Dynamic polymer with hybrid cross-linked network and application of dynamic polymer

A hybrid cross-linking and polymer technology, applied in the field of dynamic polymers, can solve the problems of difficult bond breaking, non-recycling and recycling, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

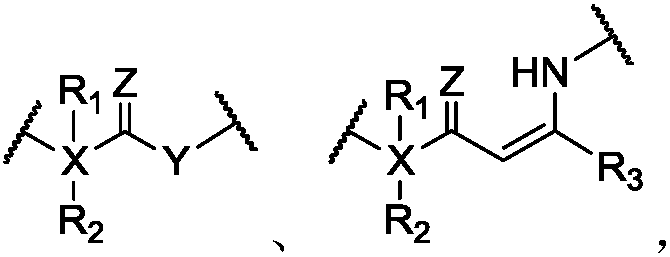

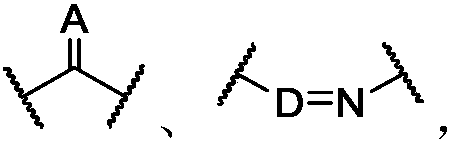

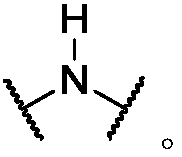

Method used

Image

Examples

preparation example Construction

[0196] The preparation method of a kind of dynamic polymer ionic liquid gel of the present invention preferably comprises the following steps: the raw material of the dynamic polymer that prepares hybrid cross-linked network is added in ionic liquid, makes the prepared hybrid cross-linked network The mass fraction of the dynamic polymer is 0.5-50%. The covalent cross-linking is carried out by the appropriate means, and after the reaction is completed, it is naturally cooled to form a dynamic polymer gel. The ionic liquids mentioned above are generally composed of organic cations and inorganic anions. The cations are usually alkyl quaternary ammonium ions, alkyl quaternary ions, 1,3-dialkyl substituted imidazolium ions, N-alkyl substituted pyridinium ions, etc. ; Anions are usually halide ions, tetrafluoroborate ions, hexafluorophosphate ions, and CF 3 SO 3- , (CF3SO 2 ) 2 N - 、C 3 f 7 COO - 、C 4 f 9 SO 3 - 、CF 3 COO - , (CF 3 SO 2 ) 3 C - , (C 2 f 5 SO 2 ) ...

Embodiment 1

[0249] 1,3-Diglycidyl ether glycerol and methyl isocyanate are mixed at a molar ratio of 1:1, and reacted in dichloromethane under the catalysis of dibutyltin dilaurate to obtain a diepoxide with a carbamate group in the side group. ethane.

[0250] Trans-1,4-cyclohexanedicarboxylic acid and the above-mentioned dioxirane containing carbamate groups in the side group are mixed according to the molar ratio of 1:1, and 5mol% Zn(OAc) is added 2 As a bond exchange reaction catalyst, a dynamic polymer containing side hydrogen bond groups and binding exchangeable ester bonds is prepared.

[0251] The prepared product also has good plasticity, and can be placed in molds of different shapes according to actual needs, and a certain stress can be applied slightly under certain temperature conditions to form polymer products of different shapes according to the mold. It can be used as a gasket material.

Embodiment 2

[0253] Bicyclo[2,2,2]octane-1,4-cyclohexanedicarboxylic acid and SOCl 2 Mix according to the molar ratio of 1:2 and react in DMF to obtain bicyclo[2,2,2]octane-1,4-cyclohexanedioyl chloride.

[0254] Pentaerythritol and butyl isocyanate are mixed at a molar ratio of 1:1, and reacted in dichloromethane under the catalysis of dibutyltin dilaurate to obtain a trihydric alcohol compound with a carbamate group in the side group.

[0255]Bicyclo[2,2,2]octane-1,4-cyclohexanedioyl chloride and the above-mentioned trihydric alcohol compound containing carbamate group in the side group are mixed according to the molar ratio of 1:1, and 6mol% 2-MI and 5mol%Zn(acac) 2 , reacted in dichloromethane to prepare a dynamic polymer containing pendant hydrogen bond groups and associative exchangeable ester linkages.

[0256] The polymer sample has certain strength and compressibility, and can be stretched within a certain range. Stress is applied to the section of the broken sample (in this pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Fracture stress | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com