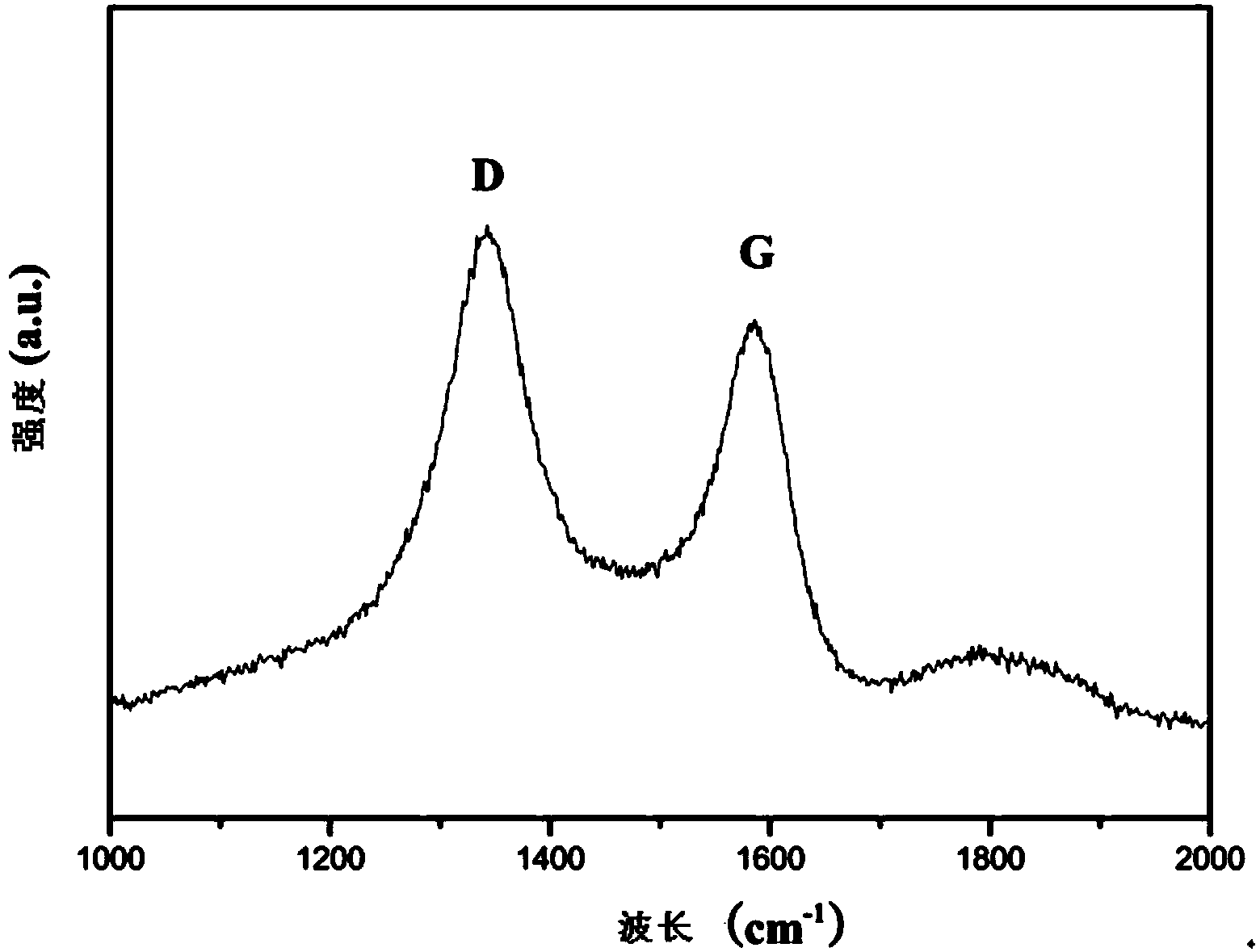

Method for preparing in-situ grown carbon nano tube reinforced silver-based electric contact material

A technology of electrical contact materials and carbon nanotubes, which is applied in the coating process of metal materials, contacts, circuits, etc., can solve the problems of many structural defects and uneven dispersion of carbon nanotubes, so as to avoid agglomeration and improve performance. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific Embodiment 1: In this embodiment, a method for preparing an in-situ grown carbon nanotube-reinforced silver-based electrical contact material is specifically prepared according to the following steps:

[0019] 1. Mix the silver powder and nickel nitrate hexahydrate, then add ethanol until the concentration of nickel nitrate hexahydrate is 0.1mol / L, then mechanically stir for 25min to 35min, then heat and stir until the ethanol is completely volatilized to obtain Ni(NO 3 ) 2 / Ag composite powder, wherein the mass ratio of nickel nitrate hexahydrate to silver powder is 2% to 10%;

[0020] Two, the Ni(NO) obtained in step one 3 ) 2 / Ag composite powder is evenly spread in the quartz boat, put the quartz boat into the plasma-enhanced chemical vapor deposition equipment, vacuumize to the pressure below 5Pa, and pass H 2 , control H 2 The flow rate is 20sccm, the pressure is kept at 200Pa, and then the temperature is raised to the working temperature of 600℃~800℃...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the purity of the silver powder in Step 1 is above 99% by mass. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment is different from Embodiment 1 in that: in step 1, heat to 200° C. and stir. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com