Corrugated cardboard cutting and pressing integrated machine

A corrugated board, all-in-one technology, applied in paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of inaccurate position of die-cutting indentation lines, insufficient displacement, unclear indentation lines, etc. Clear traces, good synchronization, no mechanical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

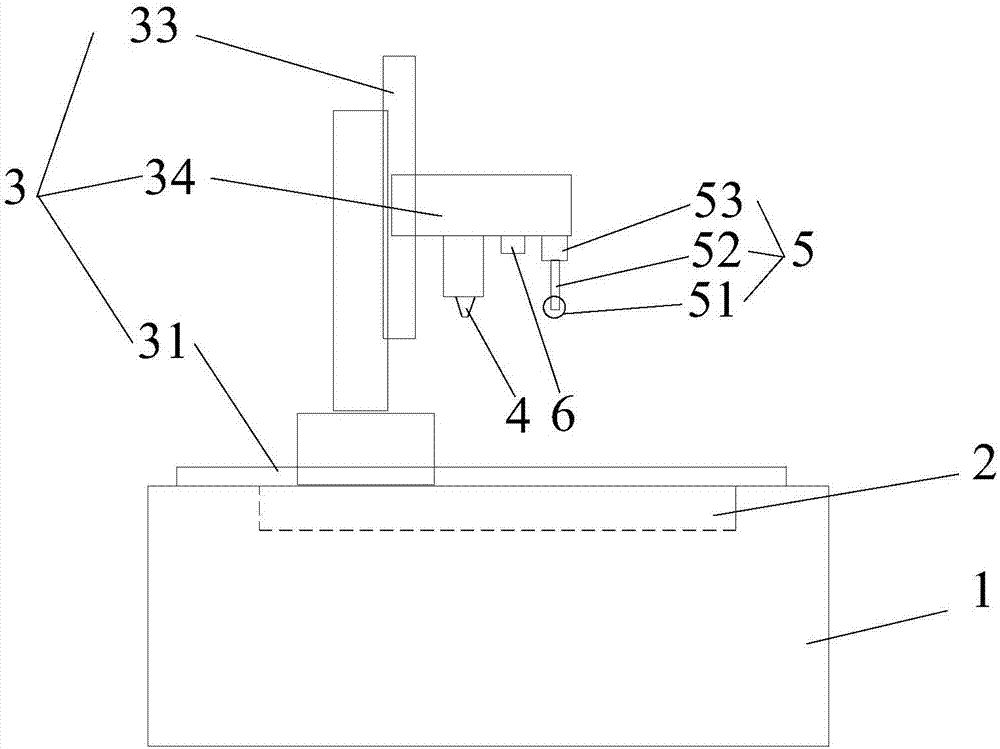

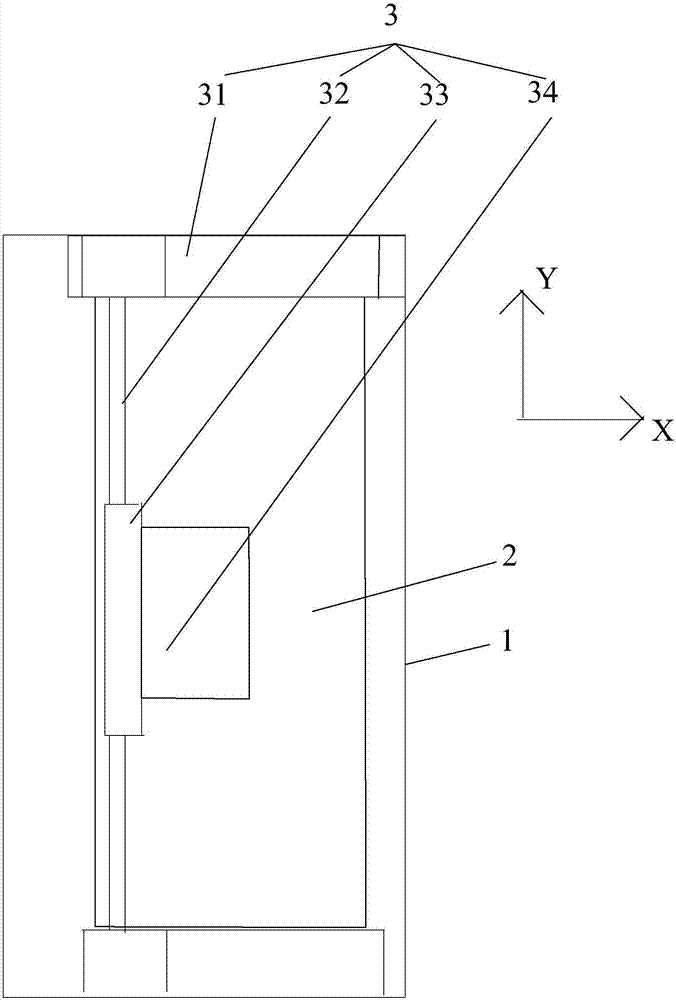

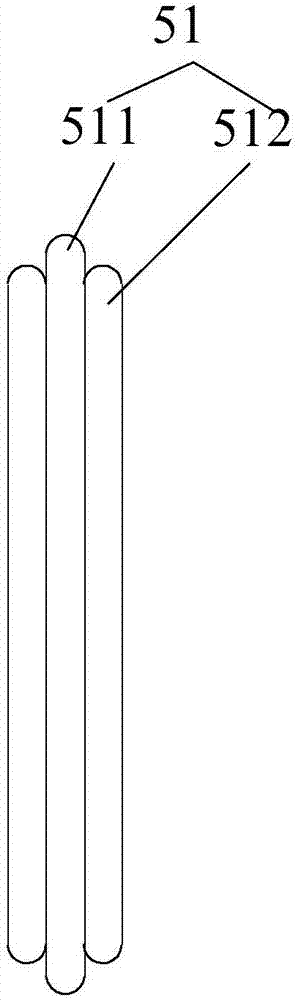

[0023] like figure 1 and figure 2 The corrugated cardboard cutting and pressing integrated machine shown in the embodiment includes a frame 1, a worktable 2 arranged on the frame 1 and used for placing the corrugated cardboard, a three-dimensional displacement structure 3 arranged on the frame 1, and a laser emitting device. A laser cutting system 4, a creasing wheel structure 5 for creasing corrugated cardboard, an image acquisition system 6 and a control device (not shown) cooperating with the work table 2. The laser cutting system 4 , the indentation wheel structure 5 and the image acquisition system 6 are arranged above the workbench ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com