Patents

Literature

45results about How to "Reduce the amount of distortion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

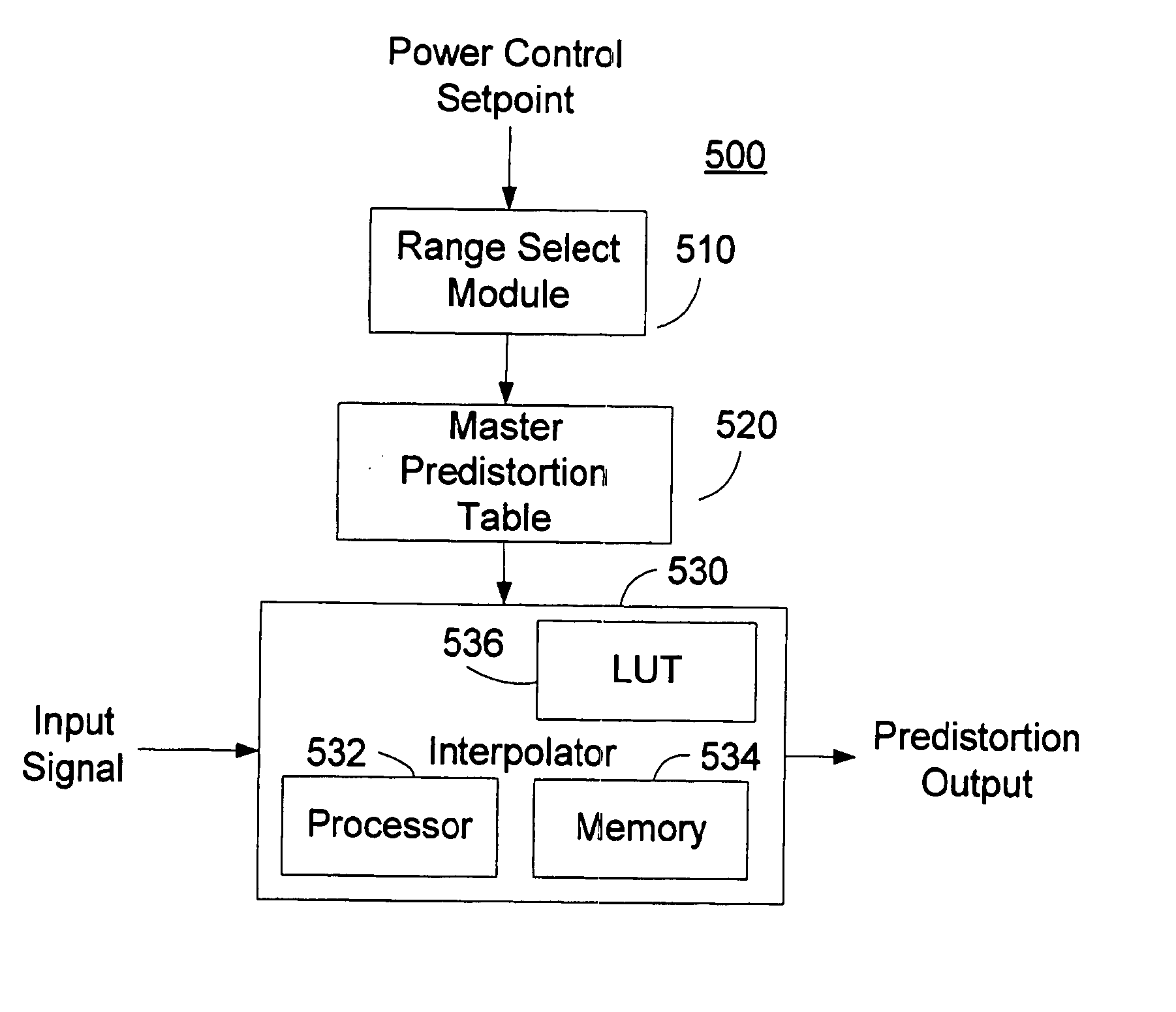

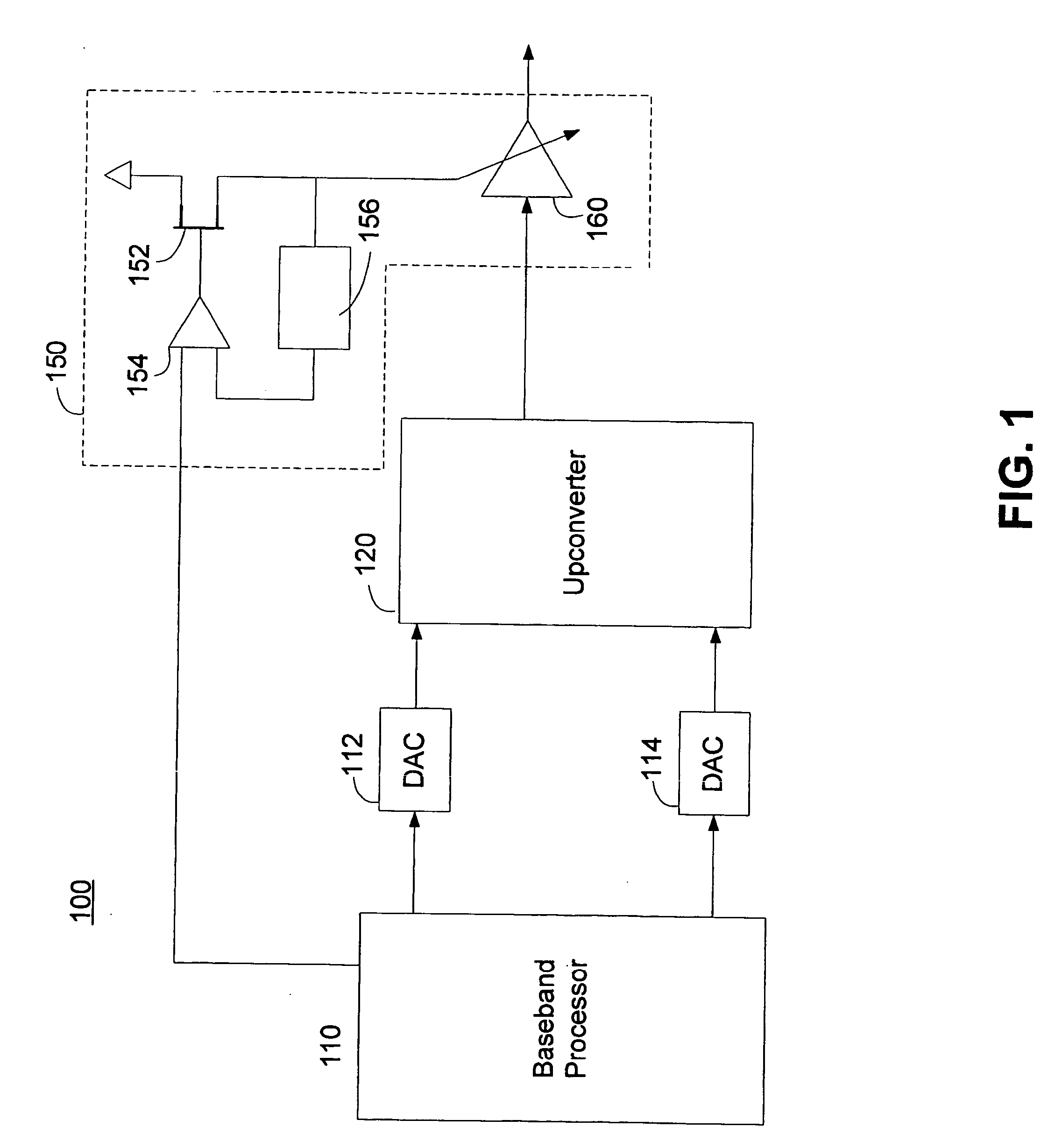

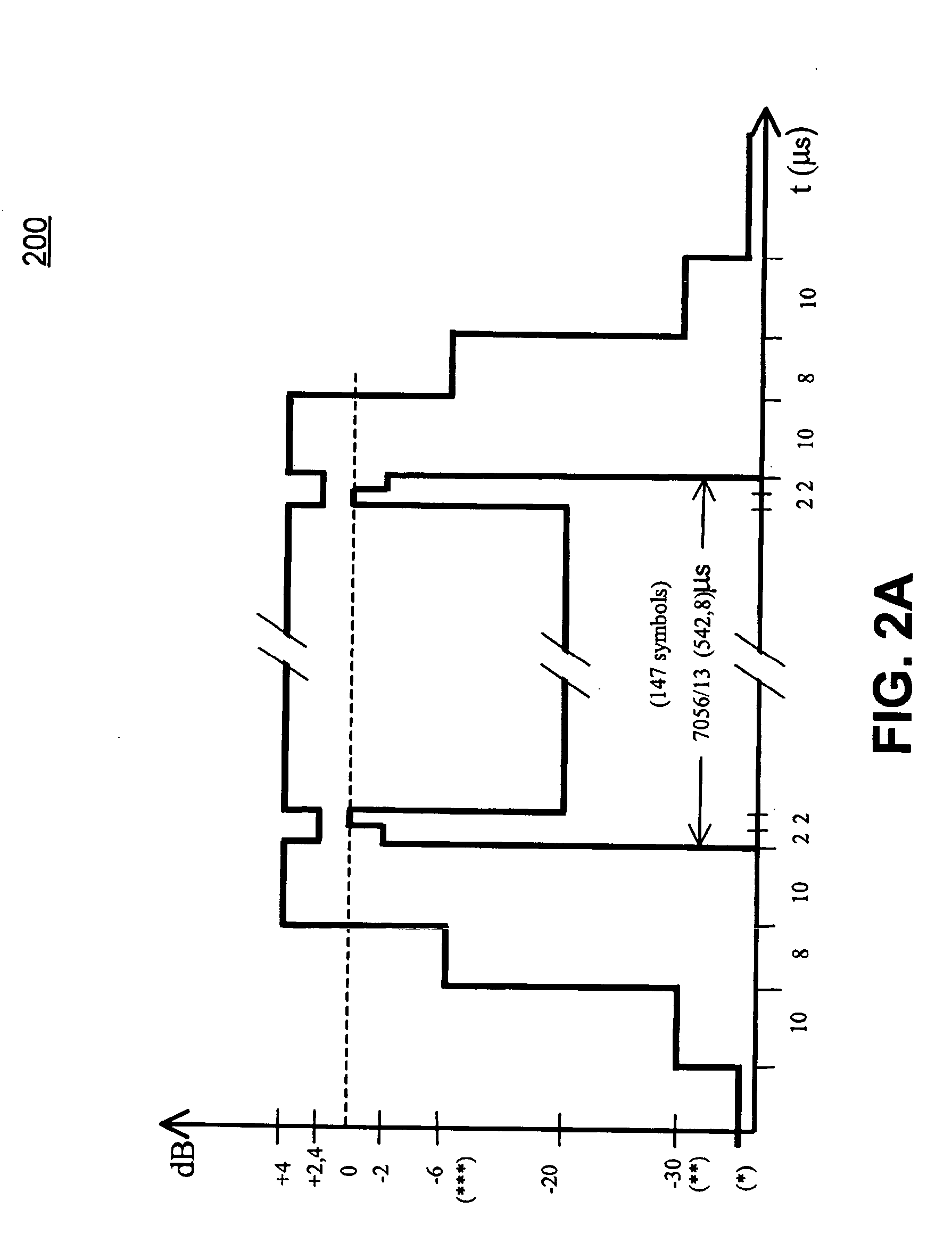

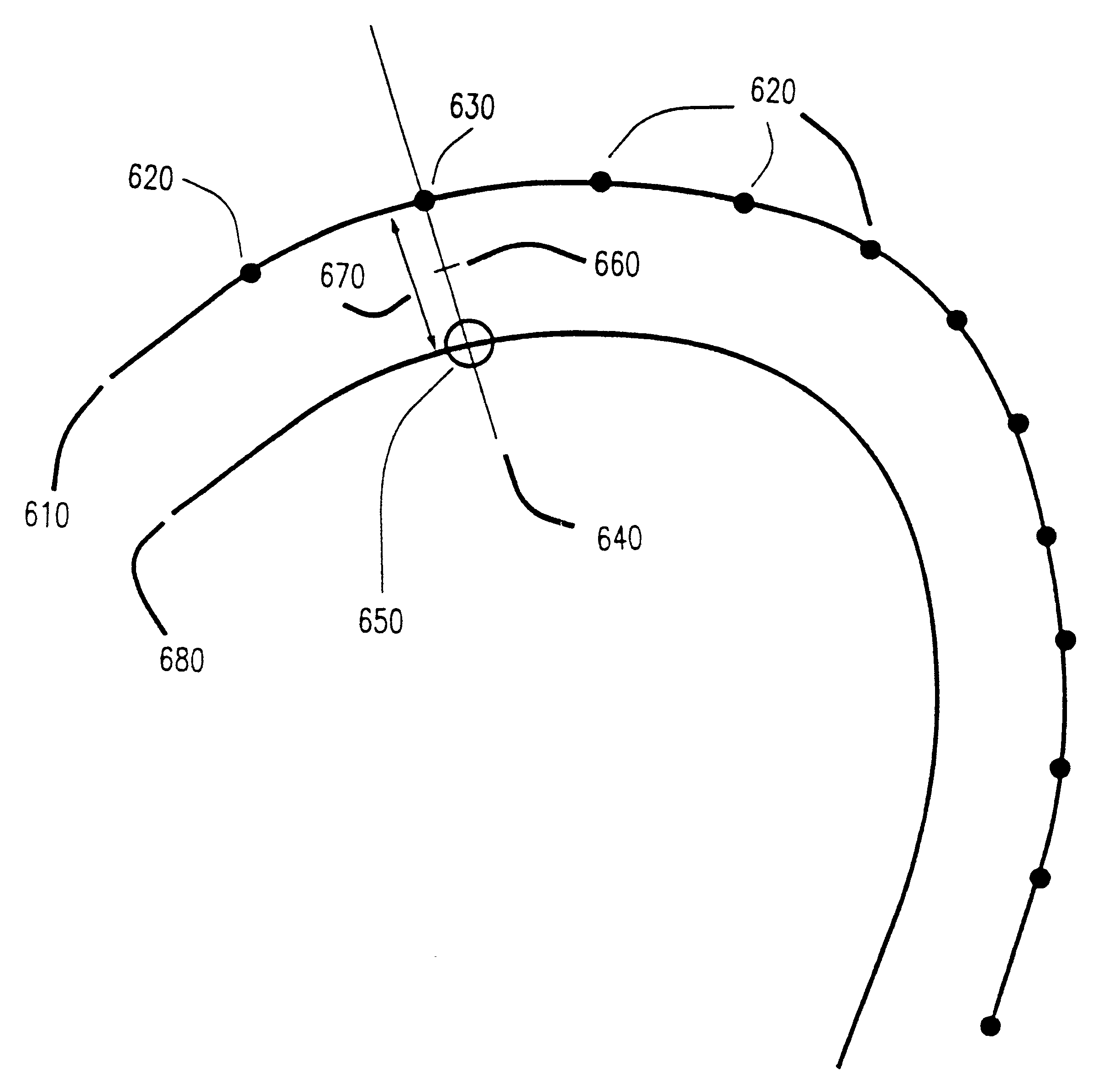

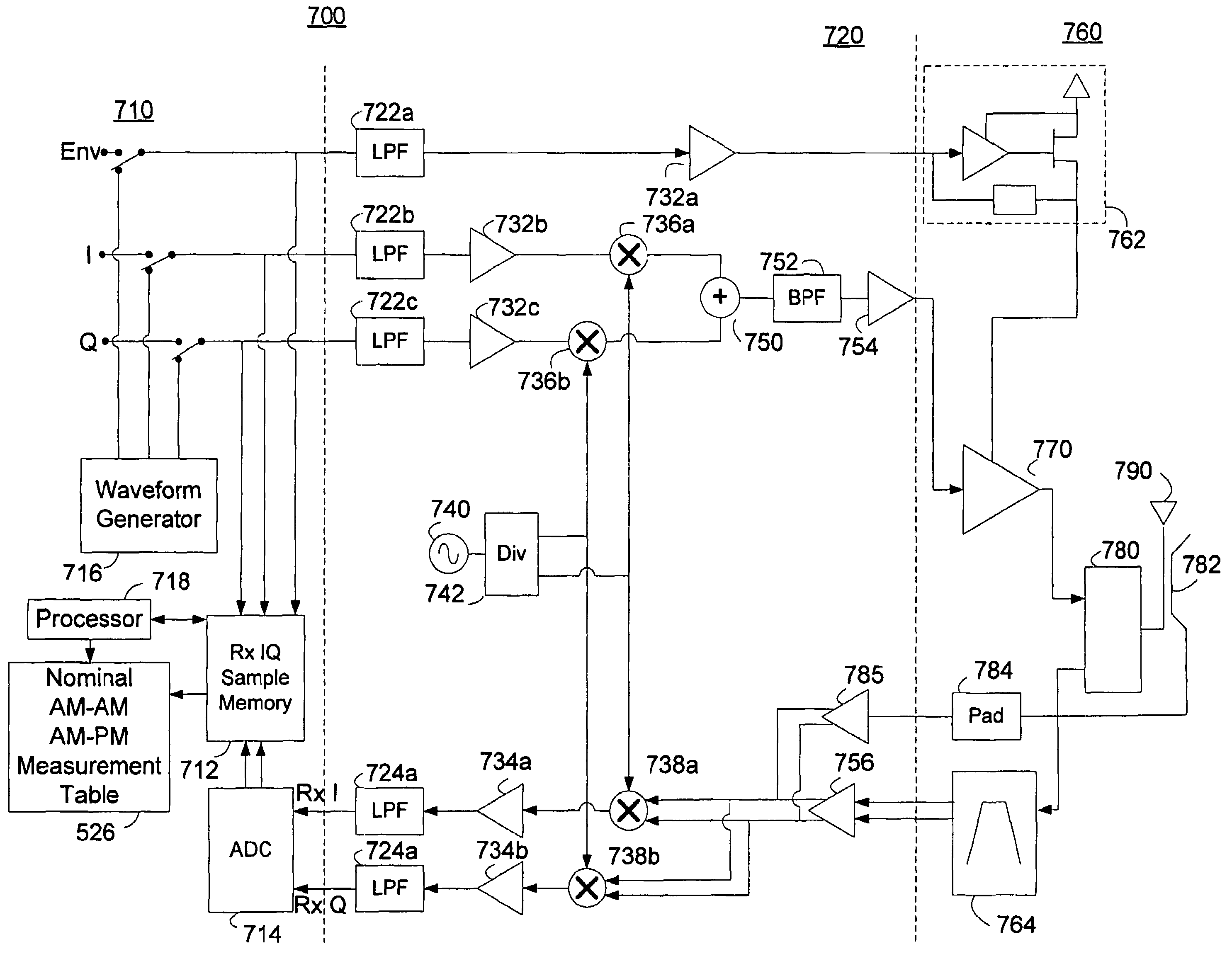

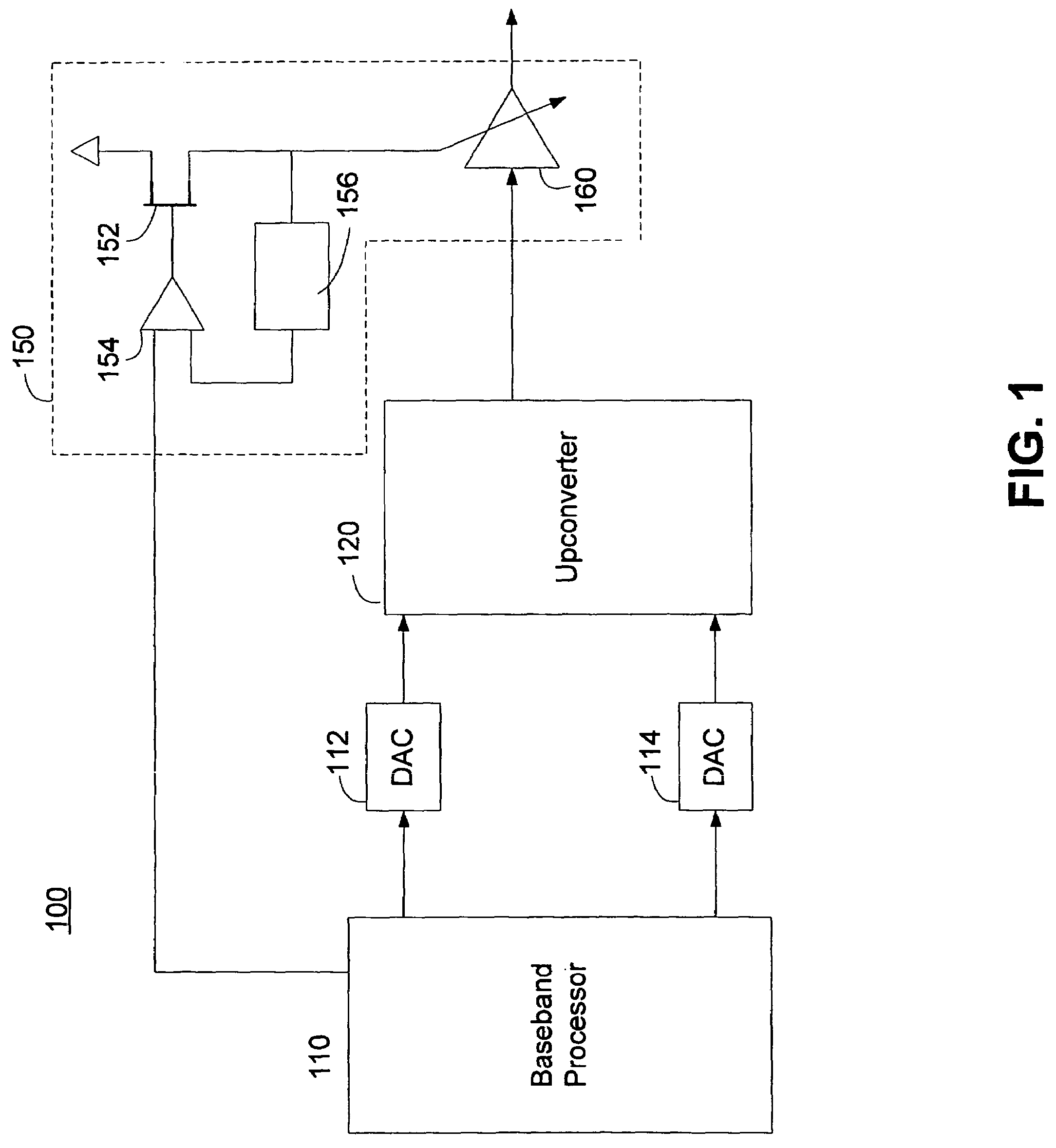

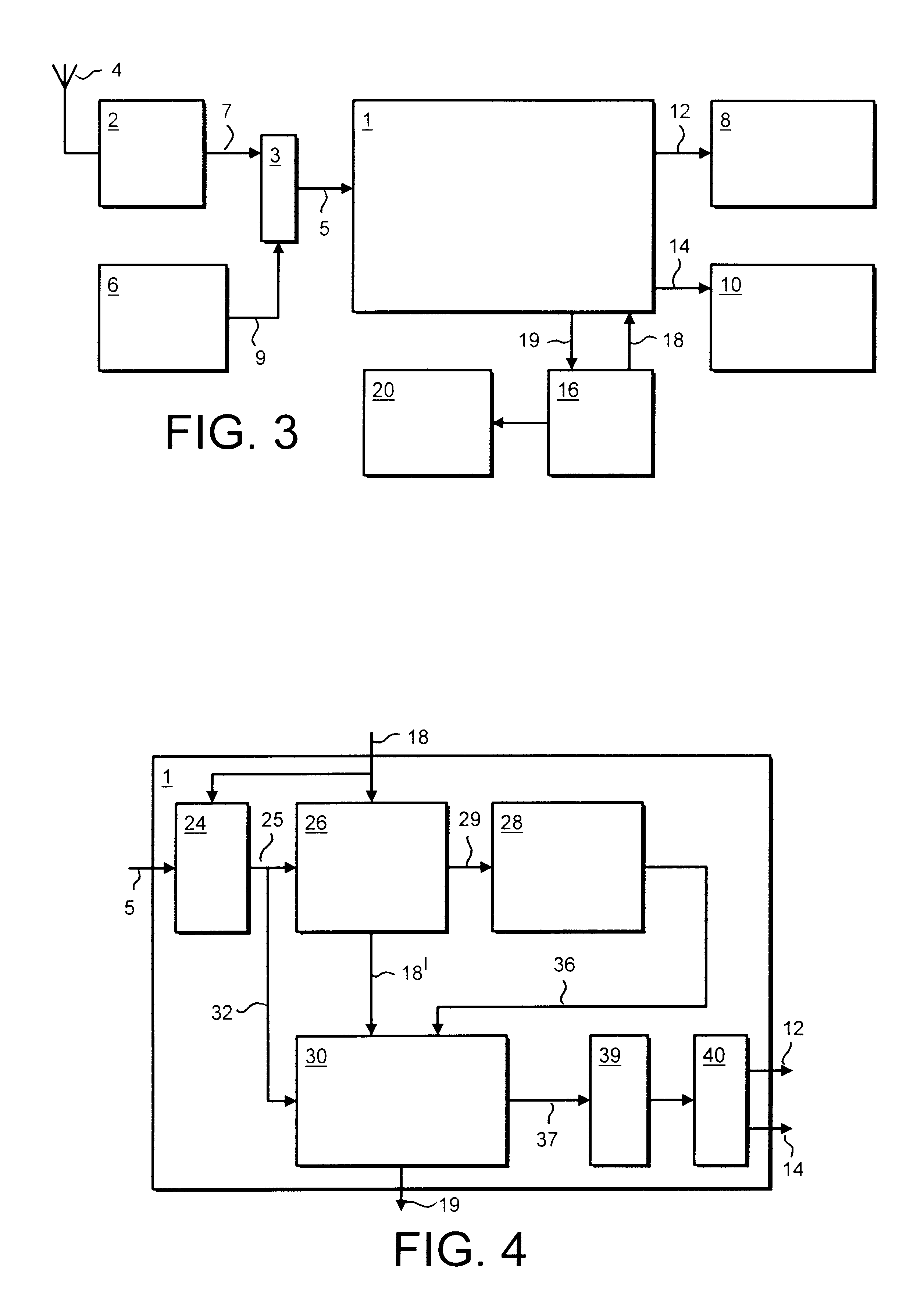

Amplifier predistortion and autocalibration method and apparatus

ActiveUS20050156662A1Improve performanceReduce the amount of distortionAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceAudio power amplifierPhysics

Methods and apparatus for amplifier AM and PM predistortion and autocalibration. AM and PM amplifier distortion can be corrected using predistortion. The AM and PM distortion characteristics of the amplifier are determined using an autocalibration technique. The amplifier characteristics can be stored in distinct look up tables. Alternatively, the inverse of the amplifier characteristics can be stored in distinct look up tables. Signals that are to be amplified are characterized in polar format having a phase component with a normalized magnitude and a magnitude component. The phase component can be predistorted by applying the inverse of the PM distortion characteristics to the signal. Similarly, the magnitude component can be predistorted by applying the inverse of the AM distortion characteristics to the signal. The predistorted phase component can be amplified using the previously characterized amplifier. The predistorted magnitude component can be used to set the gain of the previously characterized amplifier.

Owner:QUALCOMM INC

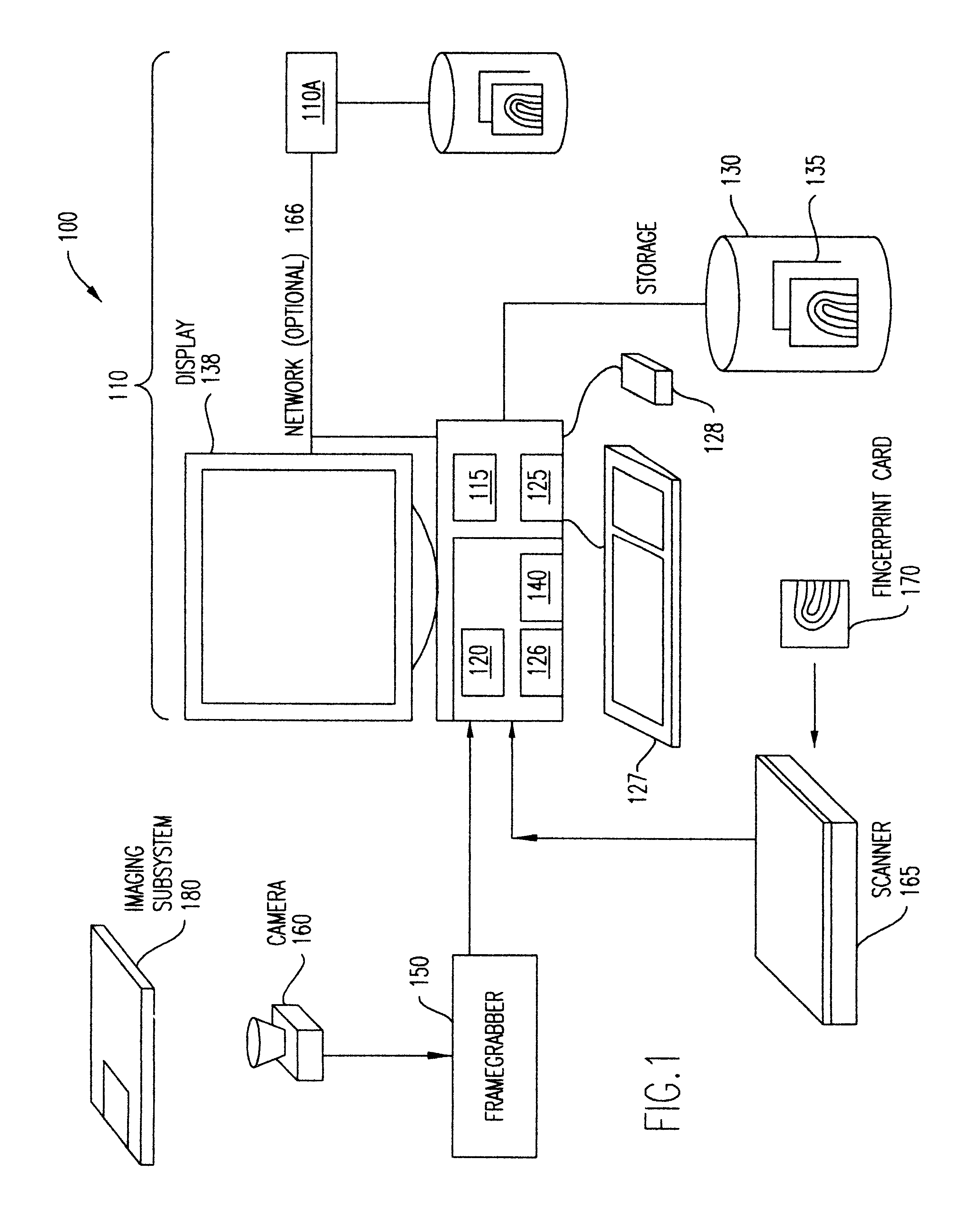

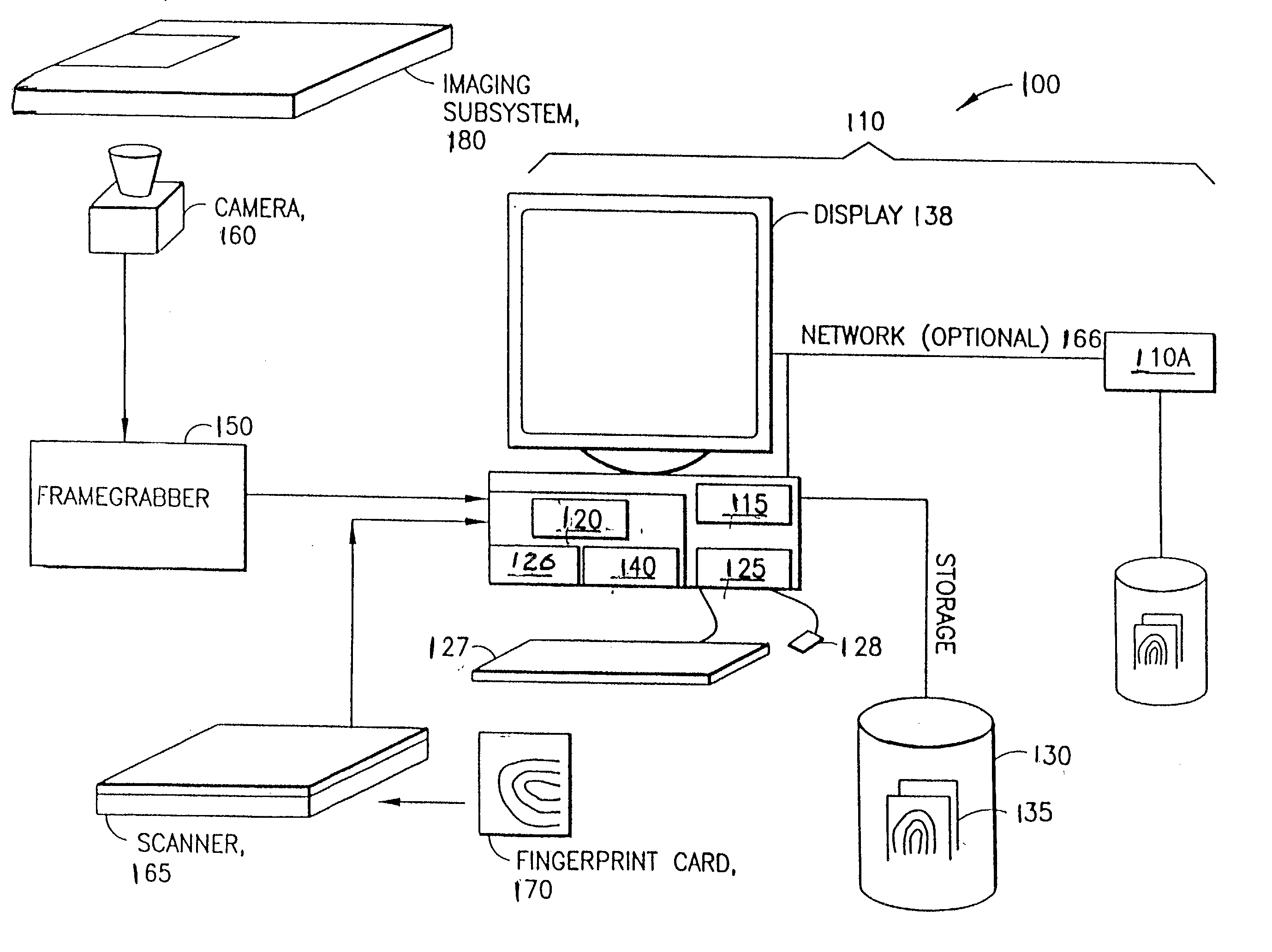

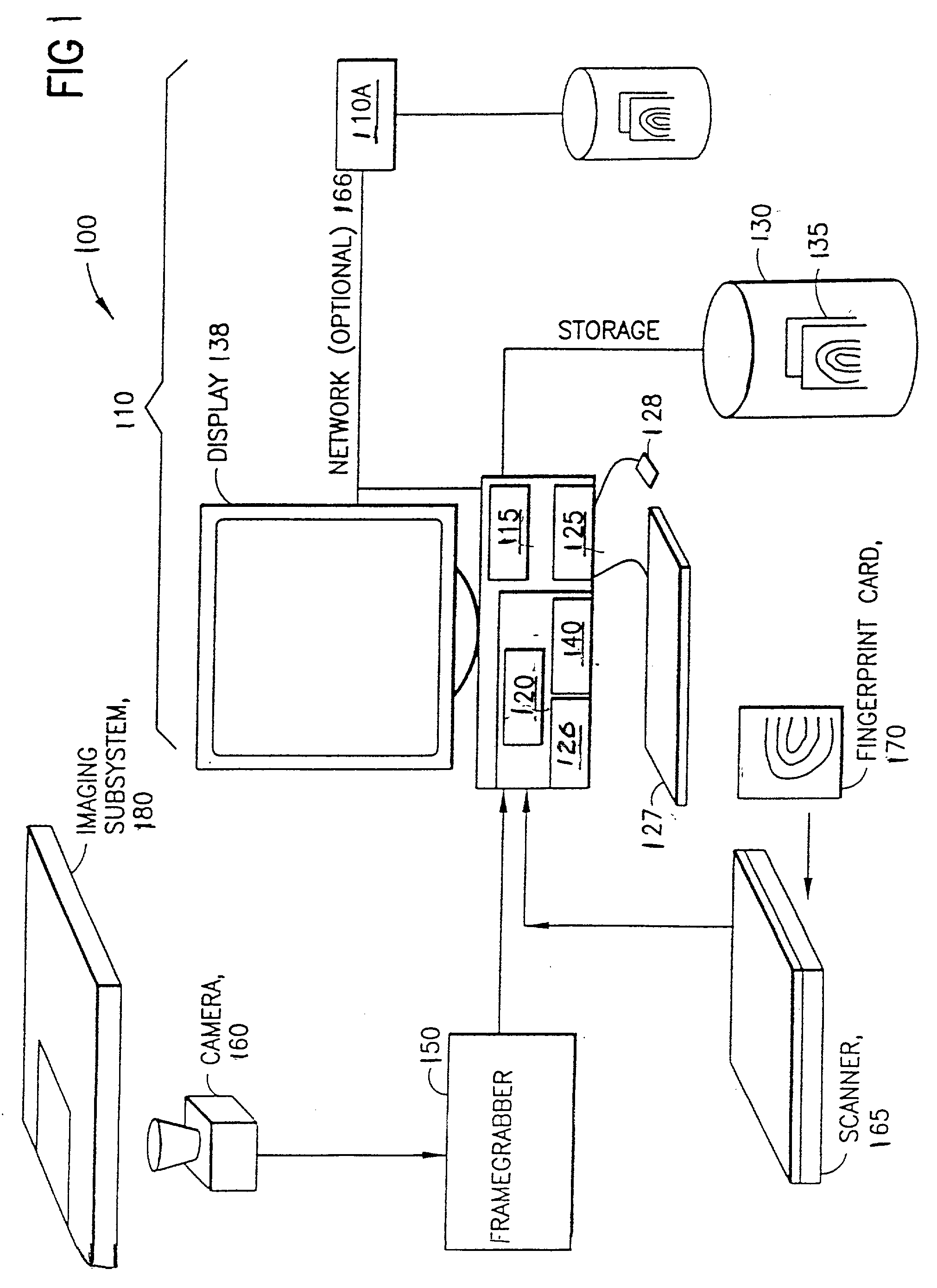

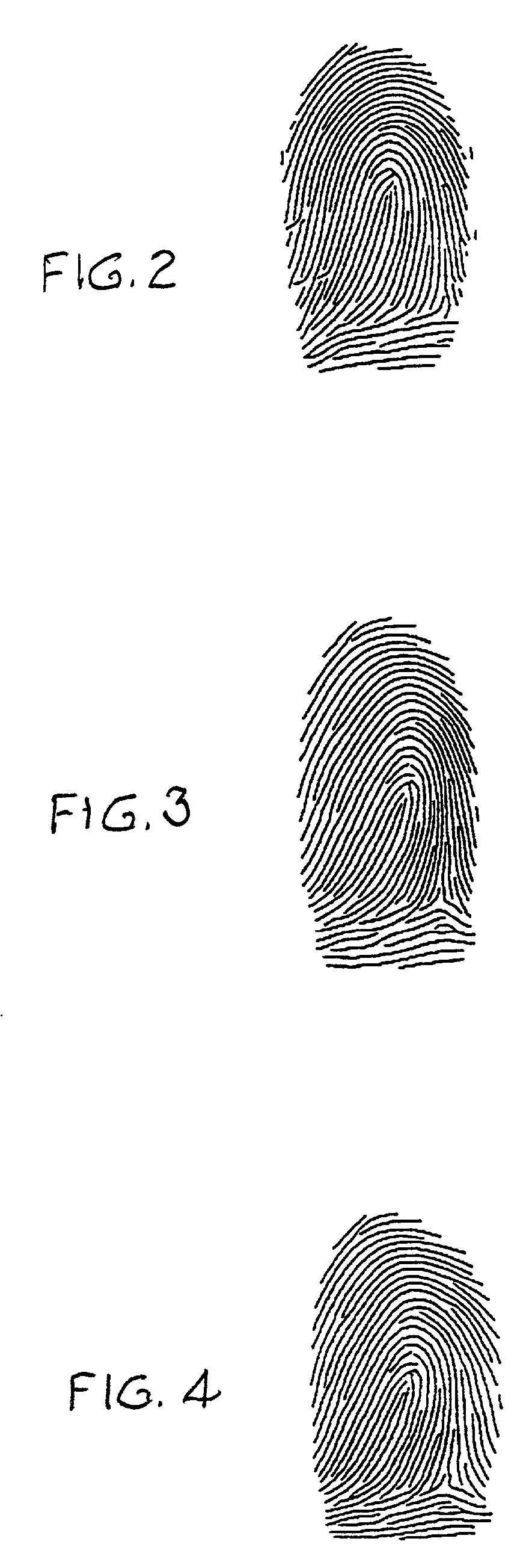

System and method for transforming fingerprints to improve recognition

InactiveUS6466686B2Reliable matchReduce the amount of distortionCharacter and pattern recognitionPattern recognitionFinger surface

A system and method reduces the amount of variation in a fingerprint image due to distortion from elastic deformation of the finger surface and projection onto a planar coordinate system. The amount and extent of distortion is estimated, and the process is inverted in a systematic way, so that the amount of distortion is minimized, and the distortion present is consistent, so that different images of the same print will have very similar distortion and thus matching of the fingerprints will be reliable and unaffected by the distortion.

Owner:UNILOC 2017 LLC

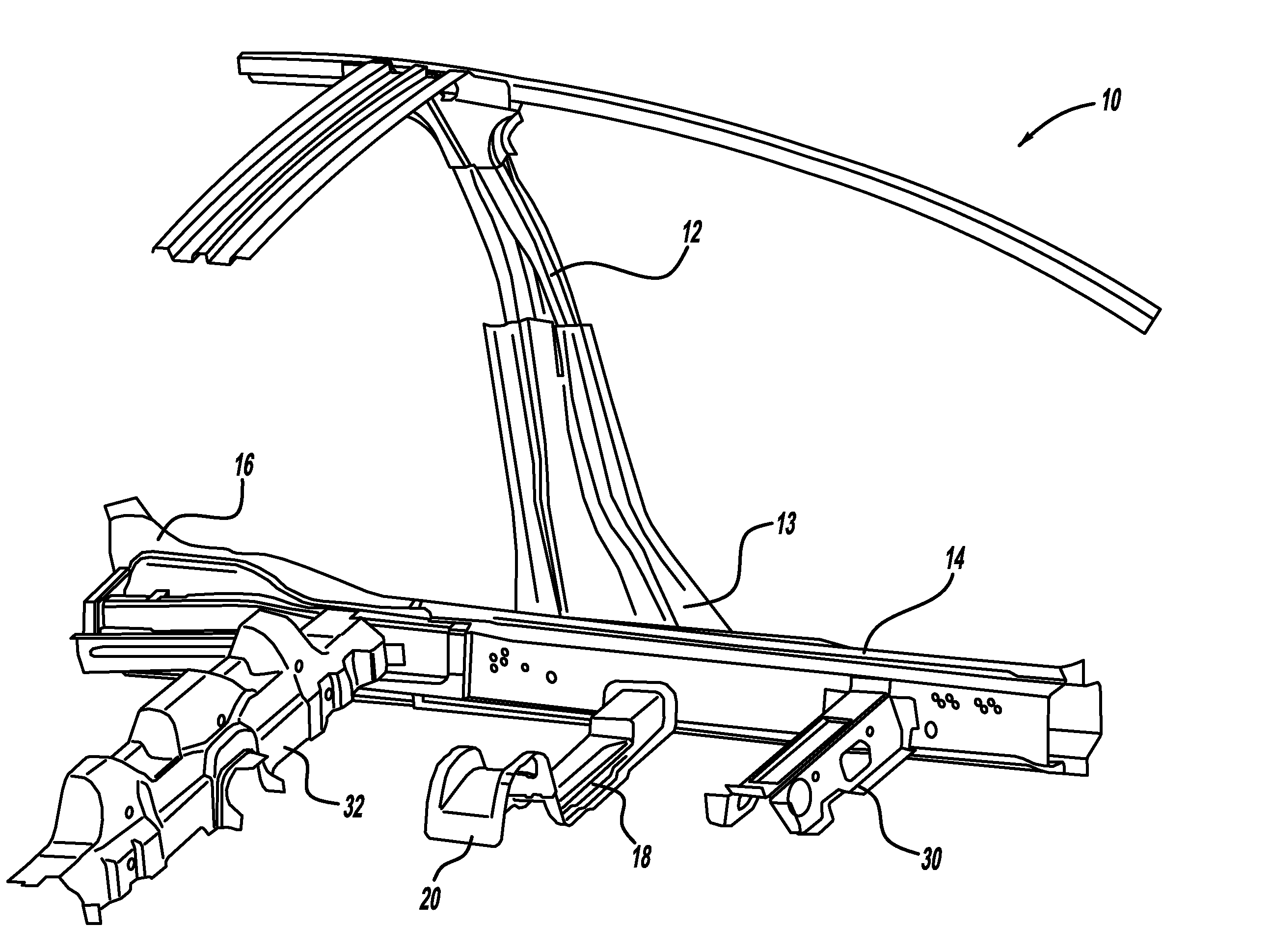

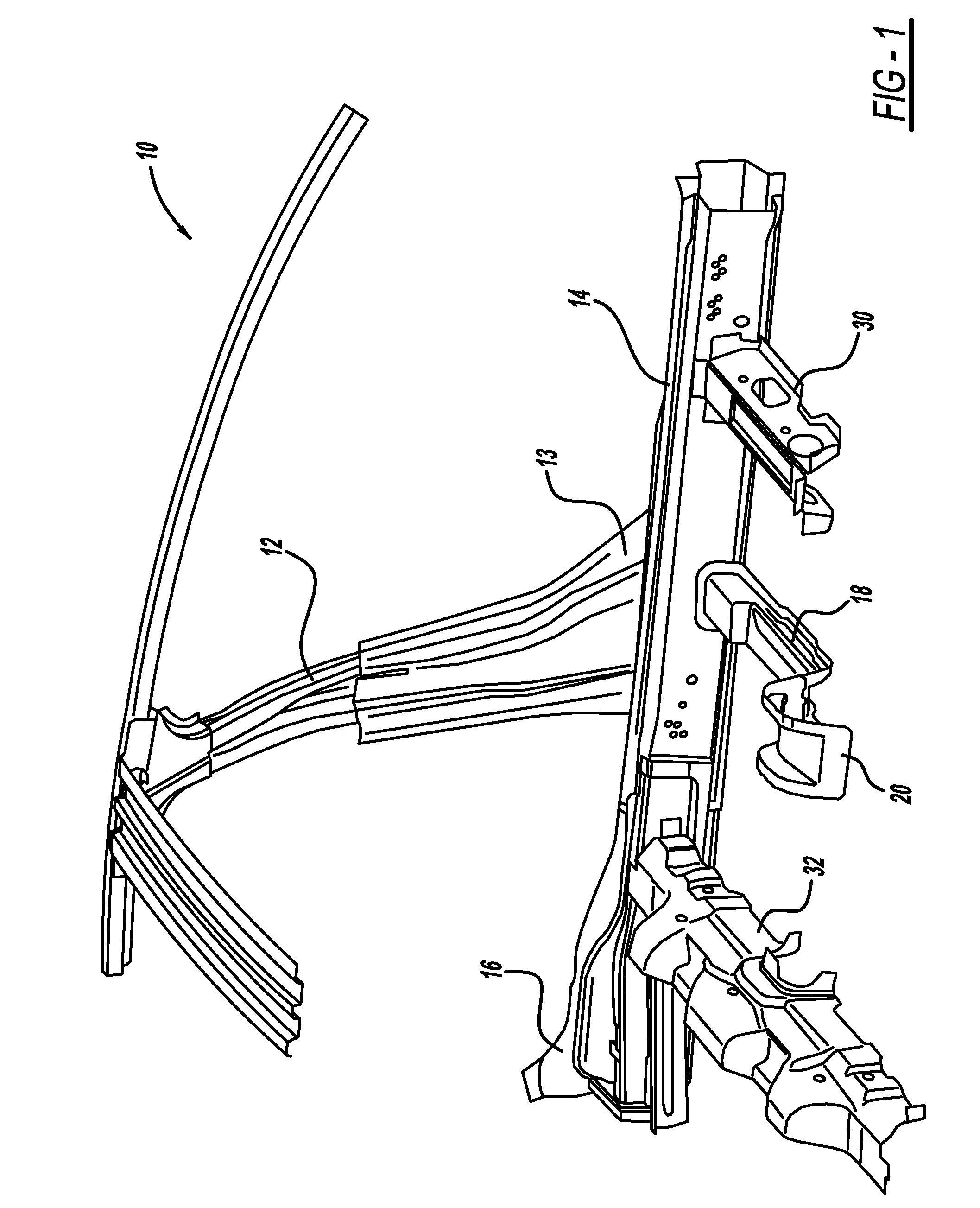

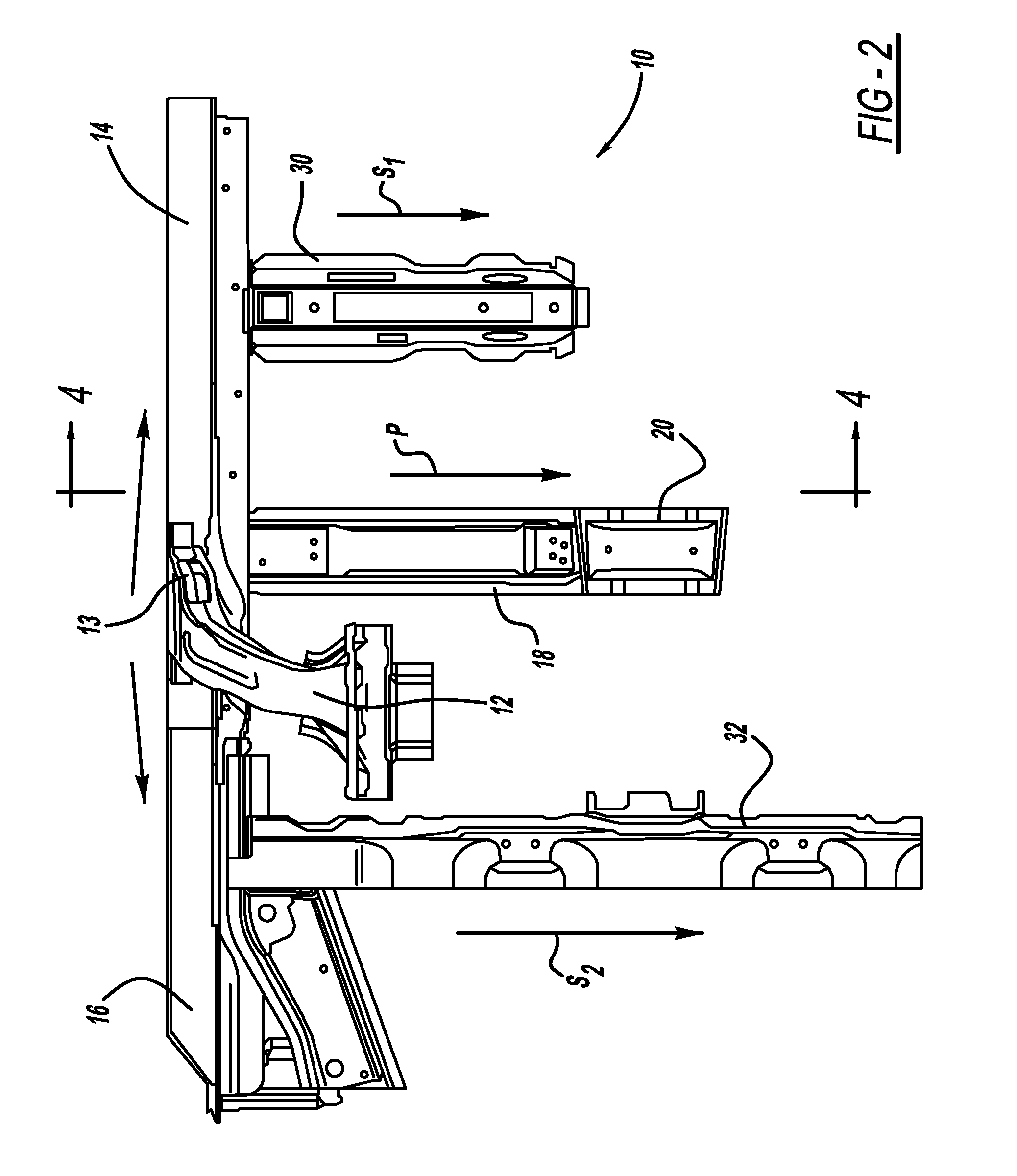

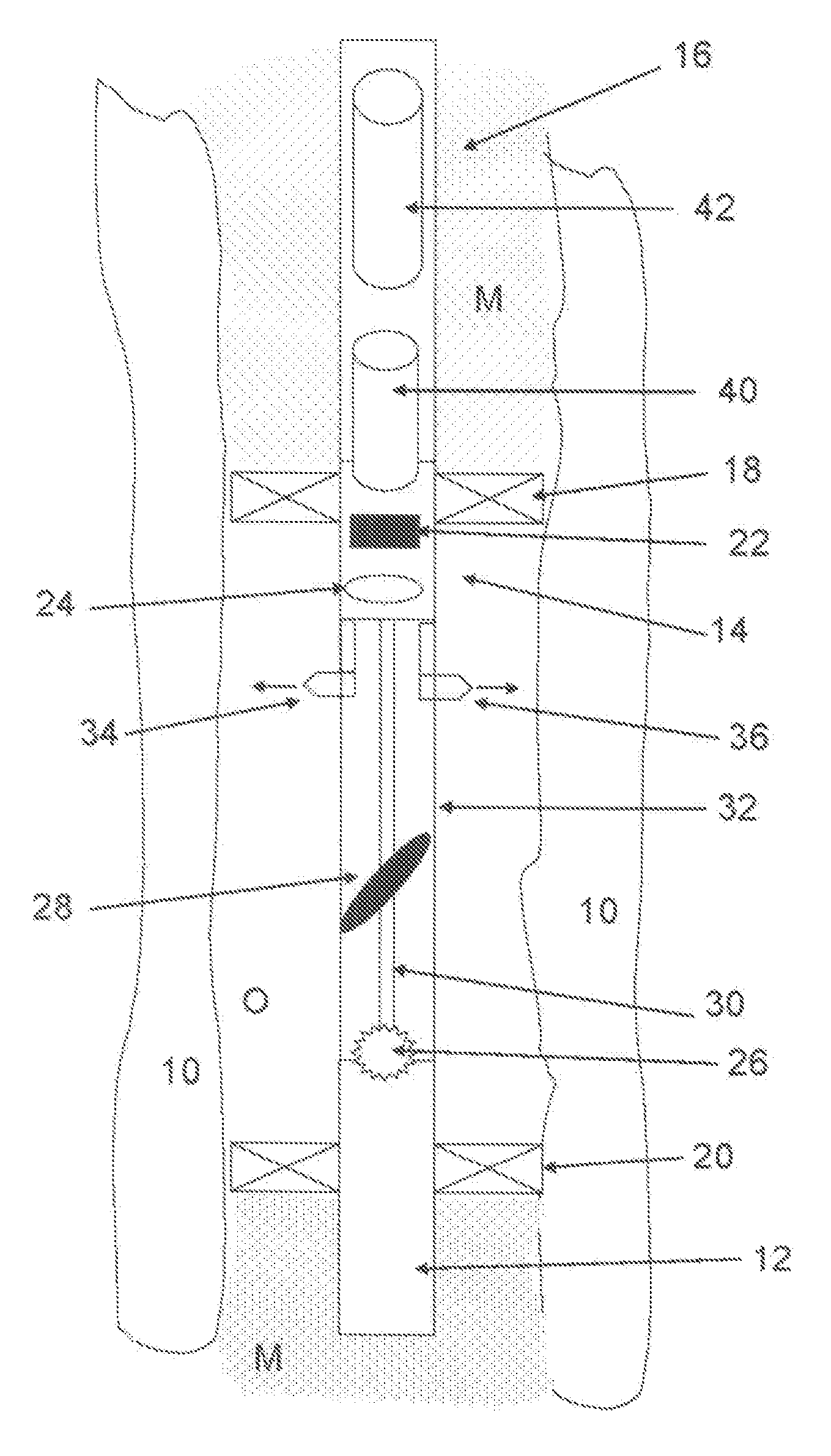

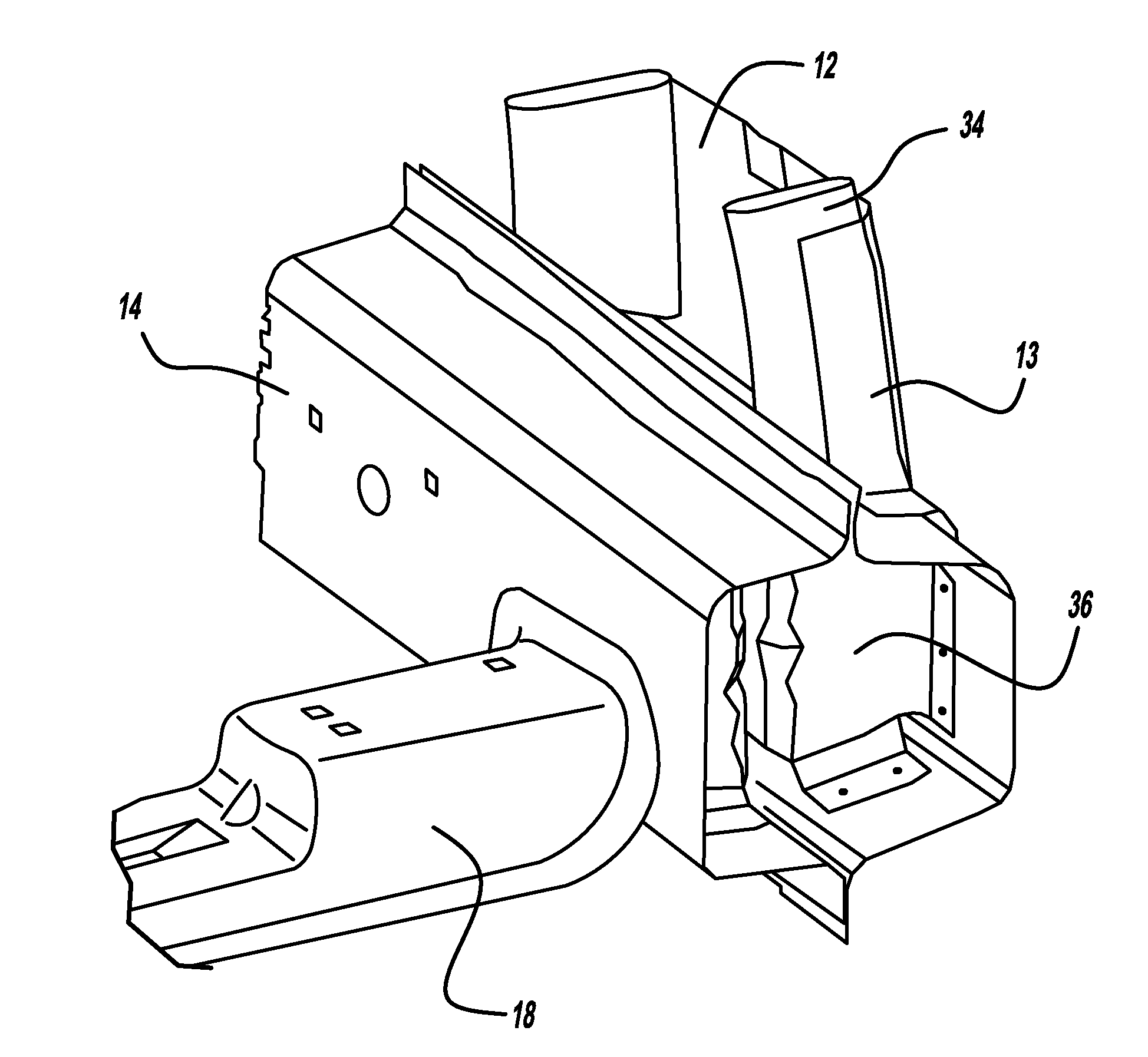

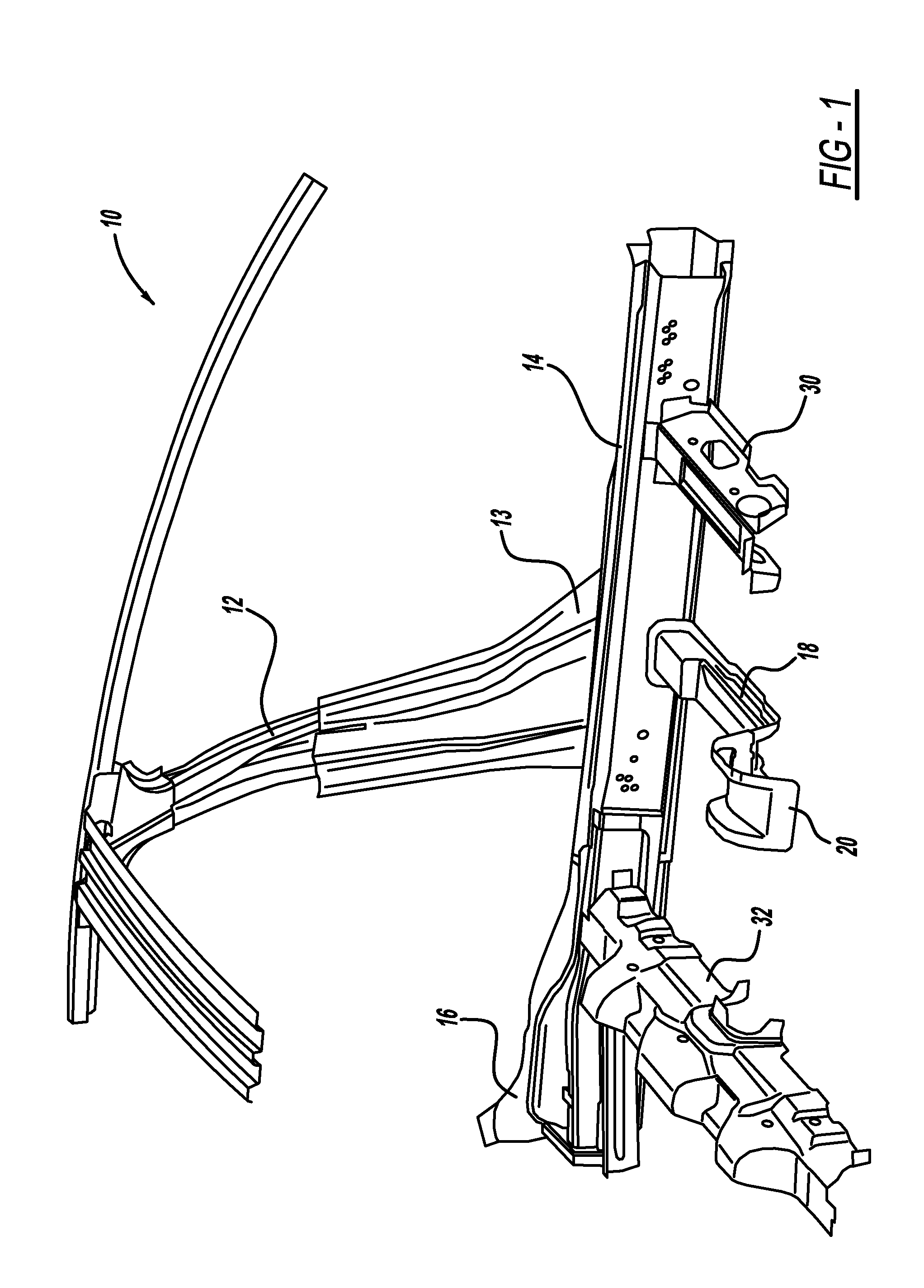

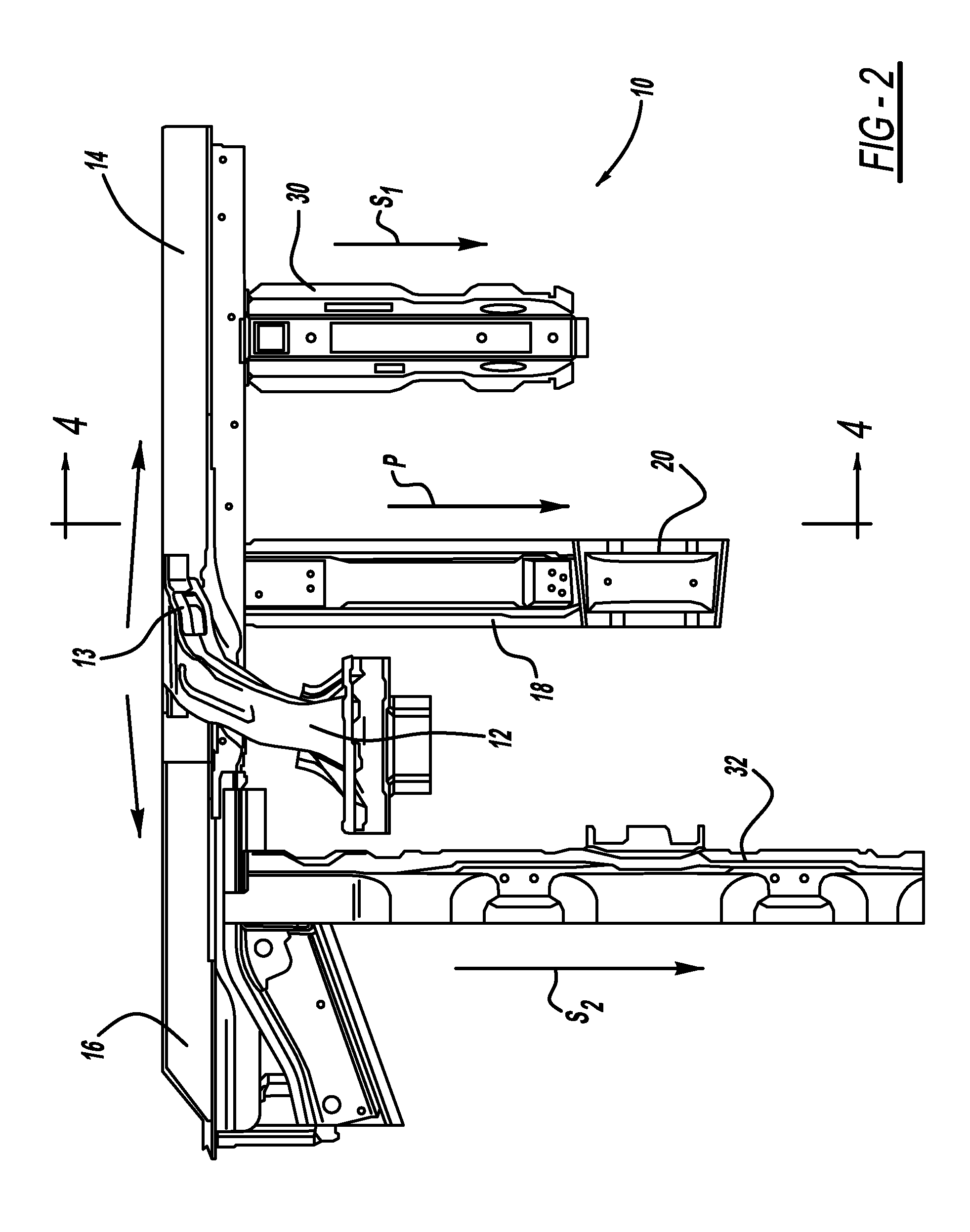

Energy distributing side structure for vehicle side impact occupant protection

ActiveUS8007032B1Less energyReduce the amount of distortionVehicle seatsUnderstructuresSide impactAutomotive engineering

An energy distributing side structure for a vehicle is disclosed. The side structure includes a B-pillar having a wide base and an internal reinforcing tube, a rocker having an internal bulkhead, a rear rocker, and at least one cross-member extending vehicle-inward from the rocker. The cross-member may extend to the vehicle tunnel and may be attached to a tunnel brace. One or more additional cross-members may be provided which also extend vehicle-inward from the rocker and define secondary load paths. By this arrangement loading is transferred to the floor and cross-members of the vehicle during a lateral impact event.

Owner:FORD GLOBAL TECH LLC

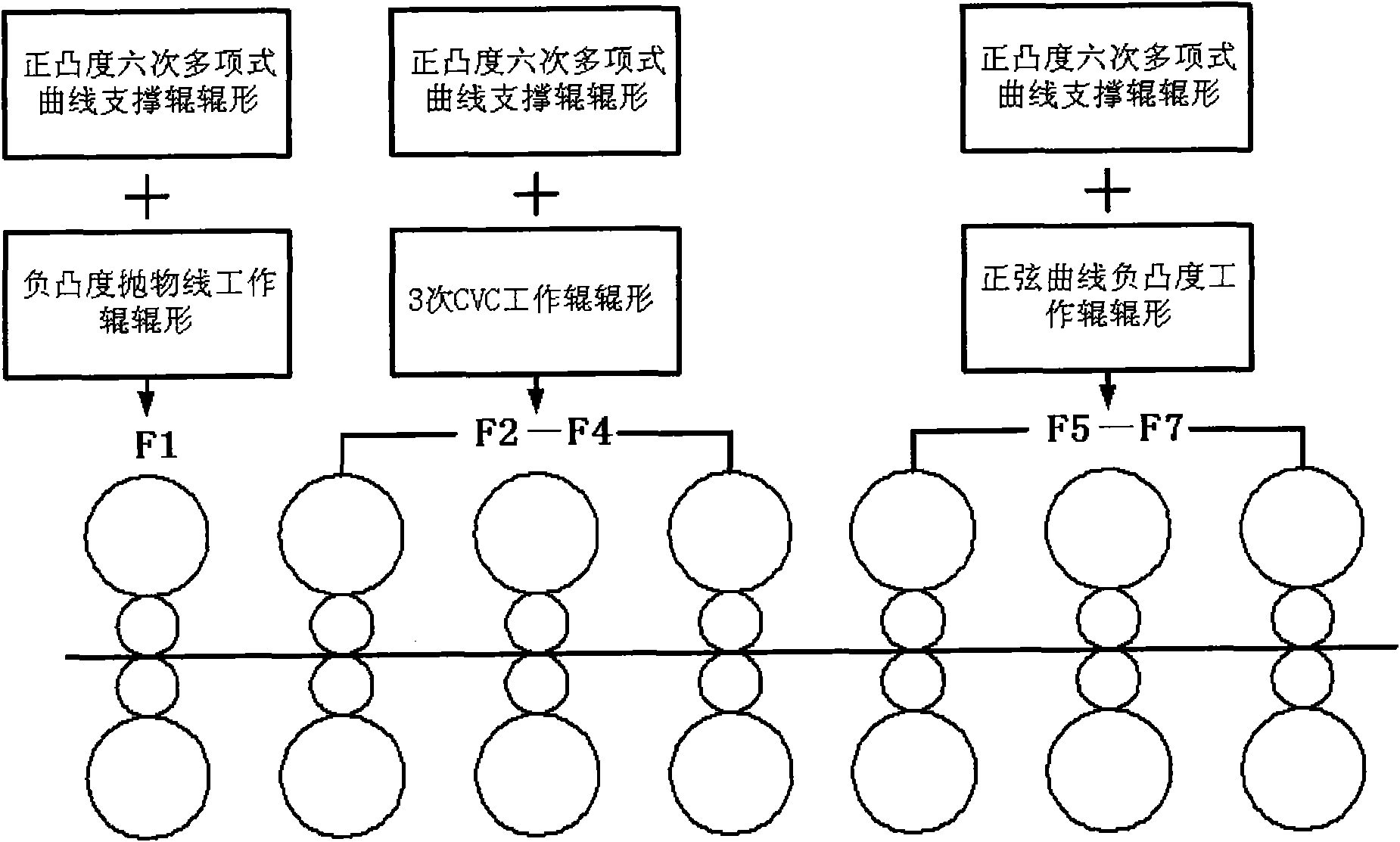

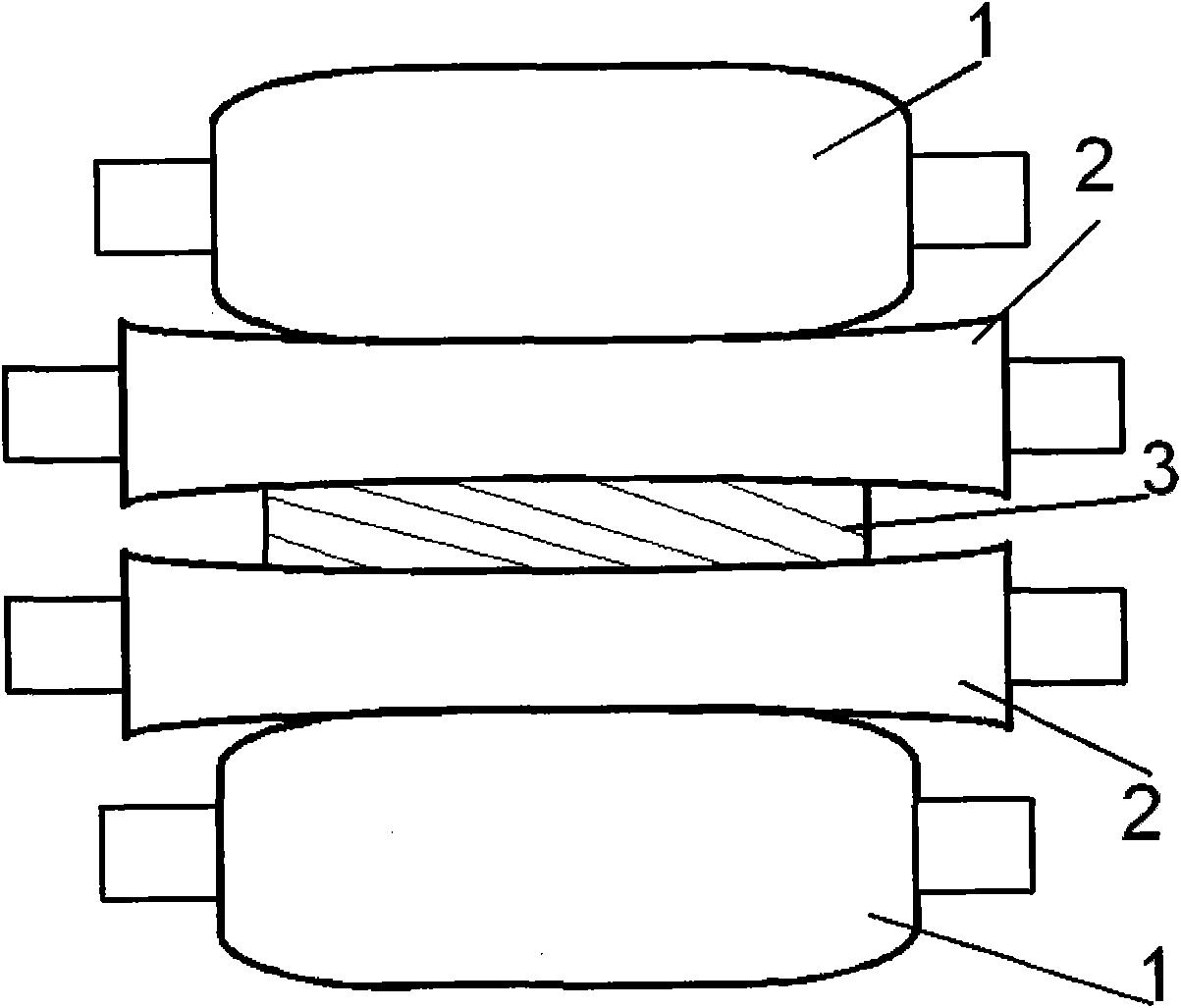

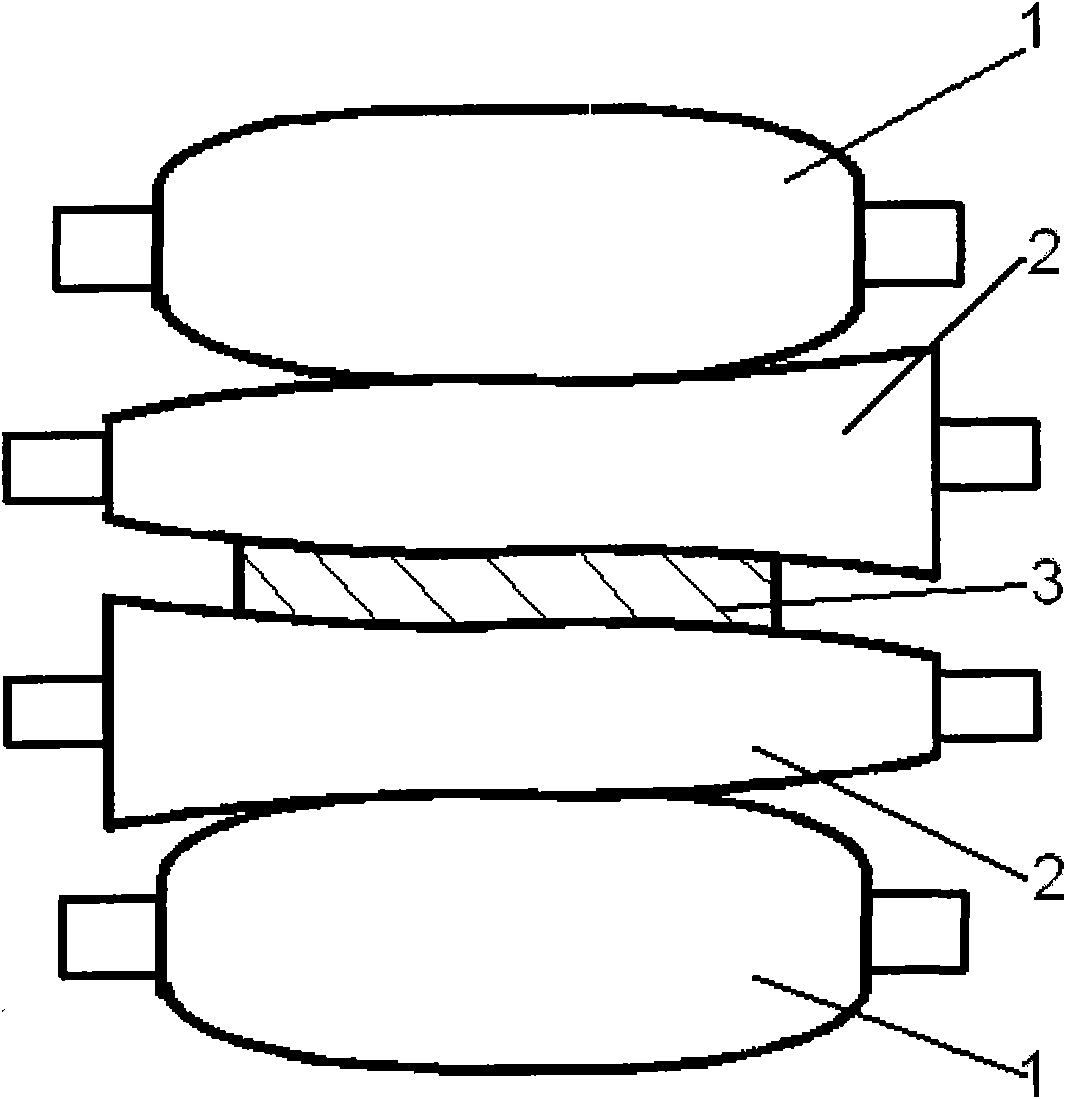

Complete roll forming configuring method for wide flat steel hot rolling finish mill set

ActiveCN101890429AReasonable configurationHigh precisionRollsMetal rolling arrangementsWork rollRoll forming

The invention relates to a complete roll forming configuring method for a wide flat steel hot rolling finish mill set. According to the characteristics that an upstream machine frame controls the convexity and a downstream machine frame controls the flatness in the seven-machine frame and four-roll hot rolling wide flat steel finish mill, a finish rolling inlet machine frame F1 adopts negative convexity working roll forming, a machine frame F2, a machine frame F3 and a machine frame F4 adopt cubic CVC working roll forming, and a machine frame F5, a machine frame F6, and a machine frame F7 adopt negative convexity working roll forming of sine curves and are matched with periodic roll shifting of the working roll with long stroke. The supporting rolls of all the machine frames of the finish mill set adopt positive convexity roll forming of sextic polynomes. The method improves the transverse rigidity of the machine frames of the finish mill, improves regulation and control efficiency of roll bending force of the working roll, and reduces flexibility deformation of the roll. The roll forming configuring method for the finish mill set improves stability of the wide flat steel rolling, reduces the deflection amount of the wide flat steel, prolongs the planned length for rolling and greatly improves profile shape control precision of the wide flat steel.

Owner:SHOUGANG CORPORATION

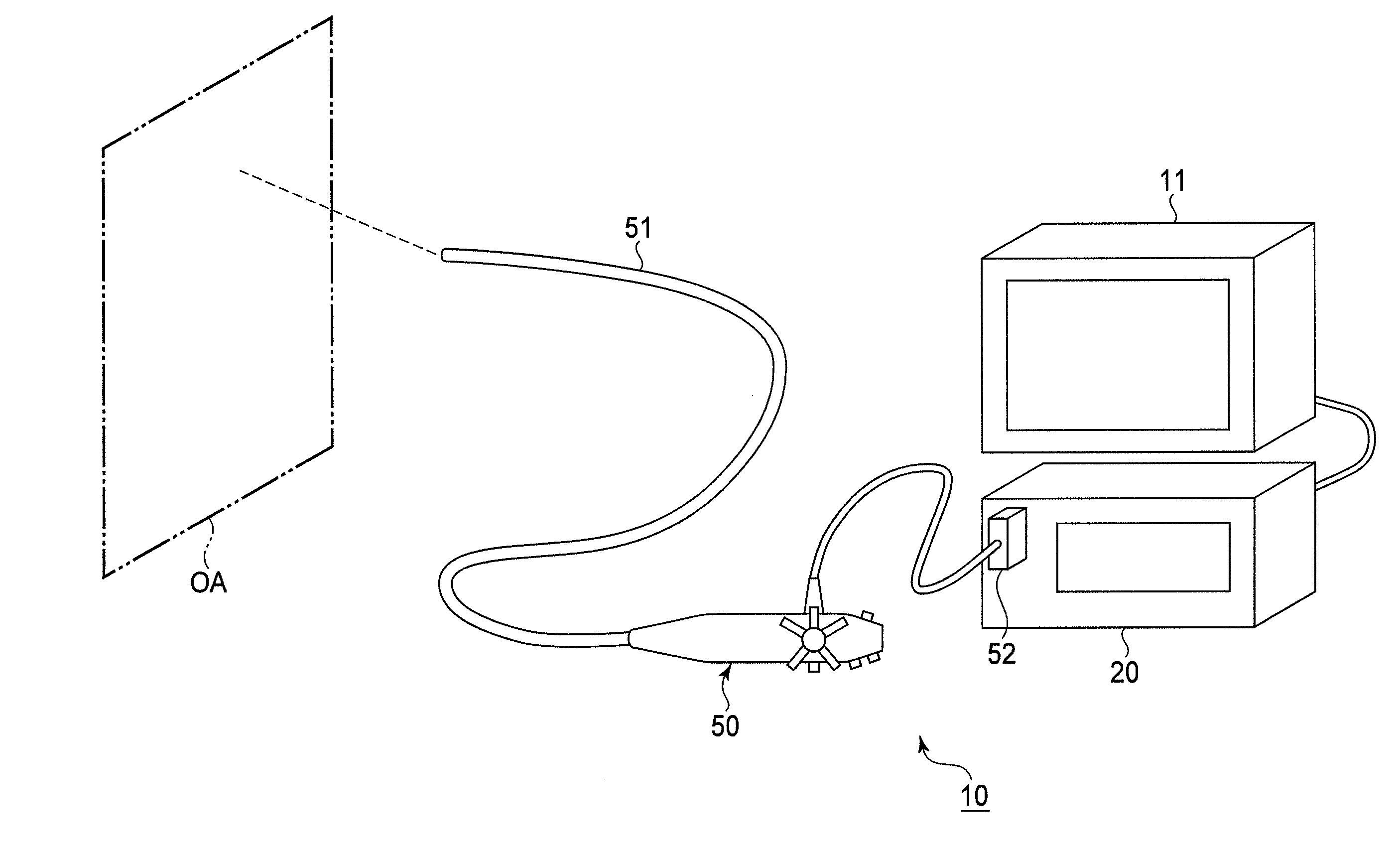

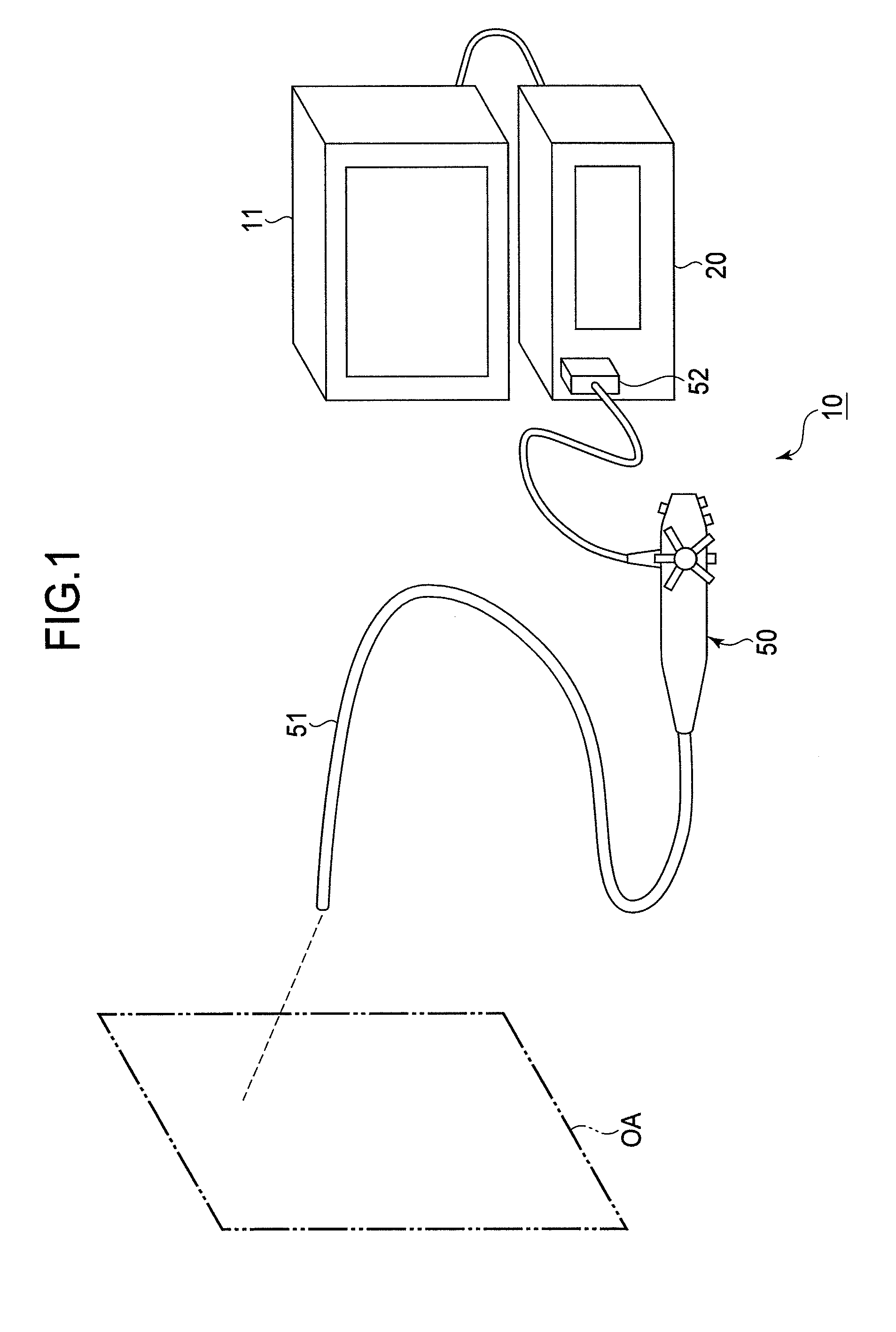

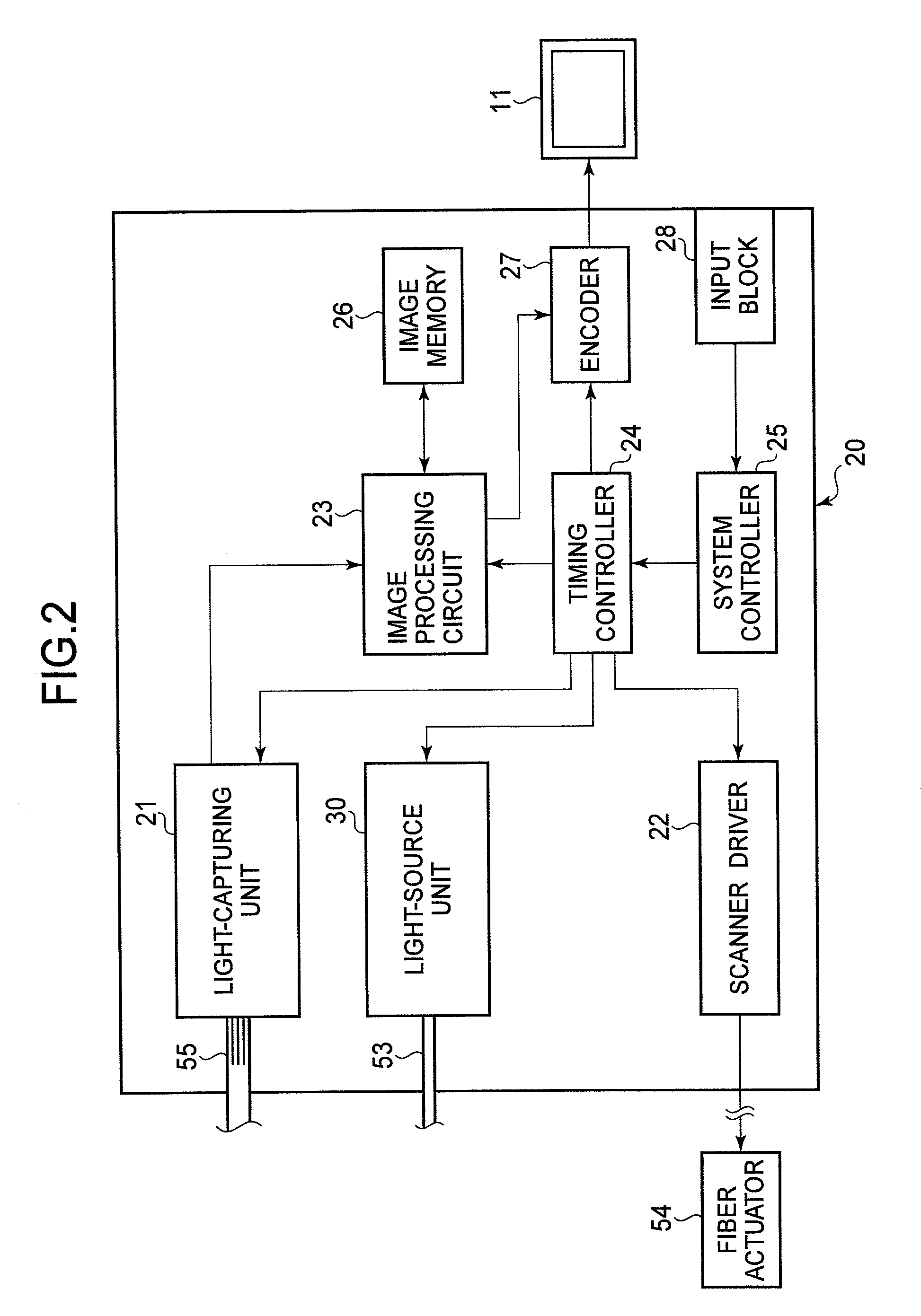

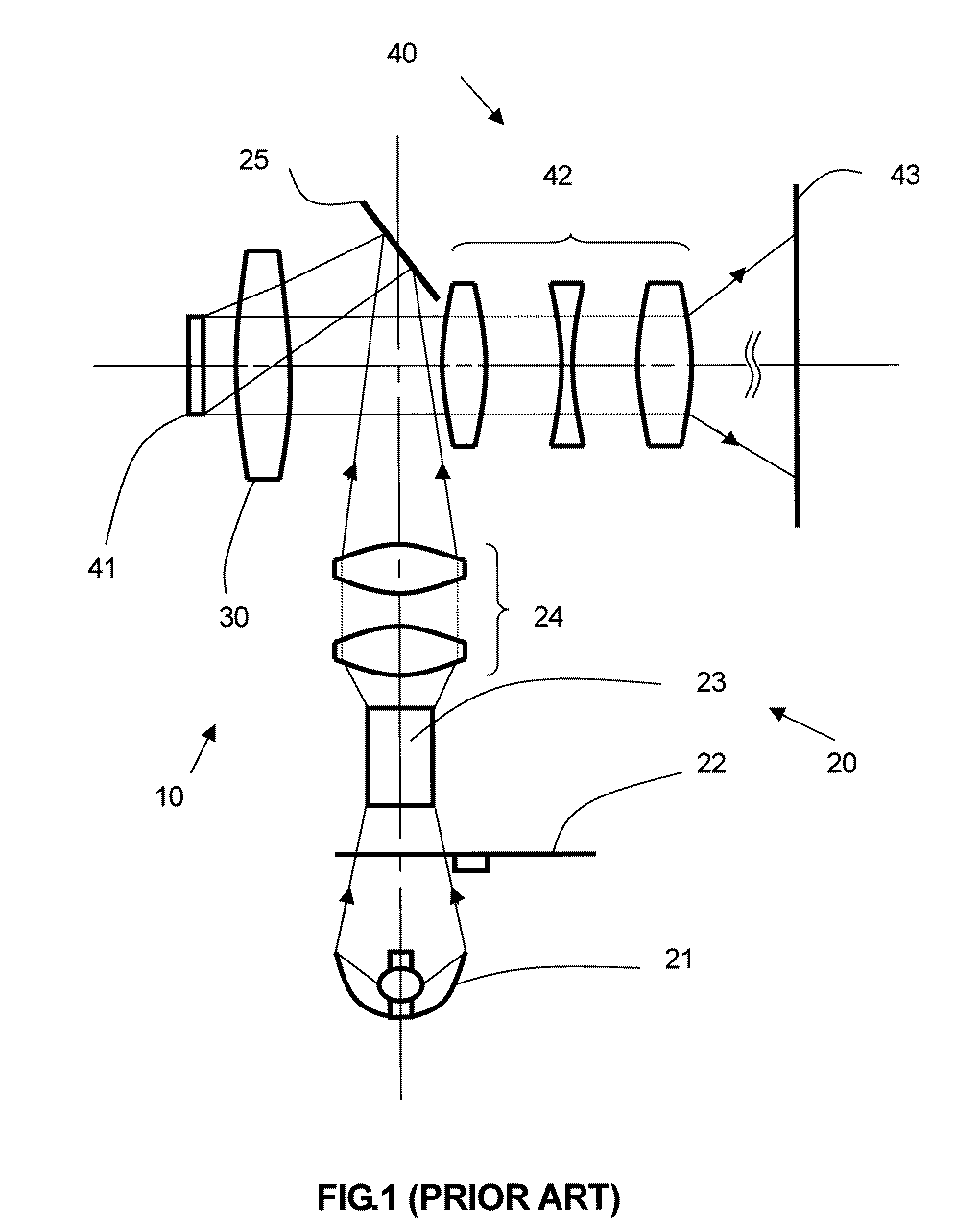

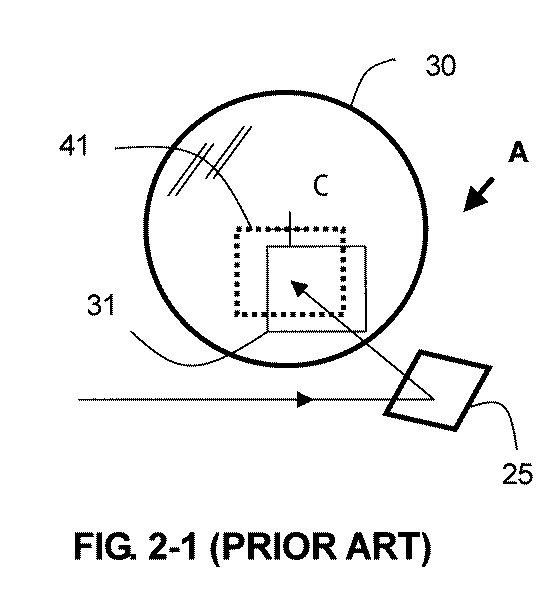

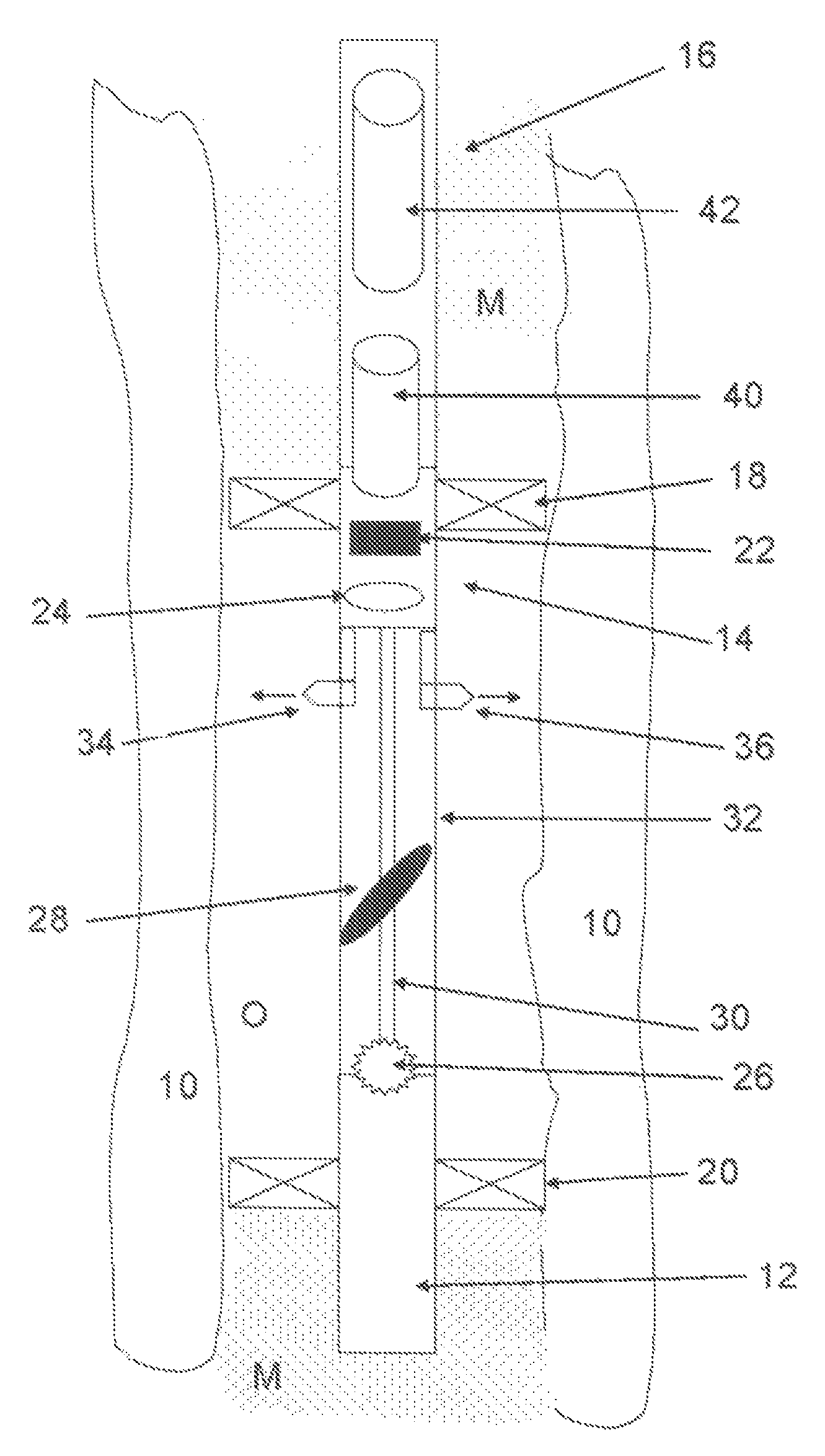

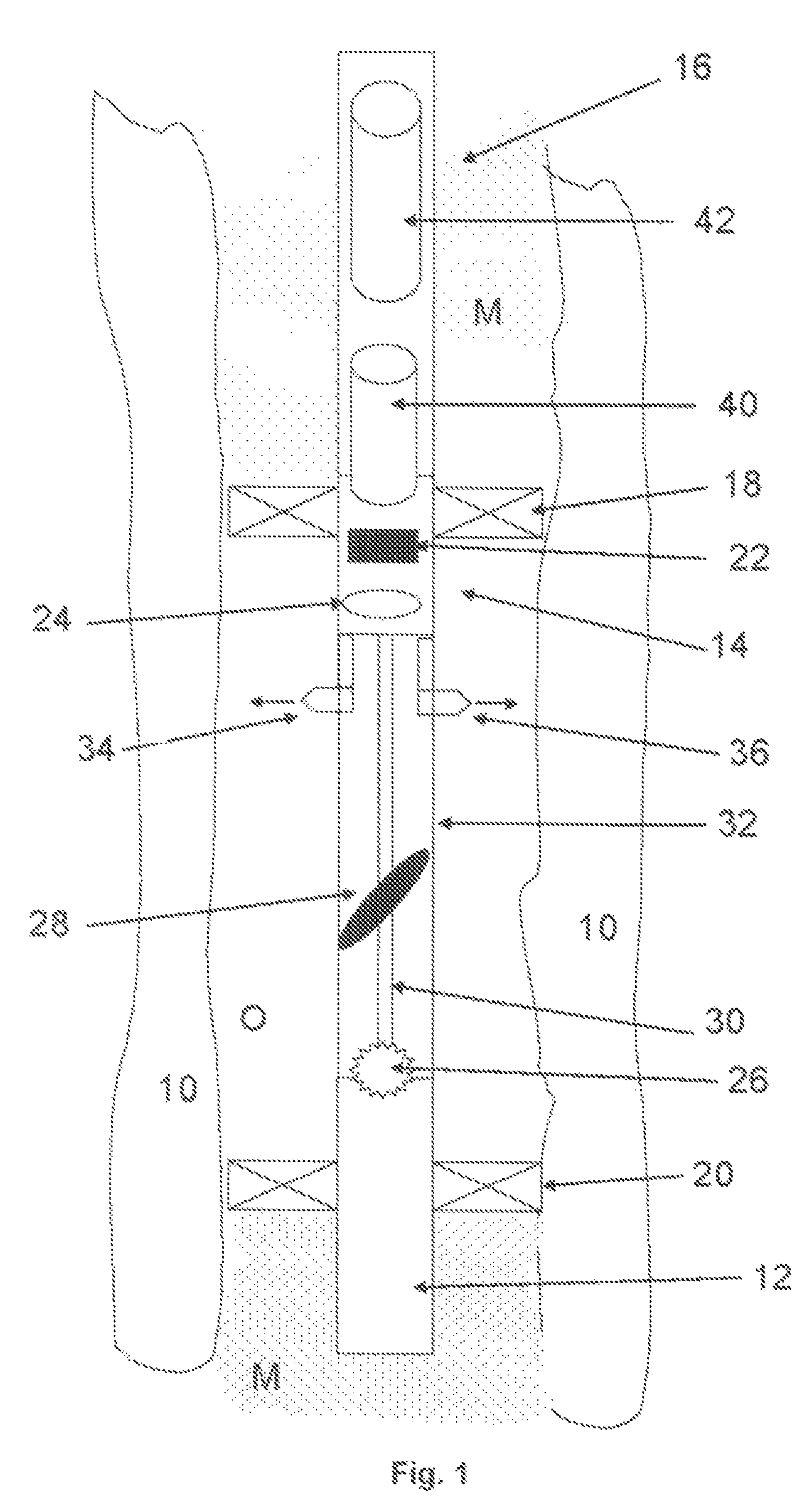

Scanning endoscope, scanning endoscope processor, and scanning endoscope apparatus

InactiveUS20100121146A1Reduce the amount of distortionTelevision system detailsSurgeryActuatorTransmitter

A scanning endoscope comprising a first transmitter, an actuator, a first mirror, and a second mirror, is provided. The first transmitter emits a beam of radiant light from an emission end. The actuator moves the emission end along a spiral course. The first mirror is arranged from the emission end toward a first direction. The first mirror comprises a first reflection surface around the first direction. The first reflection surface reflects the radiant light emitted from the first transmitter. The second mirror is arranged around the first reflection surface. The second mirror comprises a second reflection surface. The second reflection surface reflects the radiant light reflected by the first mirror in a direction that includes the first direction as a positive vector toward any points on the first line.

Owner:HOYA CORP

System and method for transforming fingerprints to improve recognition

InactiveUS20020126883A1Reliable matchReduce the amount of distortionCharacter and pattern recognitionPattern recognitionFinger surface

A system and method reduces the amount of variation in a fingerprint image due to distortion from elastic deformation of the finger surface and projection onto a planar coordinate system. The amount and extent of distortion is estimated, and the process is inverted in a systematic way, so that the amount of distortion is minimized, and the distortion present is consistent, so that different images of the same print will have very similar distortion and thus matching of the fingerprints will be reliable and unaffected by the distortion.

Owner:UNILOC 2017 LLC

Amplifier predistortion and autocalibration method and apparatus

ActiveUS7915954B2Improve performanceReduce the amount of distortionAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceAudio power amplifierPhysics

Methods and apparatus for amplifier AM and PM predistortion and autocalibration. AM and PM amplifier distortion can be corrected using predistortion. The AM and PM distortion characteristics of the amplifier are determined using an autocalibration technique. The amplifier characteristics can be stored in distinct look up tables. Alternatively, the inverse of the amplifier characteristics can be stored in distinct look up tables. Signals that are to be amplified are characterized in polar format having a phase component with a normalized magnitude and a magnitude component. The phase component can be predistorted by applying the inverse of the PM distortion characteristics to the signal. Similarly, the magnitude component can be predistorted by applying the inverse of the AM distortion characteristics to the signal. The predistorted phase component can be amplified using the previously characterized amplifier. The predistorted magnitude component can be used to set the gain of the previously characterized amplifier.

Owner:QUALCOMM INC

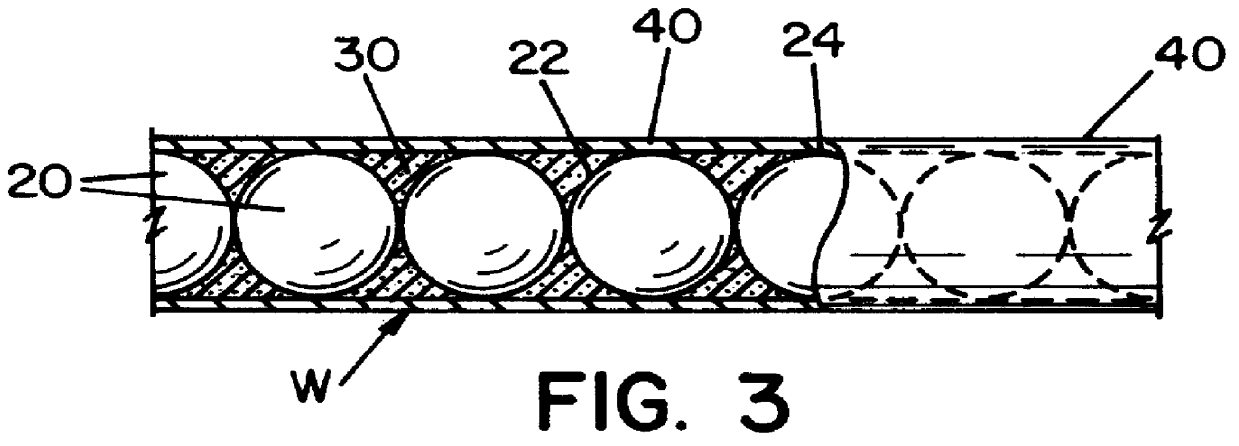

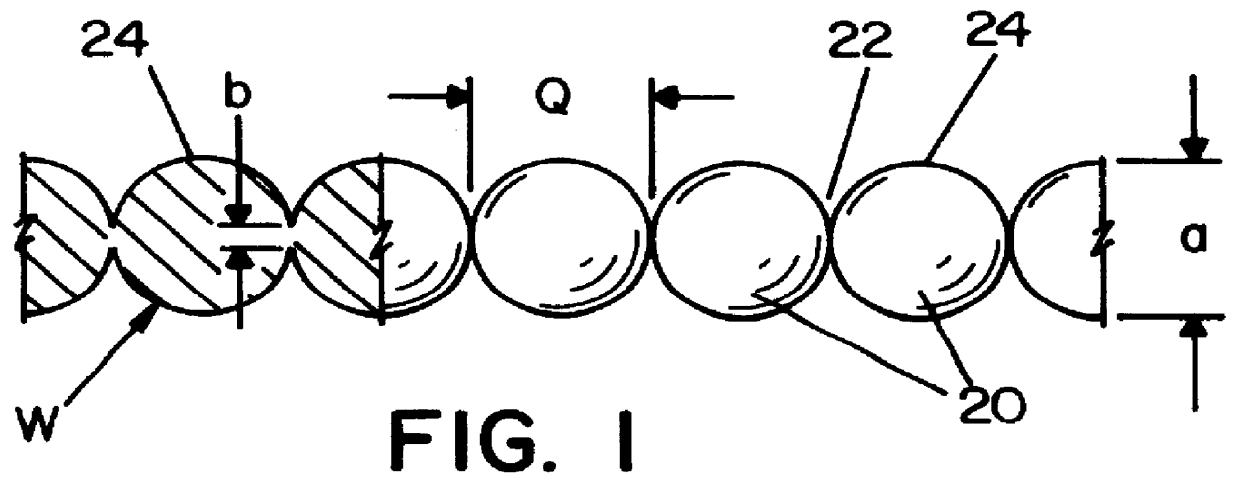

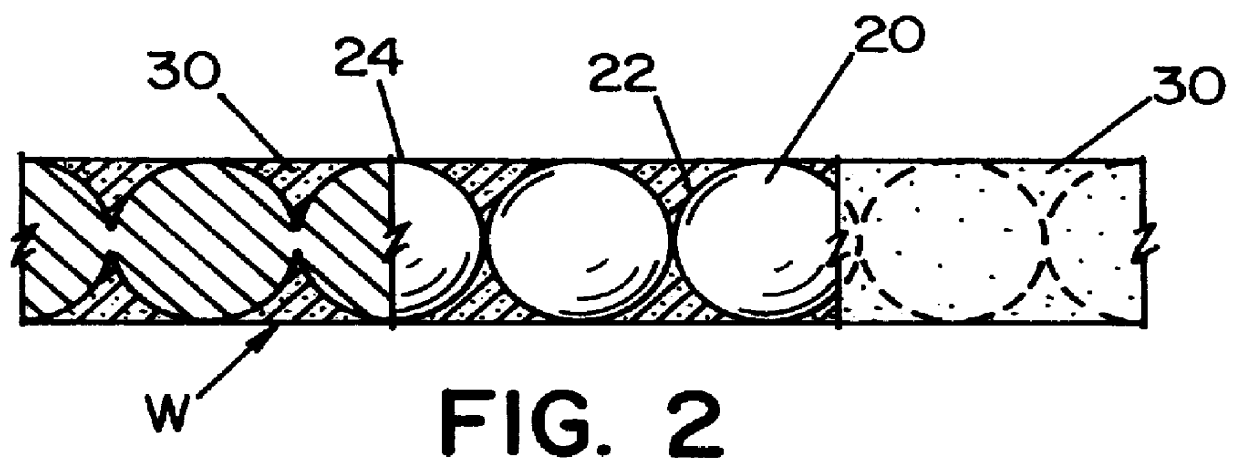

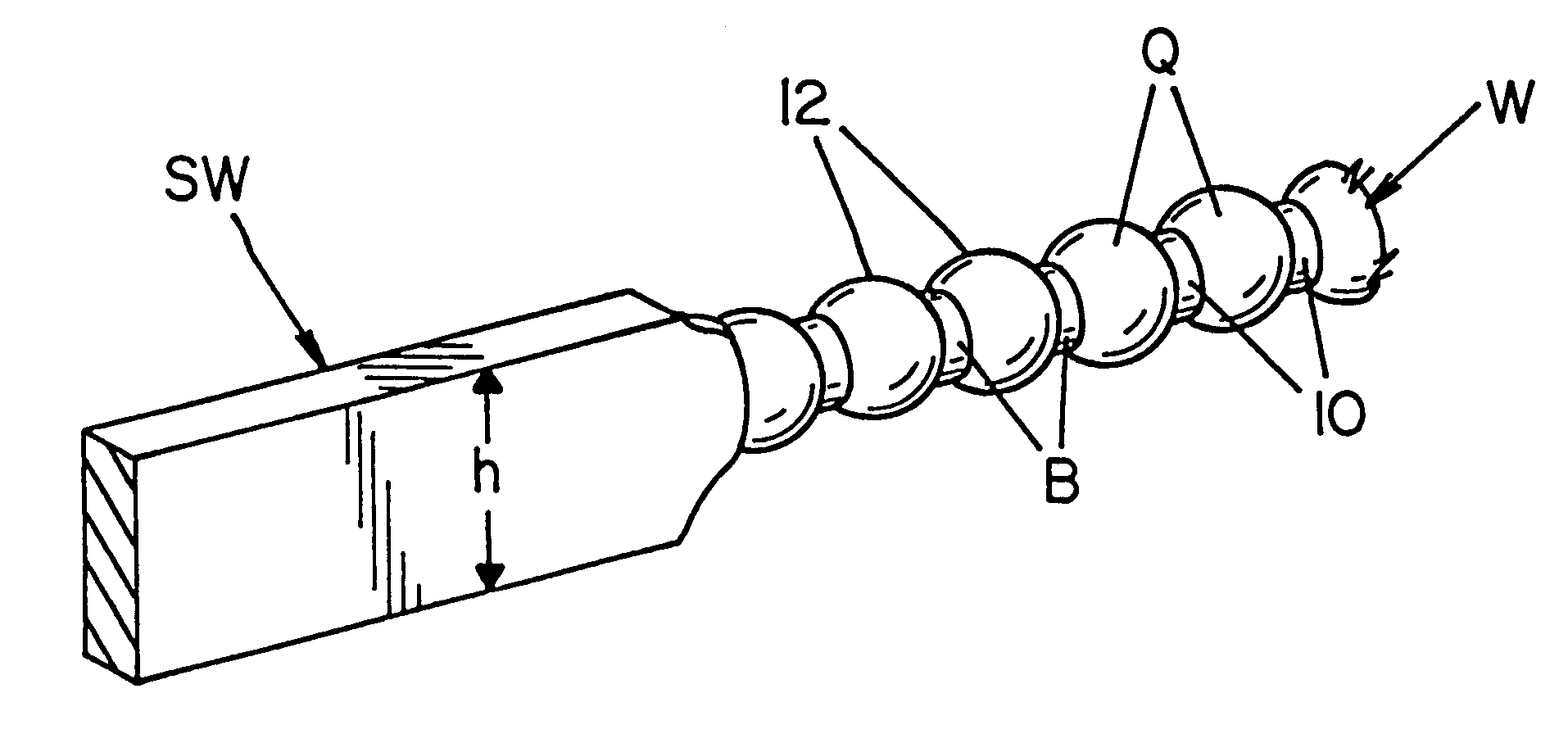

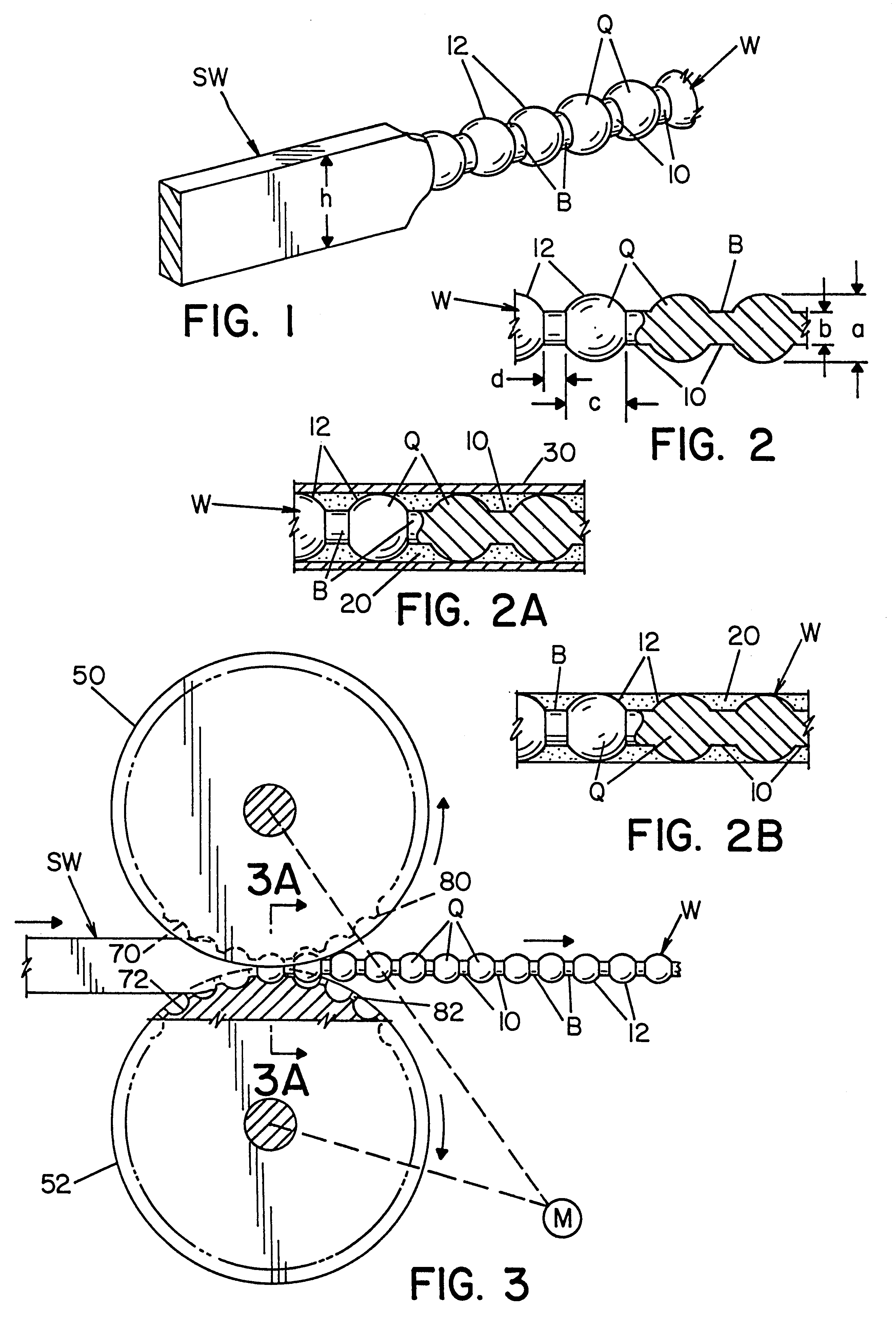

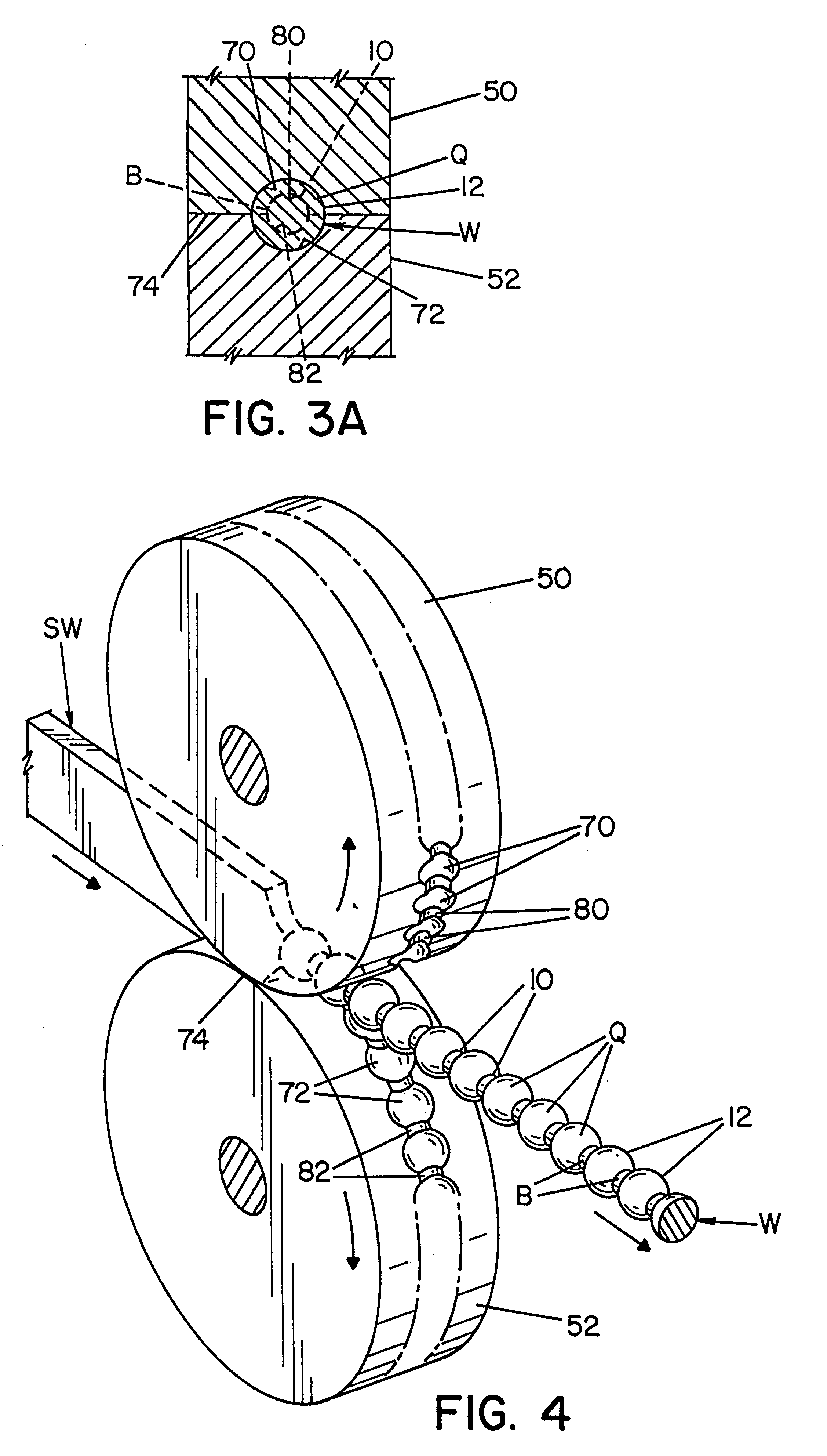

Electrode and method of making same

InactiveUS6137081AReduce the amount requiredImprove the immunityWelding/cutting media/materialsWelding electrode featuresMaterials scienceSolid metal

A welding wire for use in electric arc welding and method of making same, wherein the wire has an effective outer diameter and comprises a length of solid metal formed into a series of distinct segments each having a selected volume and having a narrow region and non-narrow region with the cross sectional area of the solid metal at said non-narrow region being greater than the cross sectional area of the solid metal at the narrow region.

Owner:LINCOLN GLOBAL INC

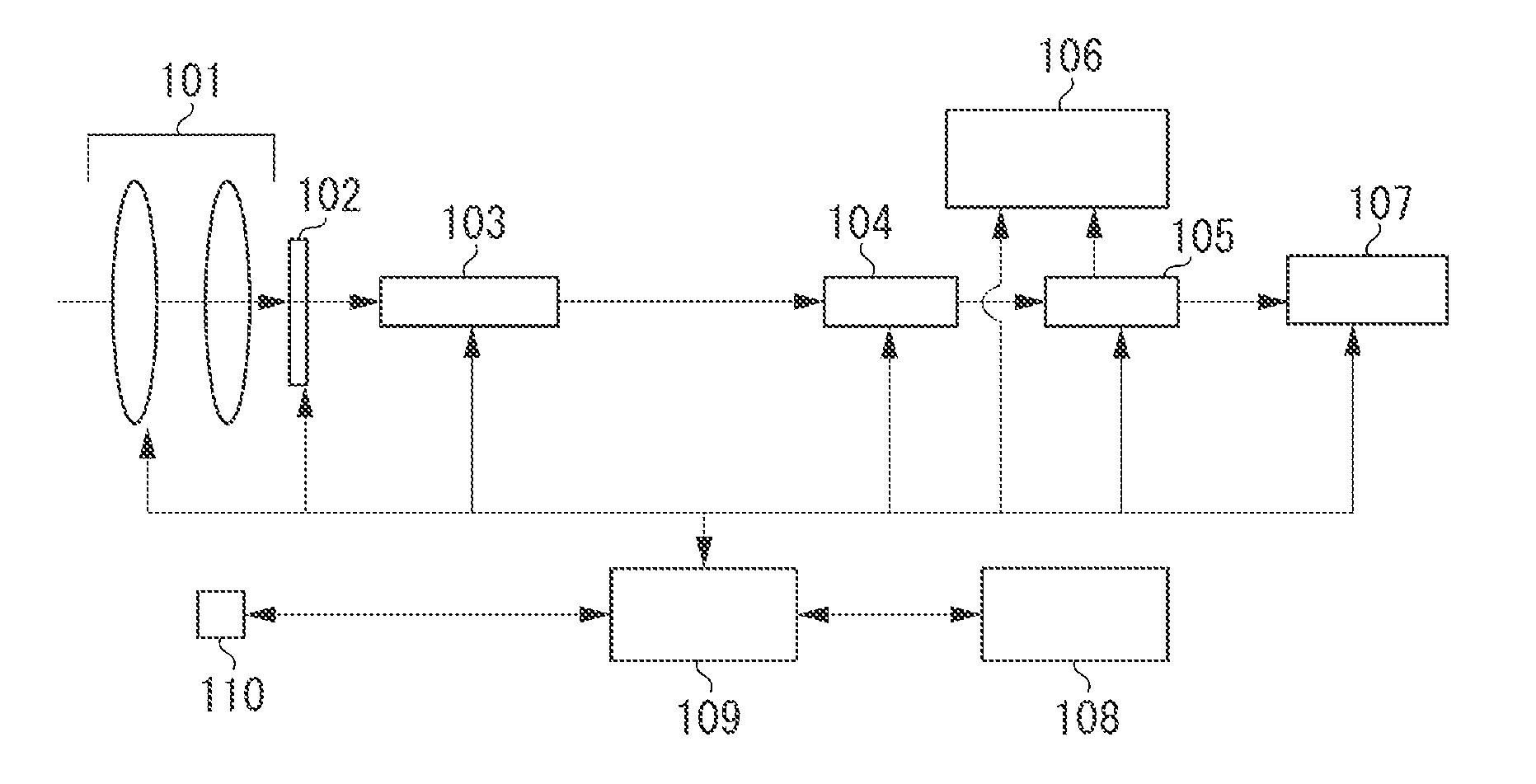

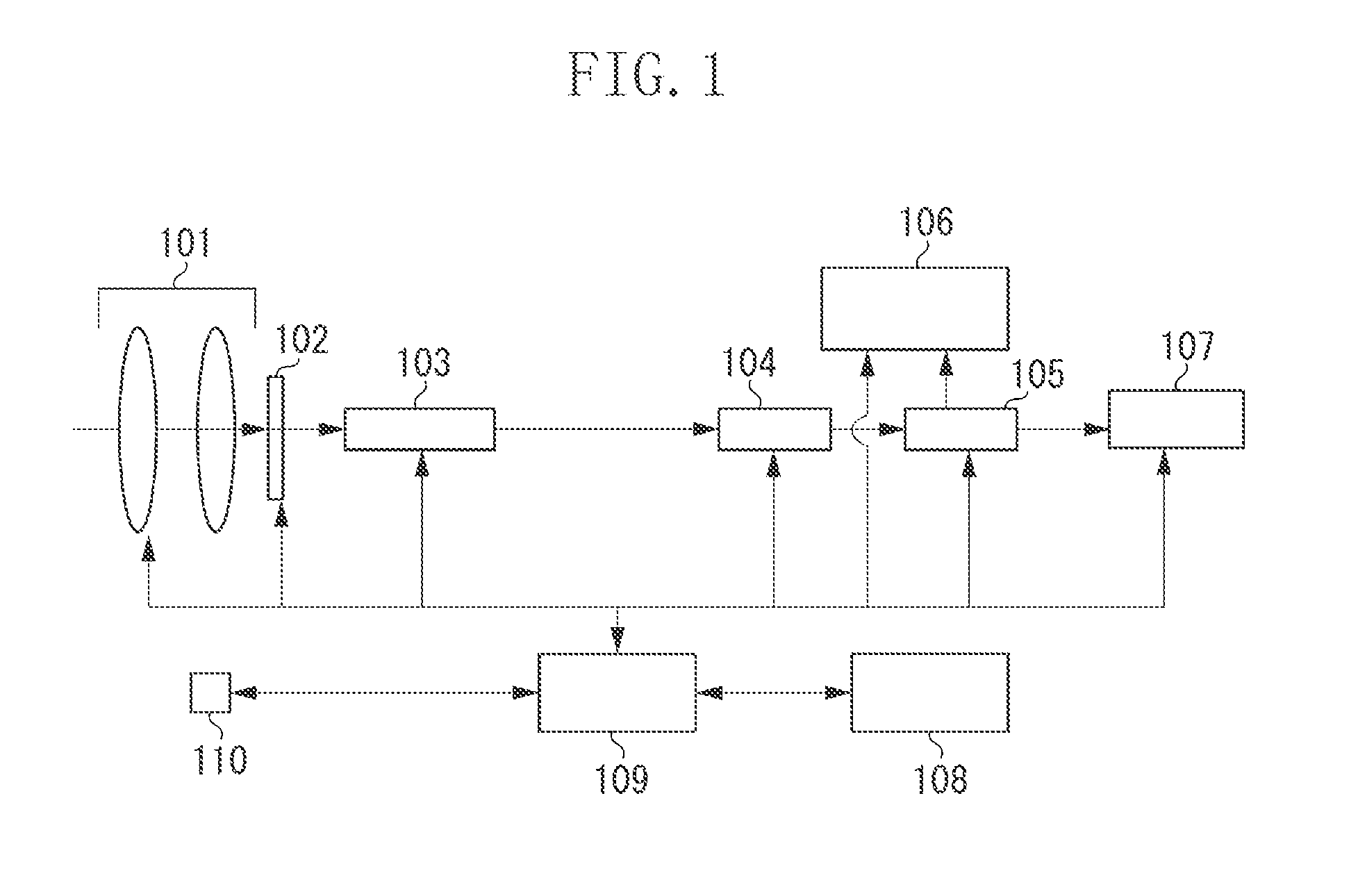

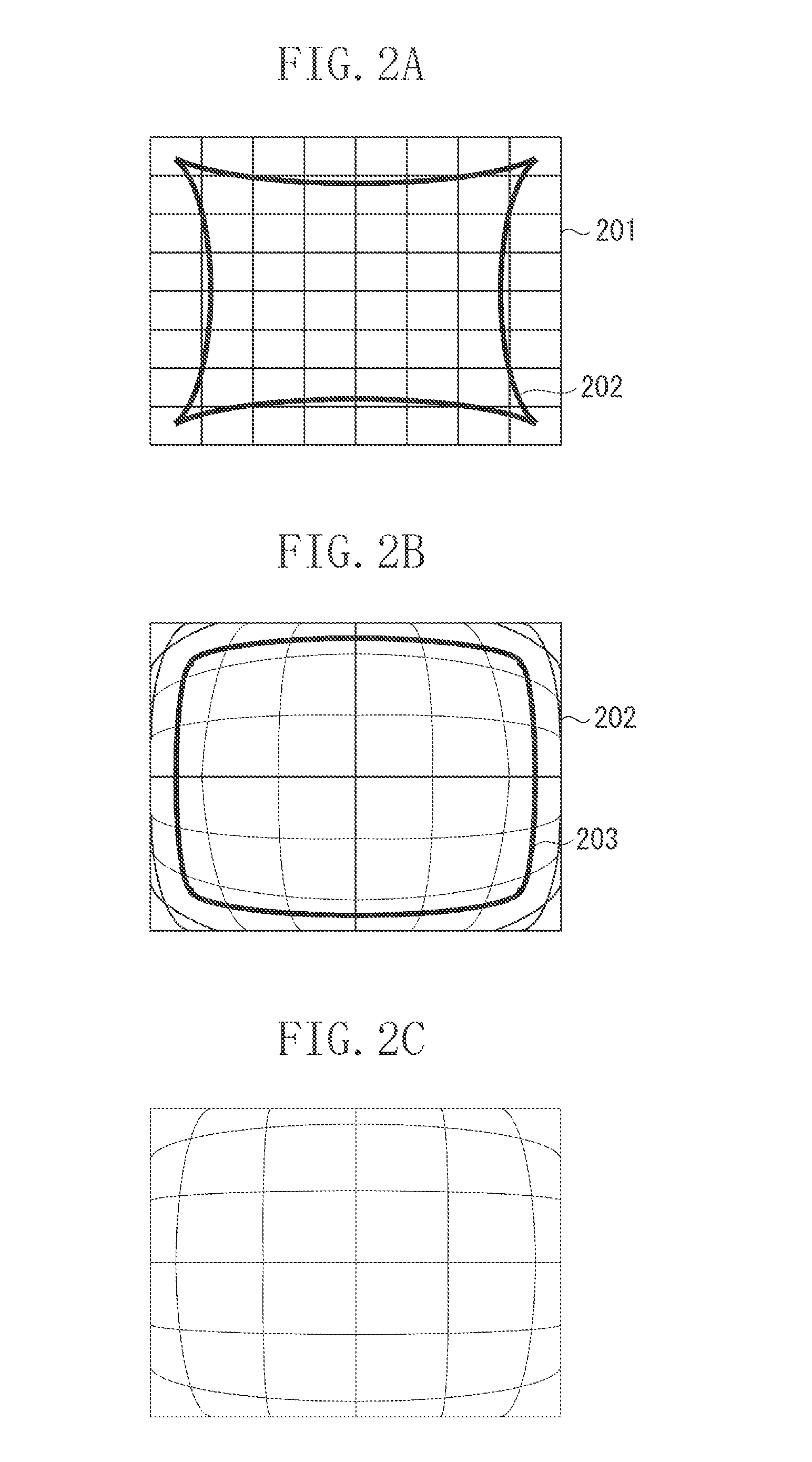

Image processing apparatus and image processing method

ActiveUS20140307111A1Reduce the amount of distortionReduce the amount requiredImage enhancementTelevision system detailsImaging processingDistortion reduction

An image processing apparatus performs distortion aberration correction appropriate for each of the cases where the image processing apparatus clips image data by performing electronic image stabilization and does not clip the image data by performing the electronic image stabilization. The image processing apparatus includes a correction unit configured to perform the distortion aberration correction on image data in which distortion aberration has, and a stabilization unit configured to perform clipping from the image data based on a movement of an imaging unit when the image data has been generated. The correction unit reduces an amount of the distortion aberration correction in a case where the stabilization unit does not clip the image data, as compared to a case where the stabilization unit clips the image data.

Owner:CANON KK

Apparatus and Method for Obtaining Images of a Borehole

ActiveUS20070296810A1Reduce the amount of distortionEasy to explainSurveyConstructionsLight sourceEnvironmental geology

Apparatus for obtaining images of the wall of a borehole, comprises a tool body; a light source mounted on the tool body and arranged to illuminate the borehole wall; a camera mounted in the tool body; and a mirror moveably mounted on the tool body and spaced axially from the camera and arranged to reflect an image of the borehole wall at the camera, wherein the movement of the mirror allows images of different parts of the borehole wall to be reflected at the camera.

Owner:SCHLUMBERGER TECH CORP

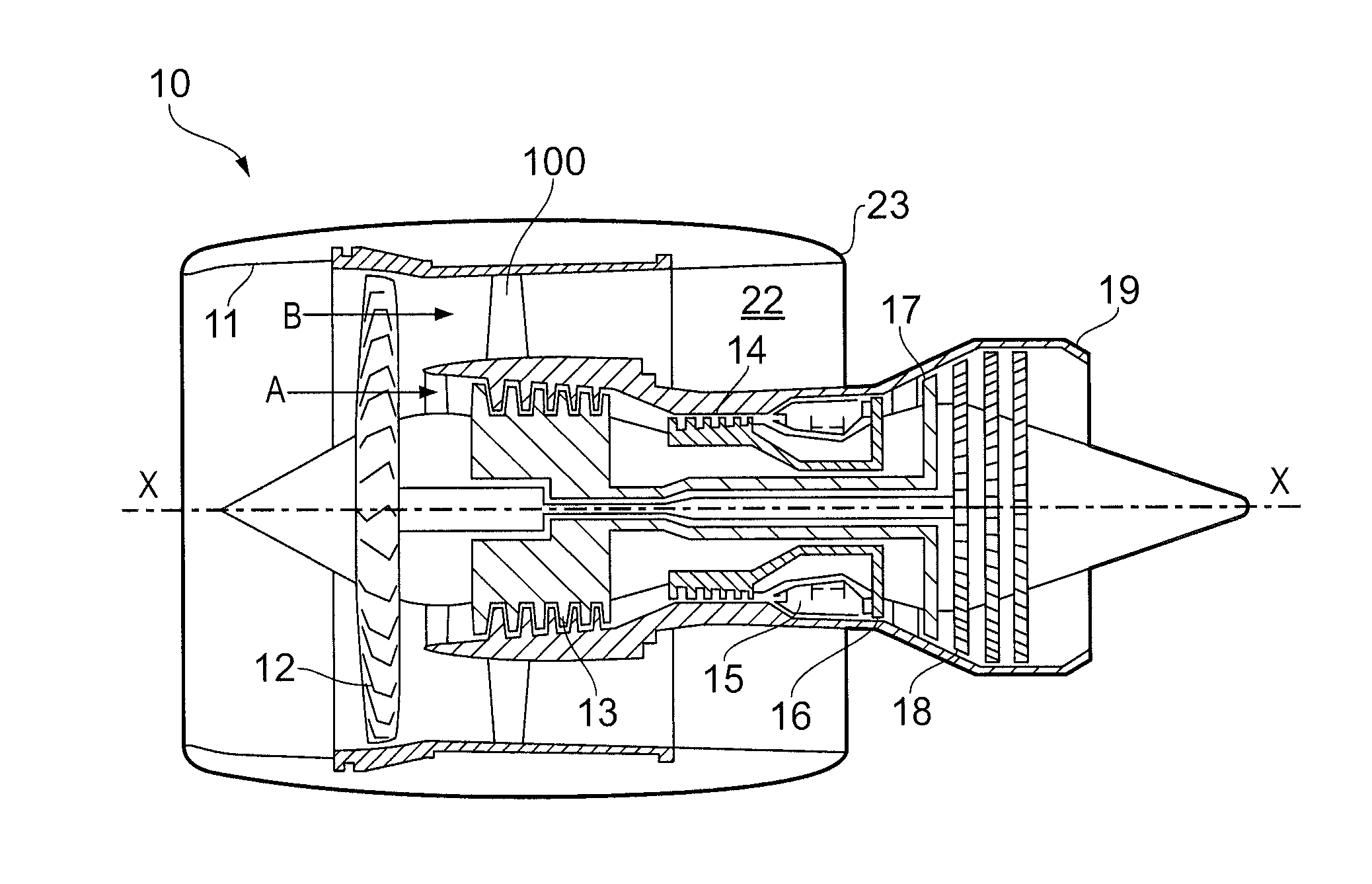

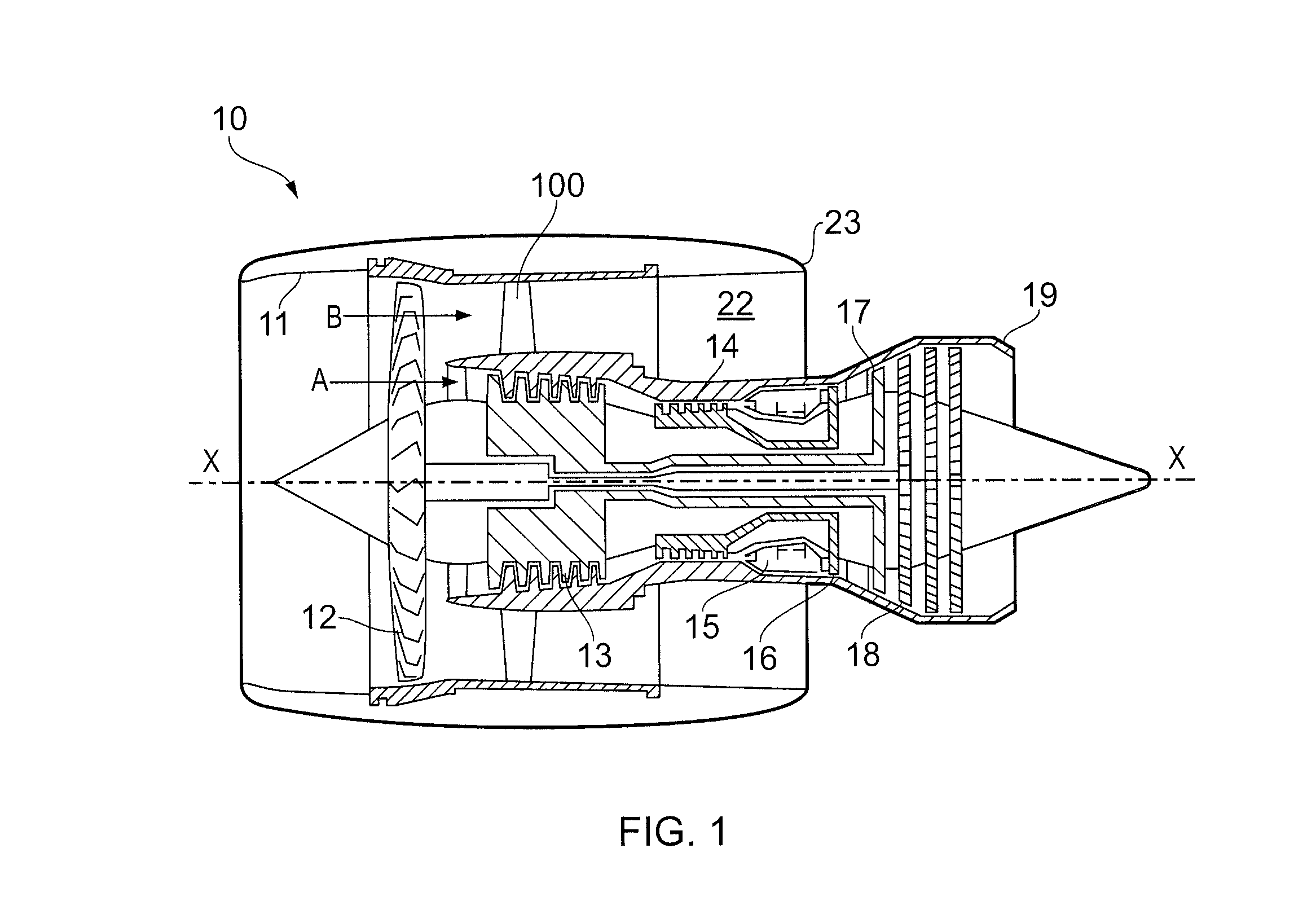

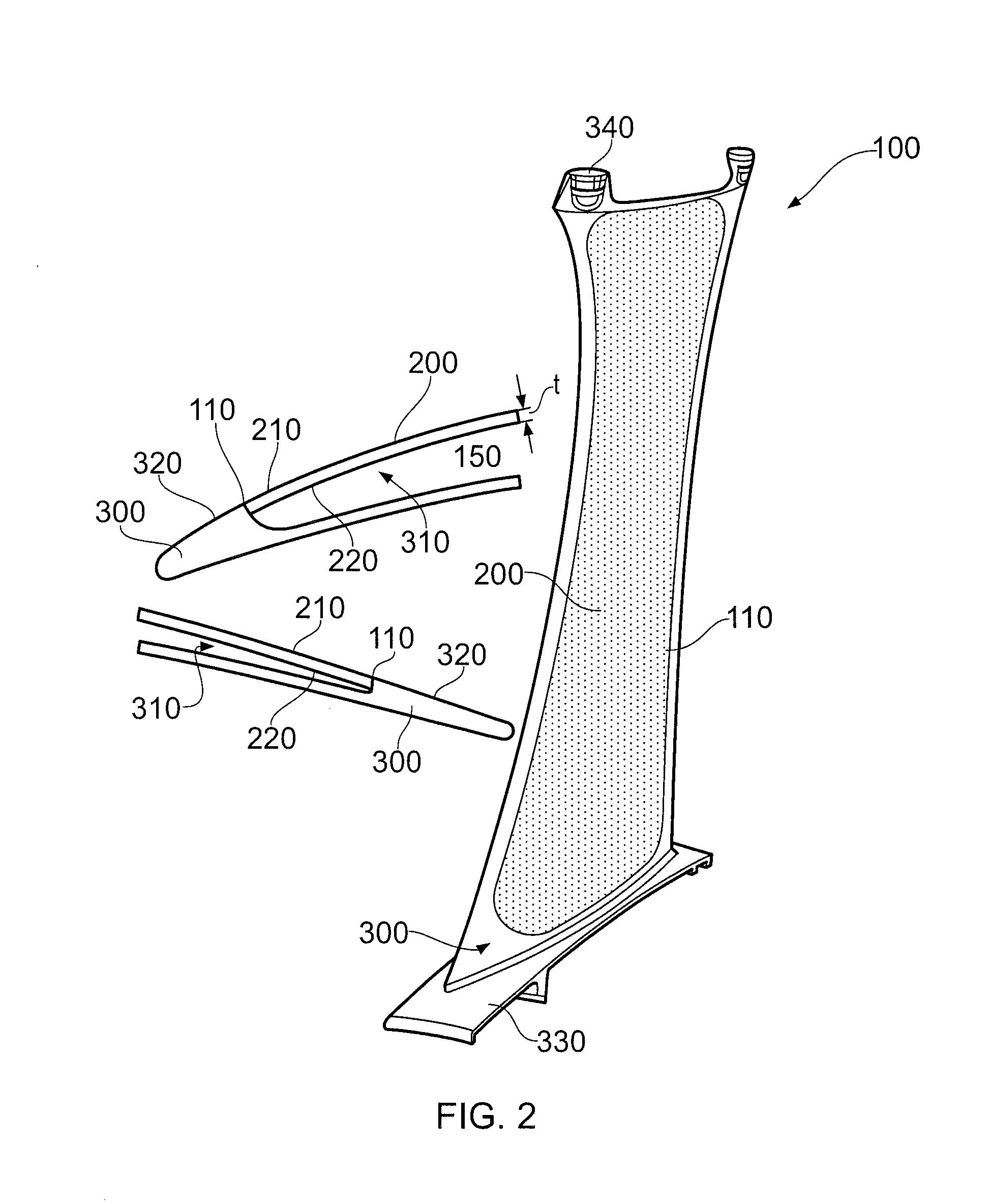

Manufacture of hollow aerofoil

ActiveUS20140271227A1Surface damageEliminate) spatterBlade accessoriesMetal-working apparatusEngineeringGas turbines

A method of manufacturing a hollow aerofoil component for a gas turbine engine includes using a capping panel to cover a pocket in a pocketed aerofoil body. During manufacture, the outer surface of the capping panel is located relative to the pocketed aerofoil body. This ensures that the outer surface of the capping panel is located as accurately as possible. This means that the capping panel can be made to be as thin as possible, which in turn reduces weight and material wastage. Once the capping panel has been located in position, it may be welded to the aerofoil body in order to produce the hollow aerofoil component.

Owner:ROLLS ROYCE PLC

Electrode and method of making same

InactiveUS6180920B1Improve the immunityReduce the amount requiredWelding/cutting media/materialsWelding electrode featuresMaterials scienceSolid metal

A welding wire for use in electric arc welding and method of making same, wherein the wire has an effective outer diameter and comprises a length of solid metal formed into a series of distinct segments each having a selected volume and having an indented and non-indented region with the cross sectional area of the solid metal at said non-indented region being greater than the cross sectional area of the solid metal at the indented region.

Owner:LINCOLN GLOBAL INC

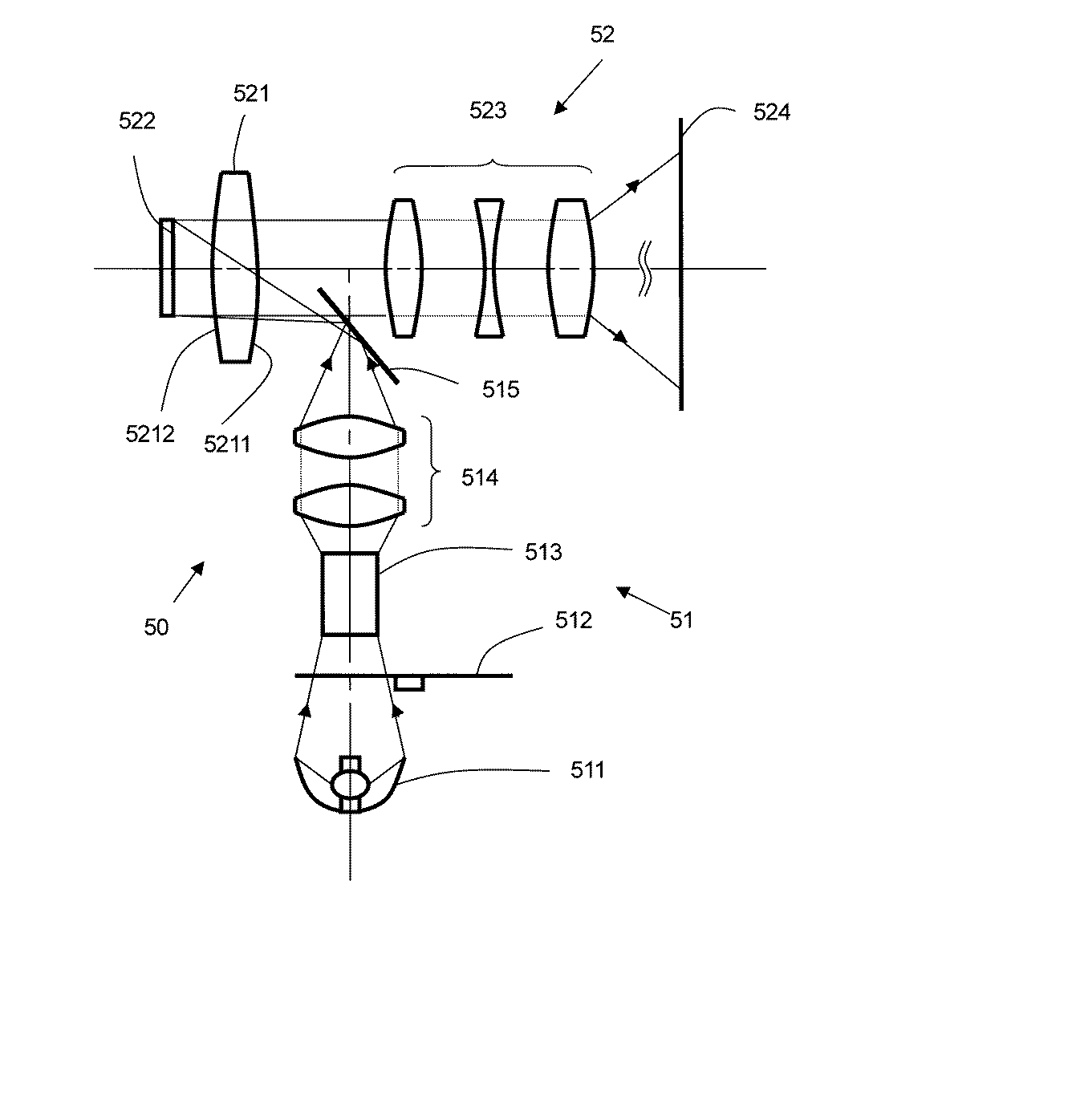

An illumination method and apparatus for projection system

InactiveUS20030107711A1Reduce lossesImprove efficiencyTelevision system detailsProjectorsCamera lensLight spot

Abstract of Disclosure The present invention mainly includes an illumination system and an imaging system, wherein the illumination system generates an incident light beam, and, by means of reflection with a reflecting lens, projects it from above in front of the field lens, into the first surface of the field lens fronting the projection lens set, then through the field lens, and onto the light valve of the imaging system, wherein the geometric center of the light valve is located at the underside of the optical axis of the second surface adjacent to the corresponding side of the first surface of the field lens, allowing the geometric center of the transmissive area created by the projection of the light beam into the field lens to be much closer to the optical axis of the field lens than the geometric center of the light valve is, thus ensuring that the transmissive area is contained within the optimized area on the field lens, while reducing the amount of distortion generated in the light spot by the light beam coming in through the field lens, wherein the said light beam is then further reflected, by means of reflection with the array of micro-mirrors poised on the light valve to differentiate the angles of reflection at ON-state or OFF-state, through the field lens, then into or away from the projection lens set, and is selectively projected onto the screen, so as to improve illumination efficiency, while lowering the cost and reducing the volume.

Owner:CORETRONIC

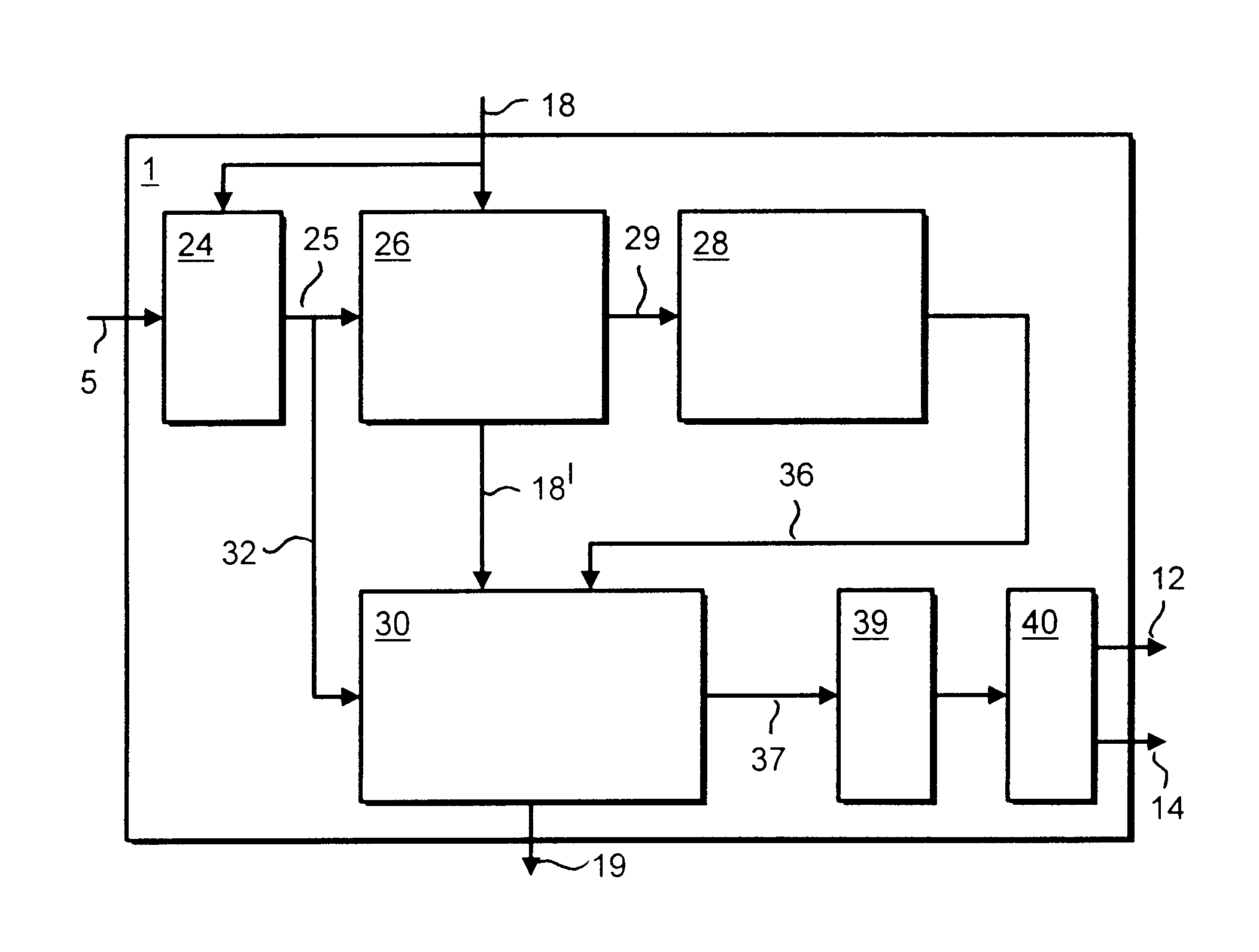

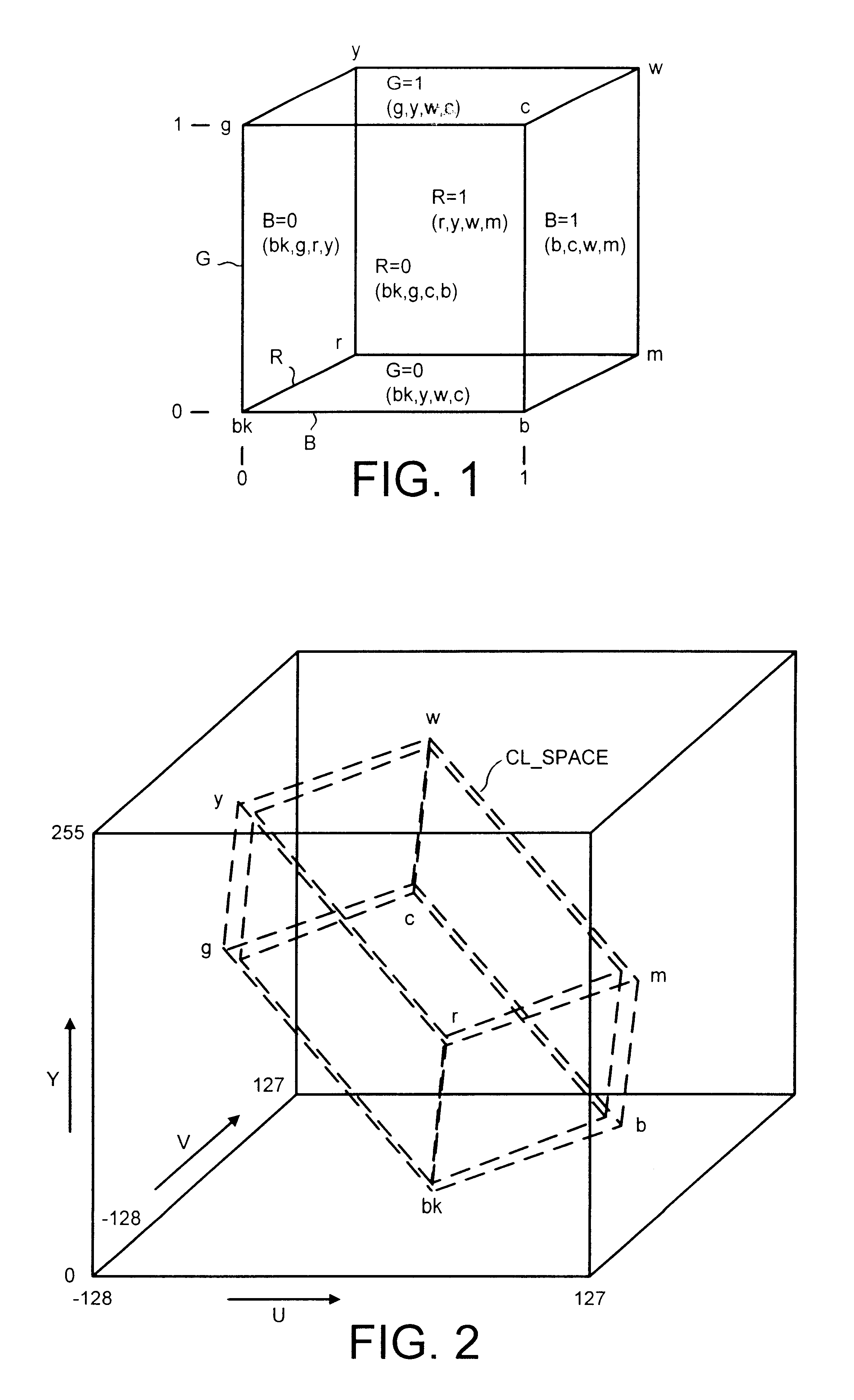

Method of processing signals and apparatus for signal processing

InactiveUS6798902B1Reduce the amount of distortionReduce the amplitudeColor signal processing circuitsPicture reproducers using cathode ray tubesPattern recognitionImaging processing

An image processing apparatus operates to process input signal samples representative of at least part of a colour video image to produce legal colour signal samples representative of a legal colour version of the image. The apparatus comprises an adjustment factor generator, which operates to generate a plurality of adjustment factors which when combined with the input signal samples have an effect of converting illegal colour pixels of the colour image into legal colour pixels, an adjustment factor softener, which operates to soften the adjustment factors whereby distortion in the legal colour video image produced when the adjustment factors are combined with the input signal samples is substantially reduced, and a colour legaliser coupled to the softener, which operates to combine the softened adjustment factors with the input signal samples to produce the legalised colour signal samples. The image processing apparatus may operate with input signal samples in the form having red, green or blue components, or in a form having luminance and chrominance components, or indeed in other forms.

Owner:SONY UK LTD

Energy distributing side structure for vehicle side impact occupant protection

InactiveUS20110227368A1Reduce the amount of distortionLess energyVehicle seatsUnderstructuresEngineeringSide impact

An energy distributing side structure for a vehicle is disclosed. The side structure includes a B-pillar having a wide base and an internal reinforcing tube, a rocker having an internal bulkhead, a rear rocker, and at least one cross-member extending vehicle-inward from the rocker. The cross-member may extend to the vehicle tunnel and may be attached to a tunnel brace. One or more additional cross-members may be provided which also extend vehicle-inward from the rocker and define secondary load paths. By this arrangement loading is transferred to the floor and cross-members of the vehicle during a lateral impact event.

Owner:FORD GLOBAL TECH LLC

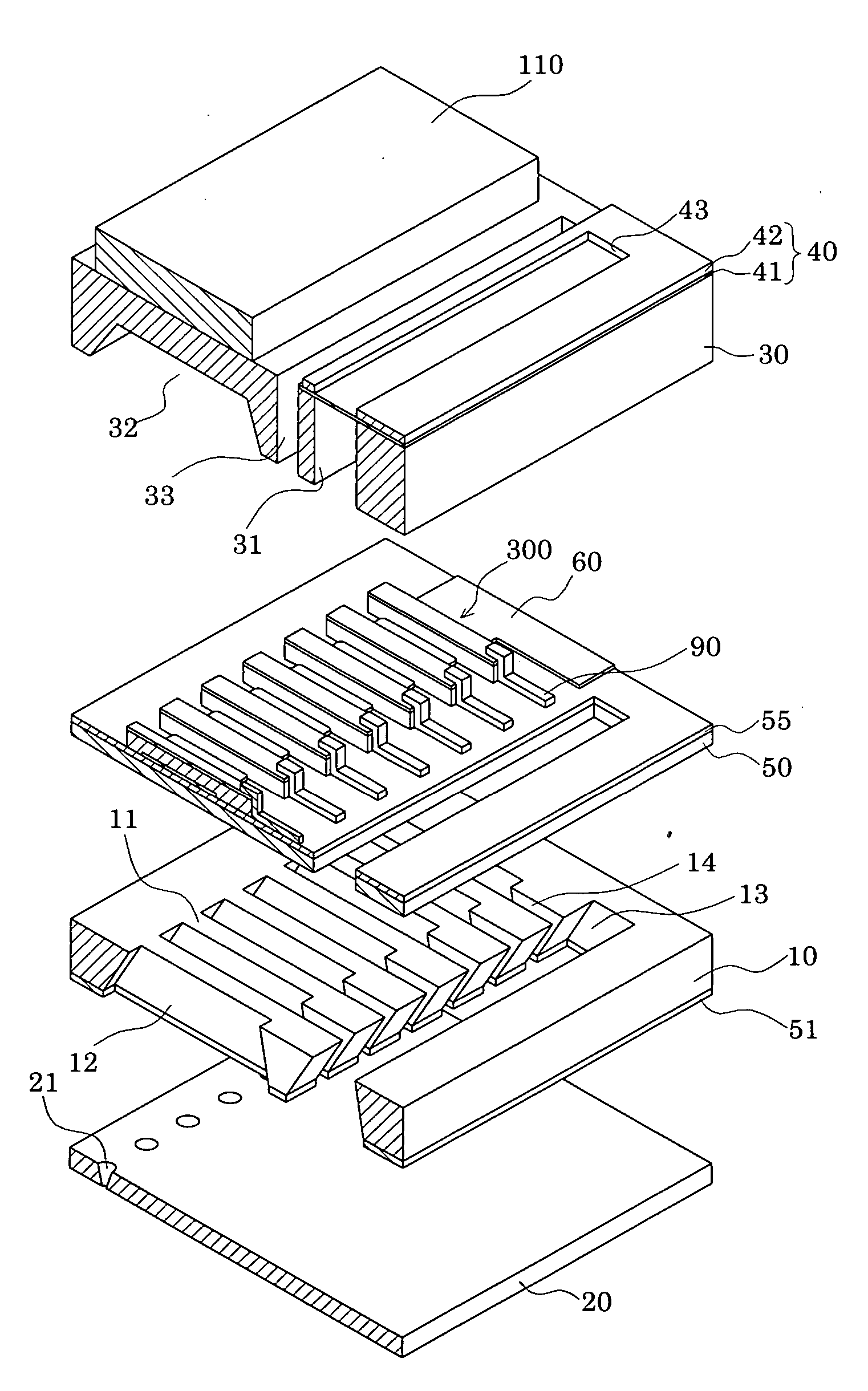

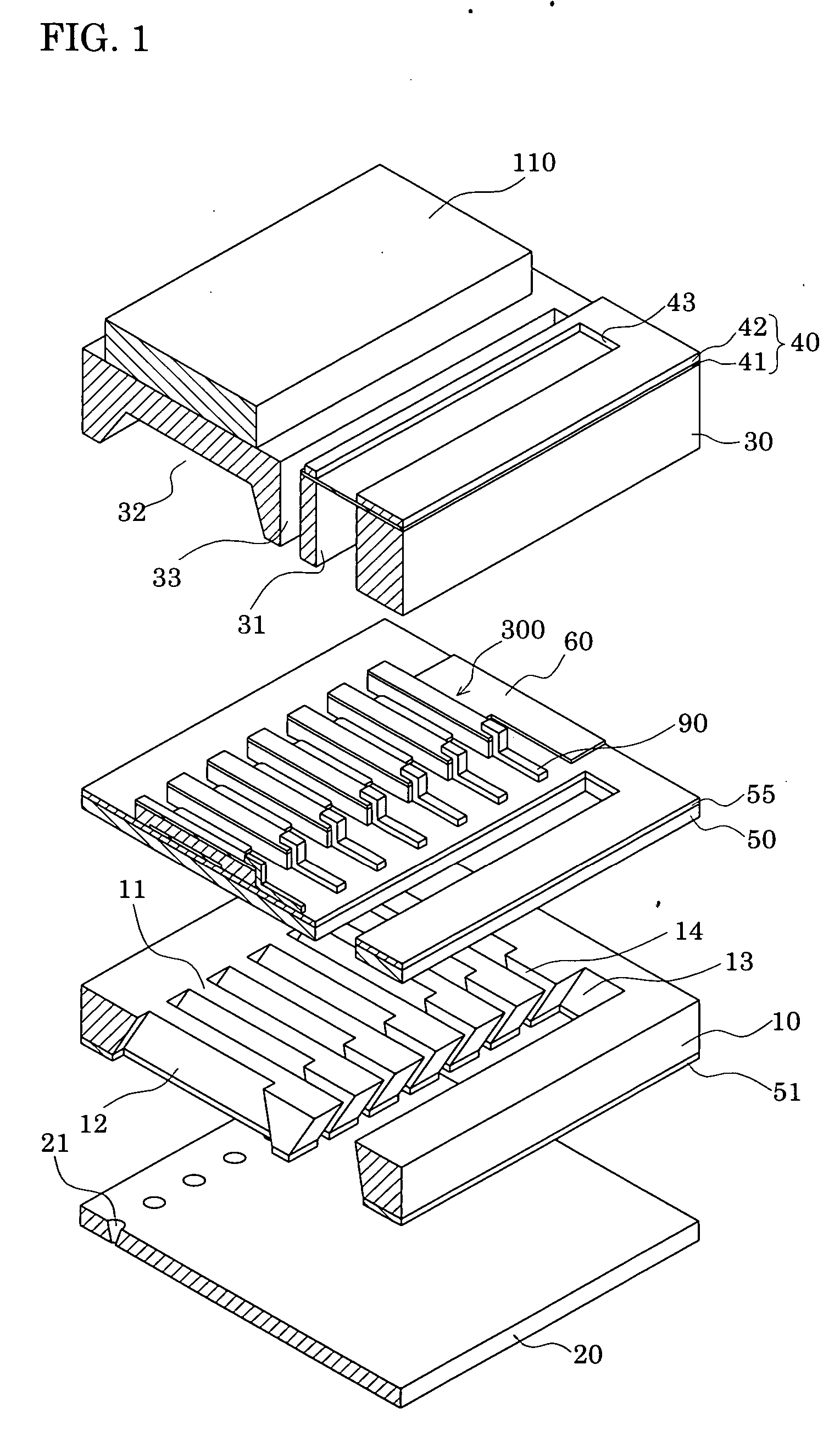

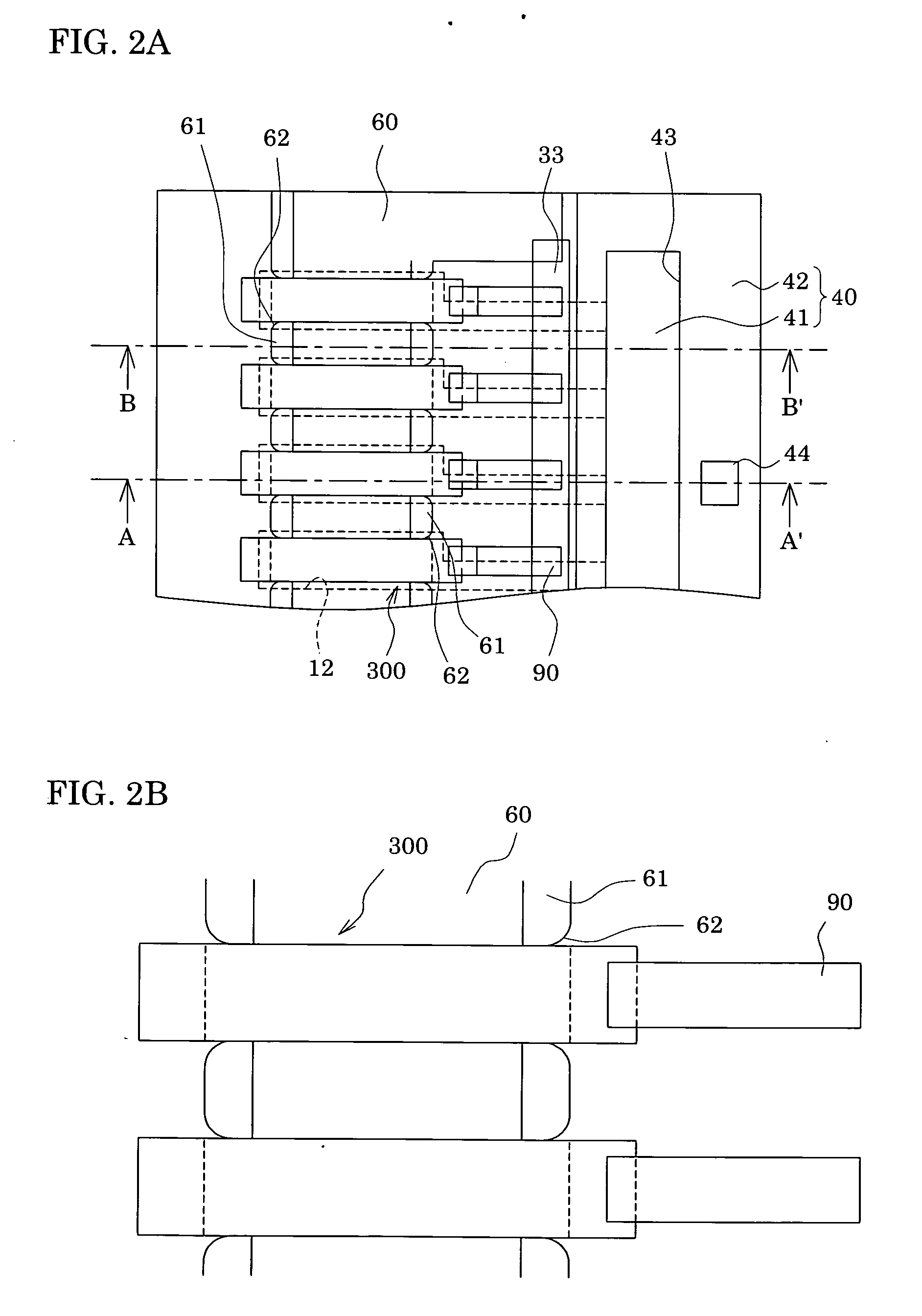

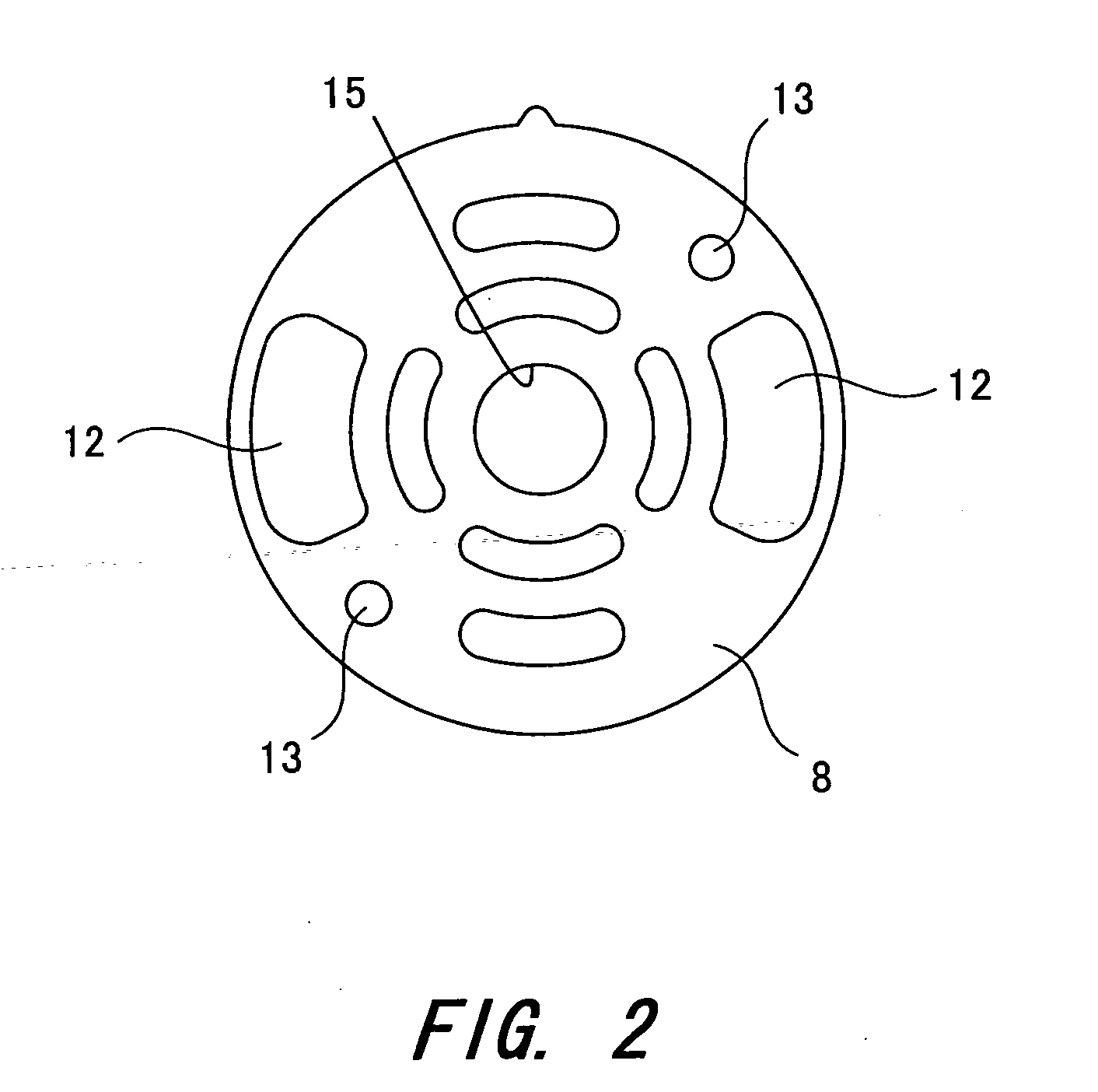

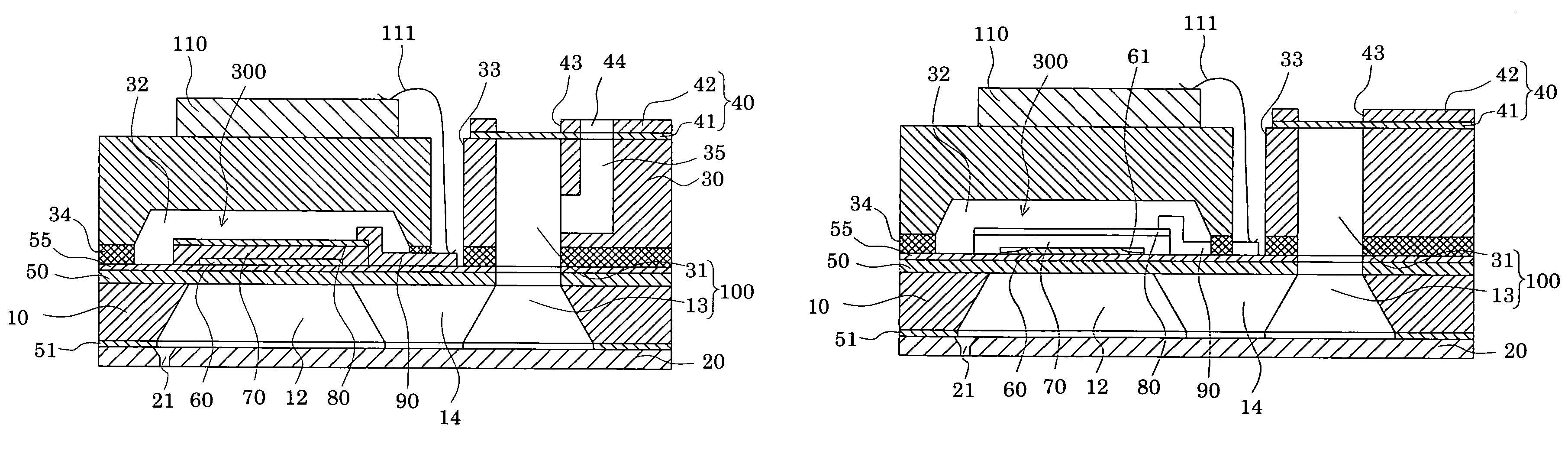

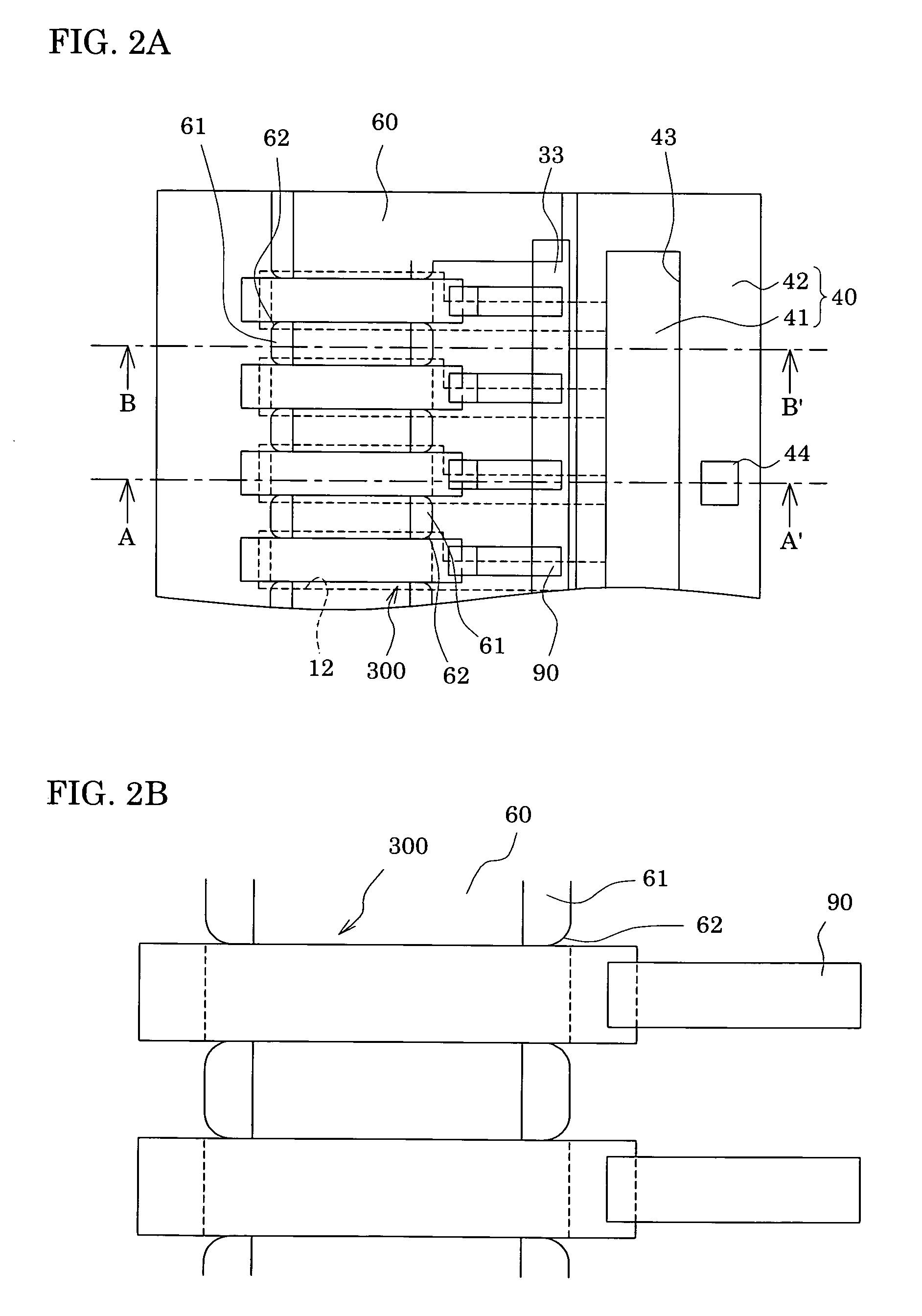

Liquid-jet head, method of manufacturing the same, and liquid-jet apparatus

ActiveUS20060290748A1Reduce electric field strengthReduce the amount of distortionPrintingLiquid jetHigh density

Provided are, a liquid-jet head capable of enhancing durability thereof when it is driven, and of making an arrangement density of piezoelectric elements high-density, a method of manufacturing the same, and a liquid-jet apparatus. The liquid-jet head includes: piezoelectric elements which are provided on a passage-forming substrate with a vibration plate interposed therebetween, and are respectively configured of a lower electrode, piezoelectric layers and upper electrodes, the passage-forming substrate having pressure generating chambers, which communicate with nozzle orifices for ejecting liquid droplets, formed therein, in which, while the lower electrode is continuously provided across plural piezoelectric elements, near-end portions of the lower electrode at least in regions of the lower electrode between adjacent ones of the piezoelectric elements are formed into thin-thickness portions thinner than portions of the lower electrode in other regions of the lower electrode.

Owner:SEIKO EPSON CORP

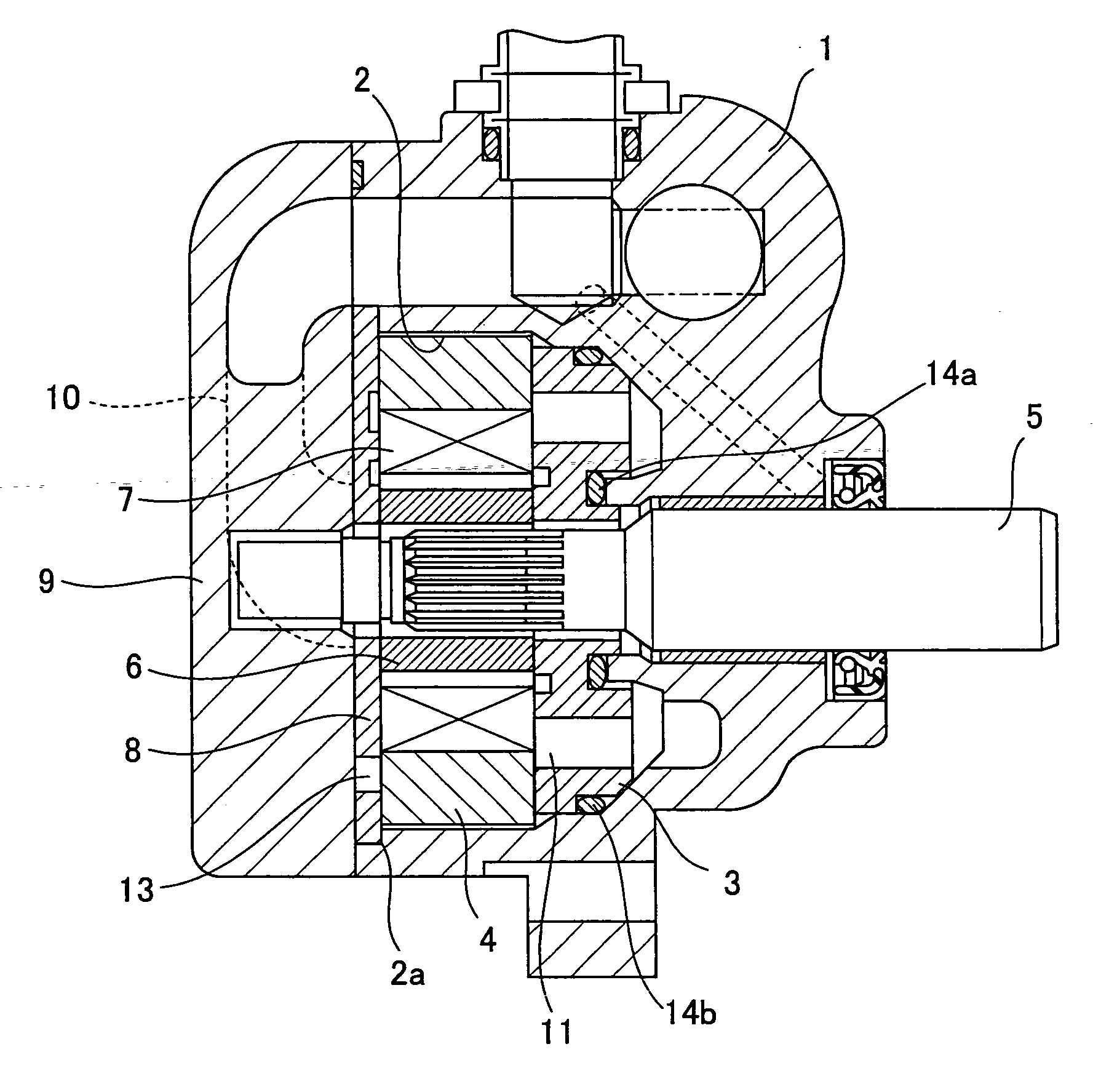

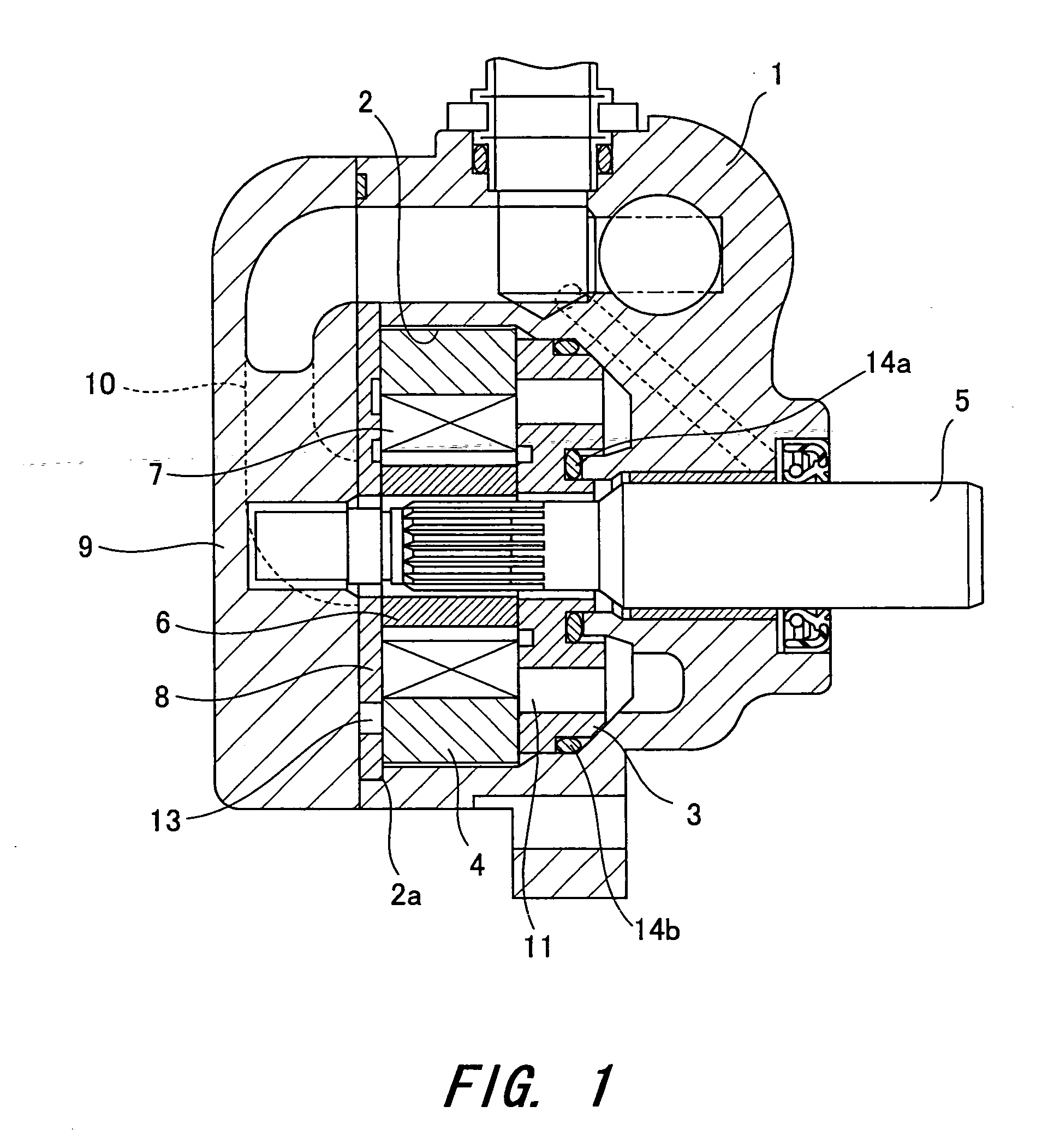

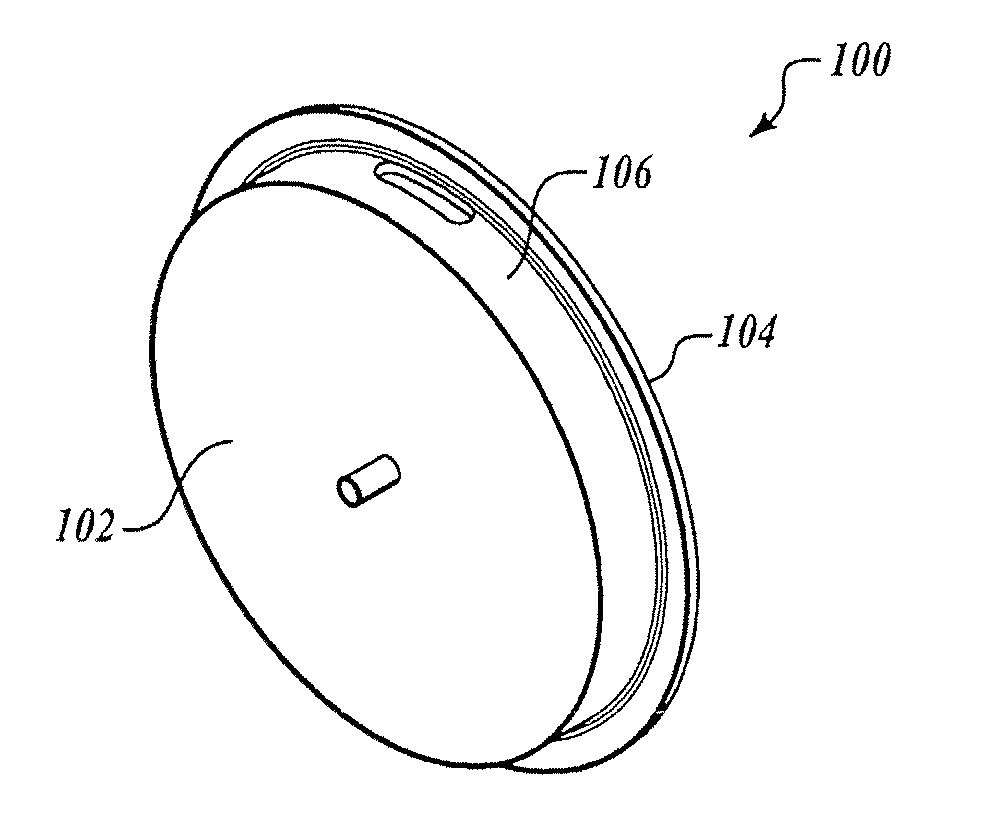

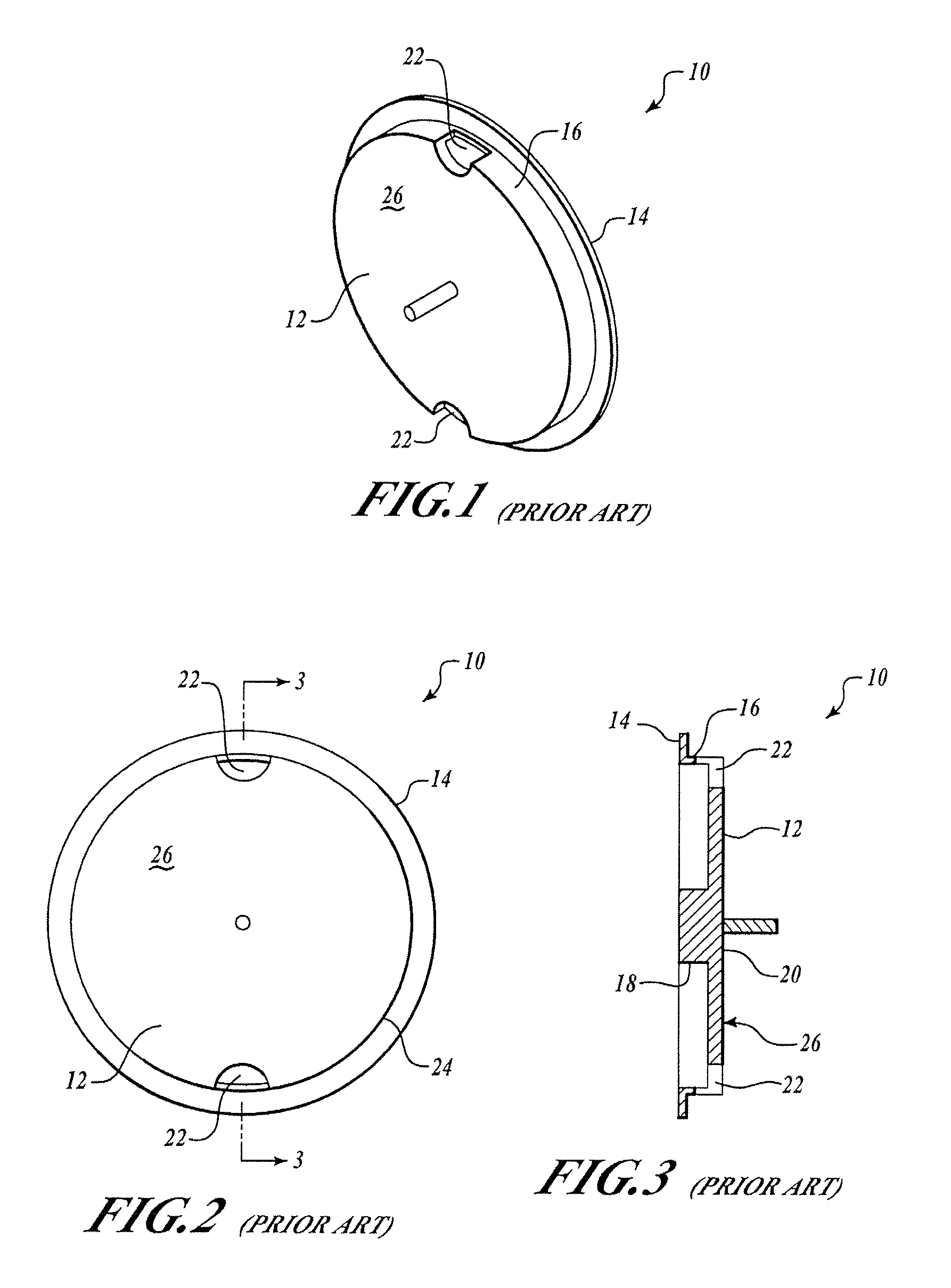

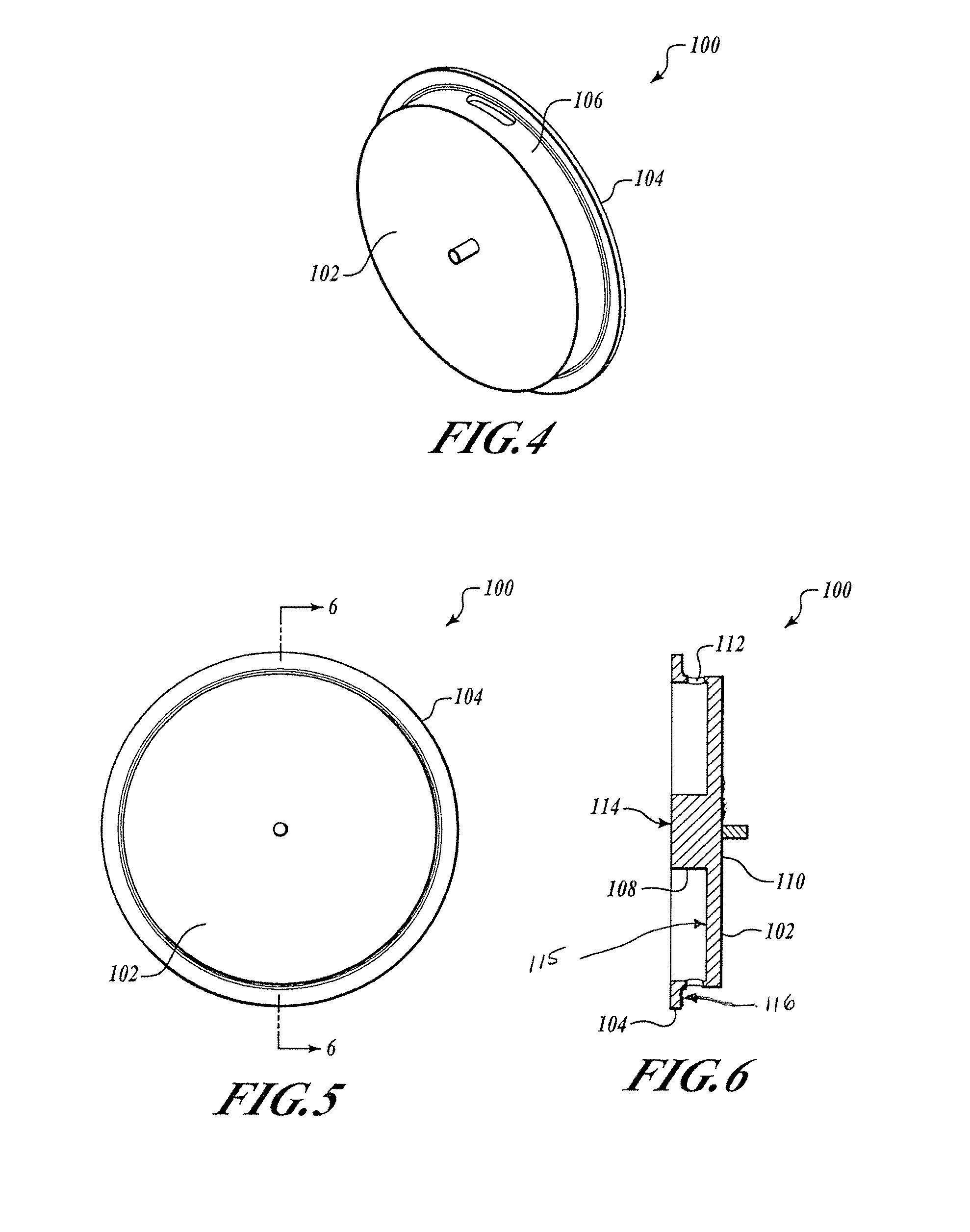

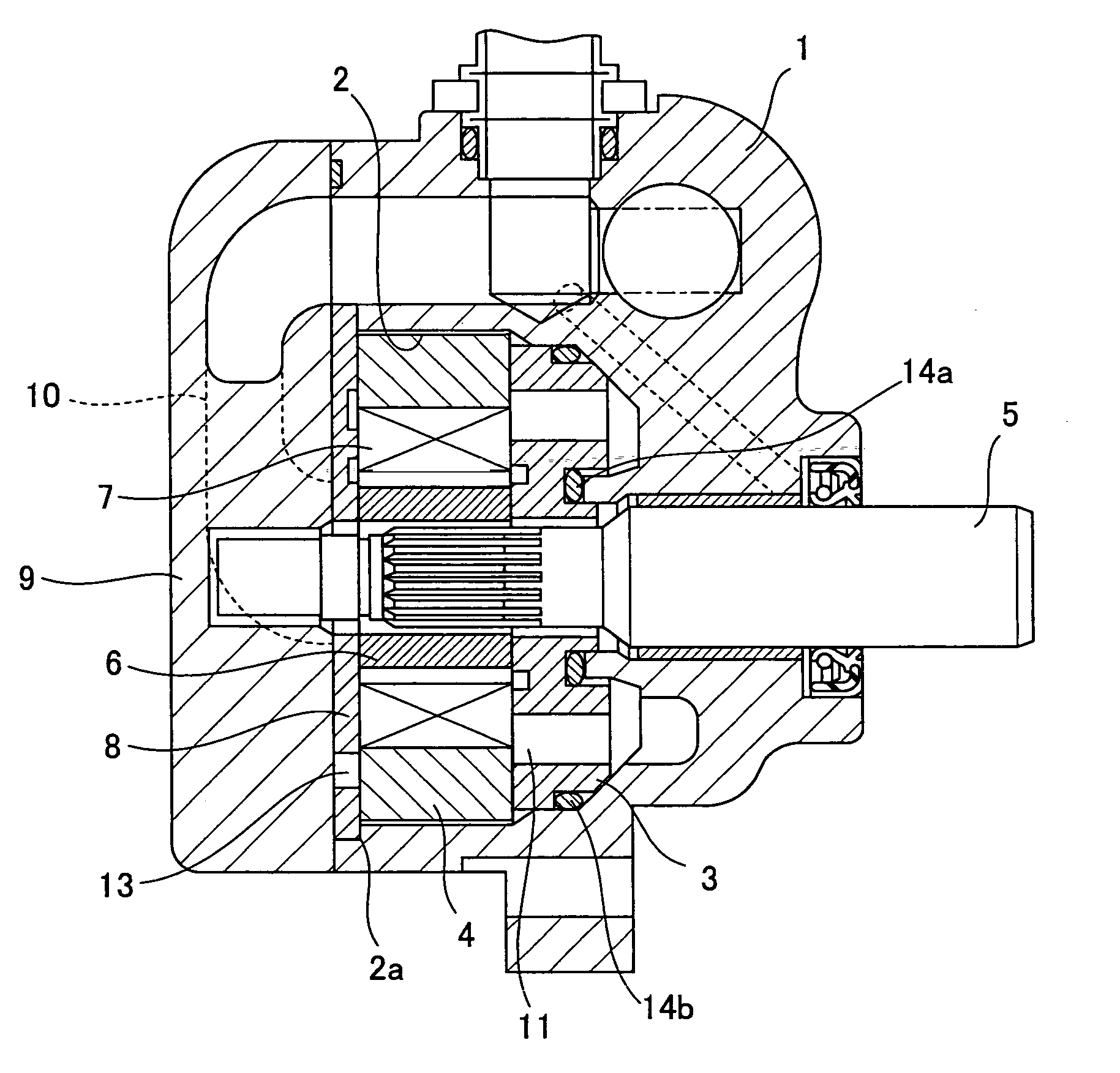

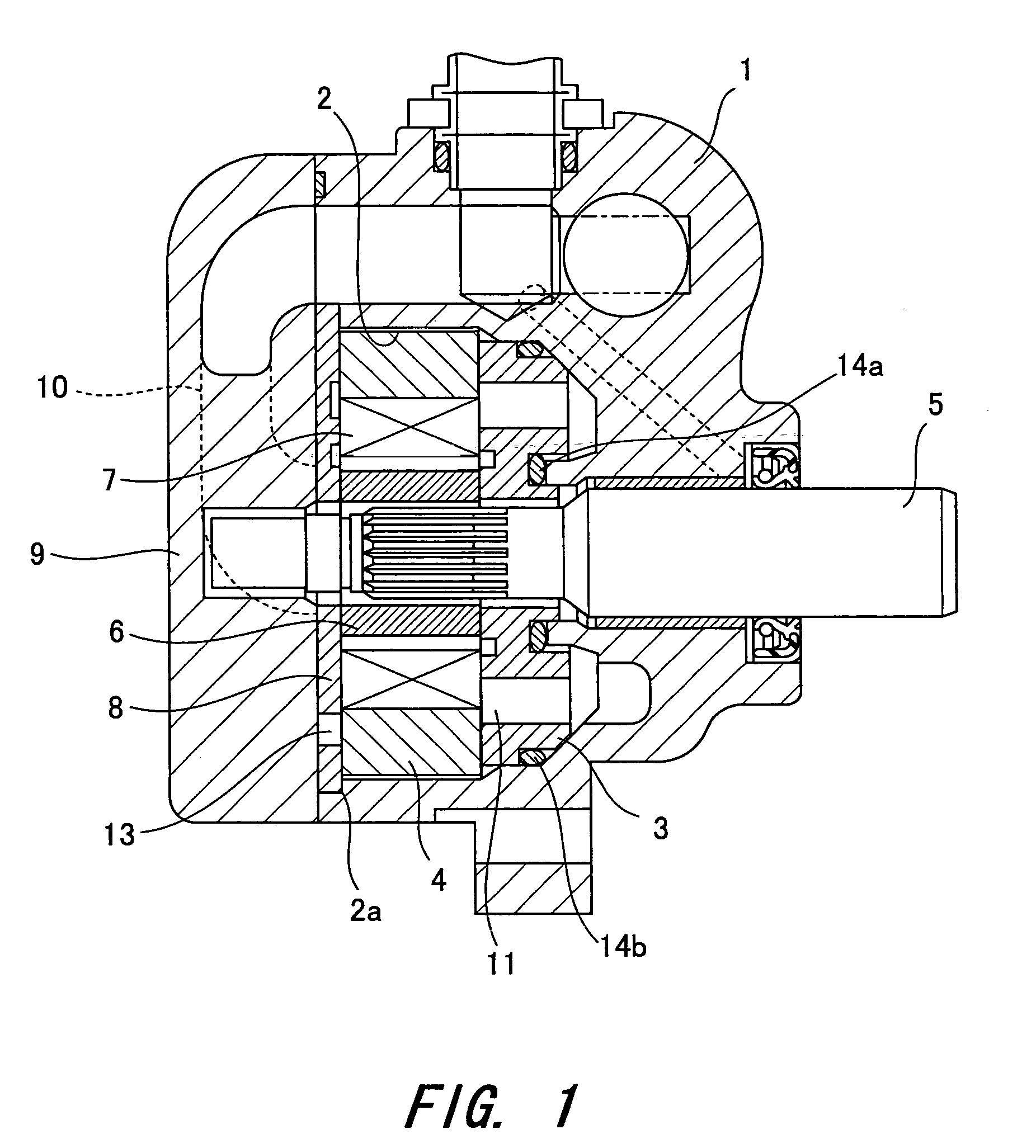

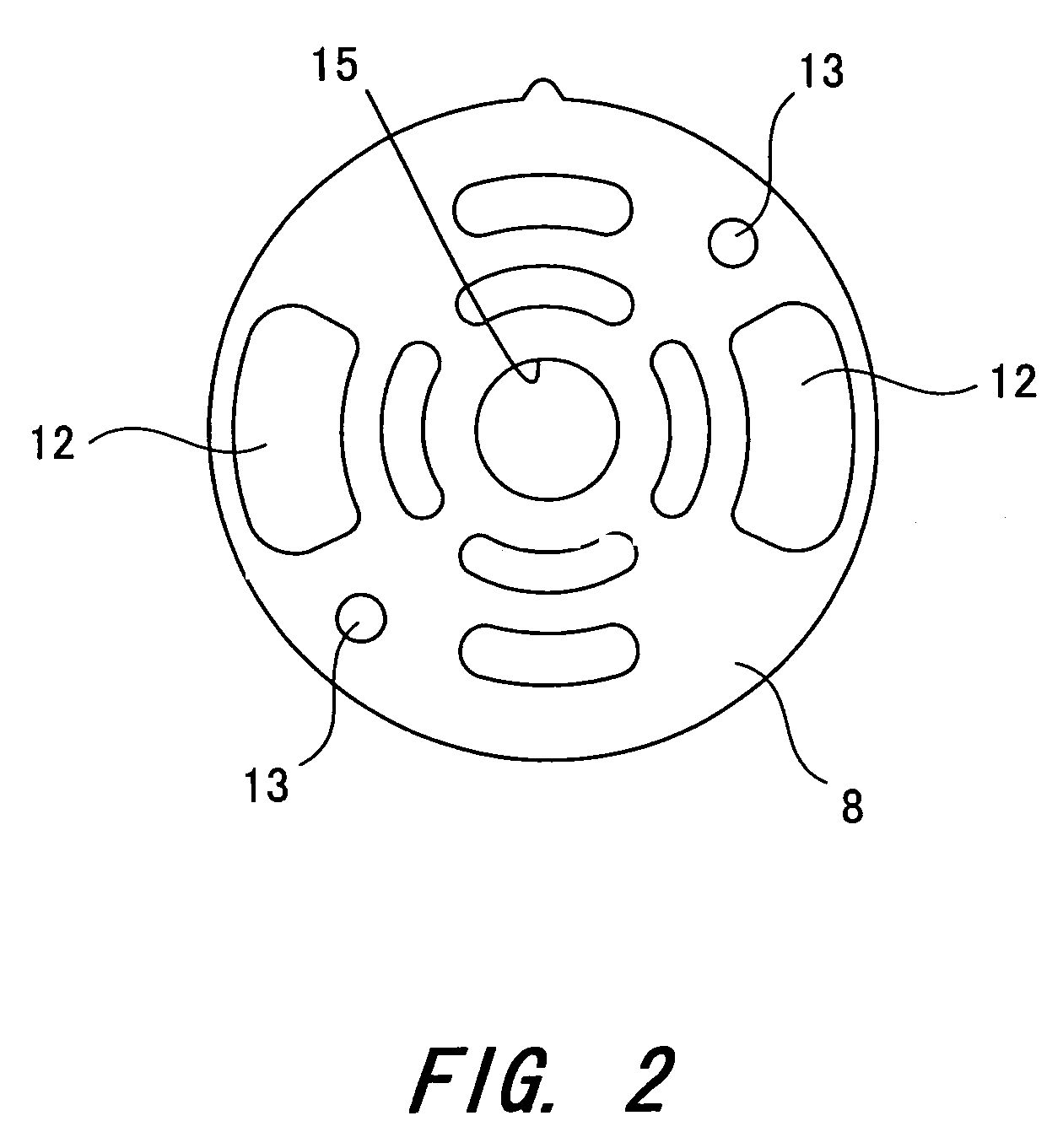

Vane pump

ActiveUS20050281690A1Reduced strengthThin thicknessOscillating piston enginesSealing arrangement for pumpsEngineeringCam

A body bore 2 formed in a body 1 is closed with a cover 9, as well as a cam ring 4 is incorporated into the body bore 2, and a rotor 6 is arranged inside the cam ring 4. Vanes 7 move in and out along an inner surface of the cam ring 4 with rotation of the rotor 6. An iron reinforcing plate 8 is interposed inside the body bore 2 between the cam ring 4 and the cover 9.

Owner:KYB CORP

Liquid-jet head, method of manufacturing the same, and liquid-jet apparatus

ActiveUS7641324B2Reduce electric field strengthReduce the amount of distortionPrintingLiquid jetHigh density

Provided are, a liquid-jet head capable of enhancing durability thereof when it is driven, and of making an arrangement density of piezoelectric elements high-density, a method of manufacturing the same, and a liquid-jet apparatus. The liquid-jet head includes: piezoelectric elements which are provided on a passage-forming substrate with a vibration plate interposed therebetween, and are respectively configured of a lower electrode, piezoelectric layers and upper electrodes, the passage-forming substrate having pressure generating chambers, which communicate with nozzle orifices for ejecting liquid droplets, formed therein, in which, while the lower electrode is continuously provided across plural piezoelectric elements, near-end portions of the lower electrode at least in regions of the lower electrode between adjacent ones of the piezoelectric elements are formed into thin-thickness portions thinner than portions of the lower electrode in other regions of the lower electrode.

Owner:SEIKO EPSON CORP

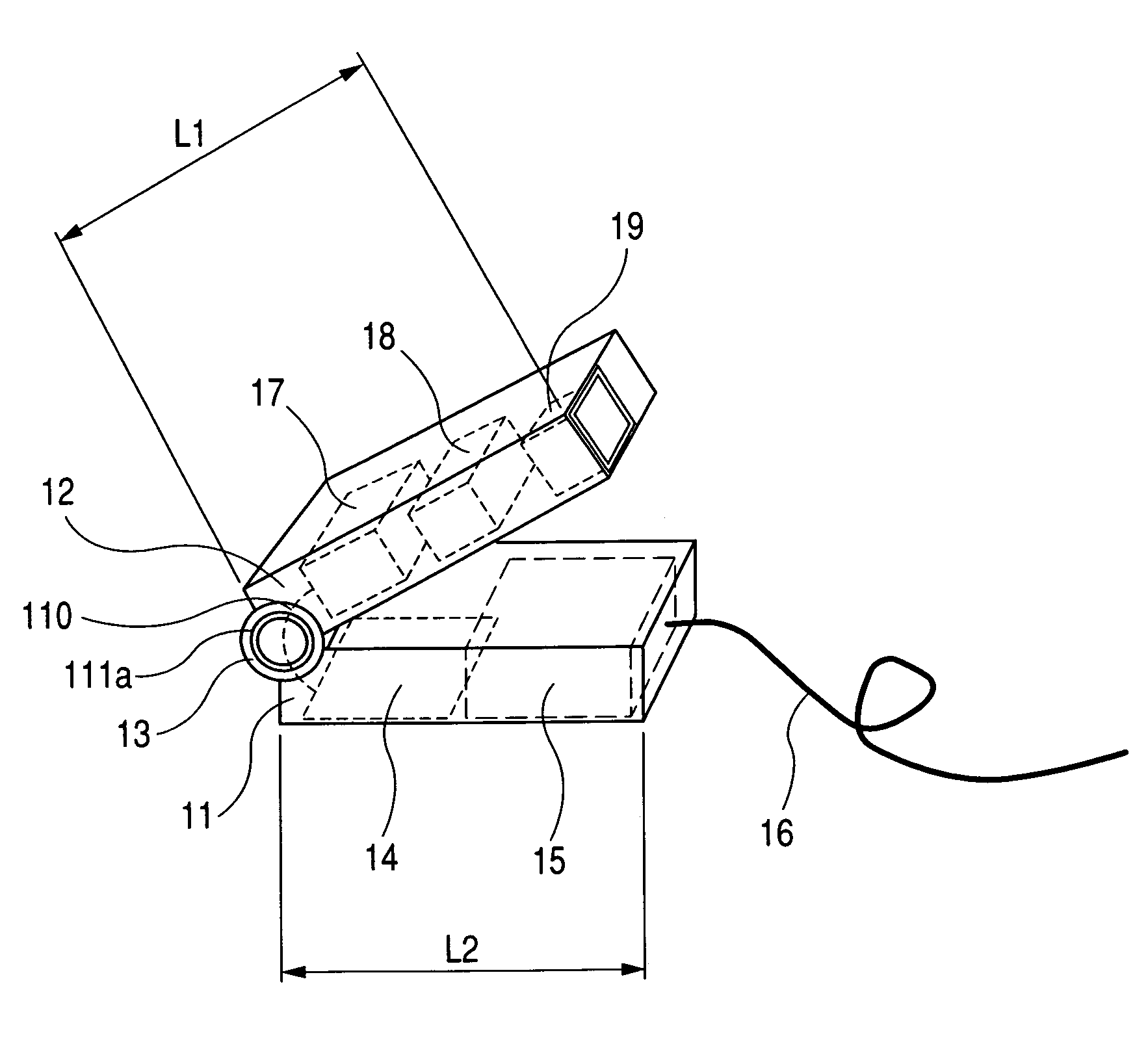

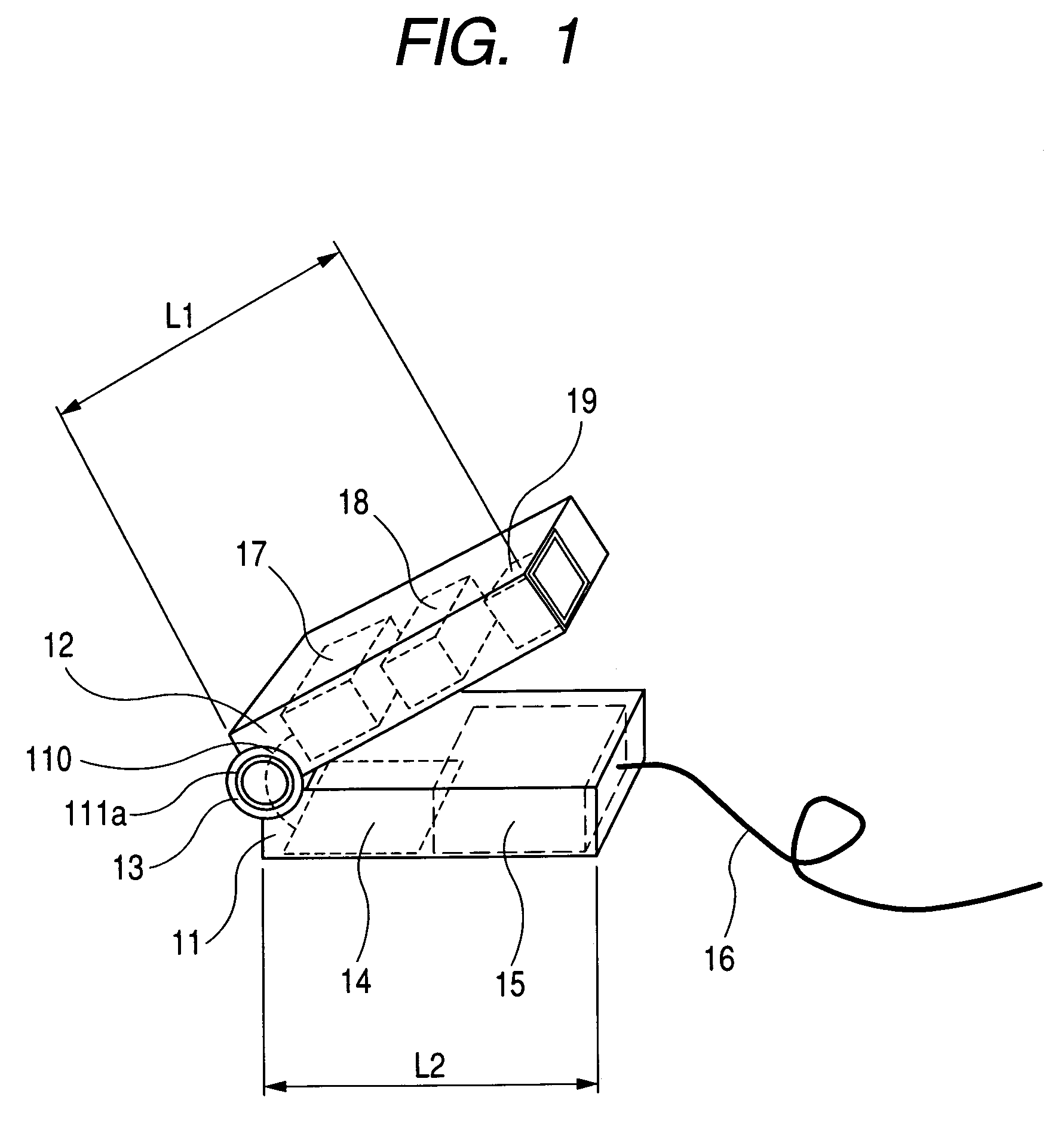

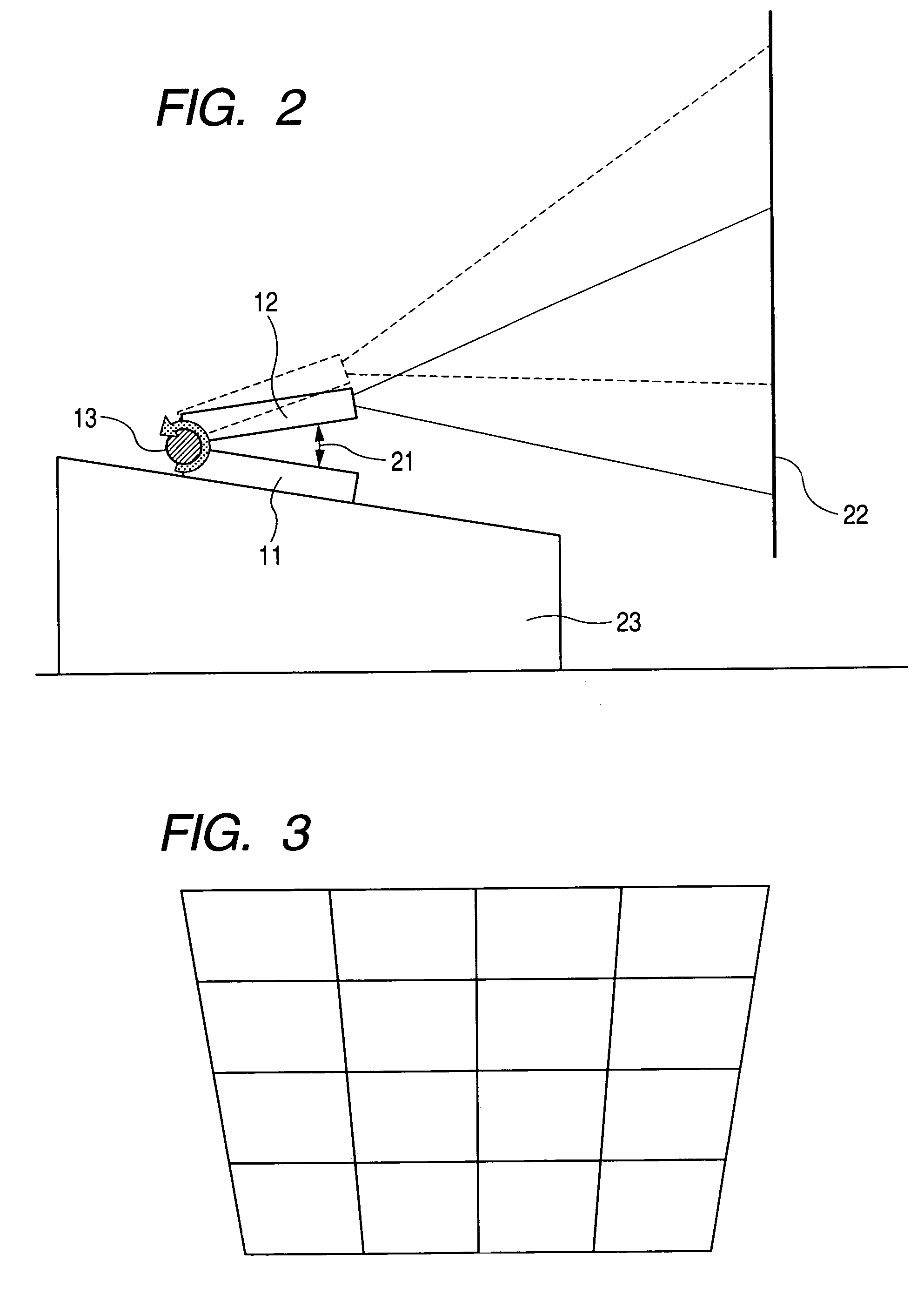

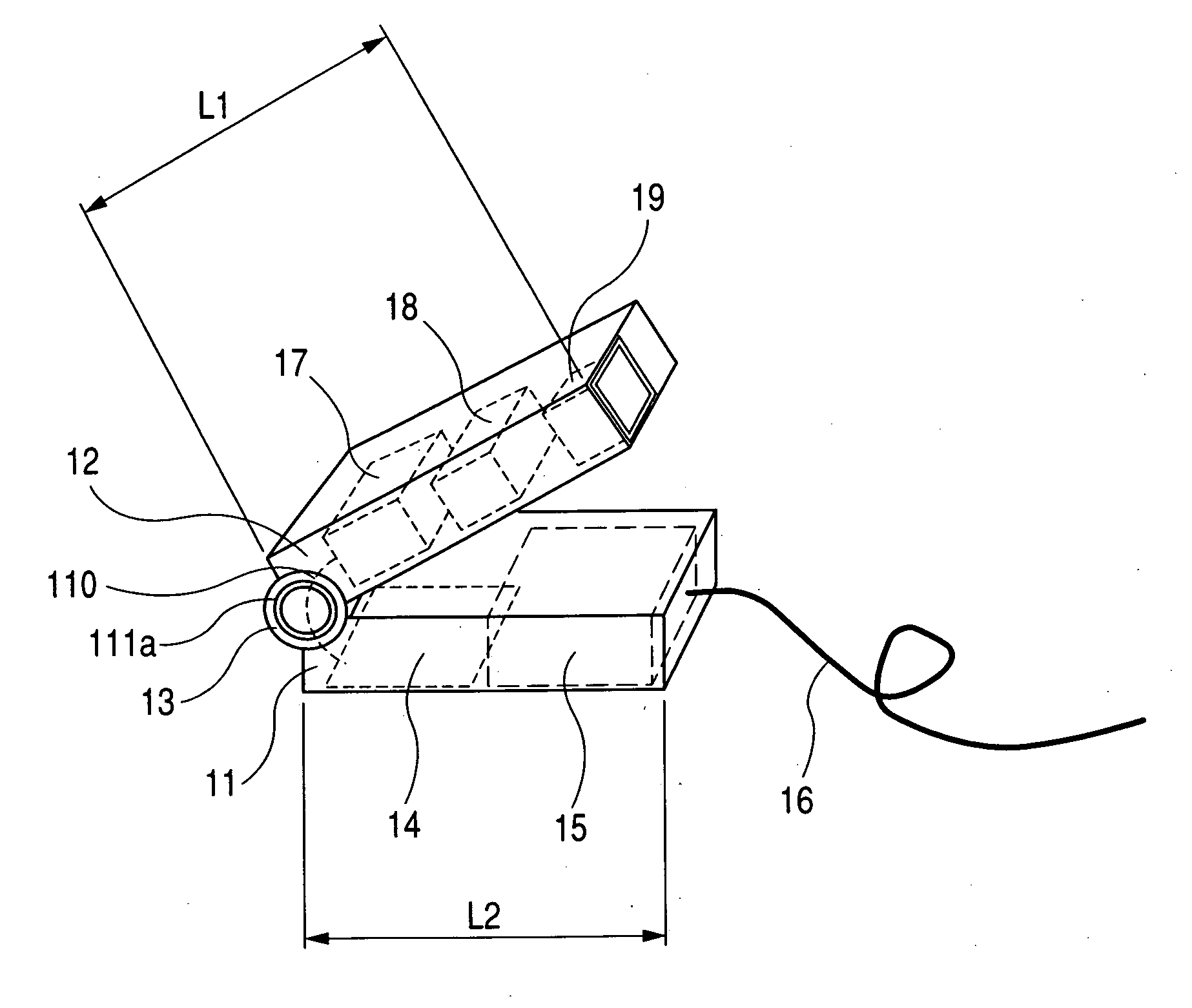

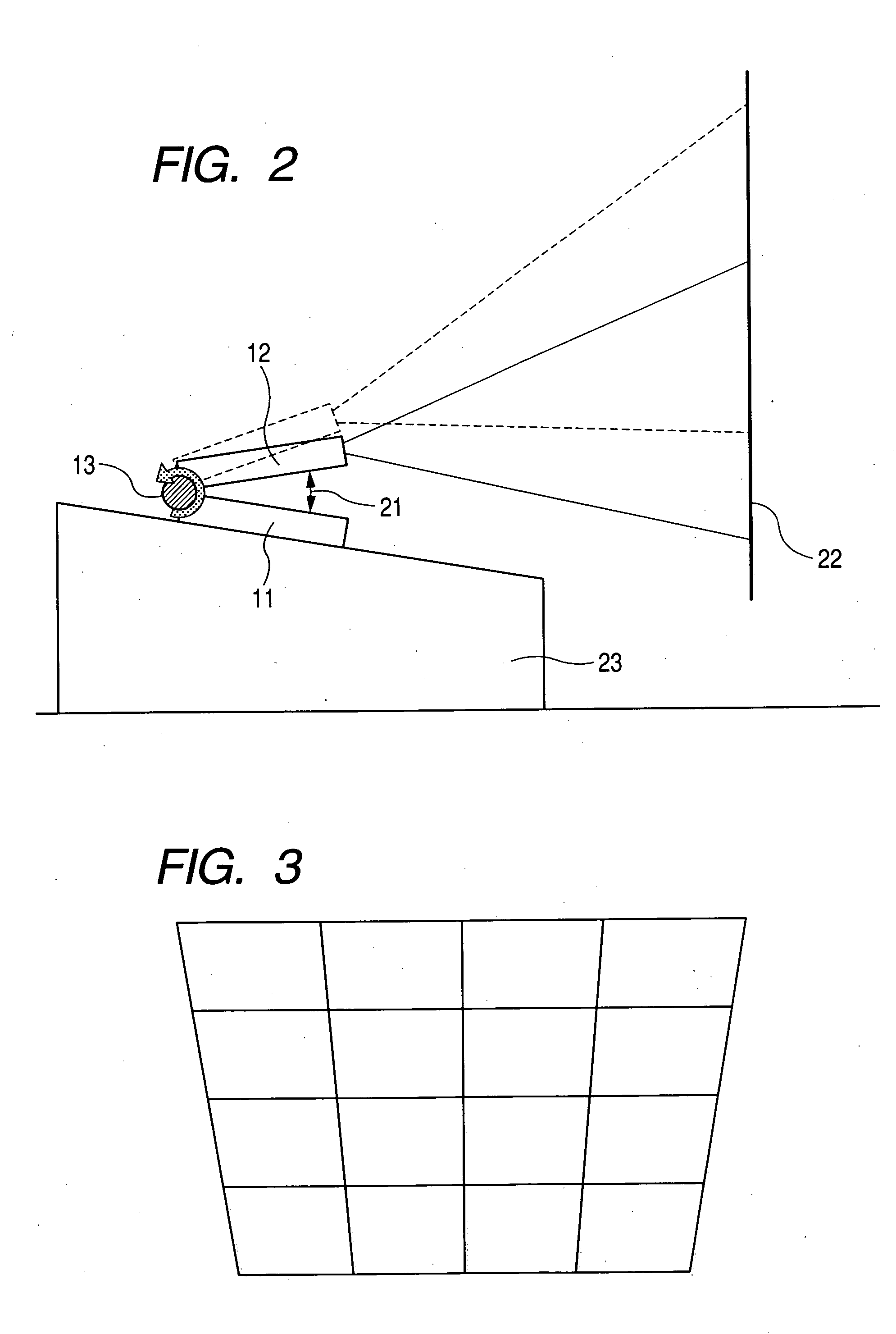

Video projection apparatus

InactiveUS7118231B2Easily projectedReduce the amount of distortionTelevision system detailsStatic indicating devicesImage signalLight modulation

An image projection apparatus includes a light modulation system, a projection optical system for projecting a two-dimensional image onto a surface to be projected with light from the light modulation system, and an image signal processing unit for supplying an image signal to the light modulation system. A power supplying portion supplies power to the light modulation system, a head portion contains the projection optical system, and a main body portion contains the power supplying portion. In addition, a drive connection portion connects the head portion with the main body portion, in which the head portion and the main body portion can be relatively driven.

Owner:CANON KK

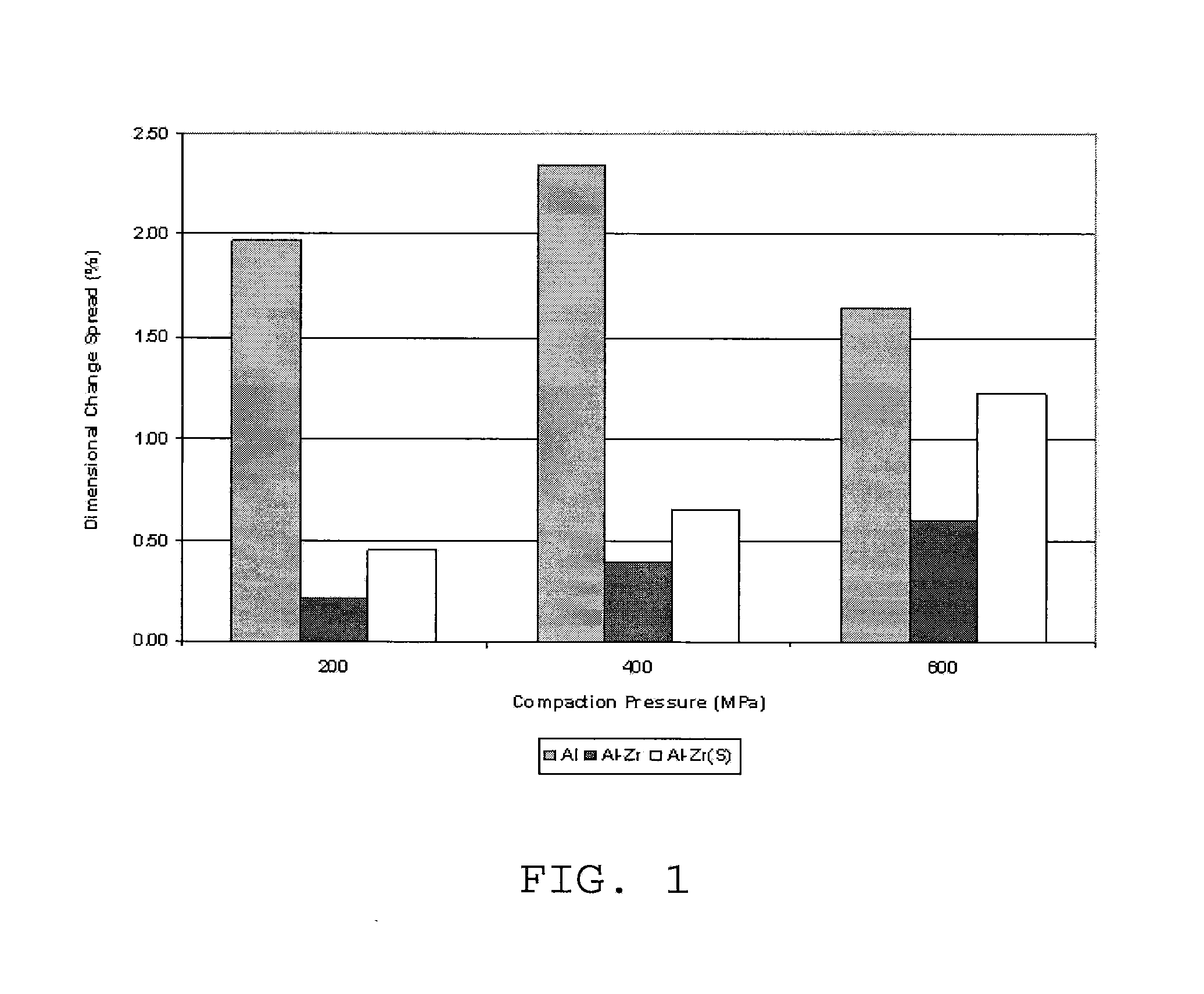

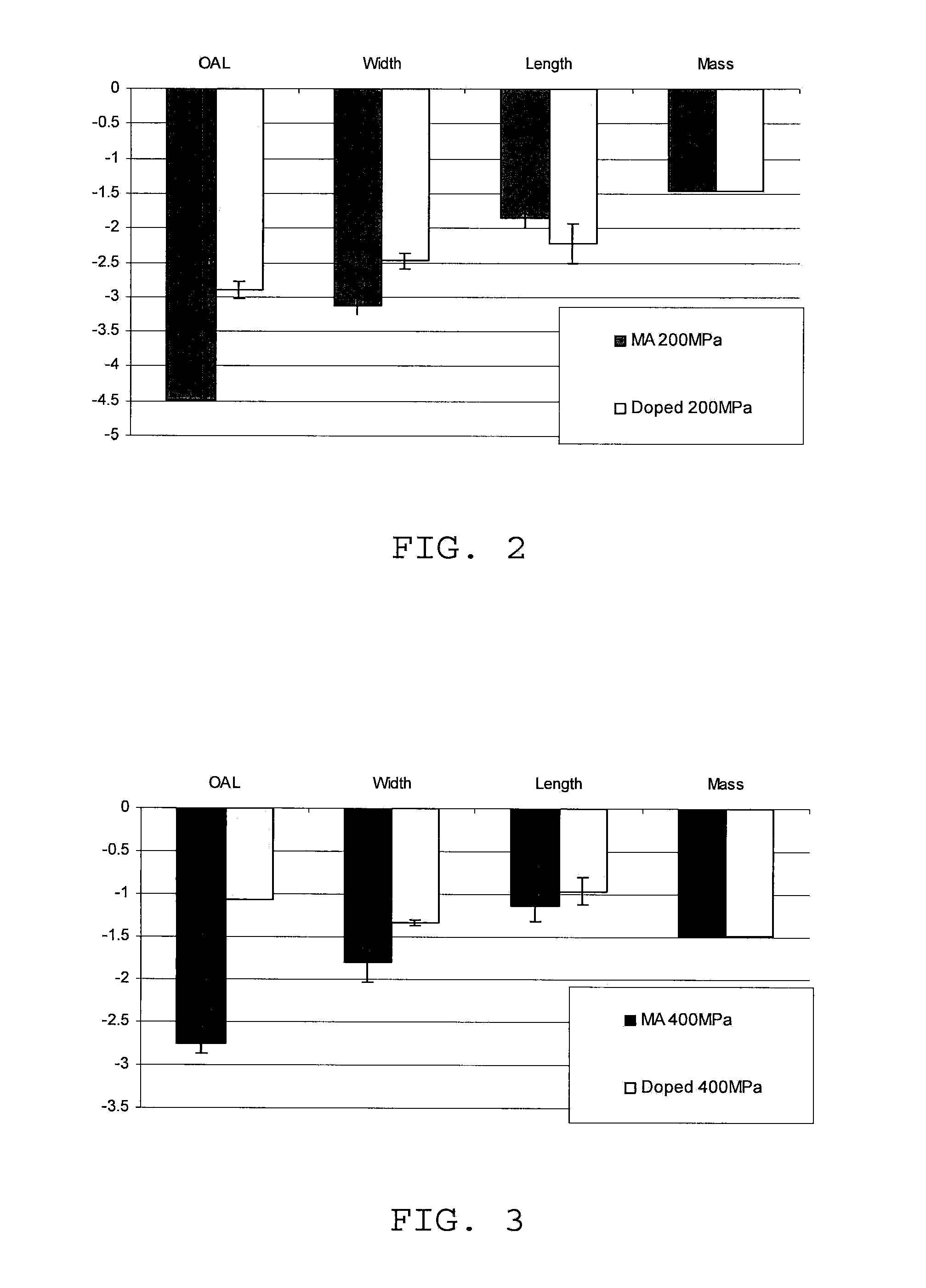

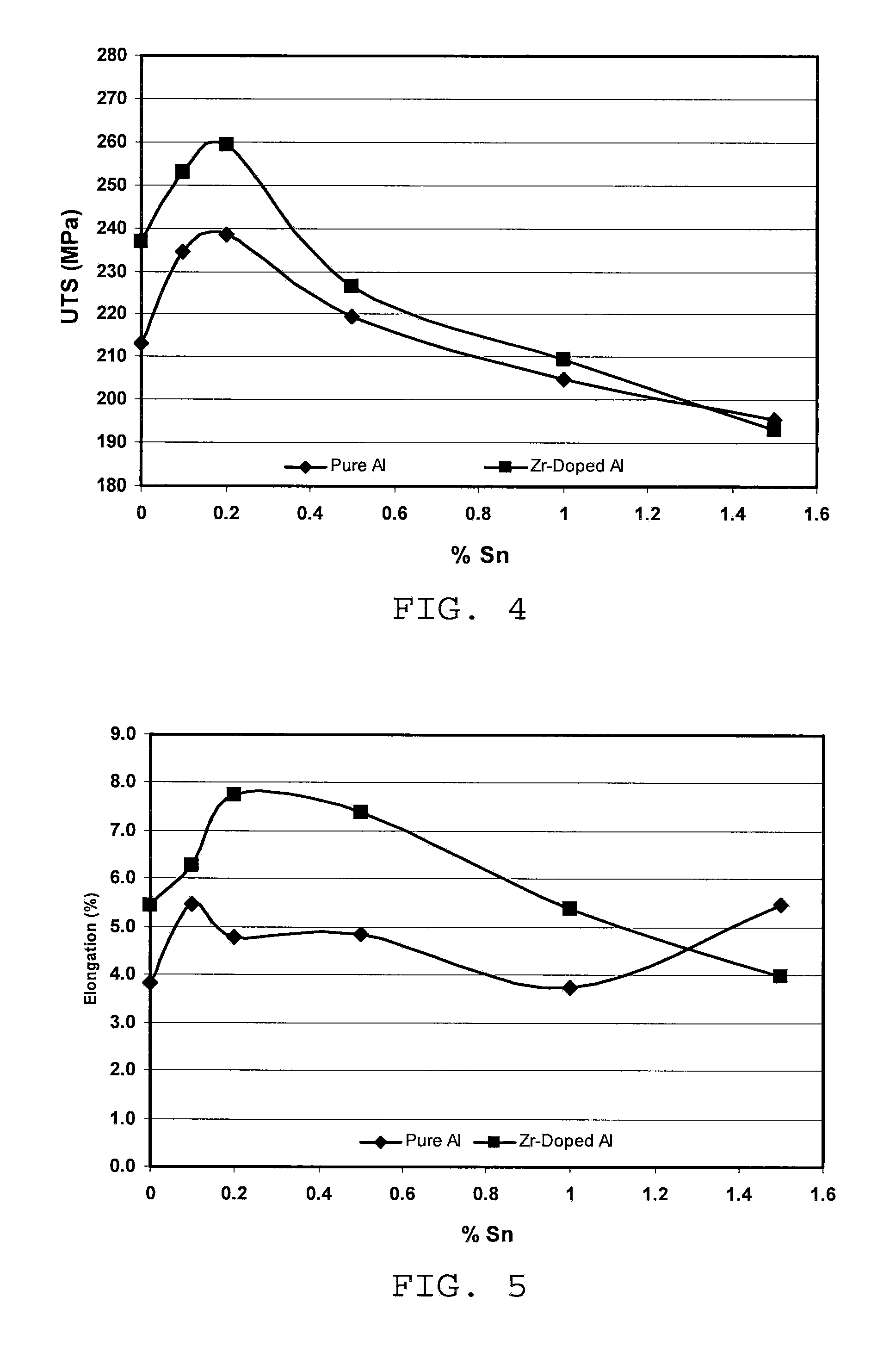

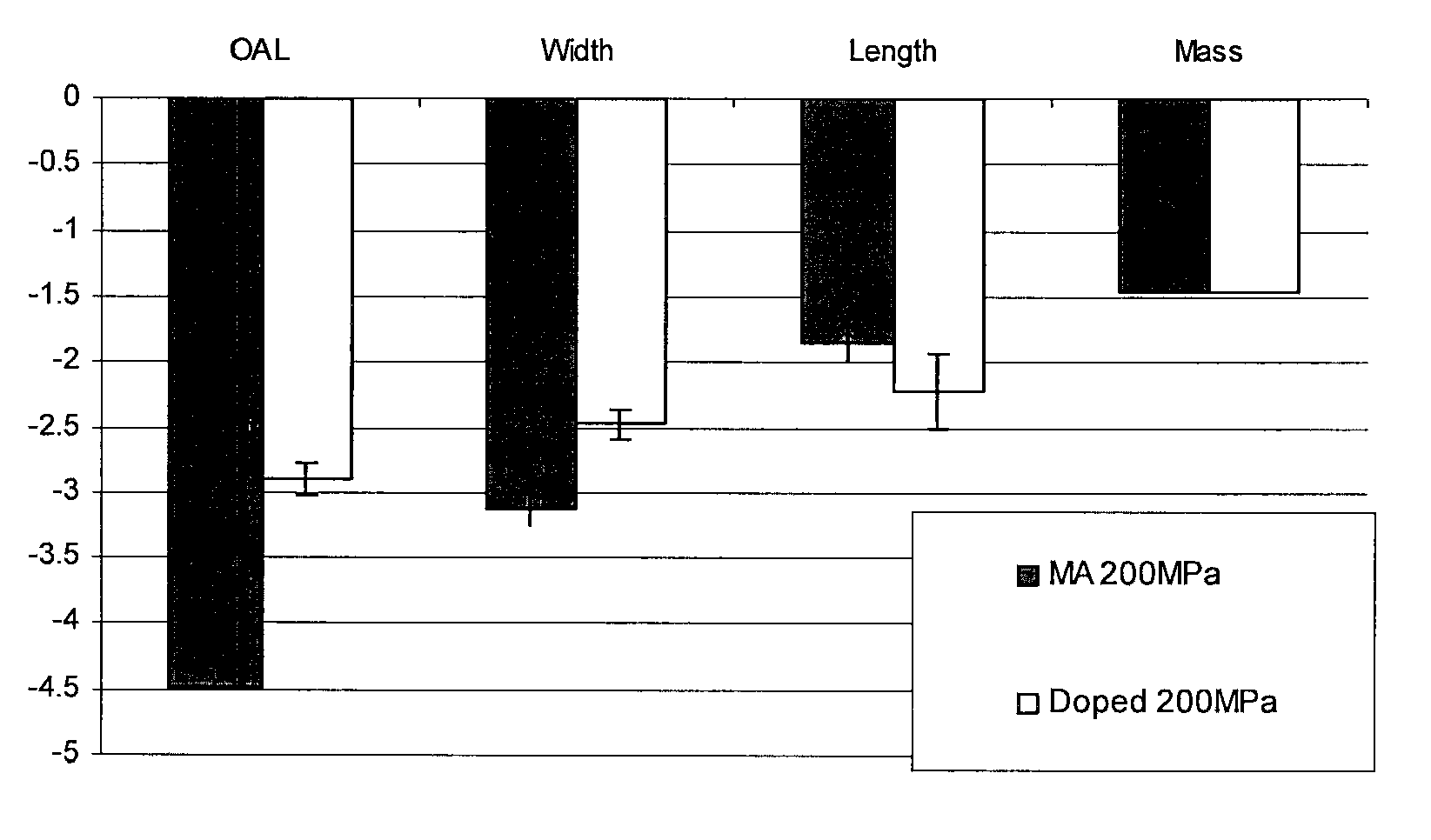

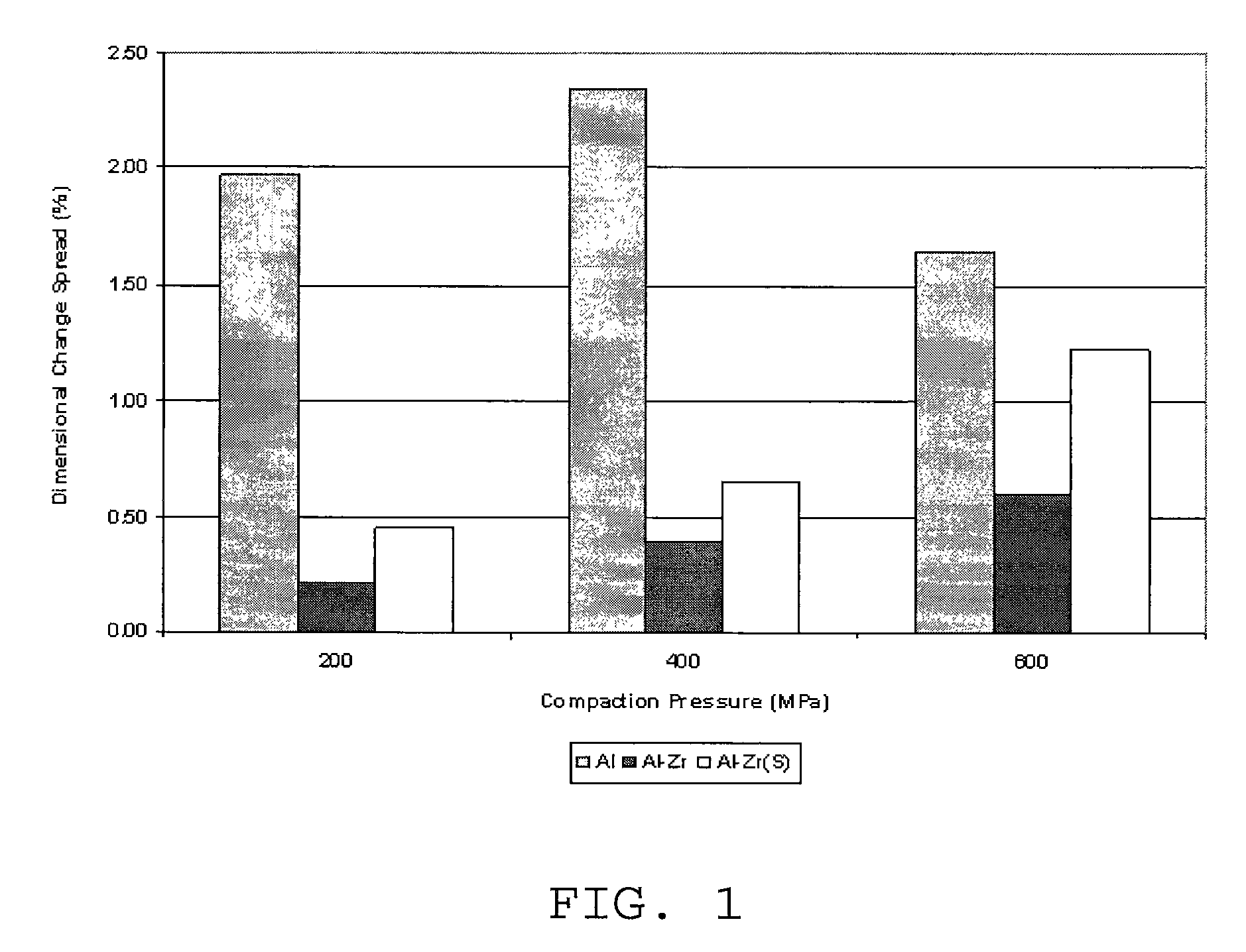

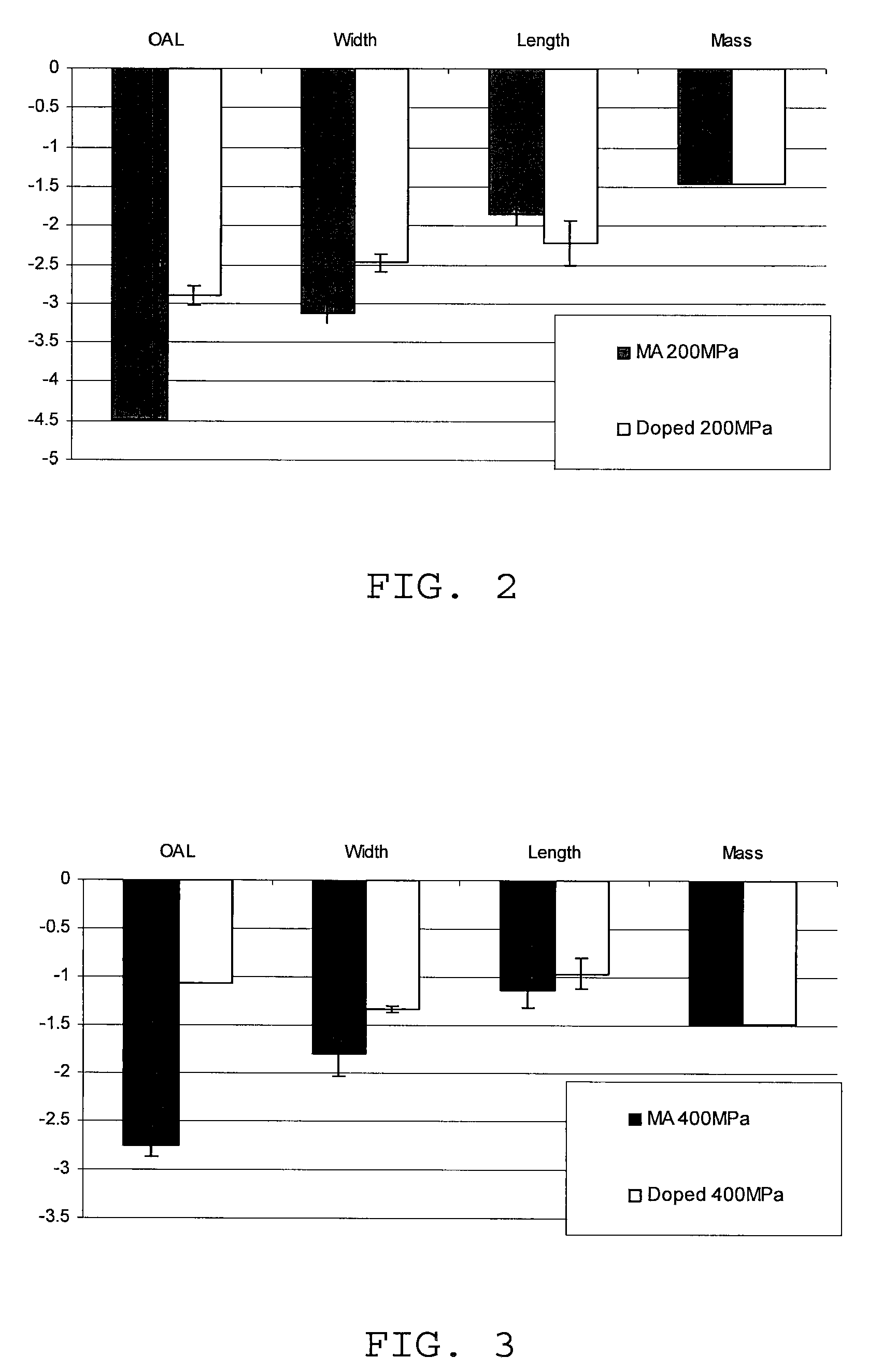

Aluminum powder metal alloying method

ActiveUS20130183189A1Reduce distortion problemsReduce the amount of distortionAluminium powderMetal powder

A zirconium-doped aluminum powder metal and a method of making this powder metal are disclosed. The method of making includes forming an aluminum-zirconium melt in which a zirconium content of the aluminum-zirconium melt is less than 2.0 percent by weight. The aluminum-zirconium melt then powderized to form a zirconium-doped aluminum powder metal. The powderization may occur by, for example, air atomization.

Owner:SKN SINTER METALS LLC (US)

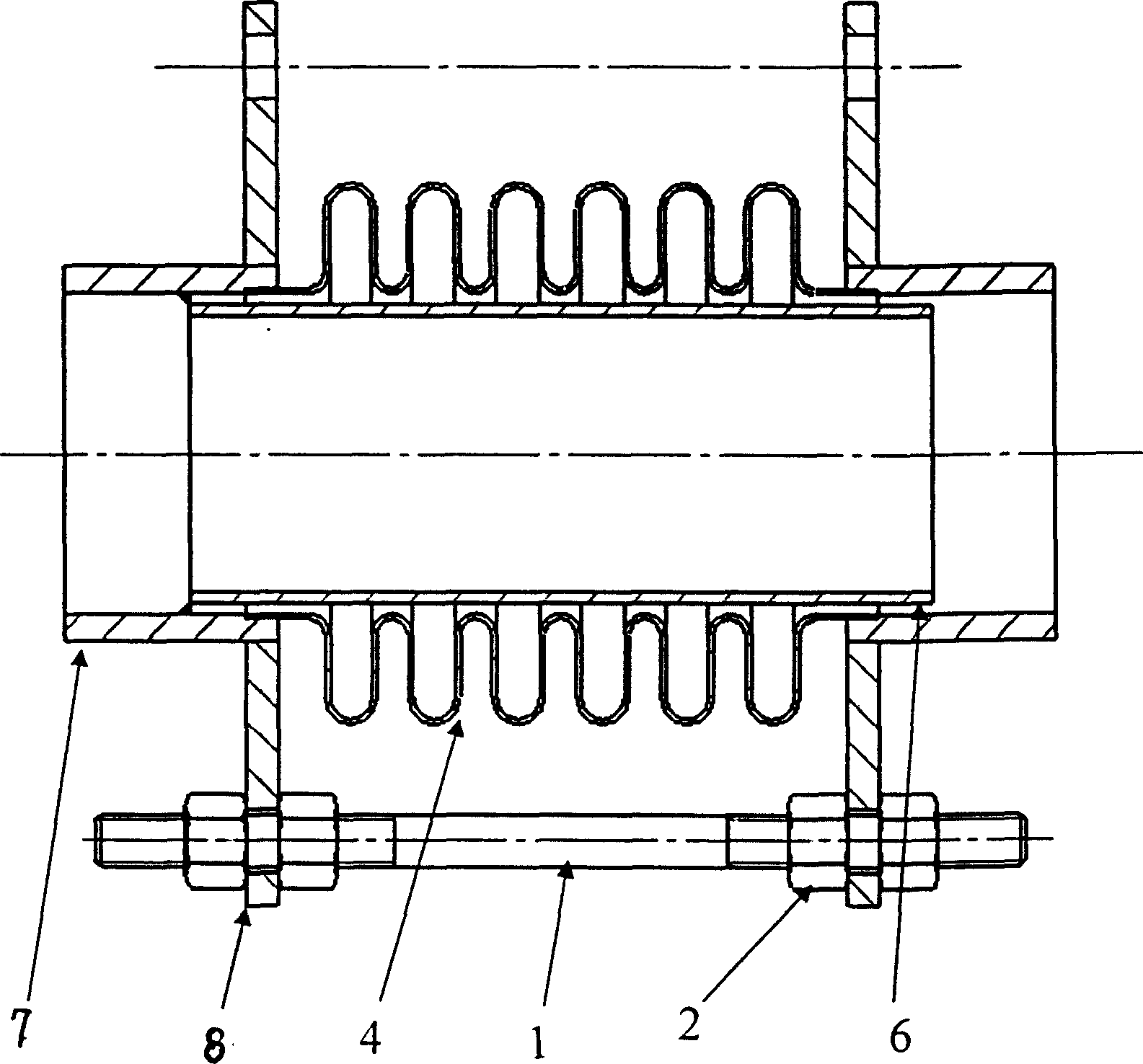

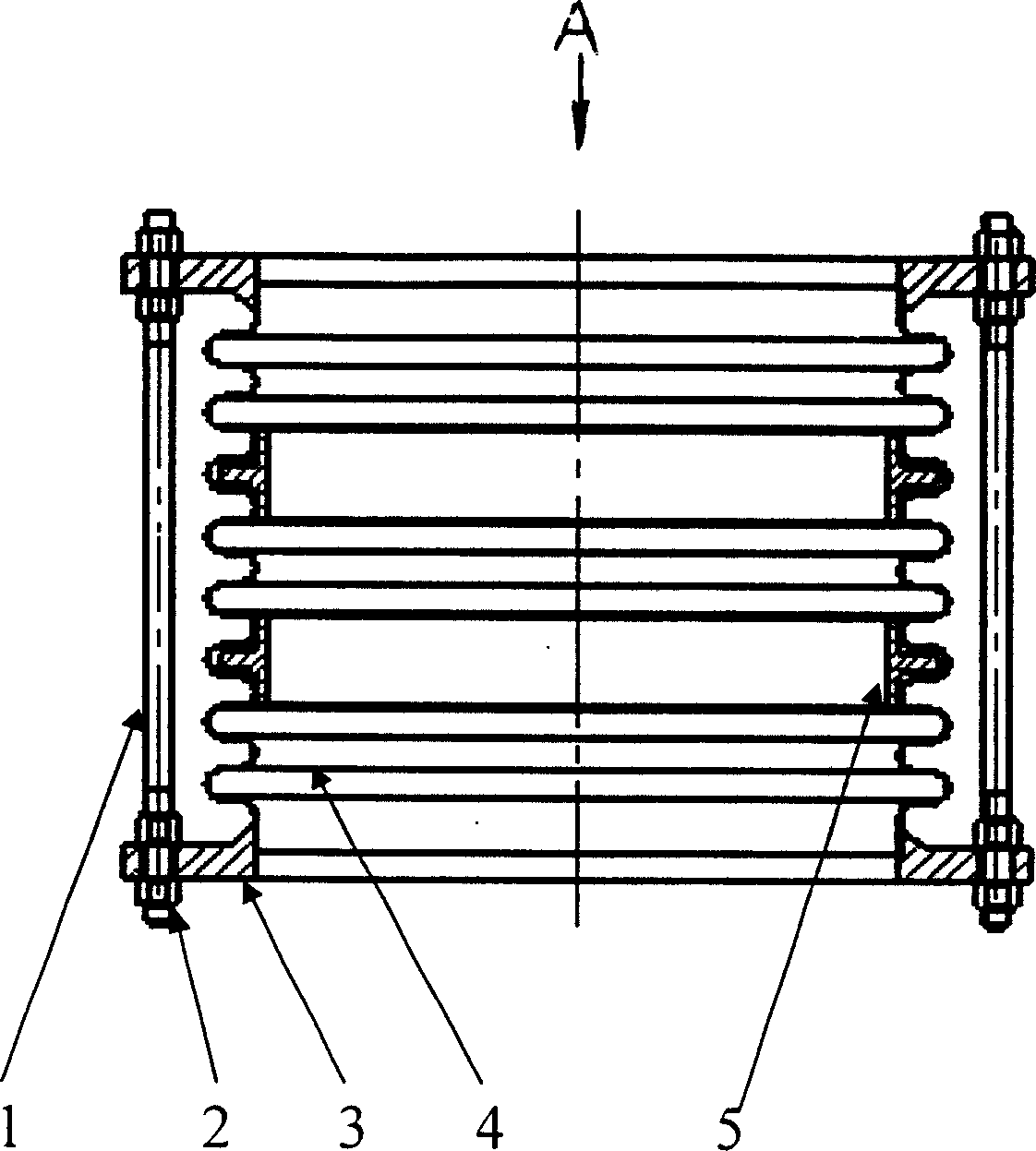

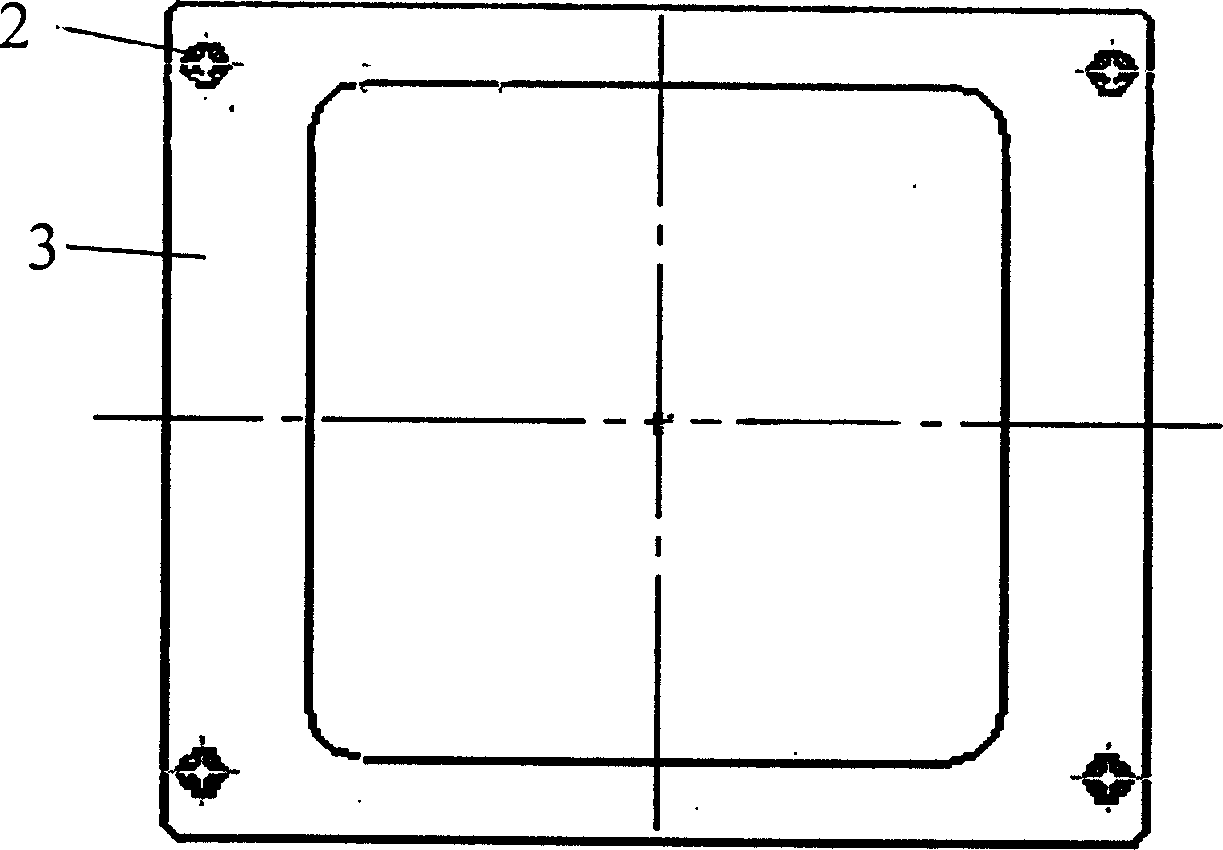

Square corrugated pipe

InactiveCN1621727AImprove pressure bearing capacityReduce leak rateFlexible pipesArchitectural engineeringShape matching

The square corrugated pipe includes corrugated pipe, positioning screws and nuts, and features that the pressed square corrugated pipe has connecting flanges welded to its ends, square stainless steel corrugated pipe of wall thickness of 0.3-0.6 mm, and the positioning screws and the corresponding nuts are set in the connecting holes of the flanges. The present invention solves the technological problems of compression capacity, flexibility, five-dimensional displacement regulation and compensation, and aperture and shape matching.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Video projection apparatus

InactiveUS20060055898A1Easily projectedReduce the amount of distortionTelevision system detailsStatic indicating devicesImage signalSignal processing

An image projection apparatus according to the present invention includes: a light modulation system; a projection optical system for projecting a two-dimensional image onto a surface to be projected with light from the light modulation system; an image signal processing unit for supplying an image signal to the light modulation system; a power supplying portion for supplying power to the light modulation system; a head portion that contains the projection optical system; a main body portion that contains the power supplying portion; and a drive connection portion for connecting the head portion with the main body portion, in which the head portion and the main body portion can be relatively driven.

Owner:CANON KK

Apparatus and method for obtaining images of a borehole

ActiveUS7751038B2Reduce the amount of distortionEasy to explainSurveyConstructionsLight sourceEnvironmental geology

Apparatus for obtaining images of the wall of a borehole, comprises a tool body; a light source mounted on the tool body and arranged to illuminate the borehole wall; a camera mounted in the tool body; and a mirror moveably mounted on the tool body and spaced axially from the camera and arranged to reflect an image of the borehole wall at the camera, wherein the movement of the mirror allows images of different parts of the borehole wall to be reflected at the camera.

Owner:SCHLUMBERGER TECH CORP

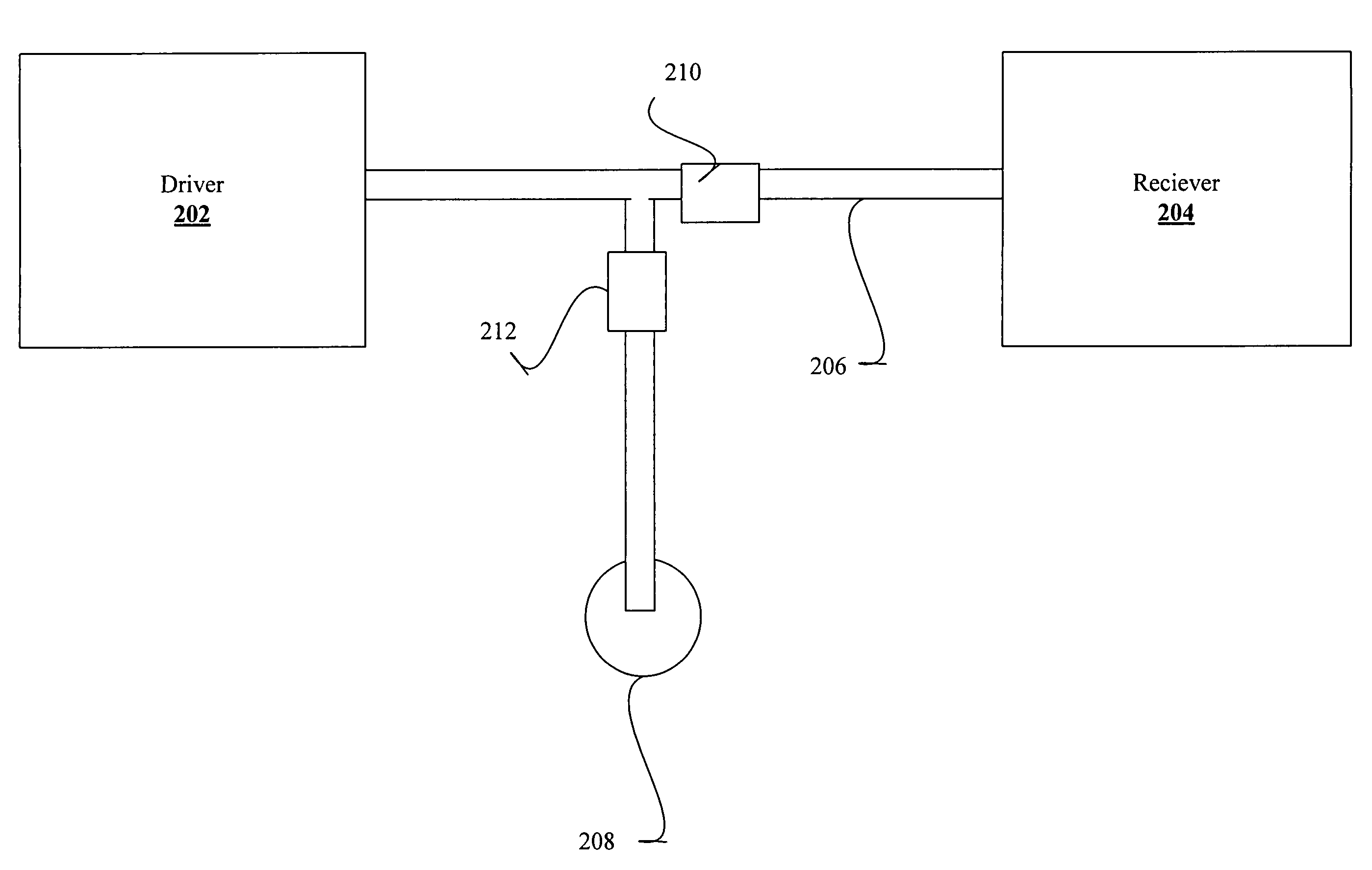

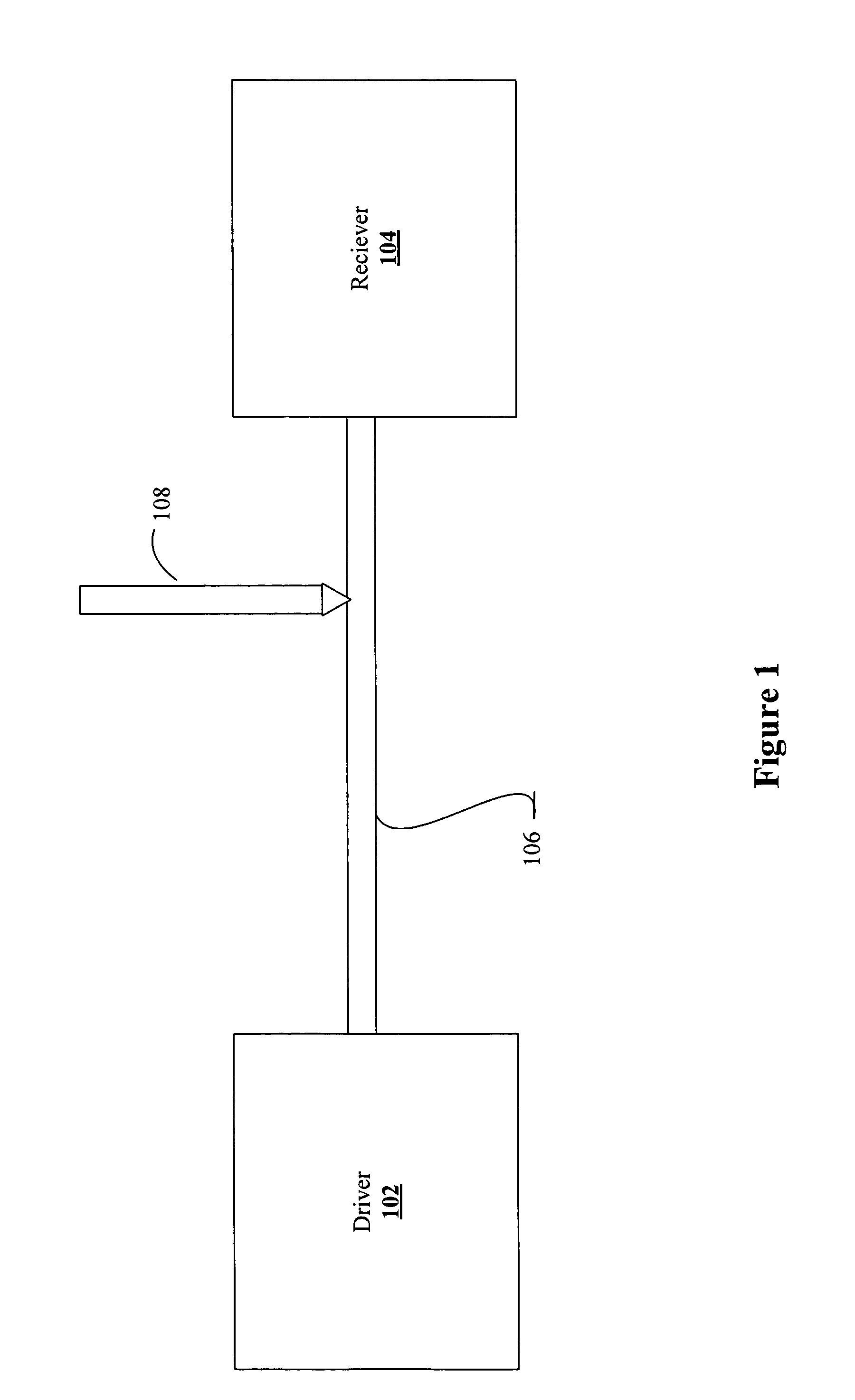

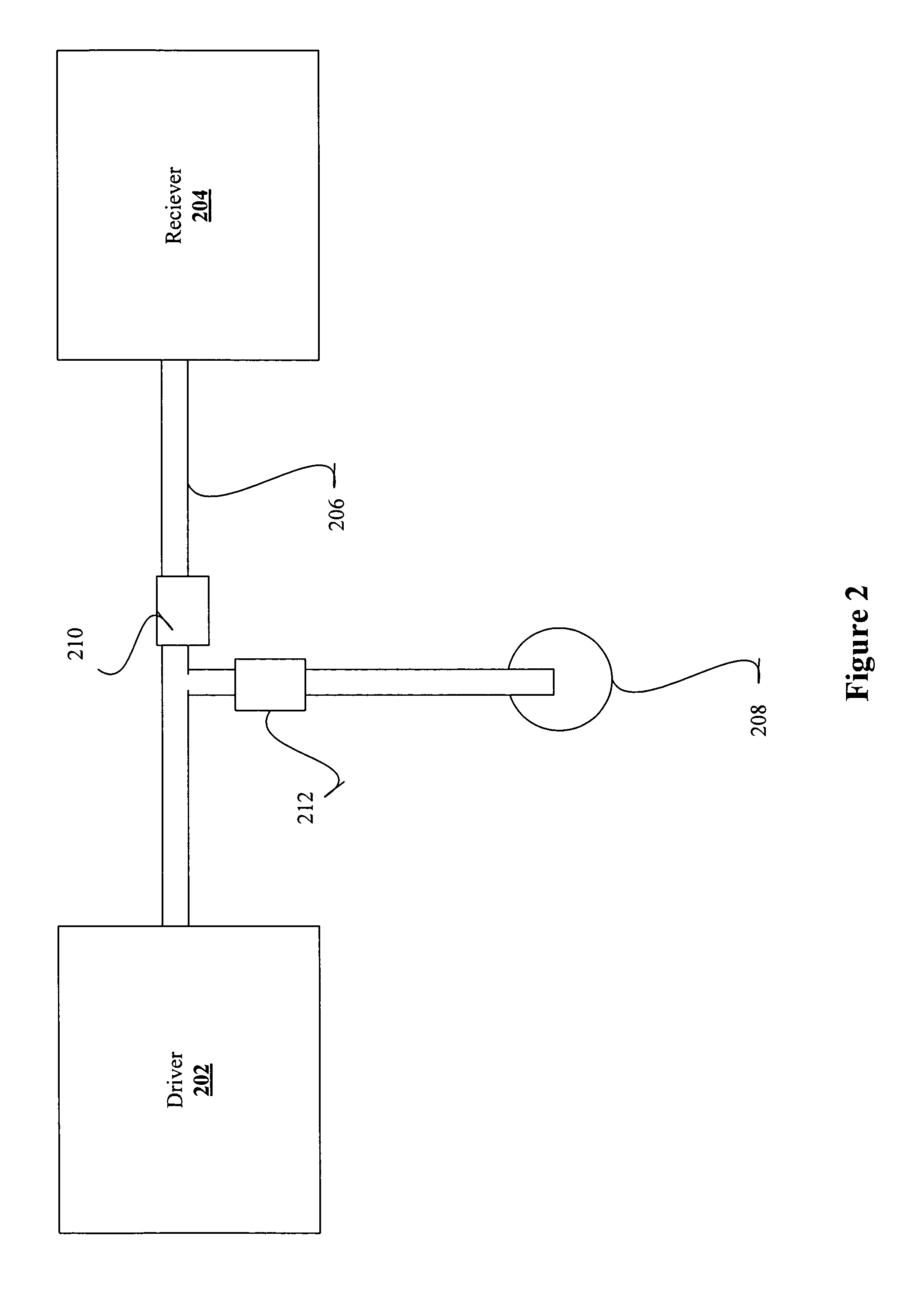

Testing high frequency signals on a trace

InactiveUS7489154B2Reduce the amount of distortionMinimizes capacitanceRadiofrequency circuit testingIndividual semiconductor device testingCapacitanceSignal on

A system, apparatus and method for testing and measuring high frequency signals on a trace is described. In one embodiment of the invention, a footprint is manufactured on a trace to allow the testing of a signal while reducing the amount of distortion caused by prior art structures and methods. The footprint is designed to reduce stub effects and capacitance on a signal being communicated on the trace.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

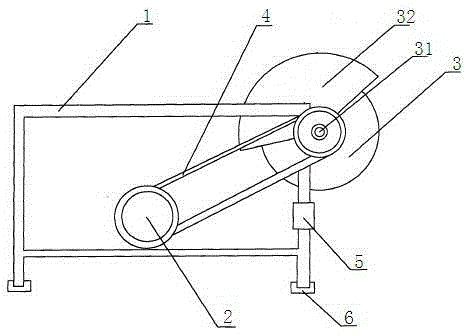

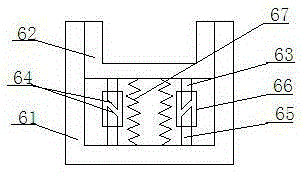

High-accuracy casting polishing machine

InactiveCN105290943AGuaranteed sizeGuaranteed machining accuracyGrinding carriagesBonded abrasive wheelsEngineeringDistortion

The invention discloses a high-accuracy casting polishing machine. The high-accuracy casting polishing machine comprises a machine frame, a motor and a cutting disc, wherein the motor is arranged on the machine frame and is connected to a rotation shaft of the cutting disc through a chain. A silencer is arranged at the part, close to the cutting disc, of the middle of the machine frame. A buffering device is arranged on the bottom of the machine frame. An installation hole is formed in the center of the cutting disc, the cutting disc is provided with through holes distributed in the radial direction of the cutting disc, and the through holes extend in the peripheral direction of the cutting disc, penetrate through the two end surfaces of the cutting disc and are used for dissipating heat and dispersing stress. According to the invention, the condition that castings are damaged in manual polishing is avoided, the speed is high, the size of the cutting disc during heating expansion is guaranteed, the influence of the heat generated in work to the size of the cutting disc is lowered, the distortion degree of the cutting disc in work is lowered, the machining efficiency of the cutting disc is guaranteed, and therefore the production efficiency is improved, the production cost is lowered, the noise generated in the reoperation process is lowered, and the steadiness in work is improved.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

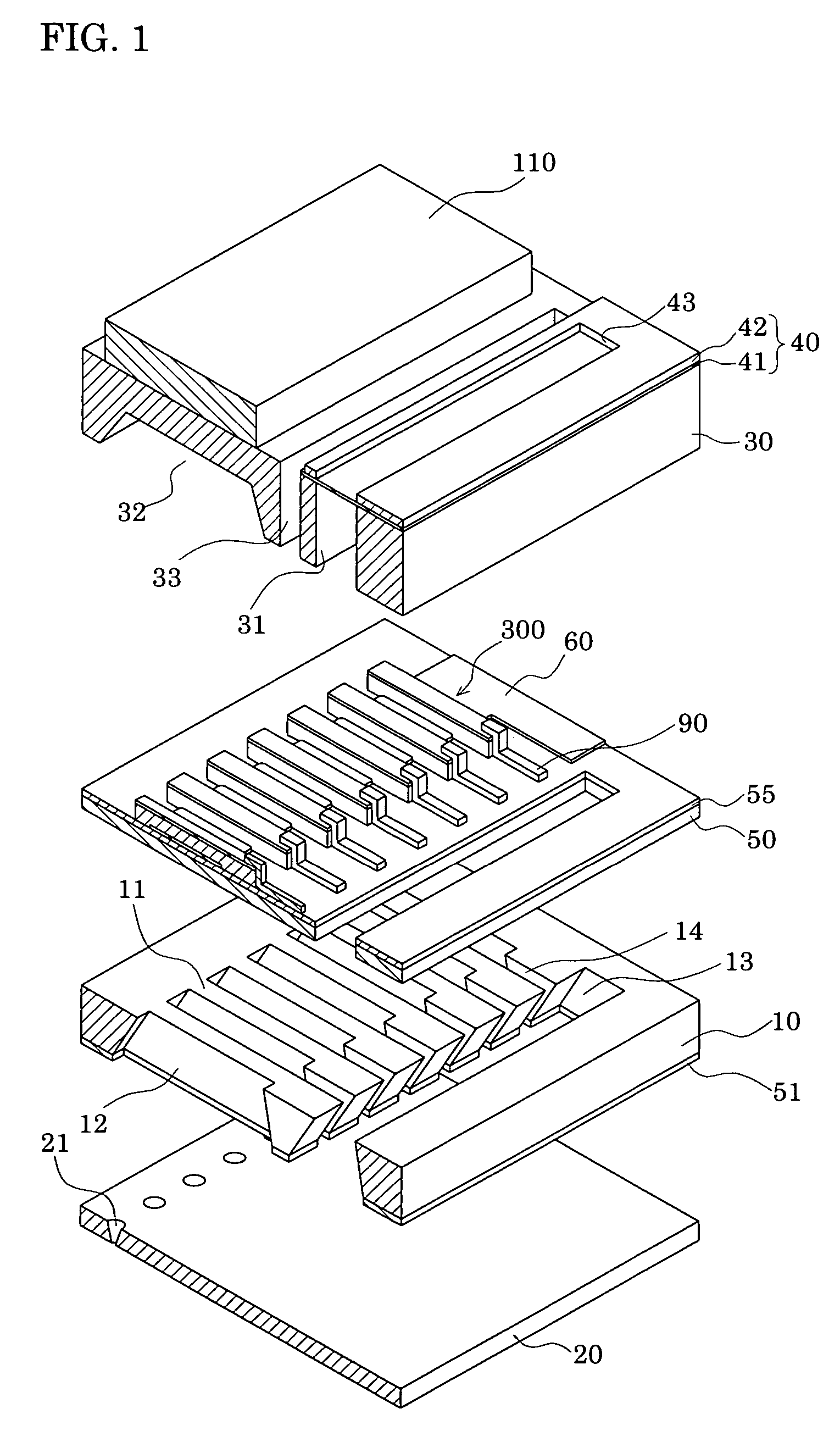

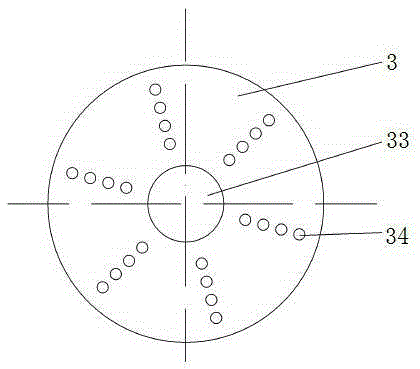

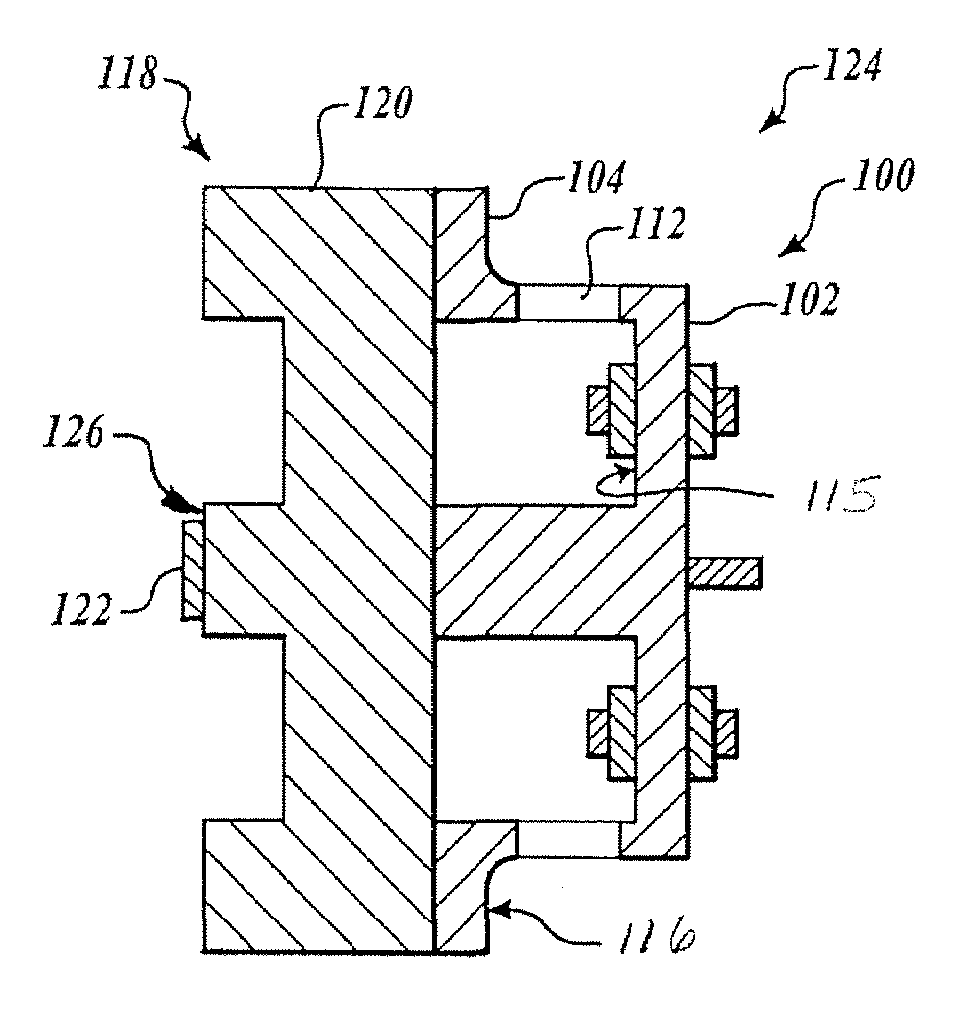

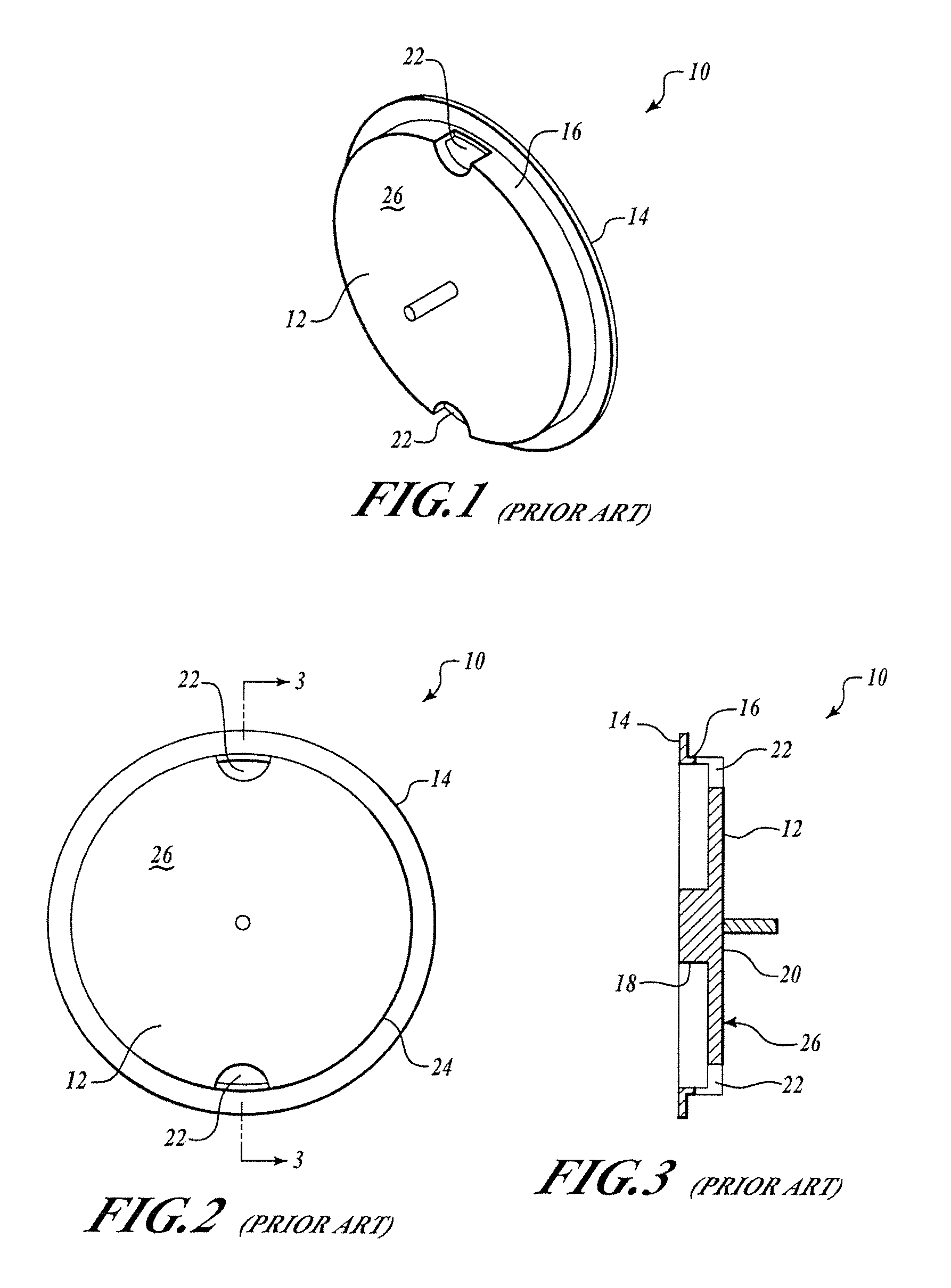

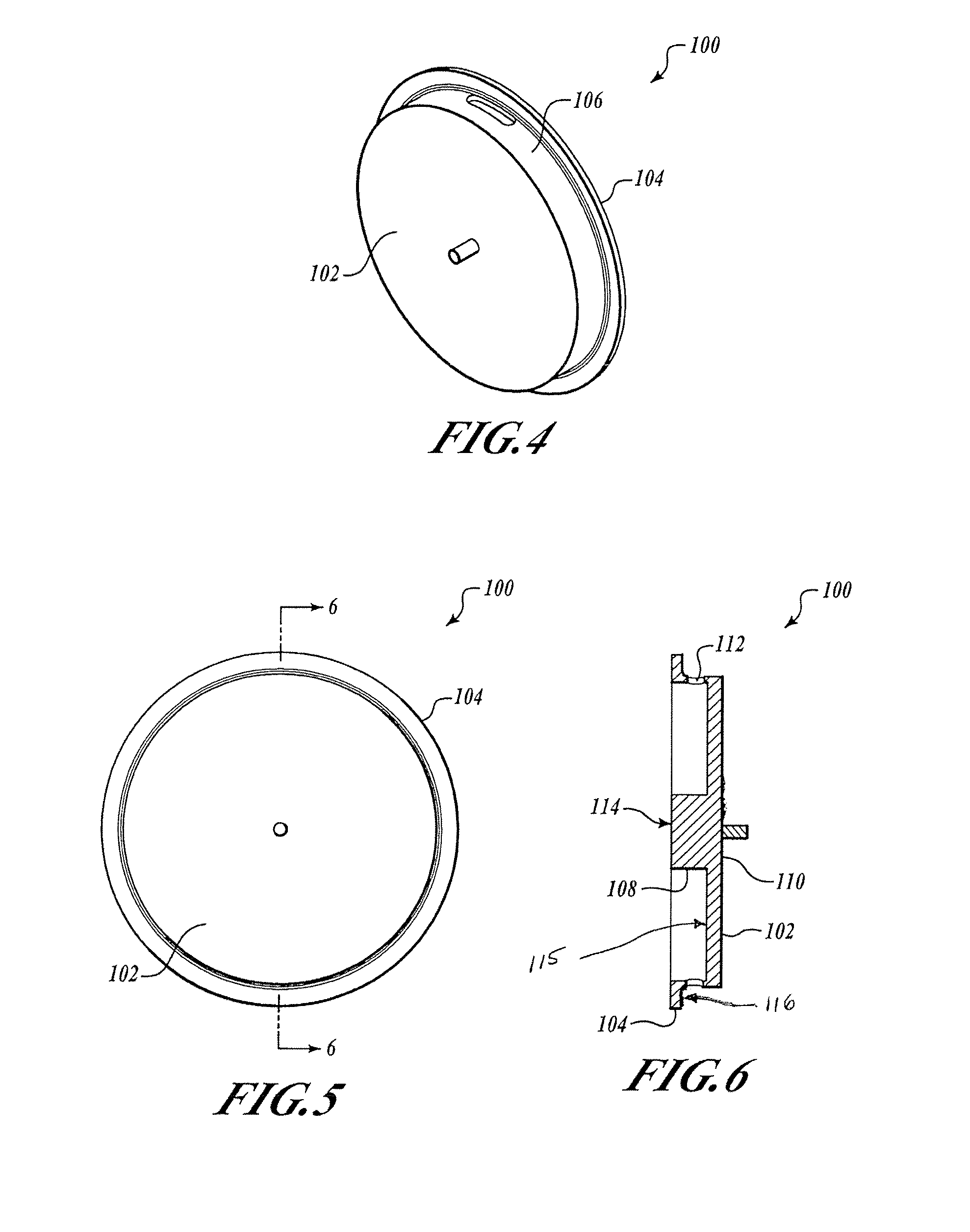

Baseplate for a ring laser gyroscope

ActiveUS20080079948A1Improved distortion characteristicsEvenly distributedSpeed measurement using gyroscopic effectsSagnac effect gyrometersElectricityPath length

A path length control driver for a ring laser gyroscope includes a baseplate, a number of piezoelectric elements, and electrodes. The baseplate includes openings selectively sized and located on the baseplate for reducing distortion thereof during thermal or other mechanical loading. The baseplate includes a central hub extending from a central portion of an actuator plate, which comprises an annular diaphragm member. The baseplate further includes an outer rim or sidewall coupled to the actuator plate and a baseplate flange extending from the sidewall. In one embodiment, a portion of the baseplate flange is attached to a mirror transducer substrate assembly. The mirror transducer substrate assembly includes a reflective device, such as a mirror, and a transducer block. The transducer block includes an optical contact surface onto which the mirror is affixed. The piezoelectric elements are employed to achieve a desired amount of movement of the baseplate, which in turn induces micro-movements or micro-adjustments of the mirror.

Owner:HONEYWELL INT INC

Vane pump

ActiveUS7347677B2Reduced strengthThin thicknessOscillating piston enginesSealing arrangement for pumpsEngineeringCam

Owner:KYB CORP

Baseplate for a ring laser gyroscope

ActiveUS7535574B2Reduce the amount of distortionEvenly distributedSpeed measurement using gyroscopic effectsSagnac effect gyrometersElectricityPath length

A path length control driver for a ring laser gyroscope includes a baseplate, a number of piezoelectric elements, and electrodes. The baseplate includes openings selectively sized and located on the baseplate for reducing distortion thereof during thermal or other mechanical loading. The baseplate includes a central hub extending from a central portion of an actuator plate, which comprises an annular diaphragm member. The baseplate further includes an outer rim or sidewall coupled to the actuator plate and a baseplate flange extending from the sidewall. In one embodiment, a portion of the baseplate flange is attached to a mirror transducer substrate assembly. The mirror transducer substrate assembly includes a reflective device, such as a mirror, and a transducer block. The transducer block includes an optical contact surface onto which the mirror is affixed. The piezoelectric elements are employed to achieve a desired amount of movement of the baseplate, which in turn induces micro-movements or micro-adjustments of the mirror.

Owner:HONEYWELL INT INC

Aluminum powder metal alloying method

A zirconium-doped aluminum powder metal and a method of making this powder metal are disclosed. The method of making includes forming an aluminum—zirconium melt in which a zirconium content of the aluminum—zirconium melt is less than 2.0 percent by weight. The aluminum—zirconium melt then powderized to form a zirconium-doped aluminum powder metal. The powderization may occur by, for example, air atomization.

Owner:SKN SINTER METALS LLC (US)

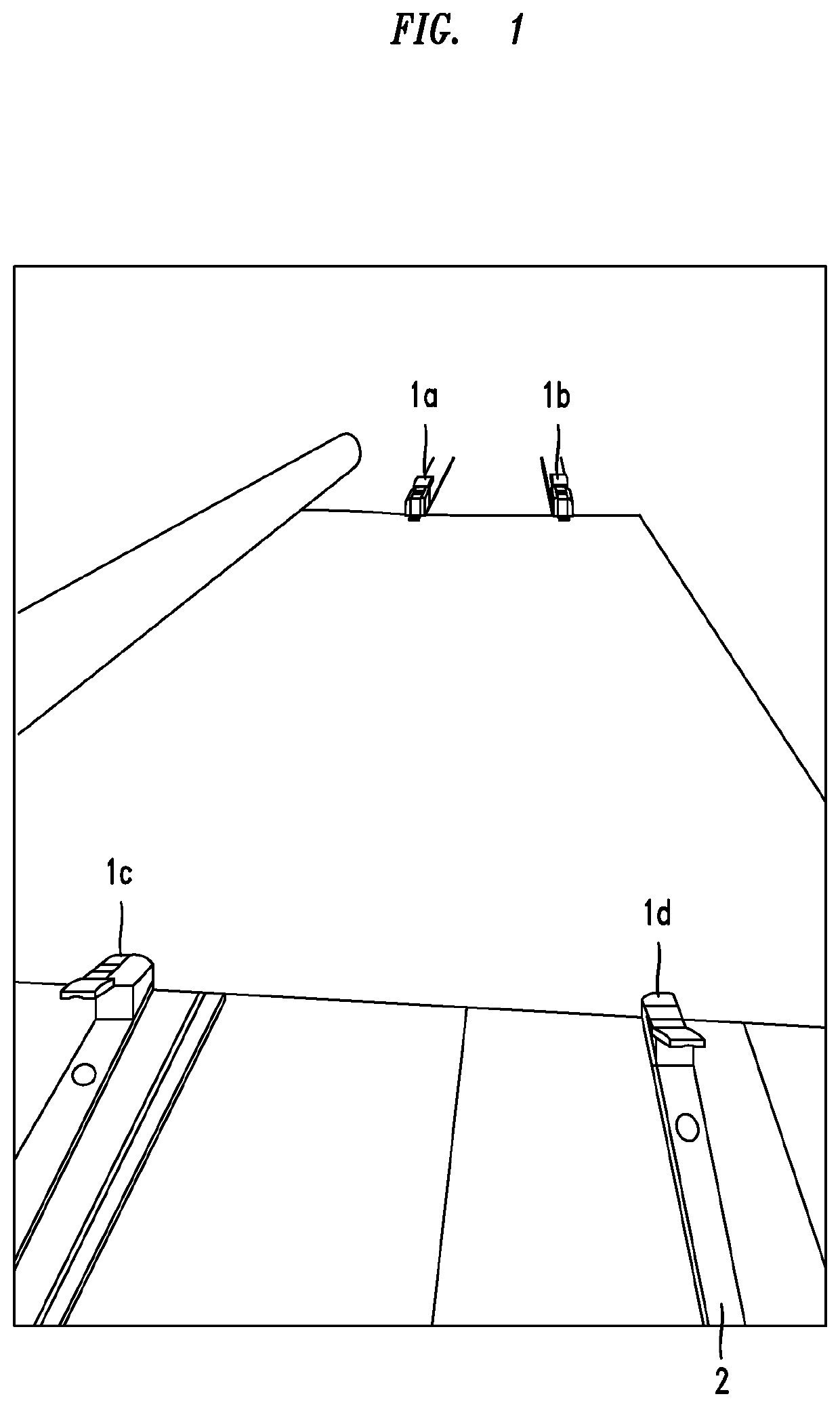

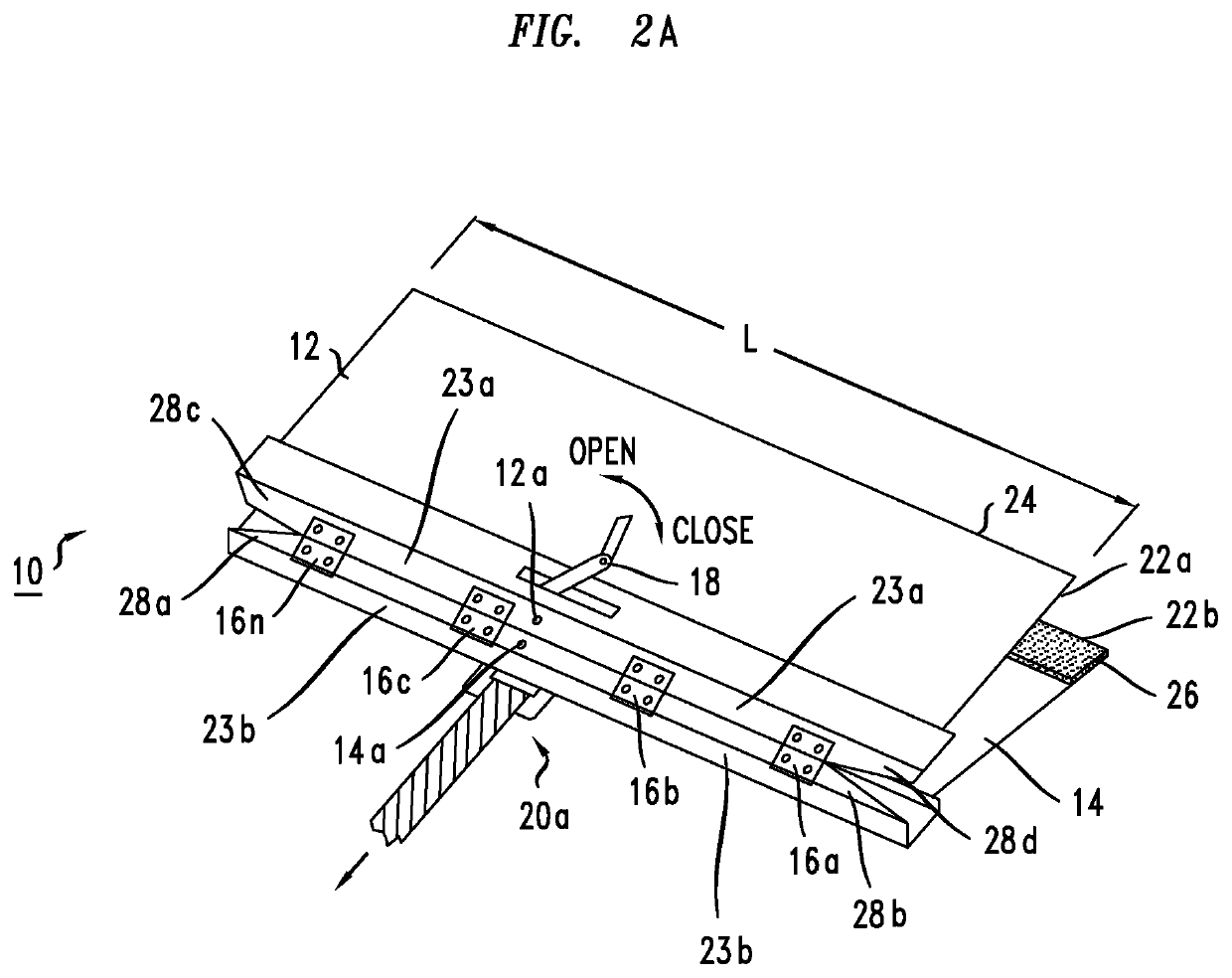

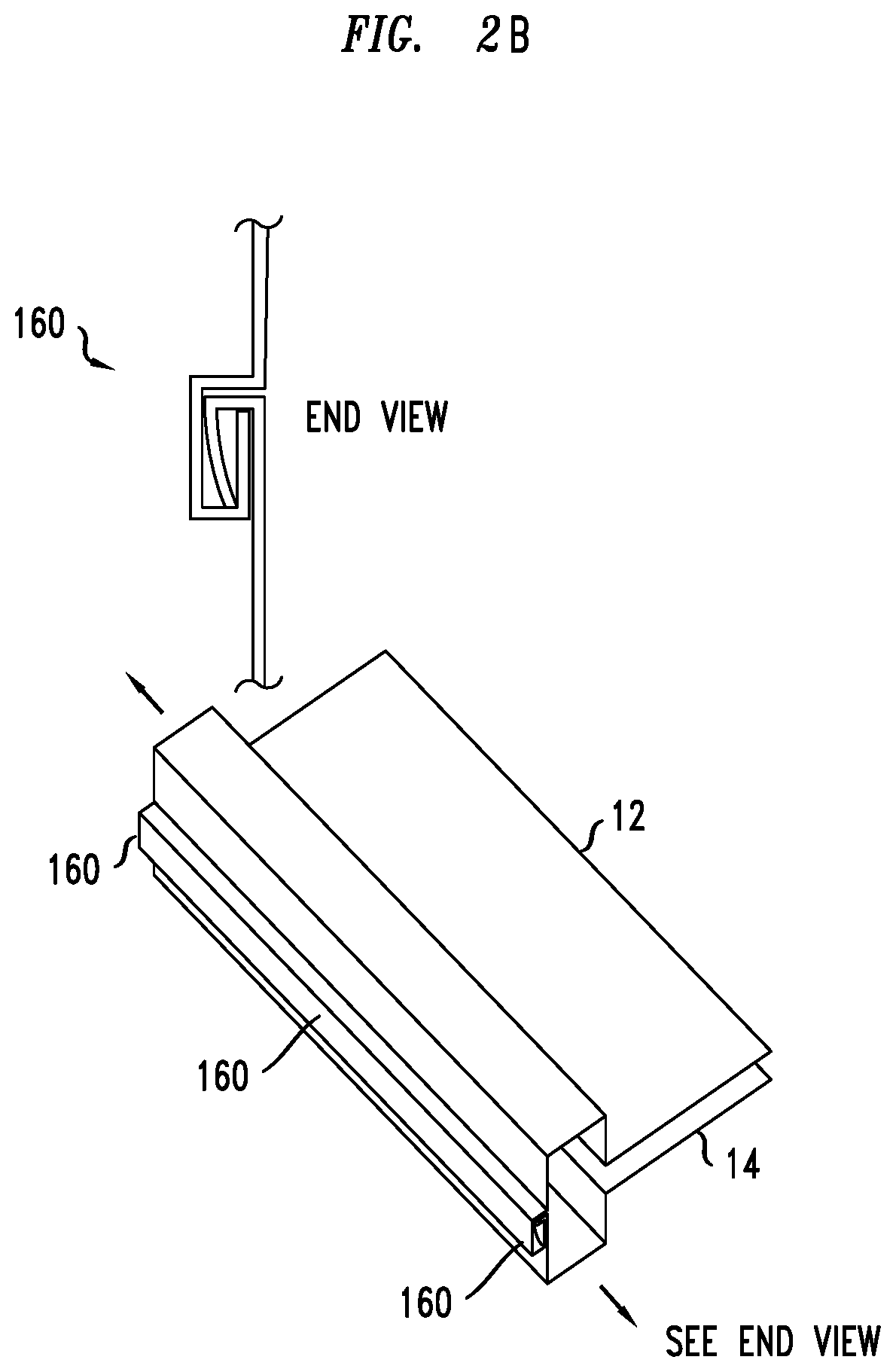

Devices and related methods for maintaining woven material in fixed orientation

ActiveUS20210025092A1Reduces and minimizesReduce the amount of distortionWork-feeding meansMattress sewingEngineeringMechanical engineering

Owner:JACKSON JANNETTE LEE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com