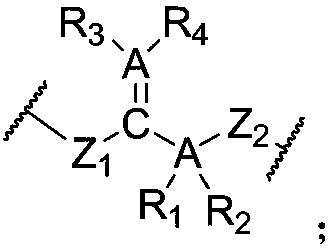

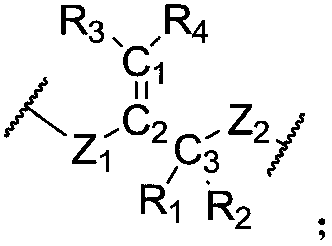

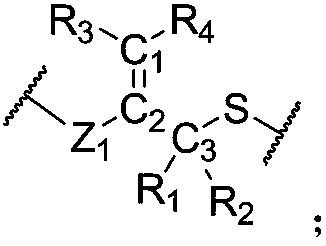

Dynamic polymer having hybrid cross-linking network structure

A network structure, hybrid cross-linking technology, applied in the field of smart polymers, can solve the problems of large thermodynamic influence, weak bond energy, easy to be destroyed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0381] The preparation method of a kind of dynamic polymer ionic liquid gel of the present invention, comprises the following steps: the raw material of the dynamic polymer that prepares hybrid cross-linked network is added in ionic liquid, makes the dynamic state of prepared hybrid cross-linked network The mass fraction of the polymer is 0.3-75%, the covalent cross-linking is carried out by the appropriate means, and after the reaction is completed, a dynamic polymer ion liquid gel is prepared. Another method for preparing a dynamic polymer ionic liquid gel of the present invention comprises the following steps: swelling a dynamic polymer having a hybrid cross-linked network structure in a solvent containing an ionic liquid, and making the prepared hybrid cross-link The mass fraction of the dynamic polymer in the network is 0.3-75%, and after fully swelling, the solvent is removed to form a dynamic polymer ion liquid gel. The above-mentioned ionic liquid is generally composed...

Embodiment 1

[0390] First add an appropriate amount of 3,3′-dipropionic acid trithiocarbonate and triphenylphosphine into the reactor, add anhydrous tetrahydrofuran solution of hydroxyethyl acrylate under anaerobic conditions, and then add azobis Toluene solution of ethyl formate, control the molar ratio of 3,3′-dipropionic acid trithiocarbonate to hydroxyethyl acrylate to 1:2, control the reaction temperature at 10°C during the whole process, and the reaction ends after the dropwise addition is completed. A diene compound containing a trithioester group is obtained.

[0391] Add N-isopropylacrylamide with a molar ratio of 15:1 to the reactor and the diene compound containing trithioester group prepared above, with anisole as solvent, azobisisobutyronitrile (AIBN) As an initiator, react at 65°C for 12 hours under anaerobic conditions to obtain a polymer fluid with a certain viscosity; then take 100 parts by mass of the polymer liquid and swell it in 75 parts by mass of epoxy soybean oil an...

Embodiment 2

[0394] Using methanol as a solvent and sodium methoxide as a catalyst, mix mercaptoethanol and 3-chloro-2-chloromethyl-1-propene at a molar ratio of 2:1, and react under heating for 16 hours to obtain Ether-based dihydric alcohols; using tetrahydrofuran as a solvent and triethylamine as a catalyst, react dihydric alcohols containing allyl sulfide groups with acryloyl chloride, and control the reaction temperature at 0-25°C to synthesize allyl sulfide-containing diols. Ether-based diene compounds.

[0395] Under anaerobic conditions, with 1-hydroxycyclohexyl phenyl ketone as photoinitiator and toluene as solvent, under the action of UV light, acrylamide and the above-mentioned diene compound containing allyl sulfide group prepared as The ratio of the amount of substances is 200:16 and the cross-linked copolymerization becomes a hybrid cross-linked dynamic polymer organogel with the first network.

[0396] The material is responsive to light stimulation, has certain self-healin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Fracture stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com