Silicon carbide friction pair used for non-contact mechanical seal and manufacturing method thereof

A technology of mechanical seals and manufacturing methods, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., and can solve problems such as economic losses and safety accidents for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

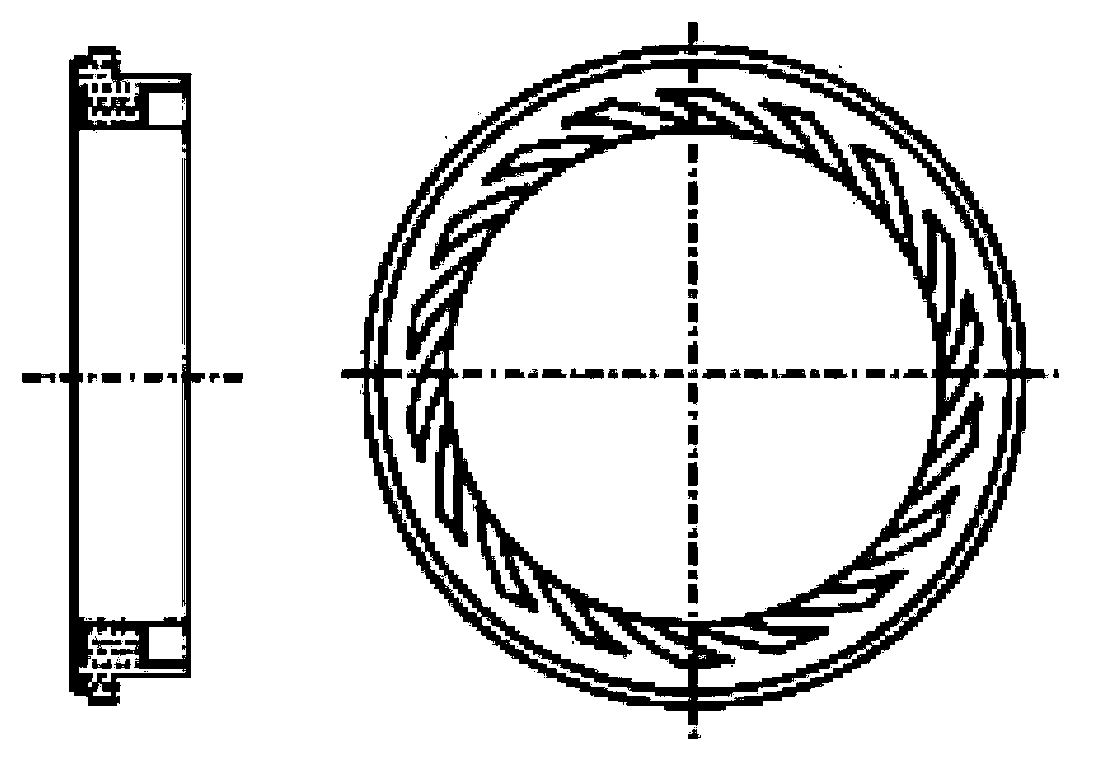

[0008] Example: A process flow for manufacturing uniformly distributed spiral grooves on the static ring friction surface of a silicon carbide friction pair with an outer diameter of 50 mm, an inner diameter of 20 mm, and a thickness of 150 mm. Prepare the static ring of the silicon carbide friction pair of the above-mentioned size and specification first. The laser processing system is selected, and the laser processing system is composed of a laser part, a galvanometer scanning head, a control system and a computer. The laser part consists of a solid-state laser and a laser power supply, which are continuously pumped. The working substance is Nd:YAG, and the wavelength is 1.06μm. The scanning head is composed of a vibrating mirror and a flat-field focusing mirror that can vibrate orderly in the X and Y two-dimensional directions. The width of the engraved line is less than 100μm, and the resolution is 1.7μm, which fully meets the processing requirements. YAG laser power i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com