Preparation process of laser welding saw blade

A technology of laser welding and preparation technology, which is applied in the direction of sawing machine tool manufacturing, manufacturing tools, metal sawing equipment, etc., to achieve the effects of low production cost, narrow kerf, and good cutting sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

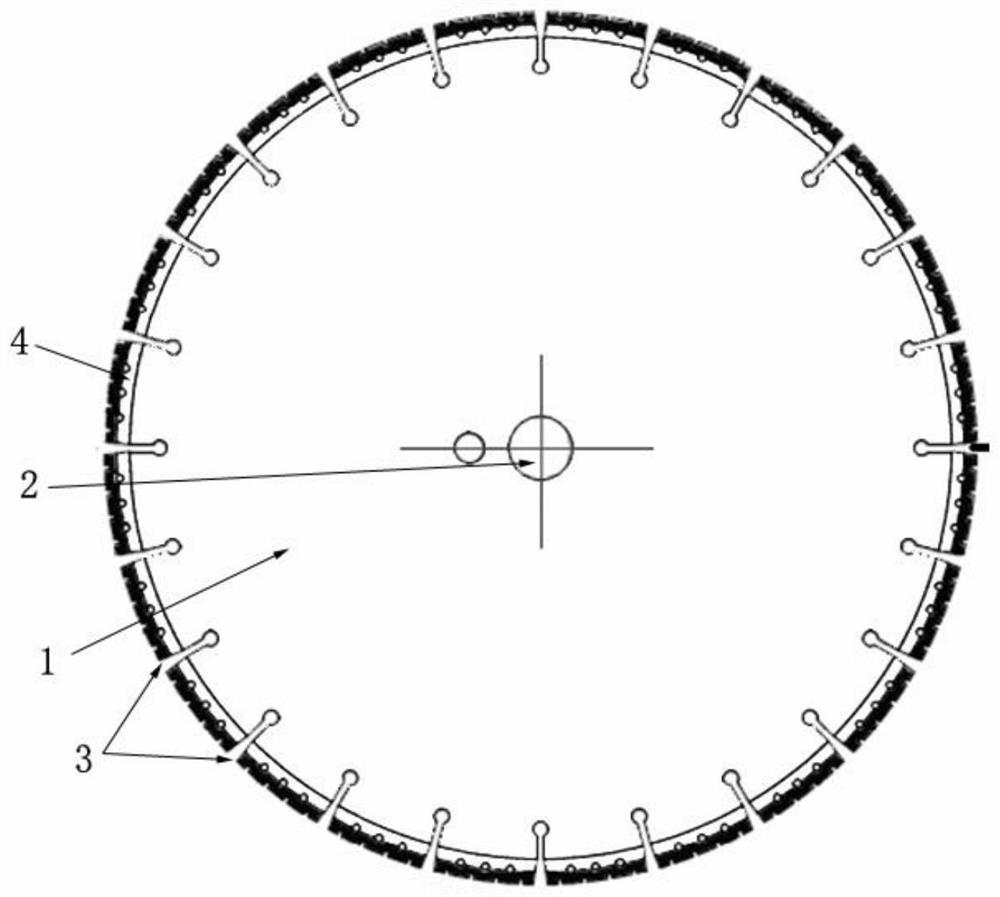

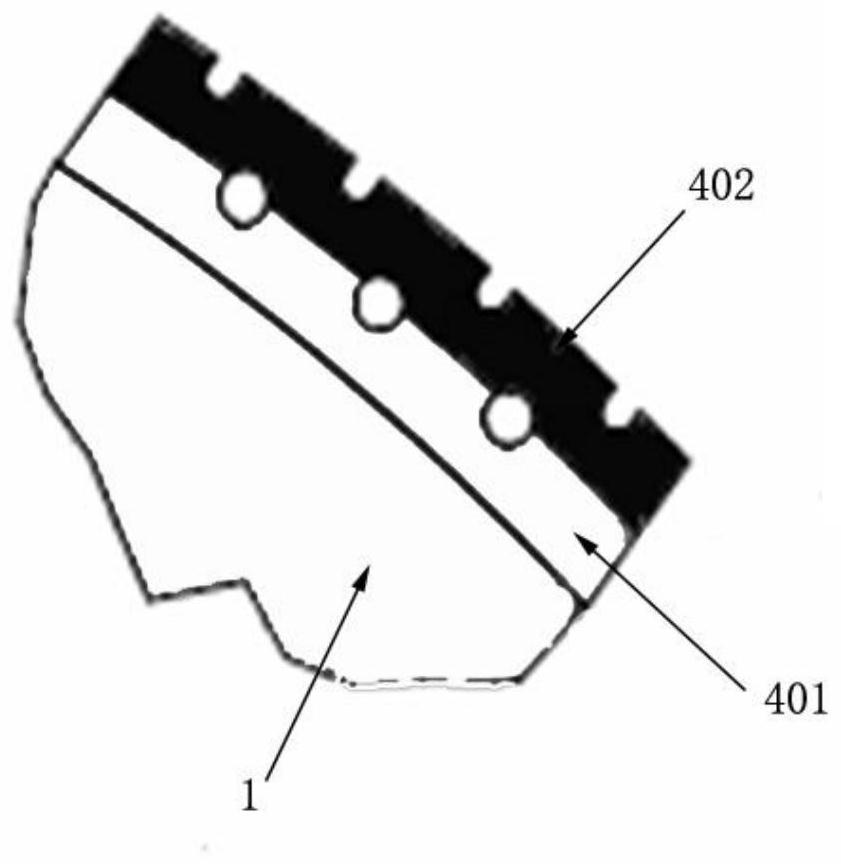

[0028] The specific preparation process of the laser welding saw blade of the present invention is as follows:

[0029] 1) Ingredients: According to the composition ratio, select a suitable nickel-based solder metal binder, add diamond particles, and pre-mix to form a molding material. A three-dimensional mixer is used for mixing, and the mixing time is 50 minutes to obtain a molding material;

[0030] 2) Cold pressing: adjust the tooling mold, first load the cutter head matrix, and then put in the molding material and assemble it into the cold pressing forming mold for press molding to obtain the diamond cutter head blank;

[0031] 3) Vacuum sintering: put the diamond blade blank into the mold, heat and sinter under vacuum conditions, the sintering temperature is 1010-1030°C, and the vacuum degree is 4.0×10 -4 Pa;

[0032] 4) Laser welding: deburr and arc-grind the brazed and sintered diamond cutter head; then perform laser welding on the laser welding equipment to connect ...

Embodiment 1

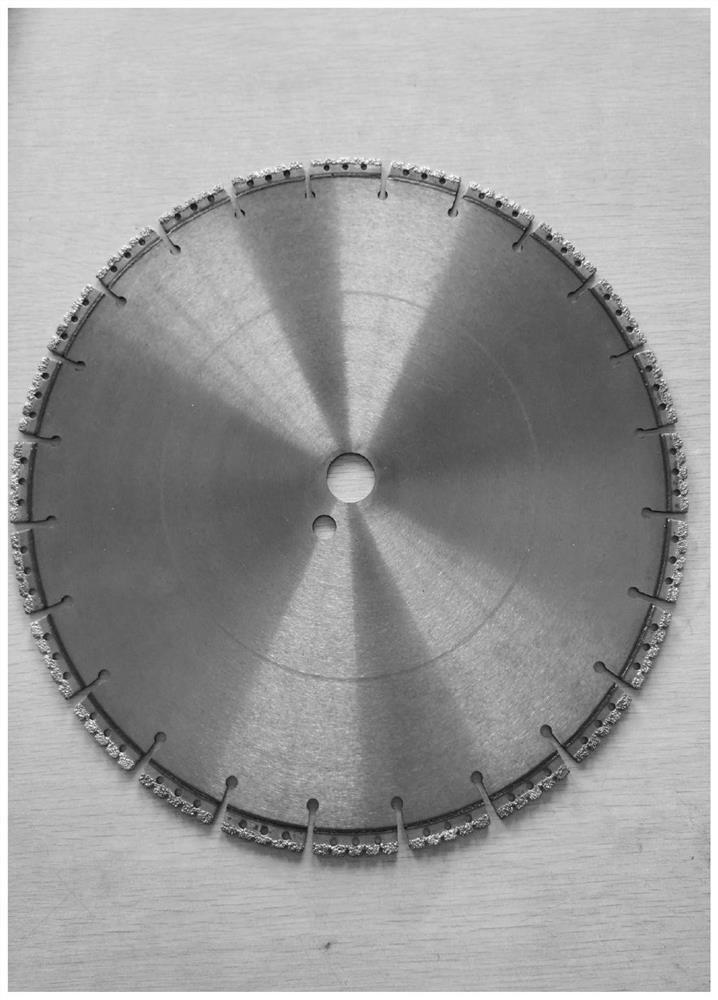

[0038] In this embodiment, the laser welding saw blade is prepared by the method of the present invention. Specifically, the saw blade of this embodiment is formed by heating and sintering nickel-based brazing filler metal and diamond particles under vacuum conditions. into, and the sintering temperature is 1020°C, the vacuum degree is 4.0×10 -3 Pa. Wherein, the matrix of the diamond cutter head is 30CrMo material. The composition of described nickel base brazing filler metal bond, expressed with weight percentage (wt%), by Ni:78.0%, Cr:9.5%, Si:5.5%, B:3.5%, Fe:3.5%, all the other are trace Elemental composition. The batching of diamond particles and metal bond: expressed in weight percent (wt%), the concentration of diamond particles is 0.60ct / cm 3 , Diamond particles of different particle sizes and their proportions are: 35 / 40 accounts for 45%, 40 / 50 accounts for 30%, and the rest is nickel-based material accounting for 25%. The brazed and sintered diamond cutter head i...

Embodiment 2

[0040] In this embodiment, the laser welding saw blade is prepared by the method of the present invention. Specifically, the diamond cutter head of this embodiment is made of nickel-based solder metal bond and diamond particles under vacuum conditions, after heating and sintering made, and the sintering temperature is 1020°C, the vacuum degree is 4.0×10 -4 Pa. Wherein, the matrix of the diamond cutter head is 30CrMo material. The composition of described nickel base brazing filler metal bond, expressed with weight percentage (wt%), by Ni:80.0%, Cr:8.5%, Si:4.5%, B:3.5%, Fe:3.5%, all the other are trace Elemental composition. The batching of diamond particles and metal bond: expressed in weight percent (wt%), the concentration of diamond particles is 0.65ct / cm 3 , Diamond particles of different particle sizes and their proportions are: 35 / 40 accounts for 45%, 40 / 50 accounts for 30%, and the rest is nickel-based material accounting for 25%. The brazed and sintered diamond cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com