Patents

Literature

778results about "Leather/skins/hides/pelt chemical treatment apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of negative oxygen ion multifunctional automotive trim leather

ActiveCN107312895AIncrease the fragranceFeel goodTanning treatmentPre-tanning chemical treatmentLiquid ratioKnurling

The invention relates to a production method of a negative oxygen ion multifunctional automotive trim leather. The production method comprises fleshing, liming, deliming, softening, pickling, tanning, retanning, neutralization, dyeing, fat liquoring, drying, softening, bottom coating, middle coating, knurling and top coating; in the pickling and tanning steps, salt is added for pickling, and aldehyde is added for tanning; the pickling by adding the salt is as follows: the leather is washed by softening water; the liquid ratio is 50%; by 100 mass parts of the leather, 50 parts of water are added; the temperature is controlled at 20+-2 DEG C; 7 parts of sodium chloride are added for reaction by 15 minutes; then, 0.5 part of 10 wt% of dilute formic acid is added for reaction by 30 minutes; then, 0.5 part of 10 wt% of dilute formic acid is added for reaction by 30 minutes; 0.35 part of 5 wt% of dilute sulfuric acid is added for reaction by 30 minutes; sulfuric acid is added again by the same mode for reaction by 90 minutes; after dilute sulfuric acid is added, the pH value is controlled within 2.8+-0.1; and the reaction is performed by 60 minutes. The production method has the functions of constant release of negative oxygen ions, sterilization and bacteria resistance, achieves the effect of efficiently absorbing, decomposing and degrading such harmful gas as formaldehyde, and achieves softness and excellent shaping property.

Owner:HAINING SENDE LEATHER

Method for manufacturing washable cow split leather

ActiveCN107502685AFully rehumidifiedImprove washing resistanceTanning treatmentPre-tanning chemical treatmentSofteningChemistry

The invention relates to a method for manufacturing washable cow split leather and belongs to the technical field of manufacture of leather. The method comprises the following steps: taking a cow split leather blank subjected to wringing and shaving, and sequentially performing re-wetting, primary washing, retanning, neutralizing, secondary washing, filling, dyeing, stuffing, acid solidification, thrice washing, fixing, quartic washing, drying, hanging and airing, vibratory softening, leather fluffing and milling. The washable cow split leather manufactured by the method has favorable washability, and is high in leather yield.

Owner:漳州香洲皮革有限公司

Non-chromium leather tanning method

The invention provides a non-chromium leather tanning method. The non-chromium leather tanning method comprises the following steps of: (a) pre-treating animal skin, soaking in water and weighing, and soaking in gangue to obtain gangue skin; (b) carrying out deliming, softening and primary pickling onto the raw gangue skin to obtain raw skin; (c) carrying out secondary pickling onto the raw skin; (d) tanning the raw skin after the secondary pickling; (e) primarily fixing the tanned raw skin in formic acid for 30 minutes after carrying out oxidizing, aldehyde-removing and re-tanning; and carrying out neutralizing treatment after rinsing for 60 minutes by virtue of oxalic acid; and (f) getting out the raw skin after the neutralizing treatment from a rotary drum after carrying out fat liquoring, secondary fixing, and water-washing, drying the raw skin after primary stabbing, re-moistening for 20 hours, knocking and softening for 8 hours, and carrying out secondary stabbing and drying to obtain the tanned leather. The leather tanning method provided by the invention is free of chromium-containing preparation, so that the leather processing process is more environment-friendly, and the harms to the construction staffs are reduced.

Owner:何裕华

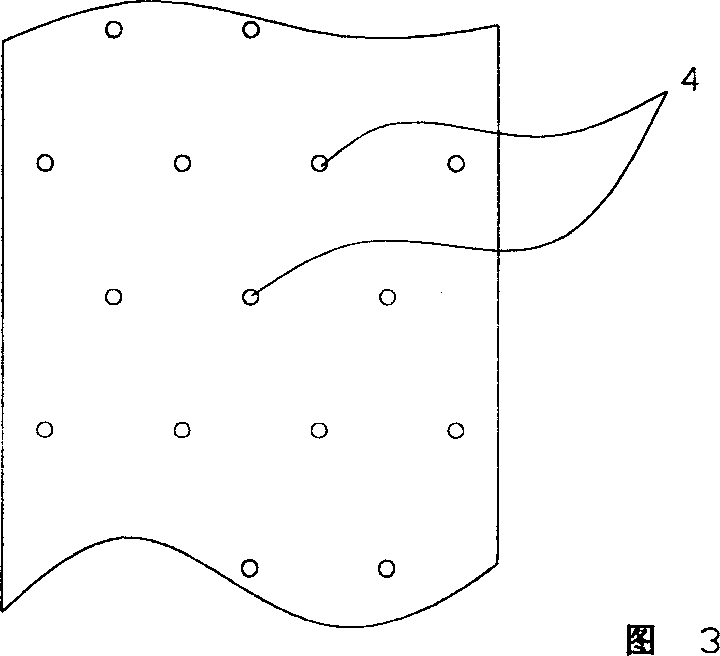

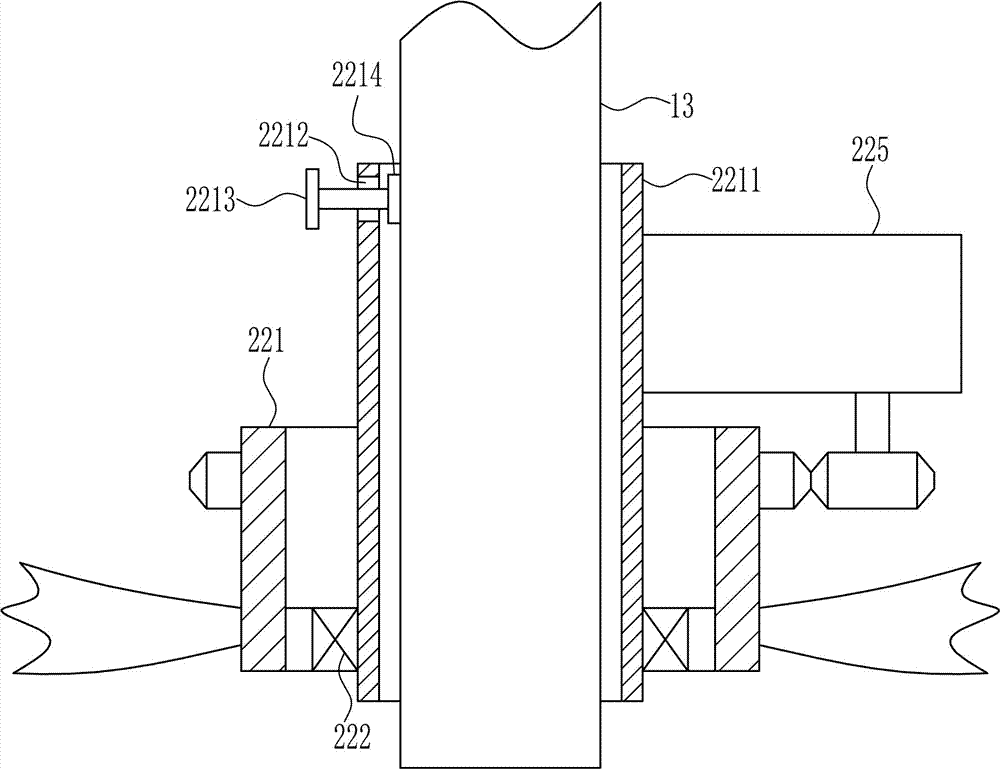

Production method of pet articles and its equipment

InactiveCN1443445ASolve the disadvantage of being expensiveLow costAnimal feeding stuffWorking-up animal fodderIt equipmentAdhesive

The present invention relates to a method for making pet article and its equipment. Its raw material adopts second layer of hide and its below various layer, and said method includes: pretreatment procedure, including removing fat from hide, layering, adding softening agent and softening and washing with water; forming procedure, wet forming procedure is a wet hide leather processing method including the steps of draining, extruding, cutting and weaving, etc. or wet hide colloidal particle material processing method including the steps of draining, extruding, mincing, adding adhesive and stirring, pressing or extruding, etc. and the dry forming procedure is a dry hide leather processing method including the steps of drying, cutting, soaking in water and weaving or pressing or dry hide colloidal particle material processing method including the steps of drying.

Owner:刘尚武 +3

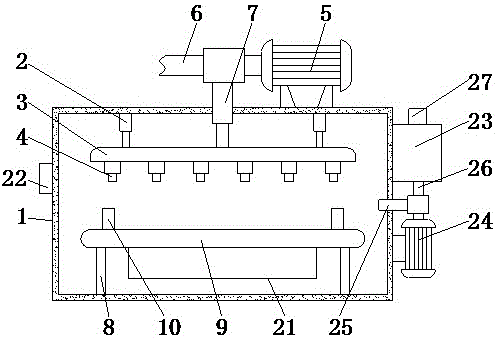

Dyeing device with flowing dyeing liquor for leather processing

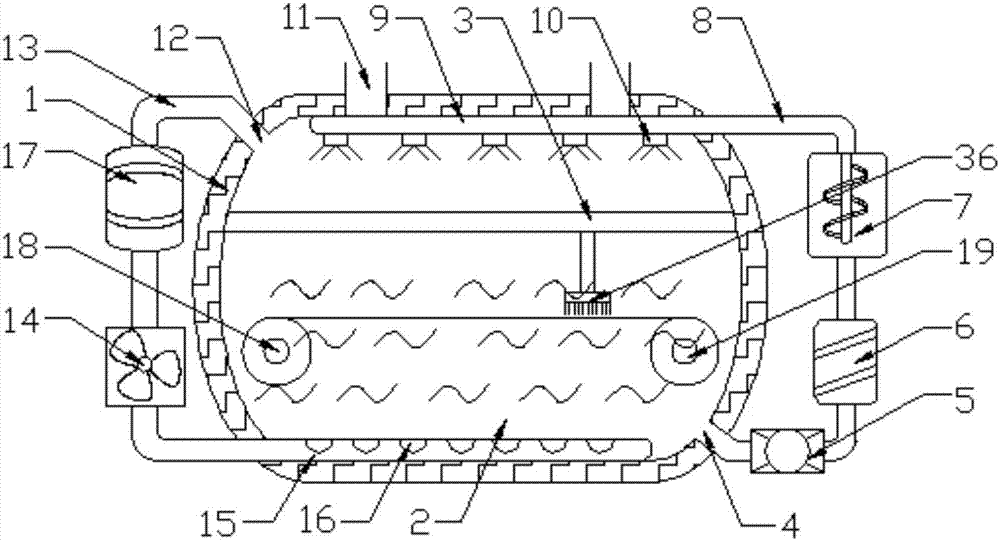

ActiveCN107460264ASpeed up the flowImprove cleanlinessLeather/skins/hides/pelt chemical treatment apparatusPulp and paper industryDyeing

The invention discloses a dyeing device with flowing dyeing liquor for leather processing. The dyeing device with the flowing dyeing liquor for leather processing comprises a dyeing cylinder, a dyeing liquor tank, a brush dyeing device, a liquor outlet, a circulating pump, a dyeing agent adding and mixing barrel, a liquor returning tube, a showering tube, spraying heads, a liquor injecting opening, a leather winding roll and a leather discharging roll; and the dyeing liquor tank is arranged at the bottom of the dyeing cylinder. The dyeing device with the flowing dyeing liquor for leather processing is reasonable and simple in structure and low in production cost, and facilitates dyeing; a soft brush can be used for carrying out brush dyeing on a special grain layer on the surface of leather, the dyeing quality of the grain layer on the surface of the leather is improved, dyeing liquor in the dyeing liquor tank is circularly supplied to the top of the dyeing liquor tank through the circulating pump and then is sprayed through the spraying heads, flowing of the dyeing liquor in the dyeing liquor tank is facilitated, the force of contact between the dyeing liquor and the leather can be increased owing to flowing of the dyeing liquor, the dyeing speed is increased, in a dyeing liquor circulating process, the dyeing liquor is filtered through a filter, the content of a dyeing agent in the dyeing liquor is increase through the dyeing agent adding and mixing barrel, therefore, the cleanliness of the dyeing liquor and the concentration of the dyeing agent are ensured, and evenness of dyeing of the leather is improved.

Owner:夏欣磊

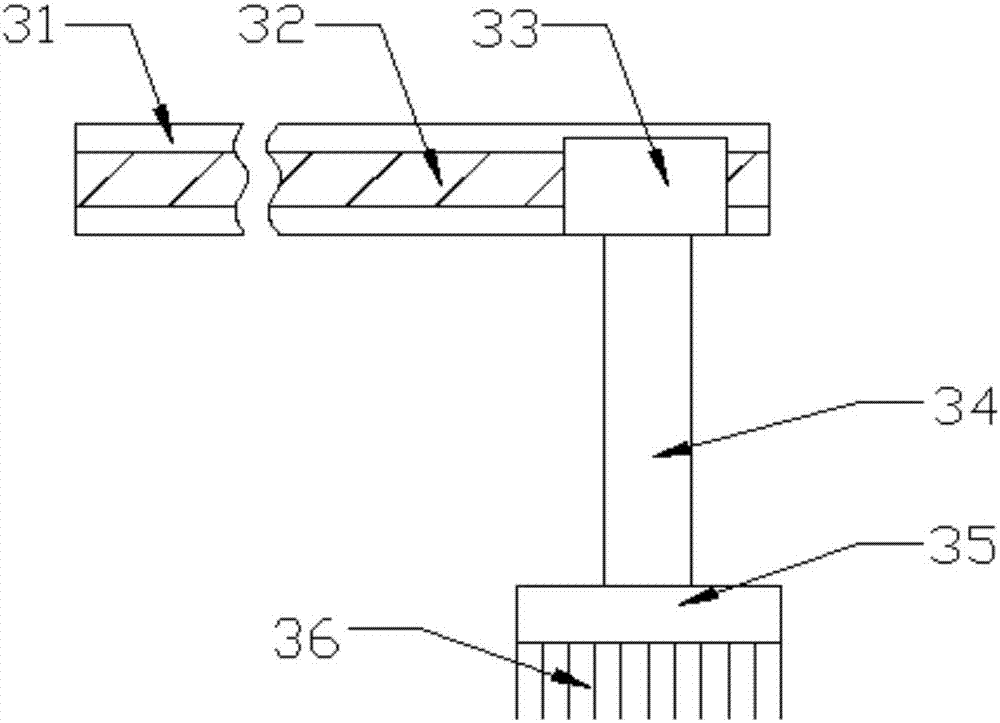

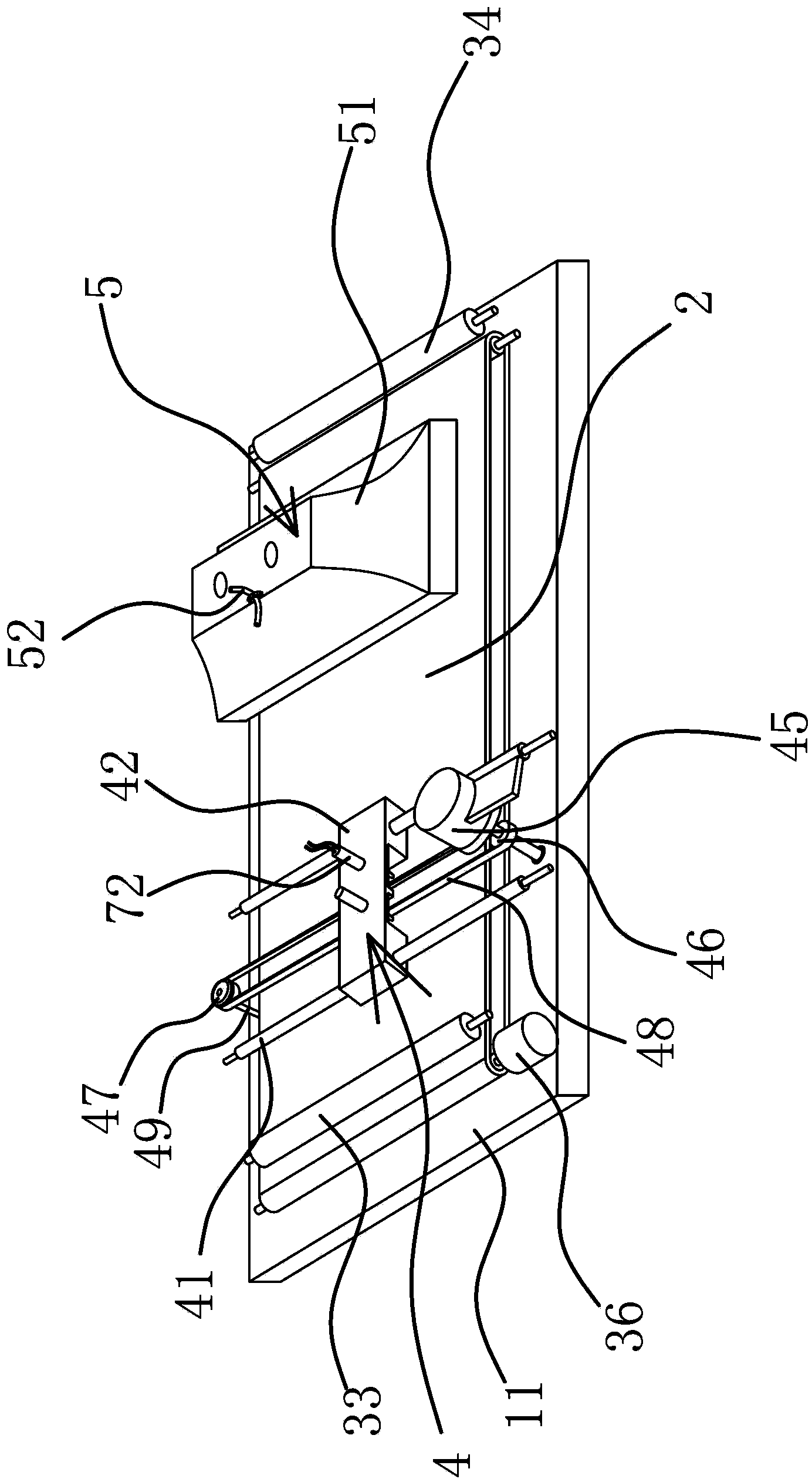

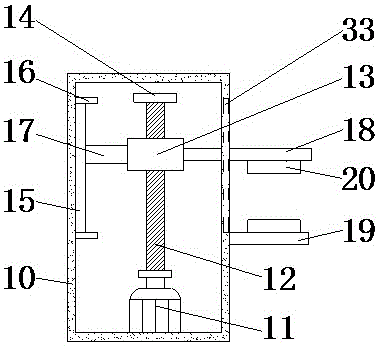

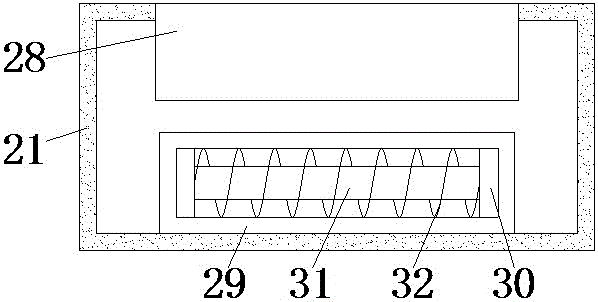

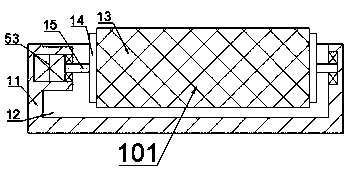

Leather pulp shooting machine

ActiveCN103397119AIncrease productivityWon't flow outLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingSlagPulp and paper industry

The invention provides a leather pulp shooting machine, belongs to the technical field of leather processing devices, and solves the technical problems, such as low production efficiency, pollution to the atmosphere and the like, of leather pulp shooting machines of the prior art. The leather pulp shooting machine comprises a bottom plate and a seal base sleeved on the bottom plate. A conveyor belt is arranged on the bottom plate. A material inlet is arranged at one end of the seal base. A material outlet is arranged at the other end of the seal base. A pulp shooting mechanism and a drying mechanism are arranged inside the seal base. A dust slag discharge pipe and a waste gas discharge pipe which are communicated with the interior of the seal base are arranged at the top of the seal base. A scrubbing cylinder is arranged on the outer wall of the seal base. The dust slag discharge pipe and the waste gas discharge pipe are both connected with the scrubbing cylinder. The leather pulp shooting machine is advantaged by high production efficiency, no pollution and the like.

Owner:江苏东方金狐狸服饰有限公司

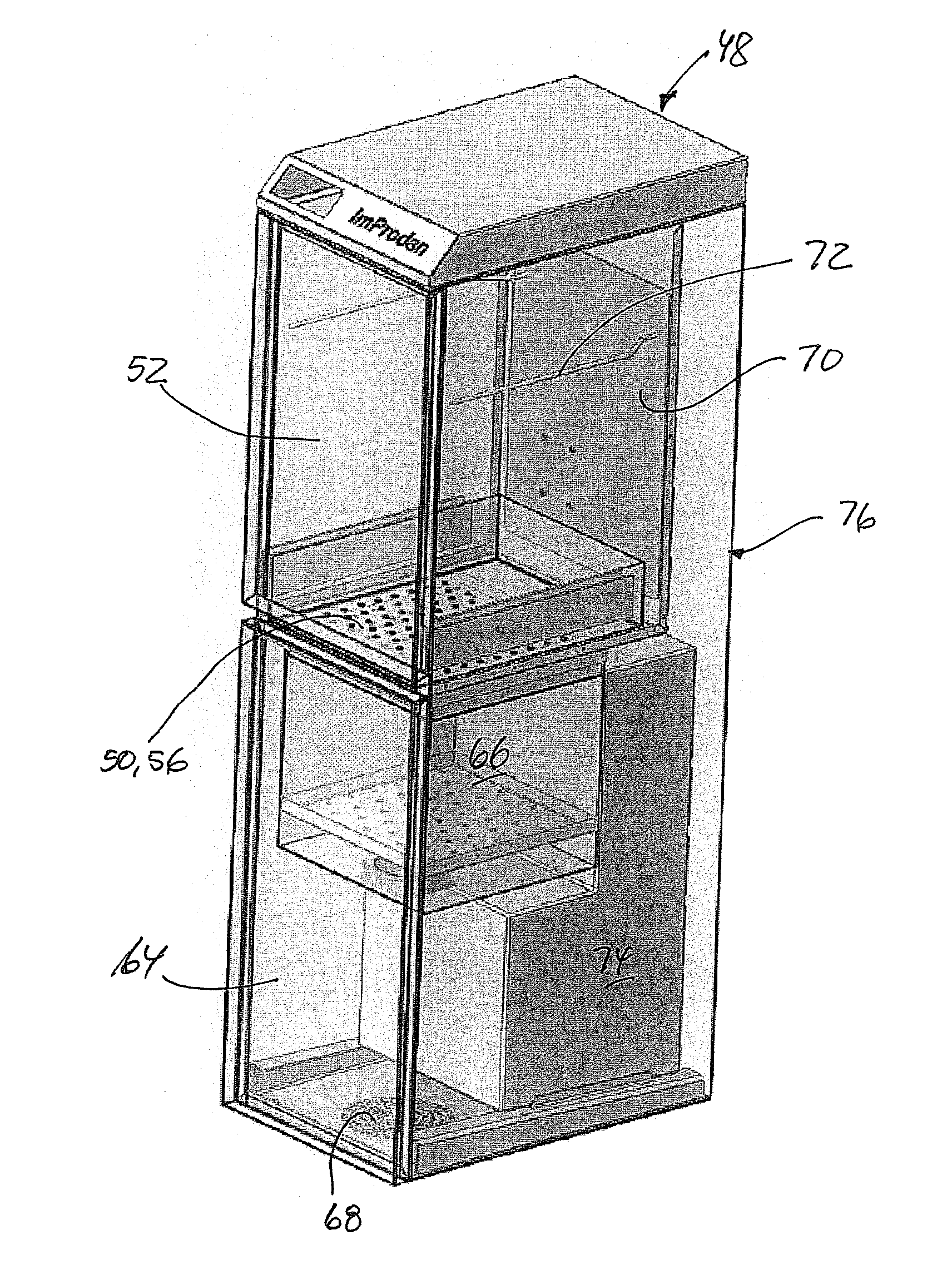

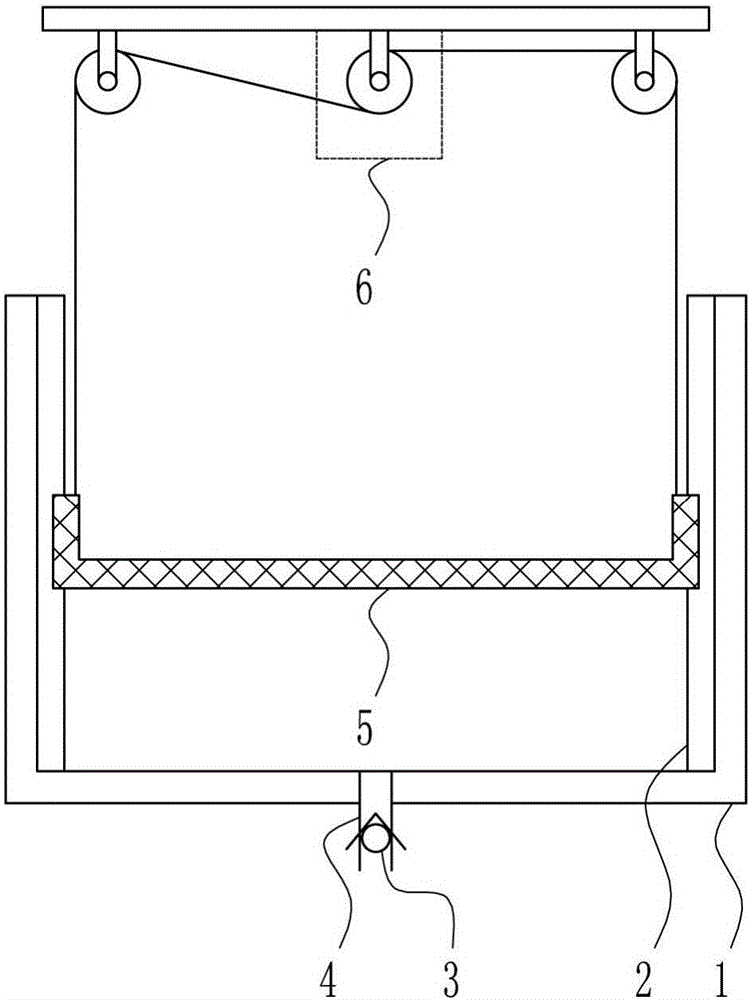

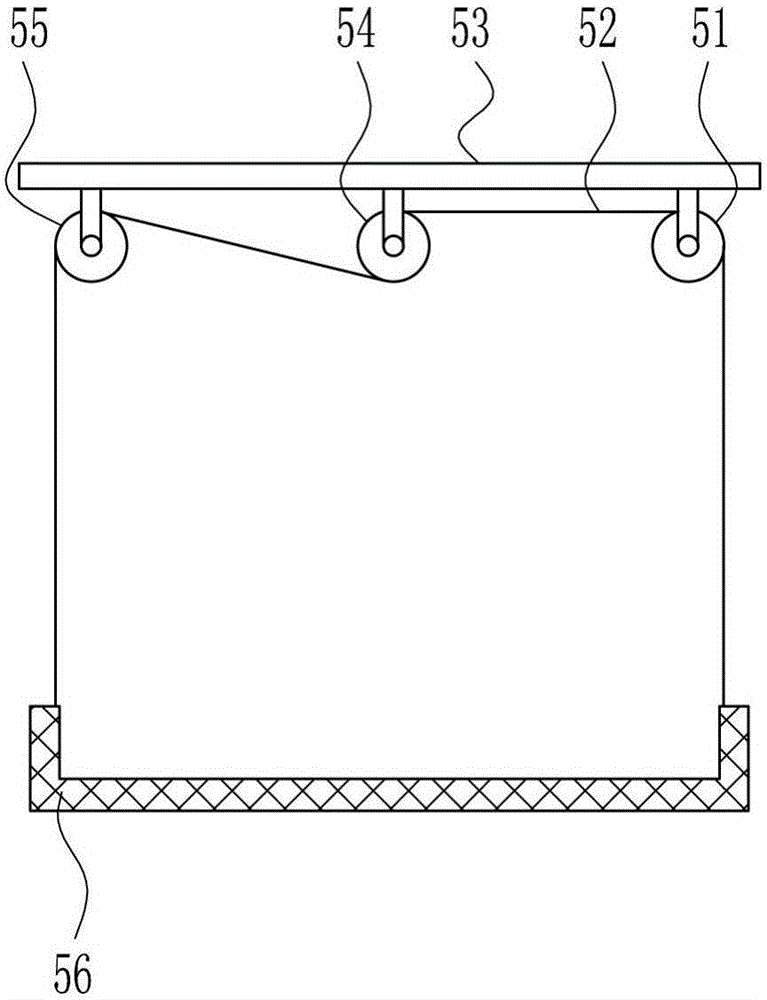

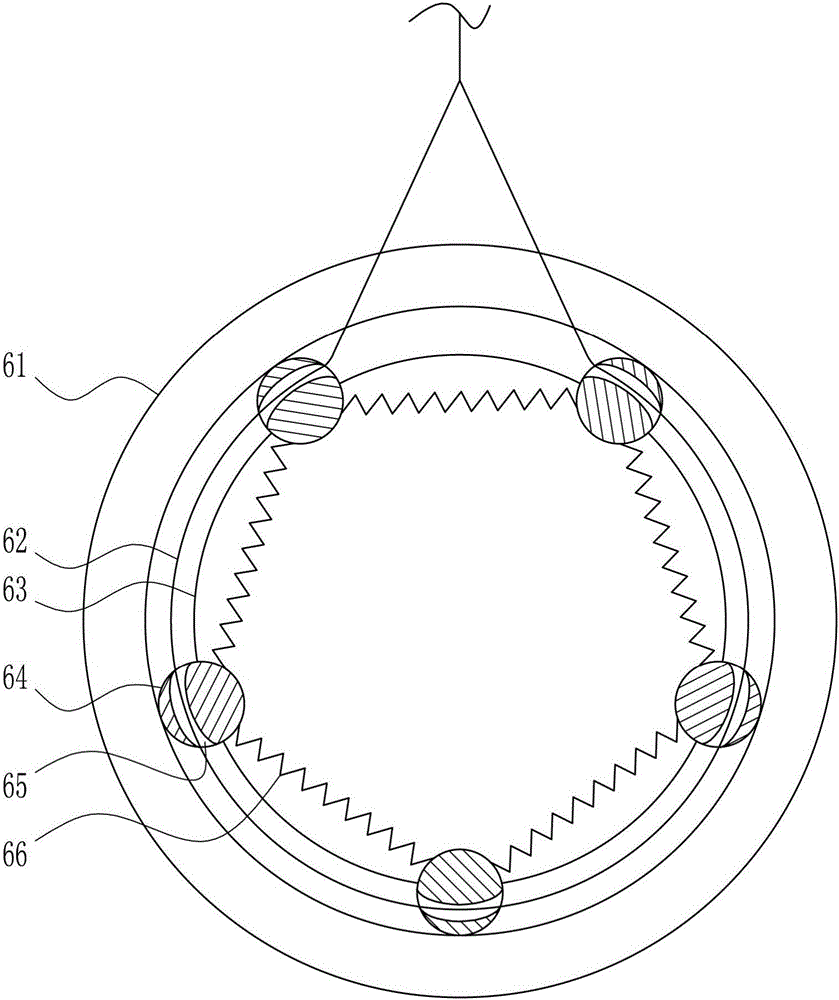

Method and apparatus for impregnation of items

ActiveUS20110091655A1Use minimizedGood surface treatmentInsolesVacuum evaporation coatingActivated carbonBiomedical engineering

A method and apparatus for surface treatment of footwear, bags, gloves, other leather items or leather-like items. The method includes optional covering a surface or a part of the items which are not to be treated; optional selecting time of operation of a spraying unit; placing items to be treated in a chamber; shutting the chamber and thereby manually or automatically initiating; activating the spraying unit for forming a mist of impregnating agent inside the chamber for applying impregnating agent onto the surfaces of the items; activating an air pump, ventilator or corresponding means for removal of excess impregnating agent from the chamber; and retaining excess impregnating agent in a filter which preferably is a filter containing activated carbon.

Owner:IMBOX SHOECARE

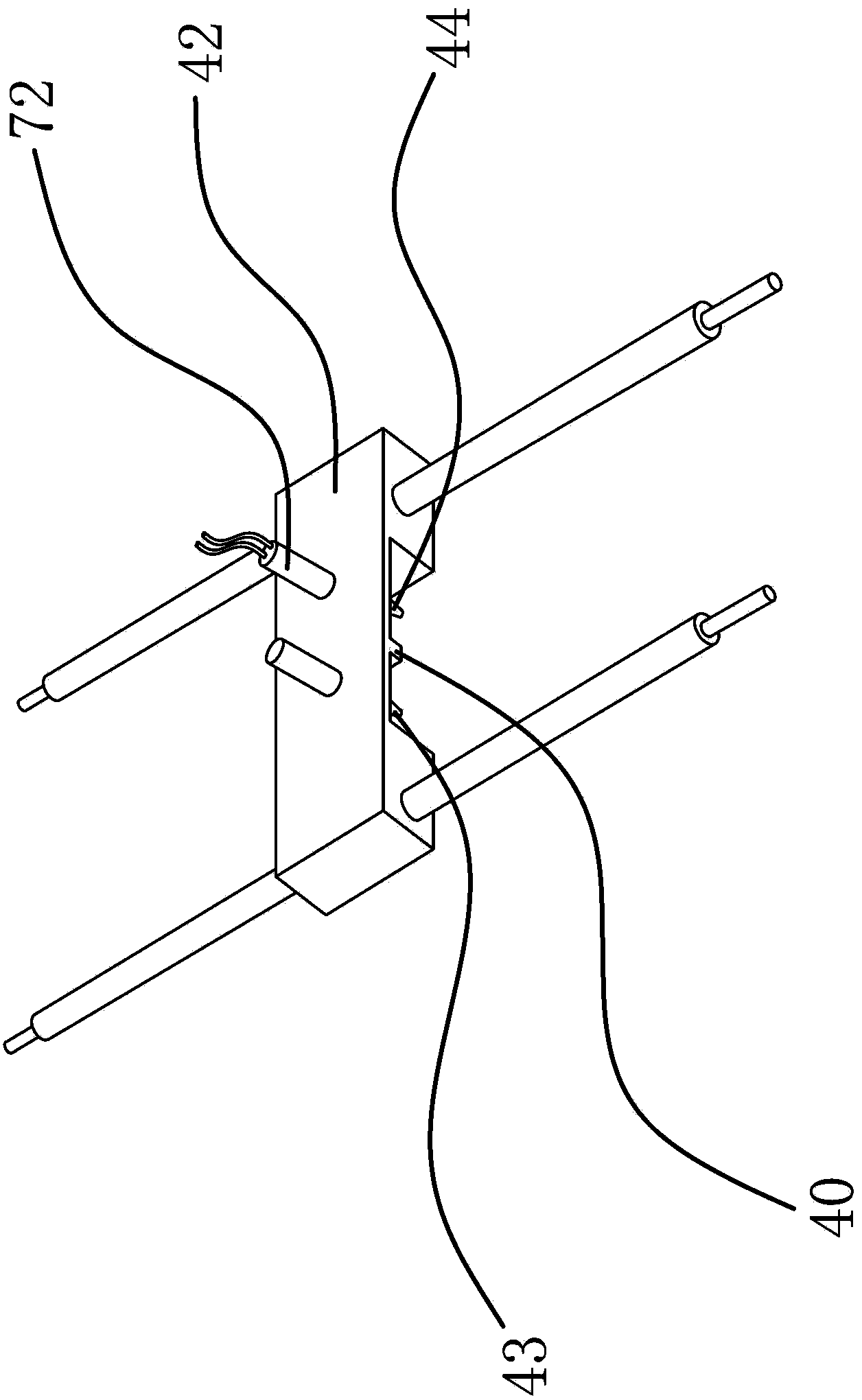

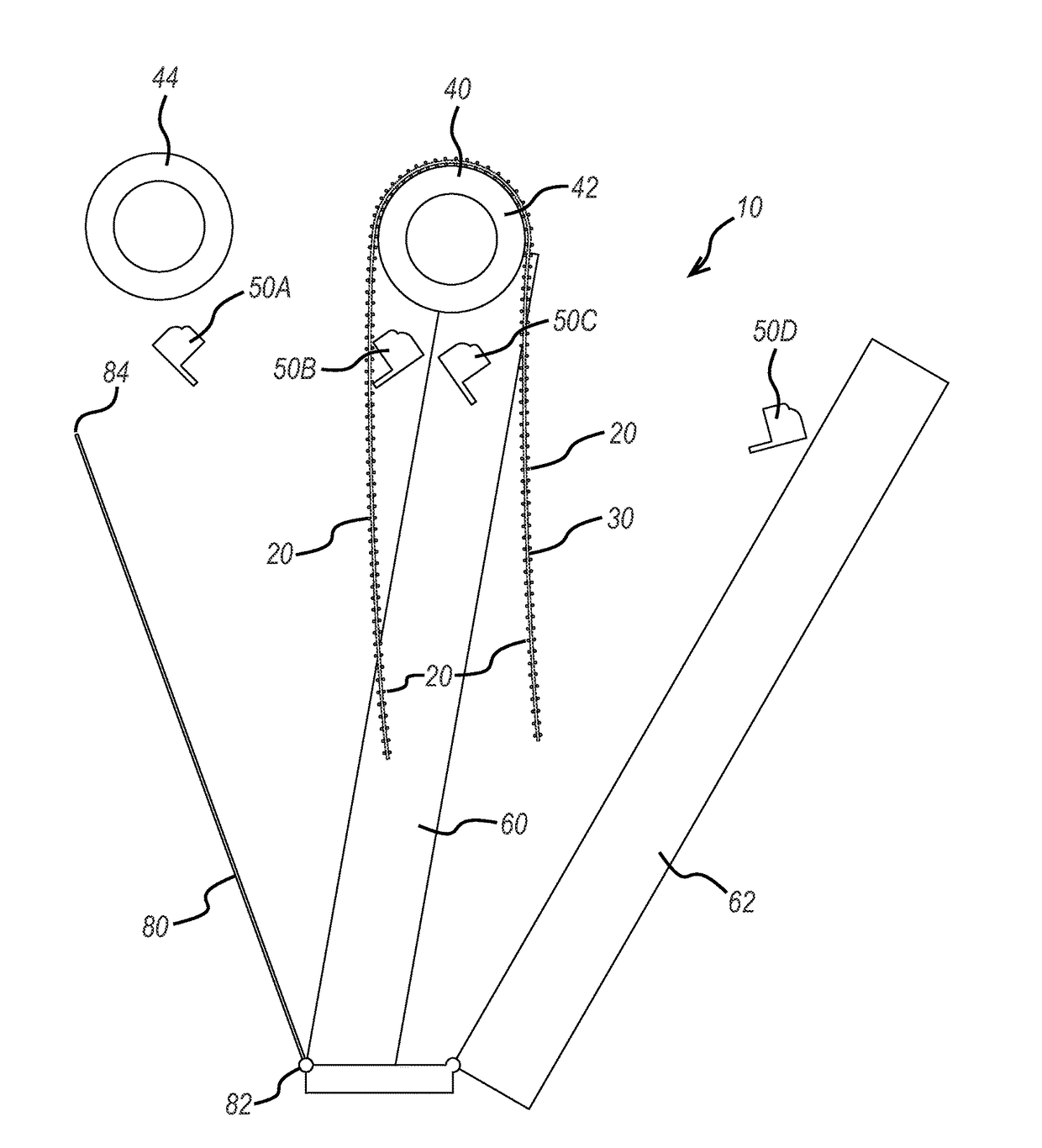

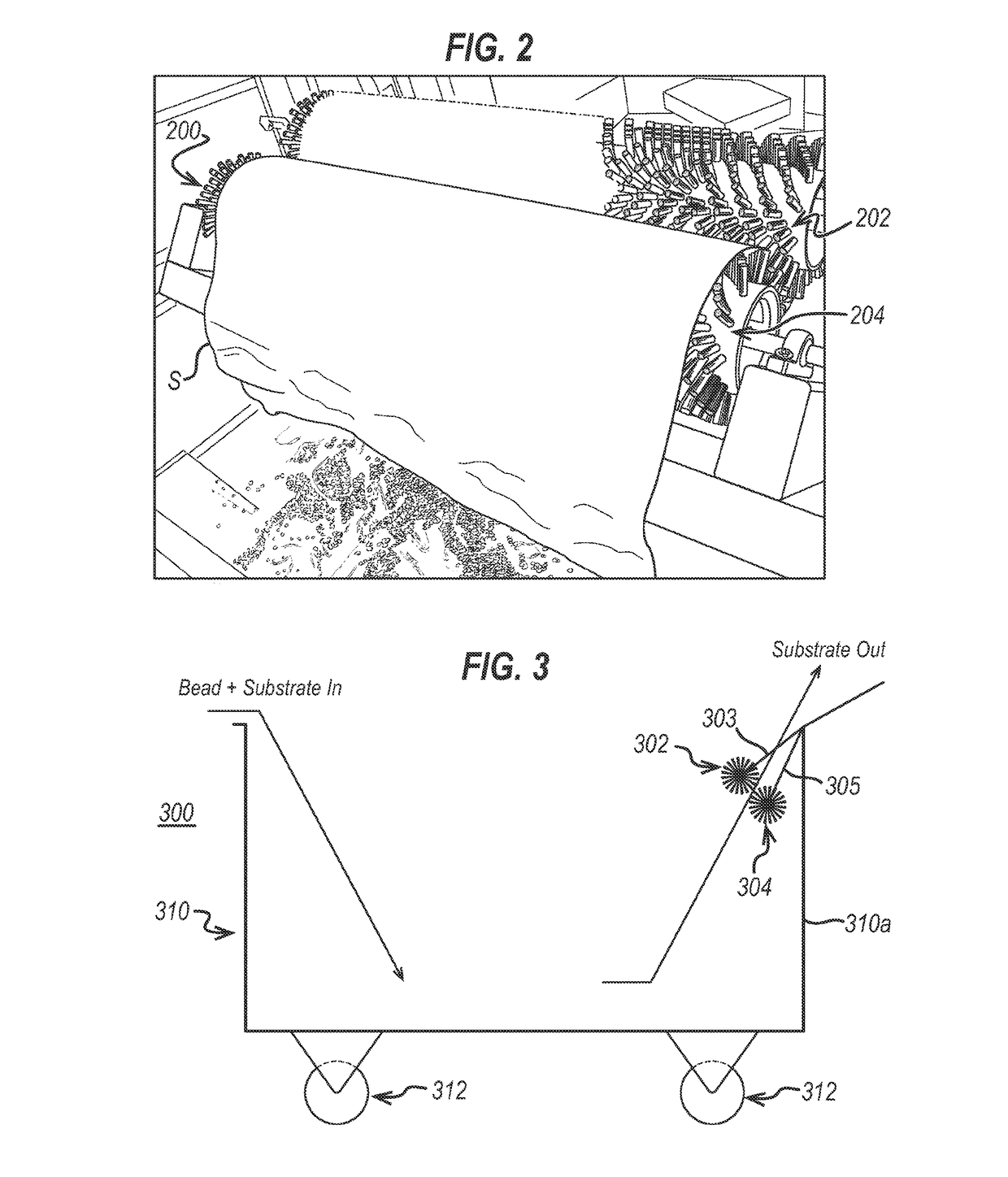

Apparatus and method for recovery of solid particulate material

InactiveUS20170247771A1Avoids and mitigates damageLeather manufacturingLeather/skins/hides/pelt chemical treatment apparatusSolid massEngineering

Apparatus for recovery of a solid particulate material from an animal skin substrate subjected to a treatment using said particulate material, comprises a support arranged to support the animal skin substrate, at least one air knife arranged to direct its output flow of air to the animal skin substrate when supported on the support, and a transport arrangement configured to move at least one of the air knife and the animal substrate relative to the other. A method of recovering solid particulate material from such an animal skin substrate is also disclosed.

Owner:XEROS LTD

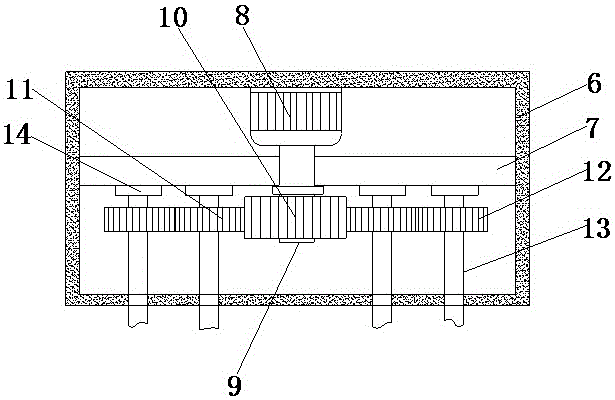

Leather spray device with excellent performance

InactiveCN106381350AImprove performanceImprove stabilityLiquid surface applicatorsDispersed particle filtrationEngineeringHigh pressure

The invention provides a leather spray device with excellent performance, and relates to the field of leather processing. The leather spray device with excellent performance comprises a box body, wherein automatic telescopic rods are symmetrically installed at the top of the inner wall of the box body; a distribution tube is fixedly installed at the bottom of each automatic telescopic rod; the bottom of each distribution tube communicates with a spray head; a high-pressure gas pump is fixedly installed at the top of the box body; the input end of the high-pressure gas pump communicates with a charge tube; the output end of the high-pressure gas pump communicates with a telescopic tube; and the bottom of the telescopic tube penetrates through the box body and extends to the interior of the box body to communicate with the distribution tubes. The leather spray device with excellent performance enables a connection plate and a fixing plate to greatly clamp a leather body through arrangement for a fixer, thus the stability of leather during spraying is effectively improved, the spraying quality of the leather is improved, the reject ratio of spraying is reduced, the production quality is effectively improved, and the production gain is increased.

Owner:扬州迈普瑞粉末冶金有限公司

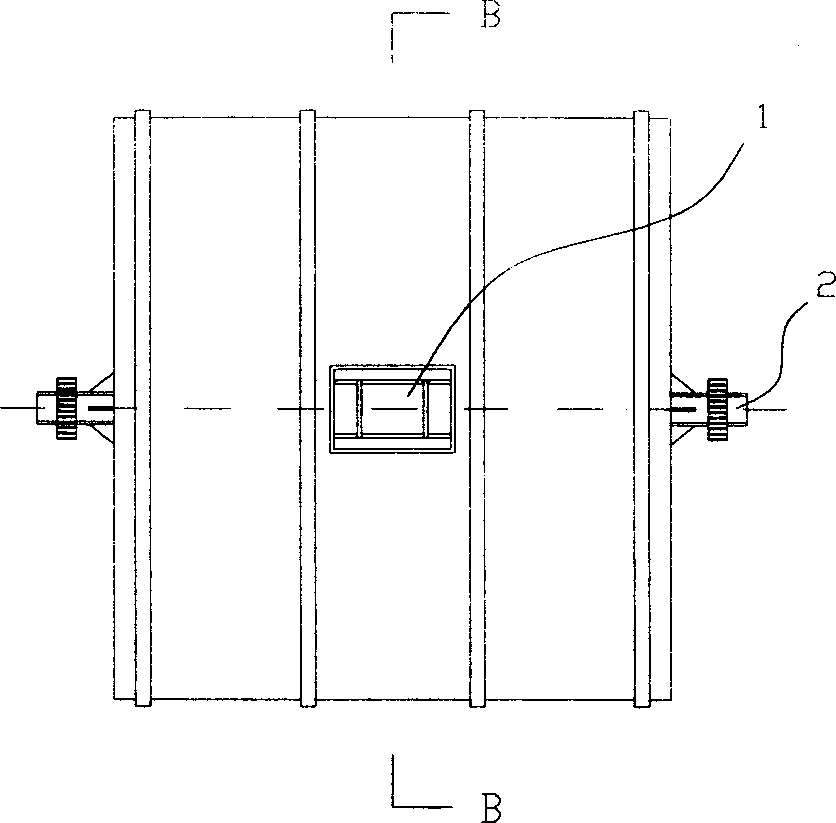

Device for leather processing

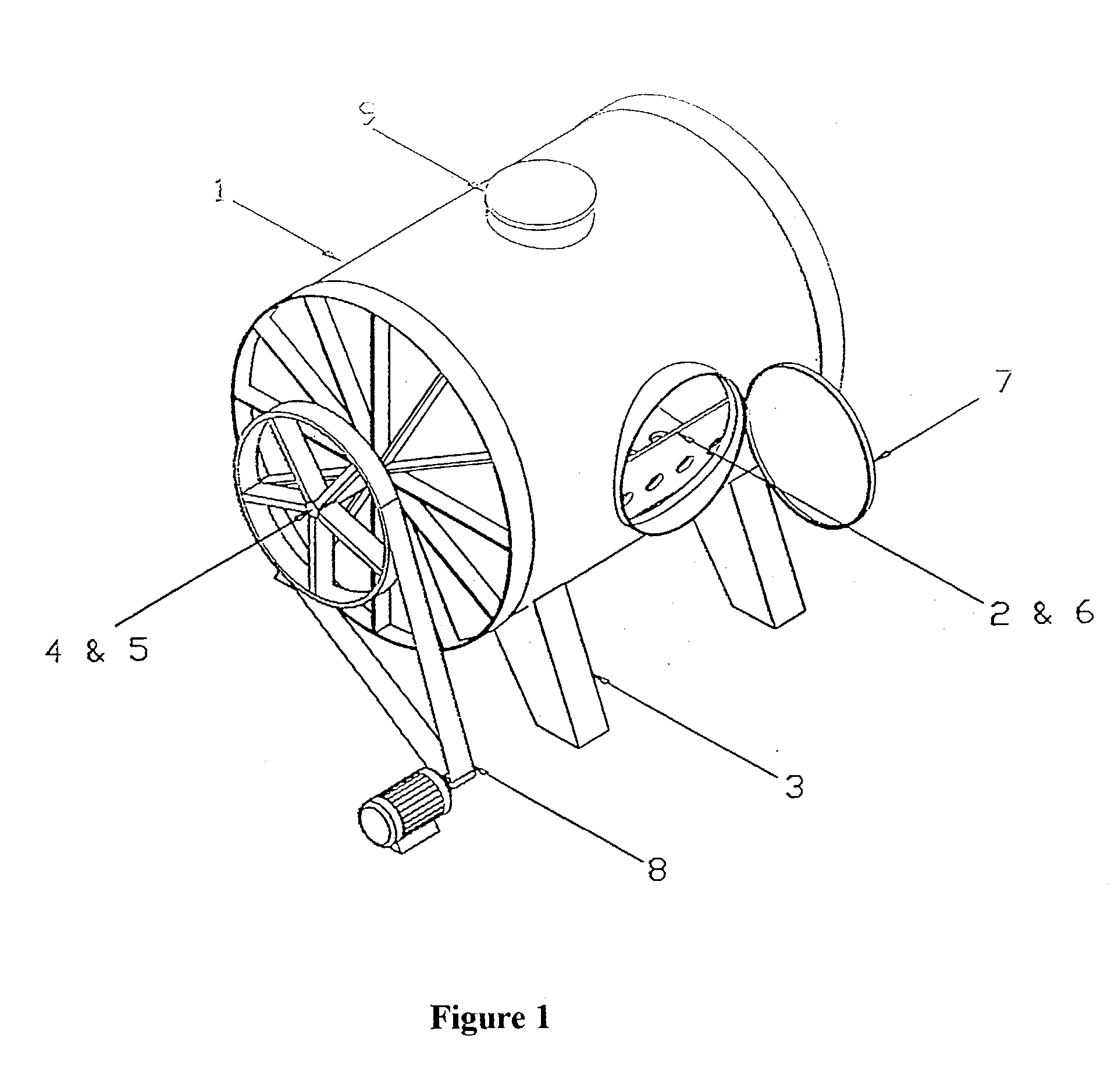

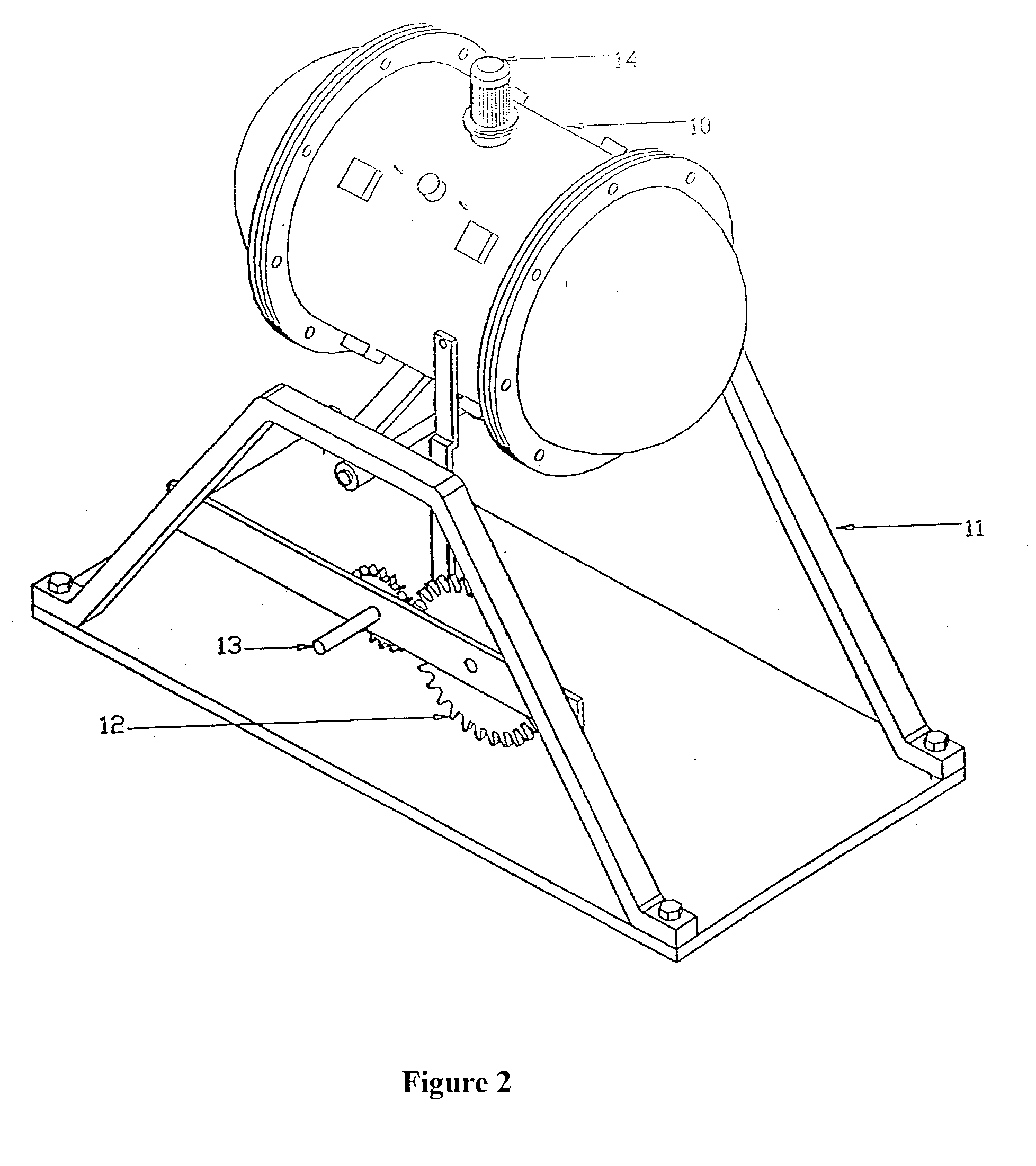

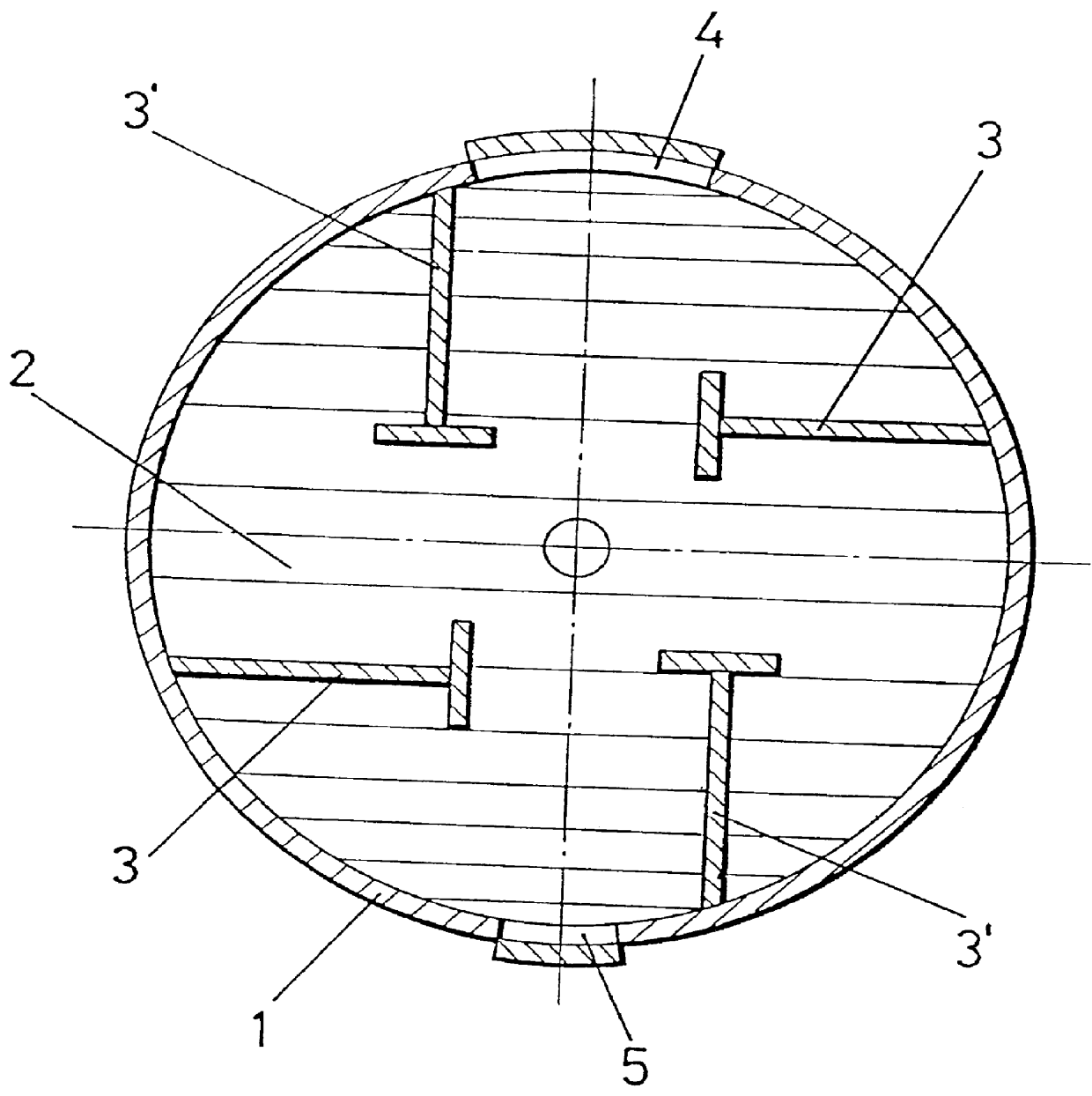

InactiveUS20040182118A1Consumes less energyReduce noisePre-tanning chemical treatmentLeather/skins/hides/pelt chemical treatment apparatusChemical solutionPressure generation

An improved device for leather processing comprising a vessel containing perforated dummy doors and compartments with pegs as well as friction disk fixed along the exterior periphery of the vessel. The leathers to be wet processed are subjected to mechanical action in terms of both rocking action as well as rotational movement simultaneously. The perpetual motion of the device help to create pressure generation for quickening the process and for addition of chemical solution continuously. The processing takes place under pressure generated inside the vessel and with the support of multiple mechanical actions, resulting in higher exhaustion of bath with less processing time and energy requirement and higher capacity utilization to produce good quality leather.

Owner:COUNCIL OF SCI & IND RES

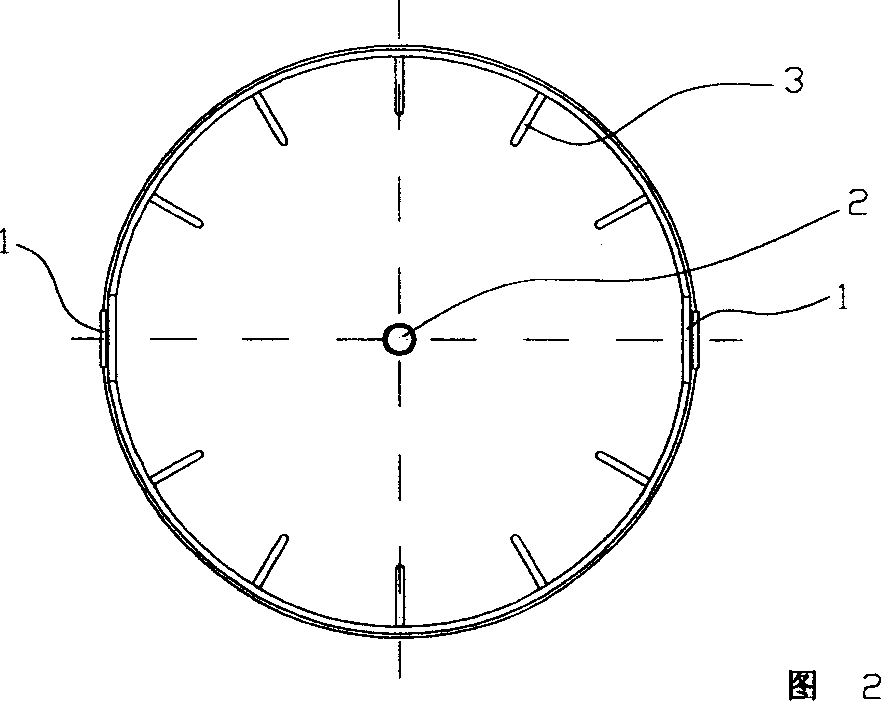

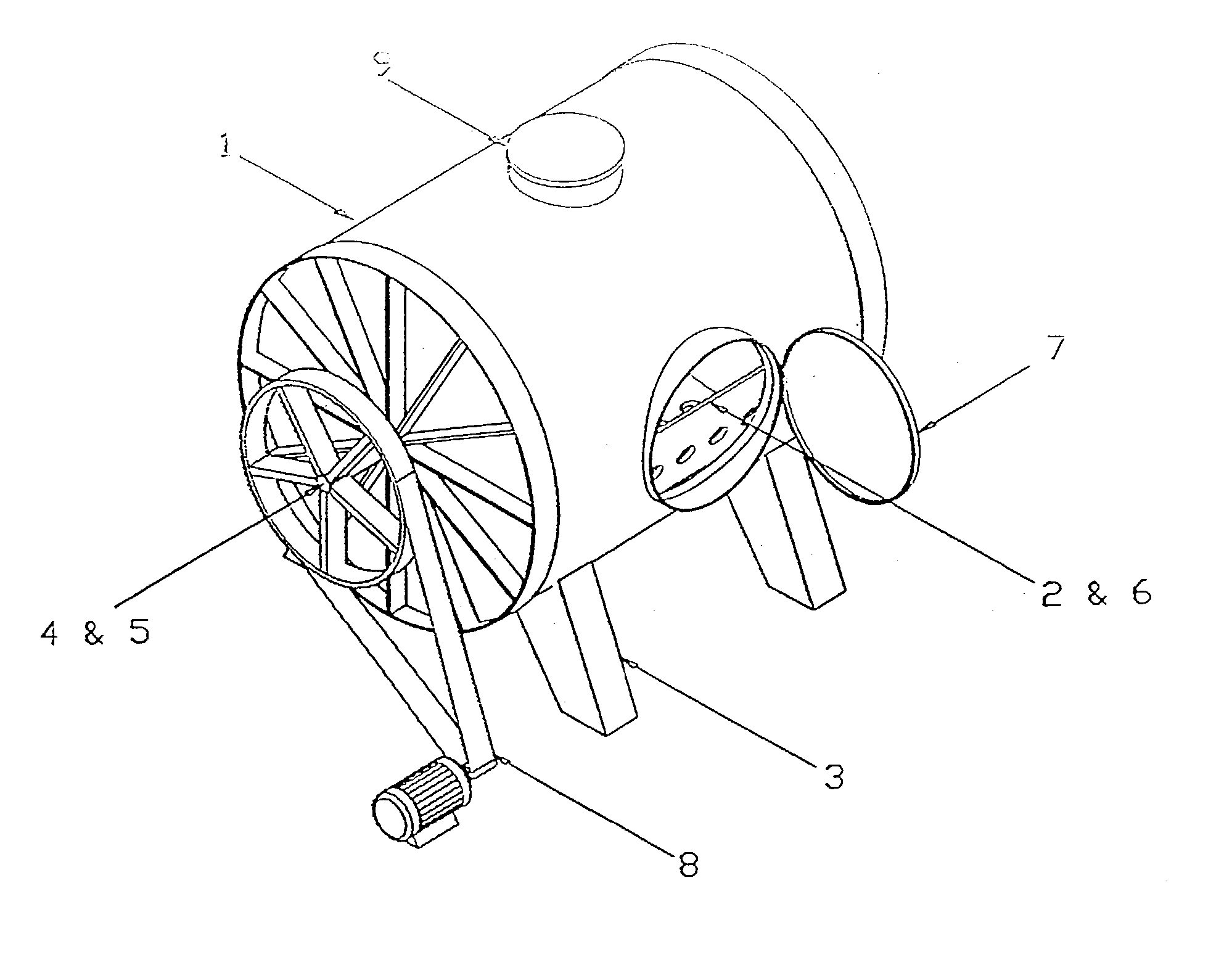

Drum for treating leather, fur and similar products

InactiveUS6151932AImproved performance and efficiencyRotating receptacle mixersPre-tanning chemical treatmentMicrochiropteraEngineering

Owner:MOLTO CONCEPCION JULIA +1

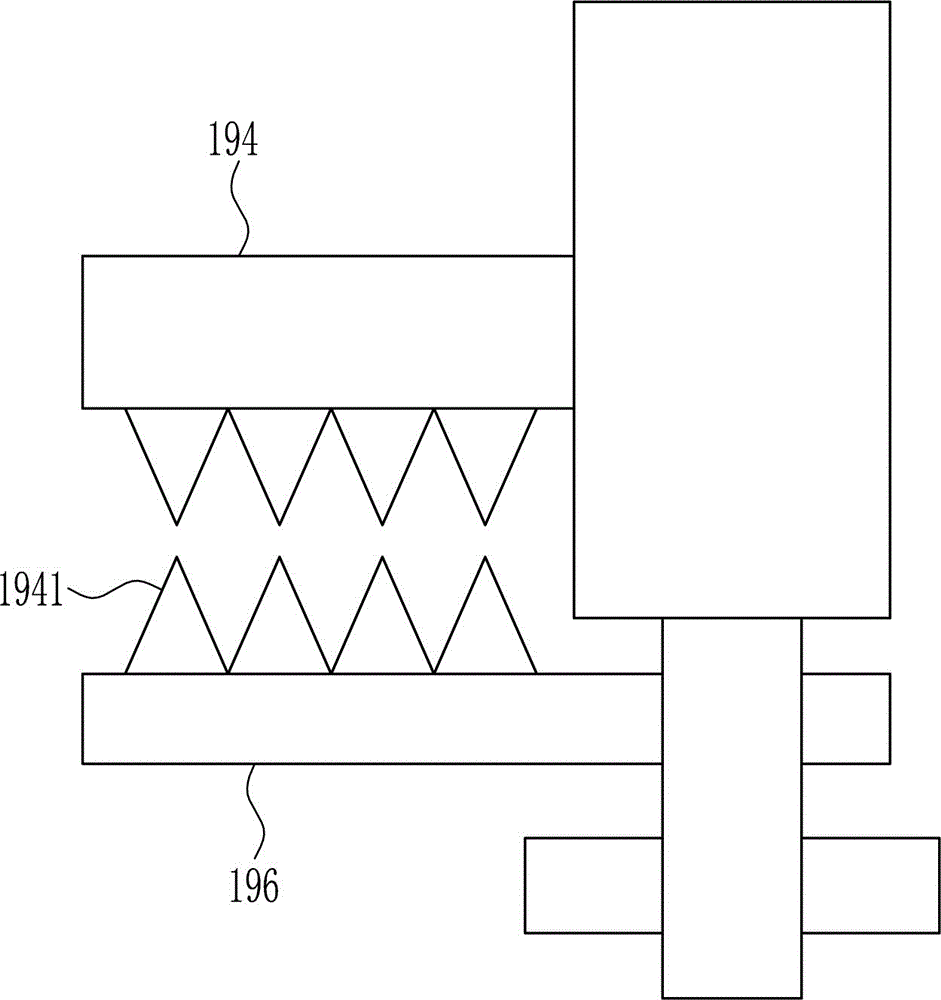

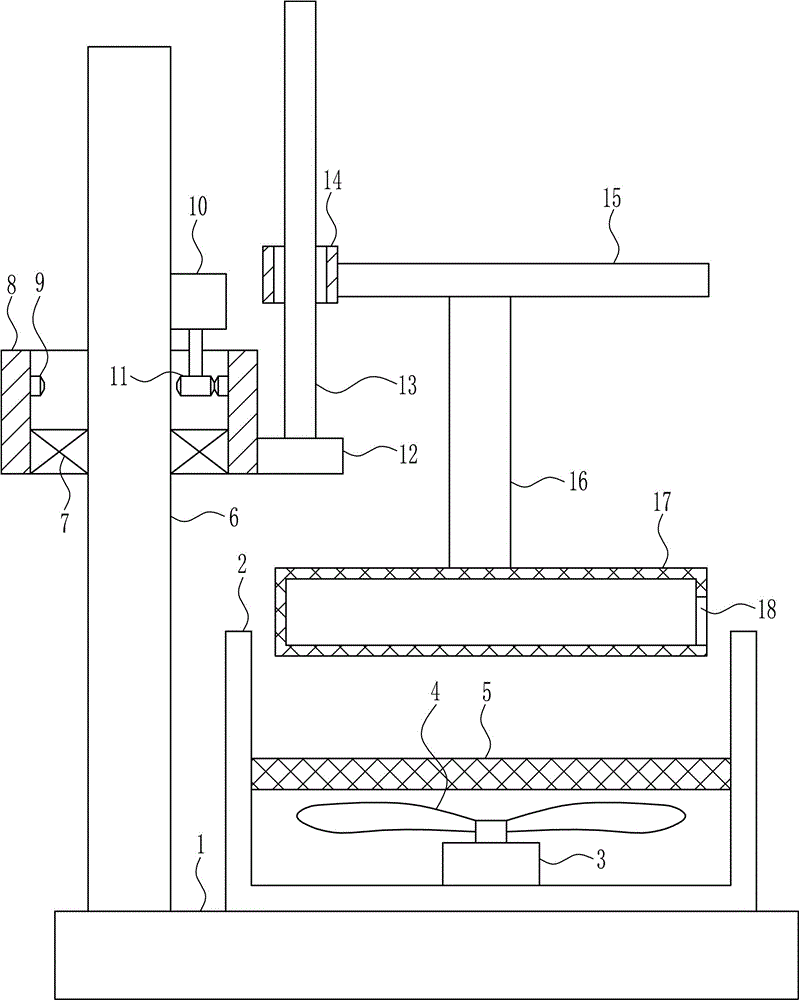

Waxing device for production of sofa leather

InactiveCN110643751AImprove uniformityGuaranteed stabilitySkins/hides/leather/fur manufacturing apparatusLeather/skins/hides/pelt chemical treatment apparatusMechanical engineering

The present invention discloses a waxing device for production of sofa leather. The device includes a feeding box provided with a feeding chamber therein; the feeding chamber is open upward and is provided with a feeding device for transporting leather; the upper side end face at the rear side of the feeding chamber is fixedly connected with a fixed plate; the front side end face of the fixed plate is provided with a spraying device; the spraying device cleans the leather with an air flow, and sprays wax to the leather; a lifting device located at the right side of the spraying device is disposed on the front side end face of the fixed plate; the lifting device is provided with a waxing device for waxing and polishing therein; and the lifting mechanism of the present invention can drive the waxing mechanism to move up and down so as to realize self-adaptation for waxing of the leather of different thicknesses, realize automatic removing of liquid wax inside a spraying pipe and preventthe cured liquid wax from blocking the spraying pipe and affecting subsequent processing.

Owner:PANAN LINSI LEATHER IND RES CO LTD

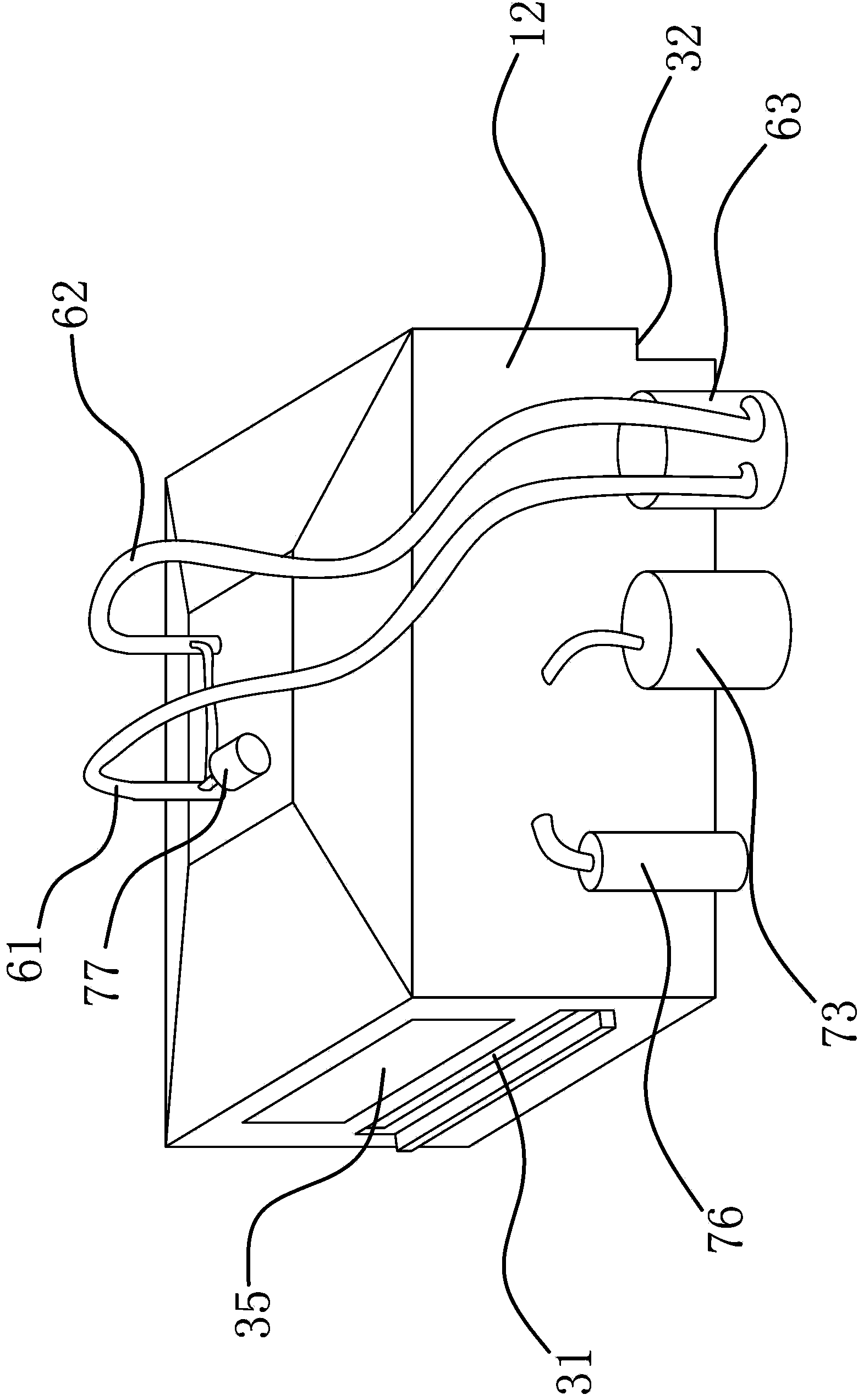

Dust removal and waxing equipment for surfaces of leather products

InactiveCN109013432AEasy to remove dustFacilitate the waxing processSkins/hides/leather/fur manufacturing apparatusLeather/skins/hides/pelt chemical treatment apparatusEngineeringConveyor belt

The invention discloses dust removal and waxing equipment for surfaces of leather products. The dust removal and waxing equipment comprises an equipment rack, conveyor belts are mounted at the upper end of the equipment rack, and a plurality of negative pressure holes are formed in the conveyor belts in a penetrating mode. A negative pressure machine is fixedly arranged between the upper and lowerlayers of conveyor belts, and a dust removal mechanism is fixedly arranged on the position, above the conveyor belts, of one side of the equipment rack. A dust suction mechanism is fixedly arranged on the position, on the right side of the dust removal mechanism, on the equipment rack. A waxing mechanism is fixedly arranged on the position, on the right side of the dust suction mechanism, on theequipment rack. When the dust removal and waxing equipment is used, large particle dust on the leather surfaces is brushed through the dust removal mechanism; after the surfaces of the leather products are primarily treated through a brush on a dust removal plate, the leather products are conveyed to pass through the dust suction mechanism by the conveyor belts, a cavity is in a negative pressurestate through a negative pressure pump, and thus dust on the surfaces of the leather products is adsorbed up; and a waxing sponge layer can ensure that in the rotating process of a waxing roll shaft,waxing grease is evenly smeared on the leather products, and automatic waxing work of the leather products is completed.

Owner:怀宁县太阳家纺有限公司

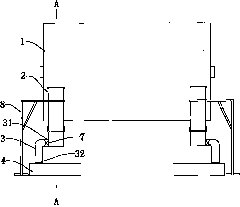

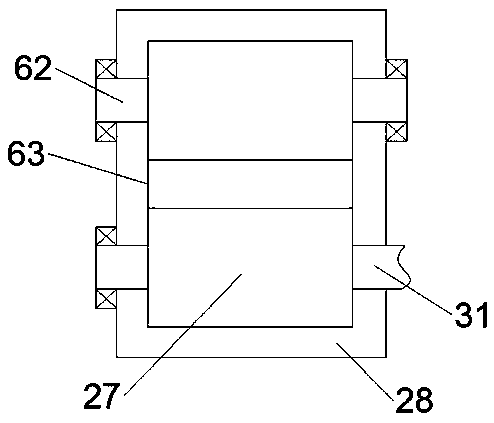

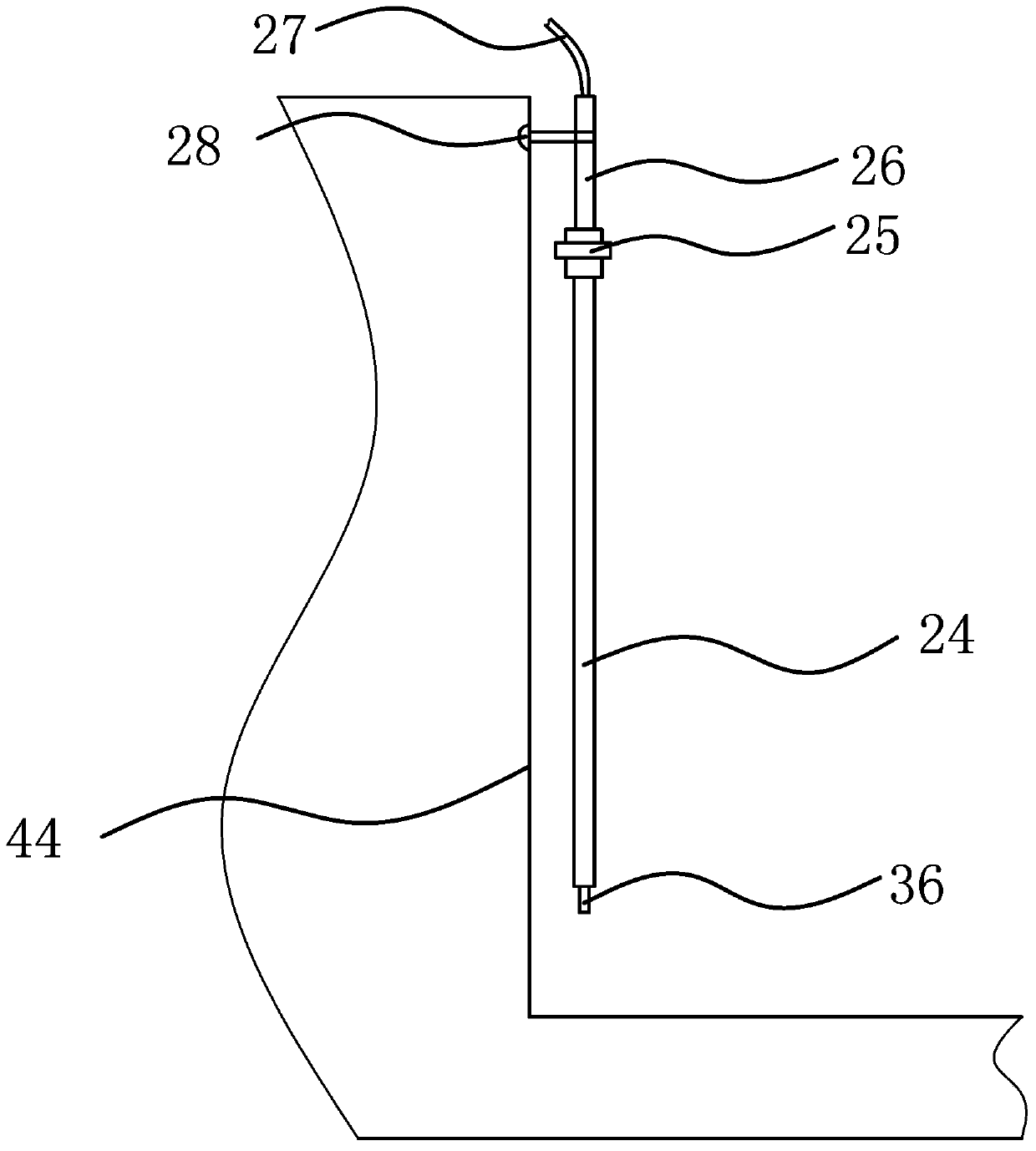

Tanning wastewater diversion device

ActiveCN101823776AReduce difficultyReduce pollutionWaste water treatment from animal processingWater/sewage treatmentWastewaterEngineering

The invention discloses a tanning wastewater diversion device, which comprises a liquid collection device arranged below a tanning drum. The liquid collection device comprises a shell and a liquid collection tank, wherein the liquid collection tank is arranged in the shell and is used for collecting wastewater. A liquid drain pipe I and a liquid drain pipe II are arranged on the shell. The liquid inlet of the liquid drain pipe I and the liquid inlet of the liquid drain pipe II are respectively communicated with the liquid collection tank. A diversion ditch I and a diversion ditch II are correspondingly arranged below the liquid outlet of the liquid drain pipe I and the liquid outlet of the liquid drain pipe II. A valve for controlling the make-and-break of the pipe is respectively arranged in the body of the liquid drain pipe I and the body of the liquid drain pipe II. Since chrome tanning wastewater is separated from other tanning wastewater during processing, the invention has the advantages that the treatment of the chrome tanning wastewater is facilitated and the treatment difficulty is reduced.

Owner:苏州盛泽科技创业园发展有限公司

Rapid pigskin dyeing equipment used in leather processing plant

ActiveCN106676209ARapid transitSave powerPre-tanning chemical treatmentLeather/skins/hides/pelt chemical treatment apparatusEngineeringProcessing plants

The invention relates to leather dyeing equipment, in particular to rapid pigskin dyeing equipment used in a leather processing plant. The rapid pigskin dyeing equipment used in the leather processing plant aims at achieving the technical effects that time and labor are saved in the dyeing process, and water jetting can be conducted when transferring is conducted only a small number of times. The rapid pigskin dyeing equipment used in the leather processing plant comprises a base plate, a material box, a first motor, stirring vanes, a filter plate, a support plate, a first bearing seat, a rotary ring, a first gear, a second motor, a second gear and the like. The material box is mounted on the base plate in a welded manner. The first motor is mounted in the middle of the lower side inside the material box in a bolt-connection manner. The rapid pigskin dyeing equipment has the beneficial effects that time and labor are saved in the dyeing process, and water jetting can be conducted when transferring is conducted only a small number of times. Pigskin is placed and dyed by rotating the rotary ring.

Owner:高域智能卫浴科技(江苏)有限公司

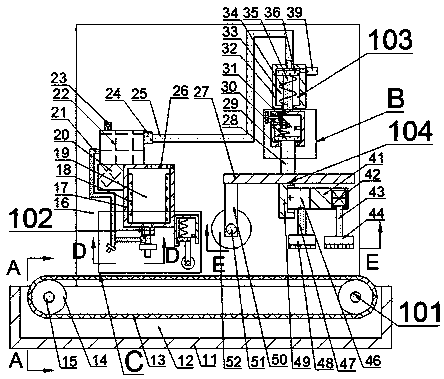

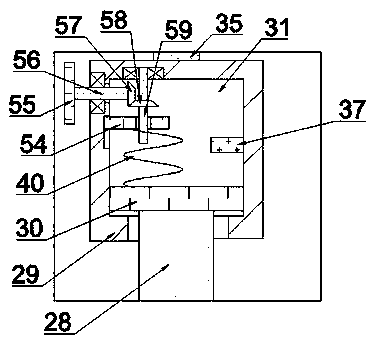

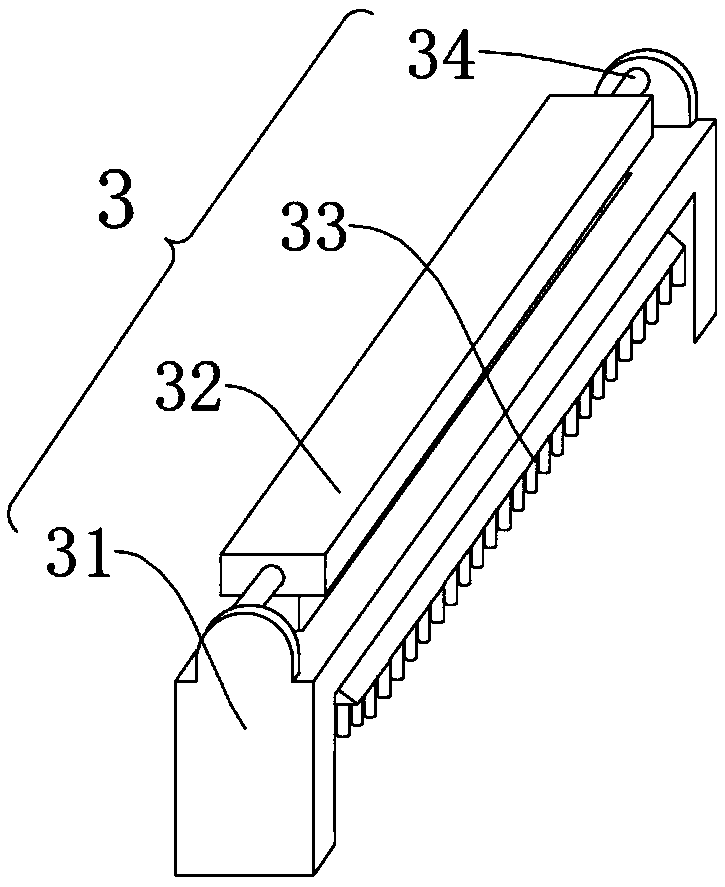

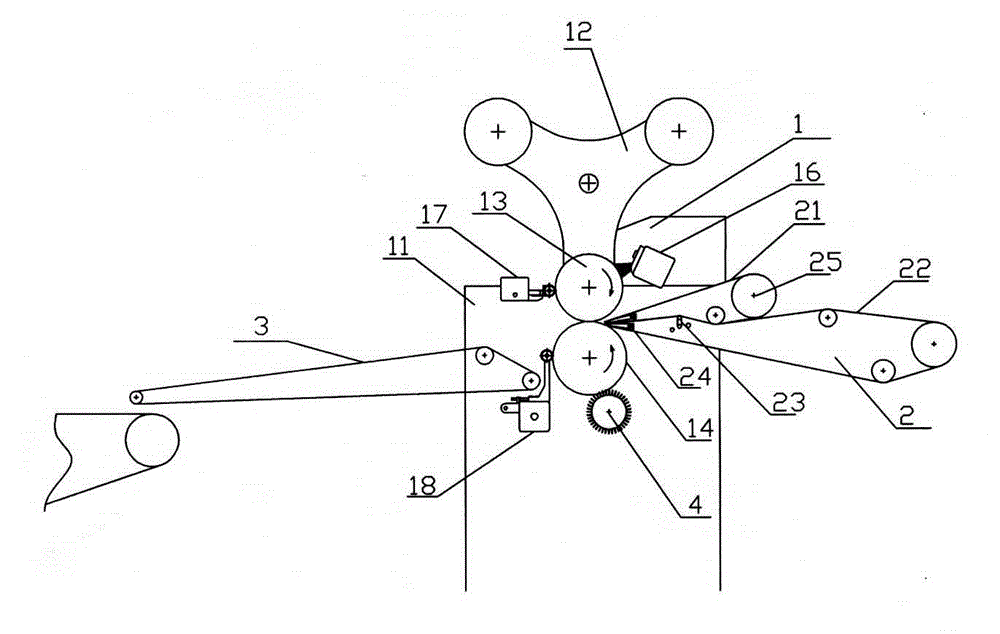

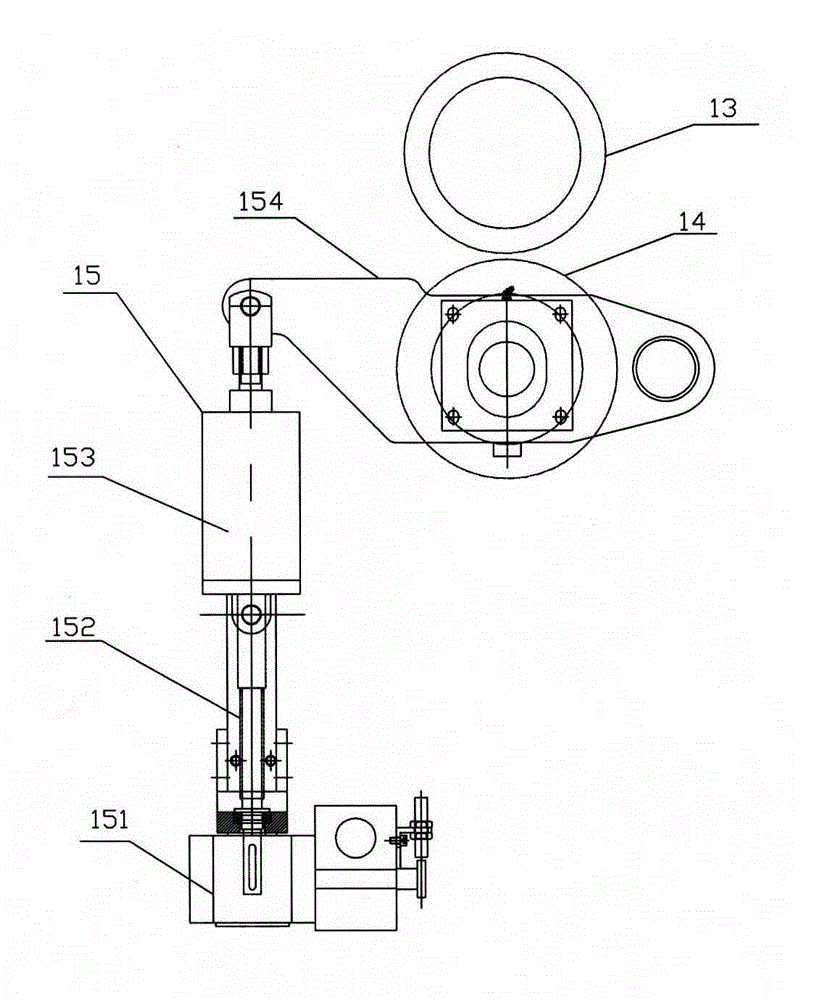

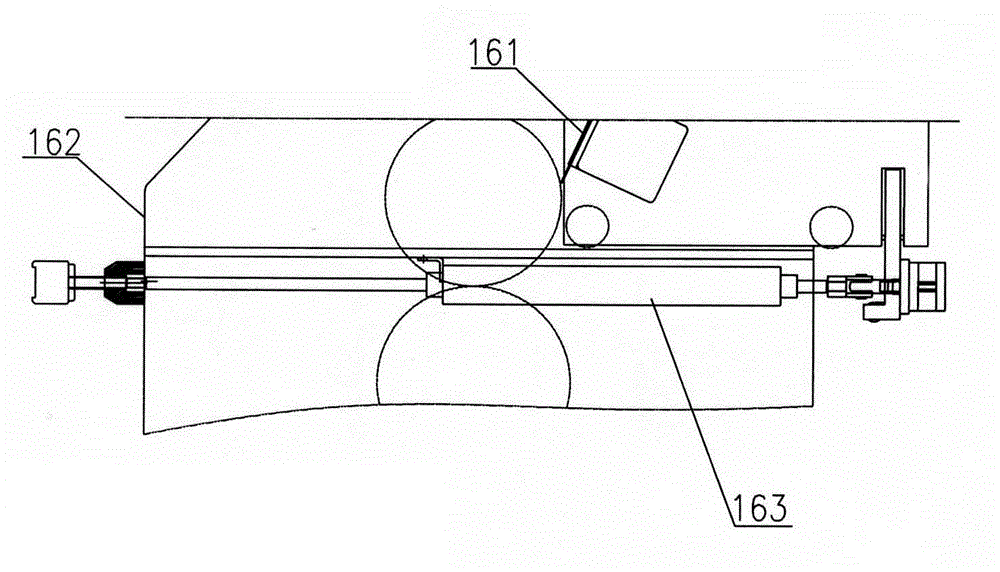

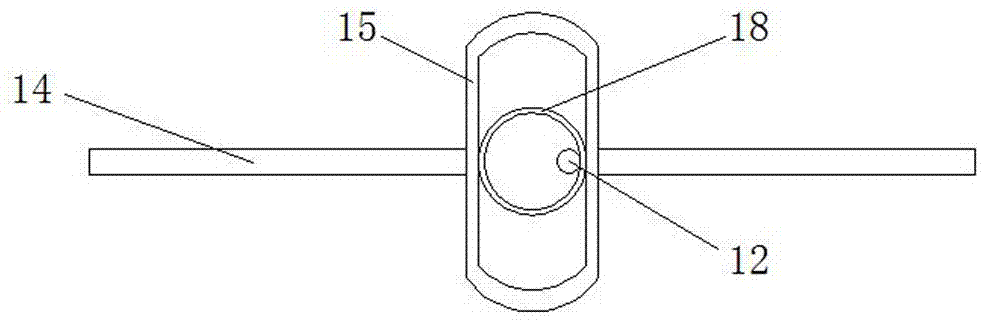

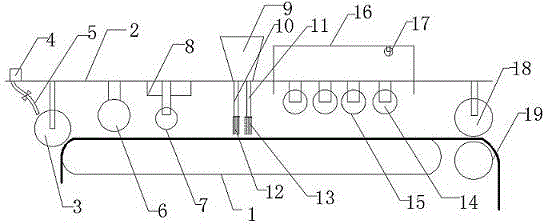

Leather mechanical roller coater

ActiveCN104388606AClean up in timeGuaranteed flatnessLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingEngineeringConveyor belt

The invention discloses a leather mechanical roller coater. The leather mechanical roller coater comprises a main machine, a leather feeding machine and a leather receiving machine, wherein the main machine comprises a rack, a roller changing frame, a rubber coating roller, a steel-made pressure roller, a pressure roller adjustment device, a scraper device, a leather beating roller device and a leather receiving roller device; the leather feeding machine comprises an upper conveyor belt, a lower conveyor belt, a flattening roller wheel device, a leather-feeding angle-pressing device as well as a hairbrush cleaning device. Since the flattening roller wheel device and the leather-feeding angle-pressing device are mounted in the leather-feeding machine, the smoothness of the surface of the leather is ensured; the leather beating roller device is mounted at the leather outlet side of the rubber coating roller and the leather receiving roller device is mounted at the leather outlet side of the steel-made pressure roller so as to ensure that the leather is smoothly transmitted onto the leather receiving machine and prevent the leather from being adsorbed onto the upper surface of the roller body due to too small thickness and further influencing the leather outlet; by virtue of the hairbrush cleaning device mounted at the lower part of the steel-made pressure roller, the roller wheel can be timely cleaned and thus the coating quality of the leather is ensured.

Owner:JIANGSU LIANGANG LEATHER MACHINERY

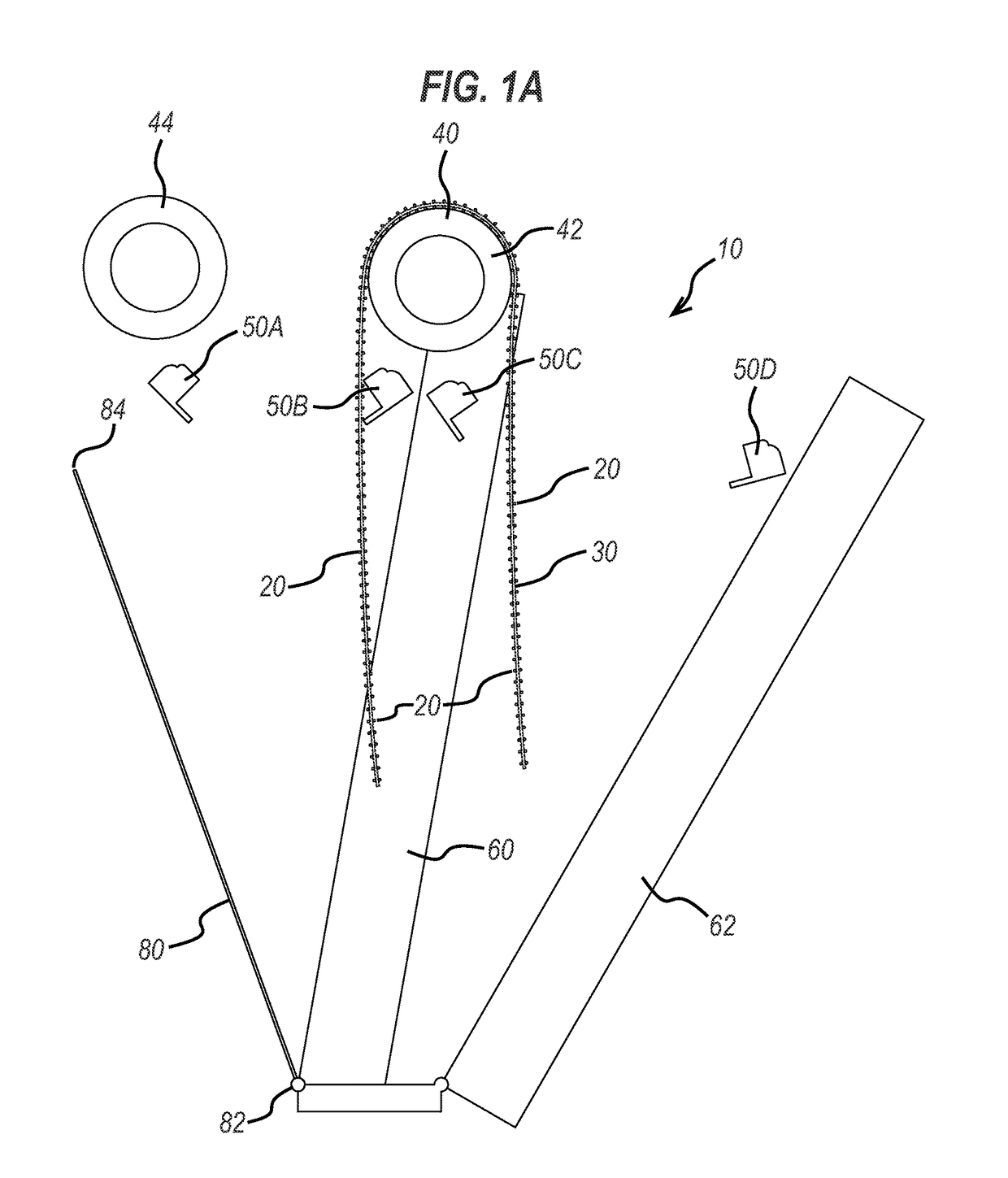

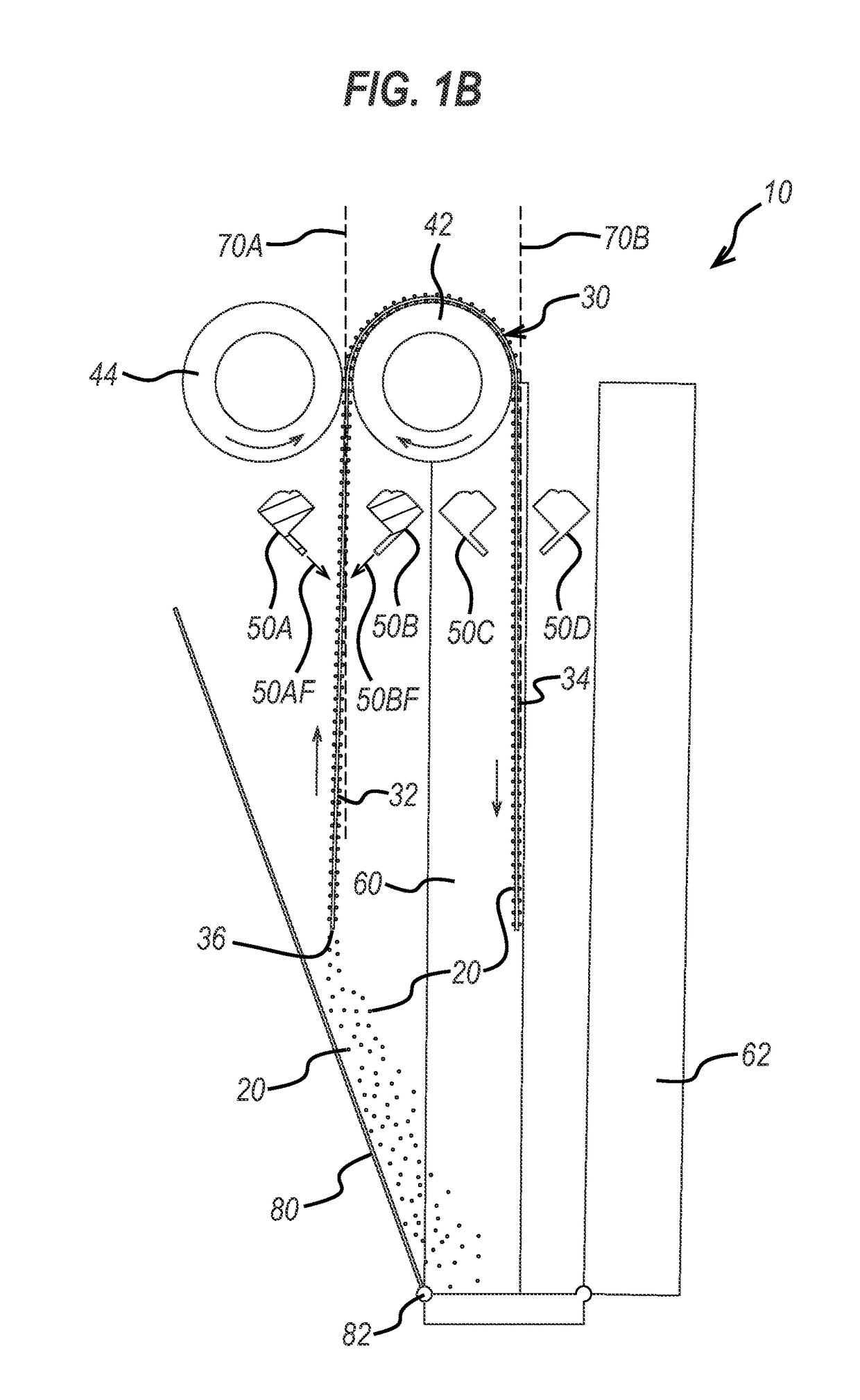

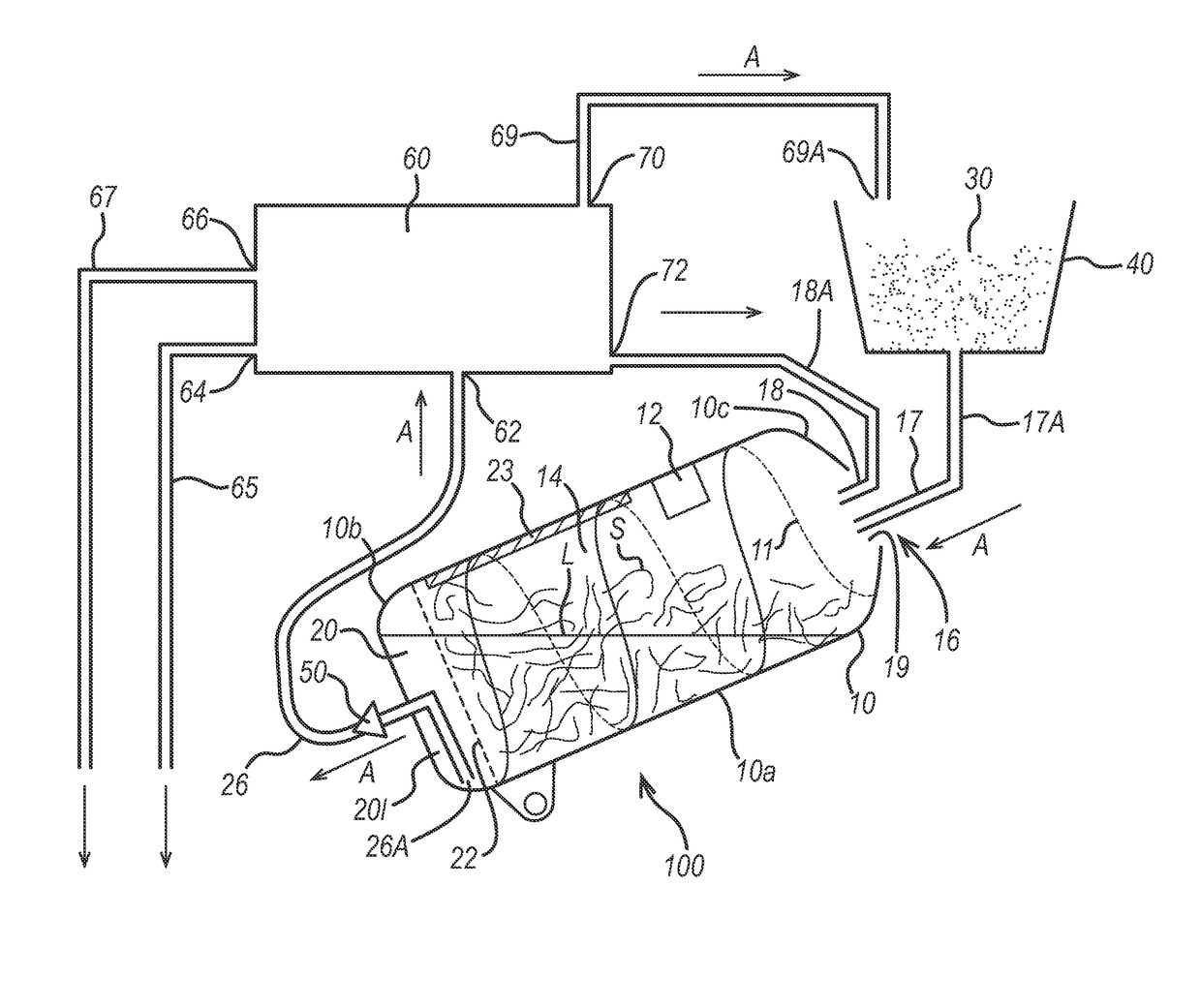

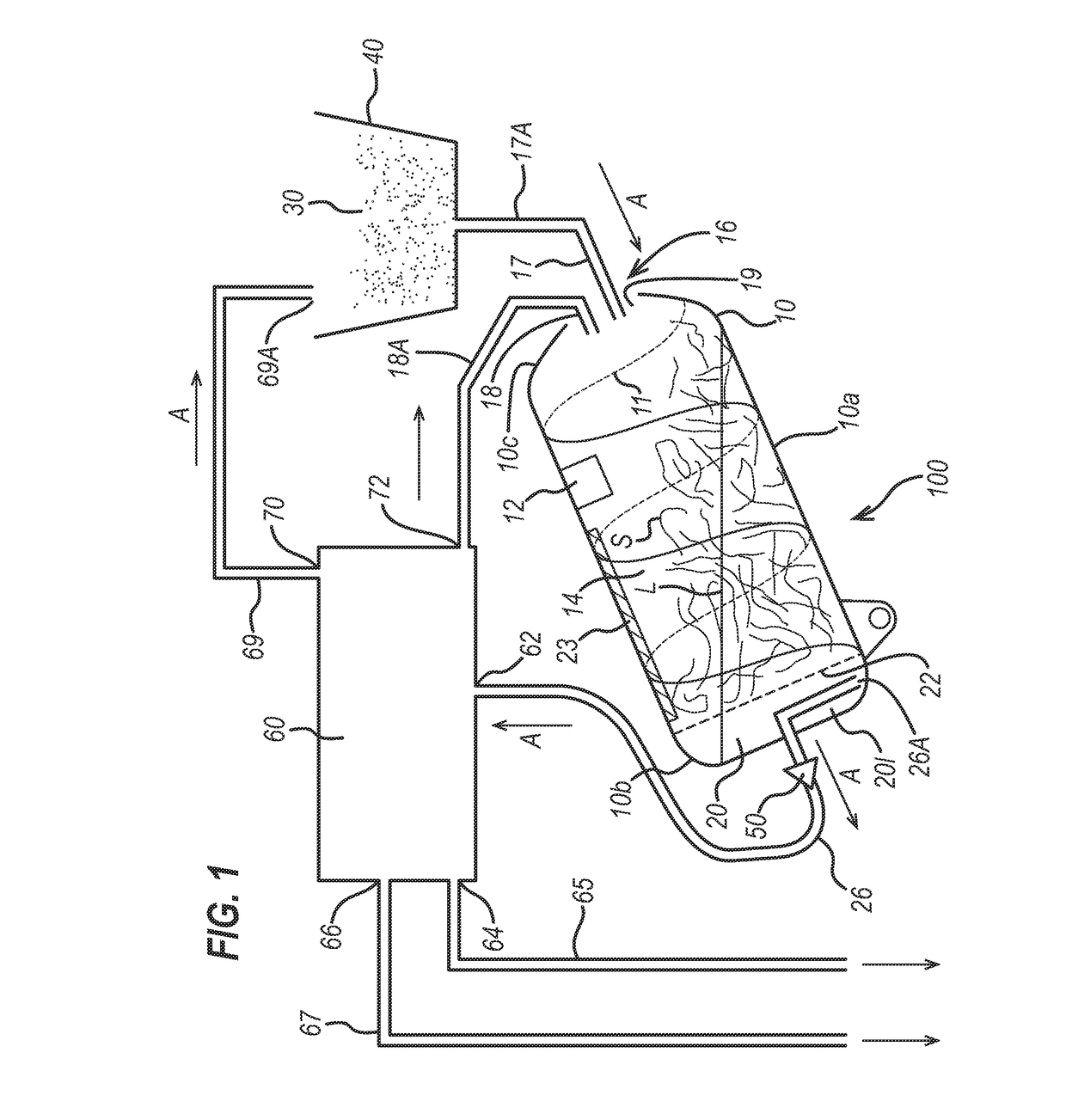

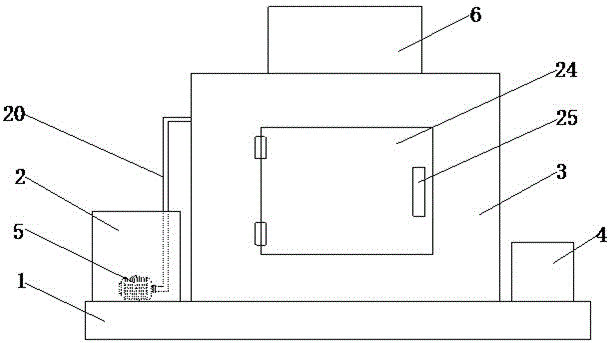

Animal skin substrate treatment apparatus and method

InactiveUS20170240981A1Extended service lifeAvoid passingLeather manufacturingTanning treatmentSolid particleEngineering

The invention relates to an improved method and apparatus for the treatment of animal skin substrates which employs a multiplicity of solid particles. There is disclosed an apparatus for treating one or more animal skin substrates with a multiplicity of solid particles and treatment liquor comprising: a rotatably mounted drum comprising an internal volume having a first portion defining a treatment volume for retaining said animal substrates and a second portion defining a collecting volume; one or more inlets for introducing solid particles and treatment liquor into said treatment volume; a partition separating said treatment volume from said collecting volume wherein said partition allows free passage of solid particles from the treatment volume to the collecting volume and prevents the passage of the substrates therethrough; a circulation path for conveying said solid particles from the collecting volume to the treatment volume; and a pumping device arranged to pump solid particles and said treatment liquor along a portion of said circulation path.

Owner:XEROS LTD

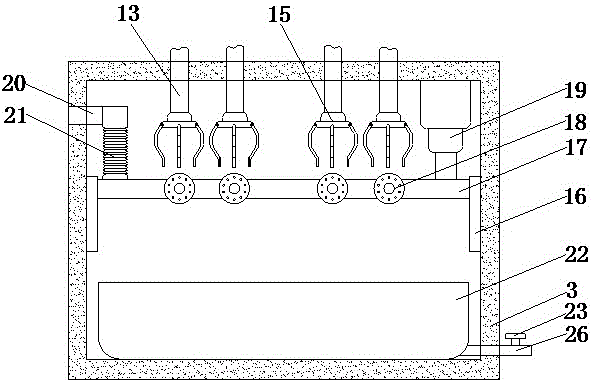

Cleaning device for leather processing

ActiveCN106222333AWash evenlyAvoid entanglementLeather/skins/hides/pelt chemical treatment apparatusSprayerManipulator

The invention discloses a cleaning device for leather processing. The cleaning device comprises a base, wherein a water tank, a cleaning tank and a controller are sequentially arranged on the top of the base from left to right; a water pump is fixedly arranged in the water tank; a machine box is fixedly connected onto the top of the cleaning tank; a clapboard is fixedly arranged in the middle part of the inner cavity of the machine box; a motor is fixedly connected onto the top of the inner cavity of the machine box; and the output shaft of the motor penetrates through the clapboard, extends to the bottom of the clapboard and is fixedly connected with a rotary rod through a coupler. According to the cleaning device for leather processing, through the arrangement of the internal part of the machine box and the internal part of the cleaning tank, under cooperation of a first gear, a second gear, a third gear, rotary shafts and bearings, working personnel hang leather on manipulators; the controller controls the motor to work; meanwhile, water is sprayed through sprayers under the action of the water pump, so that the effect that the leather is cleaned uniformly is reached; the phenomenon that leather is twined during cleaning can be avoided; and the quality of the leather is improved.

Owner:WUXI XINDA LIGHT IND MACHINERY

Processing technology of cowhide leather

InactiveCN107858458AGood removal effectNot perishableTanning treatmentPre-tanning chemical treatmentCross-linkRemoving hair

The invention discloses a processing technology of cowhide leather. The technology comprises the steps of: cleaning, degreasing, hair removal, alkali dipping, deashing, softening, acid dipping and tanning. According to the invention, the ester removal agent used in degreasing treatment can remove the residual ester well, is beneficial to intracutaneous penetration of tanning agent molecules and combination with collagen molecule active groups in a follow-up tanning process, formation of a cross-linked protein fiber three-dimensional network, and improvement of the stability and chemical resistance, and the prepared leather does not rot or deteriorate easily. Through the treatment of alkali dipping, deashing, softening and other steps, mesenchymal protein fiber in cortex can be dissolved, the softness of finished leather can be improved, and the handfeel is comfortable.

Owner:ANHUI DINGHENG LEATHER PROD

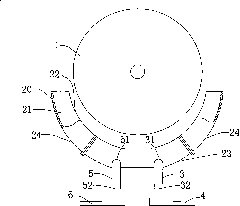

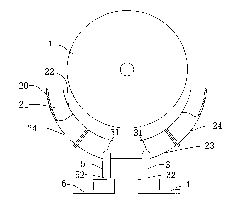

Quick sheepskin dyeing equipment for leather processing factory

ActiveCN106906319AUniform dyeingHighly corrosiveLeather/skins/hides/pelt chemical treatment apparatusInterference fitEngineering

The invention relates to leather dyeing equipment, in particular to quick sheepskin dyeing equipment for a leather processing factory. The quick sheepskin dyeing equipment for the leather processing factory is characterized in that the dyeing time is short, the upper face and the lower face of a sheepskin are uniformly dyed during dyeing, and time and labor are saved in the dyeing process. The quick sheepskin dyeing equipment for the leather processing factory comprises a bottom plate, a first bearing seat, a first rotating rod, a dye box, a first gear, a first motor, a second gear, a supporting plate, a first guide rail, a first guide sleeve and the like. The first bearing seat is installed in the middle of the interior of the bottom plate in a bolted connection mode. The first rotating rod is installed in the first bearing seat in an interference fit connection mode. According to the quick sheepskin dyeing equipment for the leather processing factory, the effects that the dyeing time is short, the upper face and the lower face of the sheepskin are uniformly dyed during dyeing, and time and labor are saved in the dyeing process are achieved.

Owner:桐乡市道远裘革科技有限公司

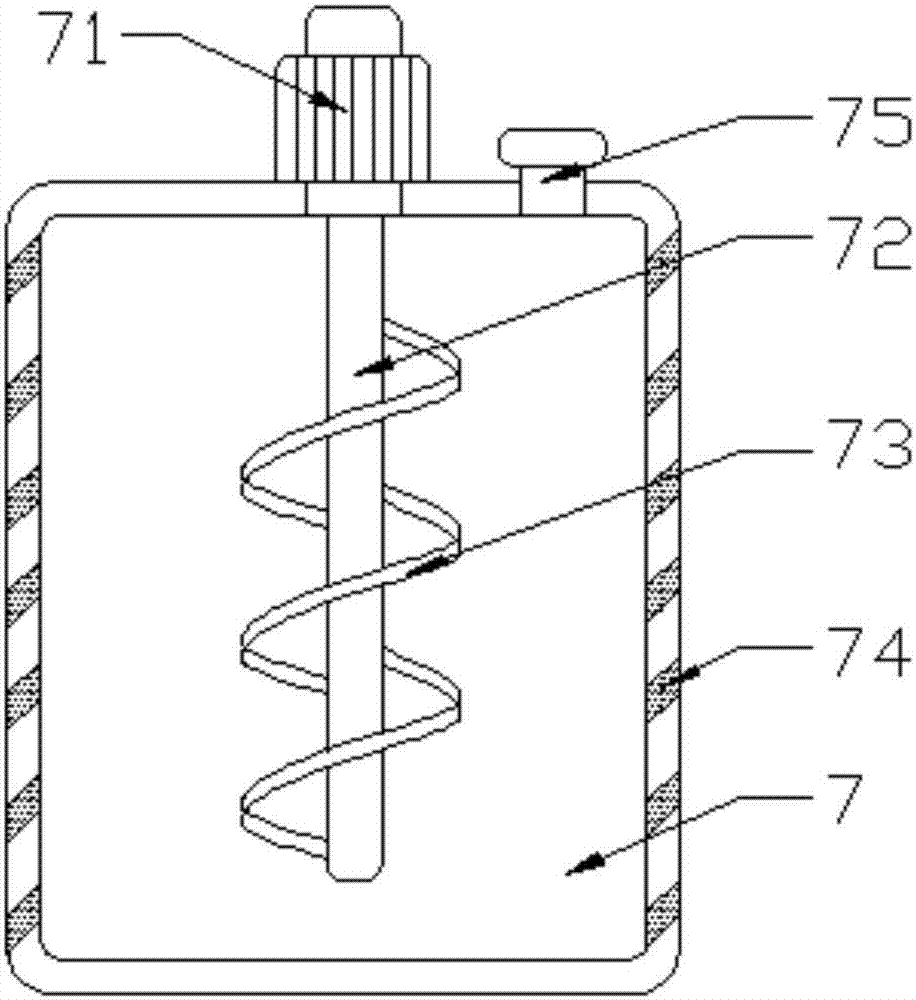

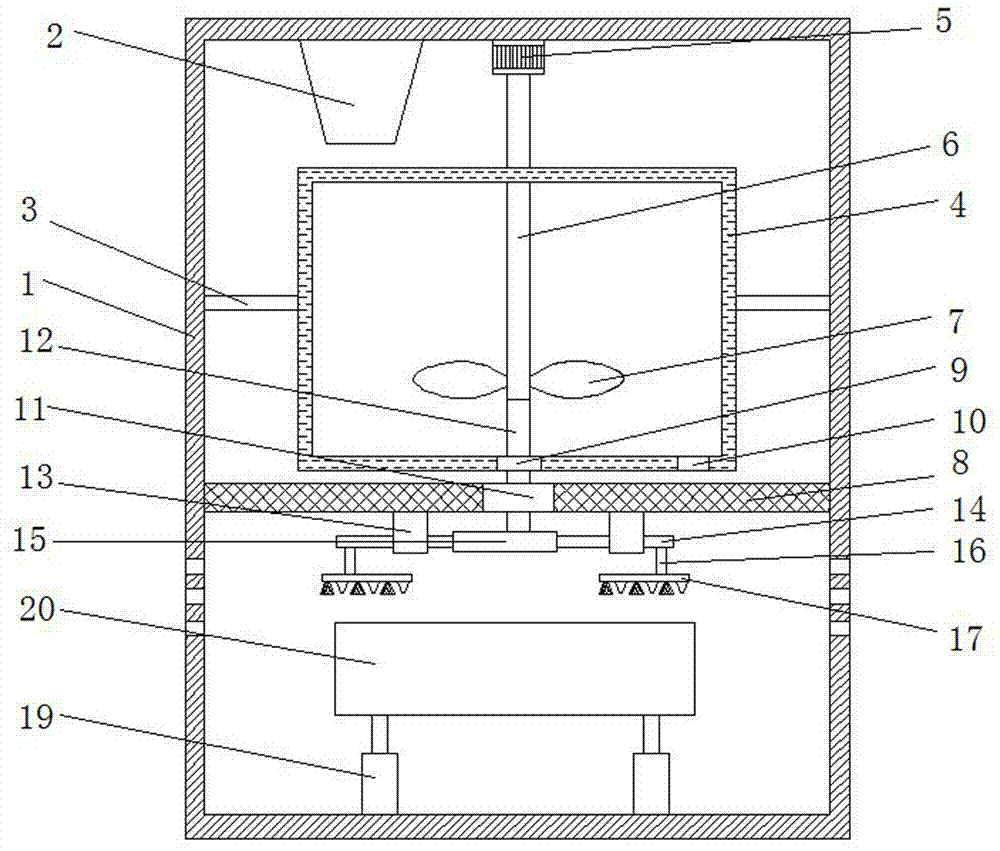

Leather waxing device for cloth manufacturing

ActiveCN107201415AEasy to useStir wellLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingWaxDrive motor

The invention discloses a leather waxing device for cloth manufacturing. The leather waxing device comprises a device body, a feeding hopper is arranged at the top of the device body, a supporting rod is installed on a set of opposite side walls in the device body, a stirring box is arranged between the two supporting rods, and an opening is formed in the top of the stirring box; a driving motor is fixed to the middle portion of the inner wall of a top plate of the device body, an output shaft of the driving motor is connected with a first rotating shaft, fan blades are arranged at the bottom of the first rotating shaft, a first through hole is formed in the middle portion of a base plate of the stirring box, and a first bearing is arranged at the position of the first through hole; and a discharging opening is formed in one side of the base plate of the stirring box, an electromagnetic valve is arranged at the discharging opening, and a fixing plate is installed on one set of opposite side walls in the device body. According to the leather waxing device, leather waxing becomes even and attractive; in addition, wax stirring and waxing are ingeniously combined, continuous production can be achieved, and the production time is shortened; and the device is simple in structure, novel in design and worthy of popularization.

Owner:湖州万顺实业有限公司

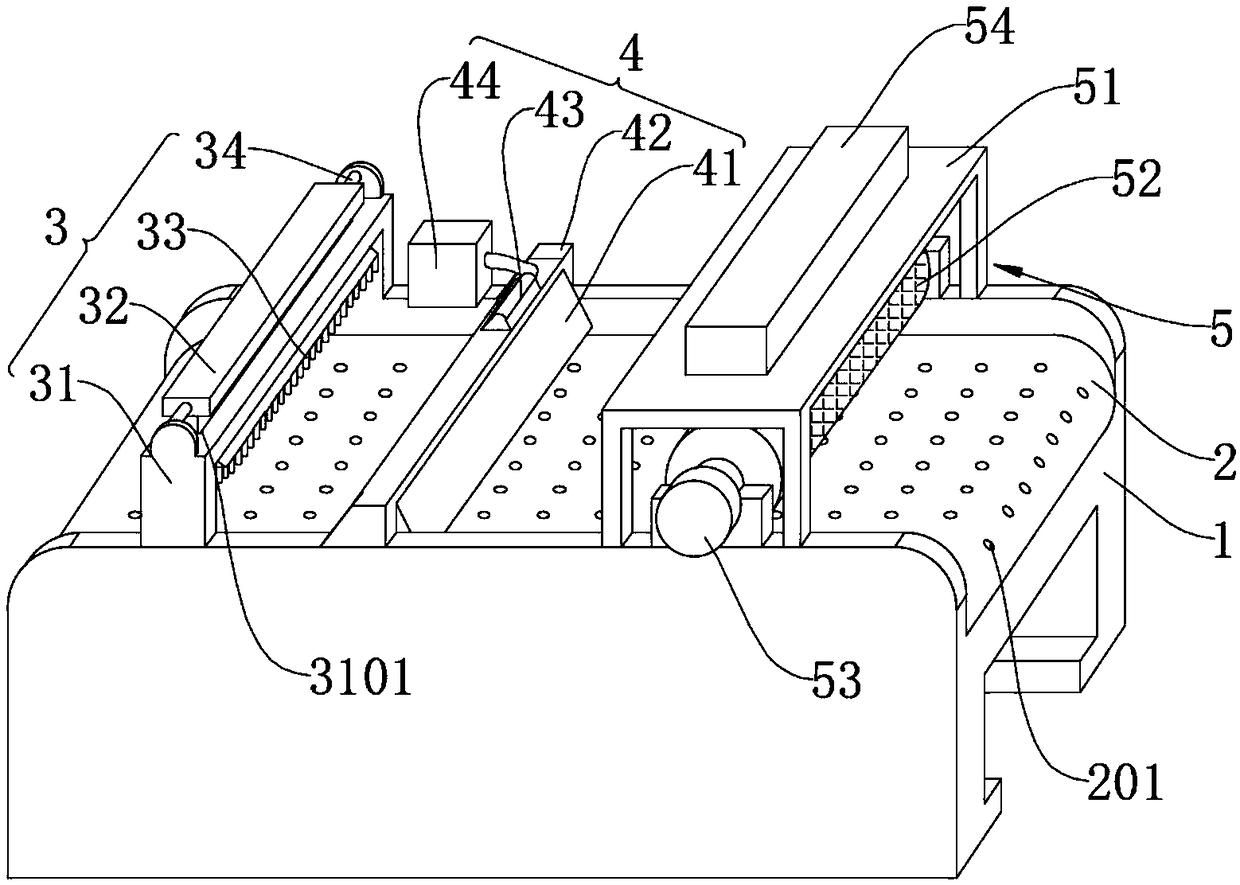

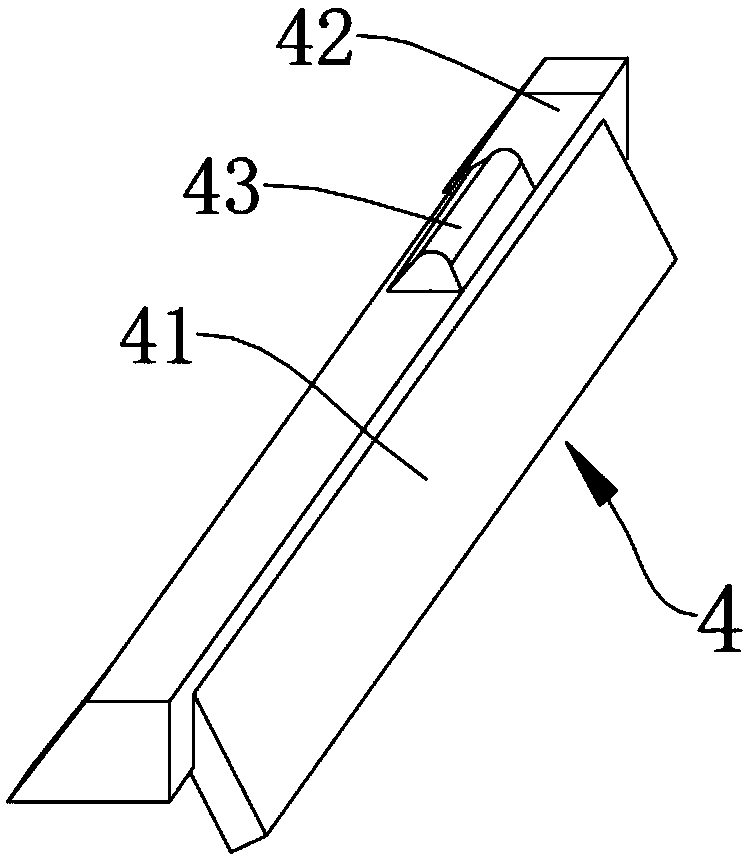

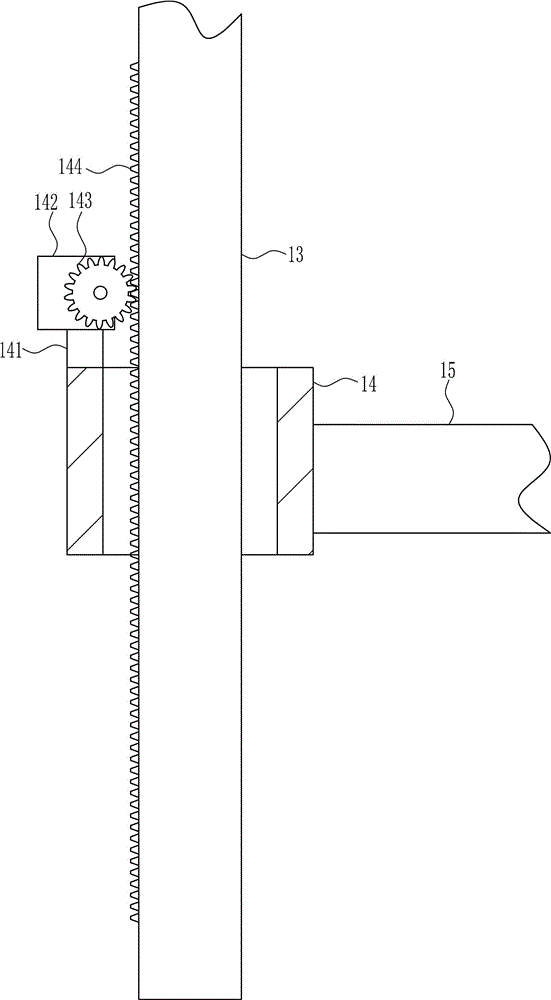

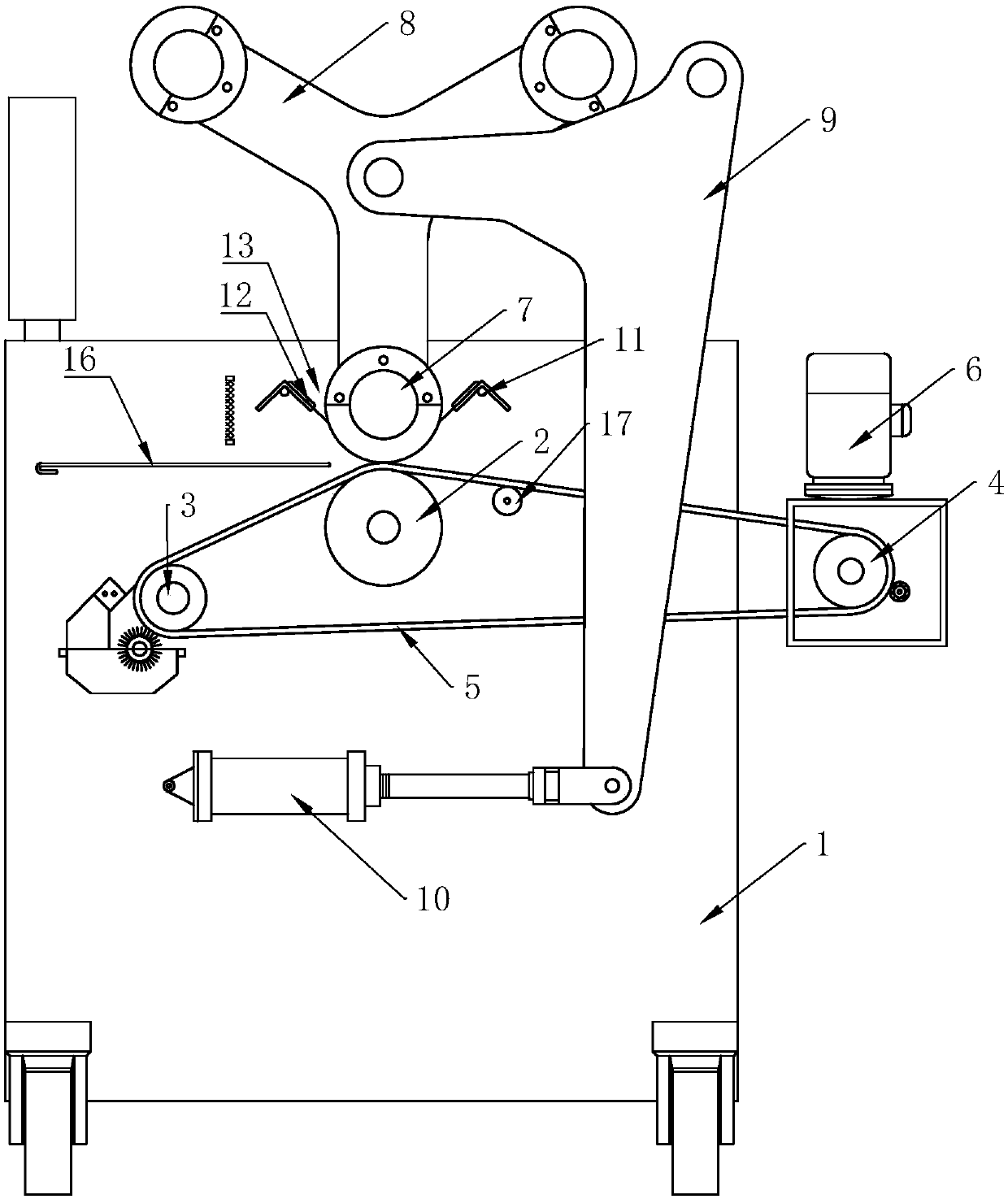

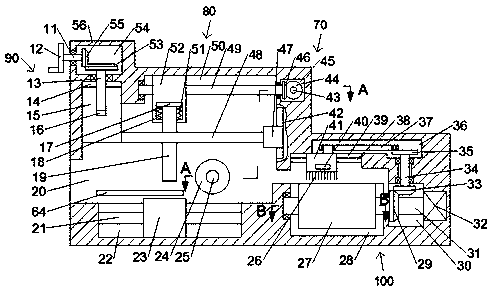

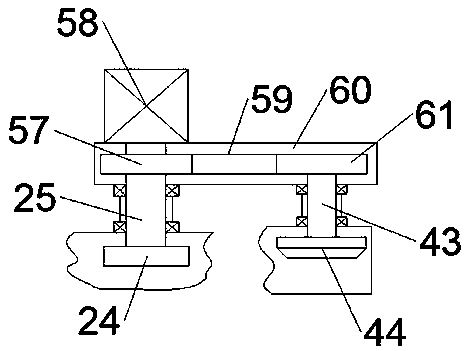

Bottom material pre-coating machine for leather waterborne finishing agent and leather surface processing equipment and technology

InactiveCN108774653AMeet the needs of regular replacementImprove replacement efficiencyLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingEngineeringSlurry

The invention provides a bottom material pre-coating machine for a leather waterborne finishing agent and leather surface processing equipment and technology. The bottom material pre-coating machine comprises a rack, wherein the rack is provided with a pressing roller, a tensioning roller and an adhesive tape transmission roller, wherein a conveyer belt for conveying leather to be covered sleeve among the pressing roller, the tensioning roller and the adhesive tape transmission roller; the adhesive tape transmission roller is in power connection with a driving mechanism; the rack is further provided with a finishing roller; the finishing roller is provided with a finishing roller rapid replacement mechanism; the leather surface processing equipment comprises the bottom material pre-coatingmachine; a leather buffing machine is arranged at the upstream of the equipment, and an ironing machine, a roller printing finishing machine, an ironing embossing machine and a slurry spraying machine are arranged at the downstream of the equipment in sequence; the leather surface processing technology comprises the steps of carrying out leather blank buffing, pre-coating a bottom material, ironing a leather blank, rolling a waterborne wet-process material, embossing and carrying out color spraying. According to the bottom material pre-coating machine for the leather waterborne finishing agent and the leather surface processing equipment and technology, the coating quality and efficiency of the bottom material of a waterborne polyurethane leather finishing agent are improved, and the problems that leather easily has an uneven surface and the edge is not ordered when the exsisting equipment utilizes the waterborne polyurethane leather finishing agent to treat leather are solved.

Owner:山东莱福特皮革制品有限公司

Leather fabric waxing device

InactiveCN104437957AGuaranteed to be straightEasy to apply waxPretreated surfacesLeather/skins/hides/pelt chemical treatment apparatusCold airEngineering

The invention relates to a leather fabric waxing device which comprises a conveying belt supported by a supporting frame to accommodate a leather fabric, wherein a clean sponge stick is arranged above one end of the conveying belt through an upper bracket, a water tank is arranged above the clean sponge stick, a downcomer with a valve is connected below the water tank and is connected above the downcomer, a blowpipe is arranged on one side of the clean sponge stick on the upper bracket, a rolling wheel of which an outer layer is a piece of dry cloth is hoisted on the upper bracket on one side of the blowpipe, a waxing box for accommodating wax liquid is arranged on the upper bracket, a pre-coating discharge pipe and a waxing pipe are respectively arranged below the waxing box, a hard brush is connected below the pre-coating discharge pipe, a soft brush is connected below the waxing pipe, a plurality of cold air pipes and a plurality of hot air pipes are also arranged on the upper bracket, and an upper rolling wheel and a lower rolling wheel are arranged at the other end of the conveying belt. The leather fabric waxing device has the benefits that the leather fabric is uniformly waxed, and the processing speed is high.

Owner:倪国权

Leather wallet material processing device

ActiveCN110172533AGuaranteed smooth grindingSimple structureEdge grinding machinesGrinding drivesEdge surfaceBristle

The invention discloses a leather wallet material processing device. The leather wallet material processing device comprises a processing box. The processing box is internally provided with a transmission cavity. A grinding threaded rod rotates to drive a grinding threaded block to move left and right. The grinding threaded block moves to drive a pressure rod to move. The moving mechanism drives the pressure rod to move up and down to adjust the position and press leather. A main motor of a transmission mechanism provides power to drive the pressure rod to move left and right and drive a grinding stone to rotate to conduct grinding on the edge of the leather. The leather wallet material processing device grinds the edge surface of the leather smooth. An auxiliary motor in a waxing mechanism provides power to drive a brush block to move left and right to conduct waxing on the surface of the leather automatically through bristles.

Owner:义乌市玉刚箱包有限公司

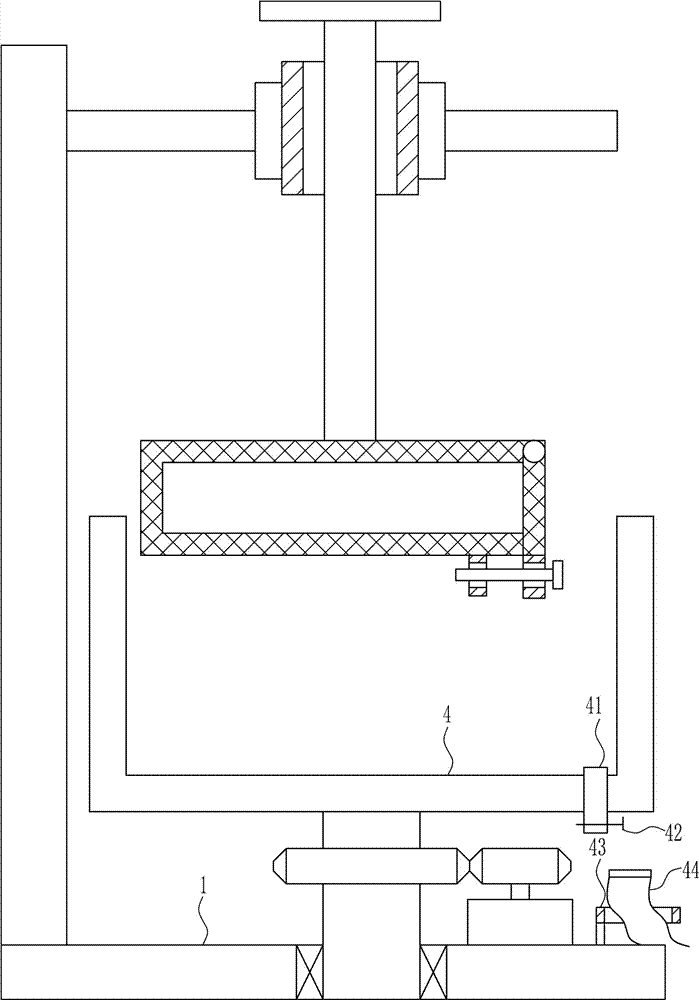

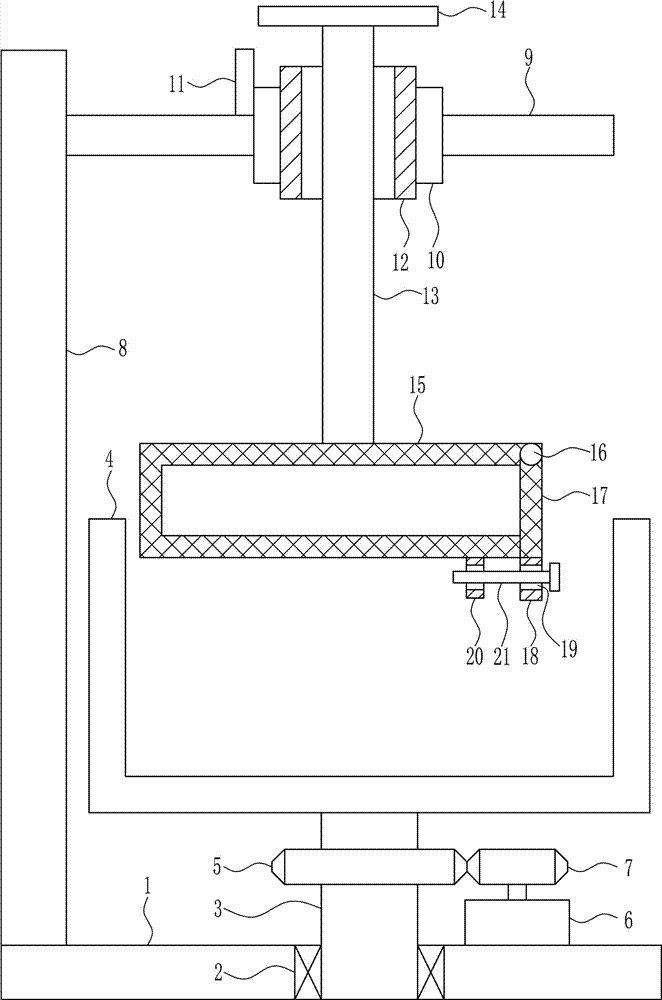

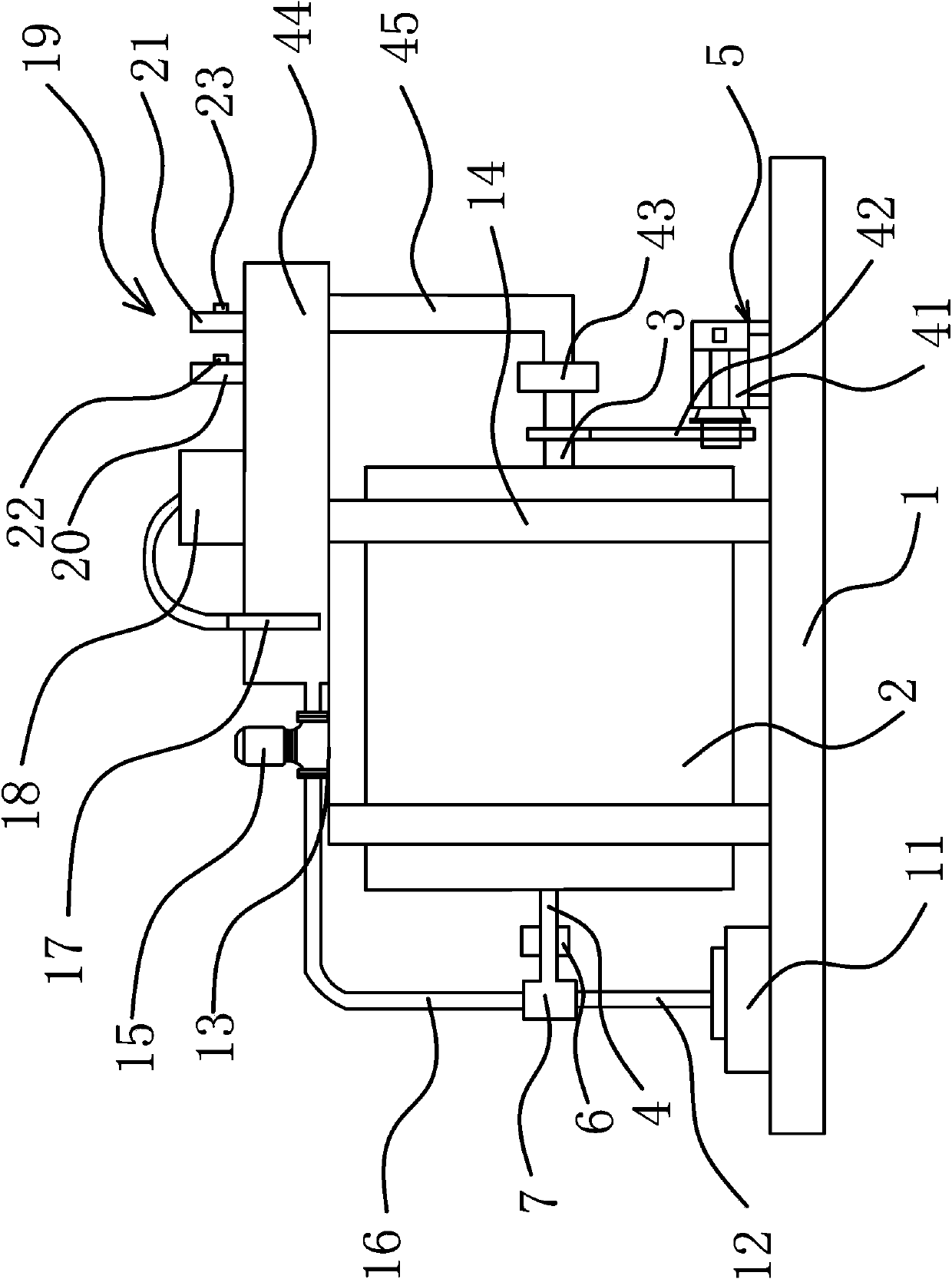

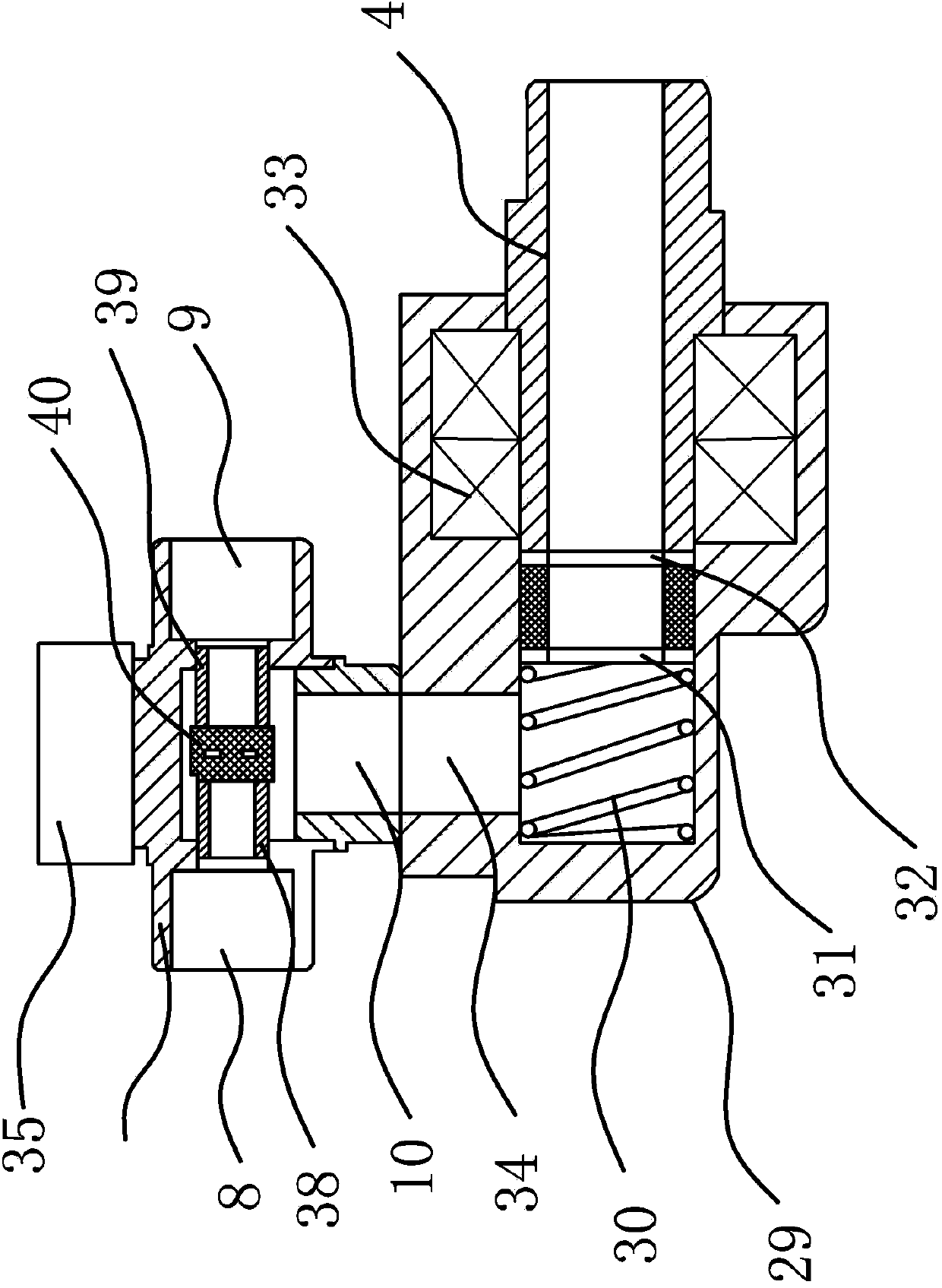

Leather dyeing machine

ActiveCN103388038AIncreased dyeing rateEliminate surface resistanceLeather/skins/hides/pelt chemical treatment apparatusDyeing processEngineeringPre treatment

The invention provides a leather dyeing machine, and belongs to the technical field of leather dyeing equipment and the leather dyeing machine can be used for solving the technical problem in the prior art that the leather dyeing machine has low dyeing efficiency. The leather dyeing machine comprises a base, wherein the base is provided with a drum body, the drum body is internally provided with an inner cavity, a rotary shaft I and a rotary shaft II are respectively fixed at two ends of the drum body, a drive device is arranged between the base and the outer end of the rotary shaft I, the rotary shaft II is pivoted on the base, a rotary joint II is arranged outside the rotary shaft II, a power-driven three-way valve is connected outside the rotary joint II, the power-driven three-way valve comprises an outlet I, an outlet II and an inlet, the inlet is communicated with the outer side of the rotary joint II, a vacuum pump is also fixed on the base, and the vacuum pump is communicated with the outlet I through a gas guide tube. Through vacuum pretreatment on the leather in the inner cavity of the drum body, the dyeing efficiency of the leather dyeing machine is improved.

Owner:浙江富邦汽车内饰科技有限公司

Leather cleaning agent

InactiveCN103666795AStay softEffective waterproof and decontaminationSurface-active detergent compositionsLeather/skins/hides/pelt chemical treatment apparatusSodium metasilicateDioxyethylene Ether

The invention relates to a leather cleaning agent and belongs to the technical field of fine chemicals. The leather cleaning agent comprises the following components in parts by weight: 1 to 3 parts of vitamin E, 20 to 25 parts of neats-foot oil, 0.1 to 0.5 part of lipase, 2 to 5 parts of polyoxyethylene lauryl ether, 0.2 to 0.5 part of pine needle essential oil, 20 to 25 parts of isopropyl alcohol, 2 to 6 parts of sodium metasilicate, 1 to 2 parts of preservative, 1 to 2 parts of foaming agent and 100 to 130 parts of water. The leather cleaning agent disclosed by the invention uses the water as a solvent, does not contain stearate and is environmental-friendly; when the product disclosed by the invention is adopted to clean leather, a layer of protective film can be formed on the leather, water can be effectively prevented, dirt can be effectively removed and the leather is kept soft; in addition, the product disclosed by the invention has a wide application range and can be used for cleaning leather sofas, leather shoes, leather bags and the like.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

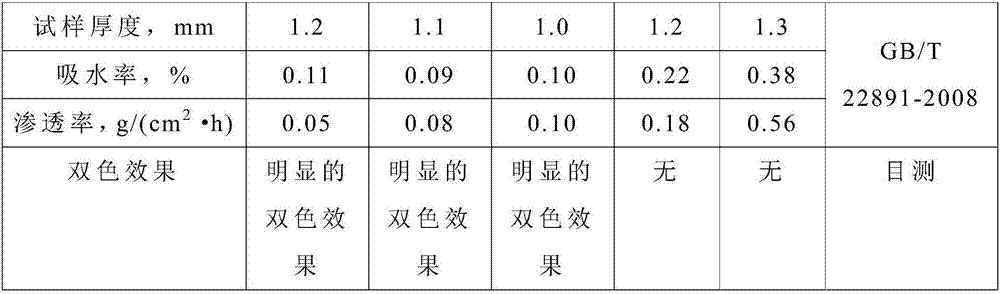

Manufacturing method of bicolor wax-texture crack split leather

ActiveCN107236833AStrong two-color contrast effectImprove performanceLeather/skins/hides/pelt chemical treatment apparatusLeather softeningWaxCrazing

The invention relates to a manufacturing method of bicolor wax-texture crack split leather and belongs to the technical field of leather. The manufacturing method of the bicolor wax-texture crack split leather comprises the following steps that processed and dyed split leather is obtained, dried, ground, milled, sprayed for the first time, roll-finished, sprayed for the second time, vibration-softened, rolled with oil wax and milled in sequence, and thus the bicolor wax-texture crack split leather is obtained. According to the manufacturing method of the bicolor wax-texture crack split leather, the processed and dyed split leather is dried, ground, milled, sprayed for the first time, roll-finished, sprayed for the second time, vibration-softened, rolled with the oil wax and milled, and the technological conditions of the steps and the chemical therapy ratio are strictly controlled and optimized, so that the low-level split leather is manufactured into the high-level crack leather with the wax texture, and the crack leather further has the strong bicolor contrast effect.

Owner:漳州香洲皮革有限公司

Leather production process

InactiveCN104894299AIncreased durabilityLow costTanning treatmentPre-tanning chemical treatmentFiberEngineering

The invention discloses a leather production process, which comprises the steps of 1) lot grouping: classifying the raw hides of leathers similar in width size and thickness; 2) soaking in water: soaking the raw hides in water after the lot grouping step; 3) unhairing and degreasing: removing grease in hide cells and hairs on the surfaces of the raw hides; 4) liming: adding alkali to expand the hides to a certain thickness for facilitating the splitting operation; 5) deliming and pickling: removing redundant alkali in the raw hides during the liming step; 6) tanning: connecting collagen groups in hide fibers by means of trivalent chromic ions, and enhancing the tensile strength and the anti-tear intensity of the leather; 7) re-tanning: selecting a retanning agent of better in filling effect to retan the tanned leather; 8) dyeing; 9) fatliquoring; 10) drying; 11) staking; 12) finishing; 13) examining and warehousing finished products. The leather production process is simple in operation, and the produced leather is good in durability. Meanwhile, the cost of manufacturers is saved, and the requirements of customers can be met at the same time.

Owner:卢家雄

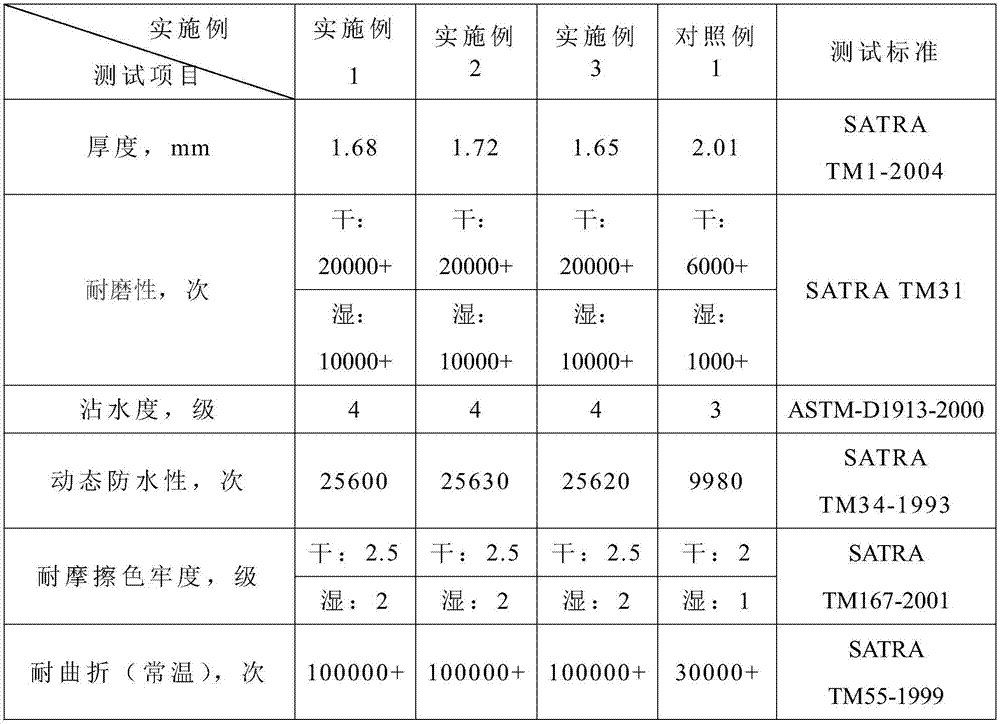

Production method for waterproof and flame-retardant shoe upper leather

ActiveCN107881269AImprove compactnessReduce usageTanning treatmentLeather/skins/hides/pelt chemical treatment apparatusManufacturing technologyAcrylic resin

The invention relates to the technical field of leather manufacturing technologies and provides a production method for waterproof and flame-retardant shoe upper leather. Chromium-zirconium-aluminum and zirconium-aluminum-titanium which have the flame-retardant property serve as a tanning agent and a retanning agent to conduct tanning and retanning; the retanning agent, a neutralizing agent and afatting agent which have the waterproof property are selected to enable the leather to have the waterproof property; an environment-friendly-type flame retardant is selected to enable the leather to have the flame-retardant property; and modified graphene-based acrylic resin and modified graphene-based polyurethane are added in filling and coating materials to serve as waterproof and flame-retardant enhancers to enable the leather to have the good waterproof and flame-retardant effects. According to the production method, under the precondition that natural leather has the excellent quality, the environment-friendly and flame-retardant effects of the leather can be achieved, the dosage of the flame retardant is reduced, the production cost is reduced, and the production method is suitablefor batch production and application.

Owner:XINGYE LEATHER TECH CO LTD

Filtering and recycling device for leather dyeing

InactiveCN106669257ADyeing fastImprove filtration efficiencyLeather/skins/hides/pelt chemical treatment apparatusMoving filtering element filtersCheck valveWaste management

The invention relates to a filtering device, in particular to a filtering and recycling device for leather dyeing, and aims to provide the filtering and recycling device for leather dyeing. In order to solve the technical problem, the filtering and recycling device for leather dyeing comprises a filter box, guide rails, a check valve, a first hose, a filtering device, a stirring device and the like, wherein the first hose is connected to the bottom of the filter box; the check valve is arranged on the first hose; the guide rails are arranged on the left and right inner walls of the filter box; the filtering device is arranged on the guide rails; the stirring device is arranged on the filtering device. The device is high in filtering efficiency, higher in filtering accuracy and convenient to replace and operate, and leather is completely mixed with dye liquor, and can be rapidly dyed by the dye liquor.

Owner:翁帆安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com