Method for improving corrosion performance of bulk amorphous alloy through oxidizing annealing in air atmosphere

A technology of amorphous alloy and air atmosphere, which is applied in the field of surface anticorrosion of amorphous alloy, can solve the problems of reducing glass forming ability, difficulty in large-scale application, and high cost of ion implantation. The effect of low annealing temperature

Inactive Publication Date: 2011-01-05

ZHEJIANG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the microalloying method often reduces the glass forming ability, and the alloying elements are limited by alloying laws such as thermodynamic phase equilibrium and solid solubility, while the ion implantation method is expensive and difficult to apply on a large scale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

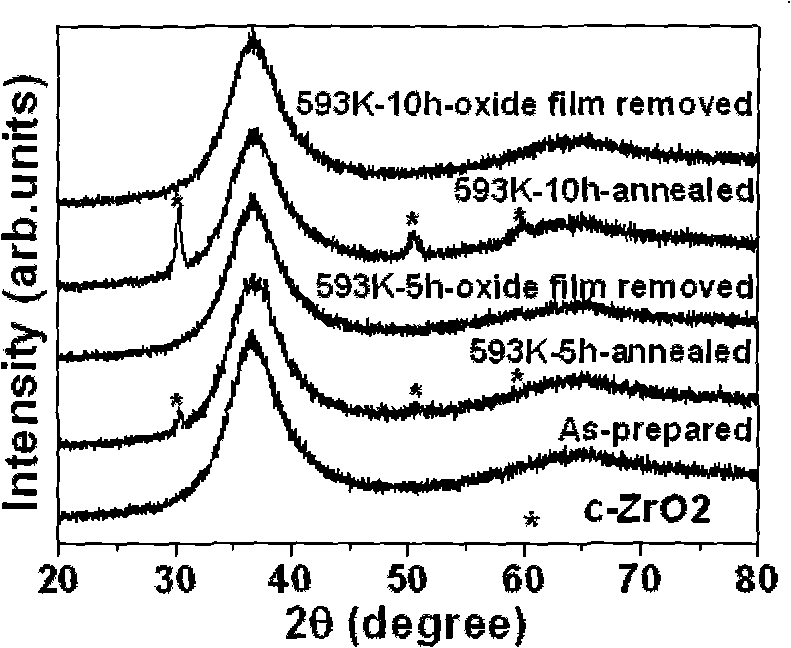

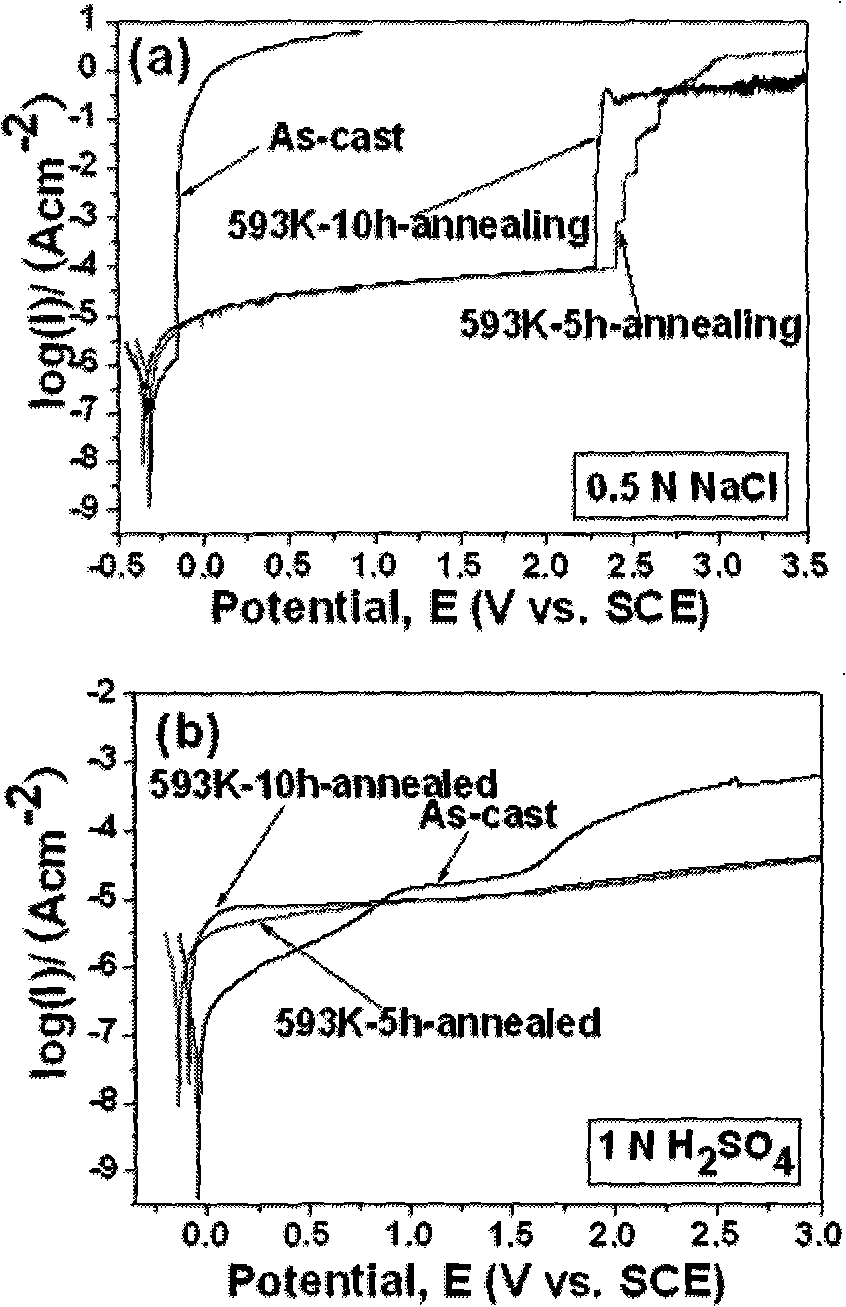

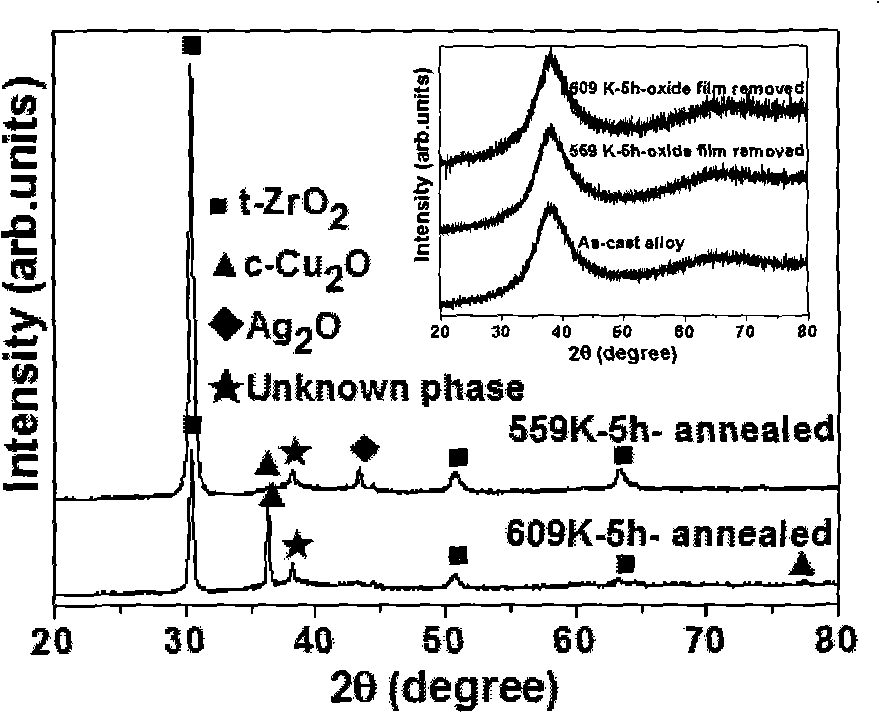

The invention discloses a method for improving the corrosion performance of bulk amorphous alloy through oxidizing annealing in an air atmosphere. The method comprises the following steps: firstly, after polishing the surface of a bulk amorphous alloy, washing the surface of the bulk amorphous alloy with alcohol; secondly, placing the bulk amorphous alloy in a muffle furnace to heat the bulk amorphous alloy to between 286 and 336 DEG C at a speed of 10 DEG C / min; and thirdly, keeping the temperature constant for 5 to 10 hours to form a metallic oxide ceramic layer with high corrosion resistance on the surface of the bulk amorphous alloy. Compared with other common methods for improving the corrosion resistance of the bulk amorphous alloy, the technology has the advantages of greatly improving the corrosion resistance of the bulk amorphous alloy without influencing the glass forming ability of the alloy, along with simplicity, easy implementation and low cost. The process avoids changes in the original dimension and shape of a workpiece, ensures an excellent bonding force between a formed oxide layer and a substrate, and is applicable to the final processing of parts and products.

Description

Method of Improving Corrosion Properties of Bulk Amorphous Alloys by Oxidation Annealing in Air Atmosphere technical field The invention relates to surface anticorrosion technology of amorphous alloys, in particular to a method for improving the corrosion performance of bulk amorphous alloys by oxidation annealing in an air atmosphere. Background technique In the 1980s, Turnbull in the United States and the Inoue research group at Tohoku University in Japan each developed a multi-element alloy system with good glass-forming ability and a critical size of several millimeters, thus revealing the vigorous research on bulk amorphous alloys. Prelude to development. For example, the research on bulk amorphous alloys has become one of the most active subjects in the field of metal materials research. Due to the special structure of amorphous alloys, it has a series of excellent physical, chemical, magnetic and especially mechanical properties, such as high strength, low modulus,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D1/74C21D1/26

Inventor 蒋建中聂西鹏

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com