Pretreatment process of crawling robot and ship steel surface

A technology for crawling robots and ships, applied in the field of laser processing, can solve the problems of low production capacity, low cleaning efficiency, and high metal loss, and achieve the effects of overcoming the effect of gravity, stable and reliable quality, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

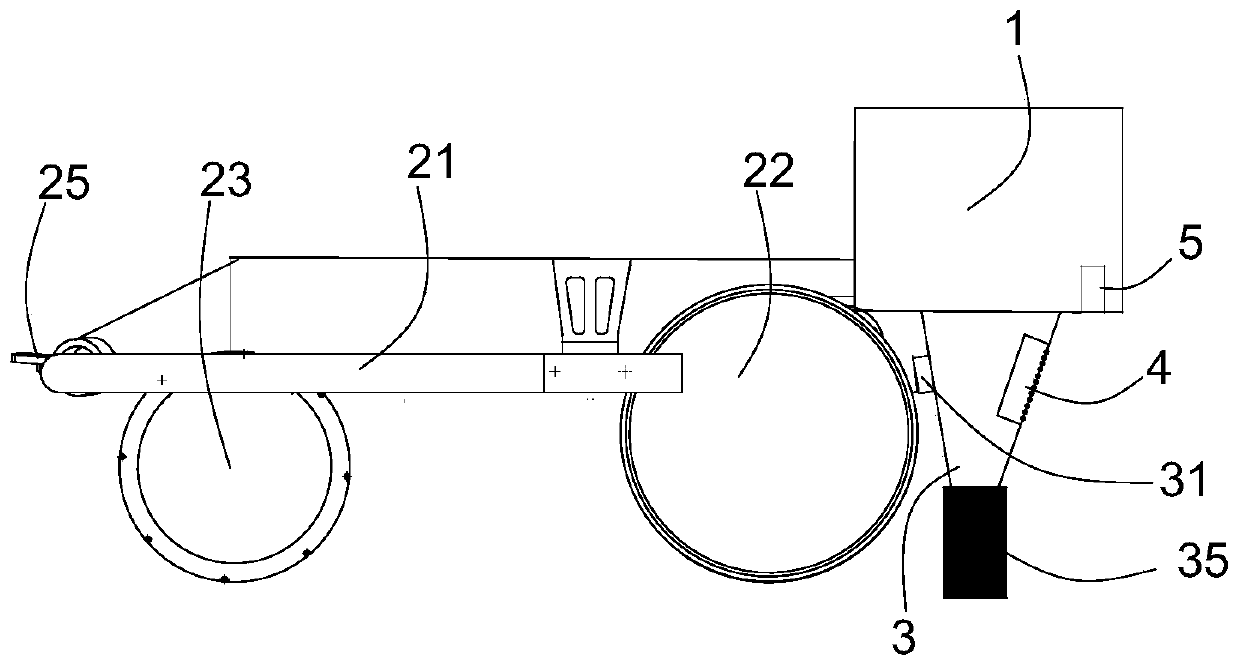

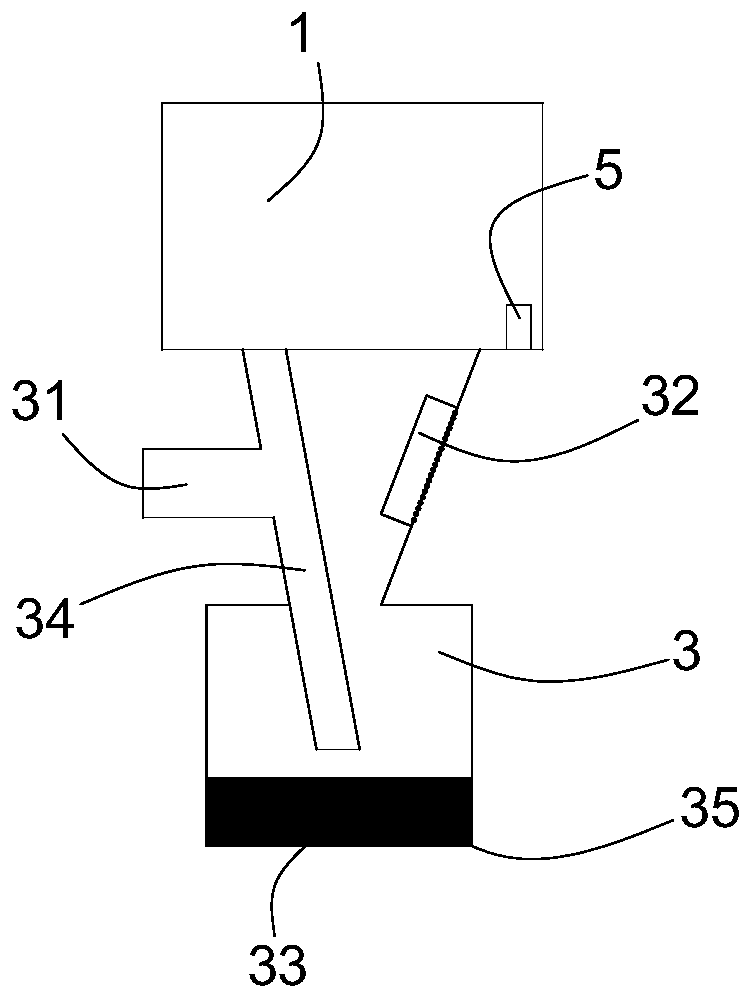

[0041] The pretreatment process of the steel surface of the ship in this embodiment adopts the crawling robot described in the first aspect of the present invention.

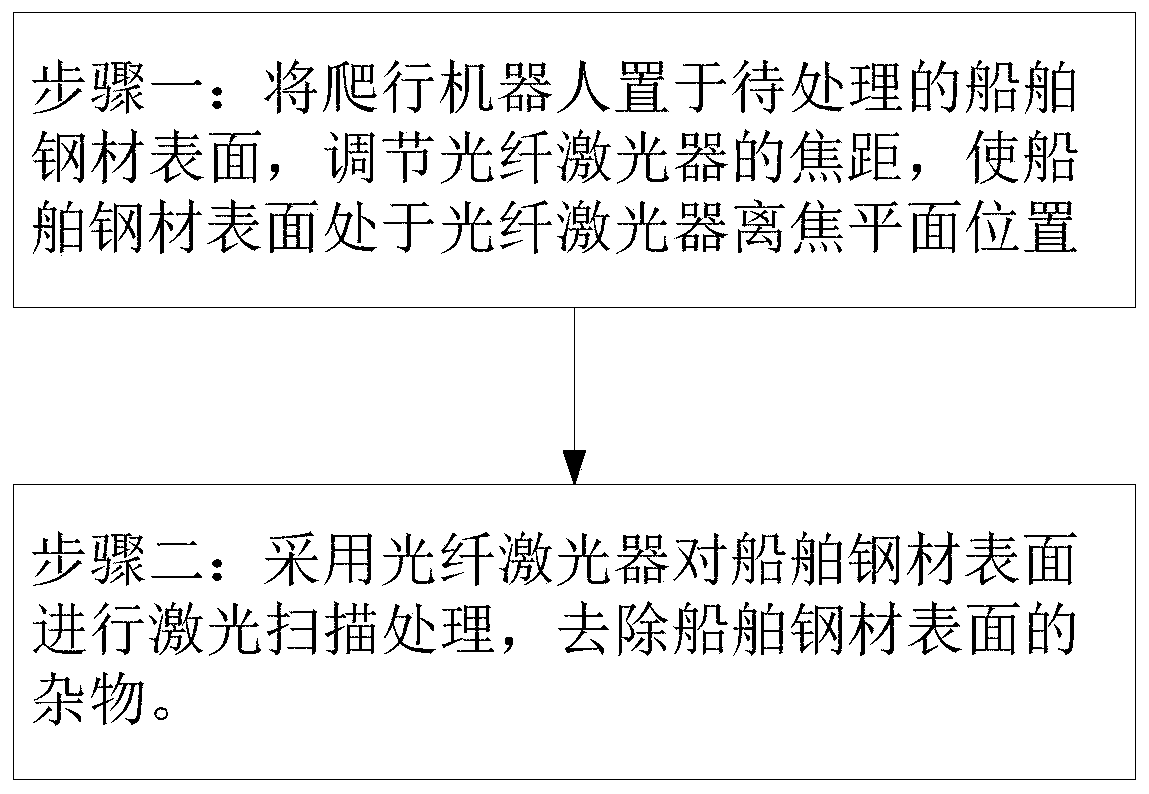

[0042] In this embodiment, the wavelength of the fiber laser 1 is 1064nm, the crawling robot is placed on the surface of the ship steel that needs to be cleaned, and the focal length of the fiber laser 1 is adjusted so that the surface of the ship steel that needs to be cleaned is placed at the laser out-of-focus plane position. Impurities on the surface of ship steel are oxide scales, old coatings, oil stains, welding slag, dust and other sundries retained by the steel products; The distribution is relatively uniform, and when processing the surface of ship steel, if the laser energy is too concentrated, it is easy to damage the surface of the substrate, and a new oxide layer will be generated, and the surface roughness will be very low.

[0043] The cleaning process is as follows: simply clean the surface of t...

Embodiment 2

[0046] A pretreatment process for the surface of ship steel in this embodiment uses the crawling robot described in the first aspect of the present invention.

[0047] In this embodiment, the wavelength of the fiber laser 1 is 1064nm, the crawling robot is placed on the surface of the ship steel that needs to be cleaned, and the focal length of the fiber laser 1 is adjusted so that the surface of the ship steel that needs to be cleaned is placed at the laser out-of-focus plane position. Impurities on the surface of ship steel are oxide scales, old coatings, oil stains, welding slag, dust and other sundries left by the steel from the factory; the position of the laser from the focal plane is negative 10mm from the focal plane, which is located below the focal plane, so that the laser spot power density The distribution is relatively uniform, and when processing the surface of ship steel, if the laser energy is too concentrated, it is easy to damage the surface of the substrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com