Low-temperature sintering matrix powder, diamond tool adopting same and preparation method thereof

A low-temperature sintering and diamond technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems that the cutting effect of diamond particles cannot reach the predetermined effect, the diamond damage is large, the mold loss and energy consumption are large, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

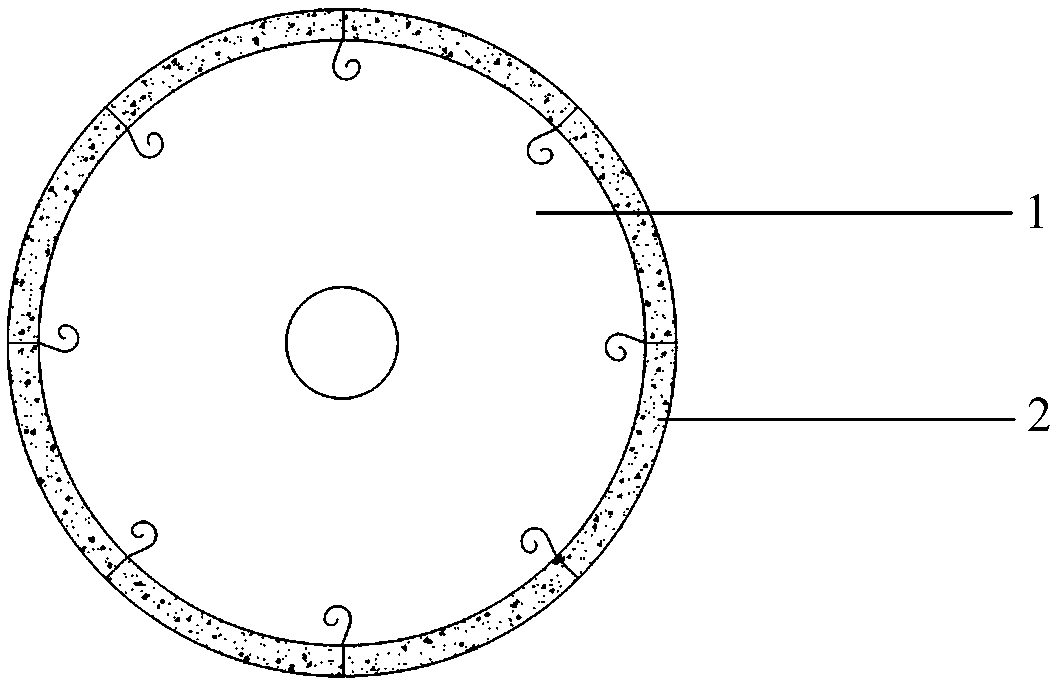

[0053] In Example 1, the specifications of the integrally sintered saw blade are: diameter 305 mm, blade height 10 mm, blade thickness 2.2 mm, substrate thickness 1.8 mm, laser equidistant cutting into tooth structures. The composition of the matrix powder in the diamond saw blade is: Cu60wt%, Co 20wt%, Sn 17wt%, graphite 2wt%, and amorphous powder AP-01 1wt%, among which Cu powder and amorphous powder AP-01 are processed by high-energy ball milling (The rotation speed is 400 rpm, the ball milling time is 20 hours). The median diameter D50 of Cu powder and amorphous powder AP-01 is 2.5 μm, and the diamond particle size used is 180 μm to 270 μm. 3% of the mass; the matrix is made of 75Cr1 and used after quenching.

[0054] The preparation steps of the overall low-temperature sintered diamond saw blade in this embodiment are as follows:

[0055] 1) Mixing: add 2% glycerol alcohol solution with a mass fraction of 2% to the metal carcass powder mixed according to the above mass...

Embodiment 2

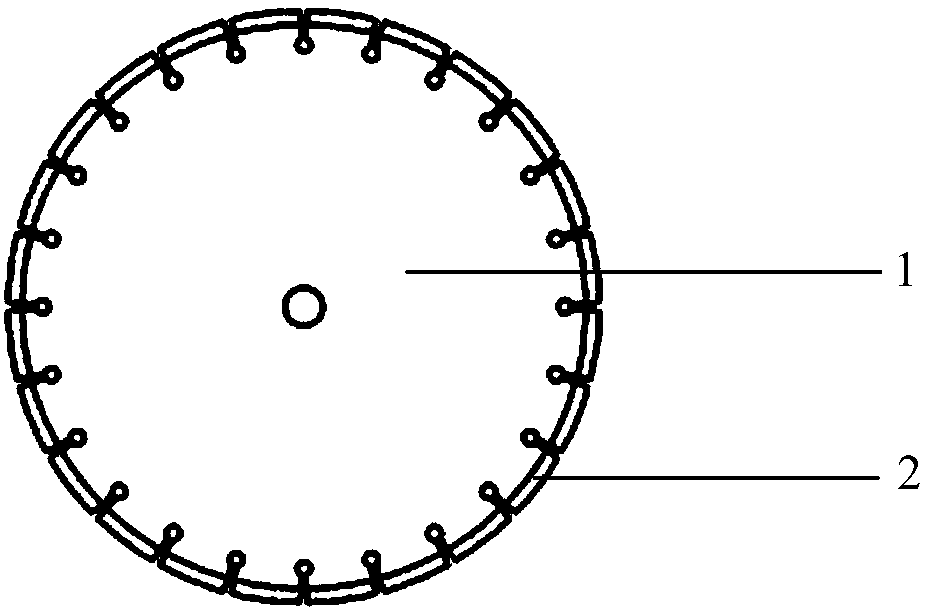

[0064]In Example 2, the specifications of the integral sintered saw blade are: diameter 254 mm, blade height 10 mm, blade thickness 1.6 mm, base thickness 1.4 mm, laser equidistant cutting into tooth structure. The matrix powder composition of diamond circular saw blade is: Cu65wt%, Co15wt%, Sn13wt%, Ni 5wt%, amorphous powder AP-01 2wt%, wherein Cu powder and amorphous powder AP-01 are high-energy ball milling (rotating speed is 400 rev / min, ball milling time 20 hours) ultra-fine particle size powder, Cu powder median diameter D50 is 7.5μm, amorphous powder AP-01 median diameter D50 is 7.5μm, the diamond particle size used is 210μm~270μm, the addition ratio It is 1.5% of the mass of the cutter head. The matrix is made of 65Mn and used after quenching.

[0065] The preparation steps of the overall low-temperature sintered diamond saw blade in this embodiment are as follows:

[0066] 1) Mixing: adding the metal matrix powder in the above mass percentage to 2% glycerol alcoho...

Embodiment 3

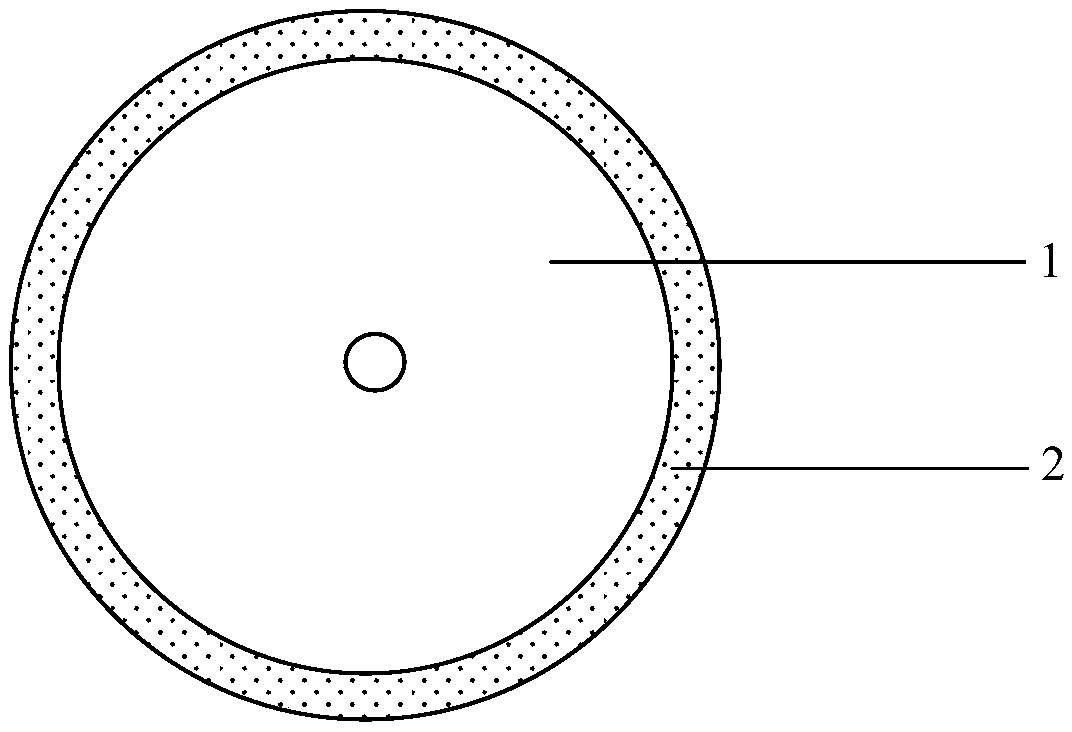

[0075] In Example 3, the specifications of the integrally sintered saw blade are: diameter 356 mm, blade height 7 mm, blade thickness 2.8 mm, base thickness 2.4 mm, continuous edge structure. The matrix powder composition of diamond saw blade is: Cu 70wt%, Co 15wt%, Sn10wt%, the prealloy powder (FOLLOW500) 5wt% that contains rare earth element, wherein Cu and contain rare earth element prealloy powder are high-energy ball milling treatment (rotating speed is 400 rev / min, ball milling time 20 hours) ultra-fine particle size powder, the Cu powder median diameter D50 is 1.5μm, the median diameter D50 of the pre-alloyed powder containing rare earth elements is 7.5μm, the diamond particle size used is 90μm~110μm, the addition ratio It accounts for 2% of the mass of the cutter head. The substrate is made of 75Cr1 and used after quenching.

[0076] The preparation steps of the overall low-temperature sintered diamond saw blade in this embodiment are as follows:

[0077] 1) Mixing: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com