Light-resistant antibacterial water-based polyurethane coating and preparation method thereof

A water-based polyurethane and light-resistant technology, applied in polyurea/polyurethane coatings, anti-fouling/underwater coatings, fire-resistant coatings, etc., can solve the problems of poor dispersion of graphene materials, achieve easy volatilization, reduce volatility, and slow down volatilization speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

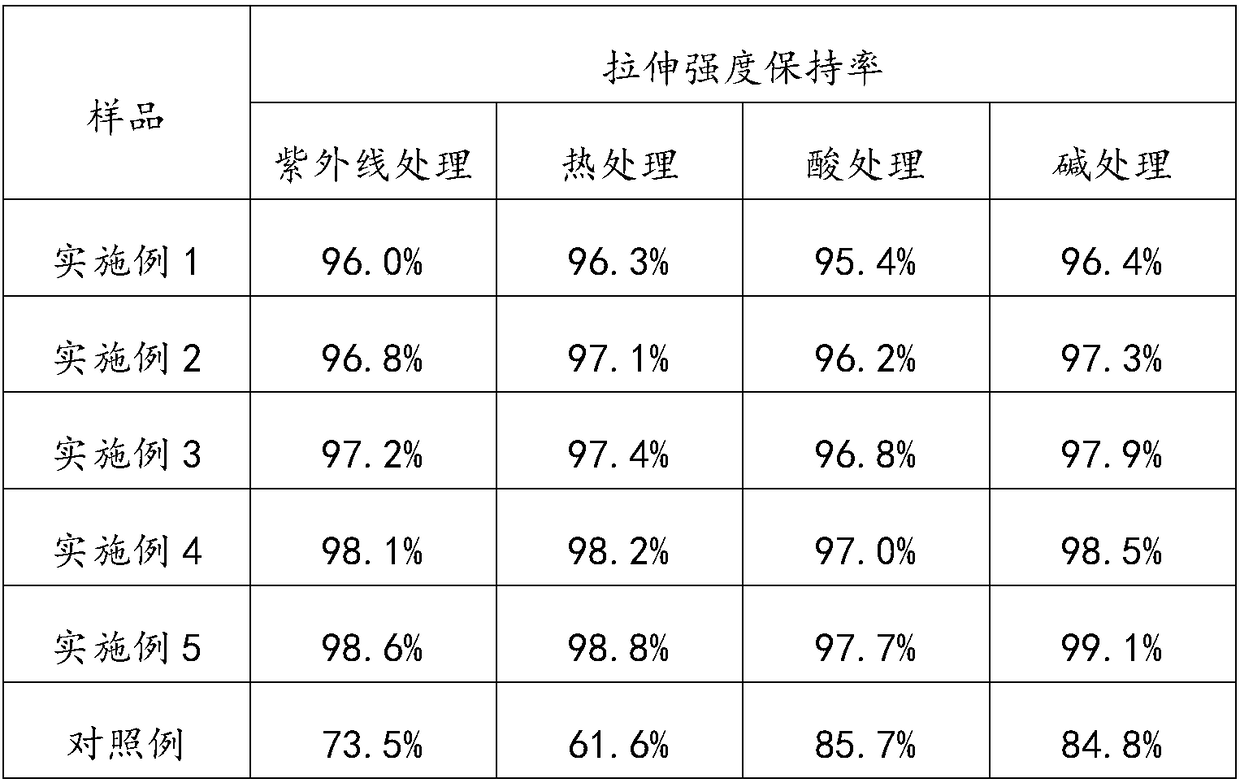

Examples

Embodiment 1

[0032] A preparation method for light-resistant and antibacterial waterborne polyurethane coating, comprising the steps of:

[0033] S1: Functionalization of graphene oxide, disperse 0.4g graphene oxide in dry 24g DMF, under nitrogen protection, add 5g polyisocyanate, then drop 0.065g dibutyltin dilaurate, react at 40°C 1h, washing and drying to obtain functionalized graphene oxide;

[0034] S2: To prepare cyclodextrin-antibacterial agent clathrate, add 1.5g sodium lauryl polyoxyethylene ether sulfate to 50mL deionized water at 25°C, stir well to obtain a dispersant aqueous solution, add 10gβ- Cyclodextrin, disperse 5min with high-speed disperser 1500rmp, make uniform suspension, then grind 30min under 2600rmp with Shanghai Senler horizontal grinder, then slowly add the ethanol solution of tea tree essential oil (4g tea tree essential oil is dissolved in 5g ethanol middle), then grind to a uniformly dispersed state with a grinding speed of 2600rmp, suction filter with a 300-m...

Embodiment 2

[0038] A preparation method for light-resistant and antibacterial waterborne polyurethane coating, comprising the steps of:

[0039] S1: Functionalization of graphene oxide, disperse 0.5g graphene oxide in dry 35g DMF, under nitrogen protection, add 7.5g polyisocyanate, then dropwise add 0.125g dibutyltin dilaurate, at 60℃ React for 1.5h, wash and dry to obtain functionalized graphene oxide;

[0040] S2: Prepare cyclodextrin-antibacterial agent clathrate, add 2.4g sodium lauryl polyoxyethylene ether sulfate to 50mL deionized water at 25°C, stir evenly to obtain dispersant aqueous solution, add 12gβ- Cyclodextrin, disperse 5min with high-speed disperser 1500rmp, make uniform suspension, then grind 30min under 2600rmp with Shanghai Senler horizontal grinder, then slowly add the ethanol solution of tea tree essential oil (6.5g tea tree essential oil is dissolved in 7g in ethanol), then grind to a uniformly dispersed state with a grinding speed of 2600rmp, filter with suction thr...

Embodiment 3

[0044] A preparation method for light-resistant and antibacterial waterborne polyurethane coating, comprising the steps of:

[0045] S1: Functionalization of graphene oxide, disperse 0.6g graphene oxide in dry 50g DMF, under nitrogen protection, add 10g polyisocyanate, then drop 0.2g dibutyltin dilaurate, react at 80°C 2h, washing and drying to obtain functionalized graphene oxide;

[0046] S2: Prepare cyclodextrin-antibacterial agent clathrate, add 2.5g sodium lauryl sulfate to 50mL deionized water at 25°C, stir evenly to obtain dispersant aqueous solution, add 20g β-cyclodextrin to the dispersant aqueous solution , disperse 5min with high-speed disperser 1500rmp, make uniform suspension, then grind 30min under 2600rmp with Shanghai Senler horizontal grinder, then slowly add the ethanol solution of tea tree essential oil (8g tea tree essential oil is dissolved in 8g ethanol), Then grind at a grinding speed of 2600rmp to a uniformly dispersed state, suction filter with a 300-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com