Shape memory polyurethane preparation method using hydroxylated perylene bisimide

A technology of hydroxylated peryleneimide and polyurethane, which is applied in the field of intelligent polymer materials to achieve simple operation and excellent thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

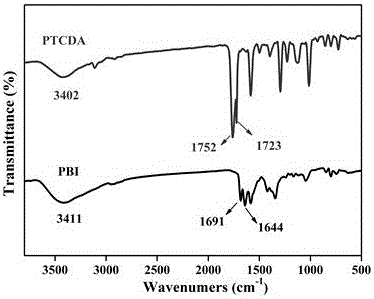

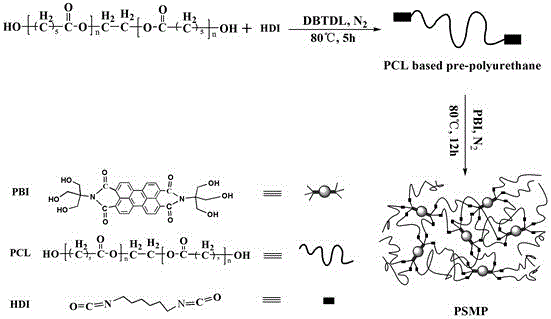

[0019] (1) Take 3.92g 3,4,9,10-perylenetetracarboxylic dianhydride (PTCDA), 9.68g trishydroxymethylaminomethane (THAM), 1.83g anhydrous zinc acetate ((CH 3 COO) 2 Zn) and 100ml N-methylpyrrolidone (NMP) were added to a 250ml three-necked flask, heated to 80°C under nitrogen atmosphere, stirred and mixed for 15min, then continued to heat up to 155°C and stirred for 16h to obtain a dark purple solution.

[0020] (2) Suction filter the deep purple solution prepared in step (1), wash the filtrate 4 times with ethanol, and then put it in a vacuum oven at 50°C to dry for 10 hours, and the obtained purple powder is hydroxylated perylene imide, labeled as PBI.

[0021] (3) Put 2.0 g of polycaprolactone diol with a weight-average molecular weight of 1000 into a round-bottomed flask, heat to 80°C under a nitrogen atmosphere and magnetically stir until it melts, then add 10 ml of N,N-dimethyl Dibutyltin dilaurate (DBTDL) and 0.1 ml dibutyltin dilaurate (DBTDL), heat the mixture to 105 ...

Embodiment 2

[0026] (1) Take 3.92g 3,4,9,10-perylenetetracarboxylic dianhydride (PTCDA), 9.68g trishydroxymethylaminomethane (THAM), 1.83g anhydrous zinc acetate ((CH 3 COO) 2 Zn) and 100ml N-methylpyrrolidone (NMP) were added to a 250ml three-necked flask, heated to 80°C under nitrogen atmosphere, stirred and mixed for 15min, then continued to heat up to 155°C and stirred for 16h to obtain a dark purple solution.

[0027] (2) Suction filter the deep purple solution prepared in step (1), wash the filtrate 4 times with ethanol, and then put it in a vacuum oven at 50°C to dry for 10 hours, and the obtained purple powder is hydroxylated perylene imide.

[0028] (3) Put 2.0 g of polycaprolactone diol with a weight-average molecular weight of 1000 into a round-bottomed flask, heat to 80°C under a nitrogen atmosphere and magnetically stir until it melts, then add 10 ml of N,N-dimethyl Dibutyltin dilaurate (DBTDL) and 0.1 ml dibutyltin dilaurate (DBTDL), heat the mixture to 105 ° C for 15 min t...

Embodiment 3

[0033] (1) Take 3.92g 3,4,9,10-perylenetetracarboxylic dianhydride (PTCDA), 9.68g trishydroxymethylaminomethane (THAM), 1.83g anhydrous zinc acetate ((CH 3 COO) 2 Zn) and 100ml N-methylpyrrolidone (NMP) were added to a 250ml three-necked flask, heated to 80°C under nitrogen atmosphere, stirred and mixed for 15min, then continued to heat up to 155°C and stirred for 16h to obtain a dark purple solution.

[0034](2) Suction filter the deep purple solution prepared in step (1), wash the filtrate 4 times with ethanol, and then put it in a vacuum oven at 50°C to dry for 10 hours, and the obtained purple powder is hydroxylated perylene imide.

[0035] (3) Put 2.0 g of polycaprolactone diol with a weight-average molecular weight of 1000 into a round-bottomed flask, heat to 80°C under a nitrogen atmosphere and magnetically stir until it melts, then add 10 ml of N,N-dimethyl Dibutyltin dilaurate (DBTDL) and 0.1 ml dibutyltin dilaurate (DBTDL), heat the mixture to 105 ° C for 15 min to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com