Distiller condenser with solvent inflow structure in fur degreasing machine

A technology of condenser and degreasing machine, which is applied in steam/steam condenser, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., which can solve the personal injury of operators , gaseous solvent overflow, tetrachlorethylene solvent acidification or chemical composition decomposition, etc., to prevent personal injury and environmental pollution, reduce the return temperature of solvent, and reduce the grade of fur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

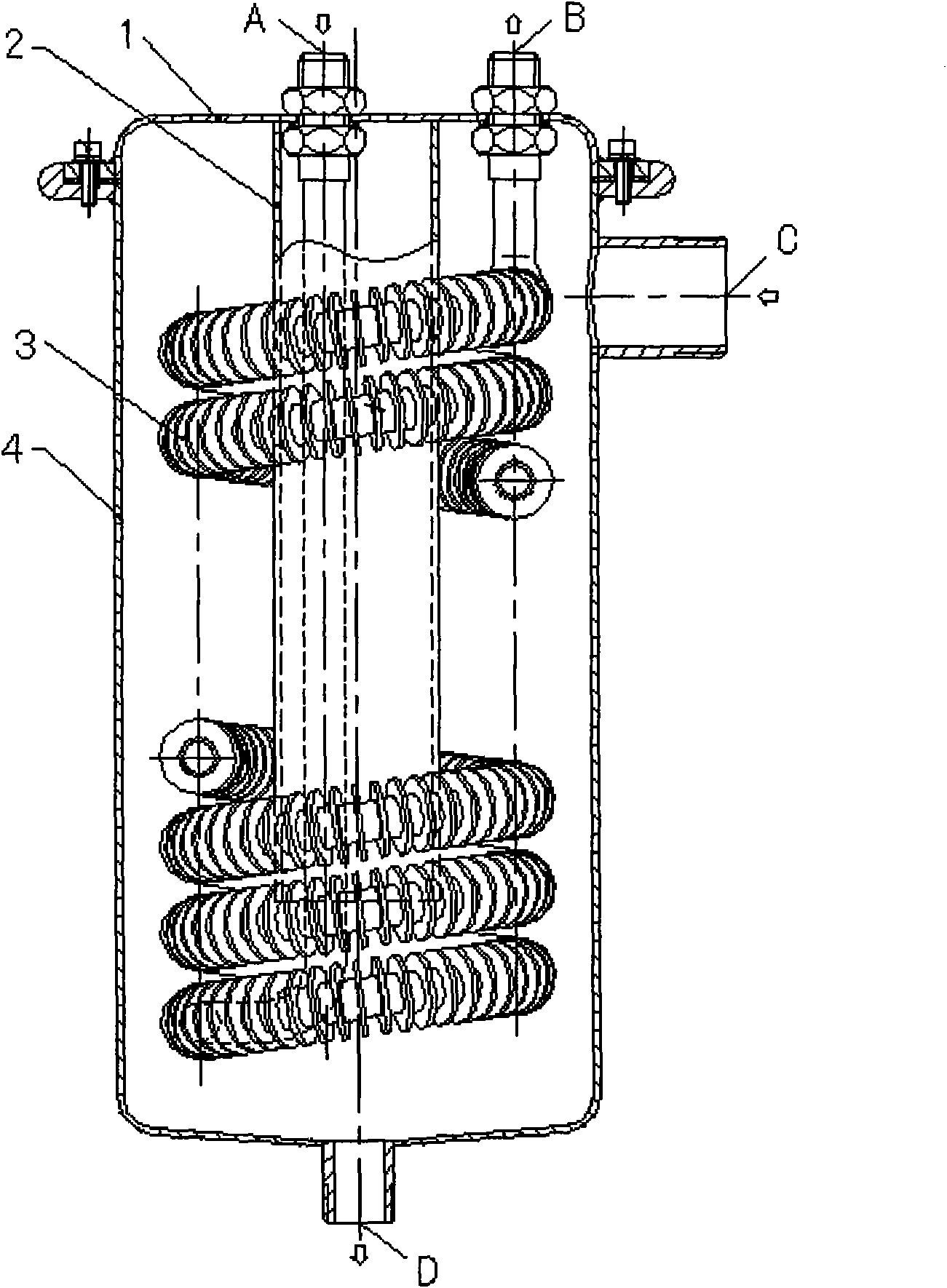

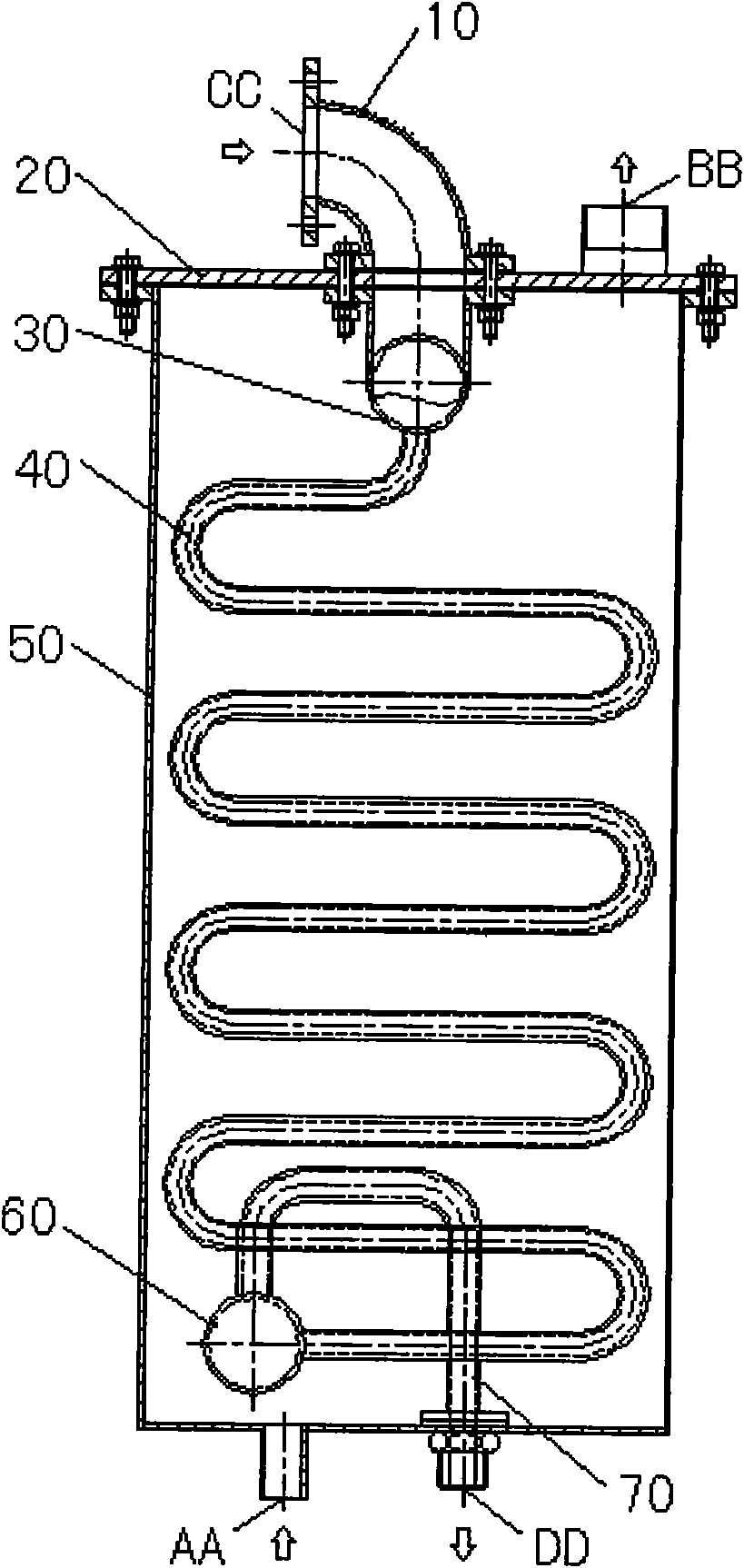

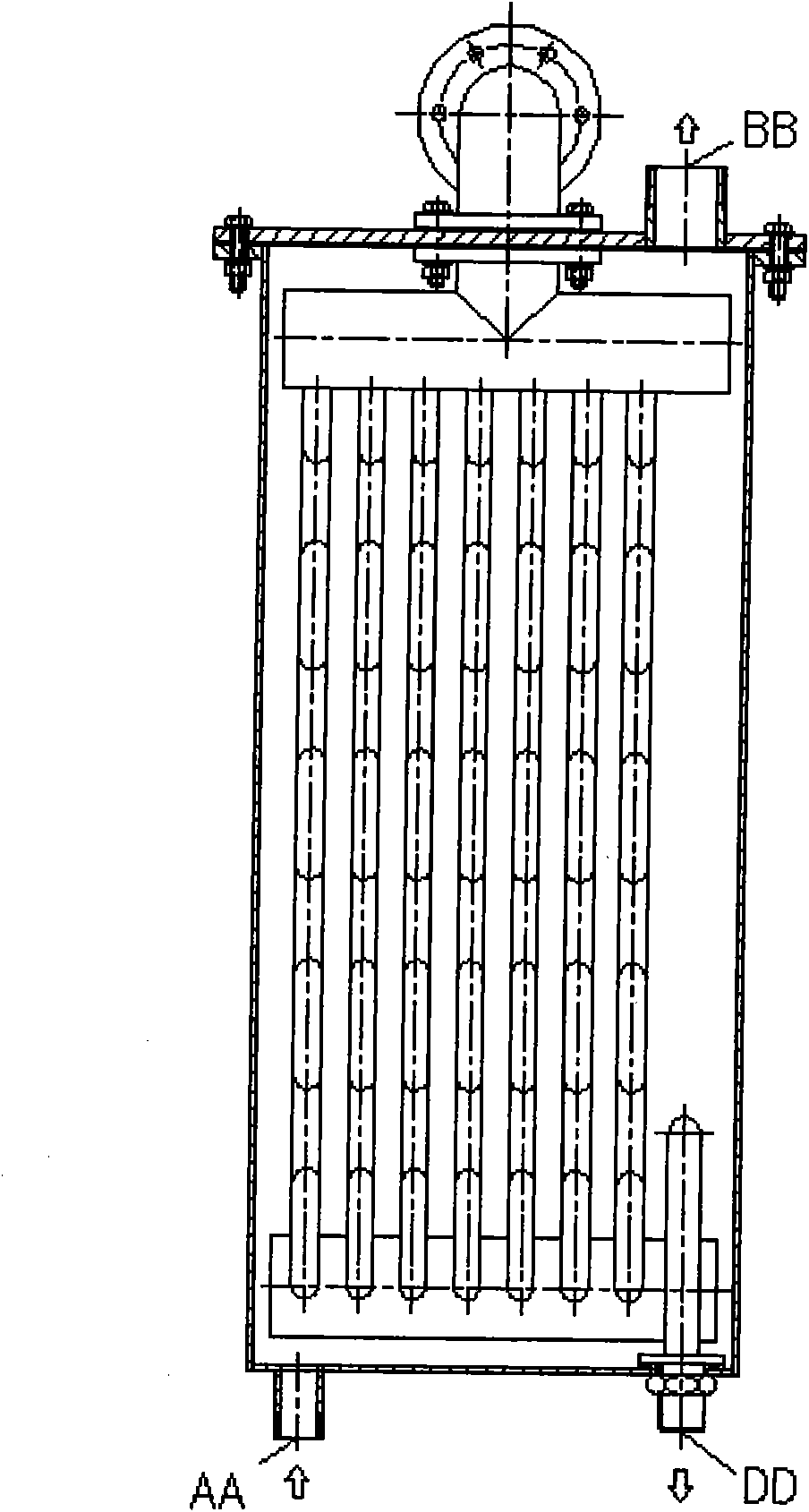

[0019] Depend on figure 2 , image 3 It can be seen that the present invention includes: a condenser cylinder 50; the condenser cylinder 50 is in sealing connection with the condenser cylinder cover 20 on the upper end surface; a cooling water inlet connection AA, a cooling water outlet connection BB, A gaseous solvent connection inlet CC and a liquid solvent outlet DD; the gaseous solvent connection inlet CC is arranged on the upper surface of the condenser cylinder cover 2 and connected to one end of the connecting elbow 10; the connecting elbow The other end of the head 10 is inside the condenser cylinder 50 and connected to one end of the upper confluence pipe 30; the other end of the upper confluence pipe 30 is connected to one end of the condensing coil 40; the other end of the condensing coil 40 passes through a The lower confluence pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com