Patents

Literature

61results about How to "Narrow kerf" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

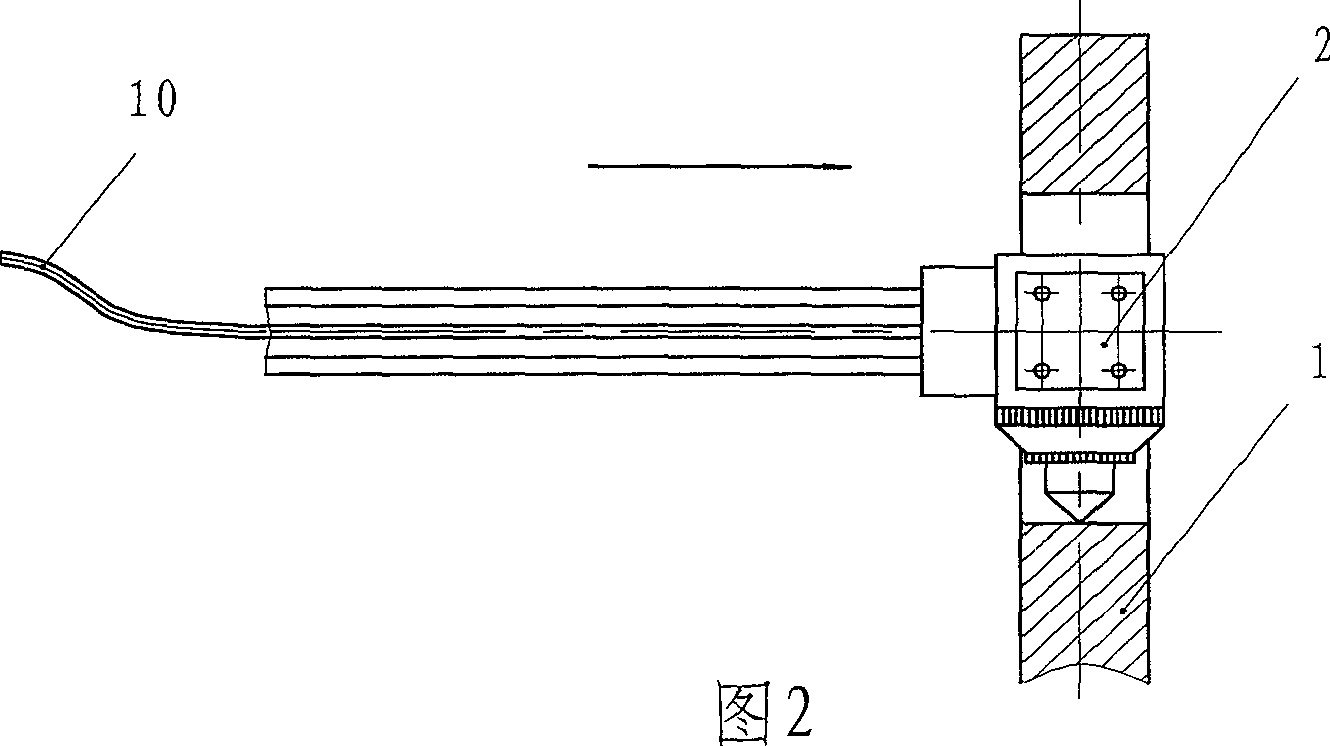

Laser cutting device of power battery pole piece

ActiveCN101777640ANarrow kerfTrimmingElectrode manufacturing processesLaser beam welding apparatusPower batteryHigh energy

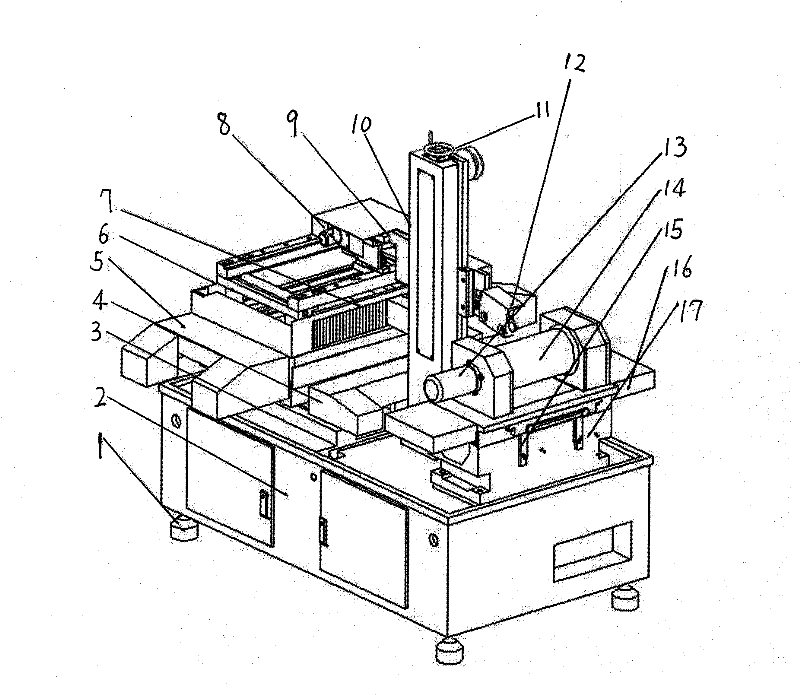

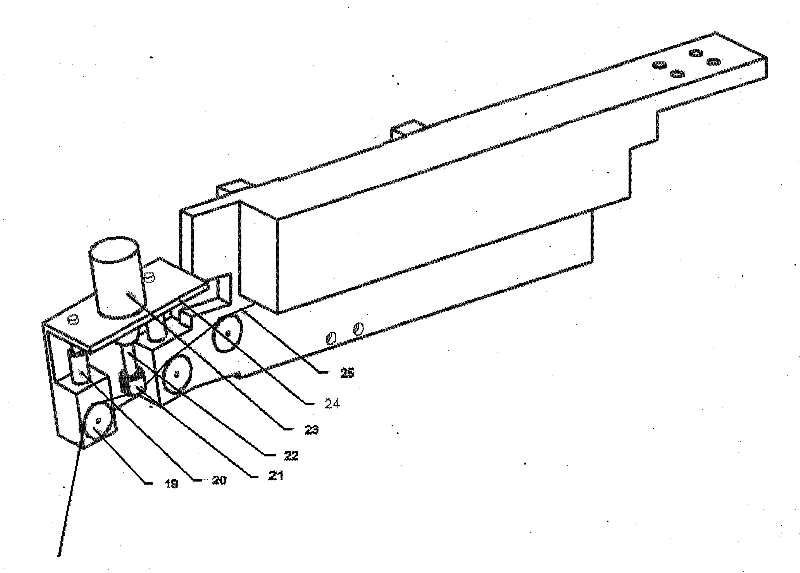

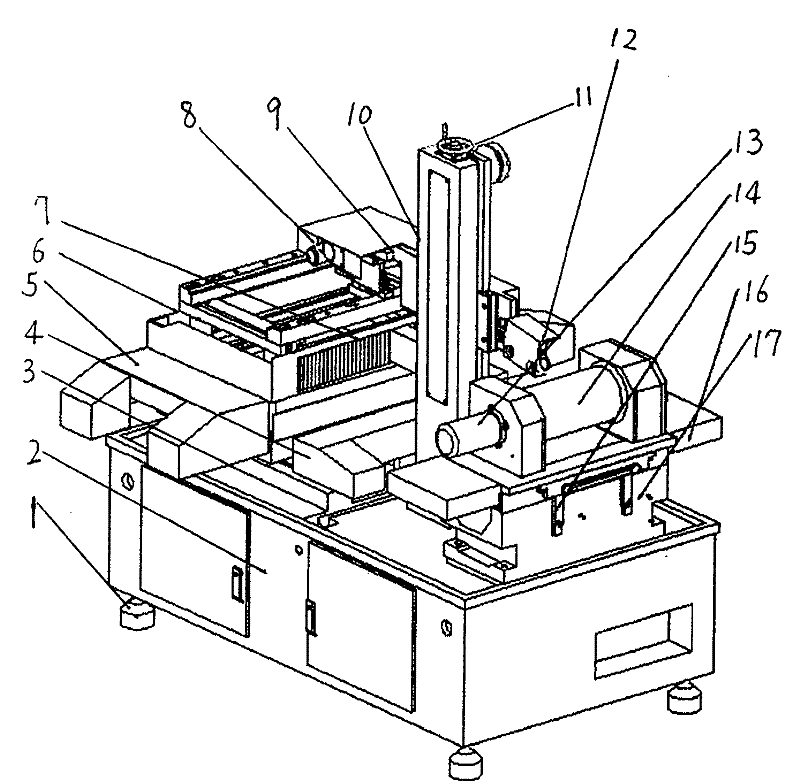

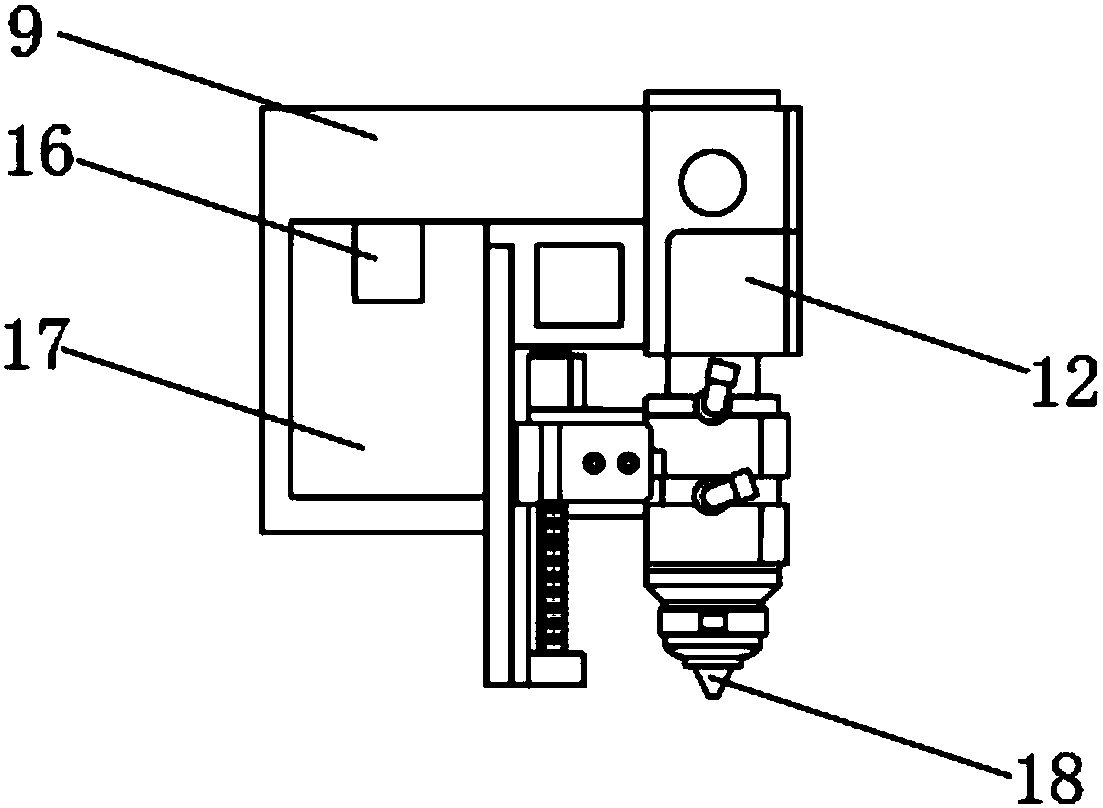

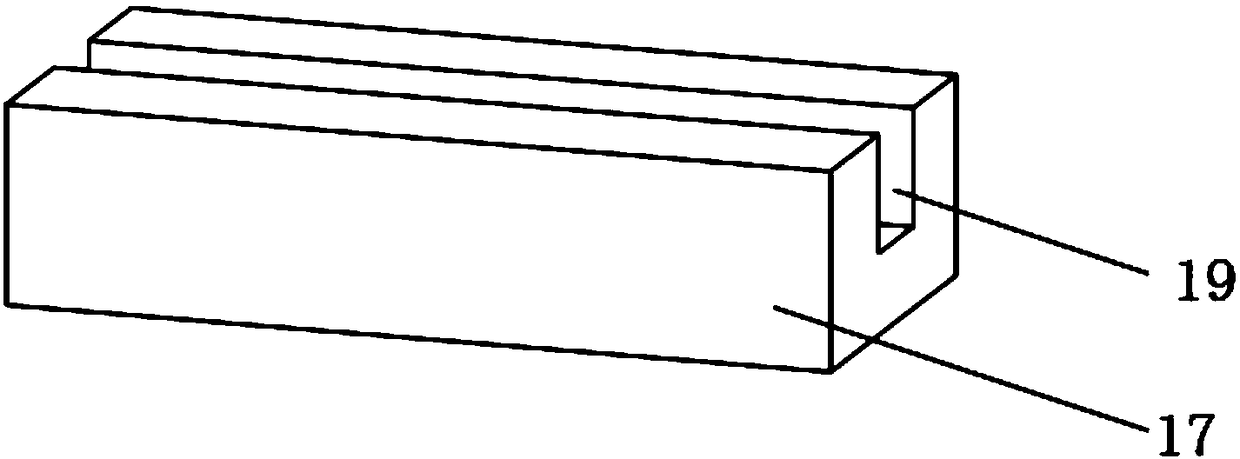

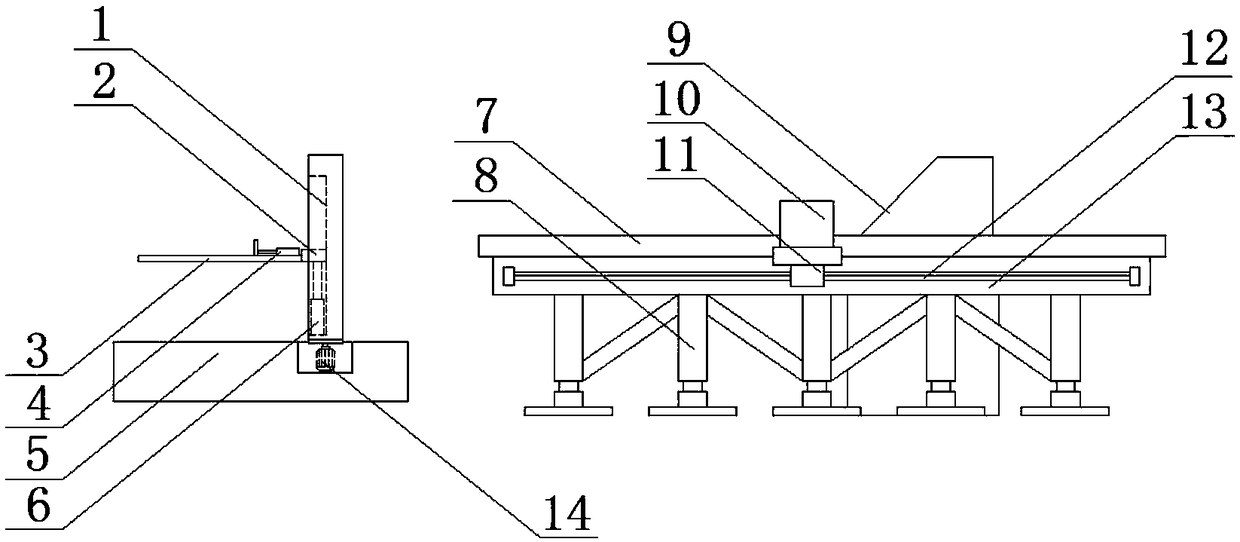

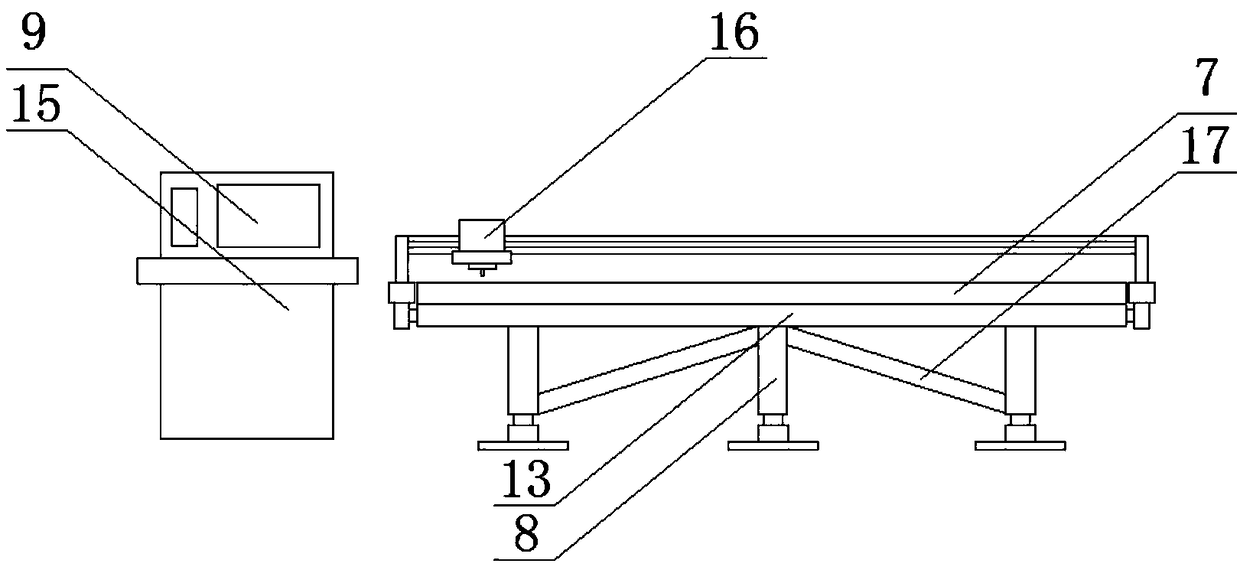

The invention relates to a laser cutting device, in particular to an optical fiber laser cutting device for a vehicle power battery pole piece, which comprises a worktable. The worktable is sequentially provided with a discharging mechanism, a conveying mechanism and a cutting mechanism, wherein a battery pole piece is arranged on the discharging mechanism, conveyed by the conveying mechanism and cut by the cutting mechanism, and a cutting head of the cutting mechanism is an optical fiber laser cutting head. By the technical scheme, the invention cuts the battery pole piece by adopting optical fiber laser, finely cuts the battery pole piece by utilizing the properties of laser, i.e. the beam quality approaching a diffraction limit, the conversion efficiency with high energy and the high stability, cuts a pole piece with narrow cutting gap, smooth cutting edge and high accuracy, favorably improves the performance of the battery pole piece and overcomes the defects of a traditional cutting method.

Owner:CHERY AUTOMOBILE CO LTD

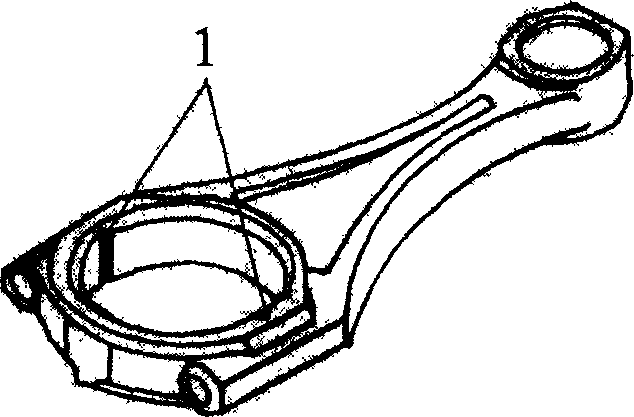

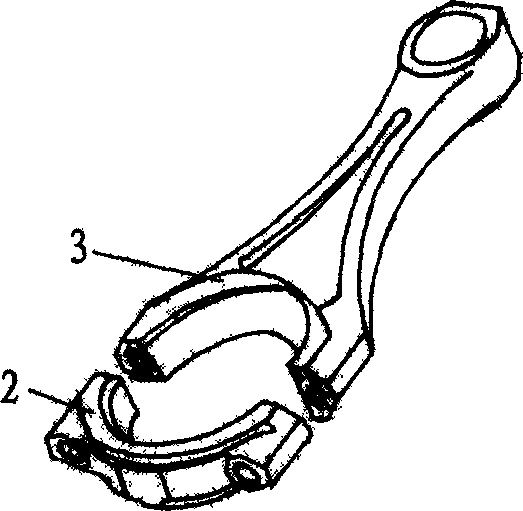

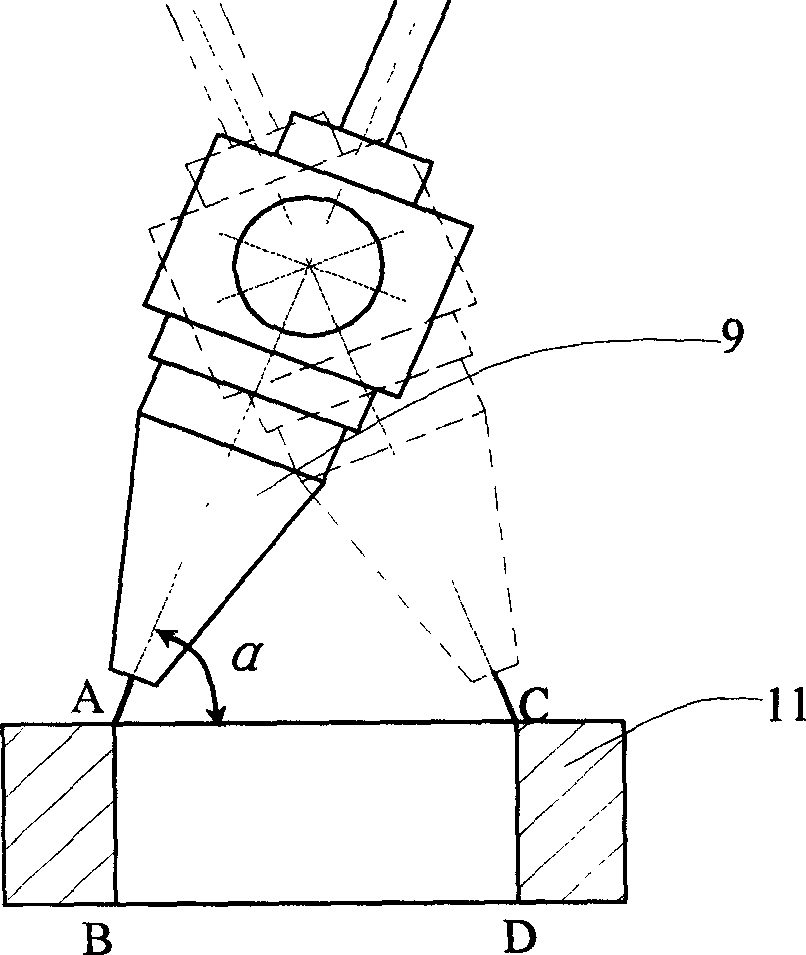

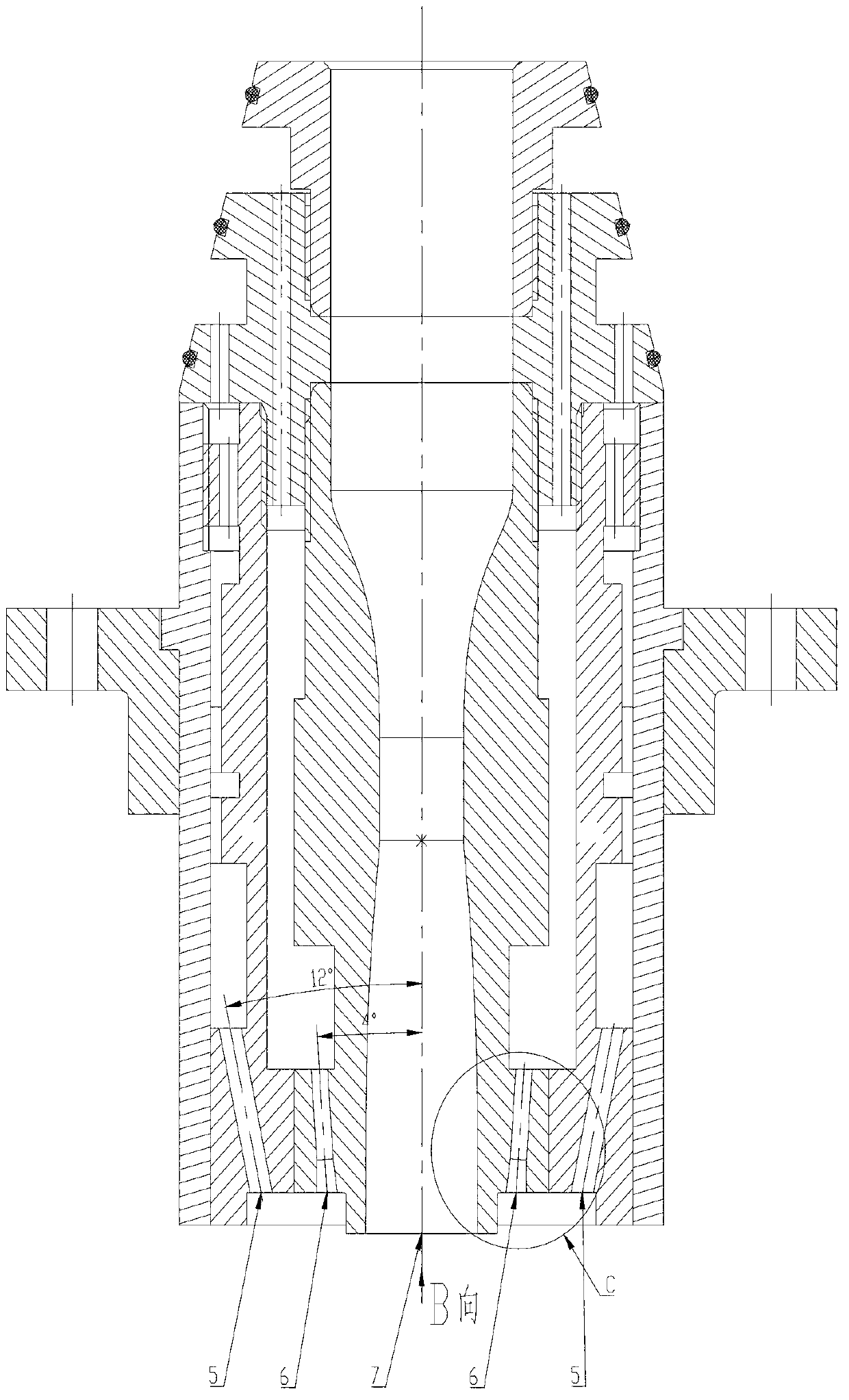

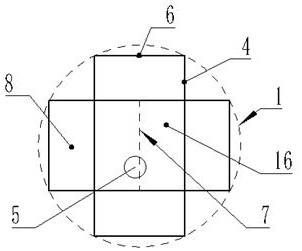

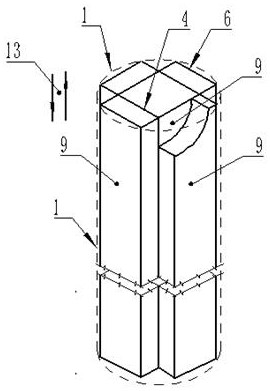

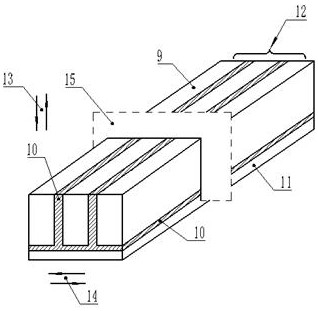

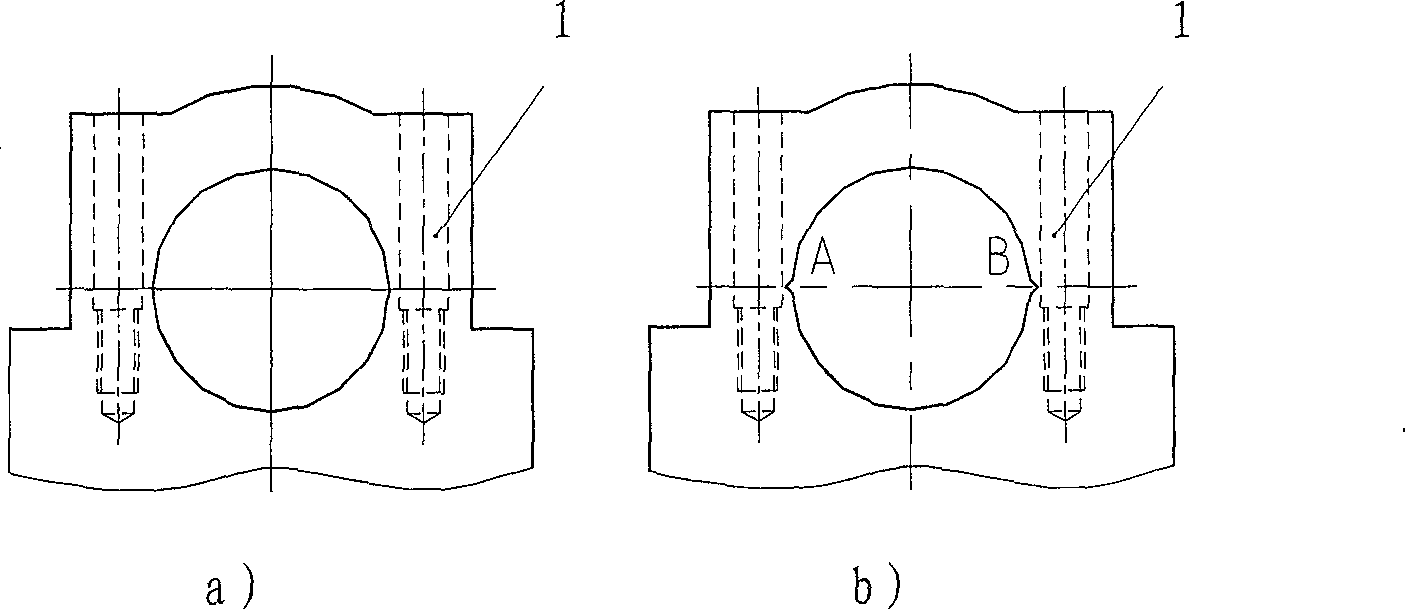

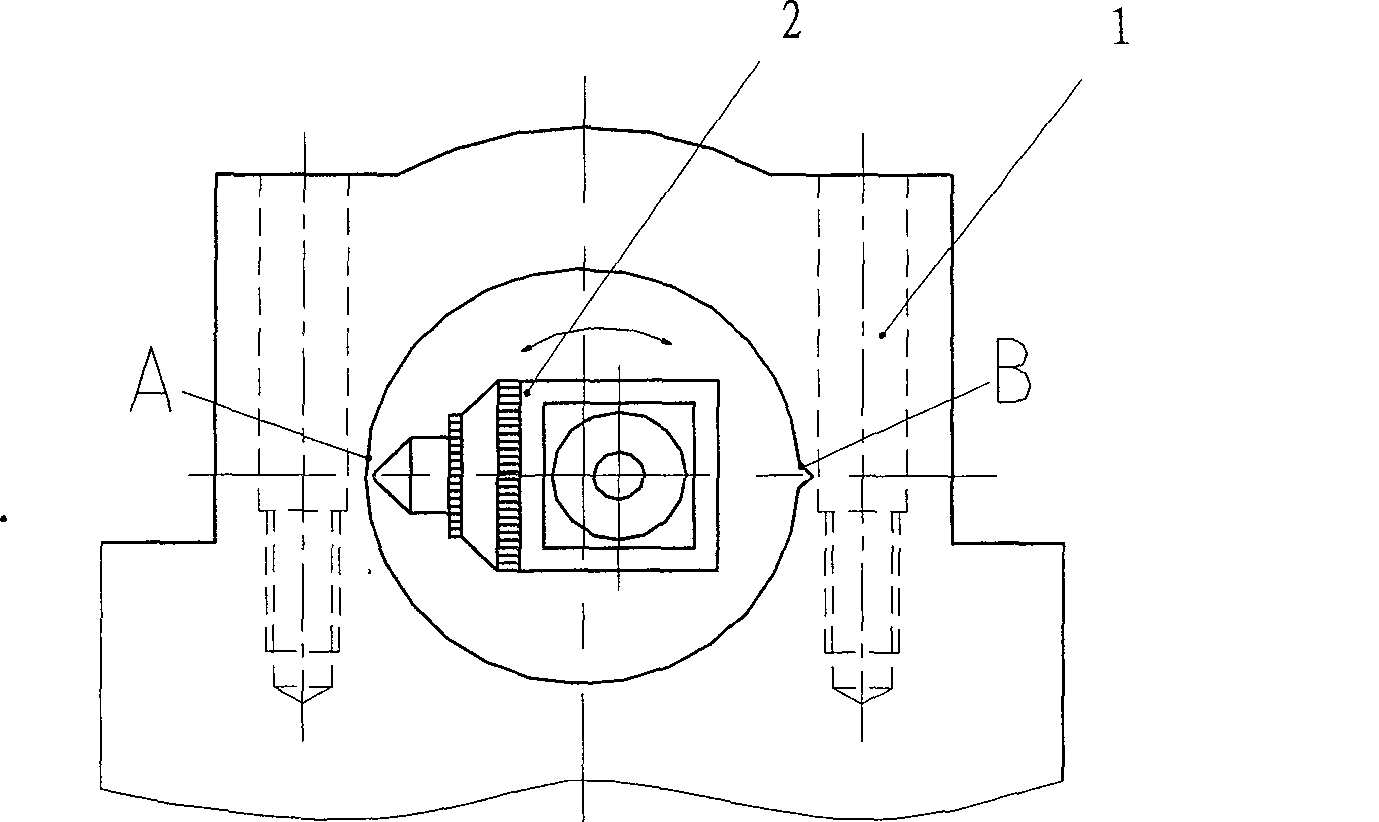

Laser processing method for connecting rod splitting groove and its equipment

InactiveCN1559744ANarrow kerfControllable depthConnecting rod bearingsShearing machinesLaser processingLaser cutting

A method for using laser to premachine the cracking slots before dividing connecting rods from each other includes such steps as fixing the laser cutting head above the position to be machined, which is near the hole on big end of connecting rod, regulating the incident angle of laser beam to 0-70 deg.C, turning on laser device, vertically moving the laser cutting head to machine the cracking slot to predefined depth, and repeating said steps to machine another cracking slot at another end of aconnecting rod.

Owner:JILIN UNIV

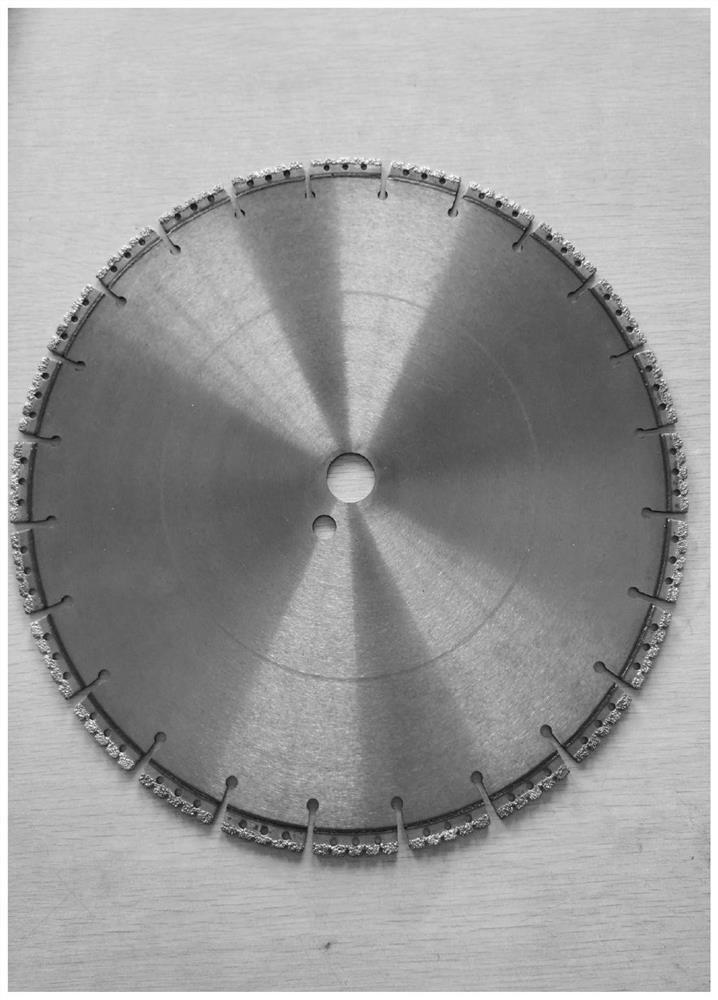

Saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method

ActiveCN104907942ANarrow kerfLess consumablesTransportation and packagingBonded abrasive wheelsBrickRebar

The invention relates to a saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method and belongs to the technical field of diamond machining tools. The preparation method is implemented through the following working procedures that a metallic bond and diamond are subjected to material preparation, granulation, cold pressing, hot pressed sintering, laser welding, first edge forming, polishing, painting, checking packaging storage in sequence. According to the saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method, a diamond tool bit is formed by the procedures that the metallic bond and diamond are subjected to the hot pressed sintering under vacuum conditions. By means of the saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method, the prepared cutting disk has the advantages that the cutting seam is narrow, the consumable items are less, the cutting deflection is small, the cut edge is neat, the cutting sharpness is good, and the cutting disk is particularly suitable for the cutting of hard materials including building materials, wall bodies, cement concrete, solidified concrete, reinforced concrete, hard concrete bricks, concrete piles and the like.

Owner:江苏华昌工具制造有限公司

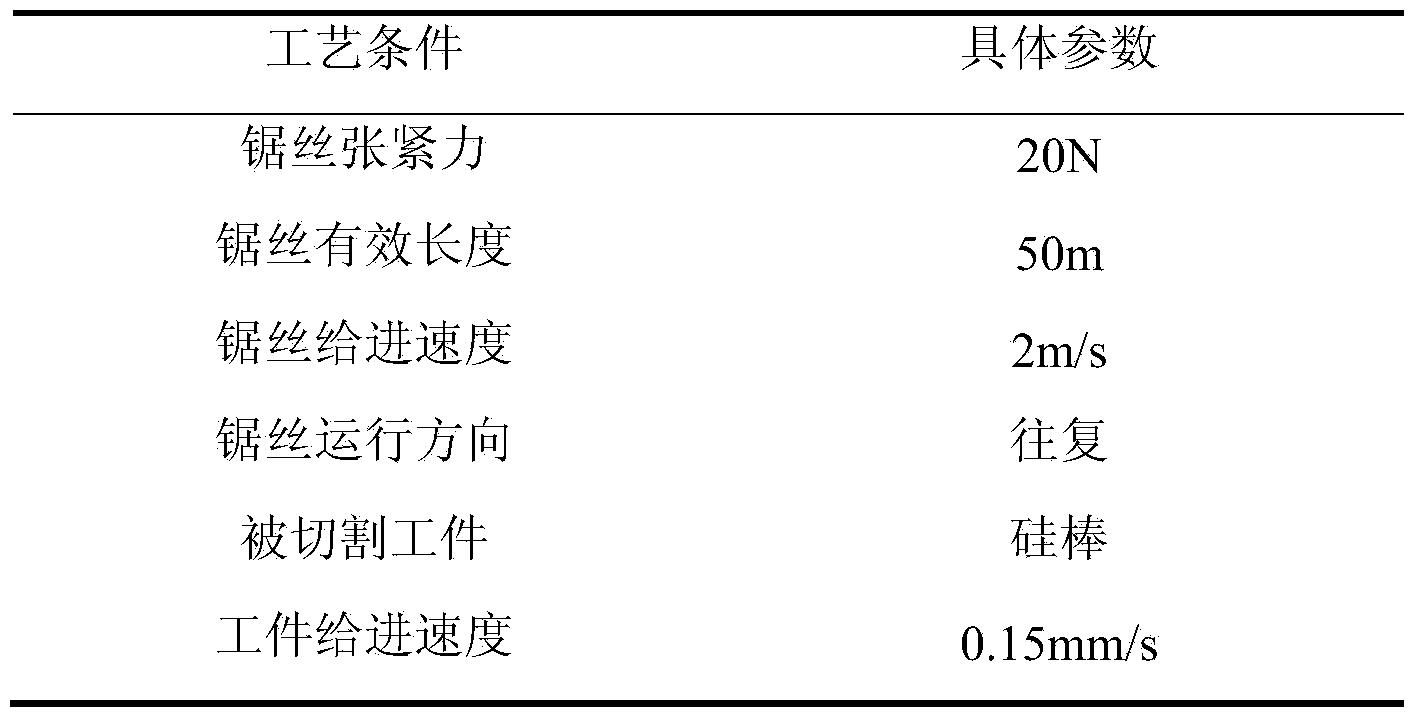

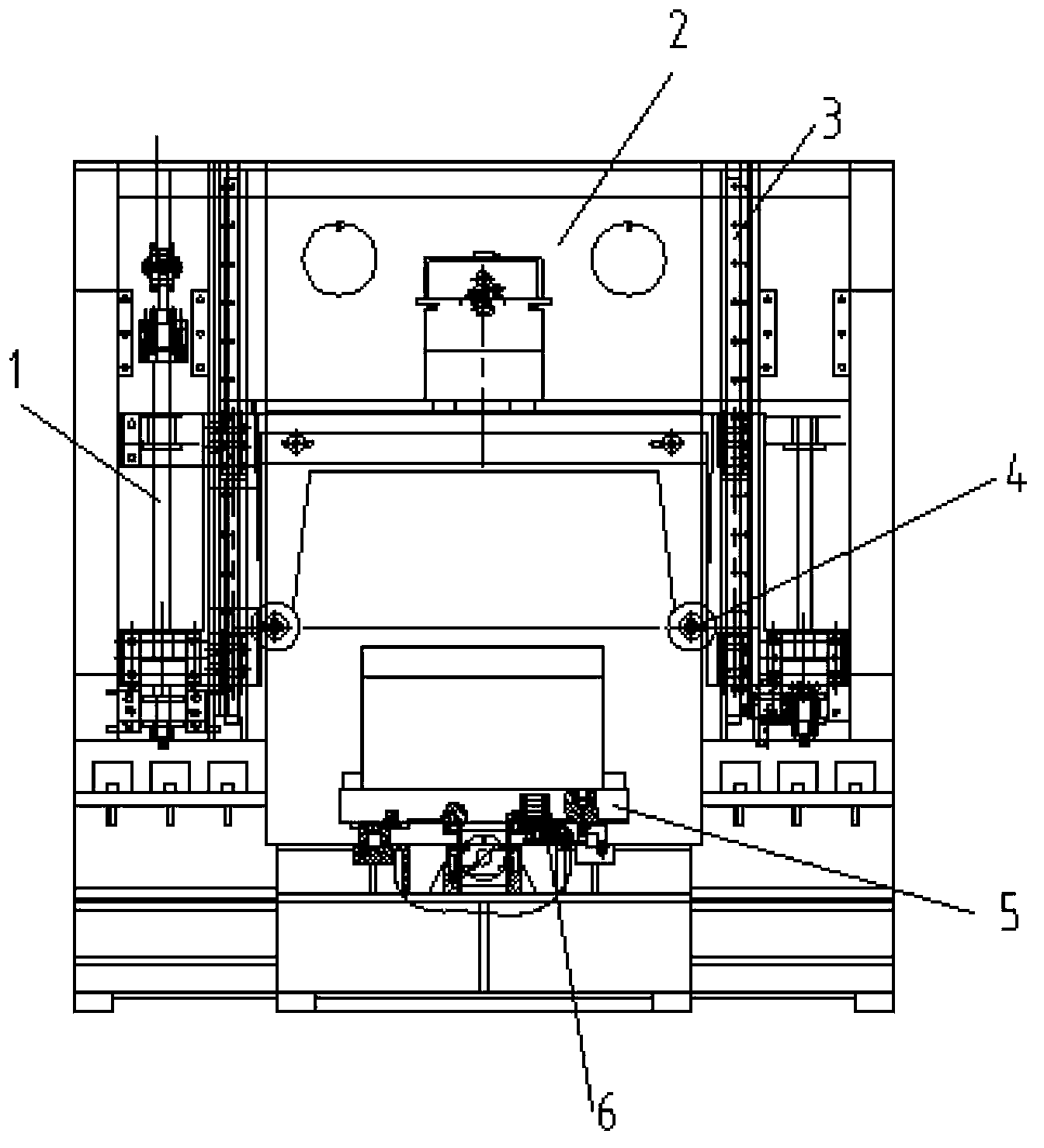

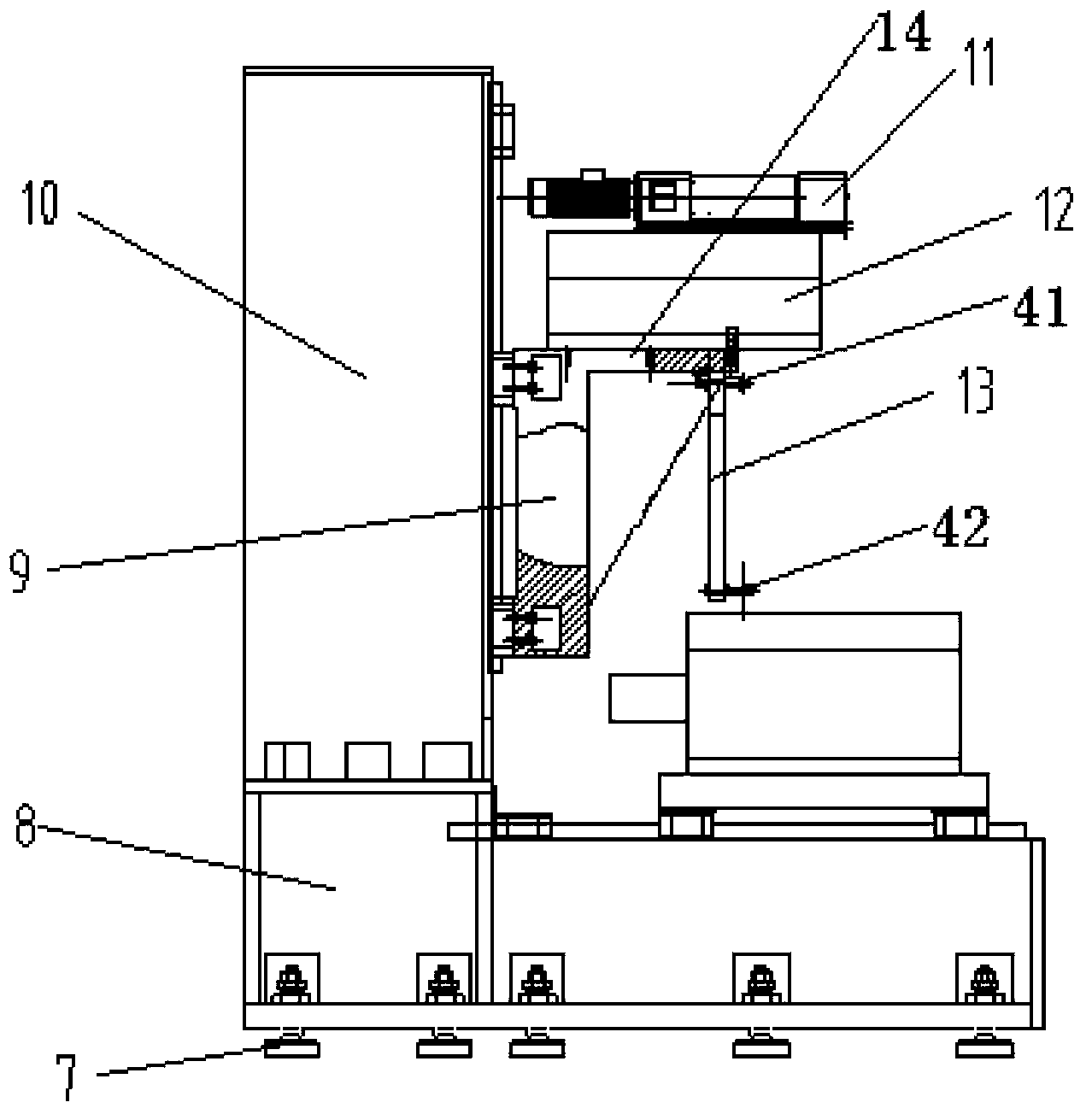

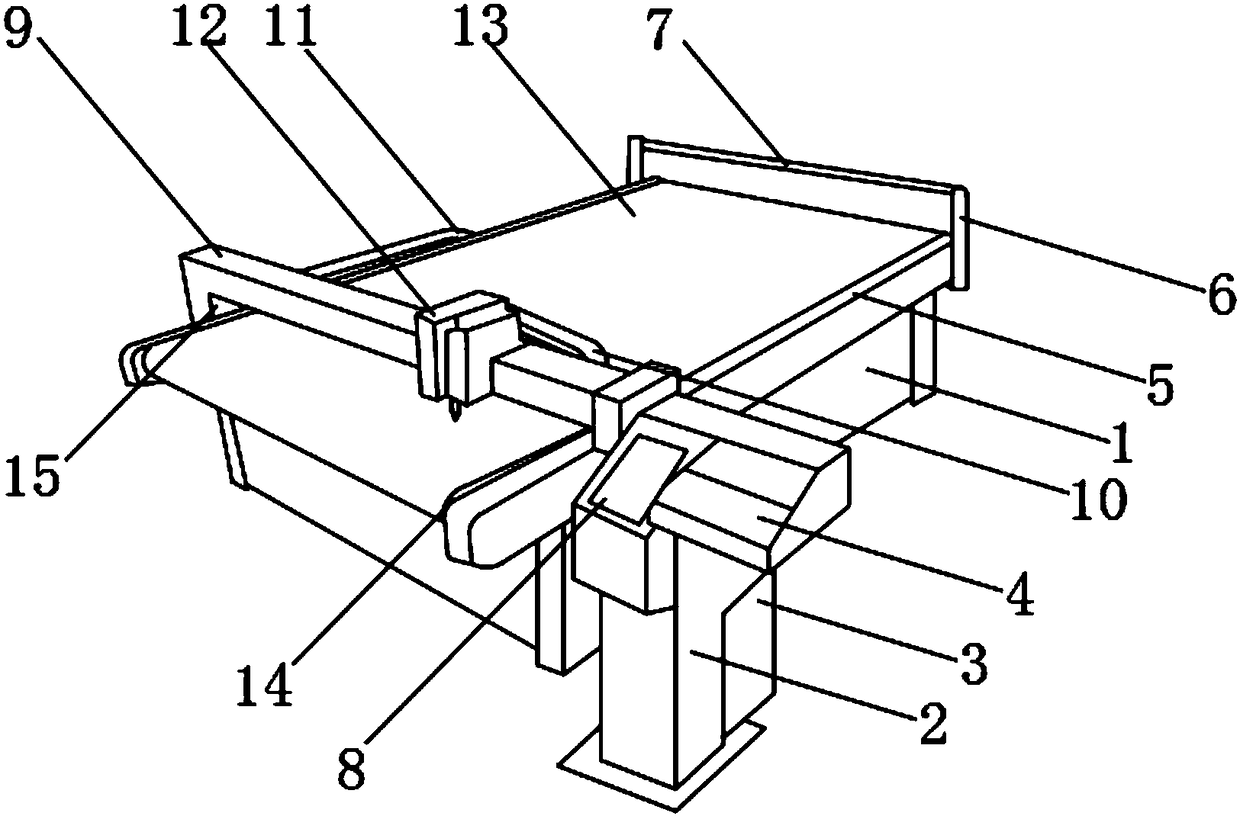

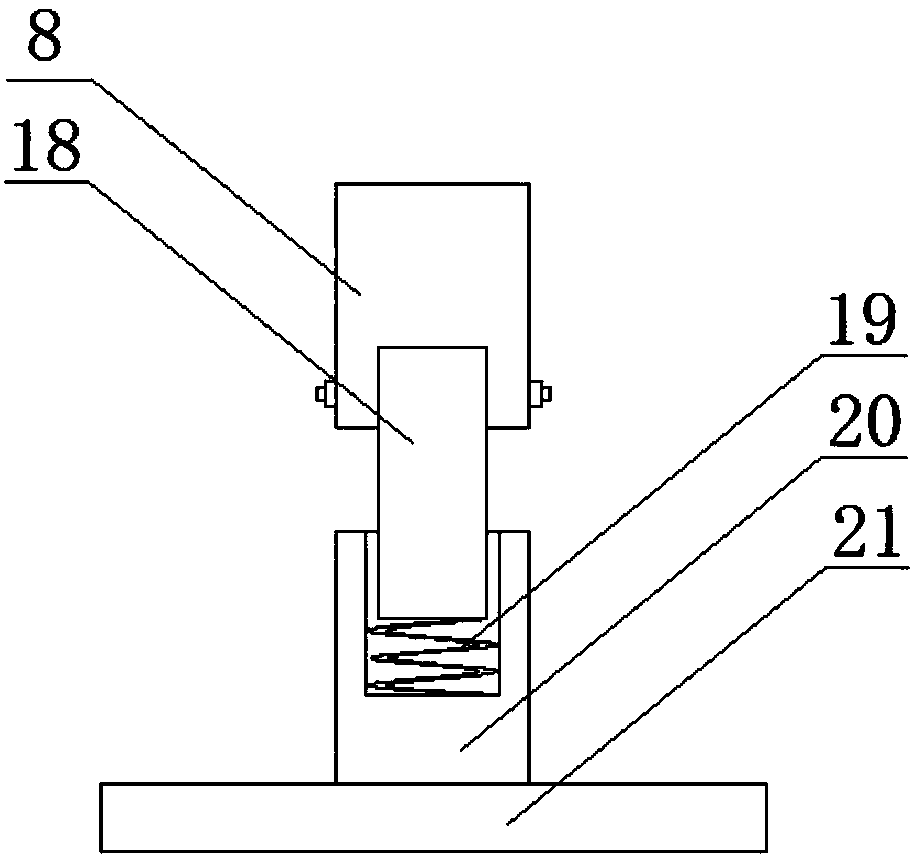

Cutting line vibrating ultrasonic sawing machine tool

InactiveCN102205560AImprove efficiencyGood precisionStone-like material working toolsLow noiseTransformer

The invention relates to a cutting line vibrating ultrasonic sawing machine tool which comprises a lathe, a guide rail, an X-directional sliding table, a Y-directional sliding table, a working platform, a lower wire-guiding frame, a wire-guiding wheel, an upper wire-guiding frame, an upright column, a screw rod, a hand wheel, a driving mechanism of an ultrasonic vibration system (a vibrator, an amplitude transformer and a transducer), a wire cylinder driving motor, a wire storage cylinder, a photoelectric switch, a wire storage cylinder sliding table, a base, a cylinder, a carriage, a cutting line, a water-cooling circulating system, an ultrasonic power supply and a control cabinet, wherein the lathe is formed by connecting the main supporting parts of an ultrasonic wire saw with the X-directional and Y-directional sliding tables; a workpiece carriage is fixed on the X-directional and Y-directional sliding tables provided with protection covers; and a workpiece is arranged on the workpiece carriage, thereby ensuring that the workpiece can move in a horizontal plane. The cutting line vibrating ultrasonic sawing machine tool has the advantages of high efficiency, high precision, low cost, narrow seam, material-saving property, low noise and environmental friendliness. The cutting line vibrating ultrasonic sawing machine tool is suitable for cutting a common hard material and especially suitable for cutting valuable hard materials such as precious stone, ceramics, and the like.

Owner:SHENYANG LIGONG UNIV

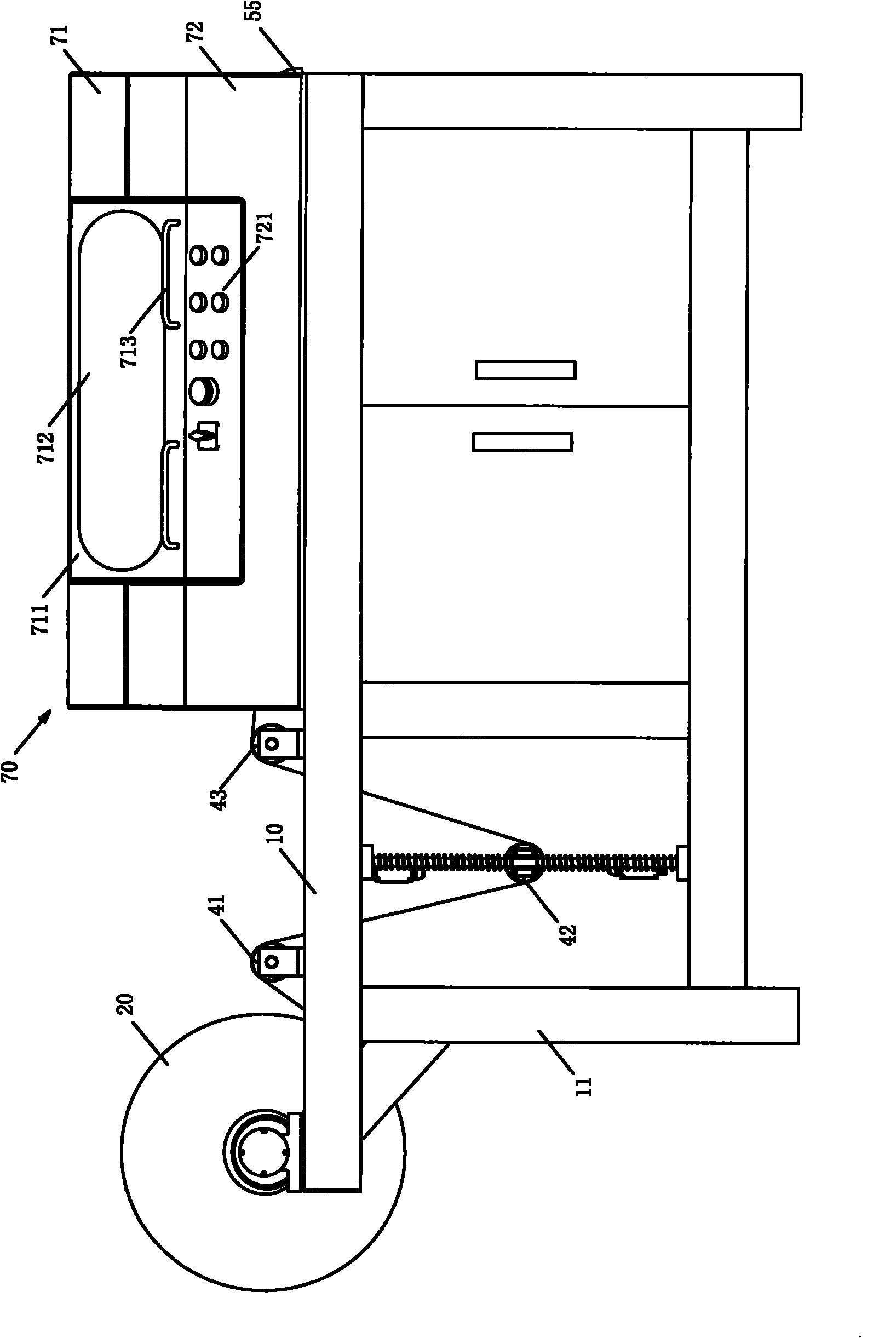

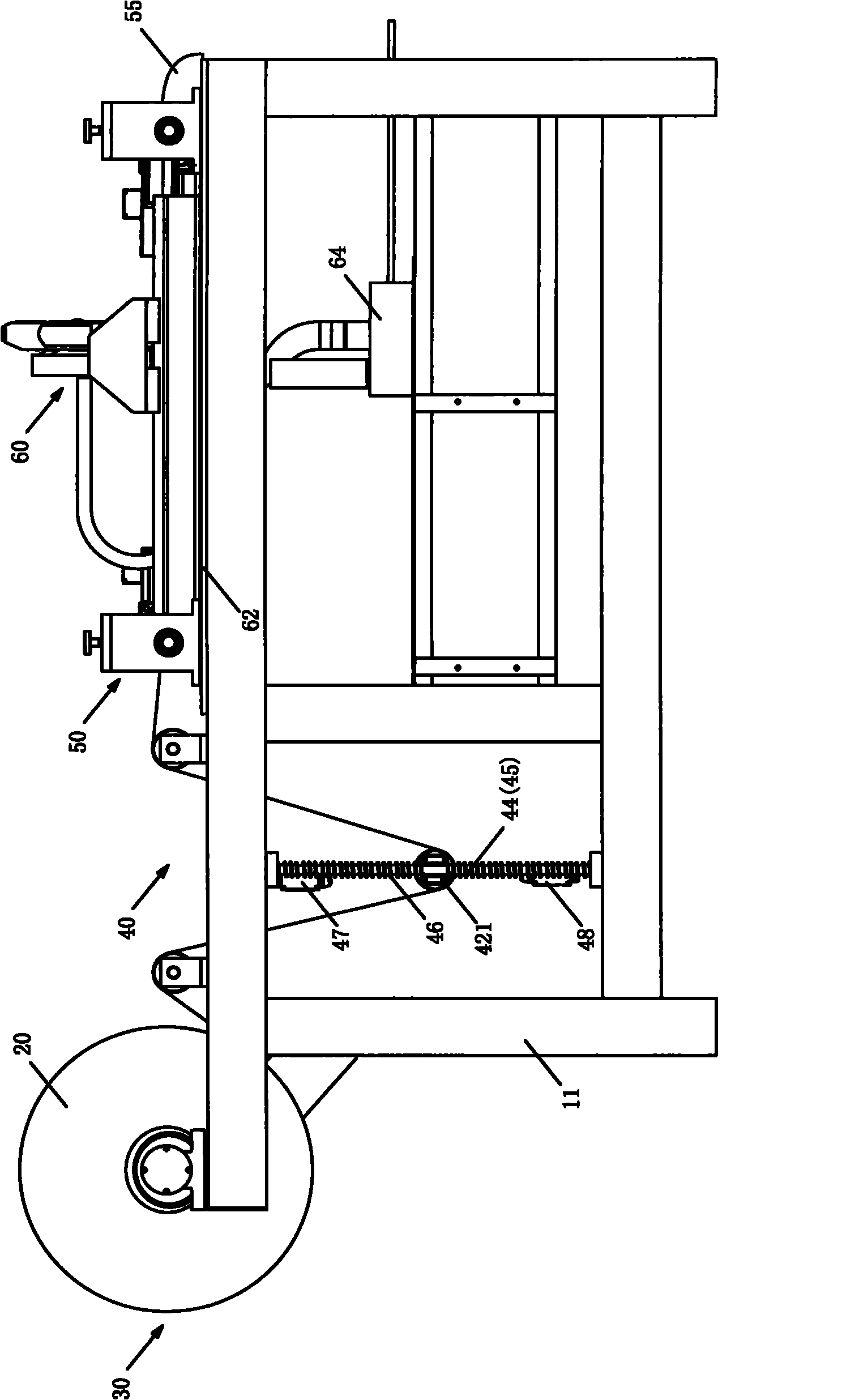

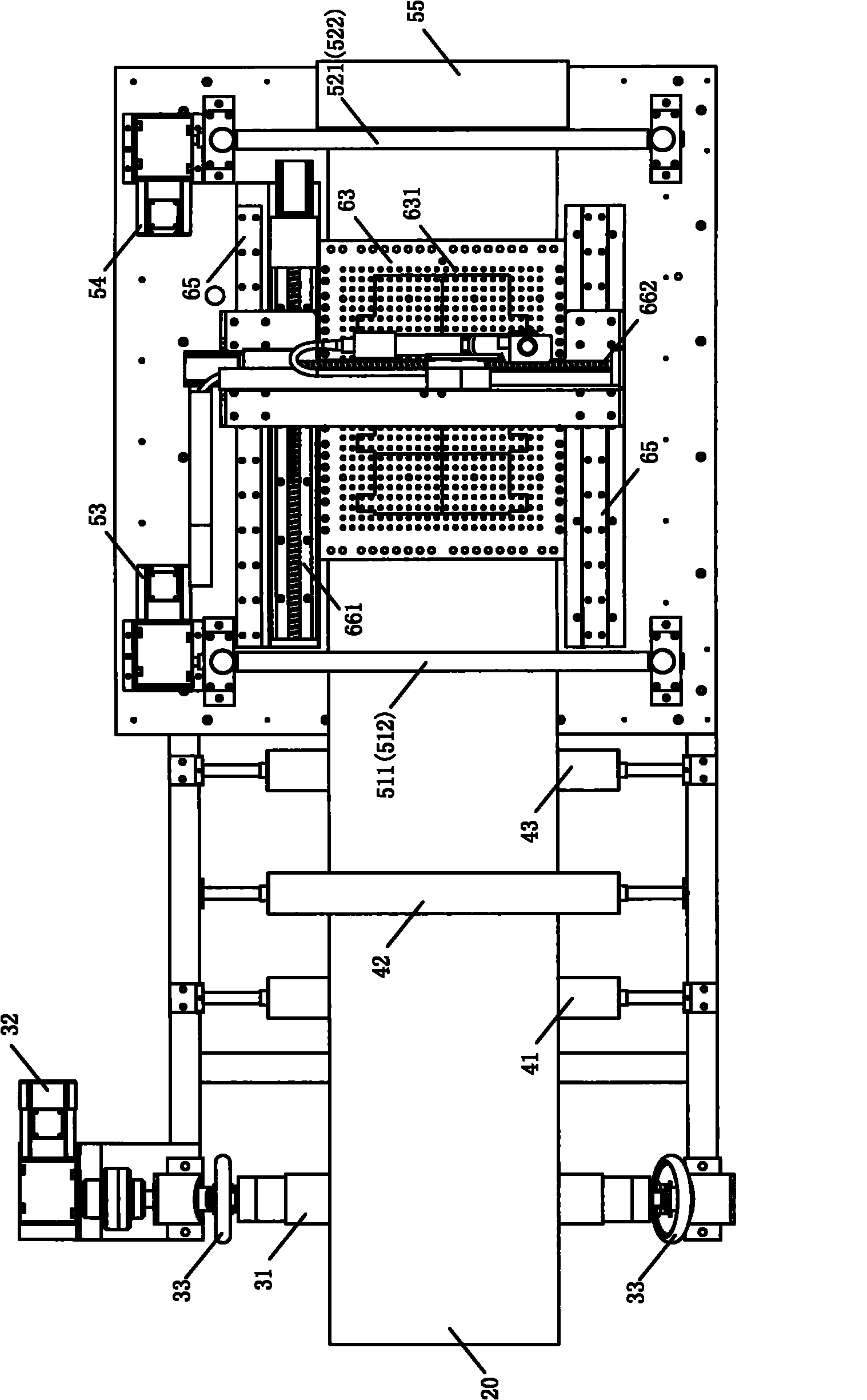

Automatic loading slitting step-shaft-type machine tool

The invention discloses an automatic loading slitting step-shaft-type machine tool. The automatic loading slitting step-shaft-type machine tool comprises a base, and a saw frame, a transmission system, a guide device, a saw belt tensioning device, a cooling system, a hydraulic system, an electrical control system, an automatic loading system, a V-shaped positioning clamping mechanism and a saw frame feed oil cylinder, which are arranged on the base, wherein the transmission system comprises a worm gear speed reducer, a driving wheel and a tensioning wheel; the driving wheel, the tensioning wheel and the guide device are respectively arranged on the saw frame; a loading movement device is arranged on one side of the V-shaped positioning clamping mechanism; the automatic loading system is arranged between the loading movement device and the V-shaped positioning clamping mechanism; the loading movement device comprises an adjustable working platform and a working platform supporting frame; one end of the adjustable working platform, which is adjacent to the automatic loading system, is hinged with the working platform supporting frame; and the other end of the adjustable working platform is connected with the working platform supporting frame through a working platform adjusting bolt. The automatic loading slitting step-shaft-type machine tool has functions of automatically loading a material, overturning the material into a material frame and clamping and sawing the material, and is convenient to operate and high in production efficiency.

Owner:ZHE JIANG CHENLONG SAWING MACHINE CO LTD

Multi-end laser cutting head

InactiveCN104889564ACompact structureExtended service lifeLaser beam welding apparatusBeam splittingLight beam

The invention discloses a multi-end laser cutting head and belongs to the technical field of application of laser cutting machinery. The multi-end laser cutting head comprises a base, a collimating mirror is mounted on one side of the base, the top end of the collimating mirror is connected with a laser with a connector, a beam splitter and reflectors are arranged in the base, and the beam splitter is communicated with the inside of the collimating mirror. Cutting ends are mounted at the bottom of the base and nozzles are mounted at the bottom ends of the cutting ends. Focus lenses are arranged in the cutting ends and are connected with adjusting nuts on the side walls of the cutting ends, and a beam adjuster is arranged between the cutting ends and the base and is communicated with the beam splitter and the reflectors. The multi-end laser cutting head is added into a beam splitting system and a beam quality adjusting system, so that on the premise of the same cutting quality, efficiency is improved by several times, machining cost is greatly reduced, laser cutting kerf is narrow, workpiece deformation is small, operation efficiency is high, and the nozzles can well protect the focus lenses.

Owner:无锡信欧光电科技有限公司

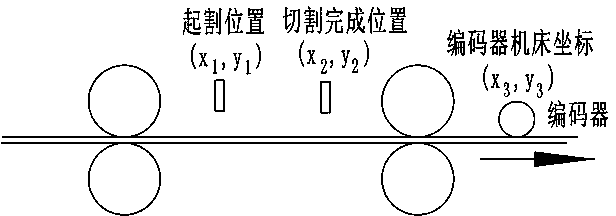

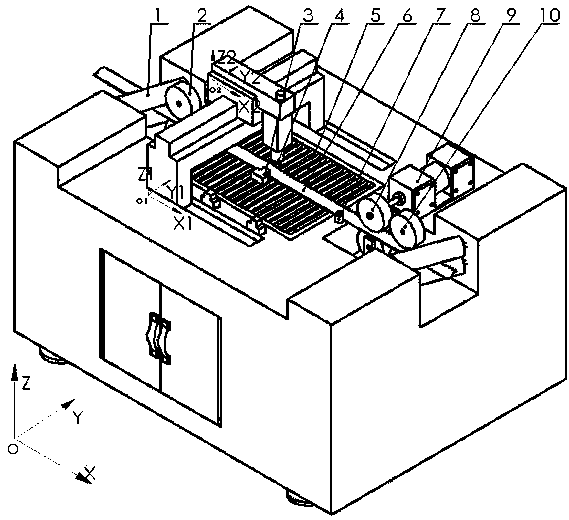

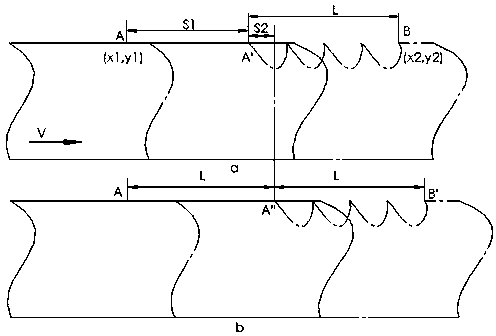

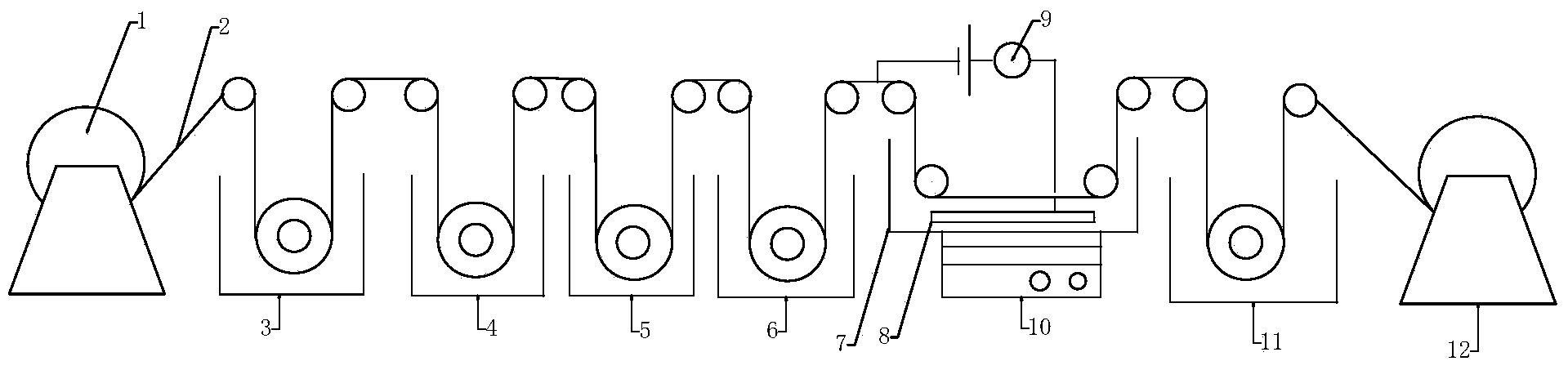

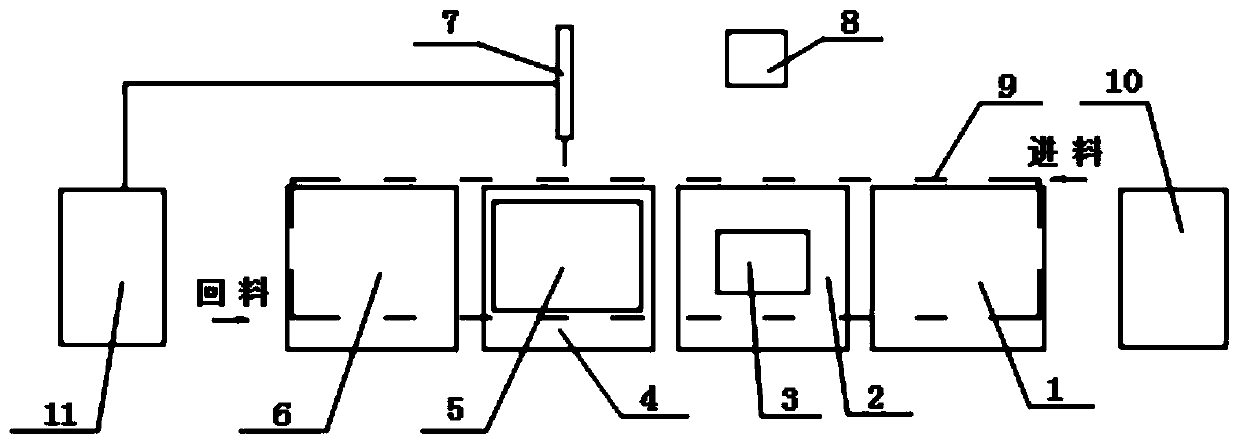

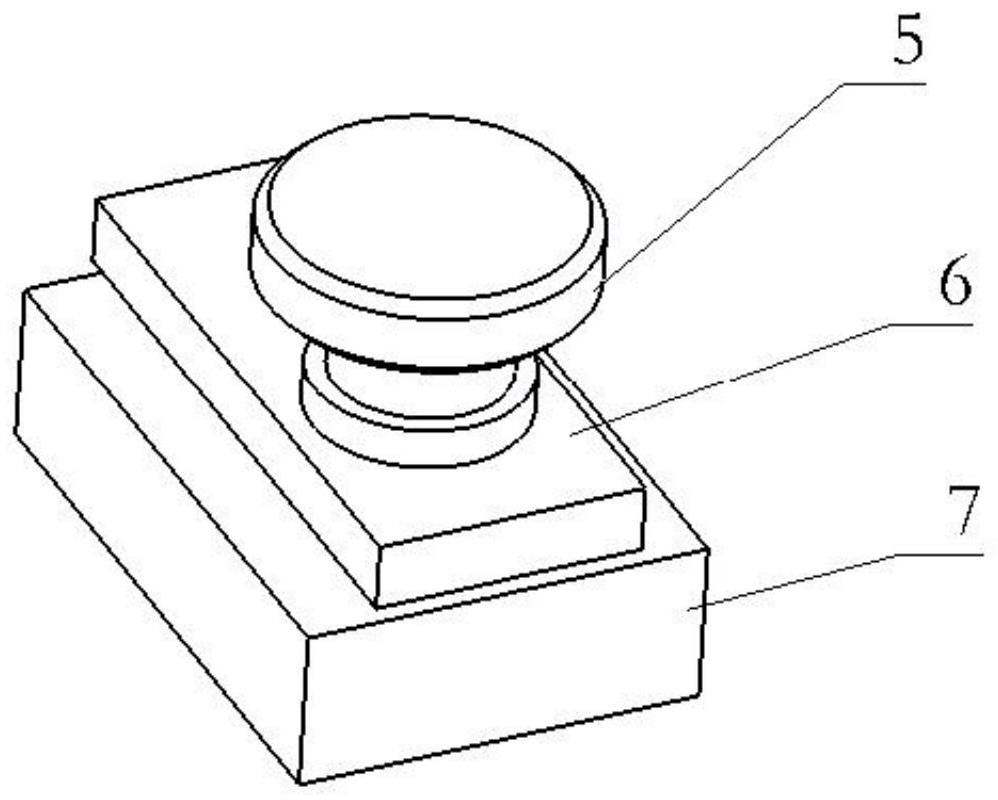

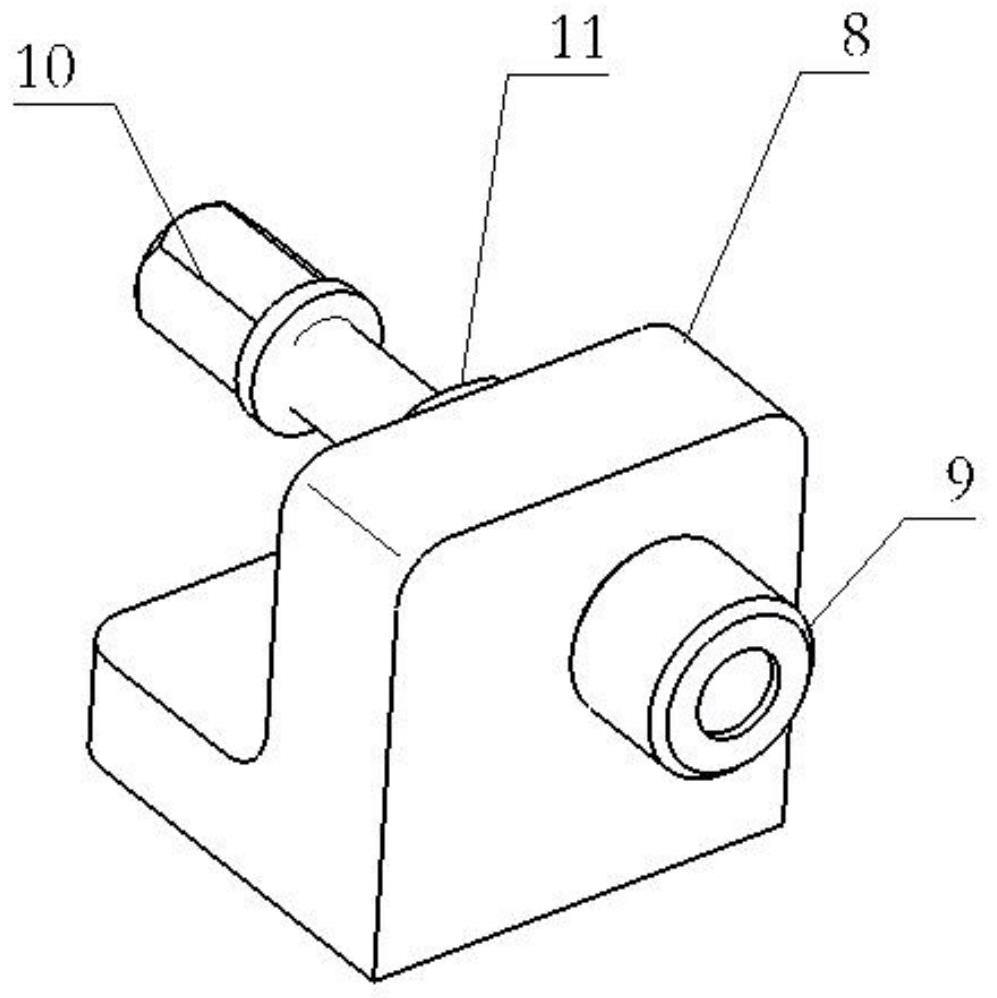

Laser continuous cutting device used for cutting saw belt and cutting method

ActiveCN104014938ANo thermal deformationNo damageWelding/soldering/cutting articlesMetal working apparatusMilling cutterLaser cutting

The invention discloses a laser continuous cutting device used for cutting a saw belt and a cutting method. The laser continuous cutting device aims to solve the problems that continuous cutting and forming of sawteeth can not be achieved, tool auxiliary time accounts for a high percentage, and cutting efficiency is low in the prior art. The laser continuous cutting device comprises a base which is sequentially provided with a driving friction roller used for regulating feeding speed of the saw belt, a pressing wheel set used for pressing the saw belt, a work platform and a driving wheel set driven by a driving device; a laser head which is arranged on a Z shaft for cutting the saw belt is arranged above the work platform; the work platform is provided with a feeler block and a transverse locating mechanism used for locating the saw belt; during cutting work, the speed of a sliding platform X1 is the same as the feeding speed of the saw belt. The laser cutting sawtooth continuous forming technique does not need a milling cutter, and the sawteeth in any two-dimensional shapes can be correspondingly manufactured very rapidly.

Owner:湖南泰嘉智能科技有限公司

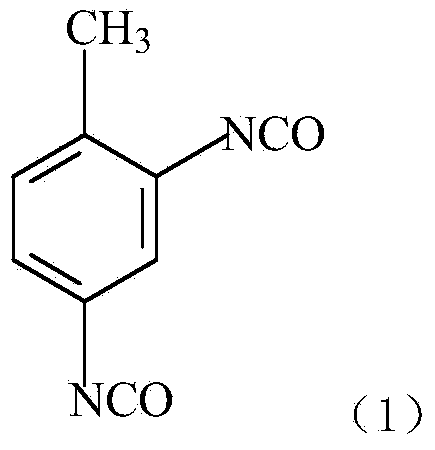

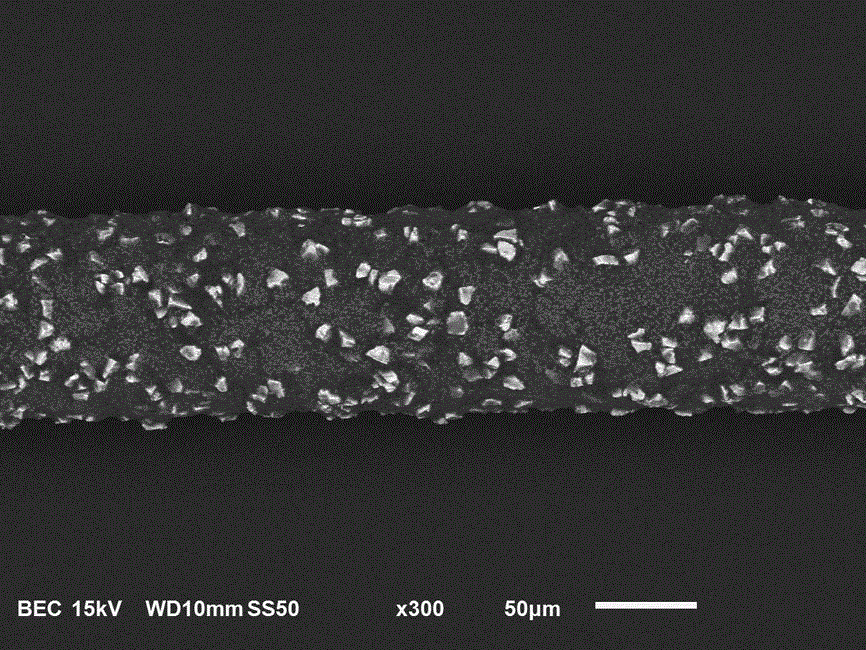

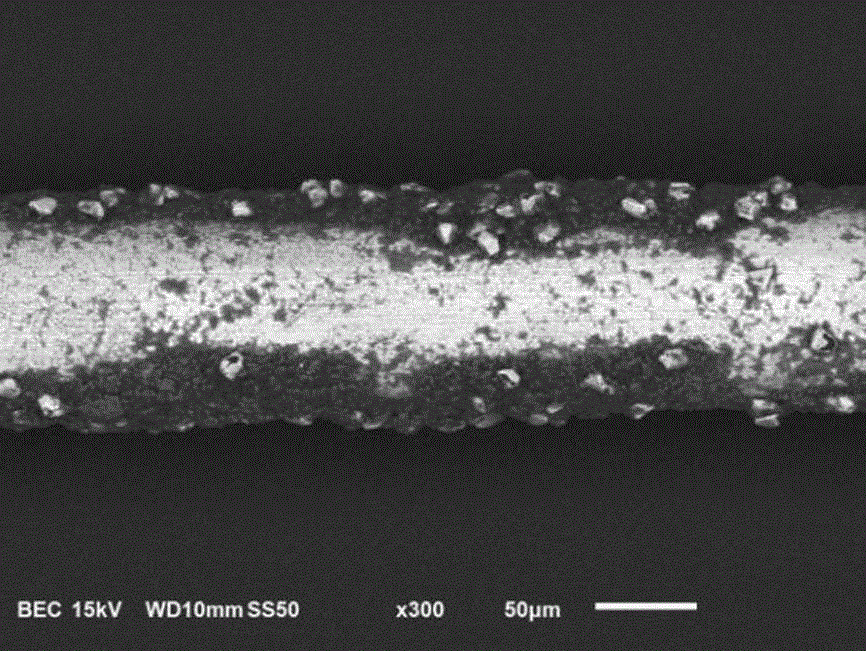

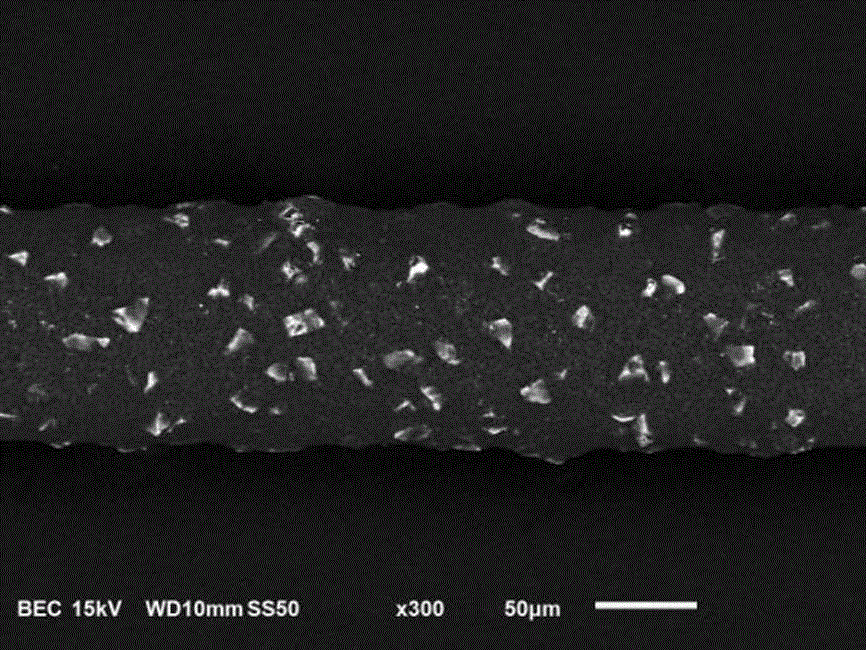

Preparation and superhigh-pressure processing method for cathode-electrophoresis-resin diamond scroll saw

ActiveCN104018207ALow unsealing temperatureHigh reactivityElectrolytic coatingsEmulsionPolymer science

The invention discloses preparation and a superhigh-pressure processing method for a cathode-electrophoresis-resin diamond scroll saw, and belongs to the field of preparation of diamond scroll saws. The diamond scroll saw is prepared by employing an electrophoresis method. The preparation method comprises: firstly preparing an emulsion of cathode electrophoresis resin, then adding diamond into the prepared emulsion, and employing an intermittent stirring manner to enable diamond to be uniformed suspended in the emulsion; and enabling a pretreated saw filament to pass through the diamond-containing emulsion in an electrophoresis way, and then performing pre-solidification, deep solidification, superhigh-pressure processing and the like, so as to finally prepare the diamond scroll saw. According to the prepared diamond scroll saw, the diamond usage amount is less, applied sand is uniform, the thickness of a resin layer is easily controllable, the resin layer is uniform, retention capability on wear debris, wear resistance and other aspects are better than those of diamond scroll saw coated with a resin binder.

Owner:SHANDONG UNIV OF SCI & TECH

Nonmagnetic material cutting machine

InactiveCN104162936AAverage cutting force is smallReduce cutting temperatureFine working devicesGlass severing apparatusEngineeringSlide plate

The invention relates to a nonmagnetic material cutting machine which comprises a machine tool body, a stand column and a line vibration ultrasonic diamond fretsaw cutting mechanism, wherein a longitudinal sliding table is arranged on the machine tool body, and a workbench is arranged on the longitudinal sliding table; the stand column is arranged on the machine tool body, a vertical guiding rail is arranged on one side, close to the sliding table, of the stand column, a sliding plate is mounted on the vertical guiding rail, and the sliding plate is driven by a motor through a lead screw inside the stand column; the line vibration ultrasonic diamond fretsaw cutting mechanism is arranged on the sliding plate. The cutting machine can be used for quickly cutting nonmagnetic material workpieces through the line vibration ultrasonic diamond fretsaw cutting mechanism, the work track of a diamond line is numerically controlled, various geometrical shapes can be accomplished, the processing efficiency is high, and the machining precision is excellent.

Owner:SHENYANG NORTH SPECIAL MACHINE TOOL

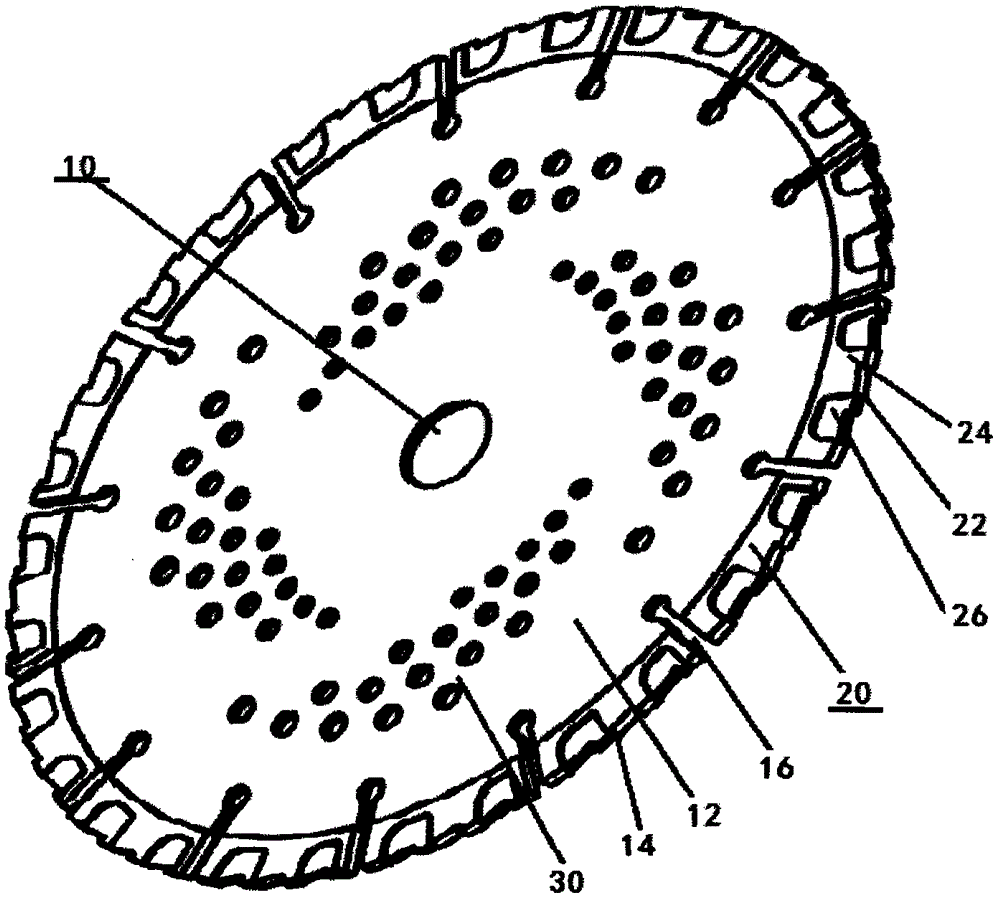

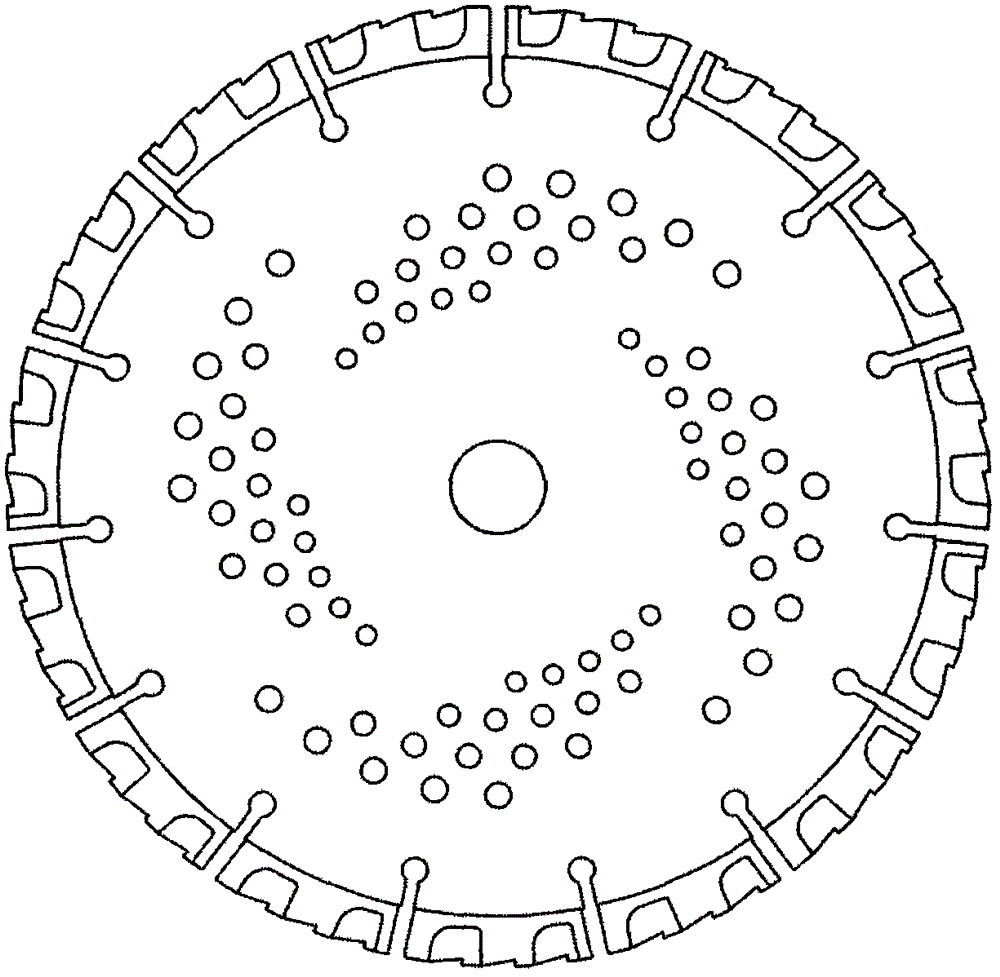

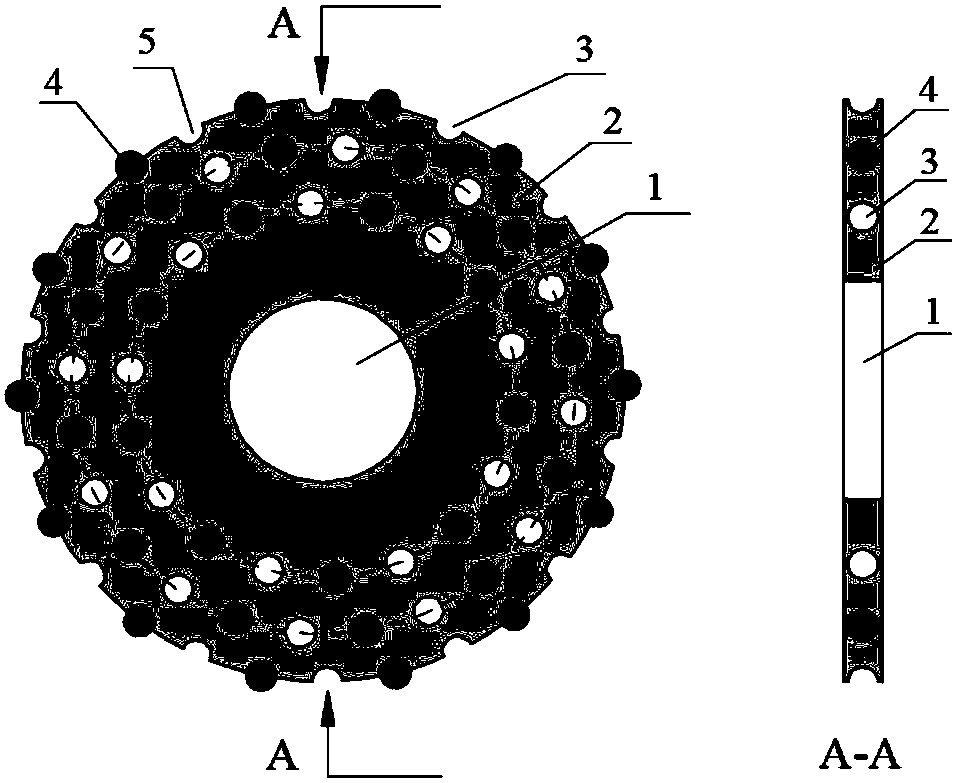

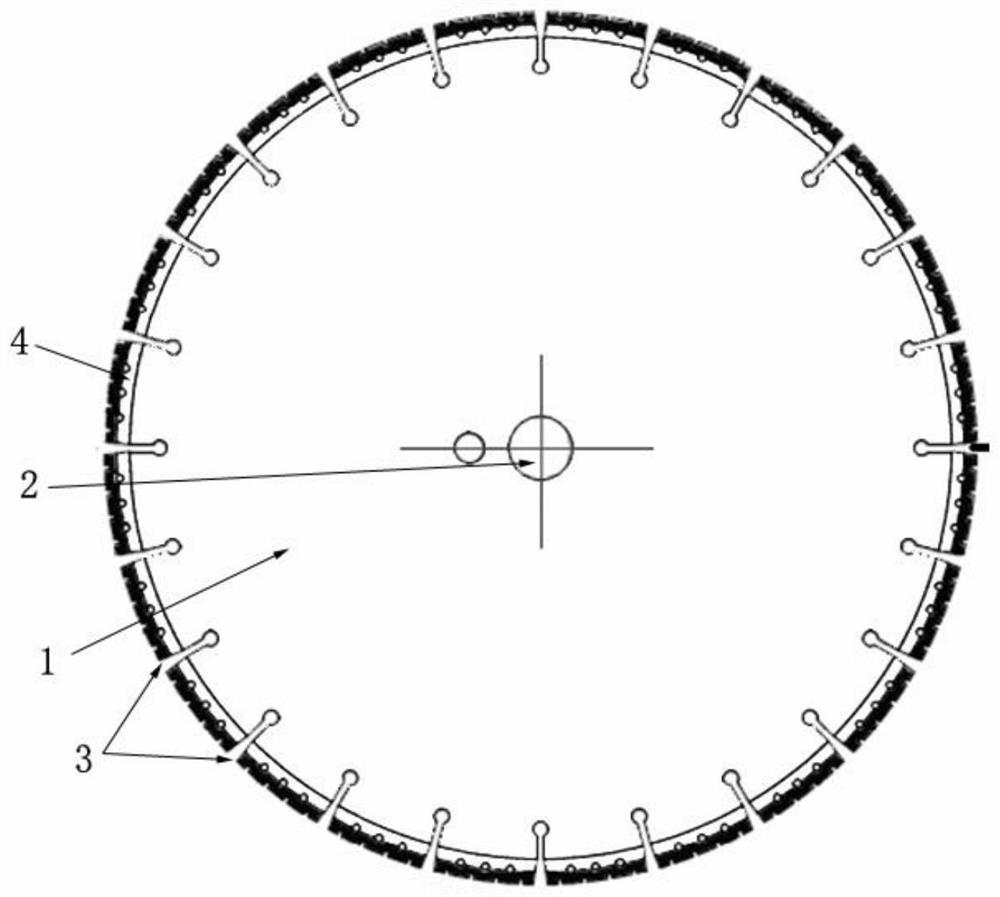

Orderly-positioned weakening matrix self-forming ultra-thin gear-shaped diamond saw blade and manufacturing process thereof

InactiveCN108356352AImprove sharpnessReduce contact areaMetal sawing tool makingMetal sawing toolsOrganic solventSelf forming

The invention discloses an orderly-positioned weakening matrix self-forming ultra-thin gear-shaped diamond saw blade. The orderly-positioned weakening matrix self-forming ultra-thin gear-shaped diamond saw blade is manufactured by adopting a powder metallurgy method, the diameter of the saw blade ranges from 30 mm to 400 mm, the thickness of the saw blade ranges from 0.2 mm to 2.0 mm, and the sawblade comprises a matrix working layer and a mounting hole; metal powder, a diamond and weakening matrix particles are selected as raw materials for the matrix working layer; an organic solvent is added into the metal powder and the diamond to be prepared into a slurry, the slurry is poured into a mold for forming, and an ultra-thin saw blade blank is made after vacuum baking and low-temperature sintering; and the weakening matrix particles are arranged in order according to the design concentration, and embedded in a preset position of the blank, and then the saw blade is manufactured by adopting a hot-pressing sintering process. According to the ordered positioning weakening matrix self-forming ultra-thin gear-shaped diamond saw blade and the manufacturing process thereof, the weakeningmatrix particles can fall off automatically in the cutting working process, so that the working end face of the ultra-thin saw blade is in a gear shape, and the ultra-thin saw blade has the advantagesthat the efficiency is high, the service life is long and energy consumption is low, and is good for saving resources and energy.

Owner:CENT SOUTH UNIV

Machining method for microcrystal glass wafers

InactiveCN110328562ANarrow kerfShallow depthWorking accessoriesFine working devicesEngineeringRaw material

The invention belongs to the technical field of glass wafer machining, and in particular, discloses a machining method for microcrystal glass wafers, and aims to solve the problems of lower utilization rate of raw materials in traditional microcrystal glass wafer machining methods and incapability of effectively improving the defects generated in the slicing process. The machining method for the microcrystal glass wafers comprises a strip shaping step, a dicing step, a block shaping step and a trimming step, and further comprises a slicing step, a finish grinding step and a polishing step. Linear cutting equipment is adopted for cutting, and can directly cut blocks to flaky blanks with a thickness below 1 mm; the diameter of steel wires is only about 0.13 mm; cutting gaps generated by slicing are narrow; and generated destruction layers are shallow. Compared with the traditional machining methods, the machining method increases the material utilization rate by about 80%, reduces the edge breakage width of the flaky blanks from initial more than 3 mm to below 0.15 mm, and can effectively improves the defects generated in the slicing process through finish grinding and polishing of the flaky blanks.

Owner:CDGM OPTICAL GLASS

Identifying and trimming device for two-dimensional irregular outer shape of soft material

PendingCN110815395AAvoid it happening againImprove efficiencyLeather clicking/perforating/clickingMetal working apparatusEngineeringSoft materials

The invention discloses an identifying and trimming device for the two-dimensional irregular outer shape of a soft material. According to the device, the trimmed material can be flattened on a machineconveying belt, the shape contour and the surface condition of the trimmed material are subjected to two-dimensional visual identification, the material appearance is automatically trimmed by a waterjet scalpel, and the trimmed material is automatically returned to the position near the feeding position; and a machine is configured with an independently developed special-purpose program for control to replace human eyes and human hands, and all the processes of acquiring edge information such as the shape, holes and surface scars, calculating a cutting path, conducting visual identification,determining a trimming track, conducting trimming machining and returning to a feeding position are automatically completed. Moreover, in the same time period during which the previous piece of material is machined, the visual identification and processing track online calculation of a last piece of material are conducted in parallel, and the efficiency is improved.

Owner:连云港善开智能科技有限公司

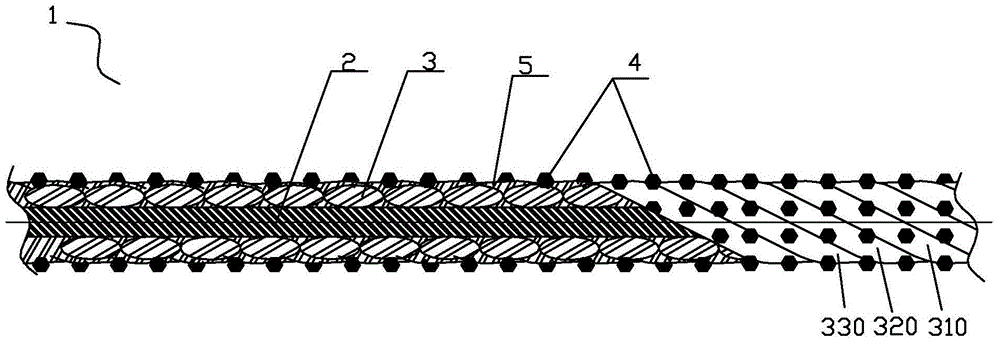

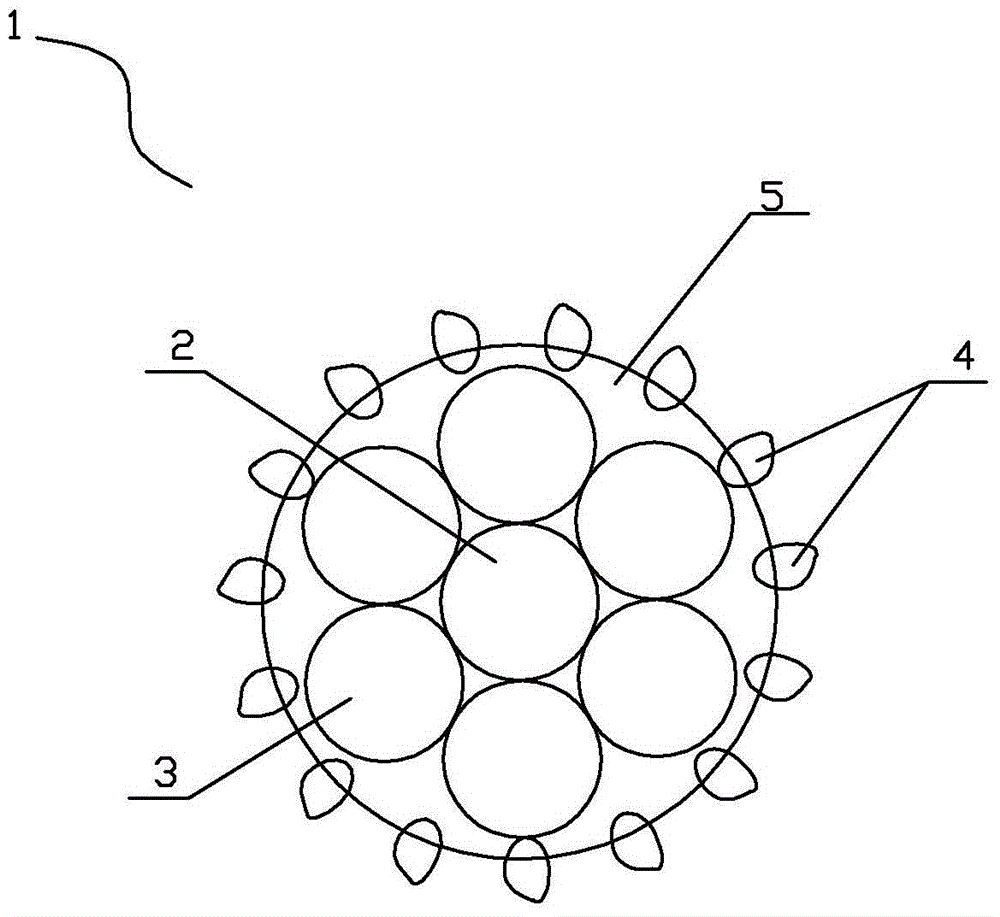

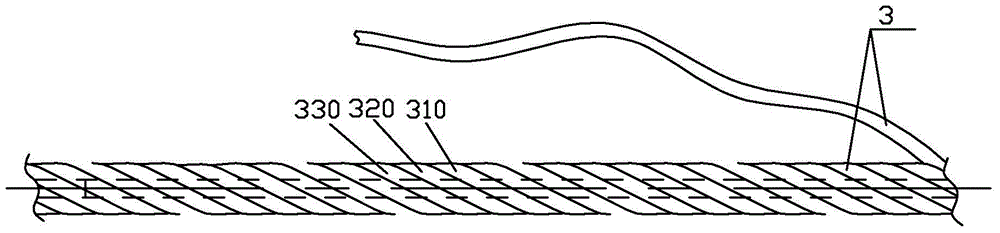

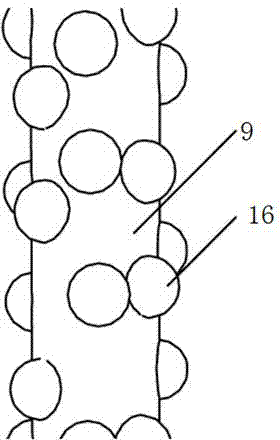

Annular superabrasive wire and manufacturing method thereof

ActiveCN104908166BReduce the numberNarrow kerfFine working devicesStone-like material working toolsYarnMaterials science

The invention discloses an annular superhard abrasive wire and a manufacturing method thereof. The base body of the annular superhard abrasive wire is a wire rope, the wire rope is connected in an end-to-end mode to form an annular shape, superhard abrasive particles are uniformly consolidated on the surface of the wire rope so as to form a superhard abrasive layer, the superhard abrasive layer is a single particle thickness layer, the wire rope comprises a core and compound yarns spirally wound on the core, the initial end and the tail end of the core are connected to form an annular shape, the length of the compound yarns wound on the core meets the requirement that the compound yarns can be wound on the core for six turns, after the compound yarns are wound on the core for six turns, the compound yarns are connected in an end-to-end mode, and joints of the compound yarns are disposed at one side of a core connecting point. The annular superhard abrasive wire is narrow in joint cutting, high in efficiency and good in cutting surface quality, and also has higher anti-fatigue strength.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

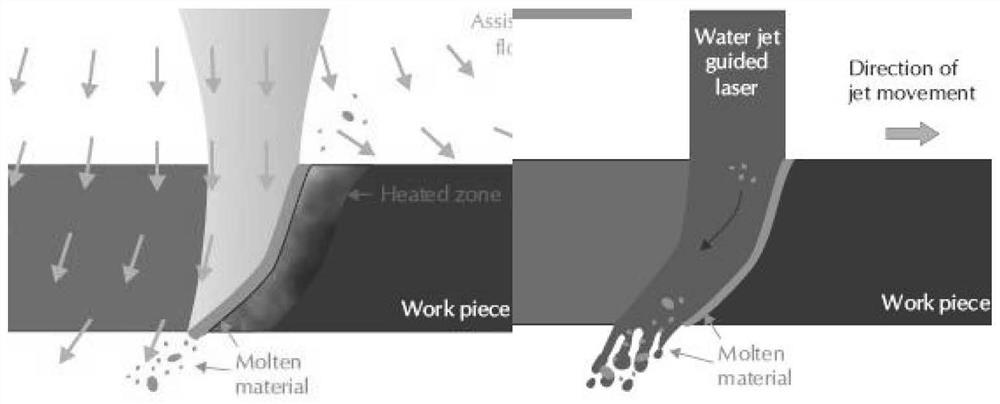

Silicon carbide wafer one-way three-time two-way six-step cutting process

ActiveCN112620973AImprove cooling effectEliminate accumulationLaser beam welding apparatusCarbide siliconWafering

The invention discloses a method for cutting a silicon carbide wafer by stepped laser. The method comprises the following steps that firstly the silicon carbide wafer is cut to the deepest position at a symmetrical position in the thickness direction of a silicon carbide crystal ingot; then three times of cutting are conducted on the left side and the right side for the same depth as the first time, so that a relatively gentle face with multiple times of water jet widths is established, and the face serves as a starting face of second-depth cutting for avoiding water column interference; second-layer first cutting is carried out on the left side of the central symmetry line to the deepest depth by adopting a same nozzle; then secondary cutting is carried out on the right side of the thickness symmetry axis to reach the same depth as the first cutting of the second layer; and a third layer is cut for the first time to reach the depth above the radius of the silicon carbide crystal ingot. High-depth cutting of the single crystal silicon carbide crystal ingot is achieved through step method cutting, a SiC single crystal substrate is prepared in a high-efficiency, high-quality, low-cost, low-damage and high-yield mode, and the method has application and popularization value.

Owner:西安晟光硅研半导体科技有限公司

Cutting torch for cutting ultrahigh-thickness 2000-3500 mm low-carbon and low-alloy steel ingot

ActiveCN102997243AImprove the heating effectHigh cutting surface qualityGaseous fuel burnerTorchIngot

The invention provides a cutting torch for cutting an ultrahigh-thickness 2000-3500 mm low-carbon and low-alloy steel ingot and belongs to the technical field of the ultrahigh-thickness low-carbon steel ingot oxygen cutting device. The invention aims to solve the technical problem in the background art that the 2000-3500 mm ultrahigh-thickness low-carbon and low-alloy steel ingot cannot be cut at high efficiency and good quality. The cutting torch is mainly characterized in that preheating oxygen and propane gas are not mixed inside the cutting tip of the cutting torch at first, and mixed and burnt in atmosphere after being jet out of the cutting torch instead, a preheating oxygen duct (5) and a gas duct (6) both are inclined toward the axis of the cutting torch, the diameter of the throat part of a large-flow cutting oxygen cutting tip (7) is 17-22 mm, each gas duct (6) is designed into a structure with the lower part thereof slightly spread, and the diameter of the inlet thereof is 4.5 mm, the spreading taper angle is 1.146% and the length of the spreading section is 8 mm. The cutting torch provided by the invention is suitable for good-quality and high-efficiency cutting of the ultrahigh-thickness 2000-3500 mm low-carbon and low-alloy steel ingot.

Owner:HARBIN WELDING INST LTD

Processing method for processing rectangular photovoltaic cell silicon wafer by using primary single crystal silicon rod

ActiveCN113601738AConsistency is easy to controlConsistent impurity concentrationFinal product manufactureFine working devicesCrystallographySilicon chip

The invention discloses a processing method for processing a rectangular photovoltaic cell silicon wafer by using a primary single crystal silicon rod. The method comprises the following steps of step 1, determining eight longitudinal tangent lines formed by four straight lines shaped like a Chinese character "jing" and four edge straight lines on a cross section plane of the primary single crystal silicon rod; step 2, longitudinally cutting the primary single crystal silicon rod to obtain rectangular silicon ingots; step 3, splicing the rectangular silicon ingots to obtain a spliced silicon ingot; and step 4, cutting the spliced silicon ingot by using multiple planes to obtain the silicon wafer of a single crystal silicon photovoltaic cell. Compared with the prior art, the processing method is favorable for using a large-diameter single crystal silicon rod, is favorable for improving the distribution uniformity and symmetry of impurities doped in the silicon wafer, is favorable for improving the working production efficiency, and is favorable for reducing the head and tail slice loss; and in the slicing process, cutting silicon powder can be discharged, the cutting environment is improved, the production efficiency is improved, and the product quality is improved.

Owner:云南宇泽半导体有限公司

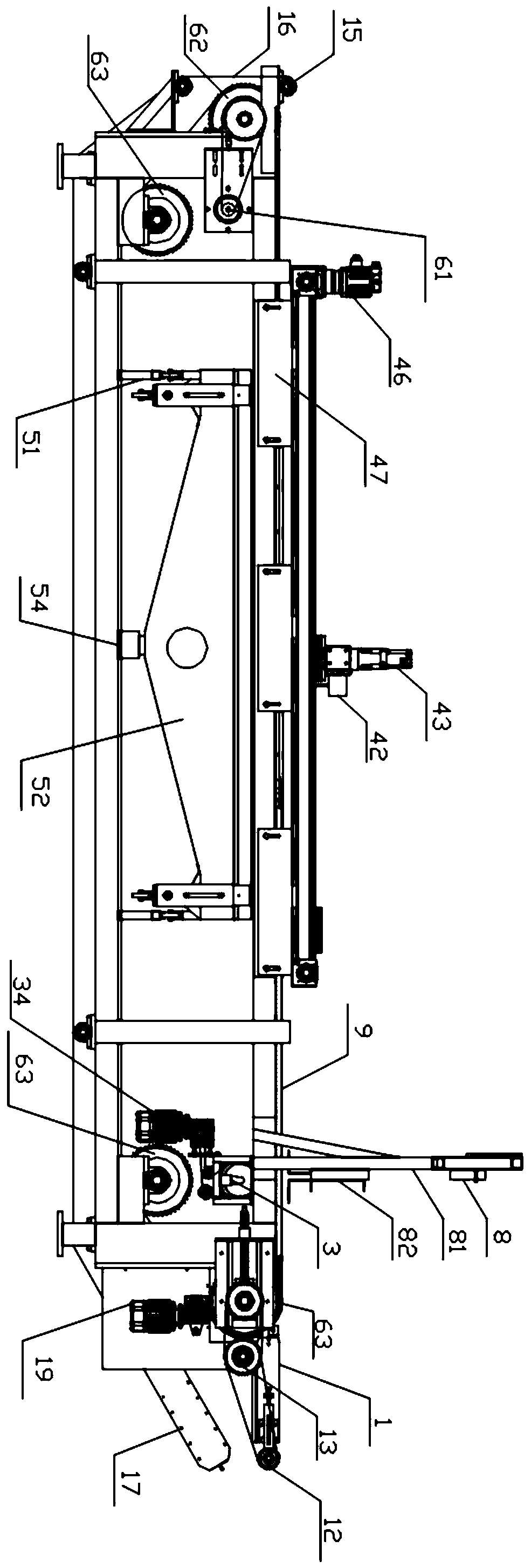

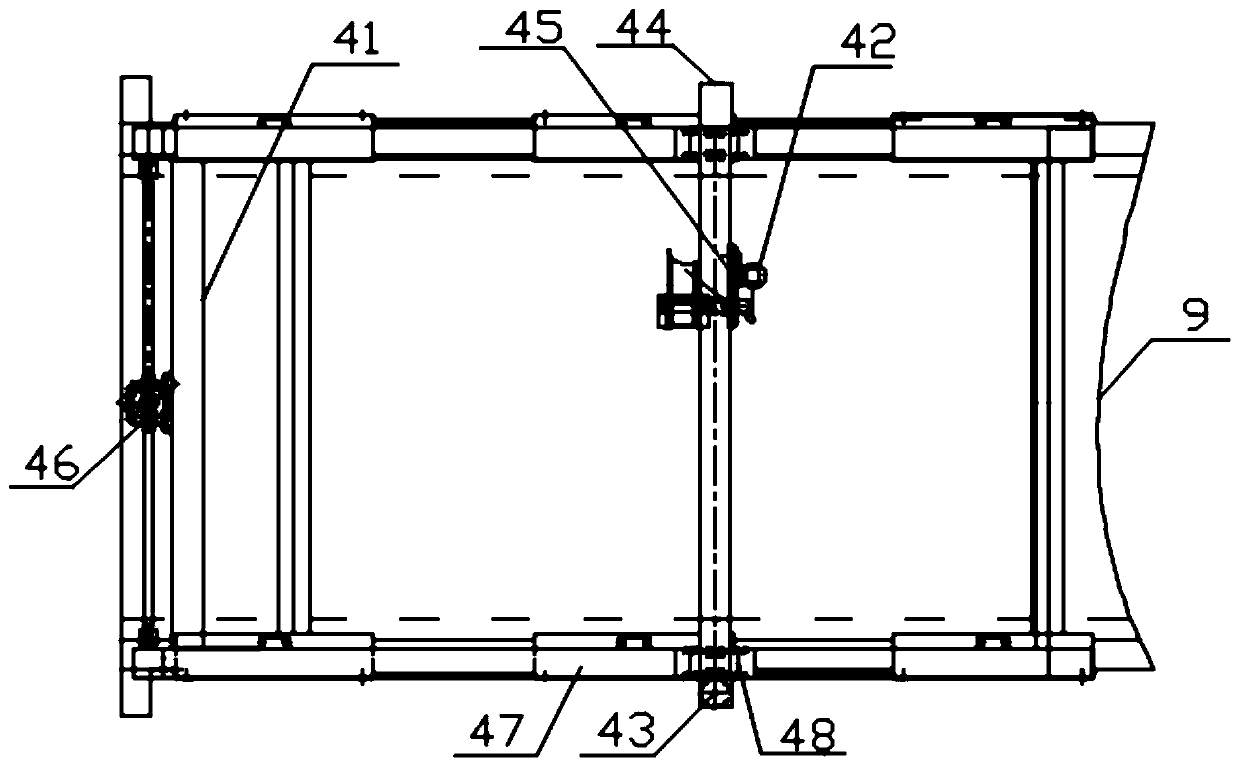

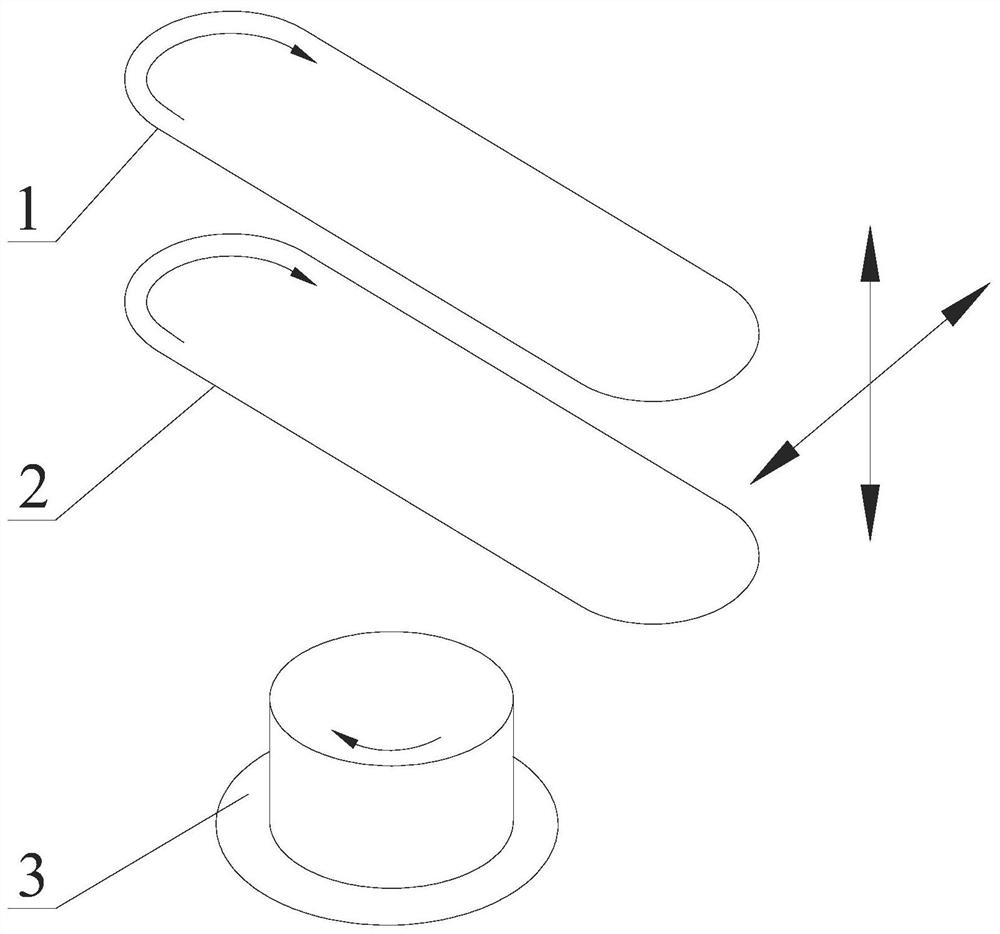

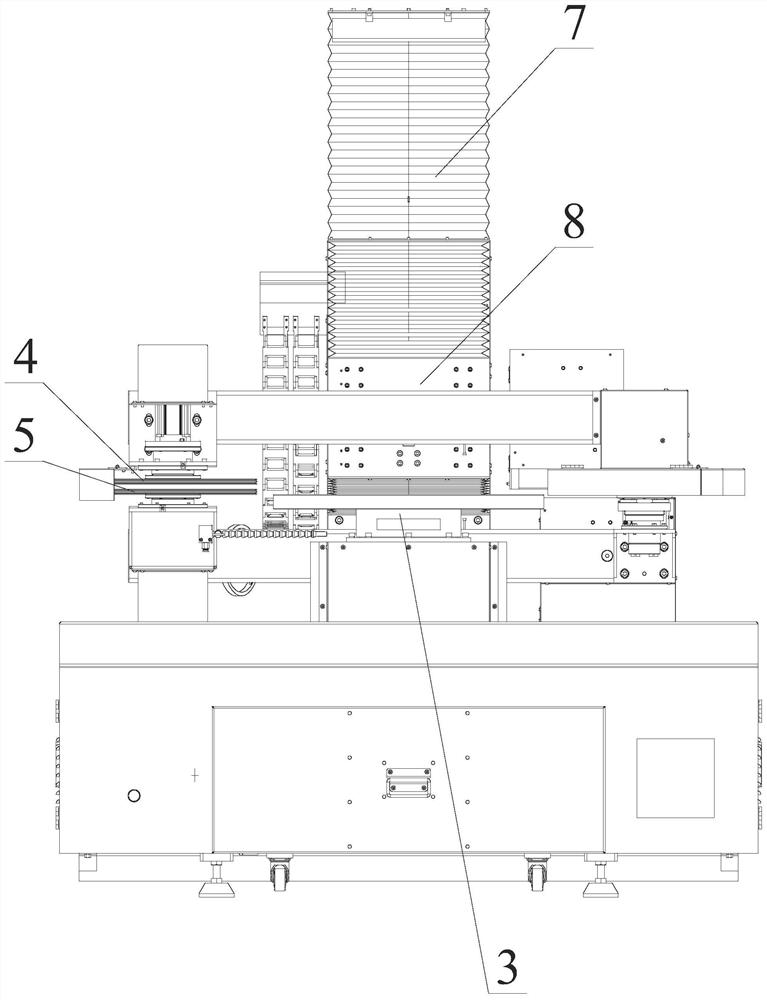

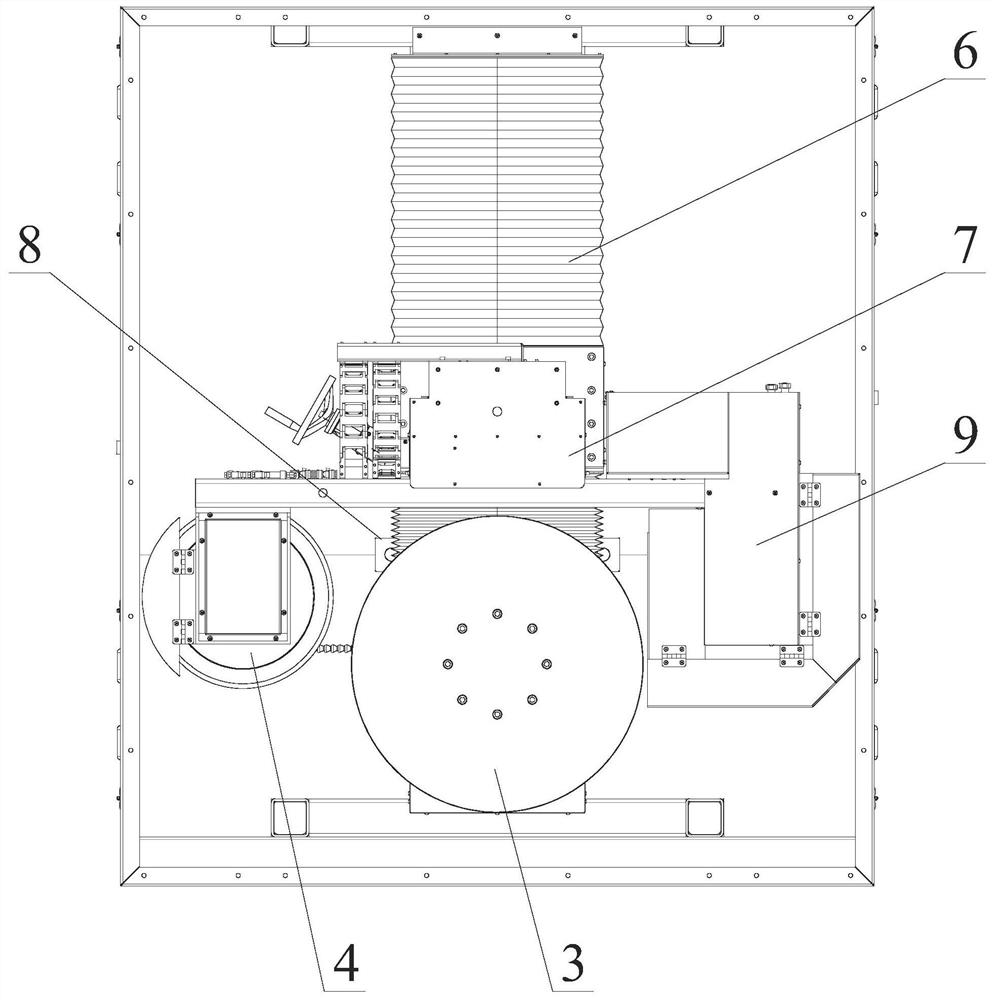

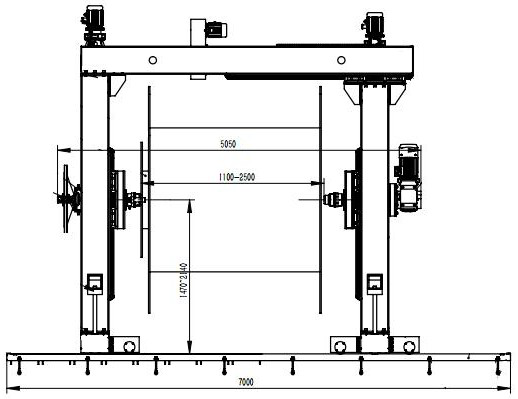

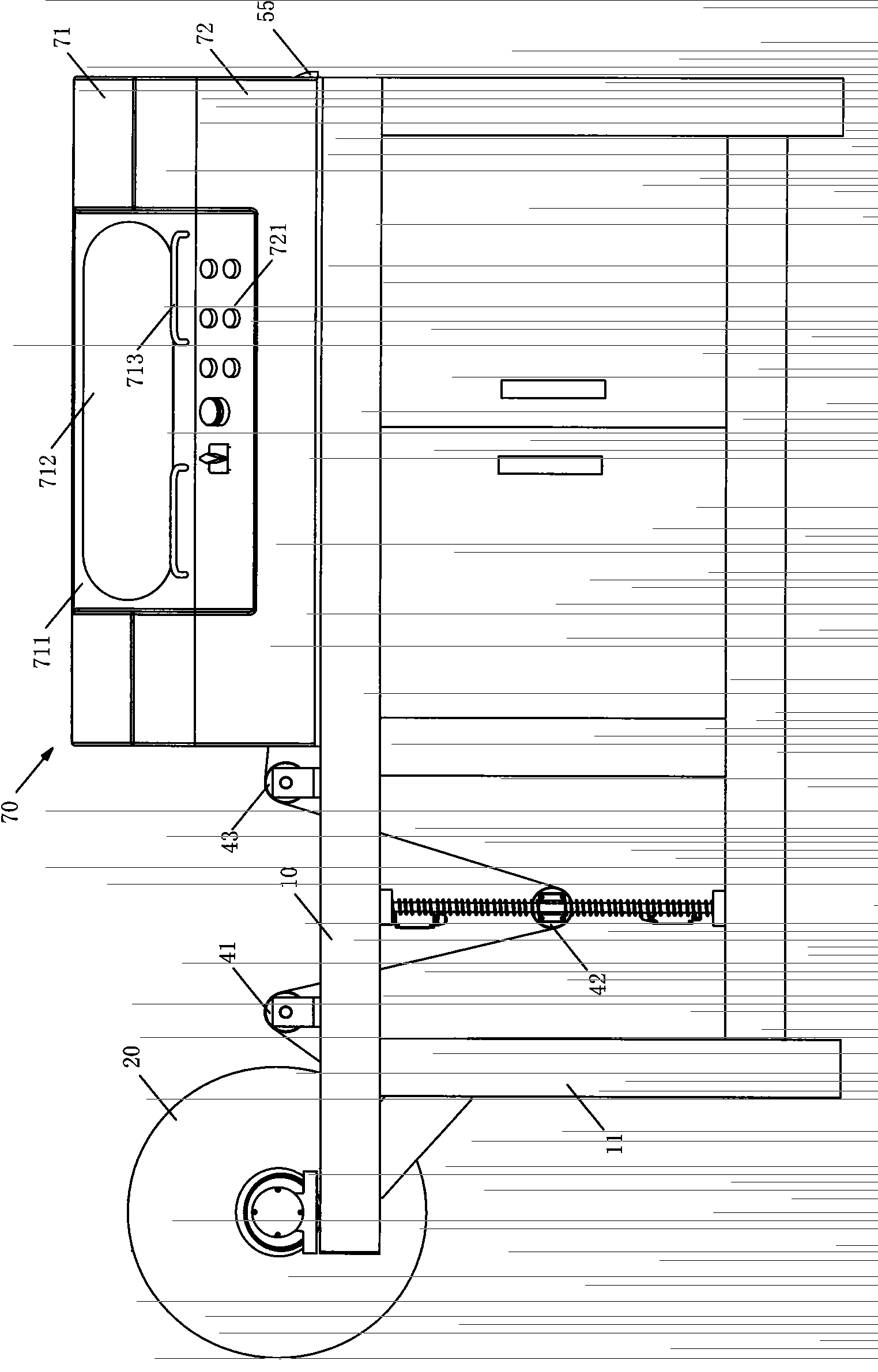

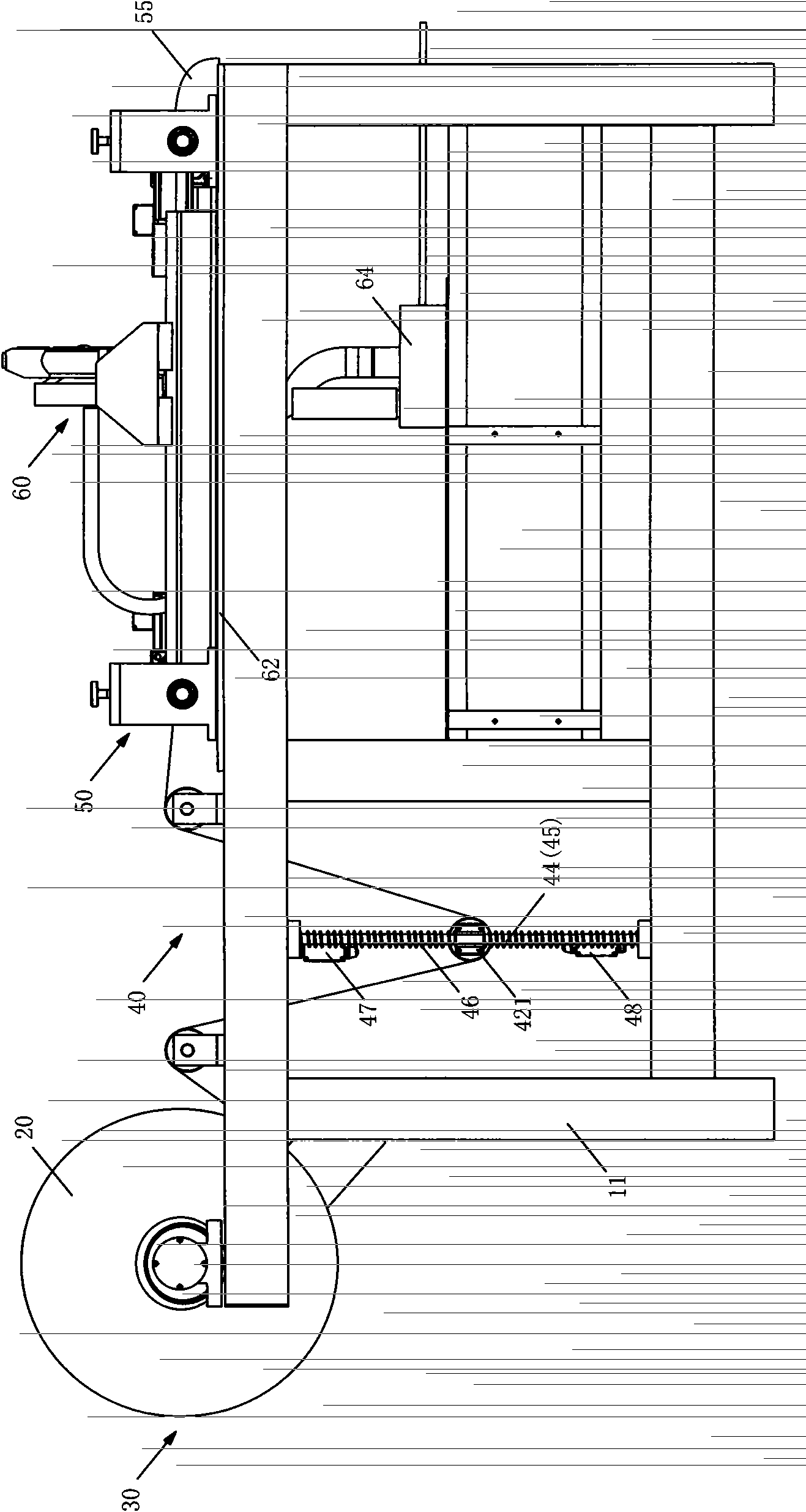

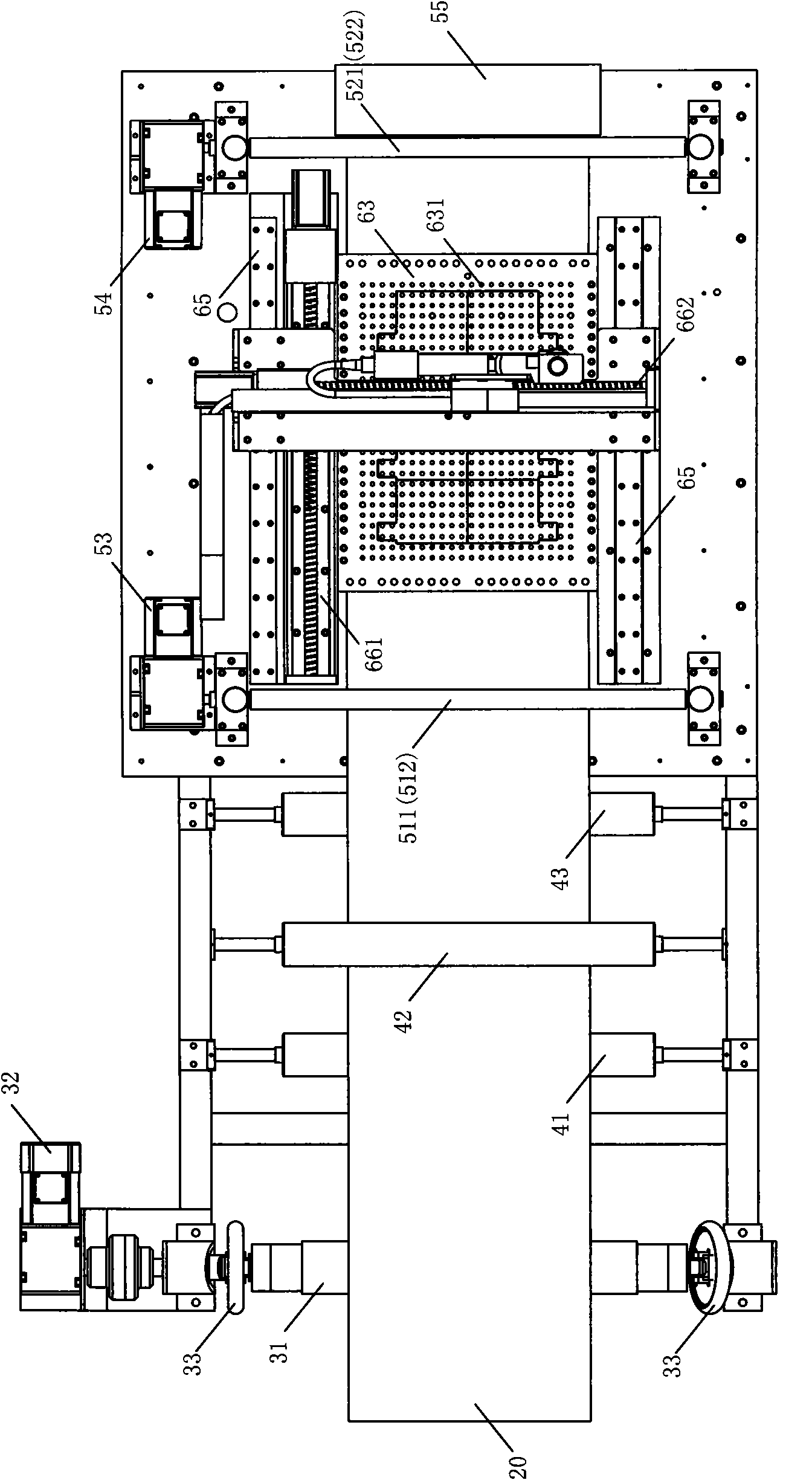

Double-wire annular diamond fretsaw horizontal cutting method and numerical control jade fretsaw machine

PendingCN112677333AEasy spacing adjustmentImprove cutting efficiencyWorking accessoriesStone-like material working toolsNumerical controlDrive wheel

The invention discloses a double-wire annular diamond fretsaw horizontal cutting method and a numerical control jade fretsaw machine. The numerical control jade fretsaw machine is provided with a first cutting loop wire and a second cutting loop wire to conduct feeding simultaneously to cut a to-be-cut workpiece fixed to a rotating platform, two annular diamond fretsaws in the numerical control jade fretsaw machine are driven by a first cutting driving wheel train and a second cutting driving wheel train correspondingly, and the two annular diamond fretsaws control cutting tension force through tension adjusting devices correspondingly, the first cutting driving wheel train and the second cutting driving wheel train are arranged on a Z-axis lifting adjusting platform capable of being controlled through a numerical control program, and the parallel distance between the two annular diamond wires in the vertical direction can be adjusted through a distance adjusting platform arranged on the Z-axis lifting adjusting platform. According to the method and the fretsaw machine, the cutting efficiency can be greatly improved, the wire diameter of the annular diamond fretsaw is small, the workpiece cutting loss is small, and the risk that a workpiece is collided to be damaged during cutting machining is greatly reduced through a horizontal cutting method, which is particularly suitable for cutting precious crisp and hard materials.

Owner:闽侯县鑫华盛机械设备有限公司

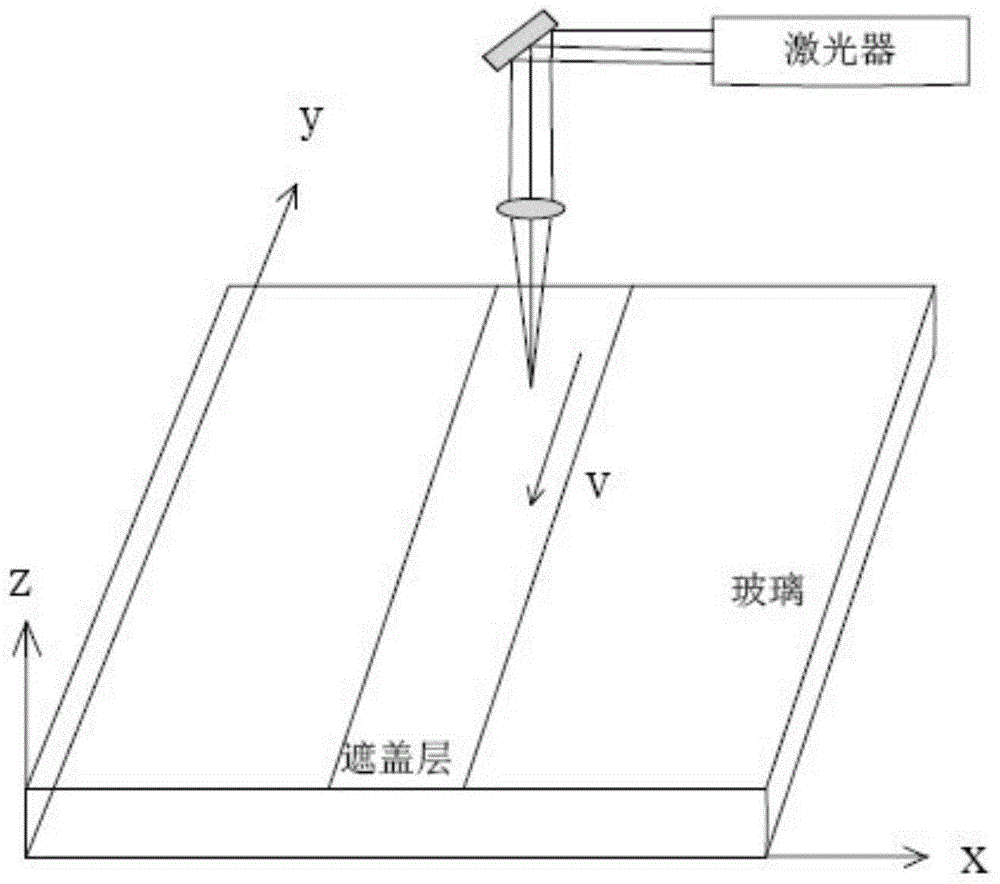

Laser cutting method for glass

InactiveCN104692638AImprove verticalityOvercoming the problems of traditional mechanical cuttingGlass severing apparatusLaser cuttingOptoelectronics

The invention discloses a laser cutting method for glass. The laser cutting method comprises the following steps: finding out a to-be-cut position of a glass plate; coating the to-be-cut part of the glass plate with a layer of non-volatile light-shading substance; and moving a laser beam along the to-be-cut part to cut. The laser cutting method for glass disclosed by the invention adopts the shading layer to prevent the laser from penetrating through the glass and absorbing heat on the shaded part, so that the cutting efficiency is improved.

Owner:BEIJING UNIV OF TECH

Production method of continuous long-distance resin diamond wire saw

InactiveCN106826597AIncrease in the number of controlsIncrease wire diameterAbrasion apparatusGrinding devicesLiquid viscosityDiamond wire saw

The invention discloses a production method of a continuous long-distance resin diamond wire saw, which comprises the steps of raw material selection, resin mixture preparation, core wire treatment, wire preparation, pre-curing, secondary curing and the like. The present invention effectively controls the final stage of line production by selecting thermoplastic resins and thermosetting resins with molecular weights within a suitable range; selecting suitable fillers, coupling agents, polymerization inhibitors, and dispersants; and controlling the appropriate initial viscosity of the resin mixture. The increase in the viscosity of the mixed liquid can effectively prevent the diameter of the diamond wire saw from becoming larger in the later stage of wire production, avoid the problem of local light caused by the gel particles of the mixed liquid blocking the drawing die, control the increase in the number of diamond micropowders, and ensure the quality of the product consistency. Ultimately solve the key technical problems in the continuous long-distance production of more than 70km.

Owner:HENAN XINDAXIN SCI & TECH

Large-size cutting device applied to leather production

InactiveCN108247218ASimple structureEasy to operateLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a large-size cutting device applied to leather production. The large-size cutting device comprises a cutting device main body, a control cabinet and a motor cabinet; the control cabinet is positioned at the outer surface of one side of the cutting device main body; the motor cabinet is positioned at the outer surface of the rear end of the control cabinet and is also positioned at the outer surface of one side of the cutting device main body; the outer surface of the upper end of the control cabinet is provided with a control panel and a display screen; and the controlpanel is positioned at the outer surface of one side of the display screen. The large-size cutting device applied to leather production disclosed by the invention is provided with a laser cutting head, a radial guide rail, a meridional guide rail, a zonal guide rail and a length measurement sensor; kerfs generated in cutting are narrow; leather deformation is small; untrimmed materials and flyingdust are not generated in cutting; cutting of leather in random sizes and specifications can be realized; the length of processed leather can also be measured; the cutting length is recorded as well;the yield can be conveniently counted; and the large-size cutting device has certain practicability and brings better application prospects.

Owner:海宁鼎达纺织有限公司

An ultra-fast femtosecond laser cutting machine

The invention discloses an ultrafast femtosecond laser cutting machine. The ultrafast femtosecond laser cutting machine comprises a bearing platform, wherein multiple support rods are arranged at the lower end of the bearing platform at equal intervals; damping devices are arranged at the lower ends of the support rods, and a connecting rod is connected between every two adjacent support rods; a bearing plate is arranged at the upper end of the bearing platform, first electric sliding rails are arranged on two sides of the bearing platform, second sliders are mounted on the first electric sliding rails, mounting blocks are arranged at the upper ends of the second sliders, first vertical plates are fixed at the upper ends of the mounting blocks, and a mounting plate is arranged between the two first vertical plates. The ultrafast femtosecond laser cutting machine had the remarkable advantages of being high in machining speeds, high in accuracy, simple in parameter setting and the like through femtosecond laser cutting; a product obtained through femtosecond laser cutting does not have the problems of microcracks, breaking or fragments in the aspect of appearance quality; no contamination or edge breakage are caused, and the edge breakage resistance is very high; washing and polishing are not required, the manufacturing cost is reduced and the ultrafast femtosecond laser cutting machine is suitable for popularization.

Owner:WUHAN HONGLEI LASER EQUIP

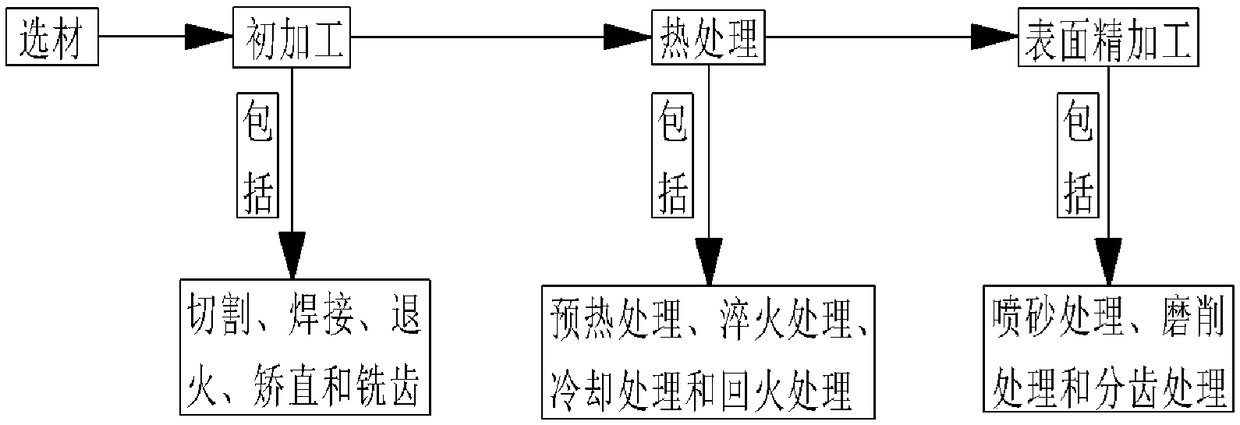

High-strength saw blade production technology

InactiveCN108817545AImprove machining accuracyNarrow kerfMetal sawing tool makingCarbon steelSurface finishing

The invention discloses a high-strength saw blade production technology. The high-strength saw blade production technology sequentially comprises the steps of material selecting, primary processing, heat treatment and surface finishing. Surface finishing comprises the step of sand blasting treatment, specifically, a dry blasting technology is adopted for sand blasting treatment, after sand blasting treatment, smooth tooth tips are formed, grinding is not needed in the sawing process, and the tooth breakage probability of tooth parts is decreased; impact force of cutting and vibrating can be borne, uniform force bearing of a cutting tool is ensured, and the cutting life of the tooth parts of the cutting tool is prolonged; and after sand blasting, the fatigue life of a backing material is prolonged, the fatigue performance of the back of a saw blade in the working condition of cutting ordinary carbon steel is greatly exerted, and the service life of the saw blade is prolonged.

Owner:多棱新材料股份有限公司

Process flow for colorizing iron prop

InactiveCN102505120AGuaranteed geometryQuality assuranceSolid state diffusion coatingHeat-affected zonePunching

The invention relates to a process flow for colorizing an iron prop. According to the process flow, the iron prop is treated by a punching machine, a welding machine, a polishing machine, a sand blasting machine, a baking oven and spraying equipment. The process flow is high in cutting speed and high in production efficiency; the cutting quality is high, and cutting seams are narrow; a heat affected zone is smallest, the local deformation of the iron prop is extremely small, the adaptability of materials is high, and tool wear is avoided; the automation degree is high, the process flow is easy to operate and is pollution-free, and the labor intensity is low; and the process flow is low in production cost and has a good economic benefit. By the advanced manufacturing process, a high-quality product can be manufactured; the process flow has a good colorization effect; and the product is durable.

Owner:QINGDAO INSTALLATION & CONSTR

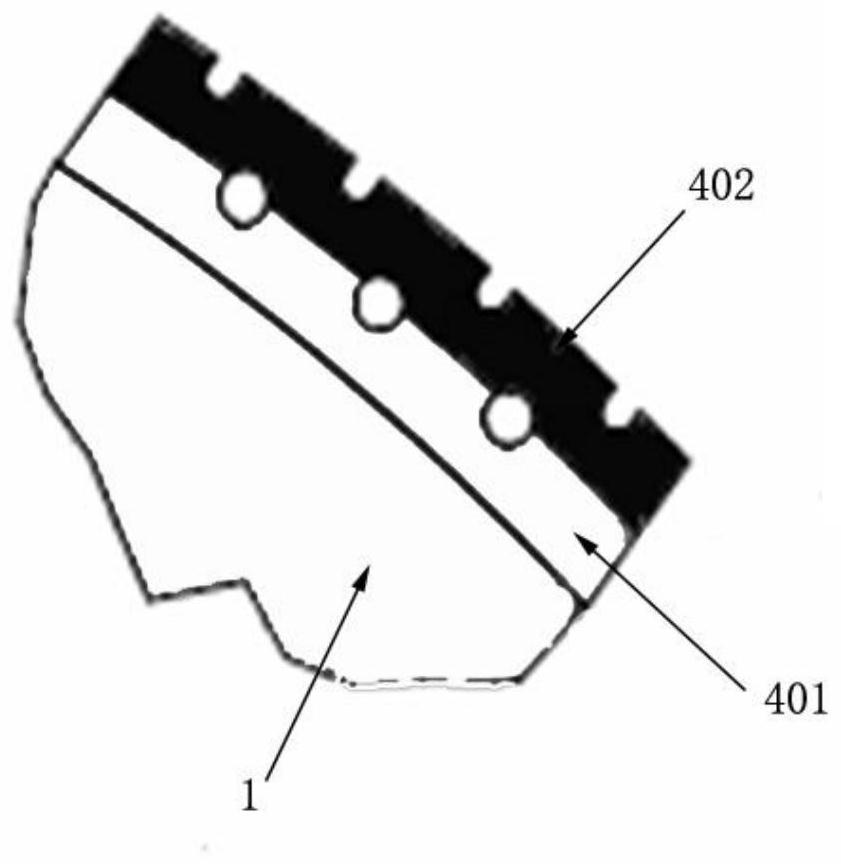

Preparation process of laser welding saw blade

The invention discloses a preparation process of a laser welding saw blade, and belongs to the technical field of preparation of material cutting machining tools. The laser welding saw blade comprisesa saw blade base body and a plurality of diamond tool bits evenly distributed on the outer edge of the saw blade base body; each diamond tool bit is composed of a tool bit base body on the inner sideand a tool bit brazing layer on the outer side; a concave notch groove is formed in each of the two sides of each diamond tool bit in the radial direction of the saw blade base body so that chip removal can be facilitated during cutting machining; each diamond tool bit of the saw blade is formed by brazing and sintering a metal bonding agent and diamond particles under the vacuum condition; and then a laser welding method is adopted to weld the diamond tool bits with the saw blade base body. The laser welding saw blade prepared through the method has the advantages that the diamond particlesand the tool bit base bodies are firmly combined, the tool bits and the saw blade base body are reliably connected, the process is simple, and the cost is low.

Owner:江苏华昌工具制造有限公司

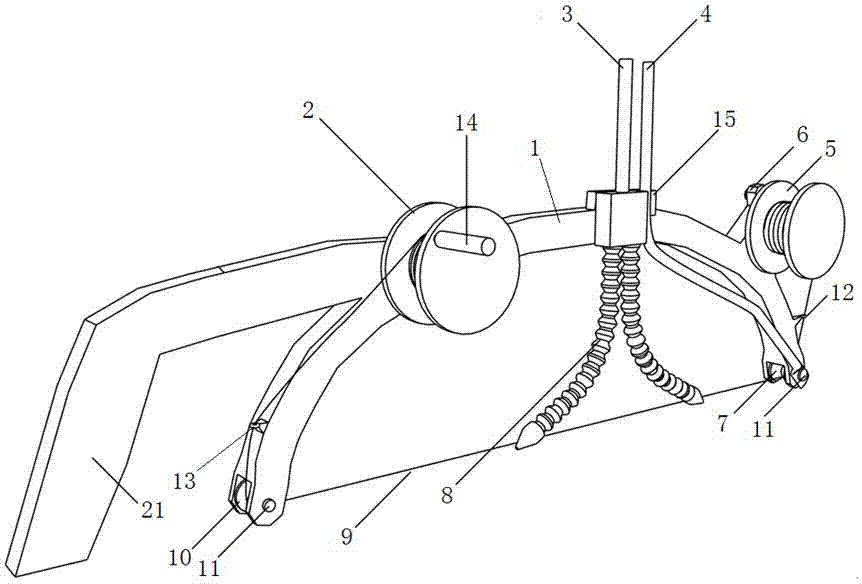

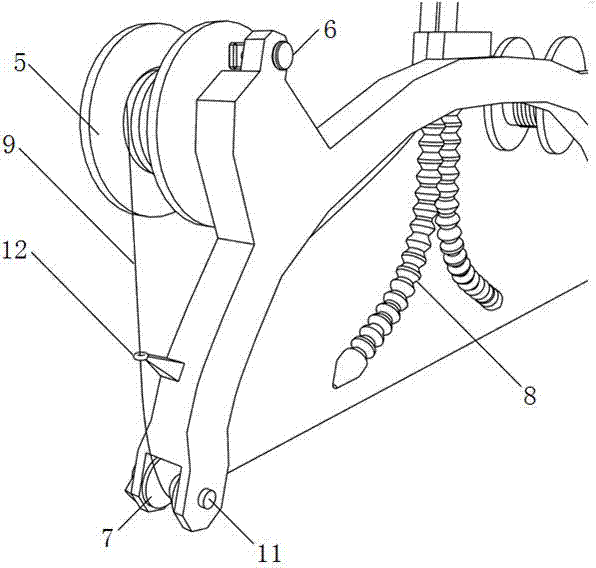

A portable wire cutting saw

InactiveCN103551685BSimple structureReduce volumeElectrical-based machining electrodesWire cuttingEngineering

The invention discloses a portable wire cutting saw and relates to the technical field of wire cutting. The wire cutting saw comprises a saw body, universal spray pipes, a wire electrode, a front wire winding mechanism, a front wire guiding mechanism, a rear wire guiding mechanism and a rear wire winding mechanism, wherein the saw body is fixedly connected with a handle, the front wire guiding mechanism is arranged at the end of the saw body, which is far from the handle, and the rear wire guiding mechanism is arranged at the end of the saw body, which is close to the handle; the front wire winding mechanism is located above the front wire guiding mechanism, and the rear wire winding mechanism is located above the rear wire guiding mechanism; one end of the wire electrode is wound on the front wire winding mechanism, the wire electrode sequentially passes through the front wire guiding mechanism and the rear wire guiding mechanism, and the other end of the wire electrode is wound on the rear wire winding mechanism. The using steps of the wire cutting saw comprise preparing the wire electrode, mounting the wire electrode, adjusting the tensioning force, spraying a working solution, starting wire cutting, dismounting for standby use after the cutting is finished. The wire cutting saw can realize narrow-slit cutting, cutting of workpieces with large thicknesses, good cutting surface texture and any curvilinear cutting.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

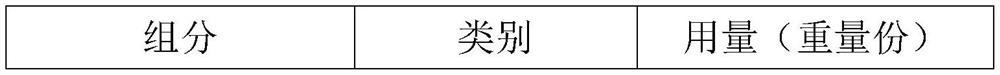

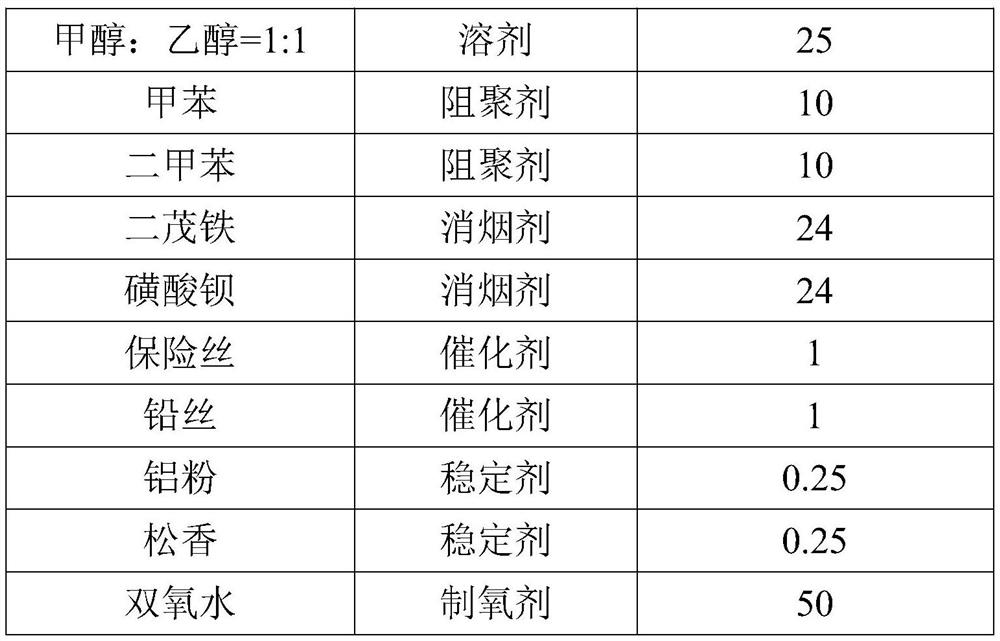

Industrial welding and cutting gas modified additive as well as preparation method and application thereof

ActiveCN114276844AAutomatically adjust the response speedEasy to cutLiquid carbonaceous fuelsGas flame welding apparatusPtru catalystProcess engineering

The invention provides an industrial welding and cutting gas modification additive. The industrial welding and cutting gas modification additive comprises the following components in parts by weight: 20-40 parts of a solvent, 10-30 parts of a polymerization inhibitor, 40-60 parts of a smoke suppressor, 0.5-4 parts of a catalyst, 0.1-1.5 parts of a stabilizer and 31-75 parts of an oxygen generating agent. According to the application of the industrial welding and cutting fuel gas modified additive, the modified additive is added into industrial fuel gas with C3 and C4 as mother liquor according to the ratio of 2-3 wt% for use. The modified additive disclosed by the invention is added into industrial fuel gases such as propane and liquefied gas, so that the gasification and activation performance of mother liquor fuel gas is improved, the wavelength and the frequency of combustion of mother liquor in oxygen are changed, and the combustion performance is improved; the flame combustion temperature of the industrial fuel gas added with the modified additive can reach about 3410 DEG C, the industrial fuel gas is superior to acetylene in the aspects of temperature, heat value, cutting effect, environmental protection, energy conservation, safety cost and the like, the cutting and welding performance of the industrial fuel gas reaches or exceeds that of acetylene gas, and the industrial fuel gas can completely replace acetylene to complete cutting and welding of metal.

Owner:HEBEI XINDA IRON & STEEL GRP CO LTD

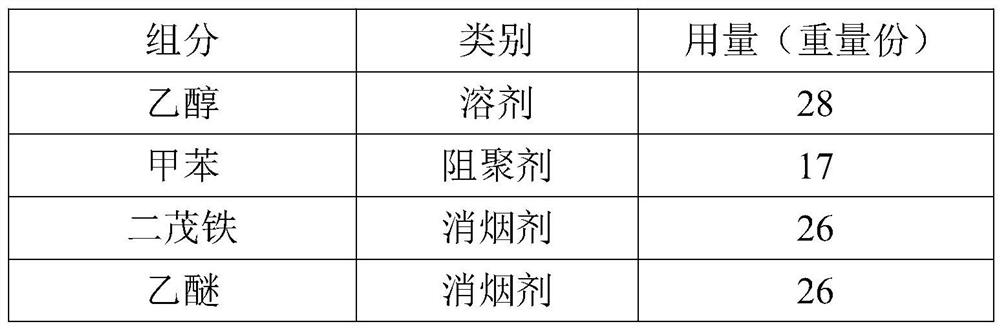

Three-dimensional laser trimming tool for L-shaped stretch-bending part

PendingCN114227030APrecise positioningHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser

The invention belongs to the field of tool design, and relates to a tool for three-dimensional laser trimming of an L-shaped stretch-bending part. The tool is composed of an edge cutting die body, an edge pressing device, a jacking device, a supporting device and a laser edge cutting assembly. The trimming die body is of a platform structure, and the edge of the platform structure is matched with the shape of an L-shaped stretch bending piece to be trimmed; the supporting device is used for supporting the trimming die body, and an arc-shaped supporting plate is further arranged on the side face, close to the edge of the trimming die body, of the upper end of the supporting device. The support is used for mounting the jacking device; the edge pressing device, the jacking device and the edge of the platform structure which are mounted on the edge cutting die body jointly define the overall appearance of the L-shaped stretch bending part to be subjected to edge cutting; a certain gap is reserved between the lower end face of the L-shaped stretch-bending piece to be trimmed and the arc-shaped supporting plate, and an upper end flange is pressed and fixed through the edge pressing device. During edge cutting, after the L-shaped stretch bending part to be subjected to edge cutting is positioned, edge cutting is conducted through the laser edge cutting assembly.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

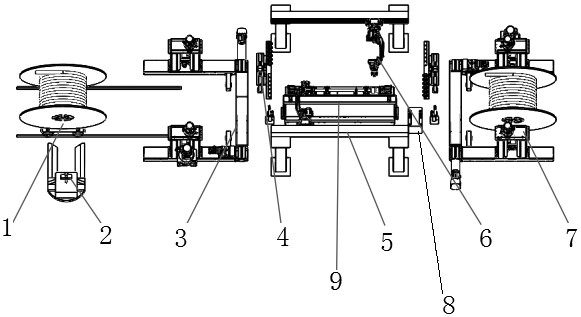

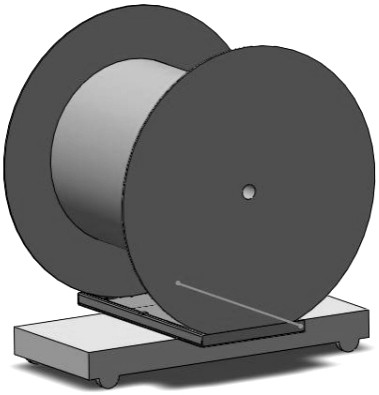

Full-automatic fixed-length cable taking machine system

PendingCN113641141AReduce labor intensityMeet various needsProgramme control in sequence/logic controllersControl systemControl signal

A full-automatic fixed-length cable taking machine system realizes a one-stop mode of cable taking and cable splitting, reduces labor intensity of operators, reduces uncertain factors in operation links, and improves operation safety. Data transmission read / write operation is carried out through the wireless touch screen and a background program of the industrial personal computer, and safety and stability are achieved; a full-disc cable is transported to the position below the paying-off gantry through the trolley, a PLC controls the gantry to ascend, descend and be clamped, a disc is loaded into the gantry, and operation is easy and convenient. Cables with different diameters are pulled and conveyed from the pay-off end to the take-up end, and the length can be accurately measured according to the perimeter of the roller and the number of rotation turns; during take-up and pay-off, the PLC outputs a control signal to the take-up and pay-off gantry after operation, and the take-up and pay-off gantry further realizes constant tension control; a cutting-off device is suitable for cutting off cables of various specifications and has the advantages of being high in cutting efficiency, capable of saving energy, narrow in saw bite and easy to operate. The fixed-length cable taking control system fully meets various requirements of customers, and the performance of electrical system elements is stable and reliable.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD TAIZHOU POWER SUPPLY BRANCH

Laser cutting device of power battery pole piece

ActiveCN101777640BNarrow kerfTrimmingElectrode manufacturing processesLaser beam welding apparatusPower batteryHigh energy

The invention relates to a laser cutting device, in particular to an optical fiber laser cutting device for a vehicle power battery pole piece, which comprises a worktable. The worktable is sequentially provided with a discharging mechanism, a conveying mechanism and a cutting mechanism, wherein a battery pole piece is arranged on the discharging mechanism, conveyed by the conveying mechanism and cut by the cutting mechanism, and a cutting head of the cutting mechanism is an optical fiber laser cutting head. By the technical scheme, the invention cuts the battery pole piece by adopting optical fiber laser, finely cuts the battery pole piece by utilizing the properties of laser, i.e. the beam quality approaching a diffraction limit, the conversion efficiency with high energy and the high stability, cuts a pole piece with narrow cutting gap, smooth cutting edge and high accuracy, favorably improves the performance of the battery pole piece and overcomes the defects of a traditional cutting method.

Owner:CHERY AUTOMOBILE CO LTD

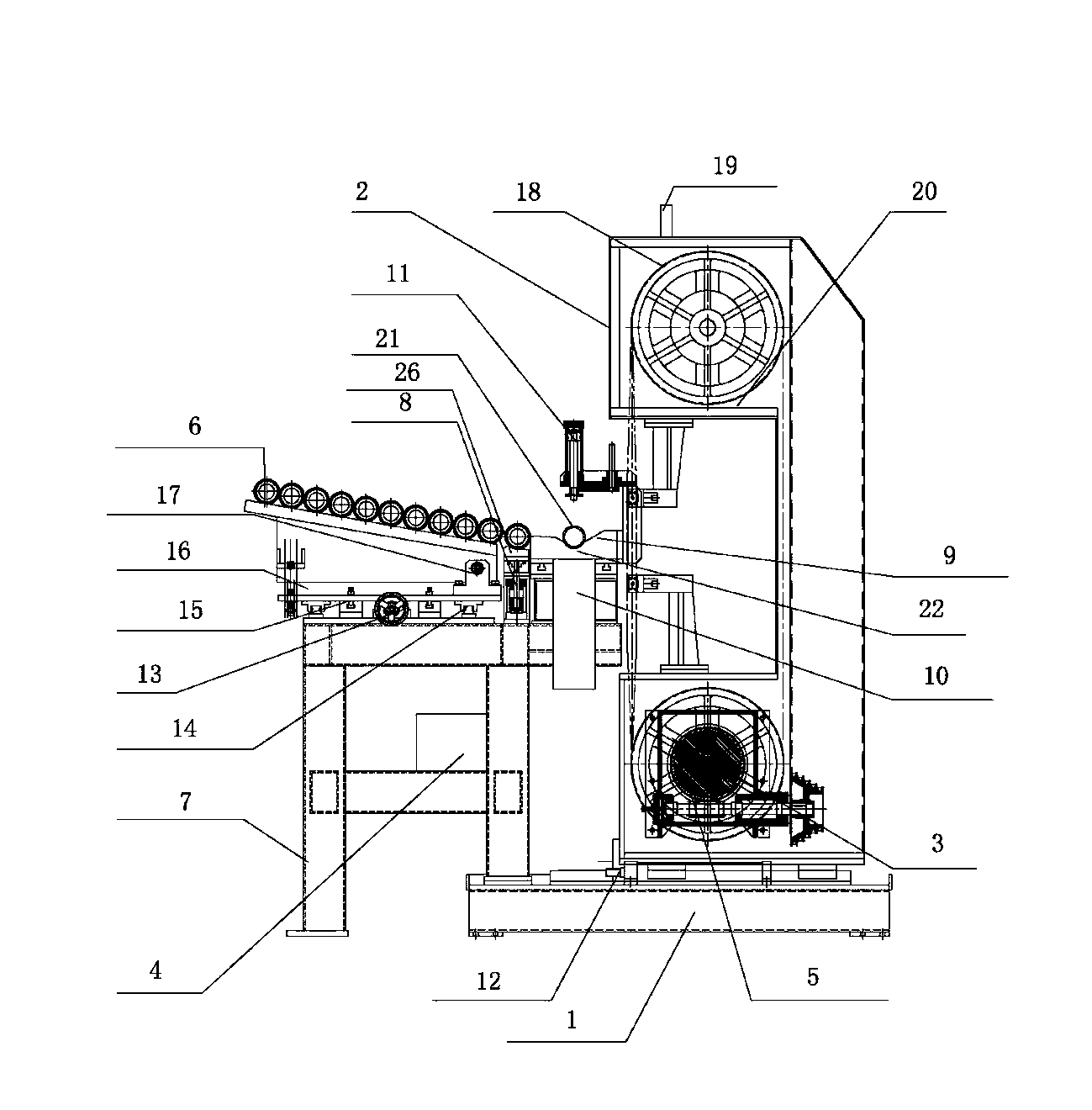

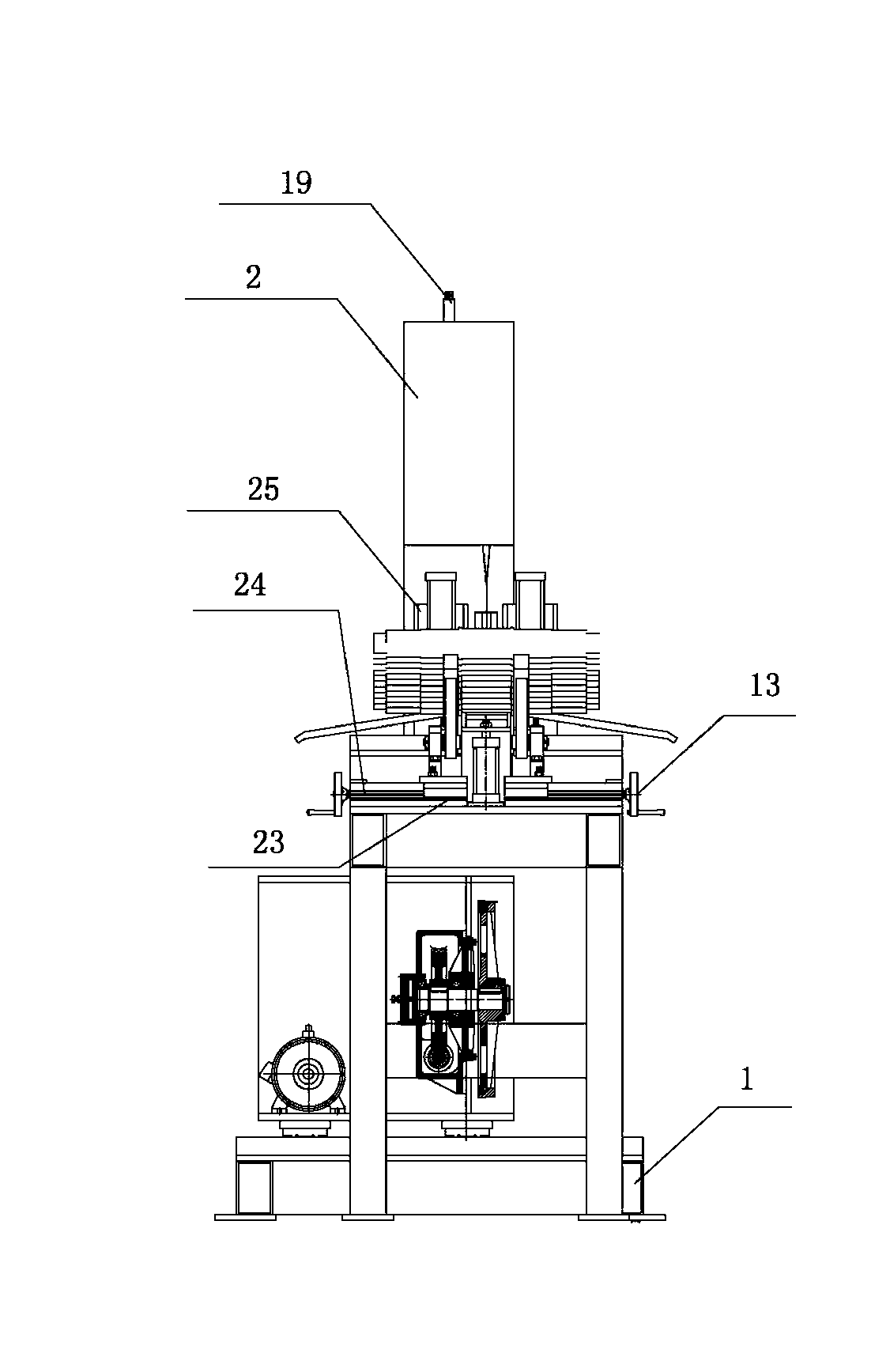

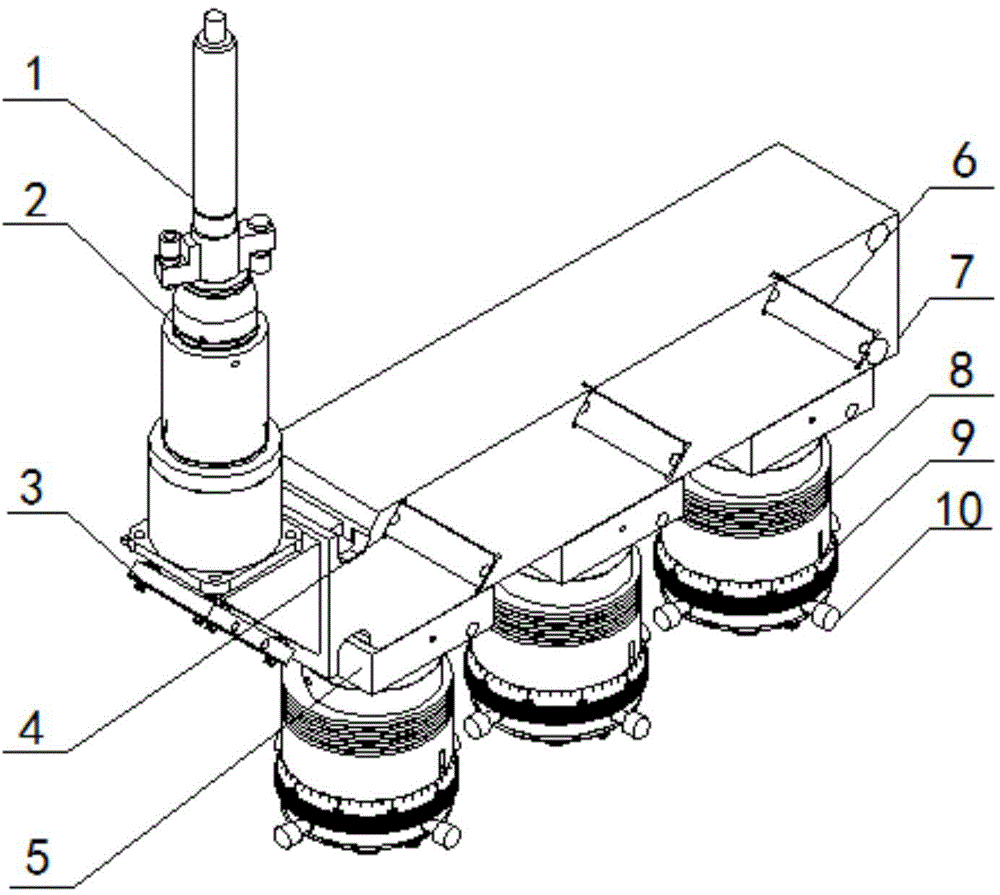

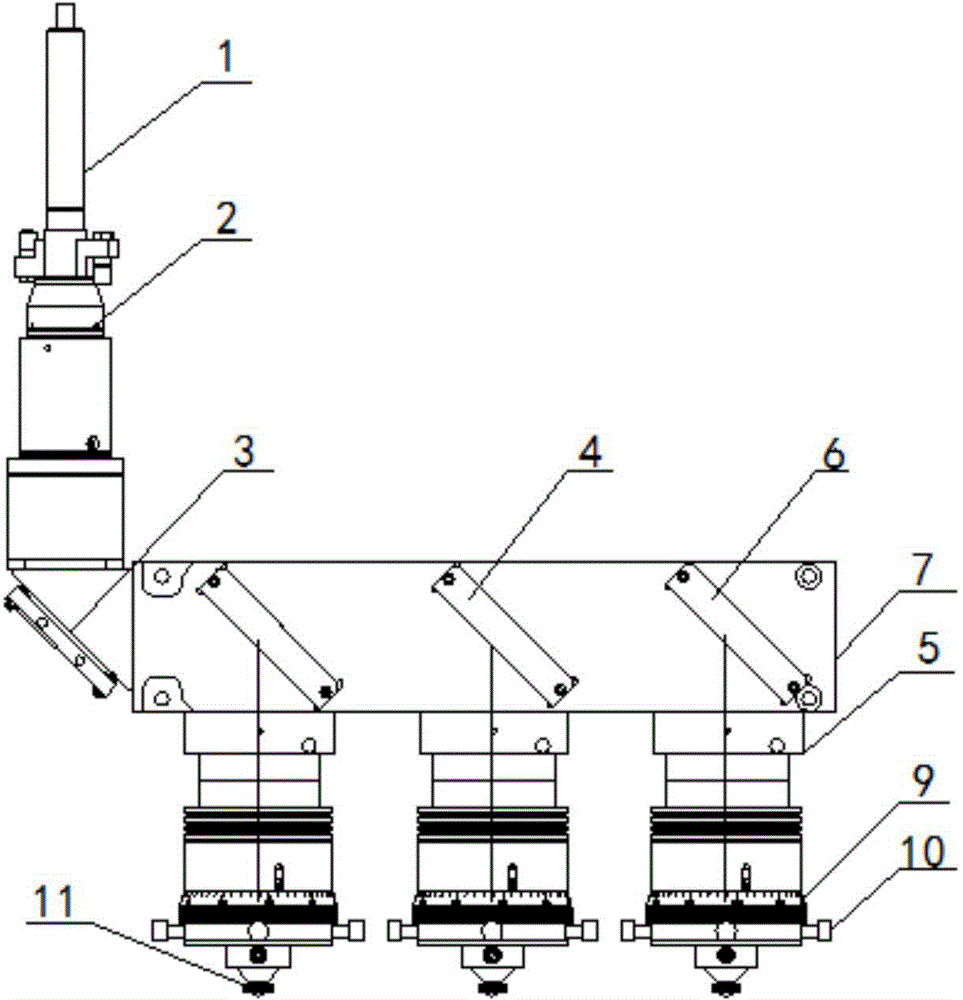

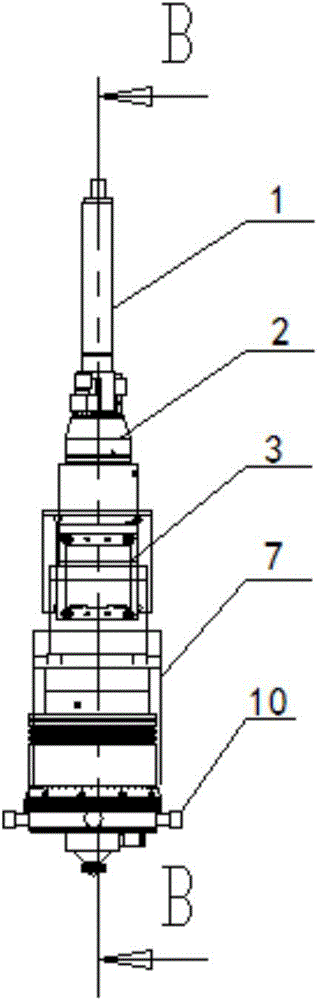

Laser machining apparatus for main-bearing cracker of engine cylinder

InactiveCN100467188CNarrow kerfImprove surface qualityLaser beam welding apparatusEngineeringLaser cutting

A laser machining apparatus for machining the splitting slot on master bearing seat for the cylinder body of engine is composed of a mechanical system and a YAG solid laser cutting system. Said mechanical system consists of cylinder body and its machine frame, and bench and its machine frame. Said bench comprises a numerally controlled X-Y bench, an X-axis bench and a Y-axis bench with a laser cutting head driven by a rotary cylinder to rotate by 180 deg.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com