Cutting device for stone angle grinder

A cutting device and angle grinder technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of easy deformation, slow ash discharge, high cost, improve wear resistance and cutting sharpness, reduce distortion The effect of deformation and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

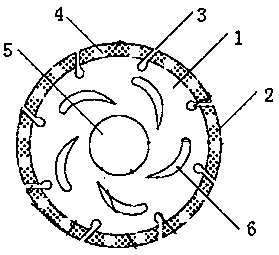

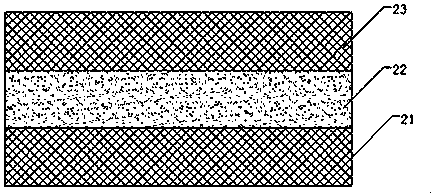

[0017] The present embodiment stone angle grinder is used cutting device, as figure 1 As shown, a disc cutting body 1 is included, and a plurality of cutting blades 2 are evenly distributed on the outer circumferential surface of the cutting body 1; between adjacent cutting blades 2, there are inclined grooves 3 extending in the radial direction, and the inclined grooves 3 The bottom of the cutting body is a chip removal groove A that is depressed from the outside to the inside, and the chute 3 is inclined clockwise from the inside to the outside in the radial direction of the cutting body. The outer surface of the cutting blade 2 is arranged with a superhard abrasive layer, and the superhard abrasive layer is a cobalt-nickel alloy layer 21, a copper layer 22 and a cobalt-nickel alloy layer 23 arranged in sequence from the inside to the outside; the superhard abrasive layer of each cutting blade 2 There are several chip removal grooves 4 extending radially along the disc cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com