Multi-end laser cutting head

A laser cutting head and cutting head technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor surface forming quality of the workpiece to be cut, poor cutting effect of the laser cutter, and insufficient cutting efficiency, etc. Small deformation of workpiece, wide adaptability and flexibility, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

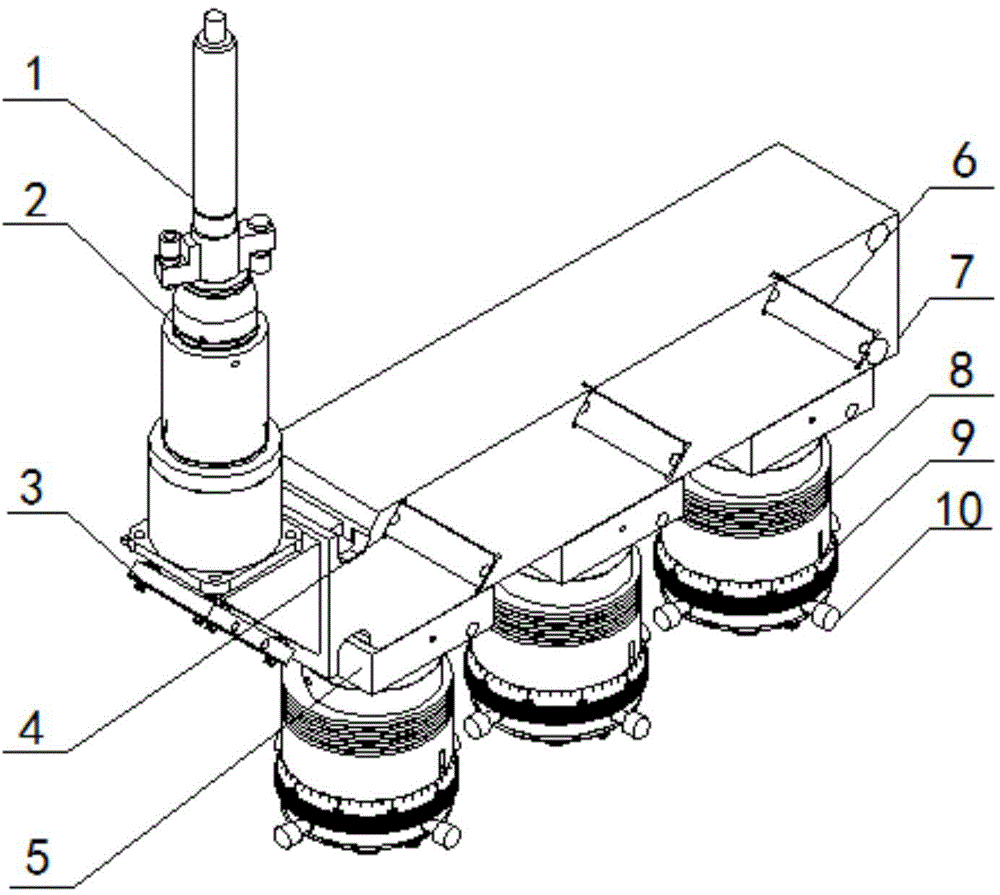

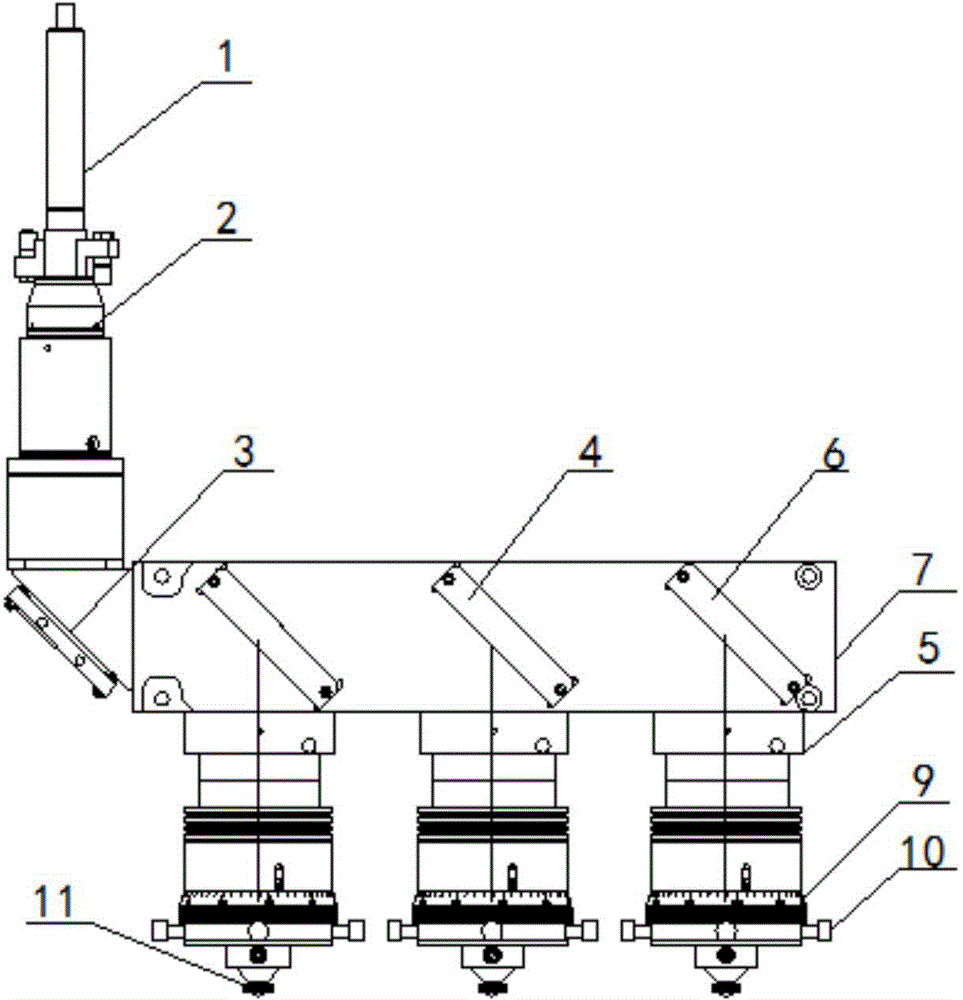

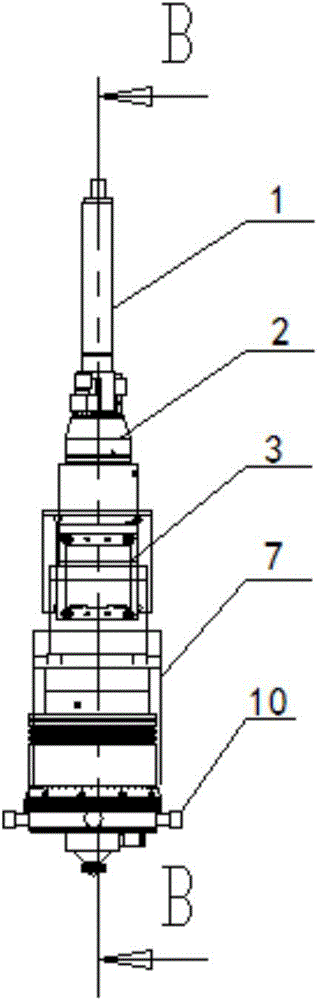

[0029] Example: such as Figure 1-7 As shown, a multi-head laser cutting head of the present invention includes a base 7, a collimating mirror 3 is installed on one side of the base 7 and the top of the collimating mirror 3 is connected to a laser 2 with a connector 1; The beam mirror 4, the reflector 6, and the beam splitter 4 communicate with the collimating mirror 3; the bottom end of the base 7 is equipped with a cutting head 8 and the bottom end of the cutting head 8 is equipped with a nozzle 11; the inside of the cutting head 8 is provided with a focusing mirror 9, and the focusing mirror 9 is connected with the adjusting nut 10 arranged on the side wall of the cutting head 8; the beam adjuster 5 is arranged between the cutting head 8 and the base 7 and the beam adjuster 5 communicates with the beam splitter 4 and the reflector 6 .

[0030] In order to make this kind of cutting head have a longer service life, it also includes a collimating lens 31 and a beam hole 111. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com