Patents

Literature

52 results about "Methyl isocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl isocyanate (MIC) is an organic compound with the molecular formula CH₃NCO. Synonyms are isocyanatomethane, methyl carbylamine and MIC. Methyl isocyanate is an intermediate chemical in the production of carbamate pesticides (such as carbaryl, carbofuran, methomyl, and aldicarb). It has also been used in the production of rubbers and adhesives. As a highly toxic and irritating material, it is extremely hazardous to human health. It was the principal toxicant involved in the Bhopal disaster, which killed 3,787 people initially and officially 19,787 people in total.

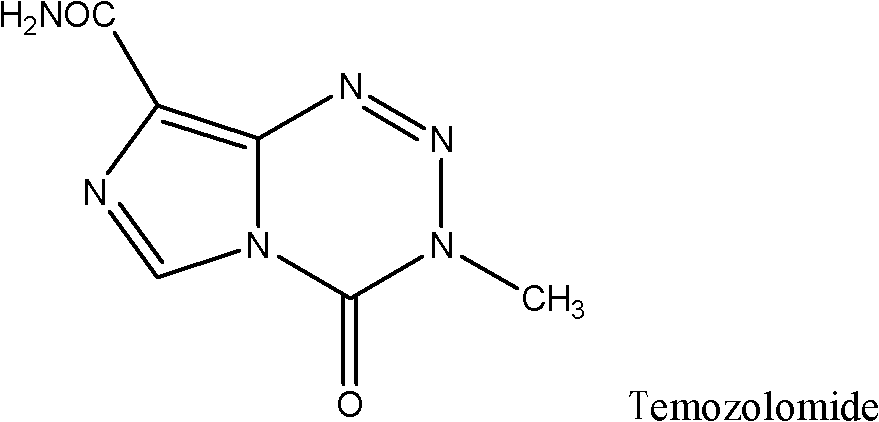

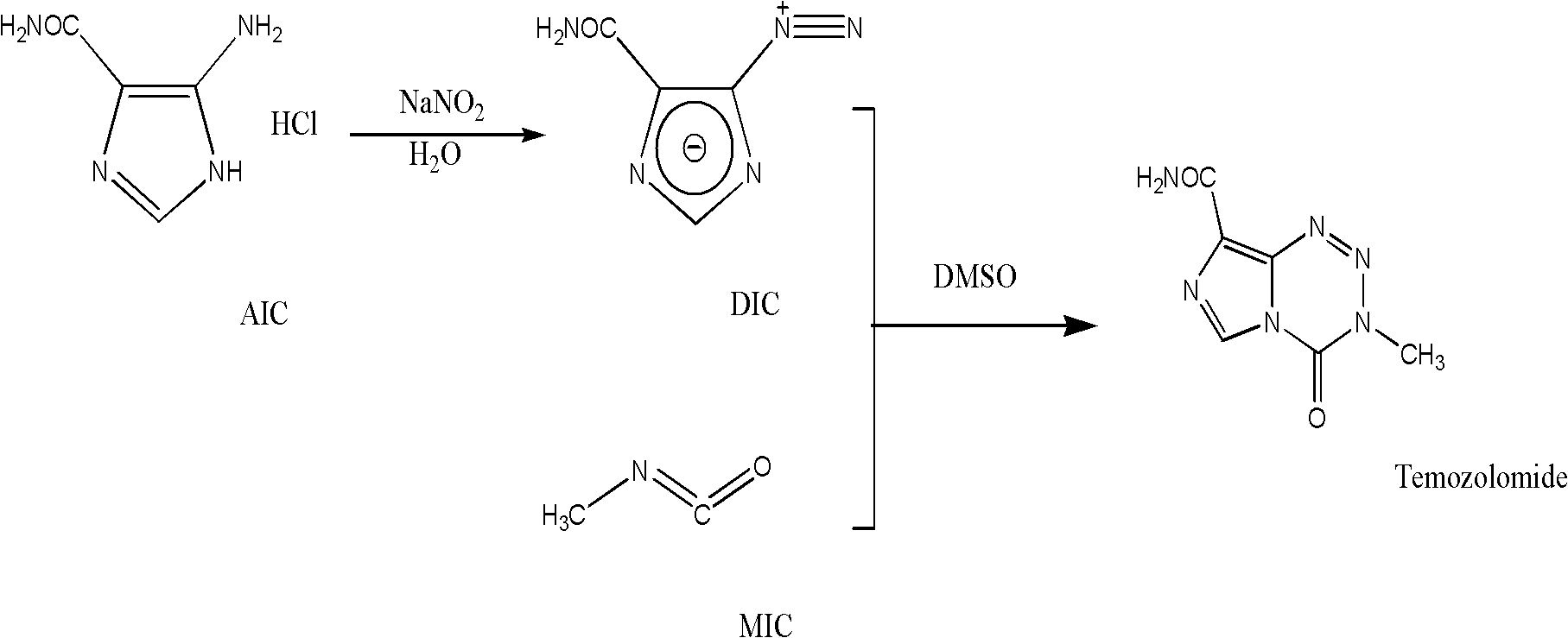

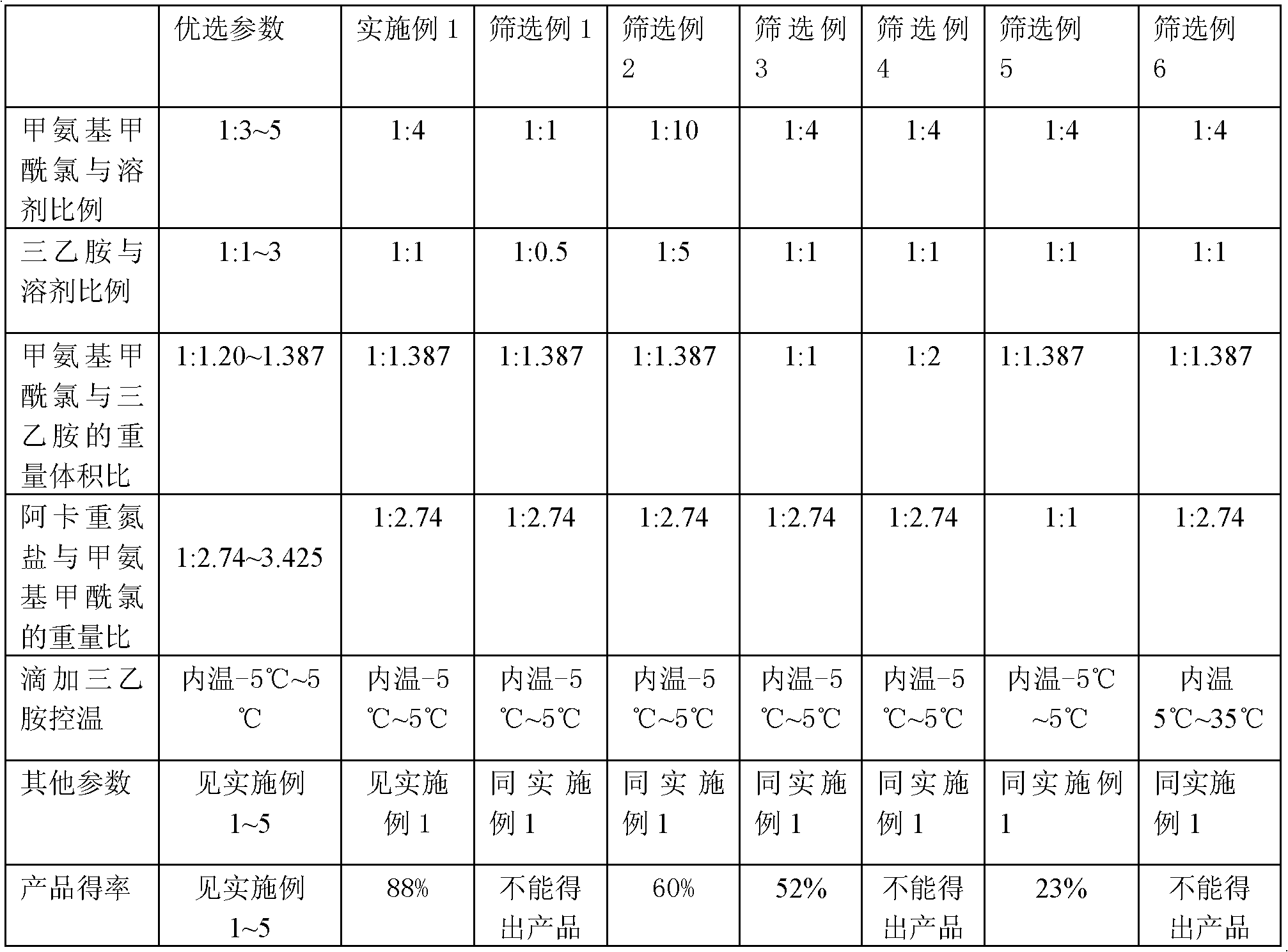

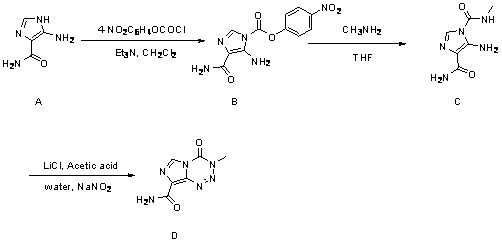

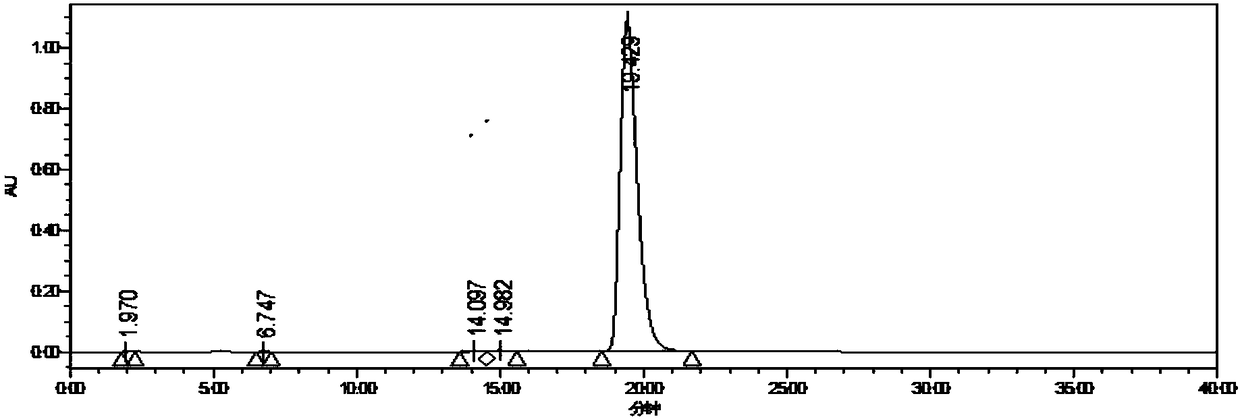

Method preparing temozolomide in one-pot mode and refining method of temozolomide

The invention discloses a method preparing temozolomide in a one-pot mode and further discloses a refining method of temozolomide. The refining method of temozolomide omits a rectification separation step of methyl isocyanate, and reduces the contacting times of temozolomide with the outside environment, thereby improving safety in the production process. By adjusting using quantities of a reaction substrate and a solvent, on the condition that the reaction steps are omitted, high yield of temozolomide can still be maintained. By screening various reaction conditions, the method achieves synthesis of temozolomide by one-pot boiling, and not only is production cost reduced, but also the industrialized mass production method is provided for production of temozolomide. Simultaneously, the improved refining method of temozolomide is adopted, recrystallization operation of temozolomide is effectively simplified, the recrystallization yield is remarkably improved, operation time for recrystallization is effectively shortened, and accordingly the whole production cycle is remarkably shortened.

Owner:凯默斯医药科技上海有限公司

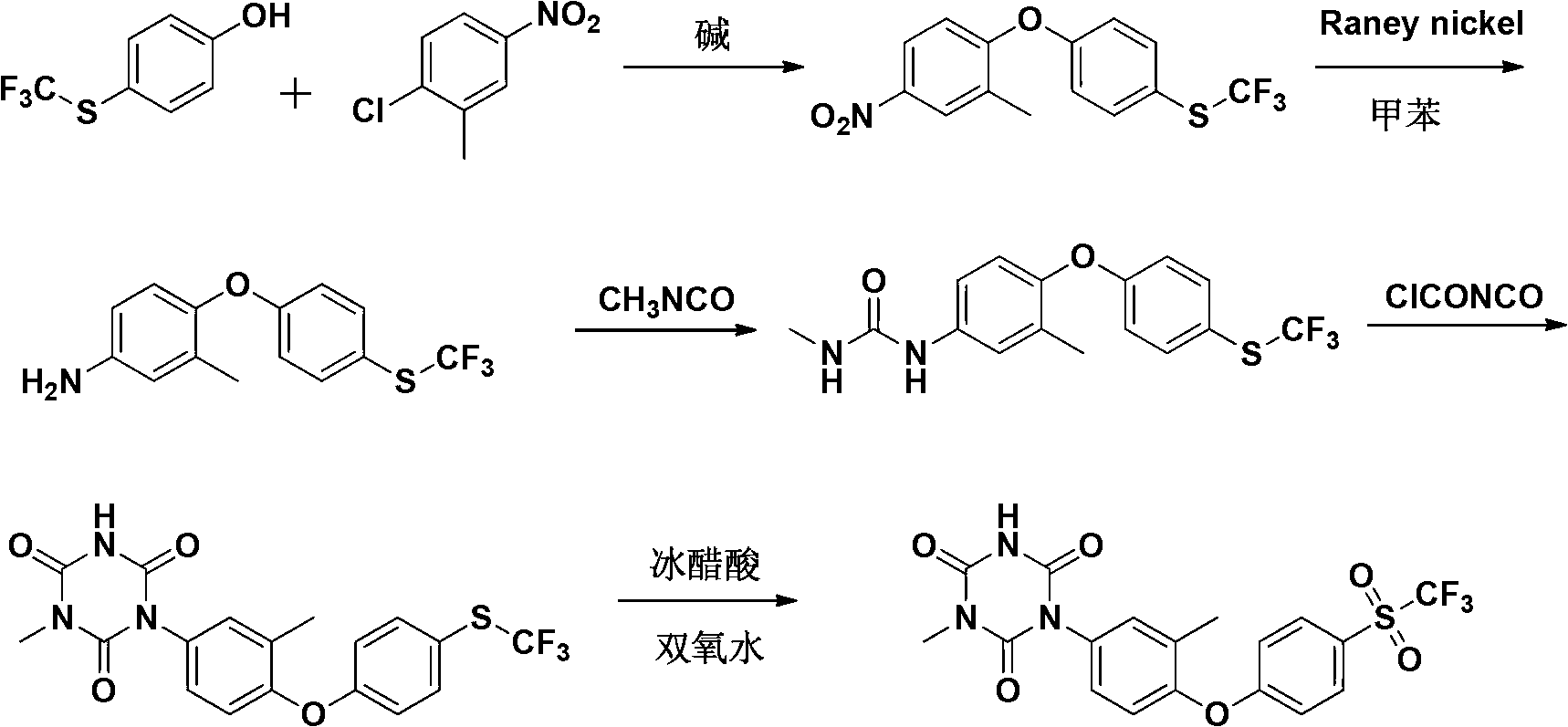

Preparation method of ponazuril

InactiveCN102936227AOperational securityRaw materials are easy to getOrganic chemistryCoccidiosisNitrobenzene

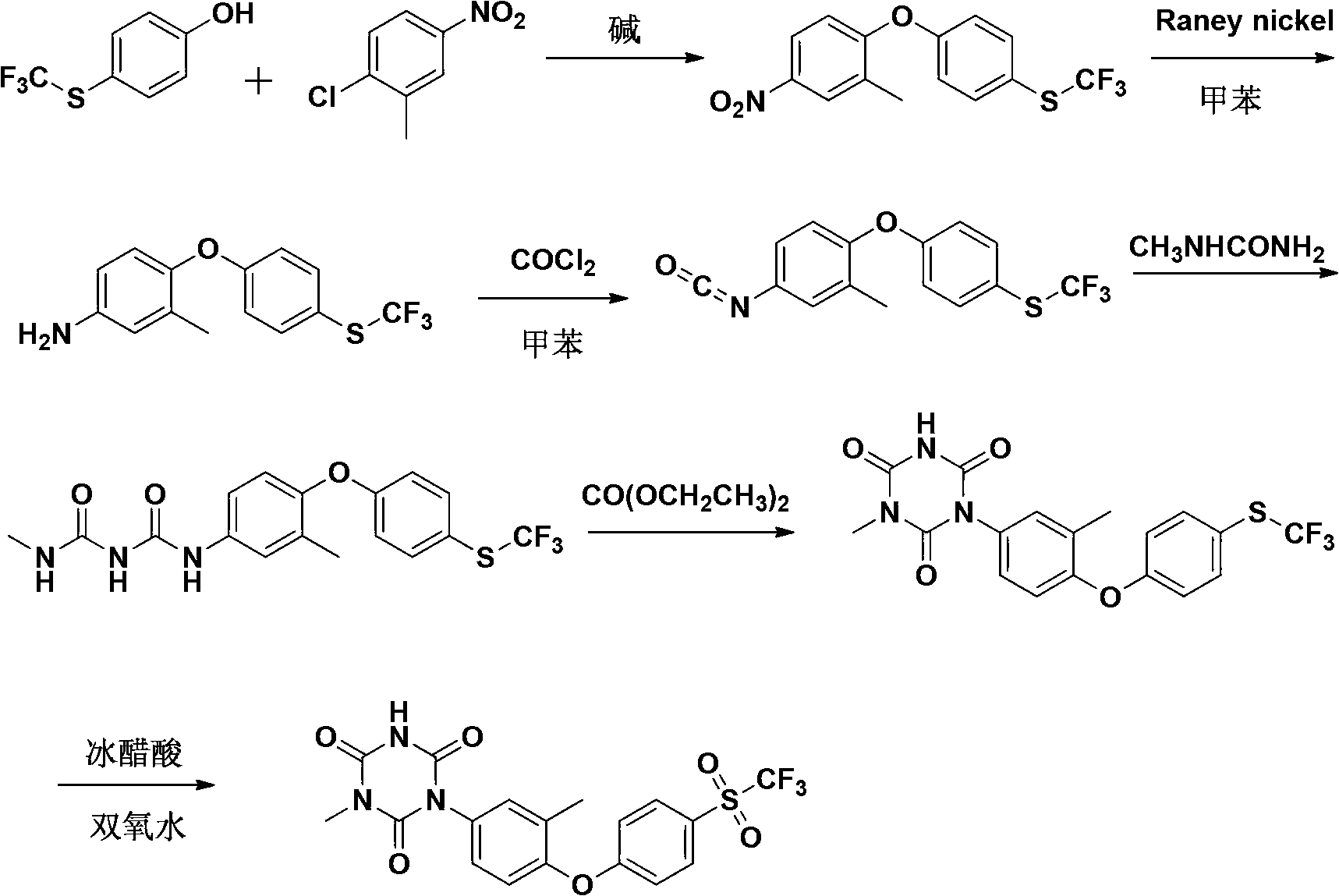

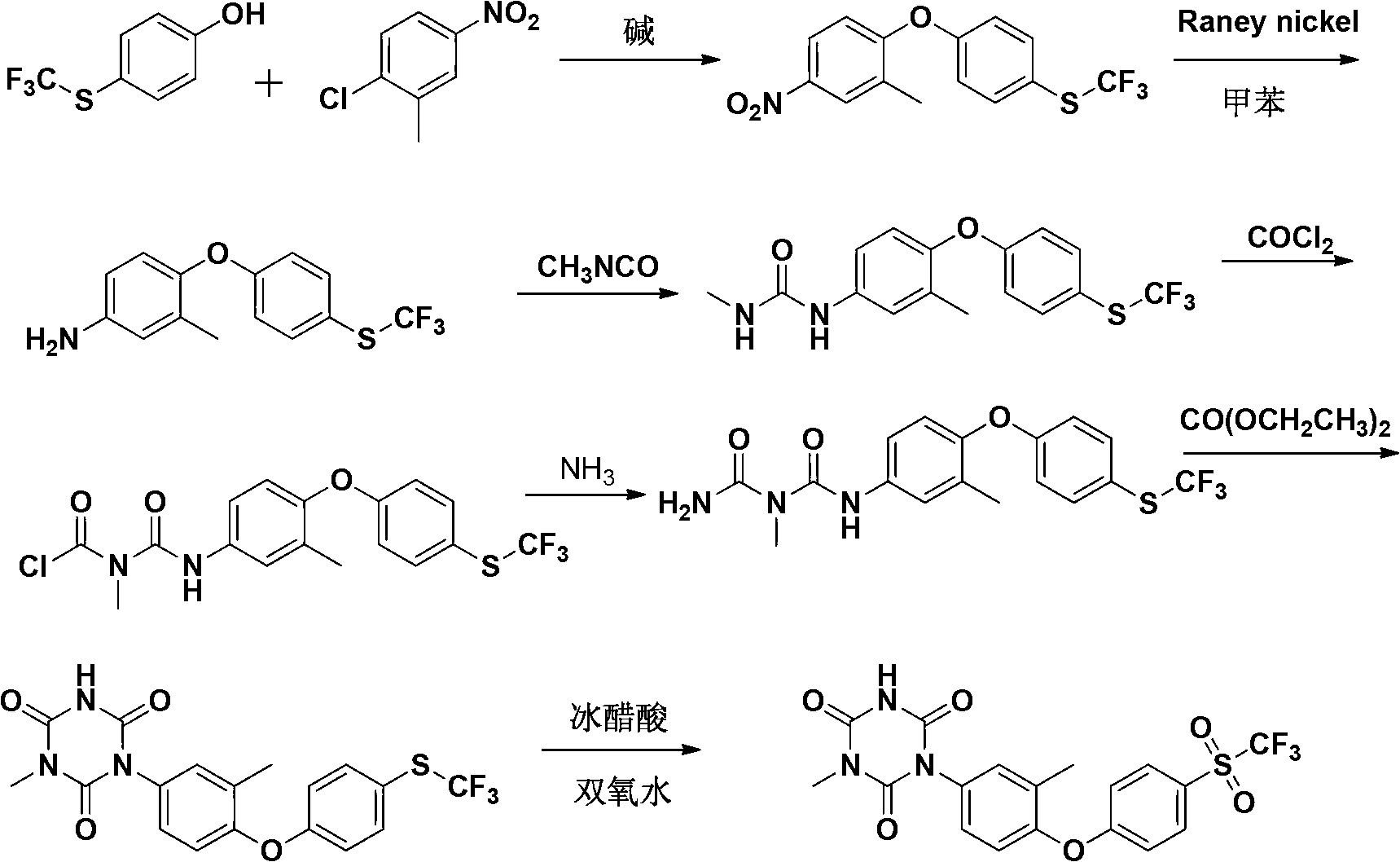

The invention relates to a preparation method of ponazuril which is an anti-coccidiosis drug. The method includes syntheses of 3-methyl-4-(4-phenoxy trifluoromethyl sulfide)-nitrobenzene, 3-methyl-4-(4-phenoxy trifluoromethyl sulfide)-aniline, 3-methyl-4-(4-phenoxy trifluoromethyl sulfide)-phenyl isocyanate, 1-[3-methyl-4-(4-phenoxy trifluoromethyl sulfide)-m-methylphenyl]-1,3,5-triazine-2,4,6-trione and ponazuril. Dangerous articles such as raney nickel, methyl isocyanate, chloroformylisocyanate, phosgene, triphosgene and hydrazine hydrate are not used during the reaction processes, and the operation is safe and reliable; raw materials are easy to obtain, the production cost and pollution are low, and the production process is environment-friendly; and the preparation method is simple, special equipment is not needed, a total yield of ponazuril product can reach above 60%, and large-scaleindustrial production is facilitated.

Owner:QILU ANIMAL HEALTH PROD +1

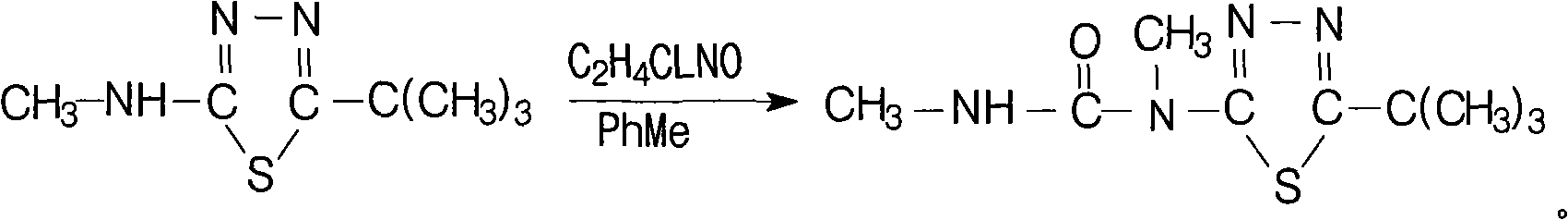

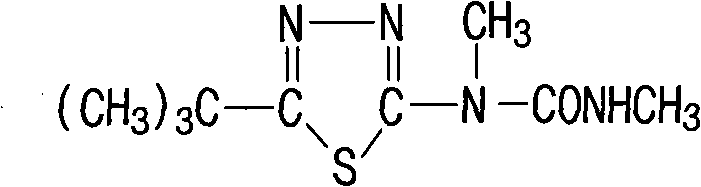

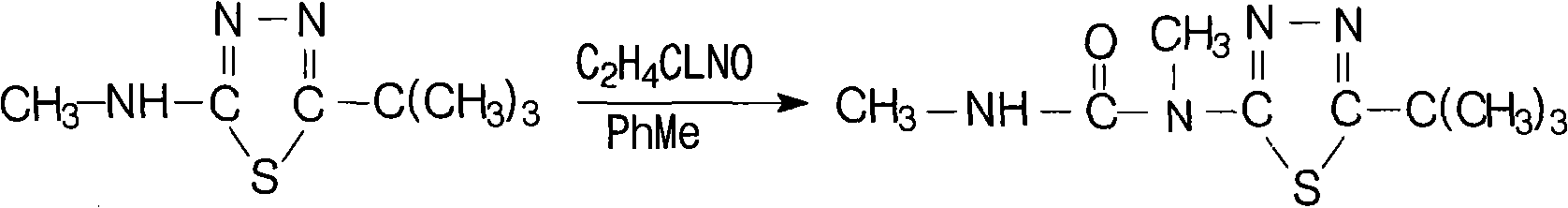

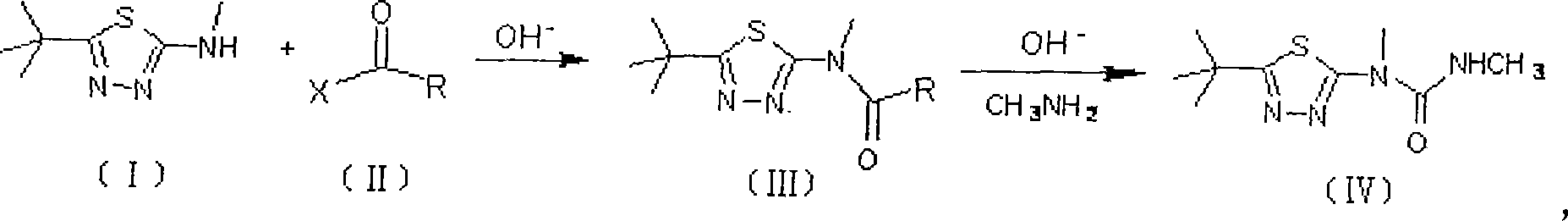

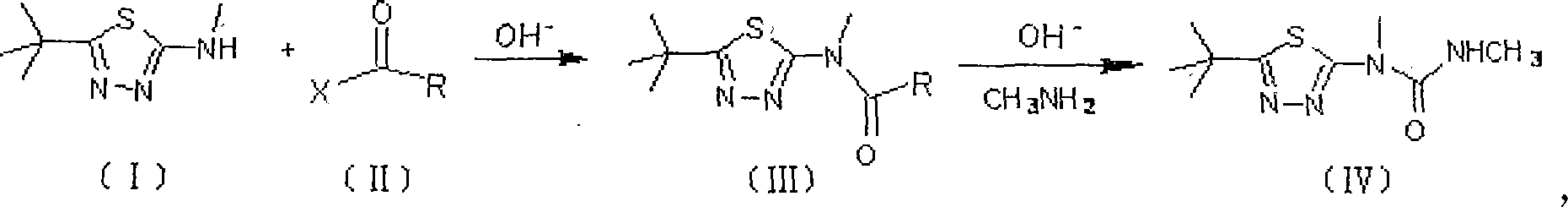

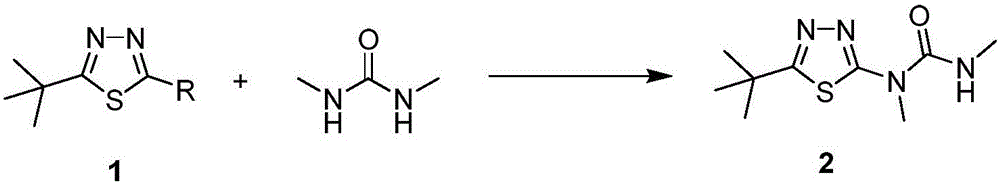

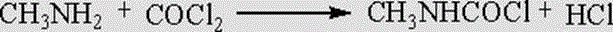

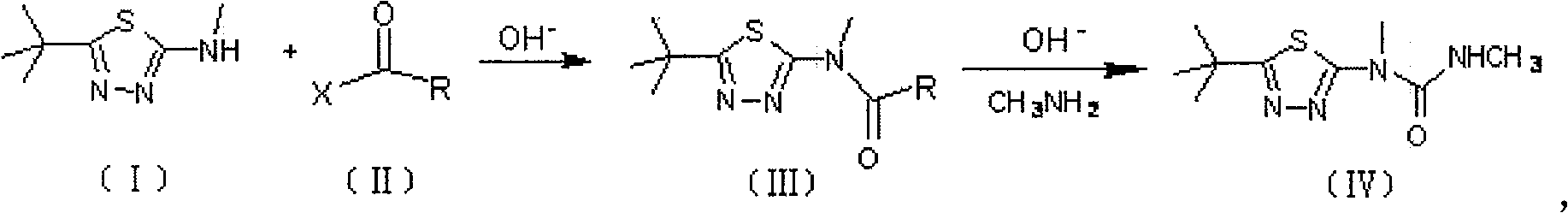

Method for synthesizing tebuthiuron technical

The invention relates to a method for synthesizing tebuthiuron technical. The method adopts methylaminoformyl chloride and 5-tert-butyl-2-methylamino-1,3,4 thiadiazole to directly react to generate the tebuthiuron with the reaction formula as the above. The new method avoids using inflammable and explosive dangerous chemical methyl isocyanate with great toxicity, and is safer for production. The method reduces the requirement on equipment materials, and reduces equipment investment.

Owner:YIFAN AGRI CHEM PLANT ZHEJIANG PROV

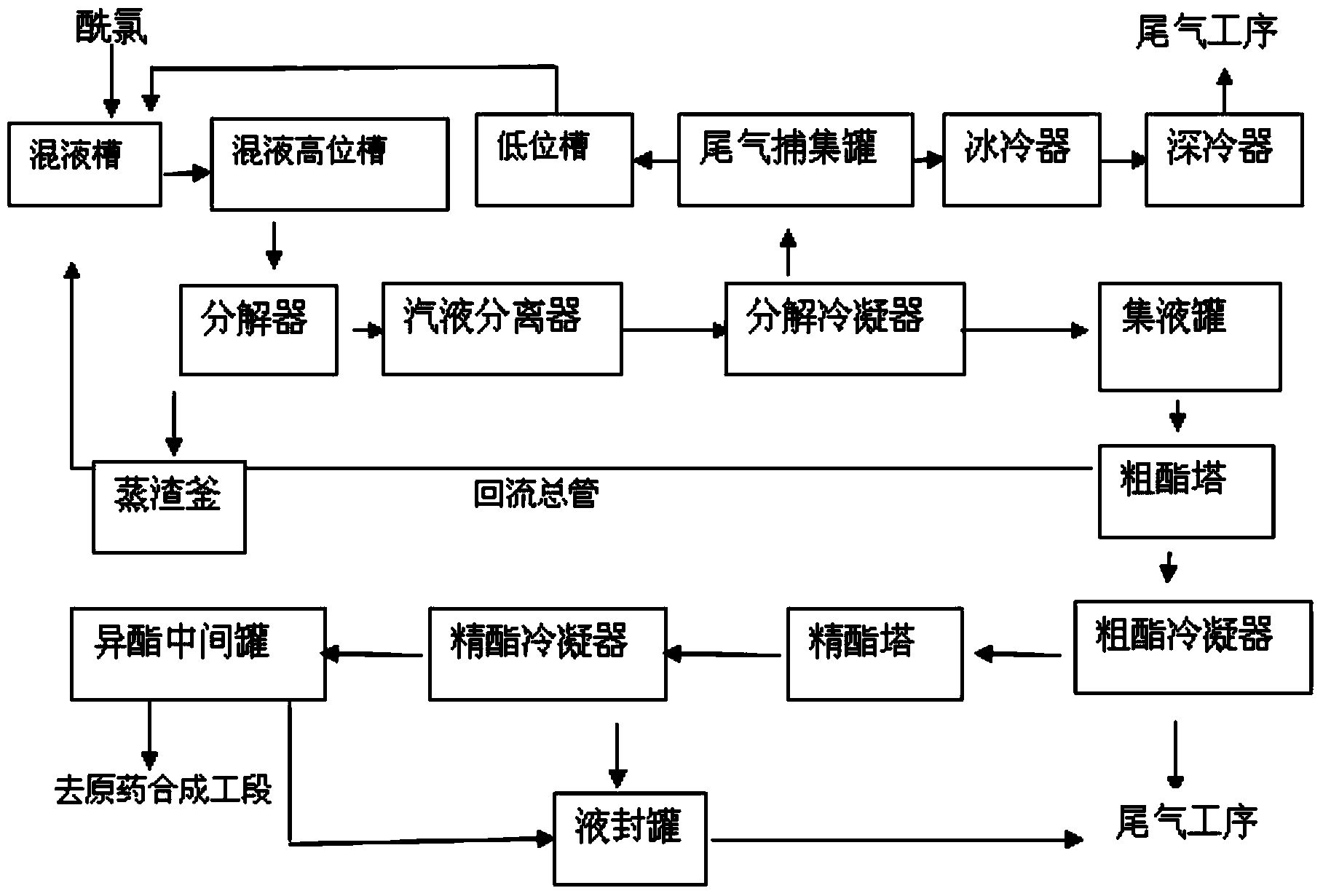

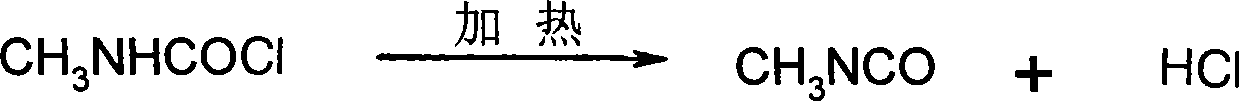

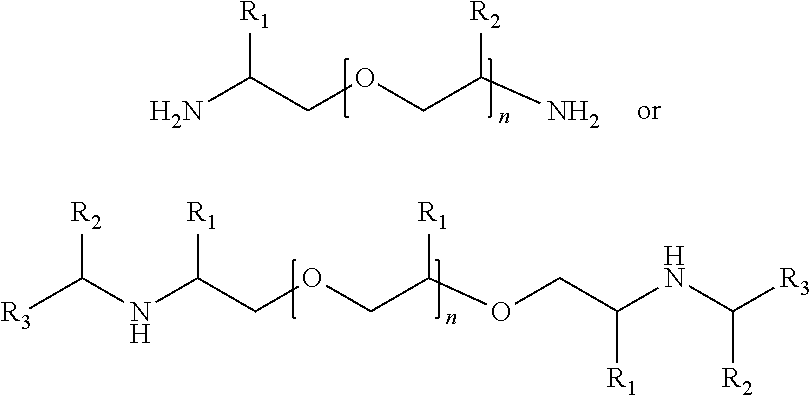

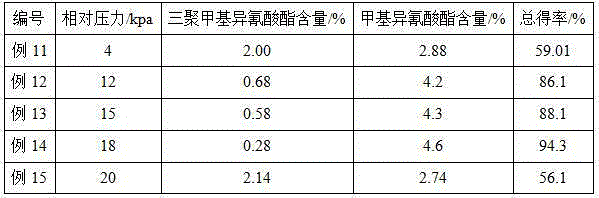

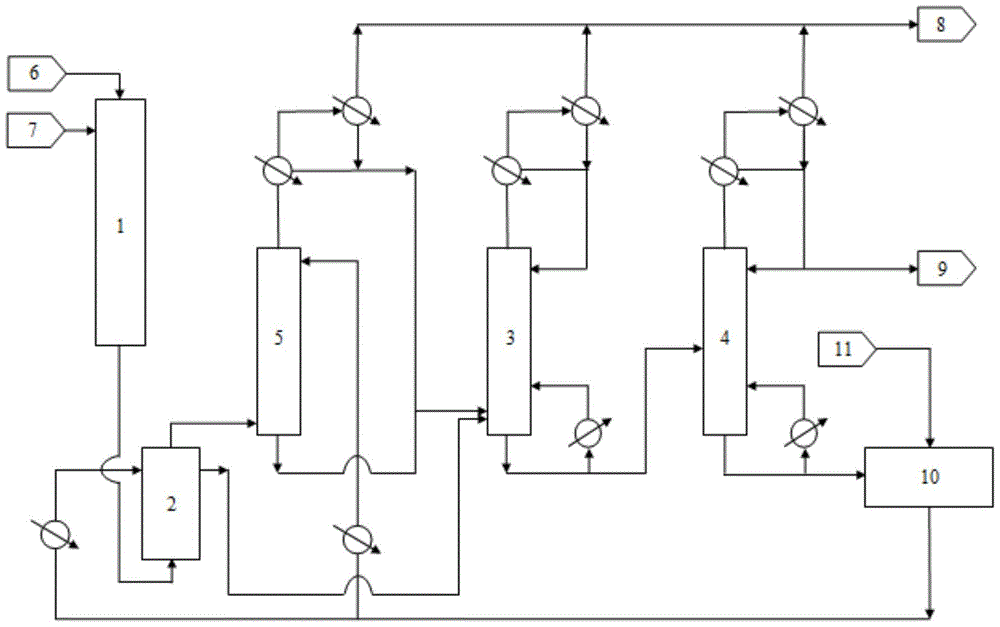

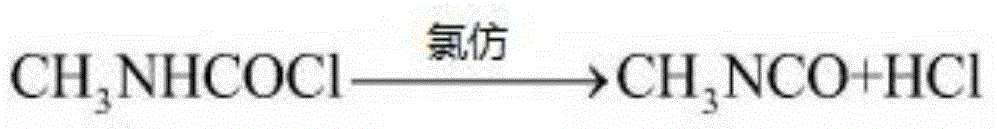

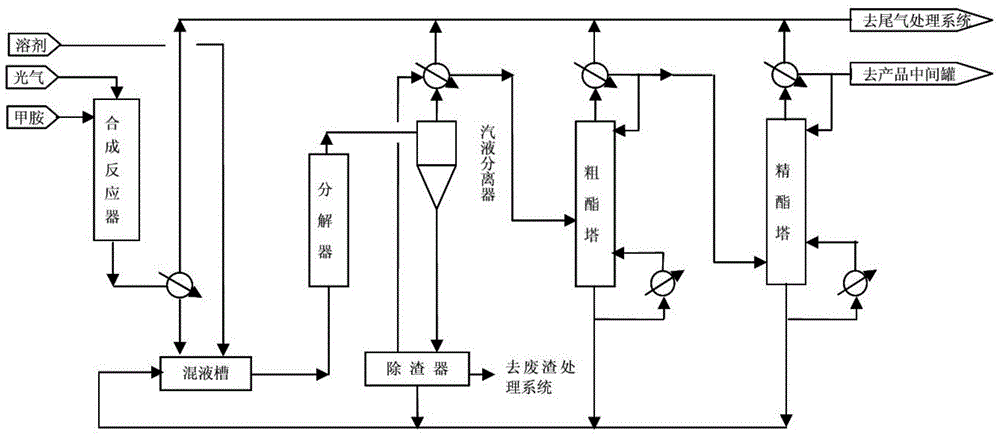

Production method and equipment of methyl isocyanate

InactiveCN103694190AAvoid downtimeEnsure continuous productionIsocyanic acid derivatives purification/separationPreparation from carbamatesChlorideMethyl isocyanate

The invention discloses a production method of methyl isocyanate. The method comprises the following steps: producing CO from CO2, O2 and coke, producing phosgene from CO and chlorine gas, synthesizing methylaminoformyl chloride from the phosgene and the monomethylamine, decomposing and purifying to prepare the methyl isocyanate. The invention further discloses production equipment of methyl isocyanate. According to the production method and equipment, the energy consumption can be effectively reduced, byproducts are reduced, the production cost is lowered, the product yield is increased, the labor intensity of workers is reduced, the production field environment is improved, the reaction safety is further enhanced, and the three-waste emission is reduced.

Owner:荆州沙隆达控股有限公司

Heat-resistant stretch-resistant modified polyurethane rubber cable material

InactiveCN105602178AExcellent heat resistance and tensile propertiesPlastic/resin/waxes insulatorsSodium BentoniteAluminum silicate

The invention discloses a heat-resistant stretch-resistant modified polyurethane rubber cable material. The cable material is prepared from the following raw materials: modified polyurethane, neoprene, ethylene propylene rubber, carboxyl-terminated nitrile rubber, ethylene propylene diene monomer, epoxy resin, ethyl acetate, poly(tetrahydrofuran) glycol, trimethylolpropane, polypropylene, ethylene glycol, tertiary amine, 1,4-methyl isocyanate cyclohexane, fumed silica, aluminum silicate, stearic acid, molybdenum disulfide, quartz powder, bentonite, zinc oxide, sulfur, magnesium oxide, a plasticizer, a stabilizing agent and an anti-aging agent. The modified polyurethane rubber cable material has excellent heat resistance and stretch resistance.

Owner:ANHUI DUJIANG CABLE GROUP

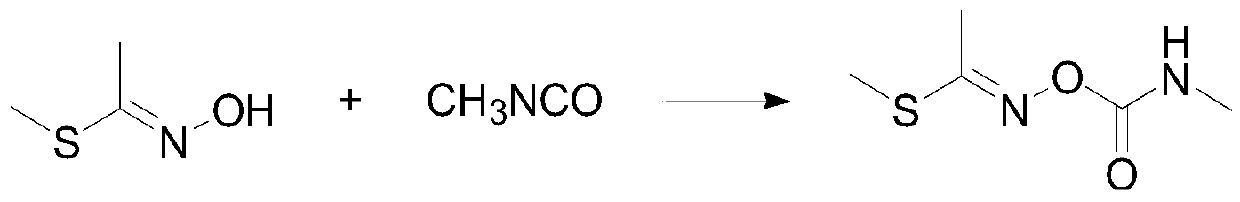

Method for preparing pesticide methomyl

InactiveCN103524389AReduce generationEmission reductionOrganic chemistrySolubilityReaction temperature

The invention discloses a method for preparing pesticide methomyl. The method comprises the following steps: pulping methylthio acetaldehyde oxi me with water, dripping methyl isocyanate into the pulped methylthio acetaldehyde oxi me solution for reaction according to a mass ratio of the methylthio acetaldehyde oxi me to the methyl isocyanate being 1:(1.0-1.3), controlling the reaction temperature to be 5-15 DEG C and reacting time to be 1.5-3 hours; filtering through micropores, cooling, crystallizing, re-filtering, and drying. The method is convenient to operate, safe and controllable in production, can reduce the generation of side products, improves the yield and the quality, reduces the energy consumption and the production cost, improves the production field environment, further improves the solubility and the safety of the reaction, and reduces the emission of 'the Three Wastes'.

Owner:荆州沙隆达控股有限公司

New method for separating and recycling methyl isocyanate-decomposed tail gas

ActiveCN101780365AAvoid pollutionReduce energy consumptionChlorine/hydrogen-chloride purificationUsing liquid separation agentProduct gasMethyl isocyanate

The invention relates to a new method for separating and recycling methyl isocyanate-decomposed tail gas, which solves the problems of the cyclic utilization of HCl and CHCl3 resources and the environmental pollution. The method comprises the following steps that: (1) the methyl isocyanate-decomposed tail gas is in cyclic contact with water scrubbing liquid through a water scrubbing tower, most of HCl gas in the tail gas is absorbed by the water scrubbing liquid, and one part of CHCl3 gas is condensed by the water scrubbing liquid until the HCl weight content in the water scrubbing liquid meet the requirements; (2) after the step (1), gas which is not absorbed by the water scrubbing liquid passes through a primary condensation and a secondary condensation to condense the CHCl3 gas, and residual gas is treated by a destroying tower and is then discharged to the upper air; and (3) finally, the water scrubbing liquid containing the HCl gas is enabled to stand to stratify, a lower layer of organic phase is pumped into a CHCl3 solvent recovery tank, and an upper layer of water phase is pumped into a hydrochloric acid tank. The overall separating and recycling process has the advantages of low energy consumption, high separation rate and high yield, removes the pollution to the environment by the tail gas, and realizes the cyclic utilization of the HCl and CHCl3 resources, thereby achieving the purpose of energy saving and emission reduction.

Owner:HUNAN GOFAR FINE CHEM IND TECH CO LDT

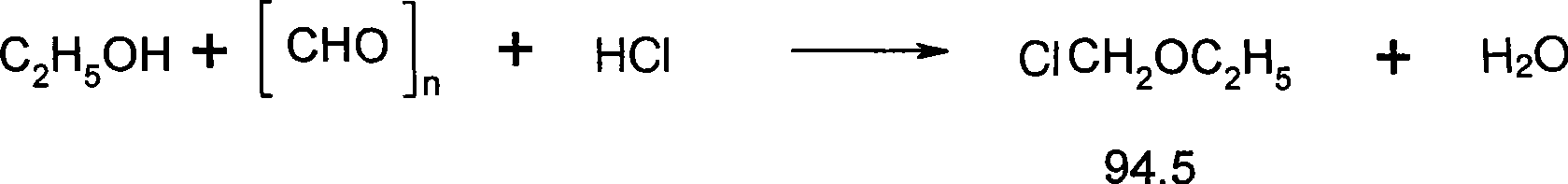

Production method of chloromethyl ethyl ether

ActiveCN101372448APromote depolymerizationLow costEther preparationChlorine dioxideReaction temperature

The invention relates to a method for producing chloromethyl ethyl ether. The chloromethyl ethyl ether with high yield and high purity is made by adding a by-product chlorine hydride generated by production of methyl isocyanate to a mixture of ethanol and paraformaldehyde while stirring for reaction at the temperature of 0-50 DEG C, wherein, the mass ratio of the paraformaldehyde to the ethanol is 1-2:1. In the process of producing the chloromethyl ethyl ether by the method, as the by-product chlorine hydride generated by production of the methyl isocyanate is used, the waste gas from the methyl isocyanate is utilized, which improves environment and lowers cost; in the method for producing the chloromethyl ethyl ether, a little amount of impurities such as the methyl isocyanate, and the like, contained in the chlorine hydride facilitate the reaction and improve the reaction yield.

Owner:JIANGSU CHANGLONG AGROCHEM CO LTD

Method for preparing terbufos benzthiazuron

ActiveCN101157665AEfficient use ofAvoid potential dangerBiocideOrganic chemistryBenzthiazuronToxic material

Owner:LIER CHEM CO LTD

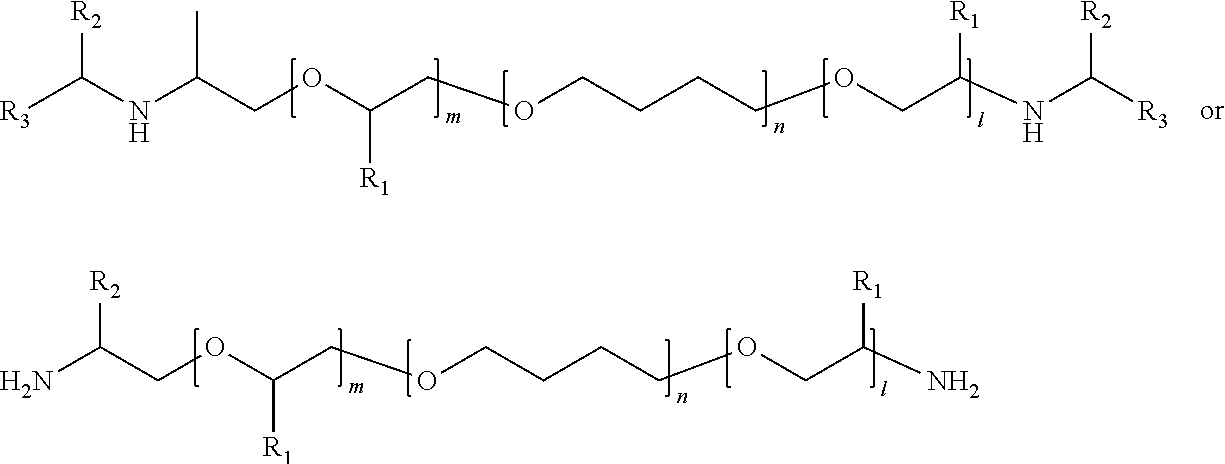

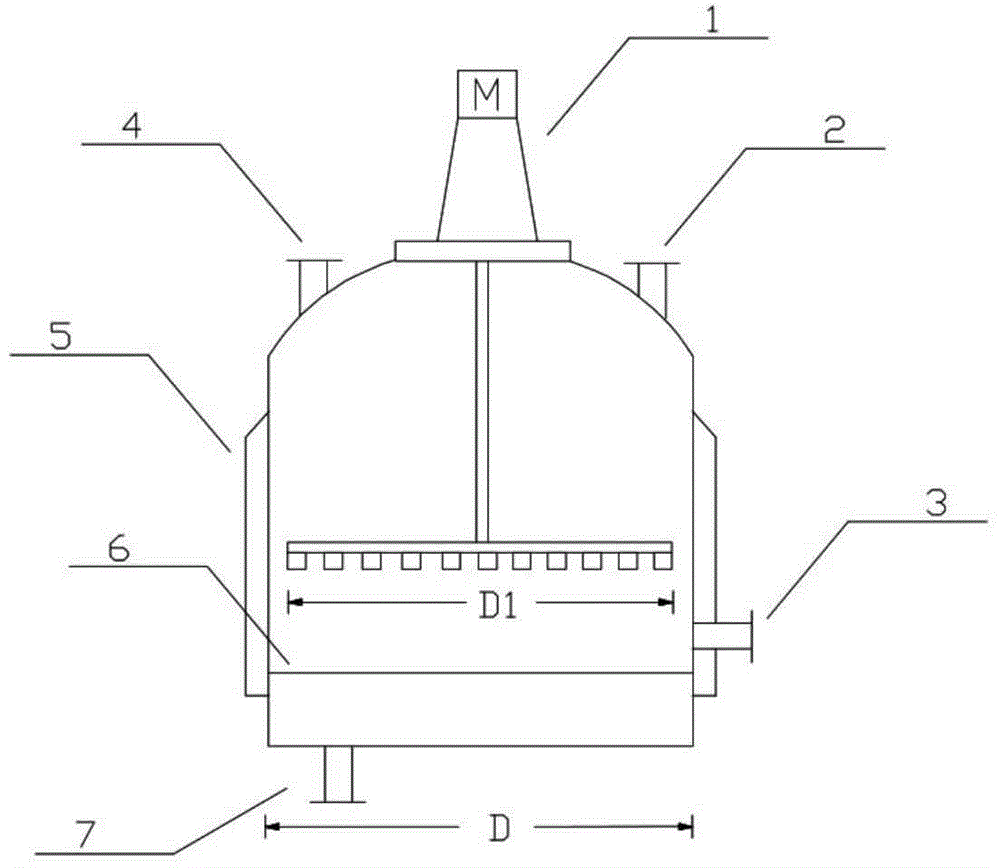

Polyurethane compositions having improved impact resistance and optical properties

A thermoset polyurethane composition having excellent impact and optical properties is prepared from a formulation comprising at least a prepolymer and a chain extender. The prepolymer includes an isocyanate component, containing 1,3-bis(isocyanatomethyl)cyclohexane and at least (20) percent by weight of 1,4-bis(isocyanatomethyl)cyclohexane, and an isocyanate-reactive component, containing hydroxyl, amine or thiol functionality. The isocyanate-reactive component includes from (70) to (95) percent by weight of a compound having a molecular weight from 150 to less than 950 Daltons, and from (5) to (30) percent by weight of a compound having a molecular weight from 2,000 to 4,500 Daltons. The chain extender is an aromatic, aliphatic, or cycloaliphatic polyamine compound containing at least one hydroxyl and / or thiol group. Articles that may be prepared include ophthalmic lenses, vehicle glazings, aircraft canopies, and the like.

Owner:DOW GLOBAL TECH LLC

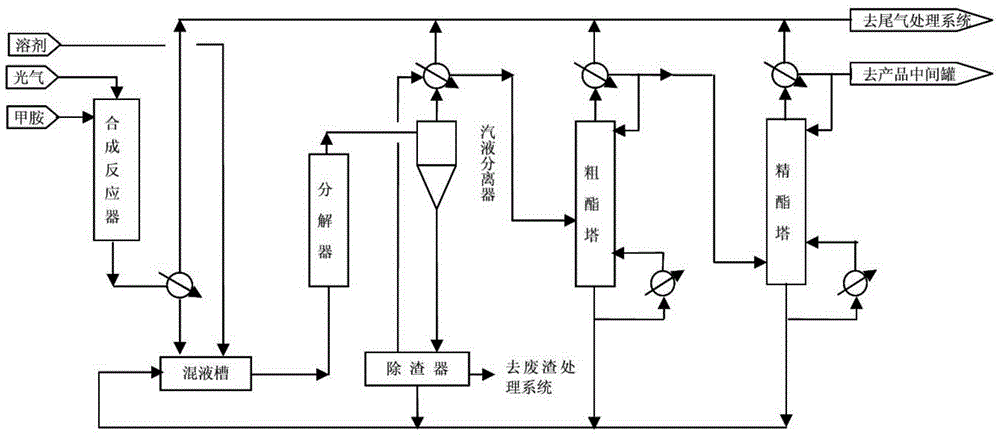

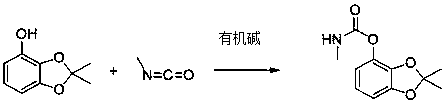

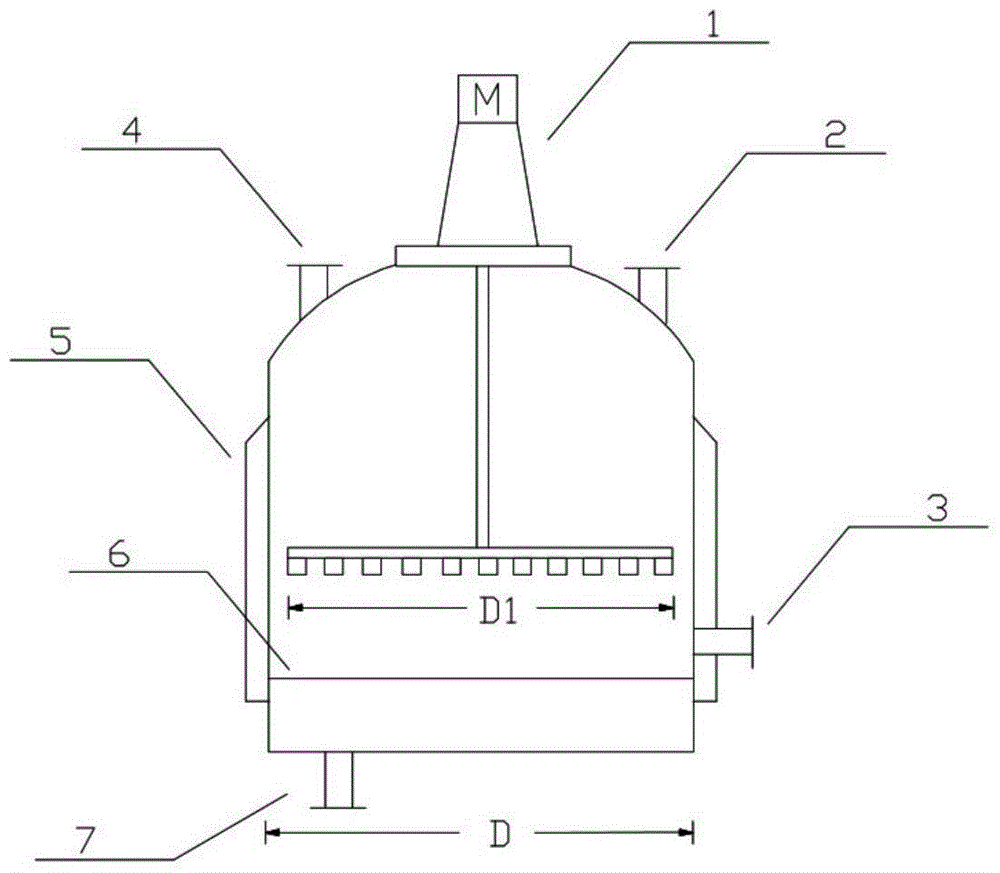

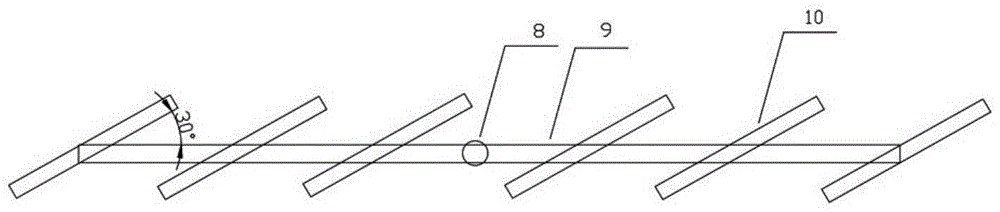

Deslagging method for continuous production of methyl isocyanate

ActiveCN104557613AAvoid direct contactReduce labor intensityOrganic compound preparationIsocyanic acid derivatives purification/separationSlagGas phase

The invention discloses a deslagging method for continuous production of methyl isocyanate. The method comprises the following steps: installing a deslagging machine below an air and liquid separator; performing air and liquid separation on a methyl isocyanate solution obtained by reaction by using the air and liquid separator; condensing a gas phase component and then rectifying and purifying to obtain a methyl isocyanate product; putting a liquid phase component in the deslagging machine and automatically removing tripolymethyl isocyanate solid slags; and returning the rest unreacted methyl carbamyl chloride, a trichloromethane solvent and a small amount of the methyl isocyanate product to a liquid mixing tank from the outlet of the deslagging machine and further reacting. The method disclosed by the invention can be used for automatically removing solid slags generated in the continuous production of the methyl isocyanate, realizing integration of deslagging and dry-recycle by adopting the deslagging machine, completely preventing direct contact between toxic materials and a person, reducing the labor strength, reducing toxication accidents, effectively evaporating residual volatile components such as raw materials, products and solvents in the solid slags and increasing the total yield of the products and the recycle rate of the solvents.

Owner:海利贵溪新材料科技有限公司

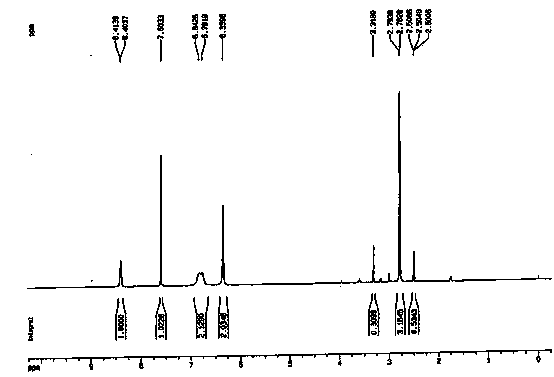

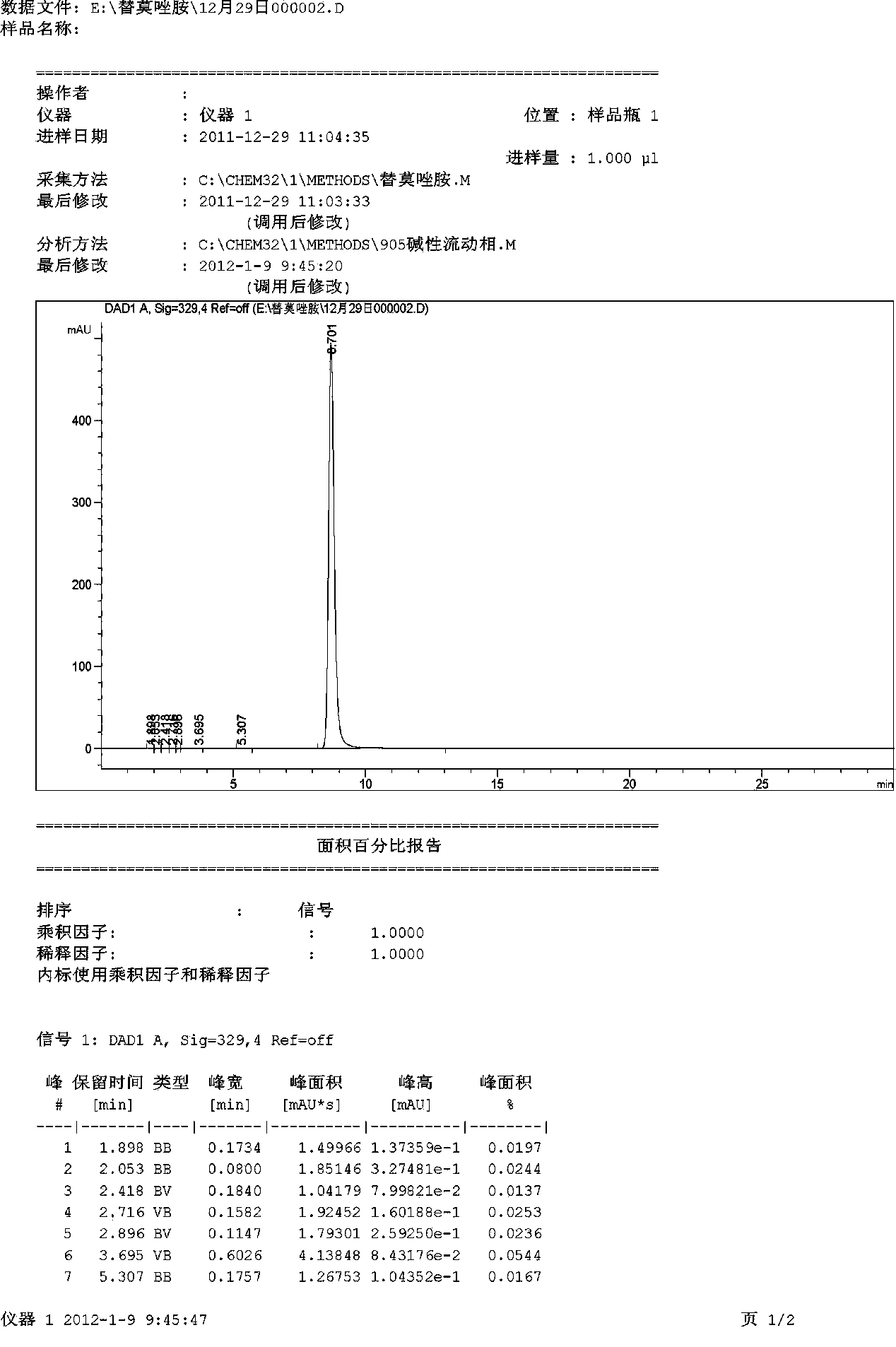

Synthetic method for temozolomide and intermediate

The invention discloses a modified optimized synthetic method for temozolomide and an intermediate thereof. The synthetic method is characterized in that a new oxidation ring-closing reagent is introduced for a reaction with lithium chloride and sodium nitrite in an aqueous solution, and the synthetic method helps to improve the yield of the reaction, increase the controllability on the reaction and avoid usage of methyl isocyanate with relatively high toxicity.

Owner:SINOPHARM A THINK PHARMA

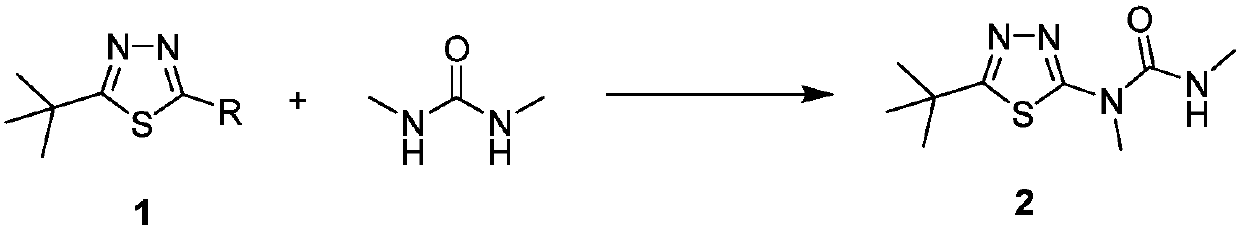

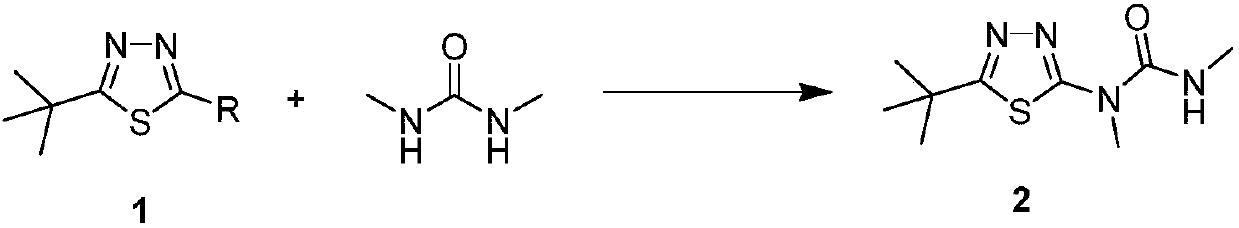

Tebuthiuron synthesis method

The invention provides a tebuthiuron synthesis method. Tebuthiuron is obtained by reaction between 1,3-dimethylurea and 5-tert-butyl-1,3,4-thiadiazole derivatives under the alkaline condition. The tebuthiuron synthesis method solves the problems of safety risks caused by use of extremely toxic substances such as methyl isocyanate and N-methyl formylchloride, presence of phosgene or the like, difficulty in production operation in traditional methods.

Owner:JIANGSU CHANGLONG AGROCHEM CO LTD

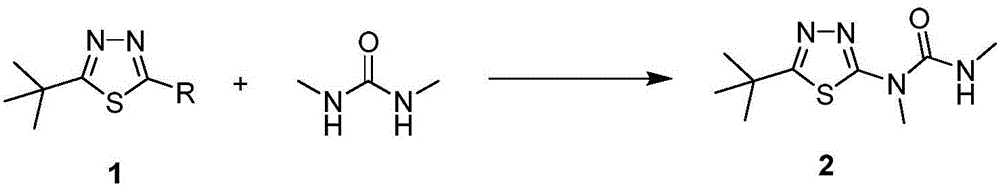

Process for producing high yield methyl isocyanate

ActiveCN105418459AInhibition of self-aggregationReduce spawn ratePreparation from carbamatesProcess engineeringMethylamines

The invention discloses a process for producing high yield methyl isocyanate. Trimerization methyl isocyanate is effectively reduced by adding a polymerization inhibitor to methyl isocyanate which is produced when a methylamine formyl chloride solution is heated in a decomposer and decomposed. The process for producing the high yield methyl isocyanate is simple in process operation, reduces nearly 60% production rate of terpolyesters, and reduces production cost. The process for producing the high yield methyl isocyanate can prevent a process pipeline from being plugged simultaneously, is excellent in production fluency, reduces labor strength of solid waste, improves work environment, is friendly in natural environment, reduces solid waste, and reduces production cost by about 3%.

Owner:海利贵溪新材料科技有限公司

Method for increasing yield of produced methomyl

The invention provides a method for increasing yield of produced methomyl. The method comprises the steps of reacting by virtue of methomyl oxime and methyl isocyanate to prepare a methomyl water solution; after the reaction is finished and the temperature of the methomyl water solution is controlled to 5-10 DEG C, adding NaCl to separate methomyl, and filtering, so as to obtain solid methomyl. According to the method, methomyl in the water solution is seperated by virtue of a salting-out method, so that the yield of methomyl is increased, furthermore, the emission load of pollutants in wastewater is reduced, and the environment is protected. The method is easy, the cost is low; furthermore, an obtained methomyl product is high in purity, good in quality and has very high practicability.

Owner:安道麦股份有限公司

Waterborne polyurethane elastomer

InactiveCN108409915AImprove mechanical propertiesMolecular-sieve and base-exchange compoundsMolecular-sieve compoundsTripropylene glycolMolecular sieve

The invention discloses a waterborne polyurethane elastomer. The waterborne polyurethane elastomer comprises, by weight, 20 parts of ethylene glycol, 10 parts of tripropylene glycol, 5 parts of 2-n-amylpropane-1,3-diol, 30 parts of isocyanate, 2 parts of 1,1-dimethyl-silanol 1-acetate, 5 parts of methyl isocyanate, 5 parts of propylene isocyanate, 3 parts of methyl 2,3-diethyl-1-( trimethyl silicyl)-2-cyclopropene-1-carboxylic ester, 30 parts of acrylate, 5 parts of modified molecular sieve, 5 parts of hydrophilic chain extender, 5 parts of enhancer, 2 parts of defoaming agent and 2 parts of leveling agent. By the arrangement, the mechanical performance of the whole waterborne polyurethane elastomer can be kept in a good state under a large day and night temperature difference.

Owner:郑细玉

Preparation method of methyl isocyanate

ActiveCN104387295AImprove one-way yieldEfficient separationOrganic compound preparationIsocyanic acid derivatives purification/separationOrganic solventChloride

The invention provides a preparation method of methyl isocyanate. A reaction product synthesized at the high temperature is directly fed into a first organic solvent for treatment at the temperature of 200-300 DEG C, effective separation of the methyl isocyanate and hydrogen chloride is realized, the fact that the methyl isocyanate reacts with the hydrogen chloride to produce methyl carbamyl chloride is avoided, the once-through yield of the methyl isocyanate is increased, repeated heating and condensation are not required, energy consumption and production of by-products are reduced, meanwhile, multiple decomposition reactors are not required and the number of condensers is decreased in the aspect of devices, and the investment cost and the production cost are greatly reduced.

Owner:HUNAN HAILI HIGH TECH IND GRP

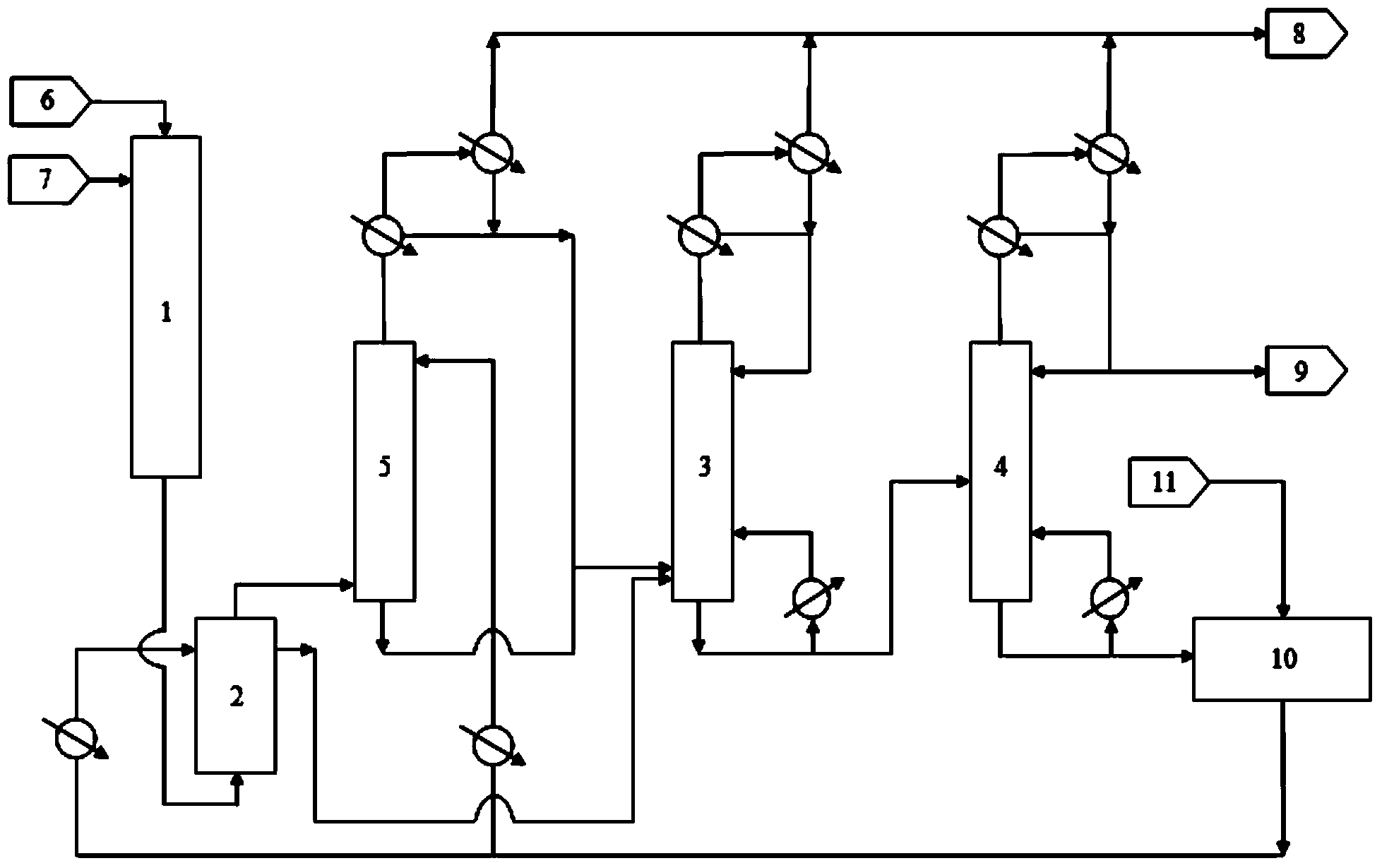

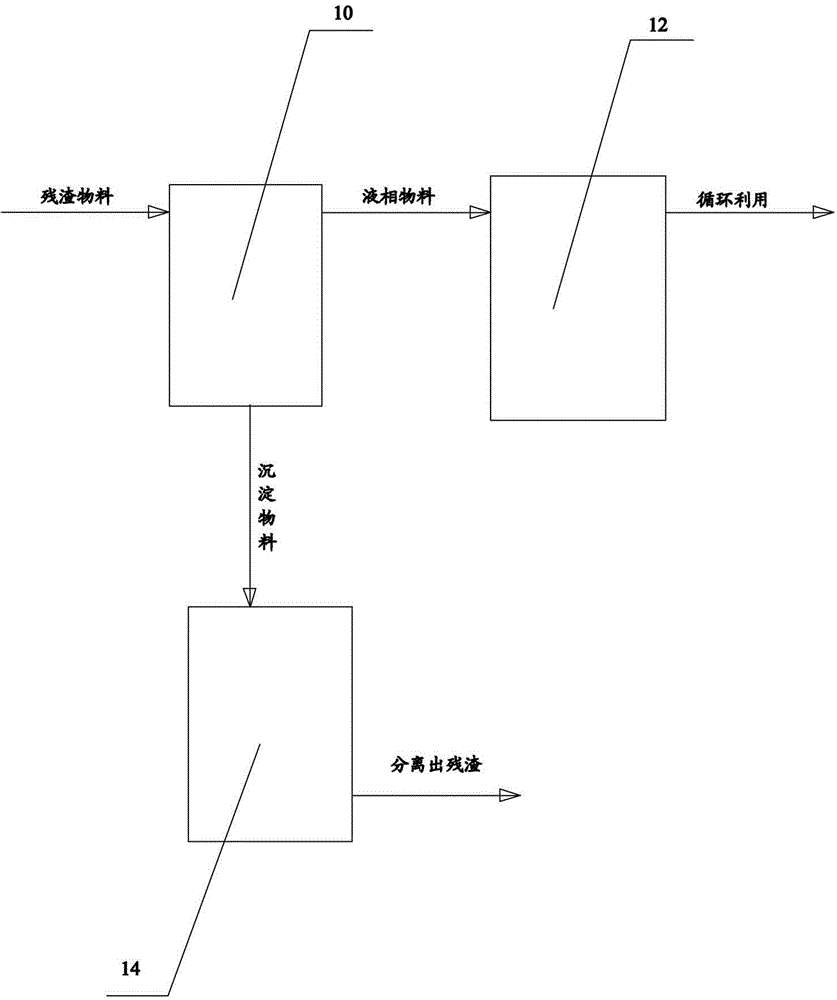

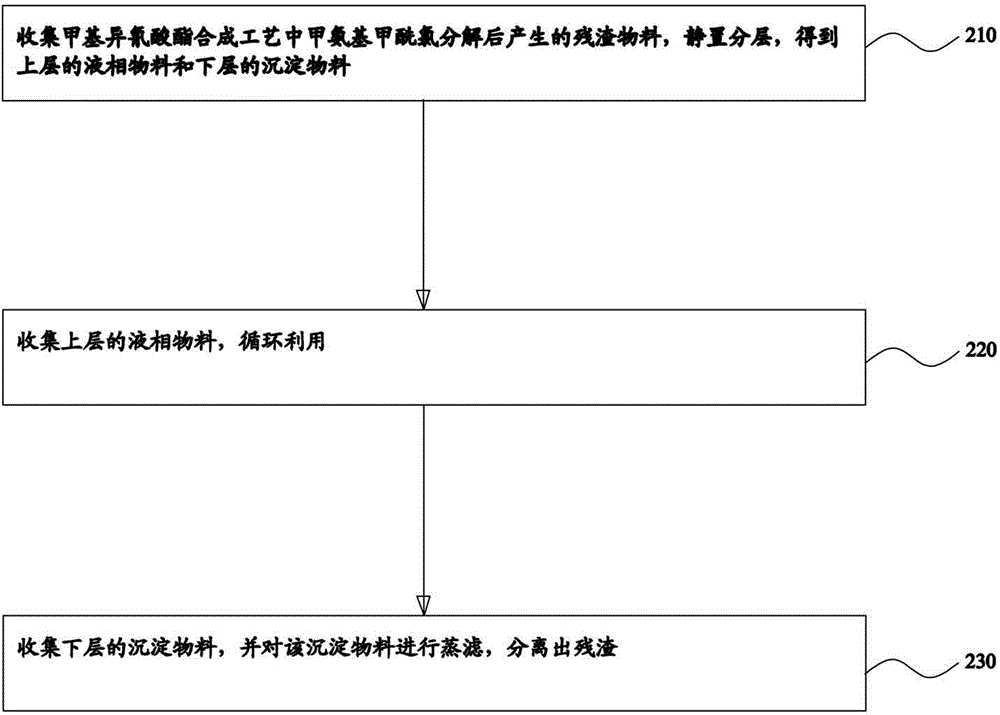

Treatment system and treatment method of residues in methyl isocyanate synthetic process

InactiveCN104447410AEfficient separationAddress effectivenessIsocyanic acid derivatives purification/separationDecompositionChloride

The invention provides a treatment system of residues in a methyl isocyanate synthetic process. The treatment system comprises a residue isolation tank, a blending groove and a residue steaming tank, wherein the residue isolation tank is used for collecting a residue material generated after decomposition of methylaminoformyl chloride in the methyl isocyanate synthetic process, standing and layering to obtain a liquid-phase material on the upper layer and a sediment material on the lower layer; the blending groove is connected with the top of the residue isolation tank and is used for collecting the liquid-phase material on the upper layer for cyclic utilization; the residue steaming tank is connected with the bottom of the residue isolation tank, and is used for collecting the sediment material on the lower layer as well as steaming and filtering the sediment material to separate the residues. The invention further provides a treatment method of the residues in the methyl isocyanate synthetic process. According to the system and the method, the generated residues can be separated effectively, and the liquid-phase material can be continuously and cyclically utilized, so that the problem that the residues in the methyl isocyanate synthetic process are difficult to effectively clear in time, and the production efficiency is improved.

Owner:HUNAN GOFAR FINE CHEM IND TECH CO LDT

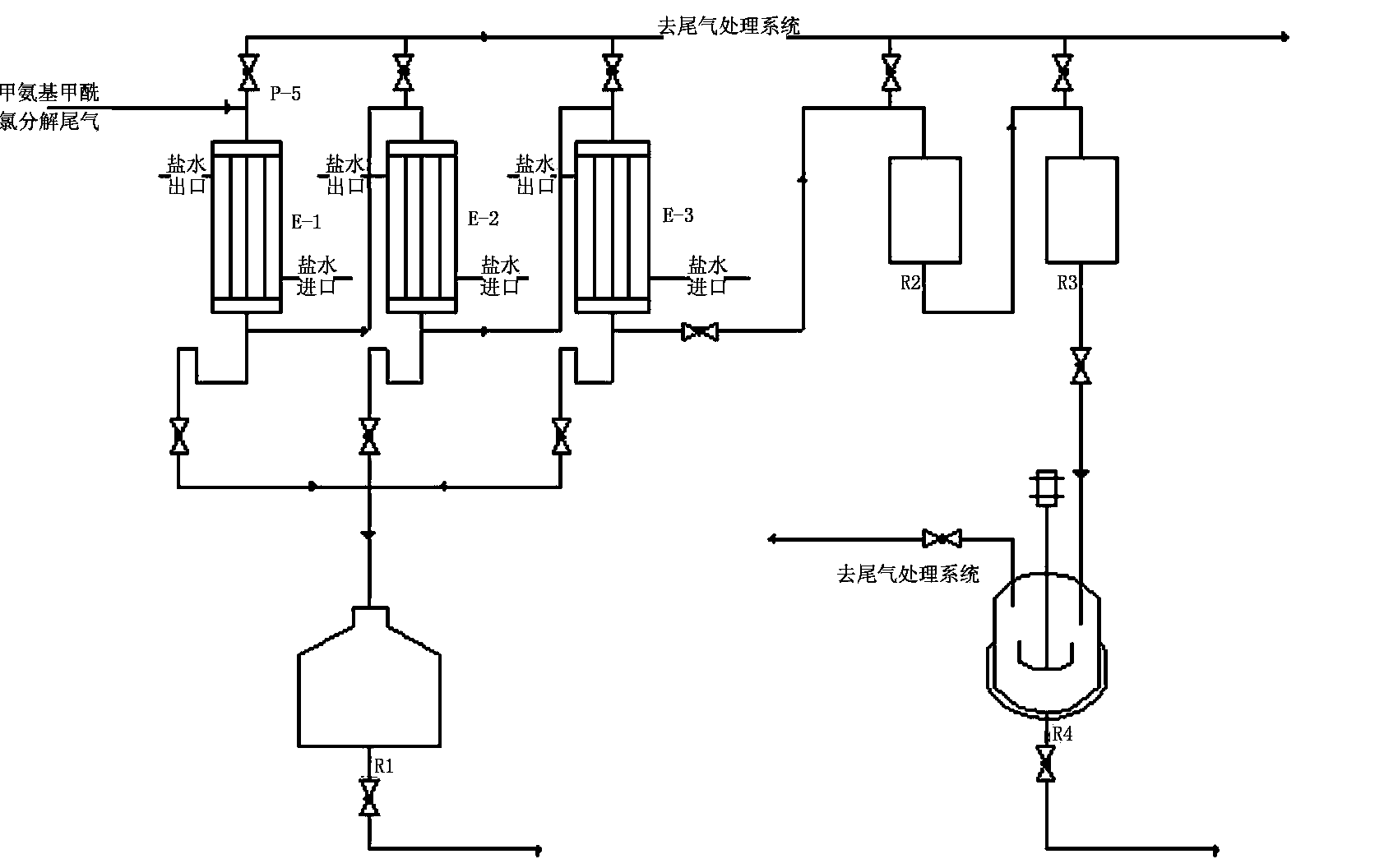

Application method of methylamino formyl chloride decomposition tail gas hydrogen chloride in cartap synthesis

ActiveCN103848768AFew preparation stepsIncrease added valueIsocyanic acid derivatives purification/separationCyanidePhysical chemistry

The invention relates to an application method of a methylamino formyl chloride decomposition tail gas hydrogen chloride in cartap synthesis. After a tail gas mixture of hydrogen chloride, trichloromethane and methyl isocyanate produced by decomposing methylamino formyl chloride is condensed by a condenser, the condensed condensate is transferred into a methylamino formyl chloride mixing slot, and then enters a circulating system of methyl isocyanate production for being collected and recycled; uncondensed gas hydrogen chloride is directly added into thiocyanide liquor of cartap synthesis after pressure is stabilized by a secondary buffer tank, so that the cartap is synthesized by catalytic hydrolysis. According to the invention, tertiary step cooling and condensing is adopted to separate a hydrogen chloride gas in the tail gas from a trichloromethane gas and a methyl isocyanate gas. The whole separating and recycling process is less in equipment investment and less in amount of byproduct hydrochloric acid; moreover, the separated hydrogen chloride gas is used for a catalytic hydrolysis process of the cartap.

Owner:HUNAN GOFAR FINE CHEM IND TECH CO LDT

The preparation method of methyl isocyanate

ActiveCN104387295BImprove one-way yieldEfficient separationOrganic compound preparationIsocyanic acid derivatives purification/separationOrganic solventChloride

The invention provides a preparation method of methyl isocyanate. A reaction product synthesized at the high temperature is directly fed into a first organic solvent for treatment at the temperature of 200-300 DEG C, effective separation of the methyl isocyanate and hydrogen chloride is realized, the fact that the methyl isocyanate reacts with the hydrogen chloride to produce methyl carbamyl chloride is avoided, the once-through yield of the methyl isocyanate is increased, repeated heating and condensation are not required, energy consumption and production of by-products are reduced, meanwhile, multiple decomposition reactors are not required and the number of condensers is decreased in the aspect of devices, and the investment cost and the production cost are greatly reduced.

Owner:HUNAN HAILI HIGH TECH IND GRP

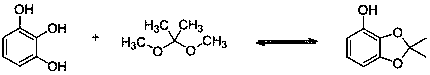

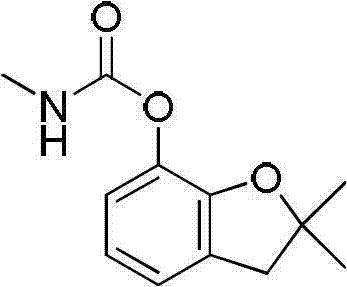

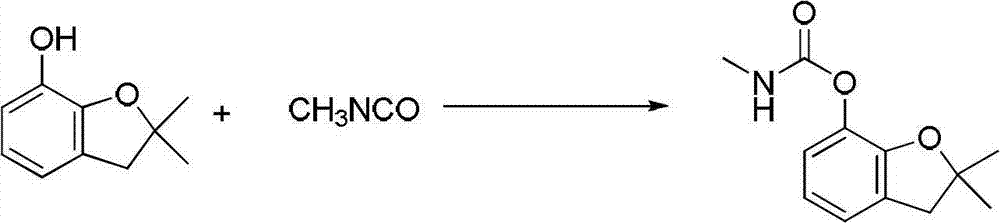

Preparation method of bendiocarb intermediate and active ingredient

InactiveCN110054609AIncrease productivityReduce consumptionOrganic chemistryBendiocarb2-Methoxypropene

The invention discloses a preparation method of a bendiocarb intermediate and an active ingredient. The preparation method includes: allowing pyrogallic acid to react with 2, 2-dimethoxypropane to generate a 2, 2-dimethyl-4-hydroxyl-1, 3-benzodioxoles solution, and directly using light components 2, 2-dimethoxypropane, 2-methoxypropene and methanol which are evaporated out for next batch after alkali washing; allowing the 2, 2-dimethyl-4-hydroxyl-1, 3-benzodioxoles solution to react with methyl isocyanate to obtain the bendiocarb active ingredient. By recycling raw materials and byproducts, cost is lowered, operation is simplified, production efficiency is improved, and convenience is brought for industrial production.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Method for increasing yield of methomyl

InactiveCN111187192AHigh product yieldImprove product qualityOrganic chemistryActivated carbonProcess engineering

The invention discloses a method for increasing the yield of methomyl, and belongs to the technical field of fine chemical engineering. The method comprises: carrying out a reaction on methomyl oximeand methyl isocyanate to obtain a methomyl crude product; putting the methomyl crude product into a heating kettle filled with water, adding active carbon, heating to 60-70 DEG C, and fully adsorbing;and transferring into a filtering device, filtering, feeding the filtrate into a crystallization kettle, and carrying out normal recrystallization, filter pressing and drying to obtain high-quality methomyl with a purity of 98.7% or above. The target product obtained by the method has the advantages of high yield, good crystal form and bright white color.

Owner:安道麦股份有限公司

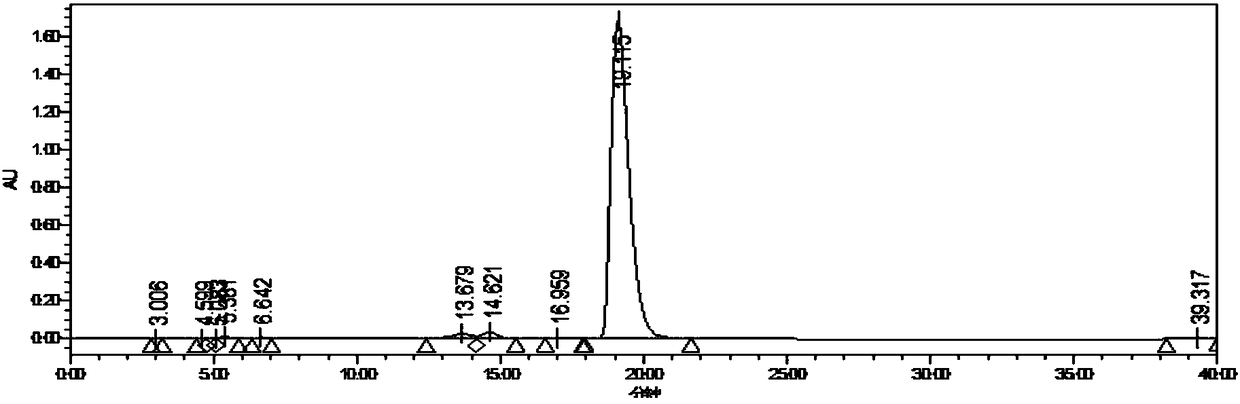

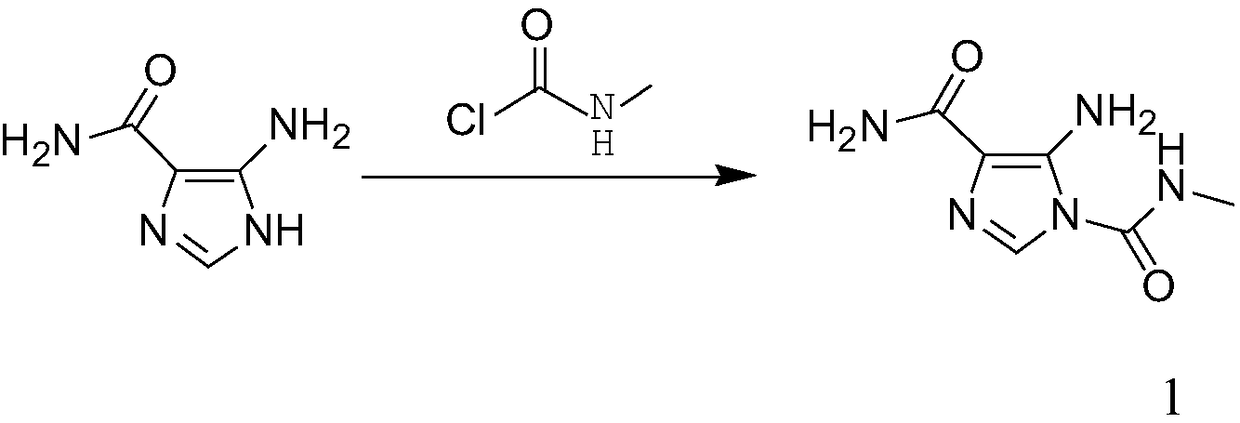

Synthetic method for temozolomide intermediate

The invention discloses a synthetic method for a temozolomide intermediate. The temozolomide intermediate is synthesized from 5-aminooimidazole-4-formamide and methylaminoformyl chloride by a one-stepmethod. The synthetic method comprises the following steps: dissolving the 5-aminooimidazole-4-formamide and the methylaminoformyl chloride in an organic solvent, cooling to the temperature of minus5-5 DEG C, dropwise adding triethylamine, heating and keeping stirring for 2-3 h, filtering, washing, and drying for 12 h at the temperature of 50+ / - 5 DEG C under vacuum to obtain the temozolomide intermediate. The method is high in safety, use of methyl isocyanate as a highly toxic reagent is avoided, the raw material conversion ratio is high and is 95% or above, the purity of the product is 98.3% or above, the reaction conditions are mild, aftertreatment is simple, and the materials can be fed directly without further purification for next reaction.

Owner:湖北一半天制药有限公司 +1

Production control method of 98 percent carbofuran

ActiveCN102731453AAvoid recrystallization operationsHigh in CarbofuranOrganic chemistry1,2-DichloropropaneDichloropropane

The invention provides a production control method of 98 percent carbofuran. The method comprises the following steps: reacting by adopting 1,2-dichloroethane or 1,2-dichloropropane as a reacting and crystallizing solvent, wherein the usage of the solvent is 2 to 4 times that of the mass of furan phenol, and the molar ratio of the furan phenol to methyl isocyanate to triethylamine is 1:1.05-0.01; dripping methyl isocyanate at a refluxing temperature; cooling, crystallizing and filtering after the reaction; drying the filter cake to obtain a main product with mass content of between 98.0 and 98.9 percent; adding a new solvent with the same mass when 10 to 15 percent of the mass of the filtrate is separated every time, and combining to be used as a mother liquor for next reaction; and distilling the filtrate which is separated in each time, using the recycled solvent as a fresh solvent, and thus obtaining the carbofuran side product with the mass content of between 84.1 and 92.7 percent, wherein the total yield is 99.0 to 99.8 percent in furan phenol. According to the production control method, recrystallization operation can be avoided, the mass content of the main product carbofuran can be stably controlled to be between 98.0 and 98.9 percent, and the solvent recycling amount is small; the side produced carbofuran product with mass content of between 84.1 and 92.7 percent can be used as a raw material of 3 percent carbofuran granules.

Owner:HUNAN HAILI CHEM IND

Preparation method of methomyl

The invention discloses a preparation method of methomyl. Methylthio acetaldoxime is used as a raw material and reacts with methyl isocyanate in water under the action of a phase transfer catalyst, the temperature is raised to 50-60 DEG C after the reaction is finished, cooling crystallization and filtration are performed after the material is completely dissolved, filtrate and a filter cake are obtained, the filtrate is extracted with an organic solvent, desolvation is then carried out, desolventized solids and the filter cake are combined and dried, and a methomyl product is obtained. The preparation method has the advantages of high yield, low cost, simplicity and convenience in operation and the like.

Owner:湖南海利常德农药化工有限公司

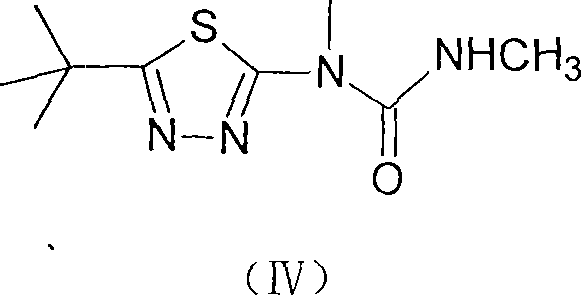

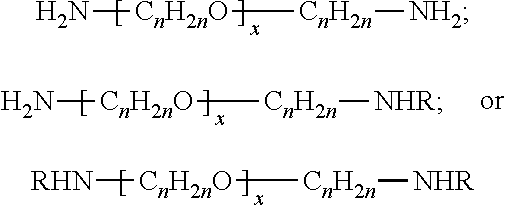

Method for preparing terbufos benzthiazuron

ActiveCN100579971CEfficient use ofAvoid potential dangerBiocideOrganic chemistryBenzthiazuronToxic material

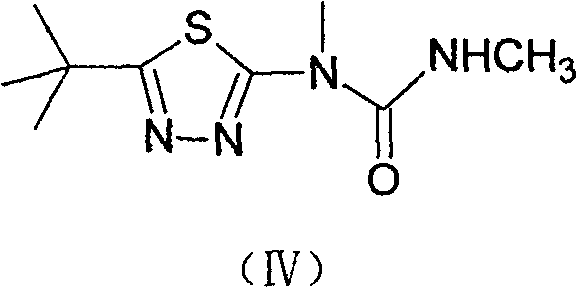

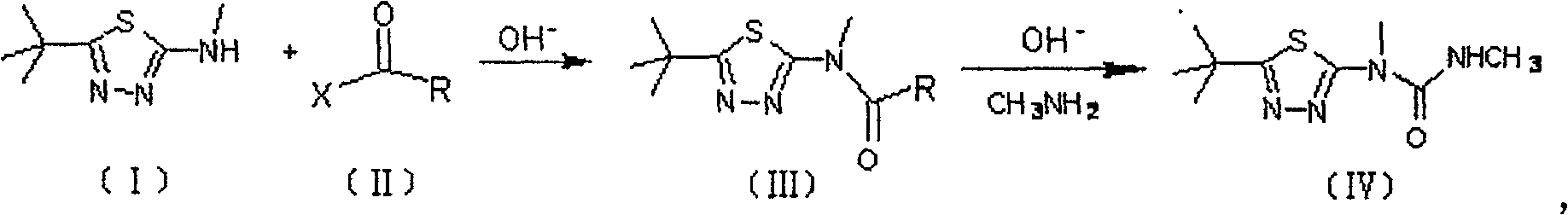

The invention relates to a preparation method of tebuthiuron, which takes 2-methylamino-5-tert-butyl-1, 3, 4-thiadiazole (I), carbonyl dihalide or the derivatives (II) and methylamine as the raw materials, the tebuthiuron (IV) is prepared and obtained by the following reactions under the alkaline conditions, wherein, X in the carbonyl dihalide or in the derivatives (II) the carbonyl dihalide is a halogen element, and R is the halogen element or the alkoxy with 1 to 4 carbons. The method can effectively solve the potential risks and the serious pollution of the environment caused by using the acutely toxic substance methyl isocyanate in the traditional methods, allow the production of tebuthiuron with high yield, and can effectively make use of the by-products and reclaim the main solvents at the same time.

Owner:LIER CHEM CO LTD

A kind of synthetic method of tebuthiauron

The invention provides a tebuthiuron synthesis method. Tebuthiuron is obtained by reaction between 1,3-dimethylurea and 5-tert-butyl-1,3,4-thiadiazole derivatives under the alkaline condition. The tebuthiuron synthesis method solves the problems of safety risks caused by use of extremely toxic substances such as methyl isocyanate and N-methyl formylchloride, presence of phosgene or the like, difficulty in production operation in traditional methods.

Owner:JIANGSU CHANGLONG AGROCHEM CO LTD

Method for recycling chloroform in process of producing methyl isocyanate

InactiveCN104557441APromote stratificationLow costChlorine/hydrogen-chloride purificationHalogenated hydrocarbon separation/purificationSolventMethyl isocyanate

The invention provides a method for recycling chloroform in a process of producing methyl isocyanate. The methyl isocyanate is prepared by reacting phosgene with monomethylamine to generate methylaminoformyl chloride, and decomposing methylaminoformyl chloride by taking chloroform as a solvent. The method for recycling chloroform in the process of producing methyl isocyanate is characterized by comprising the following steps: cooling decomposed tail gas to 30-40 DEG C by a cooler, then introducing the tail gas into a layering device, layering chloroform and hydrochloric acid in the tail gas in the layering device, enabling chloroform with high specific gravity to flow into a chloroform receiving kettle, receiving and circulating the chloroform for producing methyl isocyanate, and independently recycling hydrochloric acid with low specific gravity. The tail gas generated in the process of producing methyl isocyanate firstly flows through a falling-film absorption tower, HCl is absorbed into water, and then chloroform is quickly precipitated in a hydrochloric acid solution, so that the layering of hydrochloric acid and chloroform in the layering device is facilitated, and further hydrochloric acid and chloroform can be independently recycled; the recycled chloroform can be used for producing methyl isocyanate again; plenty of cost can be reduced. The method is simple and high in practicability.

Owner:安道麦股份有限公司

Slag removal method for continuous production of methyl isocyanate

ActiveCN104557613BAvoid direct contactReduce labor intensityOrganic compound preparationIsocyanic acid derivatives purification/separationSlagGas phase

The invention discloses a deslagging method for continuous production of methyl isocyanate. The method comprises the following steps: installing a deslagging machine below an air and liquid separator; performing air and liquid separation on a methyl isocyanate solution obtained by reaction by using the air and liquid separator; condensing a gas phase component and then rectifying and purifying to obtain a methyl isocyanate product; putting a liquid phase component in the deslagging machine and automatically removing tripolymethyl isocyanate solid slags; and returning the rest unreacted methyl carbamyl chloride, a trichloromethane solvent and a small amount of the methyl isocyanate product to a liquid mixing tank from the outlet of the deslagging machine and further reacting. The method disclosed by the invention can be used for automatically removing solid slags generated in the continuous production of the methyl isocyanate, realizing integration of deslagging and dry-recycle by adopting the deslagging machine, completely preventing direct contact between toxic materials and a person, reducing the labor strength, reducing toxication accidents, effectively evaporating residual volatile components such as raw materials, products and solvents in the solid slags and increasing the total yield of the products and the recycle rate of the solvents.

Owner:海利贵溪新材料科技有限公司

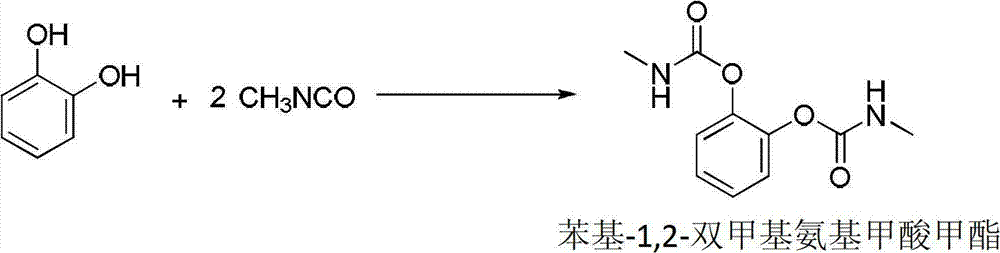

Tail gas hazard-free treatment method in synthesis of carbamate pesticide

ActiveCN101792405ASolve pollutionReduce energy consumptionCarbamic acid derivatives preparationOrganic compound preparationMethyl isocyanatePollution

The invention relates to a tail gas hazard-free treatment method in the synthesis of a carbamate pesticide. The method comprises the following steps: (1) firstly adding o-sec-butylphenol and triethylamine into a reaction kettle in a volume ratio of 1 to 0.005; (2) then introducing tail gas which comprises methyl isocyanate and is generated in the synthesis process of the carbamate pesticide, controlling the temperature of the reaction kettle between 30 and 50 DEG C and reacting for 1 to 3 hours; (3) detecting the content of BPMC in the reaction kettle after the reaction and stopping introducing the air when the content of BPMC is up to 40 to 50 percent and dropwise adding high-purity methyl isocyanate, wherein a volume ratio of the high-purity methyl isocyanate to the o-sec-butylphenol is 0.19-0.27:1; (4) then dropwise adding high-purity methyl isocyanate in the reaction kettle under the condition that the temperature of the reaction kettle is between 30 and 50 DEG C and preserving the heat for 15 to 60 minutes; and (5) finally detecting the content of BPMC which is subjected to the processing of the steps in the reaction kettle until the content of BPMC is over 95 percent. The method has low energy consumption of the process, high utilization and no pollution, ensures that the isocyanate resource is utilized and fulfills the aim of energy conservation and emission reduction.

Owner:HUNAN GOFAR FINE CHEM IND TECH CO LDT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com