Dyeing and finishing processing method of semi-elastic Huayao imitation memory fabric

A memory fabric and processing method technology, applied in the field of textile printing and dyeing, can solve the problems of poor shape memory function and high recovery deformation ability of semi-elastic Huayao imitation memory fabrics, long time for two refining and desizing, etc., so as to improve the dyeing effect. speed, improvement of dyeing effect and levelness, effect of increasing washing and abrasion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: a kind of dyeing and finishing processing method of imitation memory fabric of semi-stretch Huayao, comprises the following steps:

[0042] (1) Open-width desizing; place the semi-elastic Huayao imitation memory fabric in a padding tank filled with desizing solution for padding twice, keep the temperature of the desizing solution at 85°C, and pad for 2 hours each time, then Stack at 60°C for 8 hours, pad twice with dilute sulfuric acid with a mass concentration of 4g / L, then stack for 3 hours, and rinse with water;

[0043] Among them, the warp and weft of the semi-stretch Huayao imitation memory fabric are 75D polyester, twisted in the weft direction, and the twist is 22T / 2S2Z;

[0044] The desizing solution comprises the following components by weight: 10 parts of sodium hydroxide with a mass concentration of 10 g / L, 5 parts of ammonium tripolyphosphate, 4 parts of sodium dodecylbenzenesulfonate, 3 parts of secondary alkyl sodium sulfonate, 3 parts of a...

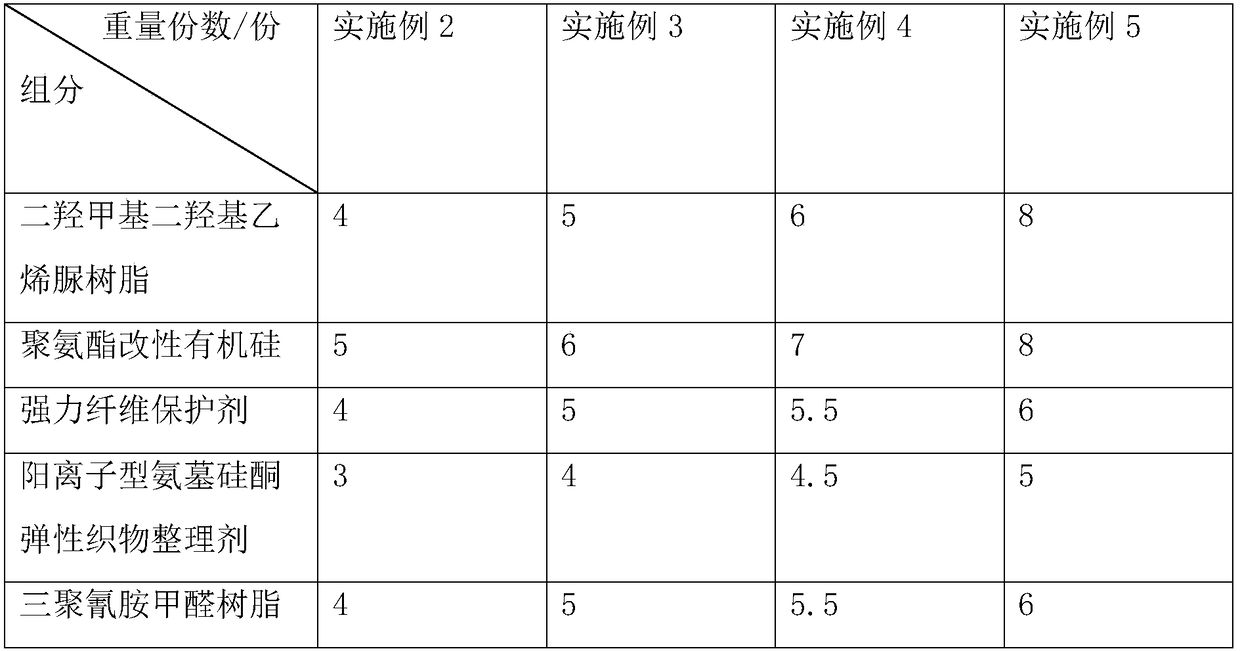

Embodiment 2-5

[0057] Example 2-5: A dyeing and finishing method for a semi-stretch Huayao imitation memory fabric, the difference from Example 1 is that the components contained in the styling aid and the parts by weight corresponding to each component are shown in Table 1 .

[0058] Components contained in the styling aid and the corresponding parts by weight of each component in the embodiment 2-5 of table 1

[0059]

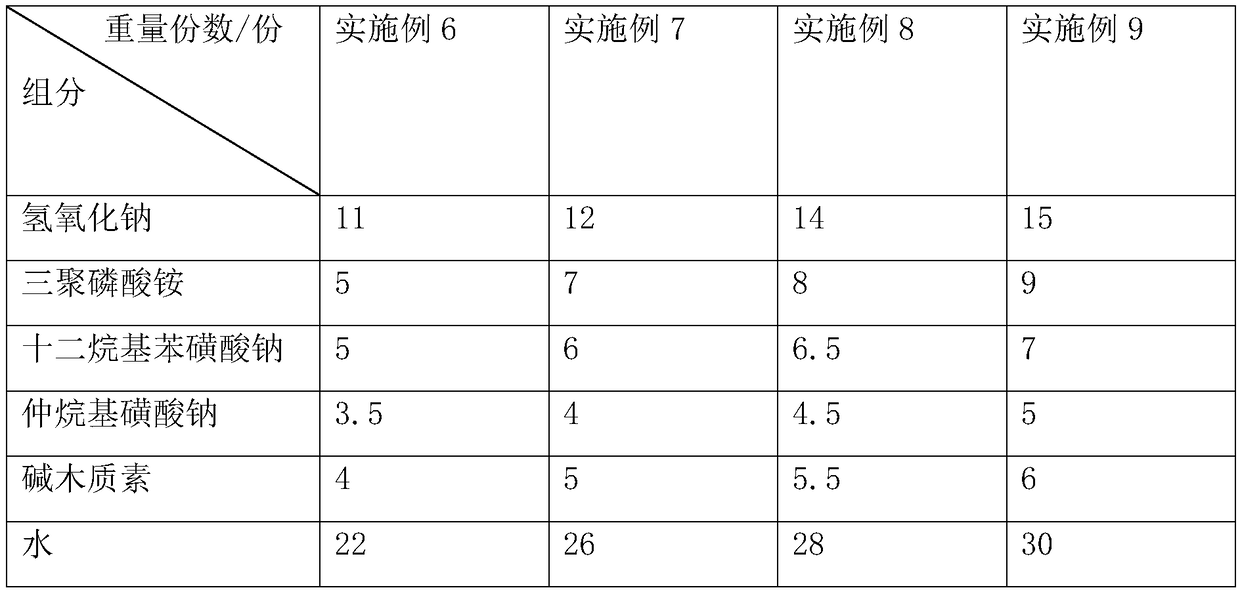

Embodiment 6-9

[0060] Example 6-9: A dyeing and finishing method for a semi-elastic Huayao imitation memory fabric, the difference from Example 1 is that the components contained in the desizing solution and the parts by weight corresponding to each component are shown in Table 2.

[0061] Components contained in the desizing solution and the corresponding parts by weight of each component in the embodiment 6-9 of table 2

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com