Patents

Literature

75results about How to "Surface damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

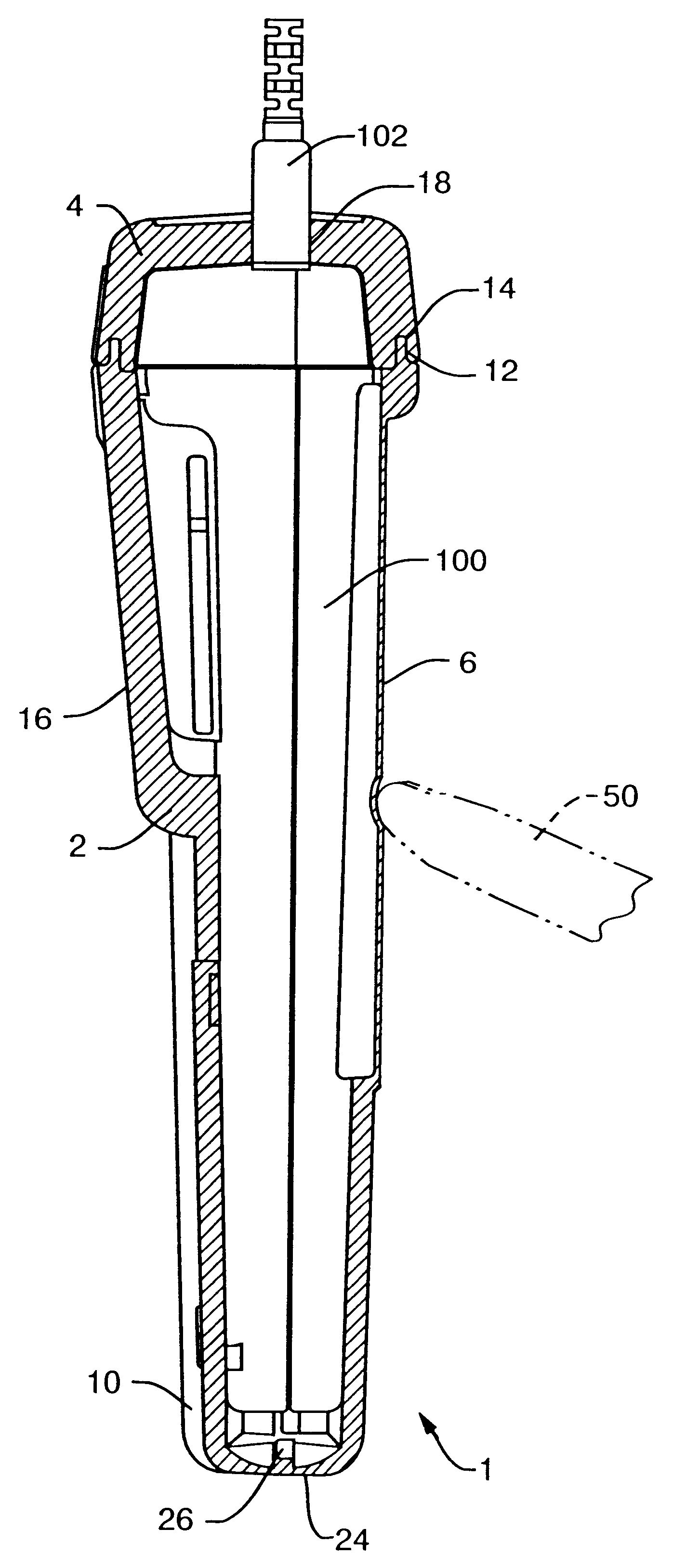

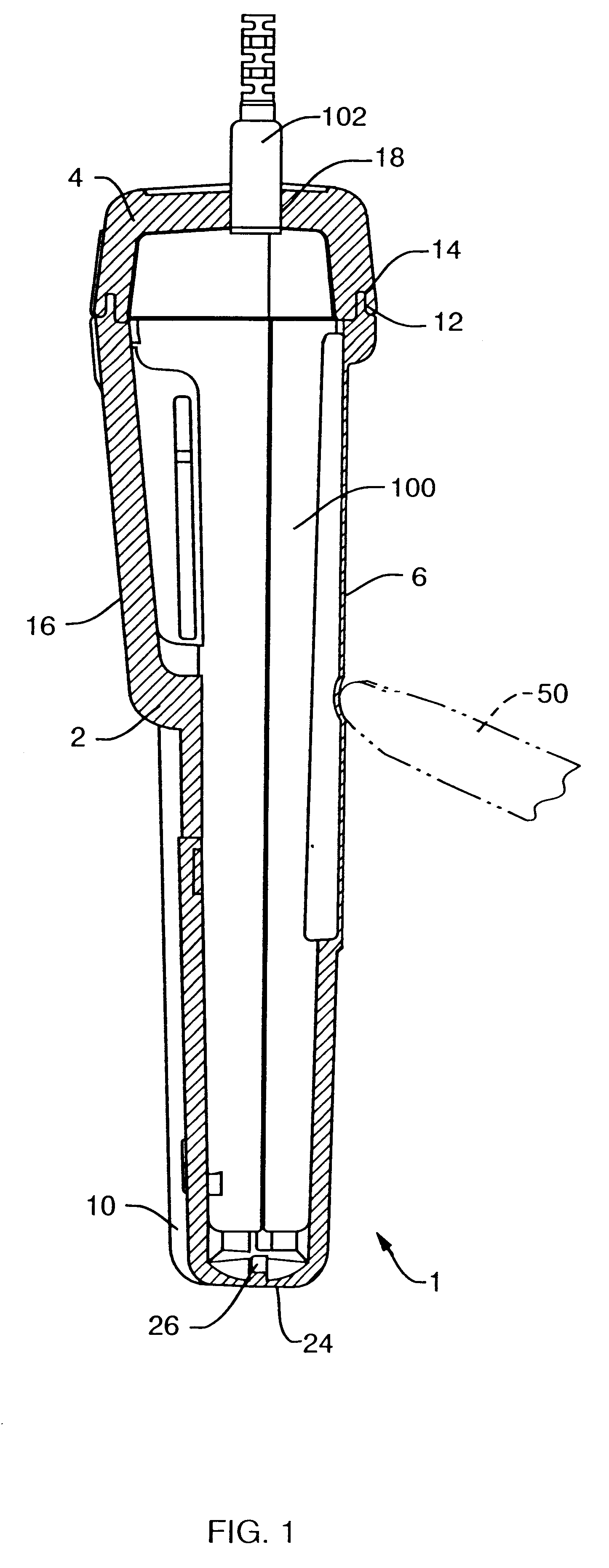

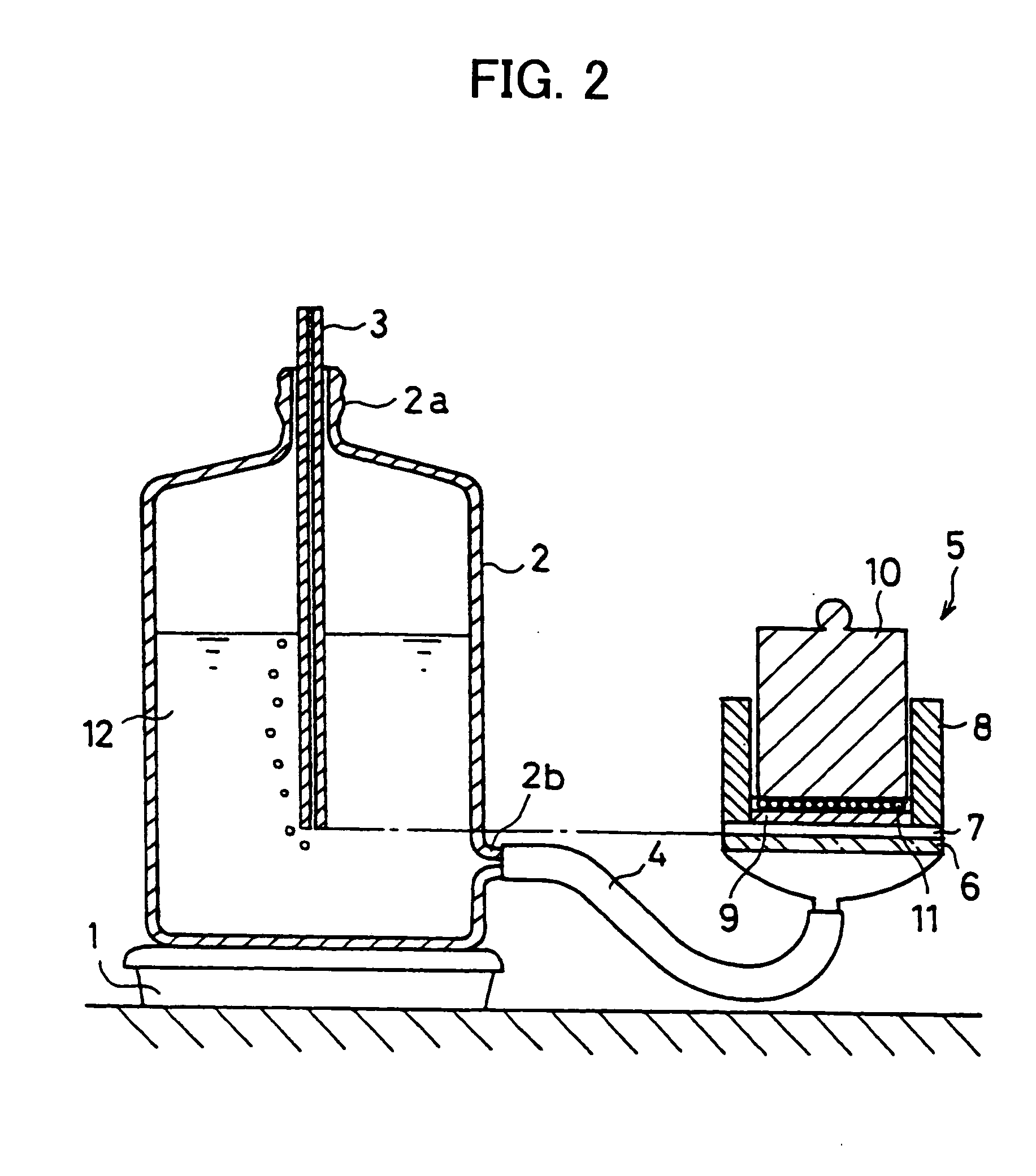

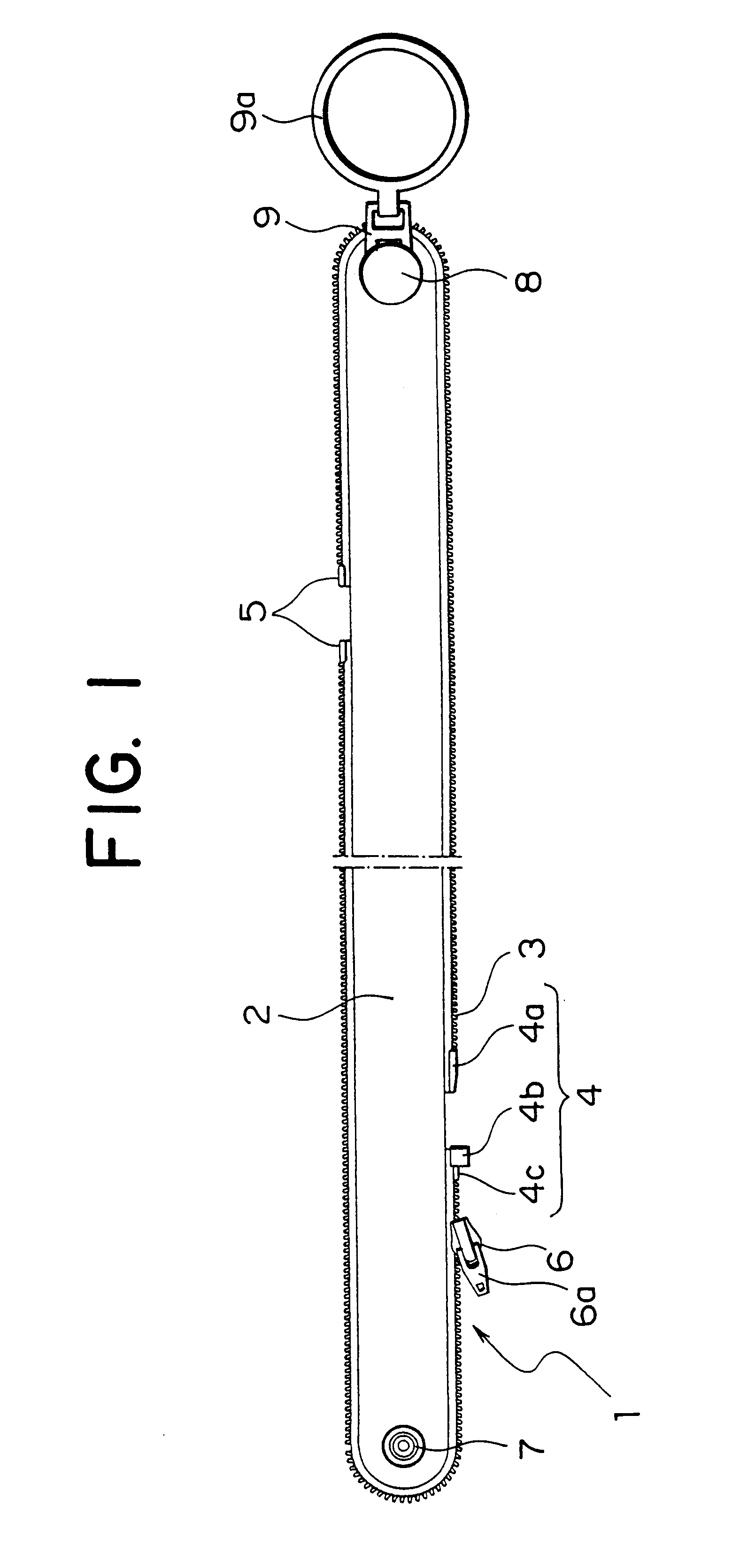

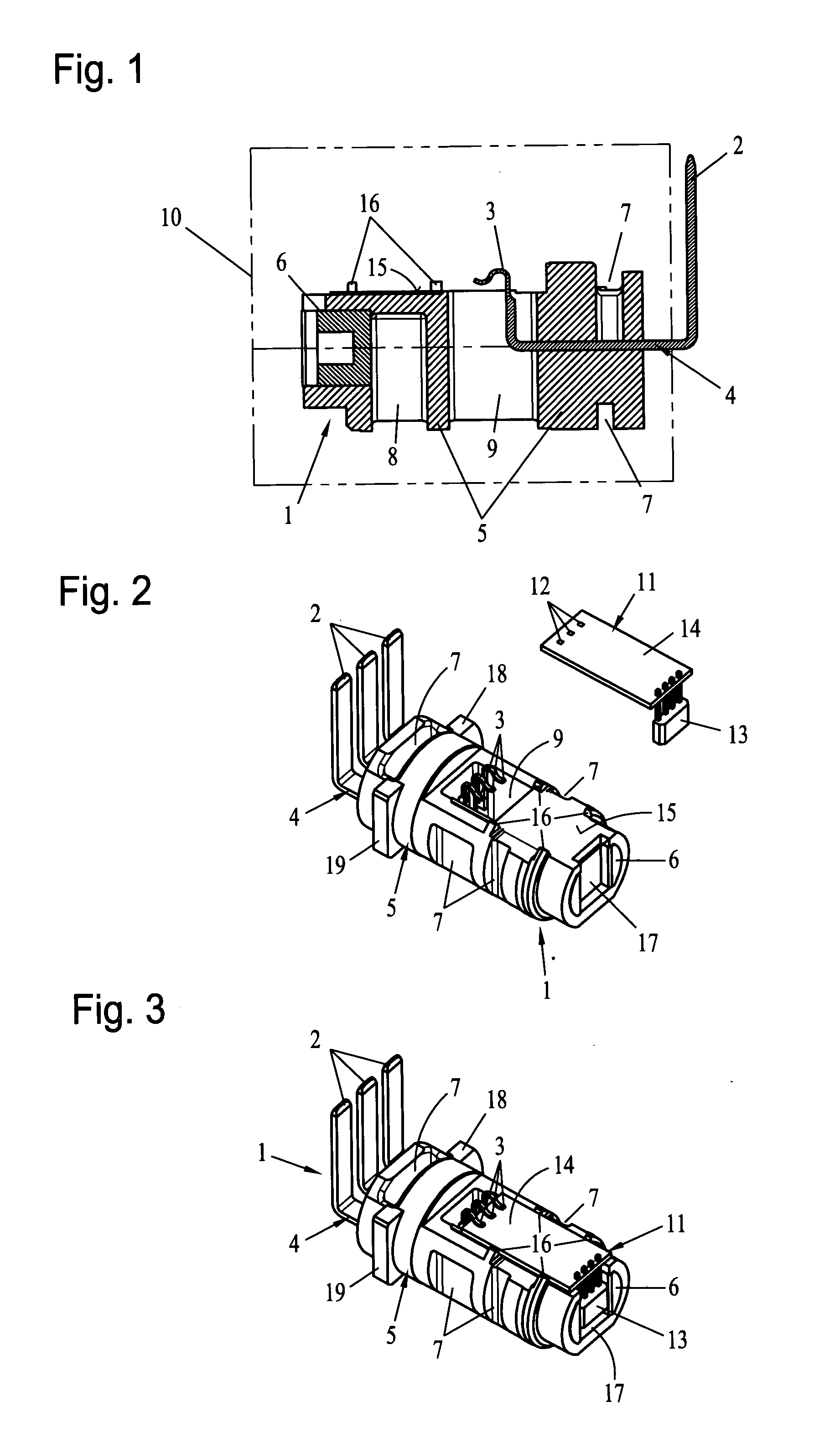

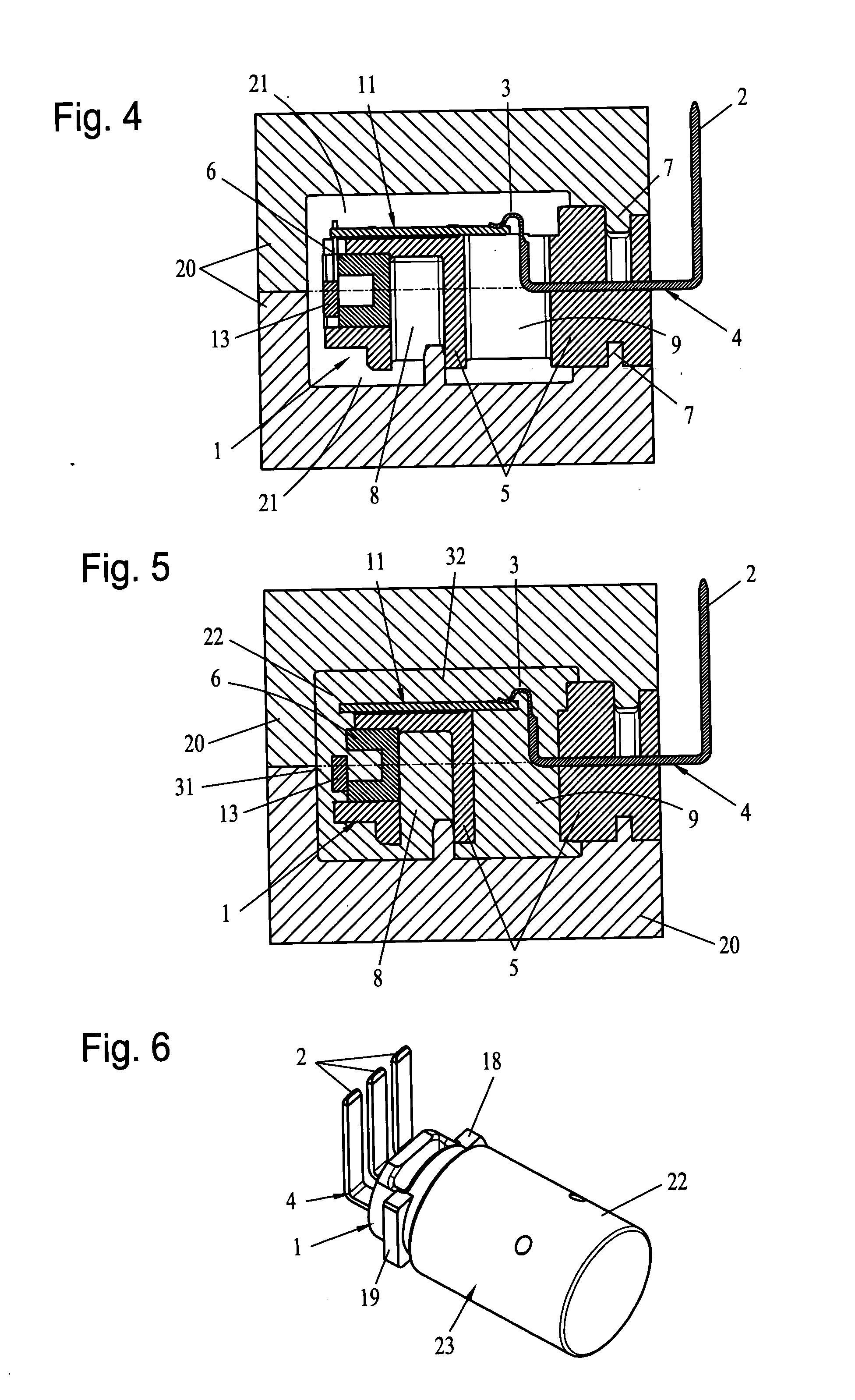

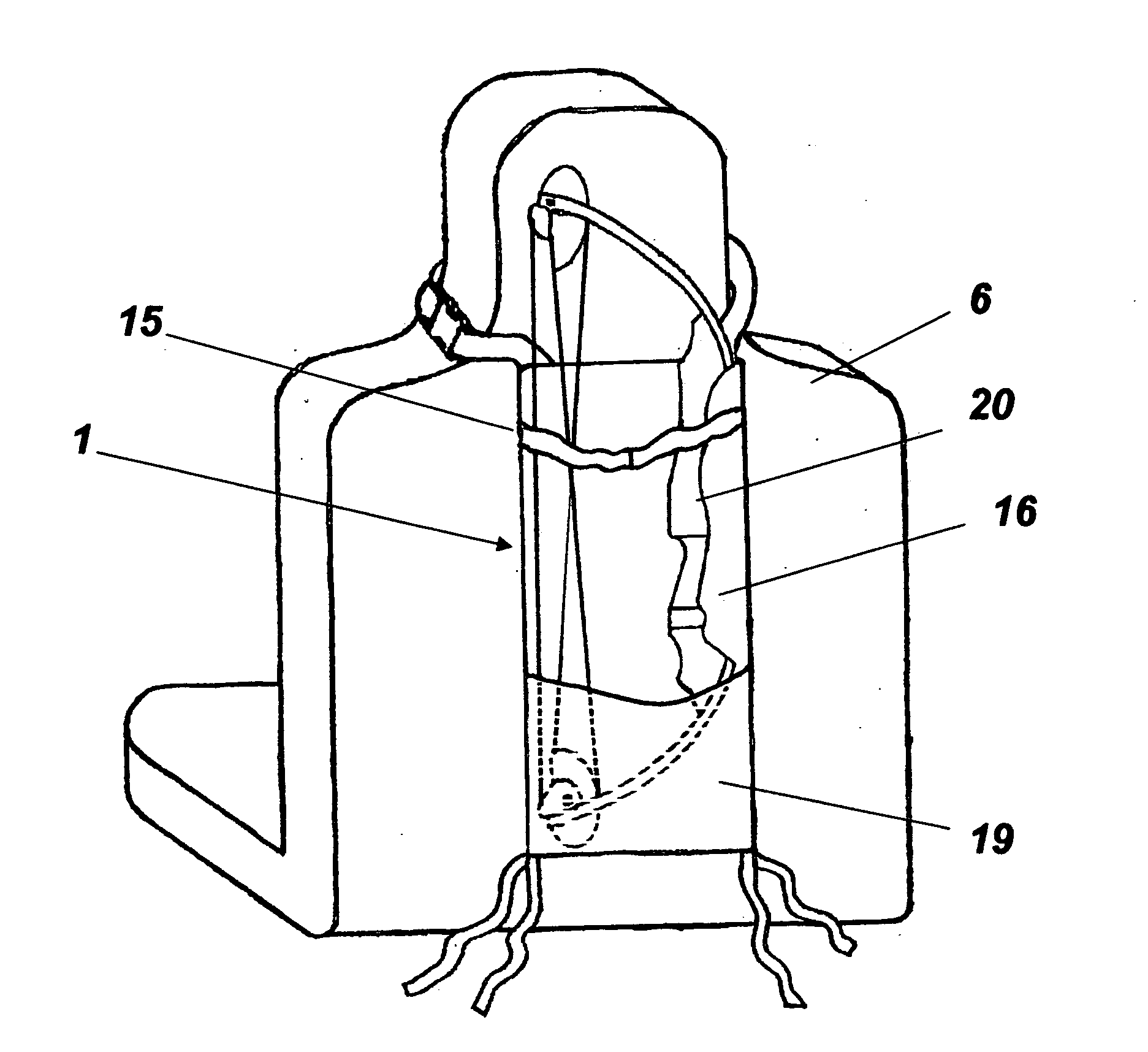

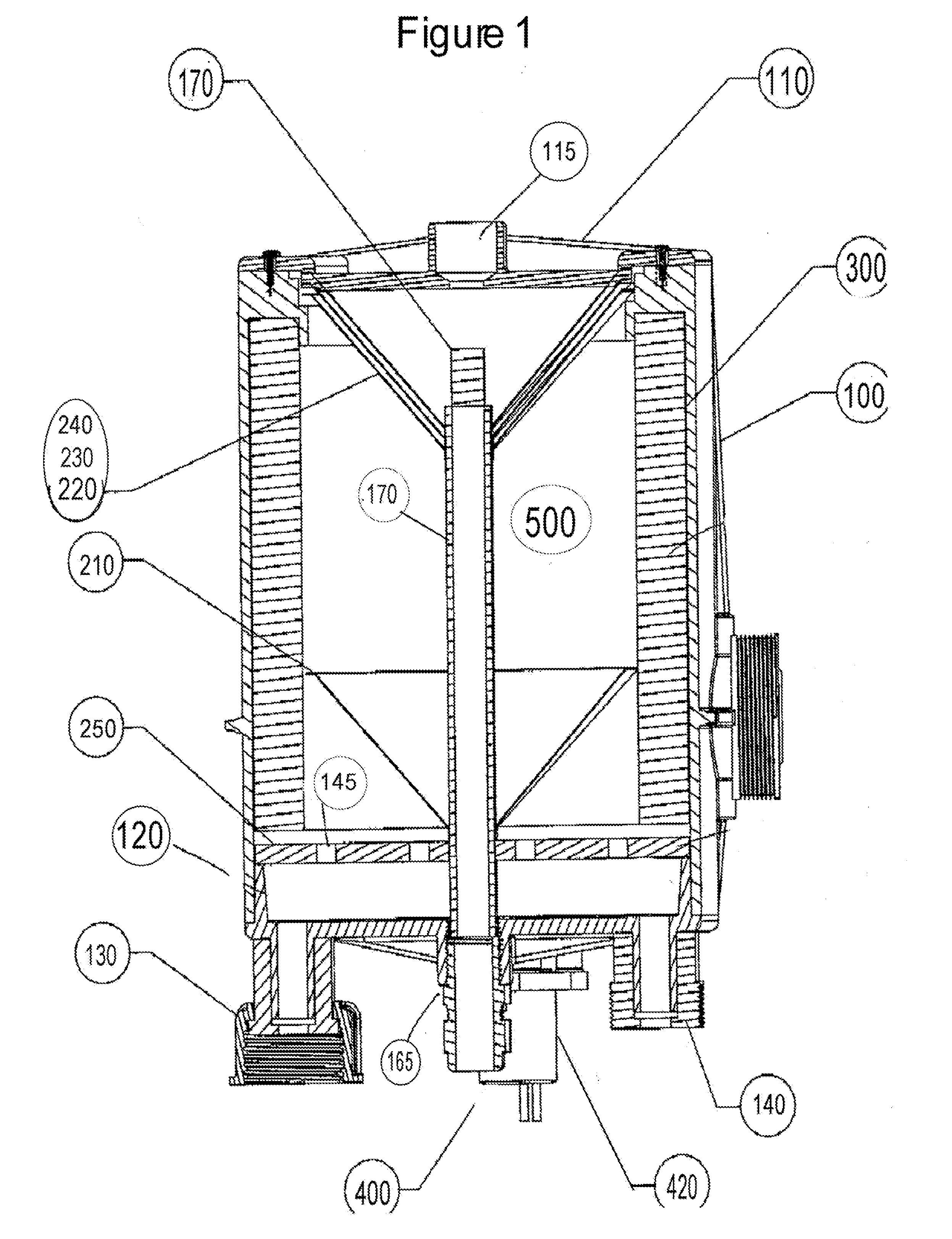

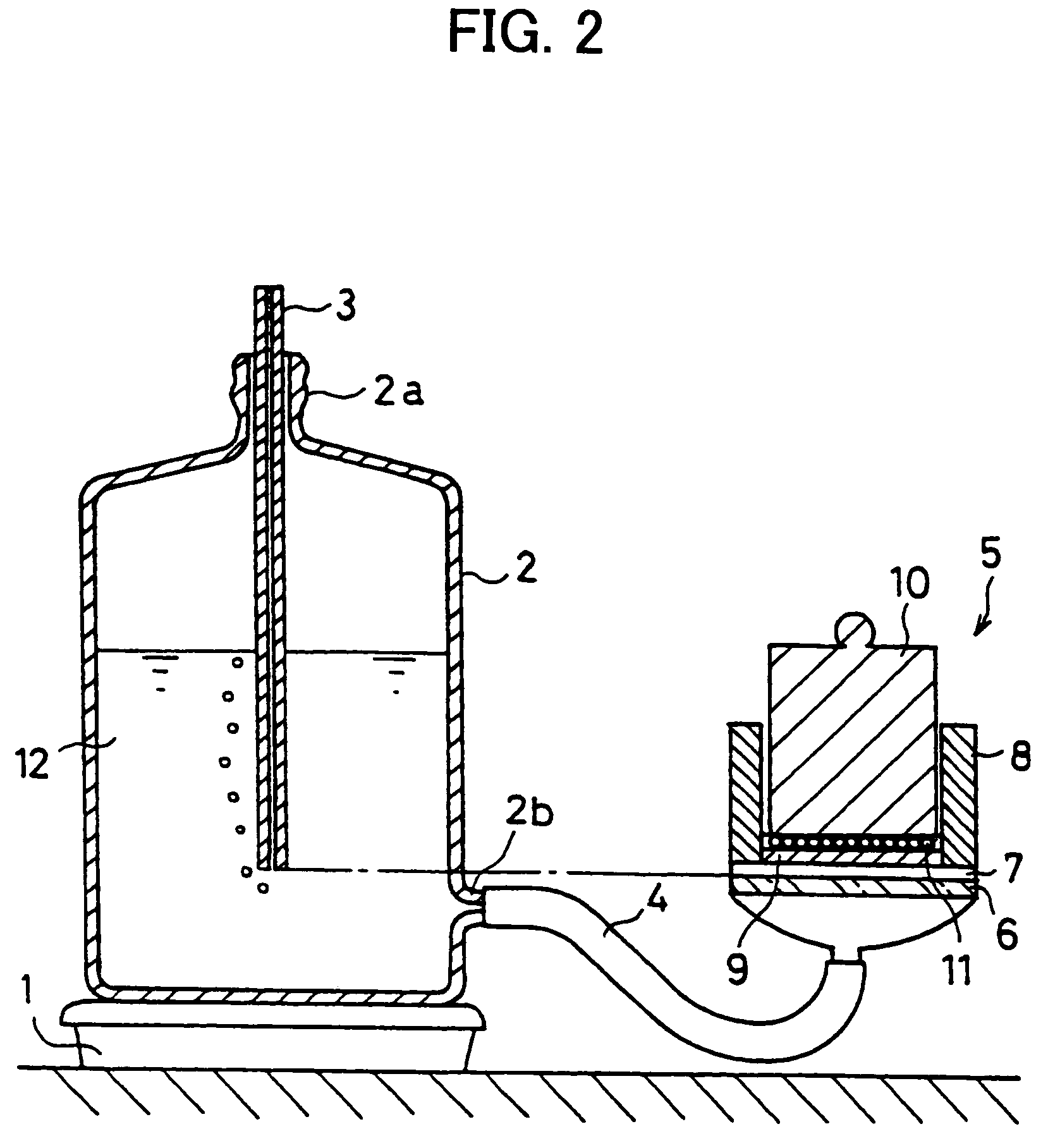

Watertight protective device for holding a measuring or display device

InactiveUS6634494B1Extended service lifeImprove protectionEmergency casingsOther accessoriesInteraction fieldEngineering

A protective device for holding an apparatus having an interaction field is formed from a dimensionally stable protective housing having a lower housing part and an upper housing part. The lower housing part and the upper housing part are releasably connected with one another and an inside contour of the protective housing is adapted and constructed to closely receive the apparatus. The protective housing may be watertight and is provided with a flexible operating area to enable an interaction field to be viewed and manipulated. The operating area may be integral with the rest of the protective housing. Seals are provided between the apparatus and the upper and / or lower housing part and possibly also between the upper and / or lower housing parts themselves. The seals may be formed of a sealing lip or O-ring mating with a circumferential groove. The protective device may also include sealed feedthroughs for connectors, such as cables and external sensors.

Owner:TESTO AG

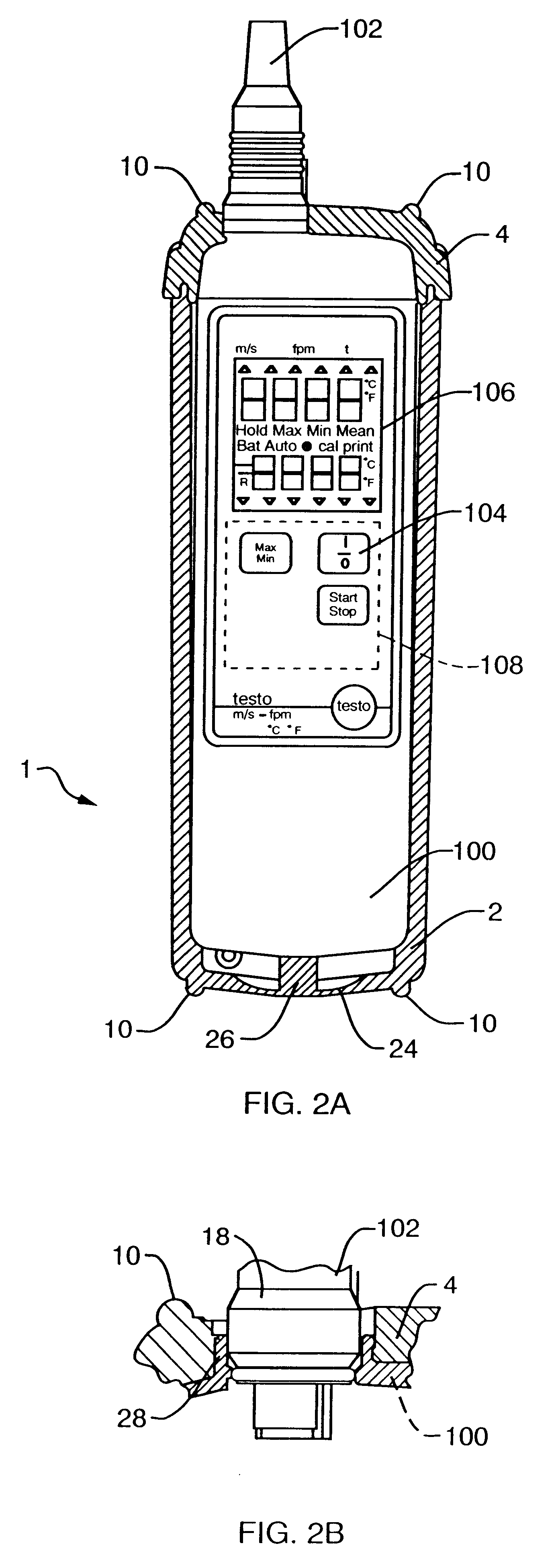

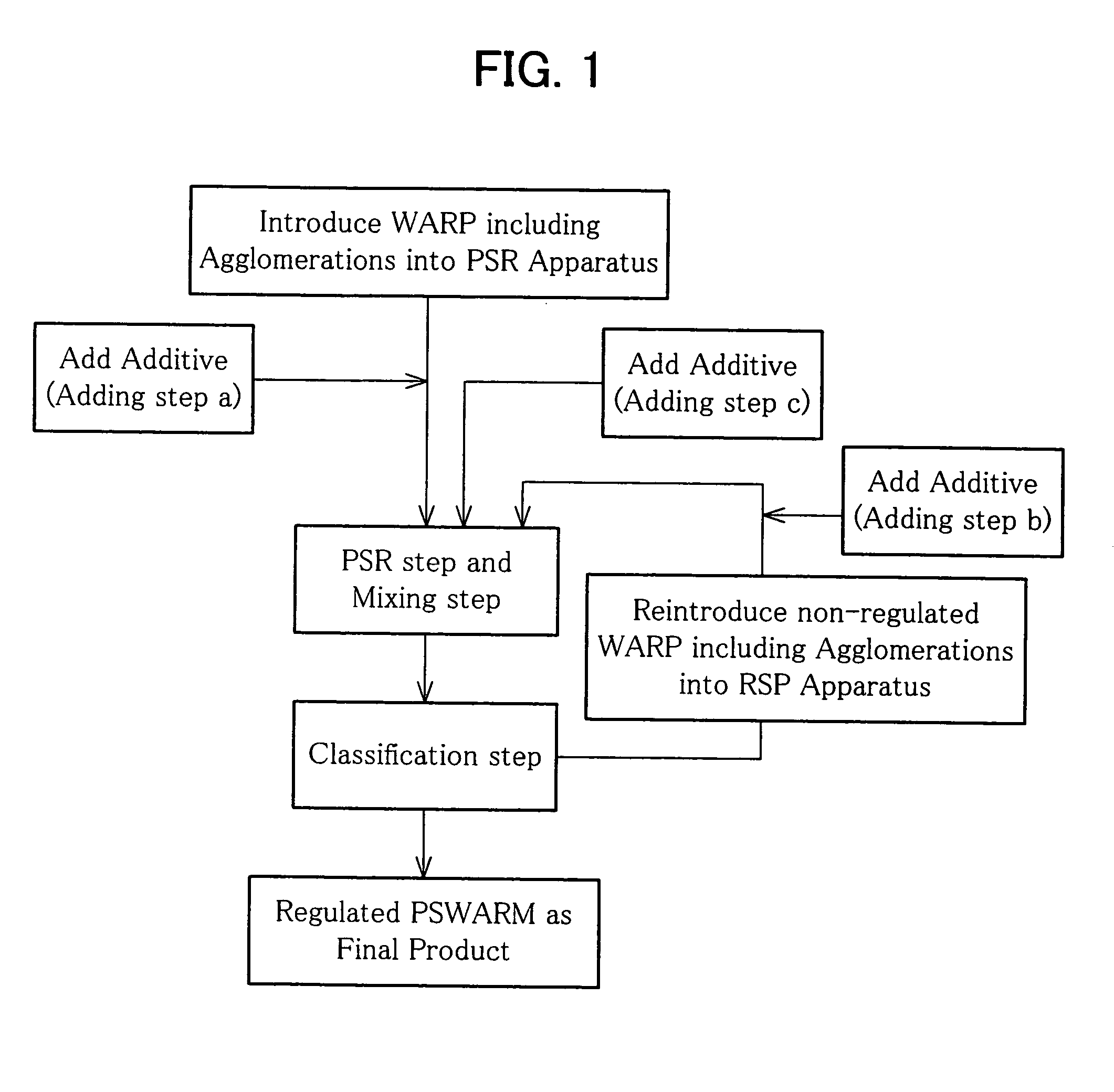

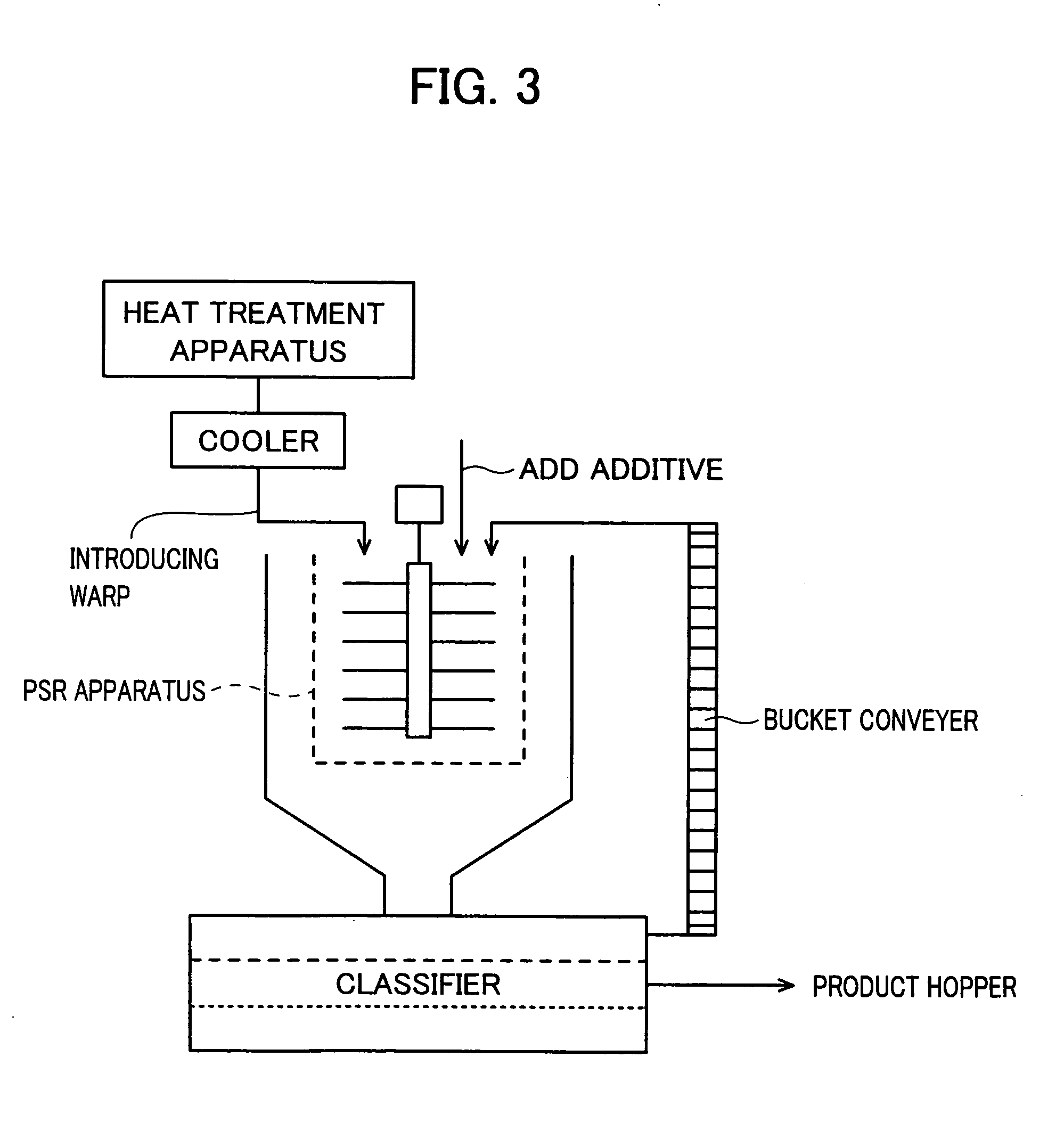

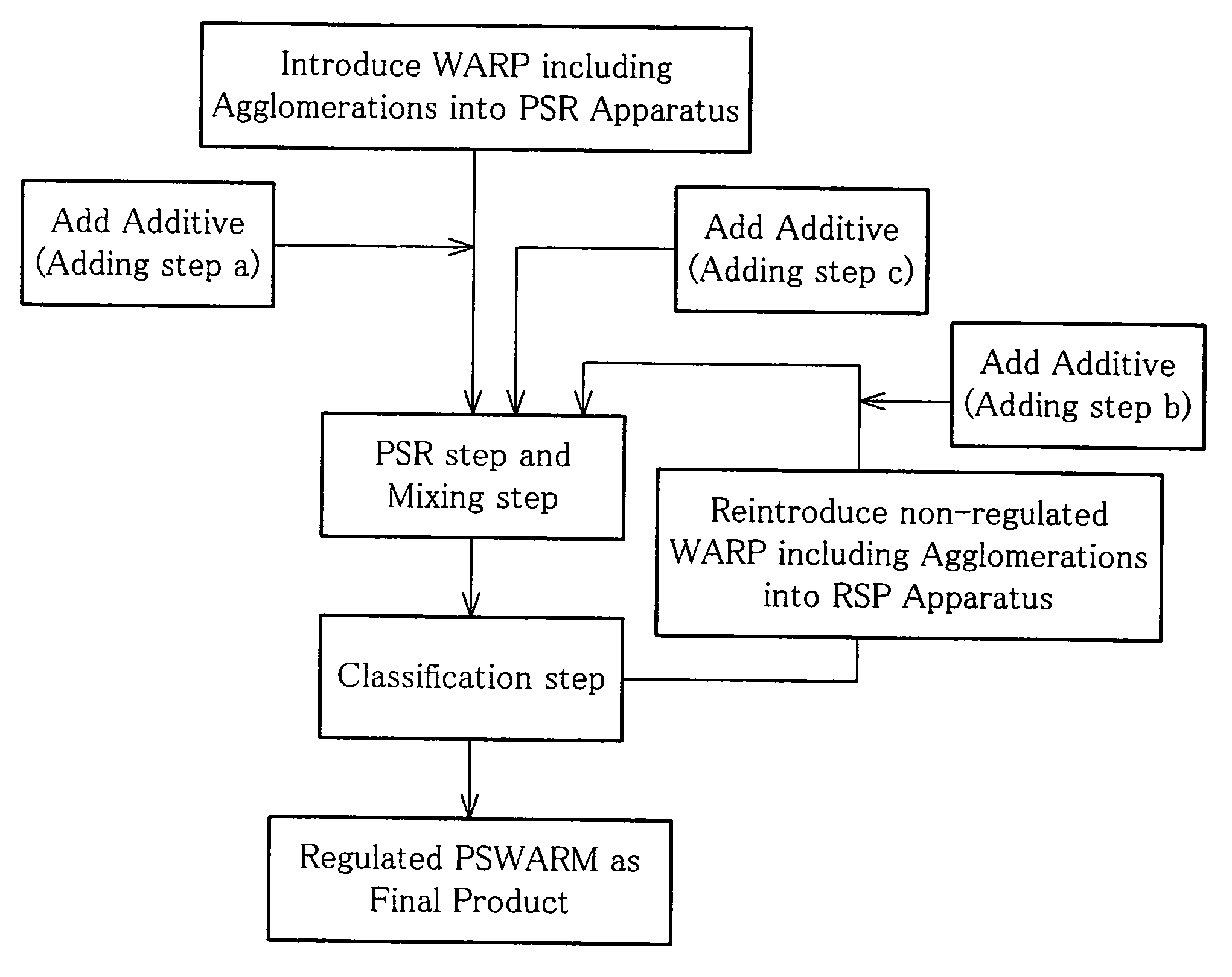

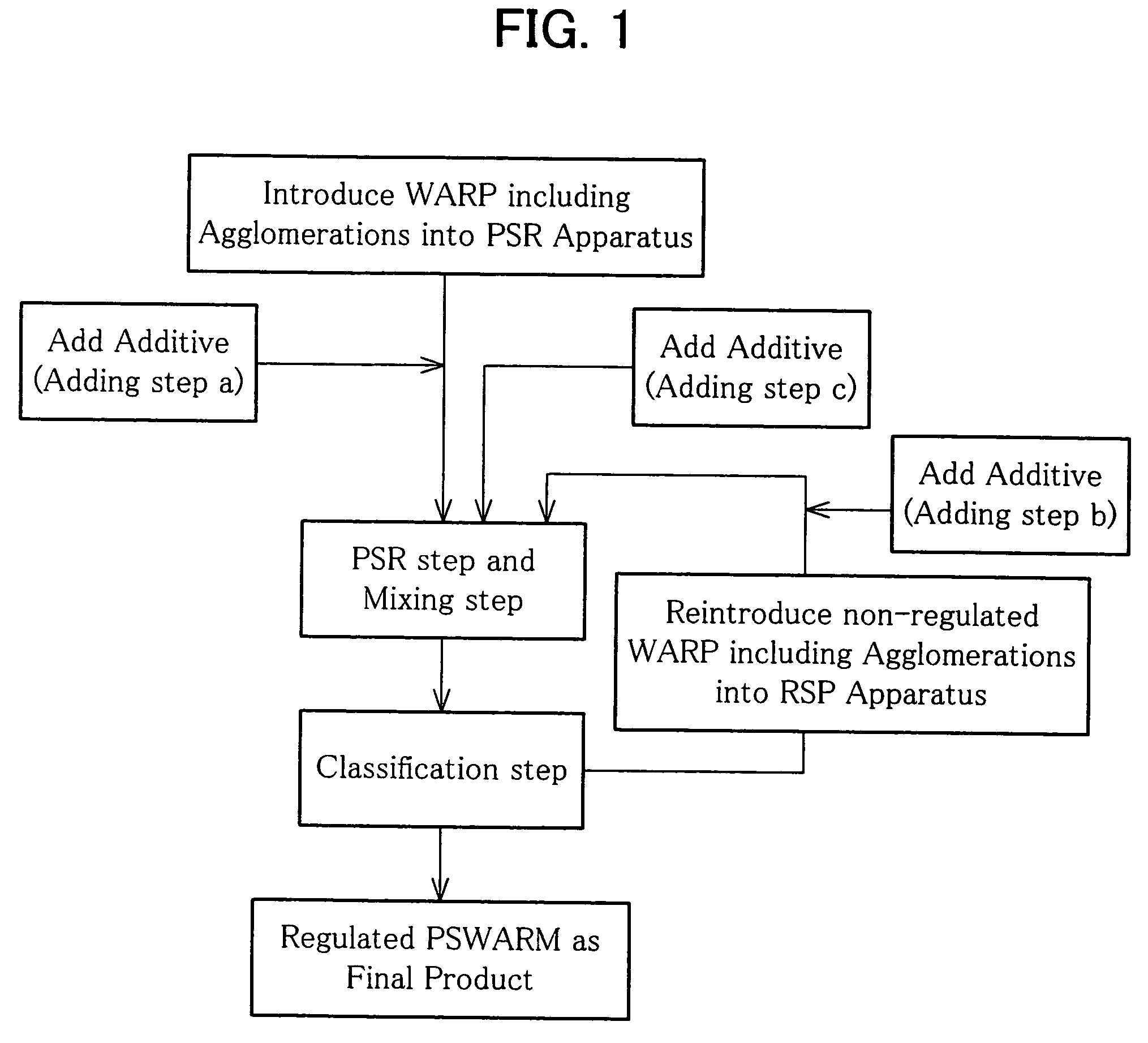

Method of producing particle-shape water-absorbing resin material

ActiveUS20050113252A1Preventing property deteriorationSurface damageOther chemical processesAbsorbent padsPolymer scienceCross linker

Owner:NIPPON SHOKUBAI CO LTD

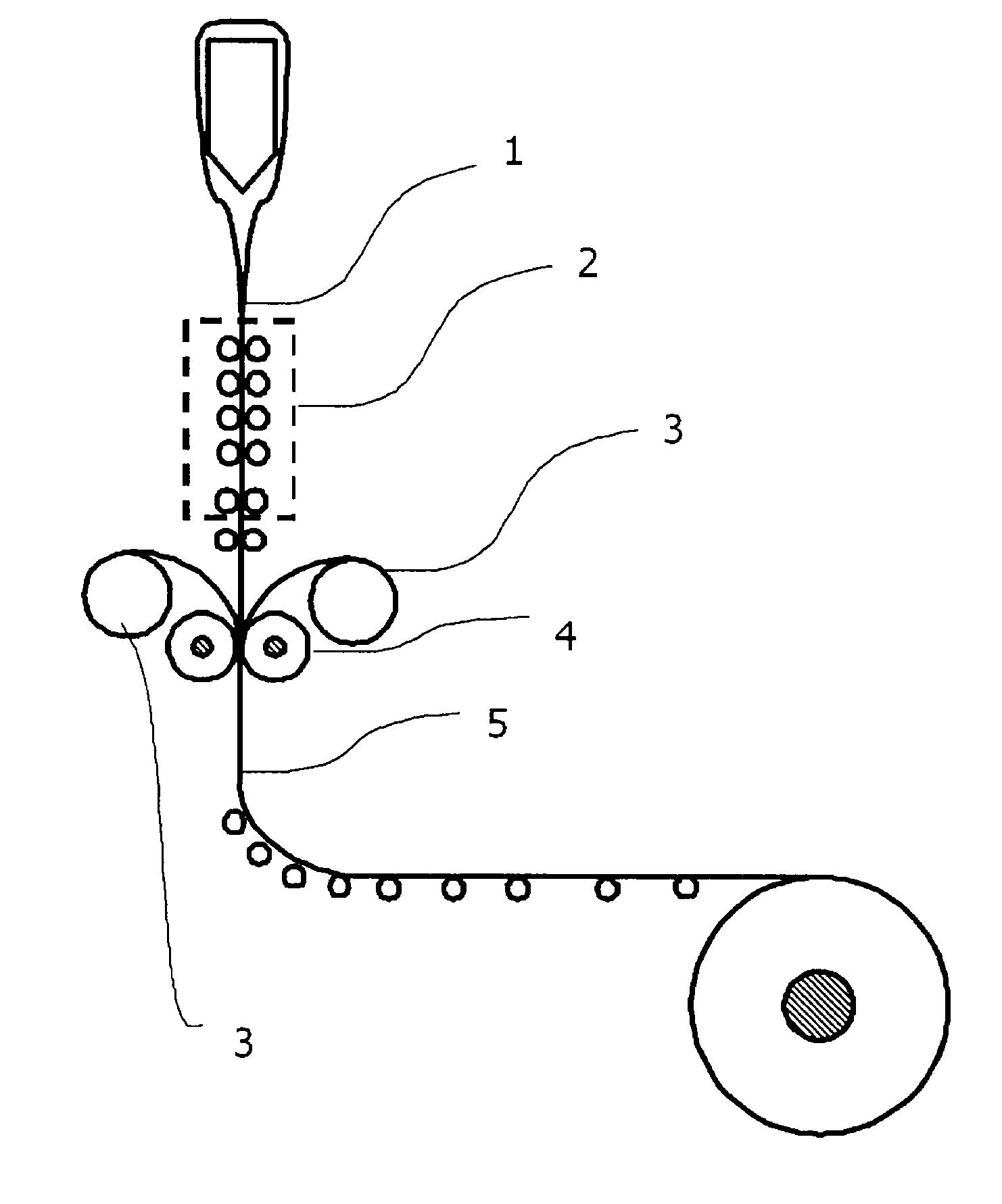

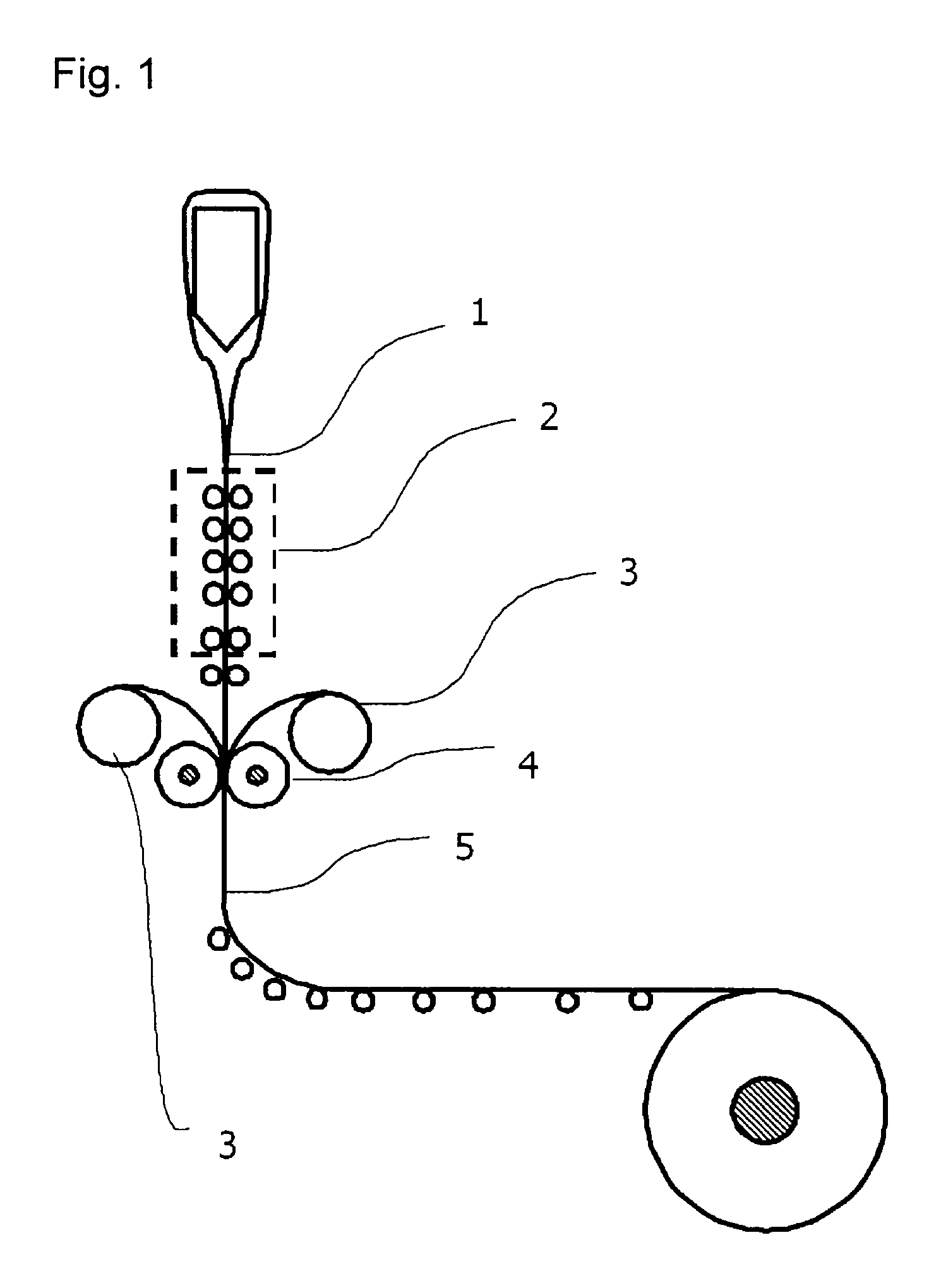

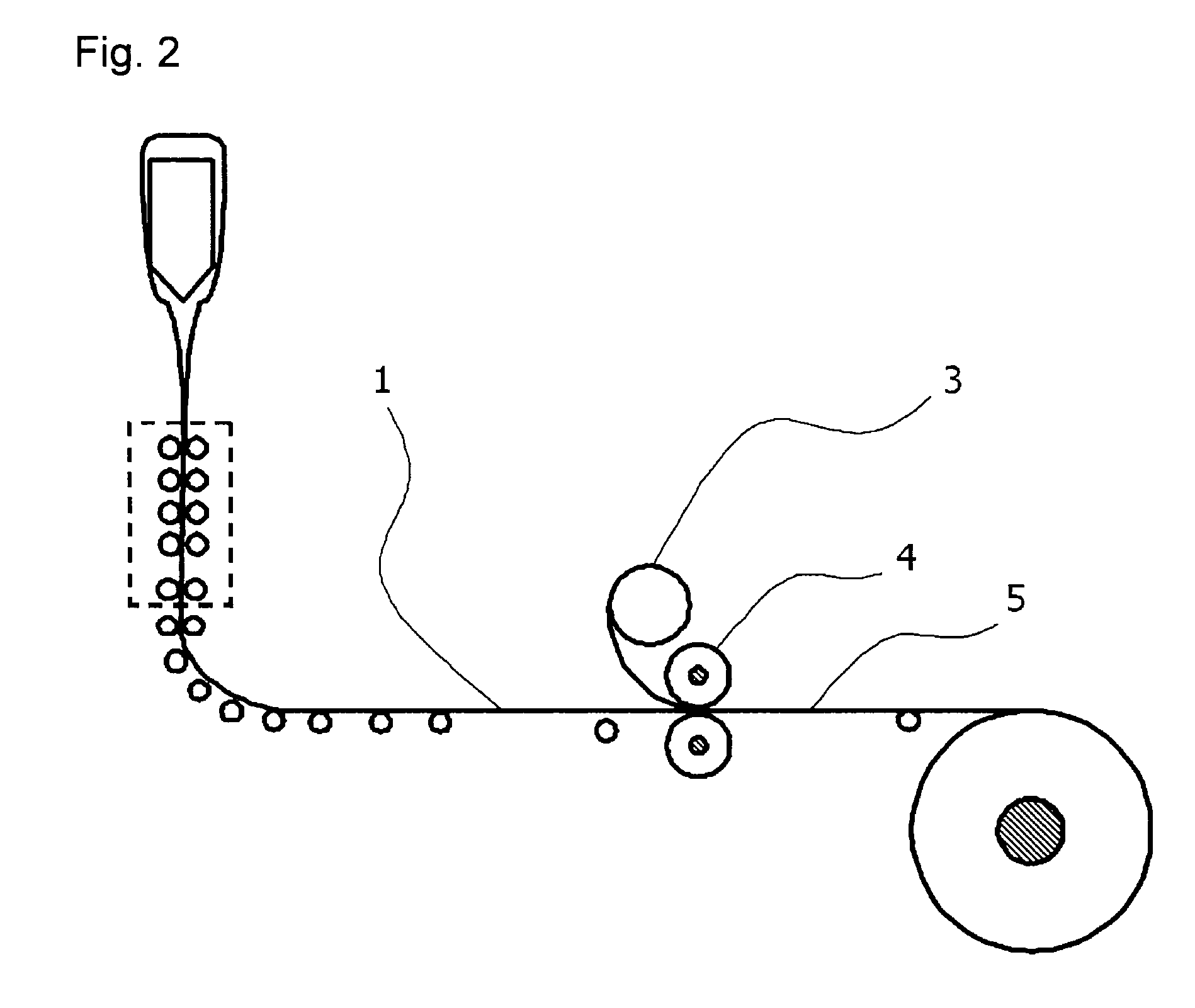

Process for producing glass/resin composite

InactiveUS20100192634A1High mechanical strengthReduce the possibilityLayered product treatmentLaminationCutting glassPolyresin

To provide a process for producing a glass / resin composite having a sufficient transportability, handling efficiency and processability, even though the thickness of the glass is very thin, without impairing excellent properties of glass.A process for producing a glass / resin composite, which comprises forming molten glass into a glass ribbon and forming a resin layer on at least one surface of the glass ribbon is provided. The resin layer is preferably formed by bonding to a glass ribbon, applying a heat melt resin or applying a curable resin. Further, a process for producing a glass / resin composite, wherein a cut glass substrate is bonded on a continuously supplied resin film is provided.

Owner:ASAHI GLASS CO LTD

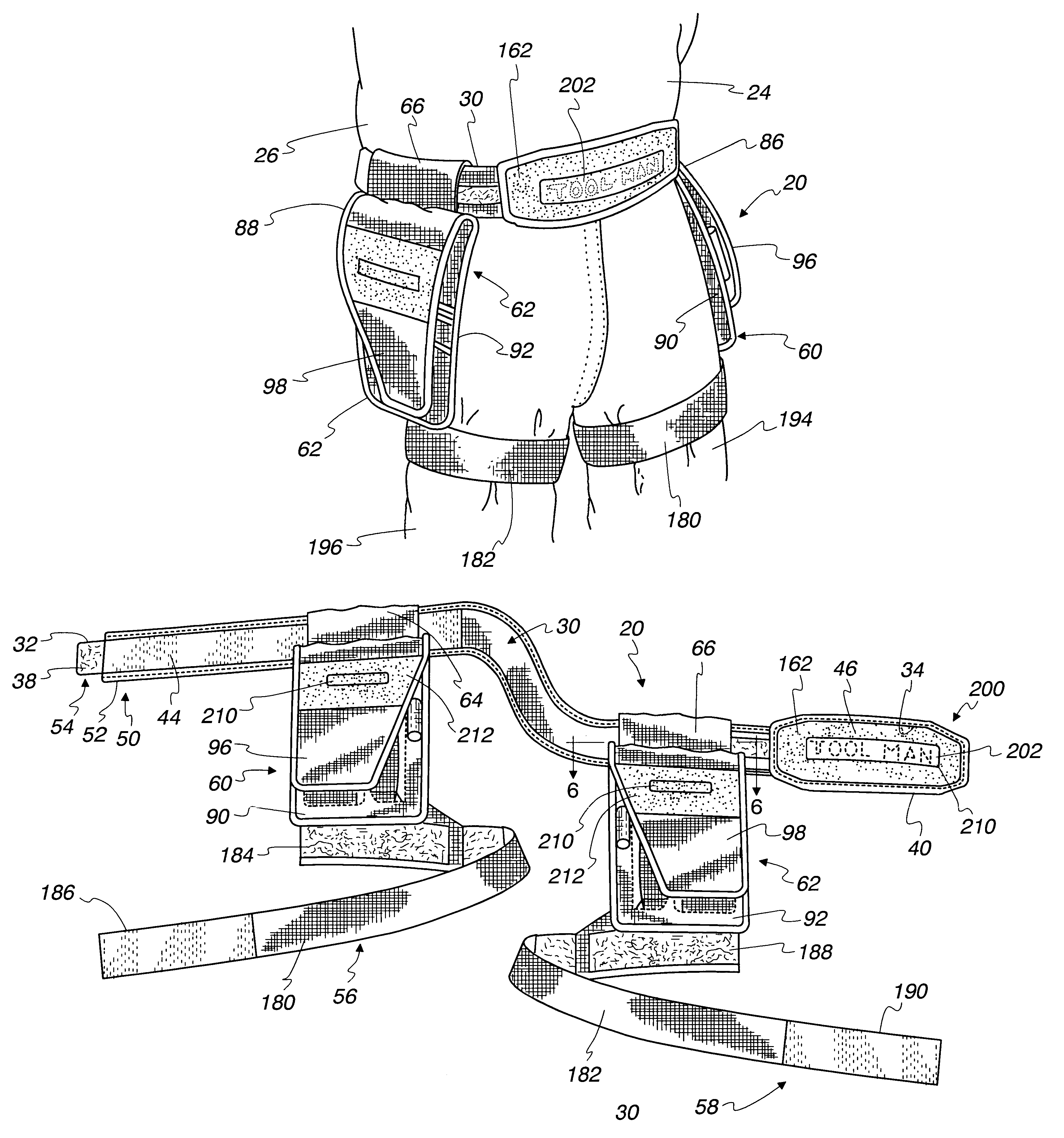

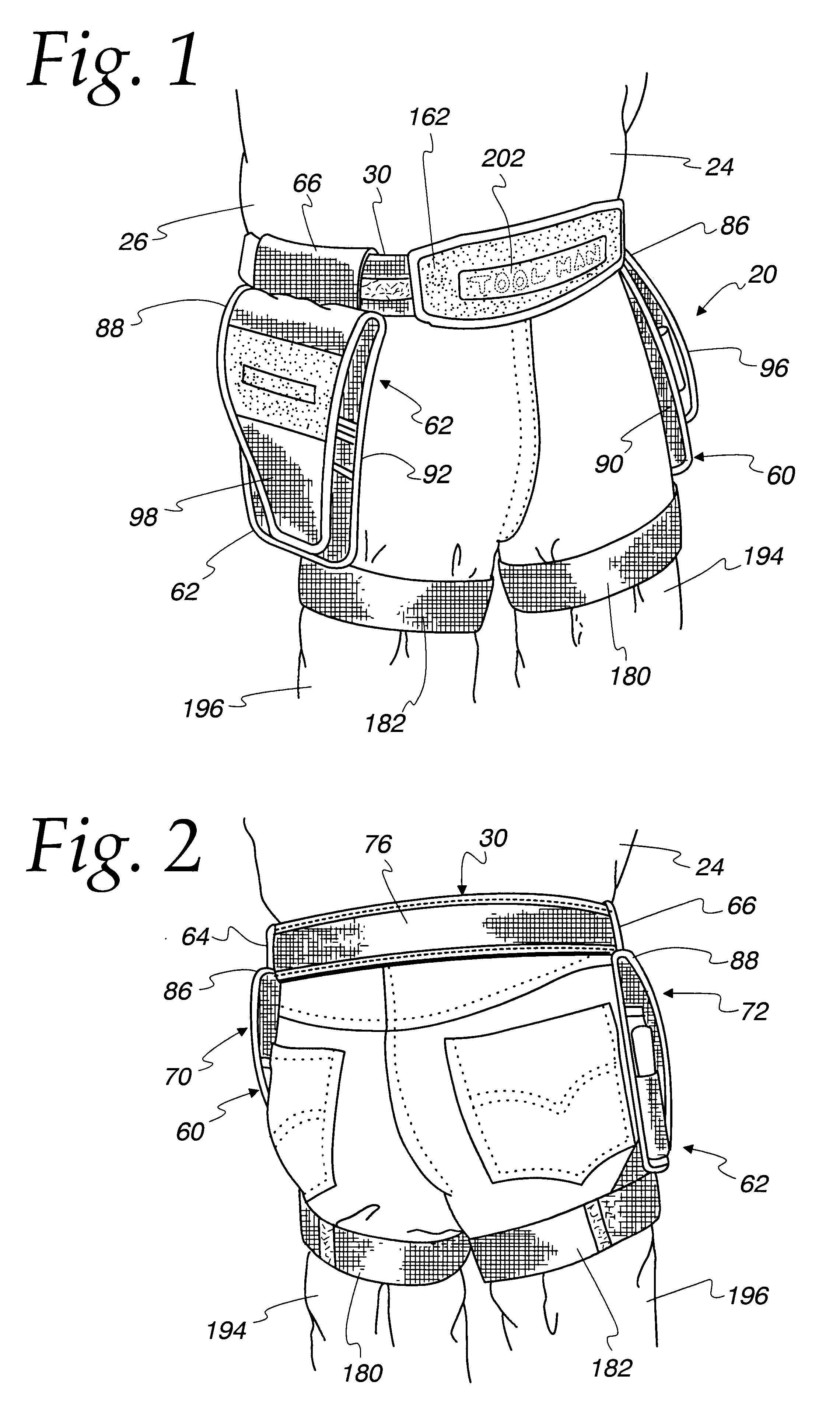

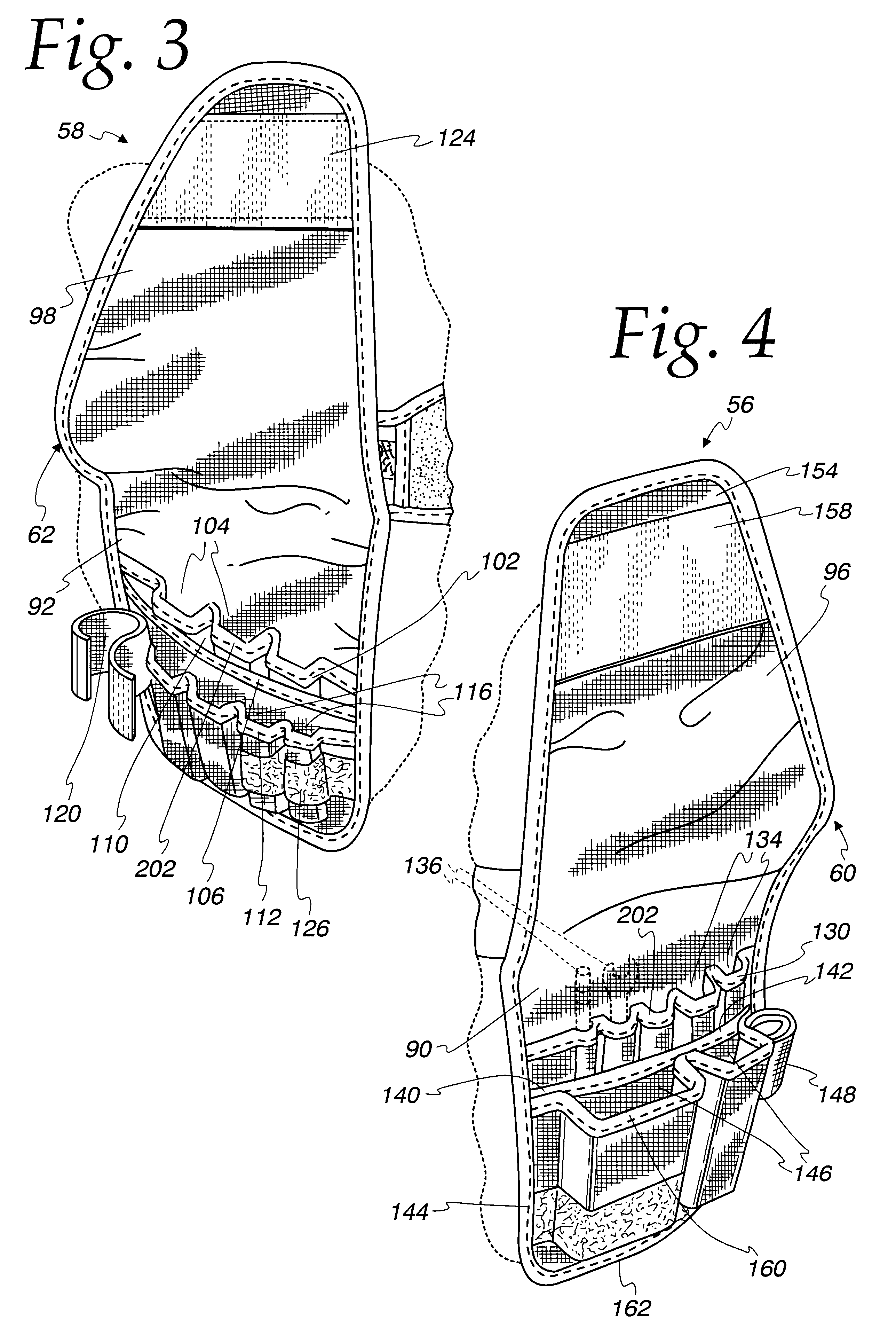

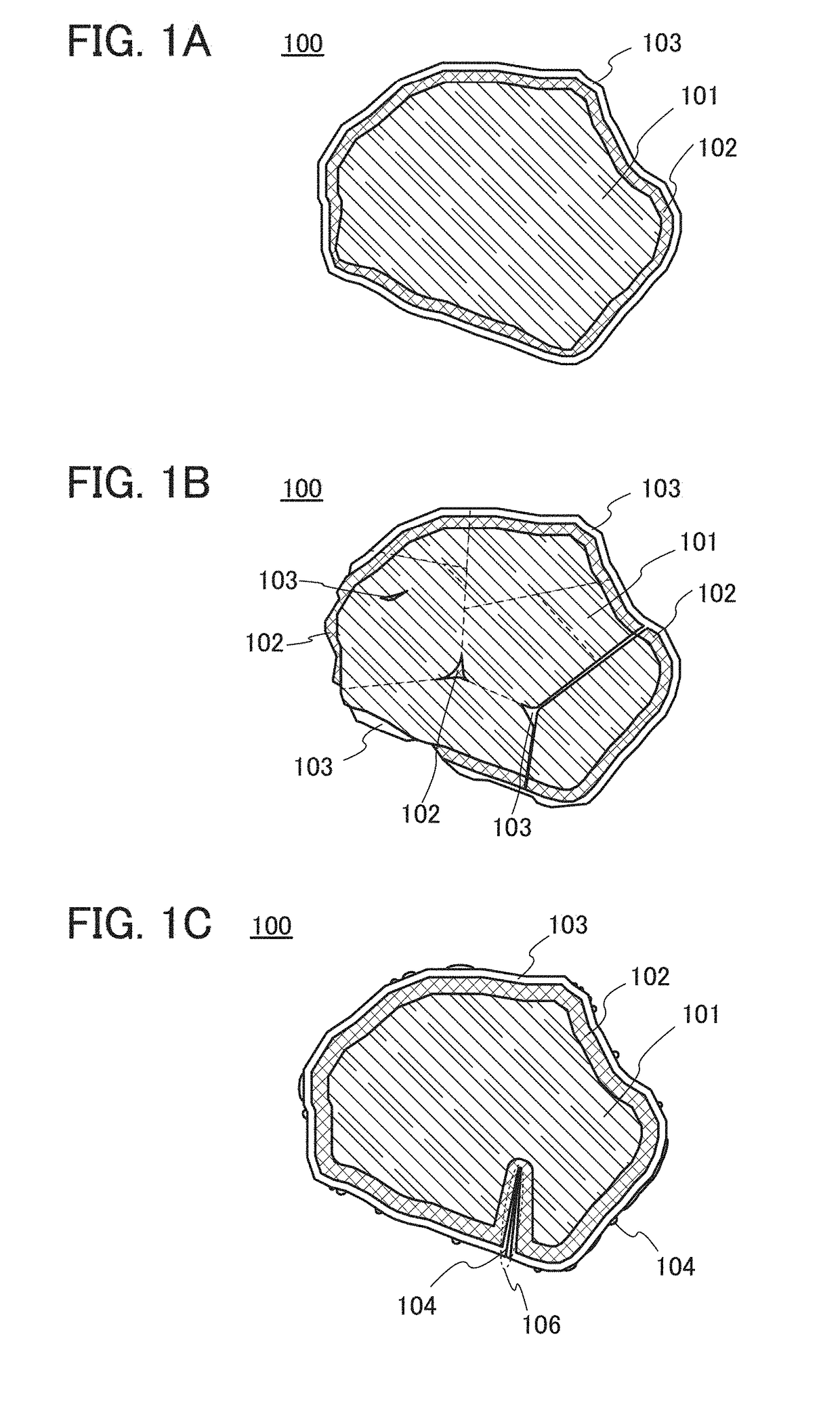

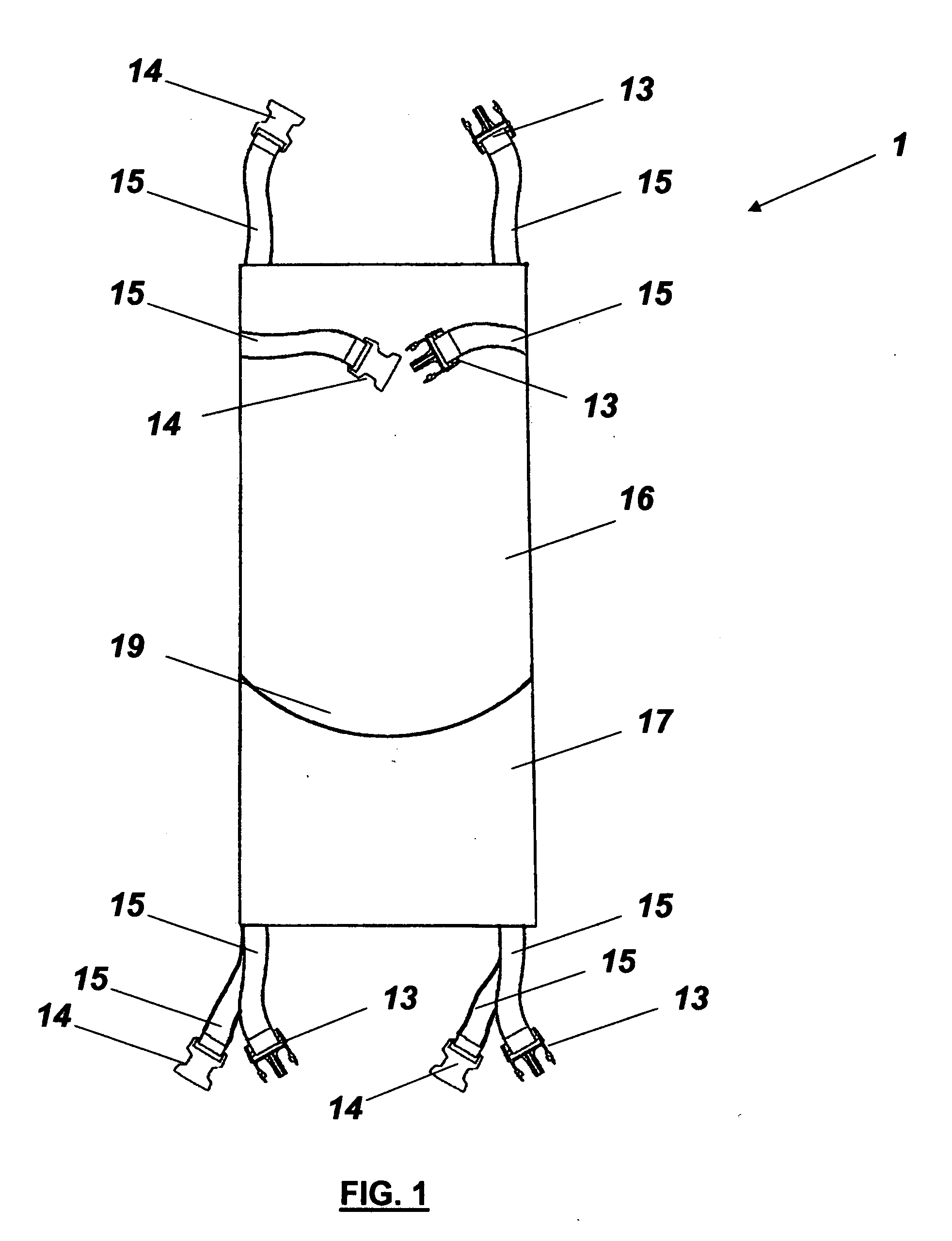

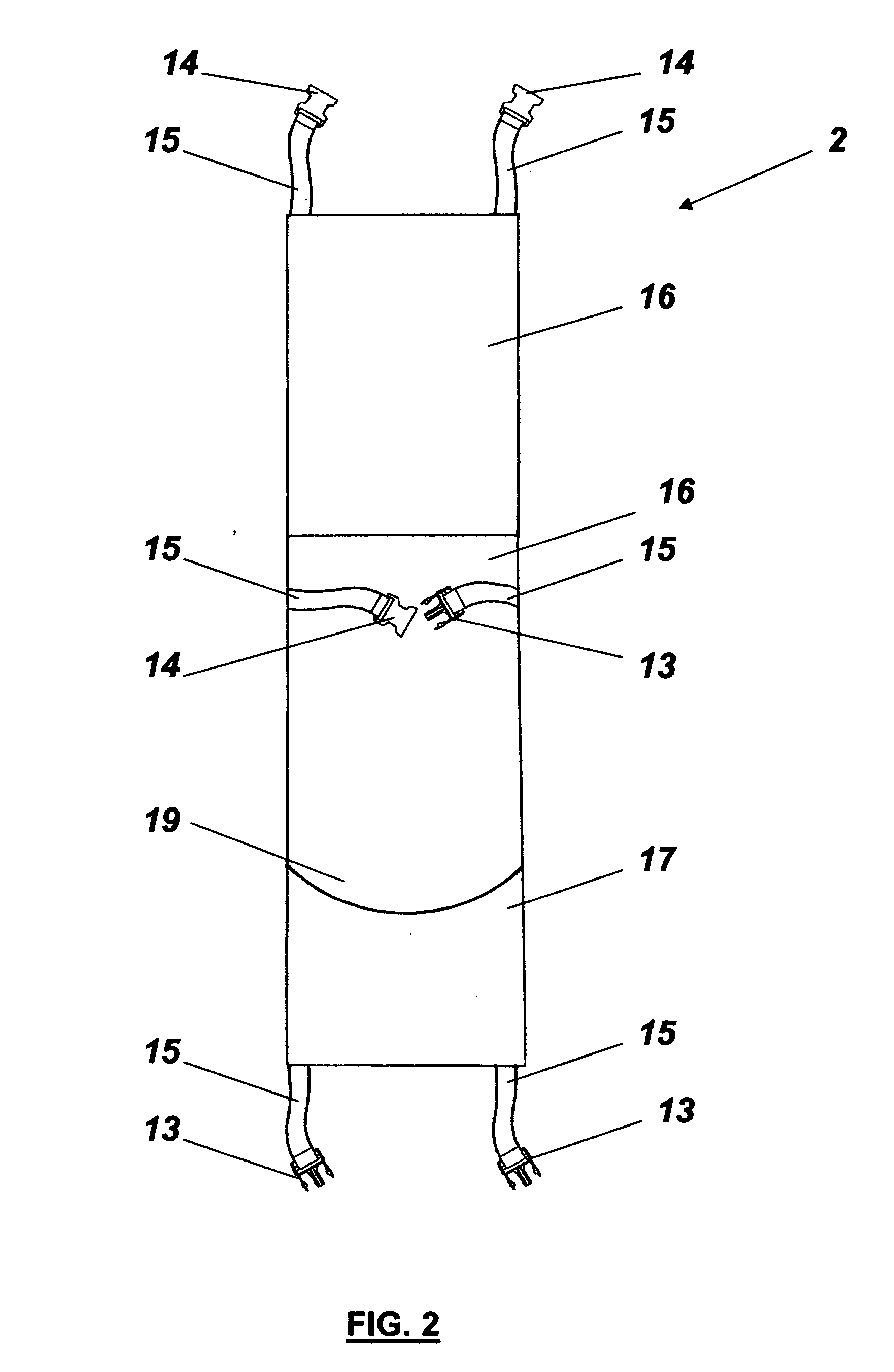

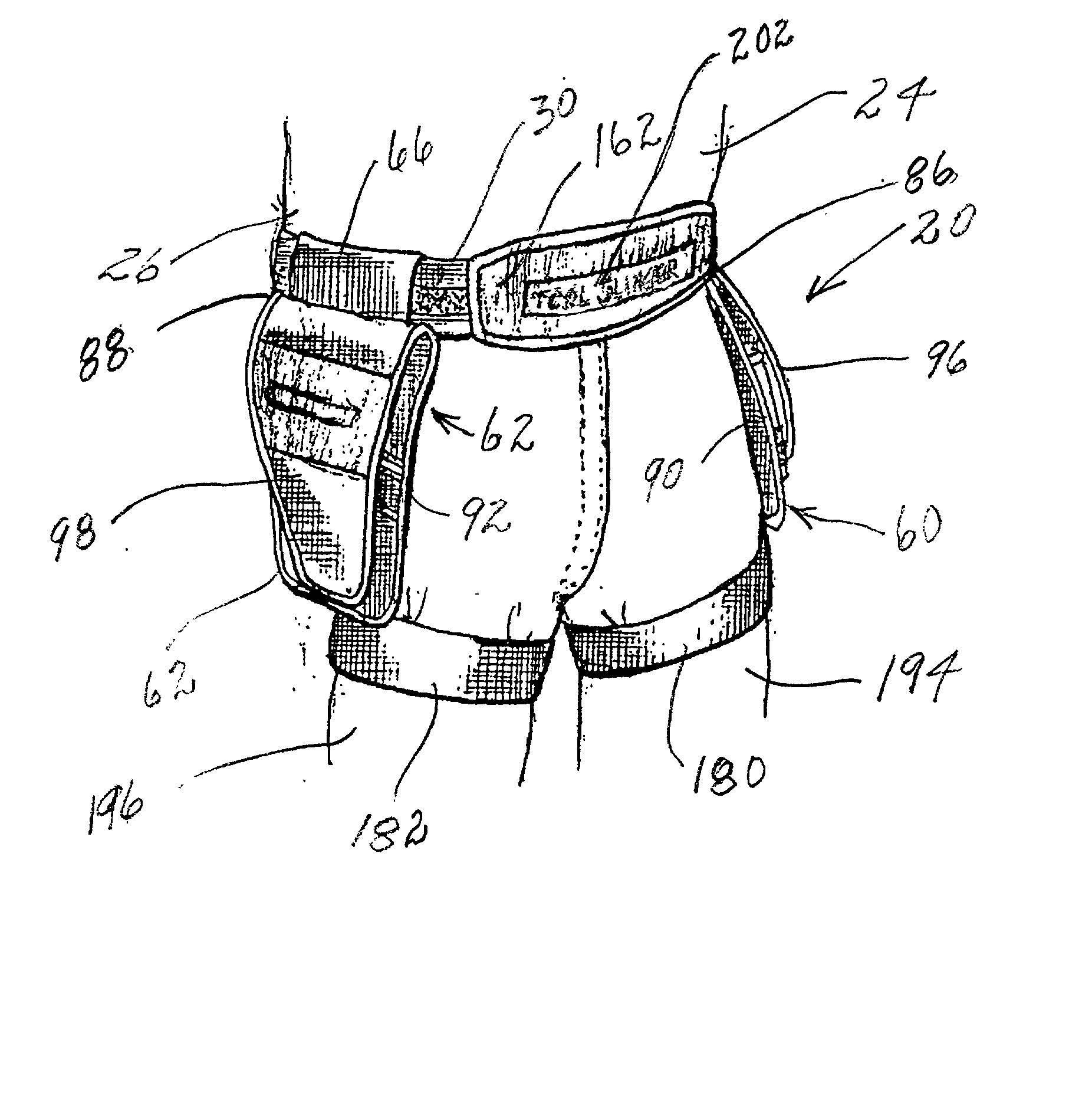

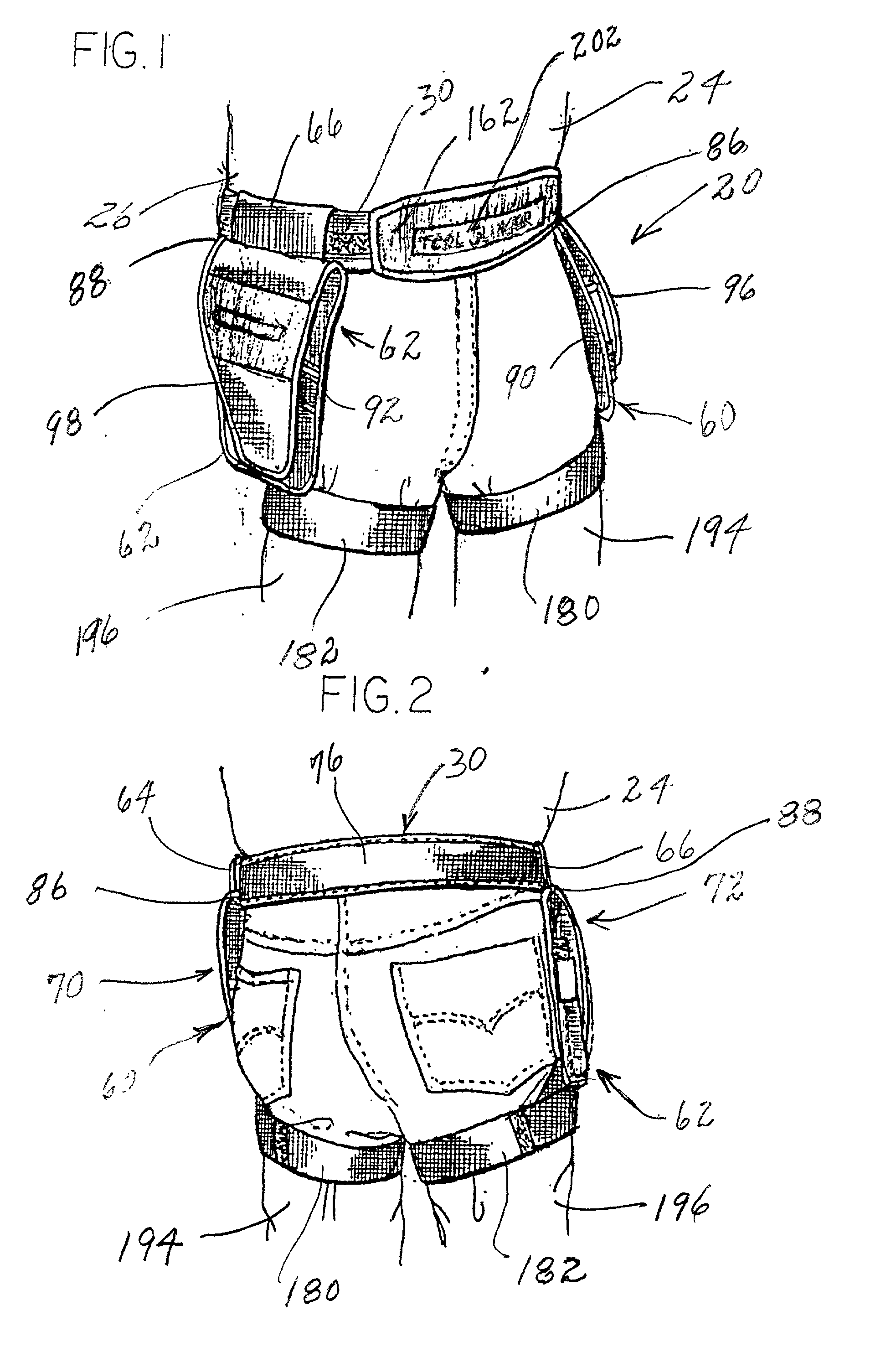

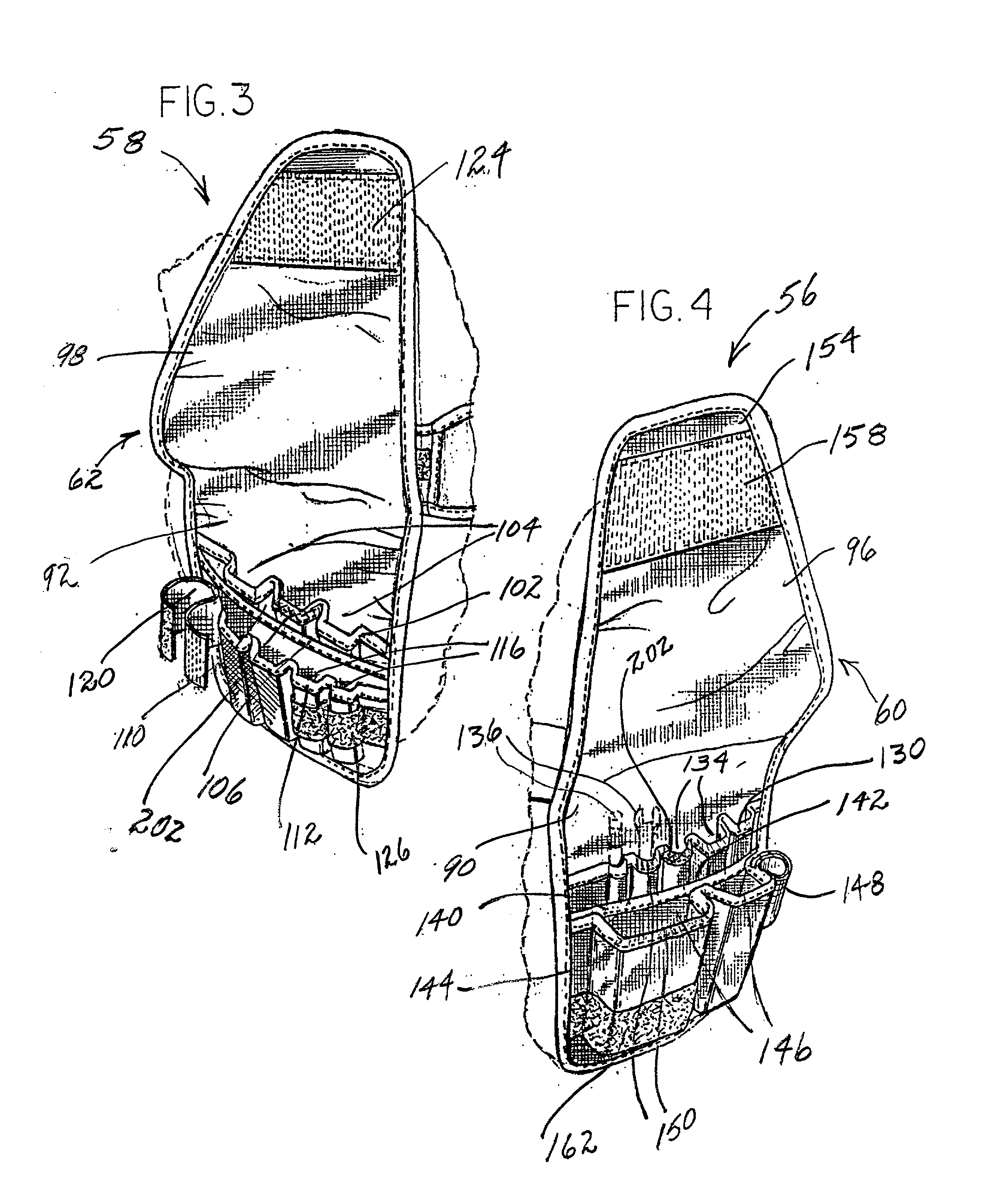

Belt assembly for storage and inventory of tools

InactiveUS6446852B1Surface damageEasy to repositionTravelling sacksTravelling carriersVisual markingEngineering

A tool-carrying assembly to be secured by a waist-encircling belt, and, additionally, by straps encircling the legs of a workman using the belt assembly. The assembly is thus stabilized, and enhanced weight distribution is achieved. Elements of the belt assembly include a waist-encircling band supporting a pair of laterally spaced, depending panels each carrying tool-accepting pockets. The pockets preferably carry visual markings and coding as well as other indicia identifying clearly the specific tools to be "housed" or carried in and to be returned to each pocket after use. Inventory control of the tools is thereby significantly enhanced. Pivotal flaps depending from the band-carried panels serve to cover the tools when not in use, and to prevent the tools from scratching or otherwise marring any article, or fixture, or "workpiece" requiring the workman's attention. The panels and the tools carried thereby are disposed in lateral, spaced zones at the wearer's sides (and not directly in the front of one's body) thus further to reduce any likelihood of the tools coming into damaging physical contact with an article being worked upon. That is, both frontal and rearwardly located zones about the wearer of the tool belt assembly are rendered essentially free and clear of all tools and other mechanical impediments. While wearing the tool assembly of the invention, a worker can, without any discomfort, lie upon and use a "creeper". Significantly, a frontal sector of the belt itself is covered with a relatively soft, non-marring protective pad, composition, or surface material effective to prevent possible damage from a workman's belt buckle. An additional feature of the invention is that the panels may be structured to constitute a core sandwiched between a pair of encasing sheet-like webs. The resulting composite is readily formable to provide selectable visual patterns, designs or indicia, for example, to identify product name or sources and / or to constitute decorations.

Owner:WMH TOOL GROUP

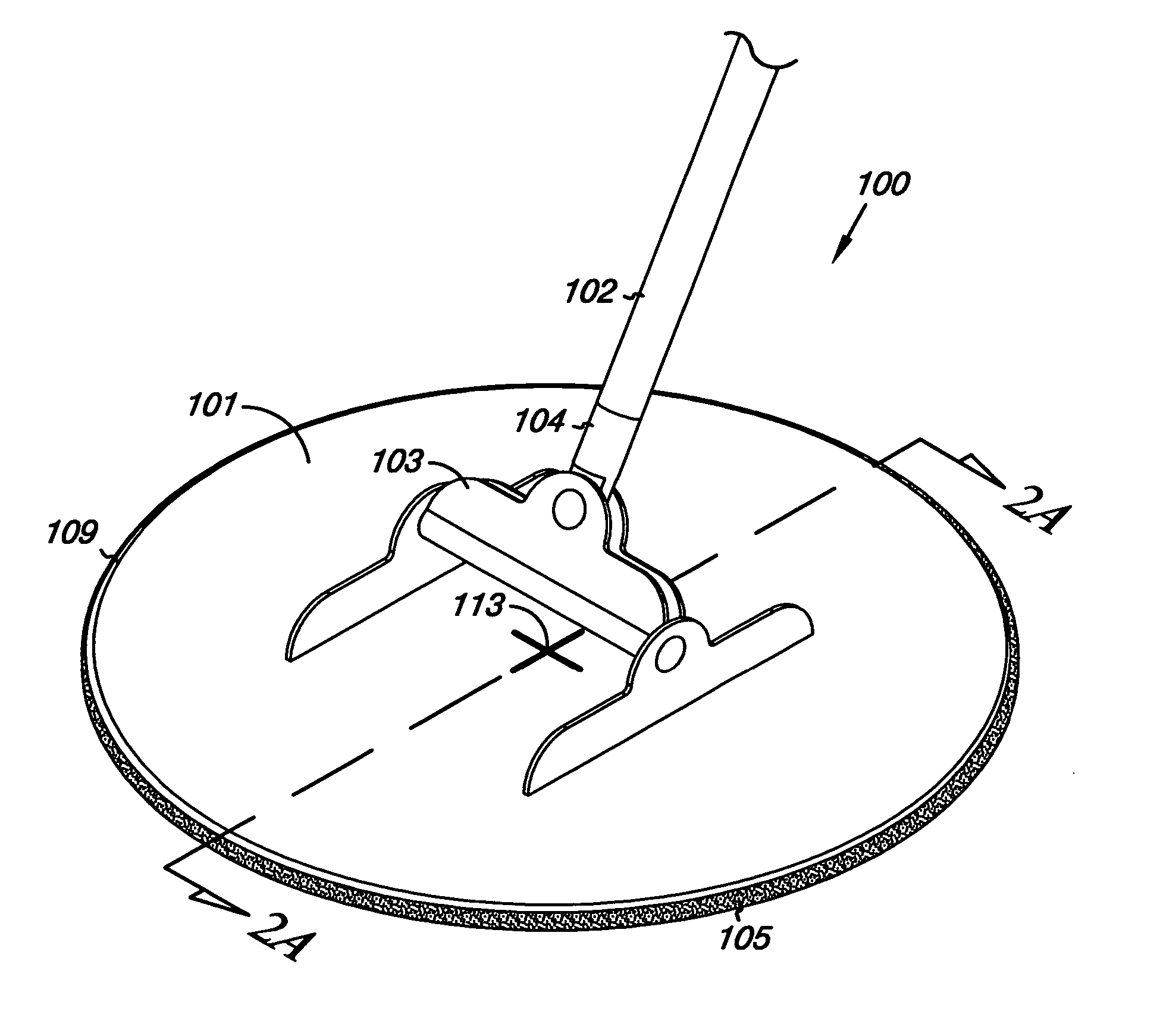

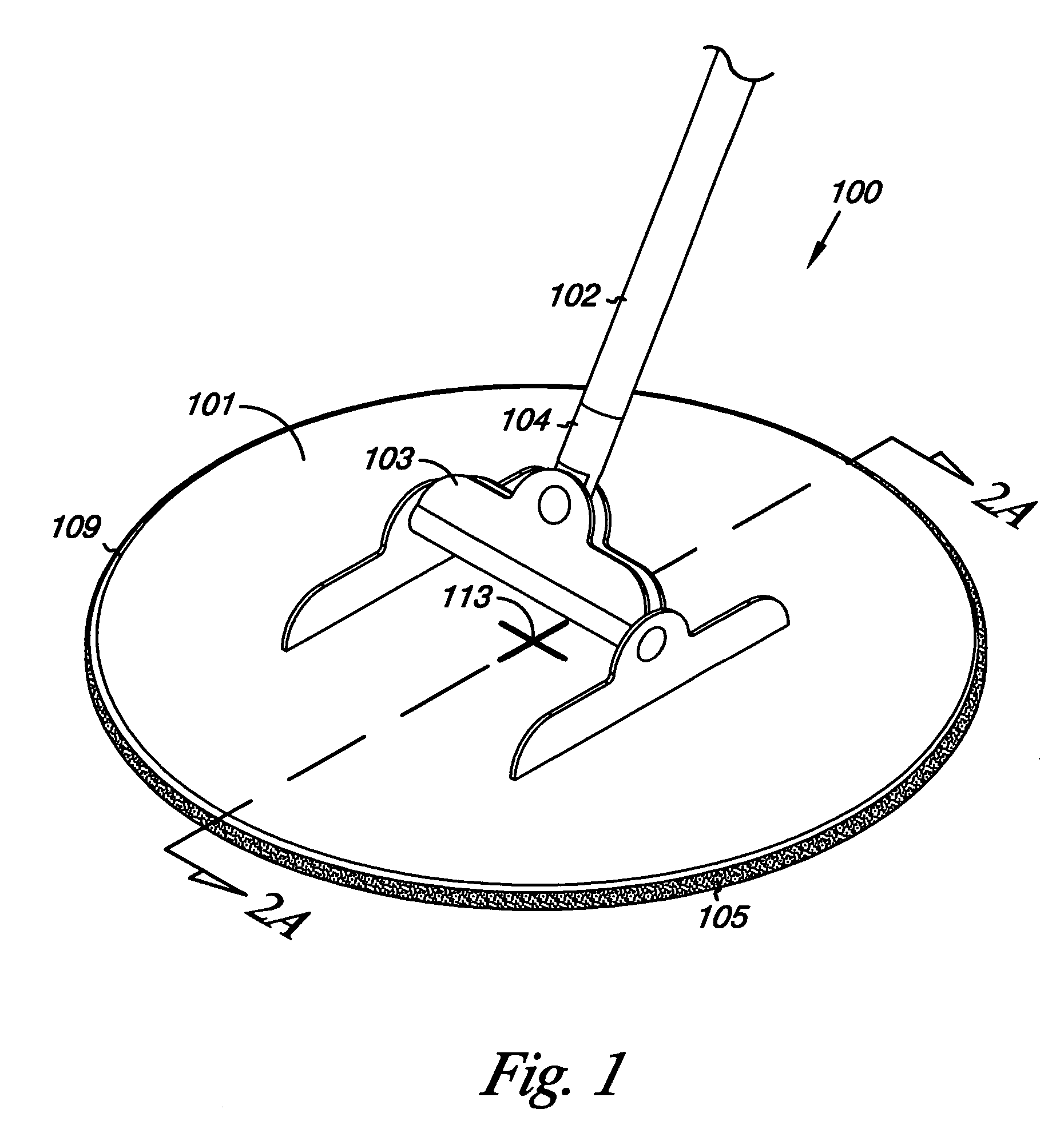

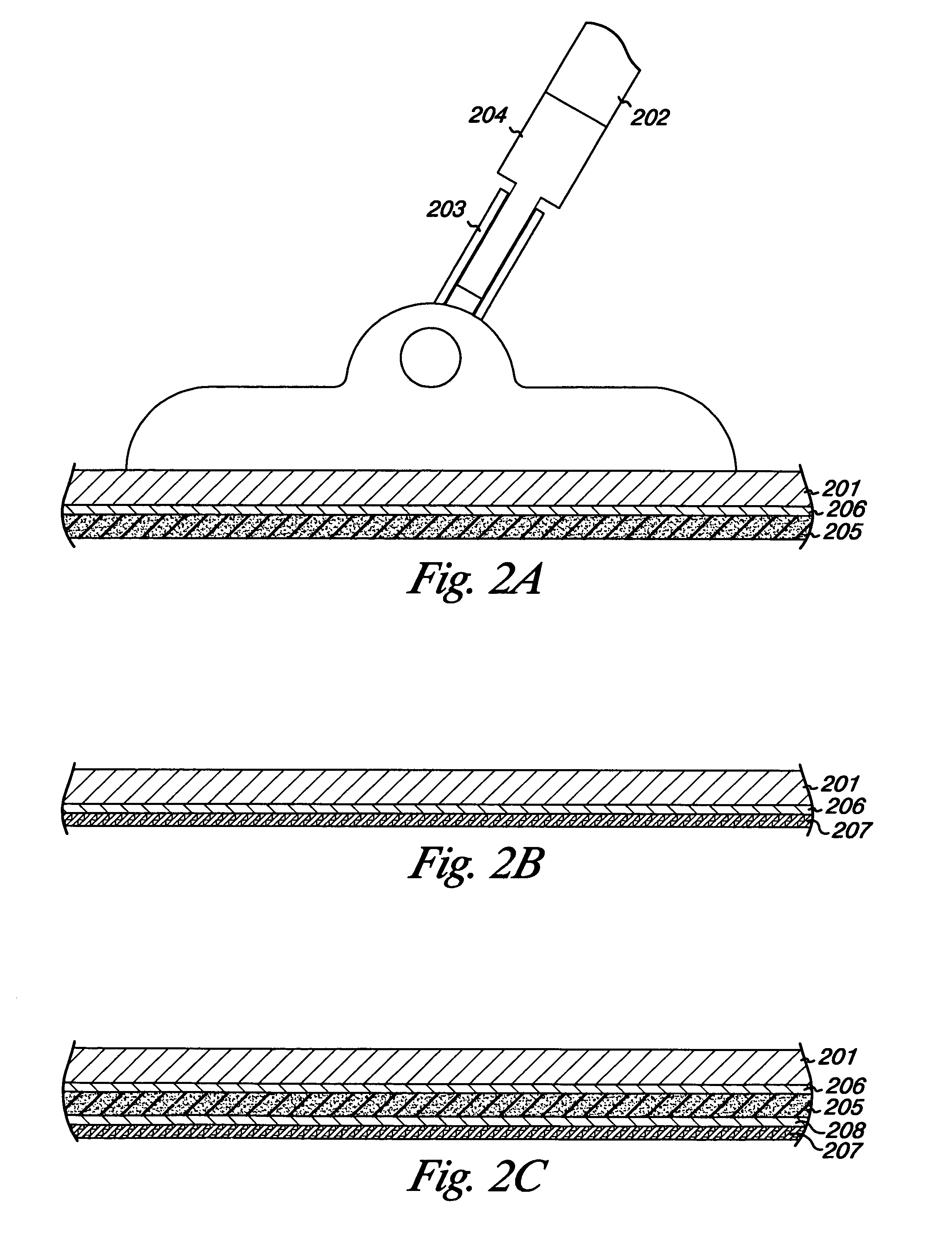

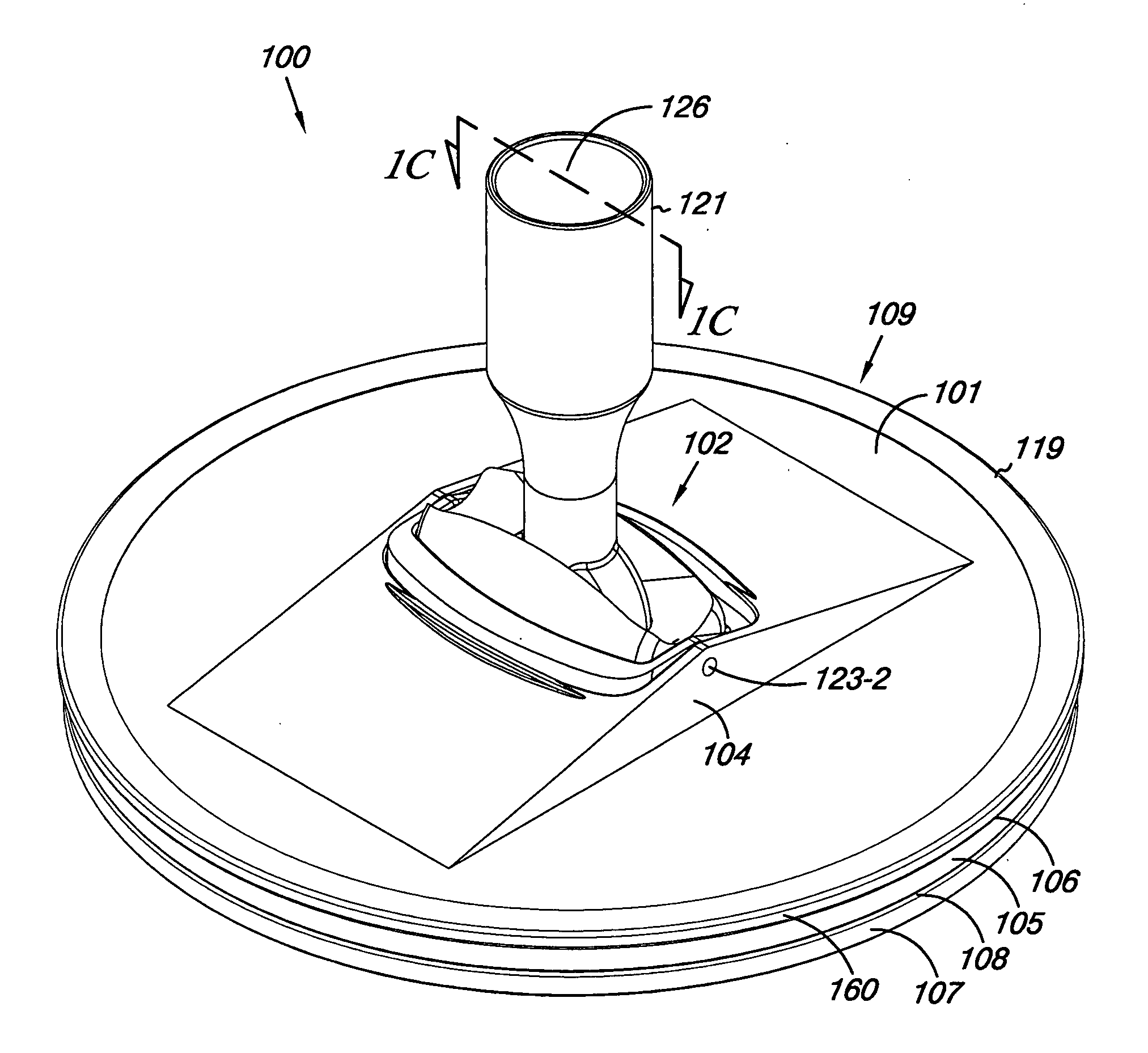

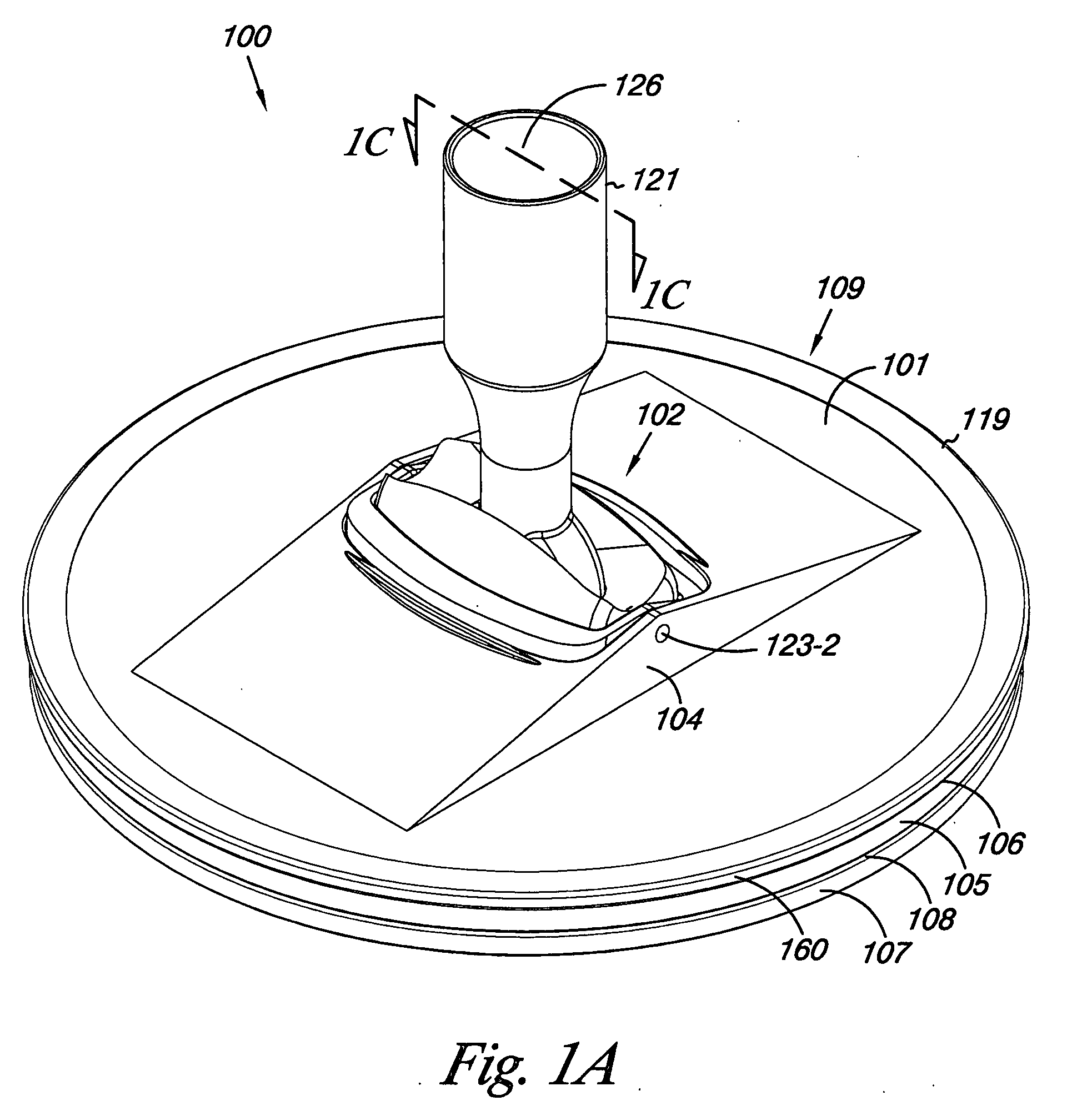

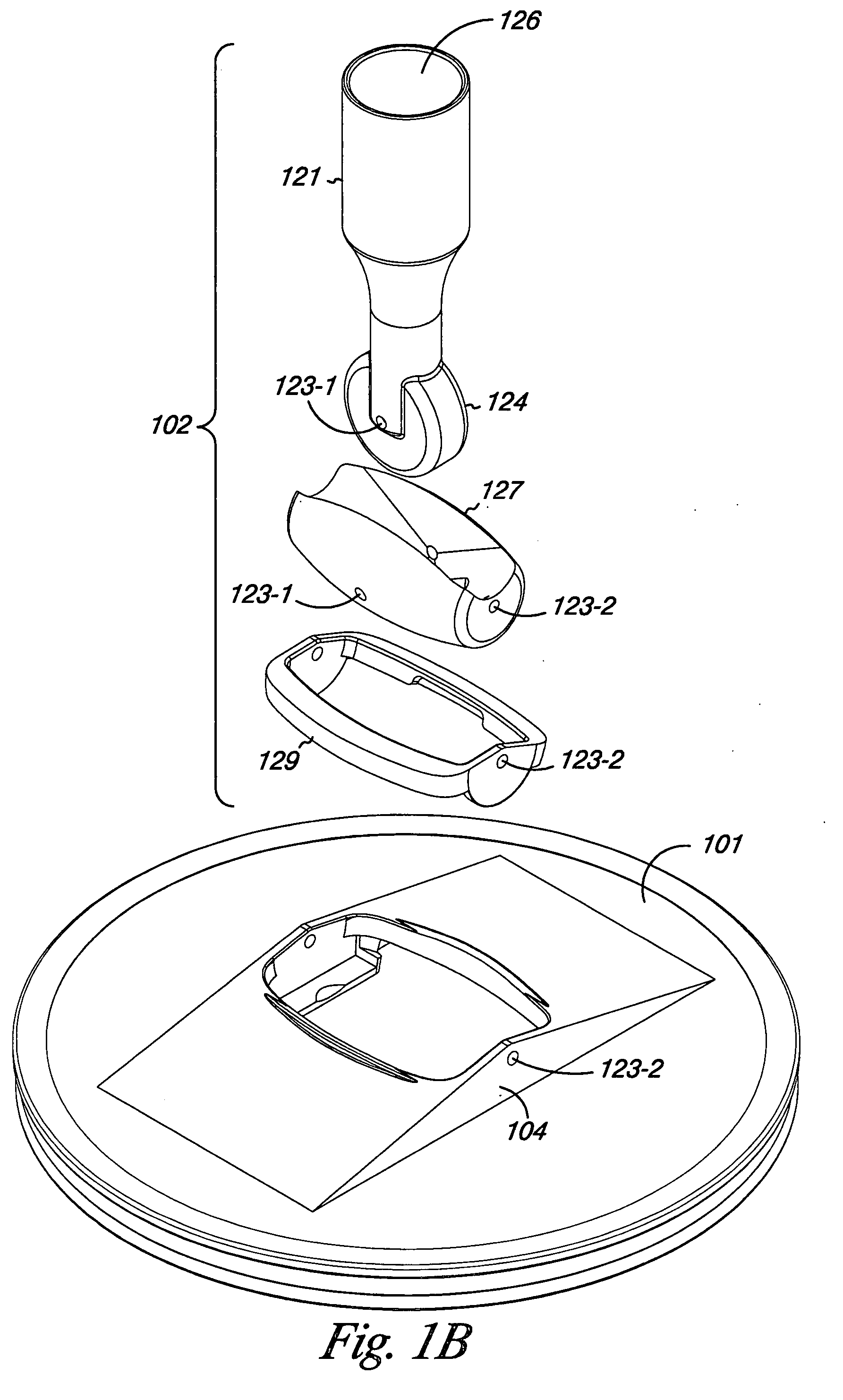

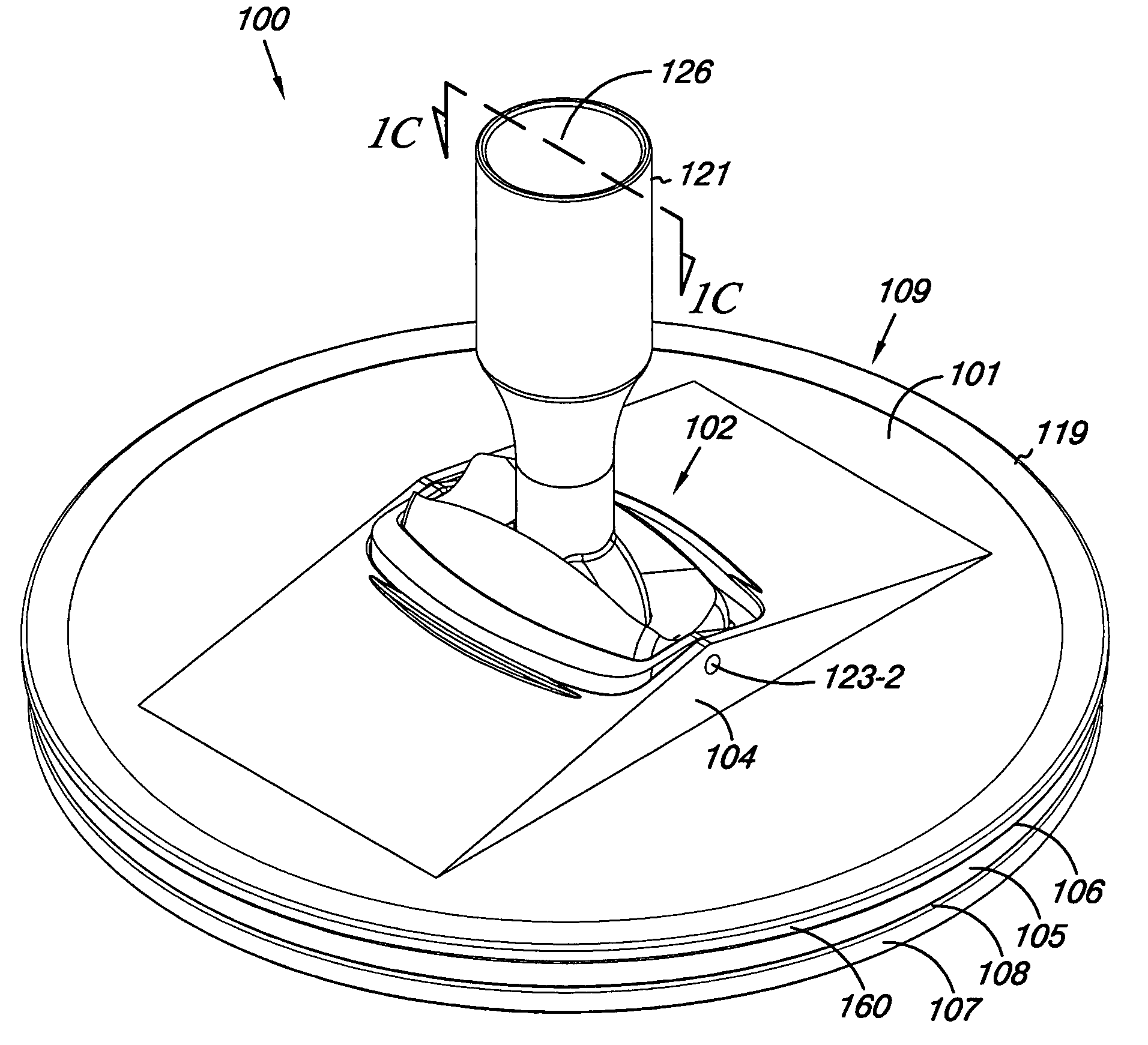

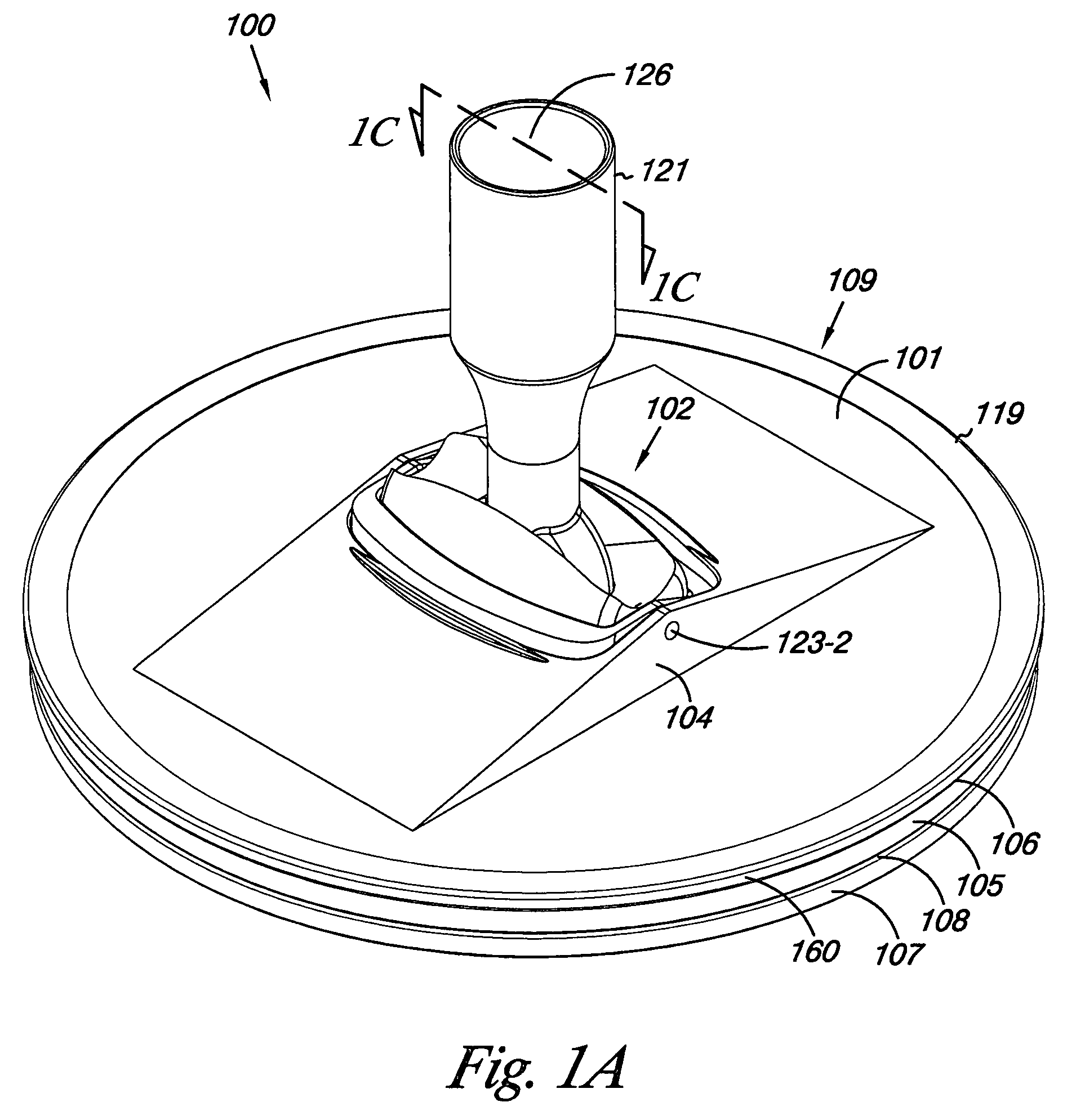

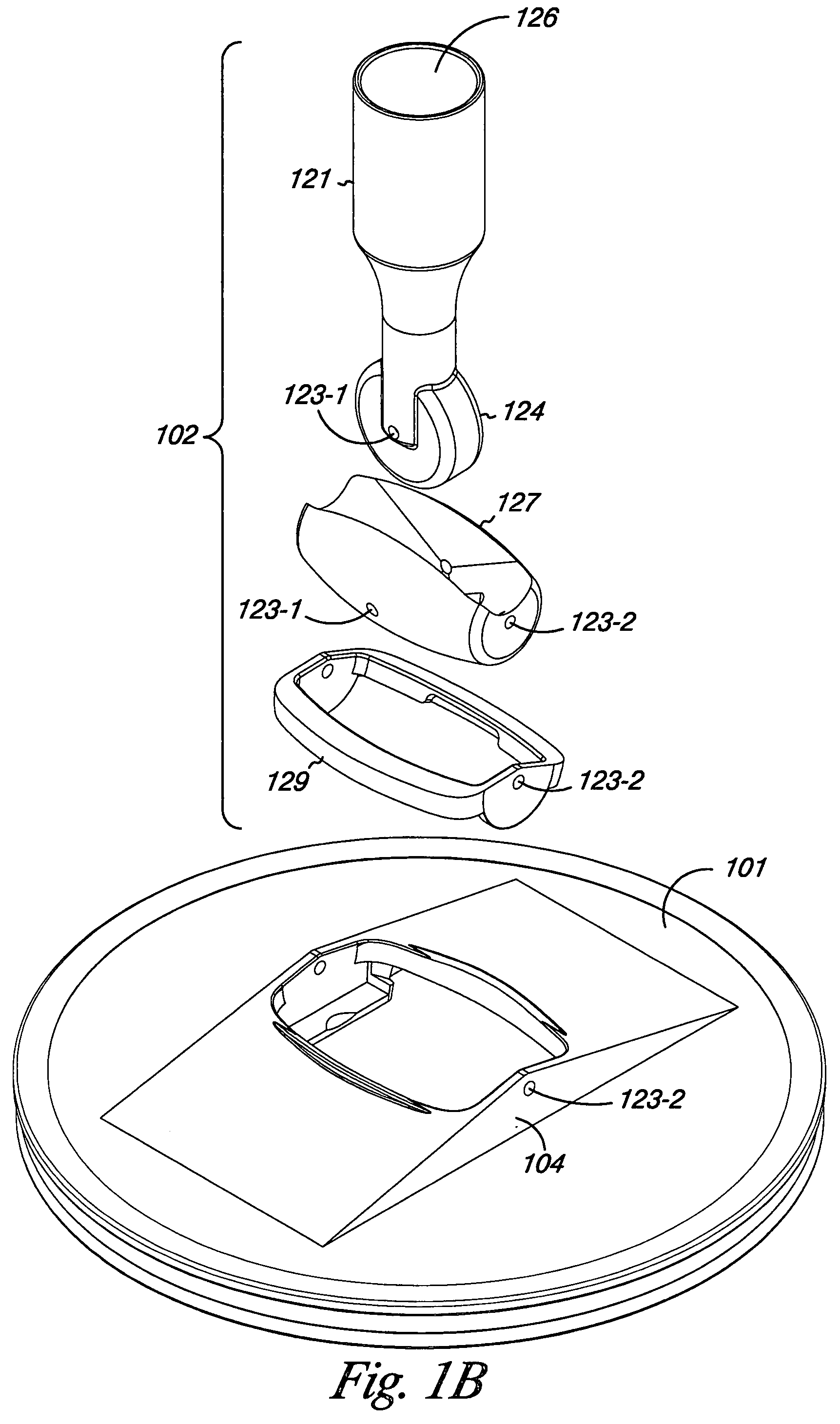

Hand manipulated tool

InactiveUS6991529B2Reduce in quantityLarge and more cumbersomeRevolution surface grinding machinesCarpet cleanersEngineeringHand tool

An embodiment of a hand manipulated tool includes an elongate handle and a tool support. The tool support has a center, rotationally fixed to the elongate handle. The tool support has a periphery with at least five points equidistant from the center.

Owner:FULL CIRCLE INT

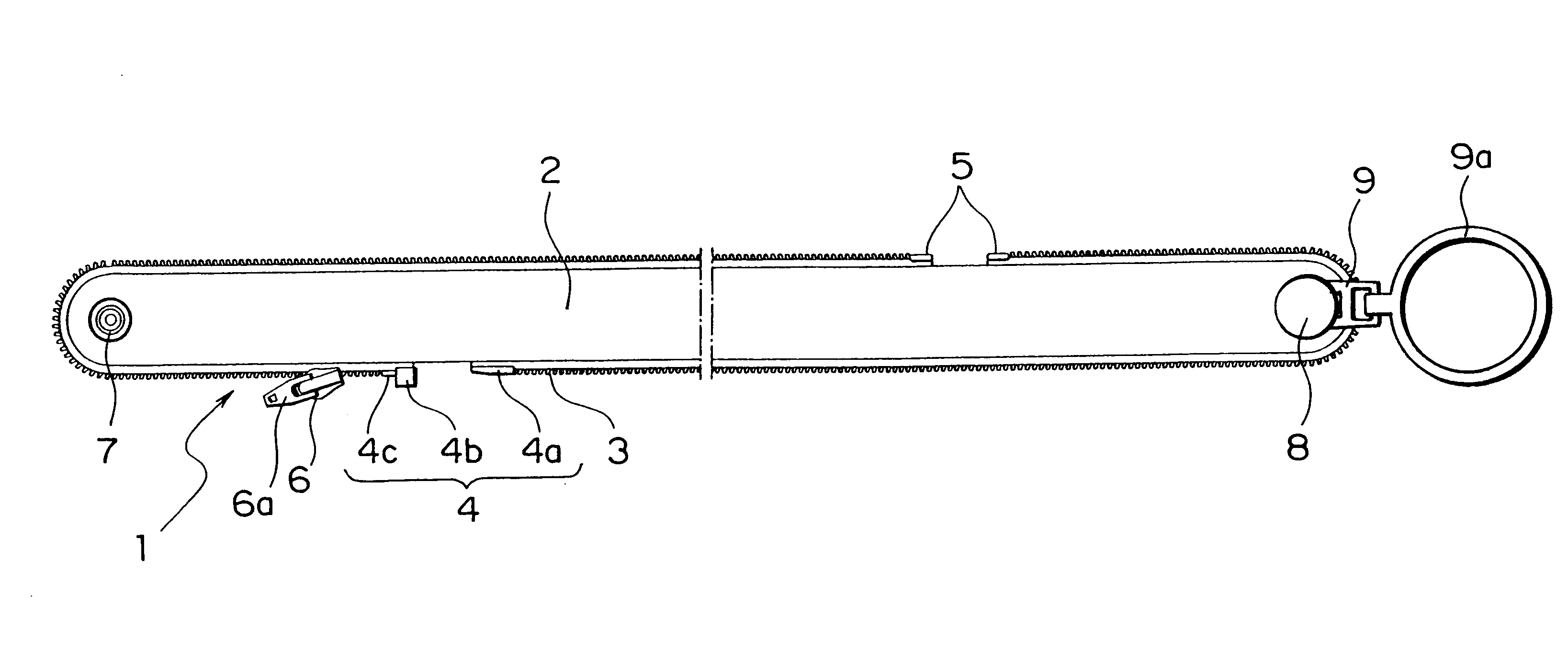

Belt-like article, and neck strap, hung-object-supporting body and product-storing body using the same belt-like article

InactiveUS6647555B2Surface damageTravelling sacksTravelling carriersBand shapeMechanical engineering

Owner:YKK CORP

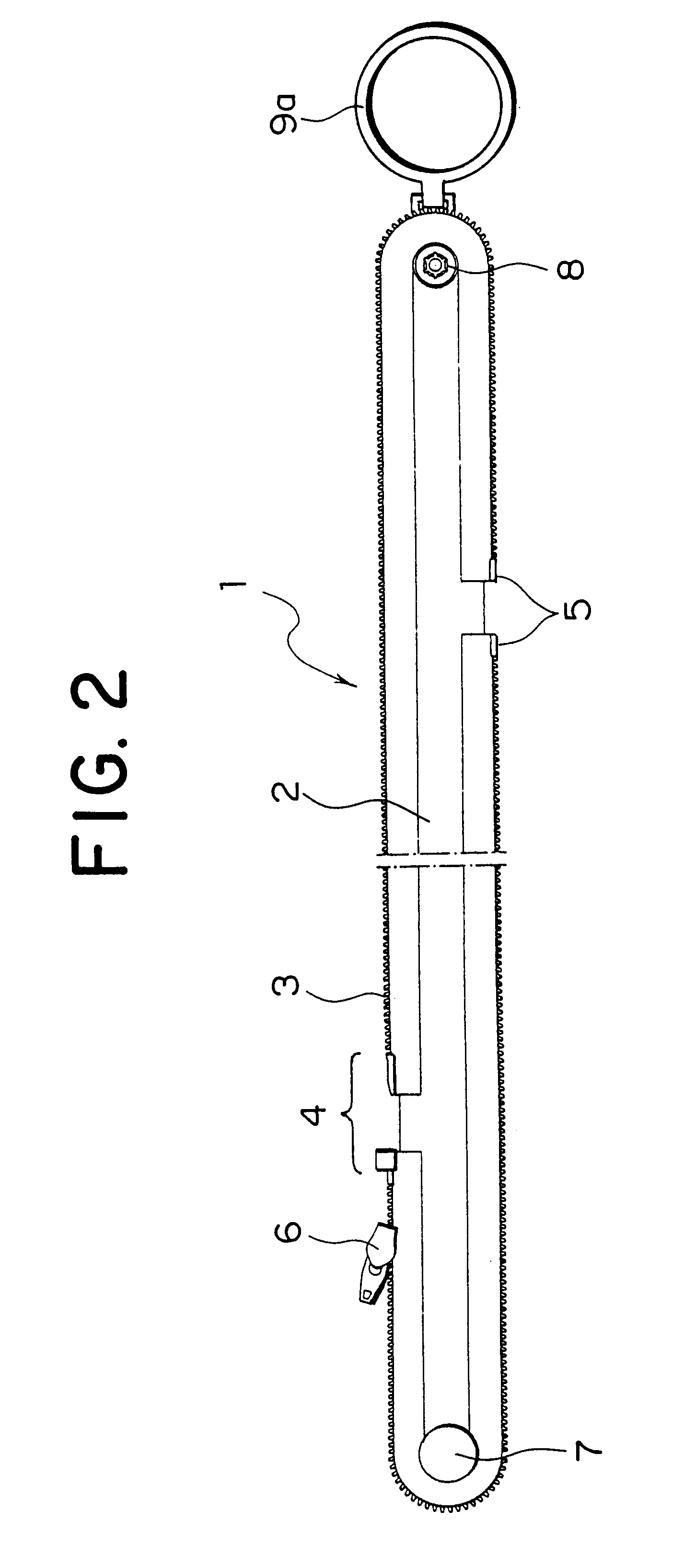

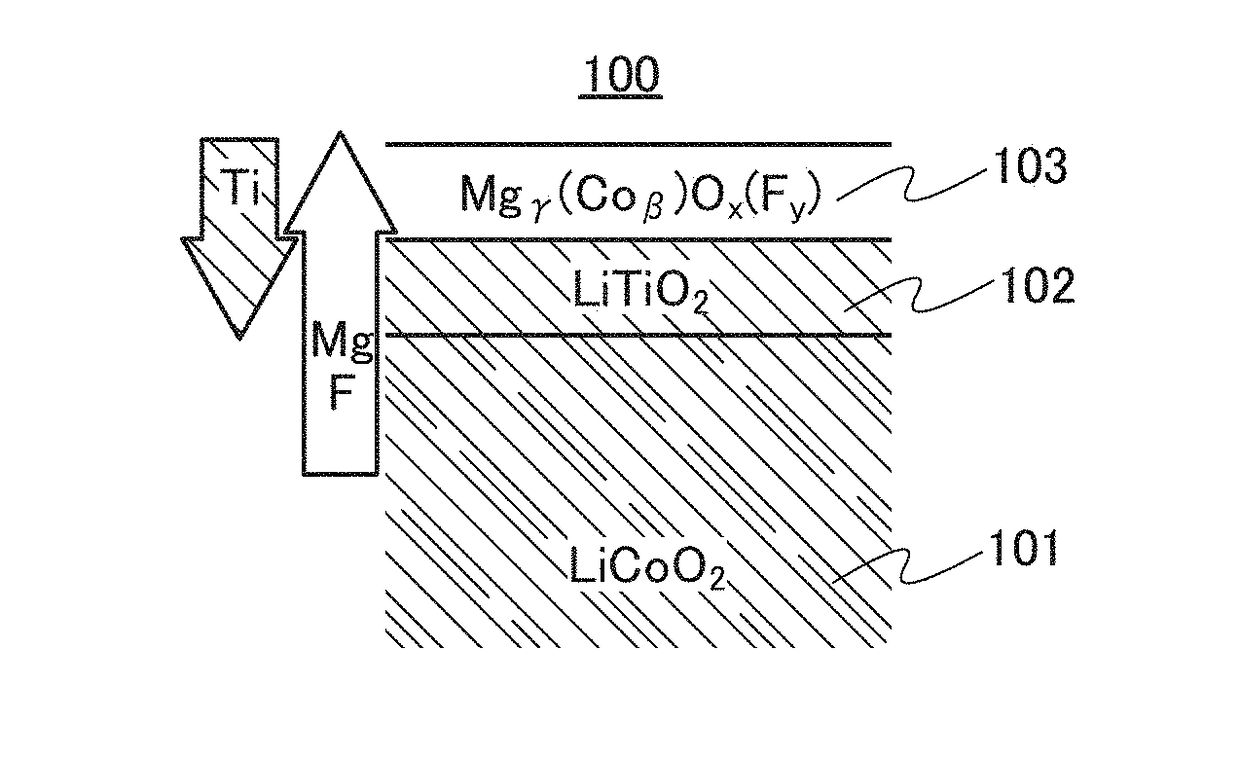

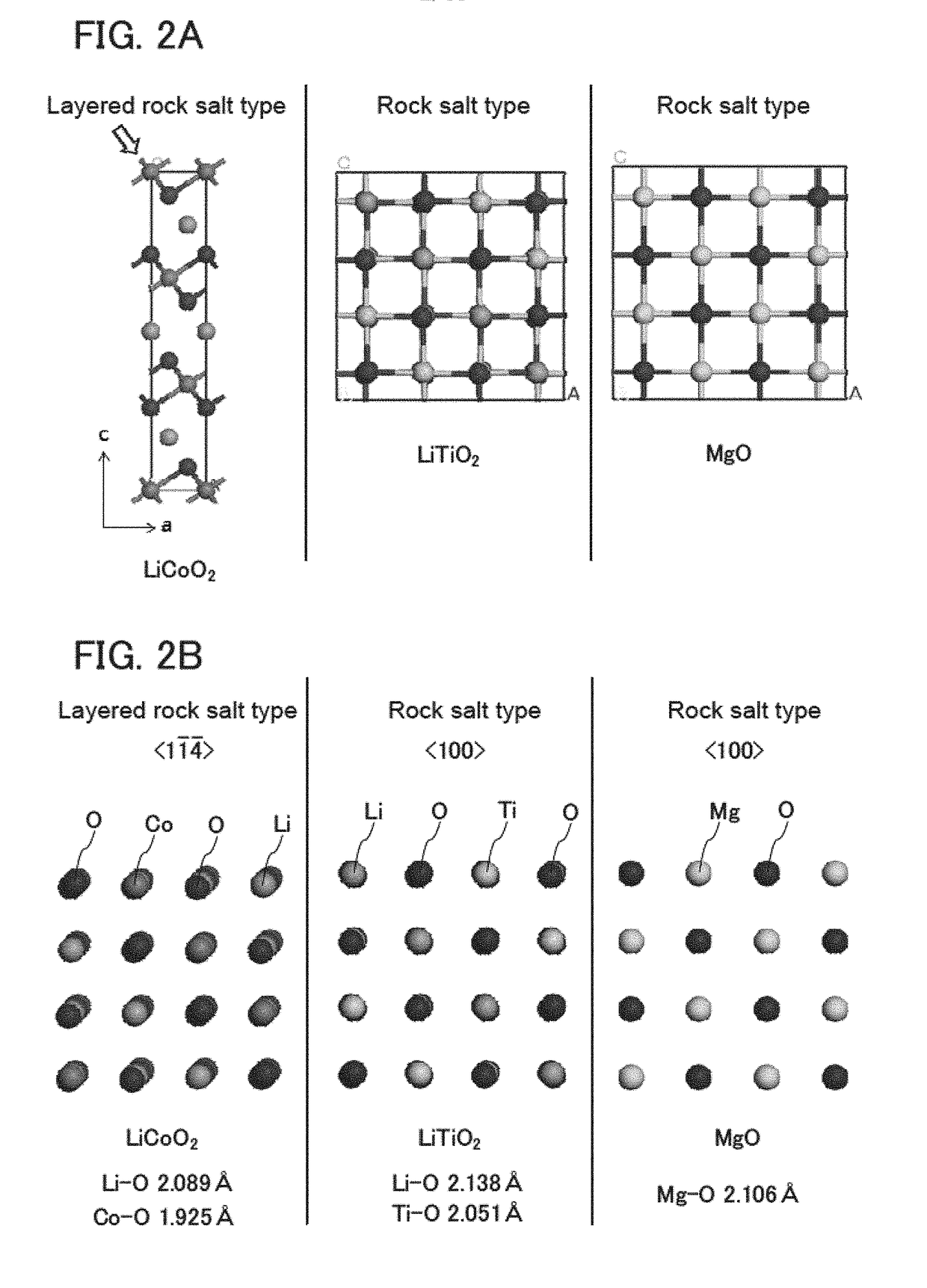

Positive electrode active material, method for manufacturing positive electrode active material, and secondary battery

ActiveUS20180013130A1Reduce capacityImprove discharge characteristicsFinal product manufactureSecondary cellsElectrolytic agentElectrical battery

A positive electrode active material which can improve cycle characteristics of a secondary battery is provided. Two kinds of regions are provided in a superficial portion of a positive electrode active material such as lithium cobaltate which has a layered rock-salt crystal structure. The inner region is a non-stoichiometric compound containing a transition metal such as titanium, and the outer region is a compound of representative elements such as magnesium oxide. The two kinds of regions each have a rock-salt crystal structure. The inner layered rock-salt crystal structure and the two kinds of regions in the superficial portion are topotaxy; thus, a change of the crystal structure of the positive electrode active material generated by charging and discharging can be effectively suppressed. In addition, since the outer coating layer in contact with an electrolyte solution is the compound of representative elements which is chemically stable, the secondary battery having excellent cycle characteristics can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

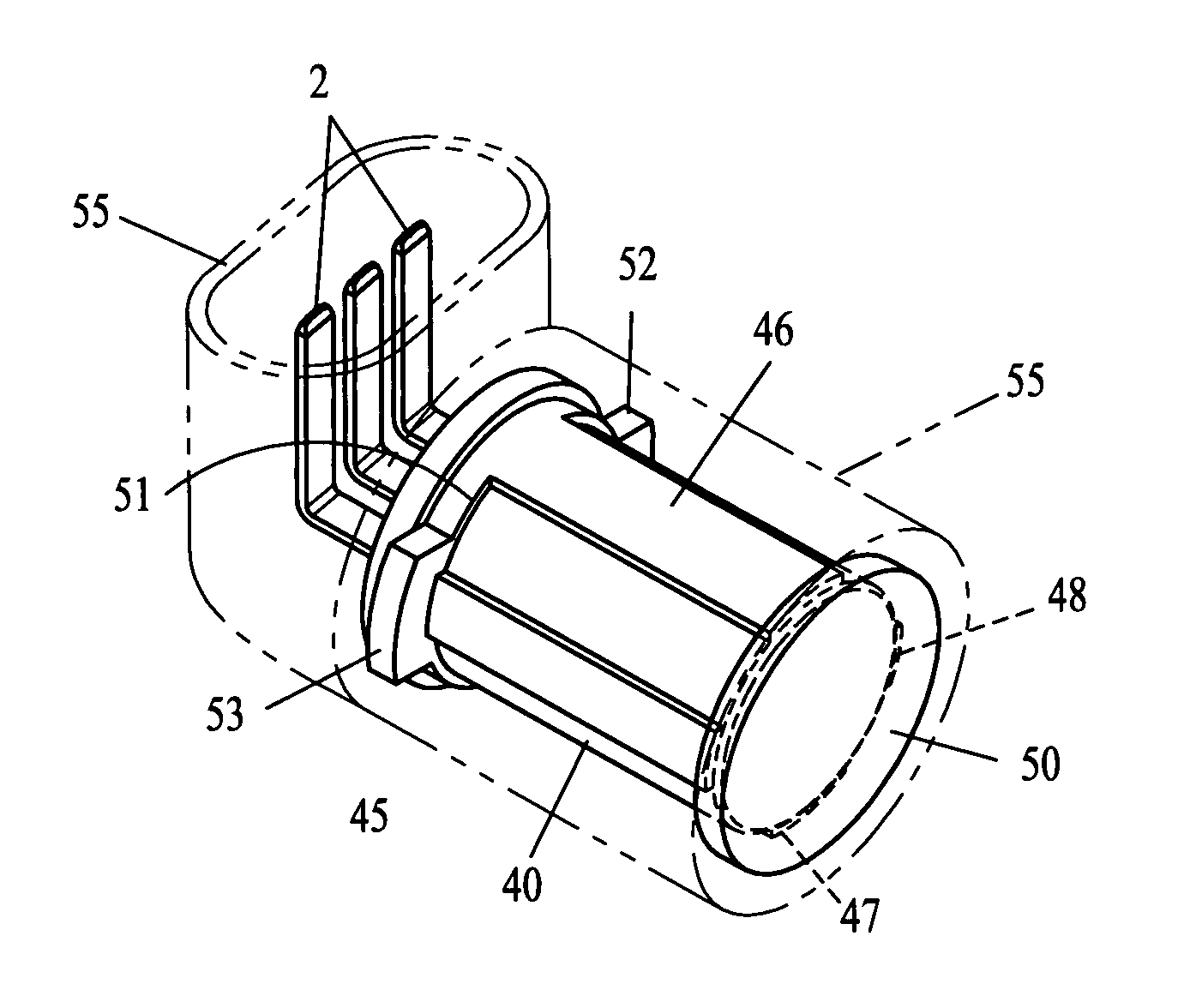

Process for manufacturing hybrid components as well as components manufactured according to this process

A process for manufacturing a hybrid component. To manufacture a hybrid component with electronic components in a possibly continuous manufacturing process, it is proposed according to the present invention that the electronic component be extrusion-coated with a hot melt adhesive melting at low temperature and to extrusion coat the intermediate product formed with a conventional plastic suitable for injection molding in an additional injection molding operation. On the one hand, damage to the electronic component is reliably prevented from occurring by this procedure, and, on the other hand, a hybrid component can be manufactured with a housing that is insensitive to external effects.

Owner:HANS HUONKER

Vehicle seat-mounted bow holder

InactiveUS20080047992A1Easy to installEasy to removeMetal working apparatusStowing appliancesHead restraintWrap around

Owner:FABIAN BENJAMIN WADE

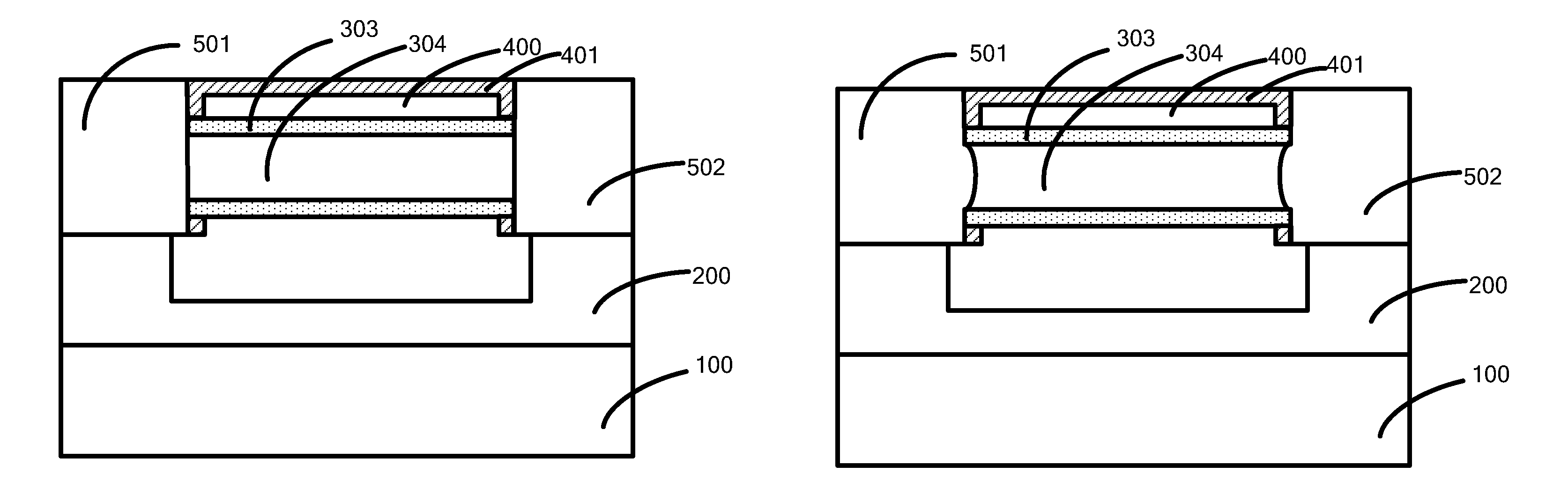

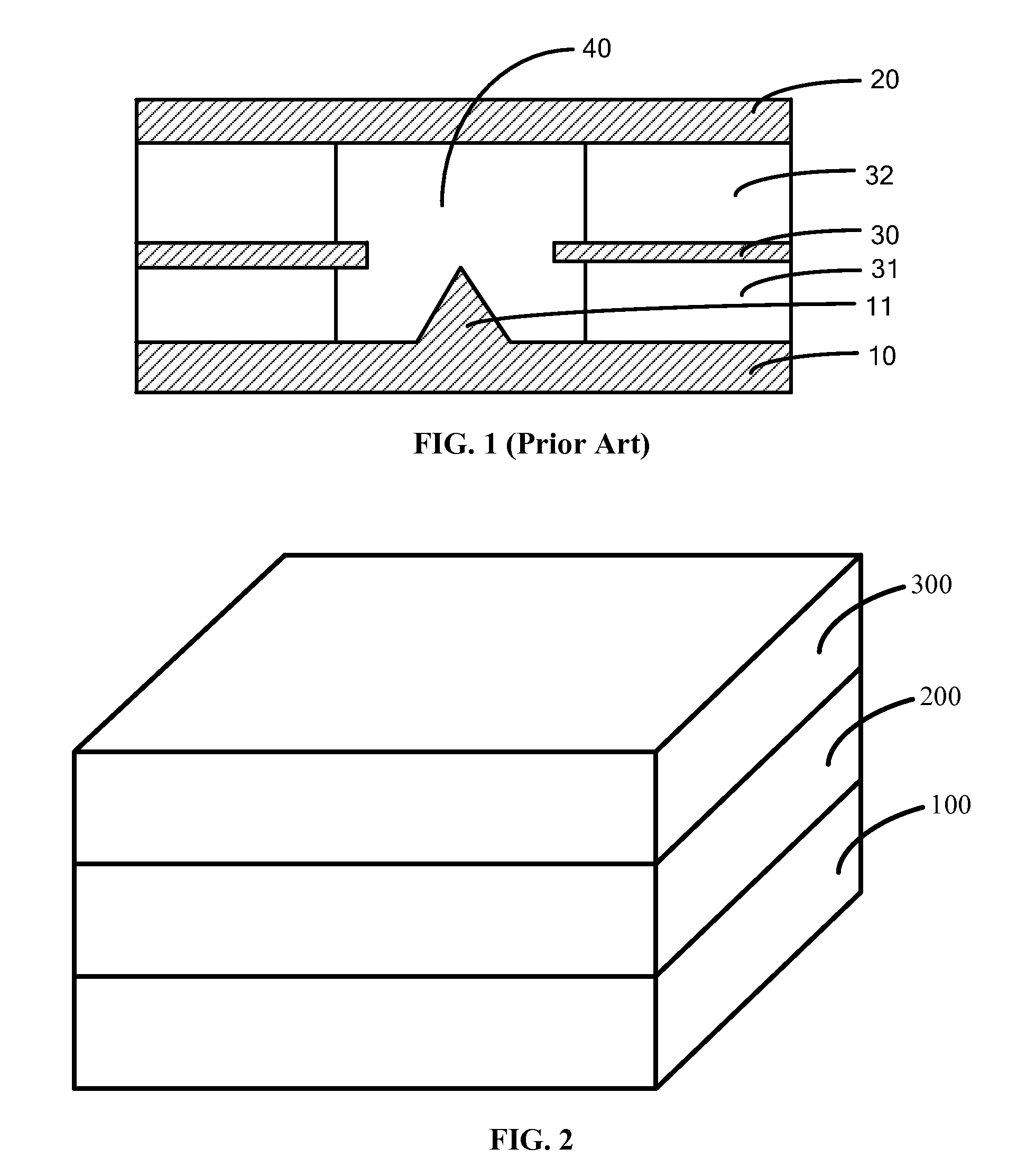

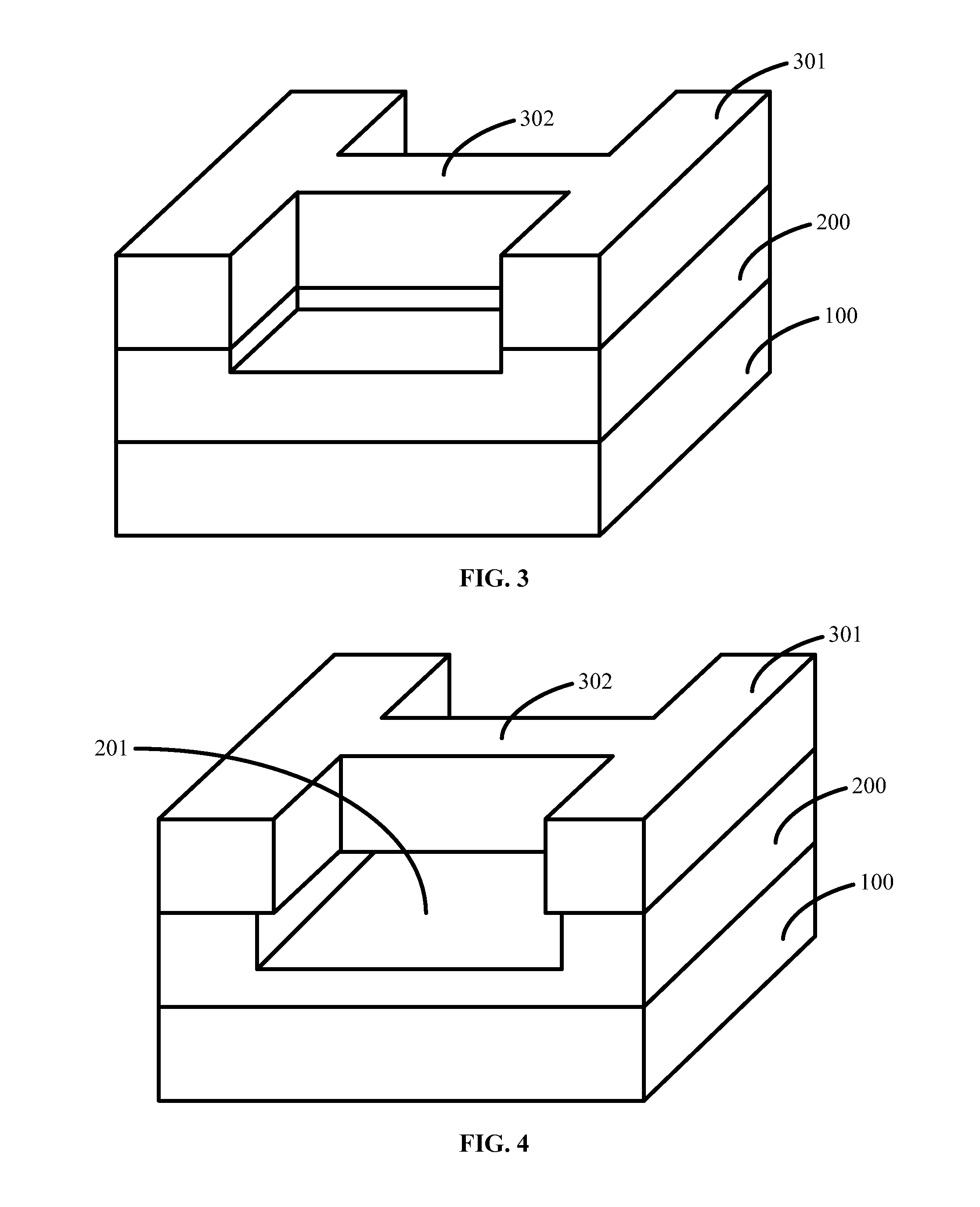

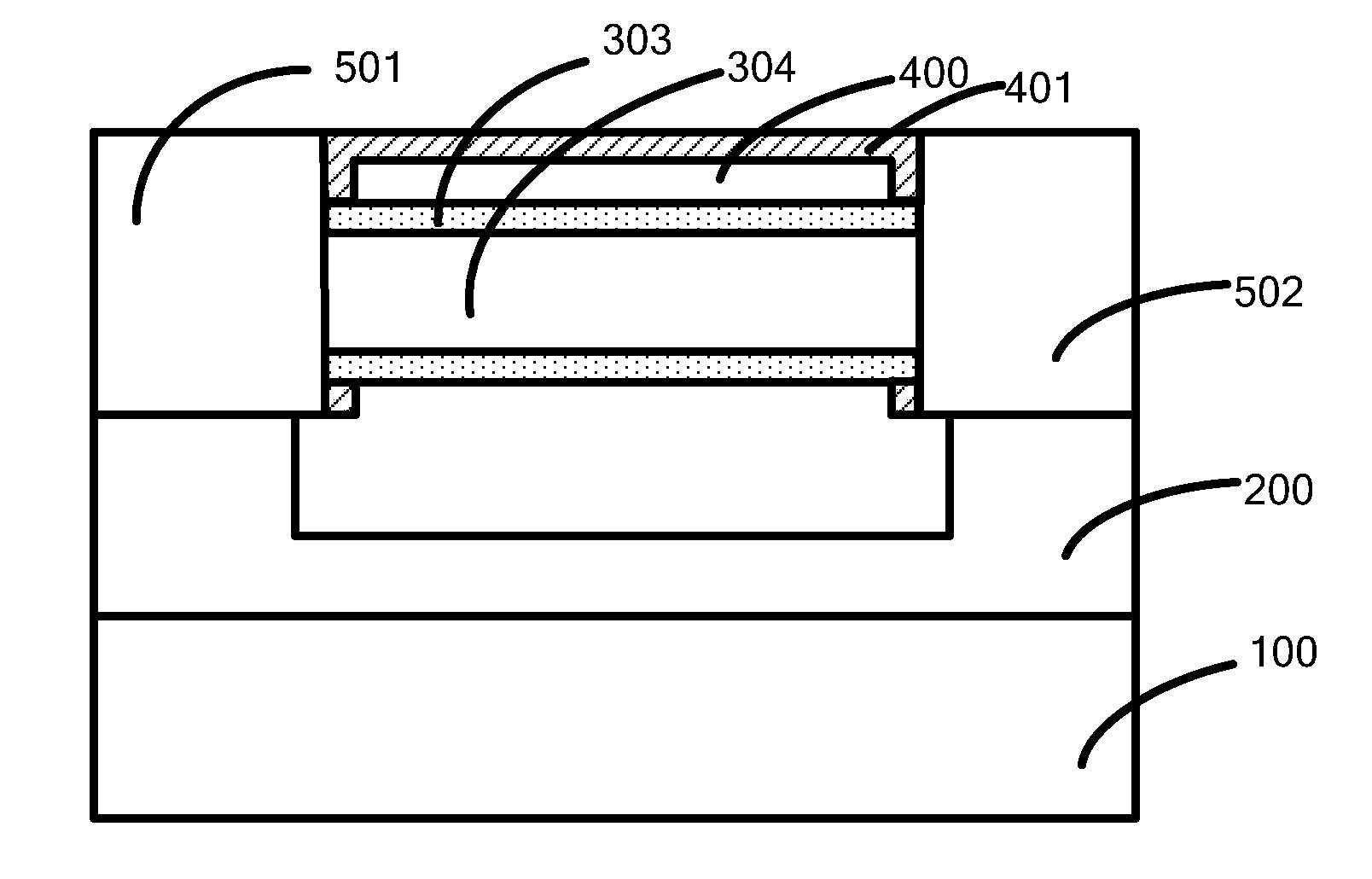

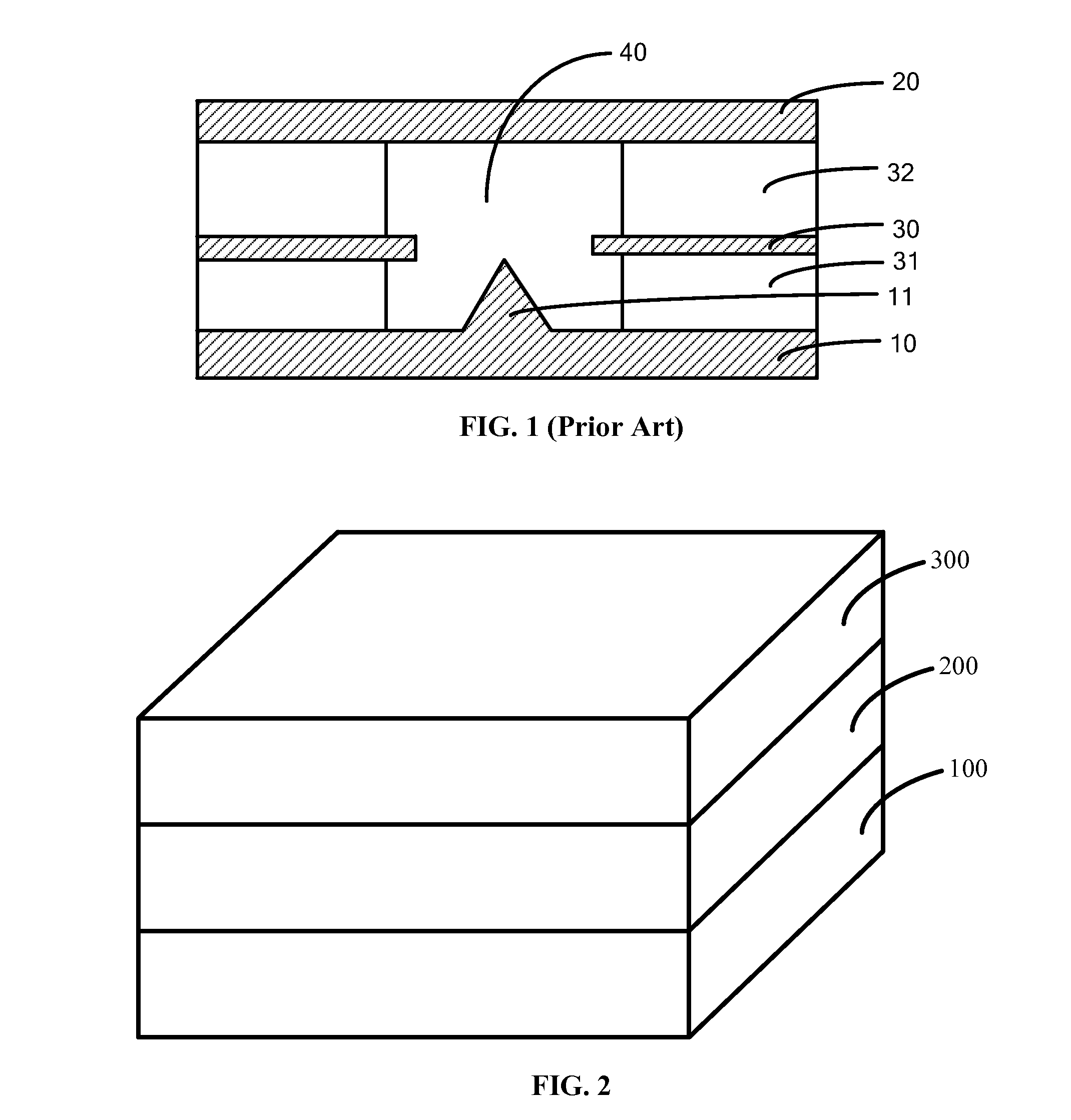

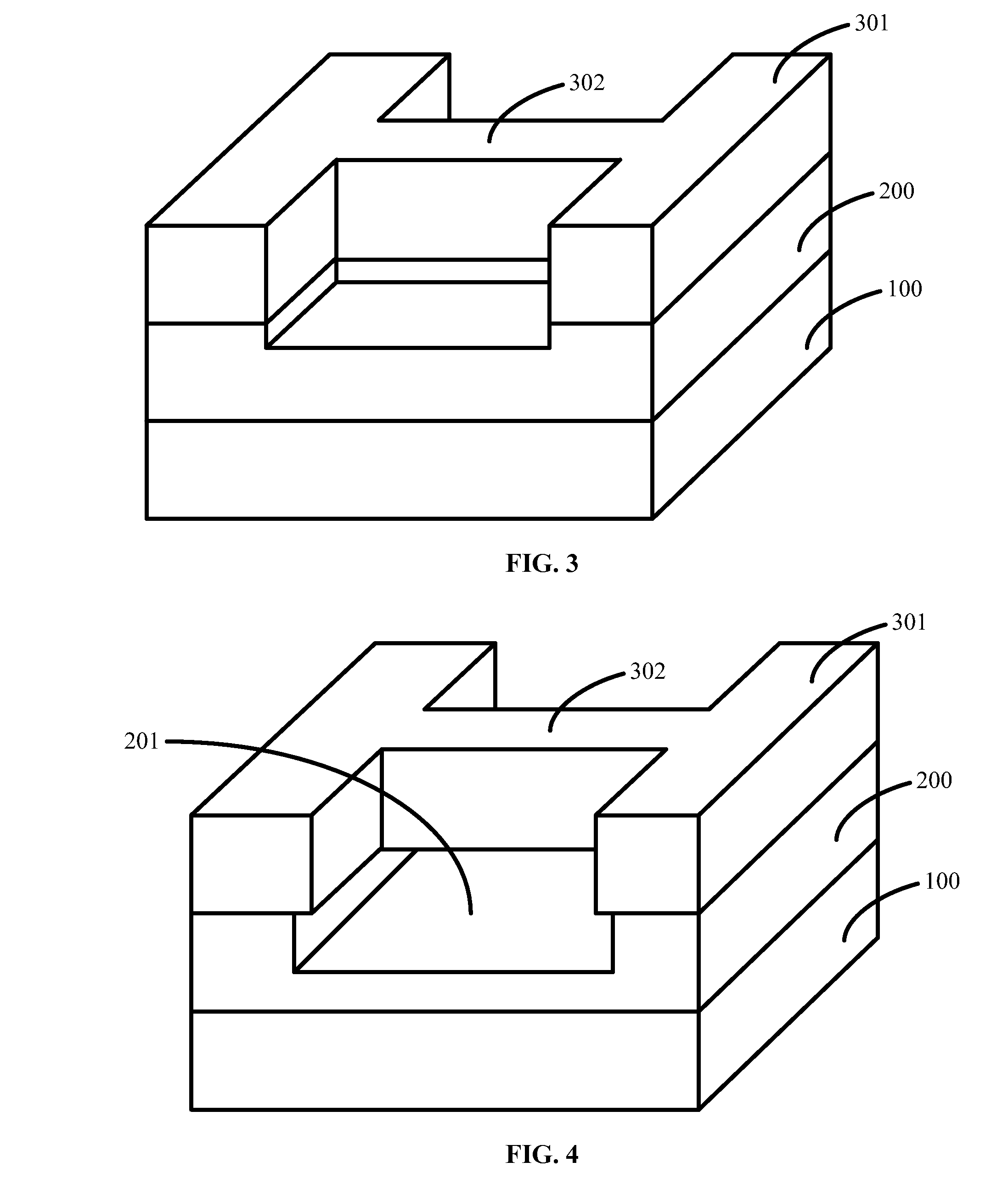

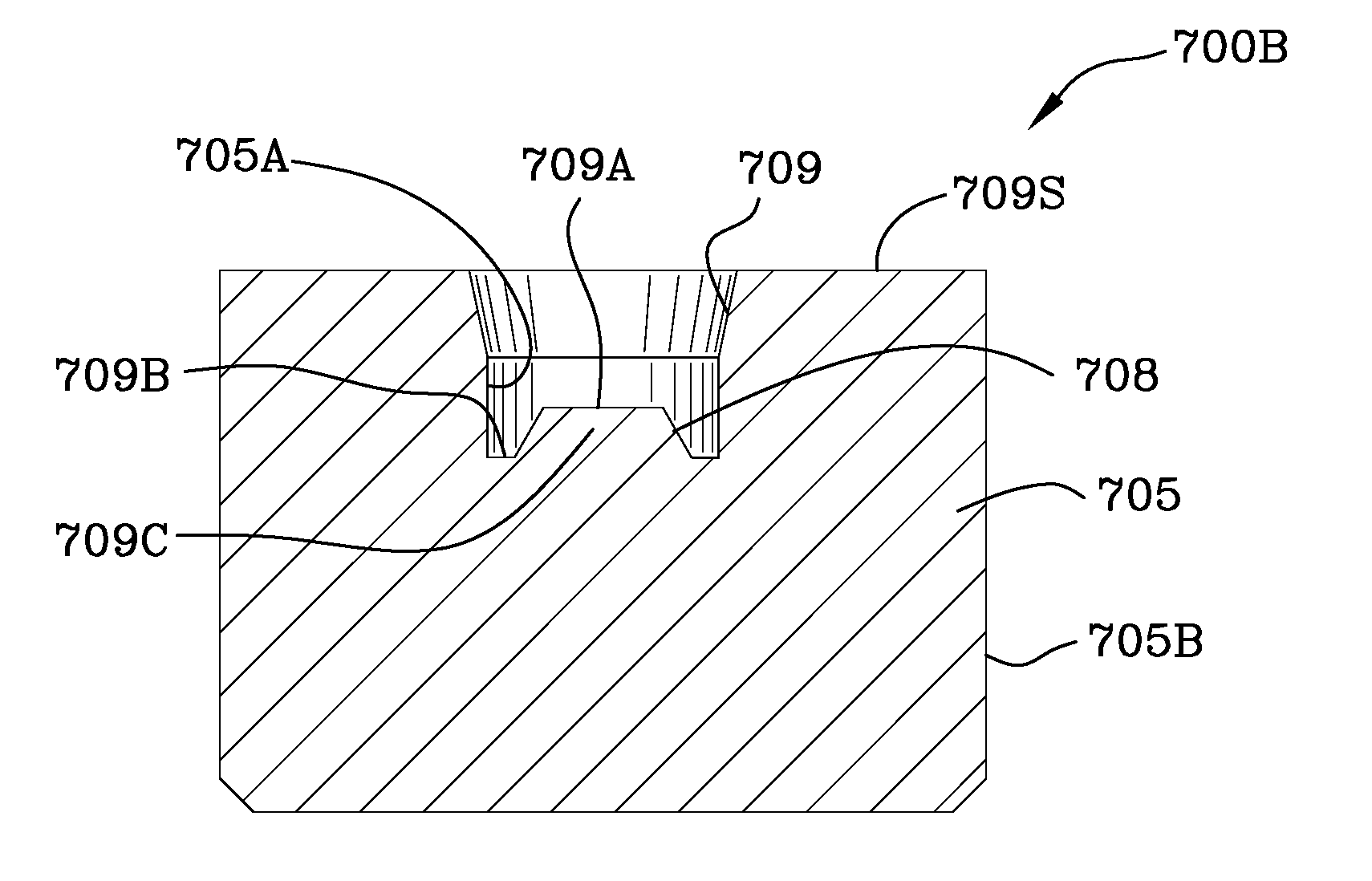

Nano field-effect vacuum tube and fabrication method thereof

ActiveUS9029211B2Promote escapeSurface damageSemiconductor/solid-state device manufacturingNanotechnologyIsolation layerDielectric layer

A method is provided for fabricating a nano field-effect vacuum tube. The method includes providing a substrate having an insulating layer and a sacrificial layer; and forming a sacrificial line, a source sacrificial layer and a drain sacrificial layer. The method also includes forming a trench in the insulating layer; and forming a dielectric layer on the surface of the sacrificial line. Further, the method includes forming a metal layer on the dielectric layer to fill up the trench, cover the sacrificial line and expose the source sacrificial layer and the drain sacrificial layer; and removing the source sacrificial layer and the drain sacrificial layer. Further, the method also includes removing the sacrificial line to form a through channel; forming an isolation layer on the metal layer; and forming a source region and a drain region on the insulating layer at both ends of the metal layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Thrust bearing for turbocharger of internal-combustion engine

ActiveUS8790574B2Easily subjected can be shearedSurface damageShaftsBearing componentsMetallurgyTurbocharger

Owner:DAIDO METAL CO LTD

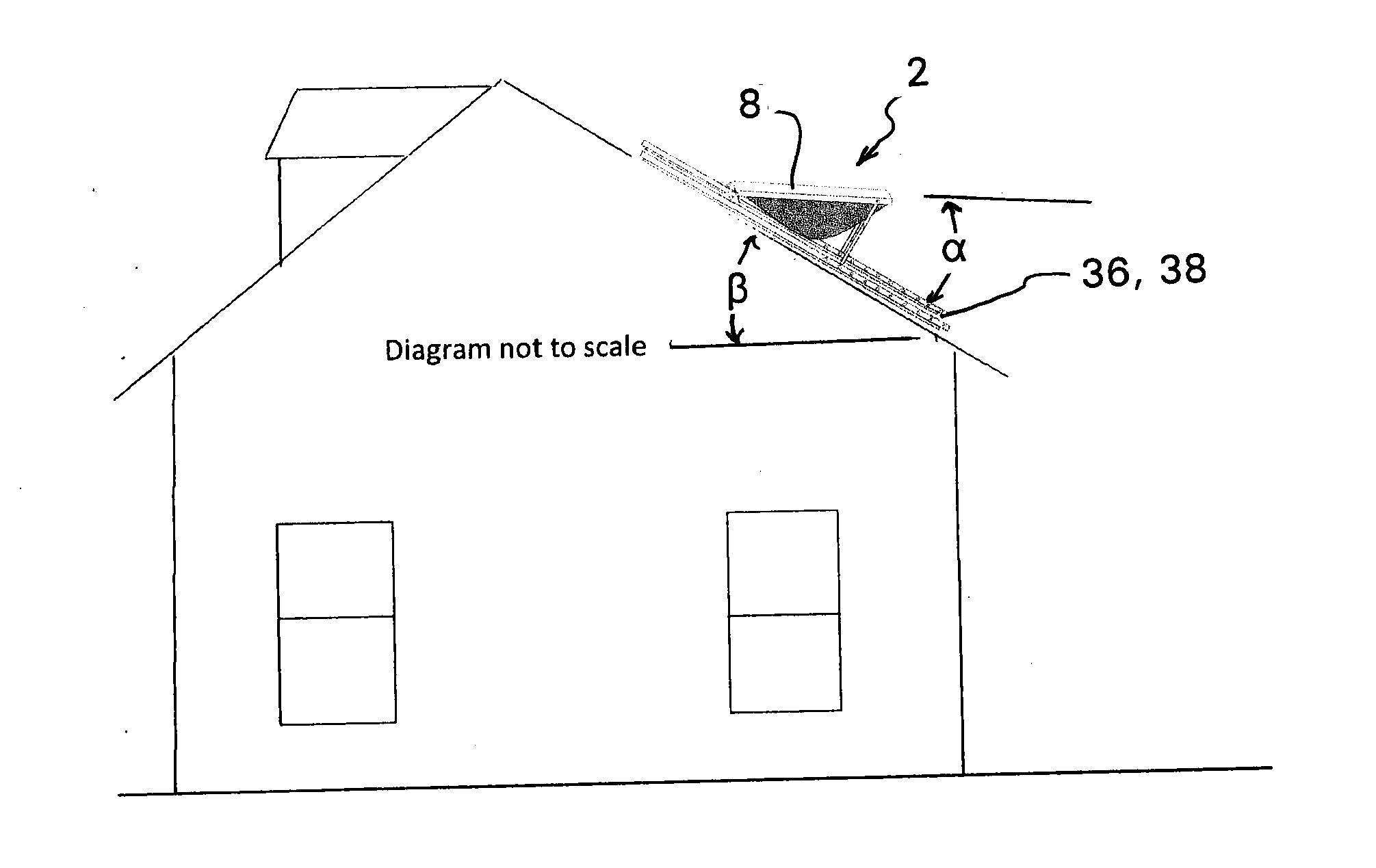

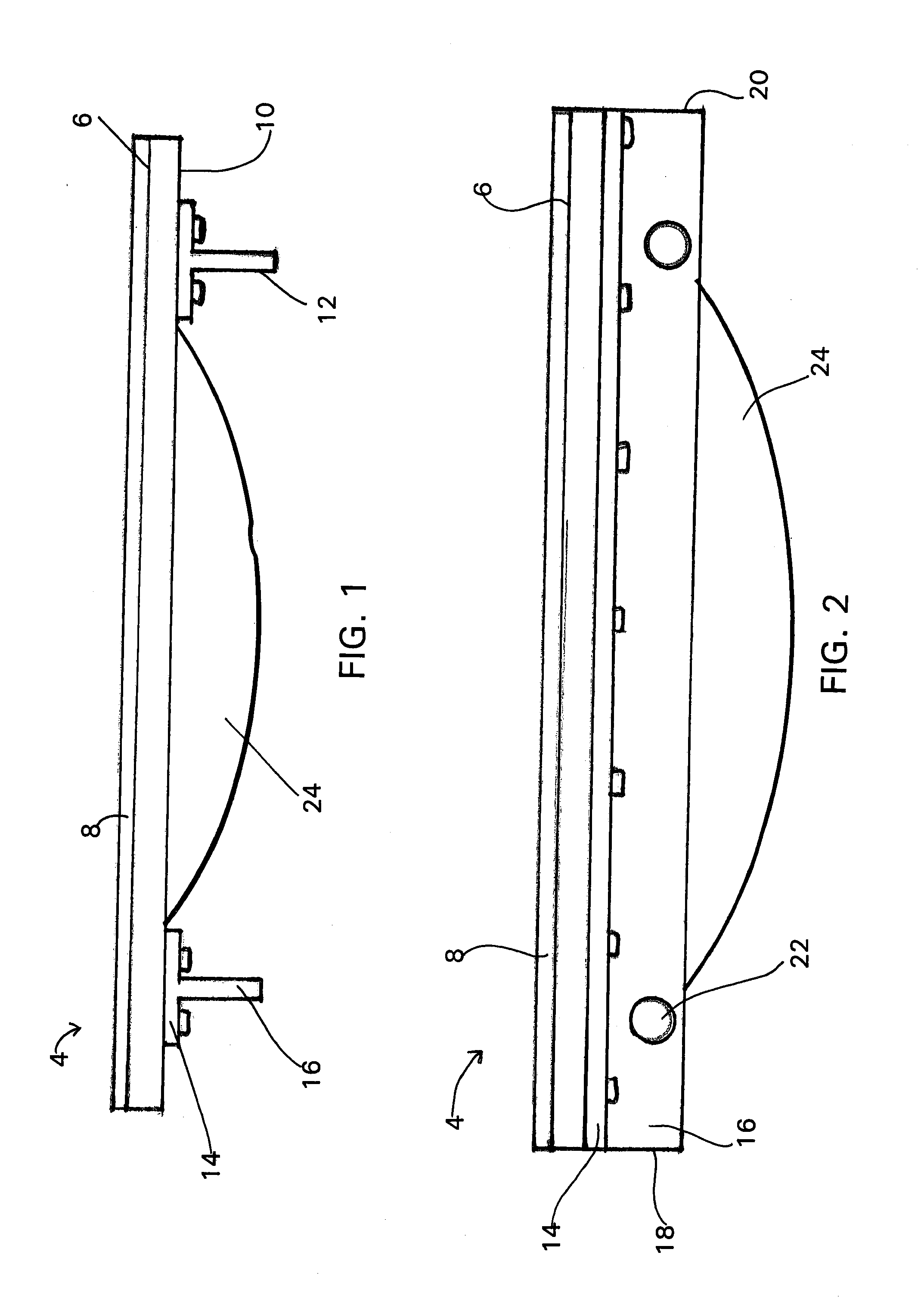

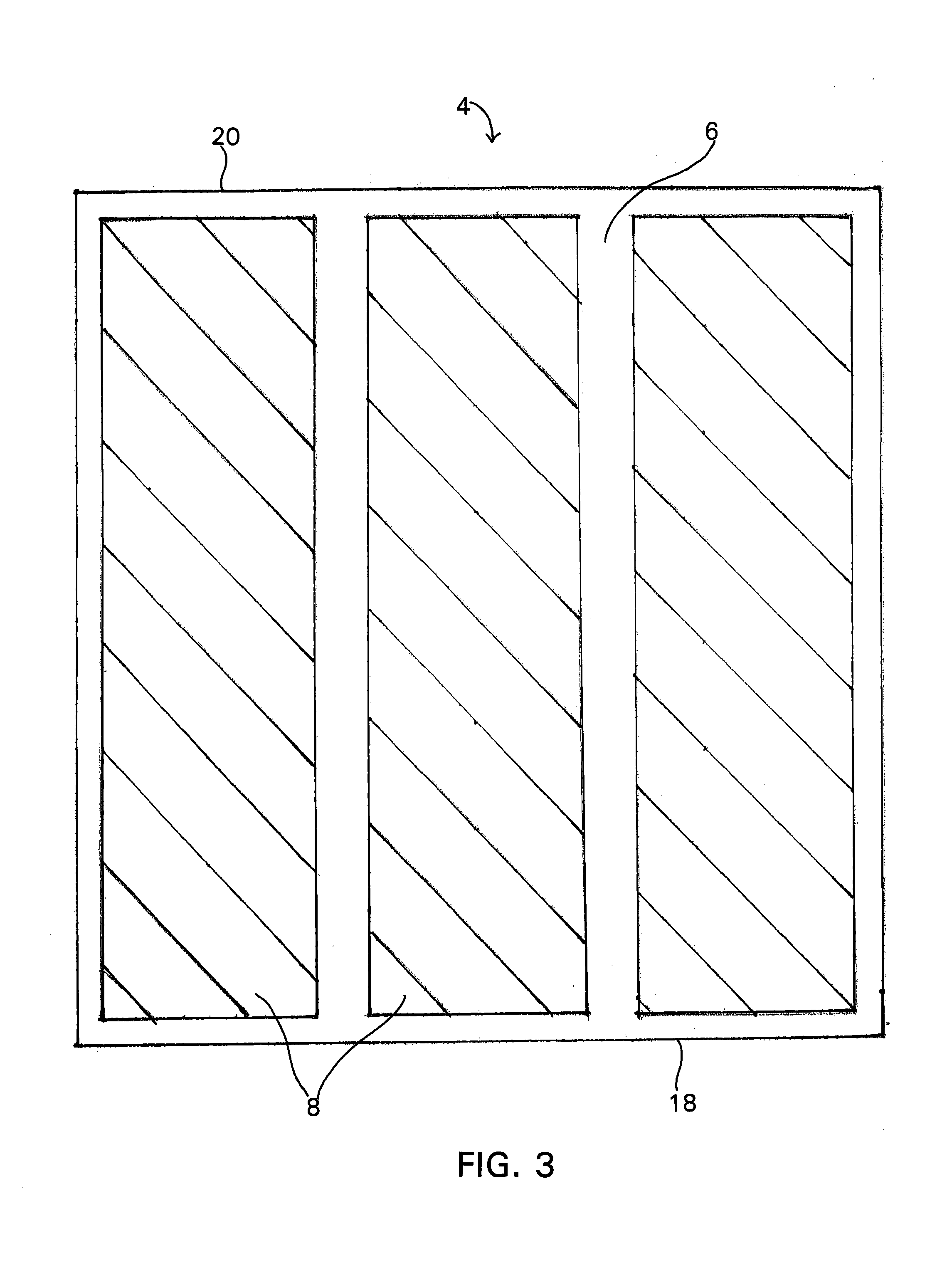

Adjustable platform for use on roof

InactiveUS20120080264A1Repeat usageSurface damageBuilding support scaffoldsEngineeringMechanical engineering

Owner:LORD ARNOLD

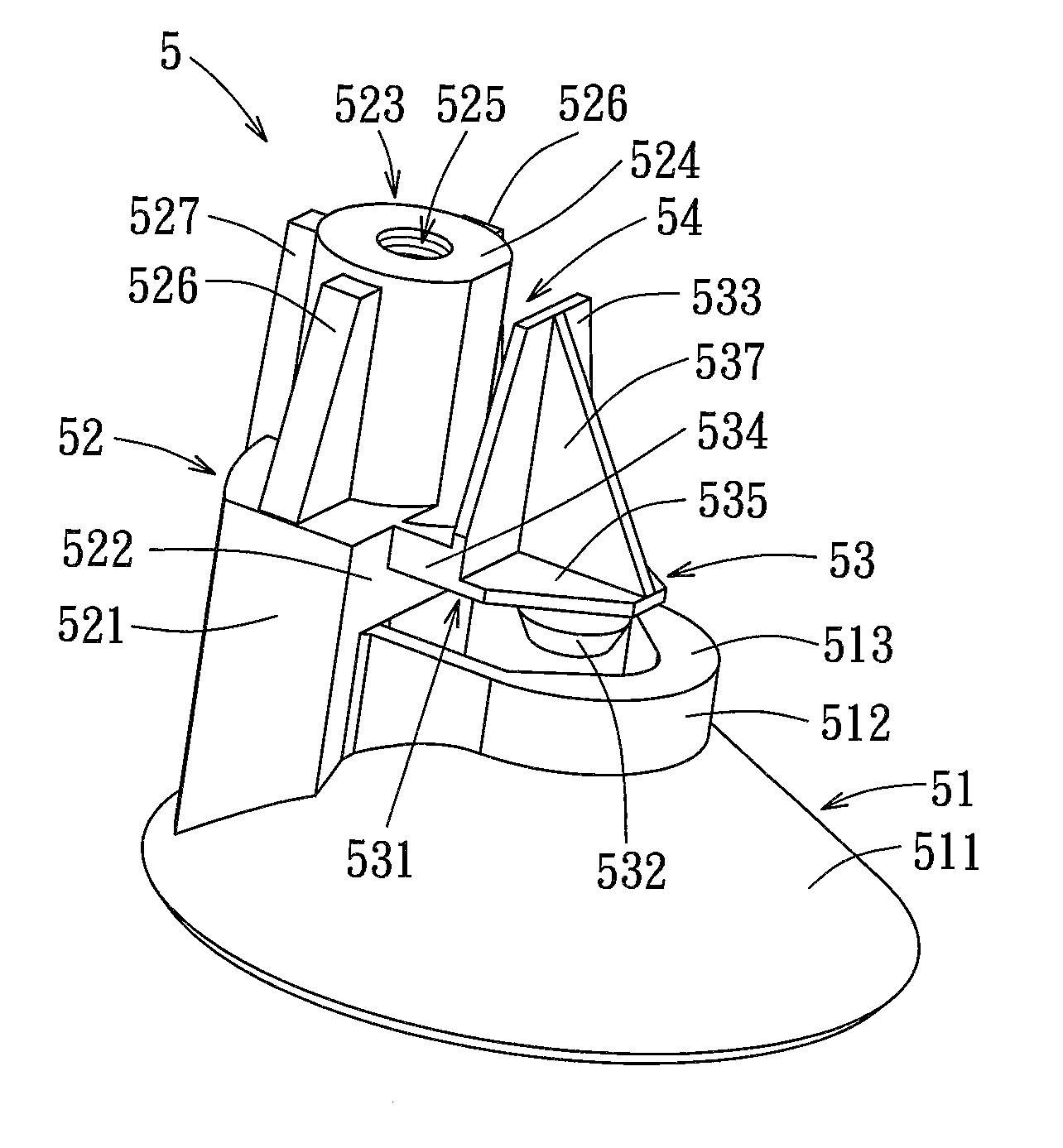

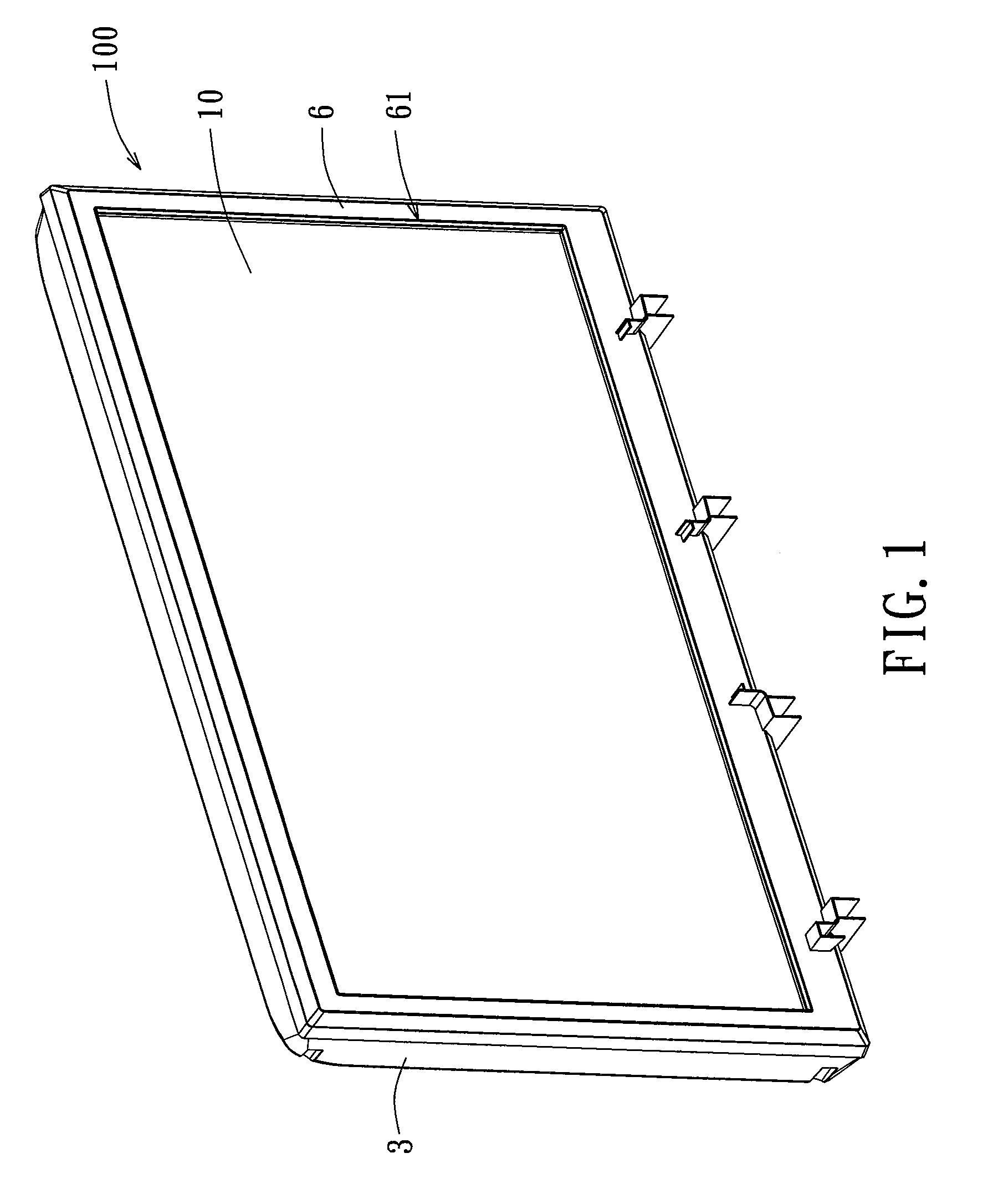

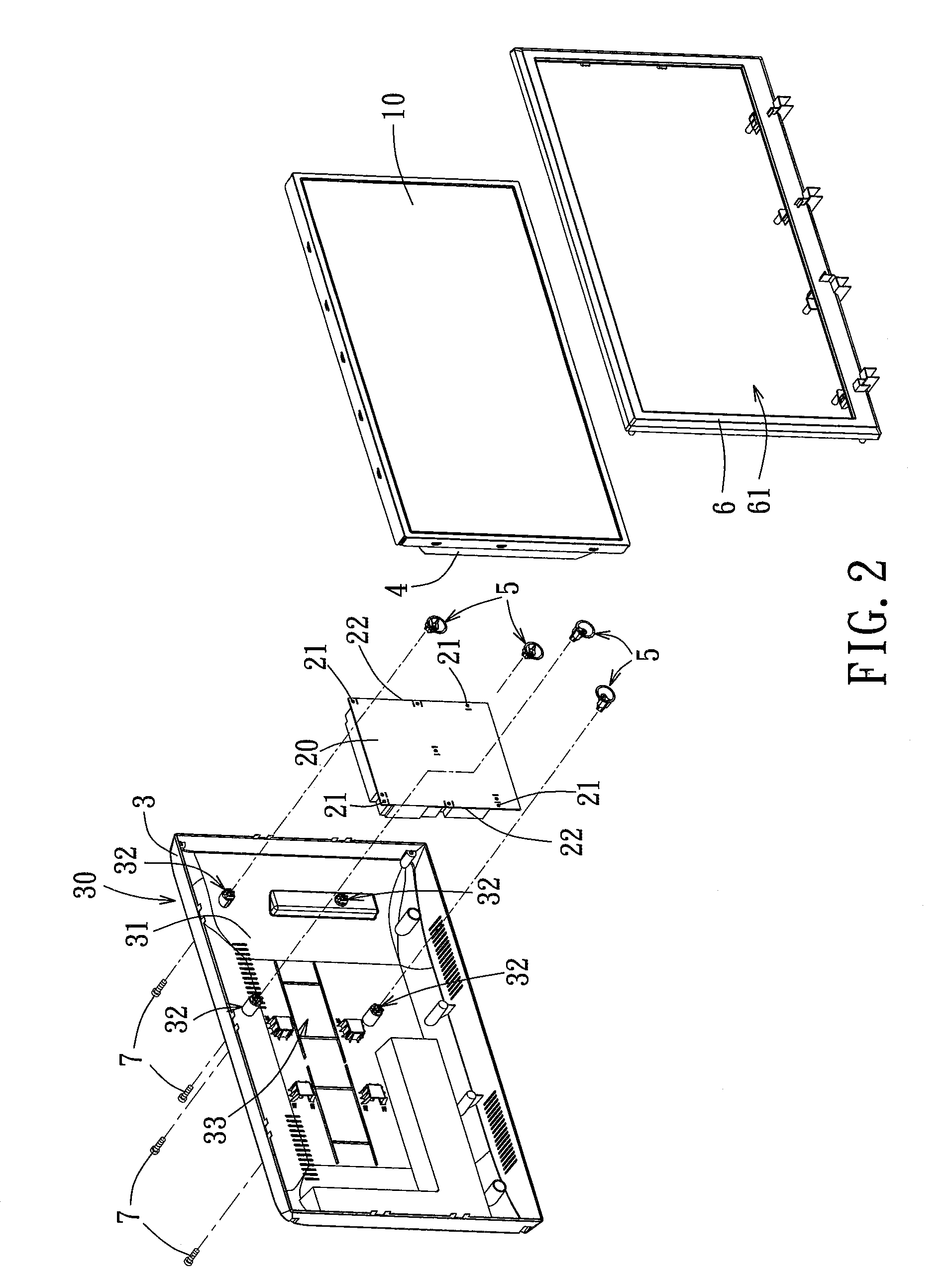

Housing, a fastening member thereof and a display device incorporating the housing

ActiveUS8848349B2Improve efficiencyReduce man-hourCasings/cabinets/drawers detailsRod connectionsEngineeringDisplay device

Owner:WISTRON CORP

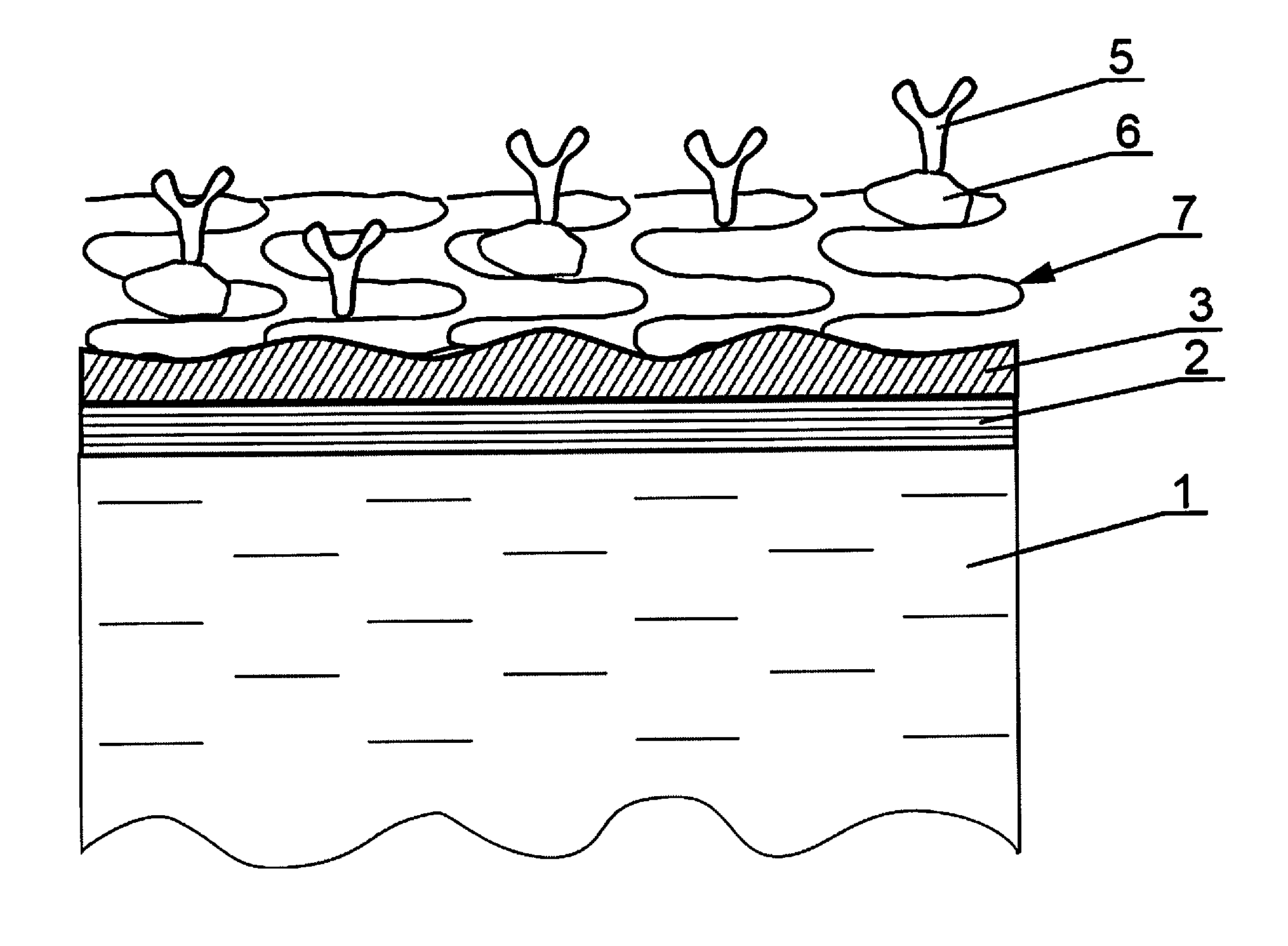

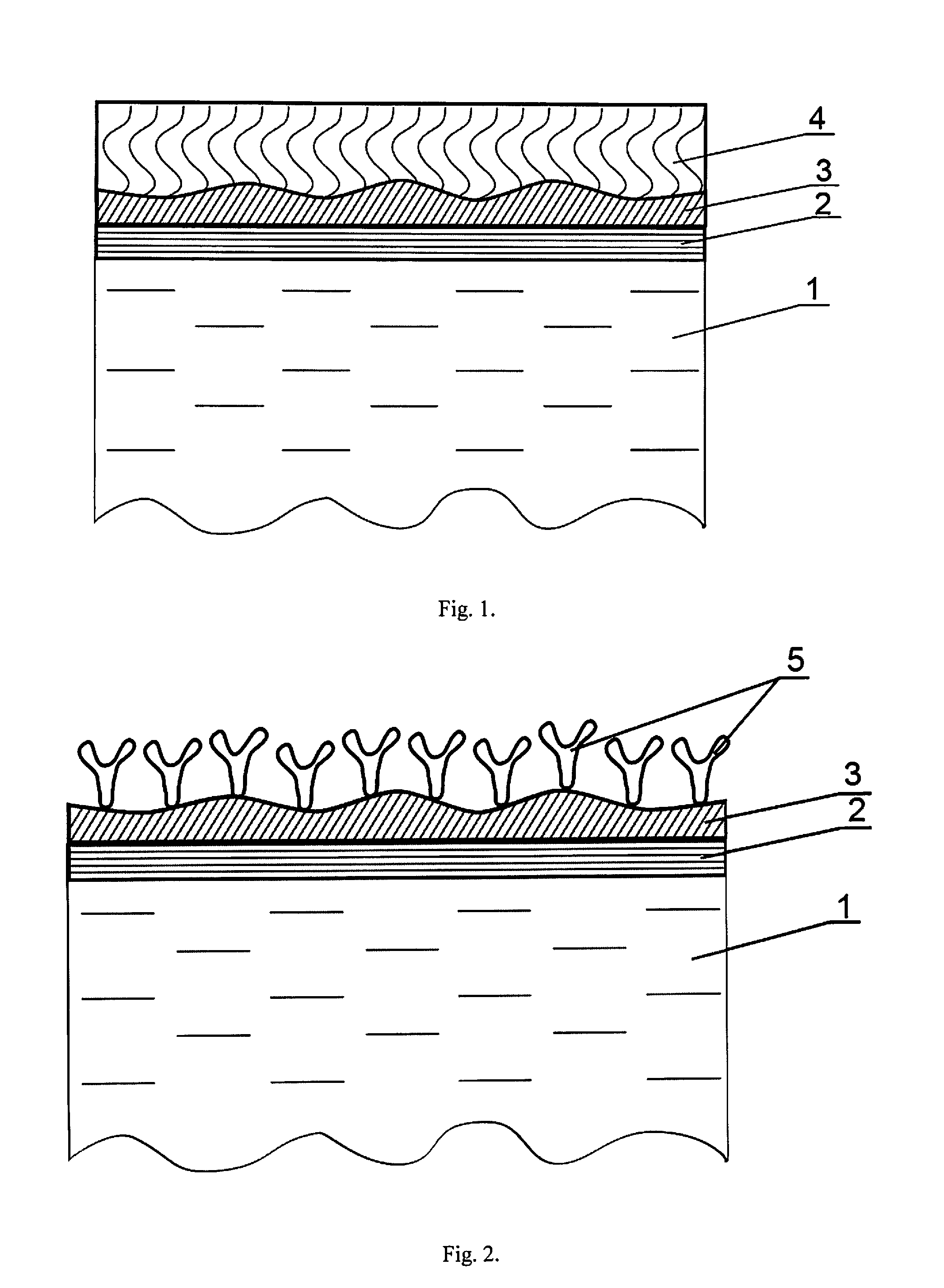

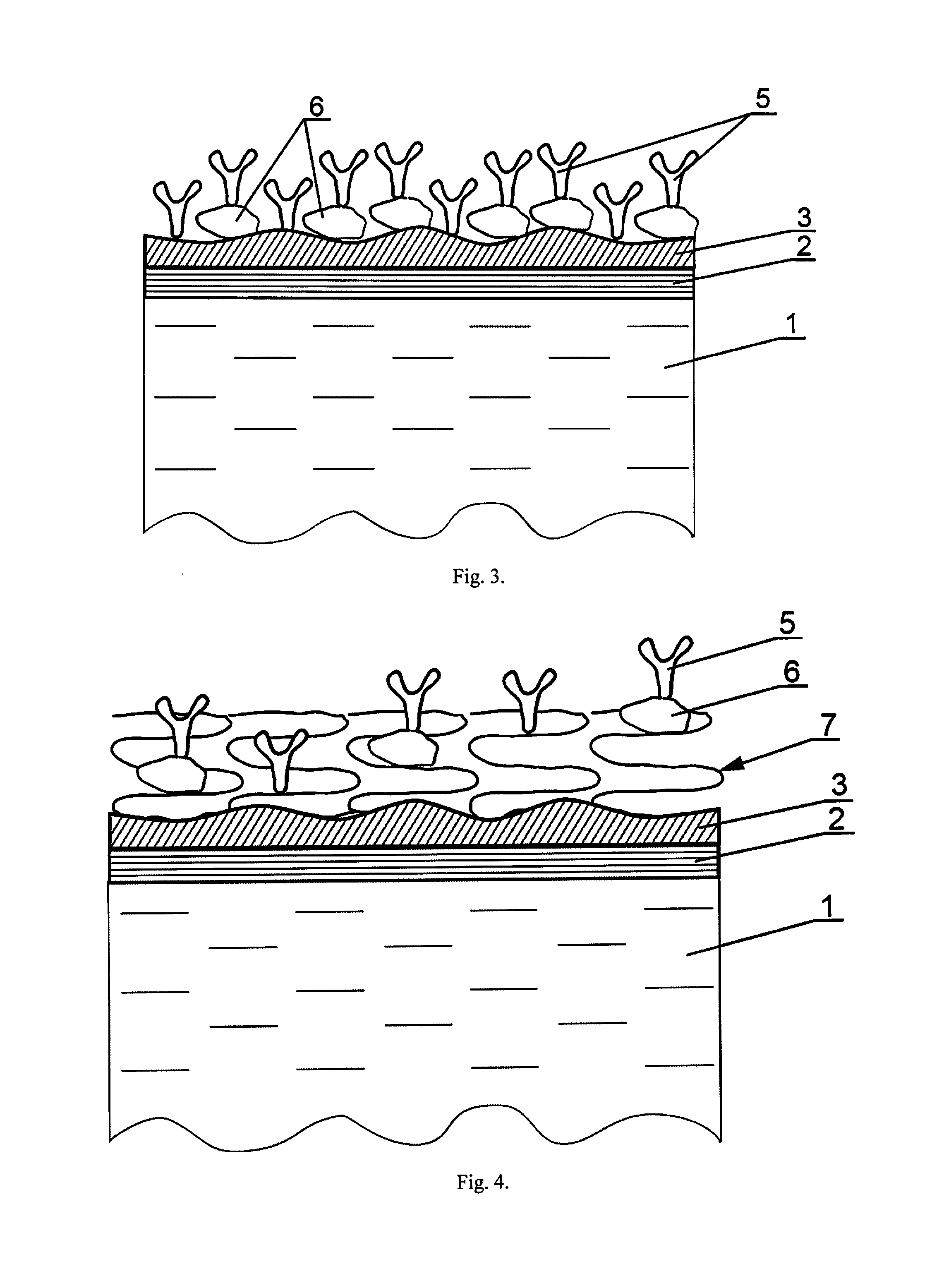

Biological Sensor and a Method of the Production of Biological Sensor

InactiveUS20150301039A1Protect the surfaceSurface damageBioreactor/fermenter combinationsBiological substance pretreatmentsCarbon nanotubeMaterials science

The invention is related to the field of biotechnology, specifically to the investigation of biomolecular interactions and sensing of biomolecules using a surface plasmon resonance. The biological sensor and a method of its production based on the thin films of graphene, graphene oxide, or single-walled or multi-walled carbon nanotubes are described.The technical results of the invention are a high sensitivity of the biosensor in combination with a high biospecificity; an expansion of the range of device applications; the protection of the metal film from an environmental exposure; the possibility to detect large biological objects.The proposed device and method of its production can be used for monitoring and recording of the concentration of chemical and biochemical substances and for the definition of parameters of biomolecular reactions in different industrial processes using biological materials, the invention can be also used in the pharmaceutical industry for the investigation of pharmacological properties and for the determination of a chemical composition of developing drugs, and also it can be used in processes of quality control of food products.

Owner:FEDERALNOE GOSUDARSTVENNOE AVTONOMNOE OBRAZOVATELNOE UCHREZHDENIE VYSSHEGO PROFESSIONALNOGO OBRAZOVANIJA MOSKOVSKIJ FIZIKO TEKHNICHESKIJ INST GOSUDARSTVENNYJ UNIV

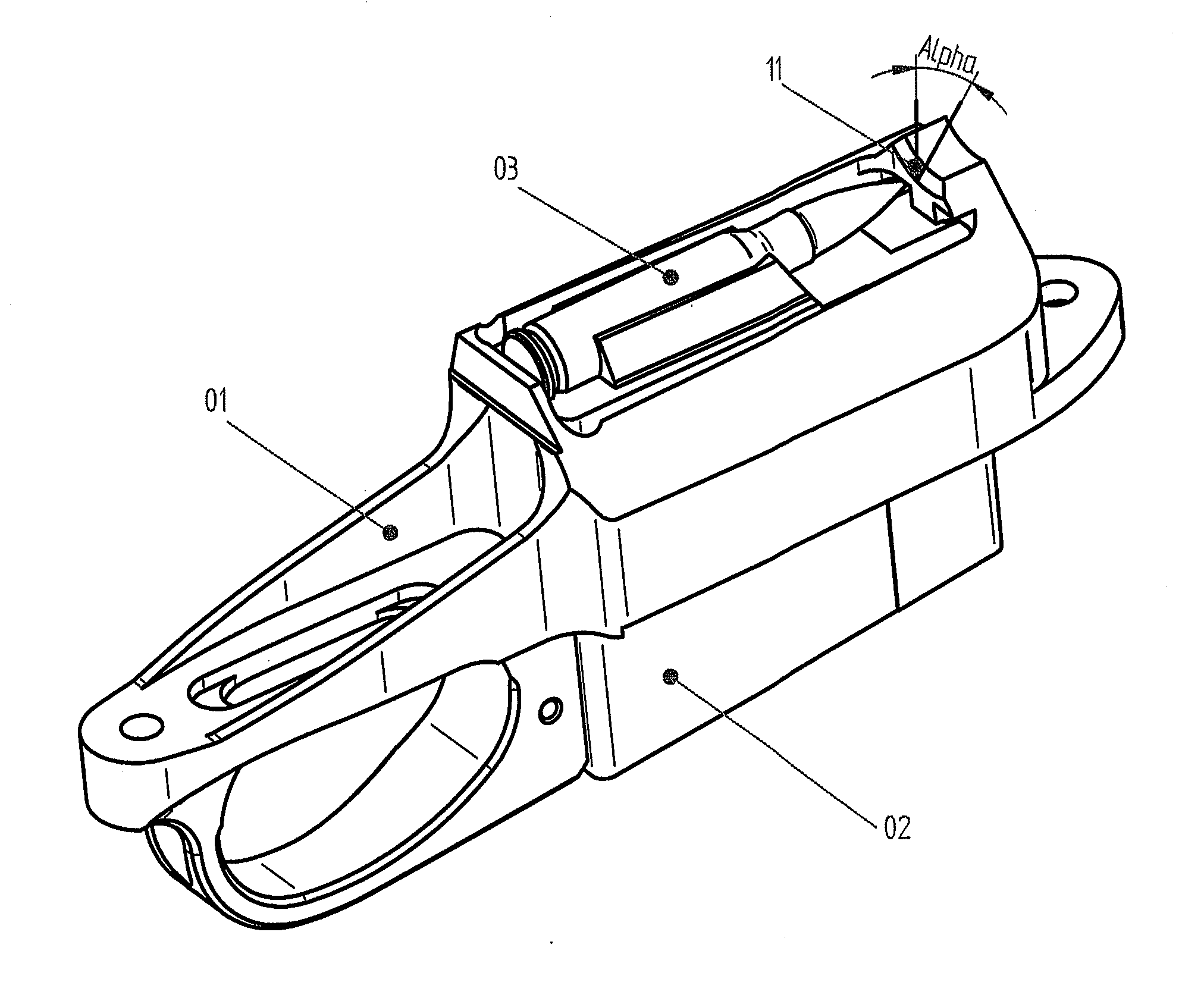

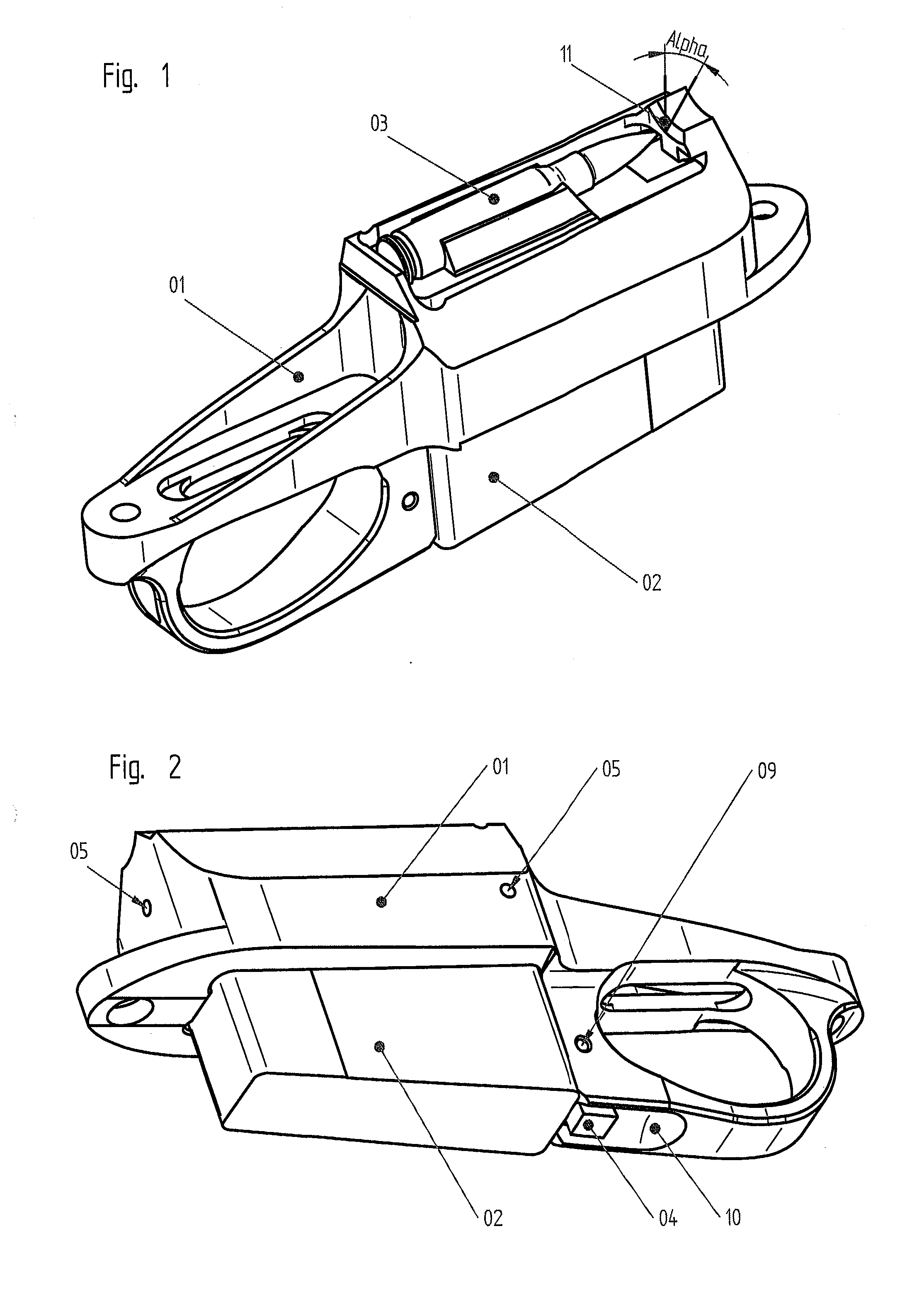

Trigger for firearms with removable magazine

ActiveUS20140165440A1Easy to processSurface damageSafety arrangementFiring/trigger mechanismsEngineeringMechanical engineering

A metal trigger for a firearm has a trigger body. A magazine receptacle is disposed in the trigger body and adapted to receive a removable cartridge magazine. A magazine securing lever is disposed on the trigger body. The trigger body has a feed ramp positioned at a slant at a ramp angle relative to a barrel of the firearm. The feed ramp is adapted to lift during reloading of the firearm a projectile tip of a cartridge from a removable cartridge magazine inserted into the magazine receptacle and to guide the cartridge in a direction of a cartridge chamber disposed in the barrel.

Owner:STYRIA ARMS - MICHAEL W MAYERL

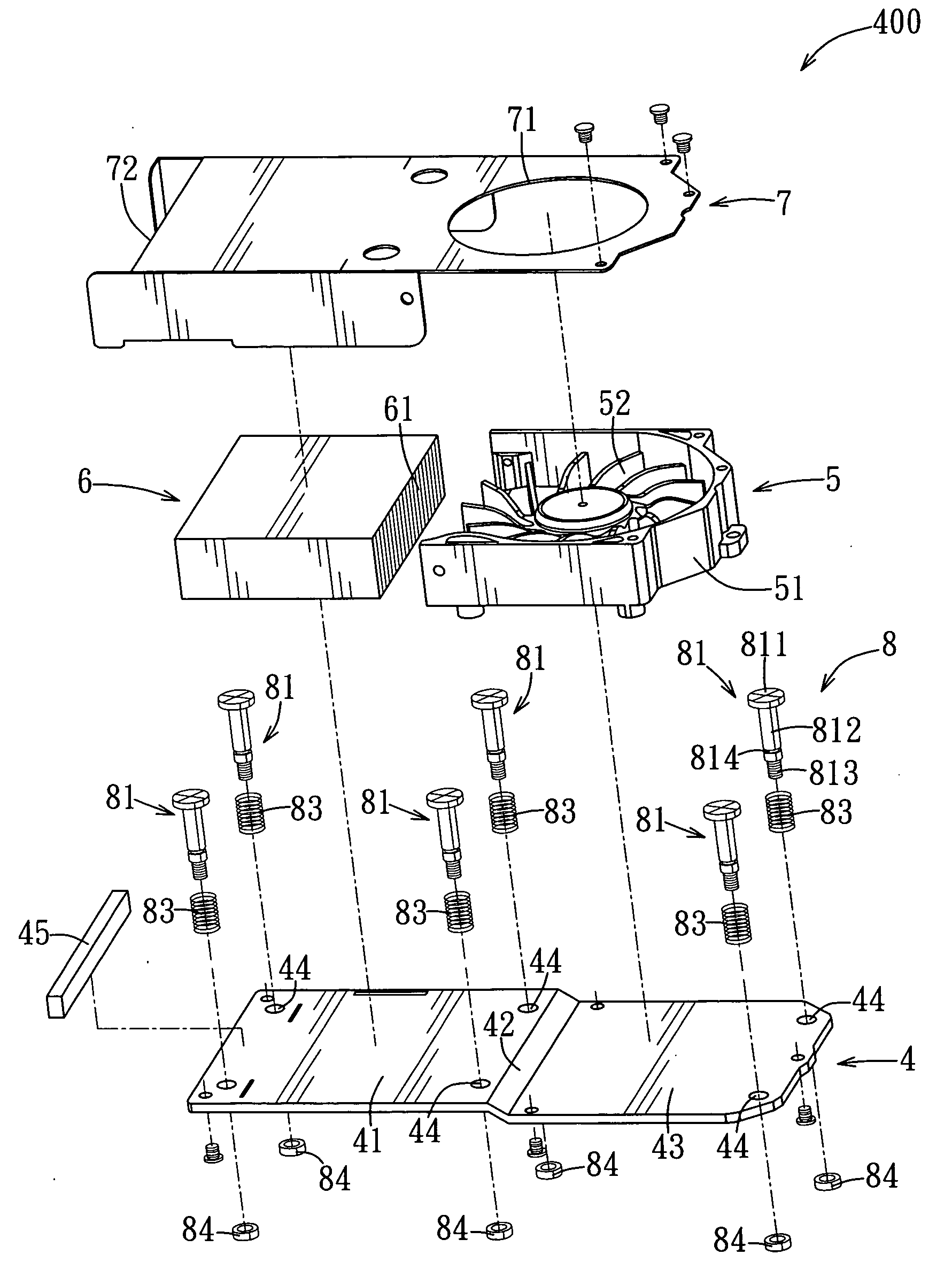

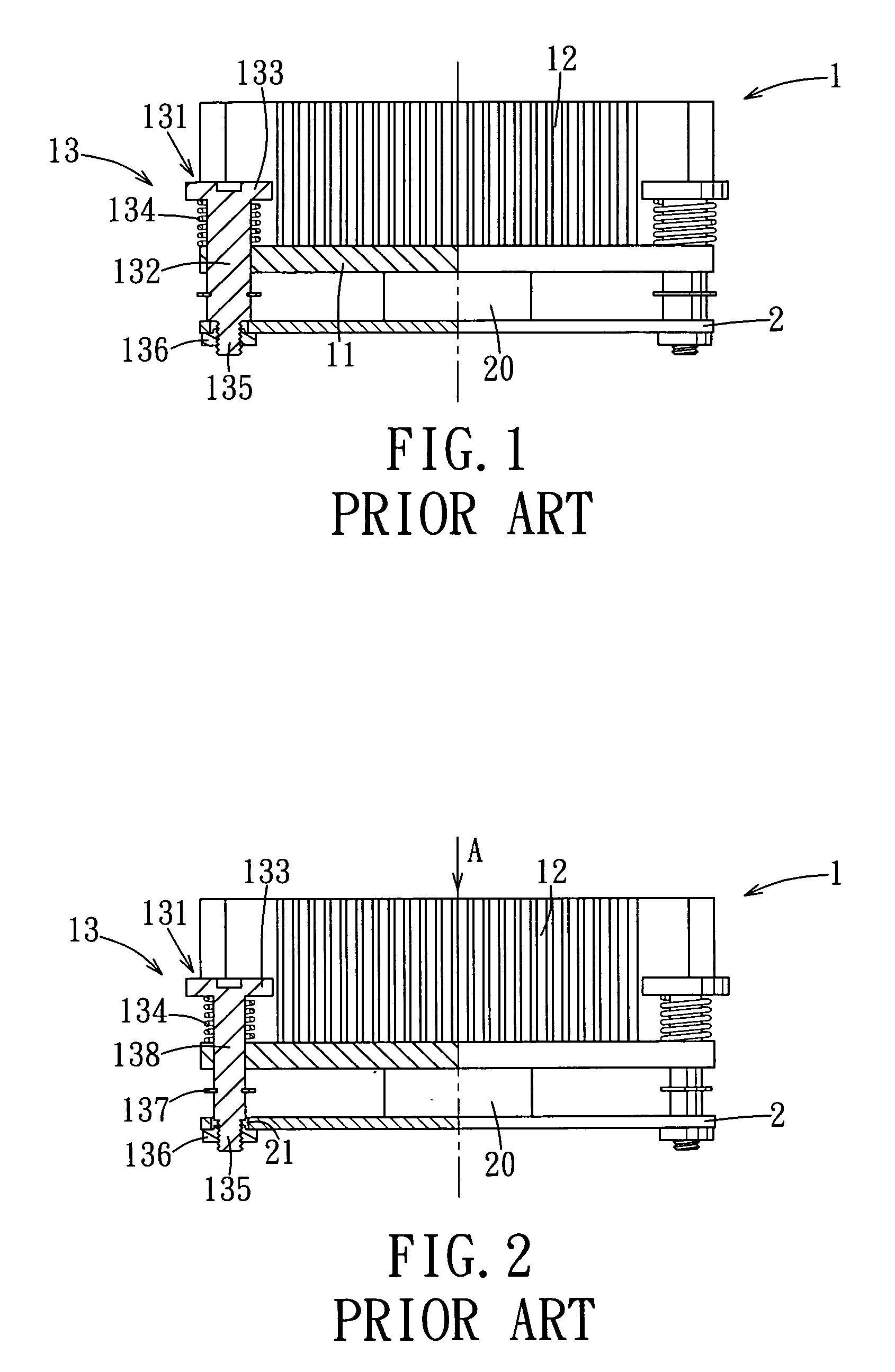

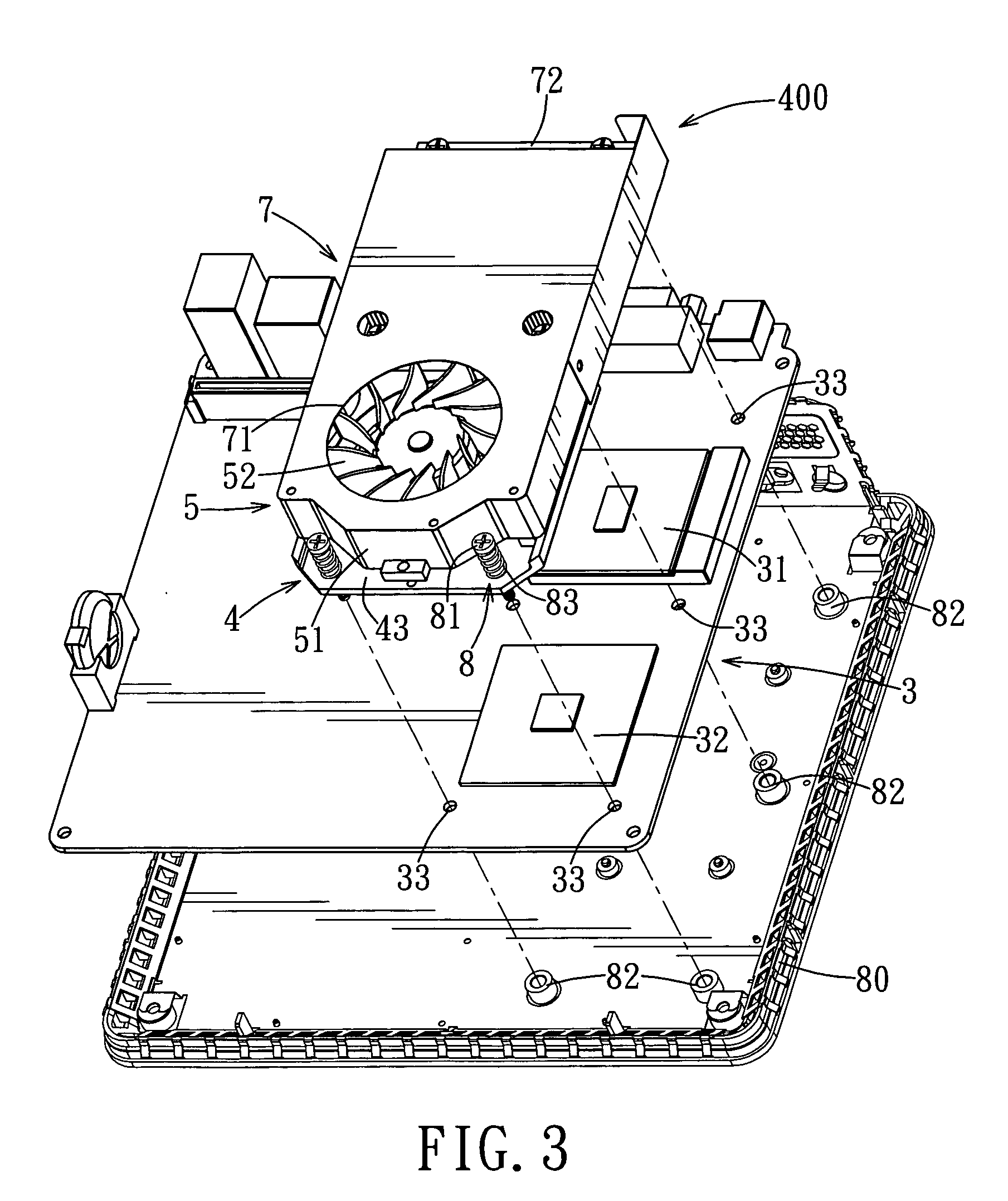

Assembly of heat-dissipating device and circuit board

InactiveUS20070230125A1Reduce likelihoodSurface damageSemiconductor/solid-state device detailsSolid-state devicesFastenerEngineering

In an assembly of a heat-dissipating device and a circuit board, the circuit board has a heat-generating component and is formed with board holes. The heat-dissipating device includes a base plate, a heat-dissipating component, fastening members, biasing members, engaging members, and resilient washers. The base plate abuts against the heat-generating component, and is formed with through-holes. The heat-dissipating component is disposed on the base plate. Each fastening member has a shank part extending through one through-hole and one board hole, a head part, and a threaded connection part. Each biasing member abuts against the base plate and the head part of one fastening member. Each engaging member is disposed at a lower surface of the circuit board and engages the threaded connection part of one fastening member. Each washer is sleeved on one fastening member, and abuts against an upper surface of the circuit board.

Owner:AOPEN

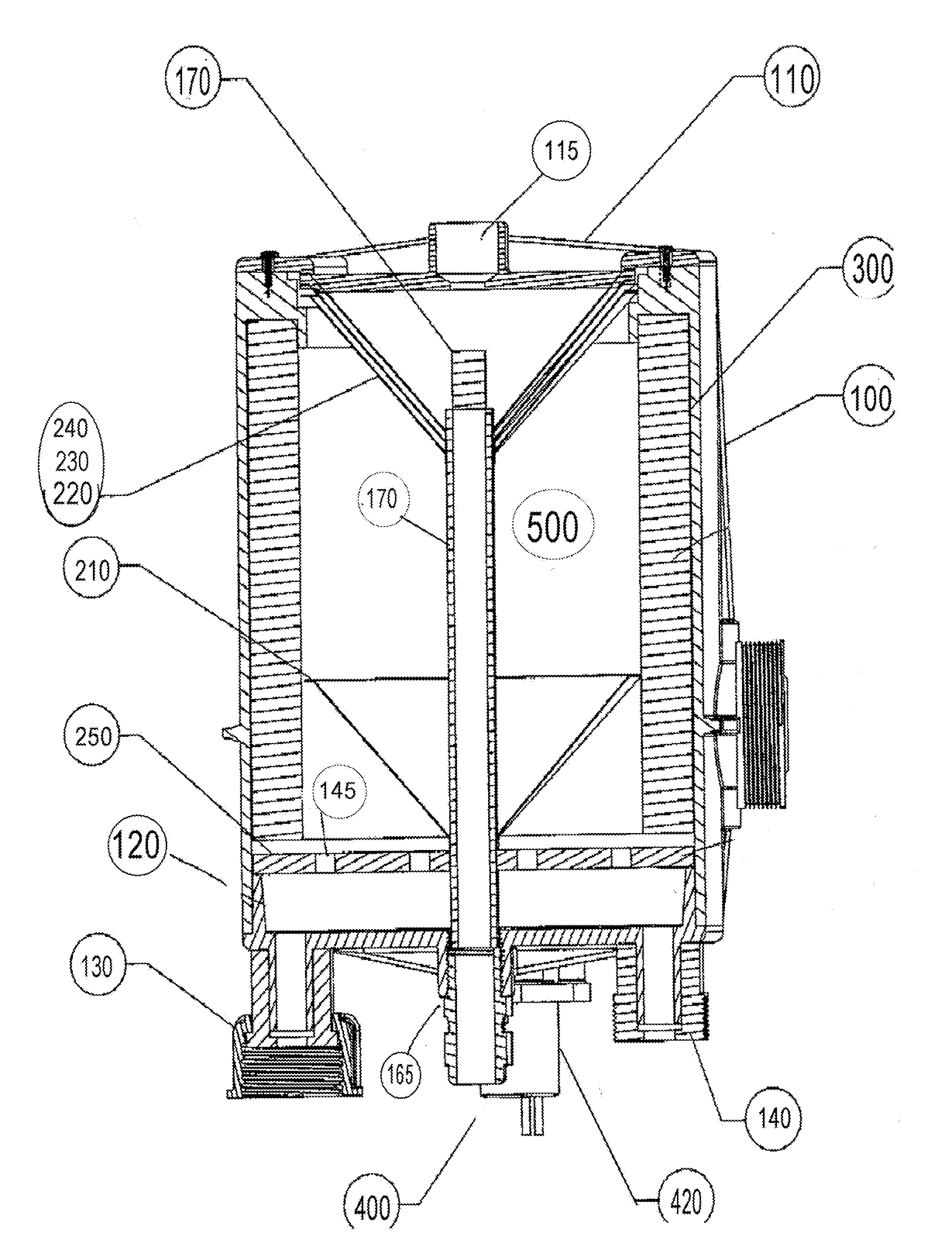

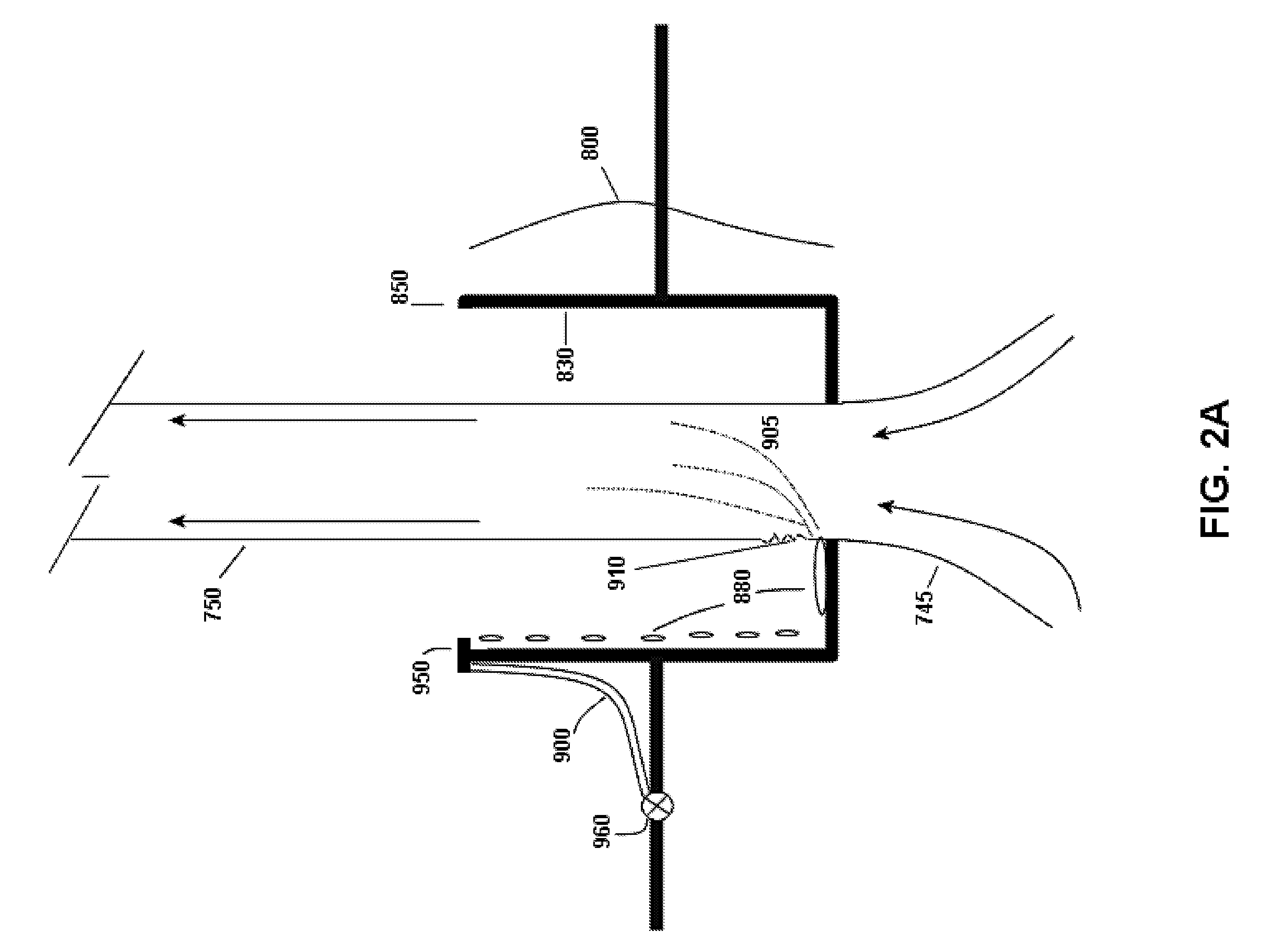

Laminar flow water jet with wave segmentation, additive, and controller

ActiveUS20110073670A1Surface damageConvenient lightingPoint-like light sourceElongate light sourcesWater channelAtmospheric air

A laminar flow water jet system has a housing with a water channel, the housing creating a laminar flow in the water channel from the water flowing through the housing. A lighting element is provided with a controller. The laminar flow passes through at least one jetting element having a cup portion and a nozzle portion and jetting a laminar flow tube from the laminar flow passing through the water channel in the housing at the base portion. The laminar flow tube is ejected from the nozzle as a laminar flow jet having a smoothed tubular surface jacket and being lit by the lighting element. An additive source drips additive into the cup portion at a rate controlled by the controller, the additive being absorbed by capillary action by the laminar flow tube as it is passed through the nozzle to become the laminar flow jet. The absorption process drawing in air from the surrounding atmosphere and creating perturbations or bubbles within the laminar flow tube. In a further mode either an energetic pulse or an additive wave formed by increasing the volume of additive in the cup portion of the jetting element creates a wave perturbation or interruption throughout the laminar flow tube creating a variation in the laminar flow tube and the smoothed tubular surface jacket of the resulting laminar flow jet.

Owner:PENTAIR WATER POOL & SPA INC

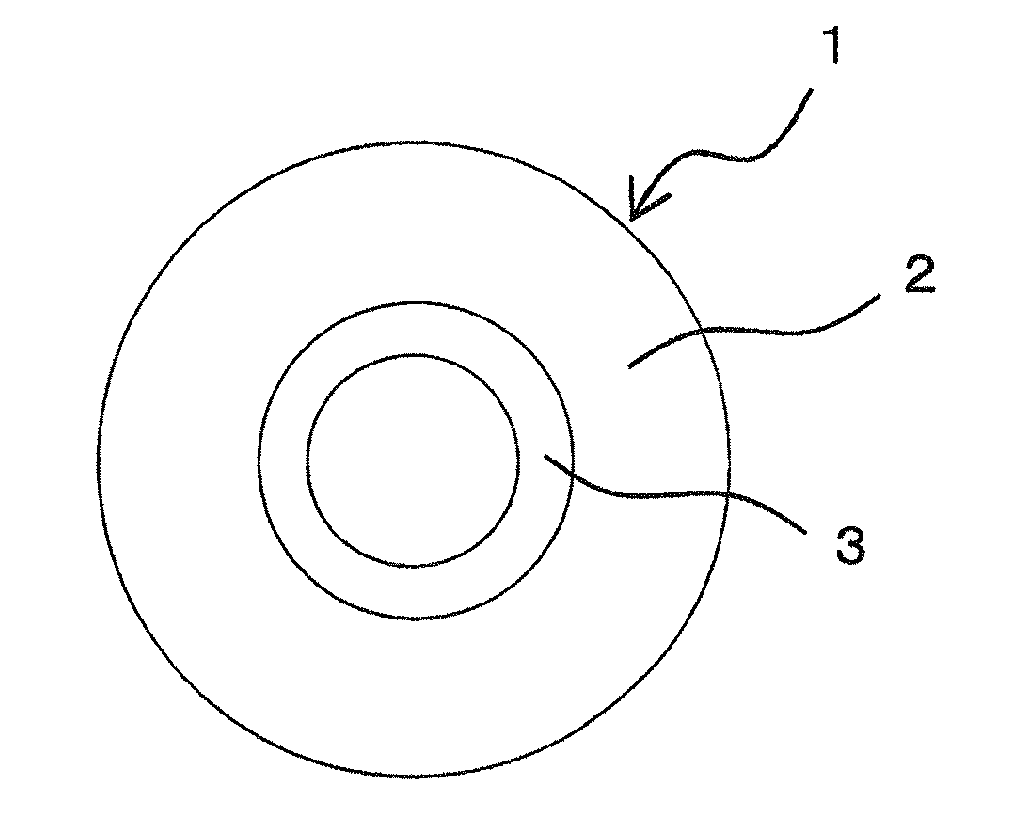

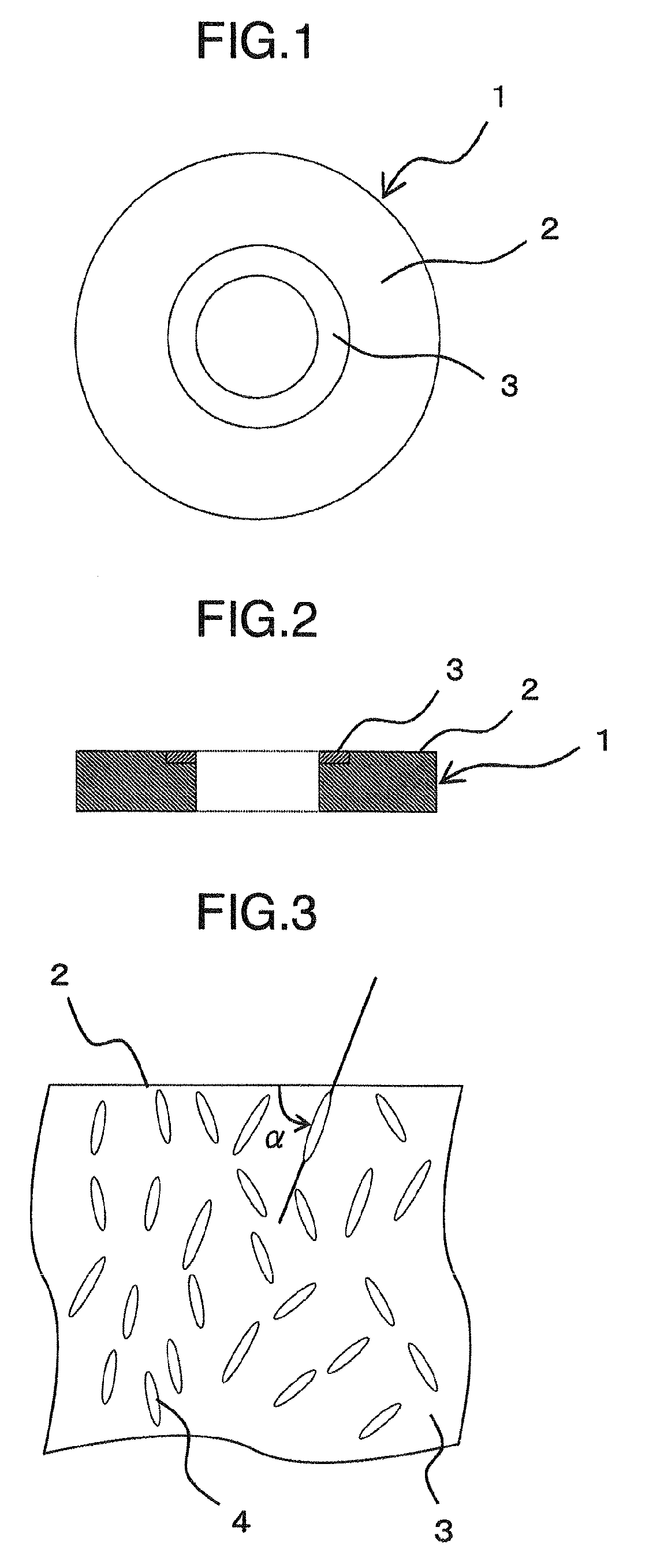

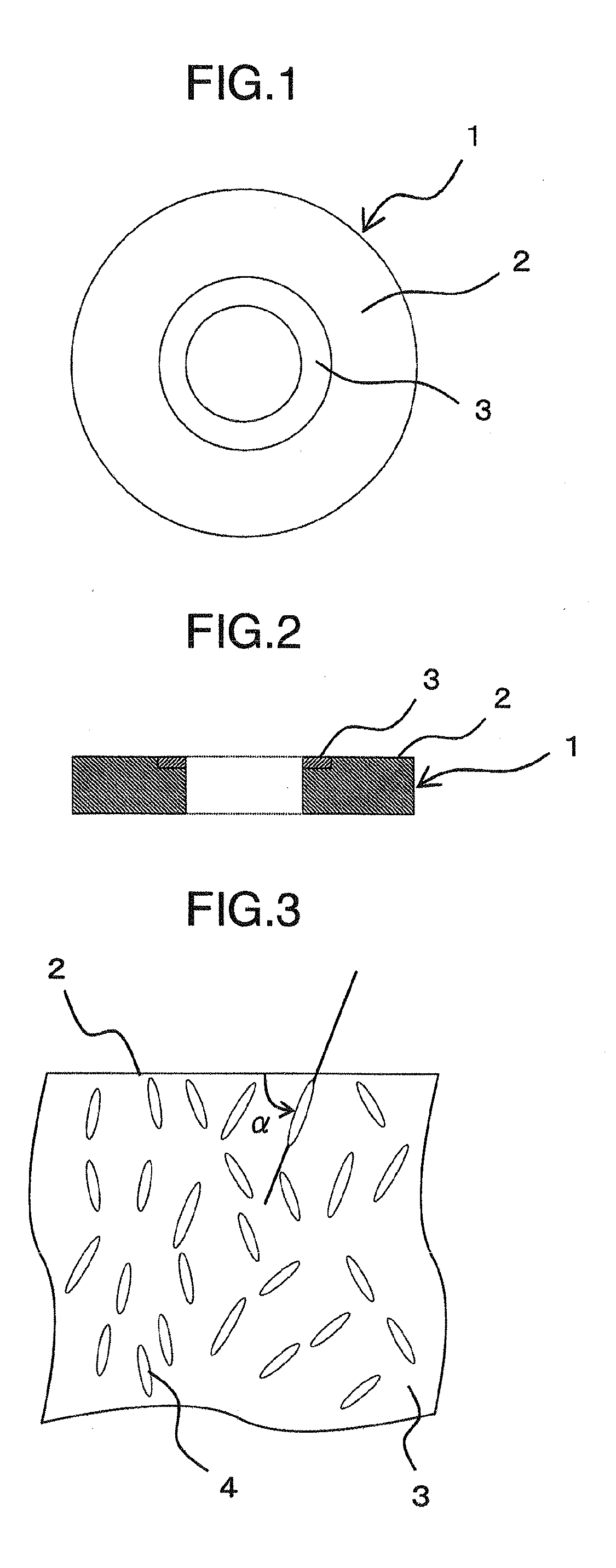

Thrust bearing for turbocharger of internal-combustion engine

ActiveUS20120251383A1Improve wear resistanceWear resistance is unsatisfactoryShaftsBearing componentsMetallurgyTurbocharger

A thrust bearing for a turbocharger of an internal-combustion engine is made of a copper alloy including a brass matrix and a needle-like Mn-Si-based compound dispersed in the brass matrix. Not less than 50% of the needle-like Mn-Si-based compound dispersed in a region from a surface of a sliding portion of the thrust bearing to a depth of 50 μm have a major axis extending from the inside of the sliding portion to the surface. The major axis makes an angle of 30° to 150° with the surface of the sliding portion when observed in a sectional view perpendicular to the surface of the sliding portion.

Owner:DAIDO METAL CO LTD

NANO field-effect vacuum tube and fabrication method thereof

ActiveUS20140332753A1Promote escapeSurface damageSemiconductor/solid-state device manufacturingNanotechnologyIsolation layerDielectric layer

A method is provided for fabricating a nano field-effect vacuum tube. The method includes providing a substrate having an insulating layer and a sacrificial layer; and forming a sacrificial line, a source sacrificial layer and a drain sacrificial layer. The method also includes forming a trench in the insulating layer; and forming a dielectric layer on the surface of the sacrificial line. Further, the method includes forming a metal layer on the dielectric layer to fill up the trench, cover the sacrificial line and expose the source sacrificial layer and the drain sacrificial layer; and removing the source sacrificial layer and the drain sacrificial layer. Further, the method also includes removing the sacrificial line to form a through channel; forming an isolation layer on the metal layer; and forming a source region and a drain region on the insulating layer at both ends of the metal layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Belt assembly for storage and inventory of tools

InactiveUS20020084299A1Surface damageEasy to repositionTravelling sacksTravelling carriersVisual markingEngineering

A tool-carrying assembly to be secured by a waist-encircking belt, and, additionally, by straps encircling the legs of a workman using the belt assembly. The assembly is thus stabilized, and enhanced weight distribution is achieved. Elements of the belt assembly include a waist-encircling band supporting a pair of laterally spaced, depending panels each carrying tool-accepting pockets. The pockets preferably carry visual markings and coding as well as other indicia identifying clearly the specific tools to be "housed" or carried in and to be returned to each pocket after use. Inventory control of the tools is thereby significantly enhanced. Pivotal flaps depending from the band-carried panels serve to cover the tools when not in use, and to prevent the tools from scratching or otherwise marring any article, or fixture, or "workpiece" requiring the workman's attention. The panels and the tools carried thereby are disposed in lateral, spaced zones at the wearer's sides (and not directly in the front of one's body) thus further to reduce any likelihood of the tools coming into damaging physical contact with an article being worked upon. That is, both frontal and rearwardly located zones about the wearer of the tool belt assembly are rendered essentially free and clear of all tools and other mechanical impediments. While wearing the tool assembly of the invention, a worker can, without any discomfort, lie upon and use a "creeper". Significantly, a frontal sector of the belt itself is covered with a relatively soft, non-marring protective pad, composition, or surface material effective to prevent possible damage from a workman's belt buckle. An additional feature of the invention is that the panels may be structured to constitute a core sandwiched between a pair of encasing sheet-like webs. The resulting composite is readily formable to provide selectable visual patterns, designs or indicia, for example, to identify product name or source, and / or to constitute decorations.

Owner:WMH TOOL GROUP

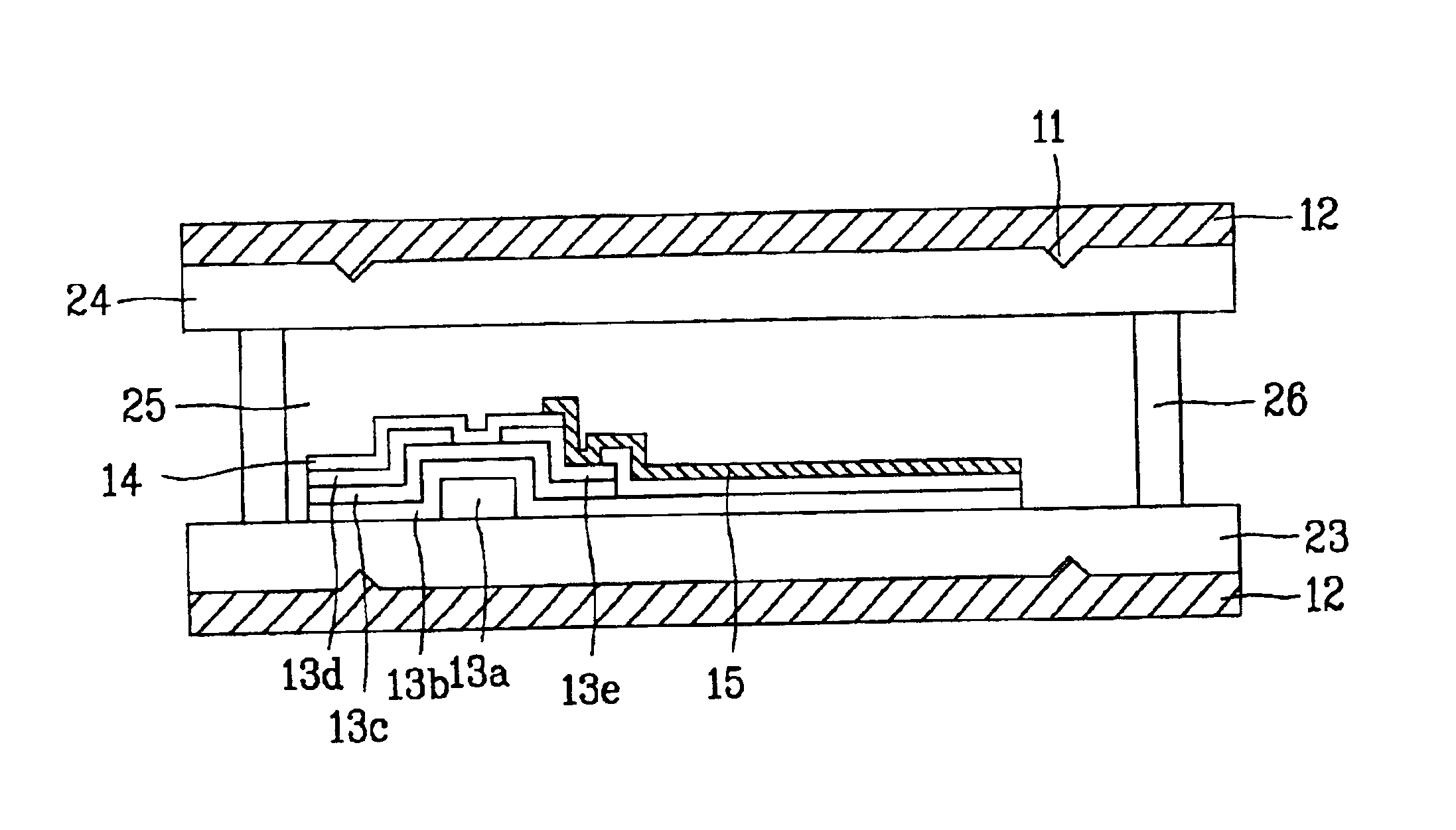

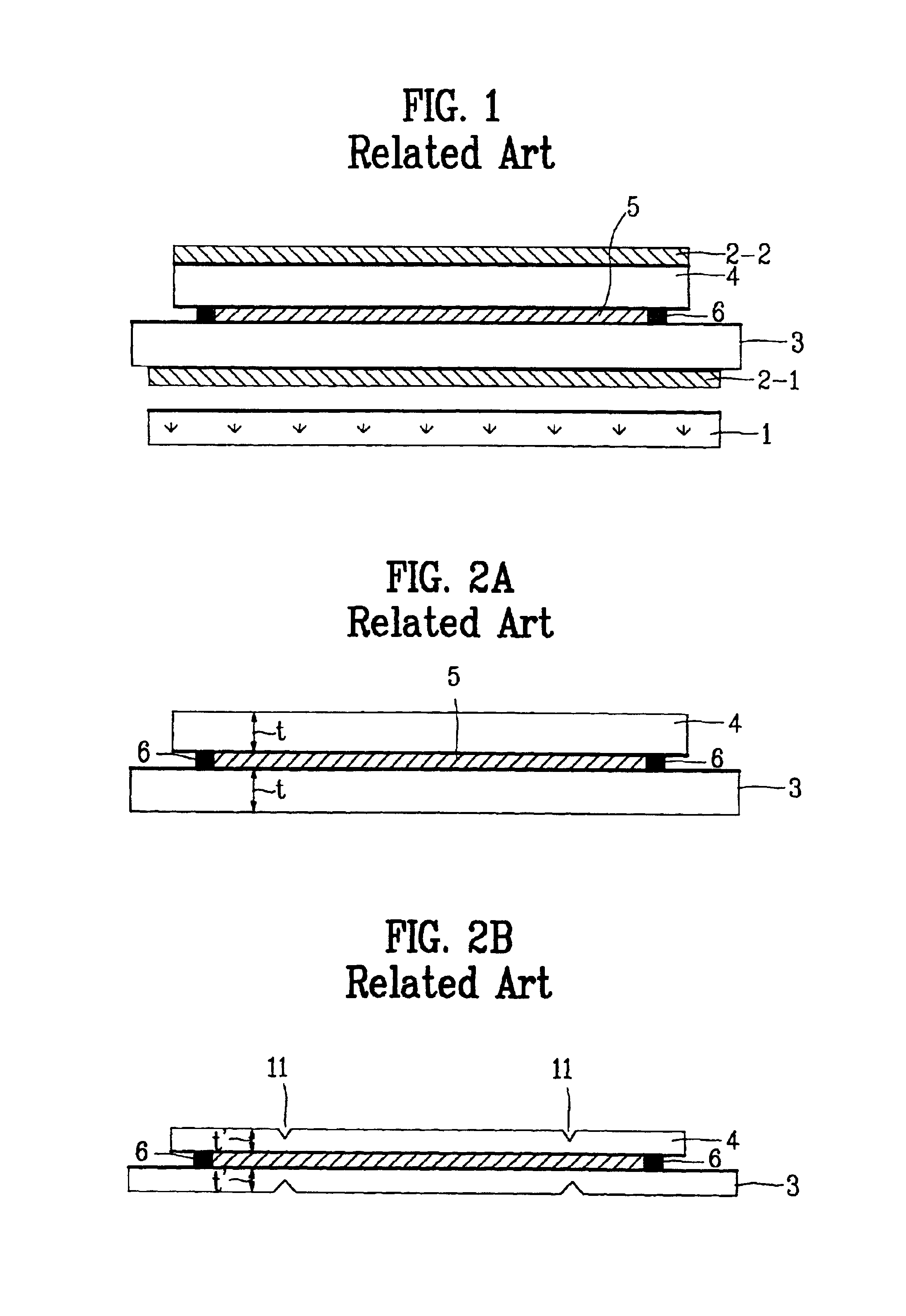

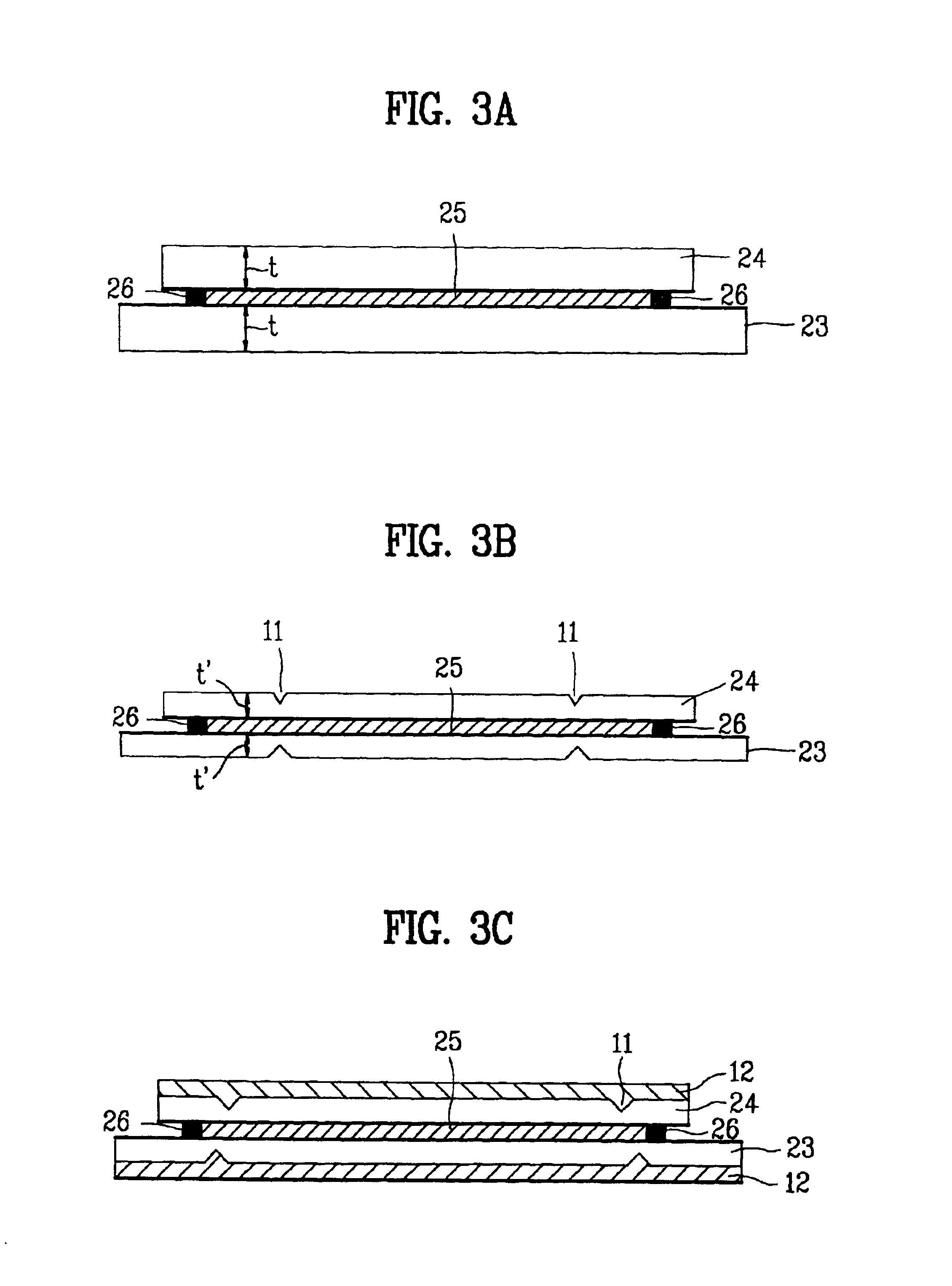

Liquid crystal display device and method for manufacturing the same

InactiveUS6930748B2Surface damageAfter-treatment detailsStatic indicating devicesLiquid-crystal displayEtching

A liquid crystal display device is disclosed, which can remove a defect generated from polishing and etching of a glass substrate. The LCD device includes first and second substrates assembled together with some spaces therebetween, each having an etched outer surface, and a passivation film outside the first and second substrates. In the LCD device, the passivation film such as BCB or photo-acrylate is formed on a surface of a glass substrate damaged by etching and polishing processes, so as to repair the damaged surface of the glass substrate.

Owner:LG DISPLAY CO LTD

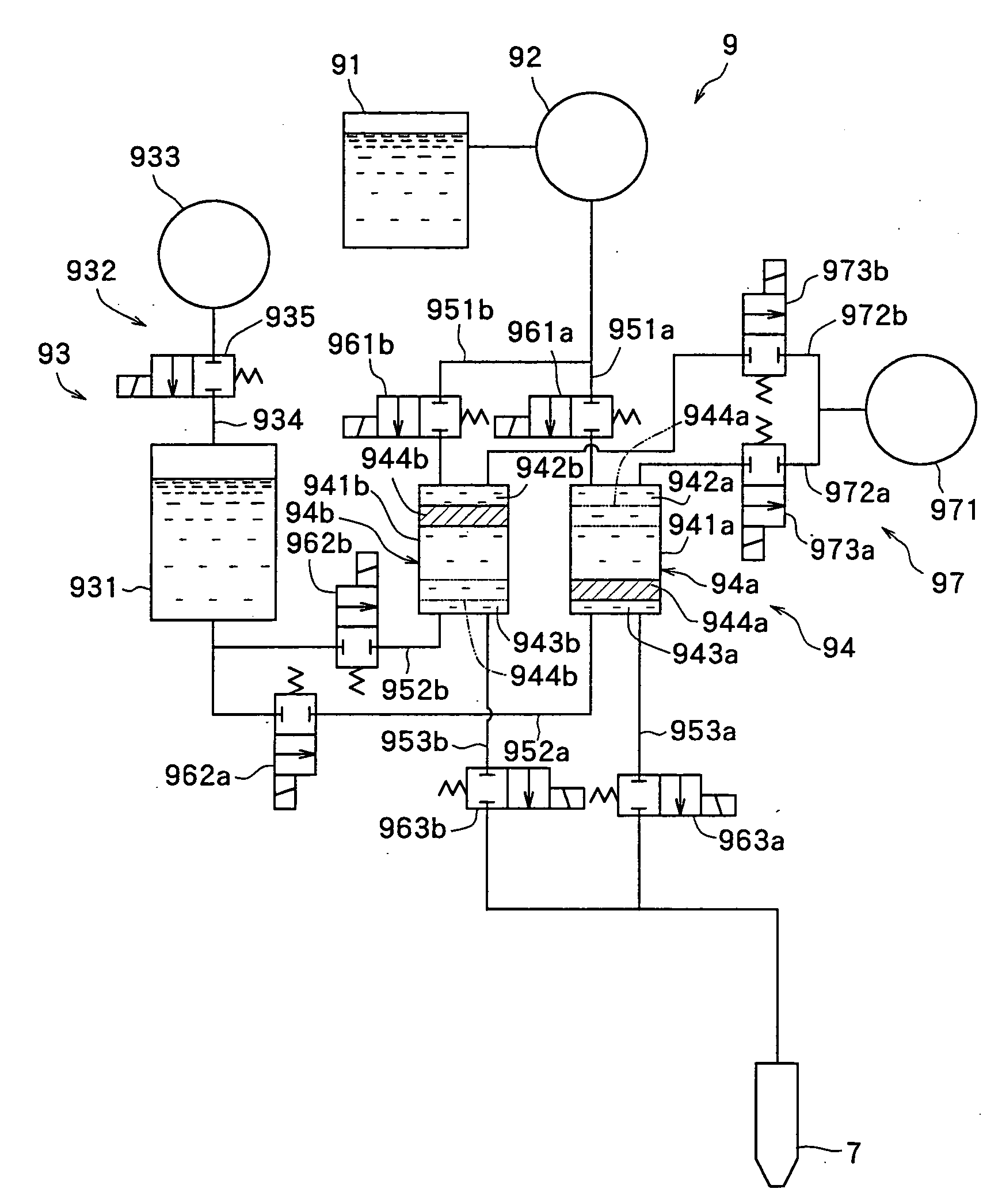

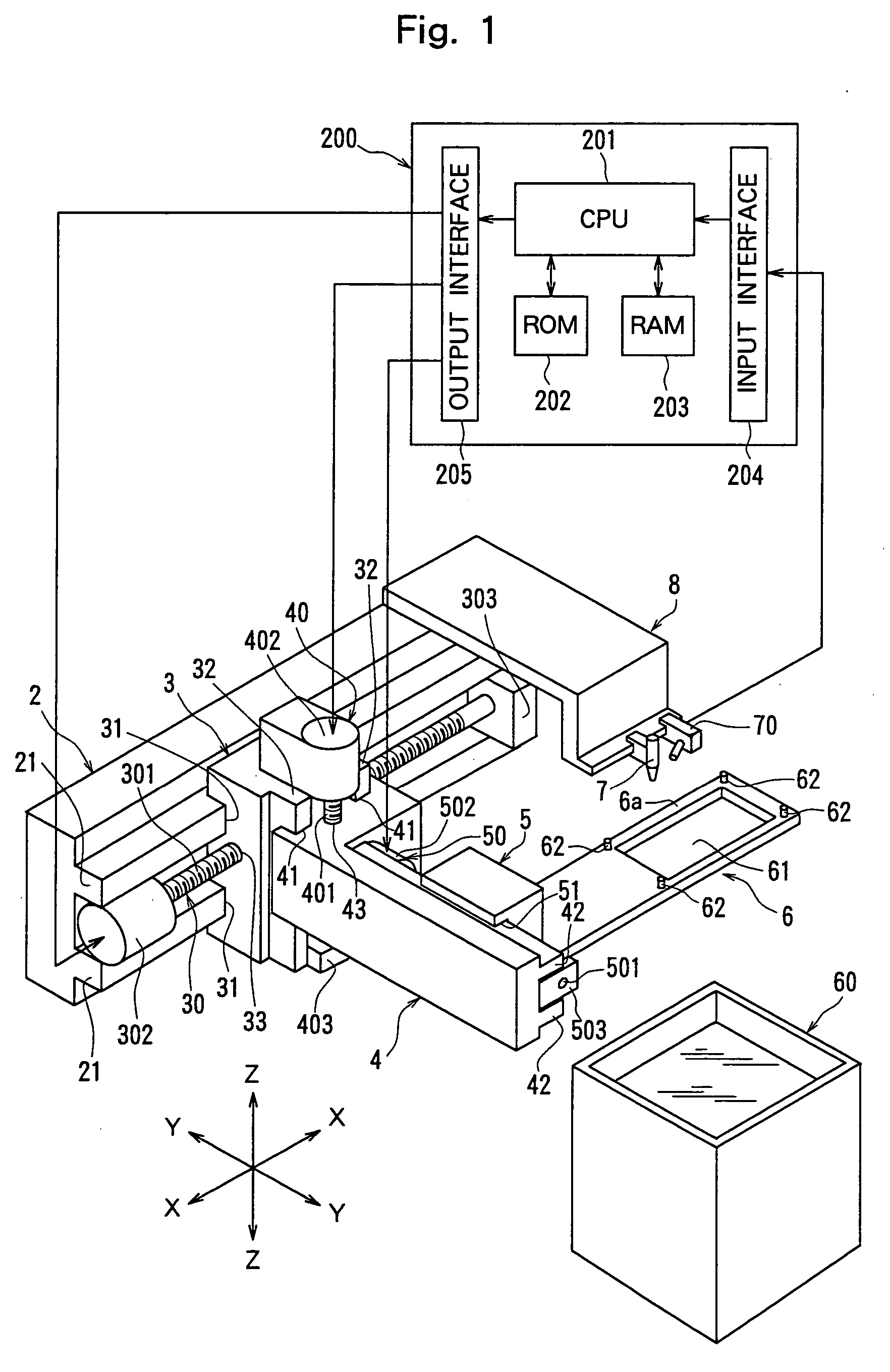

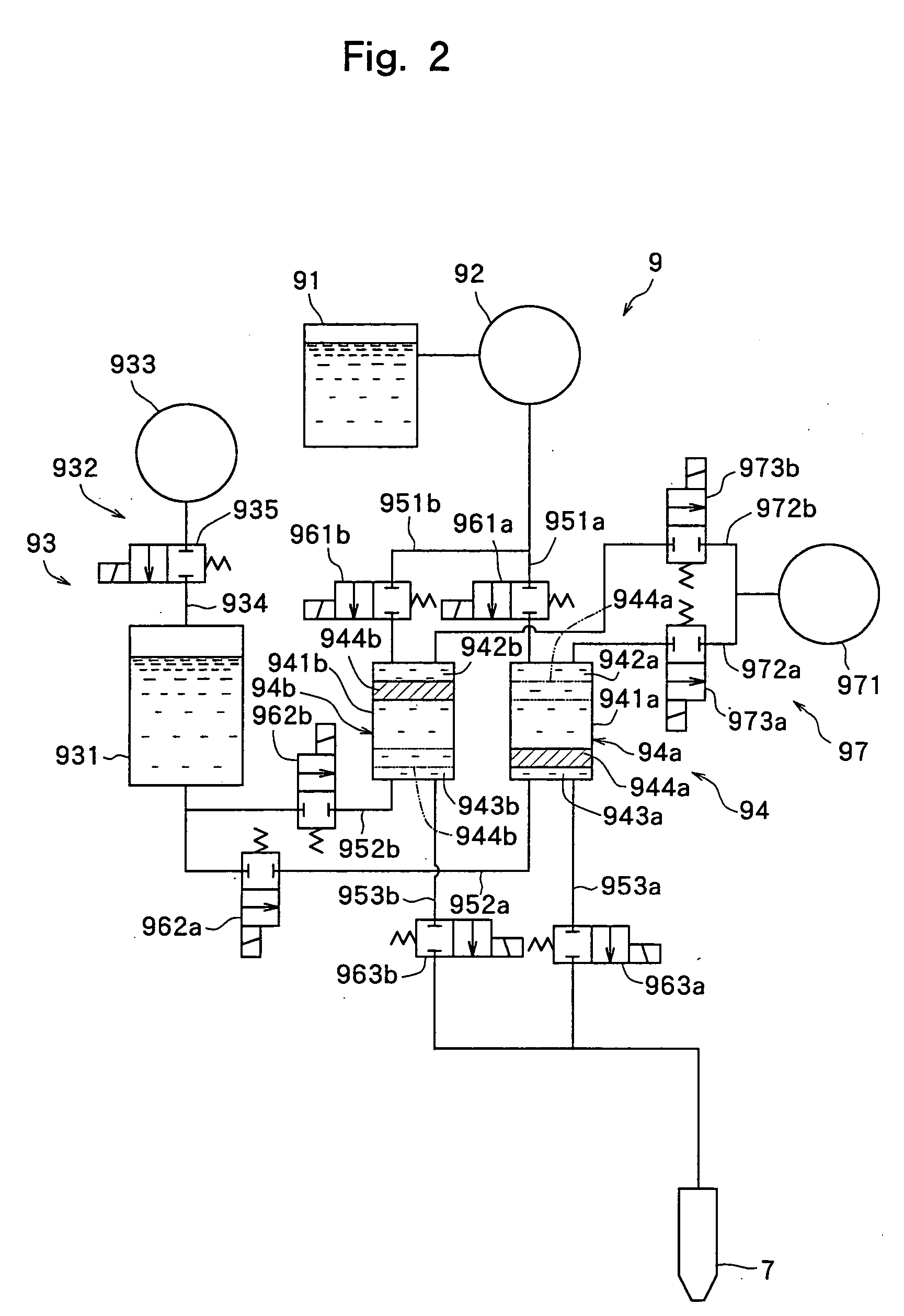

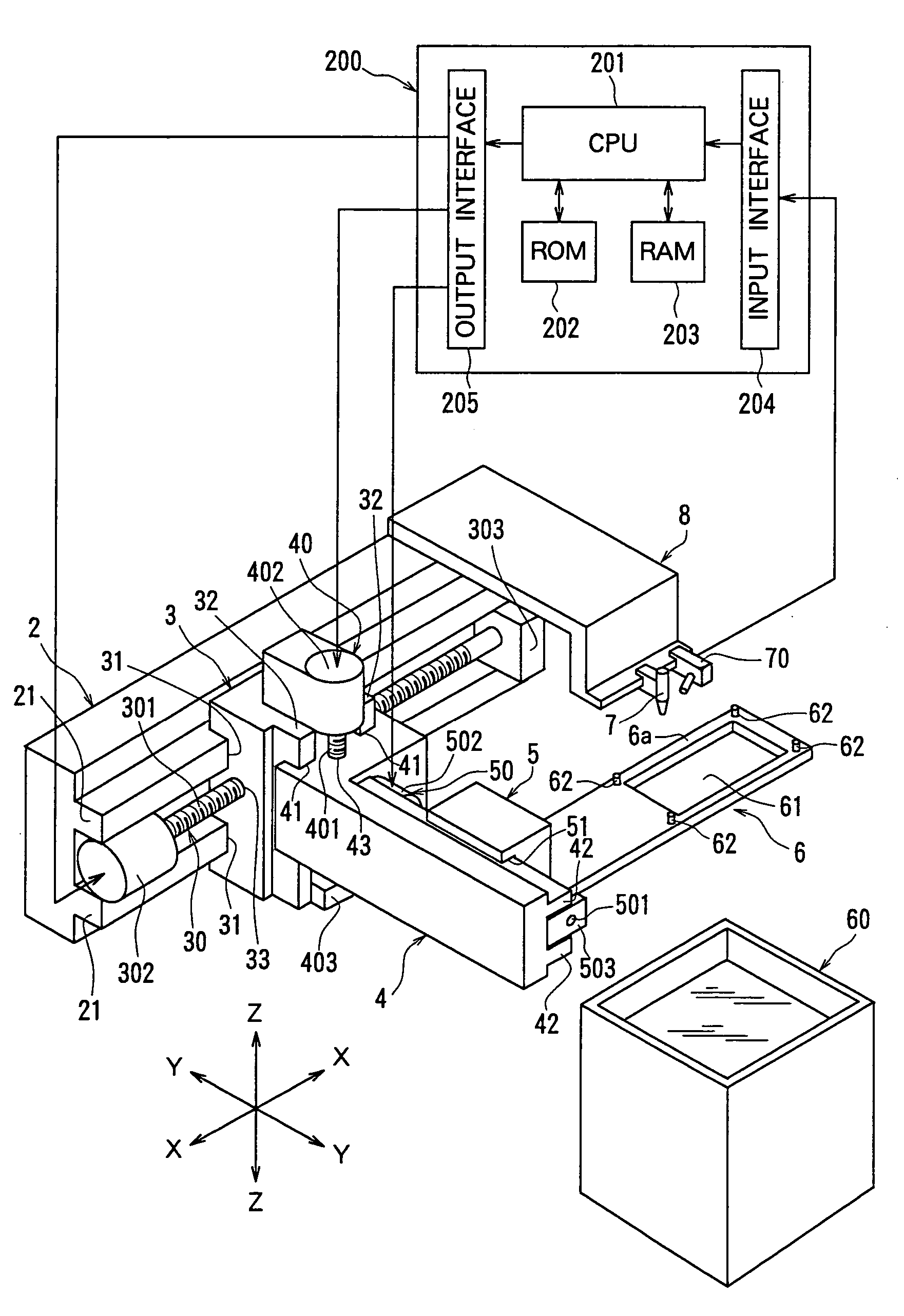

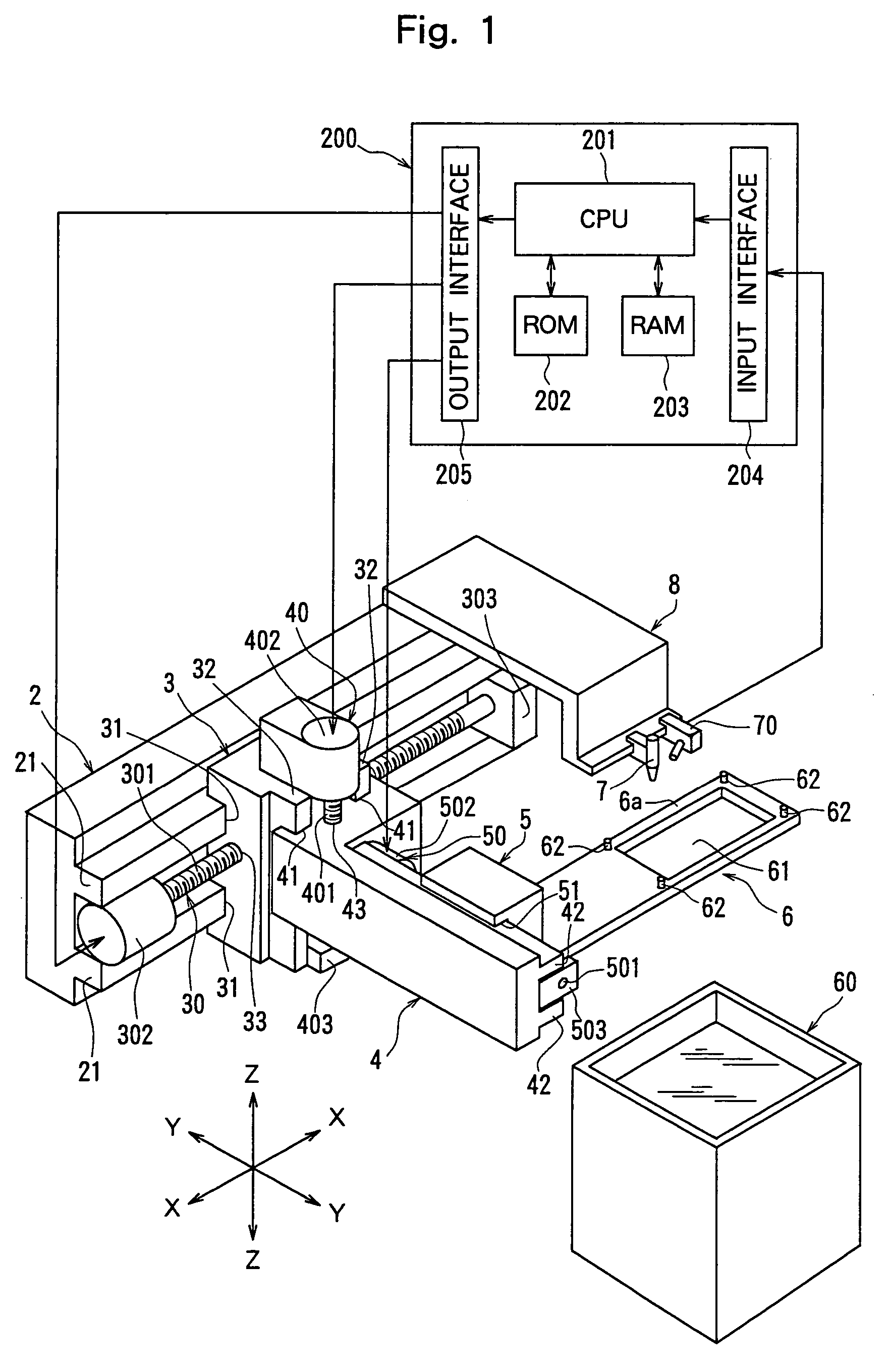

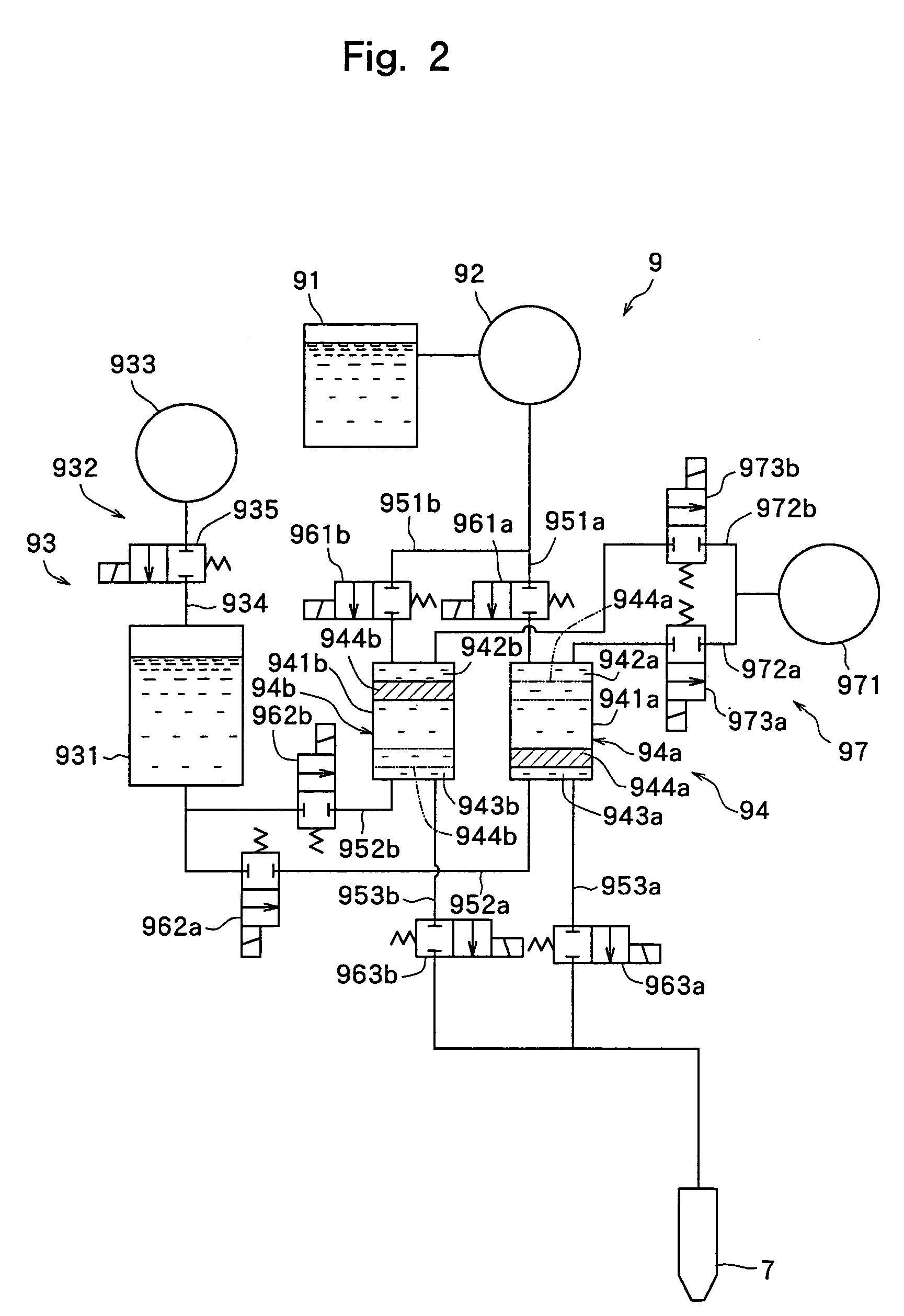

Water jet-processing machine

ActiveUS20050191951A1Surface damageCut highly accuratelyBlast gunsGrinding feed controlEngineeringAcoustic wave

A water jet-processing machine comprising a workpiece holding table having a holding surface for holding a workpiece, a nozzle for emitting a jet of processing water to the workpiece held on the holding surface of the workpiece holding table, a processing water supply means for supplying processing water containing abrasive grains to the nozzle and a moving means for moving the nozzle in a direction perpendicular to the holding surface of the workpiece holding table, wherein the machine further comprises processing sound wave detection means for detecting a processing sound wave generated by processing water ejected from the nozzle to the workpiece and a control means for controlling the moving means based on a detection signal detected by the processing sound wave detection means.

Owner:DISCO CORP

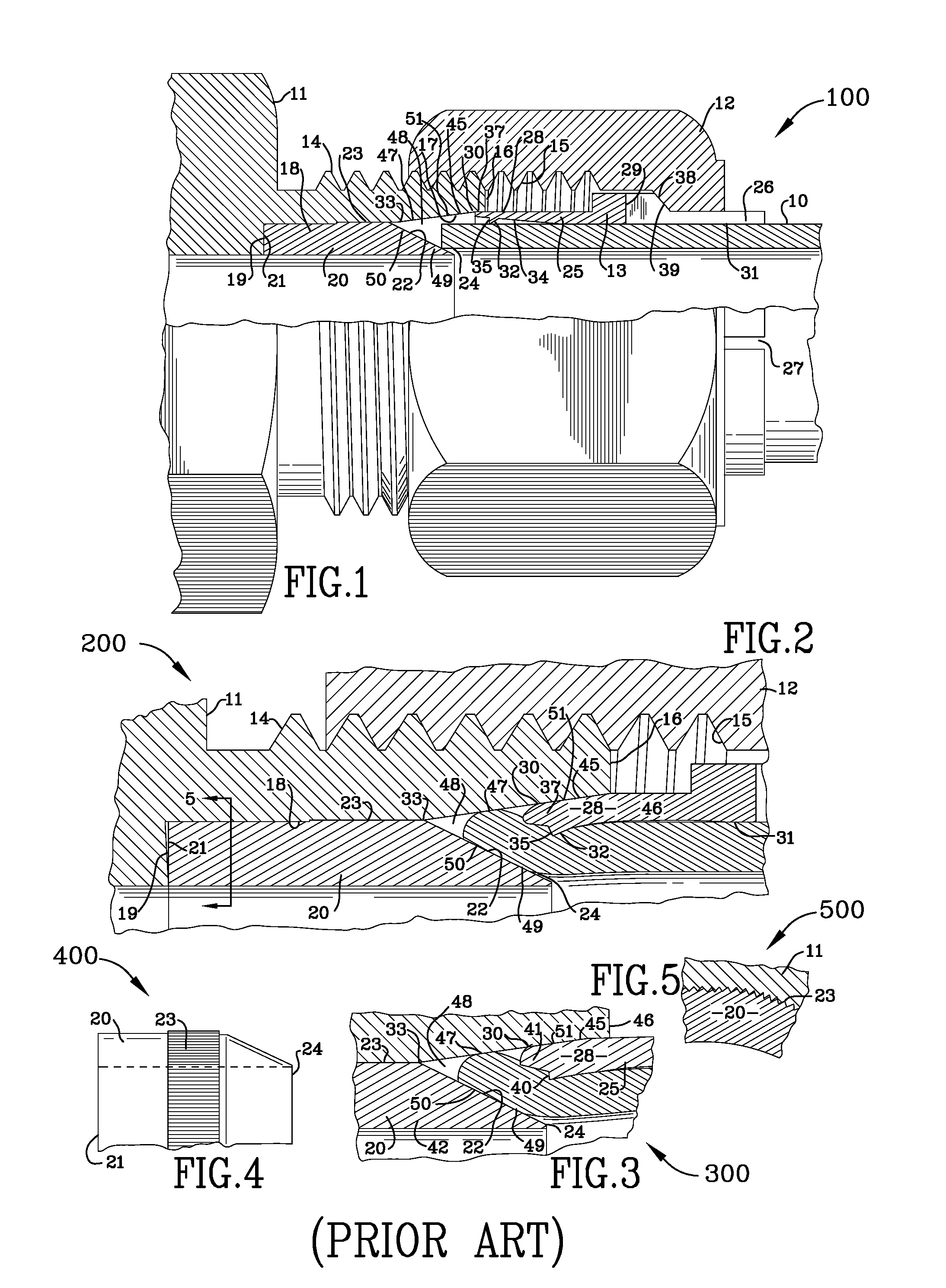

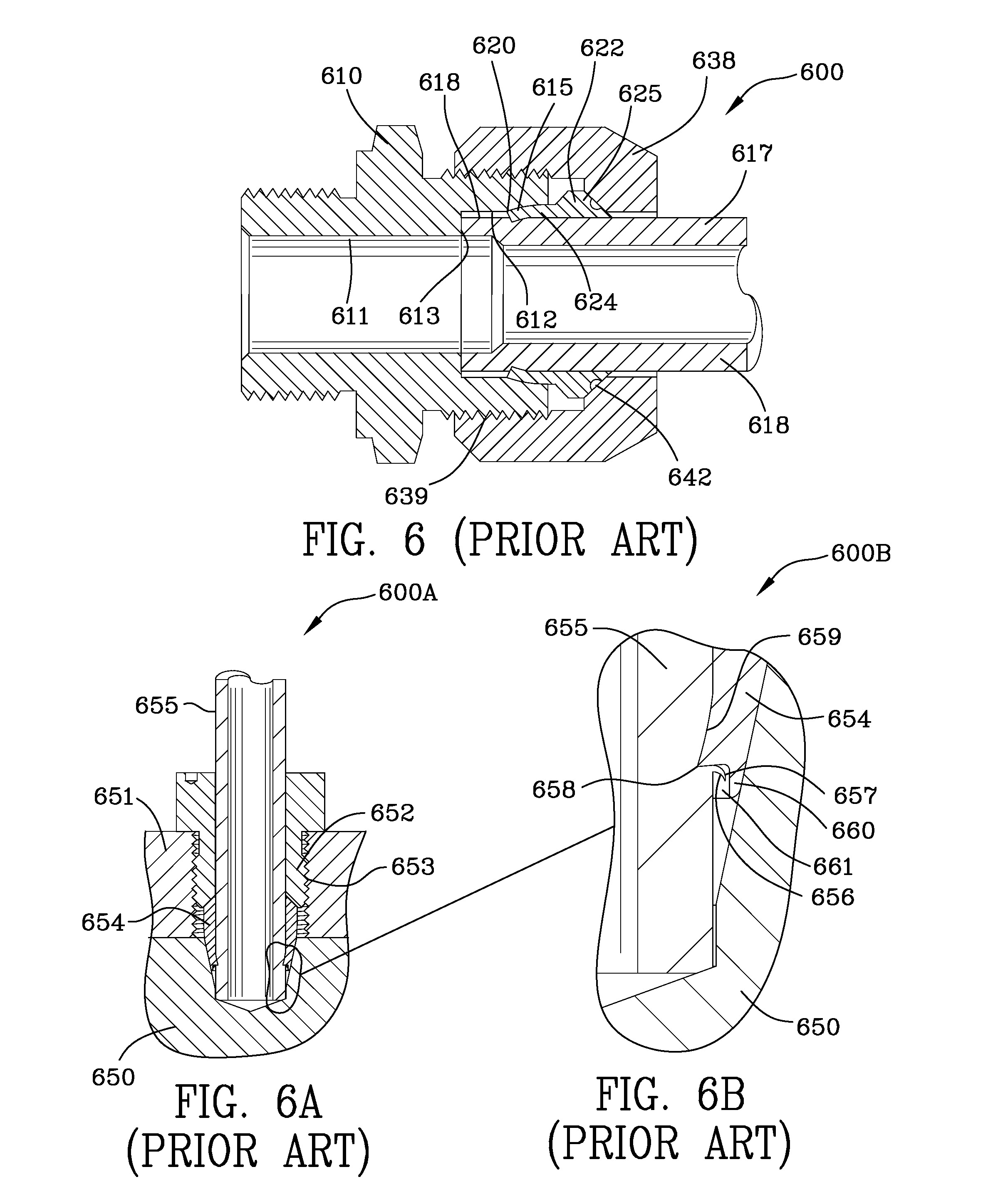

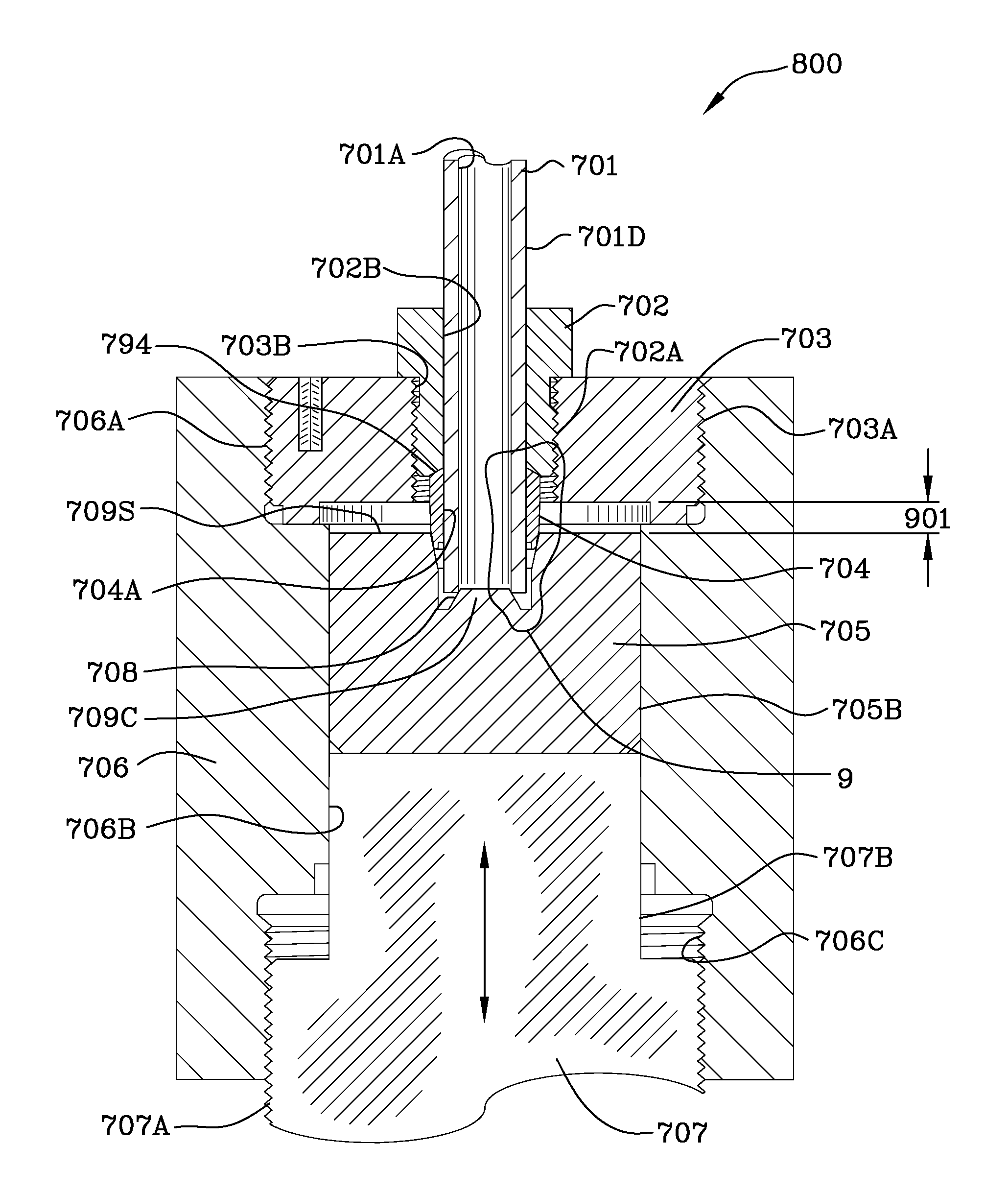

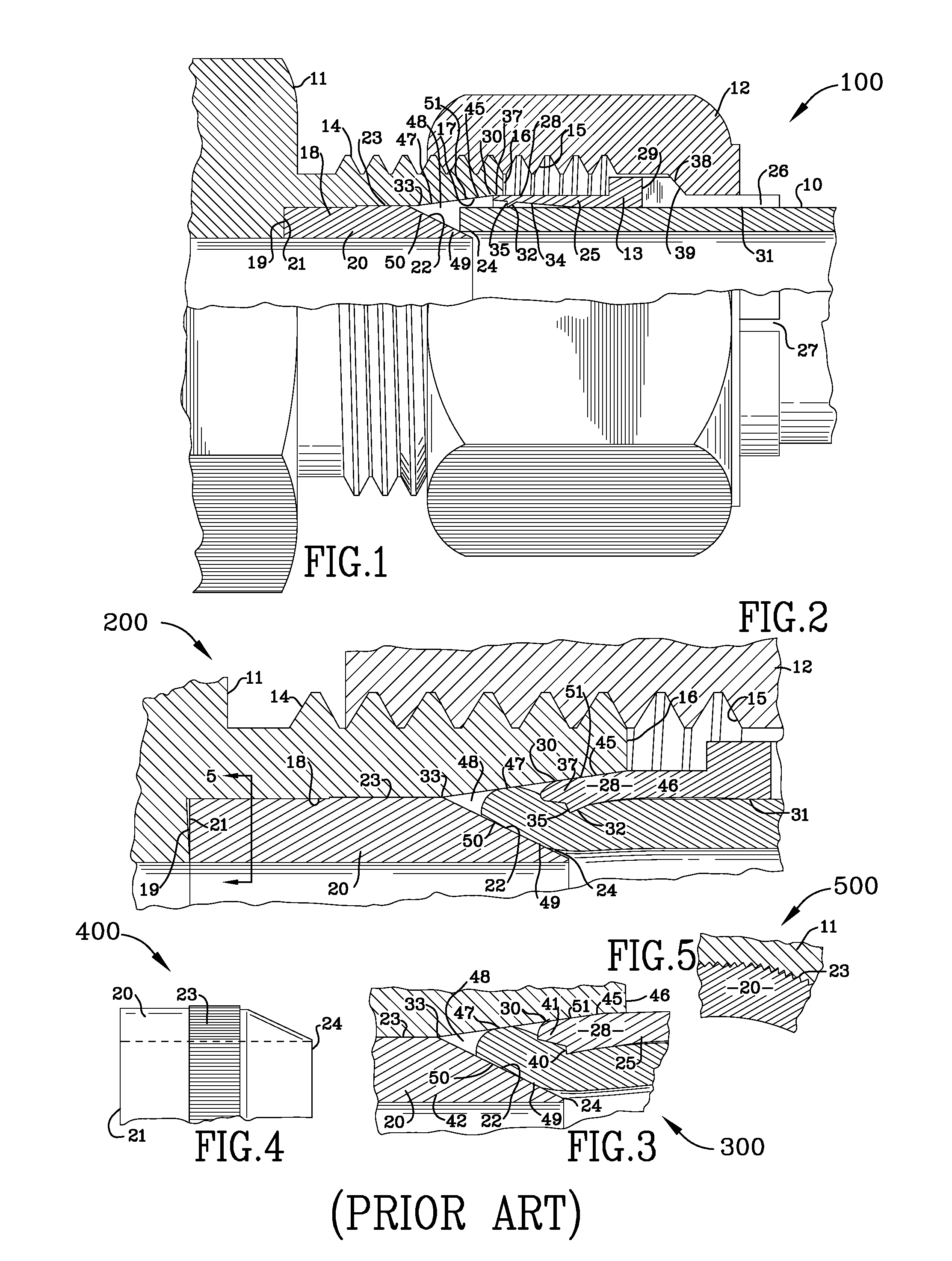

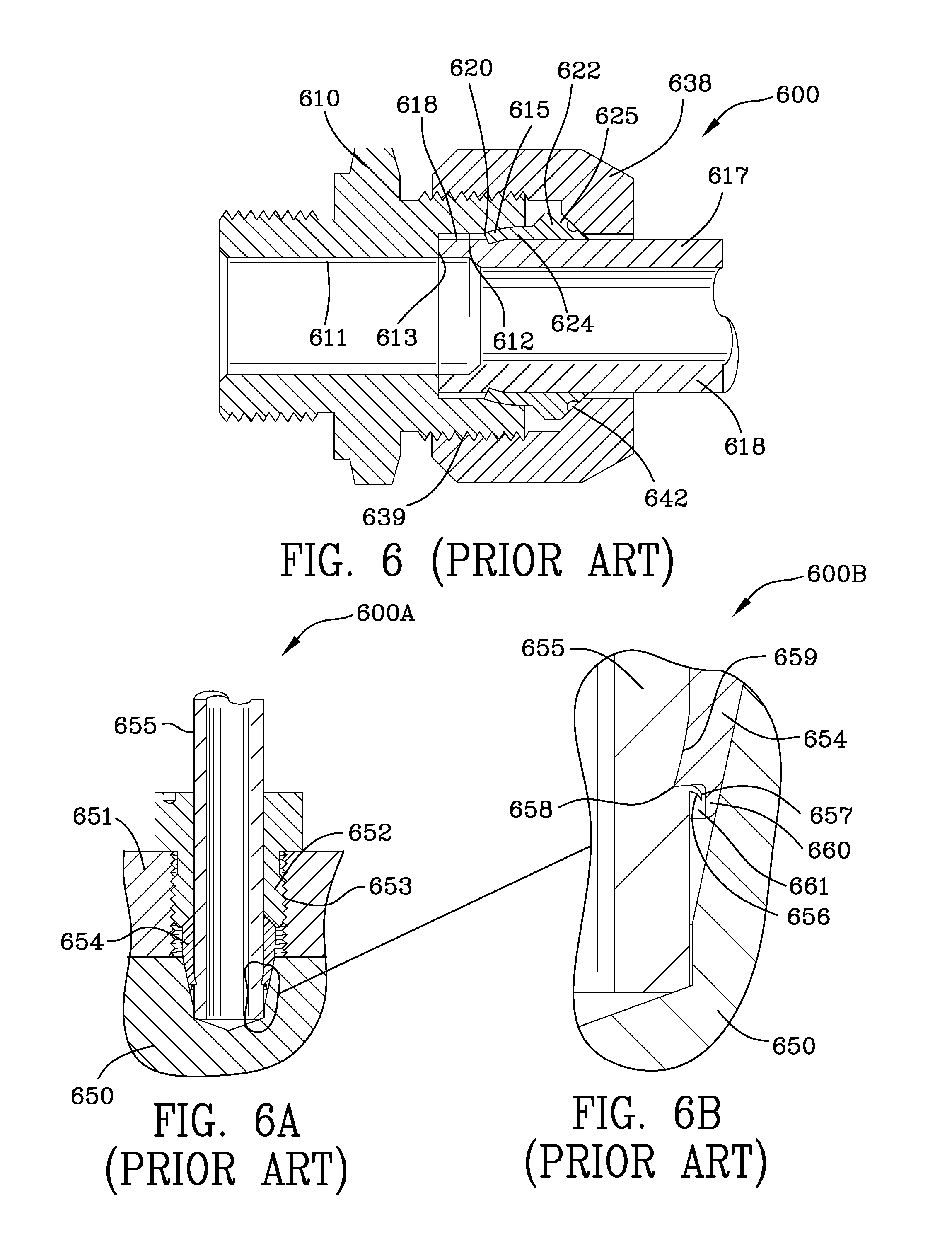

Tube compression fitting and flared fitting used with connection body and method of making same

InactiveUS20130025341A1Improve the immunityHigh strengthJoints with sealing surfacesCombined useEngineering

Owner:PARKER HANNIFIN CORP

Water jet-processing machine

ActiveUS7455568B2Cut highly accuratelySurface damageBlast gunsGrinding feed controlAcoustic waveWater jet

A water jet-processing machine comprising a workpiece holding table having a holding surface for holding a workpiece, a nozzle for emitting a jet of processing water to the workpiece held on the holding surface of the workpiece holding table, a processing water supply means for supplying processing water containing abrasive grains to the nozzle and a moving means for moving the nozzle in a direction perpendicular to the holding surface of the workpiece holding table, whereinthe machine further comprises processing sound wave detection means for detecting a processing sound wave generated by processing water ejected from the nozzle to the workpiece and a control means for controlling the moving means based on a detection signal detected by the processing sound wave detection means.

Owner:DISCO CORP

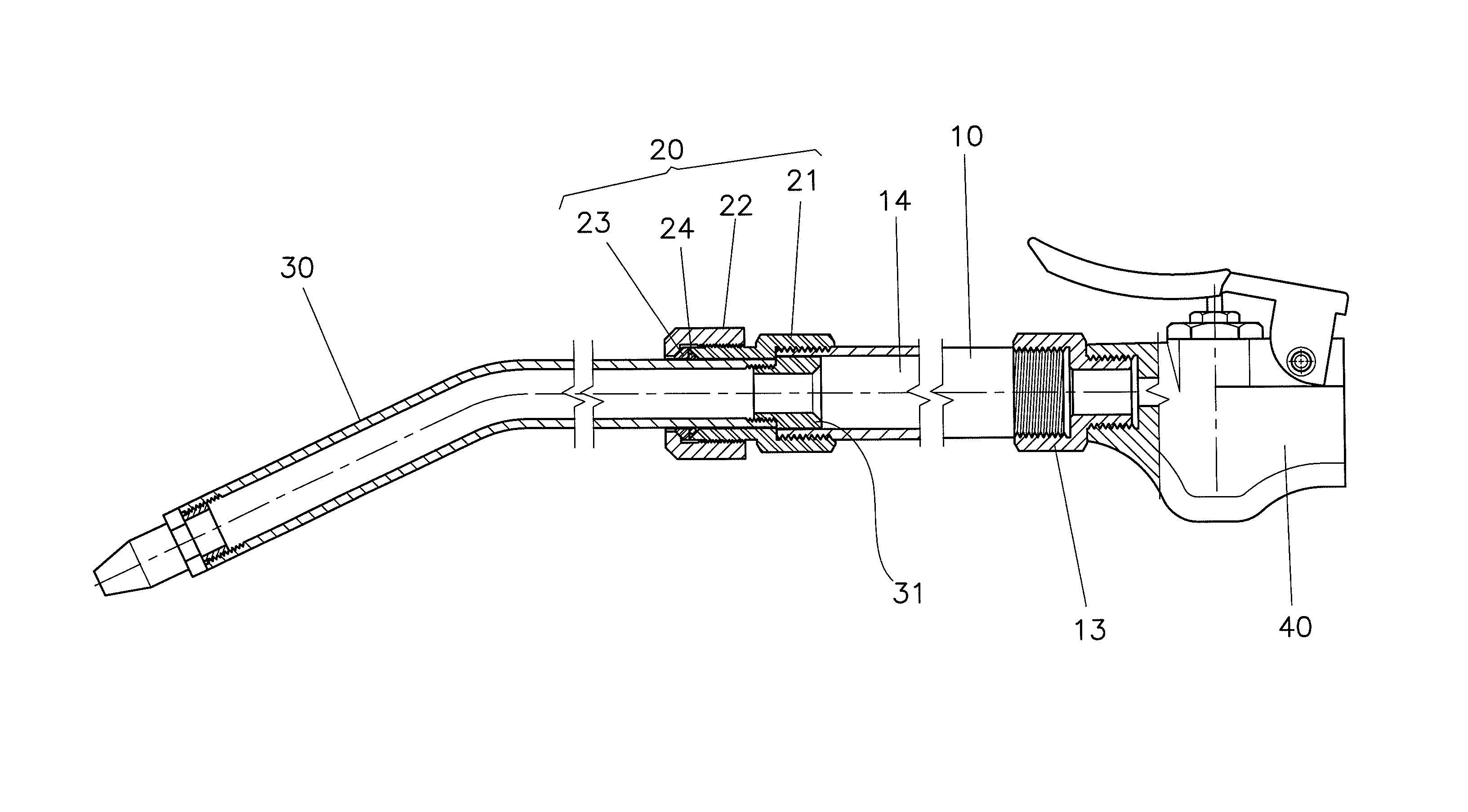

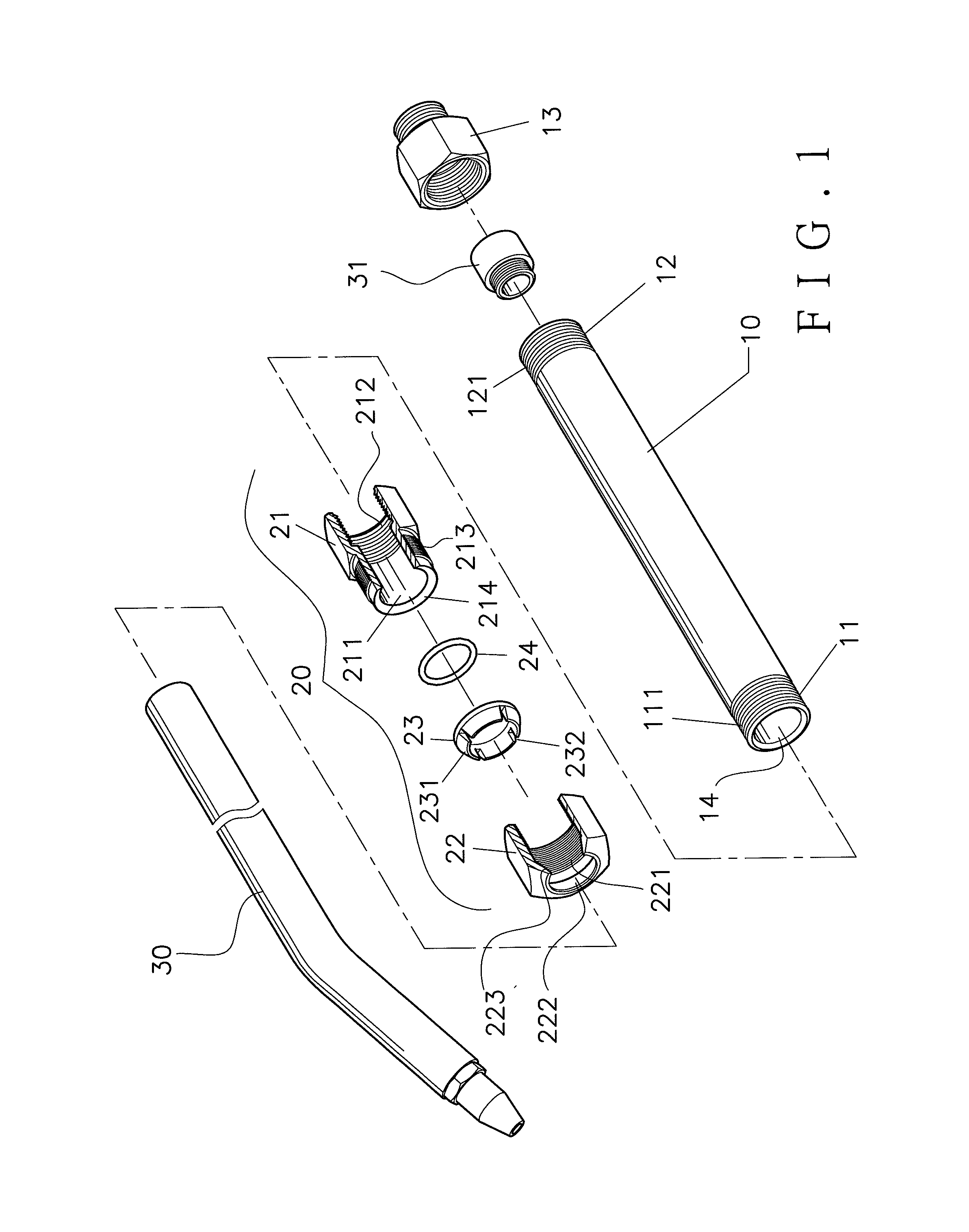

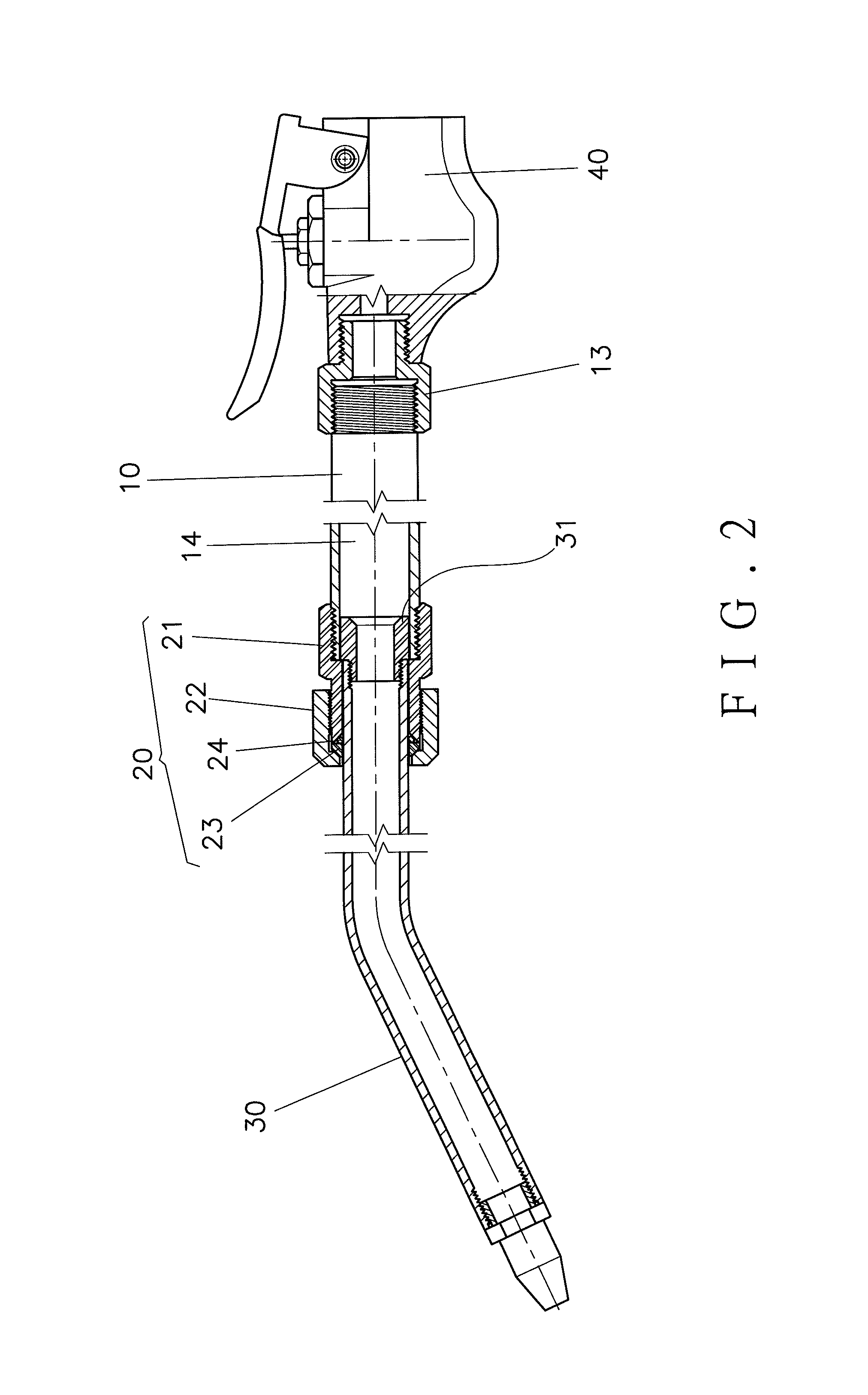

Retractable pipe structure of air blow gun

InactiveUS8777274B2Smooth movementQuick and easy to manufactureJoints with sealing surfacesDrying gas arrangementsEngineeringCollet

A retractable pipe structure of an air blow gun includes an extension pipe, a lock unit and a blow pipe. The extension pipe has a through hole therein for insertion of the blow pipe. The lock unit includes a connection member. One end of the connection member is connected to the extension pipe. The other end of the connection member is connected to a lock member. An elastic collet and a seal member are provided in the lock member. The end of the connection member has an inner inclined surface which is inclined inward. Because the inner inclined surface guides the seal member and the elastic collet pushes the seal member, the seal member is deformed to tighten the blow pipe and to seal the extension pipe. The elastic collet can clamp the blow pipe and won't damage the blow pipe.

Owner:CHOU WU CHIAO

Tool for working on a surface

ActiveUS20090104864A1Reduce in quantityLarge and more cumbersomeRevolution surface grinding machinesCarpet cleanersSuction stressEngineering

Owner:FULL CIRCLE INT

Tube compression fitting and flared fitting used with connection body and method of making same

InactiveUS20100059996A1Prevent crashSufficient lubricitySleeve/socket jointsFluid pressure sealed jointsCombined useHigh pressure

A high pressure tube compression fitting / flared fitting for use in combination with a thick-walled tube and a connection body wherein a sleeve is in engagement with a thick-walled tube. The sleeve is generally cylindrically shaped with the exterior thereof coated and then etched. The sleeve includes a sharp annular biting portion engaging the thick walled tube. The sleeve further includes an inner annular symmetric concavity which engages the thick-walled tube upon deformation thereof. The thick-walled tube includes a flared end portion. A gland about the thick-walled tube engages the sleeve forcing it into engagement with the frusto-conical portion of the connection body coupling the tube, tube fitting and connection body together. The flared end of the thick-walled tube interengages and seals the frusto-conical portion of the connection body. A process for making the device includes the step of placing the thick-walled tube into engagement with the frusto-conical portion of a die to flare the end portion of the thick-walled tube.

Owner:PARKER HANNIFIN CORP

Method of producing particle-shape water-absorbing resin material

ActiveUS8309654B2Preventing property deteriorationSurface damageOther chemical processesAbsorbent padsCross-linkPolyresin

Owner:NIPPON SHOKUBAI CO LTD

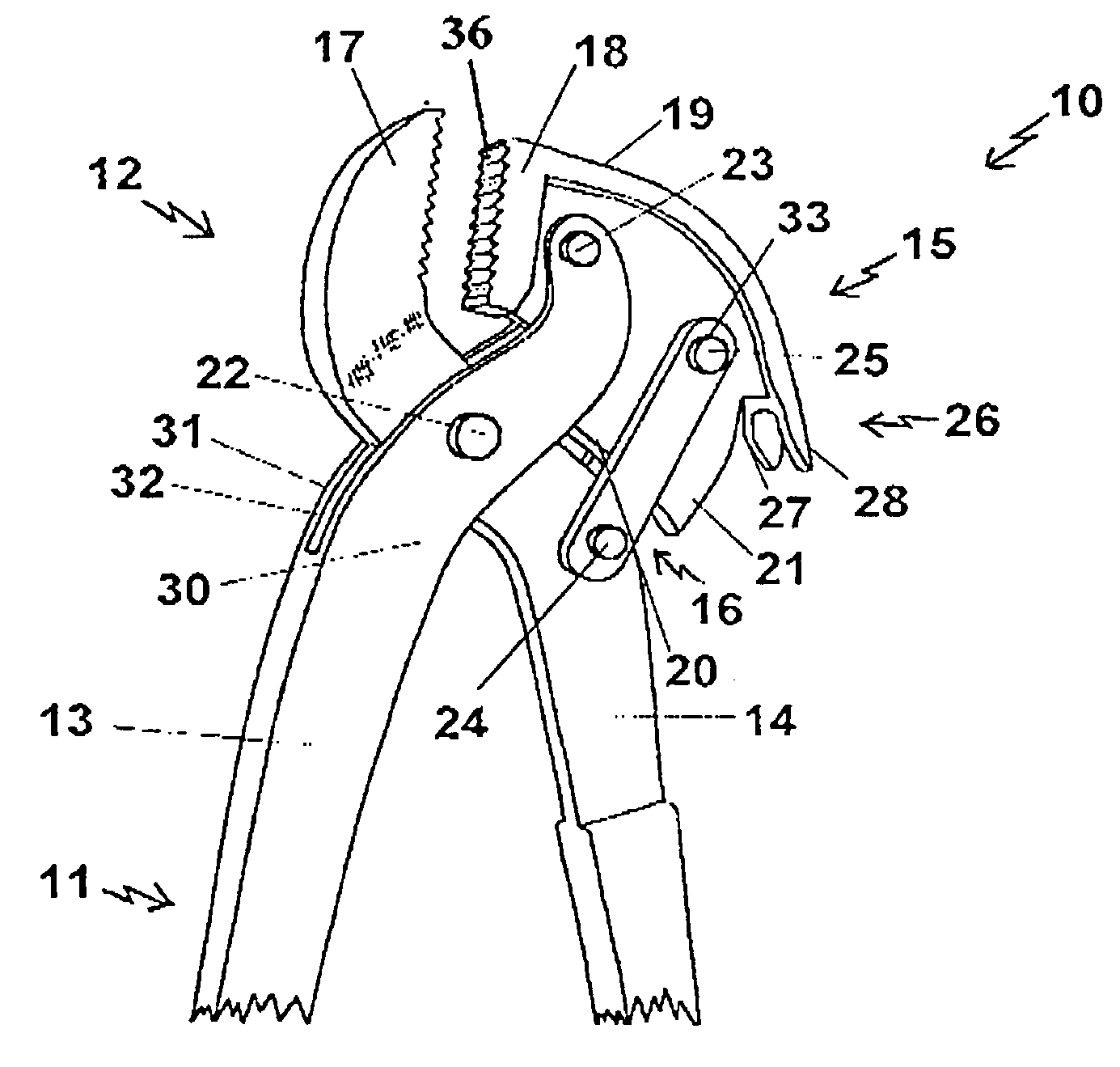

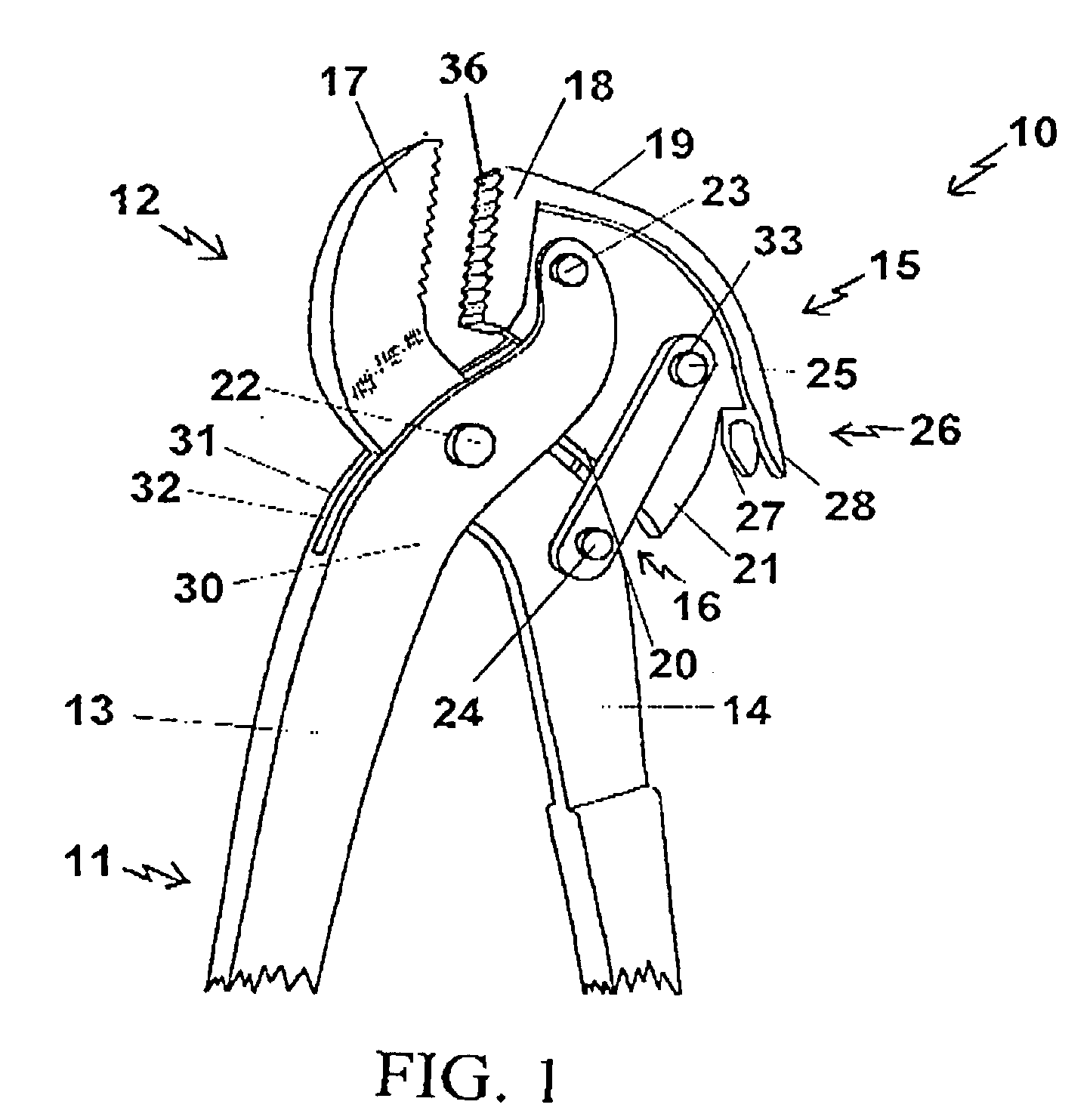

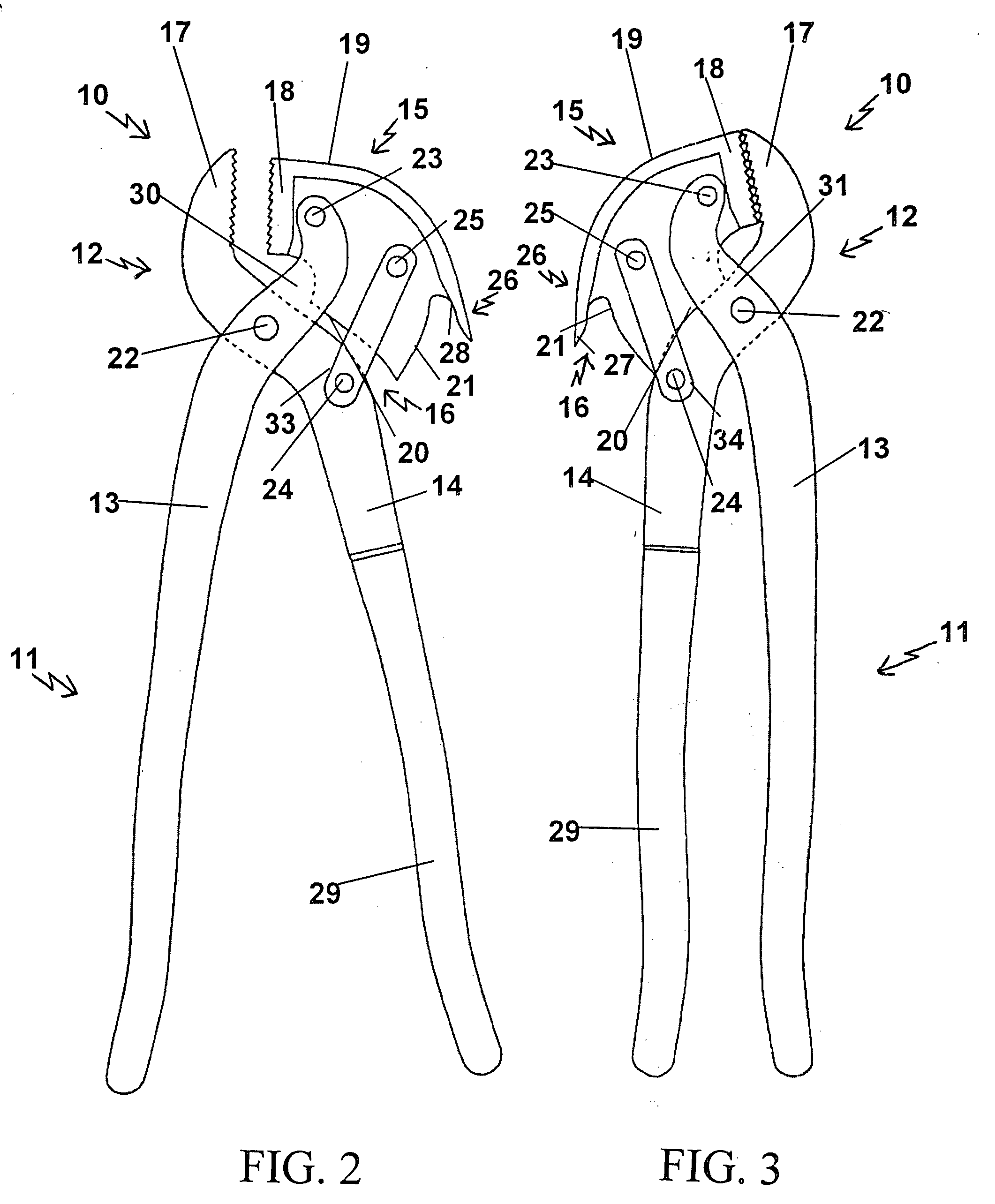

Tool for extracting an embedded elongated object

A hand operated tool for extracting an embedded elongated object, including: a) an elongated, movable first handle member with a first, upper end portion divided into two matching legs separated by an opening; b) a corresponding second handle member with a first jaw member and a first, upper end extending through the leg opening, the second handle member being pivotally attached to the first leg and the second leg; c) a floating head portion pivotally attached to the first and second legs, the floating head portion including a second jaw member and an adjacent, upper curved edge; and d) two matching lever bars facing one another from opposite sides of the extraction tool, each being pivotally connected to the second handle member and to the floating head portion; and wherein the second jaw member is engaged against the first jaw member when the extraction tool is in a closed position, and disengaged from the first jaw member when the extraction tool is in an open position.

Owner:WAGNER JEFFERSON L

Tool for working on a surface

ActiveUS7927192B2Reduce in quantityLarge and more cumbersomeRevolution surface grinding machinesCarpet cleanersEngineeringMechanical engineering

Owner:FULL CIRCLE INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com