Laser dyeing process of denim fabric

A denim and laser technology, applied in the field of dyeing, can solve problems such as unrealizable, clear gradient patterns, etc., and achieve the effect of solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

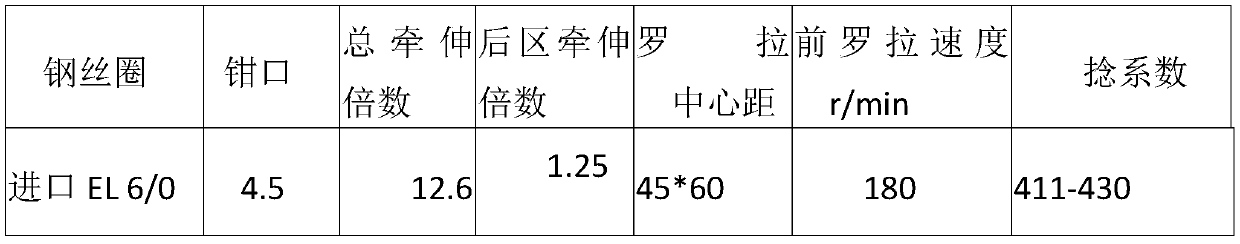

[0035] The present invention adopts 5-16 warp counts of ring-spun high-twisted yarn (metric twist coefficient 411-430) for spinning and dyeing;

[0036] (1) Configure mercerizing solvent, use 225 g / L of sodium hydroxide, 2 g / L of mercerizing penetrant, and the temperature requirement is 30 degrees Celsius. Mix the above-mentioned substances with water evenly before use;

[0037] (2) Configure sulfur black solvent: use pre-reduced sulfur black 200 g / L, caustic soda 30 g / L, chelating agent 3 g / L, penetrant 1 g / L, sodium sulfite 15 g / L, temperature requirement: 70 degrees Celsius, pass The above-mentioned substances are mixed with water for use;

[0038] ⑶ worsted spinning process

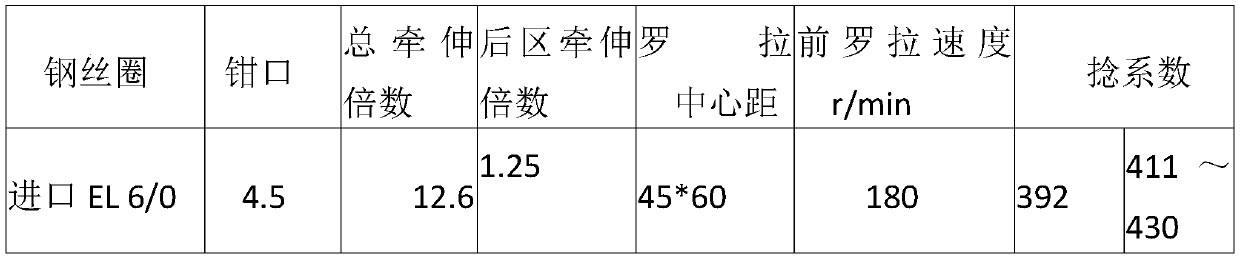

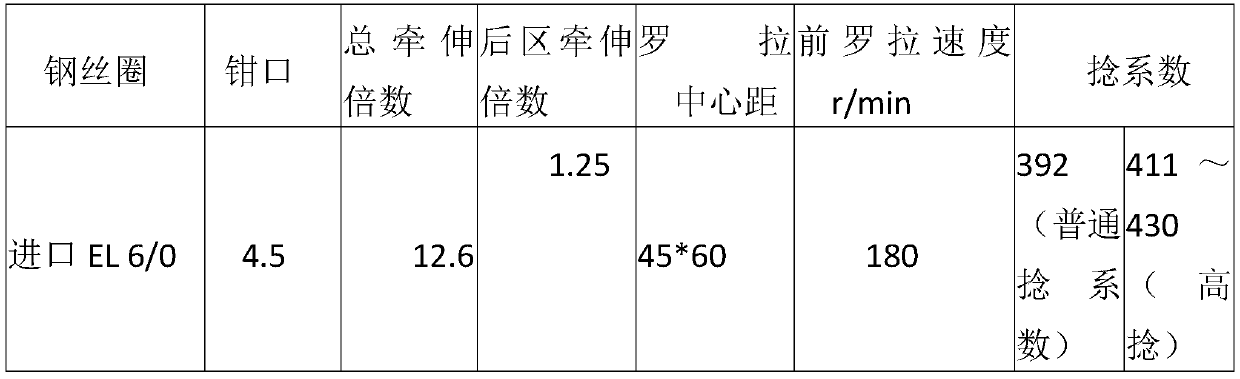

[0039] Rieter G32 spinning frame is used for spinning. The drafting gauge in the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com