Patents

Literature

48results about How to "Increased dyeing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

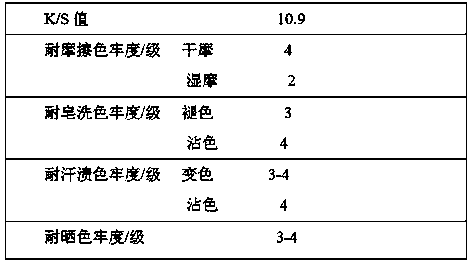

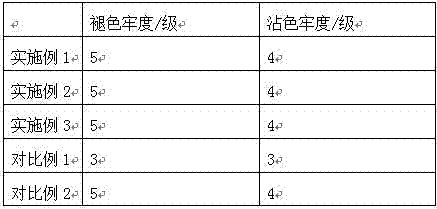

Process for dyeing silk interwoven jacquard fabric

ActiveCN104018369AShorten process timeIncrease productivityDyeing processColour fastnessPolymer science

The invention discloses a process for dyeing a silk interwoven jacquard fabric, belonging to the field of silk interwoven jacquard fabric dyeing technology. The process comprises the steps of dye fixing, primary washing, soaping, secondary washing and cylinder discharge and drying, wherein in the dye fixing step, the pretreated silk interwoven jacquard fabric is put into an active dye solution and dyed by adopting a jig dyeing method at 80-85 DEG C for 60-200 minutes; the active dye solution is obtained by mixing 1-5% owf of lanasol dye, 1-5% owf of HE type dye, 20-50g / L of anhydrous sodium sulphate, 5-20g / L of sodium carbonate and water. The process disclosed by the invention can be used for realizing bath dyeing when silk fibers and cellulose fibers in the silk interwoven jacquard fabric are dyed with different colors respectively, the color fastness of the obtained silk interwoven jacquard fabric with the double-color effect can reach the two-bath dyeing fastness, meanwhile, energy is saved, emission is reduced, and the process time is obviously shortened.

Owner:ZIBO DARANFANG SILK GRP

Reactive dye salt-free pad dyeing method

InactiveCN102199886AReduce the number of washesReduce water consumptionDyeing processLiquid/gas/vapor textile treatmentSocial benefitsSalt free

The invention relates to a reactive dye salt-free pad dyeing method. The method comprises the following steps: (1) mercerizing cotton fabrics, padding caustic soda, then expanding the fabrics, spraying diluted alkali and sucking; then washing with water 2-3 times; and then directly soaking the fabrics in the aqueous solution of caustic soda to carry out alkali wash 2-4 times, drying and cropping for later dyeing so as to obtain the mercerized fabrics with alkali; and (2) dyeing the mercerized fabrics with alkali, wherein dye padding is in an alternately soaking and rolling mode and the machine speed is 20-80m / min; and then pre-drying with infrared for 0-1min, then drying t with hot air and finally washing with cold and hot water and drying. The method has the following beneficial effects: the method is simple to operate and the cost is lowered; and salt-free dyeing is realized under the condition that the performances and color fastness of the dyed fabrics are ensured, the dyeing rate is improved, the washing frequency and water consumption in the mercerizing process are reduced, steam and energy are saved and the method has good economic and social benefits.

Owner:DONGHUA UNIV +1

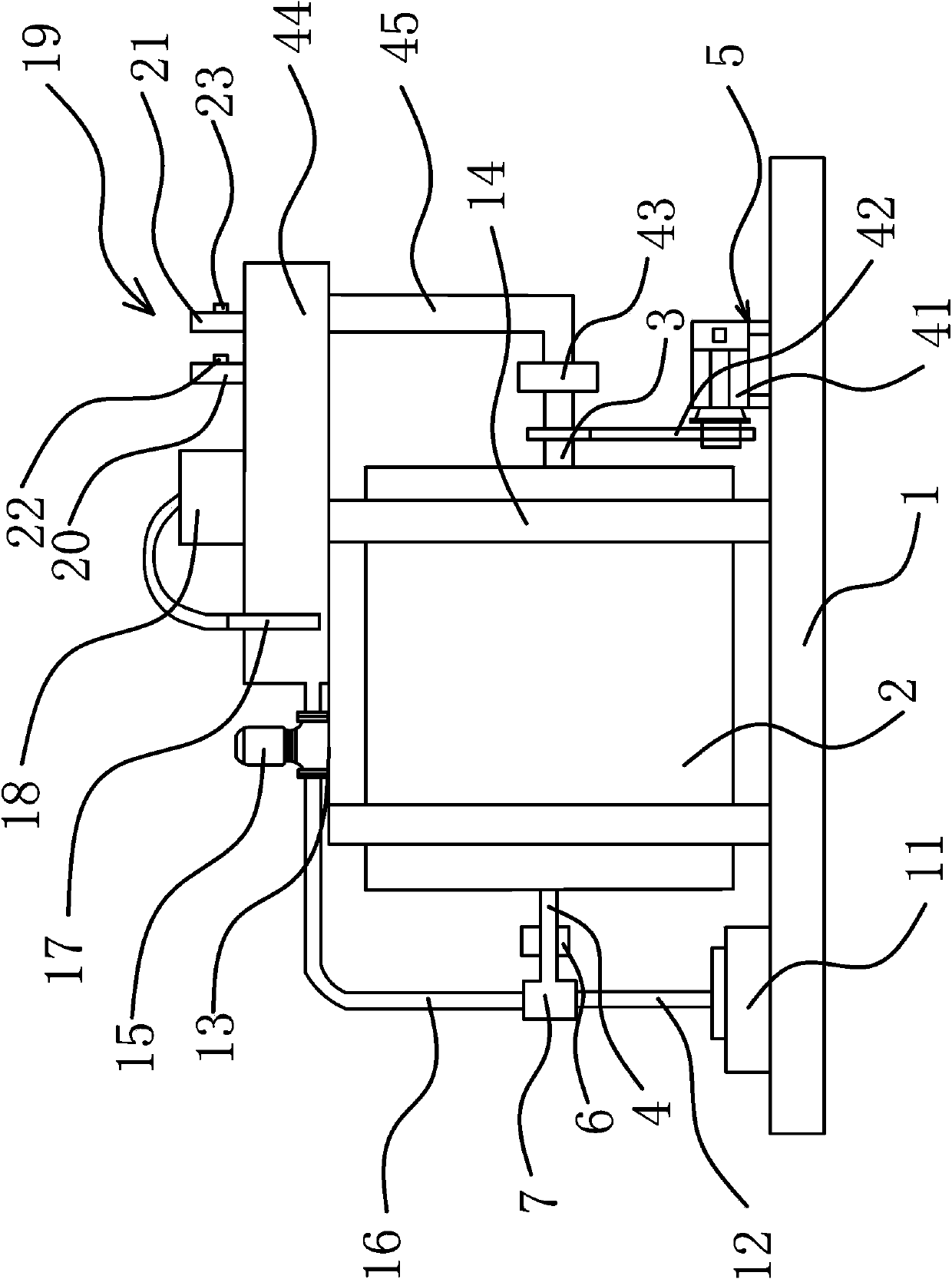

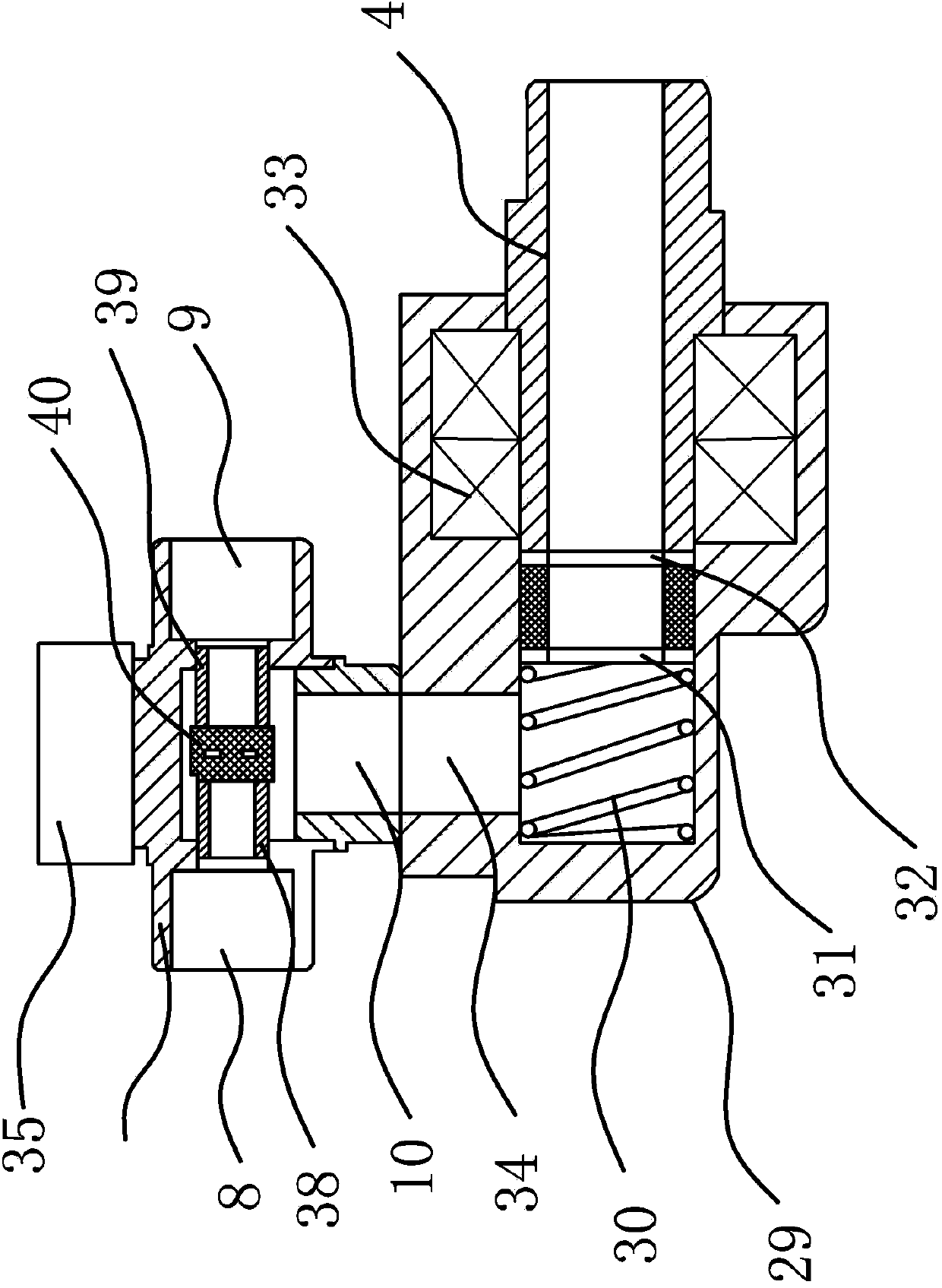

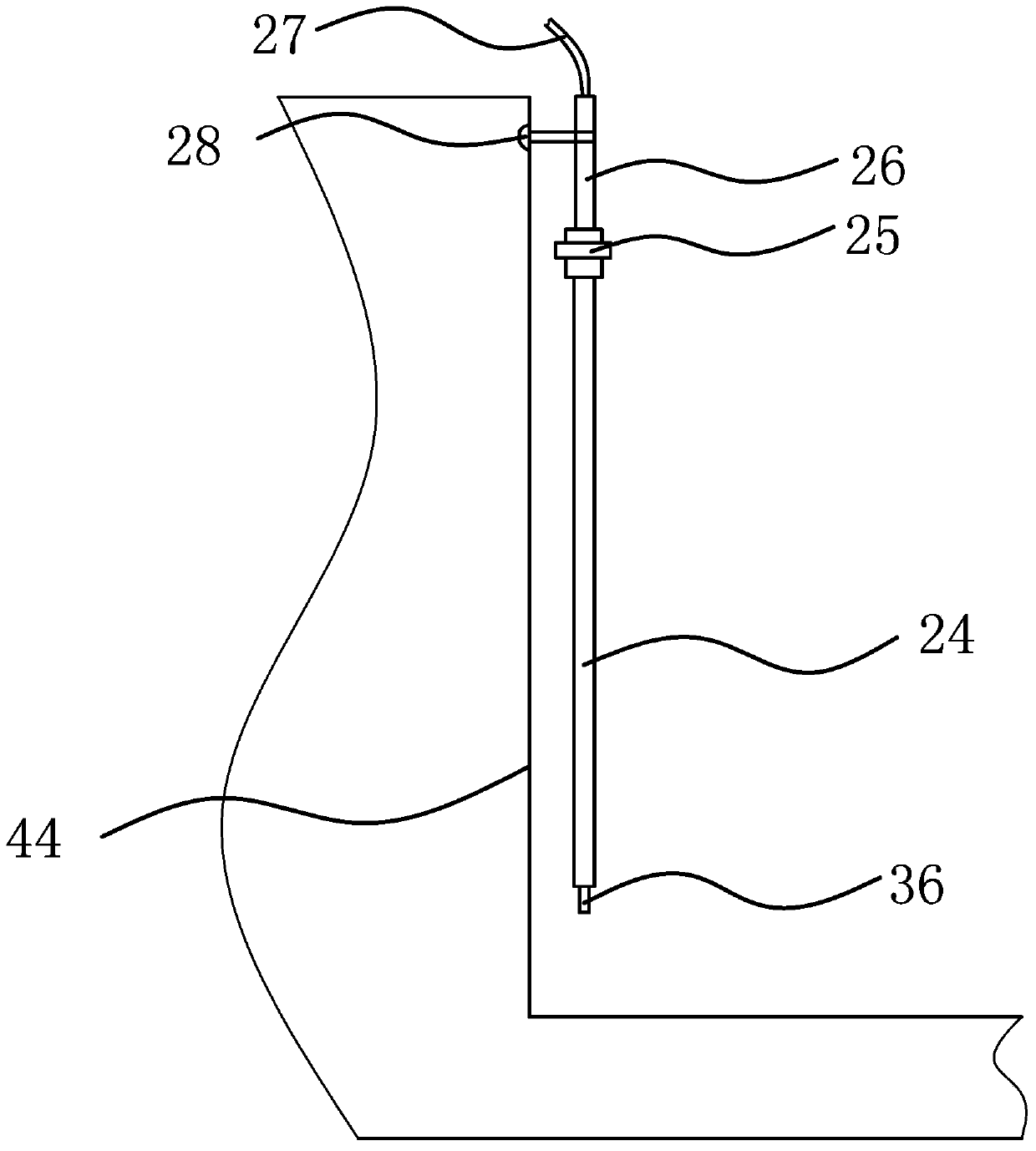

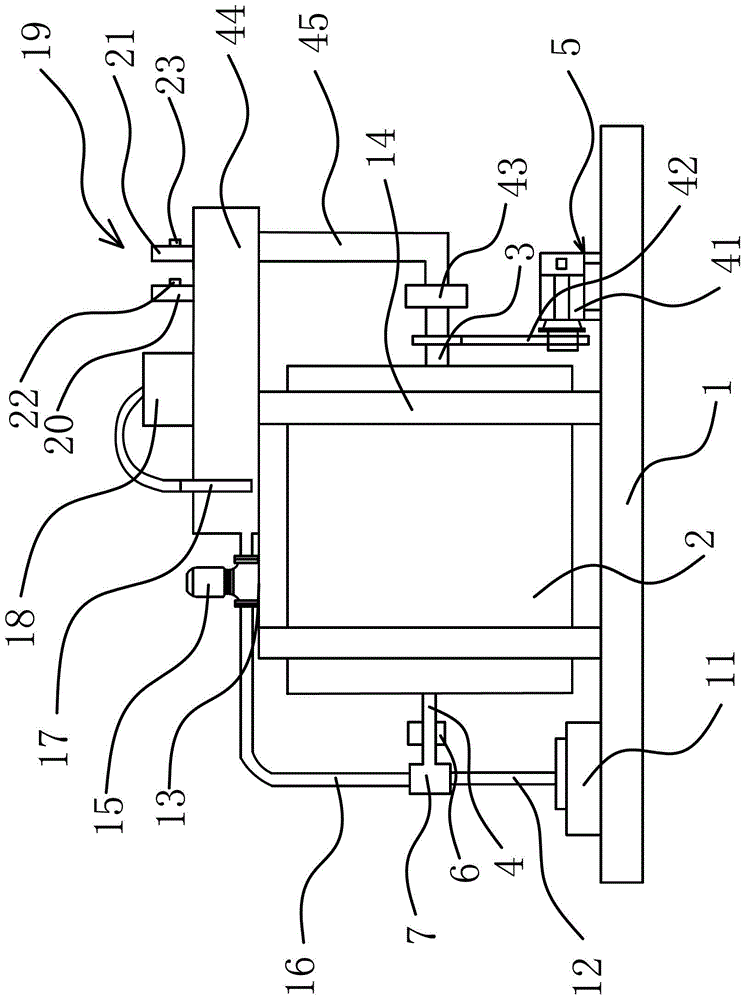

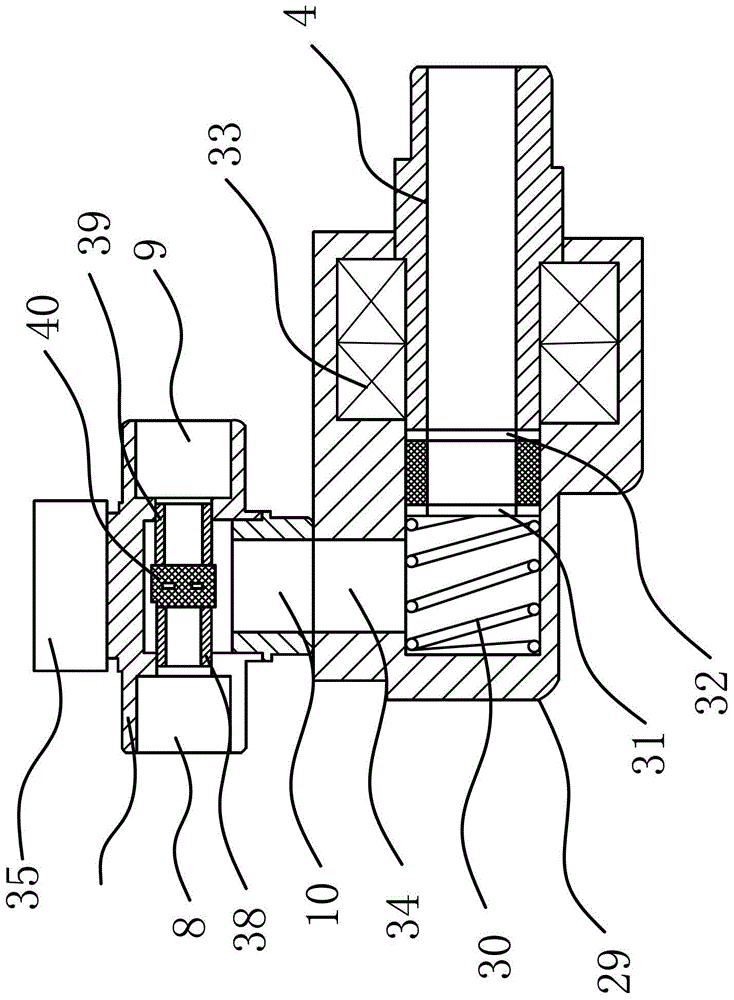

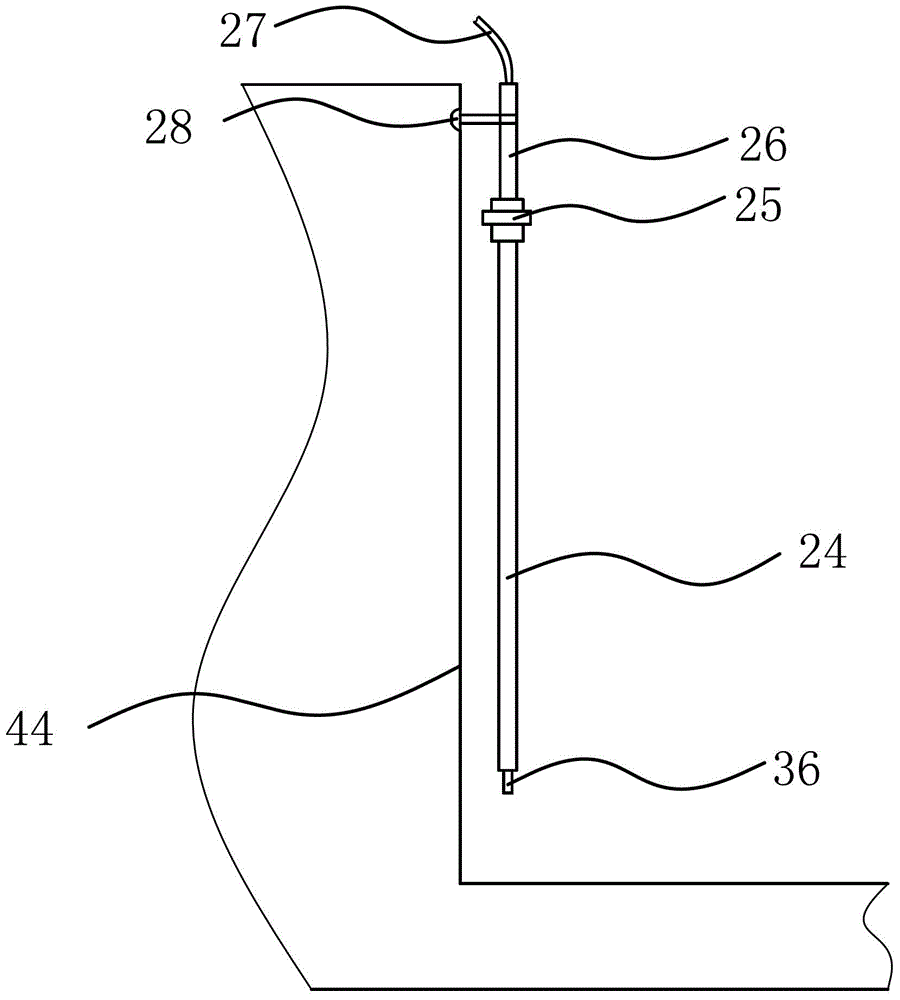

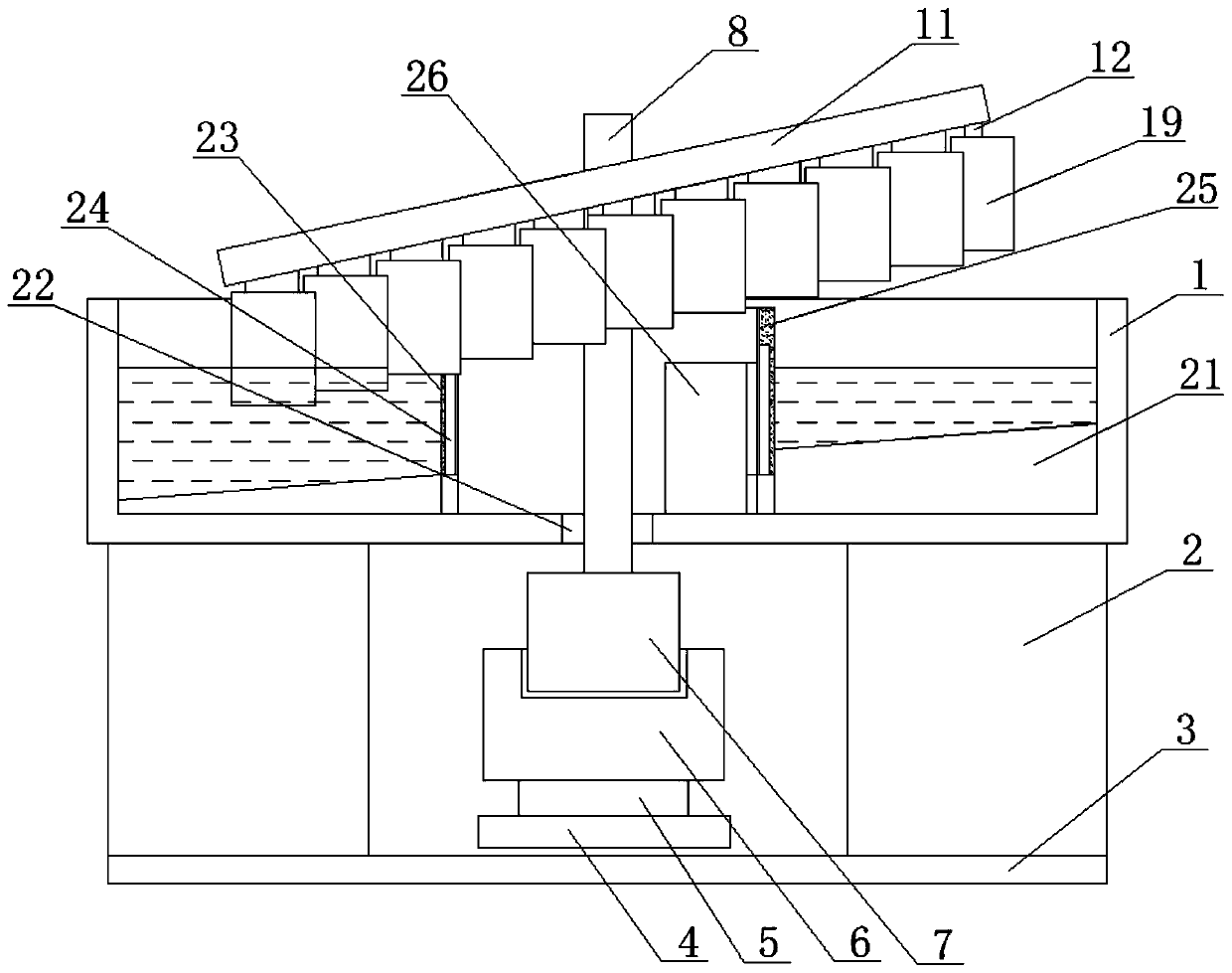

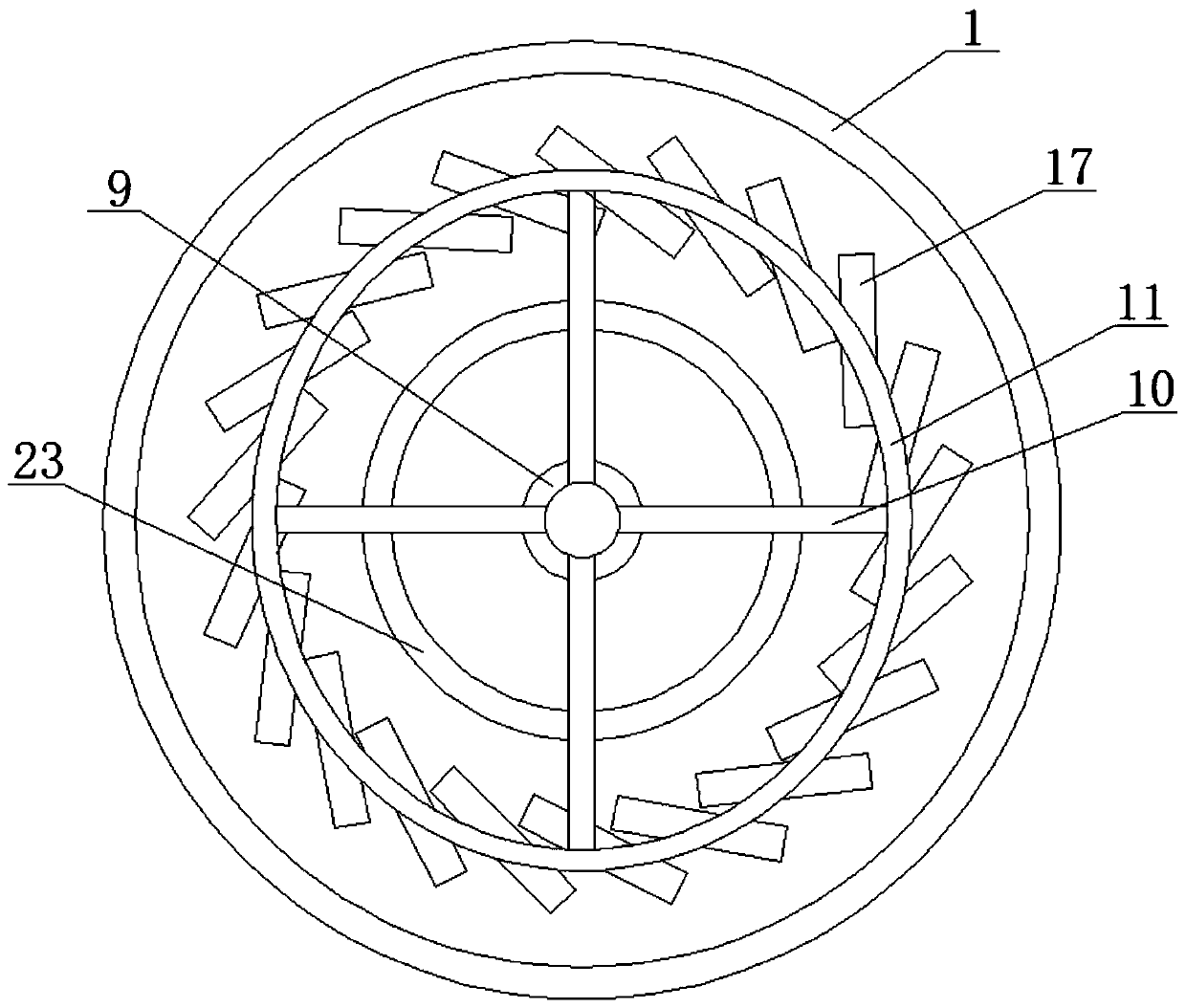

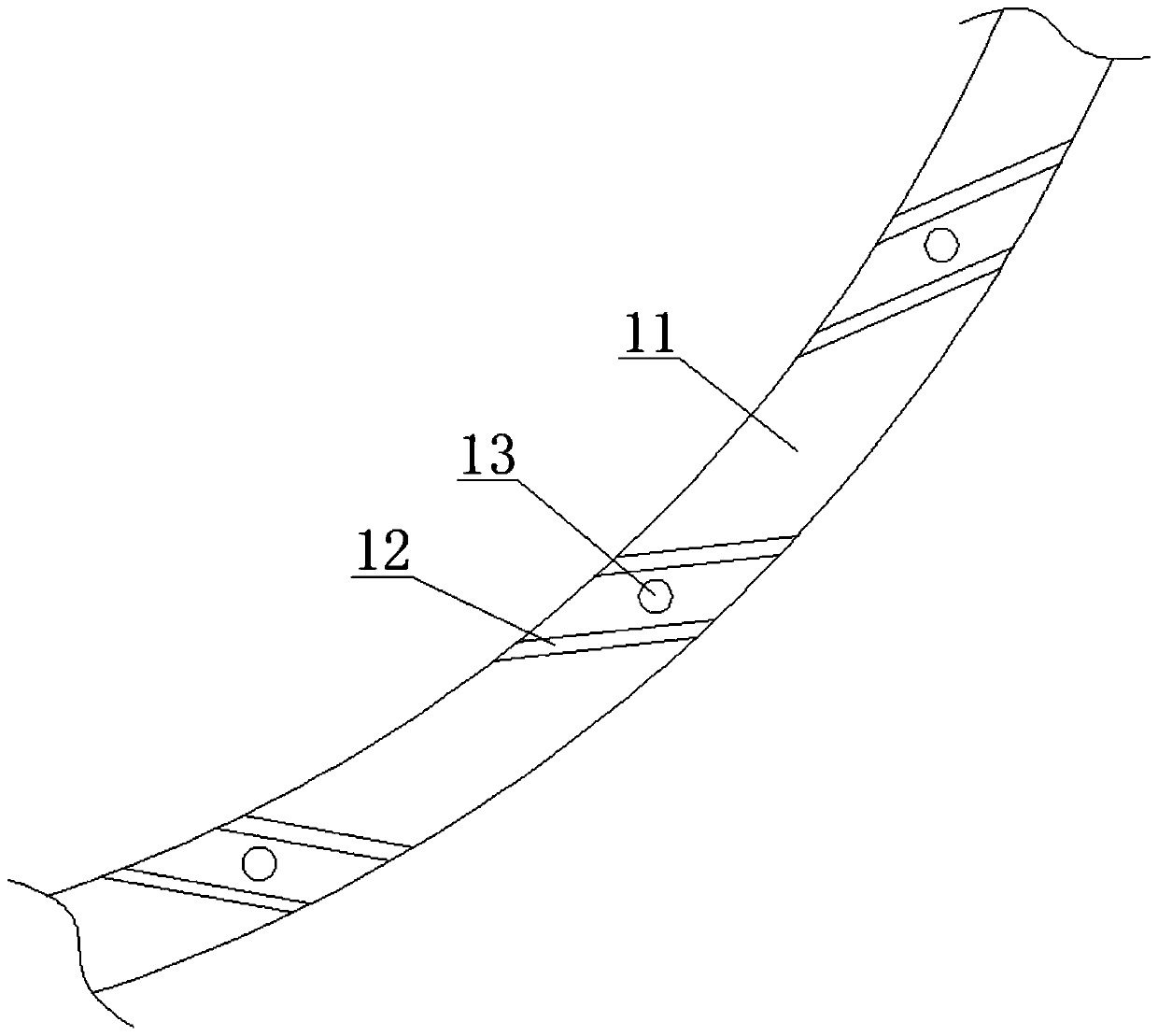

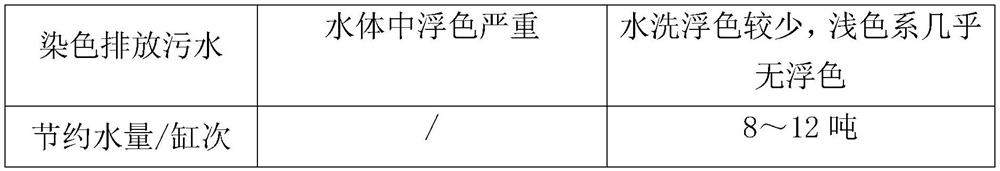

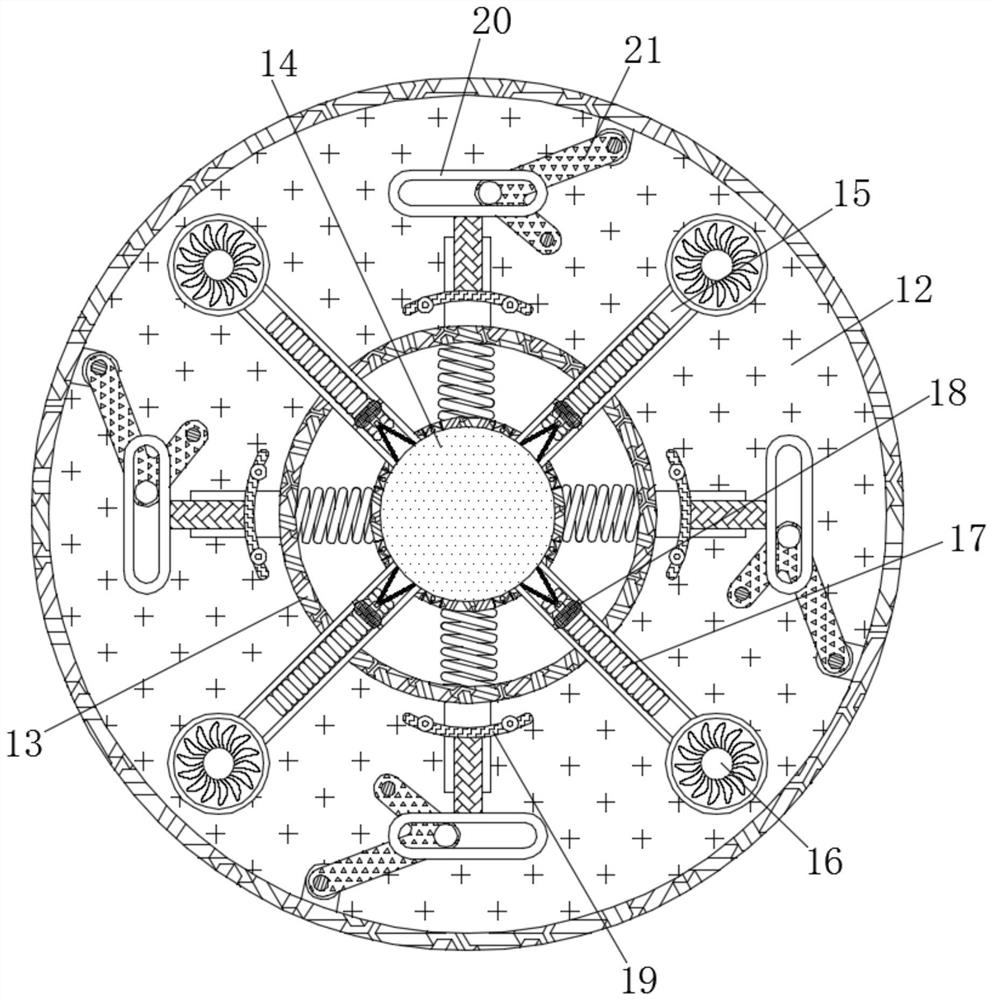

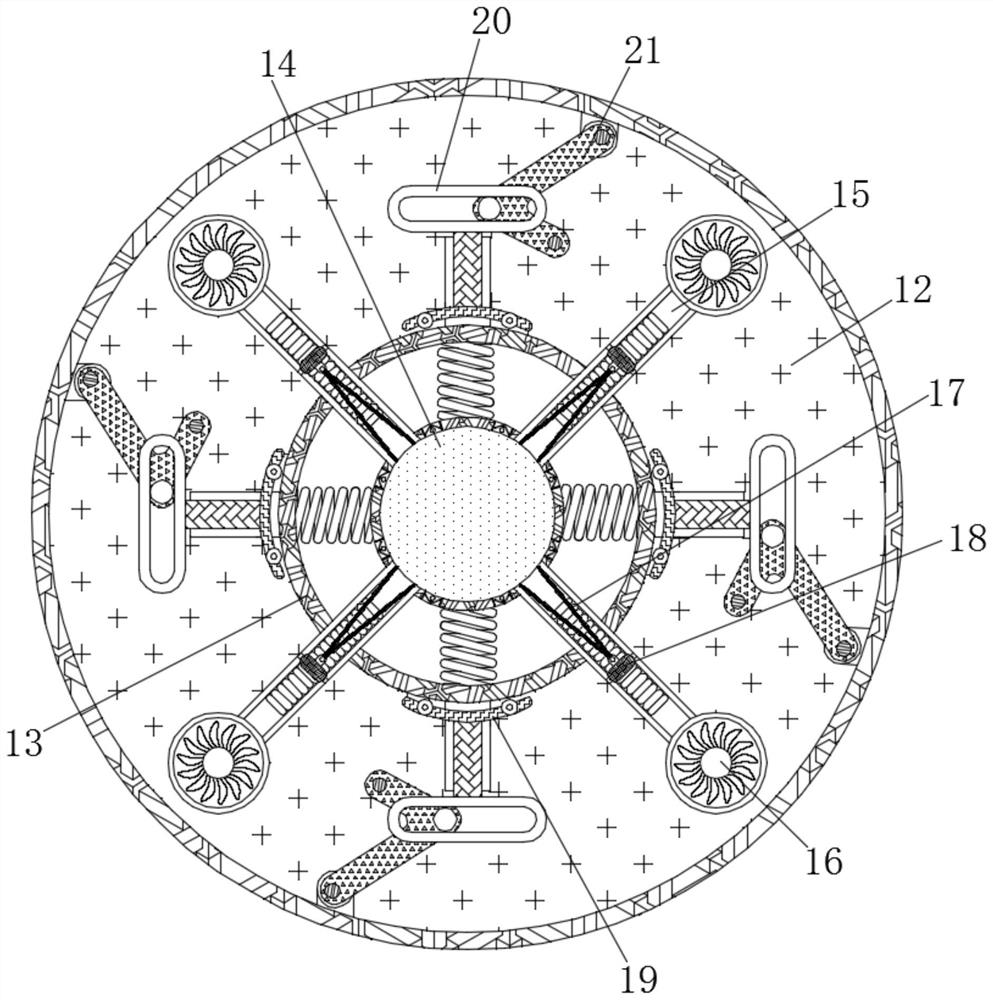

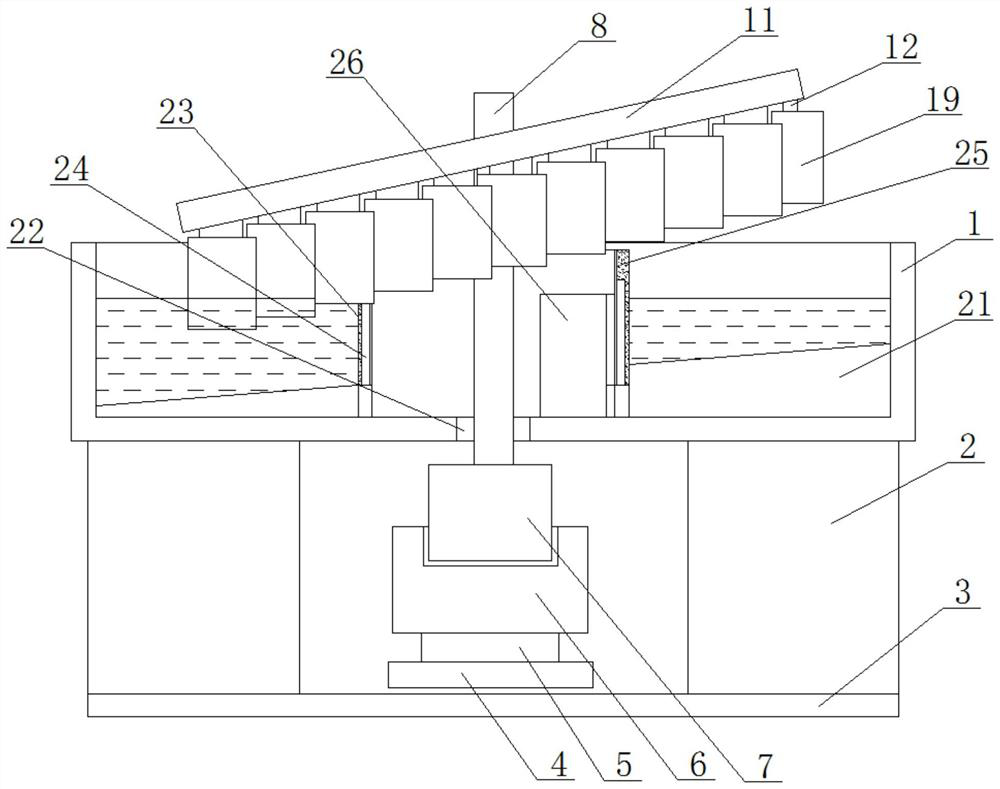

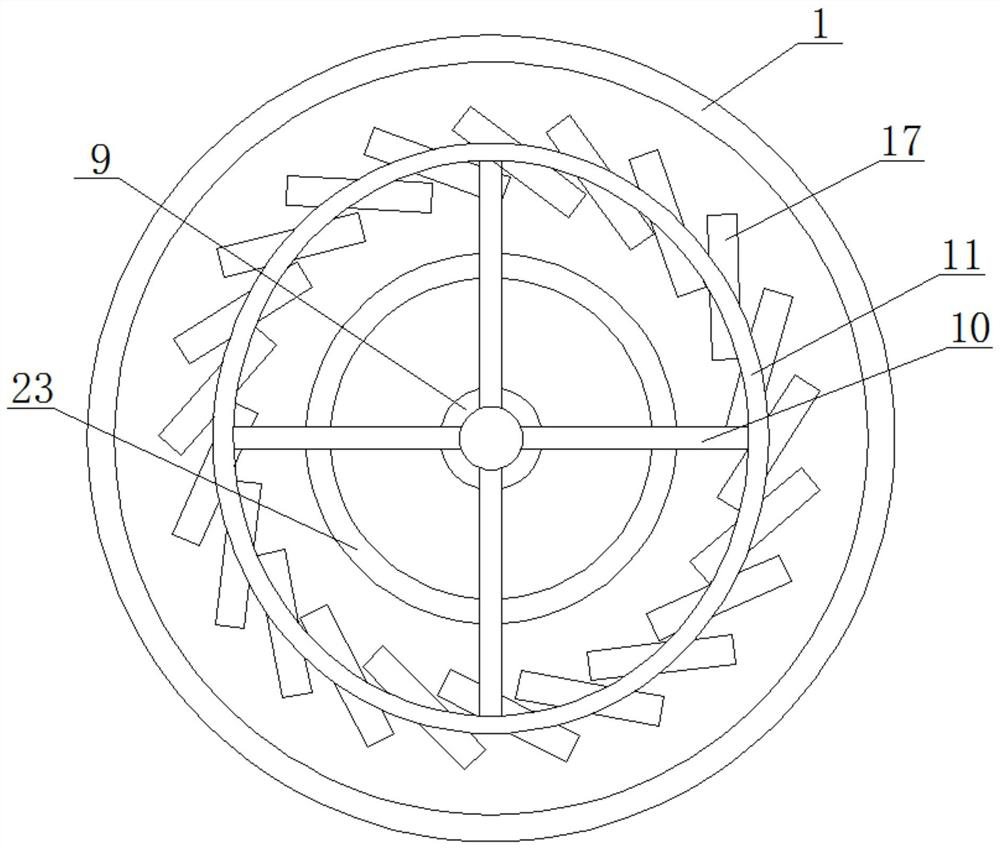

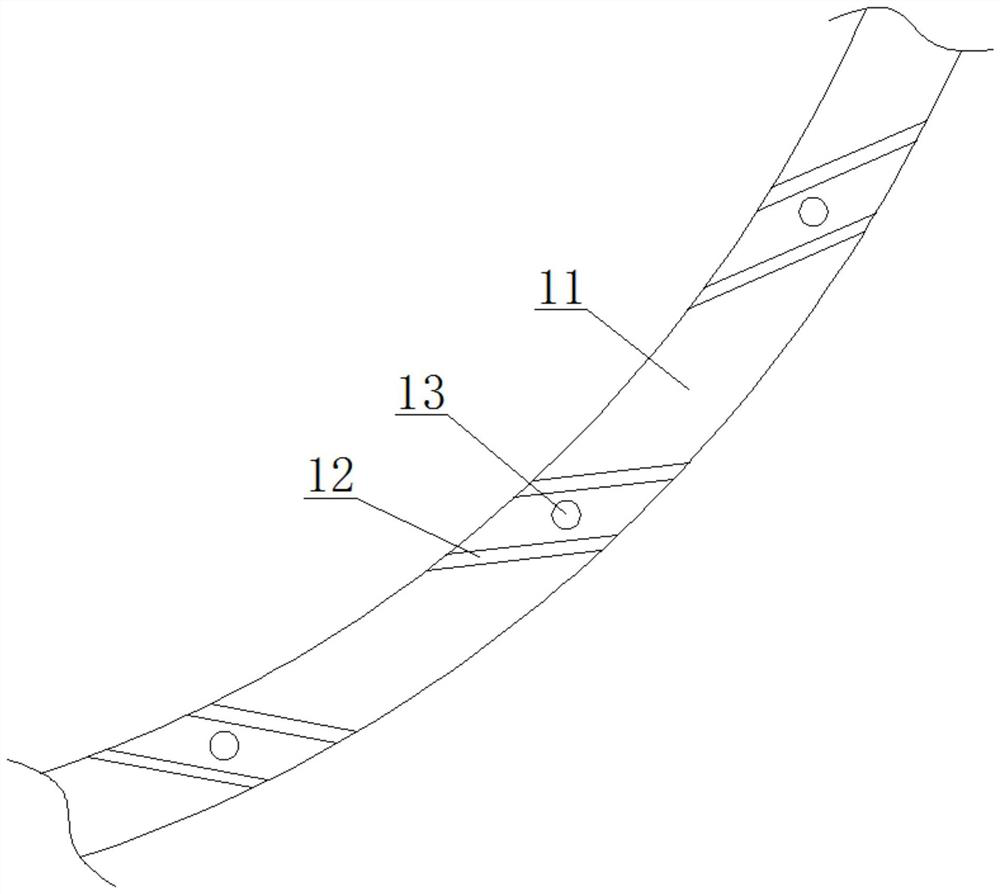

Leather dyeing machine

ActiveCN103388038AIncreased dyeing rateEliminate surface resistanceLeather/skins/hides/pelt chemical treatment apparatusDyeing processEngineeringPre treatment

The invention provides a leather dyeing machine, and belongs to the technical field of leather dyeing equipment and the leather dyeing machine can be used for solving the technical problem in the prior art that the leather dyeing machine has low dyeing efficiency. The leather dyeing machine comprises a base, wherein the base is provided with a drum body, the drum body is internally provided with an inner cavity, a rotary shaft I and a rotary shaft II are respectively fixed at two ends of the drum body, a drive device is arranged between the base and the outer end of the rotary shaft I, the rotary shaft II is pivoted on the base, a rotary joint II is arranged outside the rotary shaft II, a power-driven three-way valve is connected outside the rotary joint II, the power-driven three-way valve comprises an outlet I, an outlet II and an inlet, the inlet is communicated with the outer side of the rotary joint II, a vacuum pump is also fixed on the base, and the vacuum pump is communicated with the outlet I through a gas guide tube. Through vacuum pretreatment on the leather in the inner cavity of the drum body, the dyeing efficiency of the leather dyeing machine is improved.

Owner:浙江富邦汽车内饰科技有限公司

Method for dyeing denim yarn with natural indigo blue

ActiveCN109098011AImprove color vividnessImprove staining reproducibilityDyeing processYarnRoom temperature

The invention discloses a method for dyeing denim yarn with natural indigo blue. The method comprises the following steps: dyeing denim cotton yarns by using a leuco body multi-time padding oxidationmethod, carrying out vatting reduction at 40-50 DEG C, and dyeing denim yarns according to processes of pre-dyeing treatment, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation and aftertreatmenet with 0.5-2g / L of natural indigo blue, 1.5-4.5g / L of sodium hydroxide, 0.75-1.8g / L of sodium hydrosulfite, 0.25-0.6g / L of a sodium hydrosulfite stabilizer, 10-15g / L of a dyeing acceleration agent sodium chloride or sodium sulfate and 2g / L of a penetrant JFC2. By adopting the dyeing method of multiple times of padding, rolling and oxidation,the dyeing fastness of the denim yarns can be improved, dyeing and oxidation can be both carried out under a room temperature condition, no heating is needed, energy conservation and environment protection can be achieved, reduction is carried out by using a sodium hydrosulfite method, a high reduction velocity can be achieved, and a stable dyeing effect can be achieved.

Owner:鹤壁新歌源丹宁科技有限公司

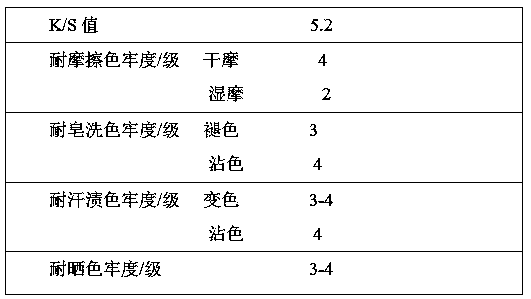

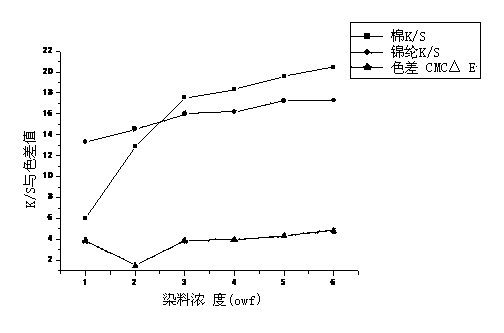

Brocade cotton fabric short-process dyeing method

The invention relates to a brocade cotton fabric short-process dyeing method, and belongs to the technical field of printing and dyeing in the textile manufacturing industry. The method includes subjecting brocade cotton fabric to pretreatment to remove oil stain and impurities and to improve handfeel and gloss; adding an active dye into an air flow cylinder to prepare into a dyeing solution; dyeing by adoption of a one-bath two-step method that includes acid dyeing and alkaline fixation; and after the dyeing step is finished, washing, soaping and airing to obtain a finished product. The method has advantages of uniform dyeing, good homochromatism, and the like when being used for air flow cylinder dyeing of the brocade cotton fabric such as brocade cotton intertexture.

Owner:金根苗

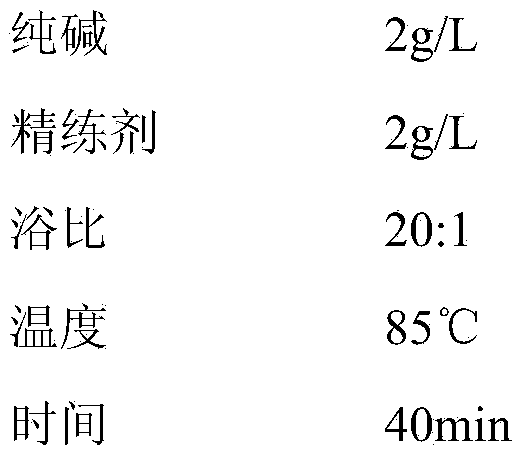

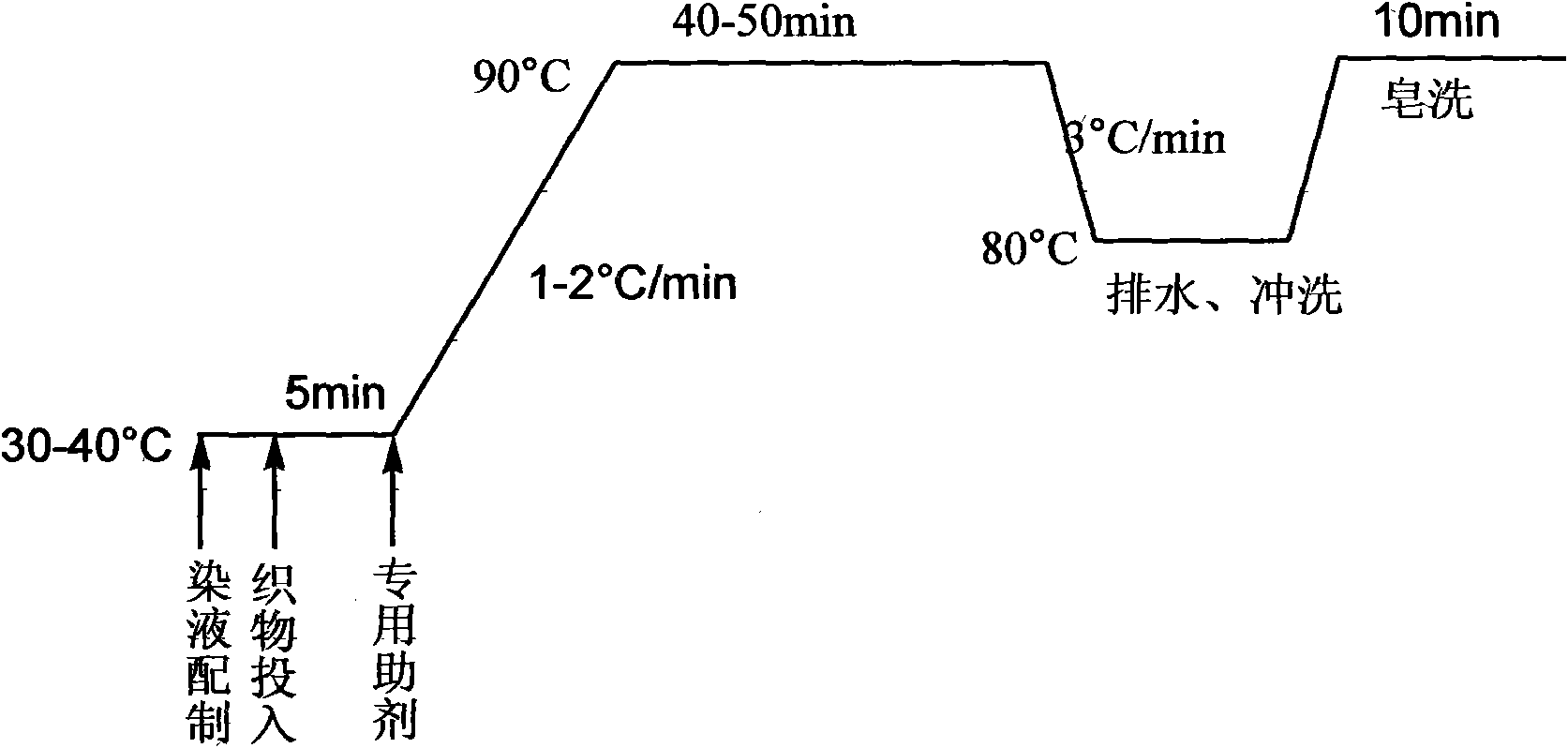

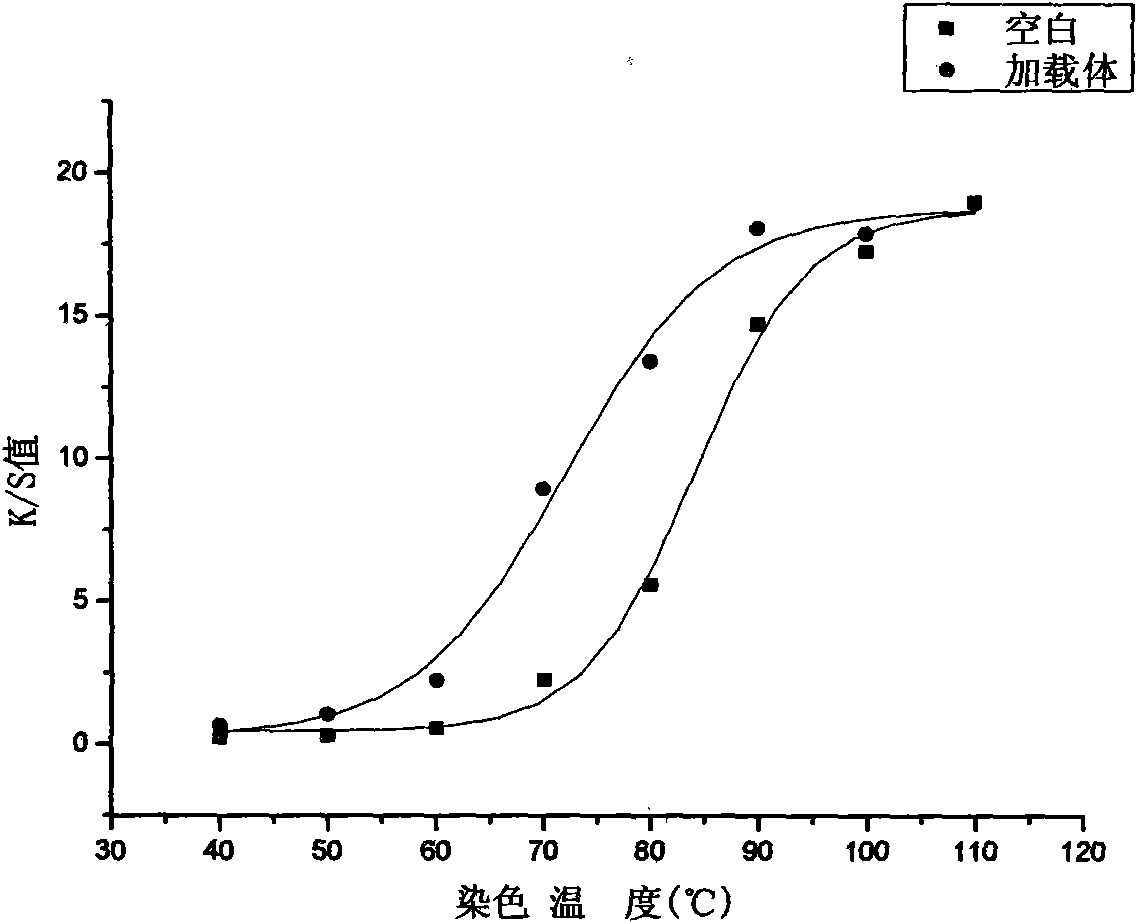

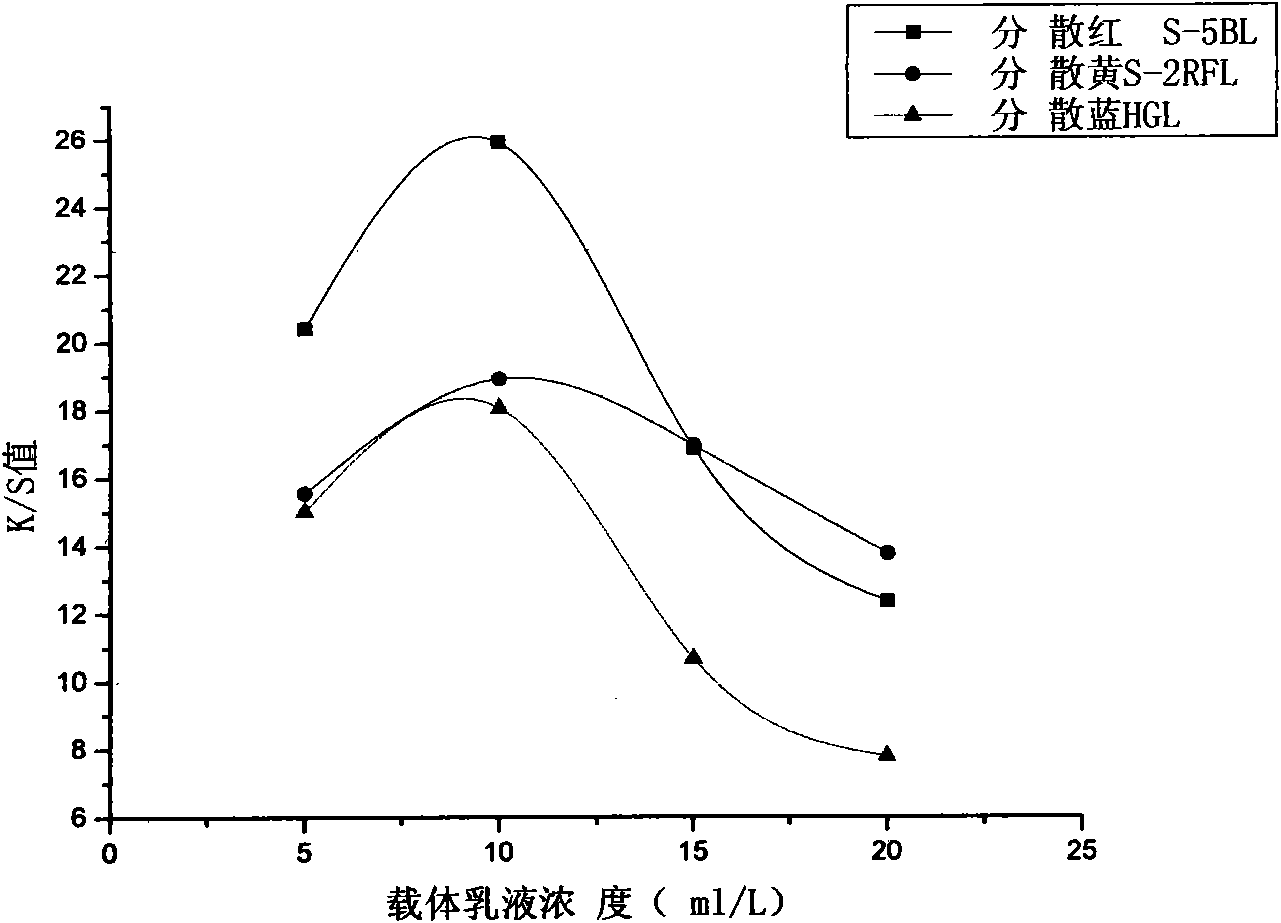

Method for dyeing polylactic acid fiber fabrics with disperse dye under low temperature

InactiveCN101768874AIncreased dyeing rateLow loss of physical and mechanical propertiesDyeing processDisperse dyeMechanical property

The invention discloses a method for dyeing polylactic acid fiber fabrics with disperse dye under low temperature, which belongs to the technical field of dyeing. The method includes the following steps that: after water is added according to the weight of a polylactic acid fiber fabric and the bath ratio of 10 to 20:1, the melted disperse dye, 1g / l to 2g / l of dispersing agent and 1g / l of ammonium sulphate are sequentially added, the fabric is put in and starts to be wetted, 10ml / l of special additive is then added after 5 minutes, the temperature is increased to 90 DEG C at 1 DEG C to 2 DEG C / min, and is kept for 40 to 50 minutes, the temperature is then increased to 80 DEG C at 3 DEG C / min, and the fabric is heated to 90 DEG C after the water is drained, and is soaped for 10 minutes under the bath ratio of 1:10 to 20. While achieving a good dyeing effect, the invention can reduce the loss of the physical and mechanical properties of polylactic acid fibers to the max.

Owner:SHAOXING UNIVERSITY

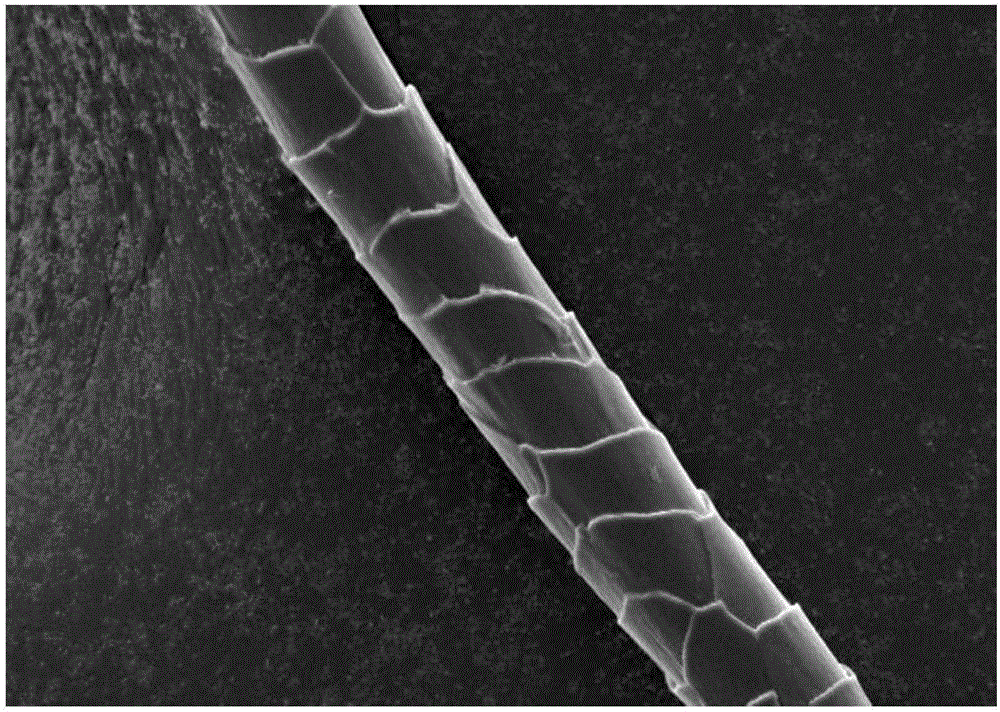

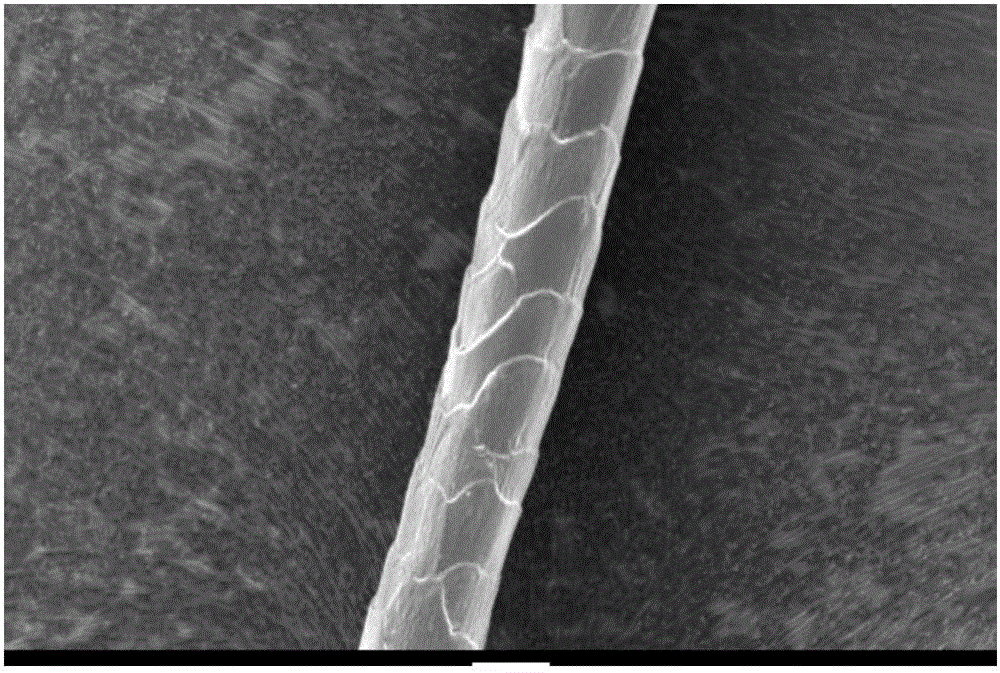

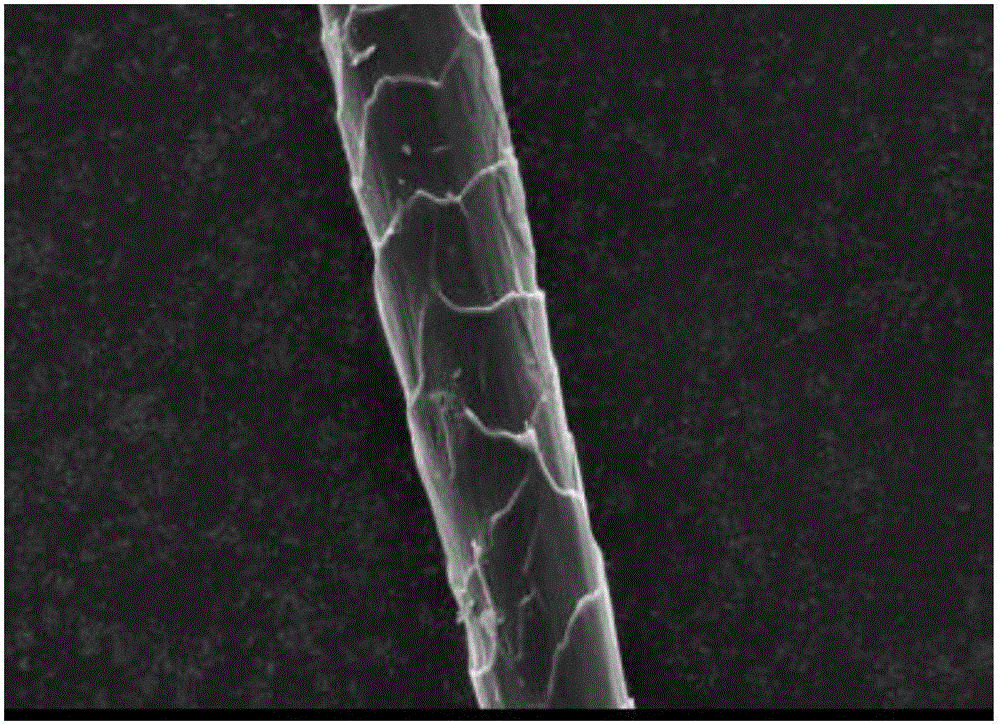

Wool fiber surface modification method

InactiveCN106637922AFast corrosionPlay a regulatory roleBiochemical treatment with enzymes/microorganismsAnimal fibresYarnPyrophosphate

A wool surface scale modification method adopts wool loose fiber, wool top, wool yarns or wool garment as wool to-be-treated products and is conducted according to the following steps sequentially: a, preparing treatment liquid; taking sodium cyanate, sodium pyrophosphate, hydrogen peroxide at the concentration of 30 percent and the balance of water, wherein in the prepared treatment liquid, the liquid sodium cyanate concentrate is 1 to 20 g / L, the sodium pyrophosphate concentration is 0 to 20 g / L and the hydrogen peroxide concentration is 10 to 70 g / L; and b, soaking the wool to-be-treated product in the above treatment liquid at the mass ratio of the to-be-treated wool to the treatment liquid being 1:15 to 1:25, maintaining the temperature of the treatment liquid at 30 to 70 DEG C, and performing oscillation in an ultrasonic oscillating instrument for 10 to 60 minutes.

Owner:ZHEJIANG LANBAO WOOL SPINNING GROUP

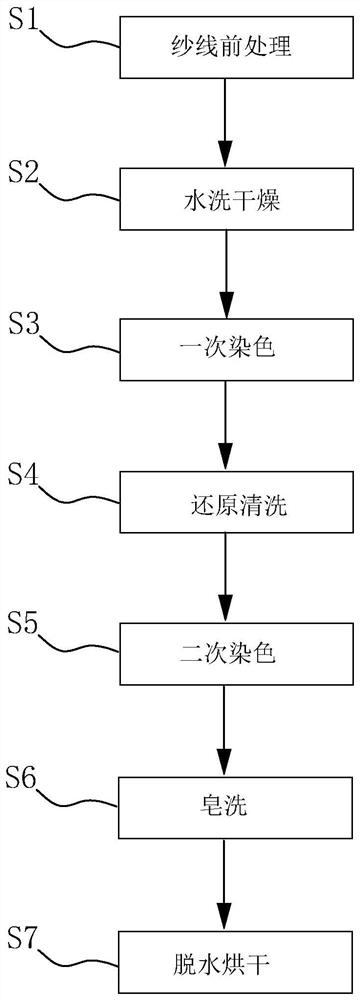

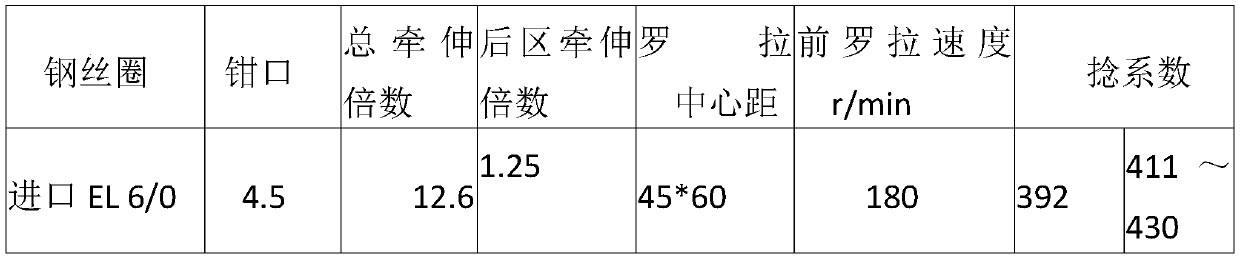

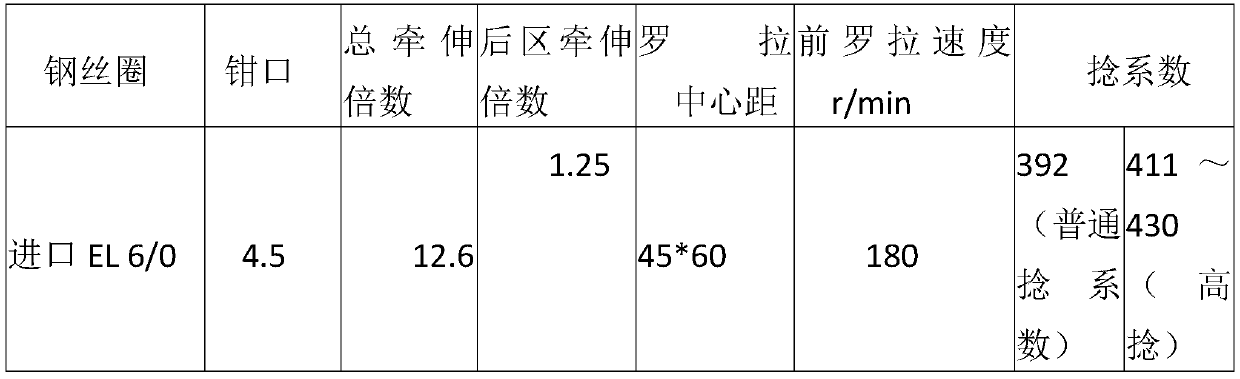

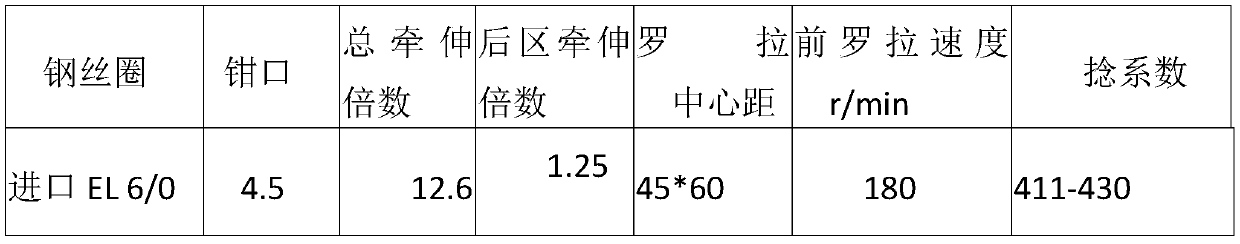

Polyester-cotton blended yarn dyeing process

The invention relates to the technical field of yarn dyeing and finishing, and particularly discloses a polyester-cotton blended yarn dyeing process. The polyester-cotton blended yarn dyeing process comprises the following steps of S1, performing yarn pretreatment; S2, performing washing and drying; S3, performing primary dyeing: adding 1.5-3 g / L of a disperse dye leveling agent into a primary dyeing bathtub, performing heating to 75 DEG C, adding a disperse dye, then performing heating to 85 DEG C, sending the washed and dried yarns into primary dyeing liquid for dip dyeing at a bath ratio of1: (9-11), and performing heat preservation dyeing for 45-55min; S4, performing reduction cleaning; S5, performing secondary dyeing, wherein the bath ratio is 1: (9-11), the temperature is increasedto 75-85 DEG C, heat preservation is performed for 18-22 min, then the temperature is increased to 90 DEG C, heat preservation dyeing is performed for 30-35 min, and secondary dyeing liquid is activedyeing liquid; S6, performing soaping; and S7, performing dehydration and drying, wherein pretreatment liquid comprises the following components in parts by weight: 3-6 parts of pectinase, 4-8 parts of alpha-amylase, 4-7 parts of hydrogen peroxide, 0.5-1 part of sodium silicate, 1-3 parts of a penetrant, 0.5-1 part of cocamidopropyl hydroxy sulfobetaine and 65-85 parts of deionized water. The method has the advantages of effectively improving the dyeing uniformity of the cotton-polyester blended yarns and improving the yarn quality.

Owner:南通云花色织有限公司

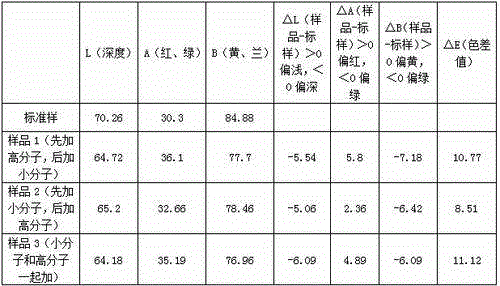

Method for union dyeing of raw silk/Eco-wash wool (mercerized wool) interwoven fabric

ActiveCN108385409AOvercome the disadvantage of low color fastnessSimple processDyeing processAcid dyeSericin

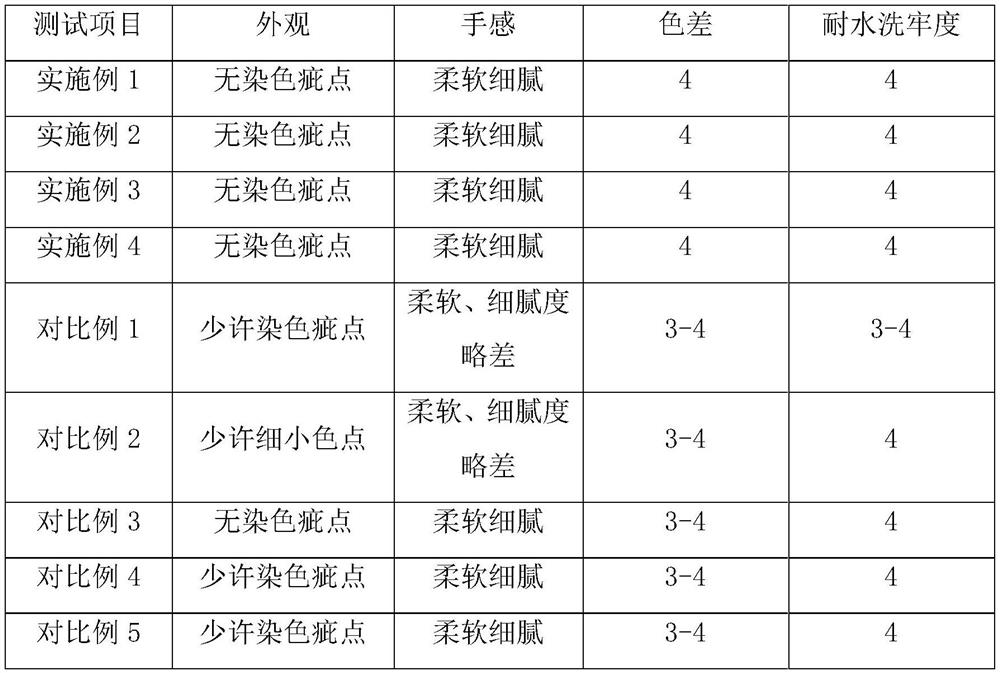

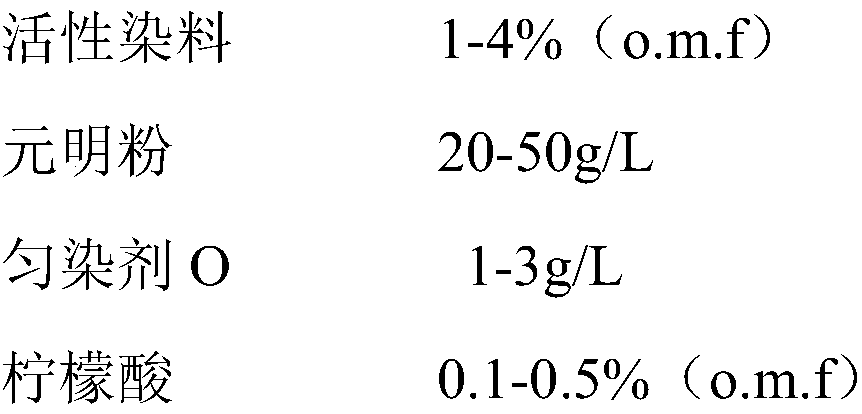

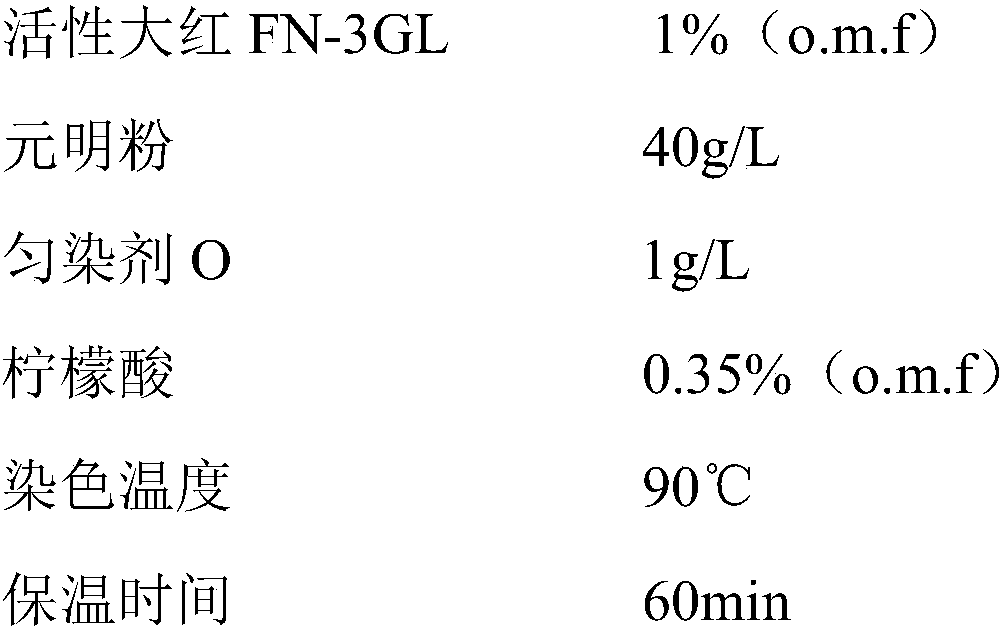

The invention discloses a method suitable for union dyeing of a raw silk / Eco-wash wool interwoven fabric. The method comprises the steps of pretreatment, dyeing and soaping. The dyeing step is performed through adding a reactive dye and a leveling agent O according to a dyeing formula in order to prepare a dyeing solution, adding citric acid to adjust the pH value of the dyeing solution, heating the dyeing solution, adding the fabric when the temperature rises to 30 DEG C, and dyeing the fabric for a certain time while rising the temperature to a heat insulation temperature at a certain heating rate. The method effectively solves the technical difficulties of low color fastness and poor homochromatism of the raw silk / wool interwoven fabric and sericin dissolving loss of a raw silk component in the dyeing process, overcomes the shortcoming of low one-bath dyeing fastness of acidic dyes, and overcomes the shortcomings of poor alkali-bath dyeing homochromatism and large sericin dissolvingrate of reactive dyes. The method has the advantages of simple and convenient process, good homochromatism, high color fastness and wide application values.

Owner:ZHEJIANG SCI-TECH UNIV

Mercerized-wool and cotton blended fabric dyeing method using pomegranate bark plant dye

InactiveCN108560284AAvoid damageIncreased dyeing rateDyeing processSodium bicarbonateNeodymium chloride

The invention discloses a mercerized-wool and cotton blended fabric dyeing method using a pomegranate bark plant dye. The mercerized-wool and cotton blended fabric dyeing method includes the followingsteps that 1, 1-3% by weight of sodium bicarbonate and 0.5-5% by weight of wetting agent are added into deionized water and then are uniformly stirred and mixed, mercerized-wool and cotton blended fabric is placed into a mixed solution to be heated to 50-70 DEG C to be processed for 20-30 min, and the bath ratio is 1:(20-30); 2, the pomegranate bark plant dye, dye mordant and a wetting agent areadded into deionized water and then are uniformly mixed and stirred to prepare a dye solution, the mercerized-wool and cotton blended fabric is placed into the dye solution, heating starts at 30-35 DEG C, the heating rate is kept at 2-3 DEG C / min, and the temperature is kept at 50-60 DEG C to carry out processing for 60-80 min, wherein the dye solution is acidic, the bath ratio is 1:(20-30), and the dye mordant is neodymium chloride and / or aluminum potassium sulfate dodecahydrate. By the adoption of the mercerized-wool and cotton blended fabric dyeing method using the pomegranate bark plant dye, neodymium chloride and / or aluminum potassium sulfate dodecahydrate is adopted as the dye mordant, the weakly acidic dyeing solution has little damage on mercerized wool during dyeing, and the dyeing rate and the color fastness are high.

Owner:JIANGSU SUNSHINE

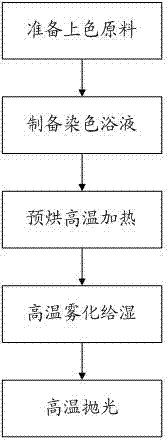

High-brightness fluorescence bright-red formula for textile, and dyeing method of high-brightness fluorescence bright-red on textile

InactiveCN104233857AEnsure stable qualityGood colorSucessive textile treatmentsDyeing processEmulsionFluorescence

The invention discloses a high-brightness fluorescence bright-red formula for textiles. The high-brightness fluorescence bright-red formula comprises the following dyeing raw materials in parts by weight: 200-300 parts of disperse red FRL, 250-350 parts of disperse bright-red 3B, 150-250 parts of disperse tender yellow 4G and 15-25 parts of emulsion paste. By adopting the mode, the high-brightness fluorescence bright-red formula for textiles and a dyeing method of the high-brightness fluorescence bright-red on the textiles can solve the problems that the quality of a textile is not stable, dark and gloomy in color and low in efficiency and benefit during production, the dyeing velocity is increased by adopting an instantaneous ultrahigh-temperature pre-baking heating mode, the dyeing rate is increased, the dewing is uniform in a high-temperature atomization mode, the brightness of color is improved, the textile has the high-brightness fluorescence bright-red color effect by adopting an instantaneous high-temperature polishing brightening mode, the working efficiency is improved, the production cost is lowered, and the benefits are increased.

Owner:SUQIAN SHENLONG HOME TEXTILE

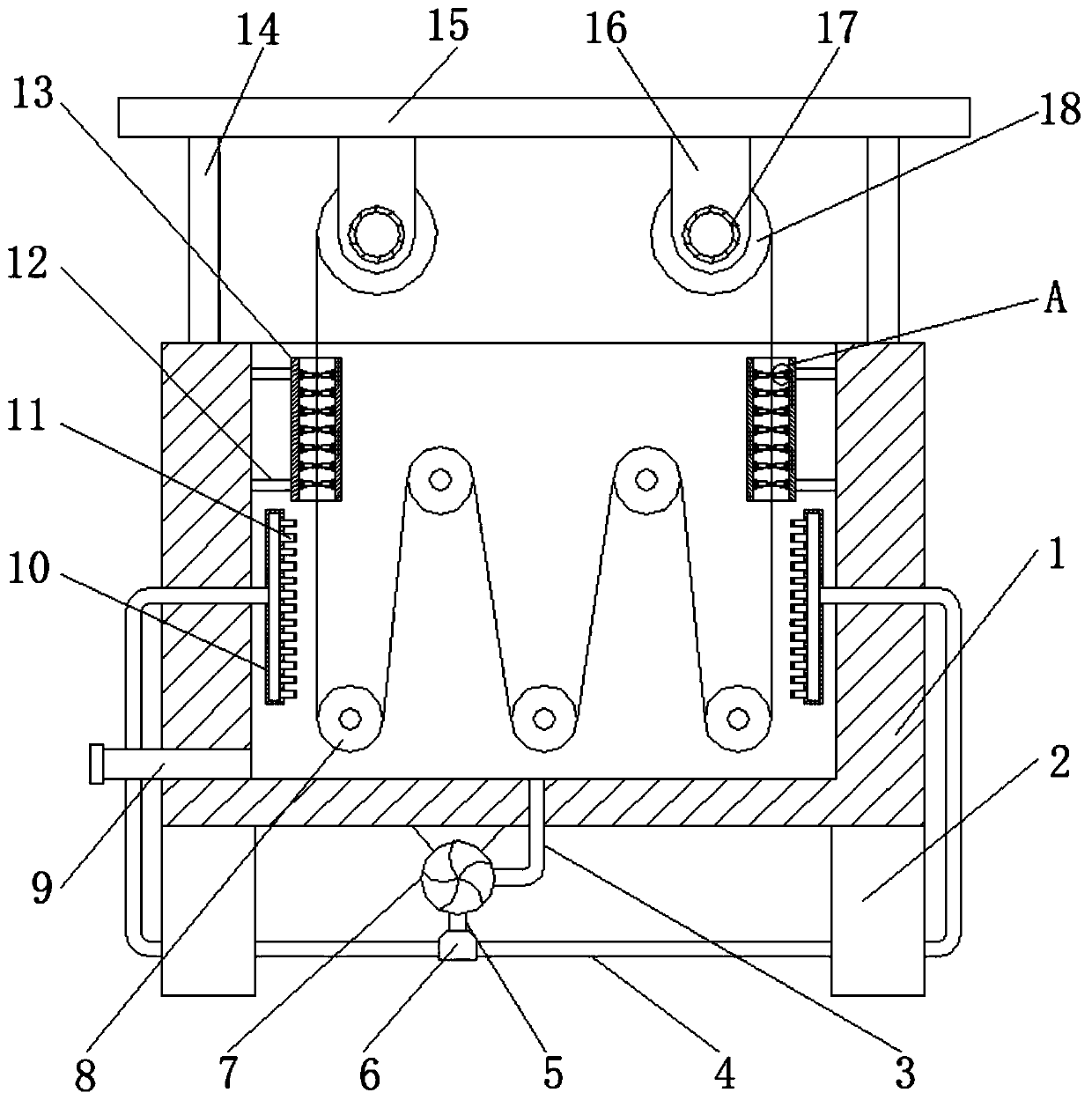

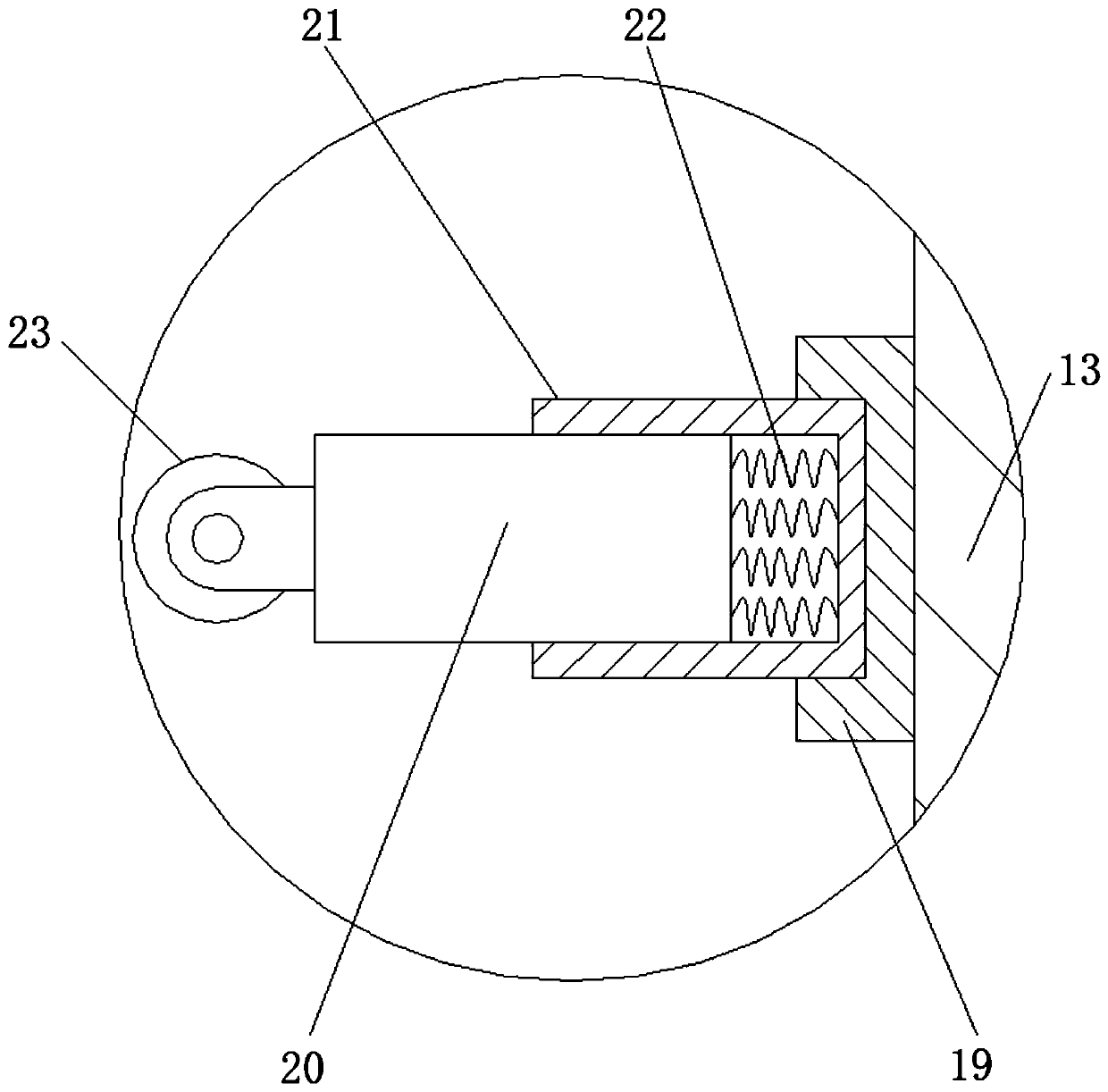

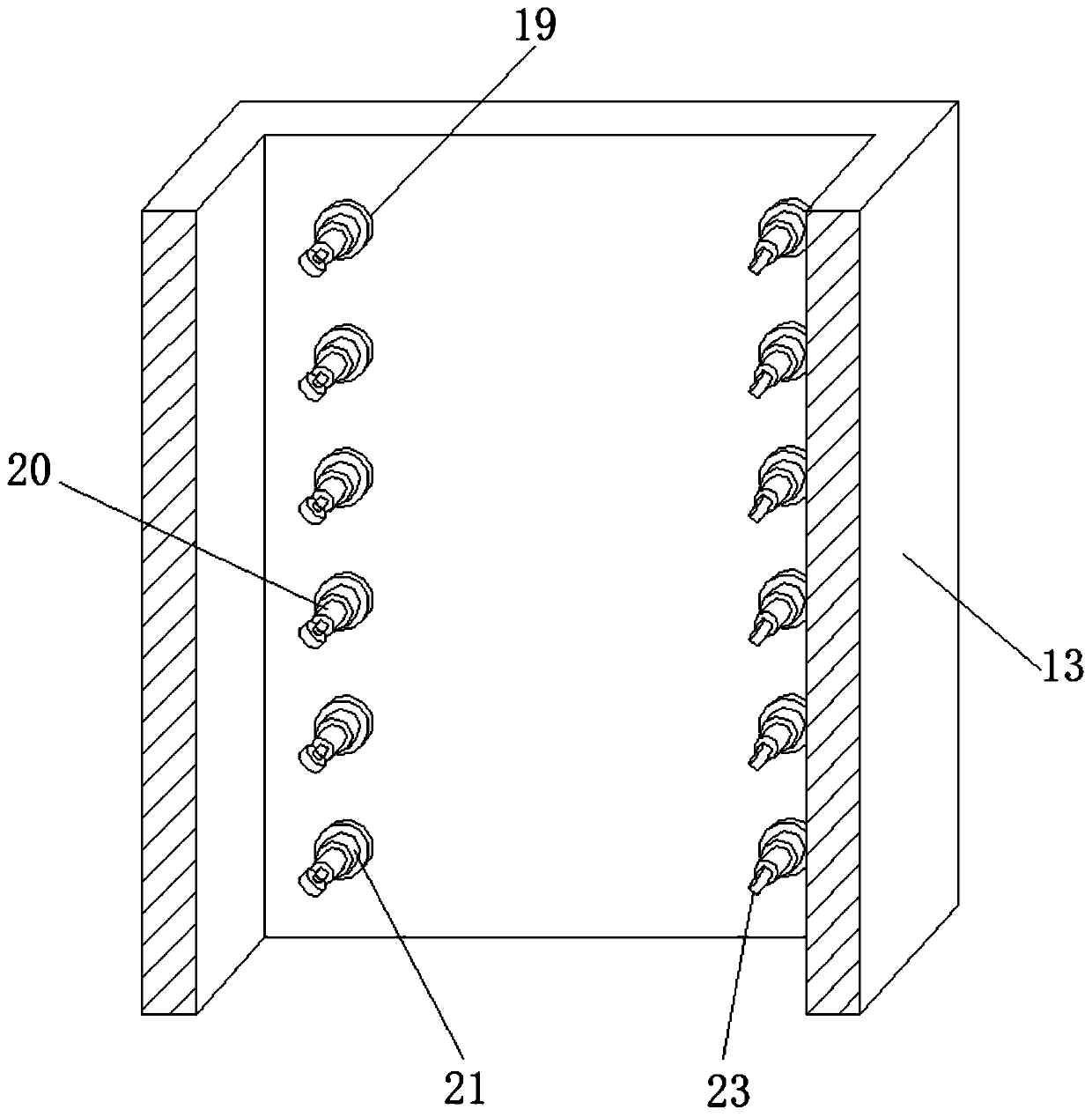

Dyeing device for textile

InactiveCN111088619AExtended stayImprove dyeing efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingPolymer scienceEngineering

The invention discloses a dyeing device for textile. The dyeing device comprises a dyeing box, wherein stand columns are correspondingly arranged at four corners of the outer wall of the top of the dyeing box; a top plate is welded to the outer walls of the tops of the stand columns; two fixing bases are correspondingly arranged at the positions, close to two sides, of the outer wall of the bottomof the top plate; a motor is connected to the outer wall of one side of the fixing base through bolts; a winding roller is arranged at one end of an output shaft of the motor; cross rods are equidistantly distributed on the inner wall of the dyeing box in a staggered mode; cloth guide rollers are rotationally connected to the outer walls of the cross rods; a water pump is connected to the outer wall of the bottom of the dyeing box through bolts; a water pumping pipe is connected to the outer wall of one side of the water pump through bolts; and one end of the water pumping pipe communicates with the dyeing box. According to the dyeing device, the staying time of cloth in the dyeing box can be effectively prolonged, so that the cloth dyeing efficiency is improved, the using effect is better; and dye can be immersed into the cloth more quickly, so that the dyeing rate of the device is further improved.

Owner:吴盟

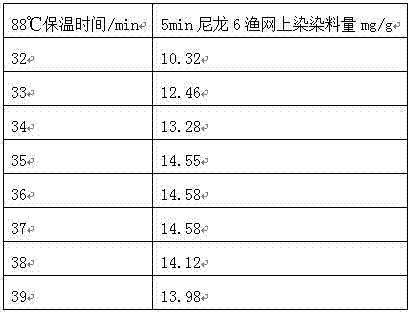

Nylon 6 fishing net dyeing process

InactiveCN107059436ASolve uneven dyeing, dyeing flowersSolve chromatic aberrationDyeing processNylon 6Pulp and paper industry

The invention discloses a nylon 6 fishing net dyeing process. The nylon 6 fishing net dyeing process comprises the following steps: (1) preprocessing, (2) dyeing and (3) color fixing. The problems of uneven dyeing, flower dyeing, aberration and color defect which are easily caused in dyeing of nylon 6 fishing nets can be solved. The utilization rate of dyestuff and the color fastness are improved, dyeing processing risks are reduced, the semi-dyeing time of the dyestuff can be greatly reduced, the dyeing speed is increased, a certain amount of cactus extracting solution is added during dyeing, a dye liquor treatment environment is gentle, damage to the nylon 6 fishing net is small, the use performance of the nylon 6 fishing net is not affected, and meanwhile, the dyeing speed is not reduced.

Owner:CHAOHU XIANGYU FISHING GEAR

Method for processing water soft cotton knitted fabric

InactiveCN101818406BGood drapabilityGood flexibilityWeft knittingBleaching apparatusSurface finishFiber

The invention relates to a method for processing water soft cotton knitted fabric, which comprises the following steps of: preparation of grey yarns, enzyme washing of the grey yarns, weaving, boiling, dyeing, dehydration, drying, super-soft treatment, sizing and preshrinking. In the method, after the yarns are subjected to enzyme treatment, the fibers become porous and loose so that the yarns become soft and fluffy and the dyeing rate is improved, and fluffs on the surfaces of the yarns are removed so as to achieve the effects on surface finish and piling resistance and improve the drapability, softness and water absorbability of the fabric; and by combining the post super-soft treatment, polyurethane in finishing liquor can easily permeate into the yarns and produce cross-linking reaction with fiber molecules and other aid groups to form a three-dimensional netlike structure so as to endow the fabric with the characteristics of durable elasticity and dimensional stability and 'watersoft cotton' softness like water. The final finished fabric produced by the method has the advantages of soft and exquisite handfeel, strong gloss sense, surface finish and good resilience.

Owner:WUXI NATURAL GREEN FIBER TECH

Salt-free low-alkali cellulose fiber modified dyeing method

The invention relates to a salt-free low-alkali cellulose fiber modified dyeing method, belonging to the technical field of textile dyeing. The dyeing method comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, an epichlorohydrin parent derivative of epoxy quaternary ammonium salt and cationic starch are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber dyeing method has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that salt-free low-alkali dyeing of the cellulose fibers is achieved, pollution is reduced, the cost is saved, the process is simplified, the difficulty is reduced, and the modification and dyeing effects are good; therefore the dyeing method is suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Biological treatment method for wool blend fabric

InactiveCN105040454AImprove dyeing effectIncreased dyeing rateBacteriaBiochemical fibre treatmentStenotrophomonas maltophiliaEngineering

The invention relates to a biological treatment method for wool blend fabric. The method includes the steps of adding stenotrophomonas maltophilia in a sterilized fermentation medium, adding the wool blend fabric, regulating the fermentation temperature to 30-40 DEG C, regulating the rotating speed to 200-400 rmp, regulating the fermentation time to 48-96 h, flushing the fabric, and airing the fabric. Application objects of the method are within a broad range. Wool fiber scales of the fabric processed according to the method are completely stripped off, the rest of fiber is not influenced, the dyeing performance is remarkably improved, the dyeing temperature is lowered, the dyeing rate is increased, and the fuzzing and pilling performance is lowered.

Owner:DONGHUA UNIV

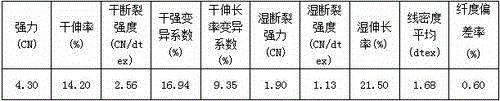

Antimony-free polyester melt preparation system and method for preparing antimony-free polyester fine denier FDY fibers

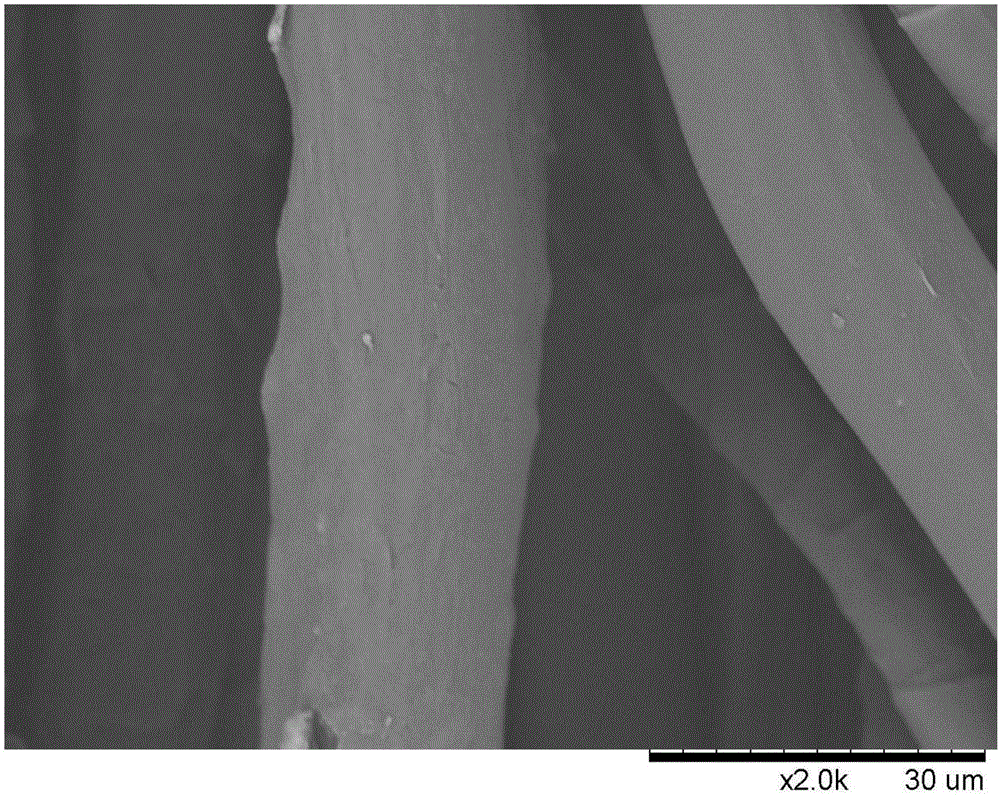

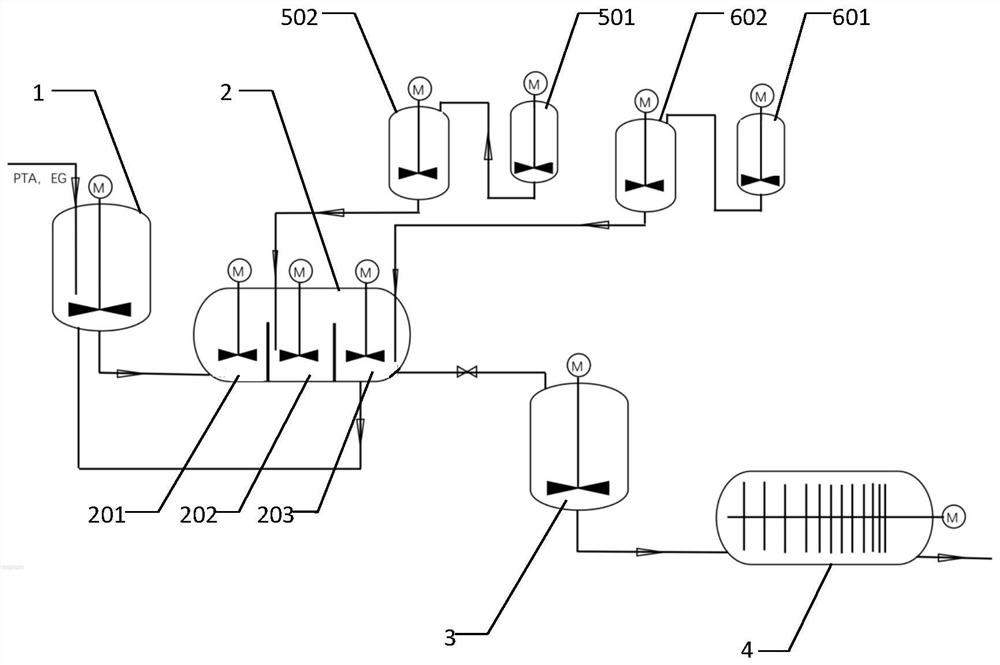

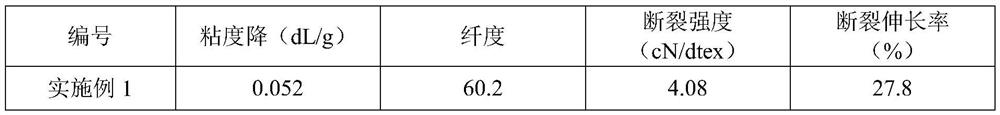

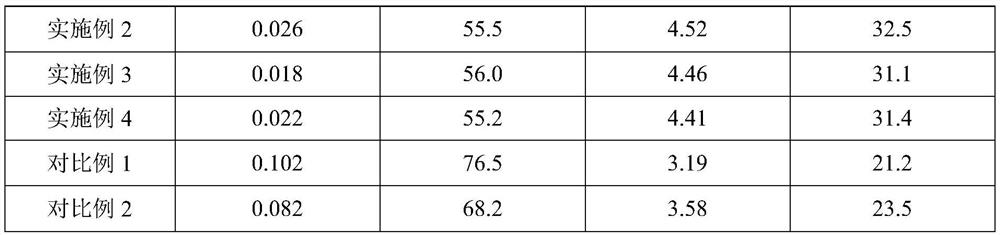

ActiveCN112724390AAccelerates the rate of esterificationHigh esterification rateFilament forming substance formingPlastic recyclingFiberYarn

The invention discloses an antimony-free polyester melt preparation system and a method for preparing antimony-free polyester fine denier FDY (Fully Drawn Yarn) fibers. The method comprises the following steps: (1) adding terephthalic acid, ethylene glycol and dihydric alcohol containing branched chains into a first esterification kettle to carry out primary esterification reaction; (2) conveying the primary esterification reaction product into a second esterification kettle, adding a coloring agent and a titanium catalyst, and carrying out secondary esterification reaction; (3) refluxing part of the secondary esterification reaction product into the first esterification kettle, and conveying the rest of the secondary esterification reaction product into a pre-polymerization kettle for reaction to obtain a pre-polycondensation product; (4) conveying the pre-polycondensation product to a final polycondensation kettle for reaction to obtain a polyester melt; and (5) carrying out melt direct spinning on the polyester melt obtained by the final polymerization kettle to obtain the antimony-free polyester fine denier FDY fiber. By improving spinning process equipment and a polyester molecular structure, the esterification rate and esterification rate in the antimony-free polyester filament melt direct spinning process are increased, the melt fluidity is improved, and the quality of the prepared antimony-free polyester filament is improved.

Owner:ZHEJIANG HENGYI PETROCHEM +1

Pure-cotton double-layer jacquard home textile dyeing and finishing method

InactiveCN108130754ASimple production processIncrease lifting powerDyeing processTextile dyeingSulfone

The invention discloses a pure-cotton double-layer jacquard home textile dyeing and finishing method, and belongs to the technical field of pure-cotton fabric dyeing. The method is characterized by comprising the following preparation steps: with a dyeing liquid formula, namely an active dye with two active groups of ethylene sulfuryl and hydroxyl ethylene sulfone sulfate in a main liquid, putting20-50% in percentage by mass of a dye liquid into a dyeing tank, and performing dyeing once; adding the rest dyeing liquid, and performing dyeing once again; adding sodium sulfate, and performing dyeing once; adding alkali powder, and performing dyeing once; adding a soaping agent SN-45, increasing the temperature, and performing dyeing for three times; washing with cold water, adding a neutralization acid, and performing dyeing for three times; performing acid pickling, and discharging a fabric roll. The inventor improves a cotton double-layer jacquard fabric dyeing process, and together with the selected active dye with two active groups of ethylene sulfuryl and hydroxyl ethylene sulfone sulfate in the main liquid, factors such as the soaping fastness, the lifting power of the dye, thedyeing velocity and the curve of the dye, the matching property of the dye, and the like are improved.

Owner:ZIBO DARANFANG SILK GRP

Laser dyeing process of denim fabric

PendingCN110644259ASolve pollutionCircular sectionLiquid/gas/vapor removal by squeezing rollersMercerisingPolymer scienceDenim

The invention discloses a laser dyeing process of denim fabric, which is characterized in that excess liquid is removed after extrusion through a mercerizing tank containing caustic soda, and then thesolution is absorbed into fibers in time through a series of cold metal drying cylinders and stretching under certain tension. The caustic soda absorbed by cotton causes substantial acidic dissociation of hydroxyl groups. The concentration of the inner ion part of the cotton fibers is higher than that of the outer ion part. As water is absorbed by permeation and the fibers swells, considerable pressure builds up within the fibers, causing loss of natural crimping property. After the caustic soda is washed off, no shrinkage occurs and the fibers have a rounder cross-section and consequently ahigher gloss. Mercerized cotton can absorb more dye and present higher dyeing rate. The sectional area of the fibers obtained by the process is increased and is rounder, and the gloss is enhanced; thedye absorption is reduced, and the dye consumption is decreased by 30-50%; the shrinkage rate is reduced, and the dimensional stability is improved; the problem of pollution in the denim dyeing process can be effectively solved.

Owner:德州元济纺织有限公司

Wax printing dye and wax printing method

InactiveCN110761088AChange color fastnessHigh color fastnessDyeing processColour fastnessPolymer science

The invention discloses a wax printing dye and a wax printing method. A substance containing a bis(monochlorotriazine) active group or monochlorodiazine active group is used as a colorant, mixed wax liquid is adopted, dyeing color fastness is changed, and tea polyphenols are added into the dye in order to improve the light aging resistance of dyeing colors. A fabric is smoothened and pretreated inthe dyeing process, a substance base is provided for natural and fine wax stripes in a follow-up wax printing process, the pretreated fabric is placed into the dye and dyed under the action of ultrasound, movement of dye molecules is facilitated by the action of ultrasound, dyeing is accelerated, and dyeing color fastness and uniformity are improved.

Owner:张家界乖幺妹土家织锦开发有限公司

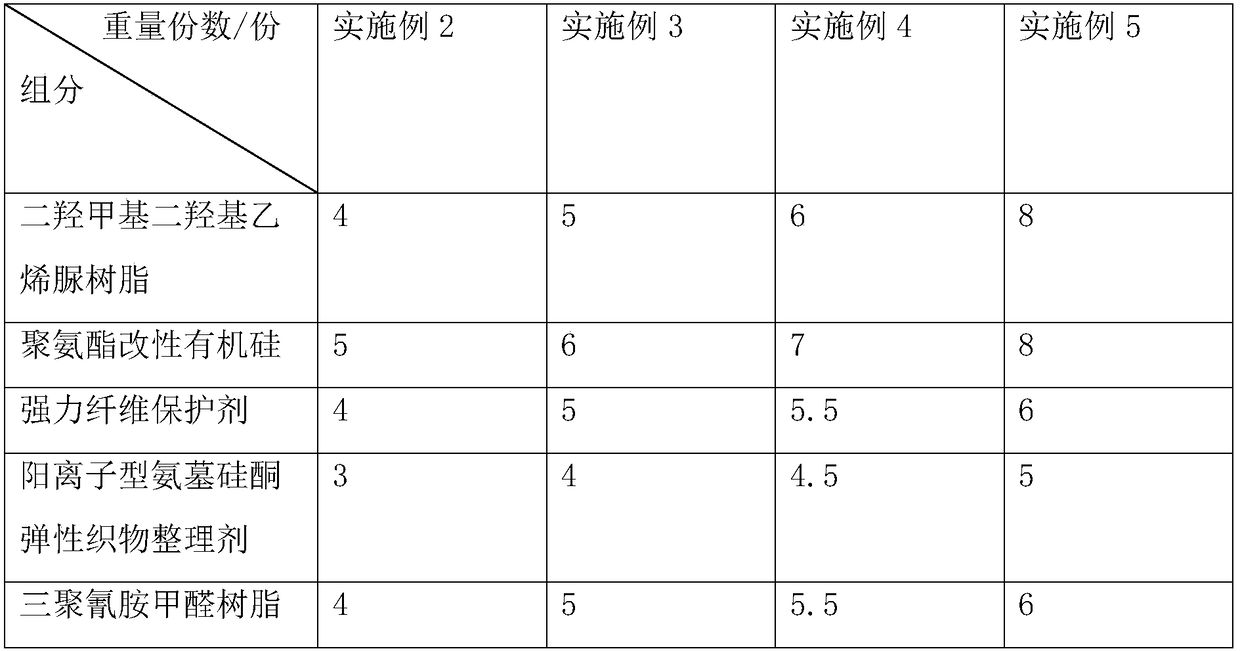

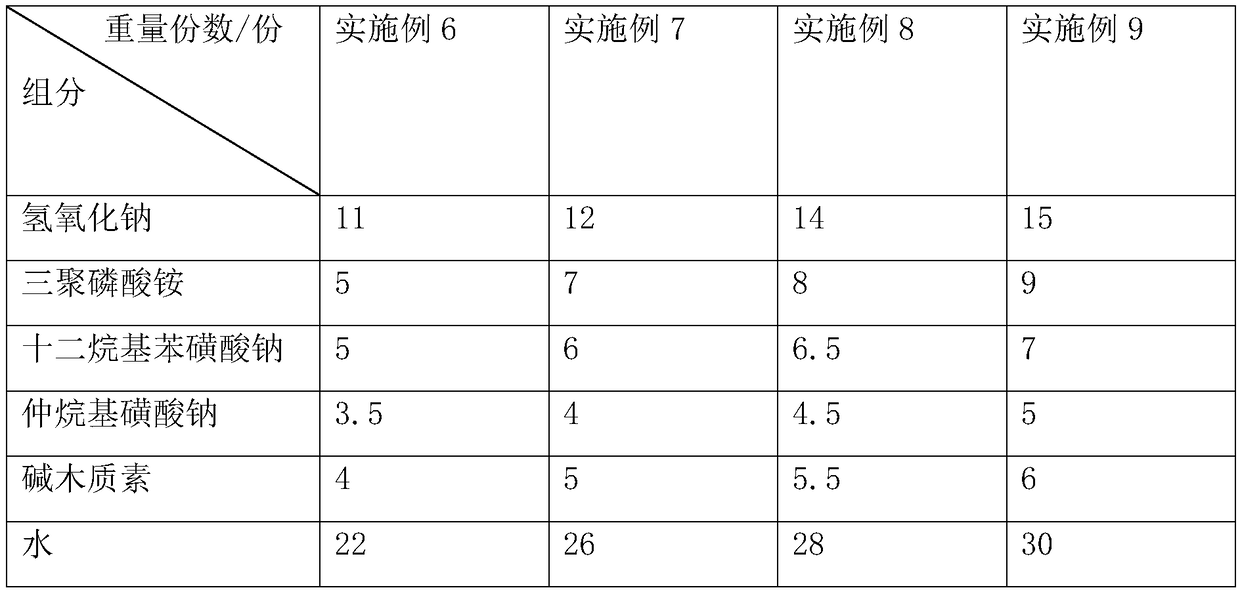

Dyeing and finishing processing method of semi-elastic Huayao imitation memory fabric

InactiveCN109281196AGood shape memoryImprove recovery effectFibre typesDry-cleaning apparatus for textilesFiberTextile printer

The invention discloses a dyeing and finishing processing method of a semi-elastic Huayao imitation memory fabric, and relates to the technical field of textile printing and dyeing, the method comprises the following steps: (1) flat-width desizing; (2) flat-cylinder refining; (3) dyeing; (4) pre-shrinking; and (5) forming, namely a fabric is subjected to soft forming through a forming machine, a softening agent TF-0404 A and a shaping auxiliary agent are added into the shaping machine, the mass ratio of the fabric to the softening agent TF-0404 A to the shaping auxiliary agent is 20: 1: 1, theforming temperature is 165-185 DEG C, the forming time is 30-50 seconds, and the width of the shaping machine is 153-155 cm; wherein the shaping agent comprises the following substances in parts by weight: 3-8 parts of dihydroxymethyl dihydroxy ethylene urea resin, 4-8 parts of polyurethane modified organic silicon, 3-6 parts of a strong fiber protective agent LH -034, 2-5 parts of a cationic amino silicone elastic fabric finishing agent and 3-6 parts of melamine formaldehyde resin. According to the method, the problems that the dyeing shape memory function and the shape recovery capability of the semi-elastic Huayao fabric are not high are solved. By means of the shaping auxiliary agent, the shape memory function and the shape recovery capability of the semi-elastic Huayao fabric can beimproved.

Owner:嘉兴市嘉盛印染有限公司

Dyeing and finishing process of tencel wool blended fabric

PendingCN111826976AImprove wash resistanceGood flexibilityChemical fixing of textilesGrip property fibresPolymer sciencePolymer chemistry

The invention discloses a dyeing and finishing process of a wool and tencel blended fabric. The dyeing and finishing process sequentially comprises the following steps of grey cloth inspection, seam turning, singeing, desizing and scouring, bleaching, drying, rolling, spraying, rolling and dyeing, loose type drying, softening finishing, air washing, tentering, preshrinking, fulling, fluffing, shearing, tank steaming, inspection and finishing and finished product obtaining. According to the tencel and wool blended fabric, in the dyeing process, an auxiliary mixed solution containing a levelingagent and a retarding agent is sprayed, an auxiliary makes contact with gray fabric firstly, then dye makes contact with the gray fabric for dyeing, and the auxiliary is separated from the dye, so that the dyeing rate between tencel fibers and wool fibers is close, and the leveling property of the fabric is improved. By adopting a dye infiltration winding dyeing method and a winding fixation method, the gray fabric does not need to be completely soaked in a dye vat, the bath ratio of dyeing and fixation is reduced, and the liquid absorption amount and the liquid absorption time of tencel are reduced, so that the dyeing rate between the tencel fibers and the wool fibers further tends to be the same, and the level dyeing property of the fabric is further improved.

Owner:JIANGYIN XINGWU WOOL FABRIC TECH

Leather dyeing machine

ActiveCN103388038BIncreased dyeing rateEliminate surface resistanceLeather/skins/hides/pelt chemical treatment apparatusDyeing processVacuum pumpGuide tube

The invention provides a leather dyeing machine, and belongs to the technical field of leather dyeing equipment and the leather dyeing machine can be used for solving the technical problem in the prior art that the leather dyeing machine has low dyeing efficiency. The leather dyeing machine comprises a base, wherein the base is provided with a drum body, the drum body is internally provided with an inner cavity, a rotary shaft I and a rotary shaft II are respectively fixed at two ends of the drum body, a drive device is arranged between the base and the outer end of the rotary shaft I, the rotary shaft II is pivoted on the base, a rotary joint II is arranged outside the rotary shaft II, a power-driven three-way valve is connected outside the rotary joint II, the power-driven three-way valve comprises an outlet I, an outlet II and an inlet, the inlet is communicated with the outer side of the rotary joint II, a vacuum pump is also fixed on the base, and the vacuum pump is communicated with the outlet I through a gas guide tube. Through vacuum pretreatment on the leather in the inner cavity of the drum body, the dyeing efficiency of the leather dyeing machine is improved.

Owner:浙江富邦汽车内饰科技有限公司

Anhydrous reactive dye printing paste and printing process

The invention provides a printing process, which comprises preparation of anhydrous reactive dye printing paste, printing, drying and aftertreatment. The preparation of the anhydrous reactive dye printing paste comprises the following steps: S1, taking a predetermined amount of dimethylformamide (DMF) and adding a predetermined amount of polyurethane into the dimethylformamide; and S2, taking a predetermined amount of polyurethane solution prepared in the step S1, adding a predetermined amount of reactive dye and a predetermined amount of halogenated hydrocarbon into the polyurethane solutionand continuously stirring for 10 to 30 minutes to obtain the anhydrous reactive dye printing paste. The anhydrous reactive dye printing paste consists of the following components in percentage by weight: 35 to 47.5 percent of dimethylformamide, 2.5 to 15 percent of polyurethane, 0.5 to 1.5 percent of reactive dye and 37.5 to 62.5 percent of halogenated hydrocarbon. Thus, in a paste system of halogenated hydrocarbon / DMF / polyurethane, reactive dye molecules are rapidly pushed and attracted to fiber and then are adsorbed by the fiber at once, and the obtained printing textile product has clear boundary and has high color fastness; and the anhydrous reactive dye printing paste has simple components and is simple in preparation process.

Owner:WUHAN TEXTILE UNIV

Hang dyeing machine for fur dyeing

ActiveCN110453021AQuality improvementImprove aestheticsLeather/skins/hides/pelt chemical treatment apparatusEngineeringOblique angle

The invention relates to the technical field of fur dyeing equipment, and discloses a hang dyeing machine for fur dyeing. The hang dyeing machine comprises a dye pool, fixed columns are fixedly connected to the two sides of the bottom of the dye pool respectively, a fixed base is fixedly connected to the bottoms of the fixed columns, and a lifting base is placed in the middle of the fixed base. According to the hang dyeing machine, a traditional up-and-down motion dyeing mode is changed into a rotary oblique dyeing mode, a rotating rod drives a hanging frame to obliquely rotate by utilizing anoblique ring shape of the hanging frame, fur hung below the hanging frame enters water at an oblique angle for dyeing, so that a gradual effect with a certain radian is formed on the dyed part of thedyed fur, the visual effect of dyeing is greatly improved, the overall quality of the fur is improved accordingly, the diversity of fur dyeing types is enhanced, the attractiveness of fur dyeing is improved, a higher economic value is brought to the fur, and the rationality and feasibility of the hang dyeing machine are greatly improved.

Owner:嘉兴巨腾信息科技有限公司

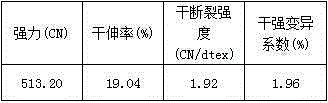

Yarn dyeing process and yarn with high dyeing property

PendingCN114875691AImprove appearance qualityIncrease surface energyDyeing processColour fastnessPolymer chemistry

The invention relates to a yarn dyeing process and high-dyeing-property yarn, and relates to the field of textile fabric dyeing, the yarn dyeing process comprises the following steps: S1, pretreatment: boiling off the yarn, washing with water and drying after boiling off, and then carrying out low-temperature plasma treatment on the yarn; s2, dyeing: immersing the yarns subjected to low-temperature plasma treatment into dye liquor, controlling the bath ratio to be 1: (2-8), and dyeing the yarns at the temperature of 35-120 DEG C; and S3, fixation: carrying out steam fixation treatment on the dyed yarns, and washing and drying the yarns after the fixation treatment is completed, so as to complete the yarn dyeing process. According to the technical scheme provided by the invention, the yarn dyeing quality and efficiency can be effectively improved, and the dyed yarn has higher color fastness and better quality.

Owner:杭州惠丰化纤有限公司

Dyeing Process of Silk Interwoven Jacquard Fabric

ActiveCN104018369BShorten process timeIncrease productivityDyeing processColour fastnessPolymer science

The invention discloses a process for dyeing a silk interwoven jacquard fabric, belonging to the field of silk interwoven jacquard fabric dyeing technology. The process comprises the steps of dye fixing, primary washing, soaping, secondary washing and cylinder discharge and drying, wherein in the dye fixing step, the pretreated silk interwoven jacquard fabric is put into an active dye solution and dyed by adopting a jig dyeing method at 80-85 DEG C for 60-200 minutes; the active dye solution is obtained by mixing 1-5% owf of lanasol dye, 1-5% owf of HE type dye, 20-50g / L of anhydrous sodium sulphate, 5-20g / L of sodium carbonate and water. The process disclosed by the invention can be used for realizing bath dyeing when silk fibers and cellulose fibers in the silk interwoven jacquard fabric are dyed with different colors respectively, the color fastness of the obtained silk interwoven jacquard fabric with the double-color effect can reach the two-bath dyeing fastness, meanwhile, energy is saved, emission is reduced, and the process time is obviously shortened.

Owner:ZIBO DARANFANG SILK GRP

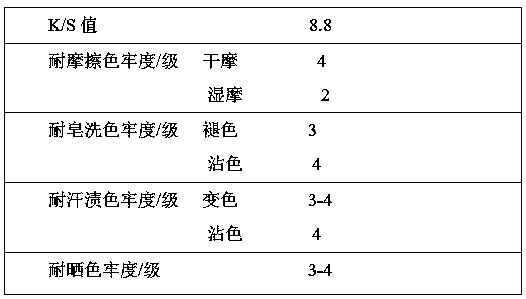

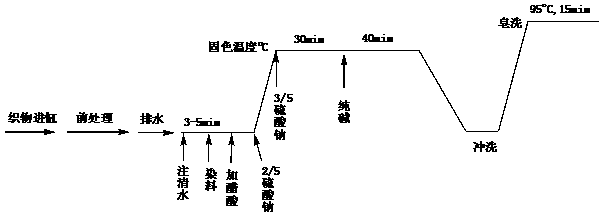

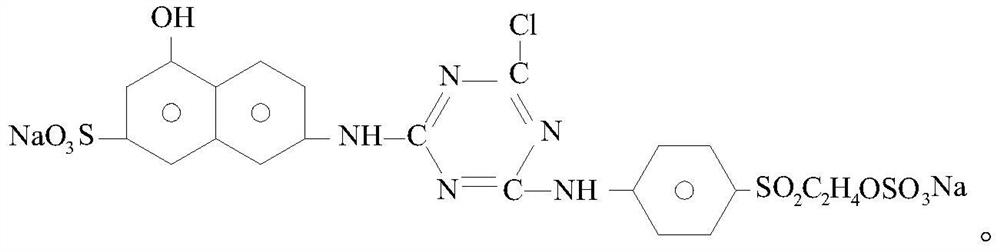

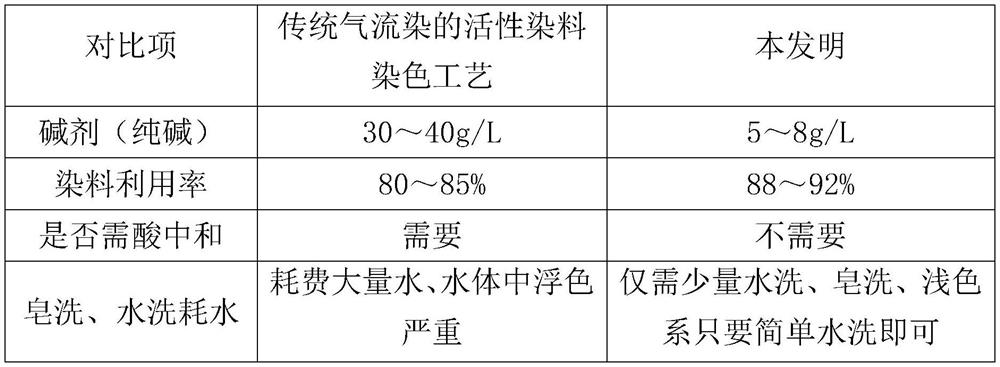

Low Salt and Low Alkali Reactive Dyeing Process by Air Dyeing

ActiveCN109518488BIncrease profitLow costDyeing processTextile treatment by spraying/projectingVinyl sulfoneSewage treatment

The invention discloses a low-salt and low-alkali active dyeing process for air dyeing, which comprises the following steps: A. Select a vinyl sulfone type reactive dye containing a group that activates the vinyl sulfone group, which is product A; Pretreat the fabric to obtain product B; C, put product B into the air-flow atomization dyeing machine, add product A into the vat, the bath ratio is 1:3~4; add sodium bicarbonate; add soda ash; heat up to 30°C , dye for 15-20min; then add soda ash; heat up to 55-65℃, dye for 20-30min; The conventional process washes and dries product D to obtain a finished product. The invention has the characteristics of improved dyestuff utilization rate, water resource saving, no need of acid neutralization, reduced cost and reduced sewage treatment difficulty.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

Dyeing tube capable of adjusting dyeing speed along with cloth transportation

InactiveCN114150454AImprove dyeing qualityLower resistanceLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine arrangementsEngineeringProcess engineering

The invention relates to the technical field of textile dyeing, and discloses a dyeing pipe capable of adjusting the dyeing speed along with cloth transportation, the dyeing pipe comprises a pipeline, the left and right sides of the pipeline are fixedly provided with material guide pipes, the interior of each material guide pipe is rotatably connected with a ball valve, and the rear end of each ball valve is fixedly provided with a gear; racks are connected to the left side and the right side of the gear in an engaged mode, magnetic blocks are fixedly installed on the peripheries of the racks, and electromagnets are fixedly installed on the sides, close to the magnetic blocks, of the peripheries of the material guiding pipes. According to the dyeing tube capable of adjusting the dyeing speed along with cloth transportation, when the cloth in the dyeing tube is transported, the spraying speed of a dyeing agent is adjusted according to the moving speed of the cloth, so that the spraying speed of the dyeing agent is in direct proportion to the cloth transportation speed, and the dyeing efficiency of the cloth is high; in addition, the temperature in the pipeline is adjusted according to the transportation speed in the transportation process, the dyeing efficiency is improved by increasing the temperature, and energy waste can be effectively prevented.

Owner:宁波精英纺织科技有限公司

Hanging dyeing machine for fur dyeing

ActiveCN110453021BQuality improvementImprove aestheticsLeather/skins/hides/pelt chemical treatment apparatusMechanical engineeringIndustrial engineering

The invention relates to the technical field of fur dyeing equipment, and discloses a hanging dyeing machine for fur dyeing, which includes a dye pool, and fixed columns are fixedly connected to both sides of the bottom end of the dye pool, and the bottom ends of the fixed columns are fixed A fixed base is connected, and a lifting base is placed in the middle of the fixed base. The present invention changes the traditional up-and-down dyeing method into rotating and tilting dyeing, and utilizes the shape of the hanger as an inclined ring, so that the rotating rod drives the hanger to tilt and rotate, and then the fur hanging under the hanger enters the water at an inclined angle. Dyeing makes the dyed part of the dyed fur form a gradient effect with a certain radian, which greatly improves the visual effect of dyeing, thereby improving the overall quality of fur, enriching the diversity of fur dyeing types, and improving the aesthetics of fur dyeing , bringing more economic value to the fur and greatly improving the rationality and feasibility of the equipment.

Owner:嘉兴巨腾信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com