Production method of reinforced ultra-thin diamond circular saw blade

A production method and enhanced technology, which are used in metal sawing equipment, tool manufacturing for sawing machines, stone processing equipment, etc., can solve the problems of reduced load bearing capacity, reduced substrate rigidity, loss of cutting ability, etc. Small, narrow kerf, the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of diamond cutter head sintered body: it is formed by mixing metal bond with diamond, pressing and sintering by hot pressing; the temperature of hot pressing and sintering is 800°C, the pressure is 2.0MPa, and the holding time is 80 minutes; wherein, the The particle size is 100 / 120, and the concentration of the diamond is 20%; in each sample, the proportioning ratio of metal binder (powder raw material, particle diameter is 1 to 5 microns, raw material purity higher than 99.0%) is shown in Table 1:

[0026] Table 1wt%

[0027] sample

sn

co

mn

Cr

Cu

Sample 1

18

12

/

/

70

Sample 2

18

5

3

/

margin

Sample 3

18

5

/

6

margin

Sample 4

18

5

3

6

margin

[0028] " / " indicates that the component was not added.

[0029] Measure the gold flexural strength and wear ratio of the above-mentioned diamond cutter head sintered bo...

Embodiment 2

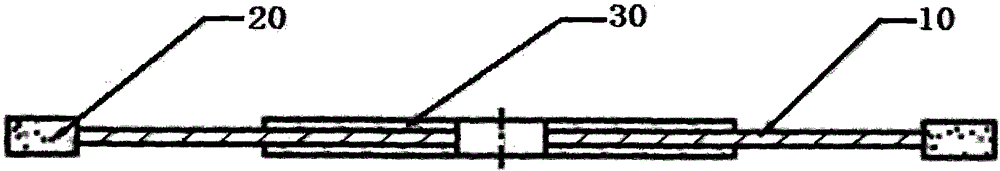

[0033] Sample 1: The Φ250mm diamond circular saw blade is made by the patent of the present invention, the thickness of the substrate is 0.8mm, the diameter of the reinforcing piece is 100mm, and the thickness is 1.0mm; The thickness of the saw blade head is 1.0mm, and the end jump is 0.12mm.

[0034] Sample 2: The Φ300mm diamond circular saw blade is made by the patent of the present invention, the thickness of the substrate is 1.0mm, the diameter of the reinforcing piece is 120mm, and the thickness is 1.0mm; after pressing, sintering, rolling, leveling, welding, and sharpening, the cutting head Thickness 1.2mm, end jump 0.14mm.

[0035] Sample 3: The Φ350mm diamond circular saw blade is made by the patent of the present invention. The thickness of the substrate is 1.2mm, the diameter of the reinforcing piece is 150mm, and the thickness is 1.0mm; the thickness of the blade head after pressing, sintering, rolling, leveling, welding, and cutting 1.4mm, end jump 0.15mm.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com