An electric shaver

An electric shaver, razor technology, applied in the direction of metal processing, etc., can solve the problems of reduced durability of the outer cutting knife, poor sharpness of the cutting edge, acceleration and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

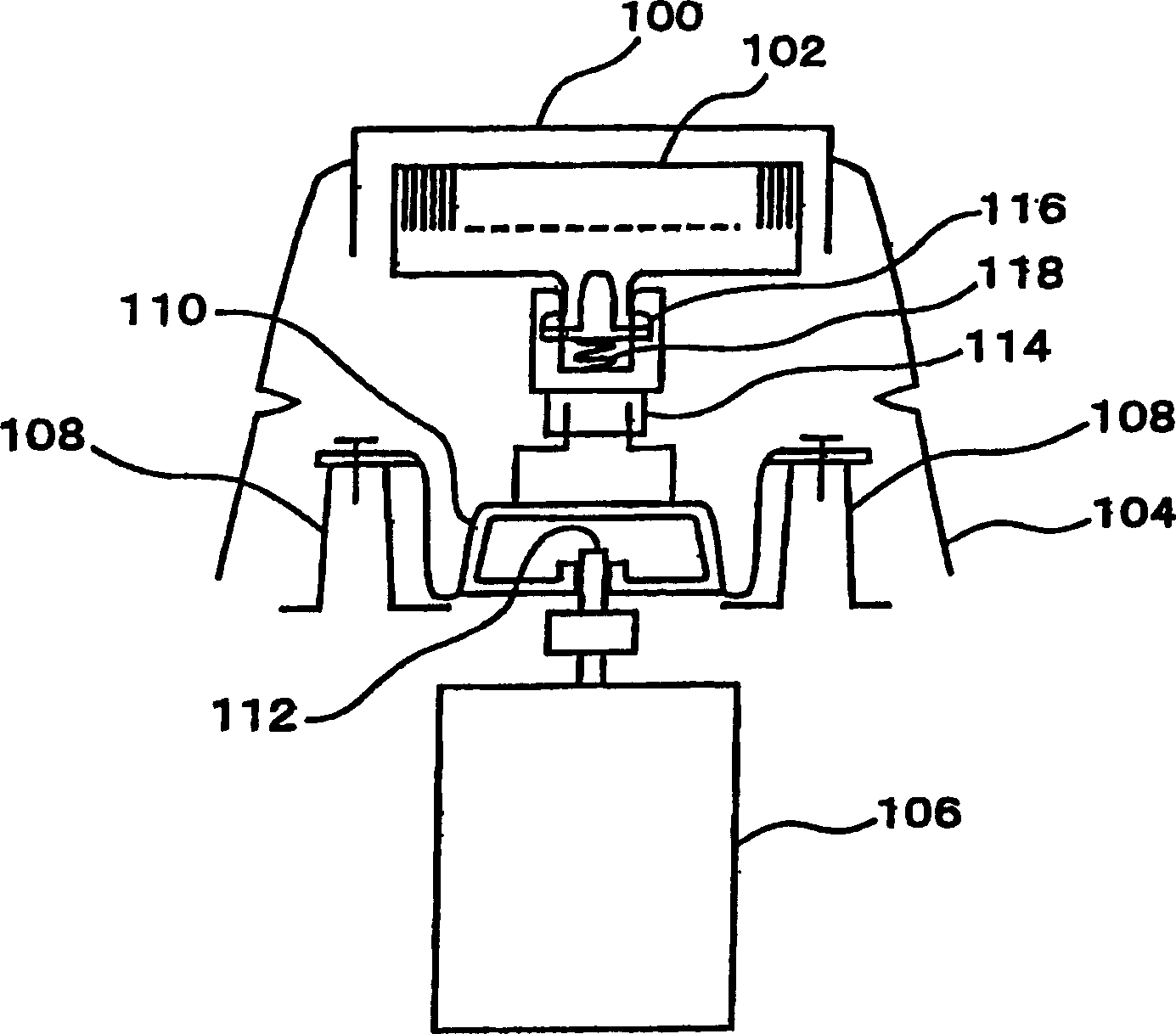

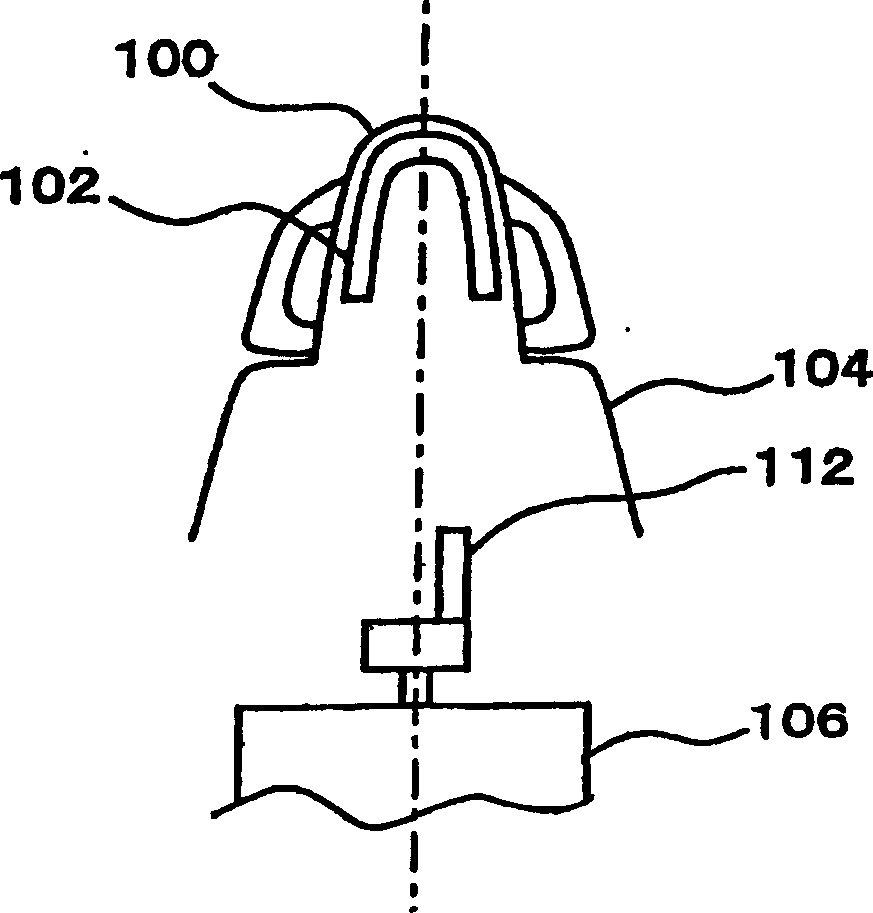

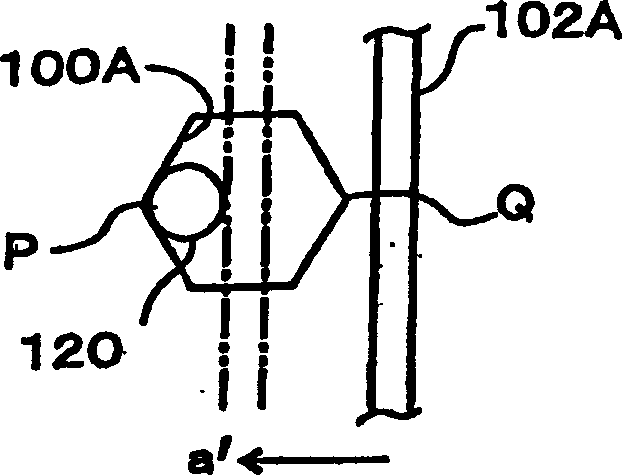

[0038] figure 1 Schematically shows the internal structure of the reciprocating electric shaver according to one embodiment of the present invention, the internal structure of the shaver body is omitted; figure 2 The shaver is shown viewed from the side.

[0039] exist figure 1 and 2 Among them, reference numeral 100 represents an arcuate outer cutting knife, and 102 represents an arcuate inner cutting knife that reciprocates in or below the outer cutting knife 100 . The outer cutter 100 is secured to a frame 104 of the shaver body (not shown). The outer cutter 100 is made of, for example, a stainless steel thin plate, and a plurality of openings (hair introduction openings) are formed on the thin metal plate by, for example, punching or etching. The outer cutter 100 may be made by electroforming.

[0040] Same as the outer cutter 100 , the inner cutter 102 is made of, for example, a stainless steel sheet, and the inner cutter 102 is driven by a motor 106 to reciprocate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com