Photo-thermal response three-dimensional shape memory polyimide, preparation method and application thereof

A three-dimensional shape, photothermal response technology, applied in the field of functional materials, can solve problems such as inability to obtain three-dimensional shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing photothermally responsive three-dimensional shape memory polyimide, comprising the following steps:

[0027] (1) mixing diamine, photothermal nanoparticles and a solvent to obtain a mixed solution;

[0028] (2) mixing the mixed solution and dianhydride to carry out polycondensation reaction to obtain a polyamic acid solution;

[0029] (3) coating the polyamic acid solution on the hard thin-layer substrate, then heating to volatilize the solvent, and obtaining a polyamic acid film on the surface of the hard thin-layer substrate;

[0030] (4) The polyamic acid film and the hard thin layer substrate at the bottom are prepared into a three-dimensional structure, and then thermal imidization is performed, and then the hard thin layer substrate is peeled off to obtain a photothermal responsive three-dimensional shape memory polyimide.

[0031] The invention mixes the diamine, photothermal nanoparticles and solvent to obtain a mix...

Embodiment 1

[0044] Add 4,4'-diaminodiphenyl ether (5mmol) and 2-(4-aminophenyl)-5-aminobenzoxazole (5mmol) into N-methyl-2-pyrrolidone, dry at room temperature Stir under a nitrogen atmosphere until dissolved, then add enhanced graphene (2 to 5 layers, the addition amount is 1 wt% of the total mass of dianhydride and diamine), and ultrasonically disperse it evenly. Then add 3,3',4,4'-biphenyldianhydride (10mmol), stir for 24h under nitrogen atmosphere and ice-water bath condition, carry out polycondensation reaction, obtain polyamic acid solution; Cover on a horizontal aluminum thin-layer substrate, heat in an oven at 80°C for 24 hours to volatilize the solvent, and cool to normal temperature to obtain a polyamic acid film.

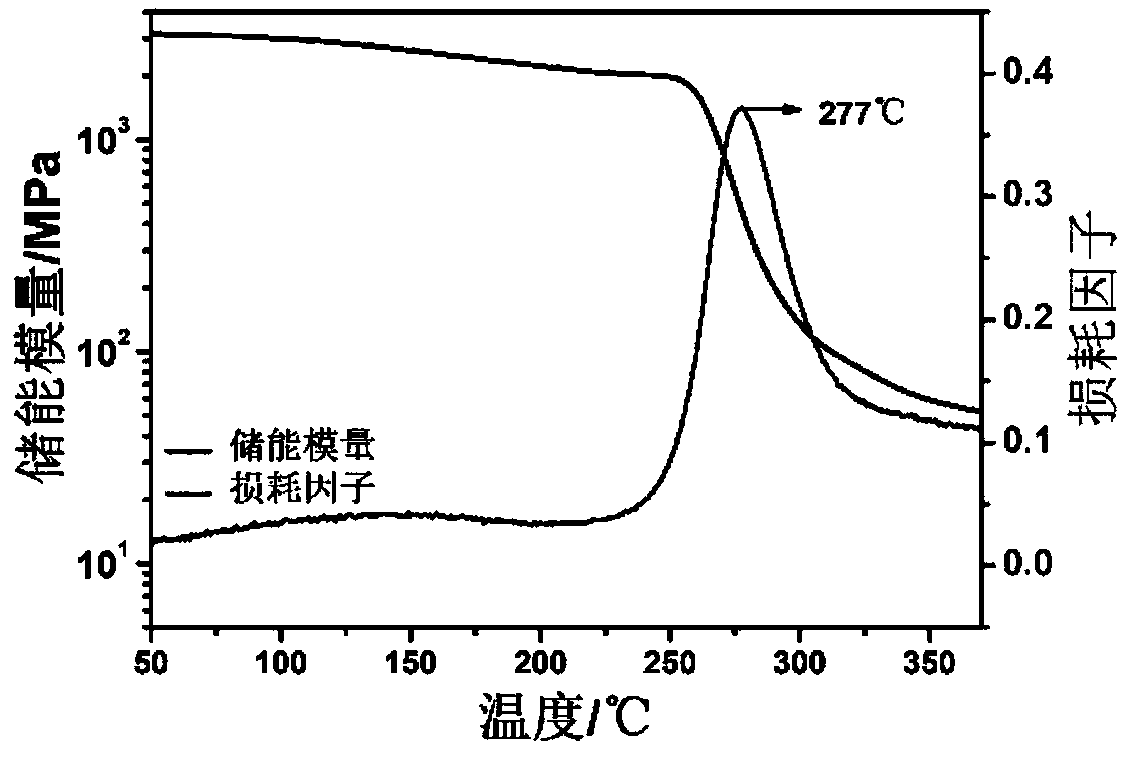

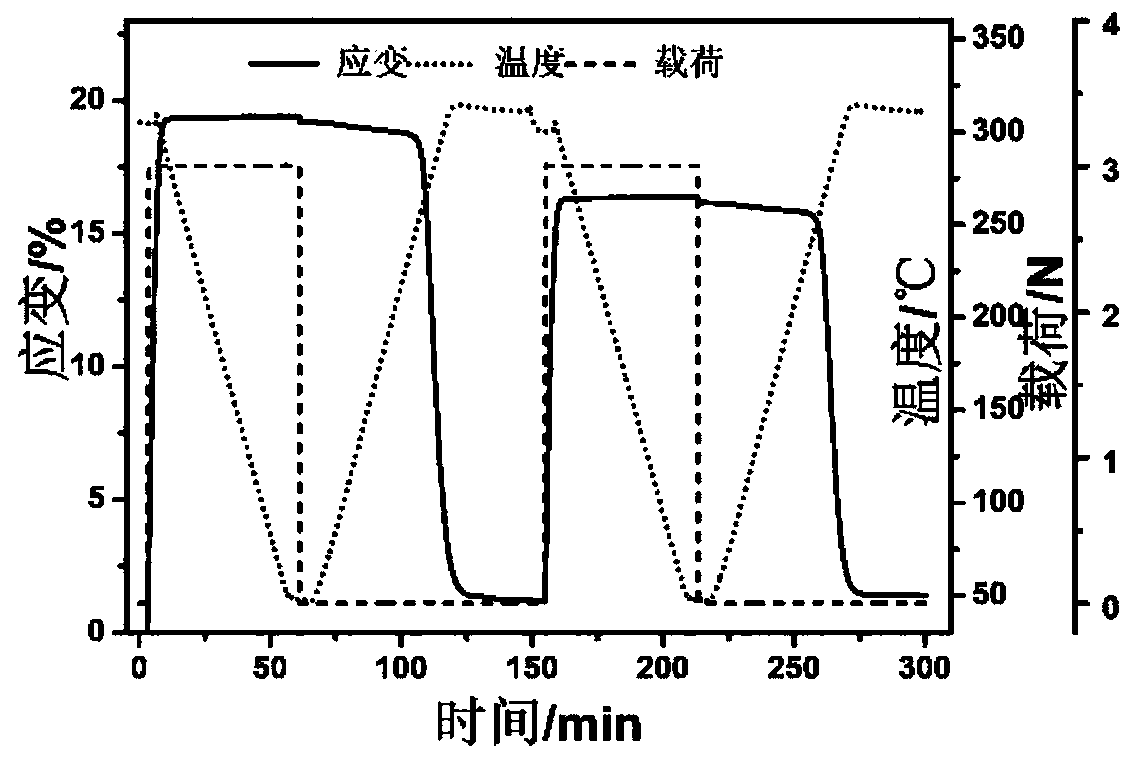

[0045] The polyamic acid film with the aluminum thin-layer base is laser cut to obtain the desired pattern, and then deformed into a three-dimensional cylinder by origami technology. Then thermal imidization was performed on the obtained three-dimensional cylindrica...

Embodiment 2

[0051] Add 4,4'-diaminodiphenyl ether (5mmol) and 2-(4-aminophenyl)-5-aminobenzoxazole (5mmol) into N-methyl-2-pyrrolidone, dry at room temperature Stir under a nitrogen atmosphere until dissolved, then add iron ferric oxide nanoparticles (the addition amount is 0.5wt% of the total mass of dianhydride and diamine), and ultrasonically disperse them evenly. Then add 3,3',4,4'-biphenyldianhydride (10mmol), stir for 24h under nitrogen atmosphere and ice-water bath condition, carry out polycondensation reaction, obtain polyamic acid solution; Cover on a horizontal aluminum thin-layer substrate, heat in an oven at 80°C for 24 hours to volatilize the solvent, and cool to normal temperature to obtain a polyamic acid film.

[0052] The polyamic acid film with the aluminum thin layer substrate is laser cut to obtain the desired pattern, and then deformed into the shape of a sunflower by origami technology. The obtained sunflower-like three-dimensional structure was subjected to thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com