Patents

Literature

263results about How to "Excellent shape memory performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

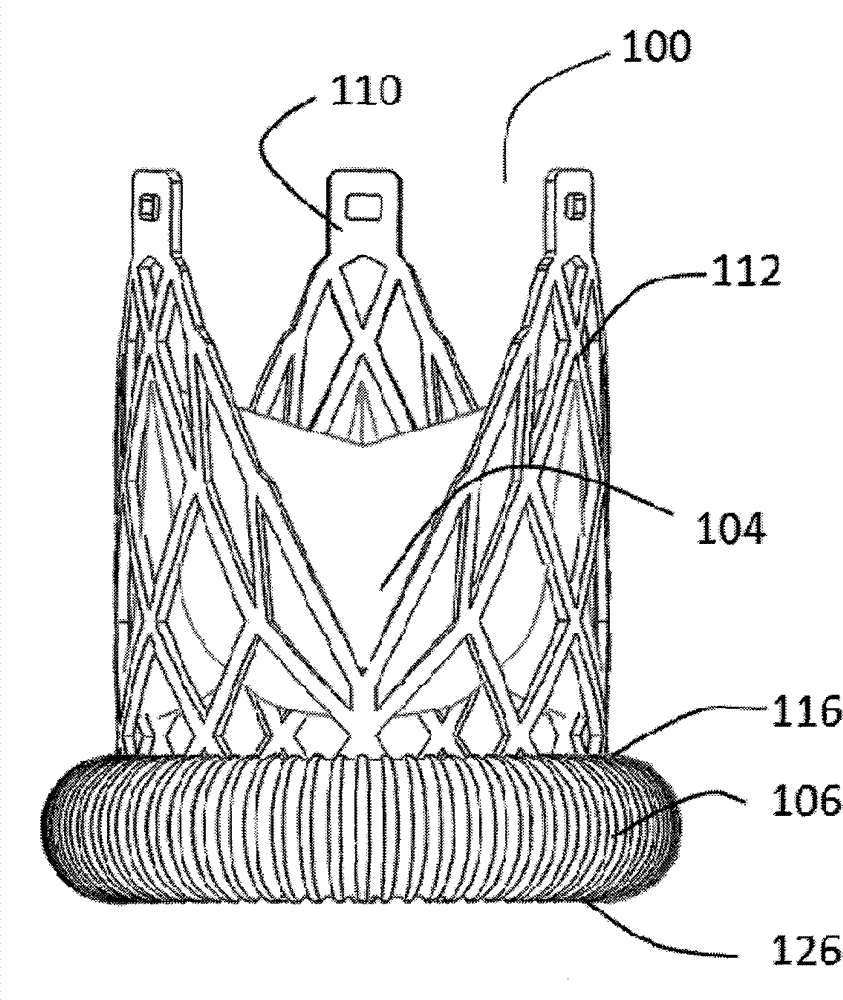

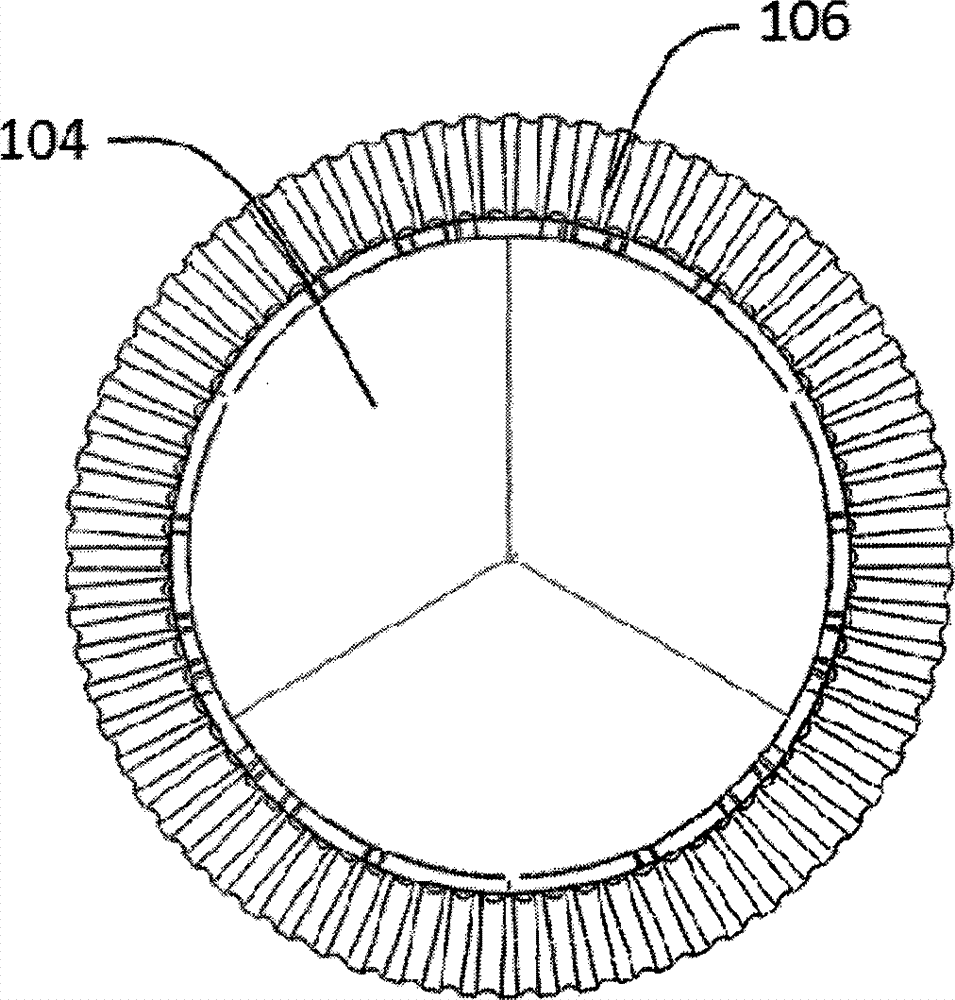

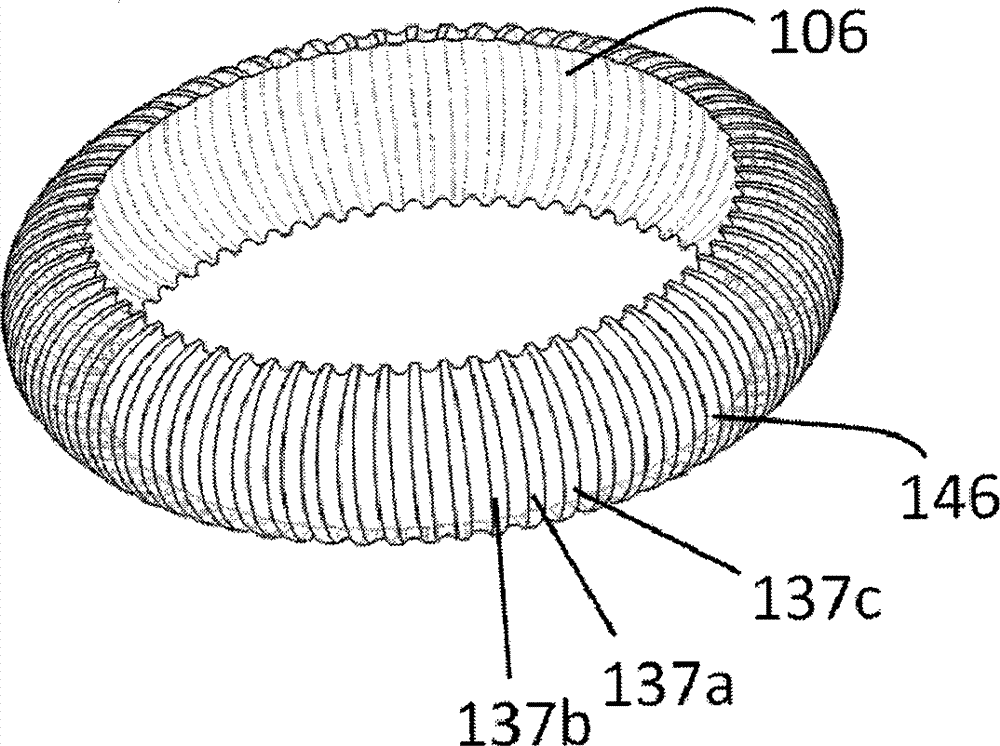

Aortic valve stent capable of preventing perivalvular leakage

ActiveCN103705315AImprove complianceExcellent shape memory performanceHeart valvesProsthetic valveNatural state

The invention discloses an aortic valve stent (100) capable of preventing perivalvular leakage. The aortic valve stent (100) capable of preventing perivalvular leakage comprises a stent (110) and an artificial valve (104), wherein the stent (110) is composed of a plurality of grid cells (112); the artificial valve (104) is connected to the grid cells (112); a sealing unit (106) is arranged at the bottom of the stent (110); the sealing unit (106) is made from a metal memory material and laminated; in a natural state, the sealing unit (106) is arched outwards along the axial direction of the stent and of an annular structure along the peripheral direction of the stent (110); one end of the sealing unit (106) is free and is a free end (116); the other end of the sealing unit (106) is fixed with the bottom of the stent (110) by a fixing element, and is a fixed end (126); when the sealing unit (106) is compressed to enter a sheathing canal, the free end (116) of the sealing unit (106) turns towards the bottom end of the stent and around the fixed end (126), thus the sealing unit (106) is not superposed with the stent (110).

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

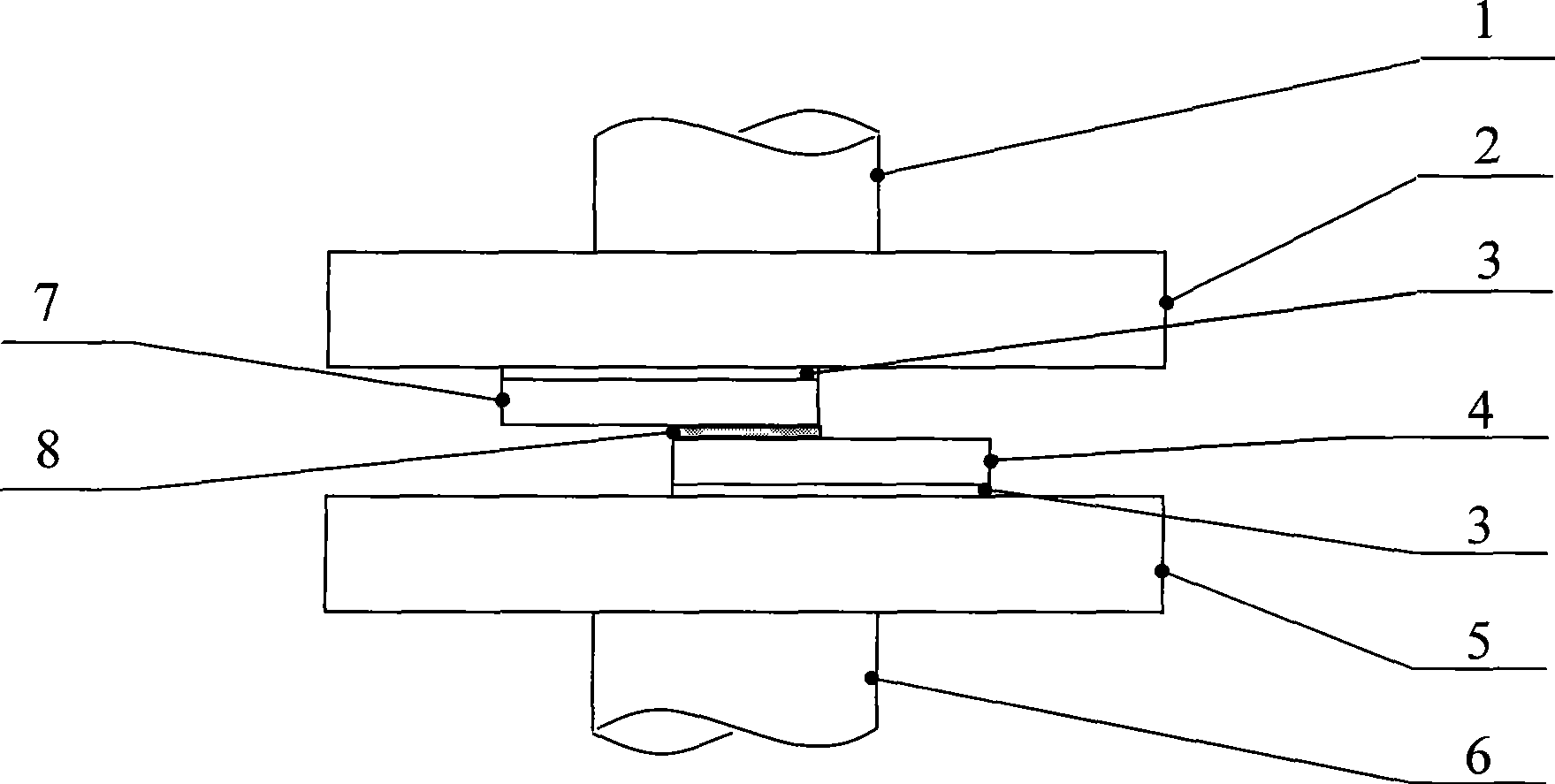

TiNi shape memory alloy and stainless steel instant liquid-phase diffusion welding connection method

InactiveCN101362253ALess loss of shape memory propertiesSmall organizationWelding/soldering/cutting articlesNon-electric welding apparatusHeat-affected zoneSurface cleaning

The invention relates to a method for transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel, which belongs to the technical field of the connection of dissimilar materials. In the prior art, the technology of the connection between TiNi shape memory alloy and stainless steel has the problems of welding crack, large crystal grains in the heat affected zone and poor mechanical properties. The transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel is realized through the following steps: after the surfaces of TiNi shape memory alloy and stainless steel to be welded and the surface of AgCuTi foil is cleaned and dried, a TiNi shape memory alloy / AgCuTi metallic foil / stainless steel structure is formed, fixed through a welding clip, and then positioned in a vacuum diffusion oven, and welding pressure and temperature are applied to the structure. The method has the advantages that the welding temperature is low (relative to fusion welding), the influence to the base material is small, the connector has no welding defect, the shearing strength of the connector in the room temperature reaches 250 MPa, and the microhardness of the area near the seam section can reach 670 Hv.

Owner:BEIJING UNIV OF TECH

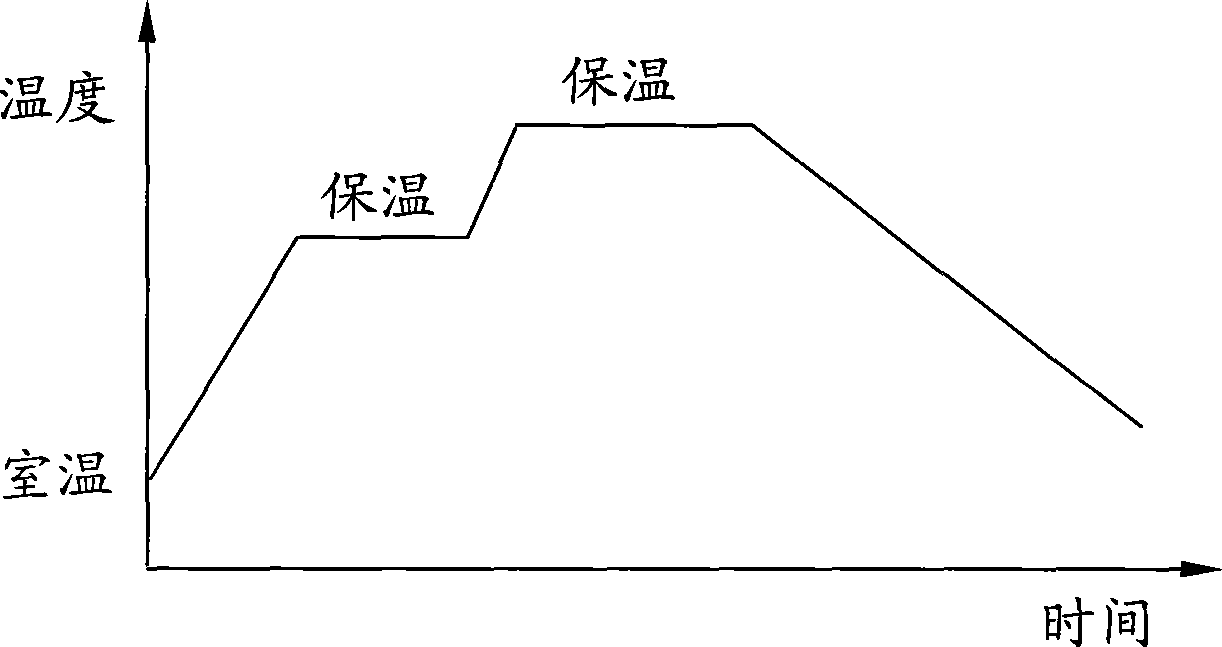

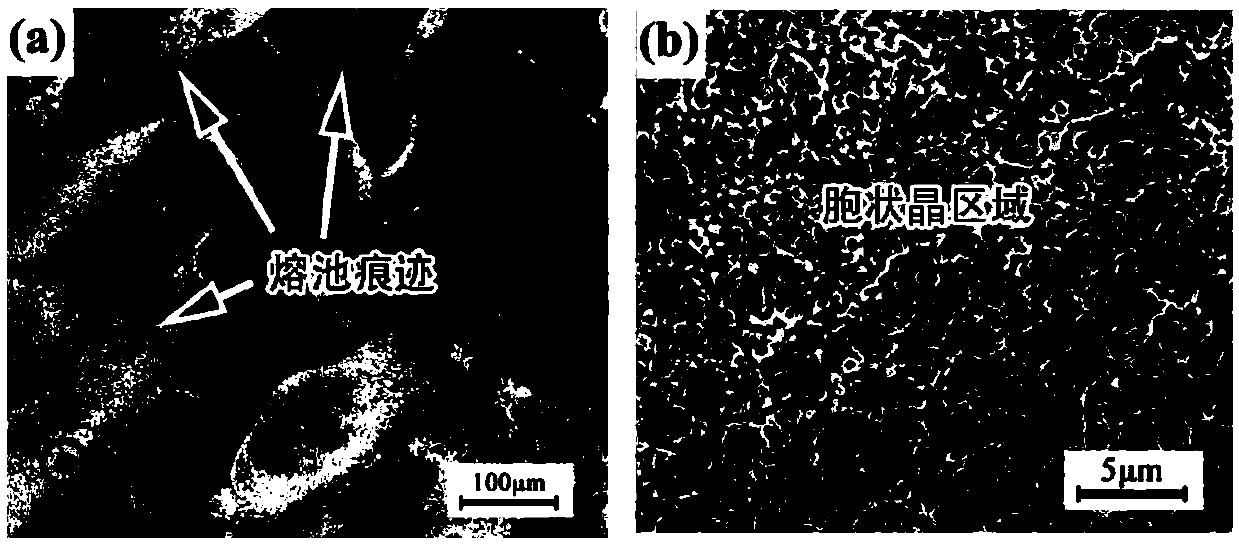

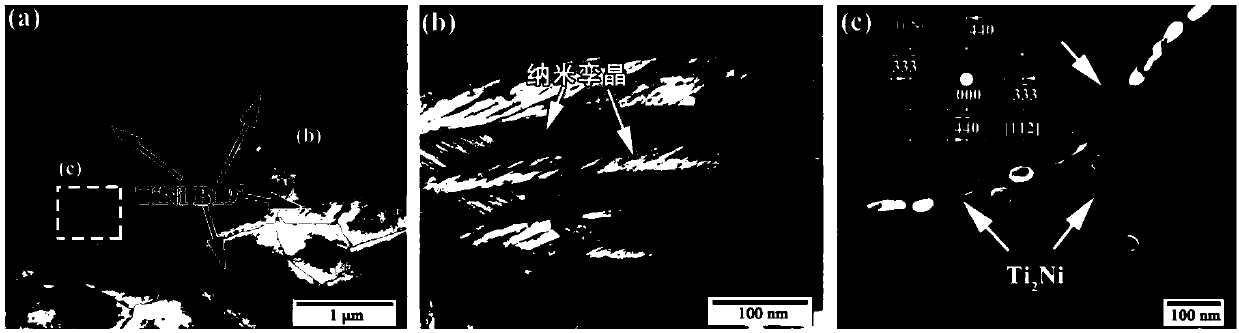

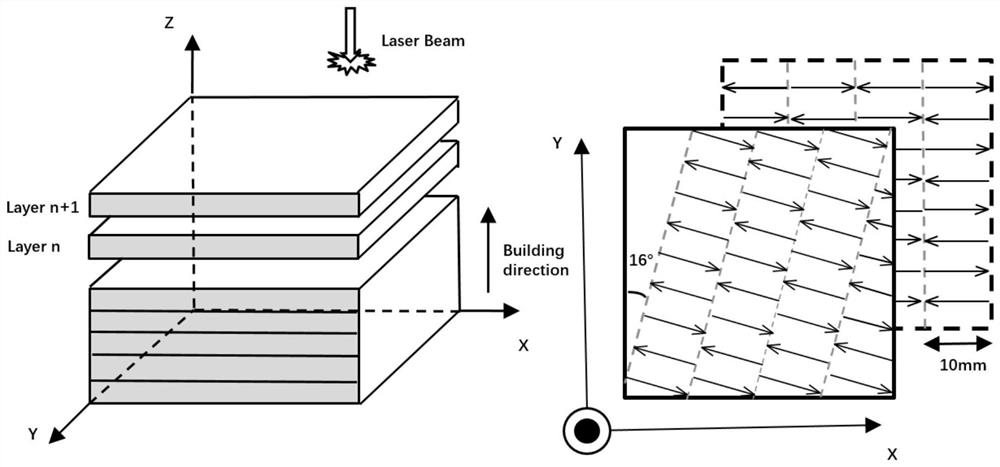

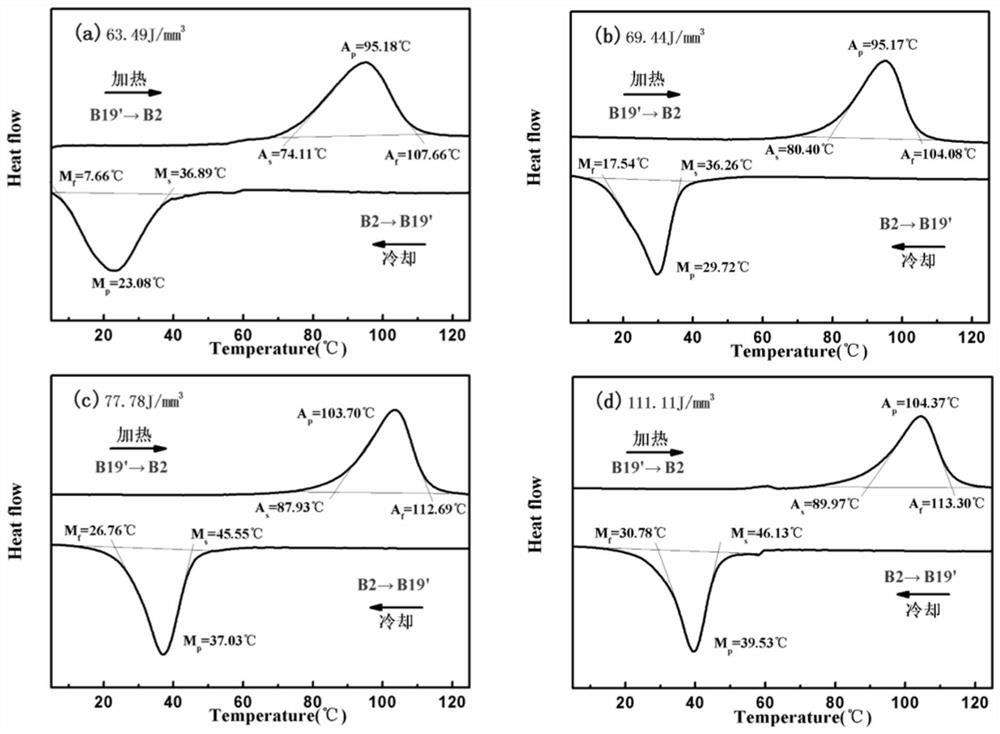

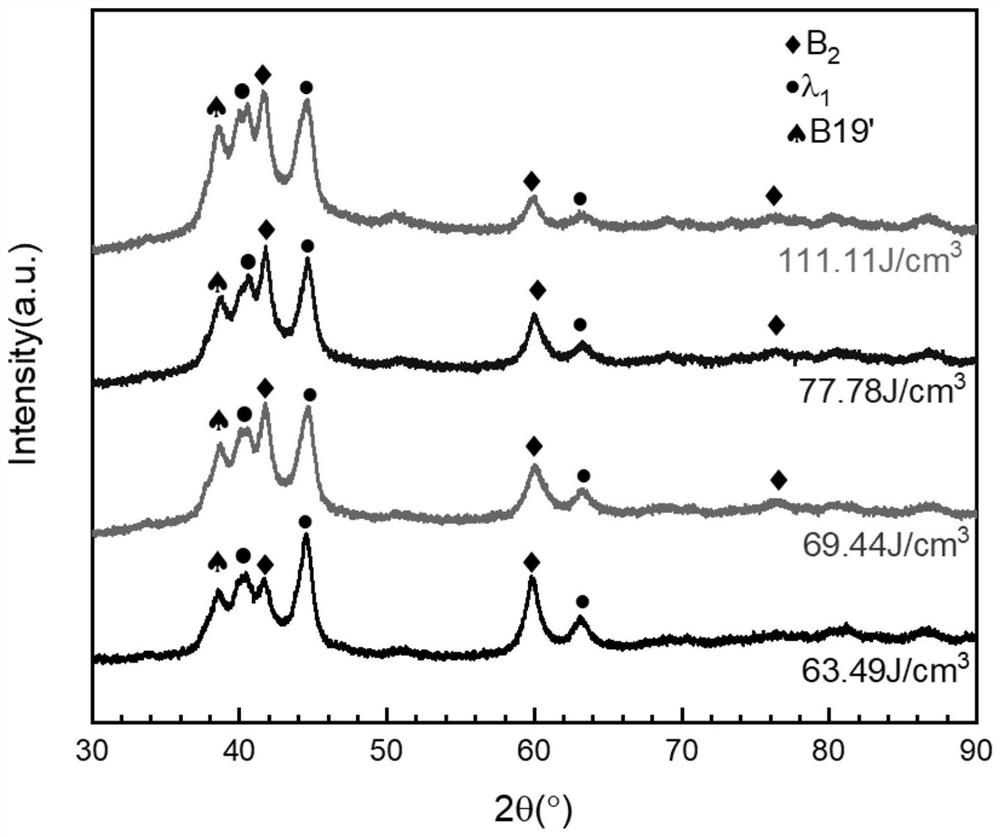

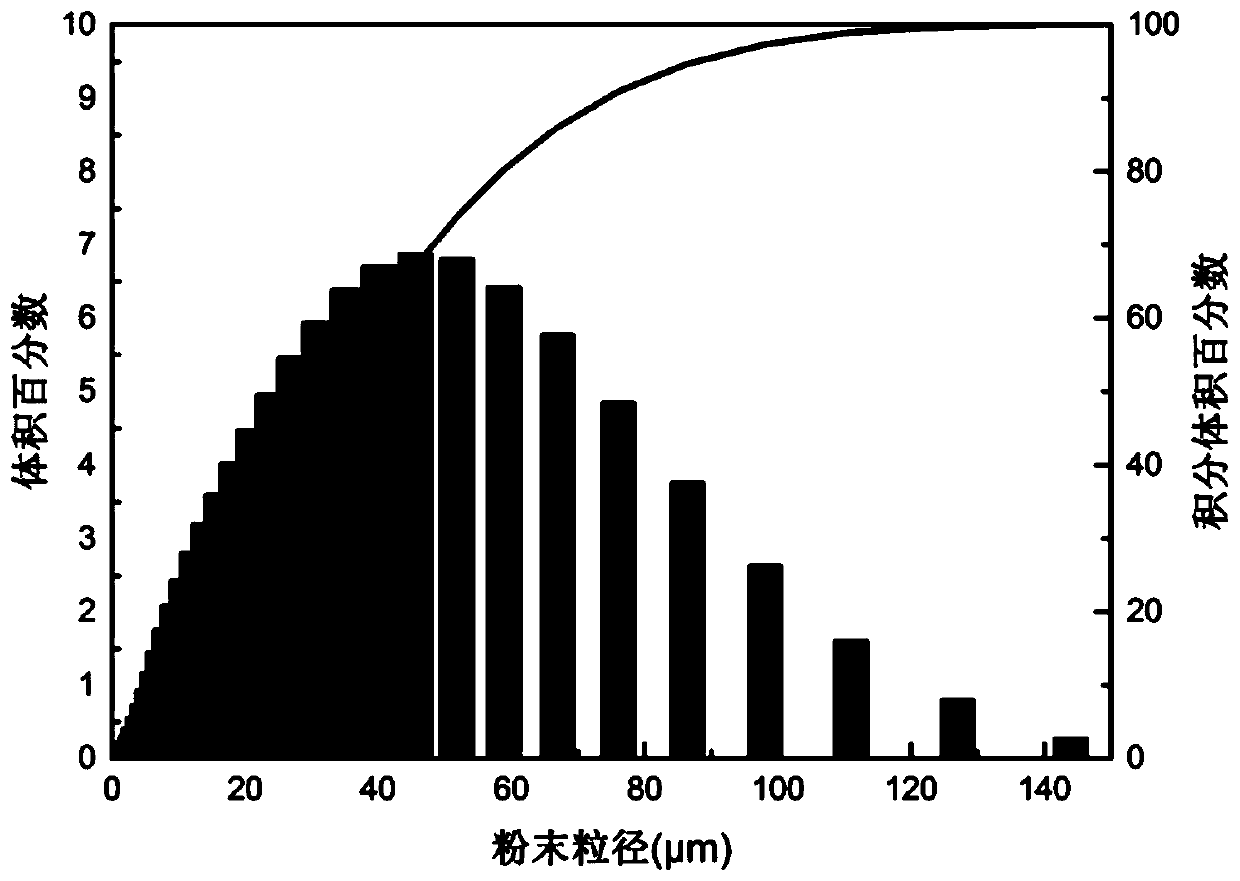

4D printing method and application of titanium-nickel shape memory alloy

ActiveCN109648082AHigh strengthHigh elongationAdditive manufacturing apparatusTransportation and packaging4d printingNickel alloy

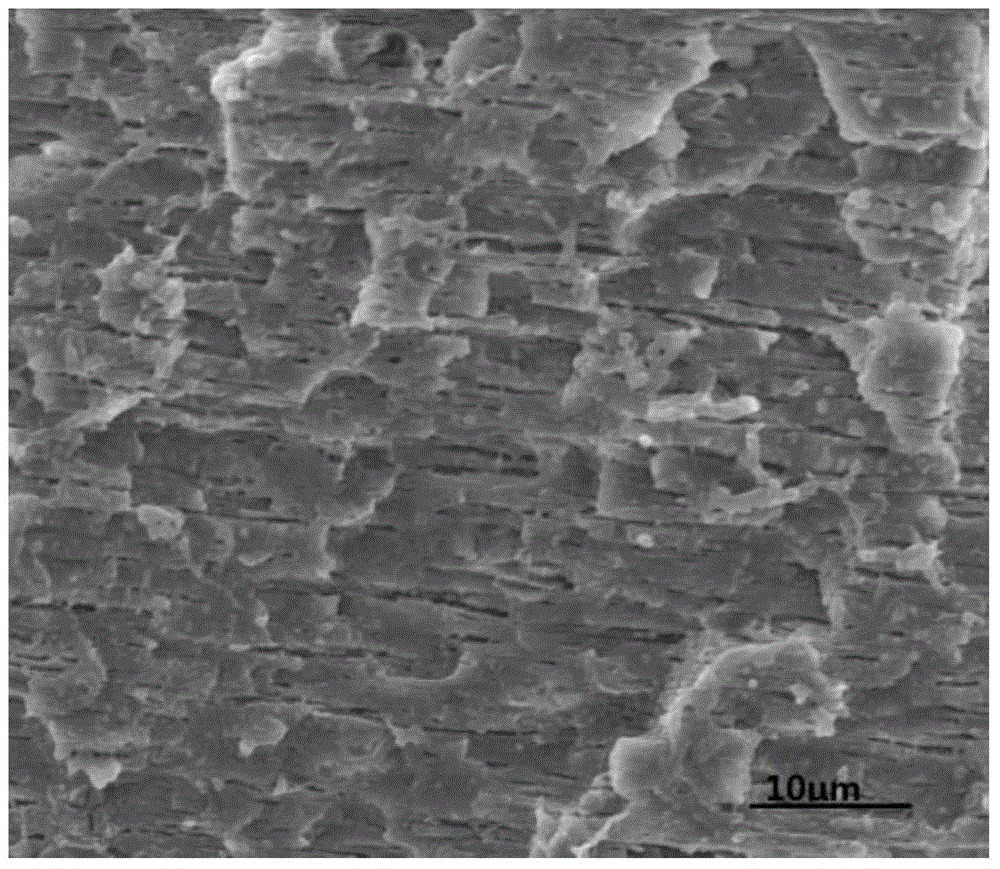

The invention belongs to the technical field of preparation of shape memory alloys, and discloses a 4D printing method and application of a titanium-nickel shape memory alloy. Pure titanium and pure nickel are matched and smelted, and titanium-nickel alloy bars are obtained; then alloy powder is prepared through a rotating electrode atomization method, the powder is screened, and titanium-nickel alloy powder with the grain size of 15 micrometers to 53 micrometers is obtained; and the obtained titanium-nickel alloy powder is placed in a discharge plasma assisted ball mill to be subjected to discharge treatment, the powder is subjected to surface modification, and finally the titanium-nickel shape memory alloy is formed by means of SLM forming. The phase composition of the obtained titanium-nickel shape memory alloy is composed of a B2 austenite phase of a CsC1 type structure, a B19' Martensite phase of a monocline structure and a Ti2Ni precipitated phase. The microstructure comprises nano-sized afterbirth-like crystals and micro dendrite, and the afterbirth-like crystals and the dendrite are alternately distributed in a layered manner. The advantages of being unique in organizationstructure, nearly fully dense and ultrahigh in performance are achieved.

Owner:SOUTH CHINA UNIV OF TECH

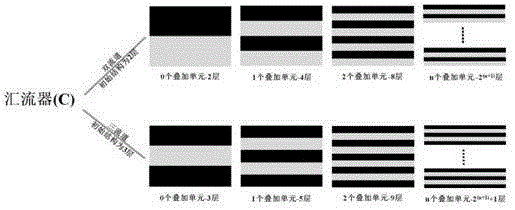

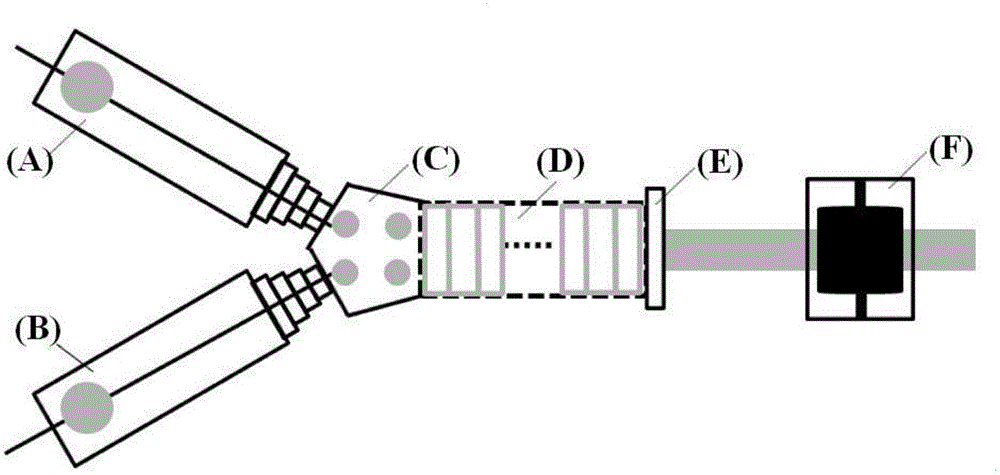

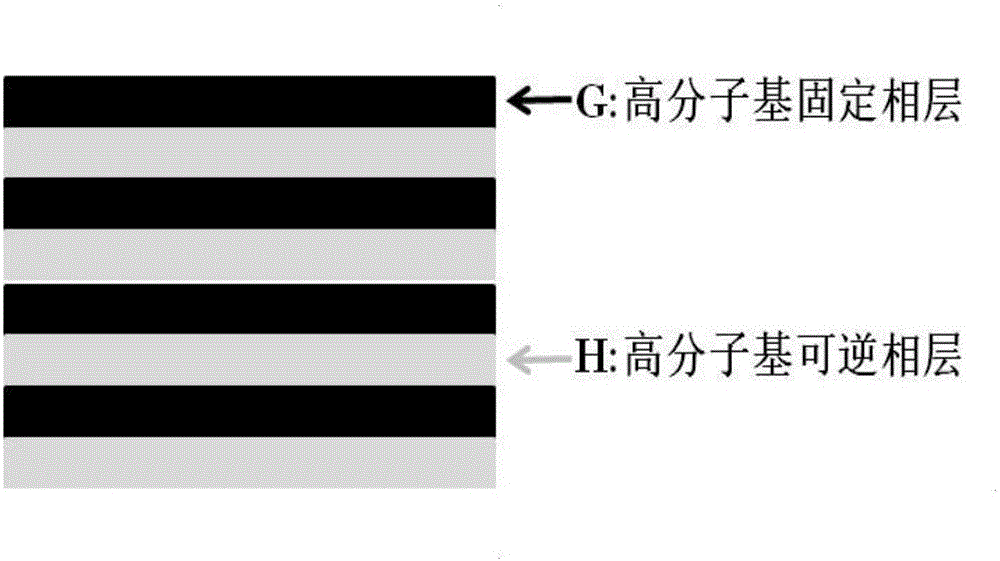

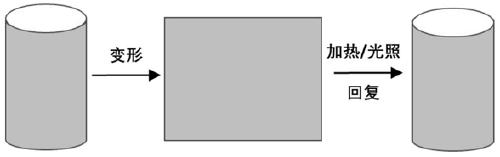

Preparation method of novel polymer-based multilayer shape memory material

ActiveCN106379011AExcellent shape memory performanceEasy to fixSynthetic resin layered productsRubber layered productsPolymer scienceRubber elasticity

The invention discloses a preparation method of a novel polymer-based multilayer shape memory material. The multilayer shape memory material prepared through the preparation method is formed by a polymer-based fixed phase layer and a polymer-based revertible phase layer, and has a two phase alternate multilayer bicontinuous structure, wherein the polymer-based fixed phase layer is a polymer having rubber elasticity at room temperature, and the polymer-based revertible phase layer is a polymer having obvious melt transition or glass transition in the heating process. The multilayer material deforms at a melting point or a glass transition temperature or above, then is cooled to room temperature in order to obtain a temporary shape, and then is heated to the melting point or the glass transition temperature or above in order to recover to an initial shape. The polymer-based multilayer shape memory material prepared through the preparation method has the advantages of controllable layer quantity, layer thickness and layer structure, adjustable raw material formula, excellent shape memory performance, commercial raw materials, and low production cost; and the preparation method has the advantages of simplicity, high production efficiency, and realization of continuous batch production.

Owner:SICHUAN UNIV

Method for preparing shape memory copper alloy

ActiveCN102808105AImprove performanceExcellent shape memory performanceElectrolysisShape-memory alloy

The invention discloses a method for preparing shape memory copper alloy. The copper alloy consists of the following components in percentage by weight: 2.5 to 3.5 percent of Ni, 5 to 6 percent of Al, 6 to 8 percent of Mn, 0.8 to 1.0 percent of Be, 2 to 3 percent of Zn, 1.0 to 1.4 percent of Sb, 0.05 to 0.1 percent of La, 0.12 to 0.14 percent of Gd, 0.02 to 0.03 percent of Dy, 0.002 to 0.004 percent of Y and the balance of Cu. The method for preparing the shape memory copper alloy comprises the following steps of: 1) preparing raw materials of all components, wherein the raw material of Al is an electrolysis aluminum plate, the raw material of Cu is an electrolysis copper rod, and the raw materials of residual components are industrial ingot metal; 2) placing the raw materials in a heating furnace and smelting at the smelting temperature of between 1,210 and 1,230 DEG C, uniformly stirring, analyzing components to ensure that the alloy components meet the requirement of the content range, preserving heat, standing for 10 to 20 minutes, adjusting pouring temperature to be 1,170 to 1,180 DEG C, and pouring to obtain a lath-shaped ingot block; 3) performing thermal treatment on the lath-shaped ingot block at the temperature of between 870 and 890 DEG C for 10 to 12 hours; and 4) after thermal treatment, performing die forging and forming at the temperature of between 880 and 920 DEG C to obtain a part or a thin plate.

Owner:鹰潭市一帆新材料有限公司

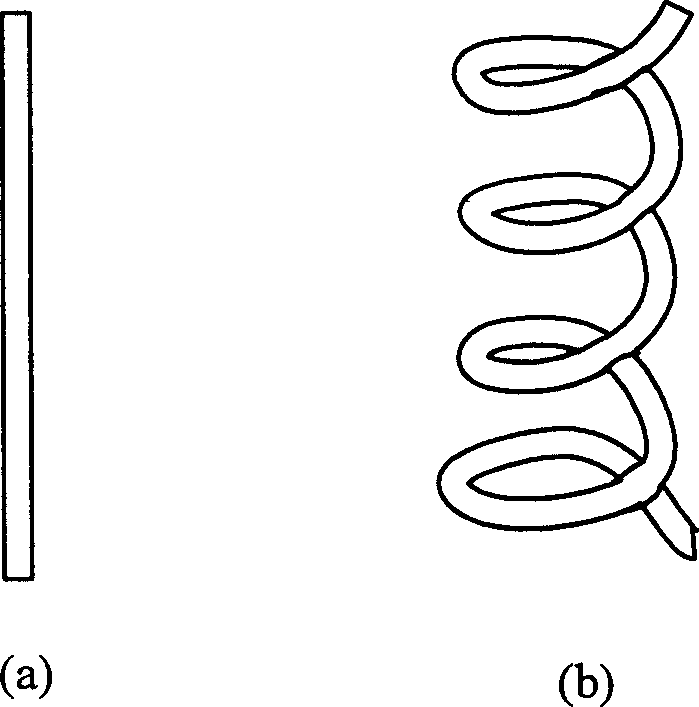

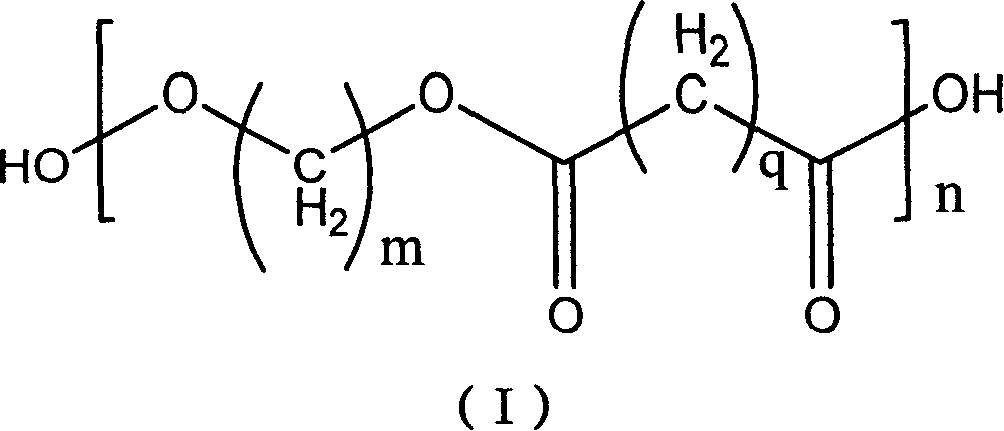

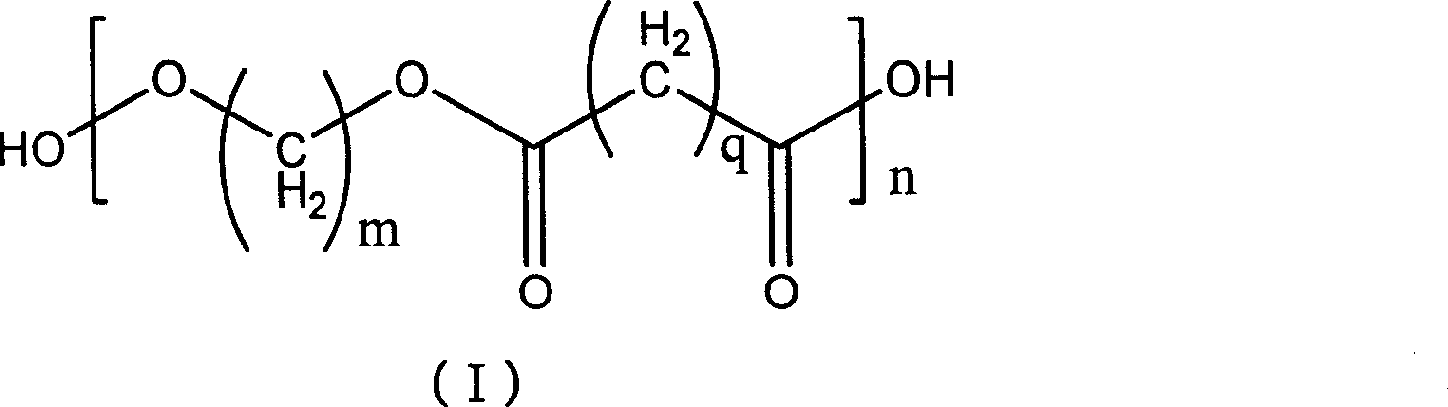

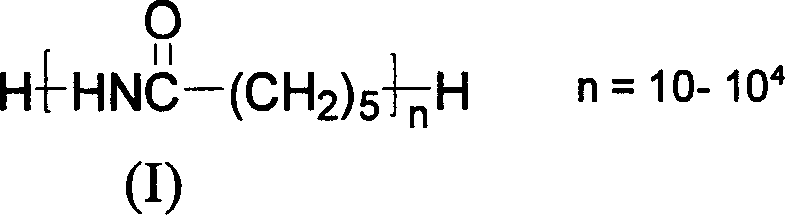

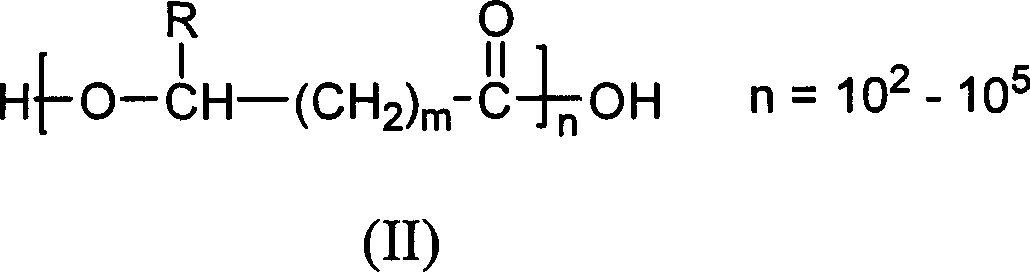

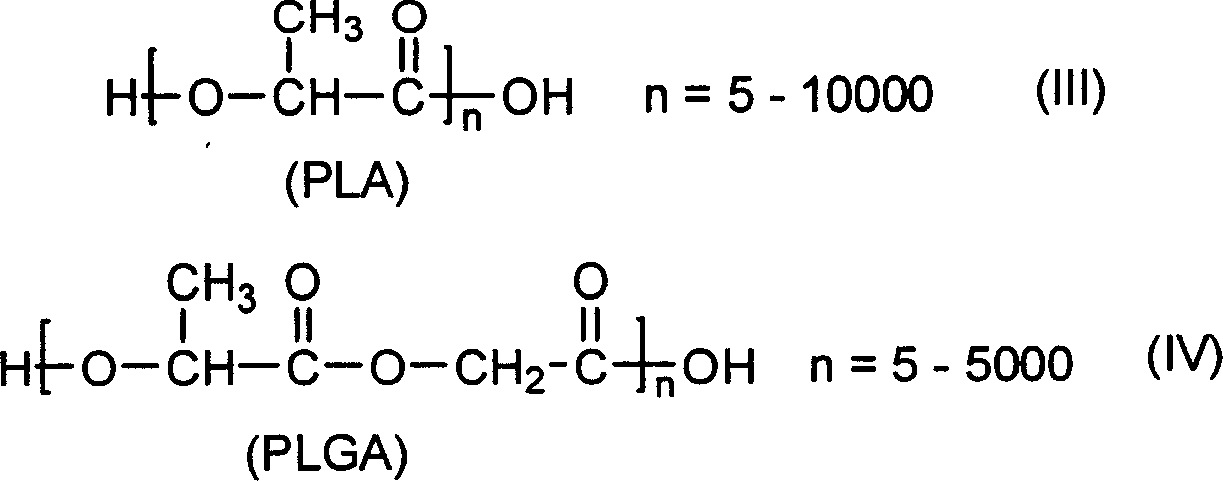

Preparation method of degradable polymer material for stent in shape memory pipe cavity

InactiveCN1911983AExcellent shape memory performanceEasy to processProsthesisPolymer scienceEndoluminal stent

The present invention belongs to the field of polymer technology, and is especially preparation process of degradable polymer for rack inside shape memory tube. Lactide, glycolide or caprolactone, biodegradable polyester and diisocyanate as materials are first bulk melt polymerized to prepare the degradable polymer with thermal deformation transforming temperature (Ttrns) of about 37 deg.c. The obtained material is processed at temperature over melting temperature (Tm) so as to shape into spiral rack, applied with stress at temperature higher than Ttrans to form shape easily operational handling and frozen to eliminate stress into the product. The rack inside shape memory tube has excellent biocompatibility, can provide temporary support on the stenotic lumen and is degradable without need of post-operational taking out. In addition, the rack may be also used as medicine carrier.

Owner:TONGJI UNIV

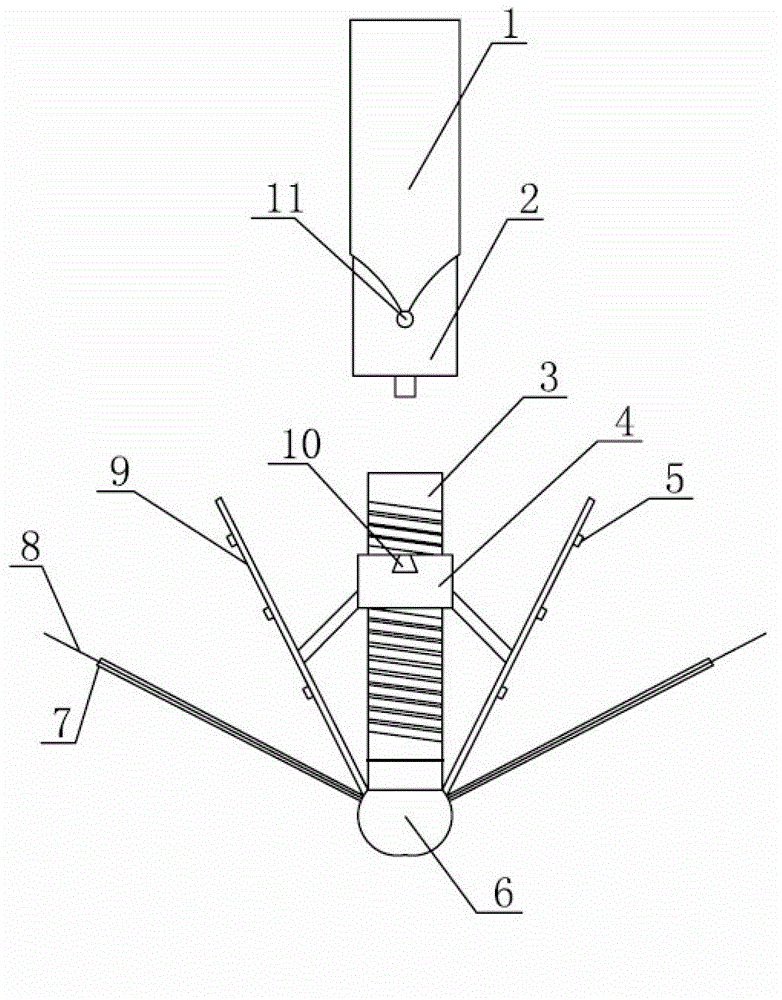

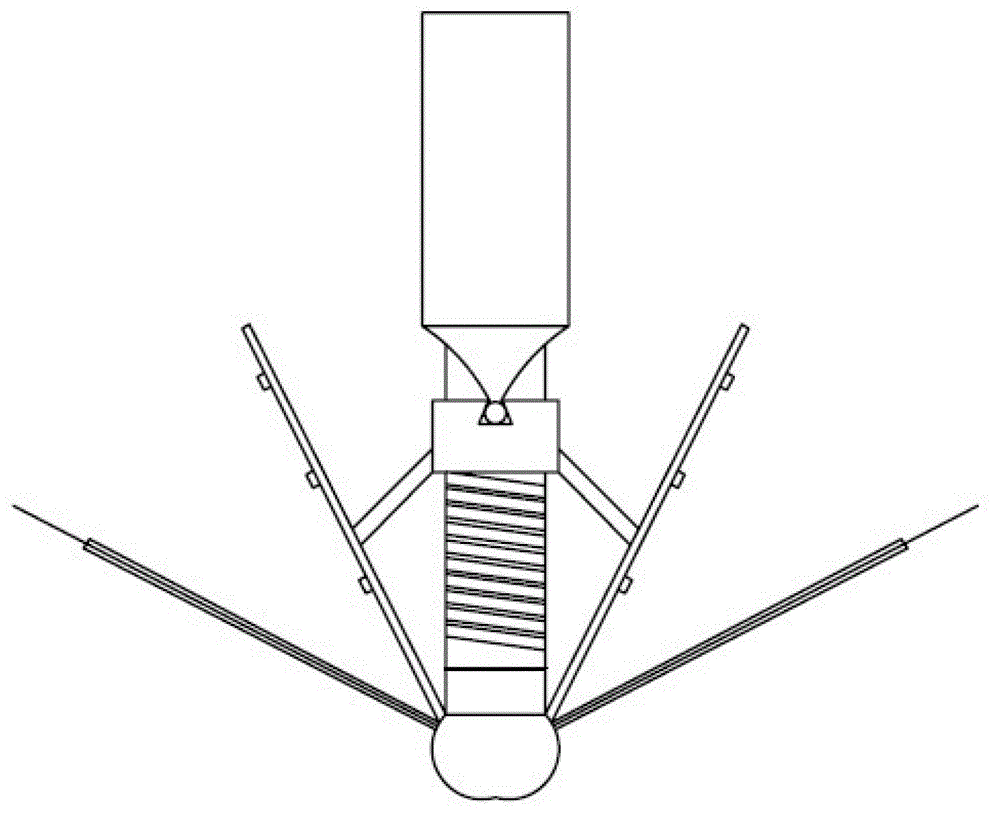

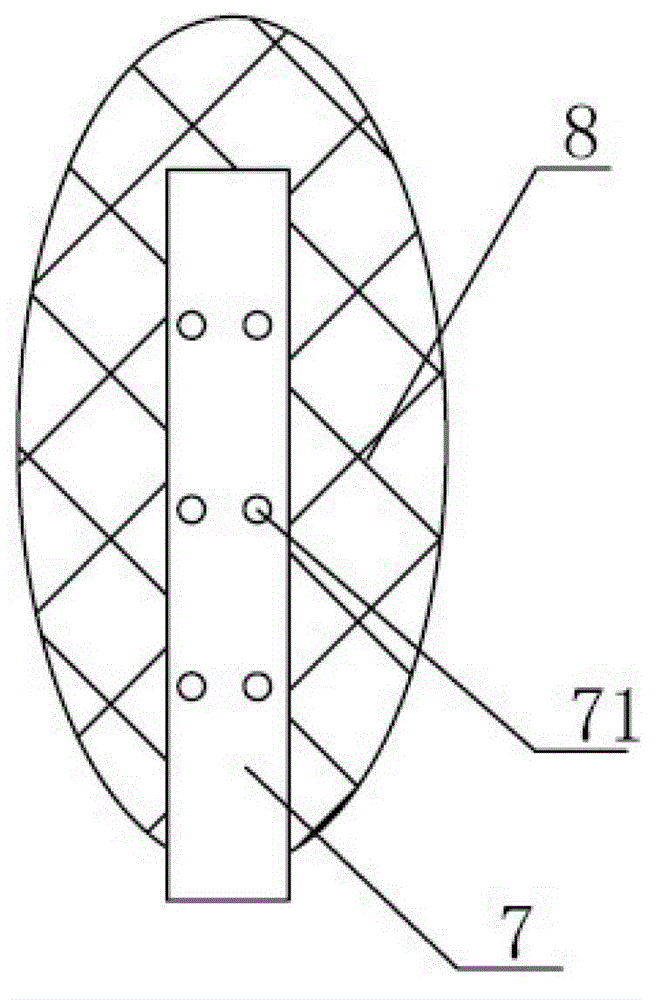

Tricuspid valve edge-to-edge clip device capable of being implanted through catheter

ActiveCN102860846AOvercome partial tensionSimple structureSurgeryBiocompatibility TestingEngineering

The invention relates to a tricuspid valve edge-to-edge clip device capable of being implanted through a catheter. The tricuspid valve edge-to-edge clip device comprises a rotating propelling operating rod, a main body support threaded rod and a nickel-titanium alloy dish-shaped dish, wherein the rotating propelling operating rod covers outside a connecting pushing rod, the connecting pushing rod is connected with the main body support threaded rod arranged under the connecting pushing rod through a cylindrical pin arranged at the lower end of the connecting pushing rod, the external side of the main body support threaded rod is in sleeved connection with a rotating support mechanism, connecting rods extending out of two sides of the rotating support mechanism are respectively connected with needle plates on the tricuspid valve arranged at two sides, the lower ends of the needle plates on tricuspid valve is connected with the lower end of the main body support threaded rod, two sides of the lower end of the main body support threaded rod are symmetrically connected with and provided with an outwards-extended base plate under the tricuspid valve, and the middle of the base plate under the tricuspid valve is fixed with the elliptic nickel-titanium alloy dish-shaped dish in a clamping way. The tricuspid valve edge-to-edge clip device is simple in structure, good in biocompatibility and tracing performance, good in mechanical support force, good in compliance and shape memory ability, and has little wound to patients in use.

Owner:PLA NO 101 HOSPITAL

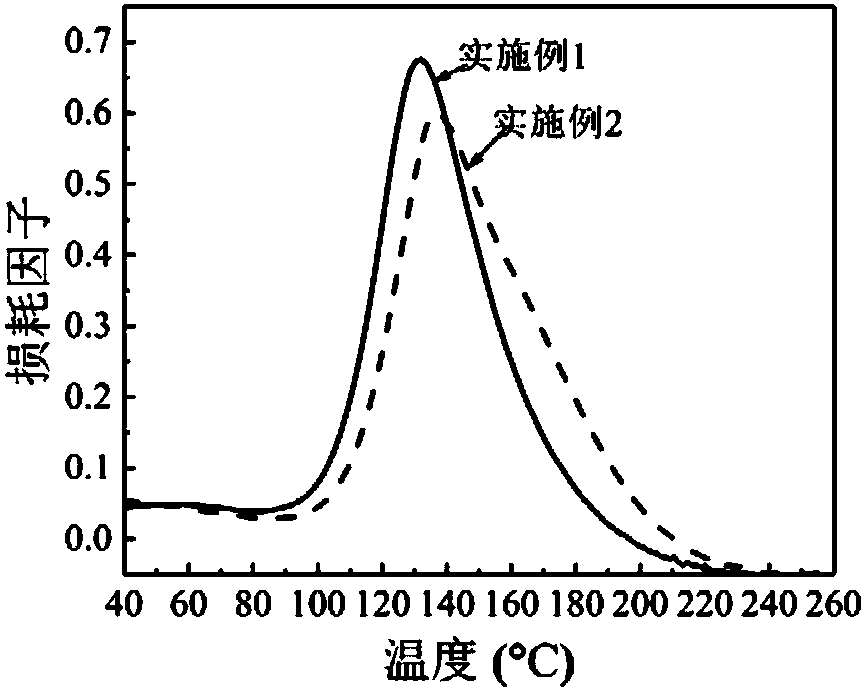

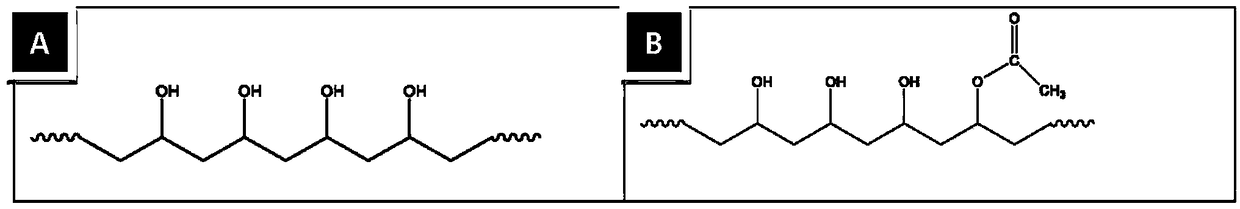

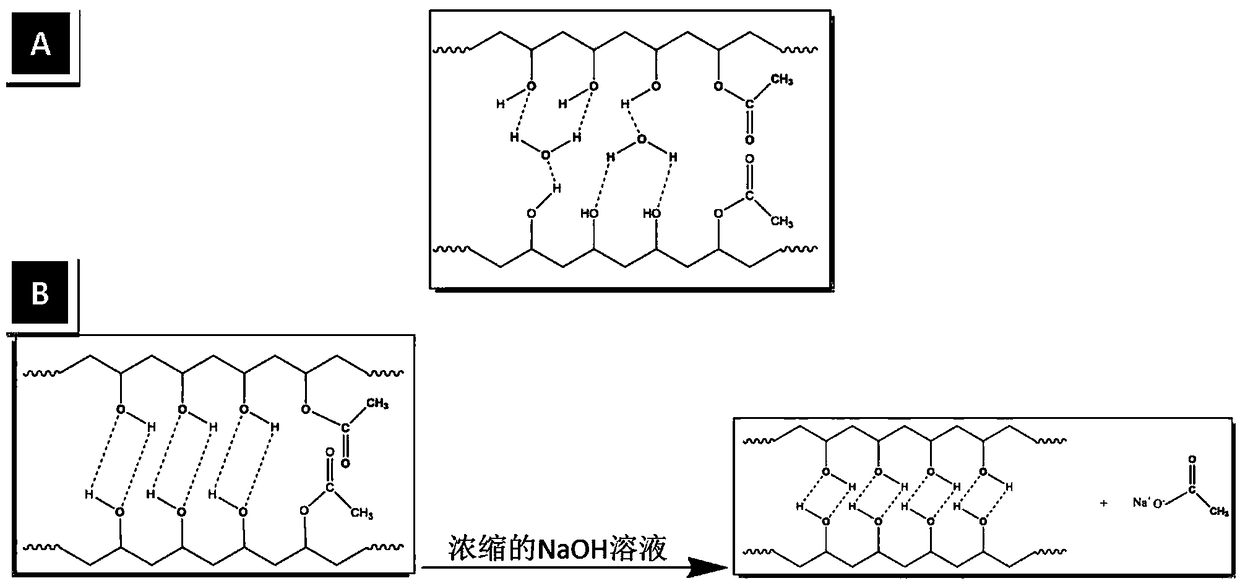

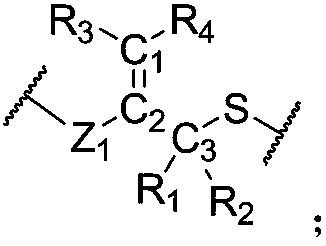

Dynamic polymer with hybrid cross-linked network and application of dynamic polymer

ActiveCN107698748AImprove structural stabilityWith bionic mechanical propertiesCross-linkPolymer science

The invention discloses a dynamic polymer with a hybrid cross-linked network structure. The dynamic polymer contains dynamic covalent bond crosslinking and supermolecular hydrogen bond crosslinking, wherein the dynamic covalent bond crosslinking is realized by associative exchangeable covalent bonds, and the supermolecular hydrogen bond crosslinking is realized by hydrogen bond groups on the sidegroups and / or side chains of a polymer chain framework and hydrogen bond groups on the optional chain frameworks. The polymer integrates dynamic characteristics of a supermolecule and dynamic covalentcharacteristics of glass-like matter; supermolecular hydrogen bonds give stimulative responsibility, energy dissipation performance and self-repairing performance to the material; the associative exchangeable covalent bonds give structural stability and mechanical strength to the covalent cross-linked polymer, and because the associative exchangeable covalent bonds have dynamic reversibility, thepolymer has self-repairing performance, recycling performance, reproducibility and the like. According to the invention, the dynamic polymer with the hybrid cross-linked network structure can be widely applied to vibration-absorptive cushioning materials, impact-resistant protective materials, self-repairing materials, toughness materials, sealing elements and the like.

Owner:厦门逍扬运动科技有限公司

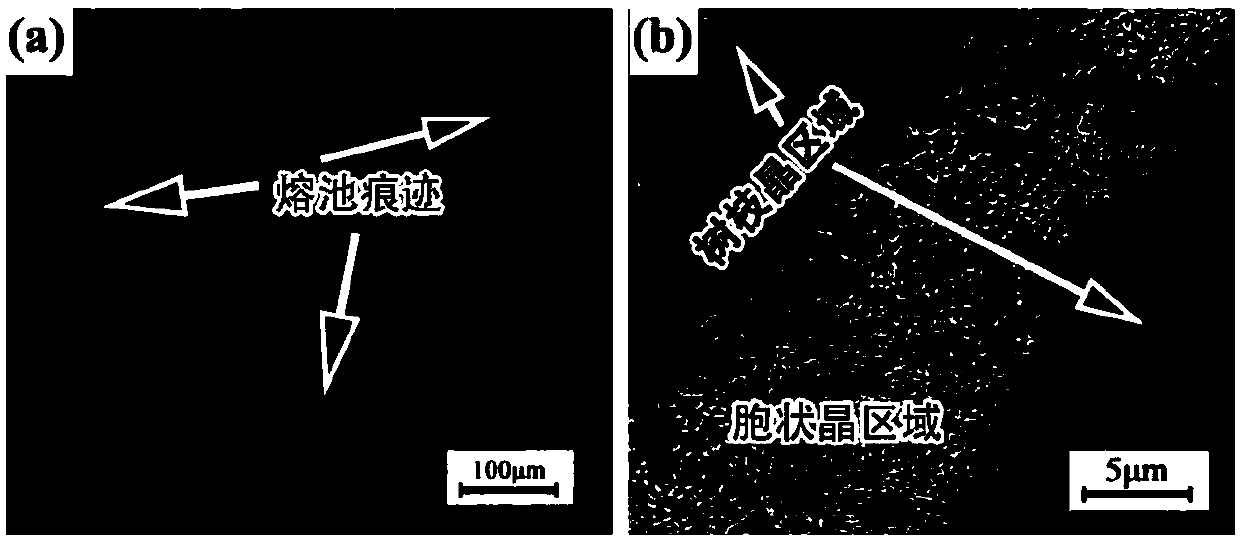

4D printing method of nickel-titanium-based ternary shape memory alloy

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

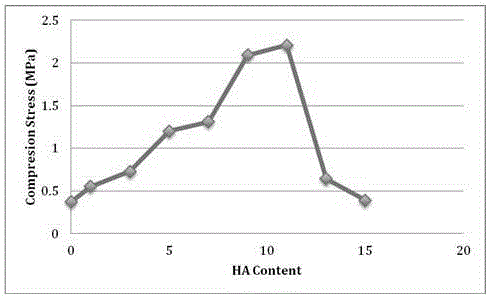

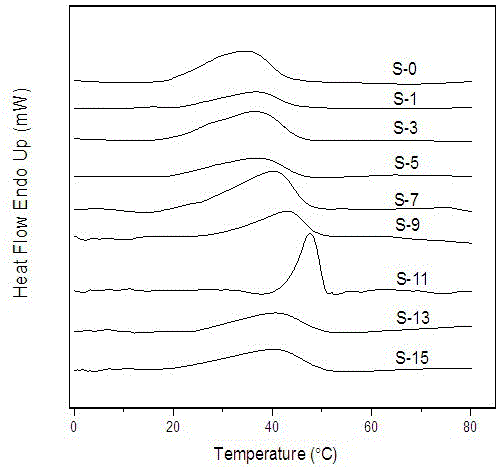

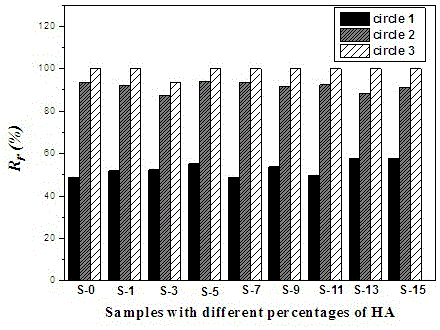

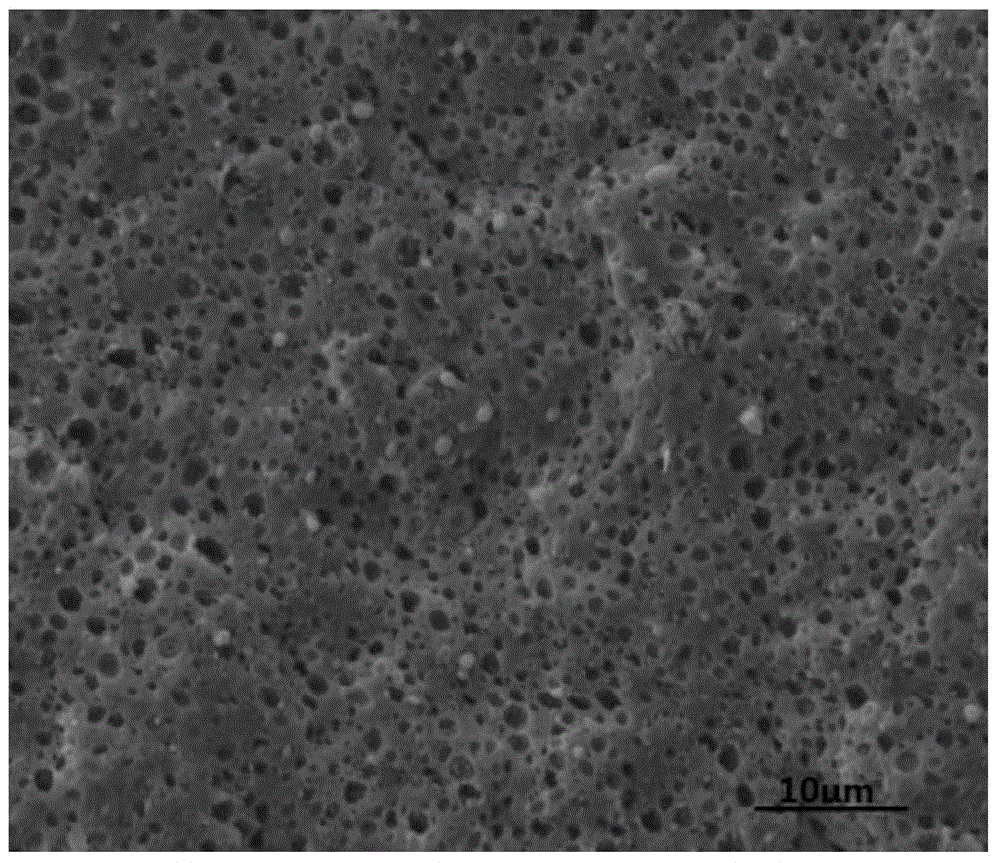

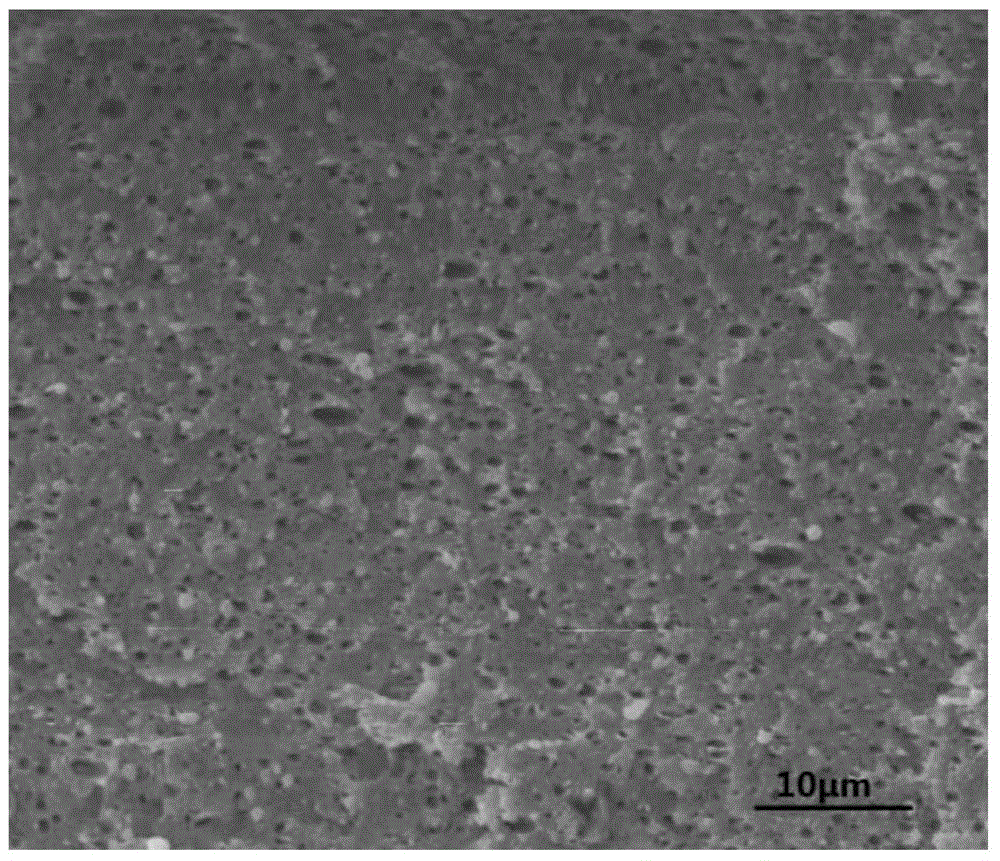

Hydroxyapatite/polyurethane shape memory bone repair scaffold and preparation method thereof

InactiveCN105013003AImprove mechanical propertiesGood shape memory propertiesProsthesisPrepolymerSolid phases

The invention discloses a hydroxyapatite / polyurethane shape memory bone repair scaffold. The hydroxyapatite / polyurethane shape memory bone repair scaffold comprises hydroxyapatite, hexamethylene diisocyanate, an organic cross-linking agent, polycaprolactone glycol and water. The molar ratio of isocyanato contained in the hexamethylene diisocyanate to hydroxyl groups contained in other raw materials is 1.8-2.2 to 1. The sum of mass of the hydroxyapatite, the hexamethylene diisocyanate and the organic cross-linking agent accounts for 15-40% of the total mass of the raw materials. The mass ratio of the organic cross-linking agent, to the hydroxyapatite and to the polycaprolactone glycol is 4-9 to 1-15 to 100. By the adoption of a prepolymer foaming method, the raw materials are synthesized into the hydroxyapatite / polyurethane shape memory bone repair scaffold. Compared with the prior art, the hydroxyapatite is introduced into the hydroxyapatite / polyurethane shape memory bone repair scaffold to serve as a solid-phase cross-linking agent, and accordingly mechanical performance of the macromolecule scaffold is greatly improved.

Owner:POLYU RES BASE SHENZHEN

A polylactic acid-based super-tough blending material with shape memory effects or a polylactic acid-based super-tough high-strength blending nanometer composite material with shape memory effects, and preparing methods thereof

ActiveCN104312113ASimple preparation processEasy to promotePhase morphologyThermoplastic polyurethane

The invention relates to the technical field of polymer materials and preparation thereof, and particularly relates to a polylactic acid-based super-tough blending material with shape memory effects or a polylactic acid-based super-tough high-strength blending nanometer composite material with shape memory effects, and preparing methods thereof. The blending material comprises polylactic acid, and ethylene-octylene copolymer grafted with glycidyl methacrylate. The composite material comprises polylactic acid, thermoplastic polyurethane and nanometer particles. The materials are prepared by melting and blending by utilization of an extruder. The extruder is a multi-side thread-groove convection type screw extruder. A co-continuous-structure, layered, fibriform or micron liquid drop phase morphology is formed. The nanometer particles are at the interface between two phases of the polylactic acid and an elastomer flexibilizer. The material has characteristics of easily available raw materials and simple processes. The prepared materials have ultra high toughness and strength, and excellent shape memory performance, and have wide application prospects.

Owner:SOUTH CHINA UNIV OF TECH

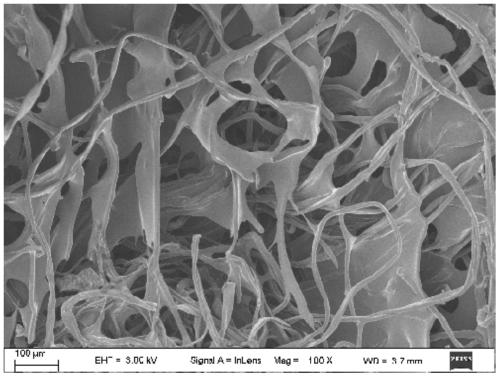

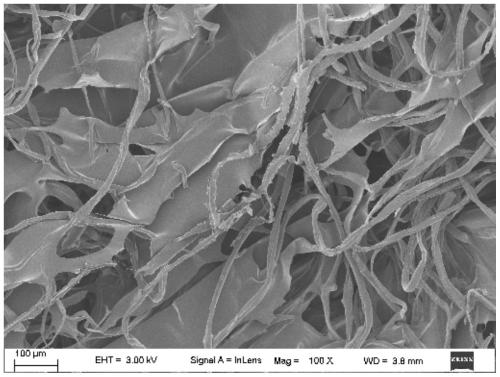

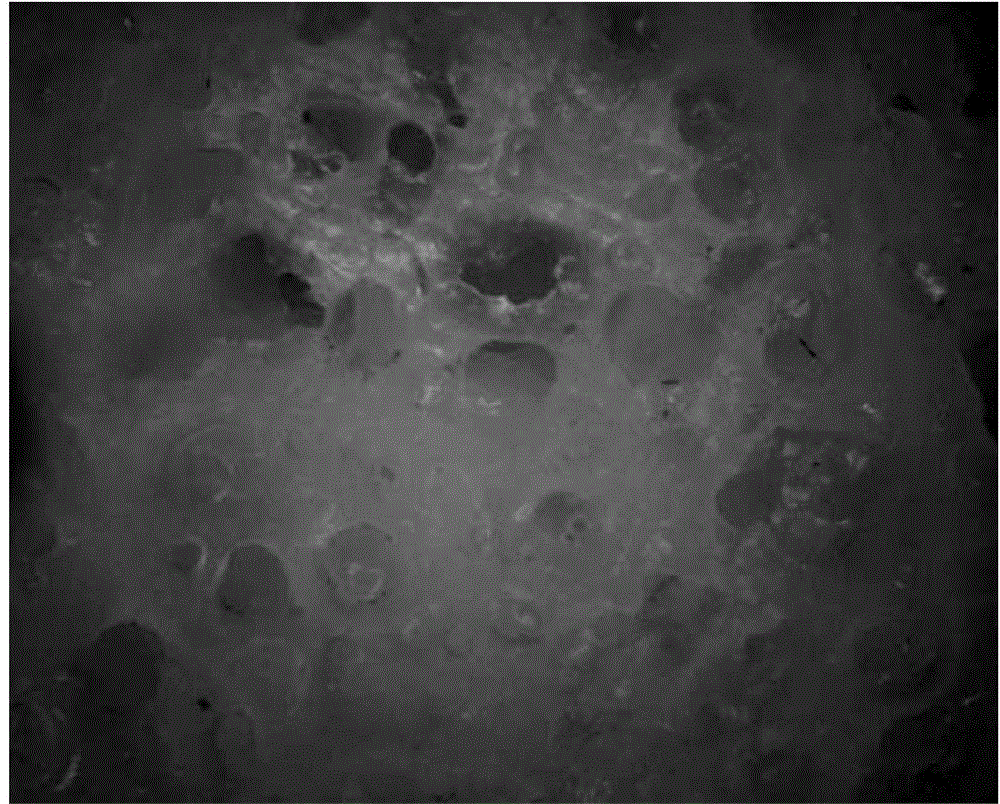

Three-dimensional fiber-based composite aerogel type adsorbent preparation method

InactiveCN110038529AImprove mechanical propertiesMaintain structureOther chemical processesWater contaminantsFreeze-dryingSorbent

The invention discloses a three-dimensional fiber-based composite aerogel type adsorbent preparation method. According to the method, cellulosic fiber, chitosan and sodium alginate which generally exist in natural world are utilized as raw materials. The method comprises the steps: firstly, utilizing periodate and metaphosphoric acid to sequentially chemically modify the cellulosic fiber; then crosslinking the modified cellulosic fiber with the chitosan; then compounding with the sodium alginate; freeze drying to obtain a three-dimensional fiber-based composite aerogel type adsorbent. The prepared adsorbent disclosed by the invention has high safe stability, has a good adsorption effect on negative ion pollutants and positive ion pollutants and can be applied to purifying heavy metal ion wastewater and dyestuff wastewater; in addition, the cellulosic fiber added into the adsorbent disclosed by the invention not only can serve as a framework and a reinforcing material, but also can be crosslinked with the chitosan to improve compression strength, morphology and structural stability of the whole aerogel adsorbent; thus, the adsorbent can be repeatedly used for many times, and the characteristics of rice inner holes and large specific surface area of the aerogel are fully played.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Gutta percha shape memory polymer composite material and preparation method thereof

The invention discloses a gutta percha shape memory polymer composite material and a preparation method thereof. The composite material is compounded from the following raw materials in parts by weight: 33-54 parts of polyethylene, 27-48 parts of gutta percha, 9-23 parts of an inorganic reinforcing material, 1.5-4.5 parts of a cross-linking agent and 0.5-1.5 parts of an antioxidant. When in preparation, all the raw materials are weighed according to the mixture ratio and uniformly mixed and stirred, then a mixture is subjected to mixing in an open mill at 135-165 DEG C for 10-15min, then hot-press forming is performed in a pressure forming machine, the temperature is controlled at 145-175 DEG C, and cooling is finally performed for preparation. The obtained composite material has the advantages of good resistance to high temperature, relatively great deformation and relatively easy figuration, and the field of use is expanded.

Owner:湖北格霖威新材料科技有限公司

Cross-linking type shape memory polyurethane

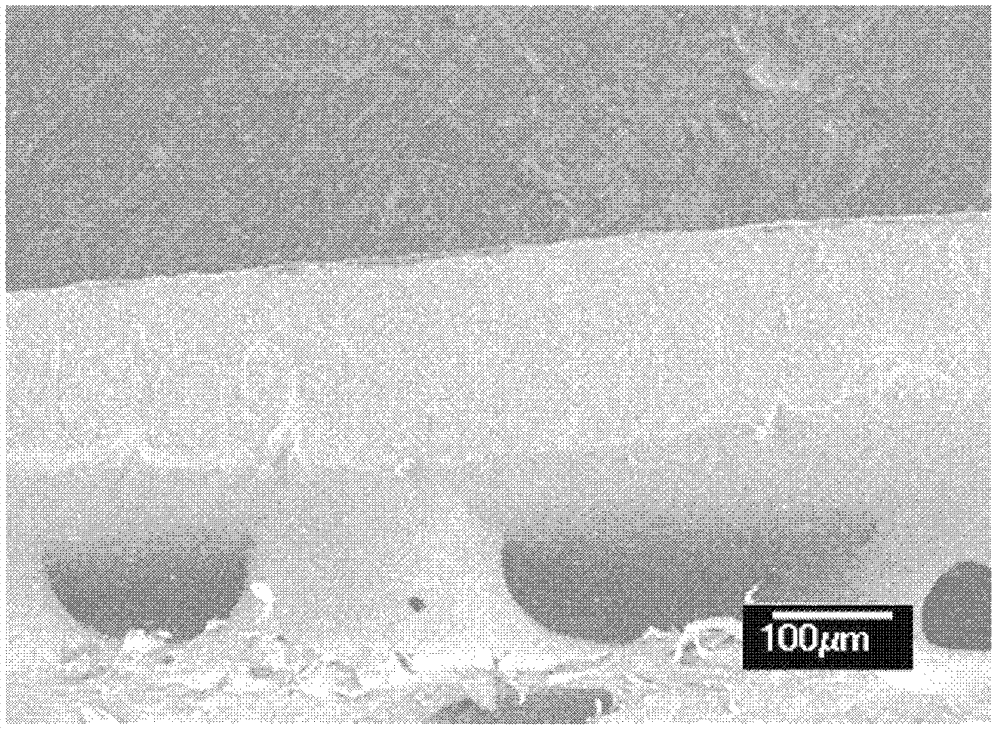

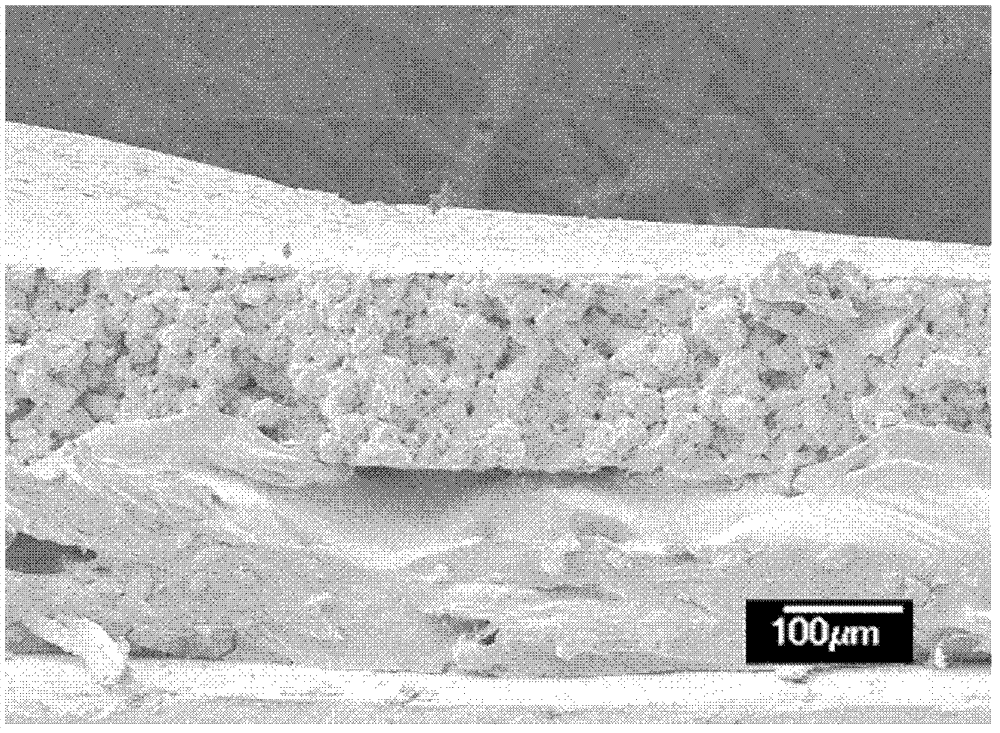

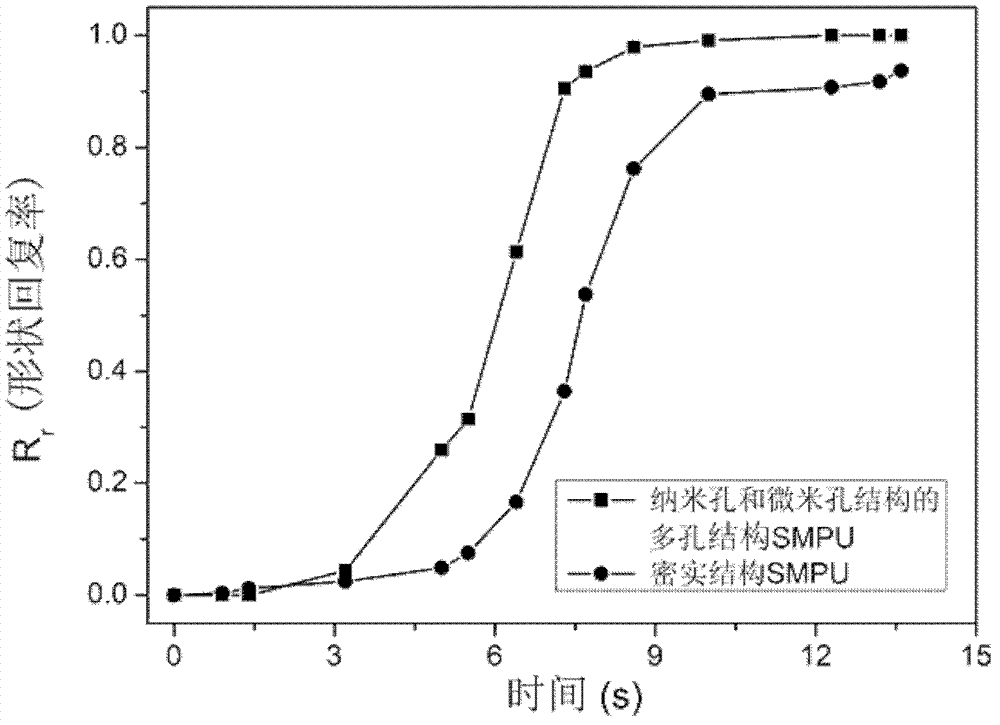

ActiveCN102786648AExcellent shape memory performanceGood shape fixationMaterials preparationEnd-group

The invention belongs to the technical field of polymer material preparation, and particularly relates to cross-linking type shape memory polyurethane. During the preparation of the cross-linking type shape memory polyurethane (SMPU) with good shape memory performance in the invention, a silane coupling agent containing three alkoxys is introduced into end groups of a polyurethane prepolymer terminated by isocyanate groups; a polyurethane prepolymer terminated by silicon alkoxys is obtained through reactions; then a catalyst is added or not added into the polyurethane prepolymer terminated by silicon alkoxys; and SMPU with good shape memory performance is prepared by silicon alkoxy crosslinking; Through the control of the catalyst amount, SMPU with a dense structure or with a porous structure containing nanometer pores or micrometer pores is respectively prepared. The SMPU has a shape fixing rate (Rf) of not less than 90%, a shape recovery rate (Rr) of not less than 90%. The SMPU with a porous structure containing nanometer pores or micrometer pores has higher recovery response speed.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Fe-based shape memory alloy and its production method

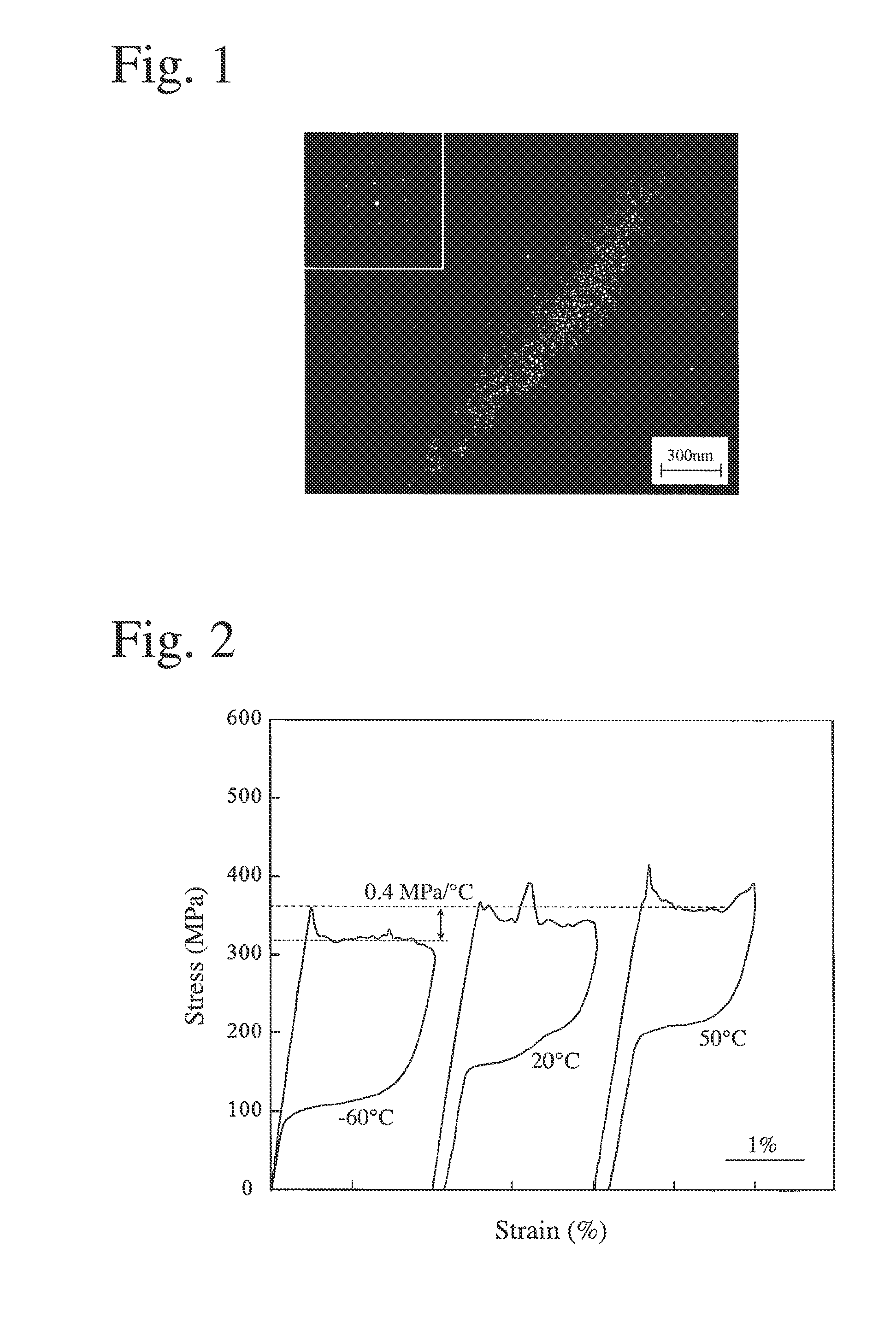

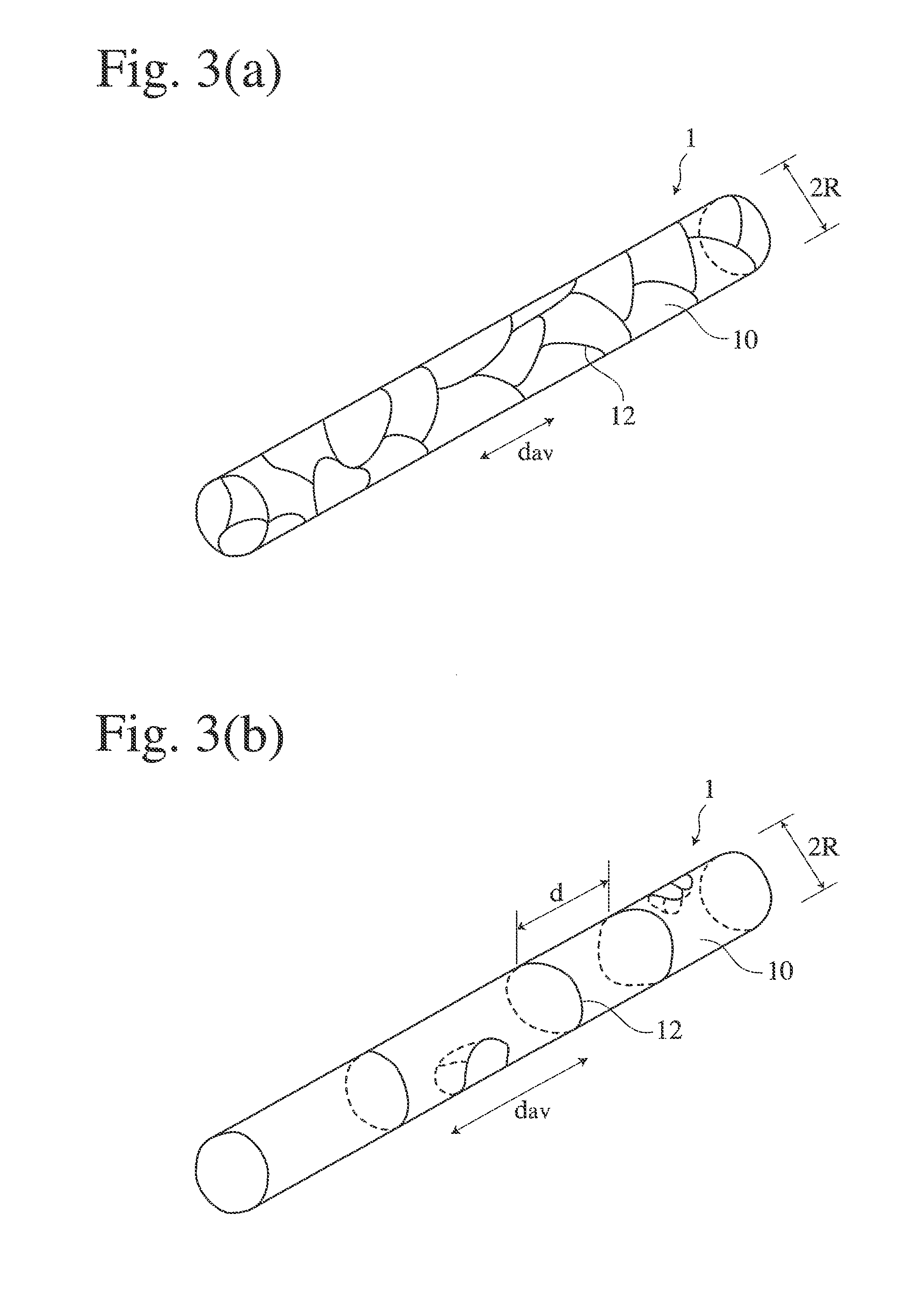

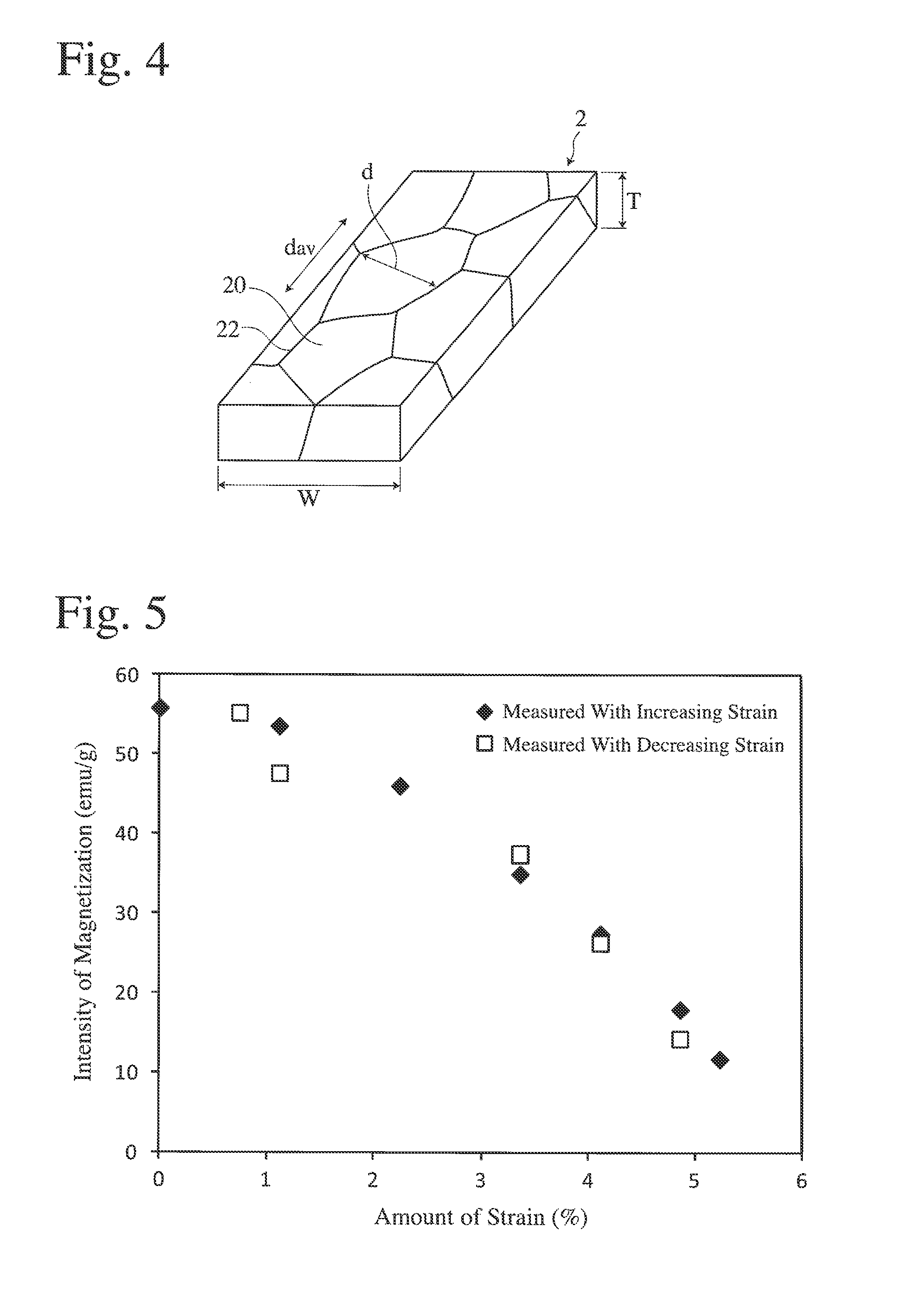

ActiveUS8815027B2Improve machinabilityExcellent shape memory performanceMagnetic materialsShape-memory alloyAlloy

An Fe-based shape memory alloy comprising 25-42 atomic % of Mn, 12-18 atomic % of Al, and 5-12 atomic % of Ni, the balance being Fe and inevitable impurities, and an Fe-based shape memory alloy comprising 25-42 atomic % of Mn, 12-18 atomic % of Al, and 5-12 atomic % of Ni, as well as 15 atomic % or less in total of at least one selected from the group consisting of 0.1-5 atomic % of Si, 0.1-5 atomic % of Ti, 0.1-5 atomic % of V, 0.1-5 atomic % of Cr, 0.1-5 atomic % of Co, 0.1-5 atomic % of Cu, 0.1-5 atomic % of Mo, 0.1-5 atomic % of W, 0.001-1 atomic % of B and 0.001-1 atomic % of C, the balance being Fe and inevitable impurities.

Owner:JAPAN SCI & TECH CORP

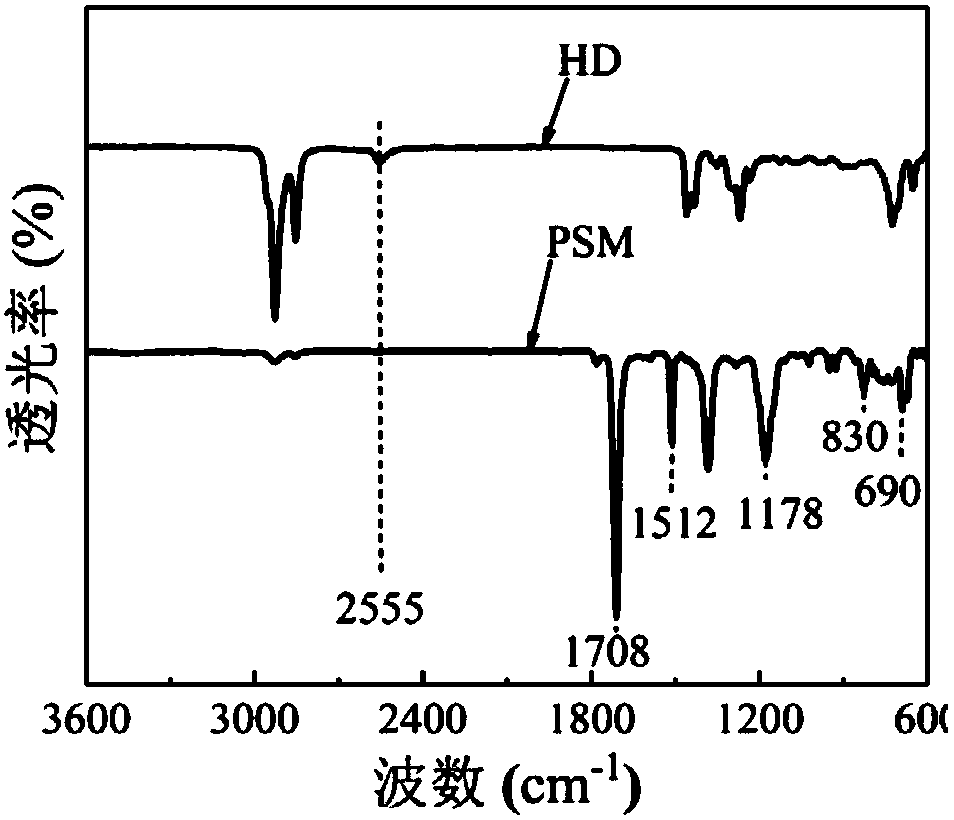

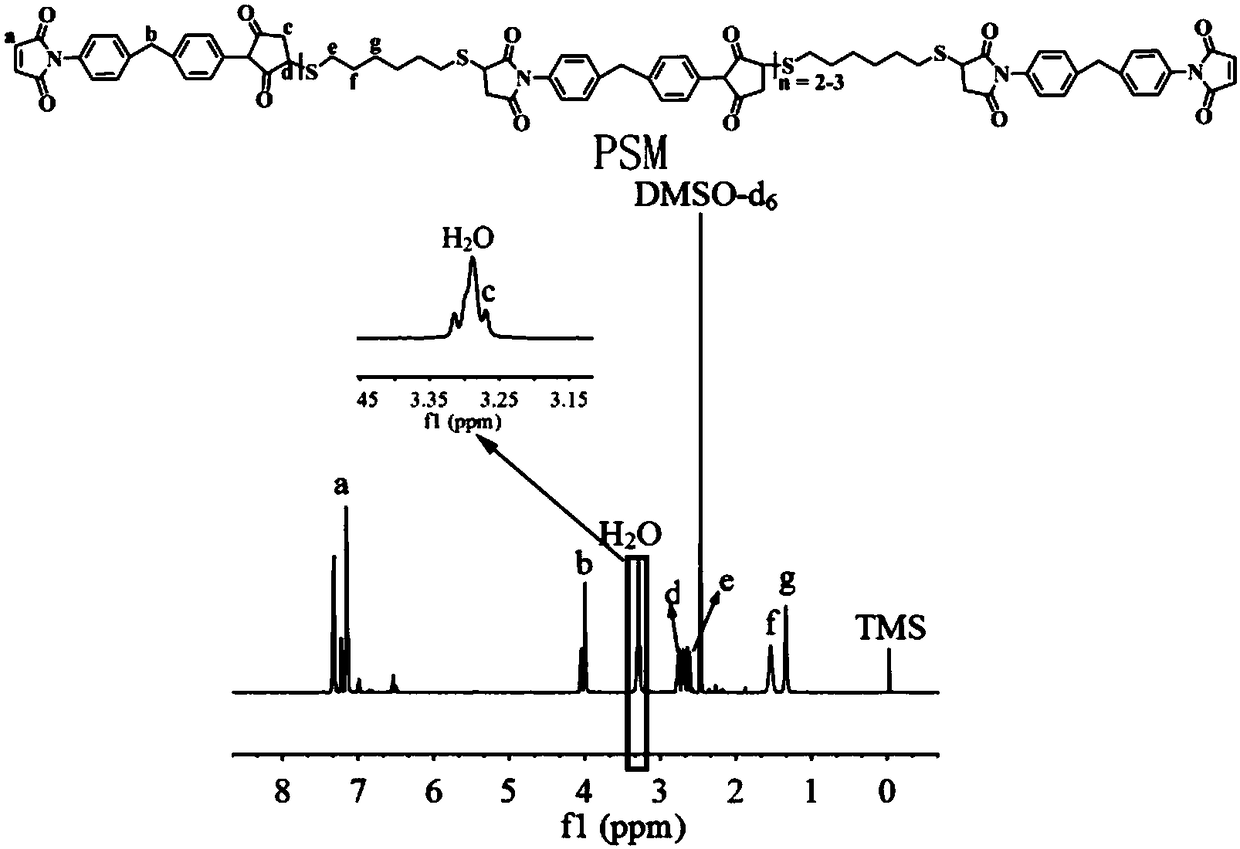

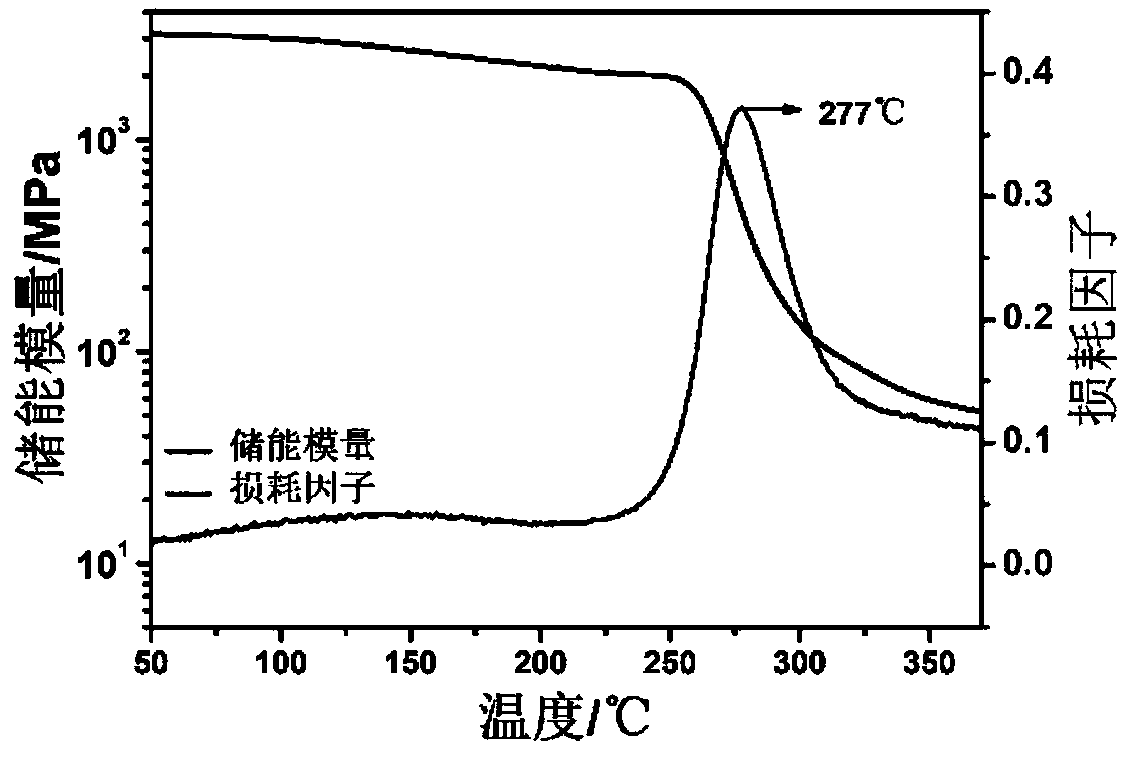

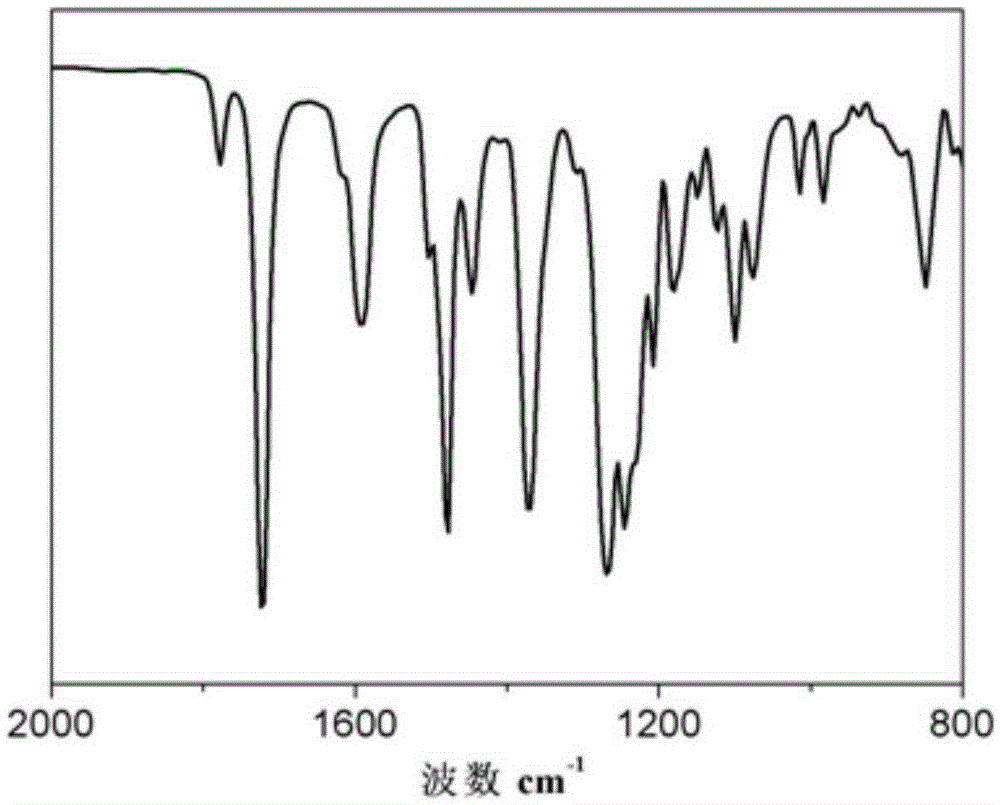

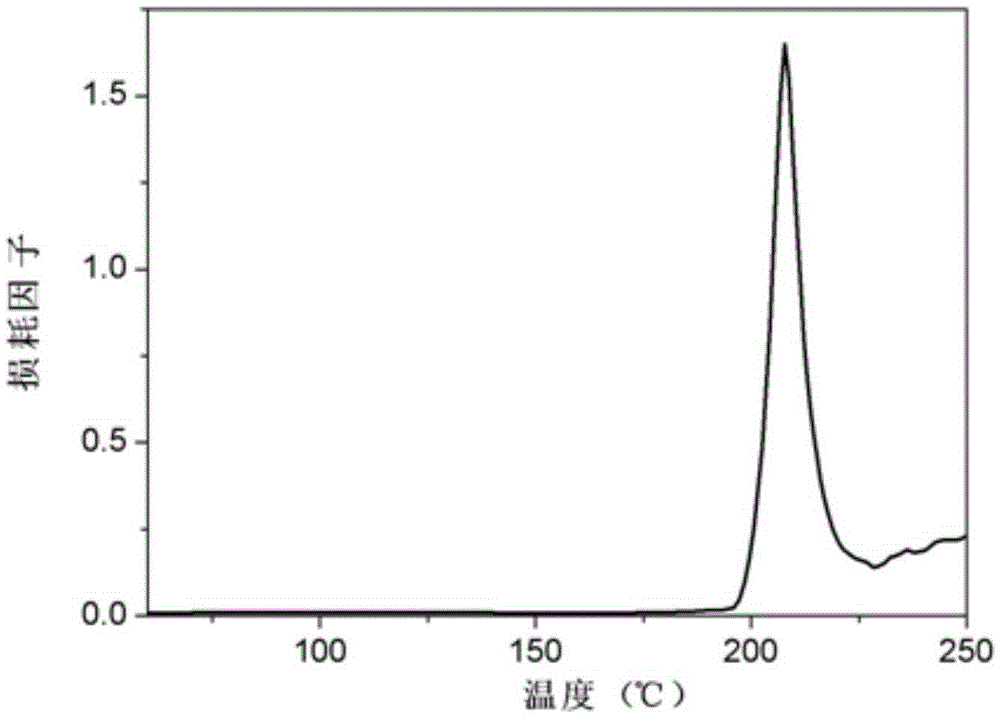

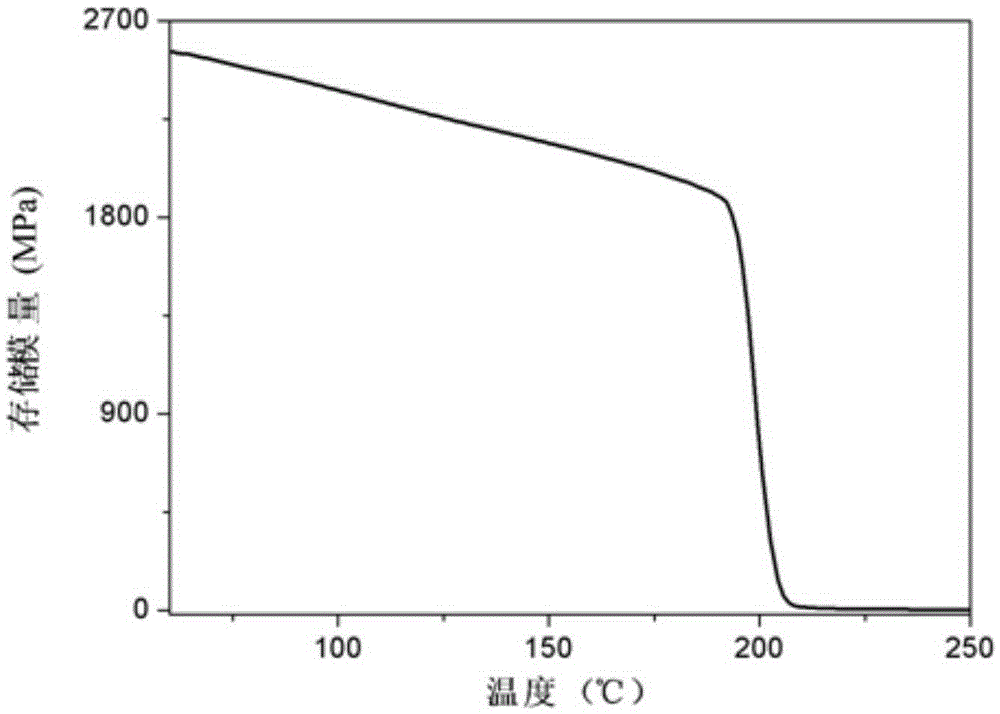

Thermosetting shape memory resin based on bismaleimide and preparation method thereof

The invention relates to high-deformation thermosetting shape memory resin based on bismaleimide and a preparation method thereof. The method includes the following steps that the bismaleimide and 1,6-ethanthiol are added into m-cresol to form a solution; triethylamine is added into the solution dropwisely, and under the protection of N2 and a stirring condition, a reaction is carried out at roomtemperature to obtain a linear oligomer; the bismaleimide, the linear oligomer and O,O'-diallylbisphenol A are mixed by mass, and the reaction is carried out at 130-150 DEG C for 25-45 min to obtain aprepolymer; the prepolymer is subjected to vacuum defoamation at the temperature of 130-150 DEG C, and through solidification and post-treatment, the thermosetting shape memory resin based on the bismaleimide is obtained. Compared with the prior art, the resin has a high deformation capability, and the breaking elongation of the resin at programming temperatures is higher than 30%; moreover, thethermosetting resin has both high glass-transition temperature (larger than 131 DEG C) and initial decomposition temperature (larger than 370 DEG C), high tenacity and outstanding shape memory performance.

Owner:SUZHOU UNIV

PVA hydrogel, composite material using same and preparation method and application of PVA hydrogel

ActiveCN108715641AGood mechanical propertiesImprove hydrophilicitySuture equipmentsPharmaceutical delivery mechanismMicro roboticsBiocompatibility Testing

The invention provides PVA hydrogel and a composite material based on the PVA hydrogel. The PVA hydrogel is excellent in mechanical performance, shape memory performance, hydrophilcity and biocompatibility and has 3D printability and injectability. The invention further provides a novel method for preparing the PVA hydrogel and application of the PVA hydrogel in various fields such as catheters, 3D printable solutions, injectable electronic devices, microfluid channels, biological absorbable sensors, miniature robots, scaffolds for tissue engineering, surgical suture lines, medical gloves andcondoms.

Owner:HUZHOU SIMAN BIOLOGICAL MATERIAL CO LTD +4

Epoxy resin with shape memory property and preparation method thereof

The invention relates to the technical field of high polymer materials, and particularly relates to an epoxy resin with the shape memory property and a preparation method thereof. The epoxy resin with the shape memory property comprises the following raw materials in parts by weight: 100 parts of epoxy resin, 20.6-35.5 parts of sebacic monobasic amine, 14.4-20.3 parts of curing agent and 0.1-2.2 parts of curing catalyst, wherein the epoxy resin is bisphenols A epoxy resin and aliphatic epoxy resin blended resin. The influence temperature can be conveniently adjusted by changing the content and the alkyl group length of the sebacic monobasic amine or the content of the epoxy resin in the formula; the epoxy resin with the shape memory property is short in heat response time and fast in shape recovery rate and has a good shape memory effect after the shape memory repeatedly circulates; the forming process of the epoxy resin with the shape memory property is mature and low in cost; the epoxy resin with the shape memory property has relatively good mechanical property and thermal property, good chemical resistance and the characteristics of super toughness, impact resistance, wear resistance, low friction coefficient and the like and is difficult to deform, melt and burn at a high temperature environment.

Owner:DONGGUAN JIEYUE SHENGSHI SPORTS GOODS

Preparation method of elastic memory alloy material for spectacle frame

ActiveCN103060611AMaintain elastic memory propertiesAvoid health problems such as allergiesChemical compositionAlloy

The invention discloses a preparation method of an elastic memory alloy material for a spectacle frame. The alloy material can comprise the following chemical components in percentage by weight: 10-12% of Zr, 6-8% of Nb, 11-13% of Al, 4-6% of Cu, 5-7% of Mg, 2-4% of Zn, 1-2% of Ag, 0.5-1.5% of Ce, no less than 0.05% of O, no less than 0.01% of N, no less than 0.02% of H and the balance of Ti and inevitable impurities; and the preparation method comprises the following steps: (1), melting and casting; (2), hot rolling: heating a continuous casting blank to about 980-1020 DEG C, preserving the heat of the continuous casting blank for about 15-25 minutes, and then rolling the continuous casting blank and obtaining a 10X10 mm wire after rolling, wherein the final rolling temperature is substantially 860 DEG C; (3), cold pulling; and (4), heat treatment: heating the cold-pulled material to about 260-280 DEG C and preserving the heat of the cold-pulled material for 4-6 minutes.

Owner:浙江极铝科技有限公司

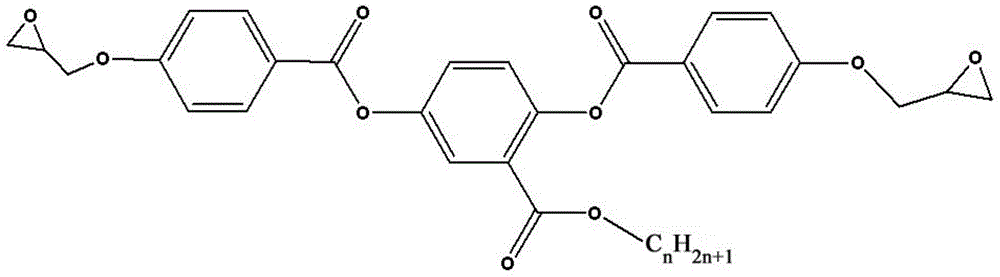

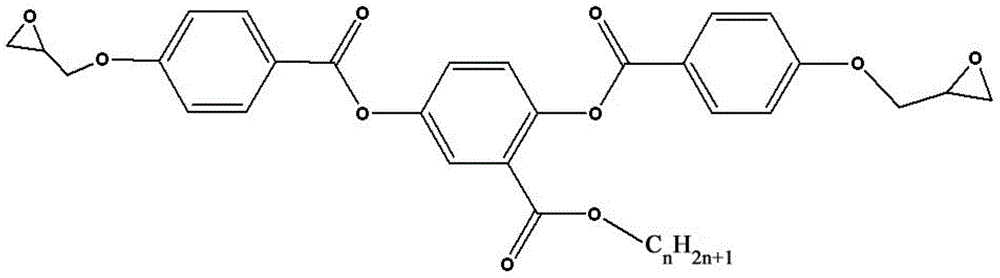

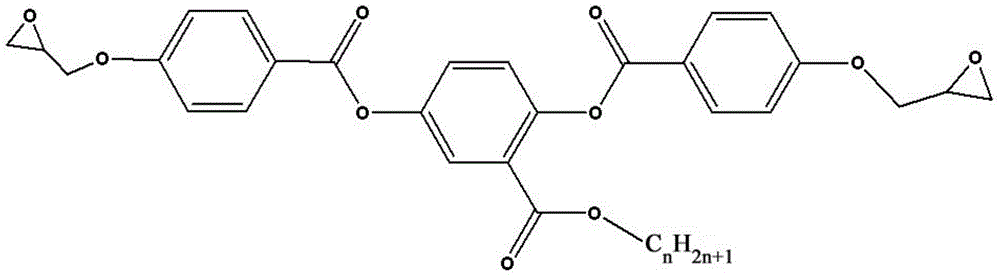

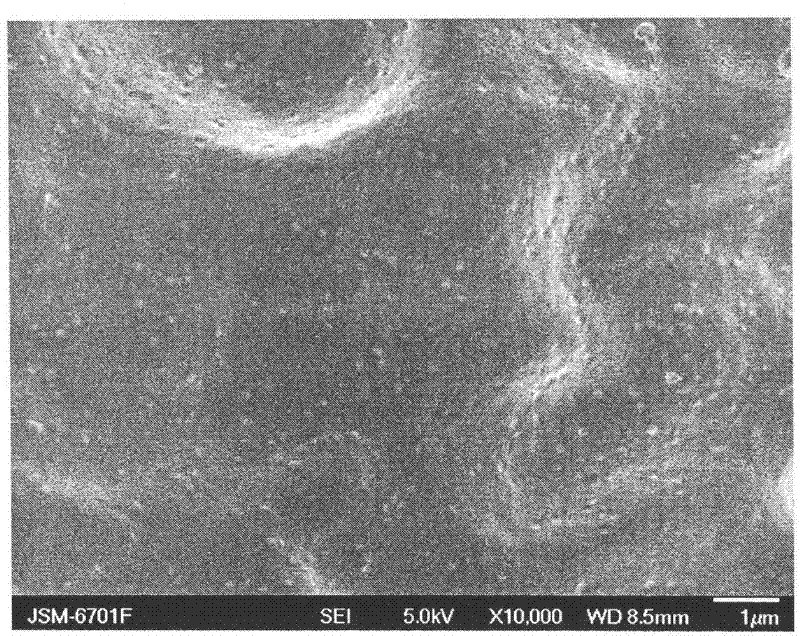

Liquid crystal epoxy resin - carbon fiber composite material and preparation method thereof

The invention belongs to the preparation field of shape memory polymers, specifically discloses a liquid crystal epoxy resin-carbon fiber composite material with shape memory properties and a preparation method thereof. The preparation method of the liquid crystal epoxy resin-carbon fiber composite material comprises three steps: (1) carbon fiber surface treatment; (2) composite material mixture preparation; and (3) curing for forming. According to the preparation method, carbon fiber is used for modifying of liquid crystal epoxy resin with branched chains, the cost can be reduced, and the thermodynamic properties of the material can be improved; and the liquid crystal epoxy resin-carbon fiber composite material prepared by the preparation method has the shape memory property, is high in response rate, is high in recovery stress, and can be applied to the technical field of biomedicine, aerospace and other sciences.

Owner:SICHUAN HUASON ELECTRONICS TECH

Silica cross-linking shape memory polymer material

The invention discloses a silica cross-linking shape memory polymer material, characterized by using silica as a cross-linking point, forming a SiO2@polymer spherical polymer in which silica is used as the shell of the core polymer through surface grafting of a polymer, and connecting polyisocyanate with the terminal hydroxy of the polymer to obtain a polymer having a cross-over network structure, wherein the soft segment is a polymer whose surface is grafted by silica, and the hard segment comprises silica and a urethane chain segment. The silica cross-linking shape memory polymer material has the advantages of regular structure, high mechanical strength, stable shape memory performance, and high shape memory fixation rate and shape memory recovery rate, and can be applied for materials in medical science and other aspects.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Photo-thermal response three-dimensional shape memory polyimide, preparation method and application thereof

InactiveCN111303425AHigh glass transition temperatureHigh mechanical strengthPolymer scienceNanoparticle

The invention relates to the technical field of functional materials, and provides photo-thermal response three-dimensional shape memory polyimide, a preparation method and application thereof. The preparation method comprises the following steps: mixing photo-thermal nanoparticles, diamine and dianhydride, synthesizing polyamic acid through in-situ condensation polymerization, dispersing the photo-thermal nanoparticles in the polyamide acid, coating a hard thin-layer substrate with the polyamic acid, and volatilizing the solvent to obtain a polyamic acid film; and preparing a three-dimensional structure from the polyamic acid film and the hard thin-layer substrate at the bottom, and removing the substrate after thermal imidization to obtain the photo-thermal response three-dimensional shape memory polyimide. According to the invention, shape memory polyimide with a complex three-dimensional structure can be obtained, and the obtained shape memory polyimide can realize dual response tolight and heat; and the photo-thermal response three-dimensional shape memory polyimide provided by the invention is high in glass-transition temperature, high in mechanical strength and excellent inshape memory performance, and can be used as a driver in harsh and complex environments such as high temperature.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

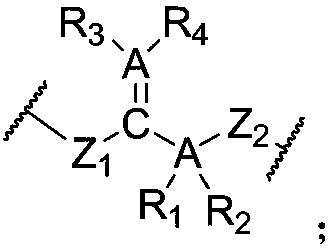

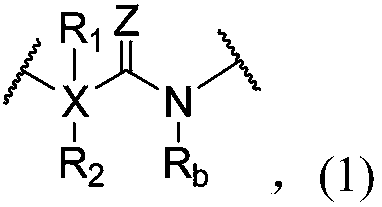

Dynamic polymer having hybrid cross-linking network structure

PendingCN109666093AExcellent self-healing performanceImprove self-healing abilitySide chainNetwork structure

The present invention discloses a dynamic polymer having a hybrid cross-linking network structure, wherein the dynamic polymer has dynamic covalent cross-linking and supramolecular hydrogen bond action, the dynamic covalent cross-linking is based on at least a reversible addition cleavage chain transfer dynamic covalent bond, and the side hydrogen bond group existing on the side group and / or the side chain of the polymer chain participates in the formation of the hydrogen bond action contained in the supramolecular hydrogen bond action. According to the present invention, the dynamic polymer integrates the advantages of the dynamic covalent bond and the supramolecular hydrogen bond, wherein the supramolecular hydrogen bond can make the material have stimulating responsiveness, super-toughness and self-healing property, and the dynamic covalent bond can make the dynamic polymer have the structural stability and the mechanical strength, and further has dynamic reversibility, such that the polymer can have characteristics of self-healing property, recyclability, repeatable processability and the like, and can be widely used in the production of self-healing materials, toughness materials, sealing materials and the like.

Owner:厦门天策材料科技有限公司

Novel block macromolecular material and preparation method thereof

The invention discloses a method of each block copolymer with Biopolyester PHA as base material, which comprises the following steps: cracking high molecular weight Biopolyester PHA to low molecular weight fragment or low molecular weight diatomic alcohol or diacid fragment of needed; connecting this fragments as block copolymer under the function of small molecule chain protecting agent; or utilizing PHA low-molecular polymer fragment as macromolecule trigger under warm condition; triggering other monomer polymerization reaction; even utilizing PHA and other macromolecule material; proceeding ester exchange under proper condition directly; getting the product. This product possesses special property and can meet the needs of biological medicine and organizing engineer, and on the other hand, the cheaper block copolymers used can decrease the selling price of PHA.

Owner:SHANTOU UNIV

Preparation method of 4D printed copper-based shape memory alloy and 4D printed copper-based shape memory alloy

ActiveCN110788340AExcellent shape memory performanceImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMechanical properties of carbon nanotubesShape-memory alloy

Owner:CENT SOUTH UNIV +1

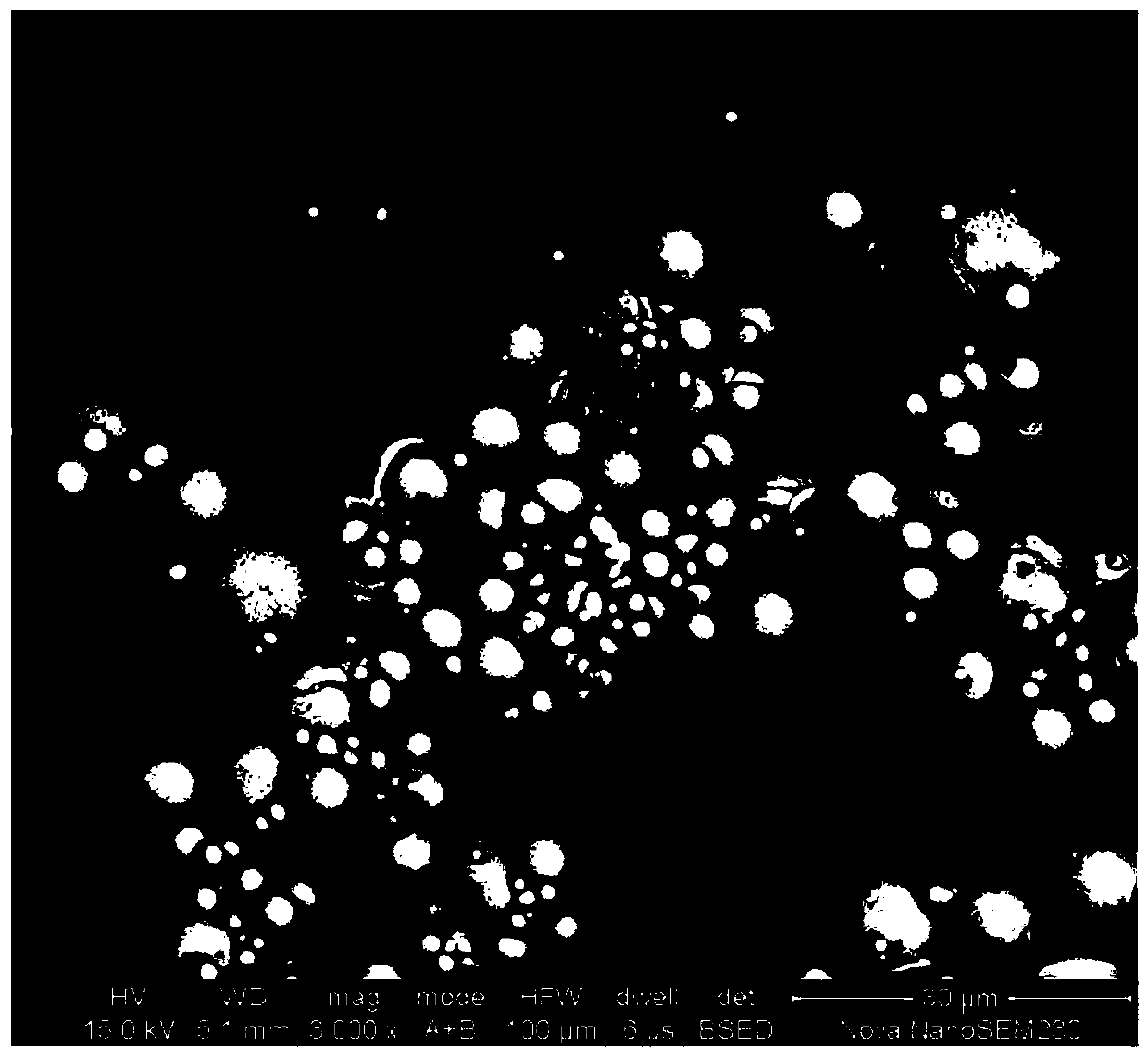

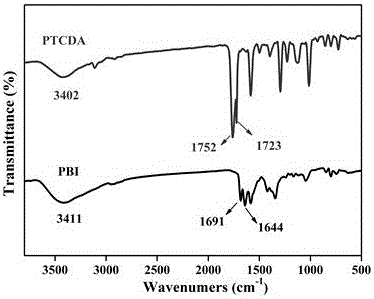

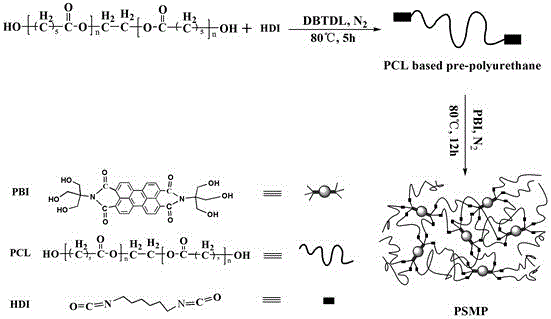

Shape memory polyurethane preparation method using hydroxylated perylene bisimide

The invention discloses a shape memory polyurethane preparation method using hydroxylated perylene bisimide. The method comprises the steps of firstly under the nitrogen gas atmosphere, using 3, 4, 9, 10-tetracarboxylicaciddianhydride and trihydroxymethyl aminomethane to prepare hydroxylated perylene bisimide, then under the nitrogen gas atmosphere, stirring the prepared hydroxylated perylene bisimide with polycaprolactone diol and hexamethylene diisocyanate for reaction under 80 DEG C for 12 hours, pouring in a mold which is preheated to 50-80 DEG C, heating and curing for 10-14 hours under 70-90 DEG C to acquire the shape memory polyurethane. The method operation is simple. The prepared shape memory polyurethane has the advantages of being good in thermal, mechanical and memory properties. The major performance parameters are as following: the breaking elongation is 600-1000%; the tensile strength is larger than or equal to 20MPa; the secondary circulation shape fixing rate is 85-100%, the secondary circulation shape recovery rate is 90-100%, and the thermal decomposition starting temperature is larger than or equal to 250 DEG C.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

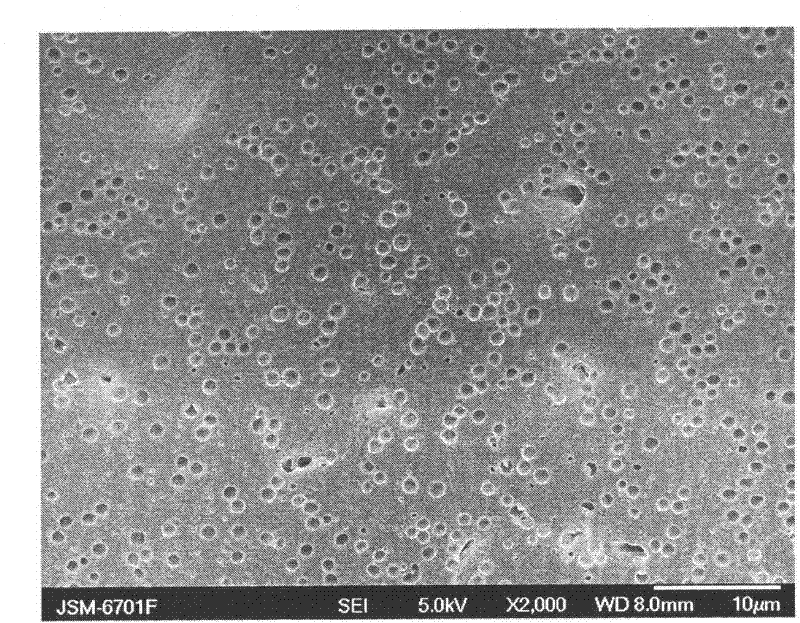

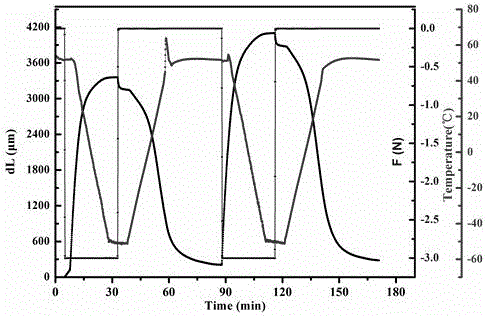

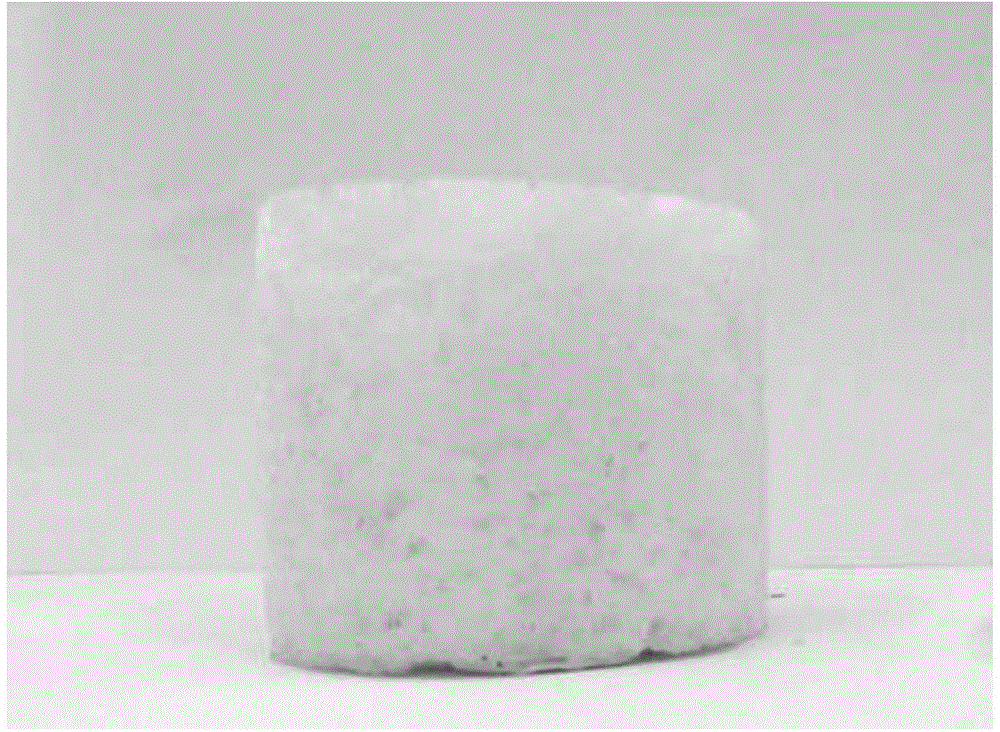

Preparation method and driving method of shape-memory polycaprolactone foam

The invention relates to a preparation method and a driving method of shape-memory polycaprolactone foam. The invention relates to the field of functional polymer materials, in particular to the preparation method and the driving method of the shape-memory polycaprolactone foam. The invention is intended to solve the problems of complex process, low production efficiency, high cost and uneasy control existing in conventional preparation methods. The preparation method includes the following steps: (1) polycaprolactone is dissolved into dichloromethane, stirring is performed at room temperature until the polycaprolactone is dissolved completely, benzamide peroxide is then added, stirring is performed at room temperature until the benzamide peroxide is dispersed uniformly, and thereby polycaprolactone solution is obtained; (2) the polycaprolactone solution obtained in step 1 is poured into a mold, and is then put into a microwave oven to be heated, and thereby the shape-memory polycaprolactone foam is obtained. The driving method is as follows: under the condition of microwave heating, the shape-memory polycaprolactone foam can be restored to an initial shape within 98s.

Owner:HARBIN INST OF TECH

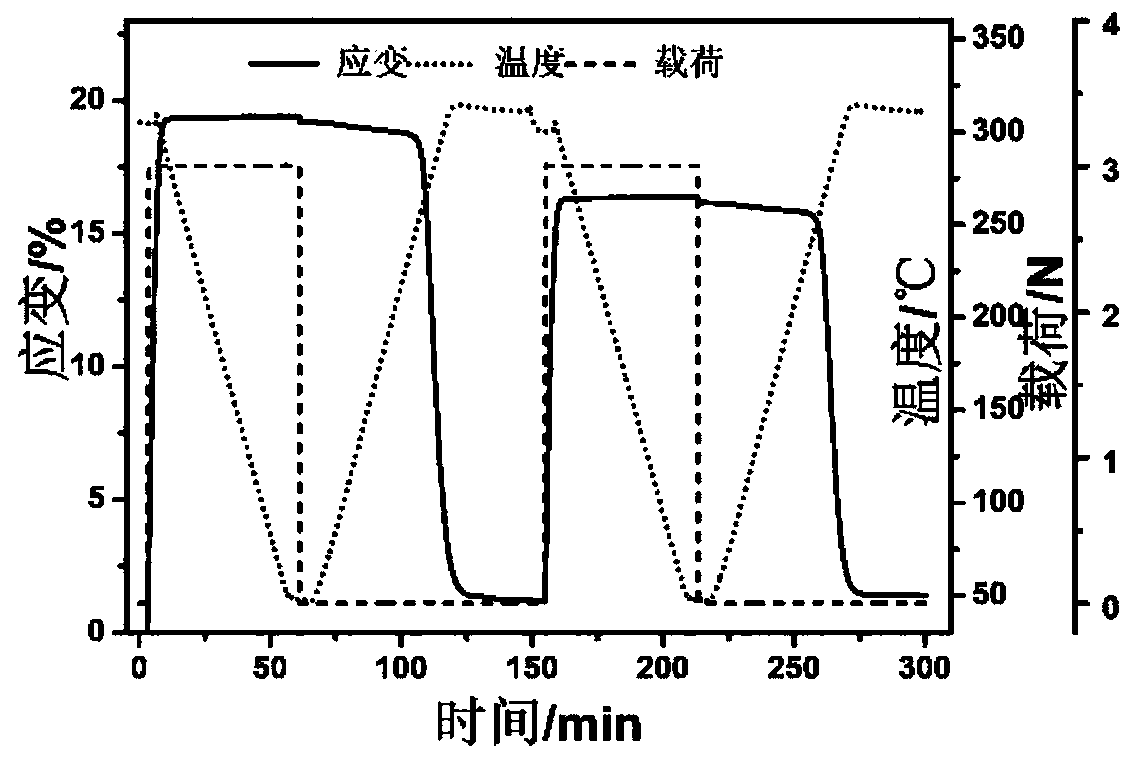

Shape memory random-copolymerized polyimide capable of being circularly used and preparation method thereof

The invention discloses a shape memory random-copolymerized polyimide capable of being circularly used and a preparation method thereof, relates to polyimide and a preparation method thereof, and aims to solve the problems that in the prior art, the preparation cost of shape memory polyimide is high, and the prepared shape memory polyimide cannot be repeatedly used. The provided polyimide is prepared from a mixture of 1,3-bis(3-aminophenoxyl)benzene, 4,4'-(4,4'-isopropylidenediphenoxy)bis(phthalic anhydride), and 4,4'-oxydiphthalic anhydride. The preparation method comprises the following steps: step one, preparing a diamine solution; step two, preparing a dianhydride solution; step three, preparing a polyamide acid solution; step four, carrying out thermal imidization to obtain a glass plate containing polyimide; step five, cleaning and drying to obtain the shape memory random-copolymerized polyimide capable of being circularly used. The provided method can obtain shape memory random-copolymerized polyimide capable of being circularly used.

Owner:HARBIN INST OF TECH

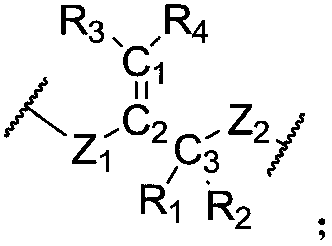

Dynamic polymer with hybrid cross-linking network

The invention discloses a dynamic polymer with a hybrid cross-linking network, wherein the dynamic polymer contains dynamic covalent cross-linking and supramolecular hydrogen bond cross-linking, the dynamic covalent cross-linking network skeleton chain at least comprises a dynamic covalent bond induced based on steric effect, and the side hydrogen bond group and / or the terminal hydrogen bond groupparticipates in the formation of the hydrogen bond contained in the supramolecular hydrogen bond cross-linking. According to the present invention, the polymer integrates the supramolecular dynamic properties and the glass-like dynamic covalent properties, wherein the supramolecular hydrogen bond can make the material have stimulating responsiveness and self-healing property, and the dynamic covalent bond induced based on steric effect can make the dynamic polymer have the structural stability and the mechanical strength, and further has dynamic reversibility, such that the polymer can have characteristics of self-healing property, recyclability, repeatable processability and the like, and can be widely used as self-healing materials, toughness materials, sealing materials, interlayer adhesives and the like.

Owner:厦门天策材料科技有限公司

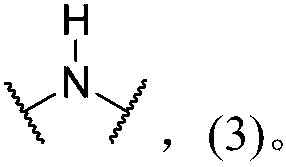

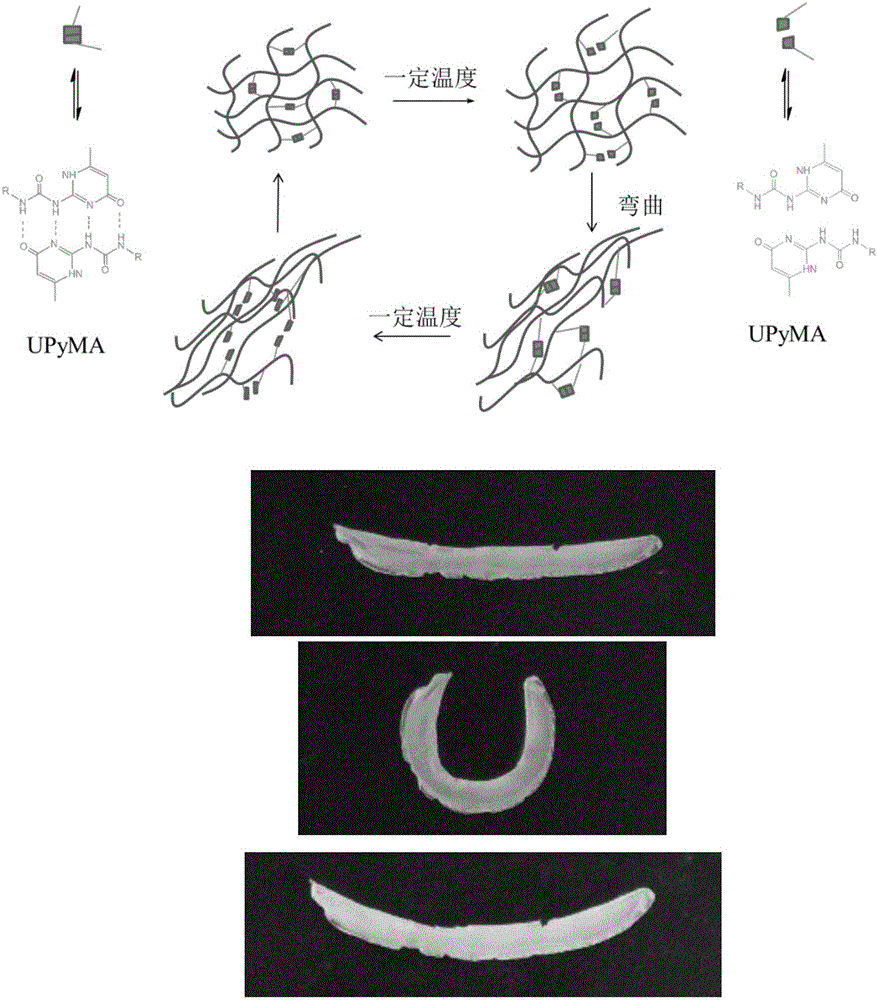

Thermal response shape memory hydrogel based on hydrogen-bond interaction and preparation method of thermal response shape memory hydrogel

The invention discloses thermal response shape memory hydrogel based on hydrogen-bond interaction and a preparation method of the thermal response shape memory hydrogel. The hydrogel is a copolymer of N,N'-dimethyl acrylamide (DMA), N,N'-methylene bisacrylamide (MBA) and 2-urea-4[1H]-UPyMA. According to the shape memory hydrogel, dynamic hydrogen bonds formed between UPy(2-urea-4-[1H]-methyl pyrimidone) units on polymer side chains are utilized, and the strength of covalent bonds and the reversibility of physical crosslinking are achieved. The raw materials are easy to obtain, and the preparation process is simple. The prepared hydrogel based on quadruple hydrogen bonds has high mechanical performance and good shape memory performance and has wide application prospects on the aspects of medicine conveying and the like.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com