Device and method for remaining amount of reagent

A detection method and residual quantity technology, applied in liquid level indicators for physical variable measurement, etc., can solve the problem of high residual quantity in scanning, and achieve the effects of improving sensitivity, enhancing anti-interference ability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

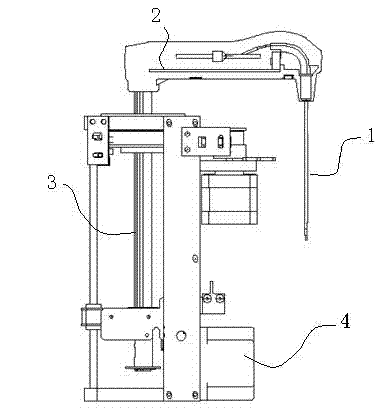

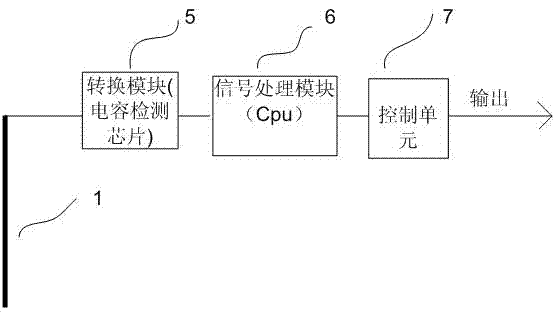

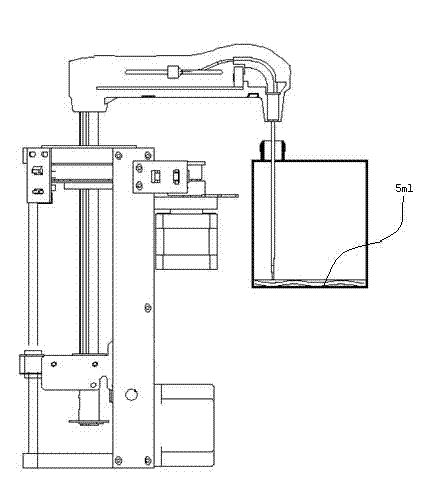

[0031] A reagent residual detection device, comprising: a liquid suction probe 1, used to absorb the measured liquid and output its capacitance to the conversion module;

[0032] The conversion module 5 is used to detect the capacitance output by the liquid suction probe, and output a digital signal corresponding to the capacitance value;

[0033] The signal processing module 6 processes the digital signal and outputs the contact liquid level signal, and the signal processing module includes:

[0034] The first judging unit, whether the downward jump of the current voltage signal value compared with the base value voltage value is greater than the liquid level threshold, if so, output the first flag setting signal, if otherwise, output the first flag clearing signal;

[0035] The first flag counter is used to respond to the output of the first judging unit, add 1 when receiving the first flag setting signal, and reset to zero after receiving the first flag clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com