Yarn dyeing process and yarn with high dyeing property

A yarn dyeing and yarn technology, which is applied in dyeing methods, textiles and papermaking, etc., can solve the problems affecting the dyeing quality of yarns, low coloring rate, and difficult control of fastness and coloring rate, so as to achieve good dyeing effect and easy Effect of penetration and improvement of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

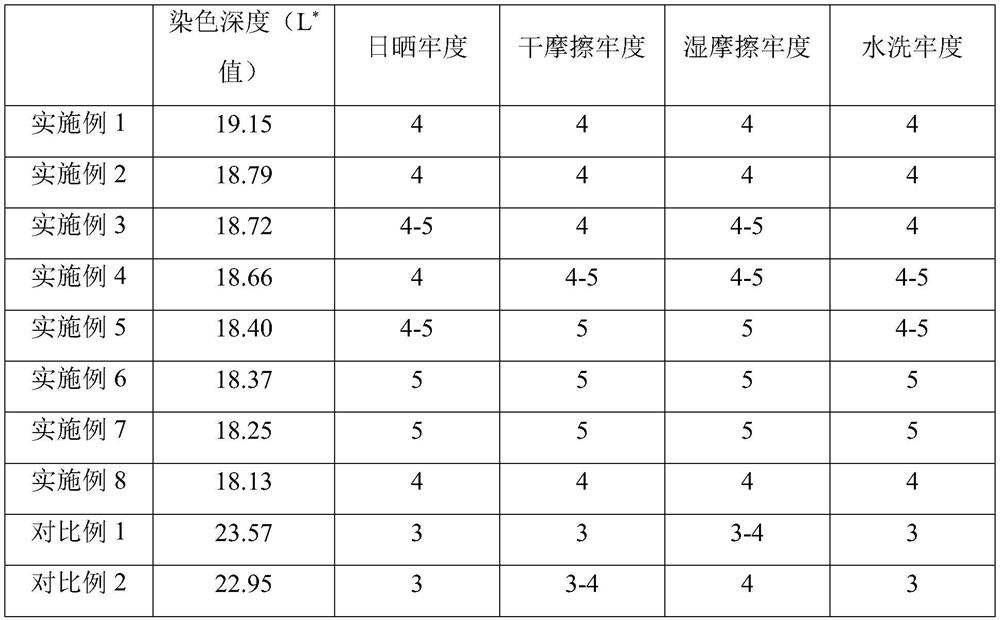

Examples

Embodiment 2

[0036] A yarn with high colorability is provided. The only difference from Example 1 is that the bath ratio in the dyeing process is 1:8, the dyeing temperature is 120°C, and the rest are the same as those in Example 1.

Embodiment 3

[0038] Provide a kind of high coloring yarn, obtained by the following process:

[0039] S1. Pretreatment: scouring the pure cotton yarn to remove most of the impurities on its surface, then drying the yarn, and then passing through a low-temperature plasma generator. In an oxygen environment, set the power of the plasma generator to 75W and the pressure 30Pa, low temperature plasma treatment for 5min;

[0040] S2. After the low-temperature plasma treatment, the yarn is dyed and dyed. The dyeing bath ratio is controlled to be 1:7.5. First, the yarn is soaked and dyed in the dye solution at 40 °C for 3 minutes. ℃, heat preservation for 15min, and finally the dye liquor is heated to 120℃ for 2min, the heating rate of the whole process is 5℃ / min;

[0041]S3. After the yarn is dyed, it is removed from the dye liquor, steam-fixed for 4 minutes at 150°C and a steam pressure of 0.55MPa, then washed with water at 30°C for 5 minutes, and dried at 105°C for 6 minutes , to complete the...

Embodiment 4

[0043] Provide a kind of high coloring yarn, obtained by the following process:

[0044] S1. Pretreatment: scouring the pure cotton yarn to remove most of the impurities on its surface, then drying the yarn, and then passing through a low-temperature plasma generator. In an oxygen environment, set the power of the plasma generator to 75W and the pressure 30Pa, low temperature plasma treatment for 5min;

[0045] S2. After the low-temperature plasma treatment, the yarn is dyed and dyed. The dyeing bath ratio is controlled to be 1:5.5. First, the yarn is soaked and dyed at 50 °C for 5 minutes, then the dye solution is heated to 75 °C and then incubated for 6 minutes. ℃, heat preservation for 18min, and finally the dye solution is heated to 120℃ for 2min, the heating rate of the whole process is 6℃ / min;

[0046] S3. After the yarn is dyed, it is removed from the dye liquor, steam-fixed for 4 minutes at 150°C and a steam pressure of 0.55MPa, then washed with water at 30°C for 5 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com