Fixed cutter, electric shaving tool bit applying fixed cutter and manufacturing method thereof

A razor and fixed knife technology, applied to the fixed knife, the electric shaver head using the fixed knife and its manufacturing field, can solve the problems of small design space, single function, difficult to break through, etc., to improve cutting sharpness, Simple process and the effect of improving shaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with accompanying drawing:

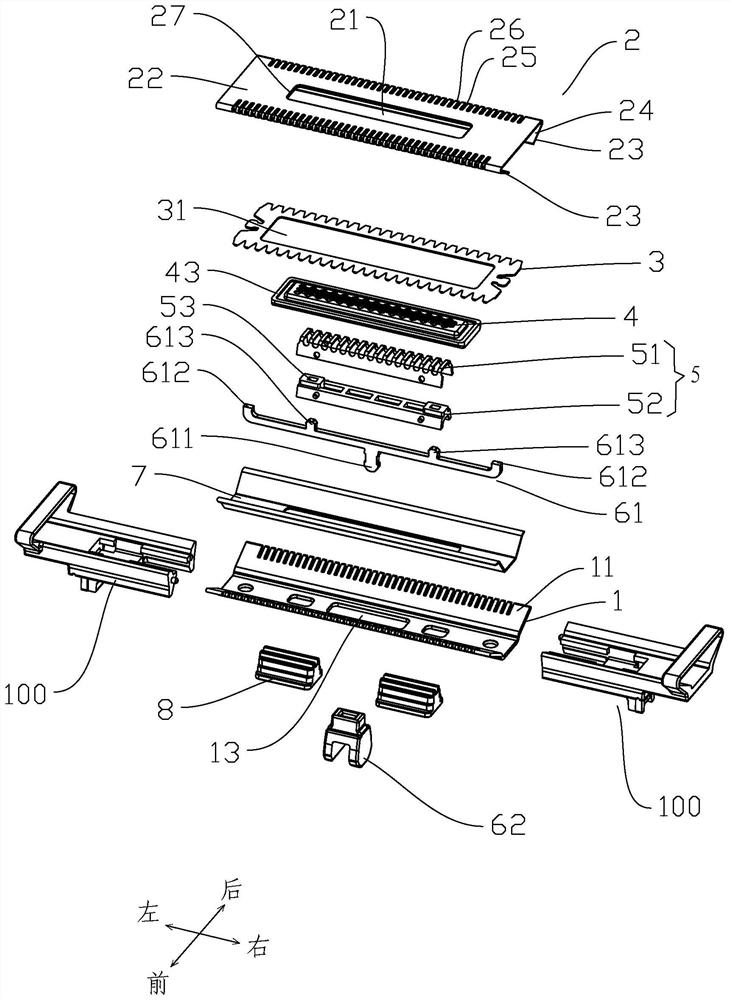

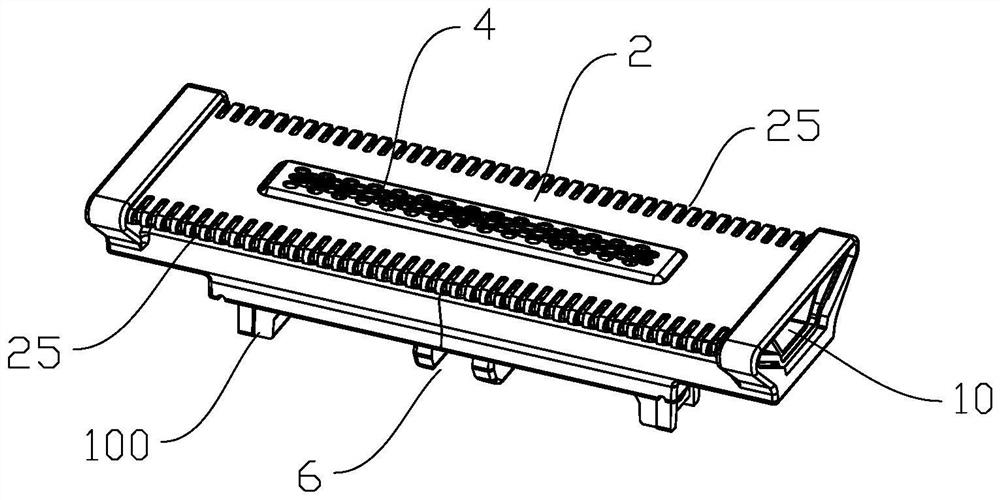

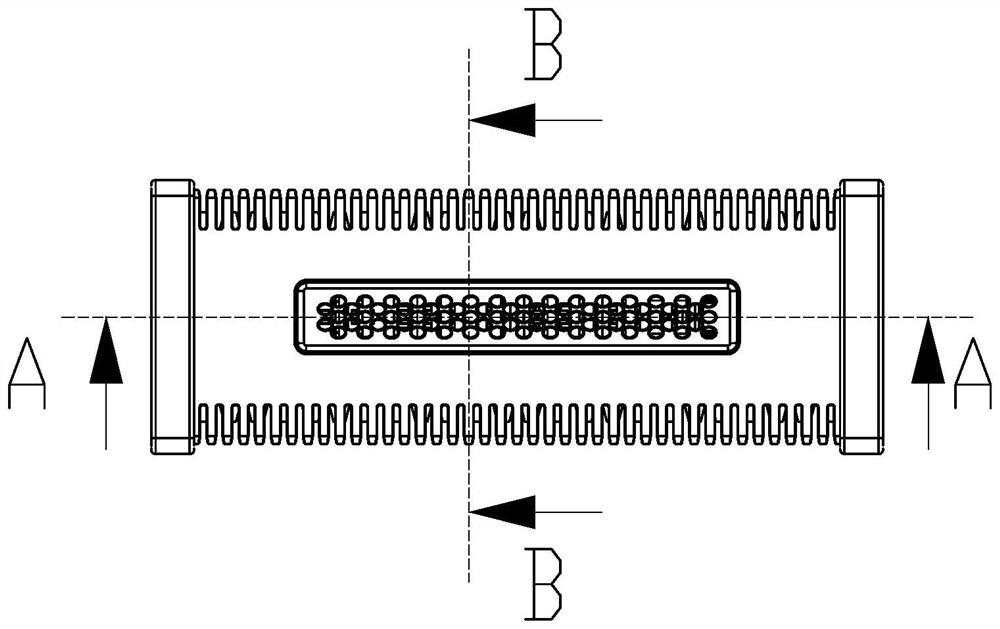

[0062] Such as Figure 1 to Figure 15 The electric razor head of a kind of reciprocating linear cutting shown includes a fixed knife bracket 1 and a fixed knife 2 fixed on the fixed knife bracket 1, and the fixed knife bracket 1 is respectively provided with a fixed blade on the left and right sides. The supporting part 11 that the knife 2 is supported from the left and right sides, the inner cavity 10 is formed between the fixed knife 2 and the fixed knife support 1, and the hair enters the inner cavity 10 between the fixed knife 2 and the fixed knife support 1. The hair feeding groove 25 in the cavity 10, the internal cavity 10 is provided with a movable knife 3 that cooperates with the fixed knife 2 and can reciprocate back and forth for cutting, and the middle part of the top wall of the fixed knife 2 is provided with a middle installation hole 21 , the inner cavity 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com