Patents

Literature

46results about How to "Lower grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low compaction, pneumatic dewatering process for producing absorbent sheet

ActiveUS20060000567A1High porosityLarge hydraulic diameterNon-fibrous pulp additionNatural cellulose pulp/paperFiberPapermaking

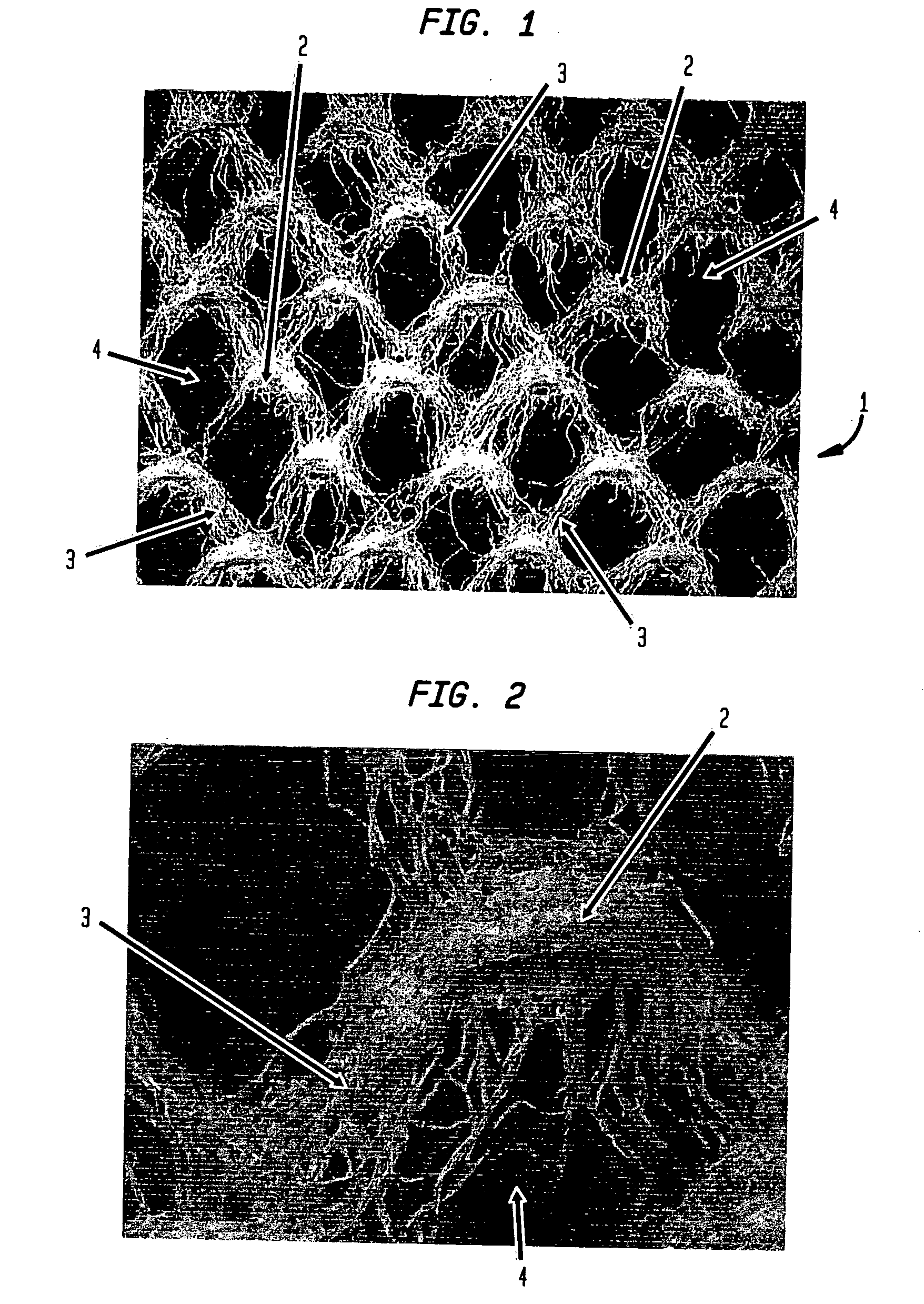

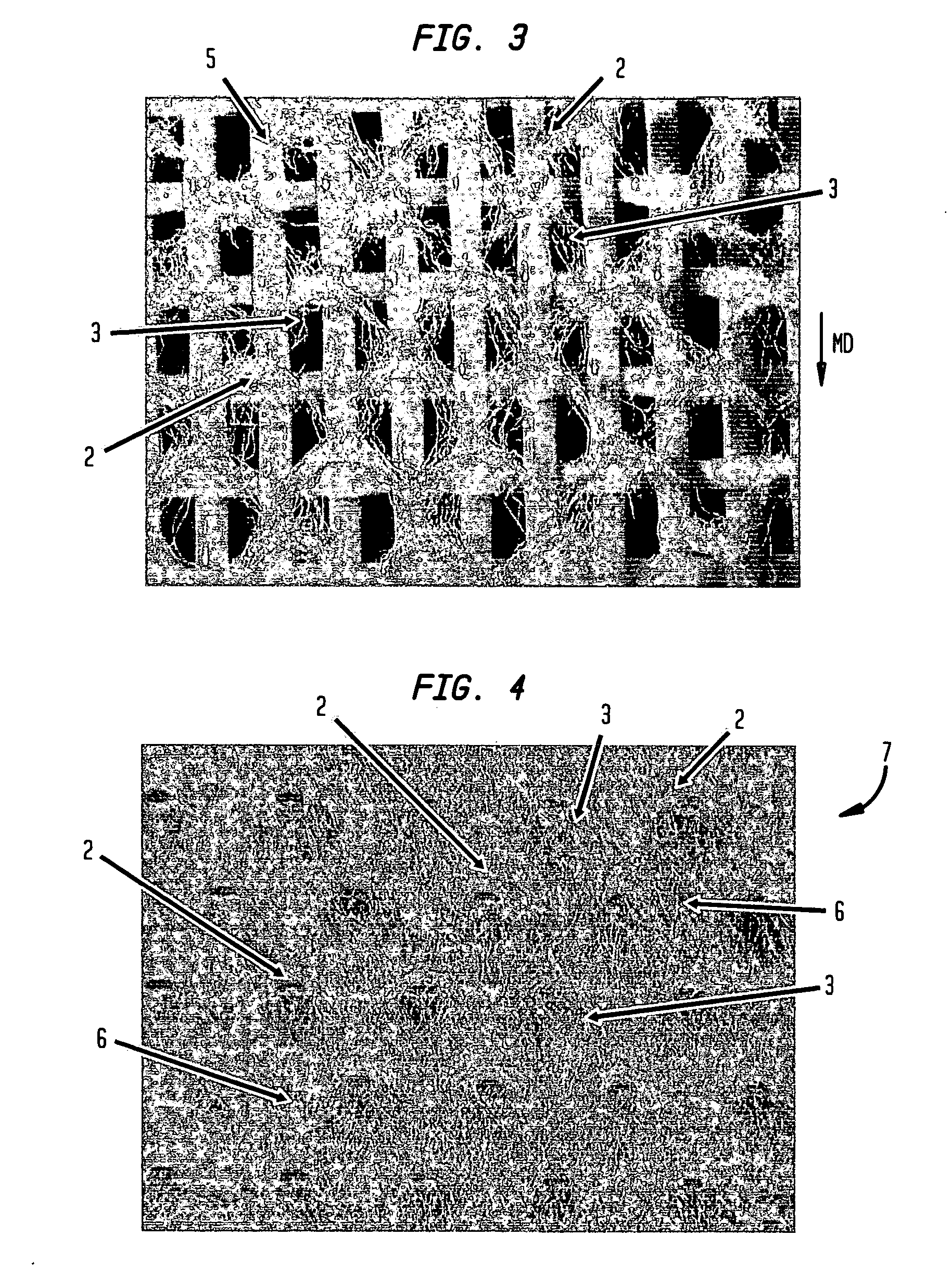

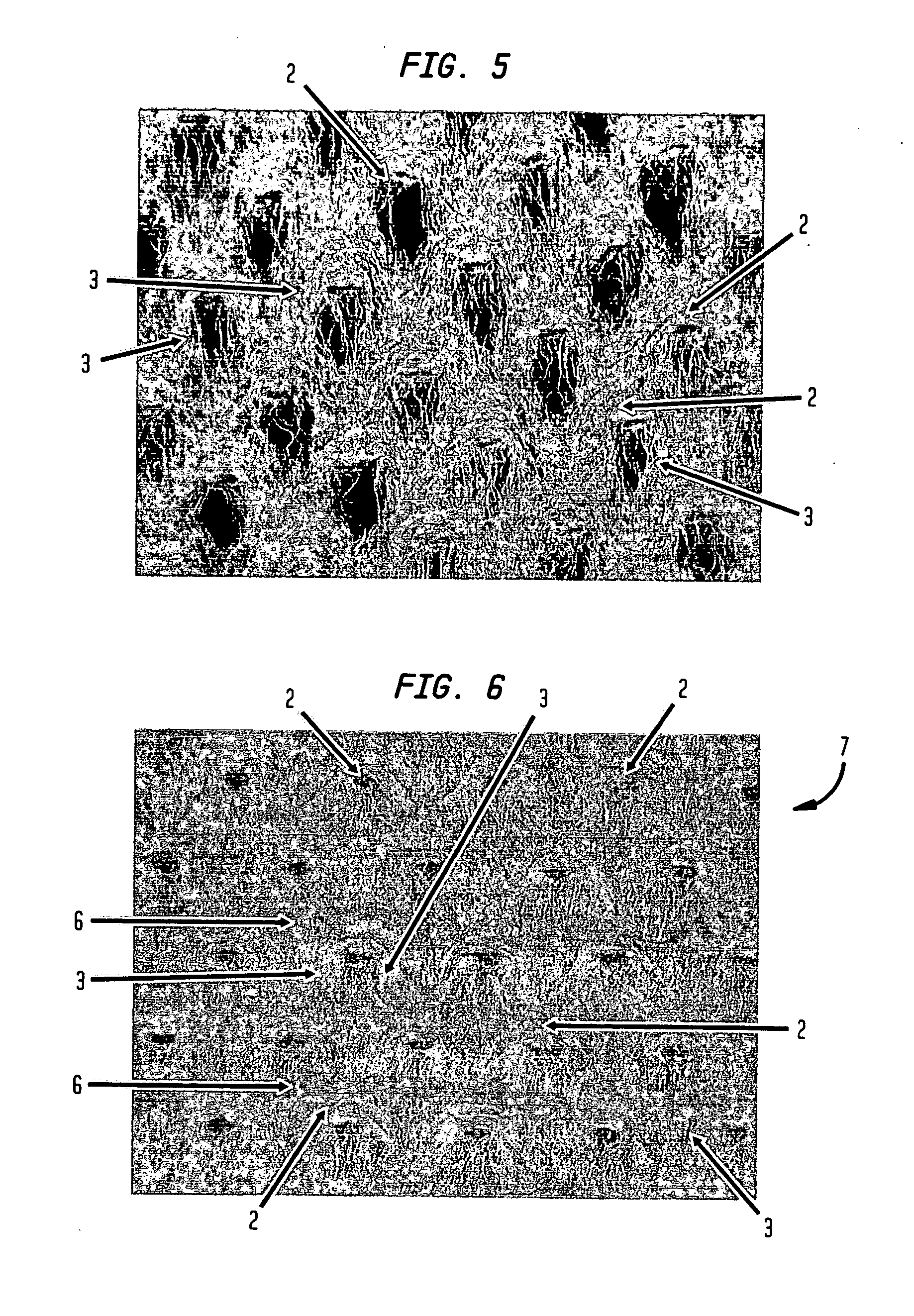

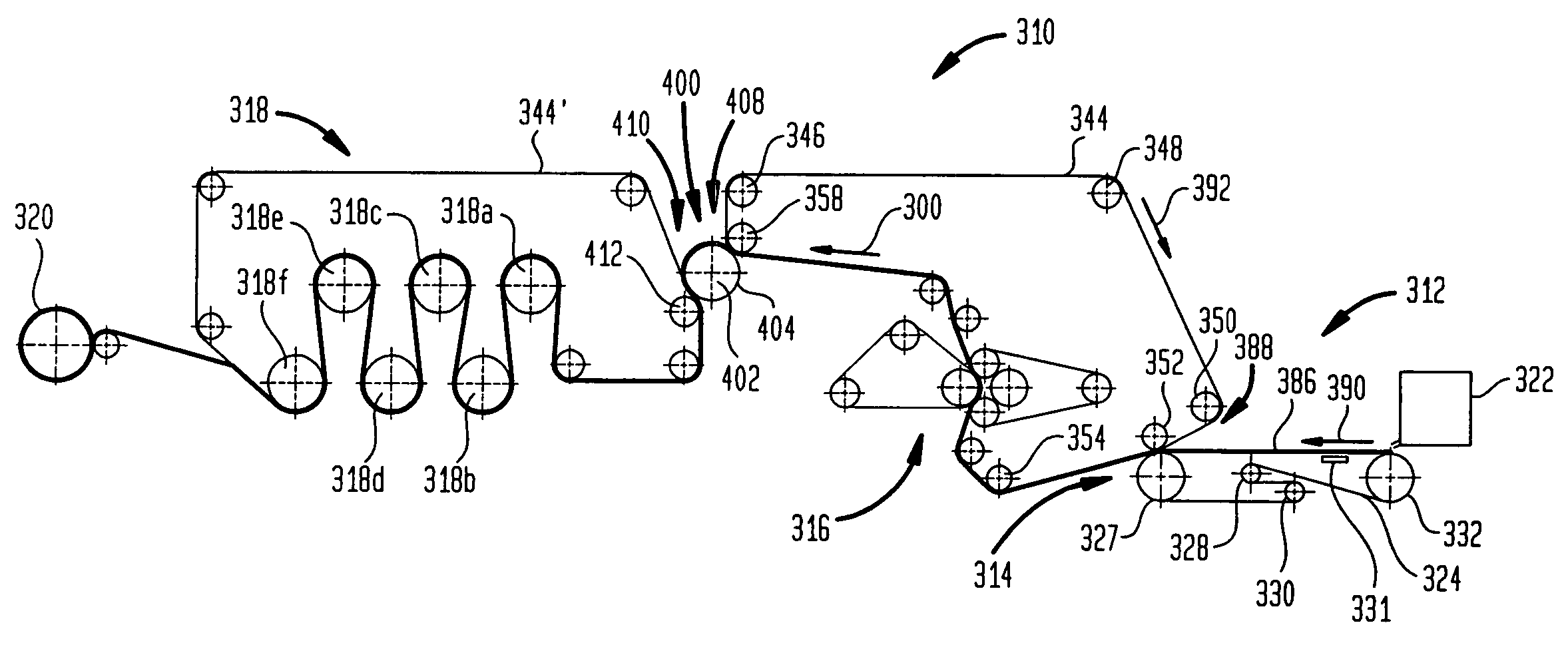

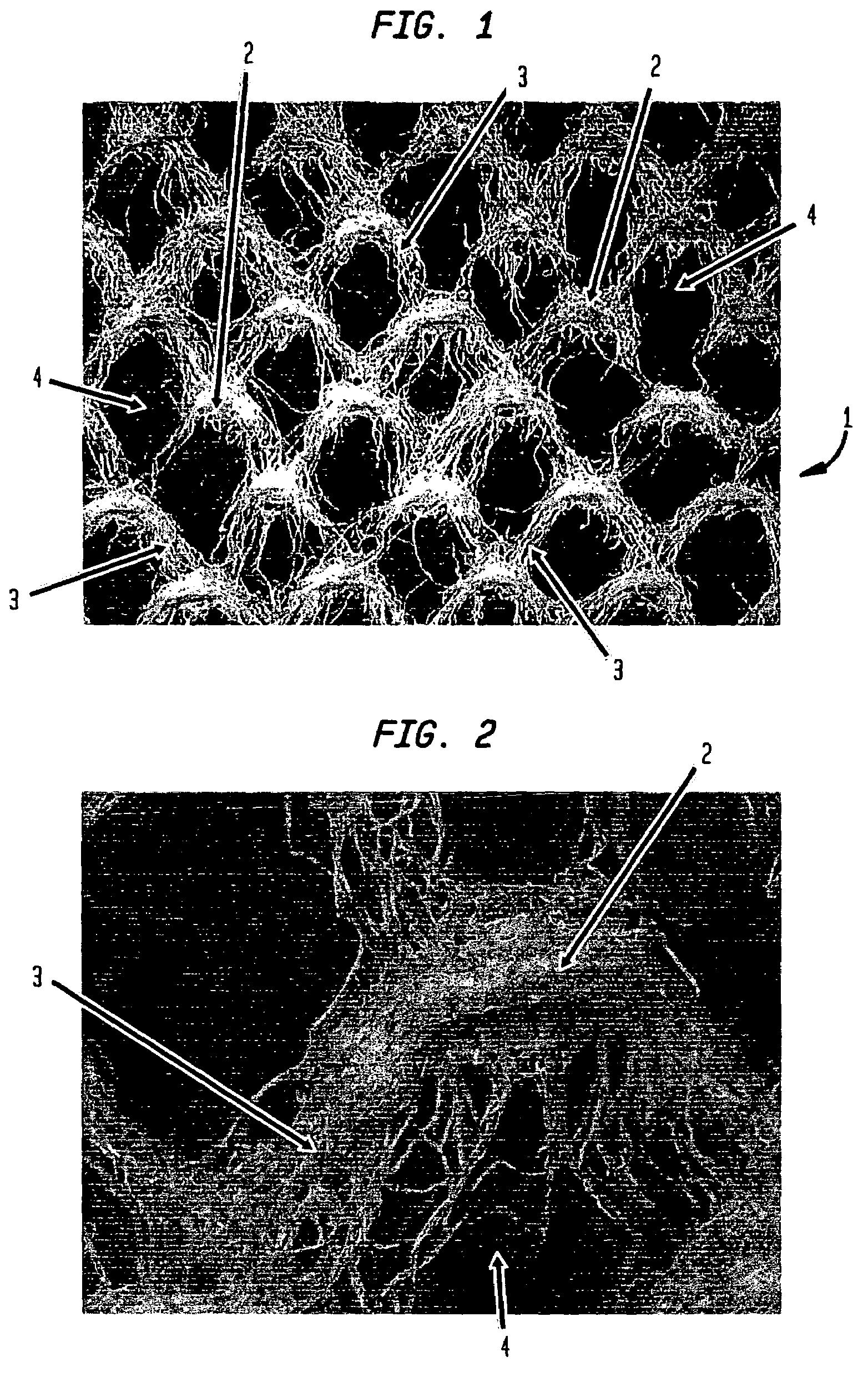

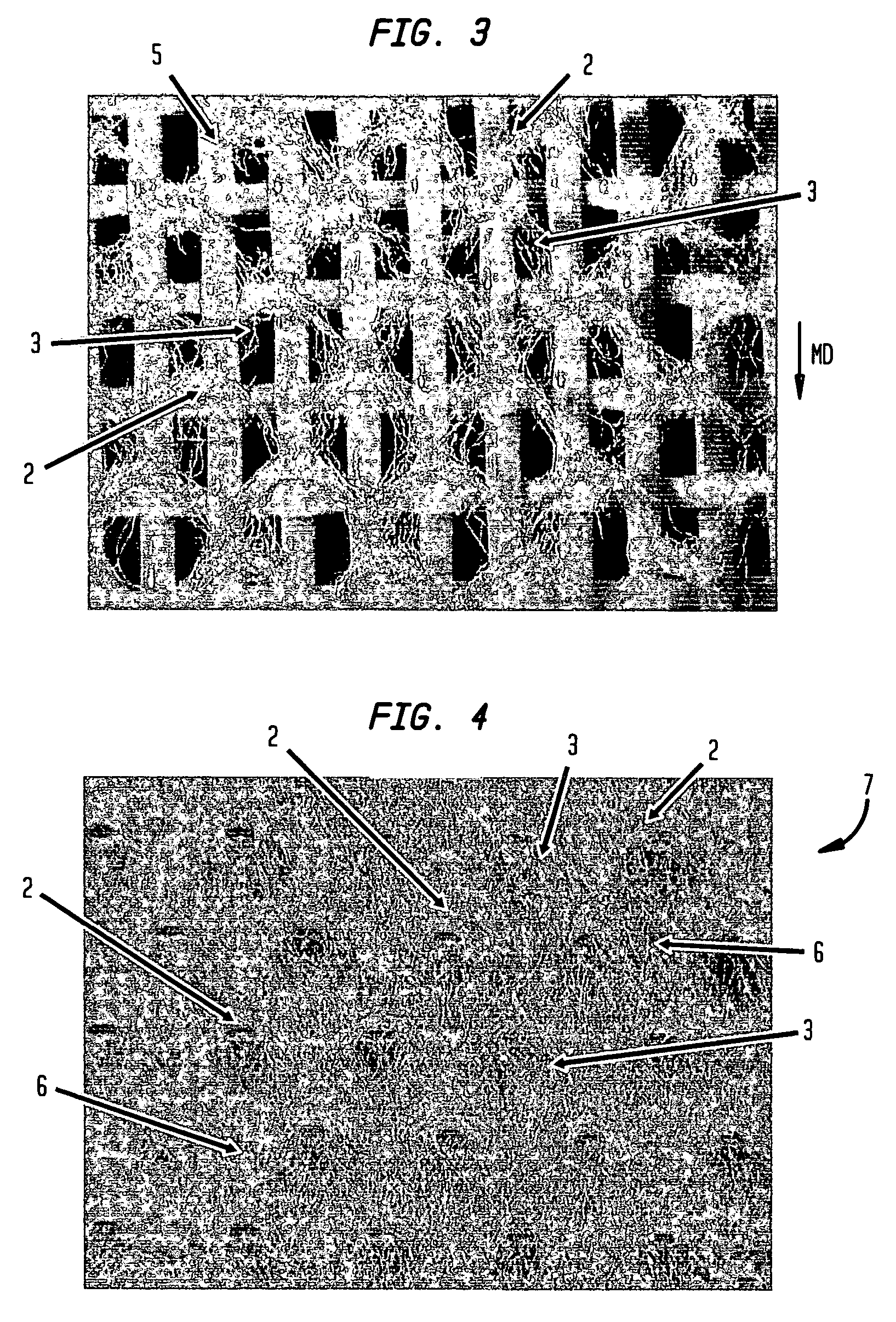

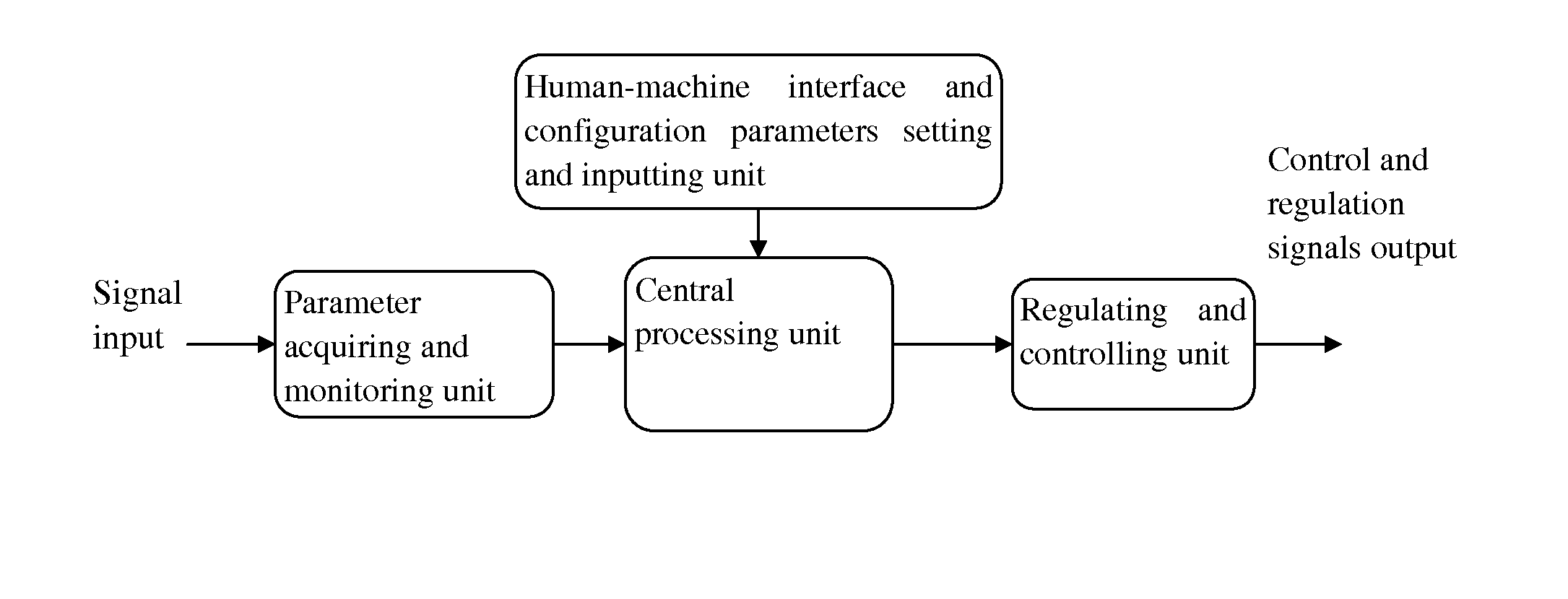

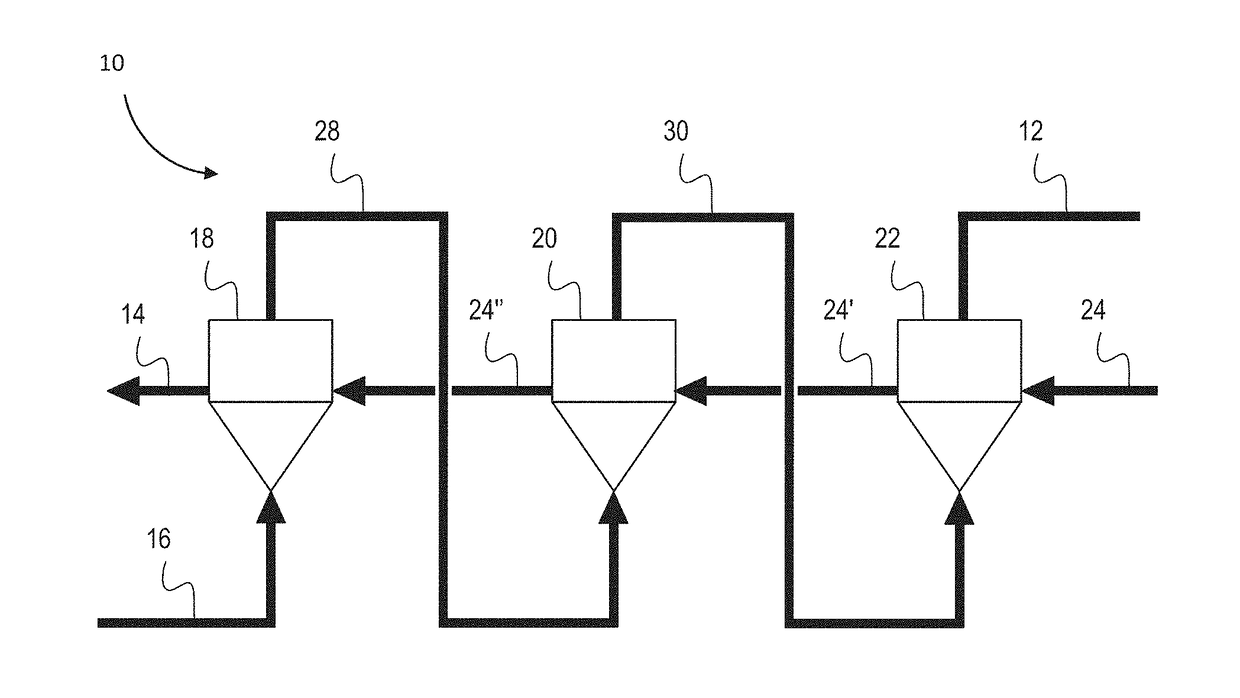

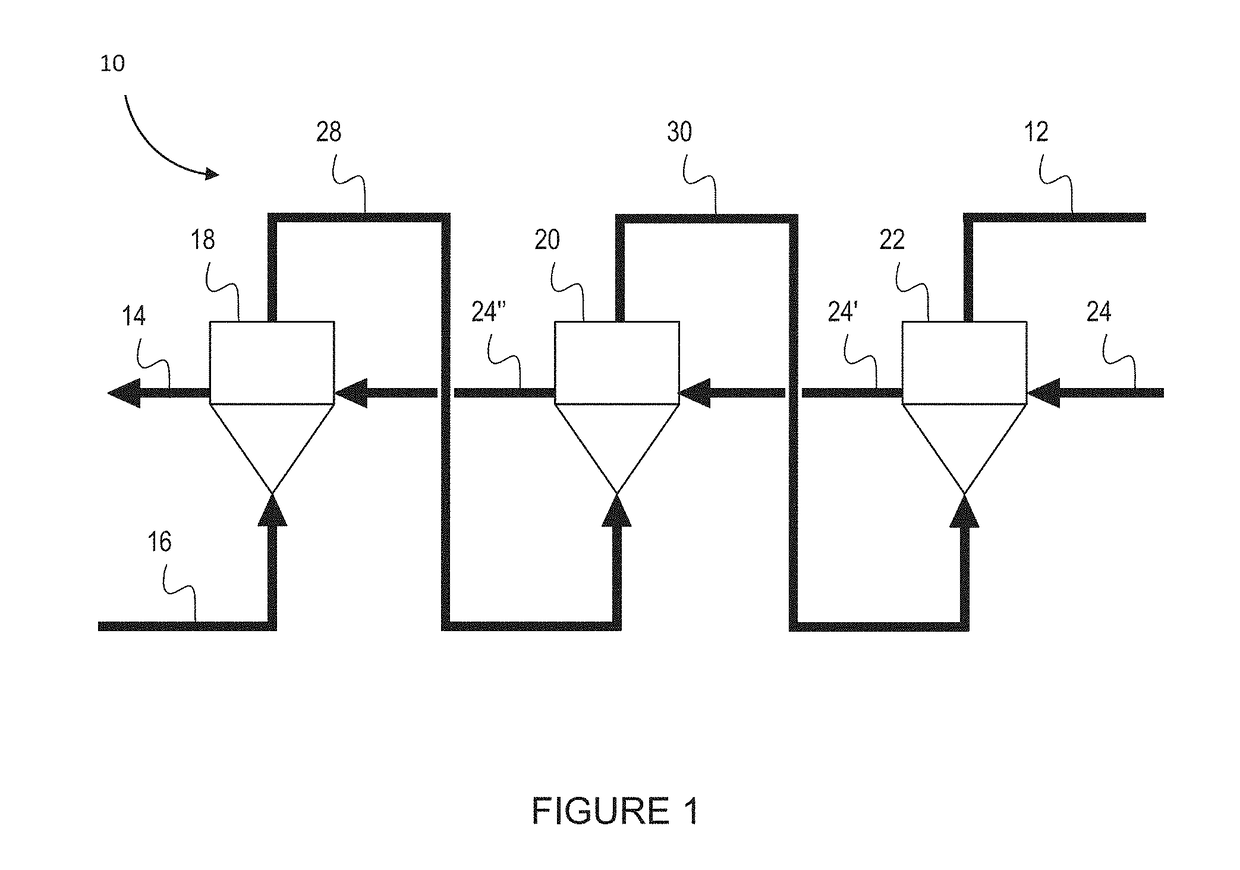

A low-compaction method of making an absorbent cellulosic web includes: forming a nascent web from a papermaking furnish; dewatering the nascent web to a consistency of from about 10 to about 30 percent on a foraminous forming support traveling at a first speed; rush-transferring the web at a consistency of from 10 to about 30 percent to an open texture fabric traveling at a second speed slower than the first speed of the forming support; further dewatering the web on the impression fabric to a consistency of from about 30 to about 60 percent by way of (i) combining the open texture fabric bearing said web with a fluid distribution membrane and an anti-rewet felt as the three pass through a nip into a pressure chamber defined in part by a plurality of nip rolls, the fluid distribution membrane bearing against the side of the open texture fabric away from the web, with the anti-rewet felt bearing against the web, and (ii) applying a pneumatic pressure gradient from the distributor membrane through the web thereby dewatering the web; and drying the web. Preferably the process includes the steps of selecting the papermaking furnish and controlling the process such that the dried web has a void volume fraction of at least 0.7, a hydraulic diameter in the range of from about 3 to about 20 microns and a Wet Springback Ratio of at least about 0.65. Optionally provided is a high solids fabric crepe in a pressure nip.

Owner:GPCP IP HLDG LLC

Low compaction, pneumatic dewatering process for producing absorbent sheet

ActiveUS7416637B2Lower gradeReduce capital investmentNon-fibrous pulp additionNatural cellulose pulp/paperFiberPapermaking

A low-compaction method of making an absorbent cellulosic web includes: forming a nascent web from a papermaking furnish; dewatering the nascent web to a consistency of from about 10 to about 30 percent on a foraminous forming support traveling at a first speed; rush-transferring the web at a consistency of from 10 to about 30 percent to an open texture fabric traveling at a second speed slower than the first speed of the forming support; further dewatering the web on the impression fabric to a consistency of from about 30 to about 60 percent by way of (i) combining the open texture fabric bearing said web with a fluid distribution membrane and an anti-rewet felt as the three pass through a nip into a pressure chamber defined in part by a plurality of nip rolls, the fluid distribution membrane bearing against the side of the open texture fabric away from the web, with the anti-rewet felt bearing against the web, and (ii) applying a pneumatic pressure gradient from the distributor membrane through the web thereby dewatering the web; and drying the web. Preferably the process includes the steps of selecting the papermaking furnish and controlling the process such that the dried web has a void volume fraction of at least 0.7, a hydraulic diameter in the range of from about 3 to about 20 microns and a Wet Springback Ratio of at least about 0.65. Optionally provided is a high solids fabric crepe in a pressure nip.

Owner:GPCP IP HLDG LLC

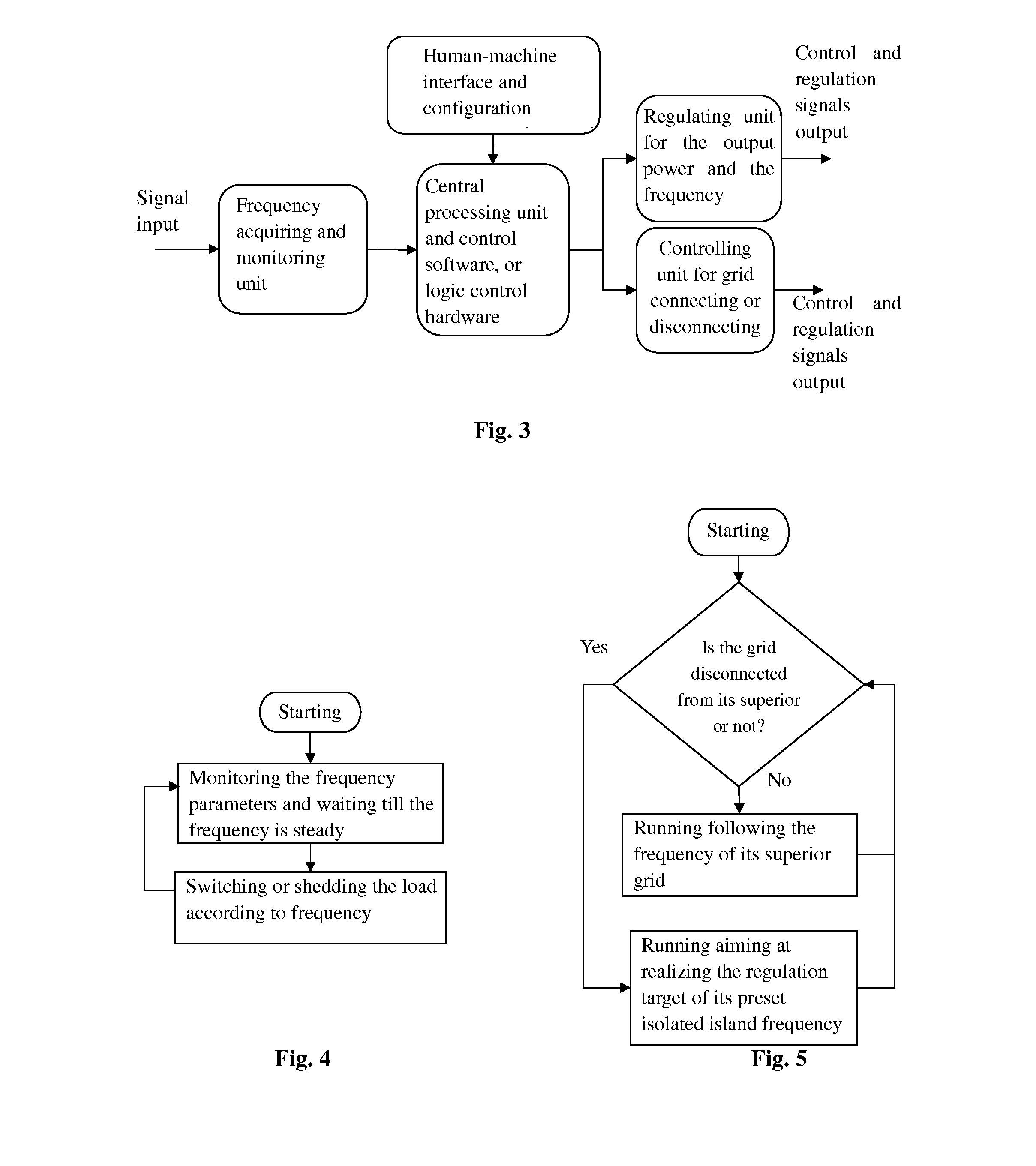

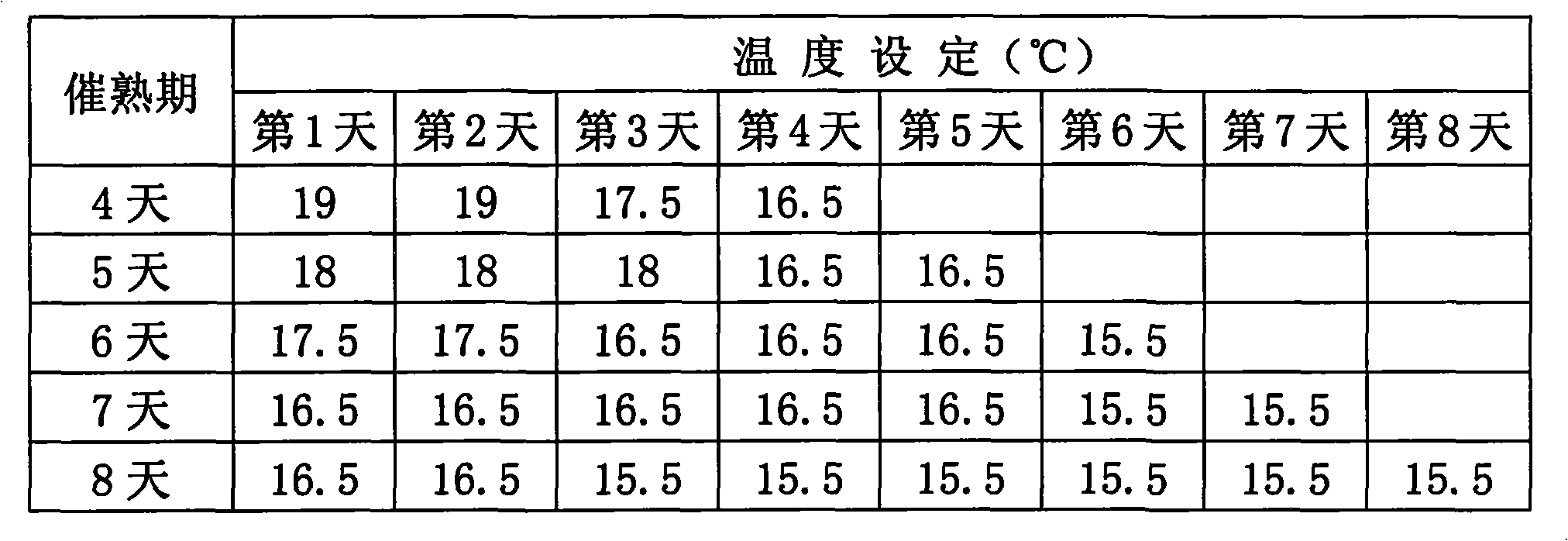

Device and method for self-healing control of a multi-level power grid

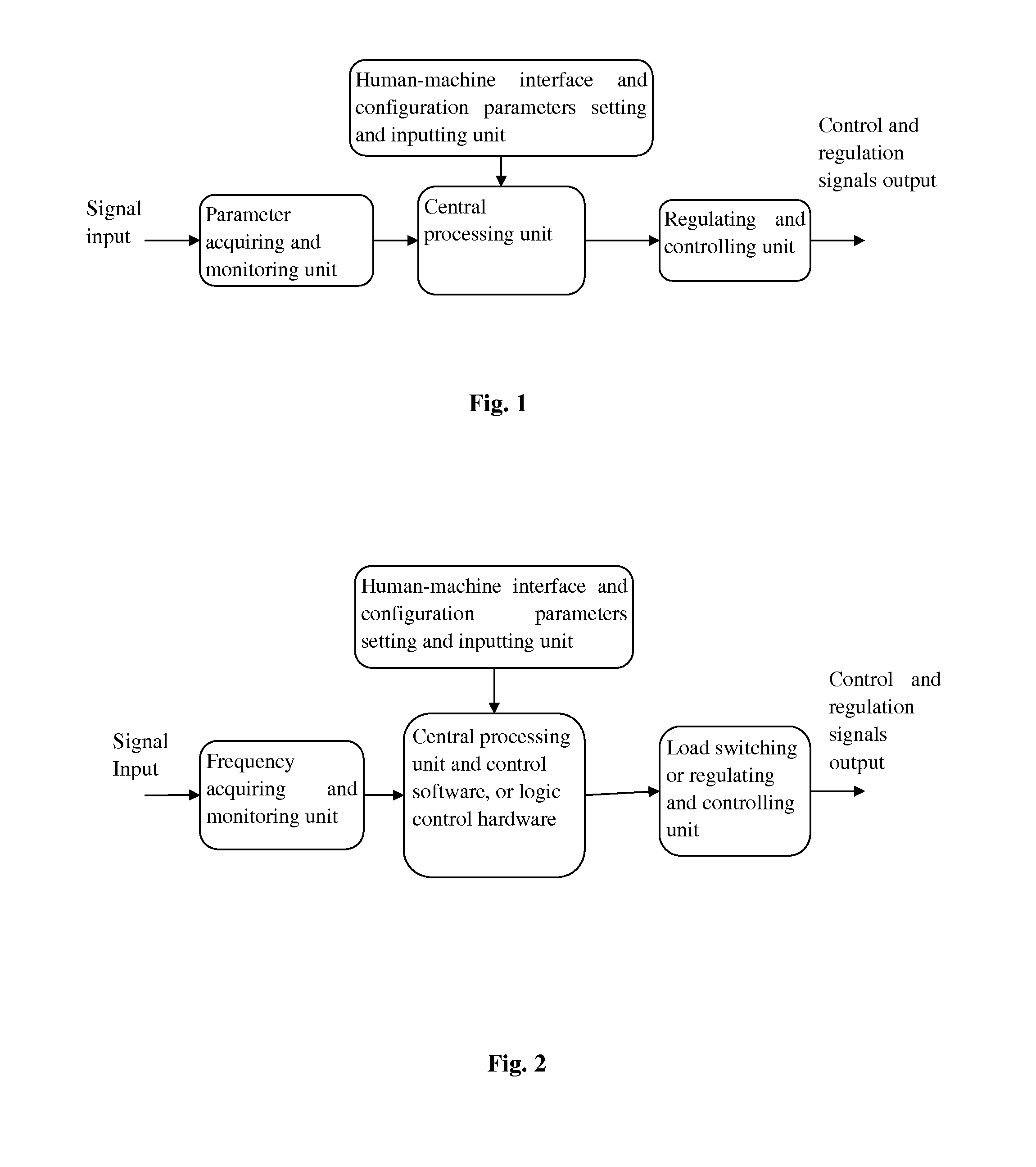

InactiveUS20140025217A1Long durationLower gradeMechanical power/torque controlLevel controlSelf-healingSupply energy

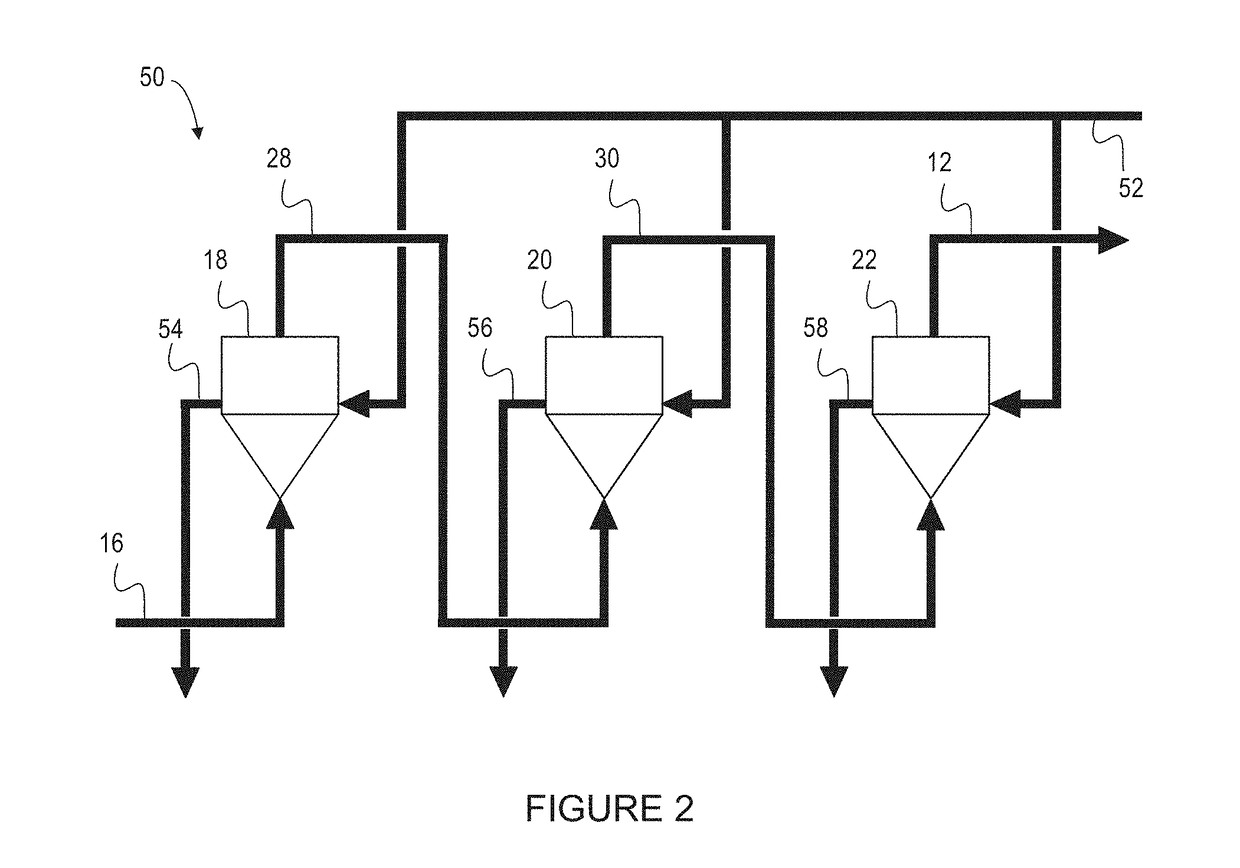

A device and method for self-healing control of multi-level power grid system are provided in the present invention. The requirements to be satisfied by the present invention are that: realizing interaction and balance between power supplies and loads; controlling and coordinating cooperation coordination and cooperation between various distributed power supplies, micro-grids in multi-levels and their main grids; automatically distinguishing an on-grid state or an isolated island state of a locale grid; and guaranteeing energy supply to the maximum. The device for self-healing control of multi-level power grid is connected in one or more levels of power grids of the multi-level power grid system, and the device includes: a parameter acquiring and monitoring unit, a central processing unit, a human-machine interface and configuration parameter setting and inputting unit, and a regulating and controlling unit. Using frequency as an information carrier to characterize the connection state and the area coverage and grids levels included in the power system, the device enables the loads and the power supplies in the power grid system to distinguish the states of their localized grids by themselves, and performs to perform automatic switching or regulating according to preset strategies. Using frequency as information tie, the device balances supply and demand of power by self-adjustment between the power supplies and the loads in the system, and guarantees the automatic balance and stabilization of the power grid system both in the on-grid state and in the isolated island state.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

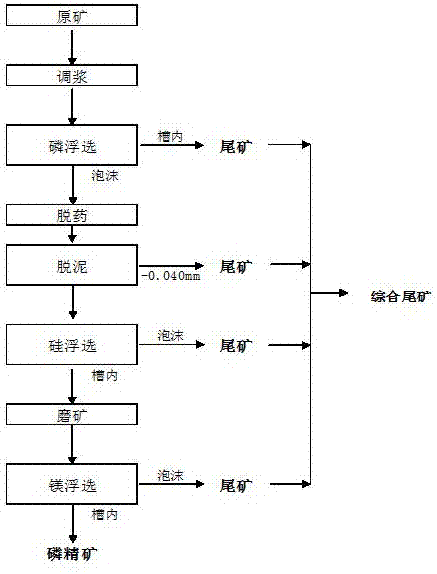

Branch flotation technology for silicon calcium collophanite

The invention relates to a branch flotation technology for collophanite, which comprises the following steps: crushing and grinding silicon calcium collophanite ores, and then adding water and mixing into slurry, and guiding the slurry to flow into a flotation groove; adding a regulator and a collecting agent for mixing the slurry, and then pouring into a reverse flotation system for performing reverse flotation, wherein products in the groove are reverse flotation concentrates; grading the reverse flotation concentrates into coarse fraction and fine fraction; pouring the coarse fraction partinto a desilicification reverse flotation groove, adding a desilicification regulator and a desilicification collecting agent for mixing the slurry, and then pouring into a desilicification system for performing reverse flotation, wherein products in the groove are desilicification reverse flotation concentrates; pouring the fine fraction part into a normal flotation groove, adding a normal flotation pH (Potential of Hydrogen) regulator, the regulator and the collecting agent for mixing the slurry, and then performing normal flotation, wherein foam products of the normal flotation are normal flotation concentrates; mixing the normal flotation concentrates with the desilicification reverse flotation concentrates, thereby forming the final phosphorus concentrates; and concentrating, filtering and drying, thereby obtaining phosphorus concentrates. The branch flotation technology for collophanite has the advantages that the separation efficiency is high, the technic index is excellent, the content of MgO in the obtained phosphorus concentrates is lower, the quality of the concentrates is high, and the comprehensive cost of the final product of the phosphor concentrates is lower.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

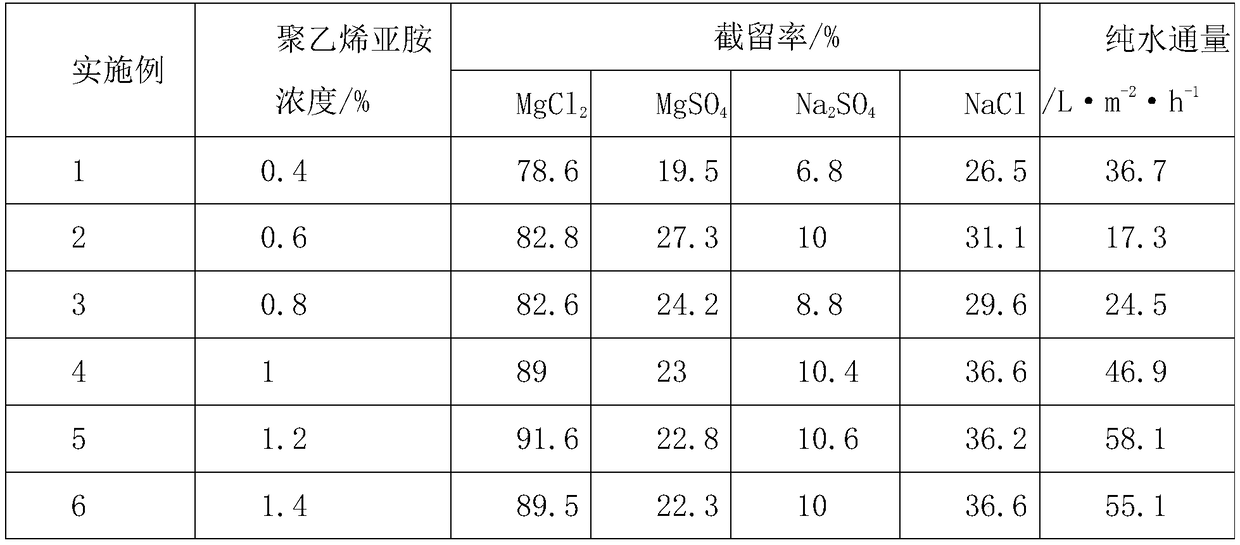

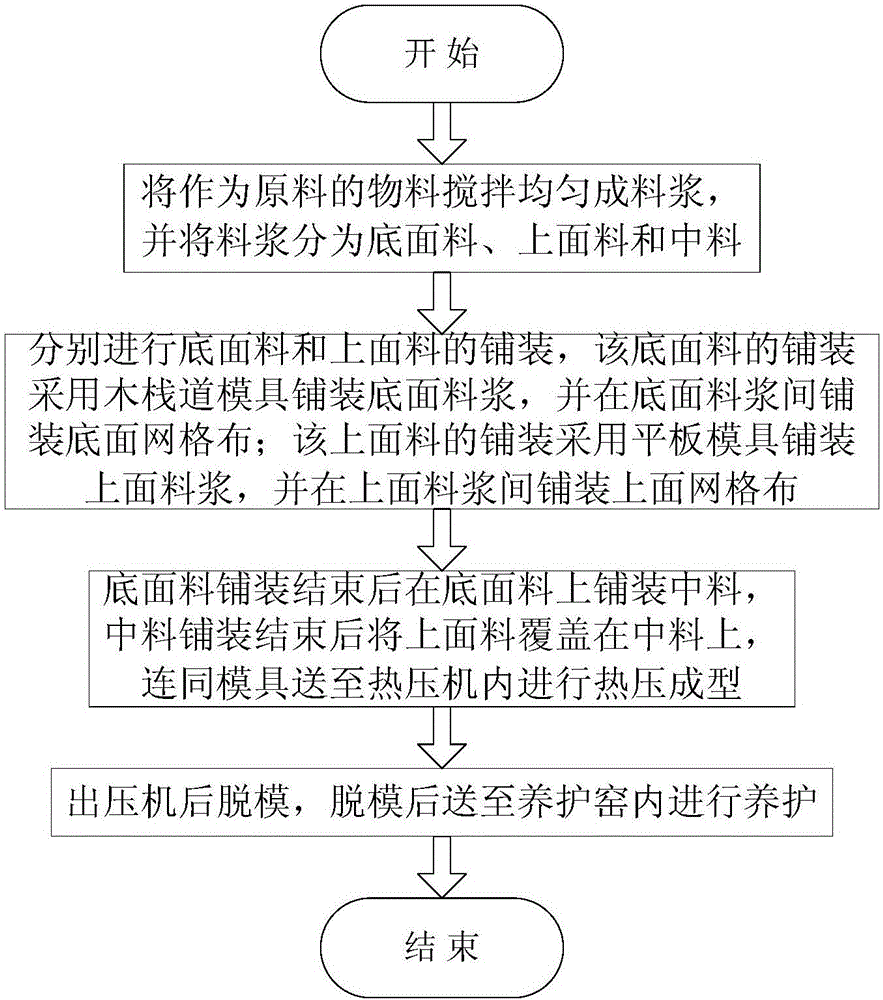

Preparation method of novel high-selectivity positively-charged nanofiltration composite membrane

InactiveCN109173737APorous structureStrong positiveMembranesGeneral water supply conservationWater softeningLithium

The invention discloses a preparation method of a novel high-selectivity positively-charged nanofiltration composite membrane. The preparation method comprises the following steps: taking positively-charged polyethylenimine as a functional layer material of the composite membrane, taking aromatic polybasic acid as a crosslinking agent and modifying, and coating and crosslinking on a nanofiltrationmembrane supporting layer to obtain the high-selectivity positively-charged nanofiltration membrane. By adopting a gradient crosslinking technology, the pore diameter of a prepared composite membranecrosslinking layer is gradually increased from bottom to top; and the water flux is greatly improved under the condition of keeping high desalting performance. The preparation method disclosed by theinvention is simple in technology and easy to operate; and the prepared composite membrane can be operated under a low-pressure condition, so that the cost is reduced and the composite membrane is easy to popularize and apply. The nanofiltration membrane prepared by the preparation method has relatively high selectivity on multivalent cations and monovalent cations and can be used for the fieldsincluding water softening, medicines, dyestuffs, lithium extraction of salt lakes, industrial wastewater and the like.

Owner:ZHEJIANG UNIV OF TECH

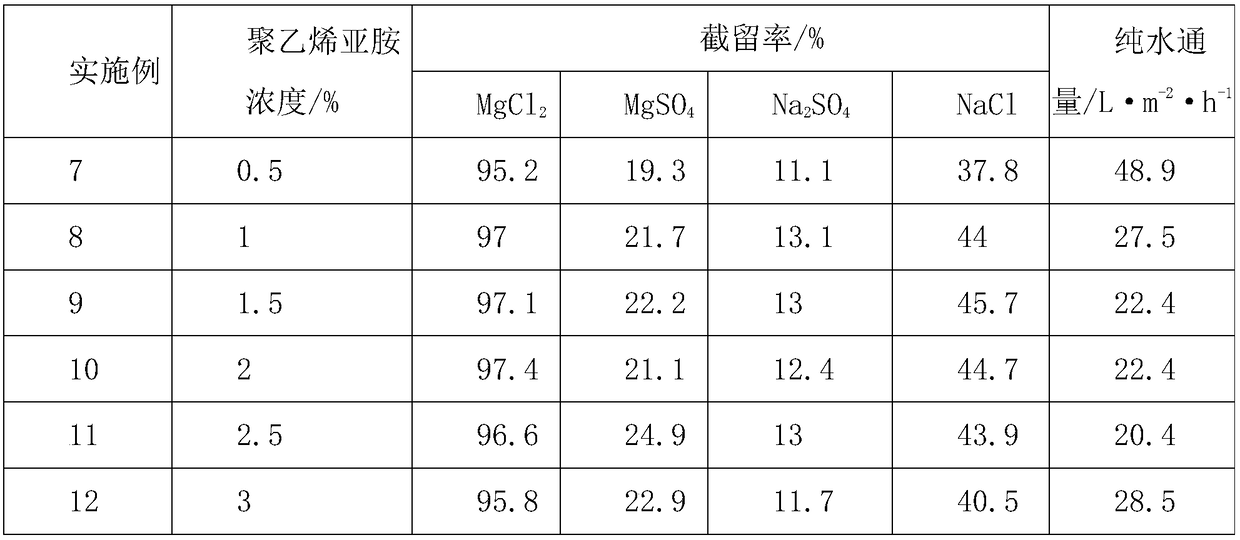

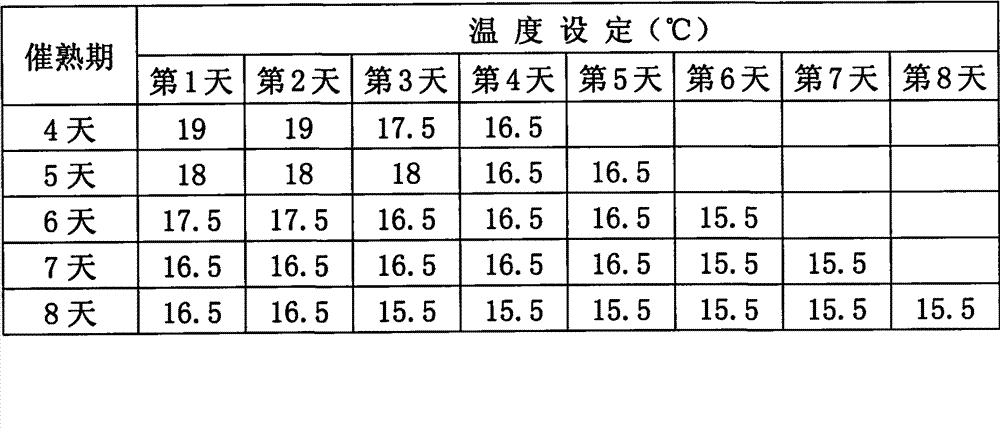

Banana fresh-keeping and variable-temperature gas-regulation ripening technique process flow

InactiveCN101347148AExtended storage timeExtended shelf lifeFruit and vegetables preservationFruit FlavorBiology

The present invention discloses a banana preservation and variable-temperature air-adjusting ripening flow. Fruit lossless harvest, batch processing and vacuum packaging are carried out by constructing a banana air-adjusting storehouse; air-adjusting preservation and a series flow of variable-temperature air-adjusting ripening are utilized for banana preservation and accelerating maturity. The flow can obviously improve the exterior and interior quality of the banana finished product and achieve the controllability of ripening period. The product can be on a par with imported banana and has the advantages of dense fruit flavor, good taste, long shelf life, and the like, thus having good market prospect.

Owner:漳州市庄怡农业发展有限公司

Pretreatment process of linen fabric

InactiveCN104611936ASoft touchImprove the fabric gradePhysical treatmentBiochemical fibre treatmentEnvironmental geologyManufacturing engineering

The invention discloses a pretreatment process of a linen fabric. The pretreatment process comprises the steps of checking bad products, sewing in an overturning manner, singeing, carrying out low-temperature plasma treatment, desizing, refining by scouring enzyme, carrying out acid washing, carrying out chlorine bleaching, carrying out oxygen bleaching, carrying out deoxidized enzyme washing, washing and drying. After the pretreatment process is adopted, the use amount of a chemical reagent is reduced, little pollution is caused, energy is saved, the emission is reduced, the difficulty of wastewater pollution control is reduced, the production efficiency is improved, the treated linen fabric is soft in hand feeling, the brightness of the linen fabric is improved, and the fabric quality is improved.

Owner:SUZHOU CHENHENG WEAVING

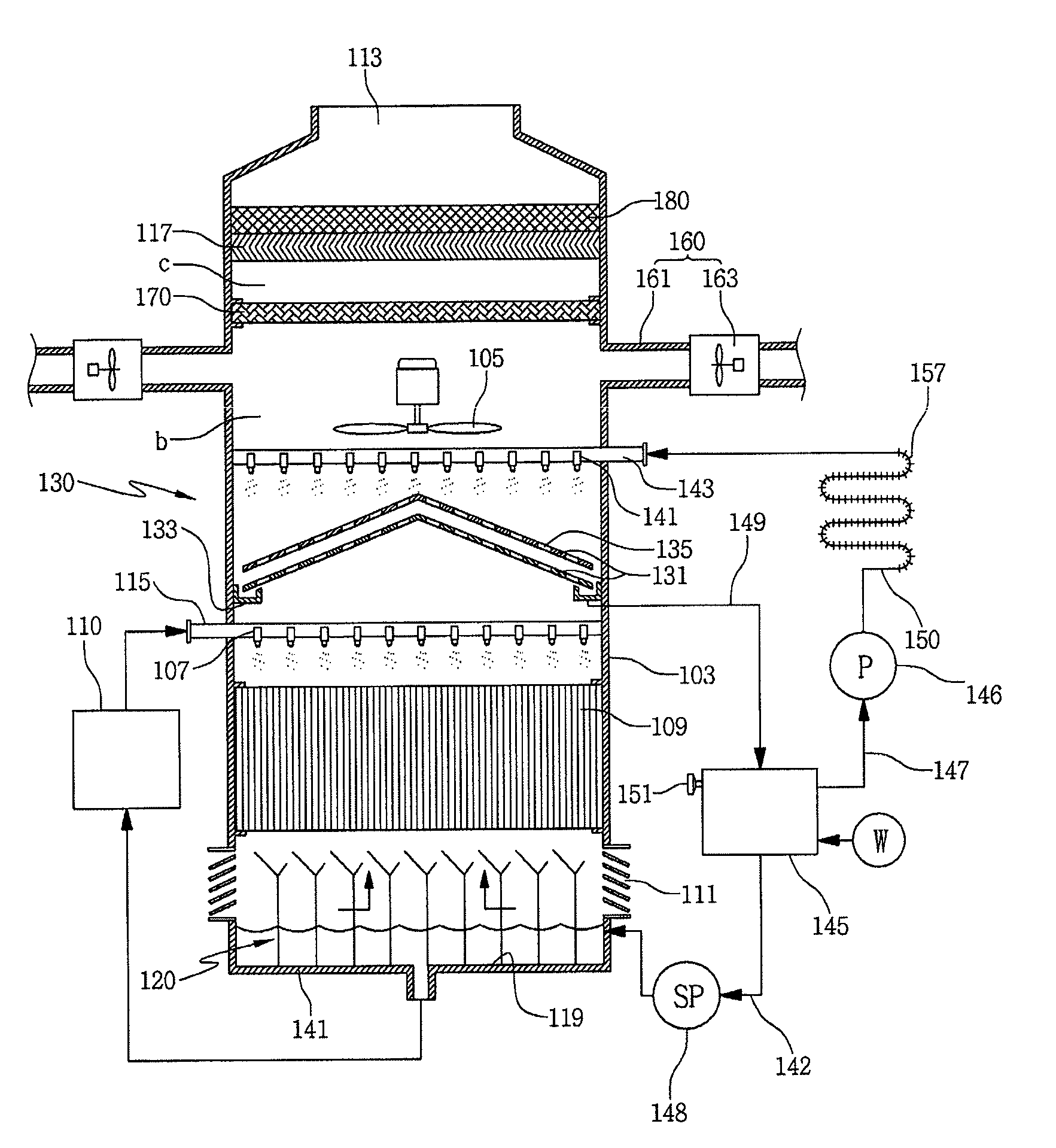

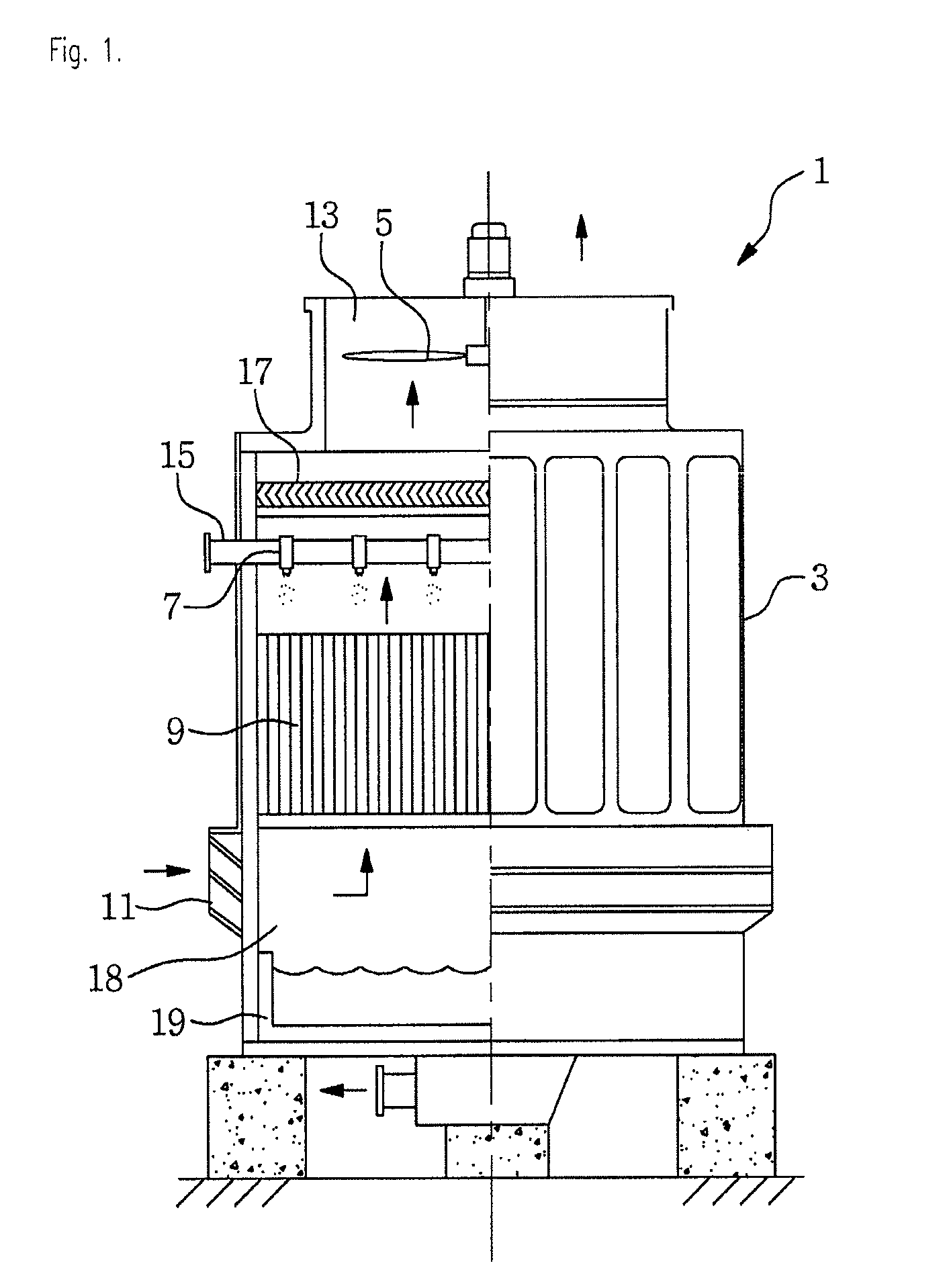

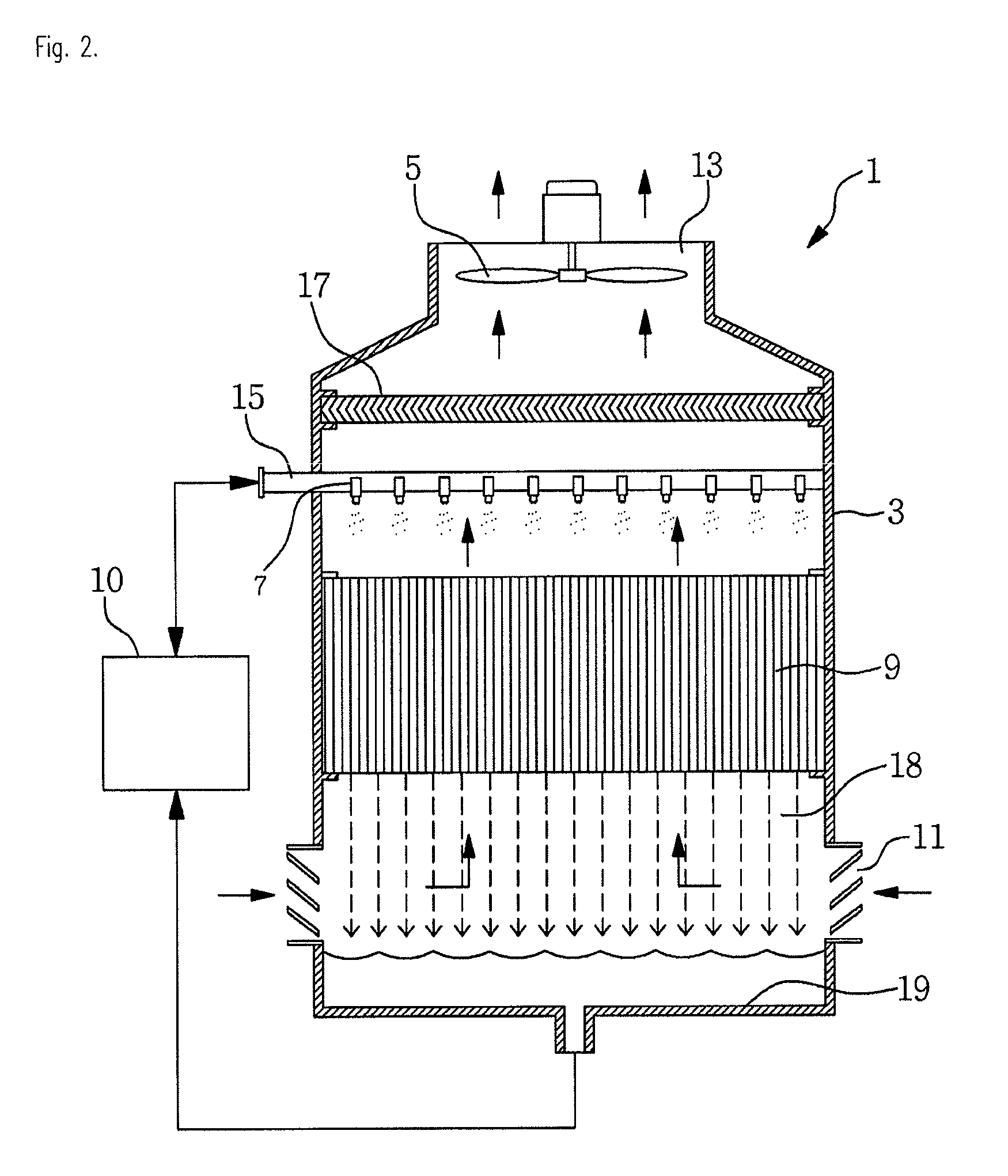

Counter flow type of cooling tower

ActiveUS8196908B2Preventing the coolant from droppingNoise is causedCarburetting airUsing liquid separation agentNoise generationCooling tower

Owner:HOOSAN

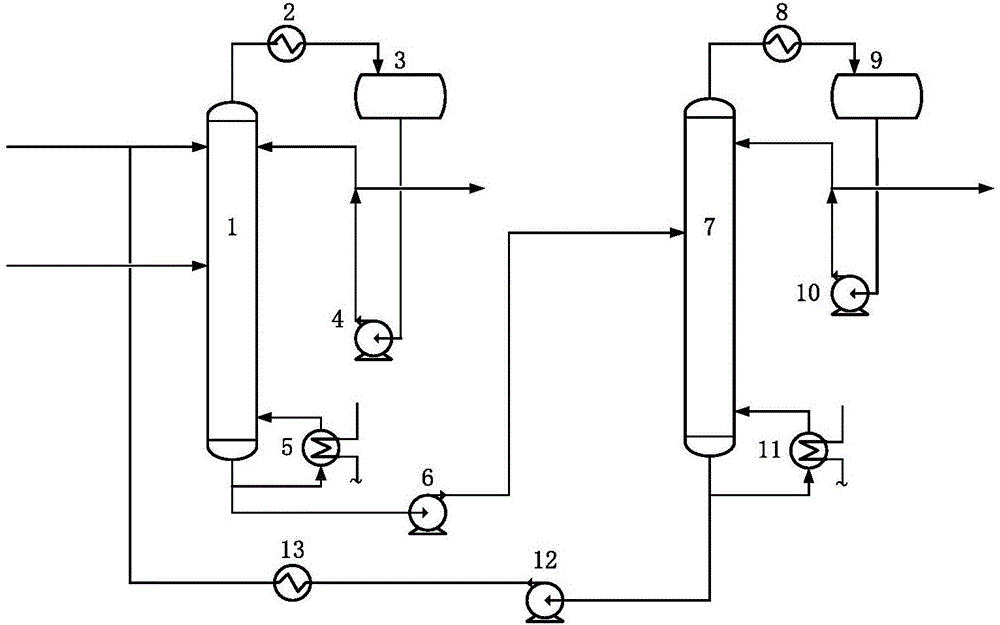

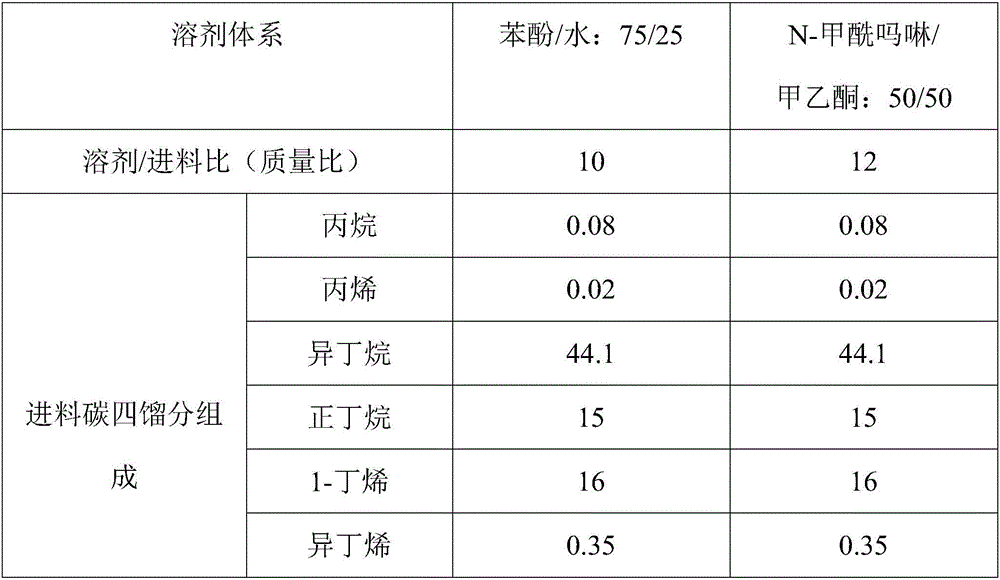

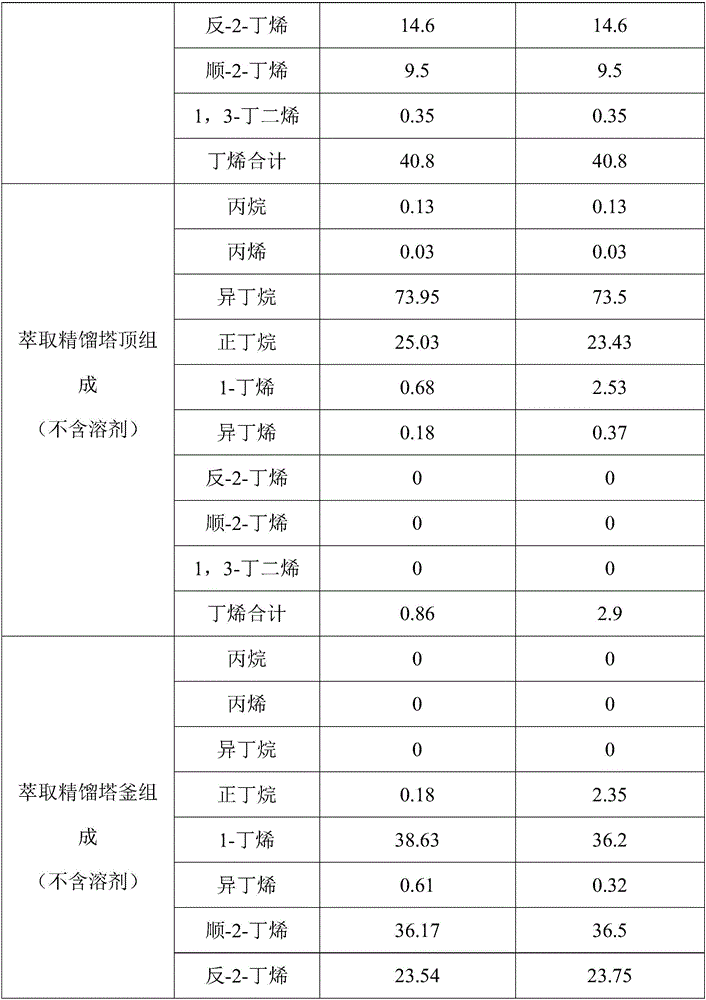

Device and process for separating C4 fractions by adopting binary mixed solvent

InactiveCN106478341ALower gradeHigh purityChemical industryDistillation purification/separationButeneSolvent

The invention provides a device and process for separating C4 fractions by adopting a binary mixed solvent. The device comprises an extraction and rectifying column, an extraction and rectifying column top condenser, an extraction and rectifying column refluxing tank, an extraction and rectifying column refluxing pump, an extraction and rectifying column bottom re-boiler, an extraction and rectifying column residue pump, a stripping column, a stripping column top condenser, a stripping column refluxing tank, a stripping column refluxing pump, a stripping column bottom re-boiler, a stripping column residue pump and a lean solvent cooler. C4 separation is carried out by adopting the process so that the relative volatility between butene and butane can be greatly improved and the solvent selectivity is improved; a solvent / feeding ratio is reduced and the temperature of a column reactor is reduced; the heat load of the column reactor is reduced and the aims of saving energy and reducing consumption are realized.

Owner:DALIAN UNIV OF TECH

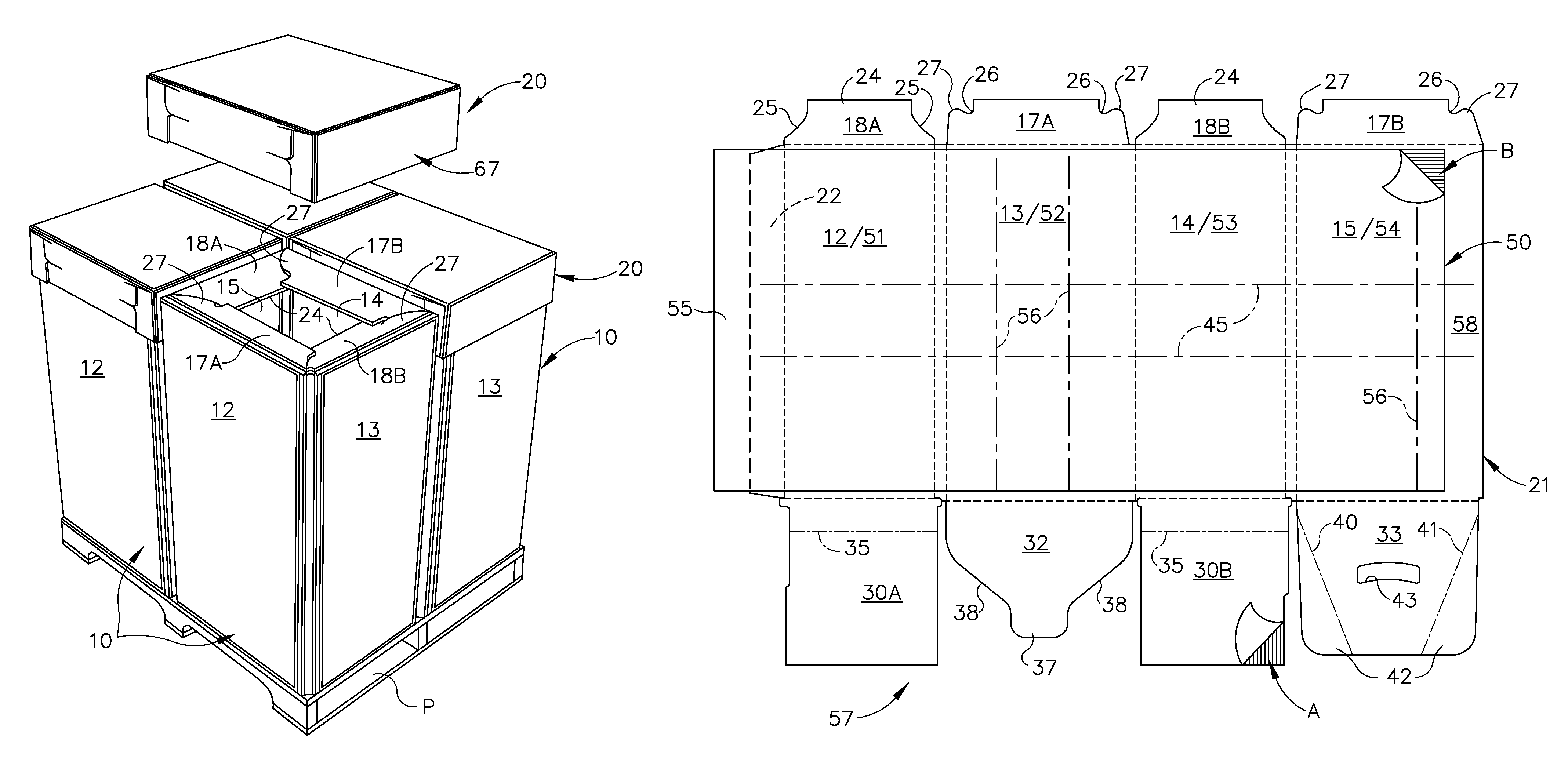

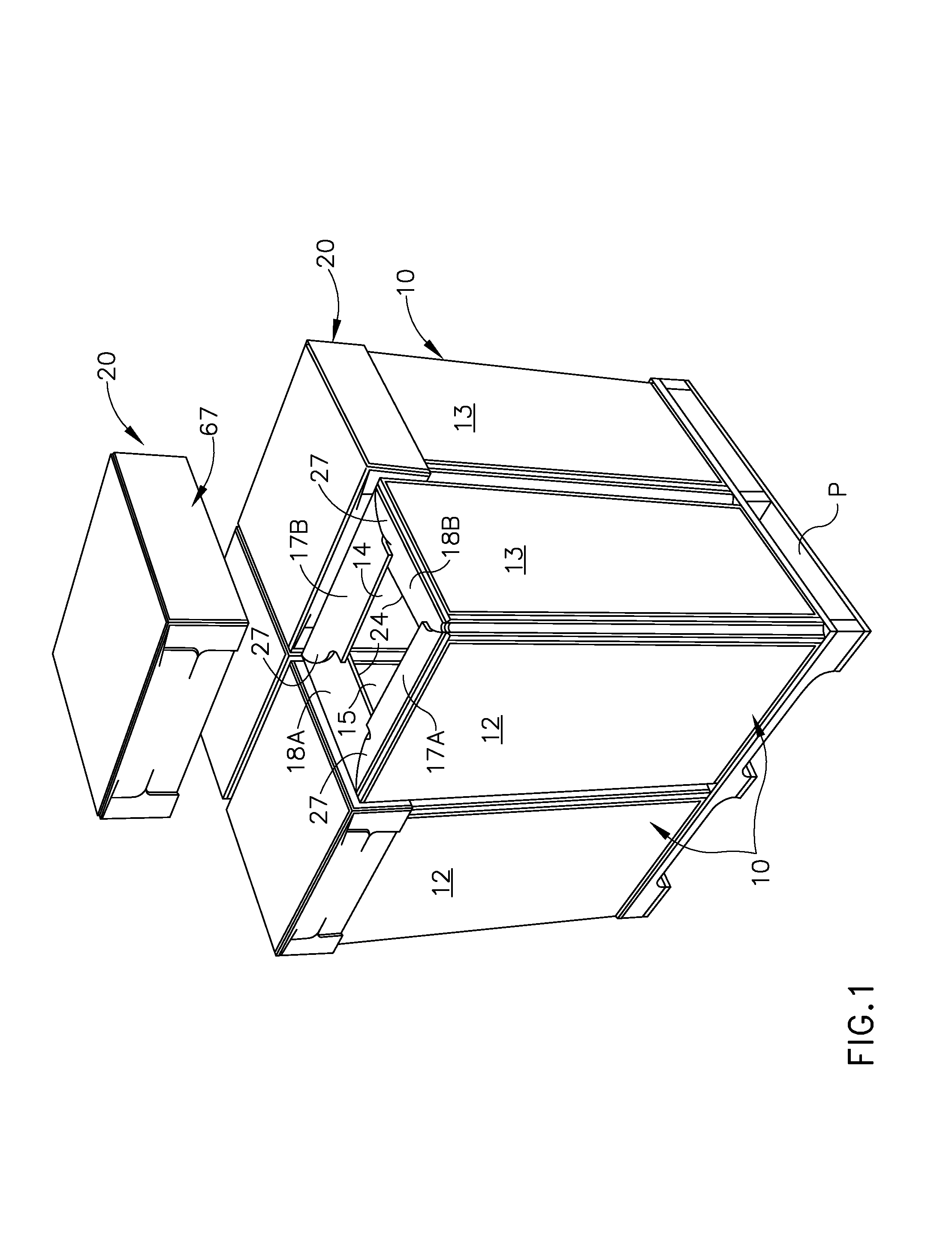

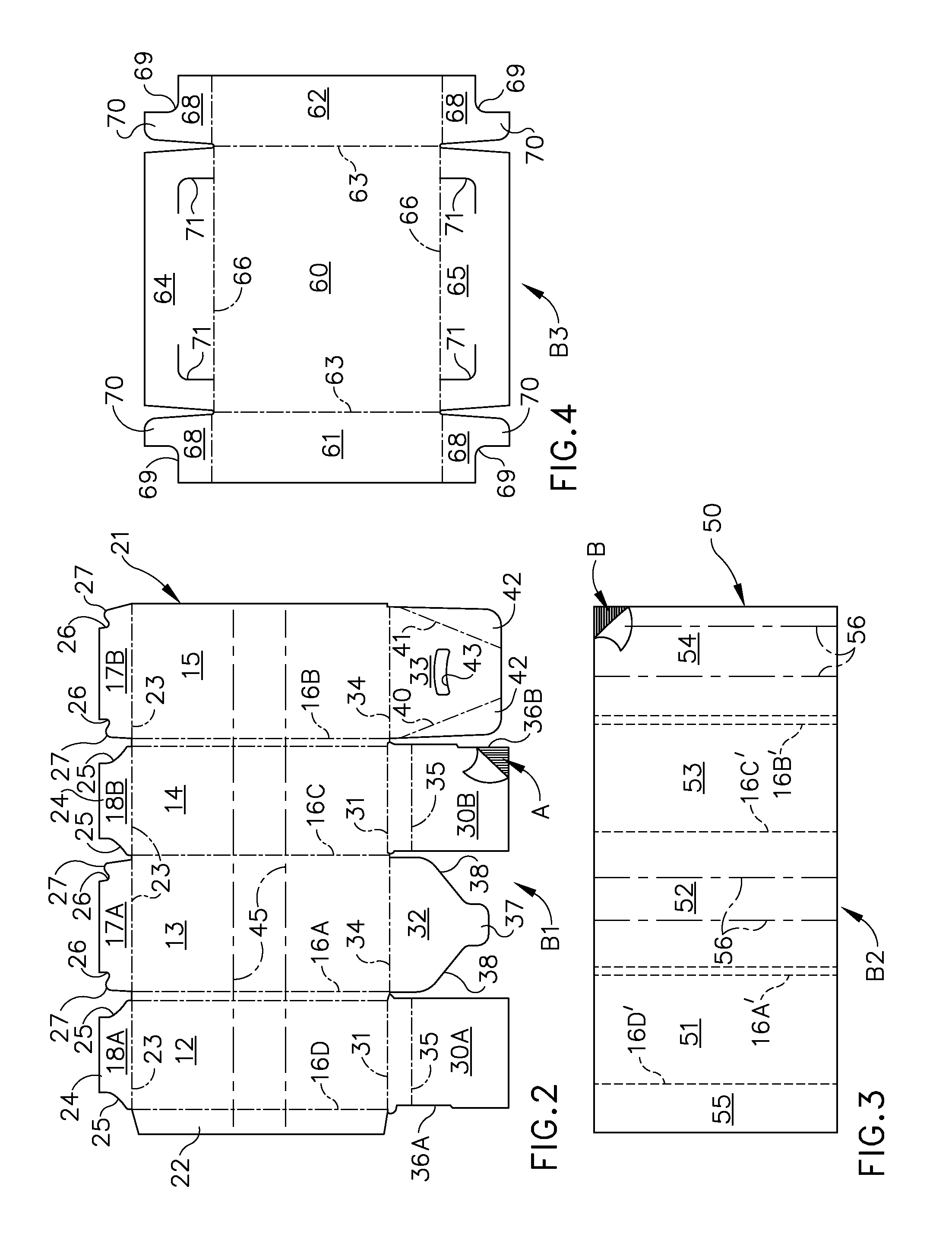

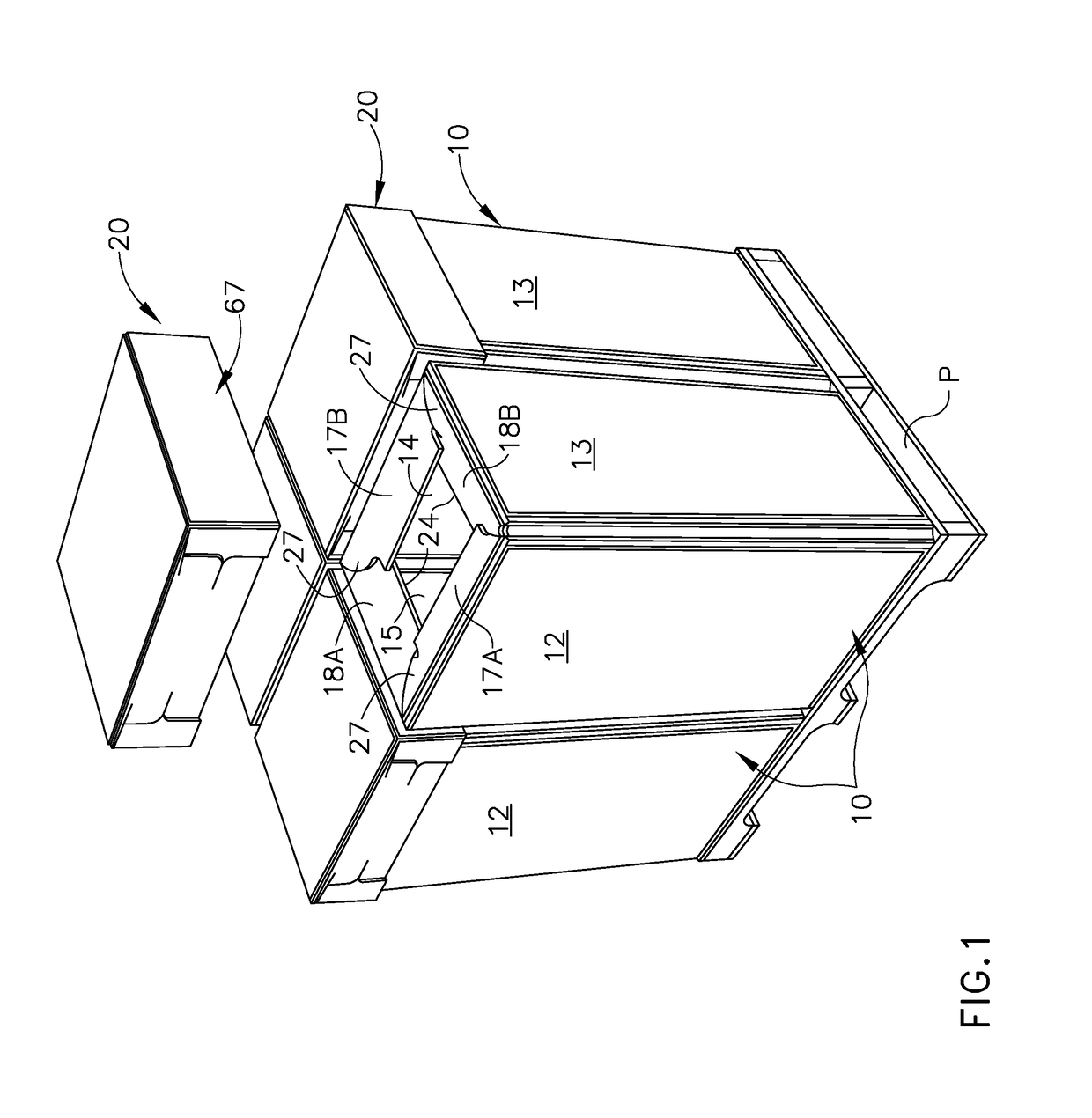

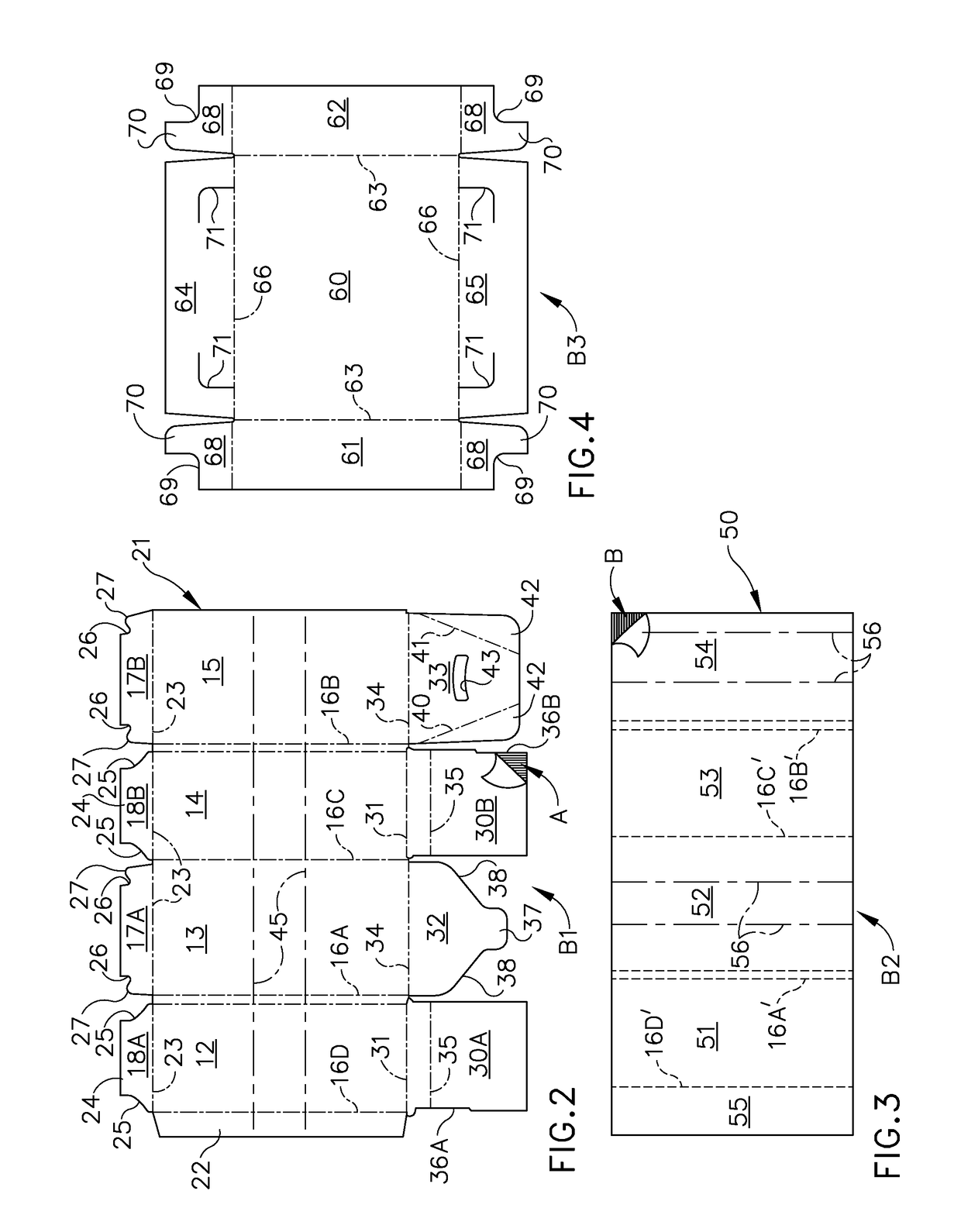

Reinforced cross-laminated bulk container

ActiveUS8490858B2Lower gradeEasy for to open up containerBoxes/cartons making machineryPaper-makingPaperboardFlange

A reinforced cross laminated corrugated paperboard bulk container has an outer component with corrugations running in a first direction, and an inner liner laminated to the outer component, with the liner having corrugations extending perpendicular to the corrugations in the outer component. Reinforcing strands are in both the liner and the outer component, extending perpendicular to the respective corrugations thereof. Interlocking top flanges are on the top edges of the outer component, and interlocking bottom flanges are on the bottom edges thereof. The interlocking bottom flanges include a chevron shaped locking slot in one flange and a locking tab on an opposed bottom flange. Folds extend across the bottom flanges to enable them to deflect and slide relative to one another during set up of the container. Vertical scores in the liner are pre-broken prior to laminating it to the outer component.

Owner:INT PAPER CO

A Process for Producing Hydrogen and Graphitic Carbon from Hydrocarbons

In accordance with the present invention, there is provided a process for producing hydrogen and graphitic carbon from a hydrocarbon gas comprising: contacting at a temperature between 600° C. and 1000° C. the catalyst with the hydrocarbon gas to catalytically convert at least a portion of the hydrocarbon gas to hydrogen and graphitic carbon, wherein the catalyst is a low grade iron oxide.

Owner:HAZER GRP

Method for preparing ultramarine blue with coal gangue calcination

InactiveCN101318661ATake advantage ofProtect environmentPigmenting treatmentSilicon compoundsSodium BentoniteInternational market

The invention relates to a method for producing an ultramarine, in particular to a method for producing an ultramarine by calcining gangue. The method comprises the steps as follows: materials are selected and mixed, the materials comprise gangue powder, quartz powder, soda, sulfur, anhydrous sodium sulphate, charcoal, bentonite, and are ground, filled into a boiler and a furnace, calcined, taken out from the furnace, selected, preliminarily washed, ground, filtered pressing, dried, and crushed, the product obtained is measured, packed and warehoused. The method for producing the ultramarine has the beneficial effect of 1 making full use of waste gangue and protecting environment, 2 meeting the domestic market demand and participating in the international market competition, and earning foreign exchange by export, 3 facilitating industrial restructuring and upgrading and updating of products, 4 relieving local employment pressure and promoting the development of local economy.

Owner:大同市晟威矸石有限责任公司

Methods and compositions for combination immunotherapy

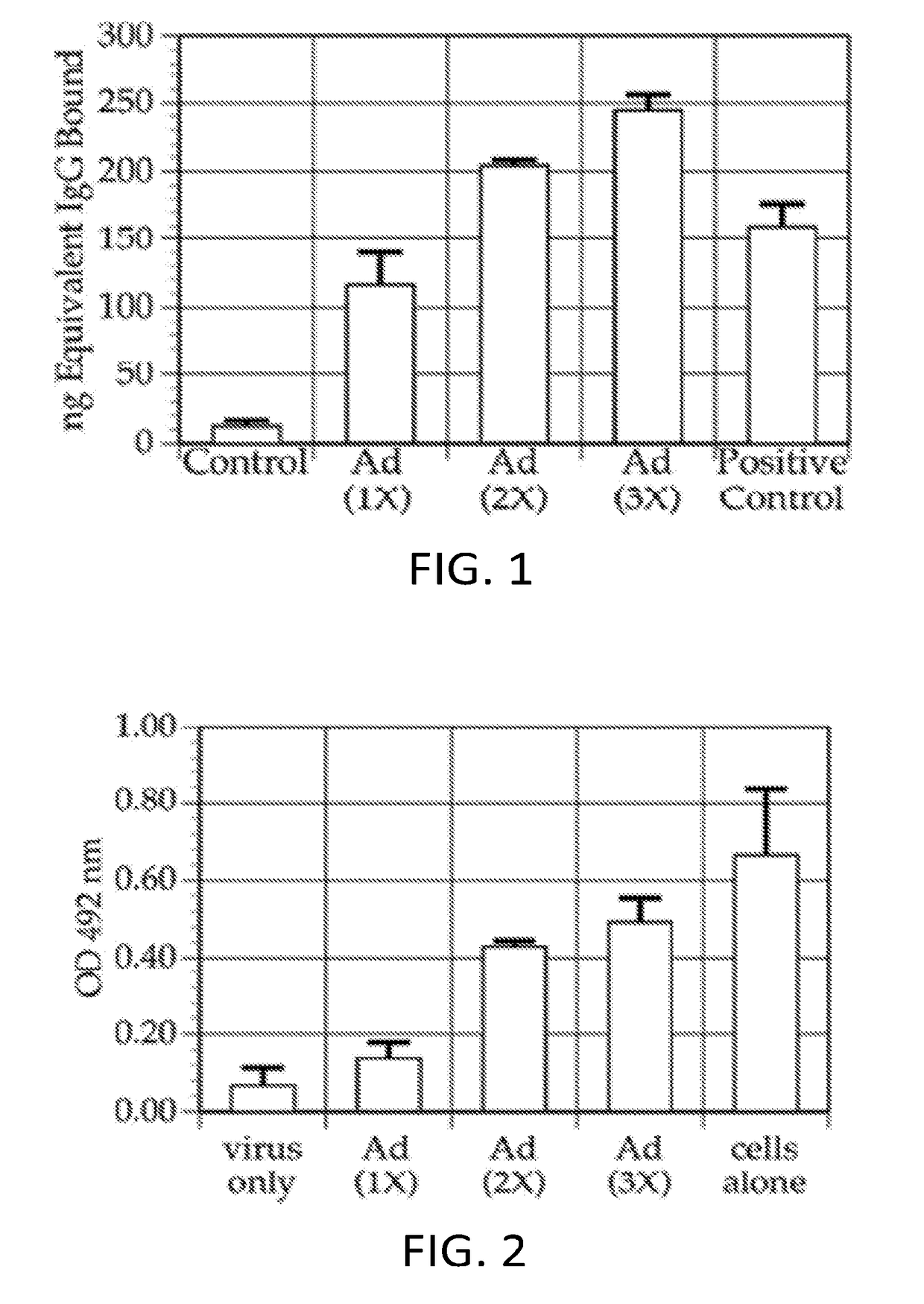

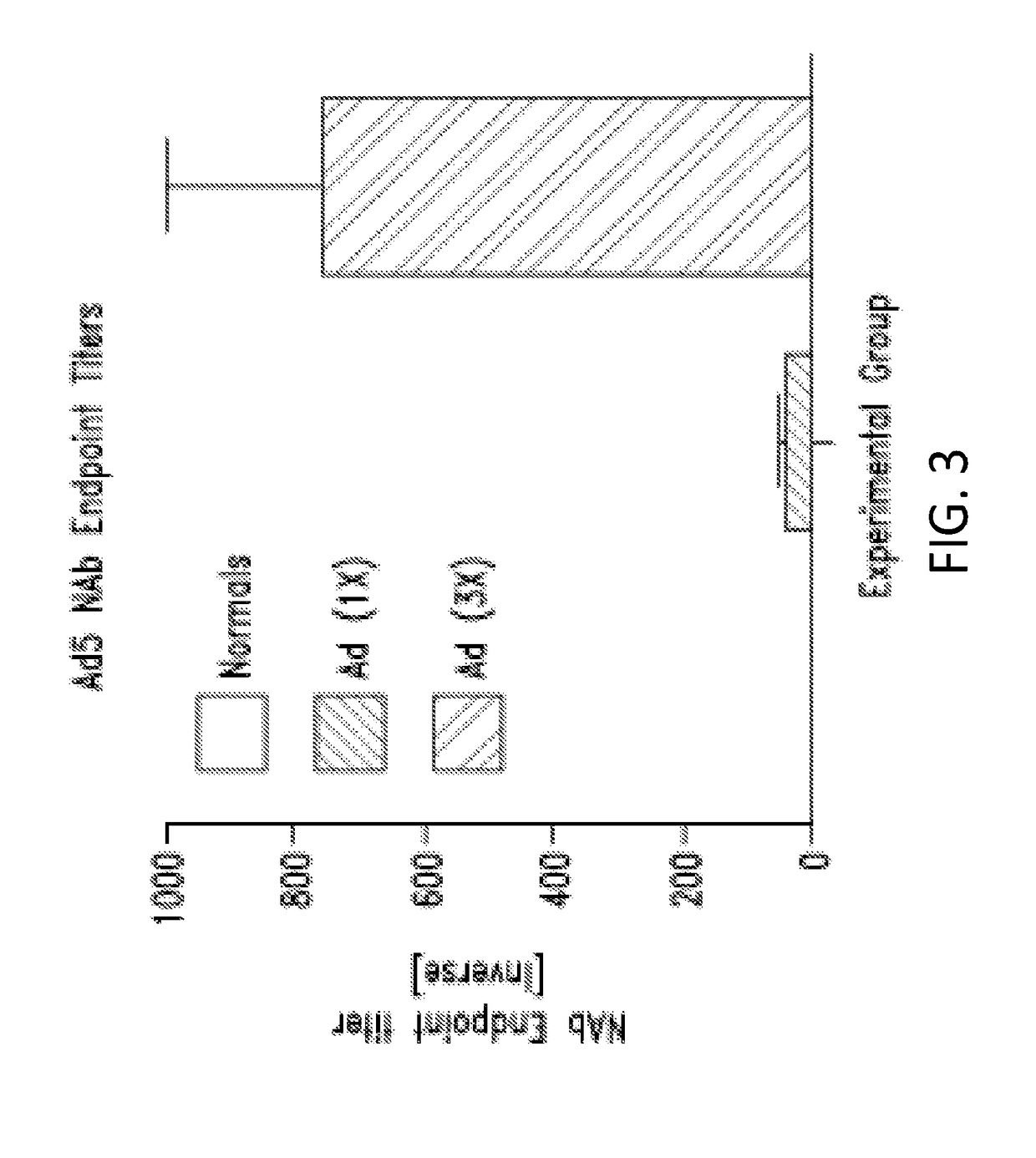

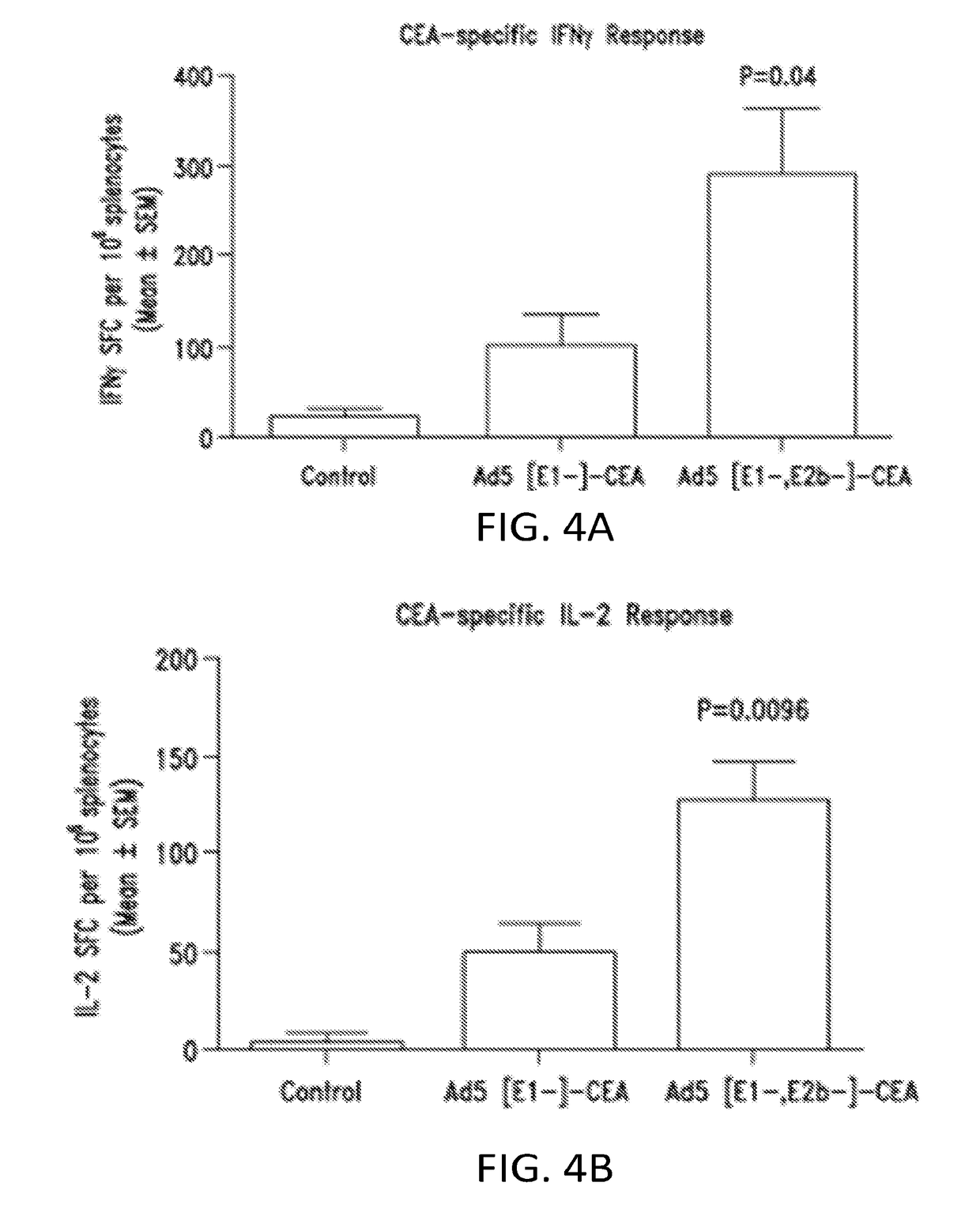

ActiveUS20180187211A1Permit immunizationOvercome obstaclesOrganic active ingredientsTumor rejection antigen precursorsVaccinationPreexisting immunity

Methods for generating immune responses using adenovirus vectors that allow multiple vaccinations with the same adenovirus vector and vaccinations in individuals with preexisting immunity to adenovirus are provided.

Owner:ETUBICS CORP

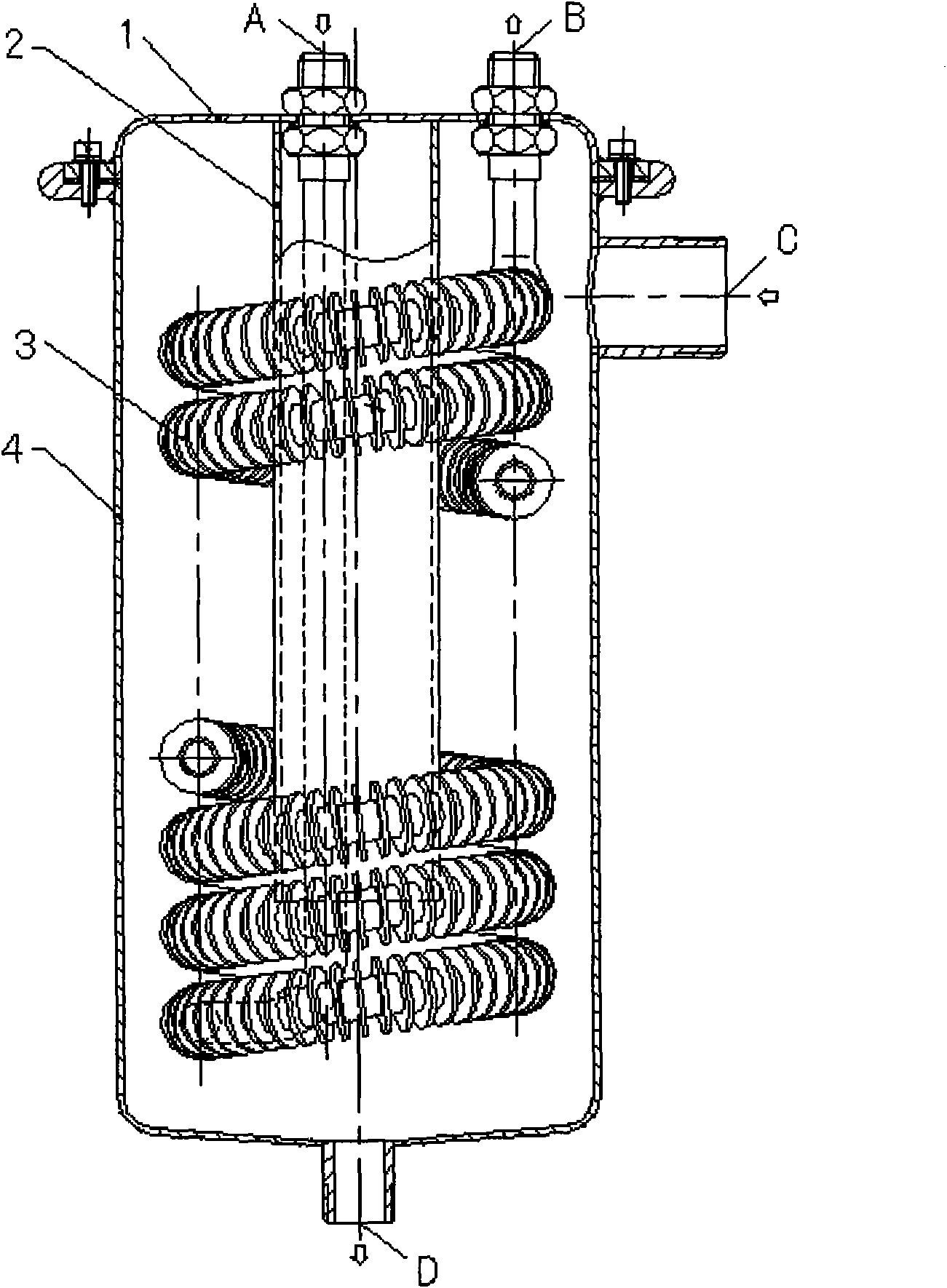

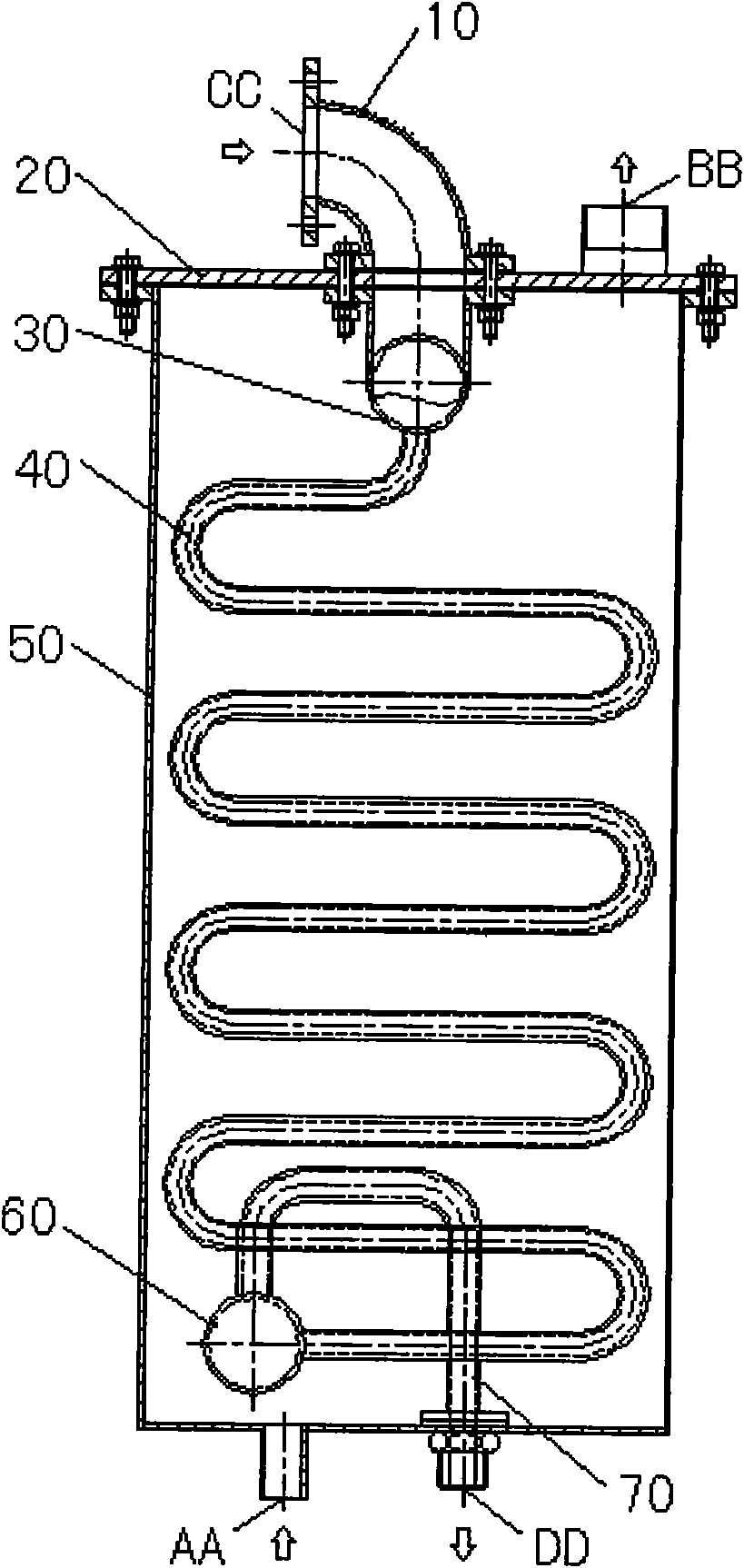

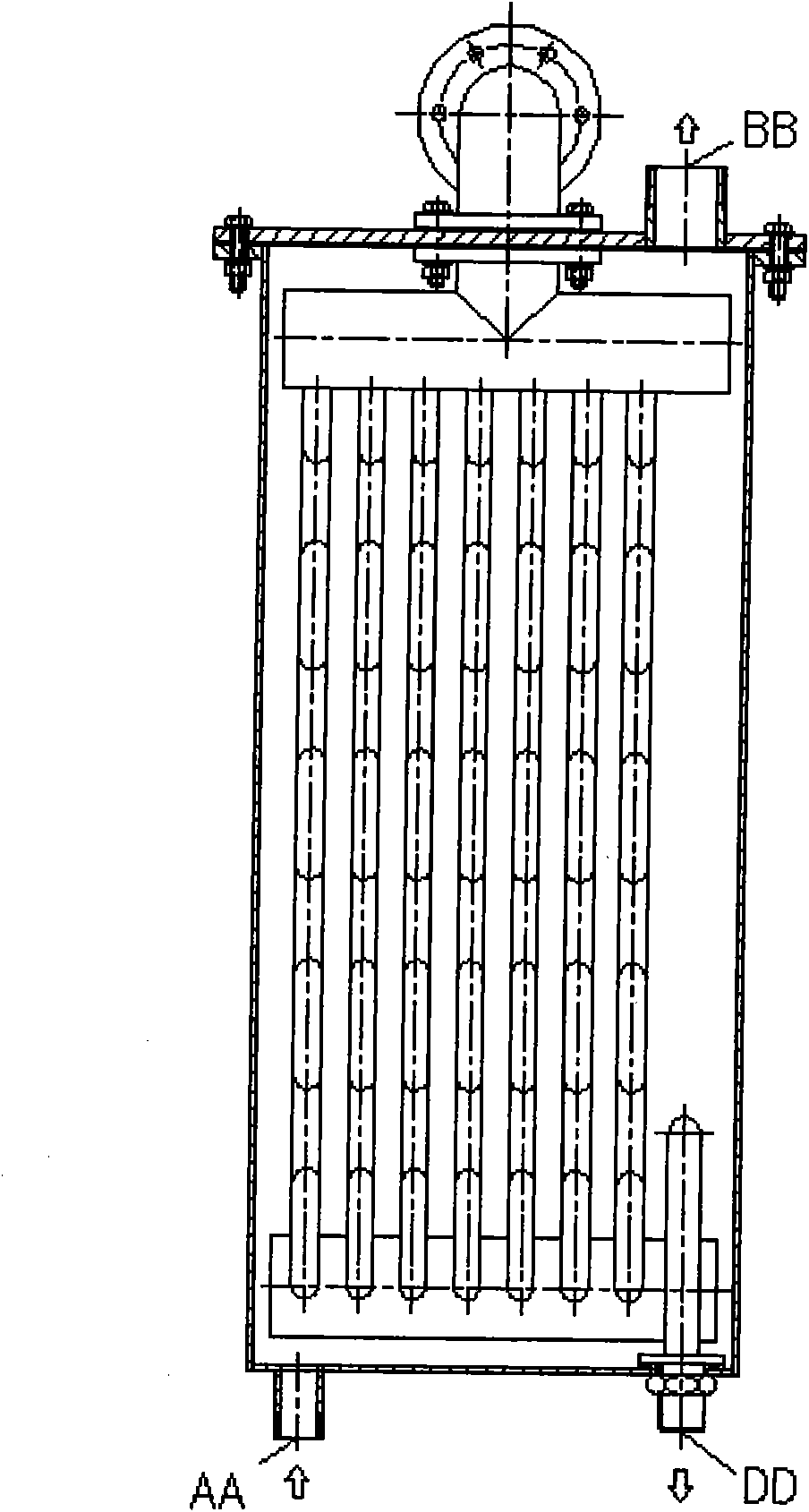

Distiller condenser with solvent inflow structure in fur degreasing machine

InactiveCN101638697AReduce consumptionReduce solvent return temperaturePre-tanning chemical treatmentSteam/vapor condensersCooling coilSolvent

The invention relates to a distiller condenser with a solvent inflow structure in a fur degreasing machine. The structure of the distiller condenser is changed from the prior cylindrical structure toa square structure; the prior spiral cooling coil is changed into a condensing coil consisting of an upper bus tube, a lower bus tube, a plurality of rows of condensing bent pipes, a gaseous solvent inlet and a liquid returning bent pipe; in the prior structure, cooling water flows through the inside of the condensing coil, and the outside of the condensing coil is provided with a gaseous solventcondensing chamber; and the prior structure is changed into a structure in which gaseous solvent passes through the inside of the condensing coil to be condensed and the outside of the condensing coilis provided with a cooling water flowing chamber. The distiller condenser has the advantages that: the distiller condenser can reduce the consumption of the cooling water in operation, take full useof the cold energy of the cooling water, effectively reduce the liquid returning temperature of the solvent, and effectively prevent the overflow of the gaseous solvent from causing personal injuriesto operators and environmental pollution; and the condensed and recycled solvent does not damage degreased and cleaned furs and degrade fur grade due to acidification or component decomposition.

Owner:上海雅森洗涤设备有限公司

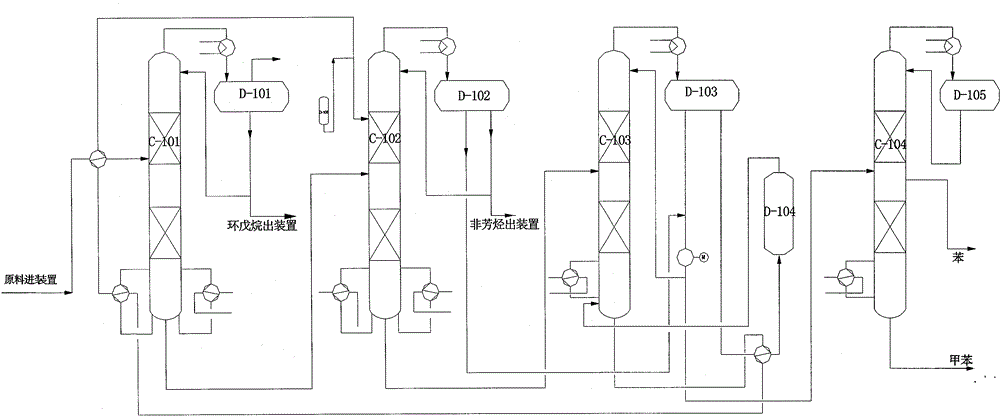

Novel extraction process for aromatic hydrocarbons

InactiveCN105085152AAvoid decompositionReduce decompositionDistillation purification/separationHydrocarbonsDecompositionReboiler

The invention relates to a novel extraction process for aromatic hydrocarbons. Key improvements in the novel extraction process are that a depentanizing tower, an extracting and rectifying tower, a solvent recovering tower and a benzene tower employ novel inward-bending arc fin flat-ring filling material and a unique liquid distribution apparatus and filling material support apparatus are cooperatively used, so resistance drop, a pressure drop ratio and loads of the towers are effectively reduced and production capacity is substantially improved. The depentanizing tower and the extracting and rectifying tower employ main and assistant reboilers for heat adjustment, so optimization of heat supply is realized and long-period stale operation of the towers is guaranteed. Meanwhile, since a sulfonic acid ionic liquid is used as a cosolvent, influence of decomposition and corrosion of the solvent is reduced, usage cost of equipment is lowered, the service life of the solvent is prolonged, the problems of high contents of aromatic hydrocarbons and napthene and easy azeotropy of aromatic hydrocarbons in the extracting process of aromatic hydrocarbons are effectively overcome, investment cost and operation cost of the facilities are substantially reduced, and substantial economic benefits are obtained.

Owner:BEIJING HUAHETUO TECH DEV CO LTD

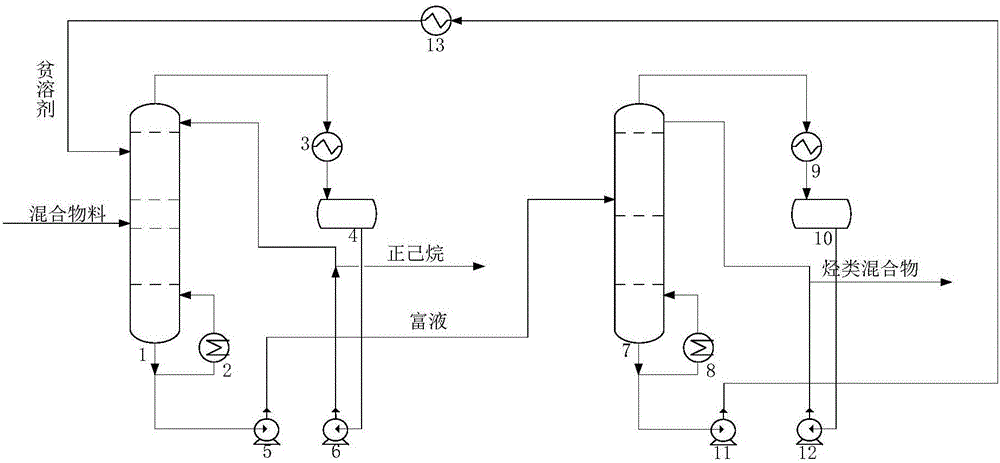

Device and method for purifying n-hexane with N,N-dimethylacetamide solvent

InactiveCN106518598ASmall running lossLower gradeDistillation purification/separationExtractive distillationReboilerEngineering

The invention provides a device and a method for purifying n-hexane with a N,N-dimethylacetamide solvent. The device comprises an n-hexane tower, an n-hexane tower top condenser, an n-hexane tower reflux tank, an n-hexane tower reflux pump, an n-hexane tower reboiler, an n-hexane tower reactor liquid pump, a solvent regeneration tower, a solvent regeneration tower top condenser, a solvent regeneration tower reflux tank, a solvent regeneration tower reflux pump, a solvent regeneration tower reboiler, a solvent regeneration tower reactor liquid pump and a poor solvent cooler. The method comprises the following steps: firstly, introducing mixed materials into the n-hexane tower, wherein the n-hexane tower is an extraction and rectification tower; introducing N,N-dimethylacetamide, serving as an extraction solvent, from the upper part of the n-hexane tower. A tower top n-hexane product is up to 99.1 percent in purity. Compared with the conventional process, the method has the advantages of simple flow, high product purity, small solvent ratio, low level of a required thermal source in a solvent regeneration process, small loss amount of the solvent and the like.

Owner:DALIAN UNIV OF TECH

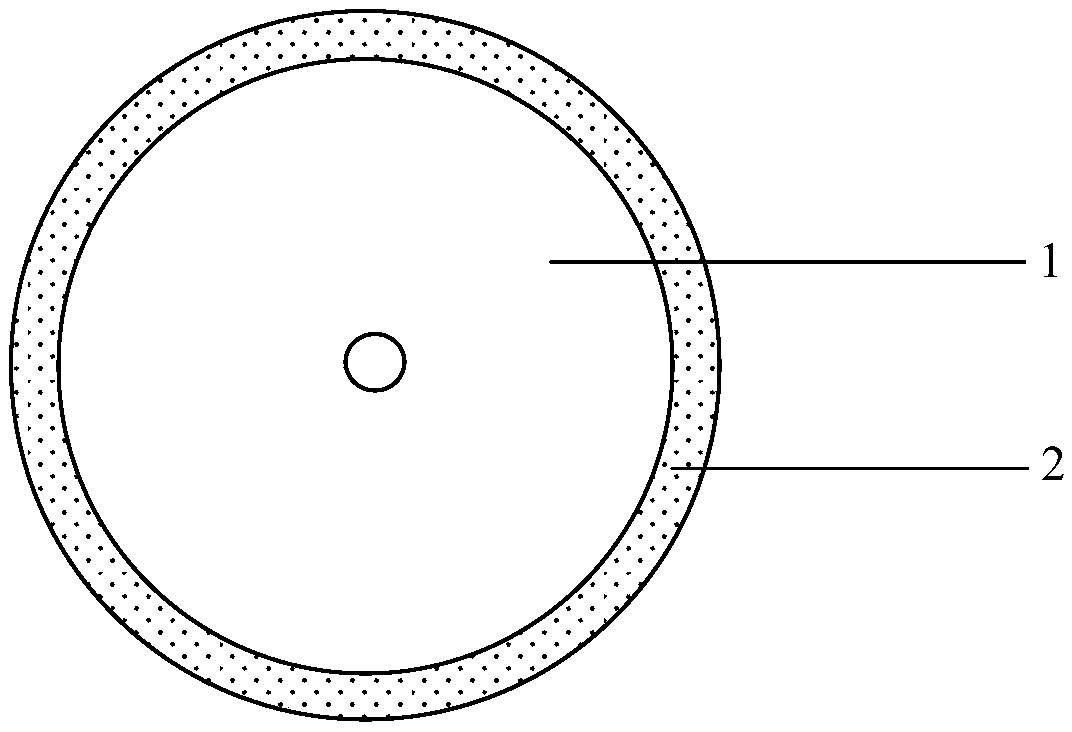

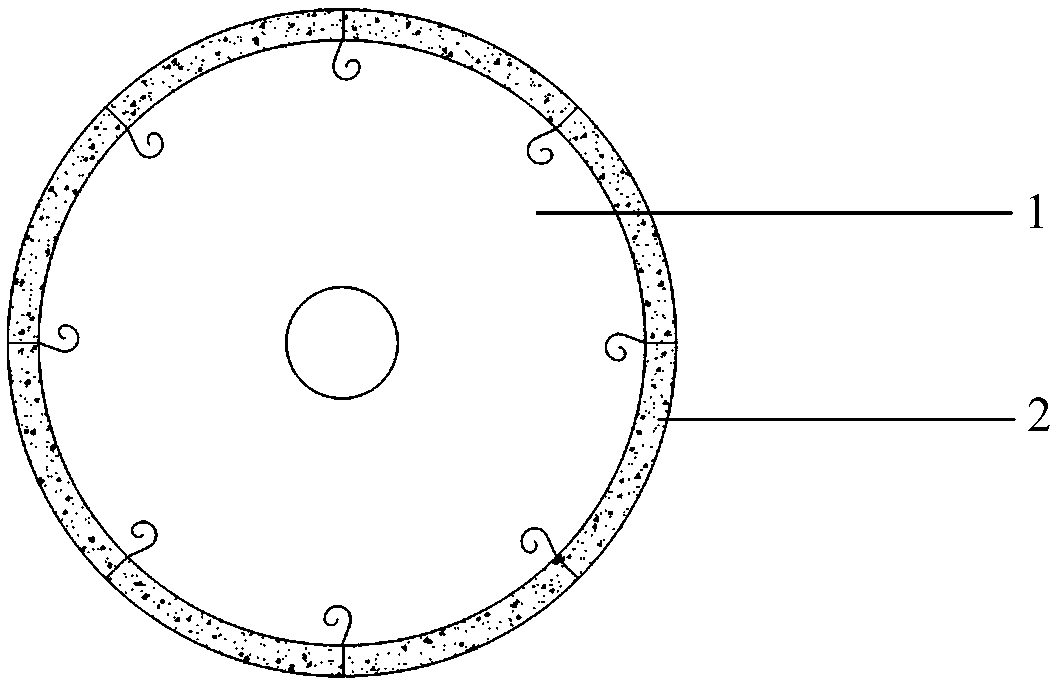

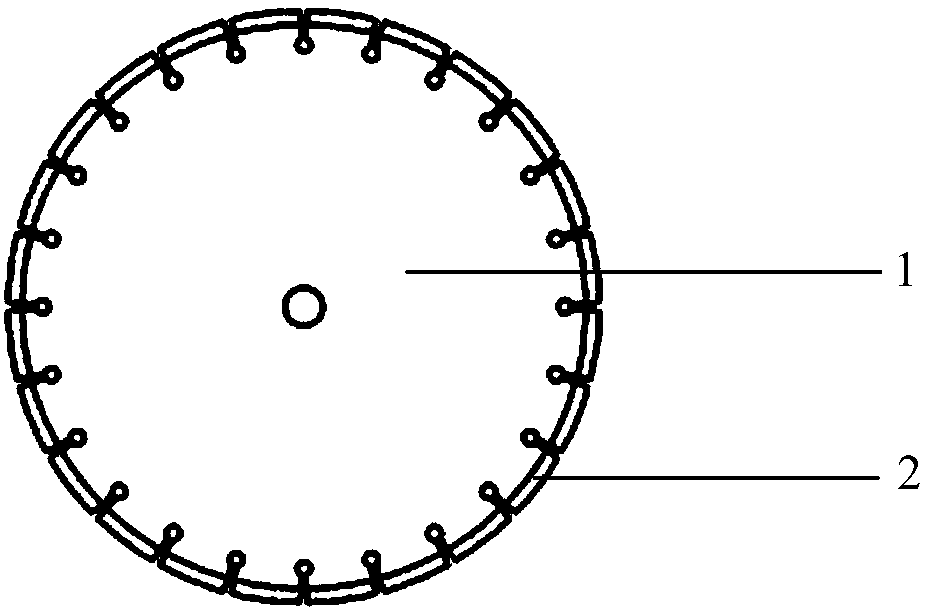

Low-temperature sintering matrix powder, diamond tool adopting same and preparation method thereof

ActiveCN108889937AAvoid damageLower gradeTransportation and packagingMetal-working apparatusRare-earth elementGraphite

The invention discloses low-temperature sintering matrix powder, a diamond tool adopting the same and a preparation method thereof. The matrix powder is prepared from, by mass, 5-17% of Sn, 5-25% of Co, 1-10% of Me, the balance Cu and inevitable impurities, wherein Me is selected from at least one of amorphous powder, pre-alloying powder containing rare earth elements, Ni and graphite. The matrixpowder is copper-based matrix powder, so that the sintering temperature is obviously decreased, energy loss is lowered, the mold loss is lowered, and the production cost is lowered; meanwhile, damageto diamond during high-temperature sintering is reduced, the level of diamond adopted by the tool can be lowered properly, and the material cost of the tool is lowered.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Chinese medicament for treating secondary pulmonary infection and preparation method thereof

InactiveCN102657793AImprove immunityReduce inflammationAntiinfectivesRespiratory disorderPulmonary infectionCodonopsis

The invention discloses a Chinese medicament for preventing and treating secondary pulmonary infection. The Chinese medicament is characterized by comprising the following raw materials in percentage by weight: 11.2 percent of pilose asiabell root, 8.3 percent of dwarf lilyturf root, 8.3 percent of rehmannia root, 6.7 percent of skullcap, 6.7 percent of ginger processed pinellia, 8.3 percent of snakegourd fruit, 8.3 percent of tuckahoe, 8.3 percent of big-head atractylodes rhizome, 6.1 percent of platycodon grandiflorum, 6.7 percent of tangerine peel, 6.1 percent of perilla seed, 6.7 percent of mulberry bark and 8.3 percent of coix seed. A preparation method comprises the following steps of: putting the medicaments into a cloth bag, and soaking in cold water for 30 minutes; putting the medicaments into a decocting machine, adding a proper amount of water, setting the temperature of the machine to be 100 DEG C, and decocting for 30 minutes; and filtering after decocting to remove decoction residue, and filling the medicinal liquid into a vacuum bag. The Chinese medicament solves the problem that a large quantity of antibiotics is used after pulmonary infection of critical infection at present, and is suitable for clinical treatment.

Owner:修相成

A kind of polyurethane moisture curing hot melt adhesive for edge sealing

ActiveCN110184019BSimple structureUnique performancePolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention relates to a polyurethane moisture curing hot melt adhesive for edge sealing, which is prepared from the following raw materials: polyester polyol 7360, 5-polyester polyol 7380, polyester polyol 7150, 1 EA28400, polyester polyol L-3017, polyester polyol H3022, copolyester resin S1402, and MDI-100. The polyurethane moisture curing hot melt adhesive for the edge sealing is prepared byweighing the raw materials, adding polyester polyol and the copolyester polyester resin into a reaction kettle, performing heating-up, melting and dehydration till no bubbles escape from a liquid material, adding MDI-100, heating up to 110-120 DEG C for a polymerization reaction for 1.5h till a mole percentage of residual isocyanic acid radicals reaches 0.5-2%, and performing filtration and discharging when a product is hot. The prepared high-adaptability polyurethane hot melt adhesive for the edge sealing has excellent bonding strength, temperature tolerance, chemical resistance and aging resistance.

Owner:广州市永隆新材料研究院有限公司

Reinforced cross-laminated bulk container

A reinforced cross laminated corrugated paperboard bulk container has an outer component and an inner liner laminated to the outer component with the liner having corrugations extending perpendicular to the corrugations in the outer component. The bottom edges of the sidewalls include a first pair of flaps and a second pair of flaps each of which foldably extend outwardly therefrom and wherein each of the second pair of flaps having a pair of spaced apart triangularly shaped slots formed therein and wherein each of the first pair of flaps includes a pair of locking tabs formed on opposed end of the respective first pair of flaps which are engaged with the slots on the second pair of the flaps to securely close the bottom of the container. Vertical scores in the liner are pre-broken prior to laminating it to the outer component.

Owner:INT PAPER CO

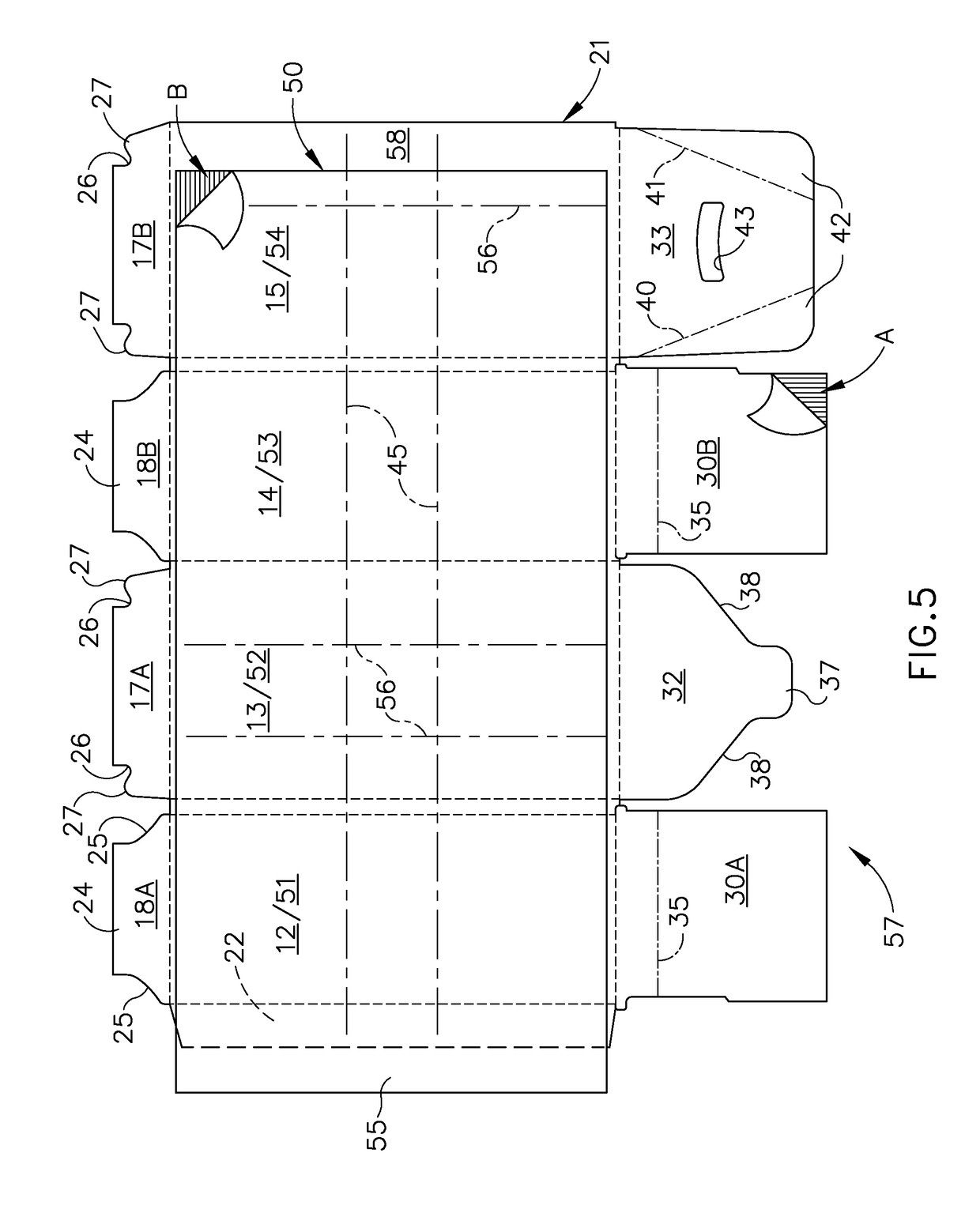

Production process of outdoor wooden trestle floor

InactiveCN106272891AMake up for color differenceLower gradeSidewalk pavingsFeeding arrangmentsFiberSulfate

The invention discloses a production process of an outdoor wooden trestle floor. The production process comprises main raw materials of fast-hardened sulfate aluminum cement, wood chips, fly ash and fibers; firstly, the materials serving as the raw materials are uniformly stirred as slurry; the slurry is divided into a bottom material, an upper material and a middle material; then, the bottom material and the upper material are respectively paved; the pavement of the bottom material is to adopt a wooden trestle mold to pave bottom slurry, and bottom gridding cloth is paved in the bottom slurry; the pavement of the upper material is to adopt a flat mold to pave upper slurry, and upper gridding cloth is paved in the upper slurry; the middle material is paved on the bottom material after pavement of the bottom surface; the upper material covers the middle material after pavement of the middle material; the mold is sent to a hot press for hot-pressed molding; and finally, the mold is stripped after being discharged from the press, and is sent to a curing kiln for curing. The production process uses the cement as a gel material, uses the saw dust as a filling material, and uses the gridding cloth as reinforcing and toughening materials.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Low-temperature sintered matrix powder, diamond tool using the matrix powder and preparation method thereof

ActiveCN108889937BAvoid damageLower gradeTransportation and packagingMetal-working apparatusRare-earth elementGraphite

The invention discloses a low-temperature sintered carcass powder, a diamond tool using the carcass powder and a preparation method thereof. The carcass powder is composed of the following components according to mass percentage: Sn 5%-17%, Co 5%-25%, Me 1%-10%, the rest is Cu and unavoidable impurities, wherein Me is selected from amorphous At least one of powder, pre-alloyed powder containing rare earth elements, Ni, and graphite. The carcass powder of the present invention is a copper-based carcass powder, so that the sintering temperature is significantly reduced, energy consumption is reduced, mold loss is reduced, and production costs are reduced; at the same time, damage to diamonds during high-temperature sintering is reduced, and tools can be appropriately reduced. The grade of diamond used reduces the material cost of the tool.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Method for preparing ultramarine blue with coal gangue calcination

InactiveCN100595145CTake advantage ofProtect environmentPigmenting treatmentSilicon compoundsSodium BentoniteULTRAMARINE BLUE

The invention relates to a method for producing an ultramarine, in particular to a method for producing an ultramarine by calcining gangue. The method comprises the steps as follows: materials are selected and mixed, the materials comprise gangue powder, quartz powder, soda, sulfur, anhydrous sodium sulphate, charcoal, bentonite, and are ground, filled into a boiler and a furnace, calcined, takenout from the furnace, selected, preliminarily washed, ground, filtered pressing, dried, and crushed, the product obtained is measured, packed and warehoused. The method for producing the ultramarine has the beneficial effect of 1 making full use of waste gangue and protecting environment, 2 meeting the domestic market demand and participating in the international market competition, and earning foreign exchange by export, 3 facilitating industrial restructuring and upgrading and updating of products, 4 relieving local employment pressure and promoting the development of local economy.

Owner:大同市晟威矸石有限责任公司

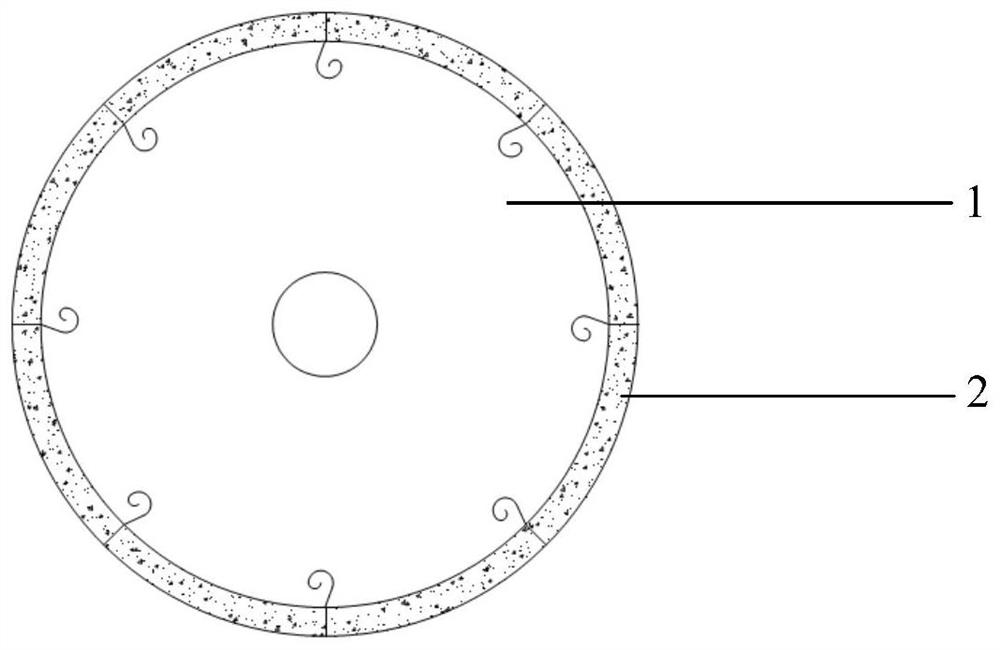

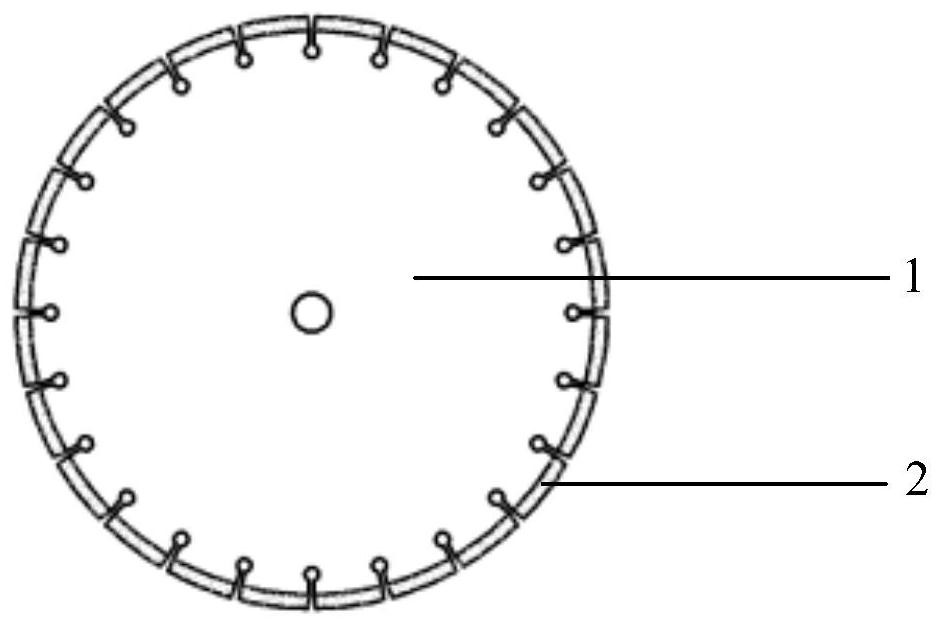

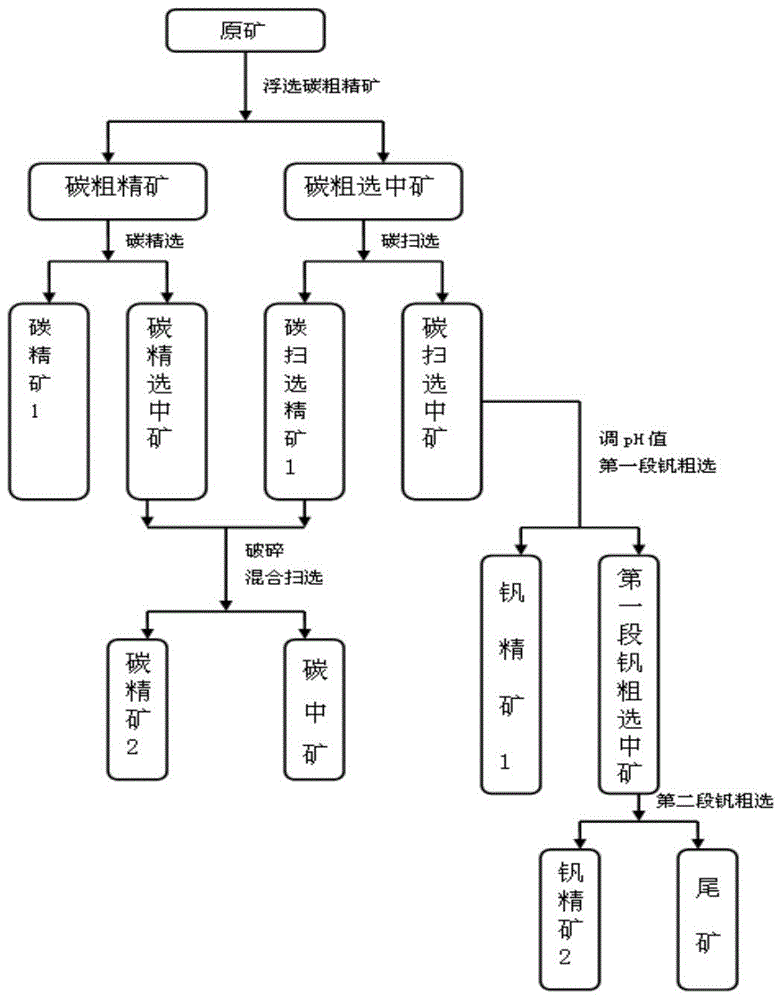

A method for extracting vanadium pentoxide and carbon from low-carbon stone coal mines

ActiveCN104138806BAchieve separationAchieve enrichmentFlotationProcess efficiency improvementCoalPollution

The invention relates to a method for extracting V2O5 and carbon from a low-carbon stone coal mine, and belongs to the field of beneficiation and metallurgy united technology. According to the method, the low-carbon stone coal mine with the grade of V2O5 larger than or equal to 0.65% and the mass percentage of carbon smaller than or equal to 18% is taken as the raw material, flotation enrichment is performed on carbon and vanadium respectively, industrial fuel with the combustion value of 2,400-3,100 cal / g as well as a vanadium-rich solution is obtained through leaching, and V2O5 is obtained by subjecting the vanadium-rich solution to purification, dissolving, vanadium precipitation and calcination. According to the technology, a pollution-free smelting process is performed through flotation enrichment of carbon and vanadium in stone coal, the smelting treatment quantity is reduced, carbon resources in the stone coal are used sufficiently, the production cost and investment cost are reduced, the total V2O5 recovery rate can reach 78%-82%, the utilization rate of carbon can reach 70%-85%, the low-carbon stone coal mine with low V2O5 grade can be treated, and the method has the advantages of low production cost, environment friendliness and the like and facilitates industrial application.

Owner:CENT SOUTH UNIV

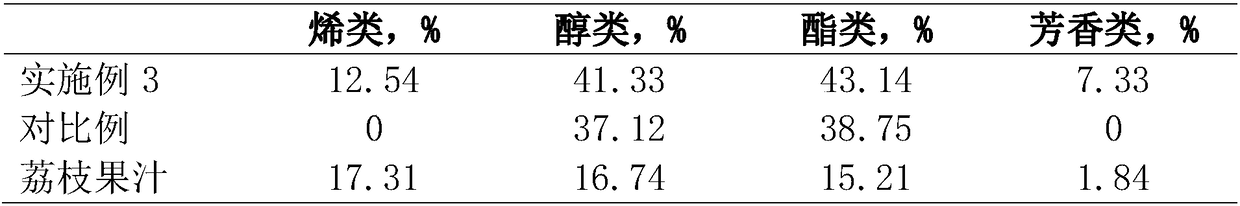

Rich-fruity aroma lychee wine and preparation method thereof

InactiveCN108359564ANatural aroma retentionSmall amount of inoculumAlcoholic beverage preparationDiseaseYeast

The invention discloses rich-fruity aroma lychee wine and a preparation method thereof. The preparation method comprises the following steps: 1), selecting and treating raw materials: selecting freshlychees, removing branches, fruits suffering from diseases and pests, rotten fruits, decayed fruits and immature fruits, washing, draining, peeling, removing kernels, and removing decayed and rotten pulps and residual kernels; 2), squeezing the lychee pulps, collecting juice, adding 14.0-15.0w / w% of a lychee extracting solution into the juice, mixing uniformly, and transferring to a fermentation tank; 3), fermenting: adjusting the pH value to 3.0 and the alcoholic strength to 4 degrees, and then adding high-activity yeast liquid according to an addition amount of 5% by weight of fermentation liquor, and fermenting for 3-4 days at the fermentation temperature of 20-21 DEG C; 4), blending: transferring the fermentation liquor obtained in the former steps to another tank, blending, performingstanding for clarifying, filtering, filling and sterilizing to obtain a finished product.

Owner:GUANGXI YUNHENG WINERY

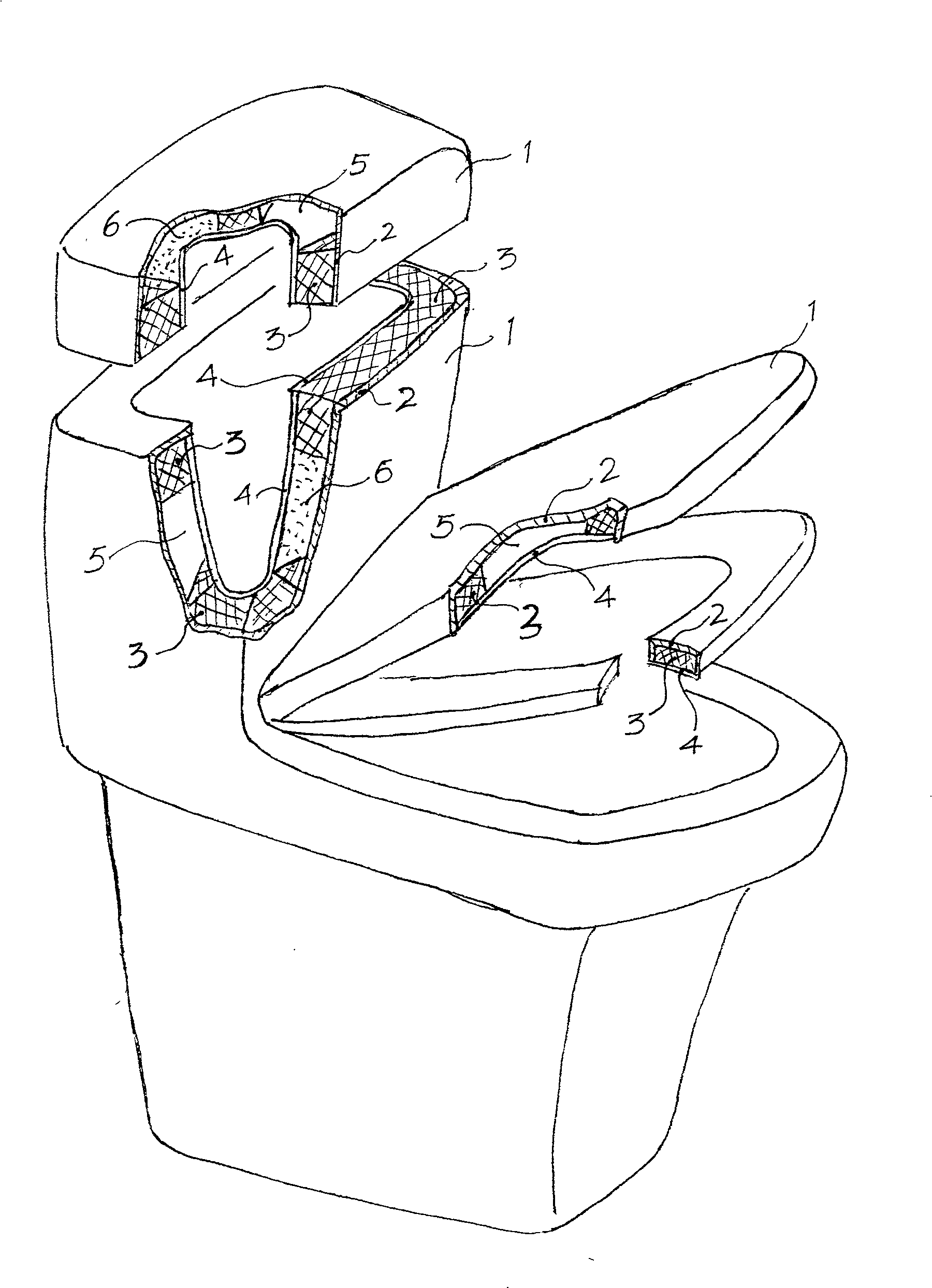

Toilet bowl with acrylic and glass fiber composite structure and manufacturing method thereof

InactiveCN100515299CSave materialEasy to operateSynthetic resin layered productsBathroom accessoriesGlass fiberSurface finish

Owner:谢兴明

A kind of forward and reverse flotation method of low-grade siliceous calcareous phosphate rock

The invention relates to a forward and reverse flotation method of low-grade siliceous-calcium collophosphine ore. In the method, phosphate minerals are added to the crushed siliceous-calcium collophosphine ore for flotation adjustment. Collectors and collectors for pulping, add water to dilute and then enter the positive flotation system for positive flotation of phosphate minerals; positive flotation concentrate desliming and desliming, enter the desiliconization reverse flotation stirring tank, the material after pulping Enter the reverse flotation desiliconization system for reverse flotation of siliceous gangue minerals; desiliconization and reverse flotation concentrates remove part of the water, and then grind the ore, add inhibitor sulfuric acid and magnesium collector fatty acid soap for slurry adjustment , carry out magnesium reverse flotation, and the product in the tank is the final phosphorus concentrate, which is concentrated, filtered and dried to obtain the finished phosphorus concentrate. The method of the present invention is more reasonable for the process design of processing low-grade siliceous-calcareous colloidal phosphate rock, and it can effectively improve the P of phosphorus concentrate. 2 o 5 Grade, reduce MgO content, that is to effectively improve the quality of phosphorus concentrate.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Banana fresh-keeping and variable-temperature gas-regulation ripening technique process flow

InactiveCN101347148BImprove controllabilityRealize factoryFruit and vegetables preservationBatch processingVacuum pack

The present invention discloses a banana preservation and variable-temperature air-adjusting ripening flow. Fruit lossless harvest, batch processing and vacuum packaging are carried out by constructing a banana air-adjusting storehouse; air-adjusting preservation and a series flow of variable-temperature air-adjusting ripening are utilized for banana preservation and accelerating maturity. The flow can obviously improve the exterior and interior quality of the banana finished product and achieve the controllability of ripening period. The product can be on a par with imported banana and has the advantages of dense fruit flavor, good taste, long shelf life, and the like, thus having good market prospect.

Owner:漳州市庄怡农业发展有限公司

Process for high pressure compaction of fluorite ball with sodium silicate as binder

The invention discloses a process for high pressure compaction of a fluorite ball with sodium silicate as a binder. The process comprises the following steps: uniformly mixing fluorite flotation powder, fluorite ore powder and a sodium silicate solution in a mixer; placing an obtained mixed material in a high pressure ball press machine for extrusion so as to obtain a ball; and roasting and cooling the ball. The fluorite ball obtained through high pressure compaction with sodium silicate as the binder has a high grade, a wide and high range (with the content of CaF2 in a range of 75 to 95 wt% and normally no less than 85 wt%), a reasonable reaction specific surface area and performances and mechanical strength satisfying requirements for a flux used in metal smelting. The fluorite ball provided by the invention can be extensively used in metal smelting in a blast furnace and for special steel, stainless steel (all the varieties), nonferrous metals and the like and enables a slugging speed to be accelerated and smelting time to be shortened; compared with a fluorite block, application amount of the fluorite ball is greatly reduced, and production cost and the quantity of discharged slag are reduced.

Owner:郴州德宇高新材料有限公司

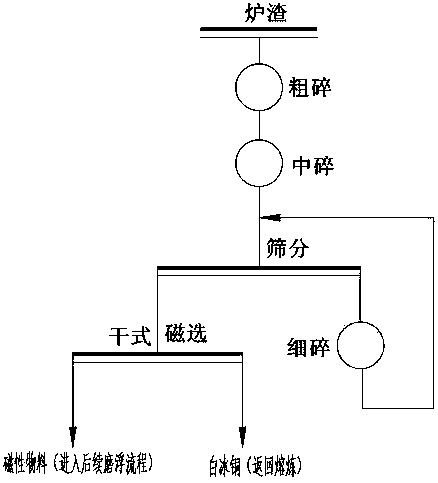

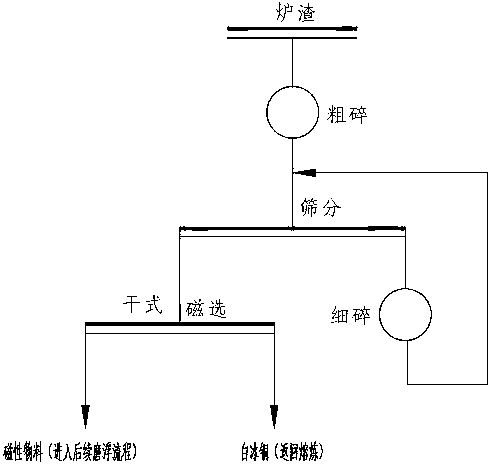

A treatment process for copper smelting converter slag containing high-grade matte

The invention discloses a high-grade matte-contained copper smelting converter slag treatment process. The process crushes and screens converter slag to feed in a drum type dry magnetic separator for magnetic separation; a white matte nonmagnetic material obtained by magnetic separation directly serves as a copper concentrate product for smelting; and a magnetic material is fed in an ore grinding classification flow consisting of a ball mill and classification equipment, and then is fed in a flotation flow. The process achieves early recovery of copper ores as far as possible to the greatest extent, reduces the material grinding quantity, reduces the flotation grade, improves the treatment capacity of dressing plants, saves the construction investment and the treatment cost of the converter slag, directly improves the enterprise benefit, and solves the development and the utilization of converter slag resources.

Owner:CHINA NERIN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com