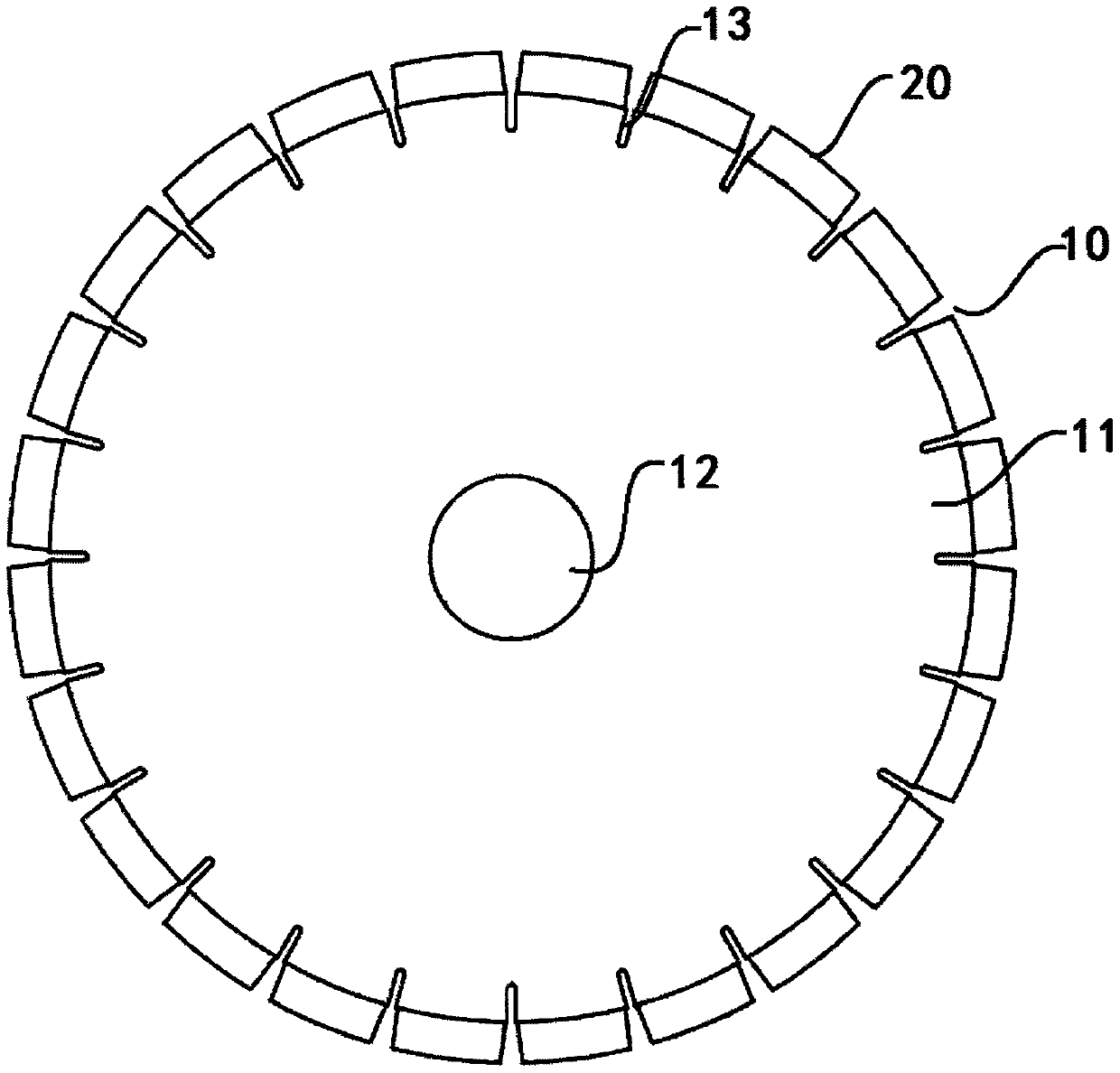

Composite multi-layer diamond cutter head and its preparation method

A diamond cutter head and diamond technology, which is applied in metal processing equipment, metal sawing equipment, stone processing equipment, etc., can solve the problems of unbalanced force on the diamond layer and occupy a lot of cost, and achieve fast cutting speed and low cost. The effect of tool cost and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

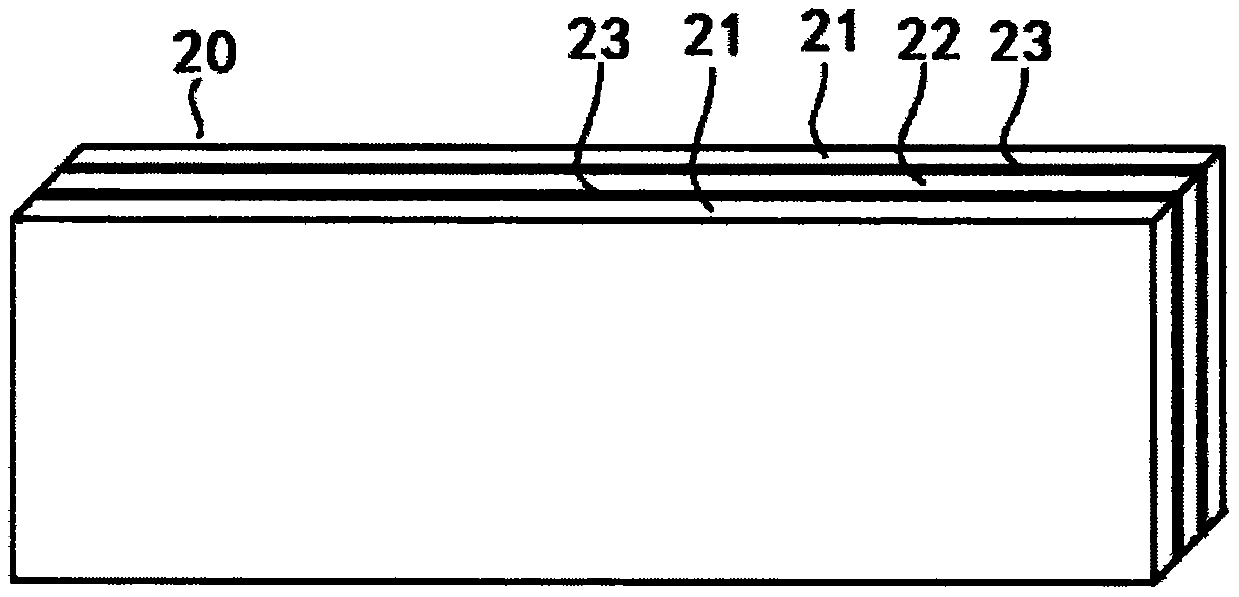

[0031] In the present invention, the preparation method of the composite multilayer diamond cutter head comprises the following steps:

[0032](1) According to the ratio, the diamond particles and the matrix powder are evenly mixed and cold-pressed into a diamond green layer in the middle and diamond green layers on both sides;

[0033] (2) cold pressing the bronze powder to form a metal blank layer;

[0034] (3) The diamond blank layer in the middle, the diamond blank layer and the metal blank layer on both sides are formed into a laminated structure according to the order;

[0035] (4) Carry out hot-press sintering on the laminated structure, the temperature of hot-press sintering is 725-800°C, and the pressure is 250-300kg / cm 2 , The holding time is 150-250 seconds.

[0036] In the examples and comparative examples of the present invention, the particle size of the diamond particles used is 50 / 60 (the corresponding particle size is 300-250 μm).

[0037] In the embodiment...

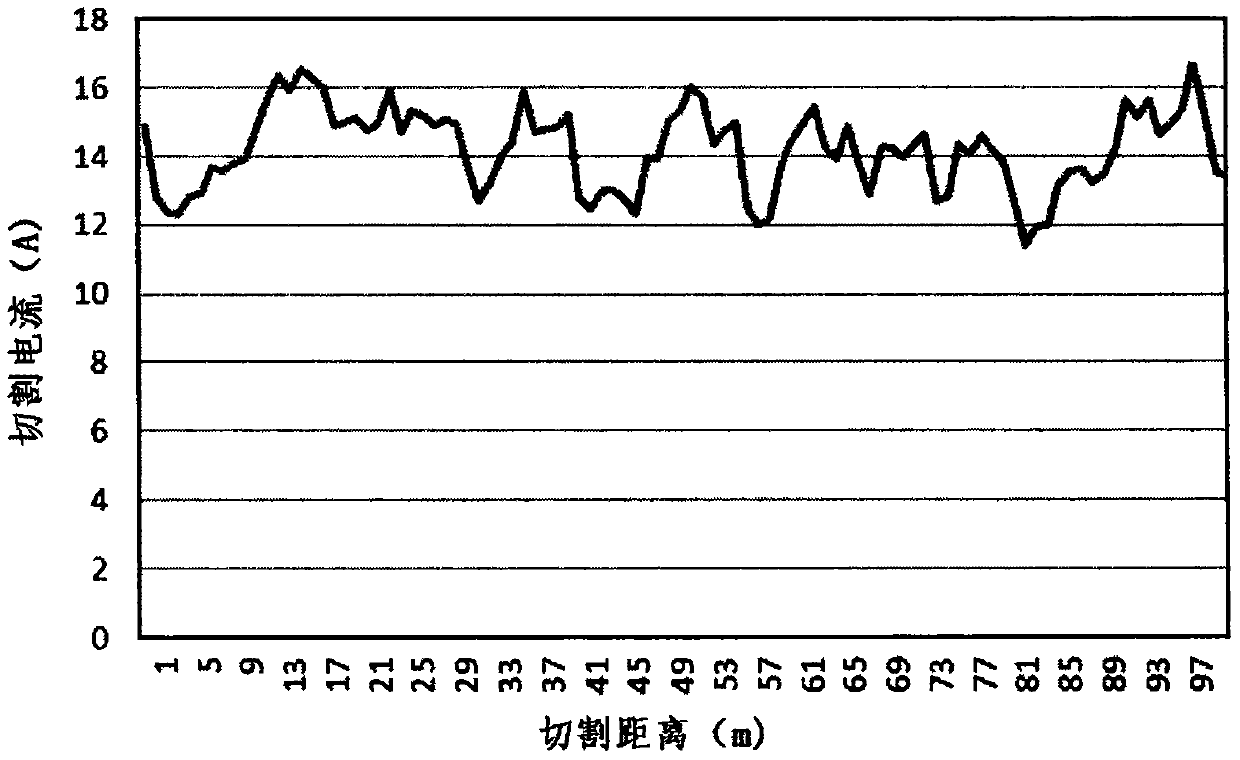

Embodiment 1

[0041] Put 3.0kg of bronze powder, 0.3kg of tin powder, 0.01kg of graphite powder and 6.64kg of pre-alloyed powder into the mixing tank and mix for 30 minutes, then add 0.05kg of liquid paraffin and 0.35kg of diamond particles, continue After 3 hours of mixing, the powder is poured into the mold and cold-pressed to obtain the diamond blank layer in the middle;

[0042] Take 1.0kg of bronze powder, 0.3kg of tin powder and 8.65kg of pre-alloyed powder and mix them in the mixing tank for 30 minutes, then add 0.05kg of liquid paraffin and 0.30kg of diamond particles, and continue mixing for 3 hours. The powder is poured into the mold and cold-pressed to obtain the diamond blank layer on both sides;

[0043] Pour the bronze powder into the mold and cold press to form the metal blank layer;

[0044] The above-mentioned diamond blank layer and the metal binder blank layer are arranged at intervals to form a laminated structure (3 layers of diamond blank layers and 2 layers of metal ...

Embodiment 2

[0046] Put 4.0kg of bronze powder, 0.4kg of tin powder, 0.01kg of graphite powder and 5.55kg of pre-alloyed powder into the mixing tank and mix for 30 minutes, then add 0.04kg of liquid paraffin and 0.30kg of diamond particles, continue After 3 hours of mixing, the powder is poured into the mold and cold-pressed to obtain the diamond blank layer in the middle;

[0047] Put 1.5kg of bronze powder, 0.5kg of tin powder and 7.95kg of pre-alloyed powder into the mixing tank and mix for 30 minutes, then add 0.05kg of liquid paraffin and 0.30kg of diamond particles, and continue mixing for 3 hours. The powder is poured into the mold and cold-pressed to obtain the diamond blank layer on both sides;

[0048] Pour the bronze powder into the mold and cold press to form the metal blank layer;

[0049] The above-mentioned diamond green layer and the metal binder green layer are arranged at intervals to form a laminated structure (3 layers of diamond green layers and 2 layers of metal bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com