Multi-response shape memory polyurethane material as well as preparation method and application thereof

A polyurethane material, multi-response technology, applied in rayon manufacturing, textile and papermaking, conductive/antistatic filament manufacturing, etc., can solve the problems of limiting the application of shape memory polyurethane materials, achieve excellent shape memory function, enhance flexible transmission sensory properties, good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The embodiment of the present invention also provides a method for preparing a multiple-response shape-memory polyurethane material, comprising the following steps:

[0048] S10. Obtain a nano-conductive material and a solvent, and disperse the nano-conductive material in the solvent to obtain a dispersion liquid of the nano-conductive material;

[0049] S20. Obtain thermoplastic polyurethane, acrylic crosslinked resin, and nano-reinforcement material, and disperse the thermoplastic polyurethane, the acrylic cross-linked resin, and the nano-reinforcement material in the solvent to obtain a mixed solution;

[0050] S30. Add the dispersion of the nano-conductive material to the mixed solution, and stir to obtain a conductive shape-memory polyurethane dispersion;

[0051] S40. Obtain an organic antibacterial material, add the organic antibacterial material to the conductive shape memory polyurethane dispersion, and perform dispersion treatment to obtain a multi-response sh...

Embodiment 1

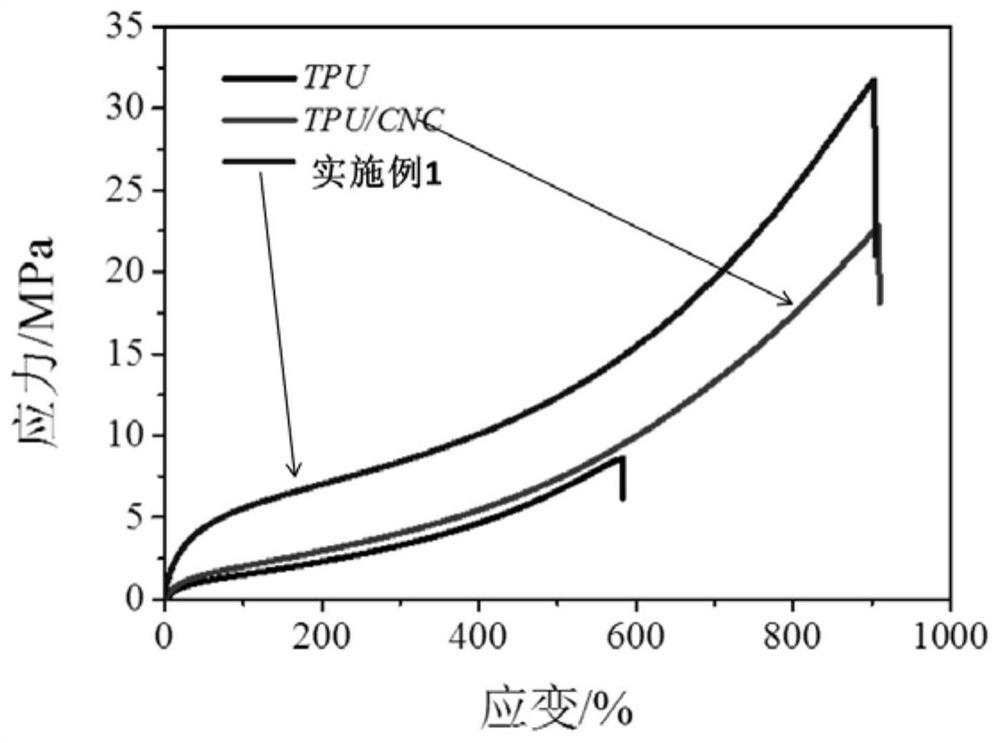

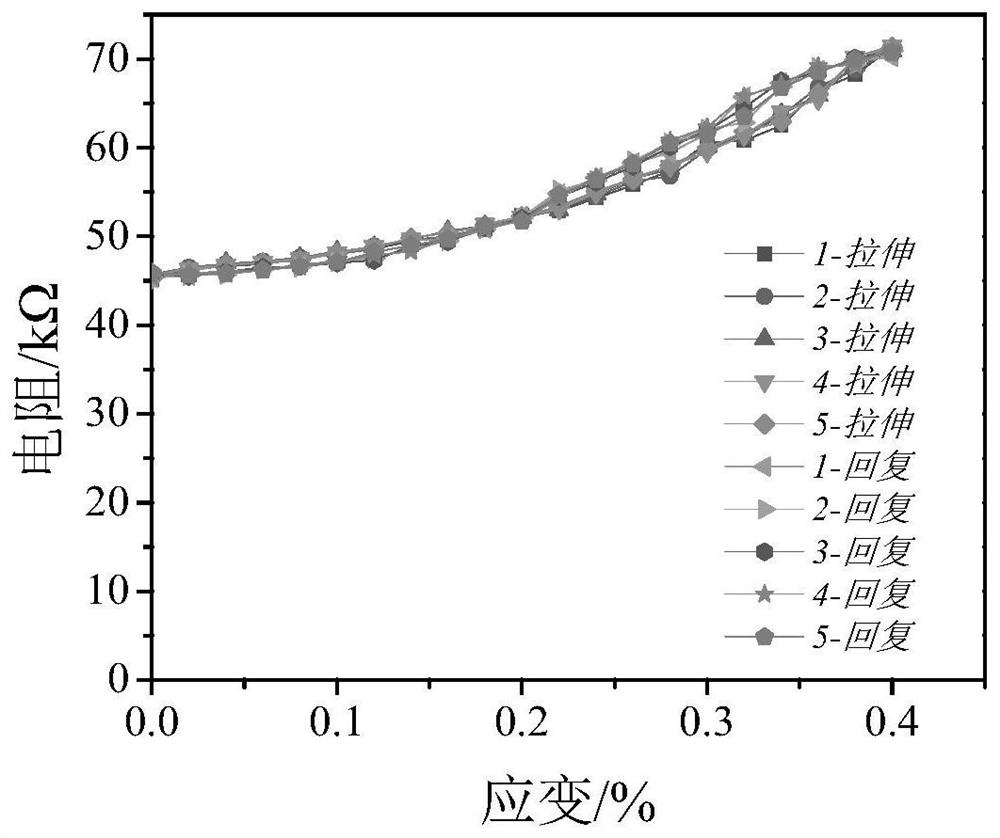

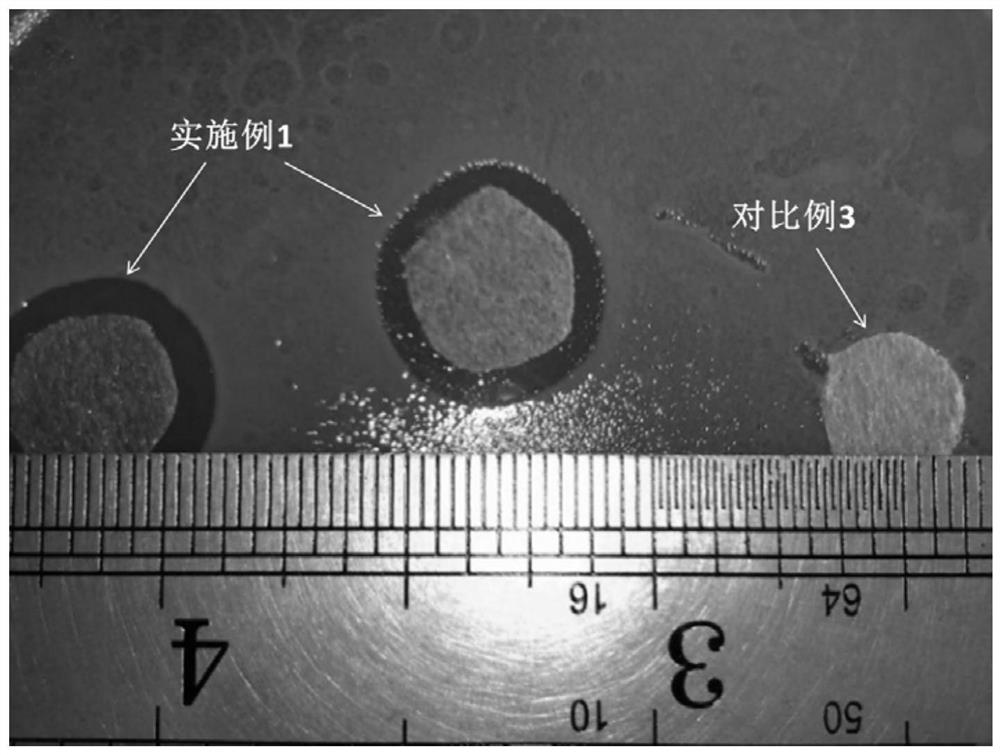

[0063] A multiple response shape memory polyurethane material, comprising the following preparation steps:

[0064] S11. Add 0.27g of carbon nanotubes (CNTs) to 20mL of N,N-dimethylformamide (DMF), and ultrasonically disperse for 30min to obtain a dispersion of CNTs;

[0065] S21. Take 4.0g of TPU, 0.5g of Carbomer-940 and 0.225g of hydroxyethyl nanocellulose (CNC), add it to 25mL of DMF, and stir magnetically at a rate of 200r / min at 75°C for 2h , so that TPU and Carbomer-940 are completely dissolved and CNC is uniformly dispersed to obtain a mixture of TPU, Carbomer-940 and CNC;

[0066] S31. Slowly add the dispersion of CNTs to the mixture of TPU, Carbomer-940 and CNC, and continue magnetic stirring at a rate of 200r / min for 3.0h at 75°C, so that the CNTs are in the shape memory polyurethane system Evenly dispersed to obtain conductive shape memory polyurethane dispersion;

[0067] S41. Add 0.2 g of chloramphenicol to the conductive shape-memory polyurethane dispersion, a...

Embodiment 2

[0069] A multiple response shape memory polyurethane material, comprising the following preparation steps:

[0070] S12. Get 0.27g of graphene and join in the N of 20mL, N-dimethylformamide (DMF), ultrasonic dispersion 30min, obtain the dispersion liquid of graphene;

[0071] S22. Take 4.0g of TPU, 0.5g of Carbomer-940 and 0.225g of hydroxyethyl nanocellulose (CNC), add it to 25mL of DMF, and stir magnetically at a rate of 200r / min at 75°C for 2h , so that TPU and Carbomer-940 are completely dissolved and CNC is uniformly dispersed to obtain a mixture of TPU, Carbomer-940 and CNC;

[0072] S32. Slowly add the dispersion of graphene into the mixture of TPU, Carbomer-940 and CNC, and continue to stir magnetically at a rate of 200r / min for 3.0h at 75°C, so that the graphene is in the shape memory polyurethane Disperse uniformly in the system to obtain conductive shape memory polyurethane dispersion;

[0073] S42. Add 0.2 g of chloramphenicol to the conductive shape-memory polyu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com