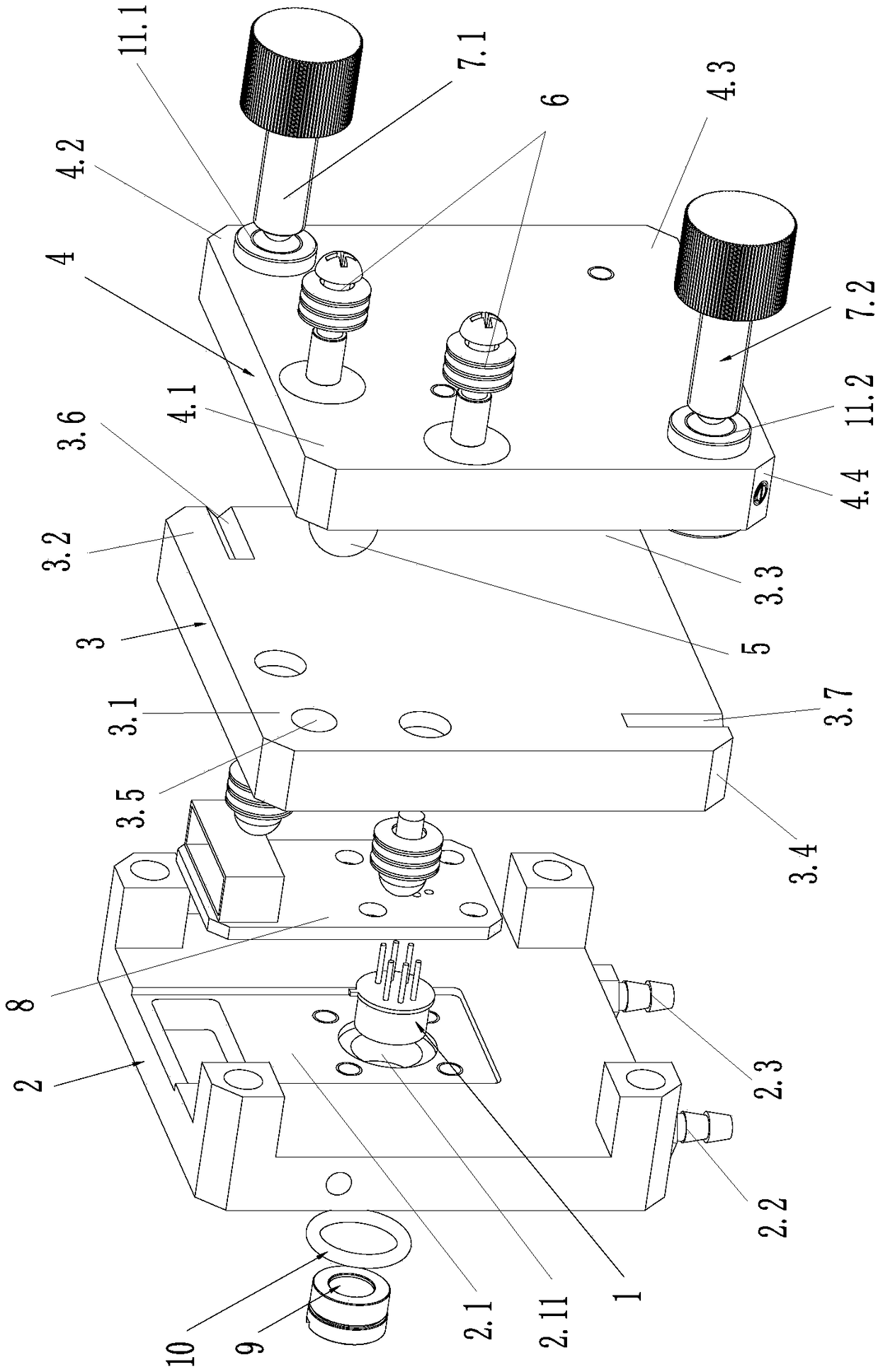

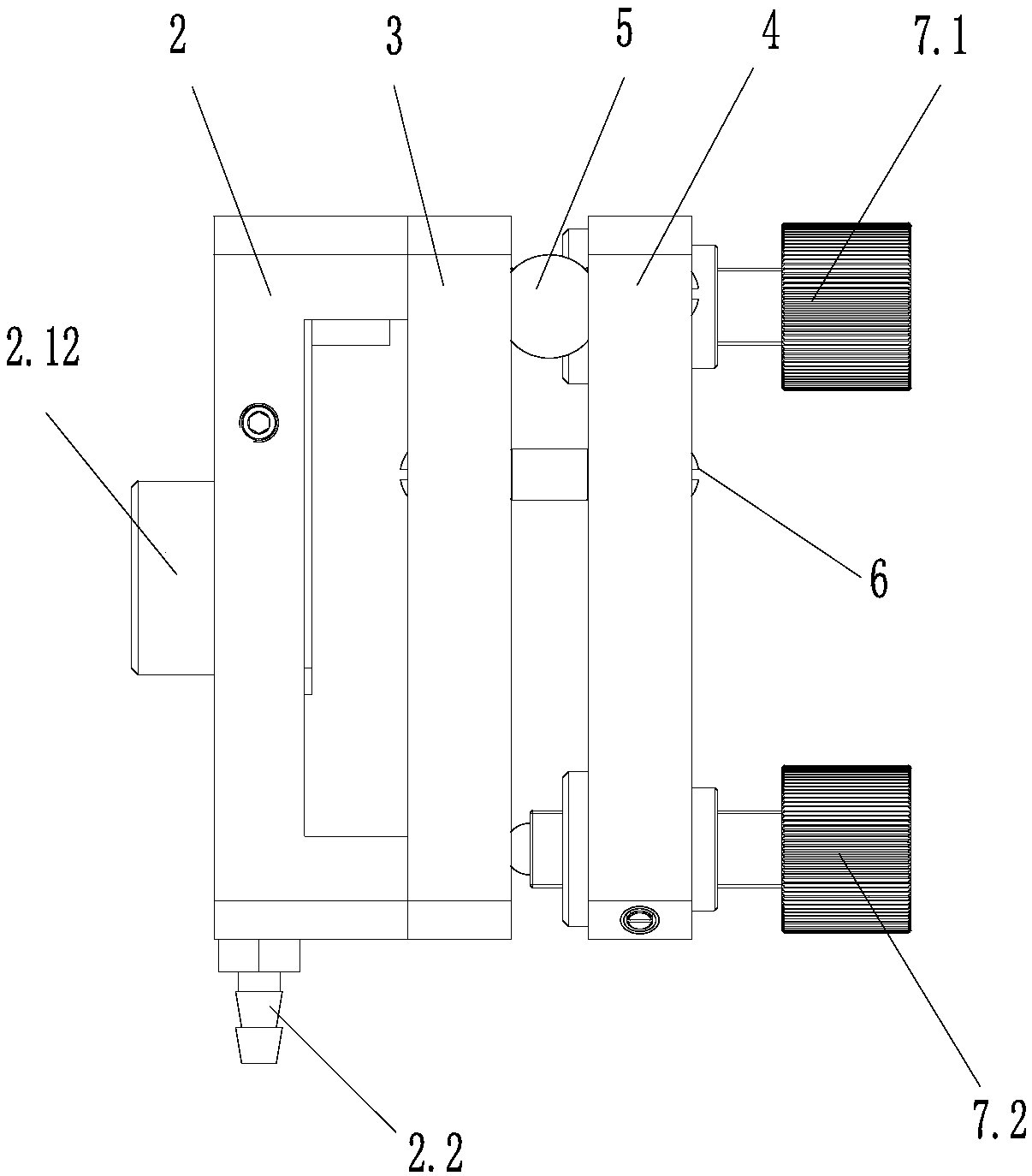

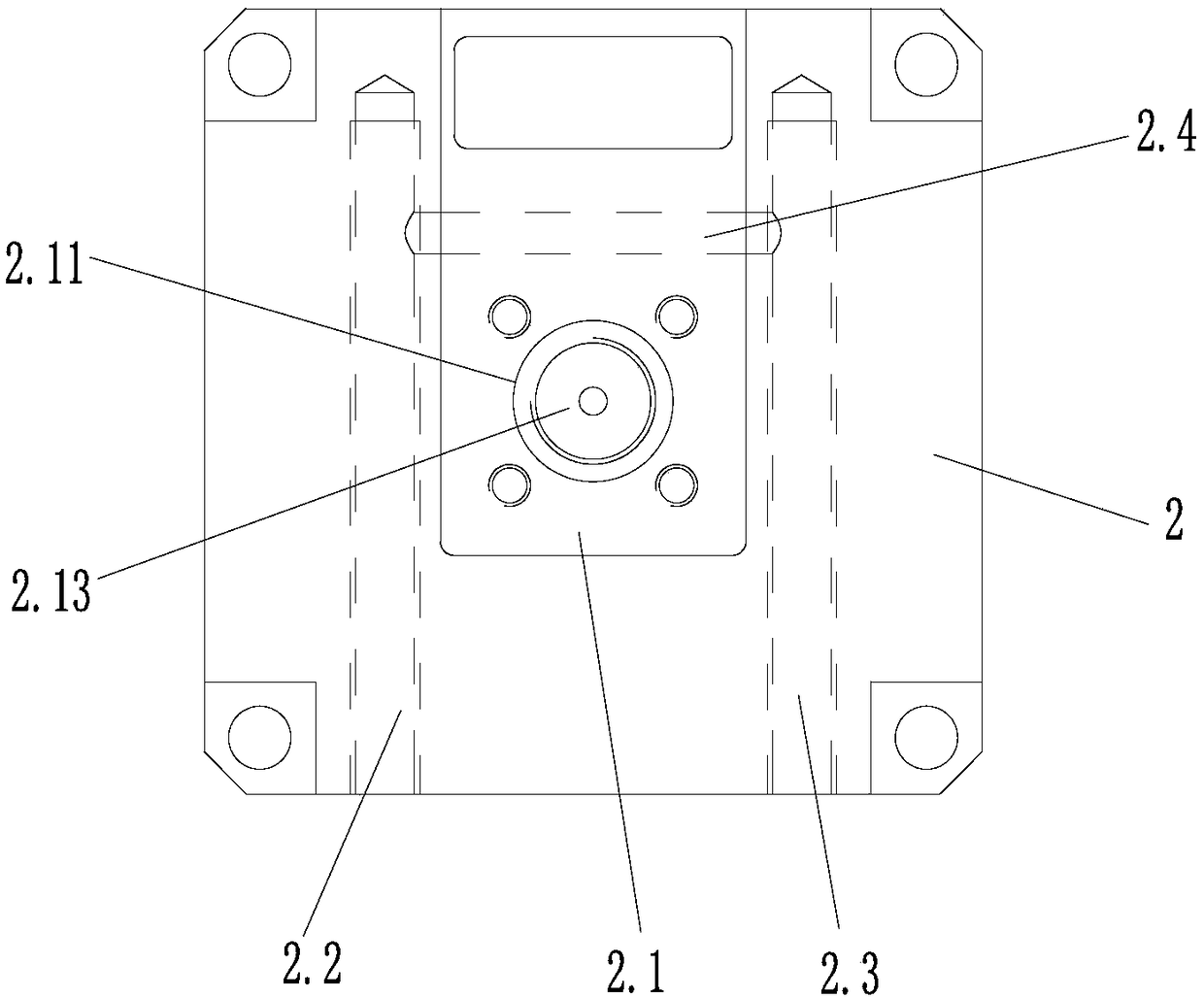

[0034] Such as figure 1 and figure 2 A laser beam multi-dimensional precision adjustment device with an integrated active heat dissipation structure is shown, including a laser 1, and a base 2 arranged in sequence along the beam propagation direction for installing the laser 1 and having a self-heating function, and a base 2 for fixed connection with the base 2. The rotating base 3 used to adjust the position of the laser spot, and the fixed base 4 that is relatively rotatable connected with the rotating base 3; the base 2, the rotating base 3, and the fixing base 4 are all treated in a special way to black the surface of the parts, effectively avoiding the occurrence of laser damage. The light is reflected and scattered between the parts, so as to avoid the interference phenomenon of the laser caused by the stray light of the parts.

[0035] The swivel seat 3 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com