Patents

Literature

35results about How to "Good cutting sharpness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-impact diamond layer, diamond composite sheet and preparation method for diamond composite sheet

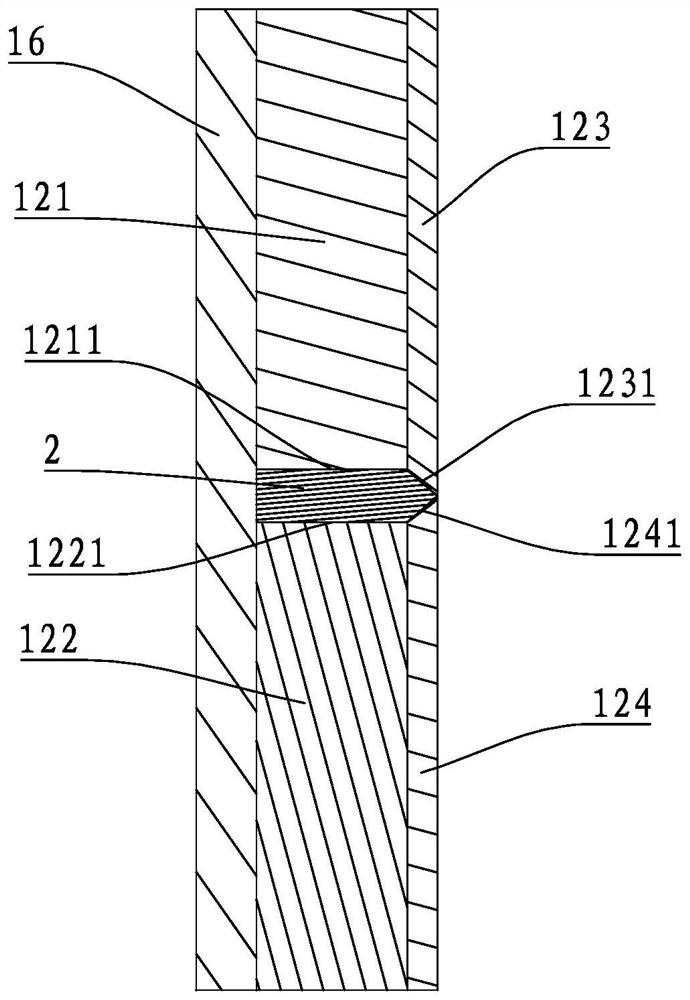

The invention discloses an anti-impact diamond layer, an anti-impact diamond composite sheet and a preparation method for the diamond composite sheet. Coarse granular diamond is used as a main raw material, graphite is used as a filling agent, and iron-based powder is used as an accelerant; the diamond layer comprises the following components in part by weight: 70 to 80 parts of diamond, 10 to 20 parts of graphite powder, and 3 to 12 parts of accelerant; and the accelerant consists of the following materials in part by weight: 45 to 60 parts of iron, 15 to 20 parts of nickel, 5 to 15 parts of cobalt, 5 to 20 parts of manganese, and 3 to 10 parts of silicon. The method comprises the following steps of: mixing the raw materials in the ratio uniformly, pre-pressing the mixture and a hard alloy matrix into a composite sheet, filling into a pyrophyllite block to form a structural block, putting the structural block into a 6-surface diamond presser, sintering and electrolyzing at a high temperature under high pressure, and thus obtaining the diamond composite sheet. The diamond composite sheet has the characteristics of big pores and a mesh connection structure, and is quite suitable for drilling medium hard and hard strata due to excellent sharpness and impact toughness.

Owner:河南亚龙金刚石制品股份有限公司

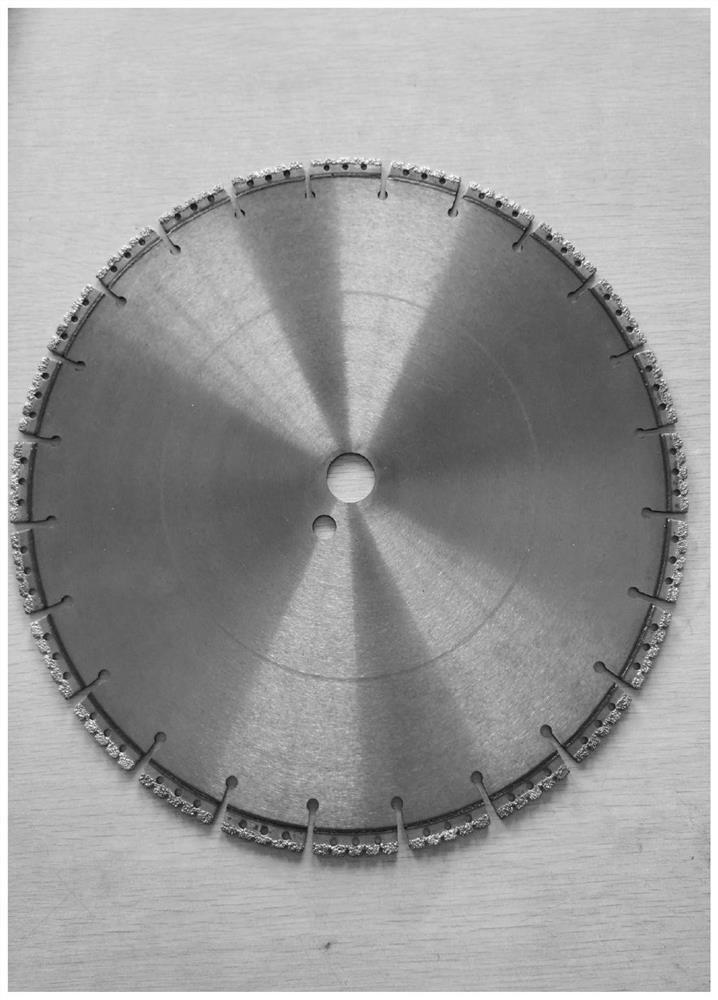

Saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method

ActiveCN104907942ANarrow kerfLess consumablesTransportation and packagingBonded abrasive wheelsBrickRebar

The invention relates to a saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method and belongs to the technical field of diamond machining tools. The preparation method is implemented through the following working procedures that a metallic bond and diamond are subjected to material preparation, granulation, cold pressing, hot pressed sintering, laser welding, first edge forming, polishing, painting, checking packaging storage in sequence. According to the saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method, a diamond tool bit is formed by the procedures that the metallic bond and diamond are subjected to the hot pressed sintering under vacuum conditions. By means of the saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method, the prepared cutting disk has the advantages that the cutting seam is narrow, the consumable items are less, the cutting deflection is small, the cut edge is neat, the cutting sharpness is good, and the cutting disk is particularly suitable for the cutting of hard materials including building materials, wall bodies, cement concrete, solidified concrete, reinforced concrete, hard concrete bricks, concrete piles and the like.

Owner:江苏华昌工具制造有限公司

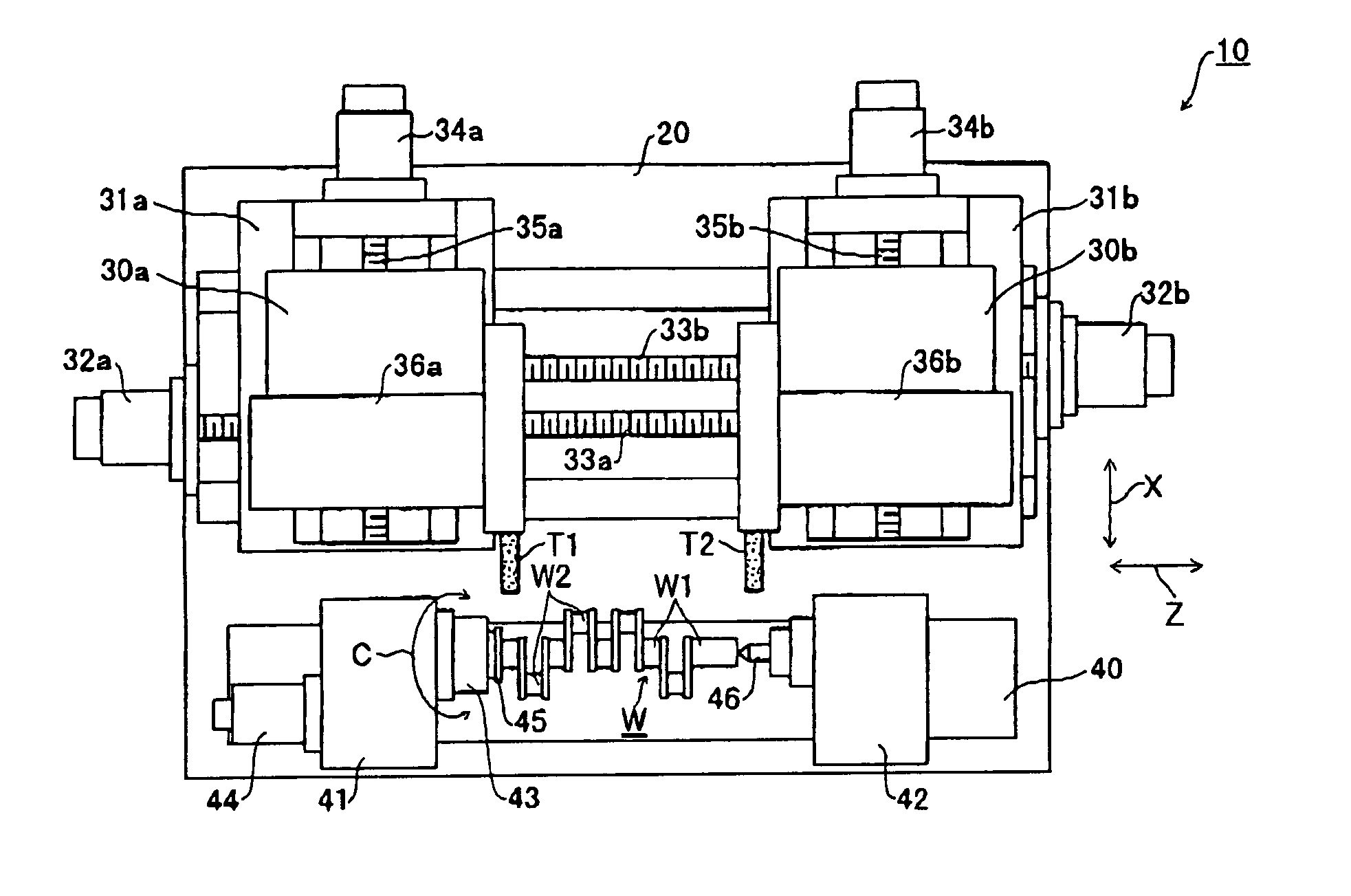

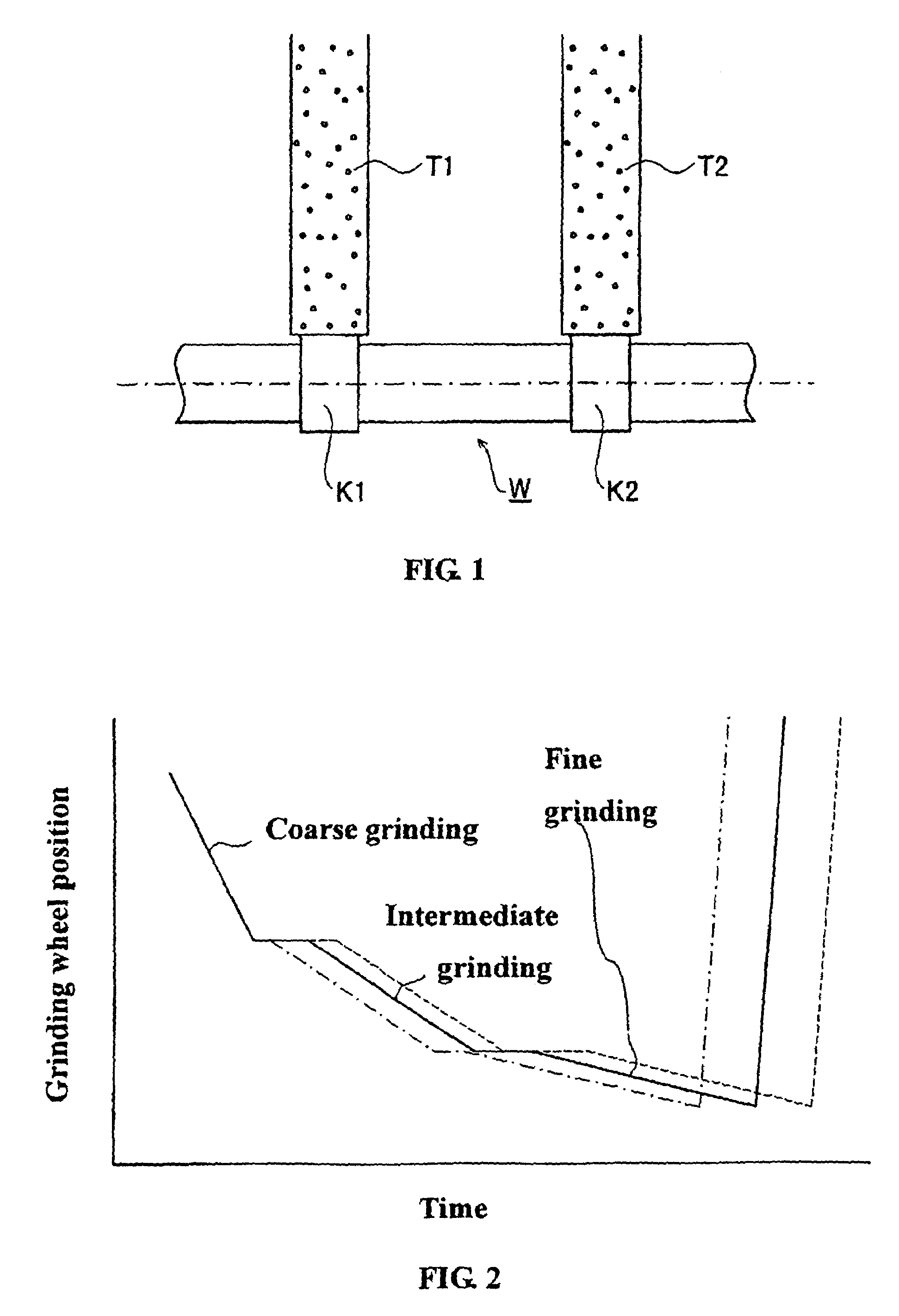

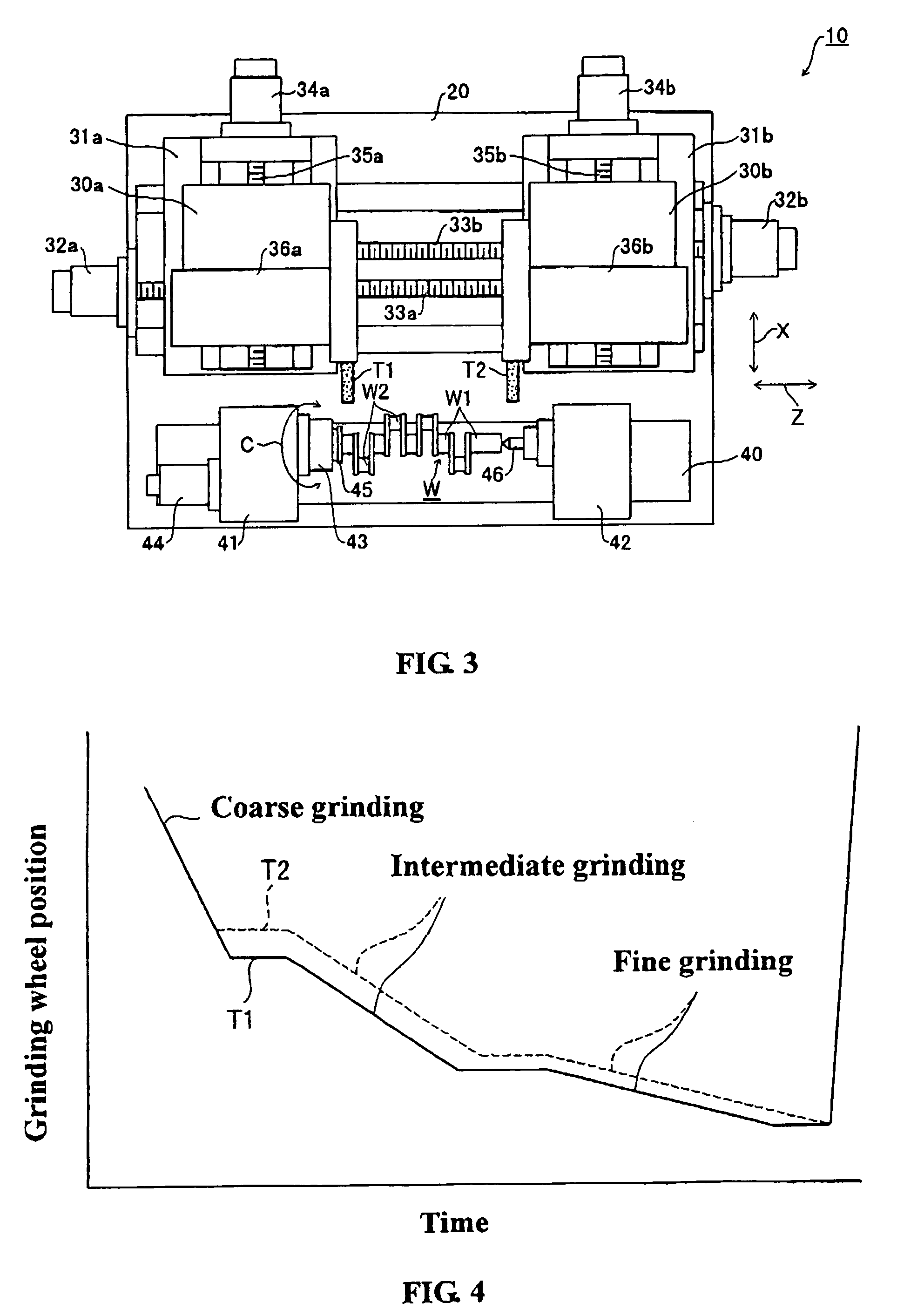

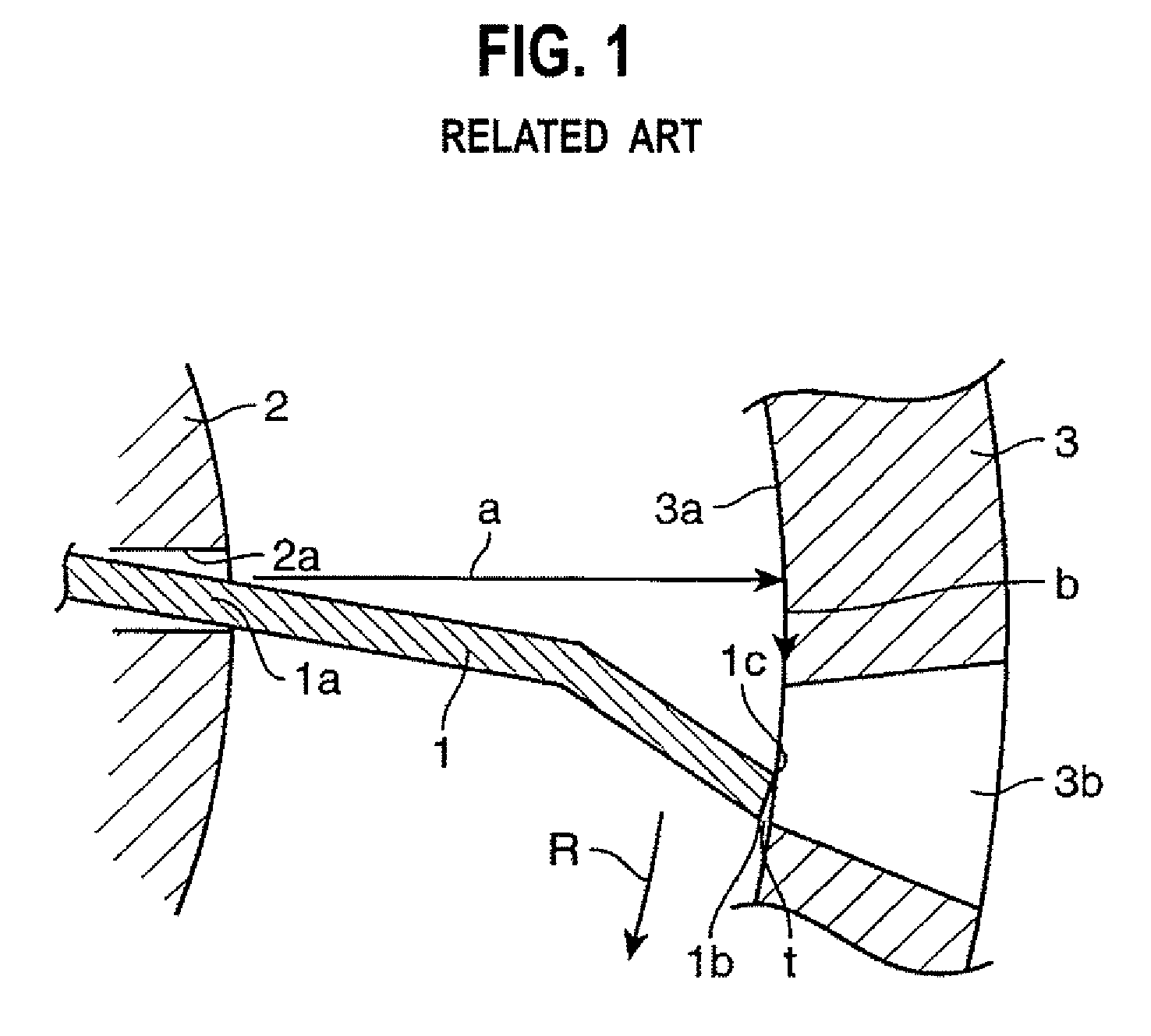

Method of grinding

InactiveUS7037173B2InhibitionGood dispersionProgramme controlAutomatic control devicesEngineeringGrinding wheel

A grinding method comprises steps of simultaneously grinding plural grinding portions of a workpiece by plural grinding wheels T1, T2 moved individually each other, and terminating said grinding by a predetermined grinding wheel T1 prior to a termination of said grinding by the other grinding wheel T2. Whereby, a content of the grinding by each grinding wheel T1, T2 can be same. A grinding condition in each grinding by each grinding wheel T1, T2 can be changed in accordance with a measuring result of the grinding portion in the grinding.

Owner:TOYODA MASCH WORKS LTD

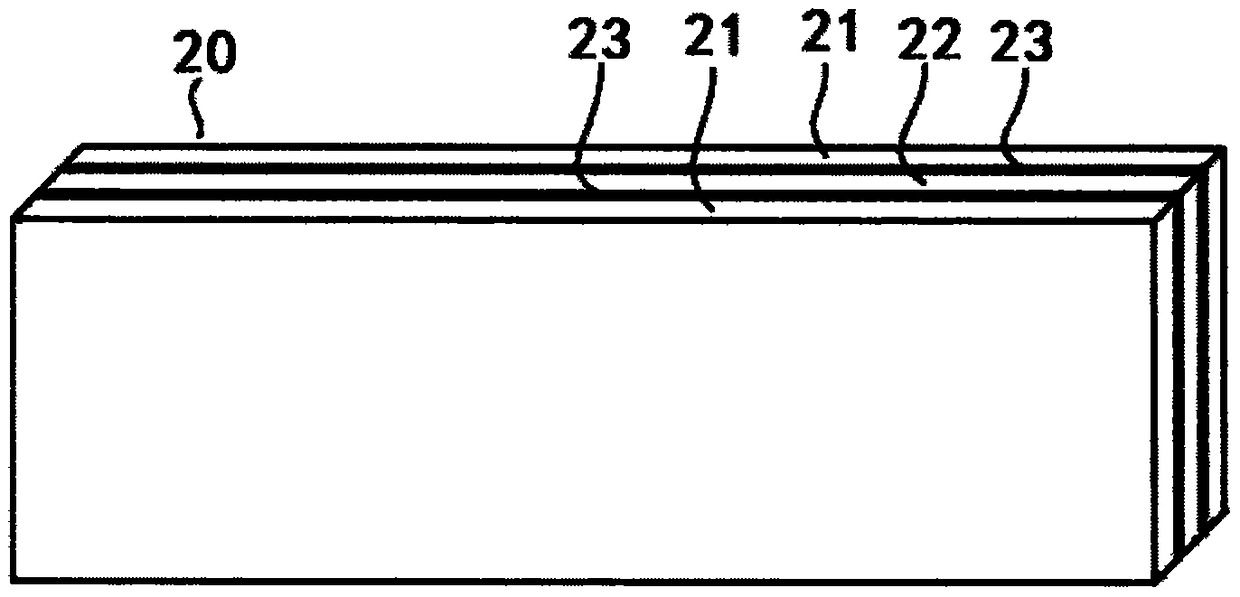

Preparation method of metallic bond tool bit and diamond saw web comprising metallic bond tool bit

ActiveCN108097972AEvenly distributedImprove gripTransportation and packagingMetal-working apparatusGraphiteTemperature difference

The invention relates to diamond tools and provides a preparation method of a metallic bond tool bit and a diamond saw web comprising the metallic bond tool bit. The metallic bond tool bit prepared through the method is high in diamond mechanically holding force and acquires appropriate wearing resistance to meet the market development requirements and the cutting requirements of various marble slabs; meanwhile, the sintering temperature range of the metallic bond tool can be expanded, adverse effects caused by sintering conditions such as non-uniform thermal conduction and edge-center temperature difference of graphite molds can be reduced, the sintering temperature can be increased, the material wastage rate can be reduced, and the quality of sintered tool bits can be improved; the welding tolerance temperature can be increased, the selecting range of welding materials can be expanded, and swelling and foaming of matrixes during secondary welding heating of the tool bit can be avoided; besides, the preparation method of the metallic bond tool bit is easy to implement, applicable of large-scale production and high in practicality.

Owner:FUJIAN QUANZHOU HUAZUAN DIAMOND TOOLS CO LTD

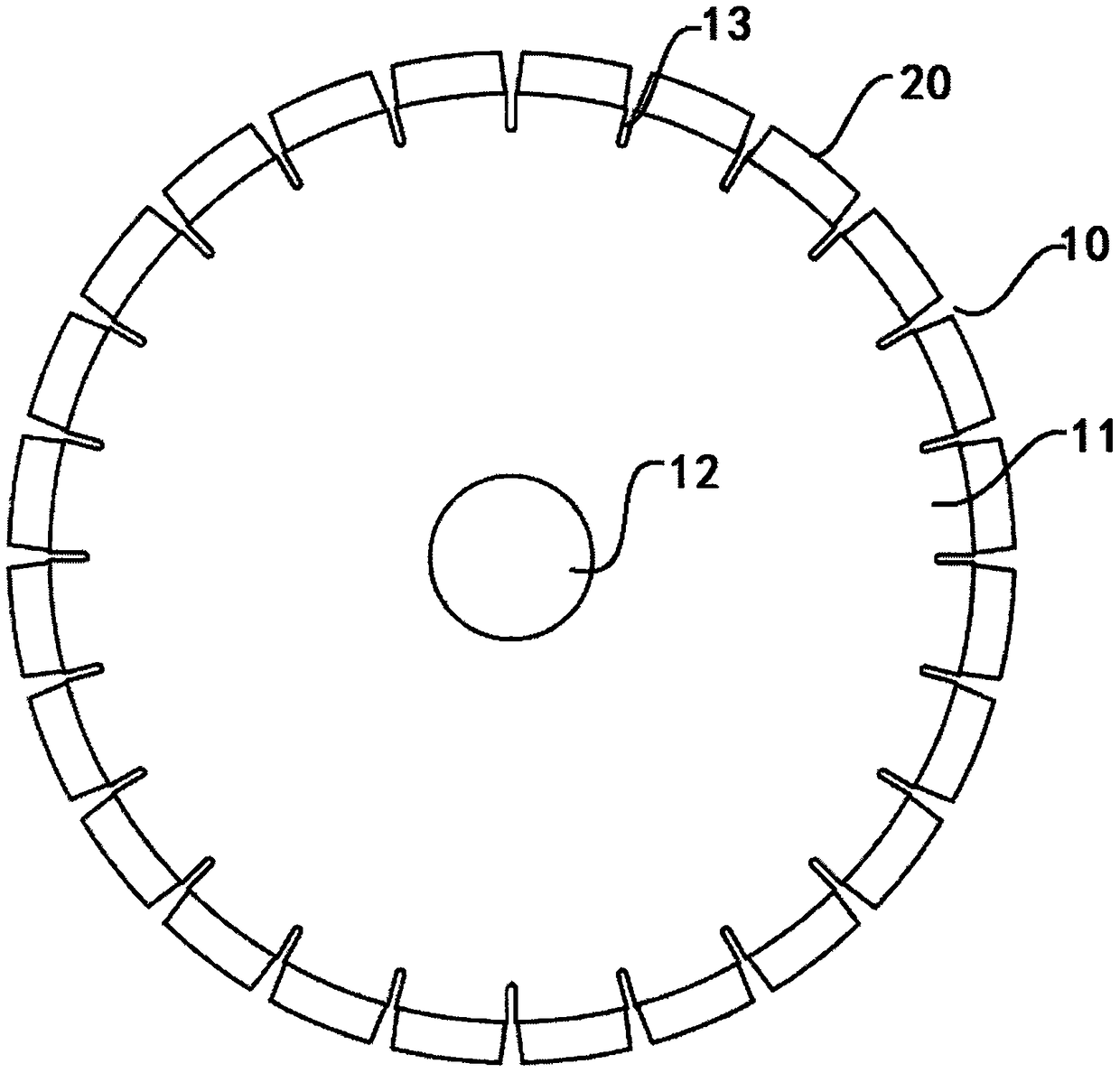

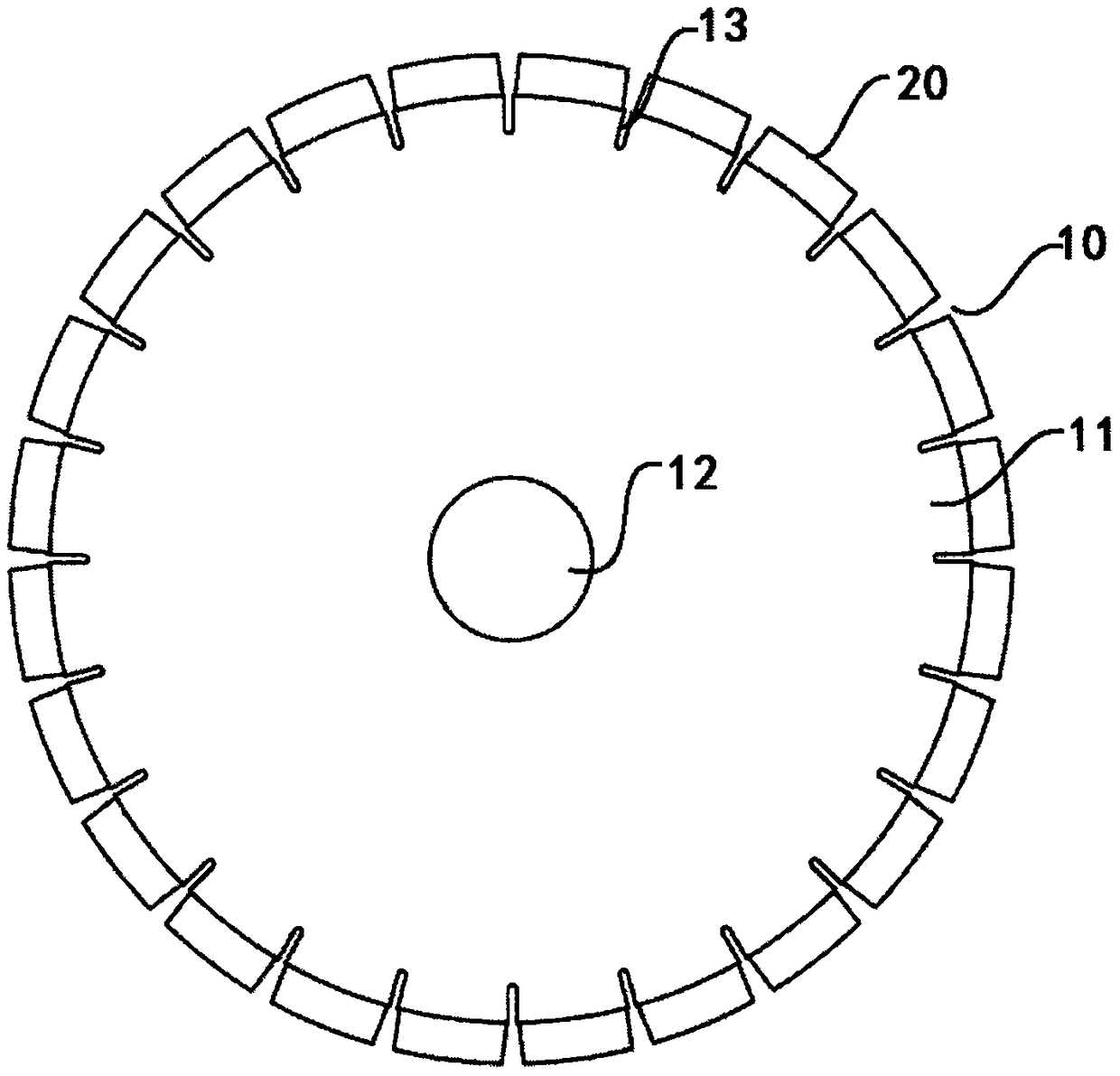

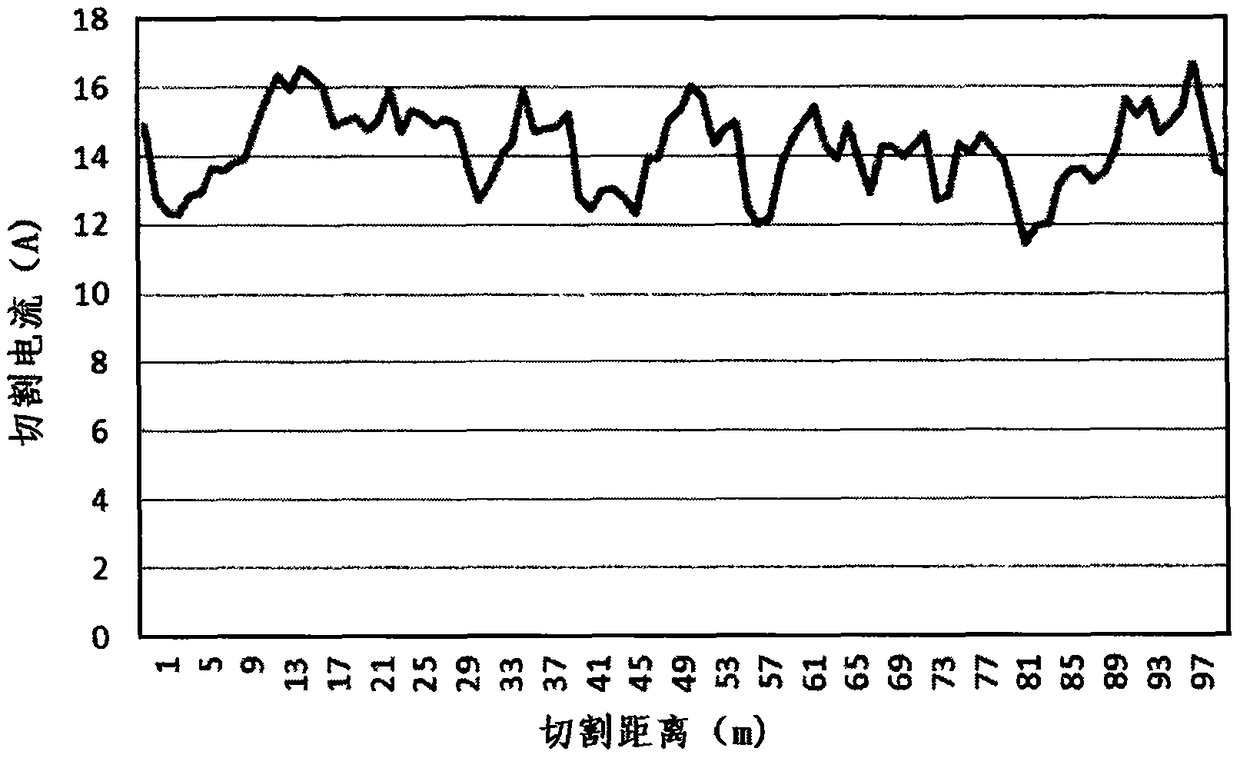

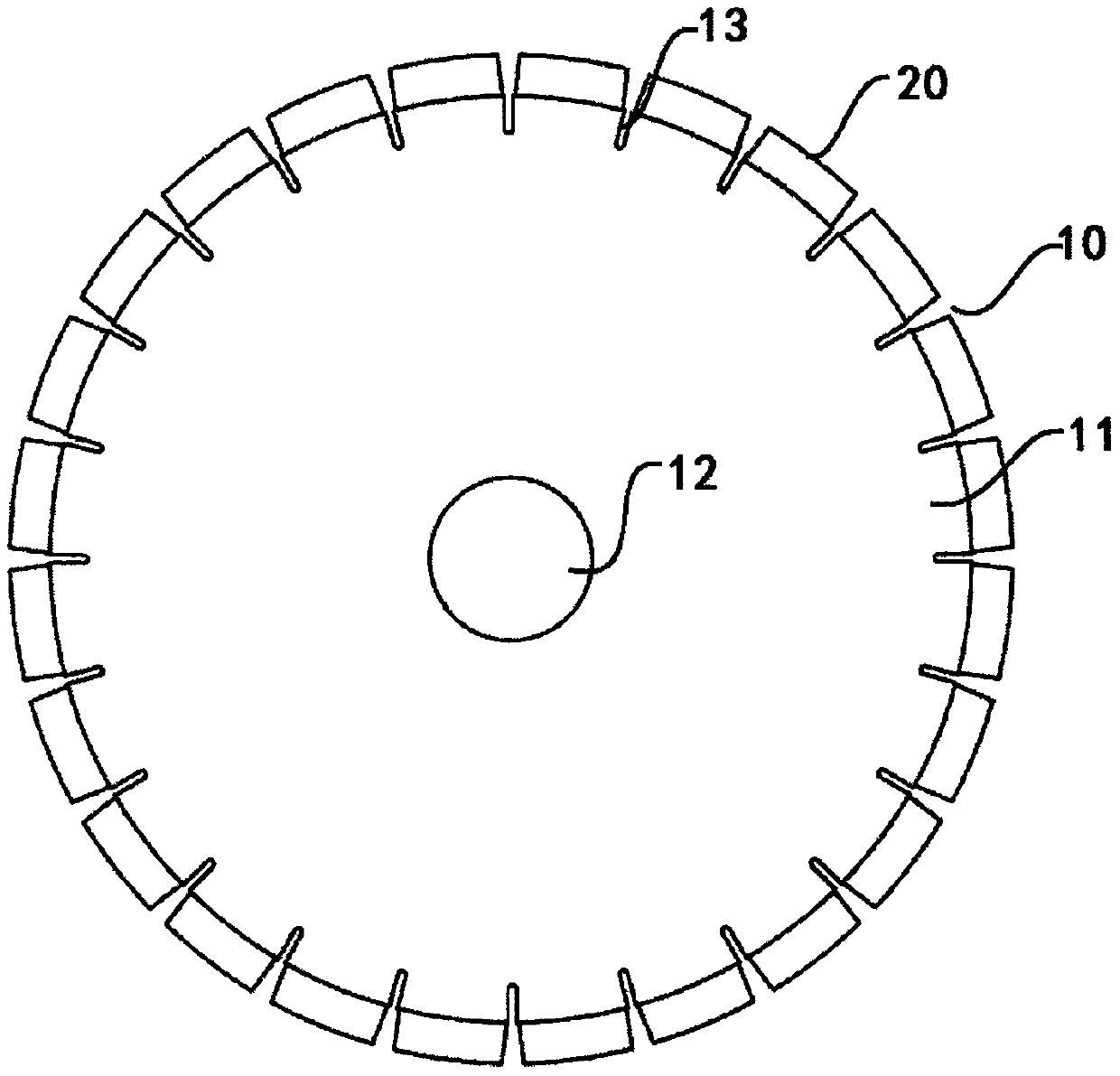

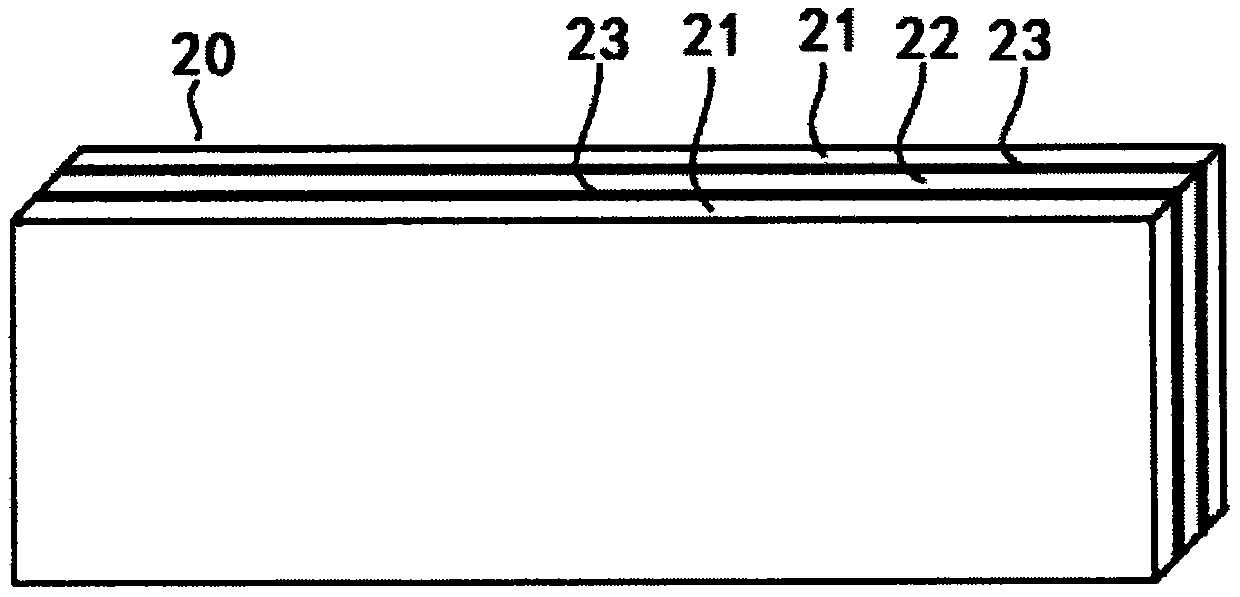

Composite multi-layer diamond tool bit and preparation method thereof

ActiveCN108656363AFast cutting speedHigh cutting sharpnessMetal sawing toolsStone-like material working toolsDiamond cuttingCo element

The invention relates to a composite multi-layer diamond tool bit and belongs to the technical field of diamond sintering tools. The composite multi-layer diamond tool bit comprises a plurality of diamond cutting layers. The adjacent diamond cutting layers are bonded through metal layers. Each diamond cutting layer is composed of a carcass and diamond particles impregnated in the carcass. The concentration of the diamond particles in the diamond cutting layer located in the middle is greater than those of diamond particles in the diamond cutting layers located on the two sides. The hardness ofthe carcass in the diamond cutting layer located in the middle is smaller than those of the carcasses in the diamond cutting layers located on the two sides. The composite multi-layer diamond tool bit is used for a diamond saw blade and applied to processing of stone materials such as granite and marble and cutting of concrete pavements, the cutting speed is high, the cutting sharpness is high, the performance is stable, energy consumption can be reduced easily, in addition, used diamond is small and does not contain the elements including the Co element and the like, and the tool cost can belowered easily.

Owner:JIANGSU FENGTAI TOOLS

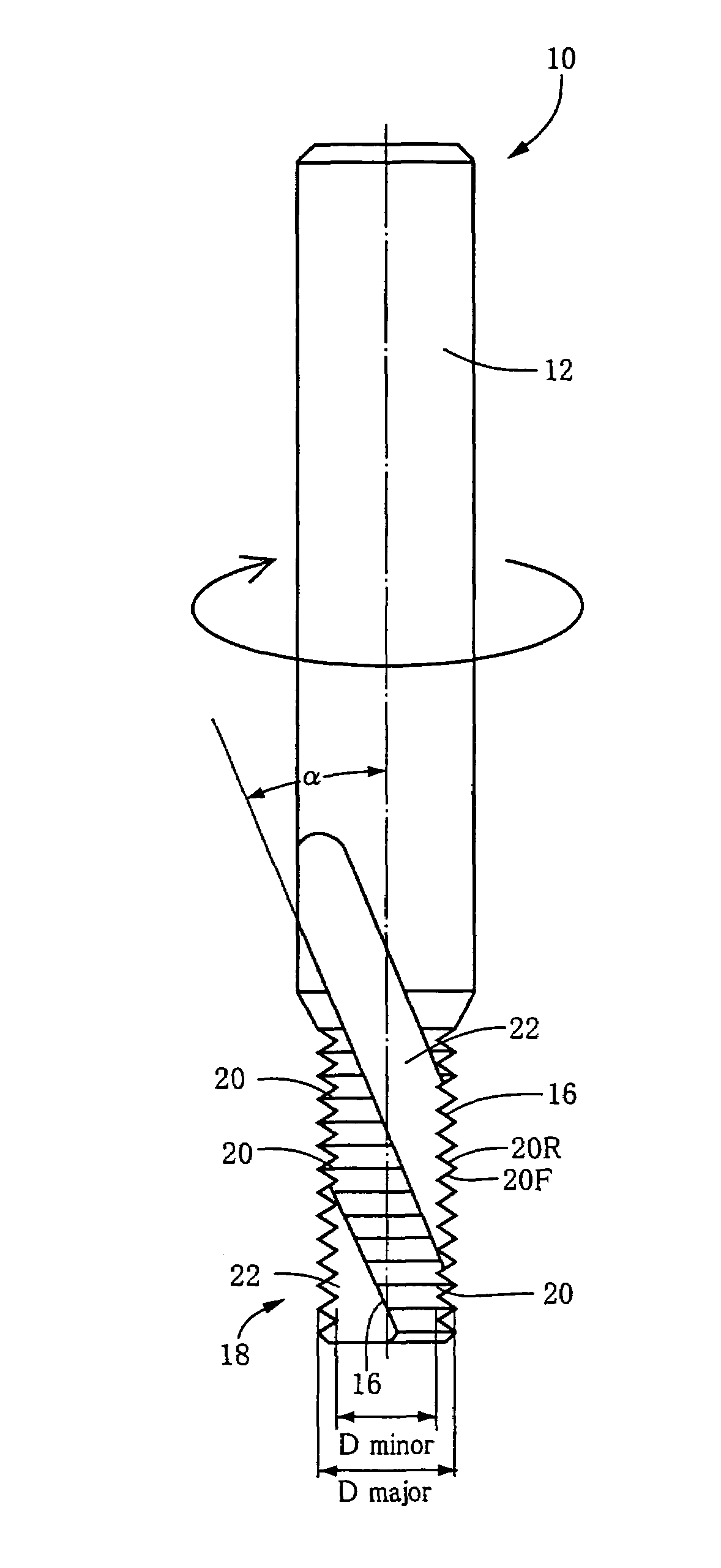

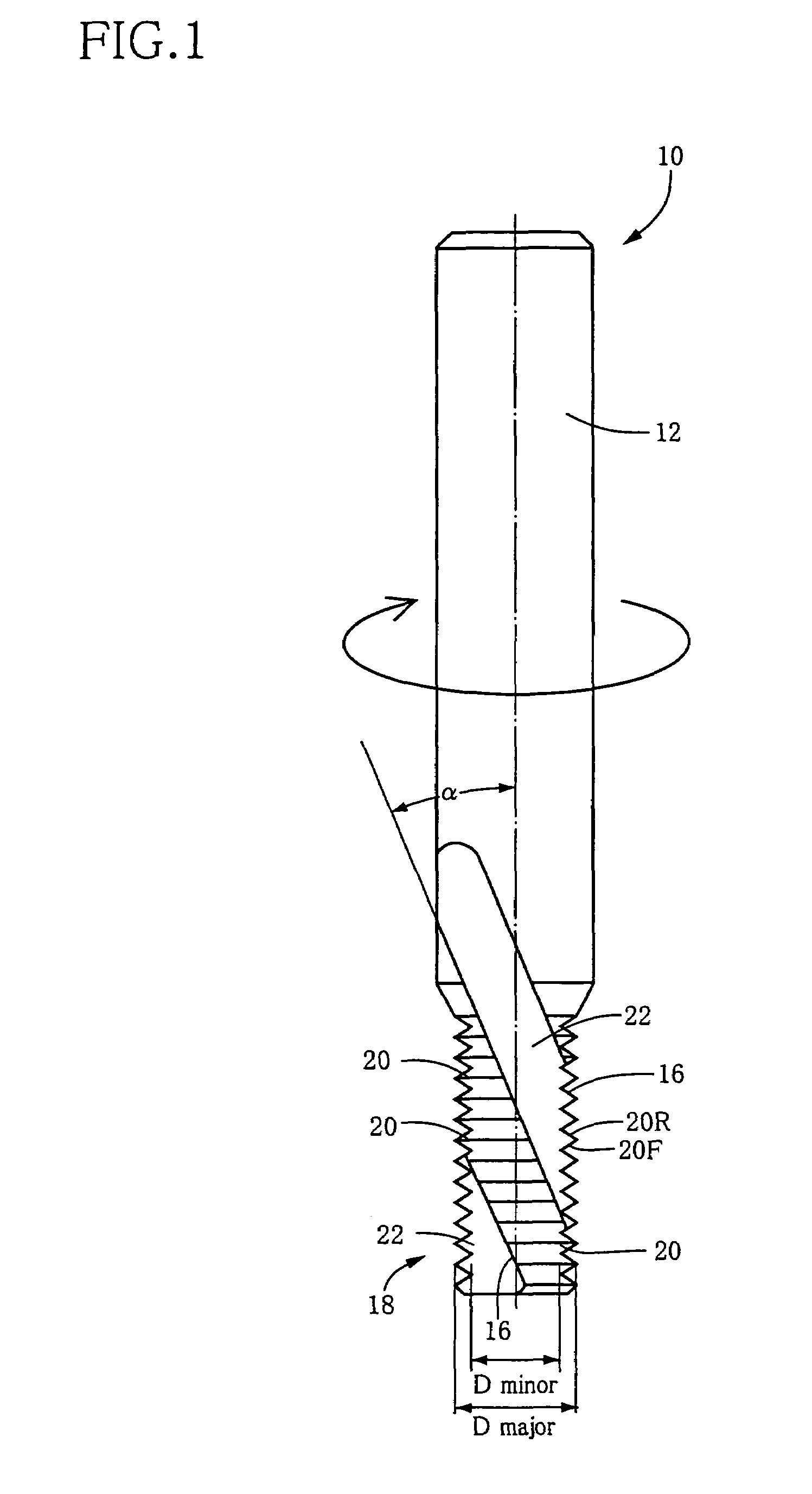

Thread mill having flute twisting in direction opposite to rotating direction

ActiveUS7377732B2Good cutting sharpnessImprove accuracyThread cutting toolsThread cutting machinesFluteEngineering

A thread mill that is to be moved along a helical interpolation path while being rotated about an axis of the thread mill in a rotating direction, for forming a thread in a circumferential surface of a workpiece. The thread mill includes a cylindrical main body having (a) at least one spiral flute formed in an outer circumferential surface of the cylindrical main body, and (b) at least one cutting edge each provided by a rear-side one of widthwise opposite edges, as viewed in the rotating direction, of a corresponding one of the at least one spiral flute. Each of the at least one spiral flute extends in a direction opposite to the rotating direction as viewed in a direction away from a proximal end of the cylindrical main body toward a distal end of the cylindrical main body. Also disclosed is a method of forming the thread by using the thread mill.

Owner:OSG

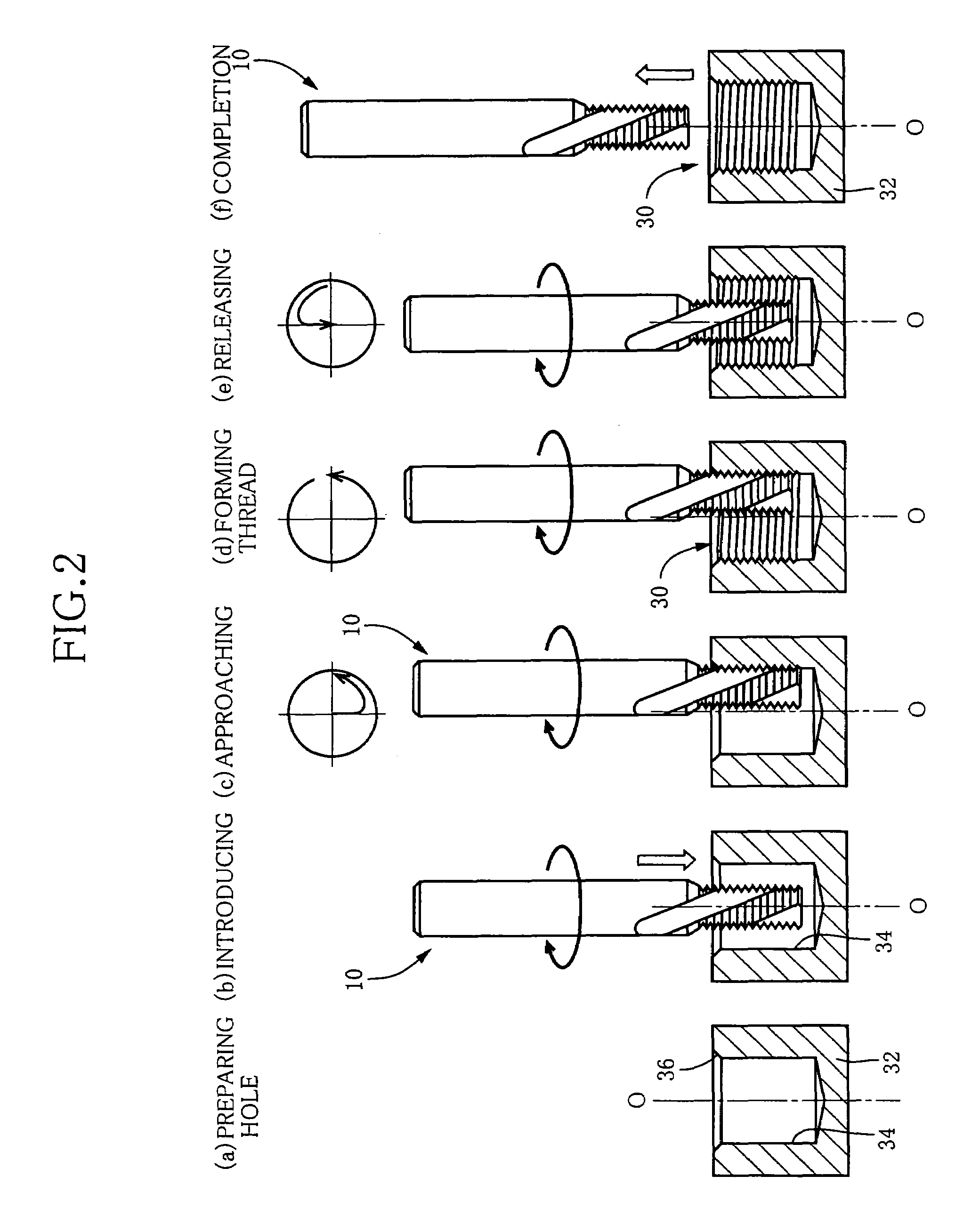

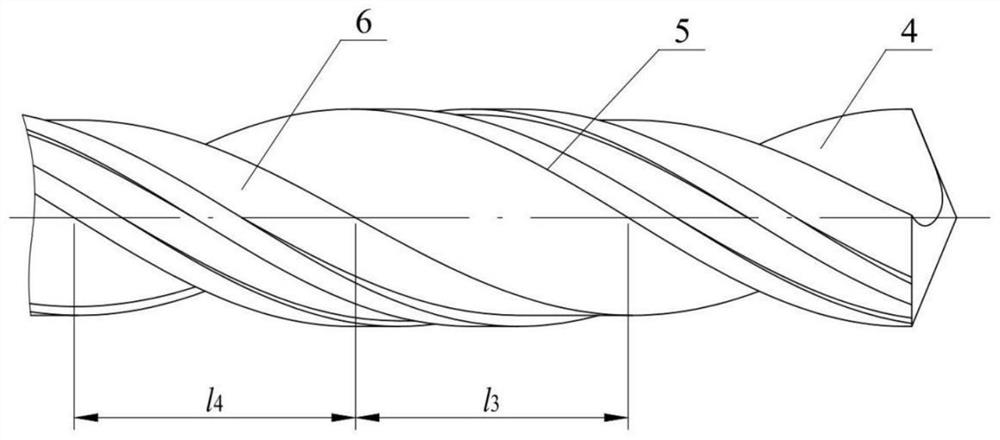

Ball end mill

ActiveCN105436588AImprove cutting efficiencyExtended service lifeMilling cuttersWorkpiecesMilling cutterEngineering

The invention discloses a ball end mill which comprises a cylindrical cutter main body with the central shaft as a rotation center, wherein two or more chip grooves which extend to the cutting end part are formed in the outer circumference of the cutting part of the cutter main body and are intersected with two or more back cutter surfaces arranged on the cutting end part to form end cutting blades; the amount of the chip grooves is equal to that of the back cutter surfaces; the adjacent two back cutter surfaces are intersected to each other to form a transverse blade; the chip grooves are composed of a main groove and a deep groove; the main groove is intersected with the corresponding back cutter surface to form an arch-shaped cutting blade; the deep groove is composed of a small front cutter surface and an inclined plane; the small front cutter surface is intersected with the corresponding back cutter surface to form a plane cutting blade; the inclined plane is intersected with the arch-shaped bottom of the main groove; the depth of the inclined plane is larger than that of the main groove; the arch-shaped cutting blade is in smooth connection with the plane cutting blade to form an end cutting blade; and the end part of the transverse blade is intersected with the middle part of the plane cutting blade. The ball end mill can ensure the boundary strength of the transverse blade and improve the sharpness of the cutting blade and the chip discharge capacity.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

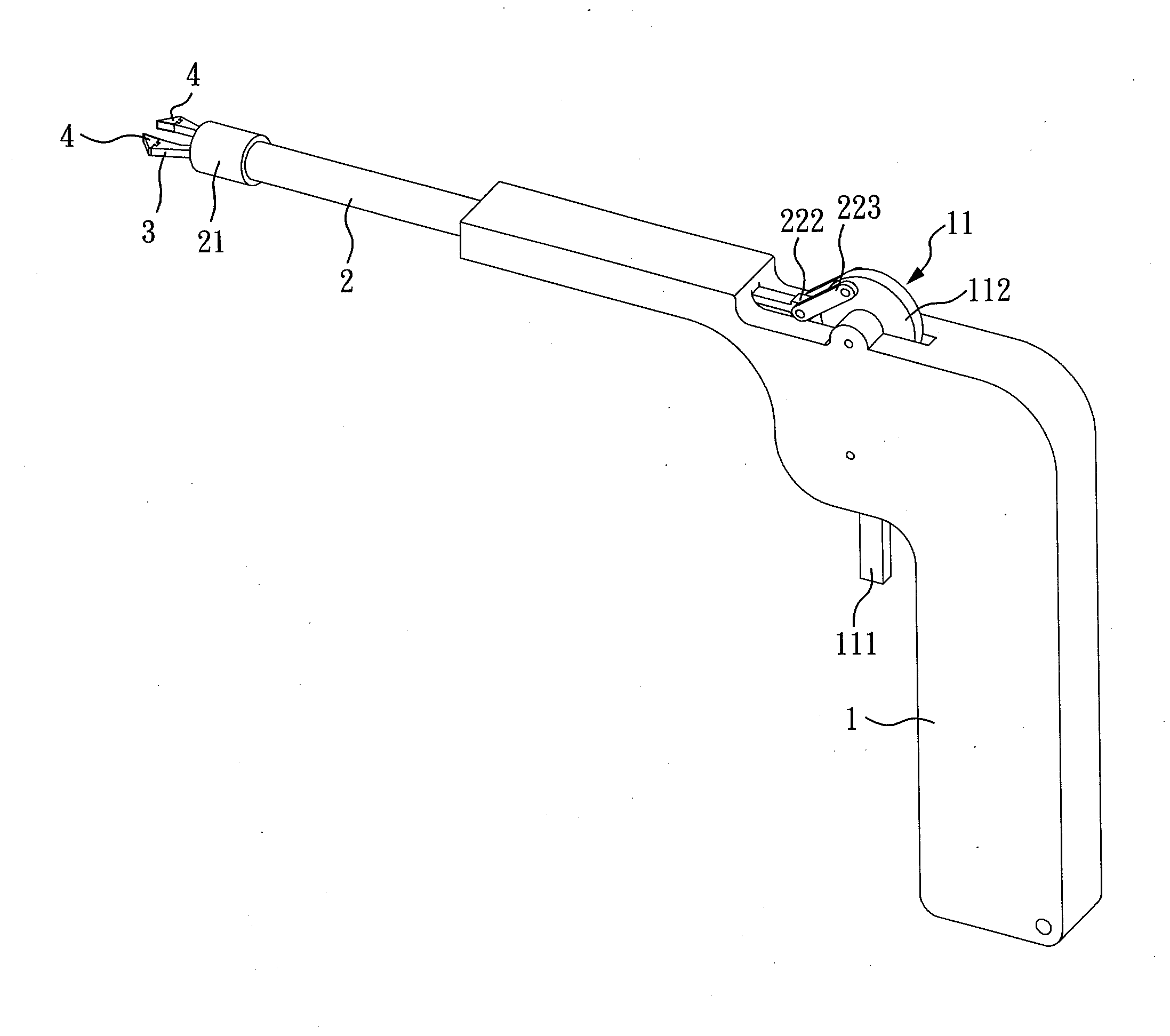

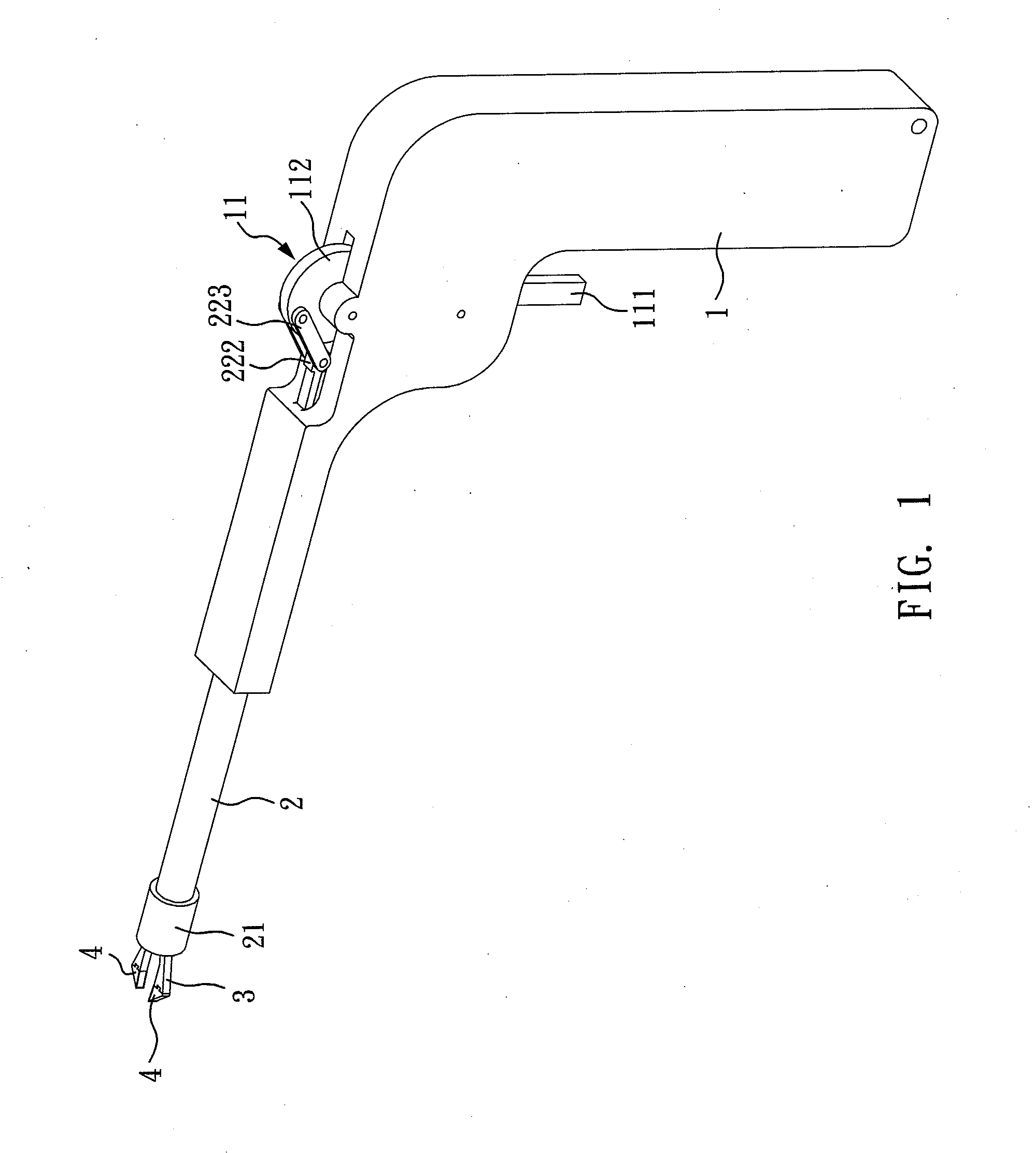

Replaceable micro-surgical instrument

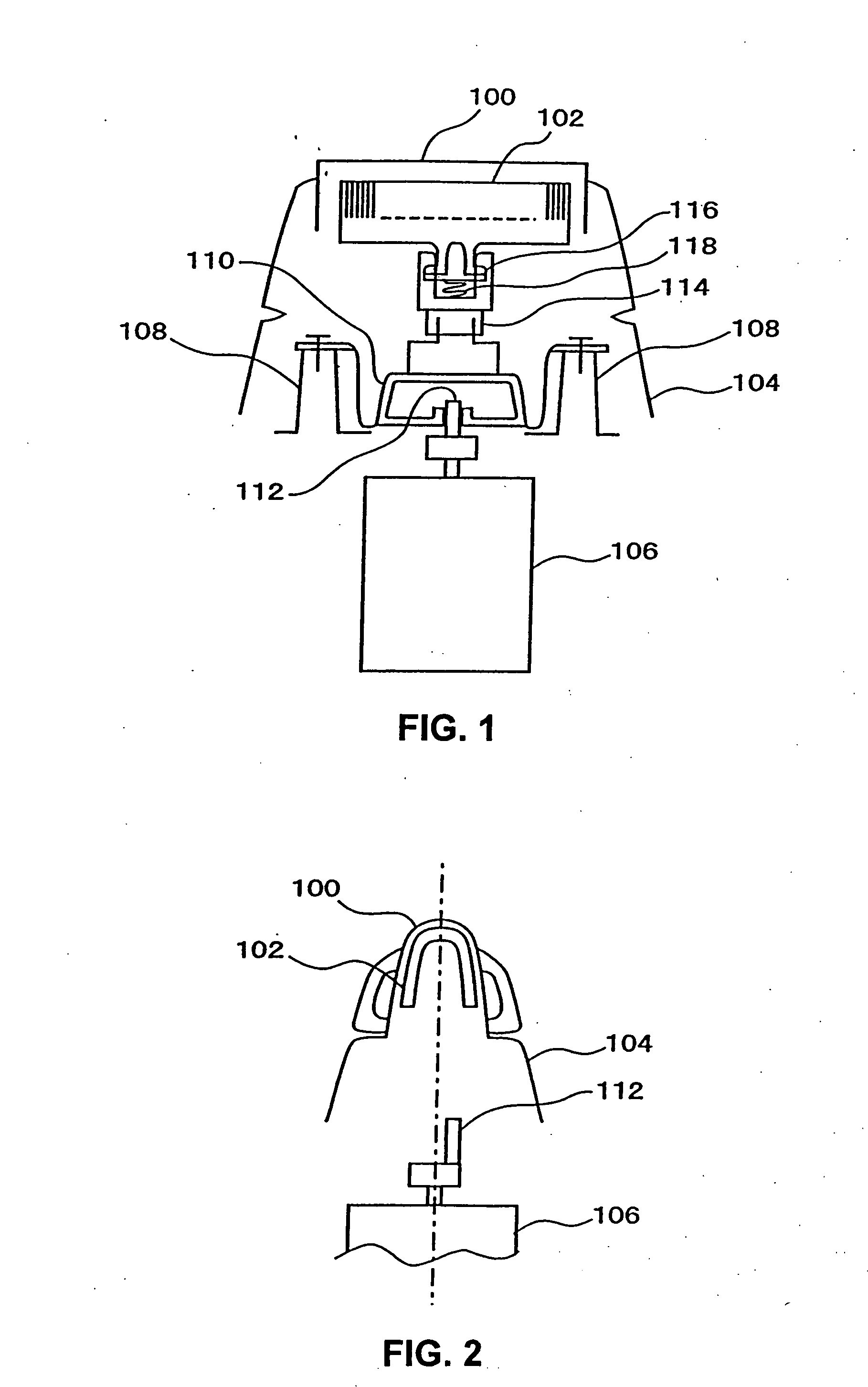

InactiveUS20130325049A1Easy to disassembleReduce instrument costSurgical pincettesEndoscopic cutting instrumentsEngineeringSurgical device

The present invention provides a replaceable micro-surgical instrument which comprises a pull structure and a hollow tube attached to a grip. The hollow tube has a sleeve at one end with a U-type elastic element sliding in. The U-type elastic element includes a spring tension section and two opposite extending arms and the outer edge of each arm is against the inner wall of the sleeve. Two arms could move according to the pull structure to selectively extend out of the sleeve to be opened or pull back into the sleeve to be clip together. Particularly, there is a replaceable micro-surgical element set in the front-end of each arm, so when the micro-surgical element becomes blunt or broken, the doctor could only replace the micro-surgical element without replace a whole new instrument in order to reduce instrument cost, increase replacement rate, and maintain the quality of medical surgery.

Owner:NAT CENT UNIV

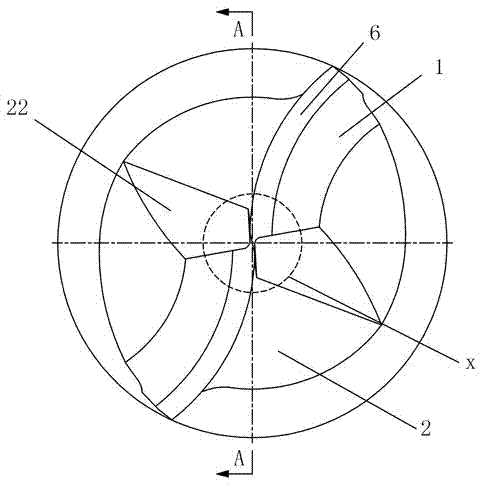

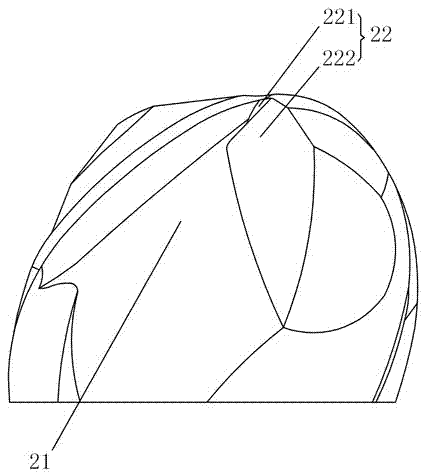

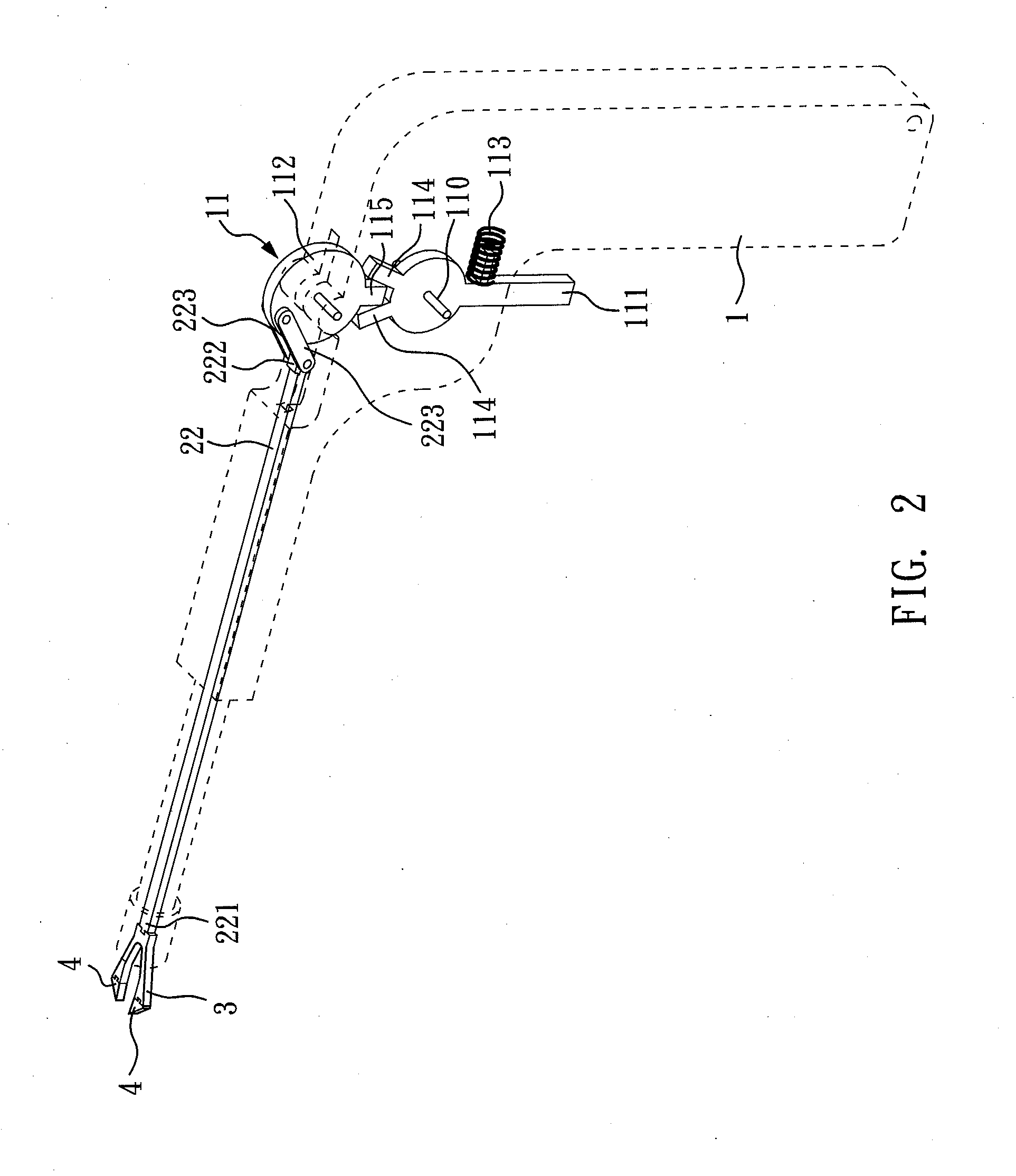

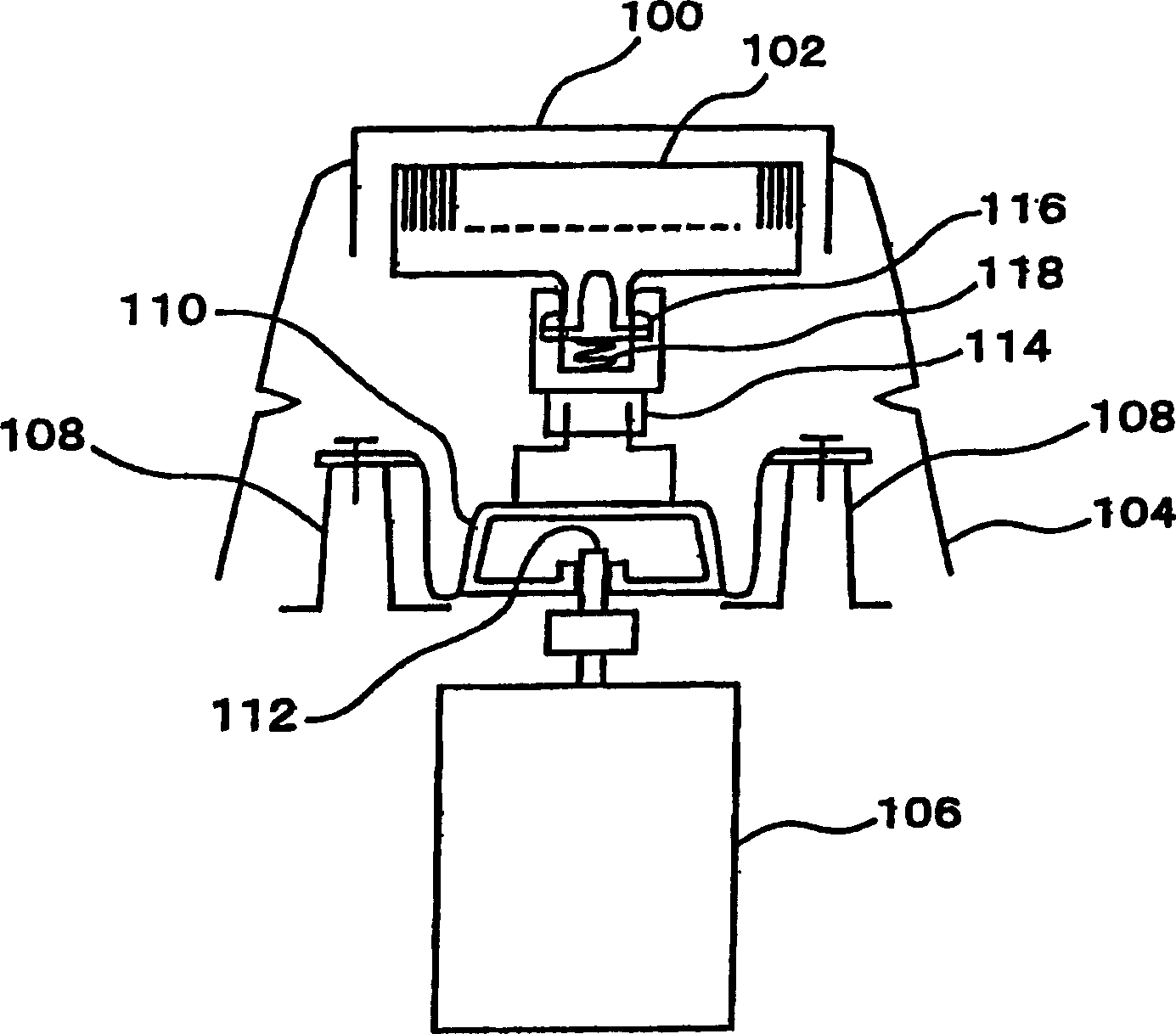

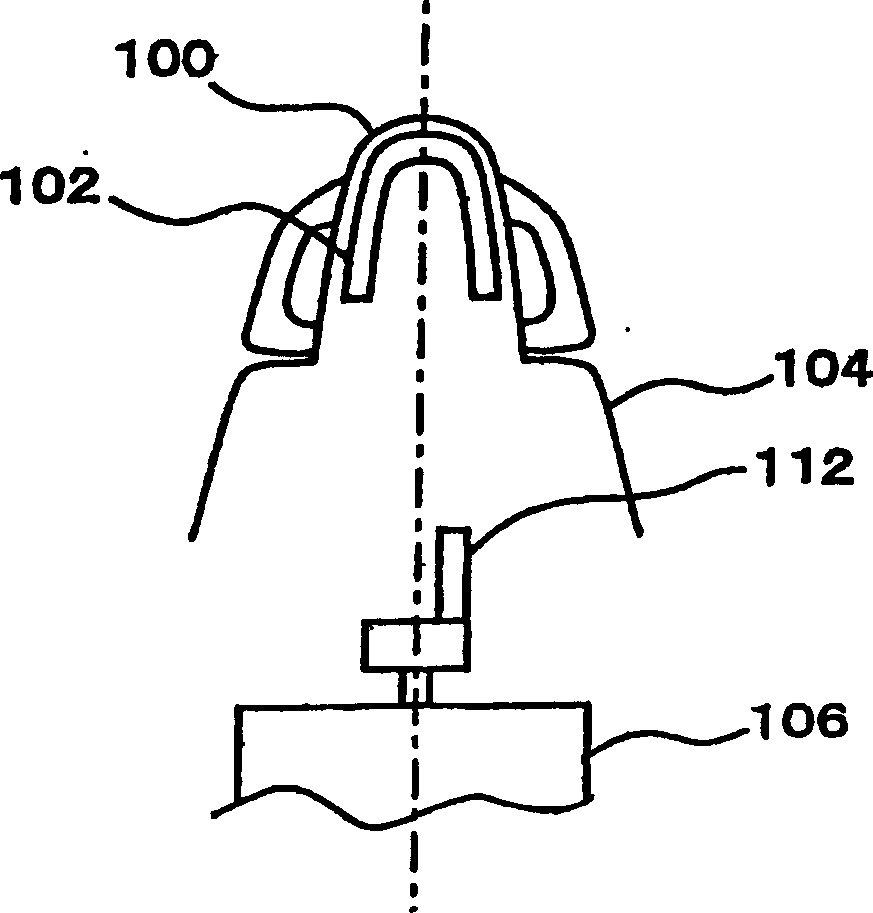

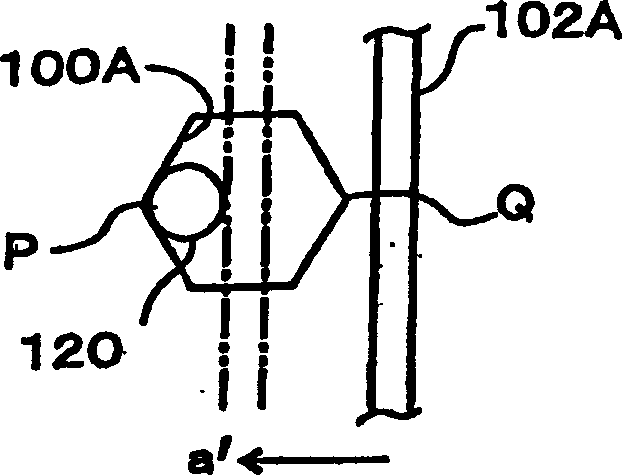

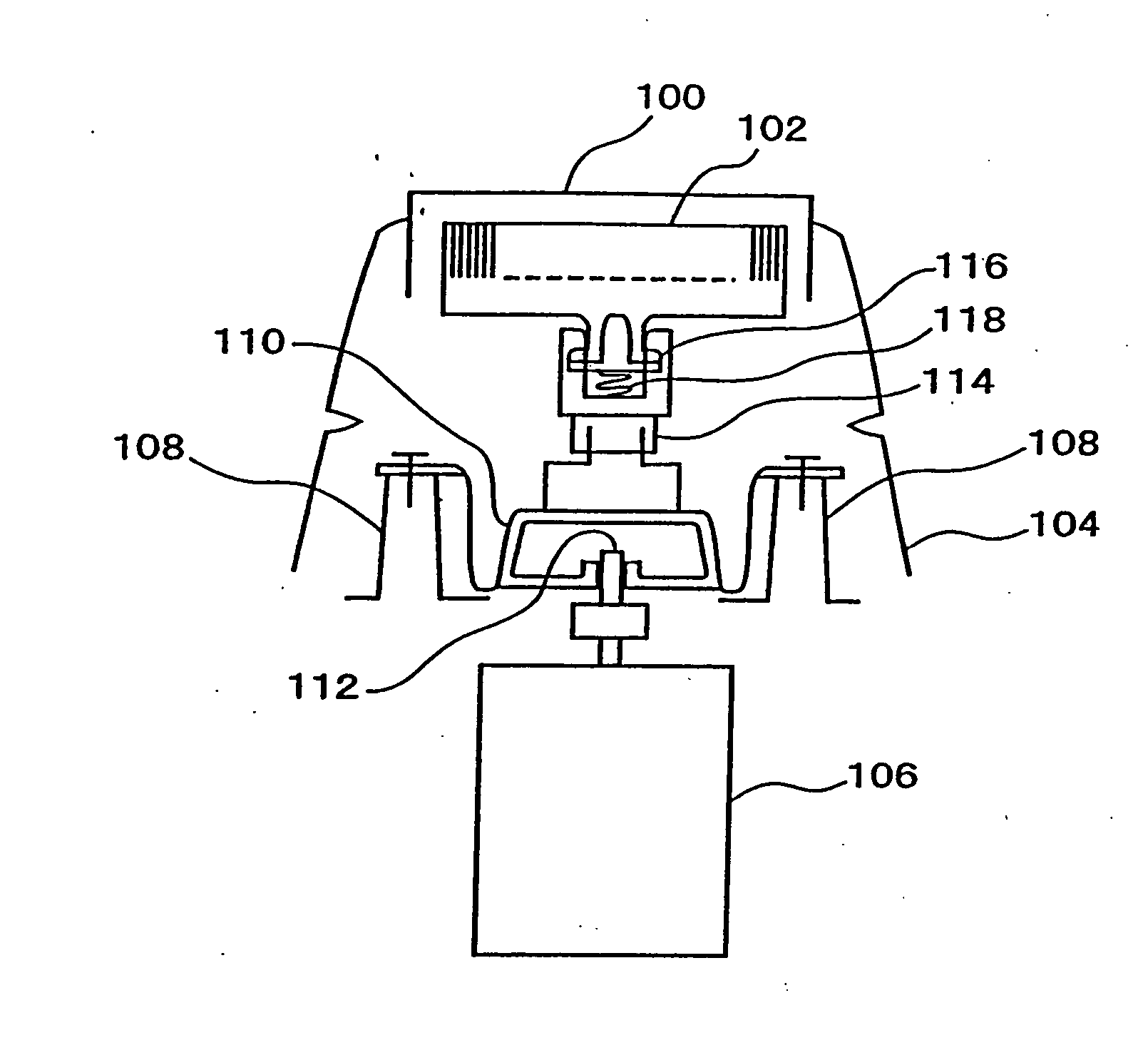

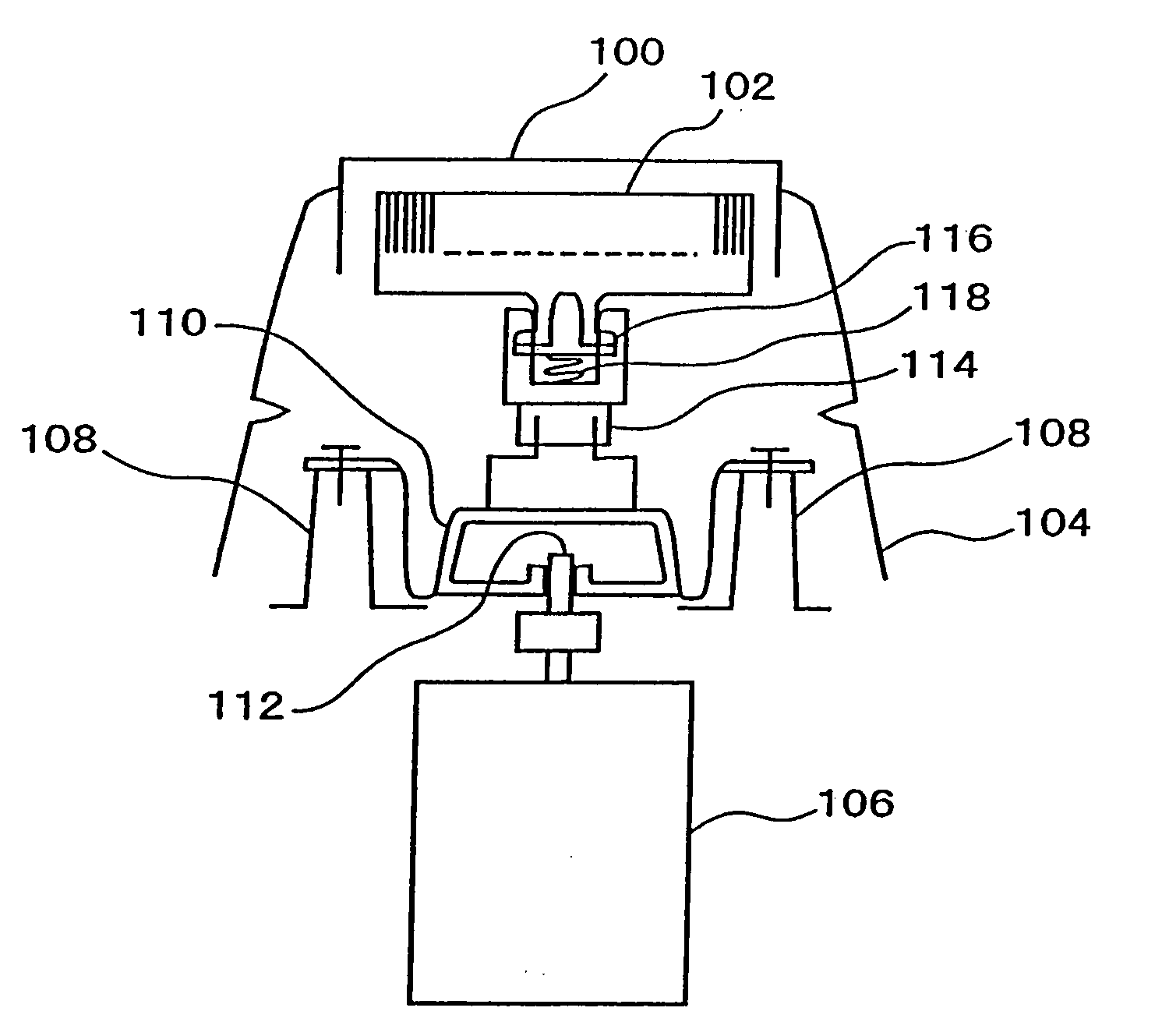

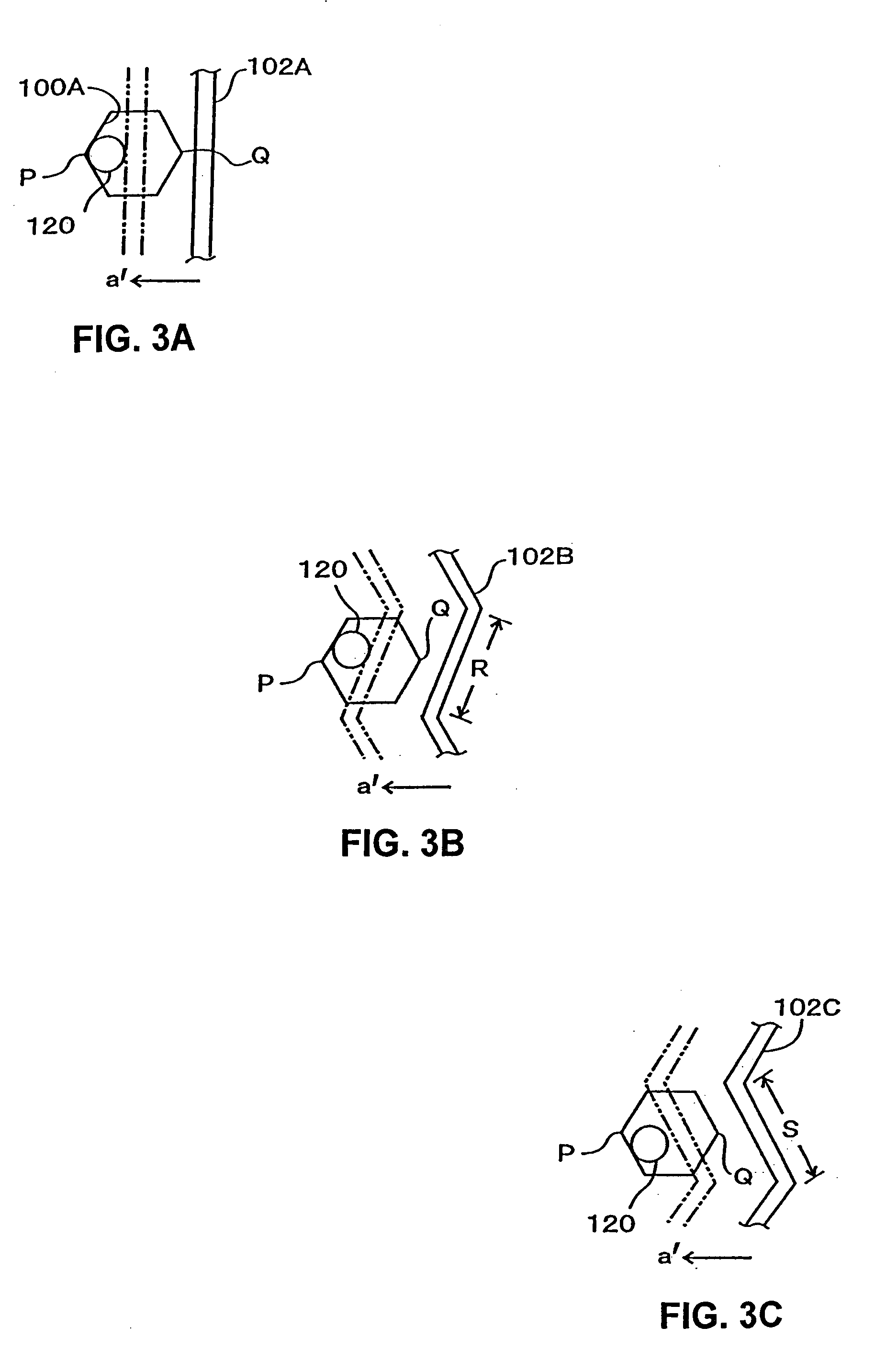

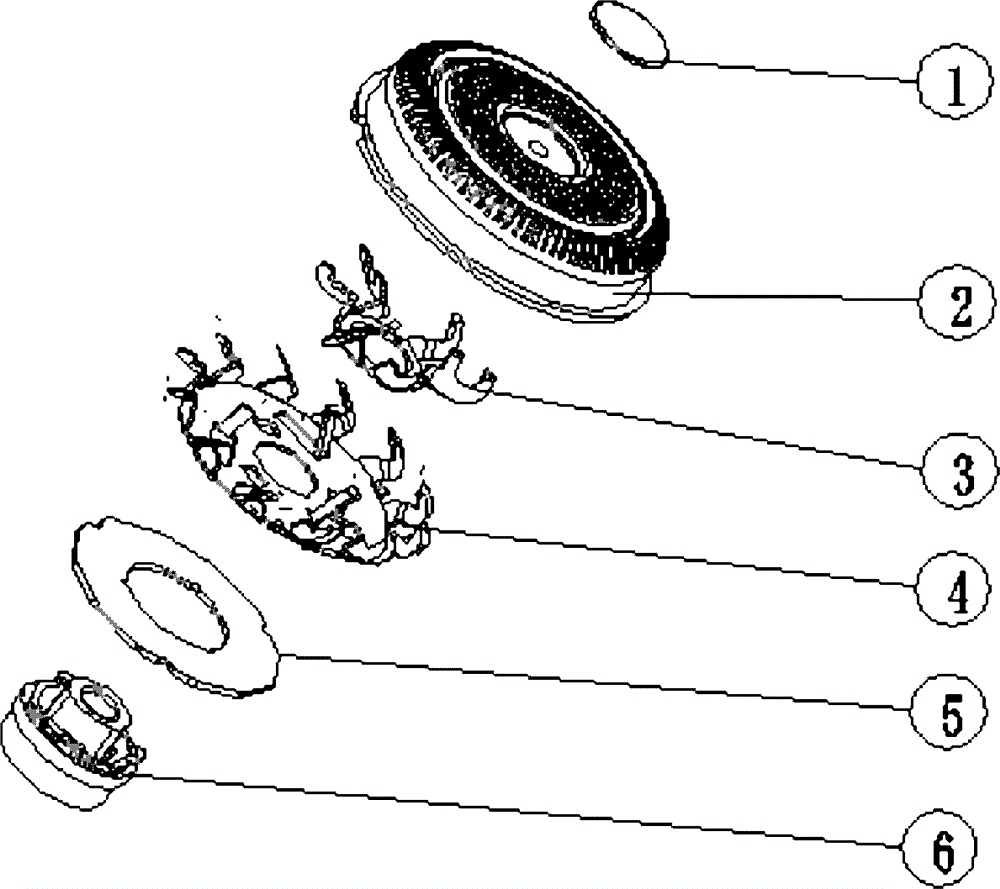

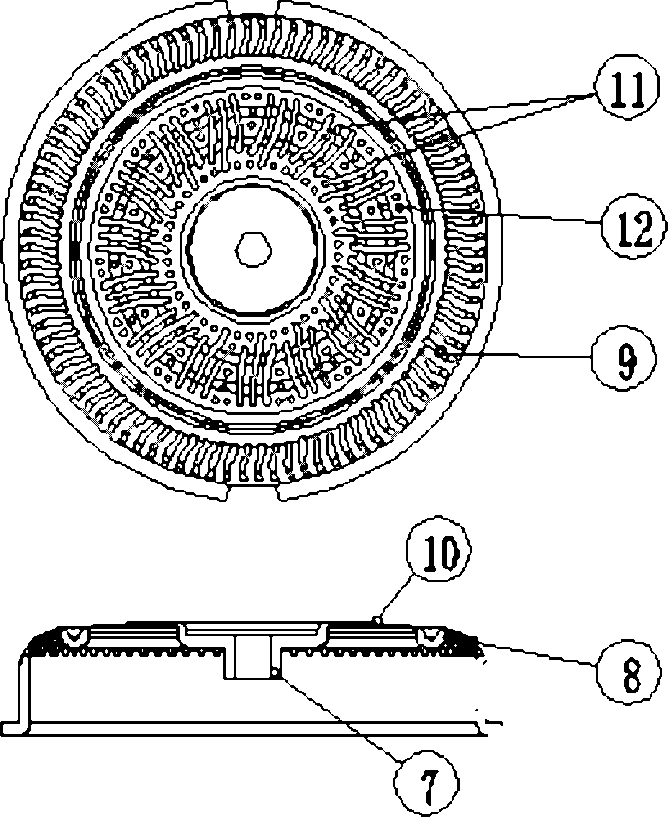

Nose hair cutter

A main body of an inner blade is inserted into an inner blade insertion hole of an inner blade frame such that the main body can extend and retreat, a tip end cutting edge is pushed by a spring such that it comes into contact with an inner peripheral surface of a slit outer blade, the main body of the inner blade projecting outward from the inner blade insertion hole is bent rearward in a rotational direction, and the cutting edge of the inner blade is located rearward of the main body in the inner blade insertion hole in the rotational direction. With this configuration, the cutting edge does not fall forward in the rotational direction, and no gap is generated between the cutting edge and the inner peripheral surface of the slit outer blade.

Owner:MATSUSHITA ELECTRIC WORKS LTD

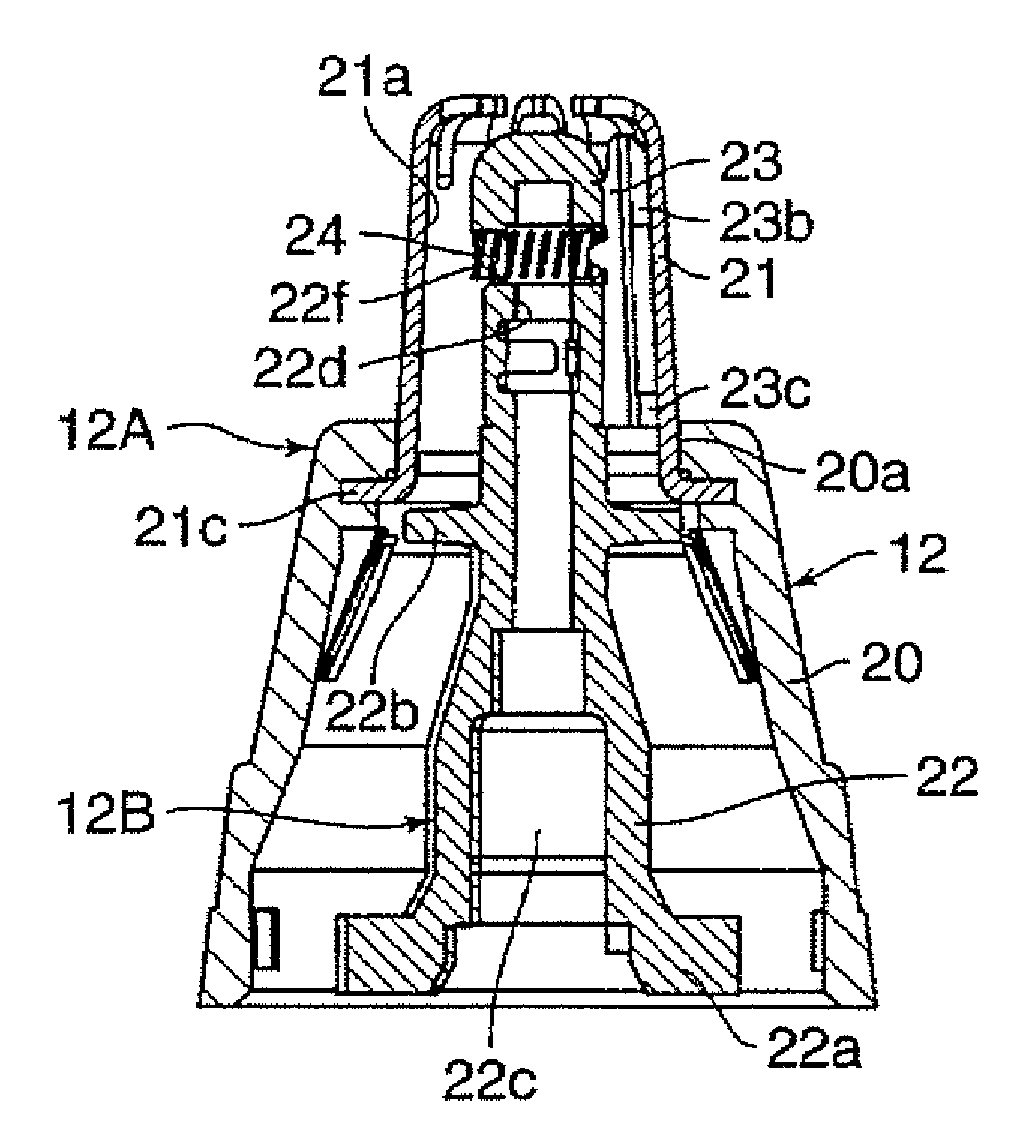

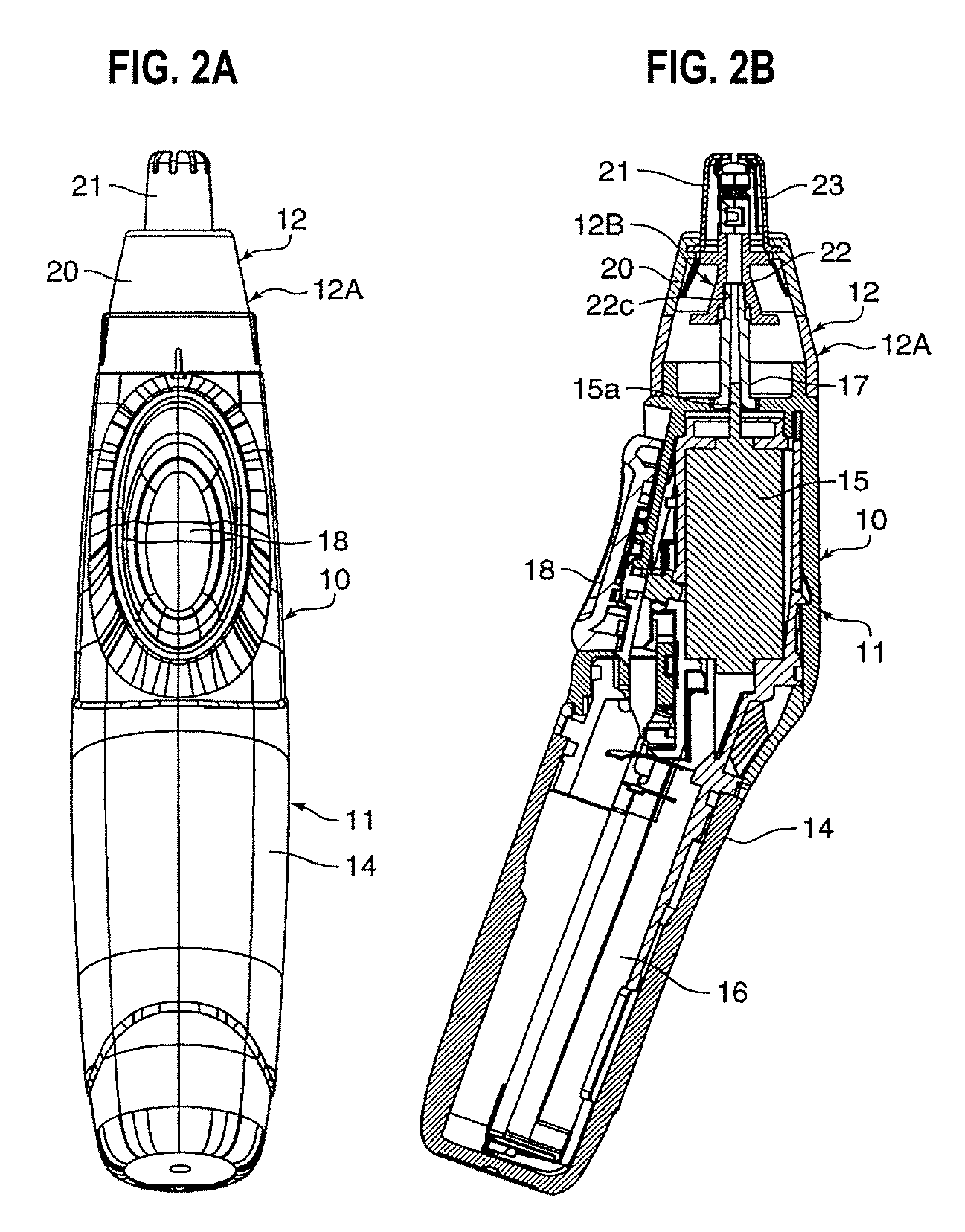

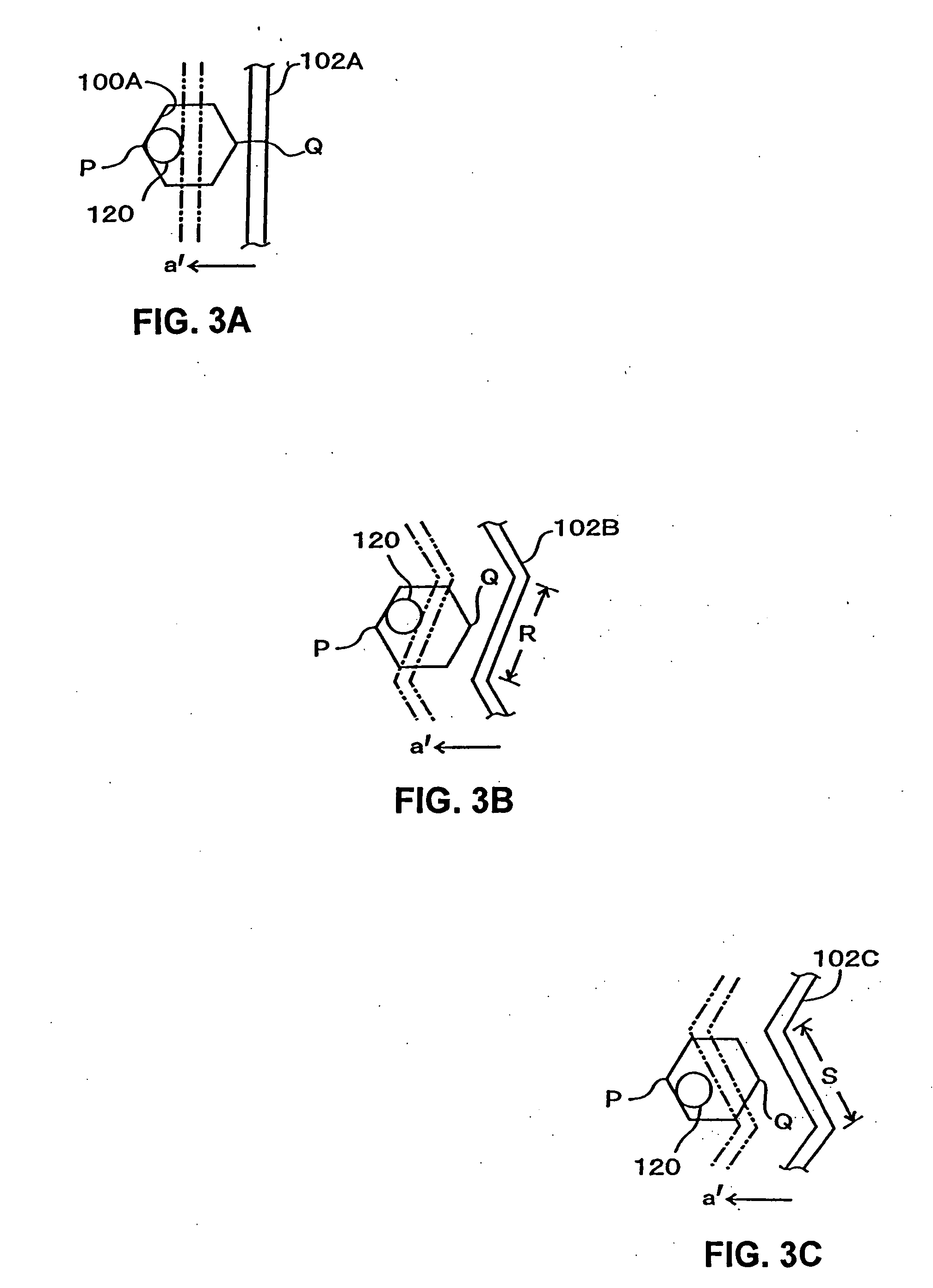

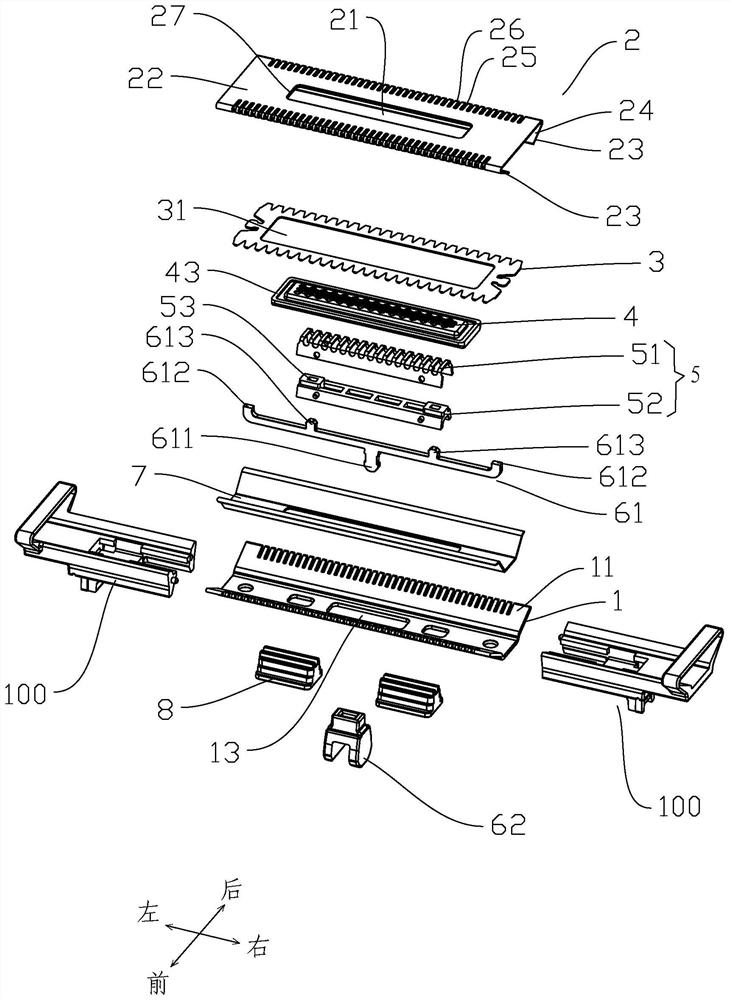

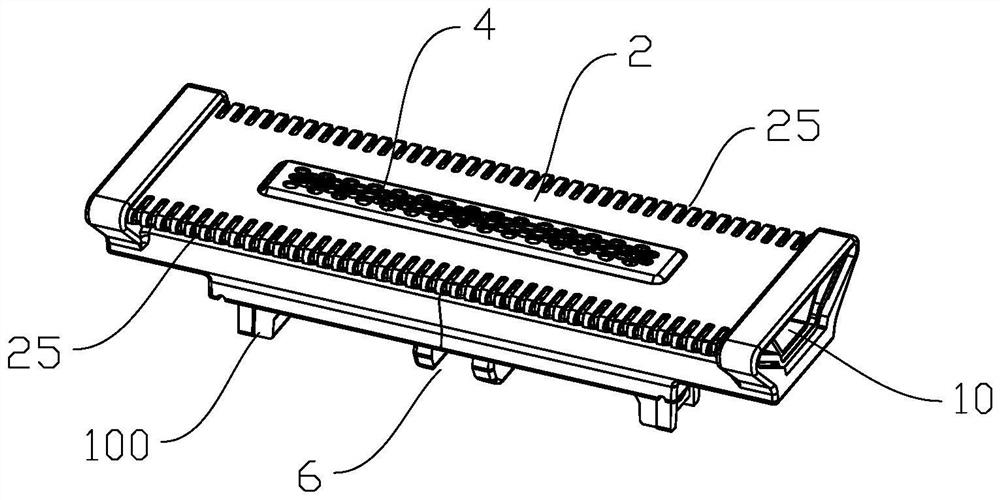

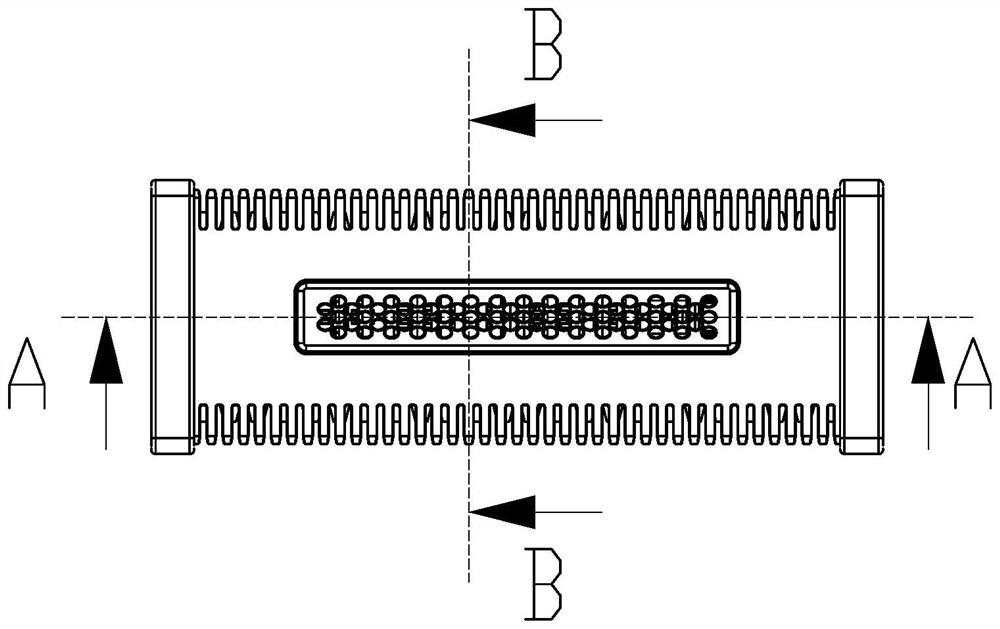

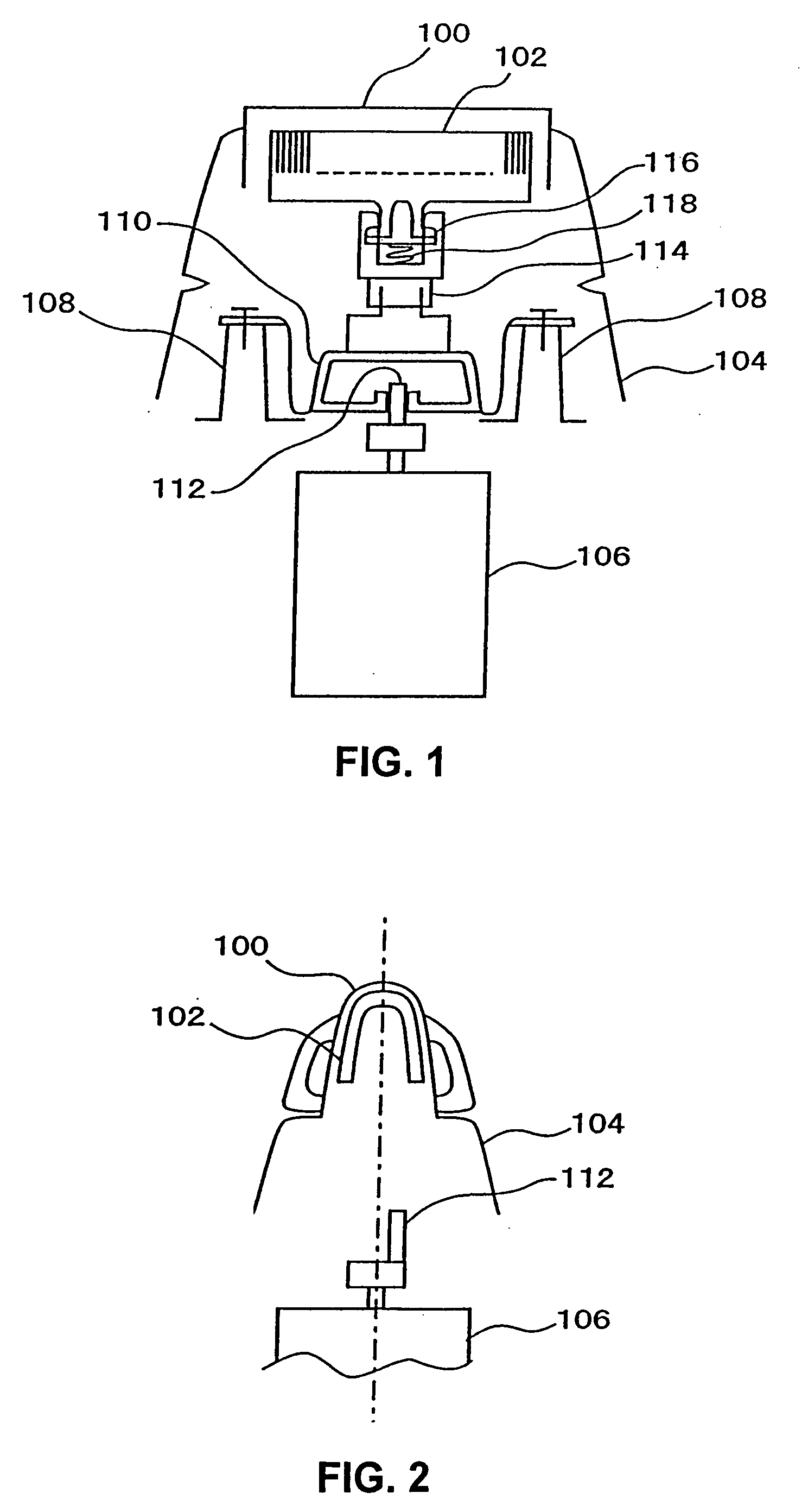

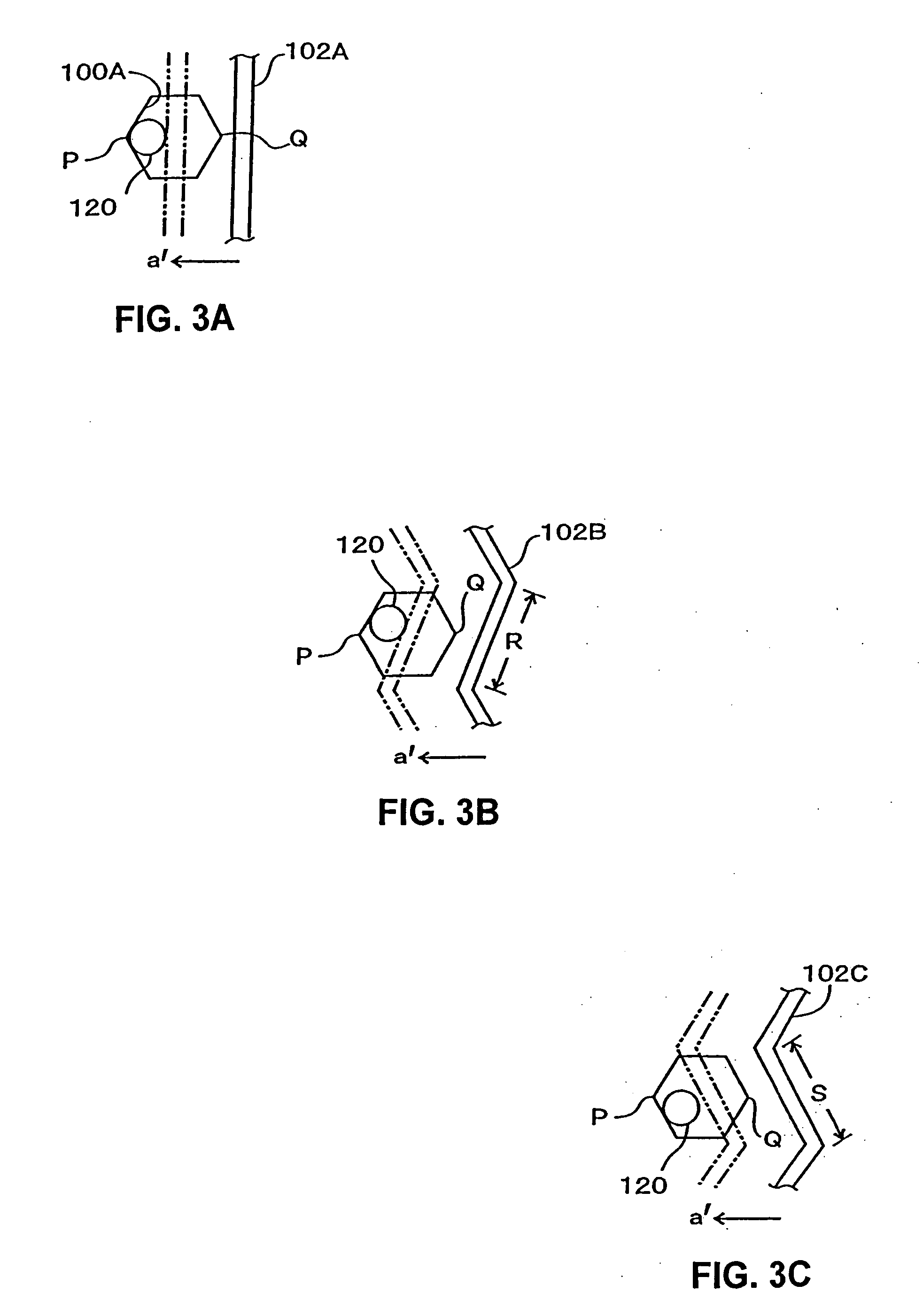

An electric shaver

InactiveCN1660547AGood cutting sharpnessReduce the burden onMetal working apparatusRelative motionKnife blades

An electric shaver in which a plurality of mutually separated cutter blades provided in an inner cutter are moved in relative terms while making sliding contact with an outer cutter that is formed with a plurality of hair introduction openings, so that hair that enters into the hair introduction openings of the outer cutter is cut by the cutter blades, wherein the cutter blades are caused to intersect the same hair introduction openings of the outer cutter at different angles.

Owner:IZUMI PROD CO

Electric shaver

InactiveUS20050183267A1Good cutting sharpnessIncreased durabilityMetal working apparatusEngineeringKnife blades

An electric shaver in which a plurality of mutually separated cutter blades provided in an inner cutter are moved in relative terms while making sliding contact with an outer cutter that is formed with a plurality of hair introduction openings, so that hair that enters into the hair introduction openings of the outer cutter is cut by the cutter blades, wherein the cutter blades are caused to intersect the same hair introduction openings of the outer cutter at different angles.

Owner:IZUMI PROD CO

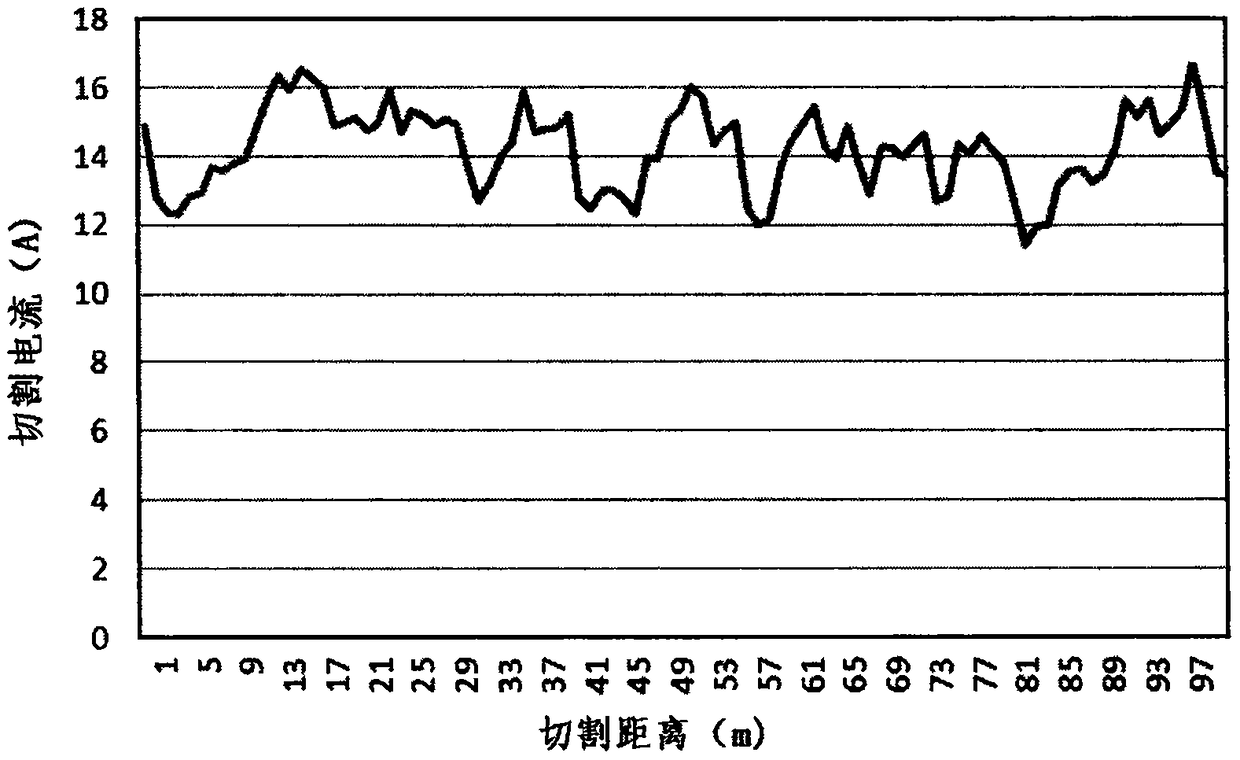

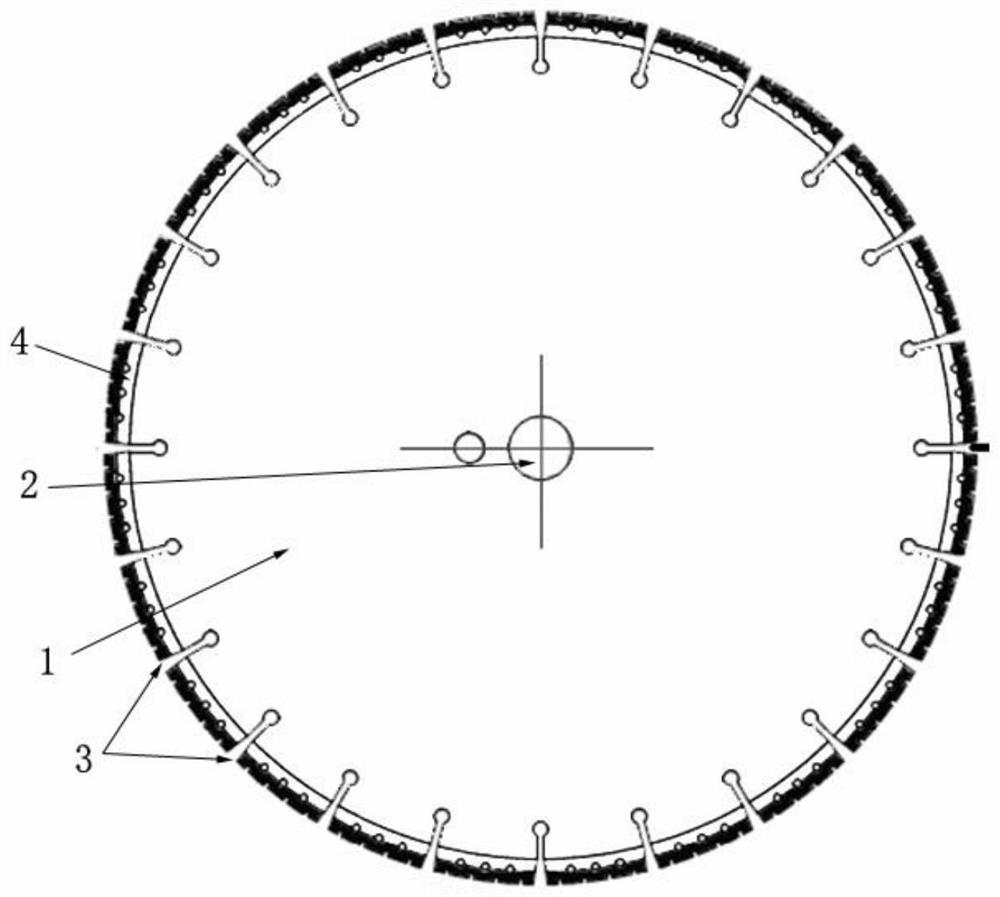

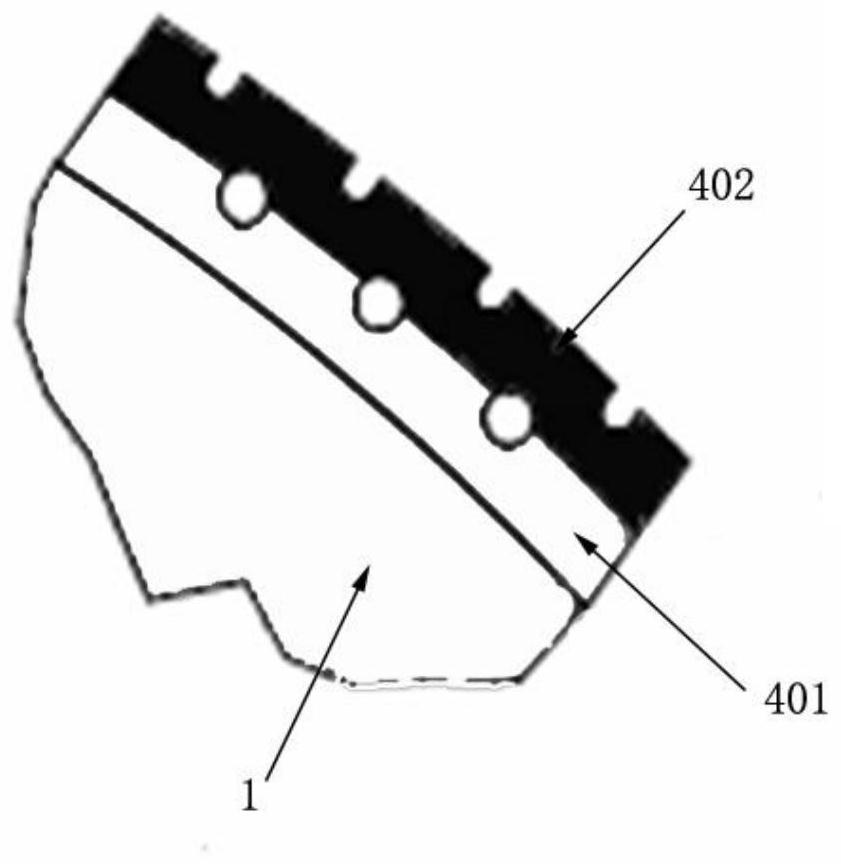

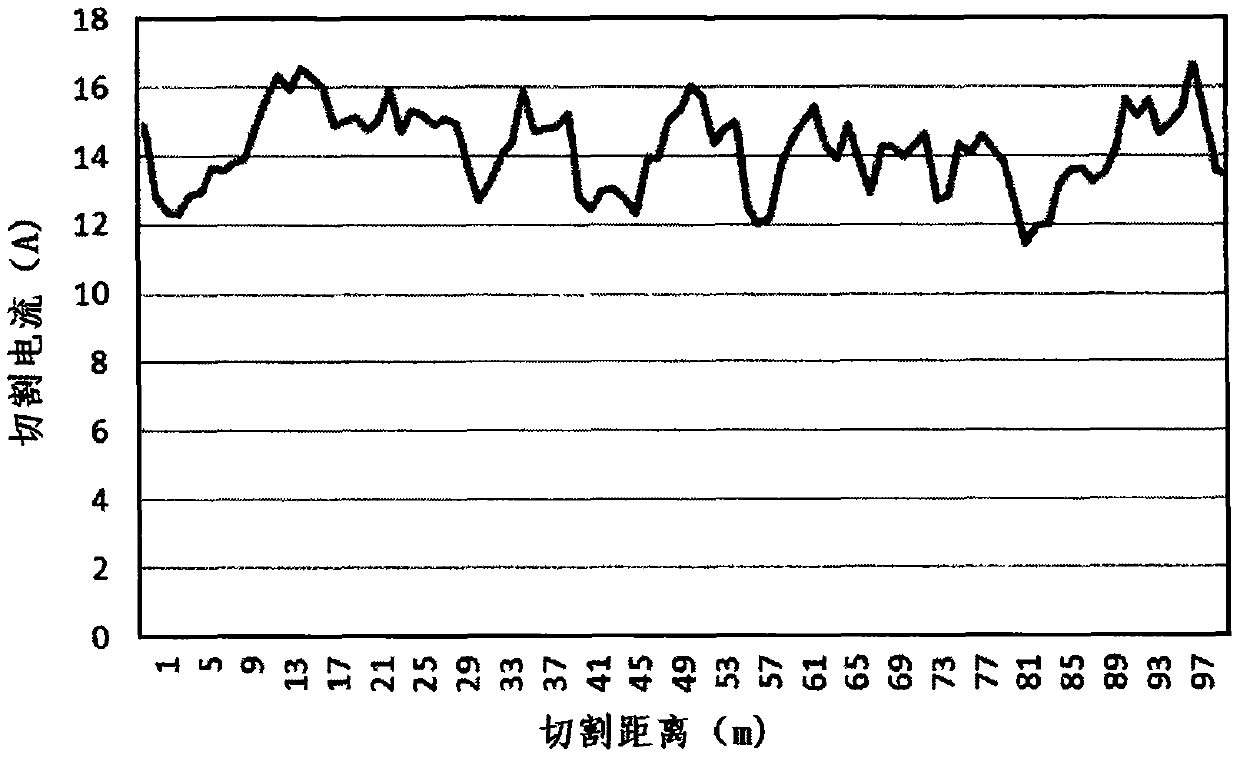

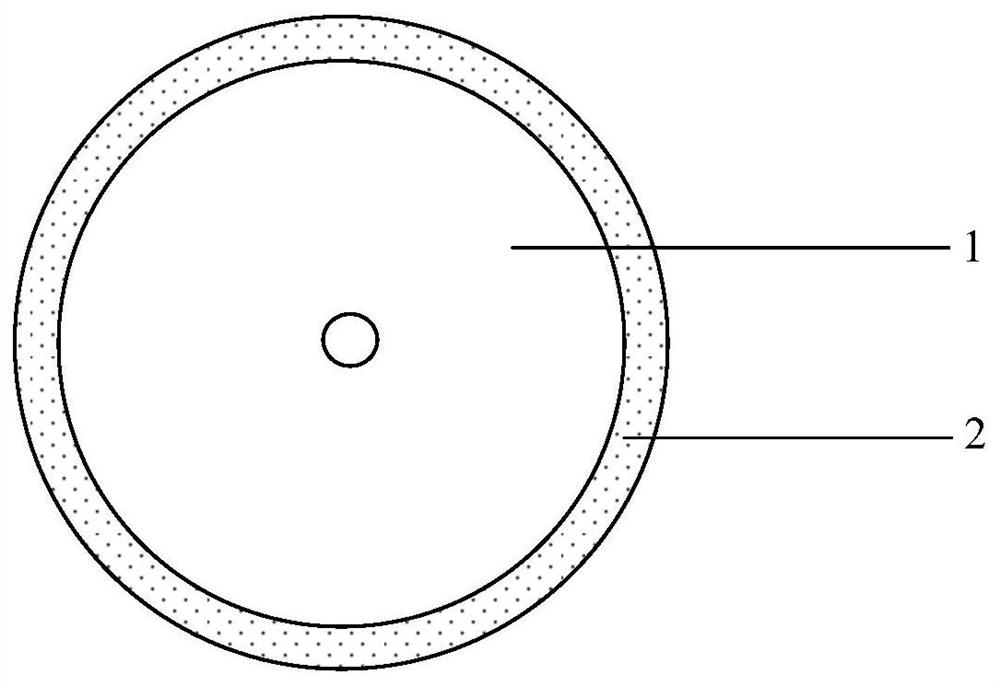

Energy-saving efficient diamond sawblade and manufacturing method thereof

ActiveCN108582504AFast cutting speedGood cutting sharpnessStone-like material working toolsDiamond cuttingHardness

The invention relates to an energy-saving efficient diamond sawblade, and belongs to the technical field of diamond sintering tools. The energy-saving efficient diamond sawblade comprises a circular steel base body, and a compound multi-layer diamond cutter head which is welded on the circular steel base body, wherein the compound multi-layer diamond cutter head comprises a plurality of diamond cutting layers, and each multi-layer diamond cutting layer comprises a blank body, and diamond particles which are embedded into the blank body; the concentration of the diamond particles in the intermediate diamond cutting layer is more than the concentration of the diamond particles at two sides; and the hardness of the blank body in the intermediate diamond cutting layer is less than the hardnessof the blanks in the diamond cutting layers at two sides. The energy-saving efficient diamond sawblade is applicable to processing of stones such as granites and marbles and cutting of a concrete pavement; the energy-saving efficient diamond sawblade has the characteristics of being quick to cut, high in cutting sharpness, and stable in performance; and moreover, the energy consumption can be decreased; in addition, the used diamond includes a little or excludes rare Co element and other components, so that the tool cost is decreased.

Owner:JIANGSU FENGTAI TOOLS

Anti-impact diamond layer, diamond composite sheet and preparation method for diamond composite sheet

InactiveCN102794447BImprove impact resistanceGood cutting sharpnessMetal layered productsManganeseAlloy

The invention discloses an anti-impact diamond layer, an anti-impact diamond composite sheet and a preparation method for the diamond composite sheet. Coarse granular diamond is used as a main raw material, graphite is used as a filling agent, and iron-based powder is used as an accelerant; the diamond layer comprises the following components in part by weight: 70 to 80 parts of diamond, 10 to 20 parts of graphite powder, and 3 to 12 parts of accelerant; and the accelerant consists of the following materials in part by weight: 45 to 60 parts of iron, 15 to 20 parts of nickel, 5 to 15 parts of cobalt, 5 to 20 parts of manganese, and 3 to 10 parts of silicon. The method comprises the following steps of: mixing the raw materials in the ratio uniformly, pre-pressing the mixture and a hard alloy matrix into a composite sheet, filling into a pyrophyllite block to form a structural block, putting the structural block into a 6-surface diamond presser, sintering and electrolyzing at a high temperature under high pressure, and thus obtaining the diamond composite sheet. The diamond composite sheet has the characteristics of big pores and a mesh connection structure, and is quite suitable for drilling medium hard and hard strata due to excellent sharpness and impact toughness.

Owner:河南亚龙金刚石制品股份有限公司

High-sharpness low-cost water drill tool bit and preparation method thereof

ActiveCN112829079AExtended service lifeImprove sintering performanceStone-like material working toolsTool bitRebar

The invention discloses a high-sharpness low-cost water drill tool bit and a preparation method thereof. The water drill tool bit is formed by mixing and sintering metal powder and diamond, the metal powder comprises the following components, in parts by weight, of 37 parts to 47 parts of iron, 20 parts to 30 parts of copper, 2 parts to 5 parts of tin, 27 parts to 35 parts of iron-based alloy and 0.3 part to 0.6 part of zinc stearate, and a volume of the diamond accounts for 20% to 30% of a volume of the metal powder. According to the water drill tool bit, different amounts of Fe, Cu, Sn and iron-based pre-alloyed powder are added to maintain a hardness HRB, bending strength and an abrasive ratio of a matrix, so that the mechanical property and wear resistance of the water drill tool bit are met, the iron-based alloy is added in a formula of the tool bit, a defect of insufficient alloying in the matrix can be reduced, an organizational structure of the matrix is improved, and the mechanical property of the matrix is further improved. The prepared water drill tool bit is sharp in cutting and moderate in service life greatly reduces the cost, is suitable for rapid cutting of reinforced concrete, and has the good market application prospect.

Owner:QINGDAO SHINHAN DIAMOND INDUSTRY CO LTD

Low-temperature sintering matrix powder, diamond tool adopting same and preparation method thereof

ActiveCN108889937AAvoid damageLower gradeTransportation and packagingMetal-working apparatusRare-earth elementGraphite

The invention discloses low-temperature sintering matrix powder, a diamond tool adopting the same and a preparation method thereof. The matrix powder is prepared from, by mass, 5-17% of Sn, 5-25% of Co, 1-10% of Me, the balance Cu and inevitable impurities, wherein Me is selected from at least one of amorphous powder, pre-alloying powder containing rare earth elements, Ni and graphite. The matrixpowder is copper-based matrix powder, so that the sintering temperature is obviously decreased, energy loss is lowered, the mold loss is lowered, and the production cost is lowered; meanwhile, damageto diamond during high-temperature sintering is reduced, the level of diamond adopted by the tool can be lowered properly, and the material cost of the tool is lowered.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Electric shaver

InactiveUS20070175042A1Good cutting sharpnessIncreased durabilityMetal working apparatusEngineeringKnife blades

An electric shaver in which a plurality of mutually separated cutter blades provided in an inner cutter are moved in relative terms while making sliding contact with an outer cutter that is formed with a plurality of hair introduction openings, so that hair that enters into the hair introduction openings of the outer cutter is cut by the cutter blades, and the cutter blades are caused to intersect the same hair introduction openings of the outer cutter at different angles.

Owner:IZUMI PROD CO

Fixed cutter, electric shaving tool bit applying fixed cutter and manufacturing method thereof

PendingCN114043533AGood skin adhesionAvoid increasing manufacturing difficultyMetal working apparatusTool bitWire cutting

The invention discloses a reciprocating type linear cutting electric shaving tool bit which comprises a fixed cutter support and a fixed cutter, wherein the fixed cutter support is provided with a left supporting part and a right supporting part for supporting the fixed cutter from the two sides, an inner containing cavity is formed between the fixed cutter and the fixed cutter support, a hair inlet groove is formed between the fixed cutter and the fixed cutter support, and a movable cutter matched with the fixed cutter is arranged in the inner containing cavity, a middle mounting hole is formed in the middle of the top wall of the fixed cutter, a middle cutter net which penetrates through the middle mounting hole and protrudes above the top surface of the fixed cutter is arranged in the inner containing cavity, and a middle cutter which is matched with the middle cutter net and can reciprocate back and forth for cutting is arranged below the middle cutter net; and also comprises a transmission part which is used for connecting the movable cutter and the middle cutter with a power device of an electric shaver; the invention further discloses the fixed cutter used for the electric shaving tool bit. The invention further discloses a method for manufacturing the electric shaving tool bit. The electric shaving tool bit is simple in structure, small in size and good in cutting performance, and has the cutting function of protruding from the middle to the upper portion of the fixed cutter.

Owner:LITTLE STONE CERAMIC BLADE ZHONGSHAN CO LTD

Electric Shaver

InactiveUS20070175043A1Good cutting sharpnessIncreased durabilityMetal working apparatusEngineeringKnife blades

Owner:IZUMI PROD CO

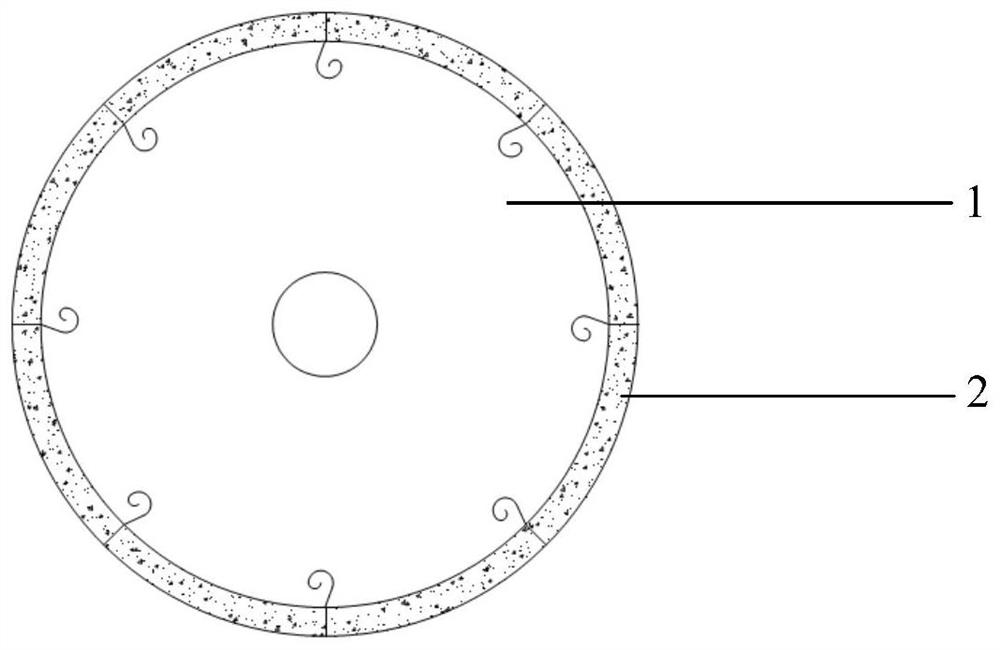

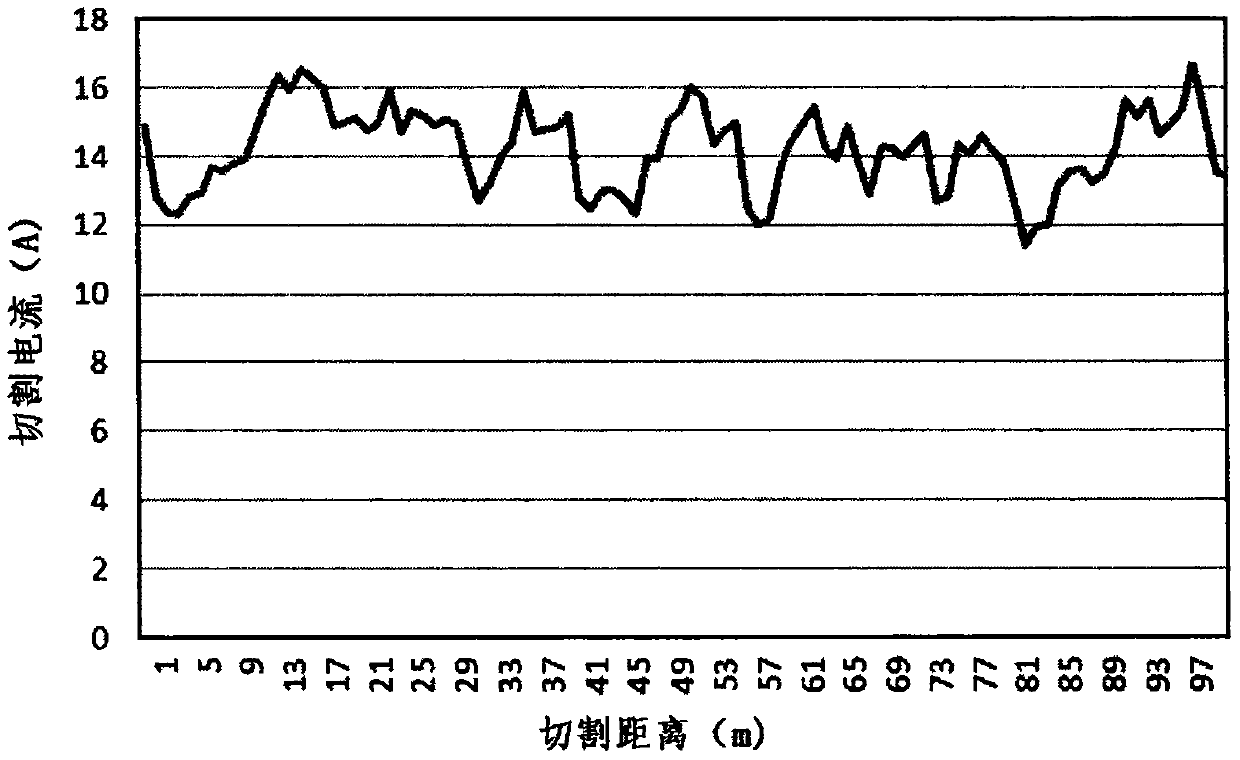

Preparation process of laser welding saw blade

The invention discloses a preparation process of a laser welding saw blade, and belongs to the technical field of preparation of material cutting machining tools. The laser welding saw blade comprisesa saw blade base body and a plurality of diamond tool bits evenly distributed on the outer edge of the saw blade base body; each diamond tool bit is composed of a tool bit base body on the inner sideand a tool bit brazing layer on the outer side; a concave notch groove is formed in each of the two sides of each diamond tool bit in the radial direction of the saw blade base body so that chip removal can be facilitated during cutting machining; each diamond tool bit of the saw blade is formed by brazing and sintering a metal bonding agent and diamond particles under the vacuum condition; and then a laser welding method is adopted to weld the diamond tool bits with the saw blade base body. The laser welding saw blade prepared through the method has the advantages that the diamond particlesand the tool bit base bodies are firmly combined, the tool bits and the saw blade base body are reliably connected, the process is simple, and the cost is low.

Owner:江苏华昌工具制造有限公司

Energy-saving and high-efficiency diamond saw blade and its preparation method

ActiveCN108582504BLow costGood cutting sharpnessStone-like material working toolsDiamond cuttingTool bit

Owner:JIANGSU FENGTAI TOOLS

Low-temperature sintered matrix powder, diamond tool using the matrix powder and preparation method thereof

ActiveCN108889937BAvoid damageLower gradeTransportation and packagingMetal-working apparatusRare-earth elementGraphite

The invention discloses a low-temperature sintered carcass powder, a diamond tool using the carcass powder and a preparation method thereof. The carcass powder is composed of the following components according to mass percentage: Sn 5%-17%, Co 5%-25%, Me 1%-10%, the rest is Cu and unavoidable impurities, wherein Me is selected from amorphous At least one of powder, pre-alloyed powder containing rare earth elements, Ni, and graphite. The carcass powder of the present invention is a copper-based carcass powder, so that the sintering temperature is significantly reduced, energy consumption is reduced, mold loss is reduced, and production costs are reduced; at the same time, damage to diamonds during high-temperature sintering is reduced, and tools can be appropriately reduced. The grade of diamond used reduces the material cost of the tool.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Composite multi-layer diamond cutter head and its preparation method

ActiveCN108656363BLow costFast cutting speedMetal sawing toolsStone-like material working toolsDiamond cuttingTool bit

The invention relates to a composite multi-layer diamond tool bit and belongs to the technical field of diamond sintering tools. The composite multi-layer diamond tool bit comprises a plurality of diamond cutting layers. The adjacent diamond cutting layers are bonded through metal layers. Each diamond cutting layer is composed of a carcass and diamond particles impregnated in the carcass. The concentration of the diamond particles in the diamond cutting layer located in the middle is greater than those of diamond particles in the diamond cutting layers located on the two sides. The hardness ofthe carcass in the diamond cutting layer located in the middle is smaller than those of the carcasses in the diamond cutting layers located on the two sides. The composite multi-layer diamond tool bit is used for a diamond saw blade and applied to processing of stone materials such as granite and marble and cutting of concrete pavements, the cutting speed is high, the cutting sharpness is high, the performance is stable, energy consumption can be reduced easily, in addition, used diamond is small and does not contain the elements including the Co element and the like, and the tool cost can belowered easily.

Owner:JIANGSU FENGTAI TOOLS

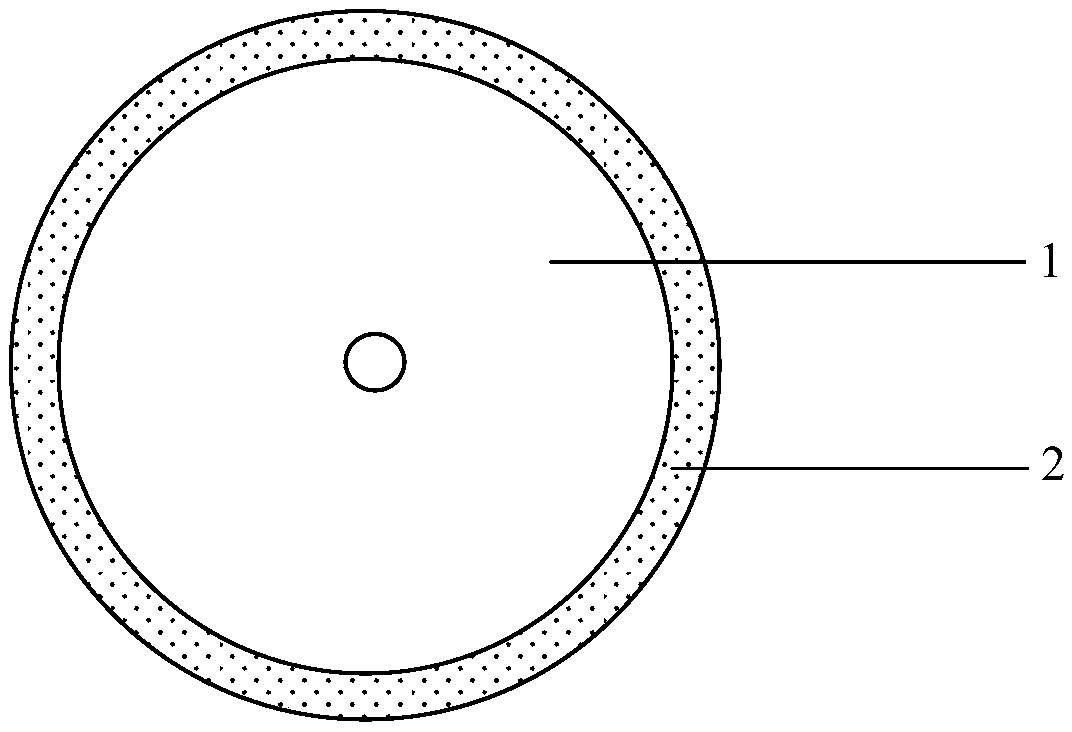

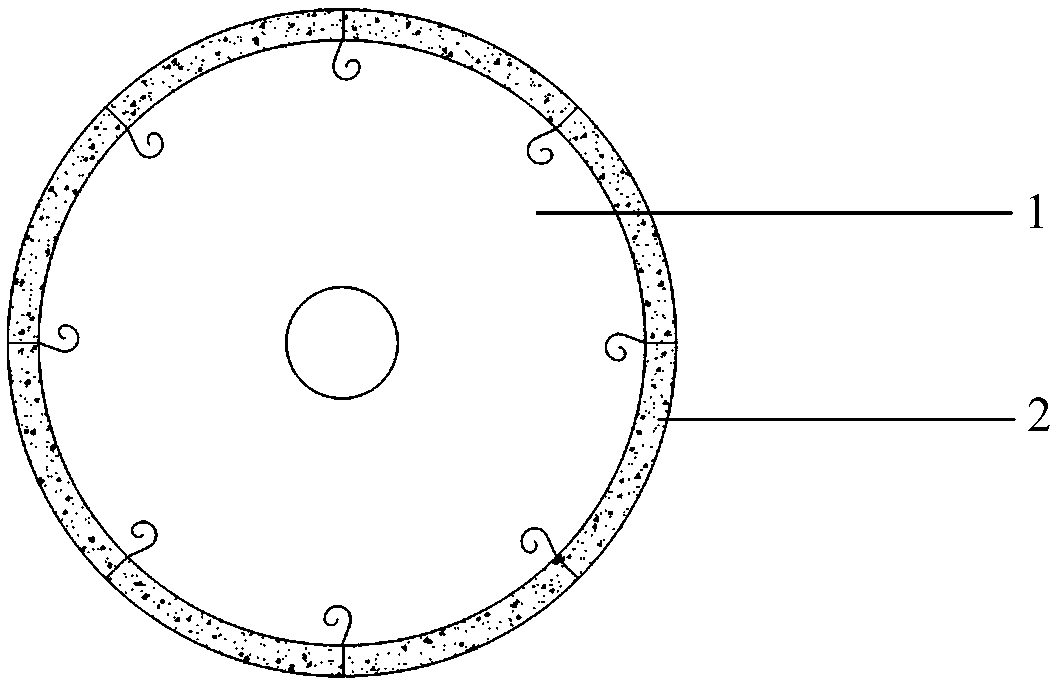

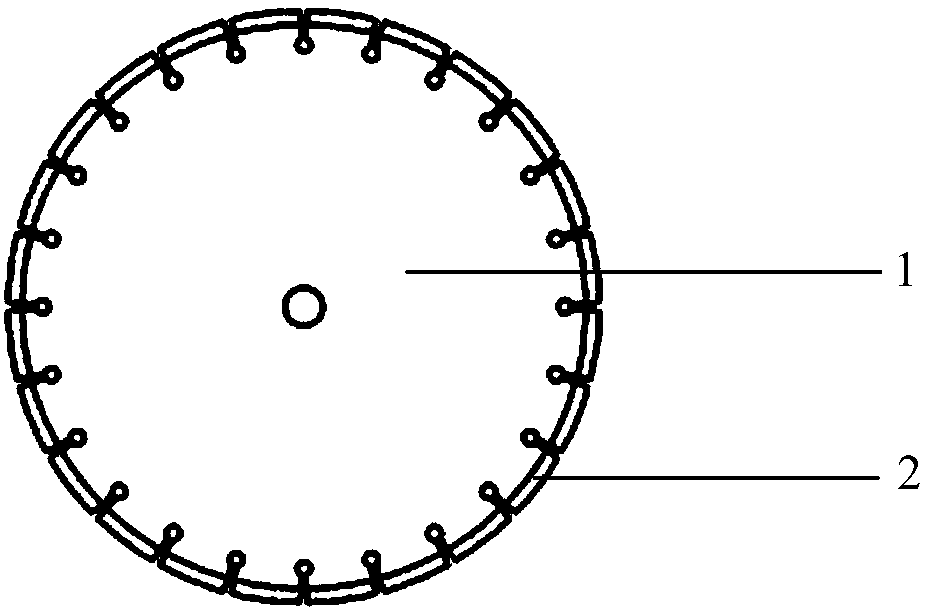

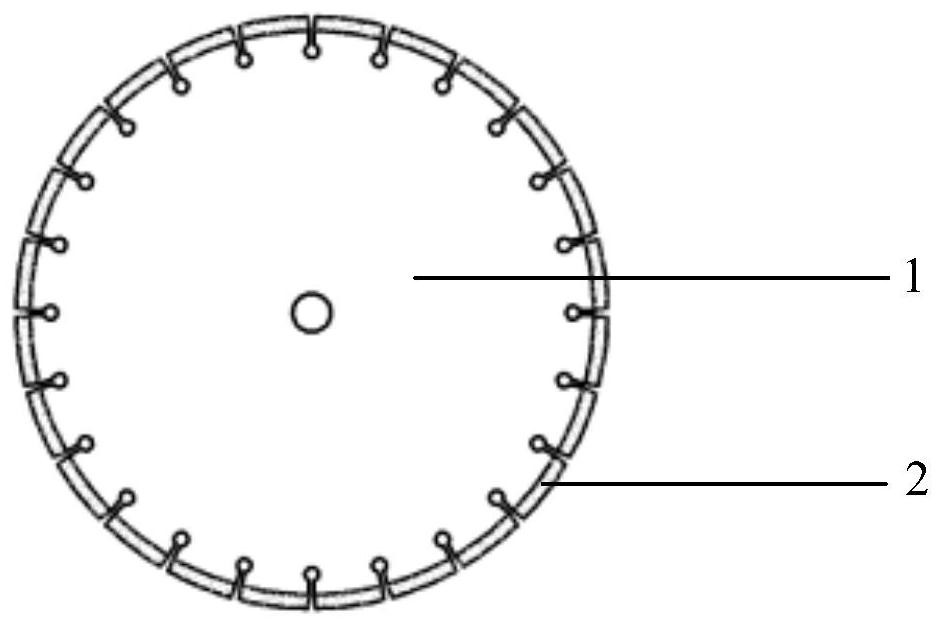

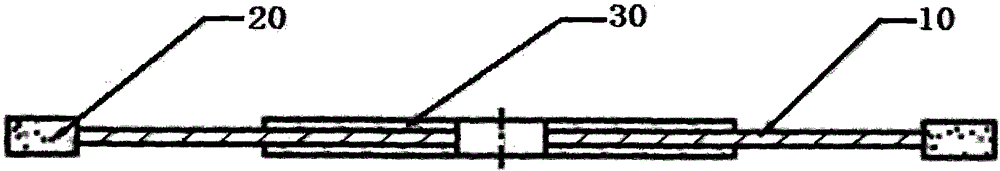

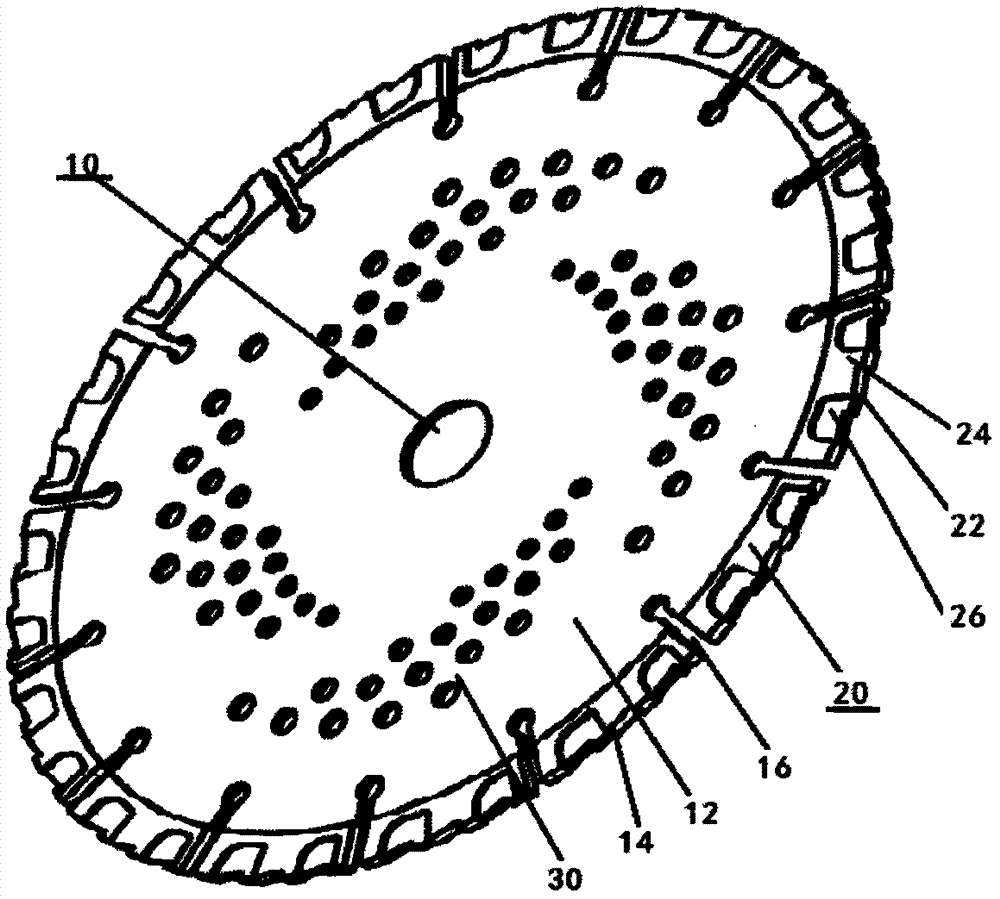

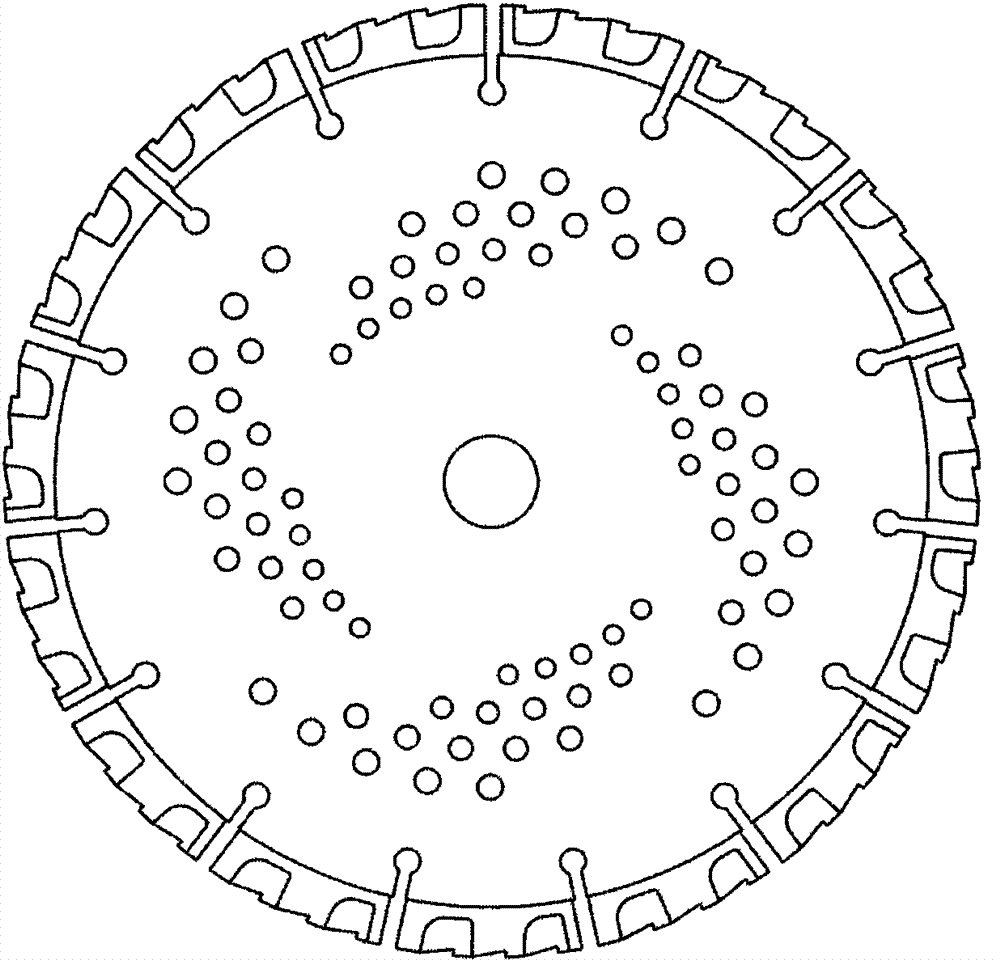

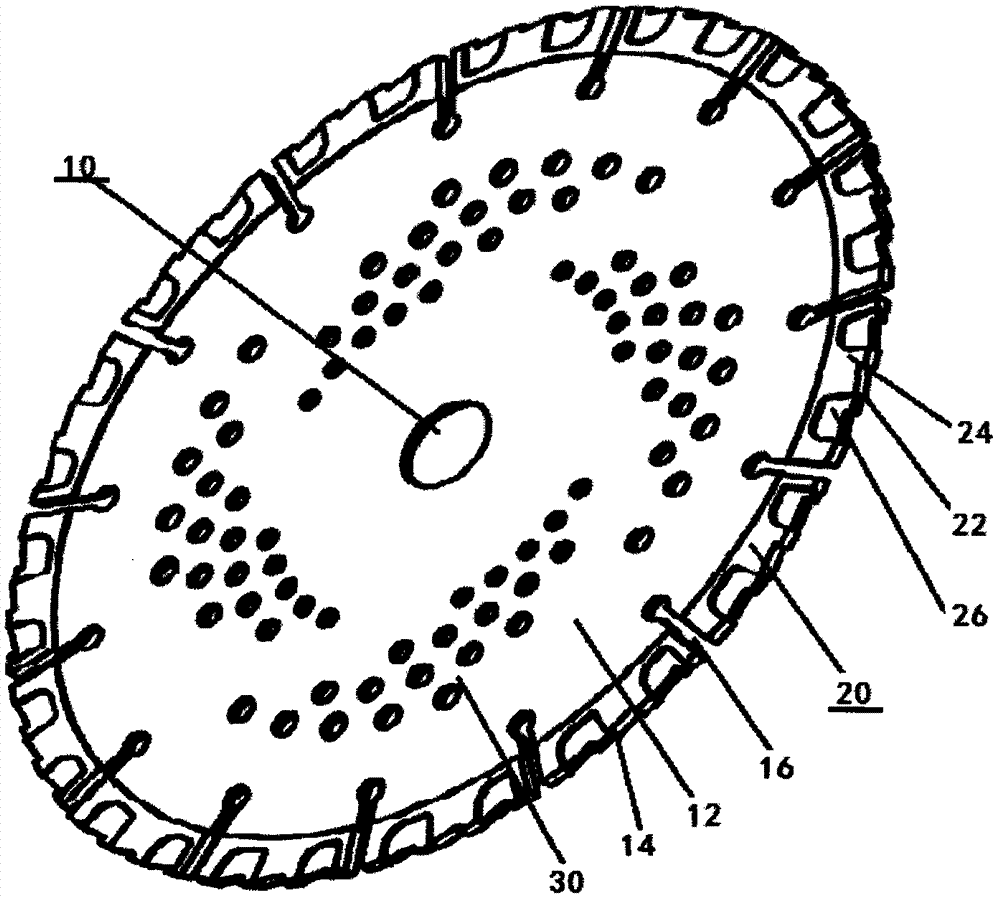

Production method of reinforced ultra-thin diamond circular saw blade

ActiveCN103962646BThe overall thickness is thinLow costMetal sawing tool makingGlass severing apparatusCircular sawMaterial consumption

The invention relates to a method for producing a strengthened ultrathin diamond circular saw web. The method comprises the first step of providing a circular saw web base body, wherein the ratio of the thickness of the saw web base body to the diameter of the saw web base body ranges from 0.0020 to 0.0035; the second step of welding a diamond cutting head to the end of the saw web base body according to the laser welding technology; the third step of concentrically arranging strengthened circular saw web bodies on the two sides of the circular saw web base body, wherein the ratio of the diameter of the strengthened circular saw web bodies to the diameter of the saw web base body ranges from 0.24 to 0.45. The strengthened ultrathin diamond circular saw web produced with the production method has the advantages of being narrow in cutting joint, small in number of consumed materials and cutting deviation, neat in cutting edge, good in cutting sharpness and the like and solves the problems that the cutting joint is large, the number of the consumed materials is large, the cutting edge is not neat, and material consumption is large in the ceramic, glass and jade machining process.

Owner:JIANGSU FENGTAI TOOLS

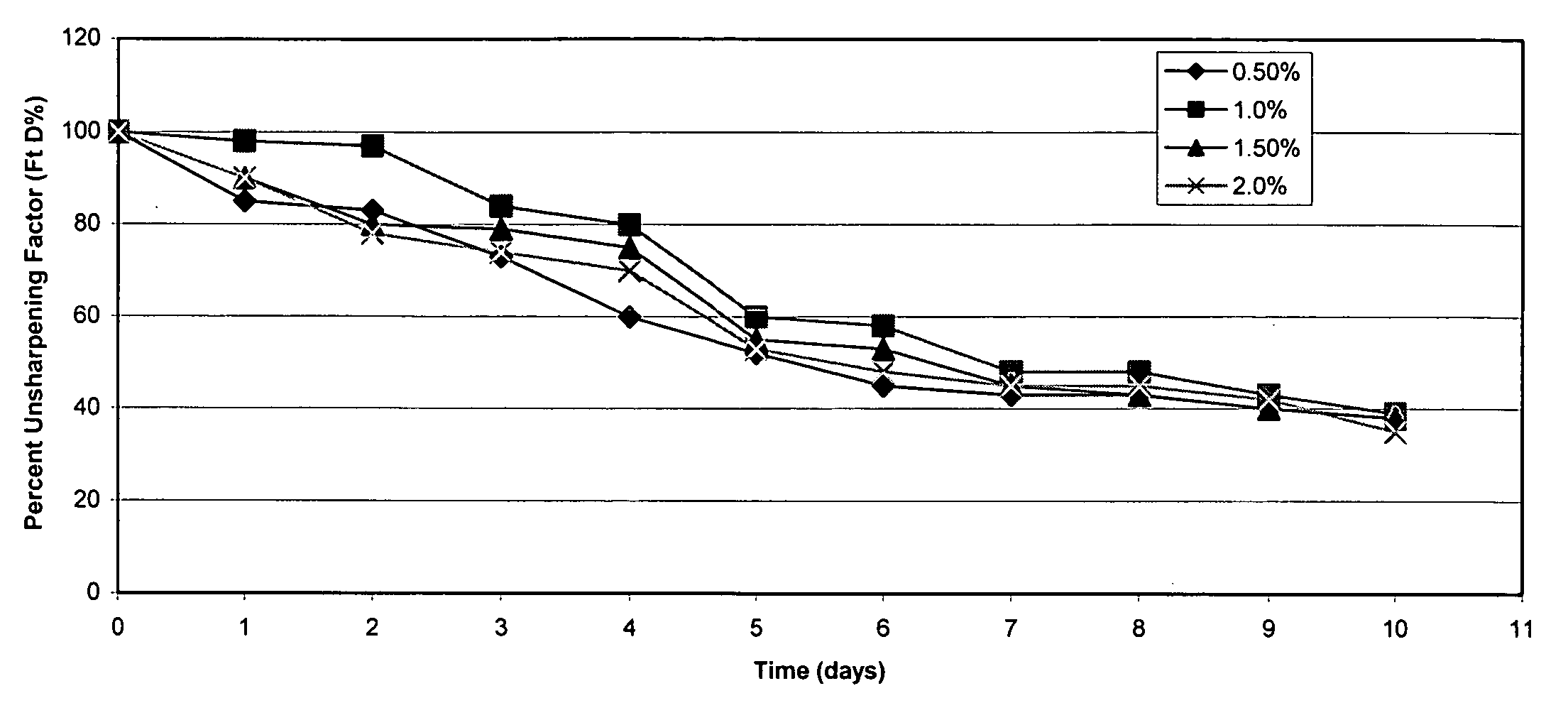

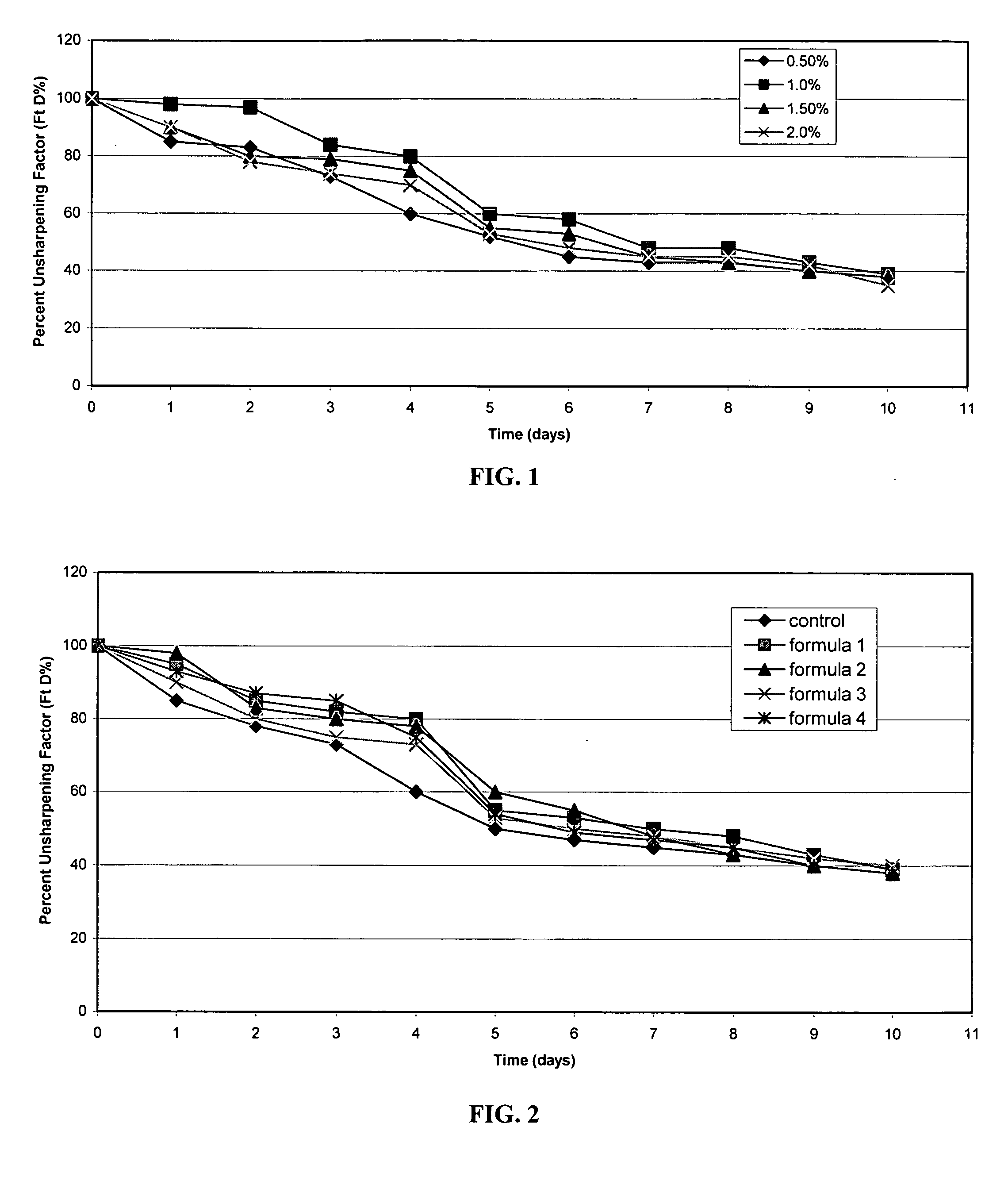

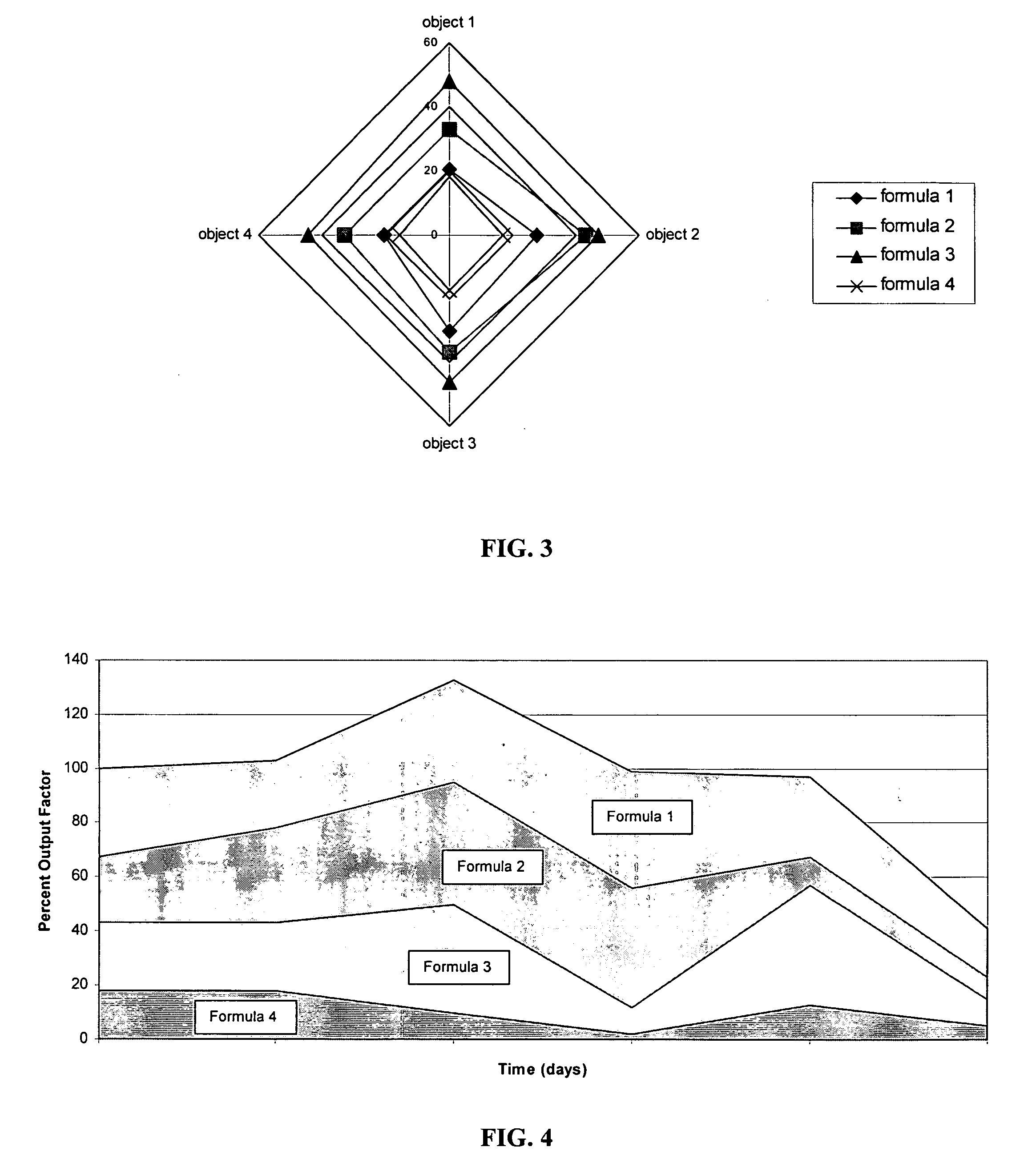

Emulsion to preserve keen edge of a utensil

InactiveUS20040235696A1Preserve cutting effectProlong lifeInorganic/elemental detergent compounding agentsCationic surface-active compoundsAlcoholEmulsion

A method and emulsion for preserving the cutting edge of a metal utensil, such as cutlery, surgical tools, and shave blades. The method includes immersing the utensil in the emulsion of the invention, and leaving it immersed for the time in-between use of the utensil. The emulsion includes a water-soluble salt of an ether compound or a chloride compound or both in an amount sufficient to preserve the cutting edge of a utensil, a hydrophobic substance in an amount sufficient to reduce water contact with the edge of the utensil, and an alcohol in an amount sufficient to assist in solubilizing the hydrophobic substance. Immersion of the utensil in the emulsion preserves the sharpness of the cutting edge to facilitate longer service of the utensil.

Owner:PFEFFER SLOBODINSKY ARIEL S

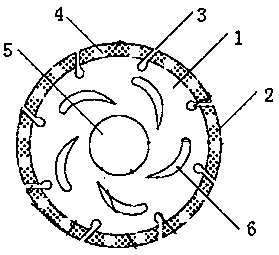

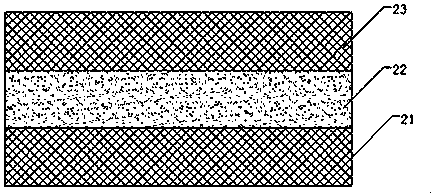

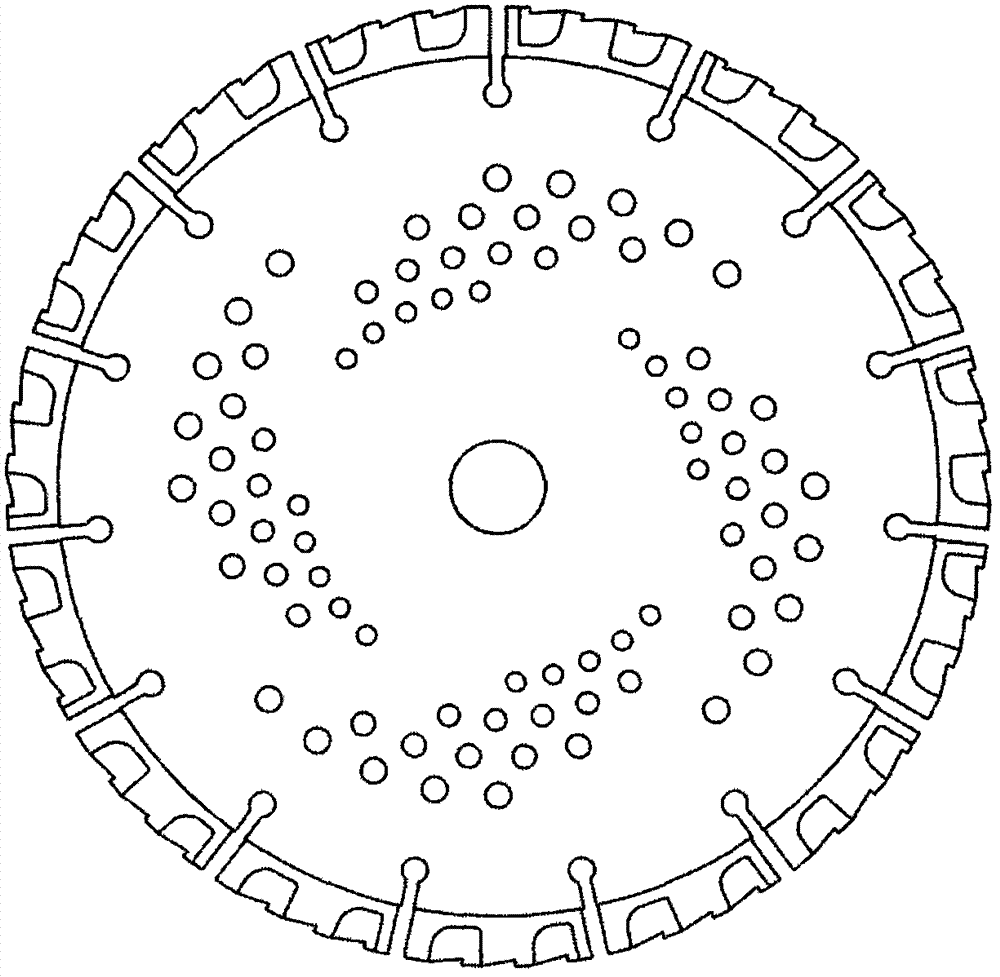

Cutting device for stone angle grinder

InactiveCN107671754ACutting stabilityImprove cutting efficiencyBonded abrasive wheelsAngle grinderCobalt nickel alloy

The invention relates to a cutting device for a stone angle grinder. The cutting device for the stone angle grinder comprises a disc cutting body, wherein a plurality of cutting knife edges are uniformly distributed on the circumferential surface of the outer side of the cutting body; an inclined groove extending in the radial direction is formed between each two adjacent cutting knife edges, a chip removal groove A sunken from outside to inside is formed in the bottom of each inclined groove, an ultrahard abrasive material layer is arranged on the outer surface of each cutting knife edge, theultrahard abrasive material layer comprises one cobalt-nickel alloy layer, one copper layer and one cobalt-nickel alloy layer which are sequentially arranged from inside to outside, a plurality of chip removal grooves B extending in the radial direction of the disc cutting body are formed in the ultrahard abrasive material layer of each cutting knife edge, and then a plurality of fine ultrahard abrasive material layers are formed; and an installation hole is formed in the central position of the cutting body, a plurality of heat dissipation holes are uniformly distributed along the peripheryof the installation hole, the heat dissipation holes are arc-shaped, and the heat dissipation holes are bent in the circumferential direction of the cutting body in the anticlockwise direction from inside to outside. The cutting device for the stone angle grinder has the advantages of being capable of increasing an ash discharge speed and increasing the cutting efficiency, improving the abrasive resistance and the cutting sharpness, and lowering the production cost.

Owner:QIDONG TIANSHAN TOOLS CO LTD

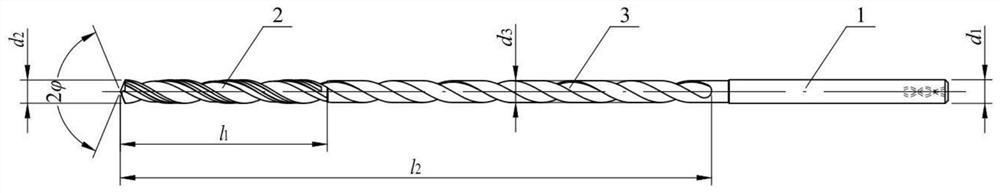

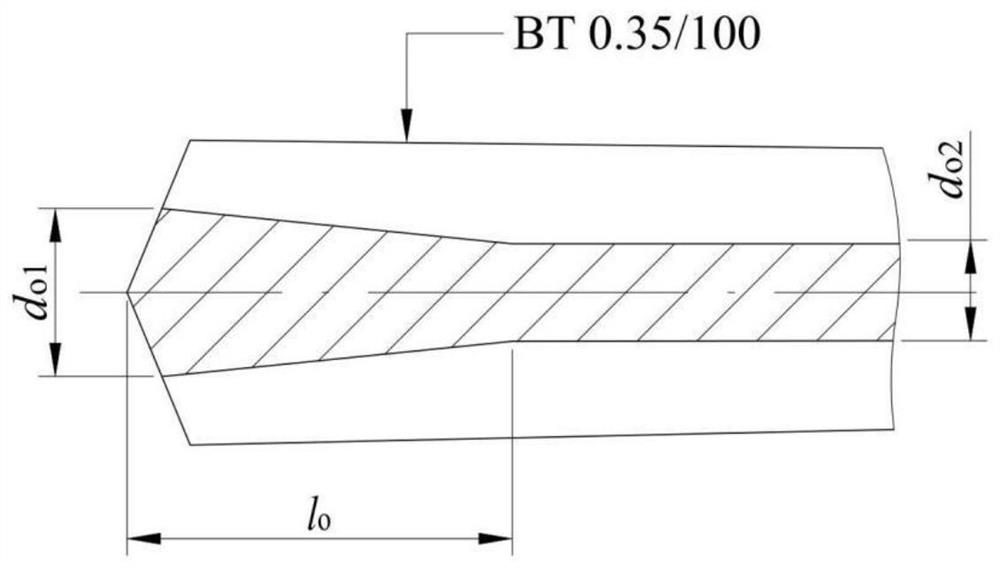

Novel hard alloy inner-cooling deep hole twist drill

PendingCN112775468AIncreased durabilityImprove cutting efficiencyTransportation and packagingTwist drillsChiselEngineering

The invention discloses a novel hard alloy inner-cooling deep hole twist drill. The novel hard alloy inner-cooling deep hole twist drill comprises a cylindrical handle part and a cutter body arranged on the cylindrical handle part, the cutter body comprises a cutting edge part and a transition neck part connected with the cylindrical handle part and the cutting edge part, chip grooves are formed in the cutting edge part, and the cutting edge part adopts the front inverted cone and rear parallel core thickness design. The chip grooves intersect with the solid part of the cutter body to form two auxiliary cutting edges and two edge flaps, the cutting edge part is provided with two rear cutter faces and two chip containing grooves, the two rear cutter faces intersect to form a chisel edge, the two rear cutter faces intersect with the two chip grooves to form two main cutting edges, the two rear cutter faces intersect with the two chip containing grooves to form two inner cutting edges, and the cutting rake angles of the main cutting edges and the inner cutting edges are different. According to the novel hard alloy inner-cooling deep hole twist drill, the problems that the deep hole machining cutting temperature is high, chip removal is not smooth, the cutter rigidity is poor, vibration deflection is prone to happening during drilling, consequently, the cutter is worn, the cutting edge is broken, and a drill rod is broken are solved.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

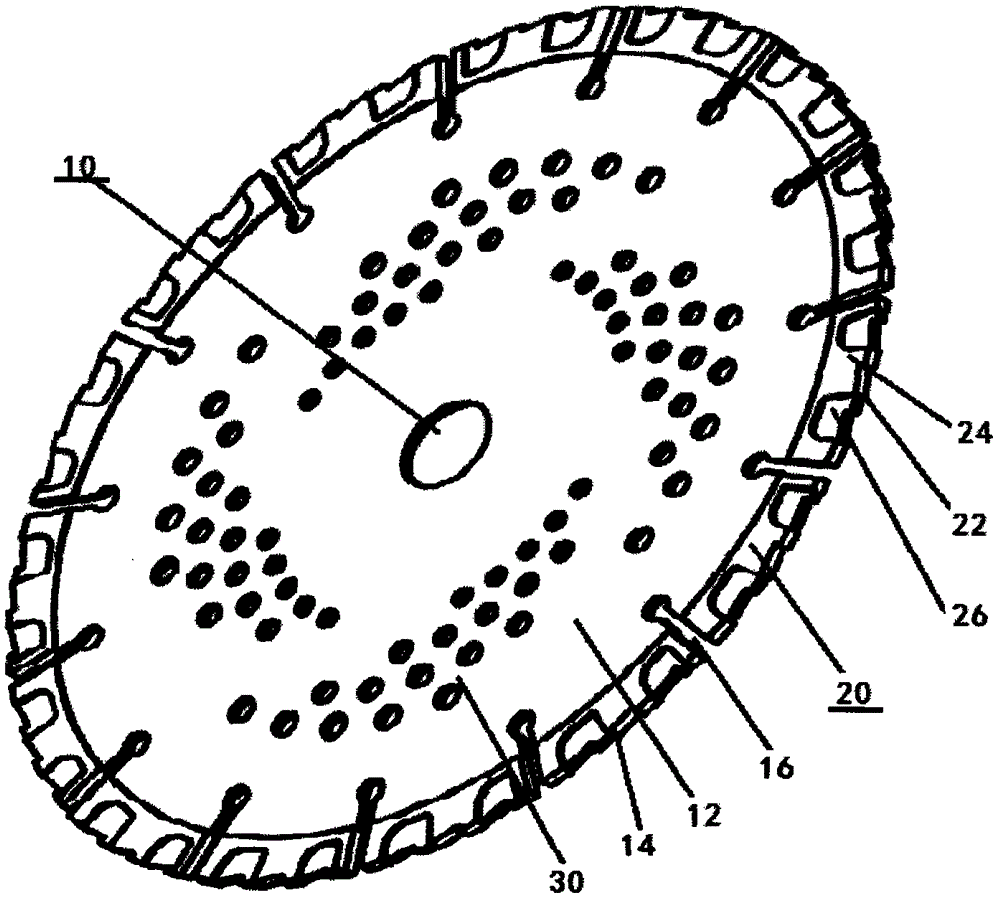

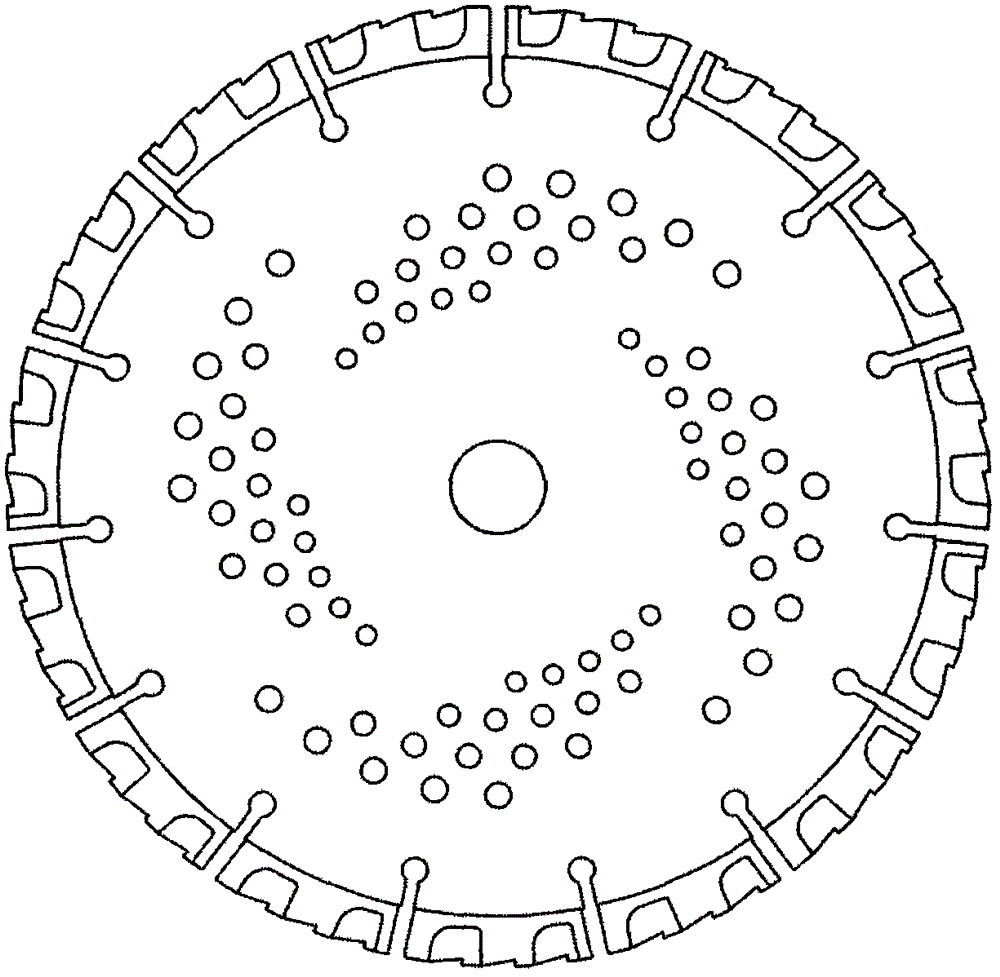

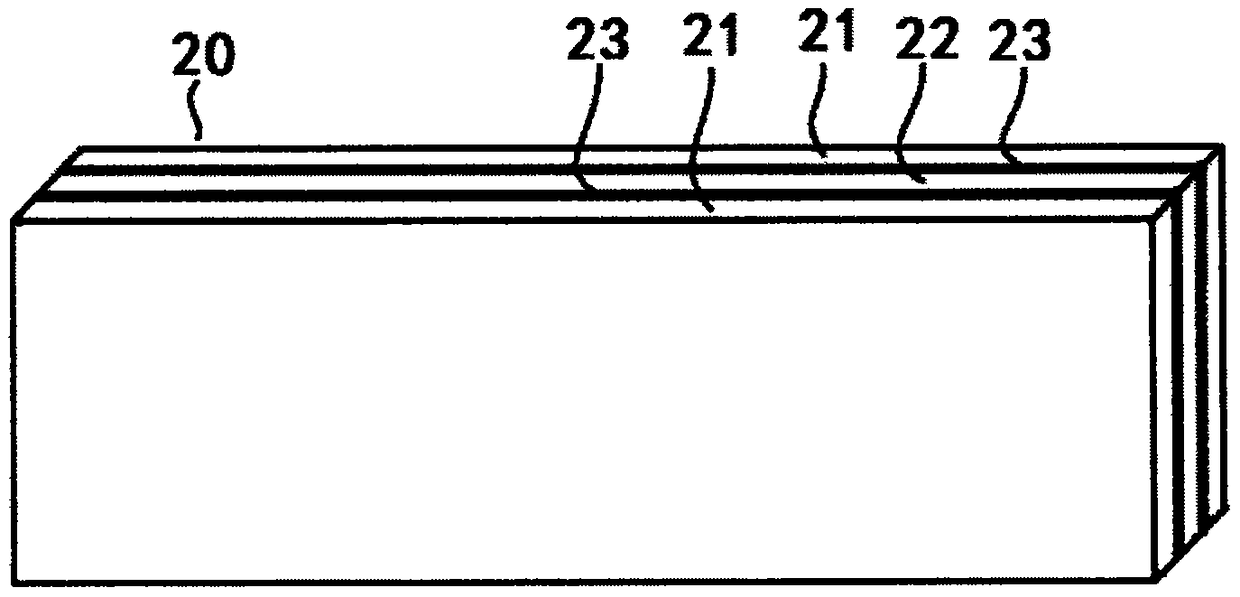

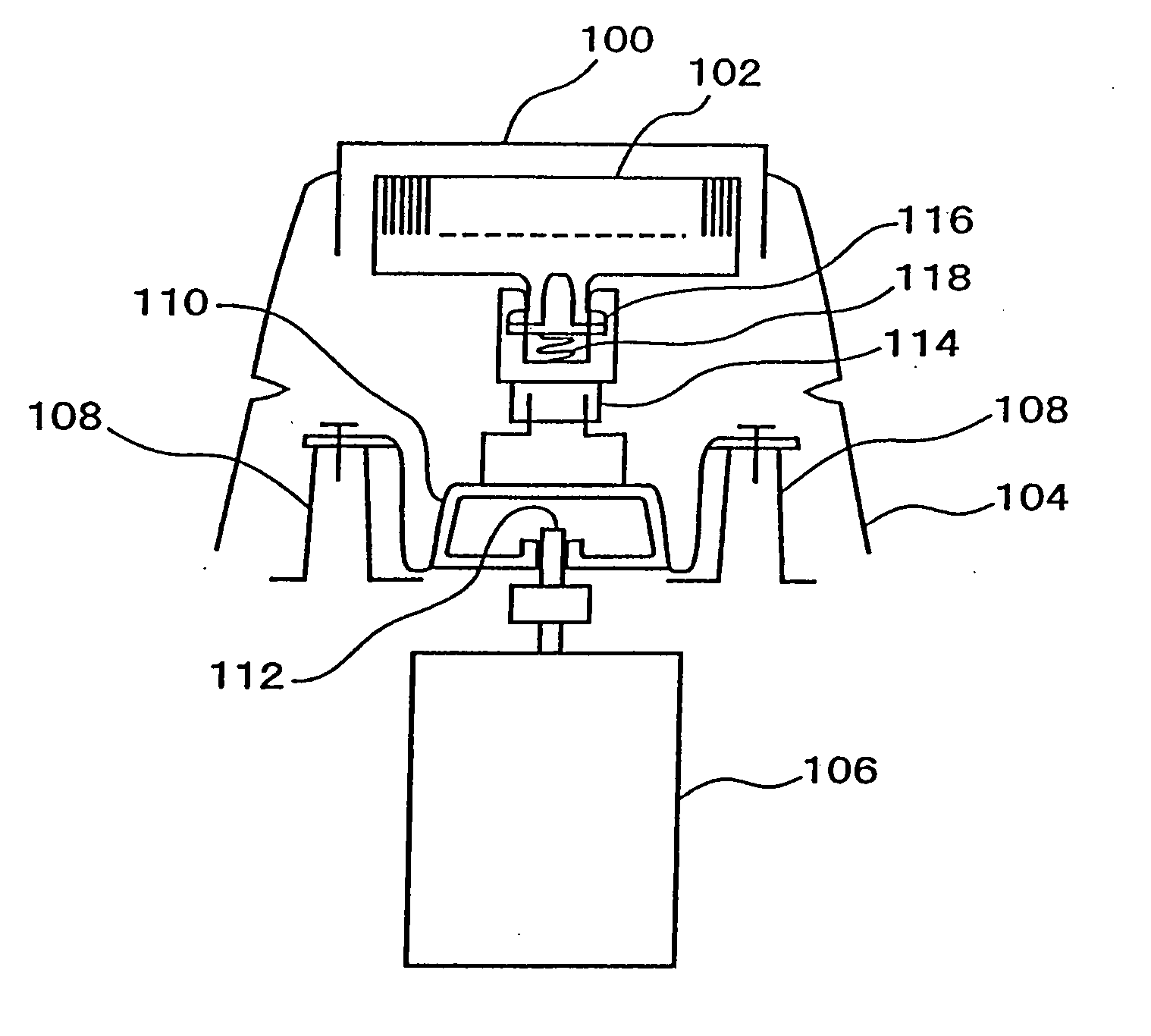

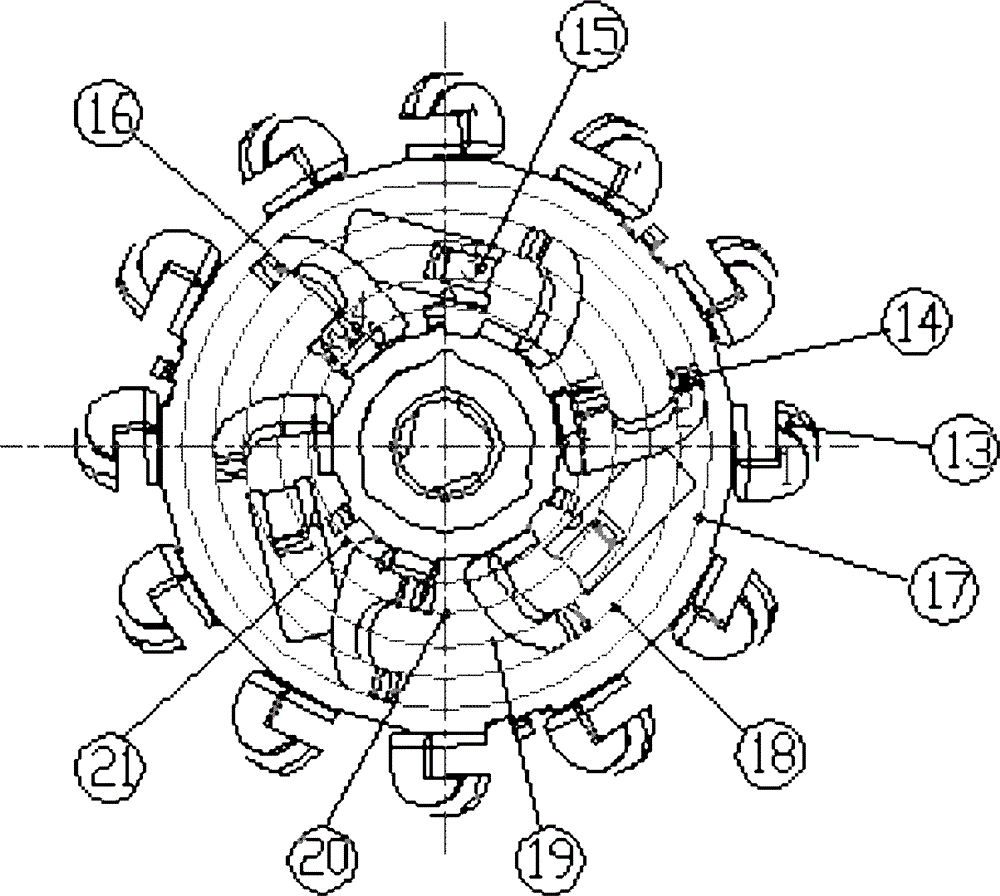

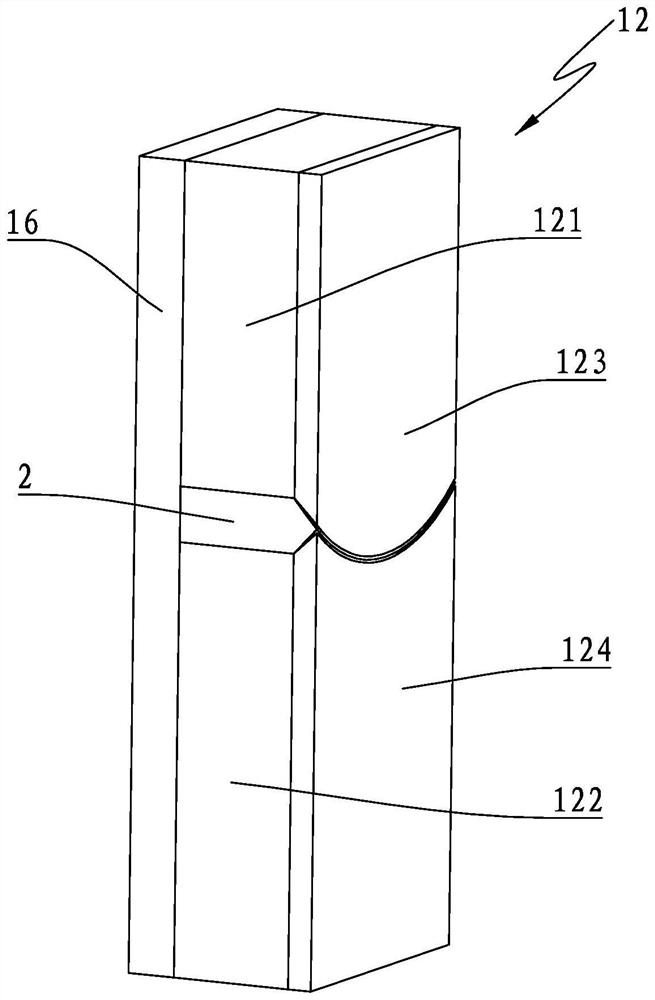

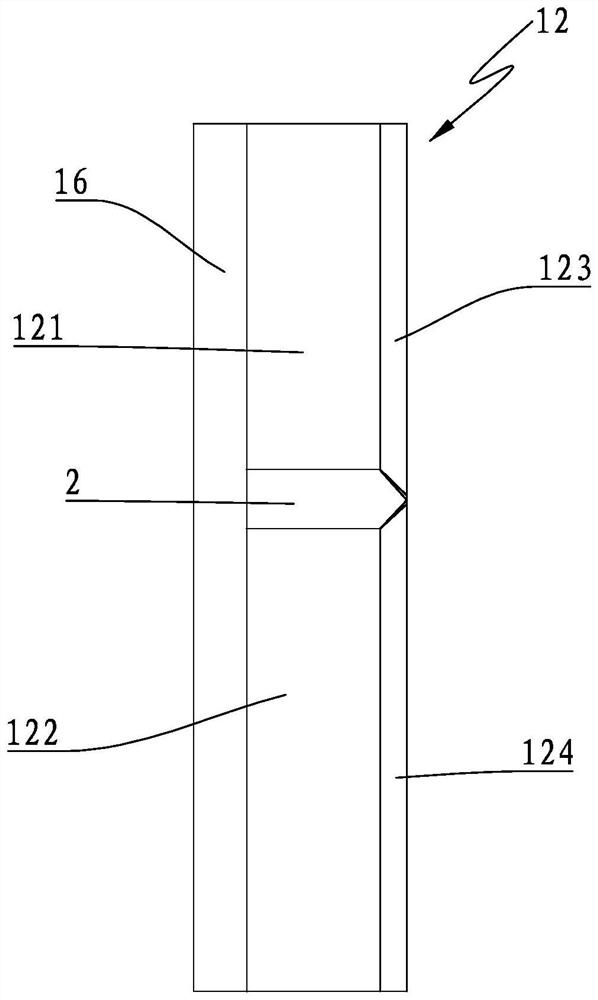

Continuous four-blade seamless rotary type shaver head system with large-circle arc

ActiveCN102729265BAvoiding the Defect of Beard PullingIncrease shaving areaMetal working apparatusRazor stropInjection moulding

The invention discloses a continuous four-blade seamless rotary type shaver head system with a large-circle arc, which comprises a blade mesh, a first movable razor, a second movable razor, a balance fixing plate and a plastic connecting piece, wherein the first and the second movable razors are welded and fixed through laser; and the balance fixing plate and the plastic connecting piece are integrally formed through an injection moulding technology, and are fixed and connected with the four layers of razor blades of the first and the second razors through laser welding into a seamless four-blade shaver head system. By the shaver head system, the beard clamping, pulling and drawing defects of a traditional shaver can be effectively overcome, and the shaver head system has high beard capture efficiency and a good face attachment effect, so better shaving acoustic quality and shaving skin-touch can be obtained.

Owner:SHANGHAI POVOS ELECTRIC WORKS

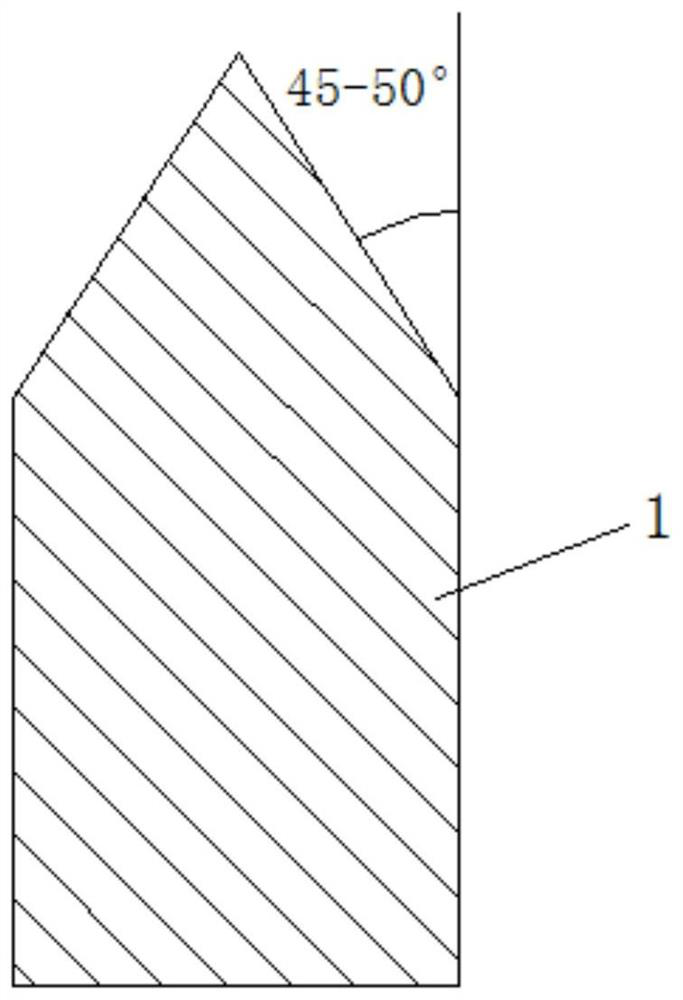

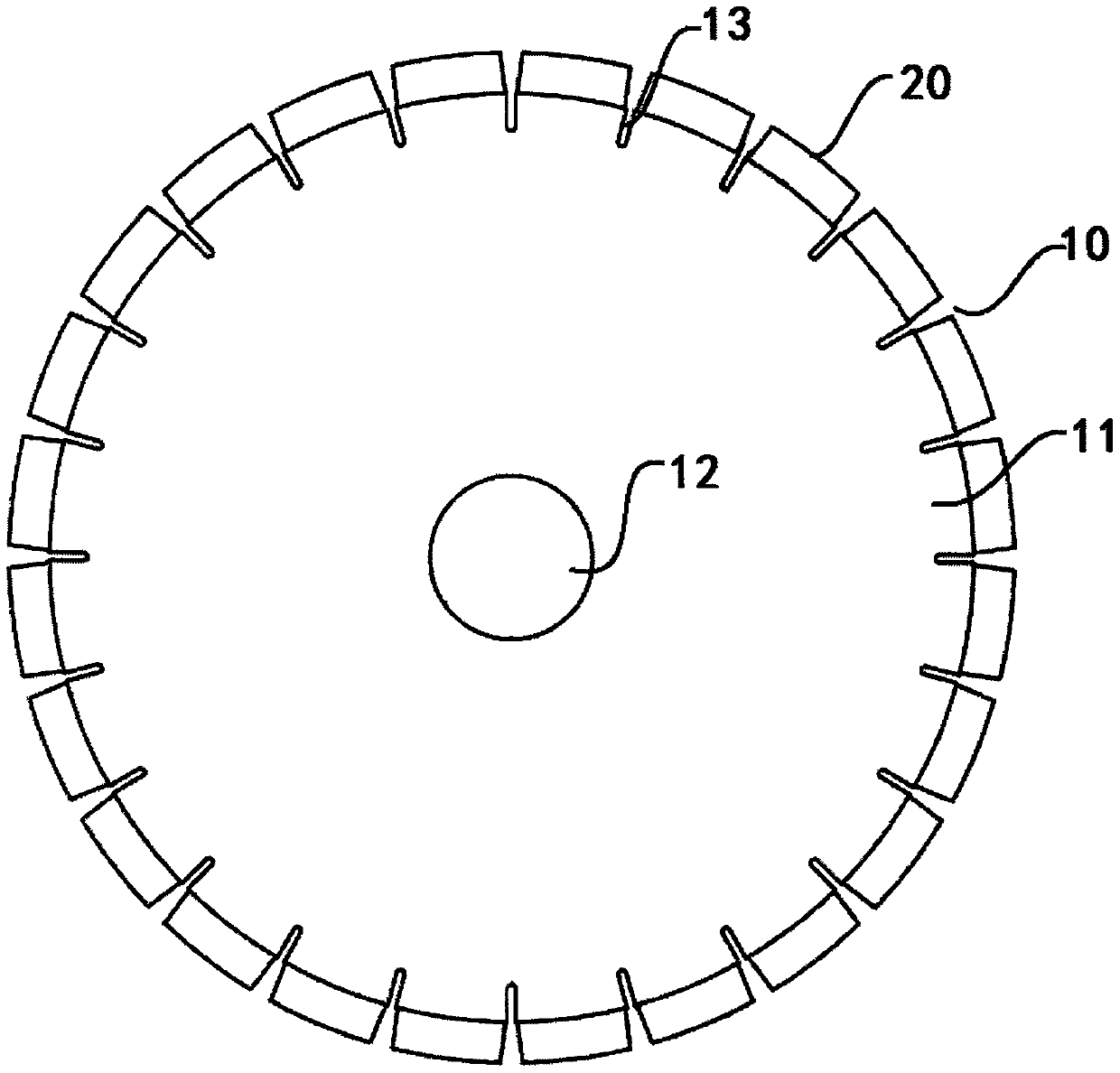

Hot pressing die of diamond tool bit, preparation method of diamond tool bit, diamond tool bit and diamond drill bit

PendingCN114871434ADrilling and cutting speedGood cutting sharpnessStone-like material working toolsTool bitDiamond knife

The invention discloses a hot pressing die of a diamond tool bit, a preparation method of the diamond tool bit, the diamond tool bit and a diamond drill bit, and the prepared diamond tool bit is in an arc sheet shape and comprises a drilling and cutting tool bit with a rectangular longitudinal section and a sharp-corner tool bit with a triangular longitudinal section; according to the hot-pressing die for the diamond tool bit, the upper pressing head and the lower pressing head are respectively divided into two parts for the drilling and cutting tool bit and the sharp-corner tool bit, so that the structure of the die pressing head group is simpler, and the manufacturing cost is lower; hot-pressing pressure can be provided according to a shrinkage ratio during hot-pressing sintering, so that the use is more flexible; the top of the drilling end face of the manufactured diamond tool bit forms a triangular pinnacle tool edge, so that excellent self-sharpening and sharpness of the tool bit are kept, and the diamond tool bit is high in wear resistance and long in service life; the formed diamond tool bit is small in size and shape error, high in precision and good in quality; the diamond drill bit can rapidly cut in a material to be drilled and cut, the drilling and cutting speed of the tool bit is increased, the drilling and cutting sharpness is improved, and the cutting stability and safety are guaranteed.

Owner:QUANZHOU ZHONGZHI NEW MATERIAL TECH

Preparation method of serrated double-sided concave u-sharp concrete laser welding cutting blade

ActiveCN104907942BNarrow kerfLess consumablesTransportation and packagingBonded abrasive wheelsReinforced concreteRebar

The invention relates to a method for preparing a sawtooth double-sided concave U-sharp concrete laser welding cutting piece, which belongs to the technical field of diamond processing tools. The preparation method of the present invention is prepared through the following steps: batching of metal bond and diamond, granulation-cold pressing-hot pressing-sintering-laser welding-blading, polishing, painting-inspection, packaging and storage; it is characterized in that: The diamond cutter head is formed by hot pressing and sintering of metal bond and diamond under vacuum condition. The cutting sheet prepared by the method of the present invention has the advantages of narrow slit, less consumables, small cutting deflection, neat cutting edge, good cutting sharpness, etc., and is especially suitable for building materials, walls, cement concrete, cured concrete, steel bars Cutting of hard materials such as concrete, hard concrete bricks and concrete piles.

Owner:江苏华昌工具制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com