Wool fiber surface modification method

A wool modification technology, applied in the field of wool modification, can solve the problems of insufficient effect, high investment in equipment, yellowing of wool, etc., and achieve the effect of convenient sewage treatment, guaranteed source, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

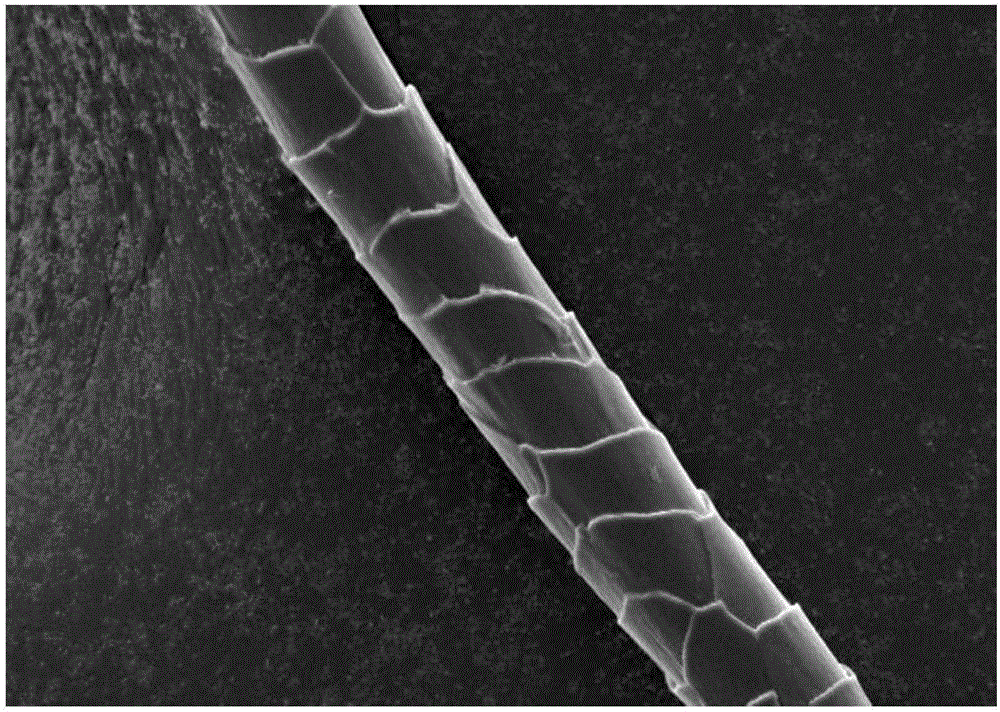

[0022] A method for modifying wool surface scales, using loose wool fibers as wool to be treated, and performing the following steps in sequence:

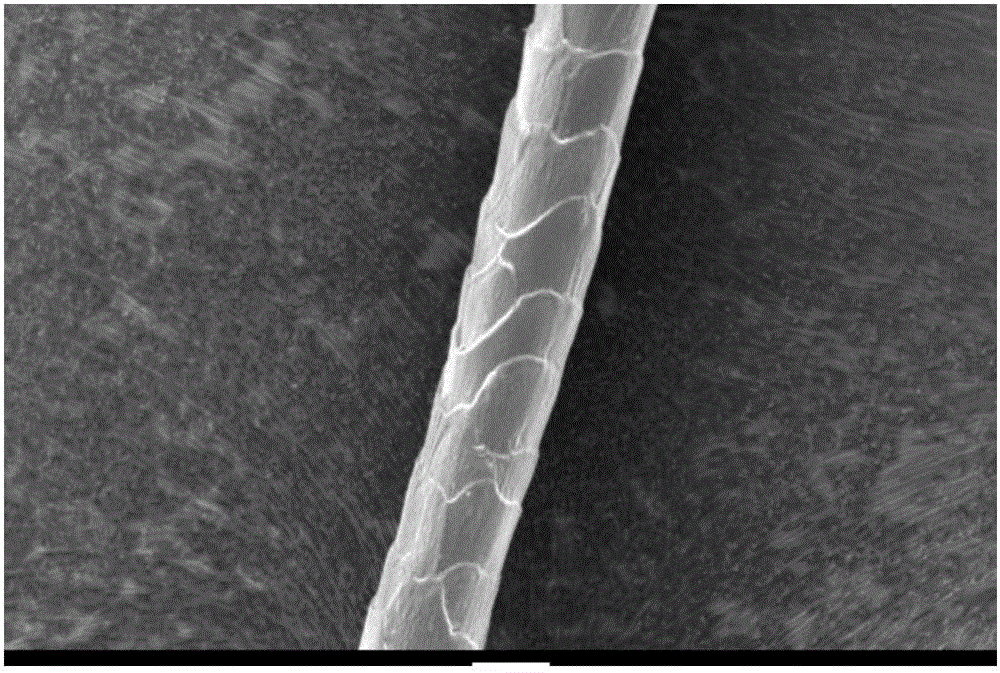

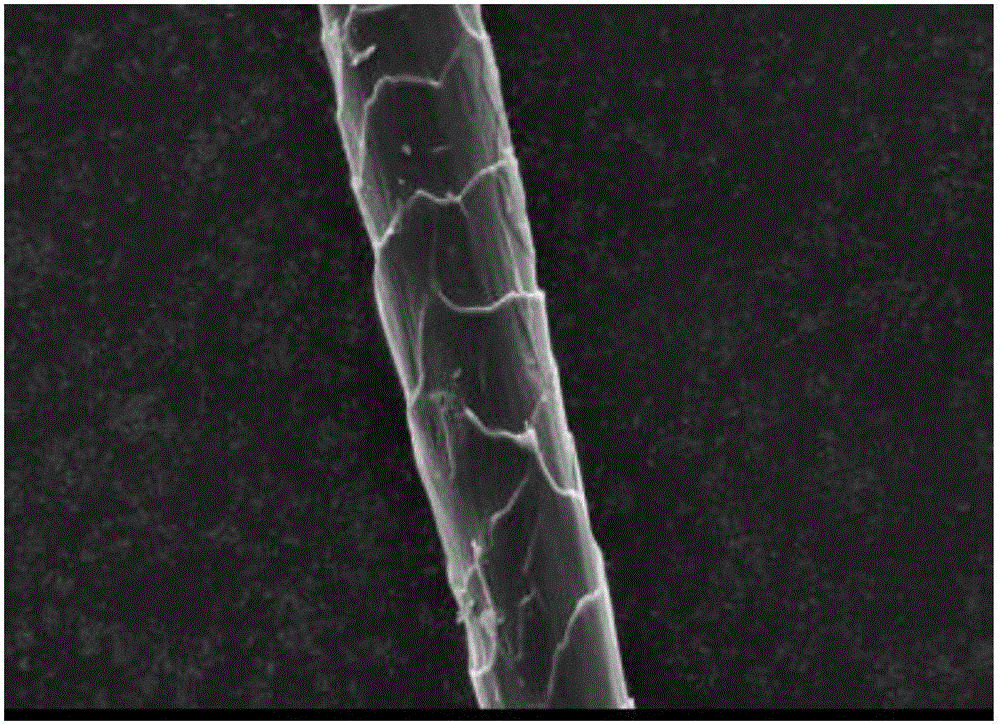

[0023] The method for modifying wool surface scales, using wool loose fibers, wool tops, wool yarn or wool garments as wool to be treated, the following steps are carried out in sequence: a. Prepare treatment liquid; take sodium cyanate, sodium pyrophosphate, 30% concentration of hydrogen peroxide and the remaining water, the concentration of liquid sodium cyanate in the treatment solution after preparation is 1-20g / L, the concentration of sodium pyrophosphate is 0-20g / L, and the concentration of hydrogen peroxide is 10-70g / L; b. The mass ratio of the wool to be treated to the treatment liquid is 1:15-1:25, soak the wool to be treated in the above treatment liquid, keep the temperature of the treatment liquid at 30-70°C, and vibrate in an ultrasonic oscillator for 10-60 minutes; c. Cleaning treatment: Soak and wash the above-mentio...

Embodiment 2

[0027] The method for modifying wool surface scales, using wool loose fibers, wool tops, wool yarn or wool garments as wool to be treated, the following steps are carried out in sequence: a. Prepare treatment liquid; take sodium cyanate, sodium pyrophosphate, 30% concentration of hydrogen peroxide and the remaining water, the concentration of liquid sodium cyanate in the treatment solution after preparation is 1-20g / L, the concentration of sodium pyrophosphate is 0-20g / L, and the concentration of hydrogen peroxide is 10-70g / L; b. The mass ratio of the wool to be treated to the treatment liquid is 1:15-1:25, soak the wool to be treated in the above treatment liquid, keep the temperature of the treatment liquid at 30-70°C, and vibrate in an ultrasonic oscillator for 10-60 minutes; c. Cleaning treatment: Soak and wash the above-mentioned wool treated with the treated liquid for 2-4 times in clear water at 20-30°C, 20-60 minutes each time; remove excess treatment liquid from the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com