Method for increasing yield of methomyl

A technology for the yield of methomyl and methomyl, which is applied in the field of recycling target products and improving the yield of methomyl, can solve the problem of chemical synthesis reaction selection and low yield, product quality cannot be guaranteed, and reaction temperature is not high. Good control and other issues, to achieve the effect of low cost, increase production yield and quality, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This example discloses that methomyl is reacted with methyl isocyanate to prepare methomyl aqueous solution, and then the crude methomyl product is obtained through the process of heating up, recrystallization, pressure filtration, and drying, wherein the mother liquor from pressure filtration is recovered and salted out again , the methomyl mother liquor obtained by pressure filtration is measured again and put into industrial sodium chloride in proportion, and the methomyl crystallization is separated out by using the difference in solubility, and then the methomyl crude product is obtained through suction filtration.

Embodiment 2

[0024] Put 1.7-1.8t of the crude methomyl obtained in Example 1 into a warming kettle prepared with fresh water, put in 20kg of activated carbon to absorb the decolorizing agent, raise the temperature to 60-70°C, fully absorb for 1.5-2.0h, and then pass The above-mentioned special filter device absorbs the impurities in the crude methomyl,

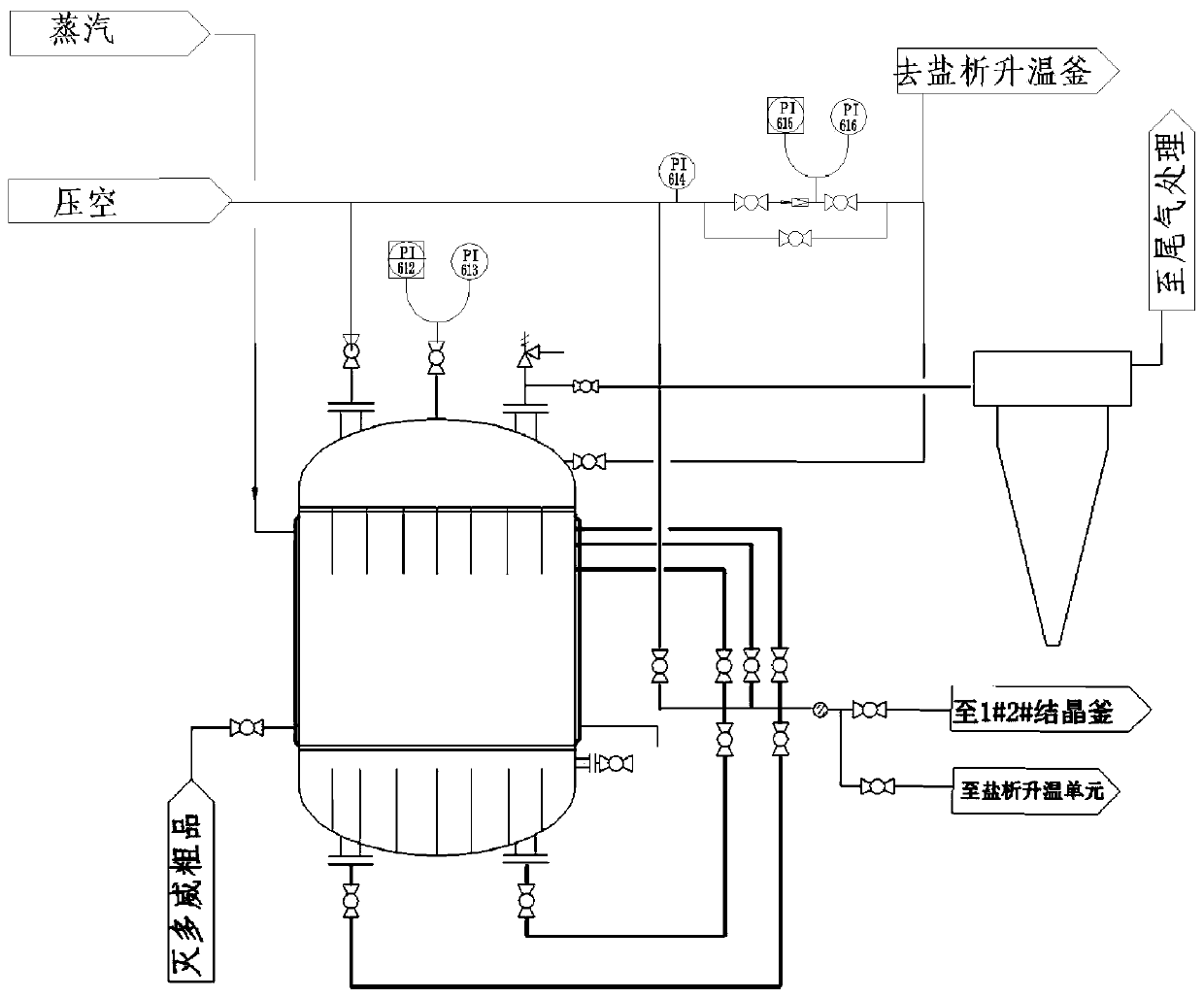

[0025] The device is a precision filter, which is equipped with 5 sets of precision filter carbon rods, with a pore size of 0.5 mesh, which can completely intercept the adsorbed activated carbon and impurities in the crude product, especially the bottom of the filter device. Rod, can completely filter the filtrate in the filter device, and then discharge the dry filter residue from the slag outlet at the bottom, which can not only facilitate the activation and regeneration of the carbon rod, but also prevent excessive solid residue from clogging and affecting the filtration efficiency. The specific process flow See attached figure 1 Descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com