Laser texturing method for plate welding machine box

A laser and engraving technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that the accuracy and consistency of parts cannot be guaranteed, it is difficult to ensure the accuracy of outline lines, and a large number of engraving templates, etc. , to achieve the effect of improving processing efficiency and dimensional accuracy, high degree of automation, and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

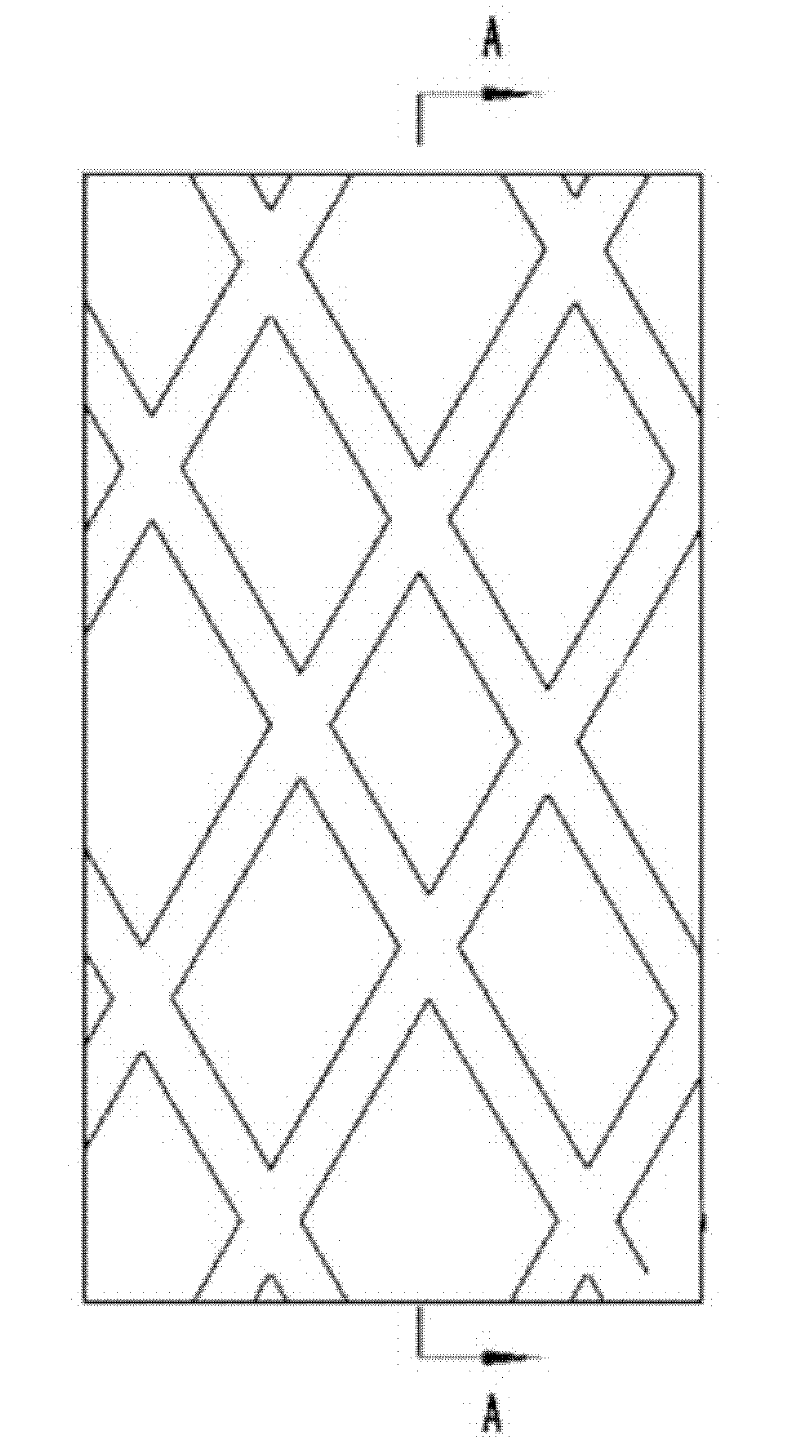

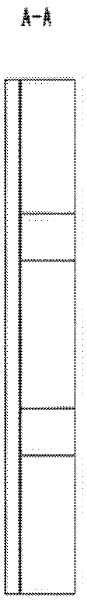

Image

Examples

Embodiment Construction

[0019] A laser engraving method for a sheet welding casing, comprising the following steps:

[0020] Step 1: Apply a protective layer on the surface of the part;

[0021] The marking process is affected by the properties of the cover material, including reflectivity, absorption properties, thermal conductivity, color and surface finish of the workpiece. The laser must be absorbed to generate heat. If the material to be processed is highly reflective to the laser, it is necessary to increase the laser power and reduce the pulse frequency to obtain a higher peak power. For reflective materials, marking may not be possible at all. The thickness of the protective layer is generally selected from 10 μm to 50 μm, so that it is easy to cut through the protective layer during laser cutting without damaging the base material of the part; the protective layer used in this embodiment is AC850 glue.

[0022] Step 2: Select the laser parameters of the laser according to the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com