Belt assembly for storage and inventory of tools

a technology for tools and belts, applied in the field of belt assembly for tools storage and inventory, can solve problems such as real and unsatisfactory needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

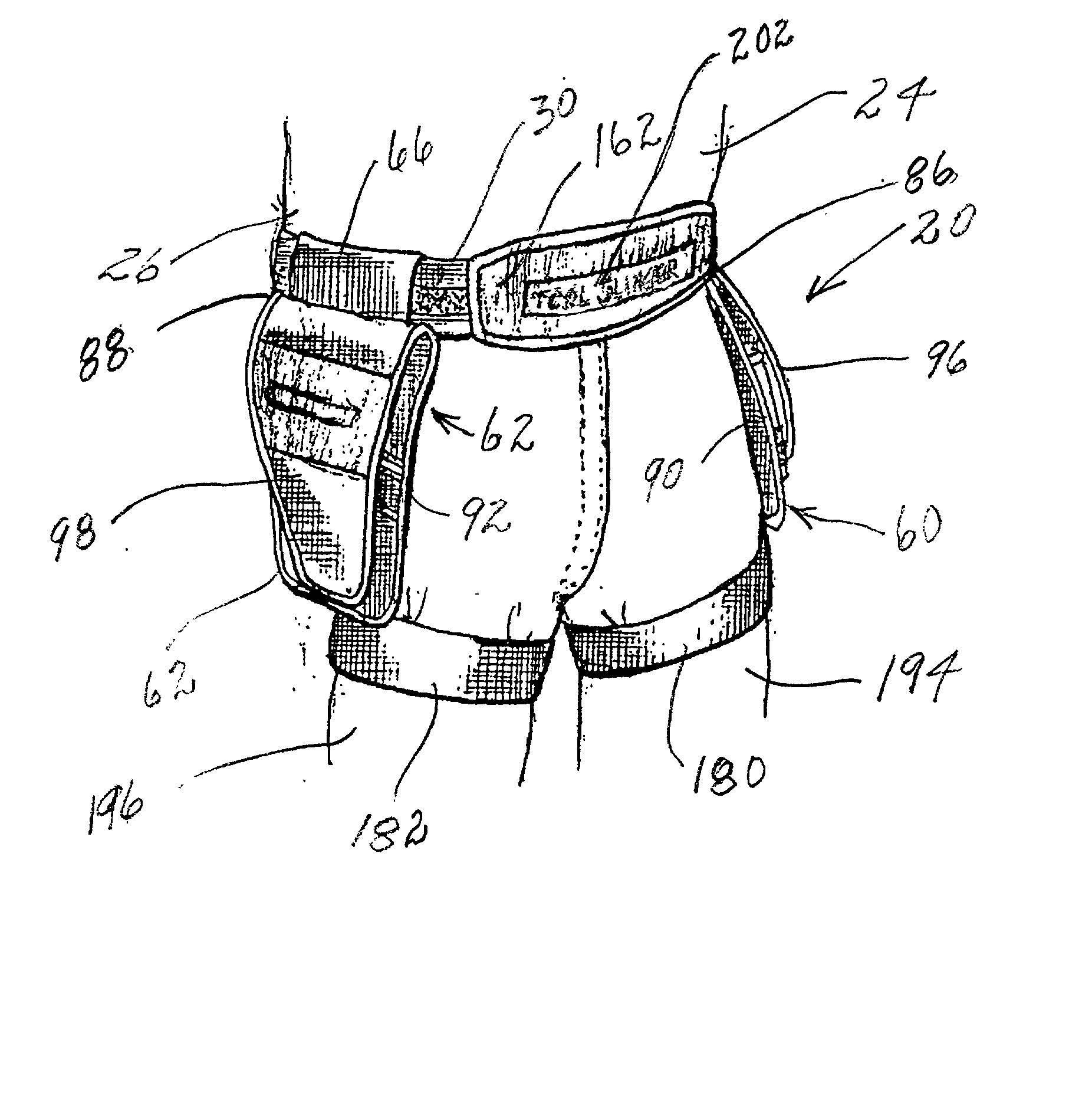

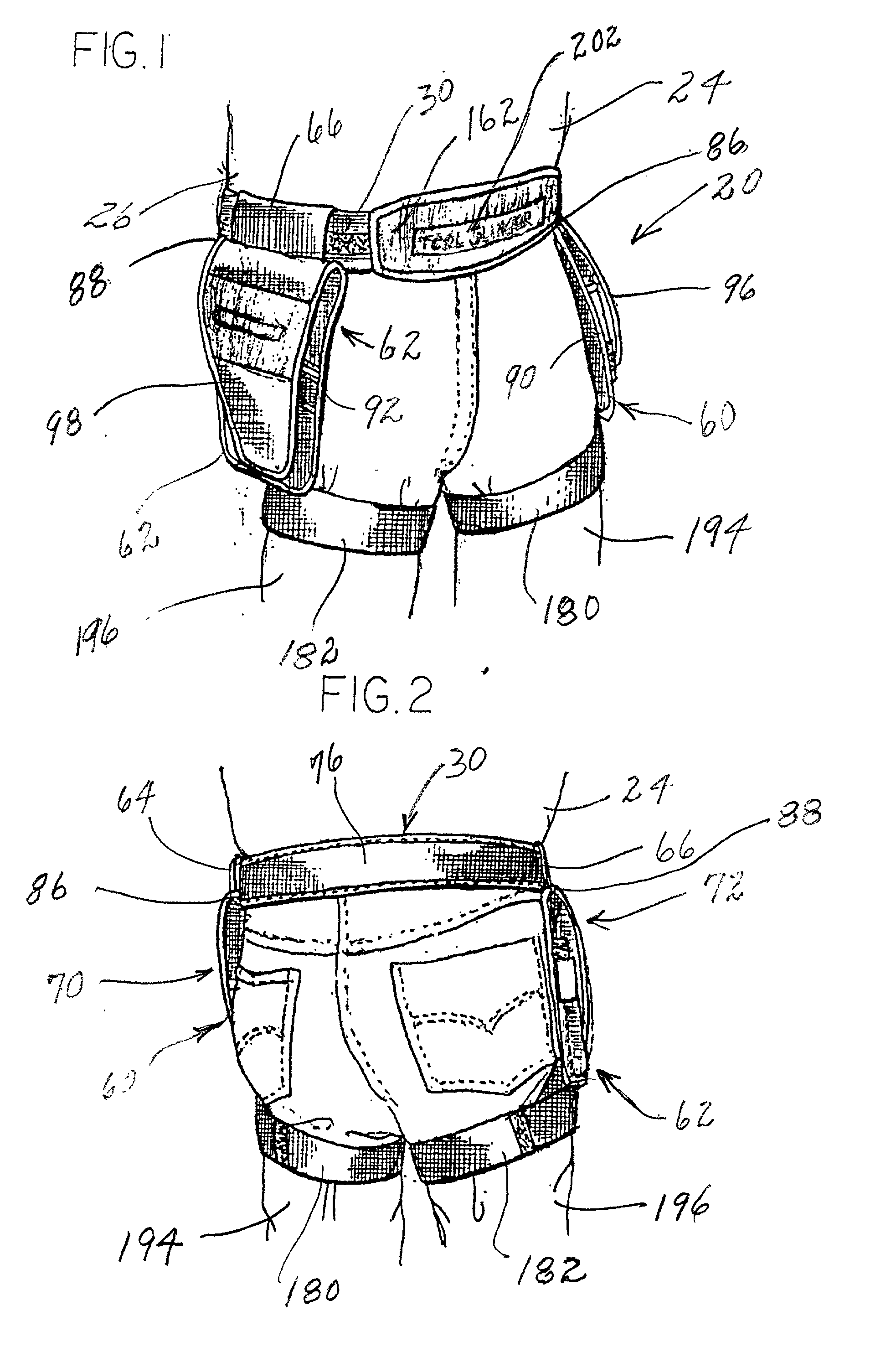

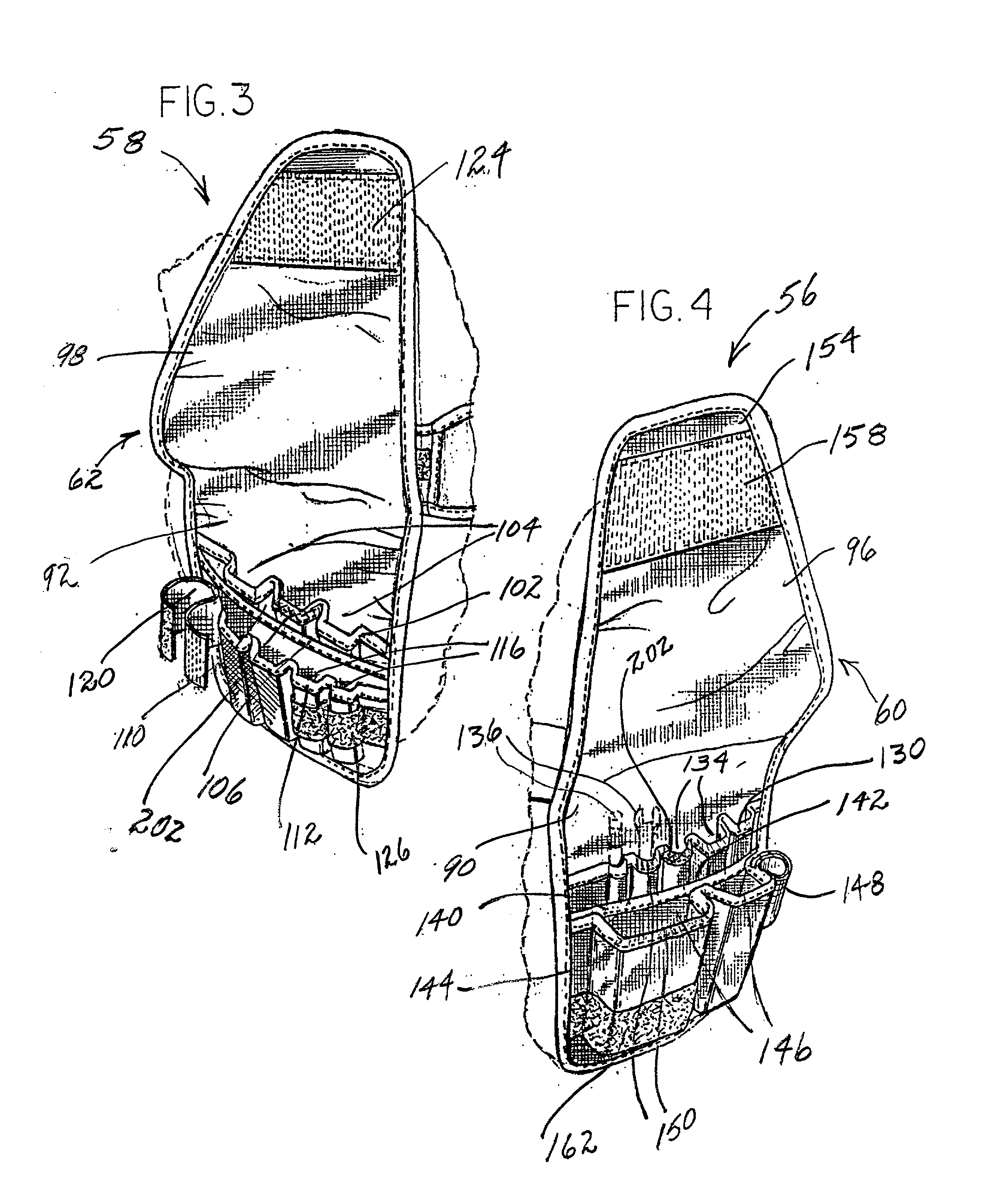

[0027] In accordance with the present invention, the aims and objects are achieved by providing a uniquely-configured tool-carrying assembly supported at and secured about the waist of a workman, for example, an automobile mechanic. Auxiliary support, stablization and enhanced weight distribution are provided by adjustable, leg-encircling straps. The invention is characterized in that it is fabricated and configured to provide a generous number of readily accessable receptacles in the form of outwardly-presented, protected, upwardly opening slots, pockets or recesses. These are designed and sized for carrying therewithin a collection of selectable different tools of the type used, for example, by an automobile mechanic. The tool-housing, belt-supported, tool-carrying assembly is provided with protective covering flaps securable to overlie the encased tools to prevent loss and to protect the surface of the automobile or any other workpiece which may be involved.

[0028] Referring now t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com