Treatment system and treatment method of residues in methyl isocyanate synthetic process

A technology of methyl isocyanate and synthesis process, which is applied in the field of chemical industry, can solve the problems of difficult and difficult removal of residues, achieve the effect of improving production efficiency and solving the problems of difficult and effective removal in a timely manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

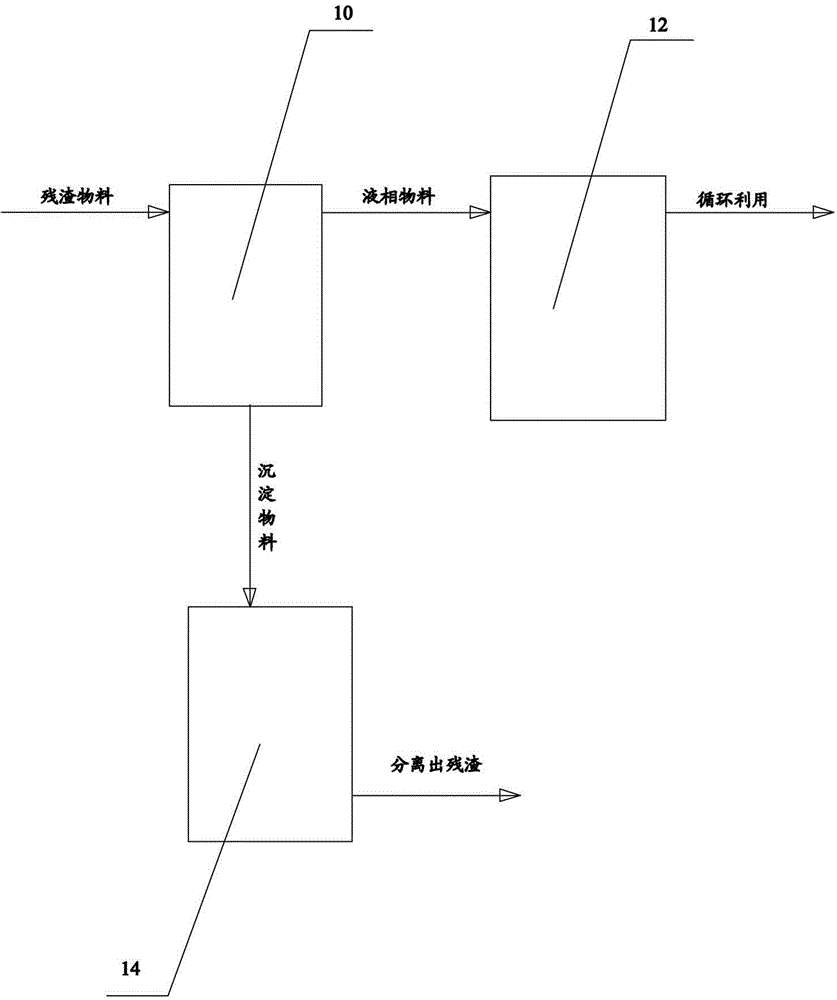

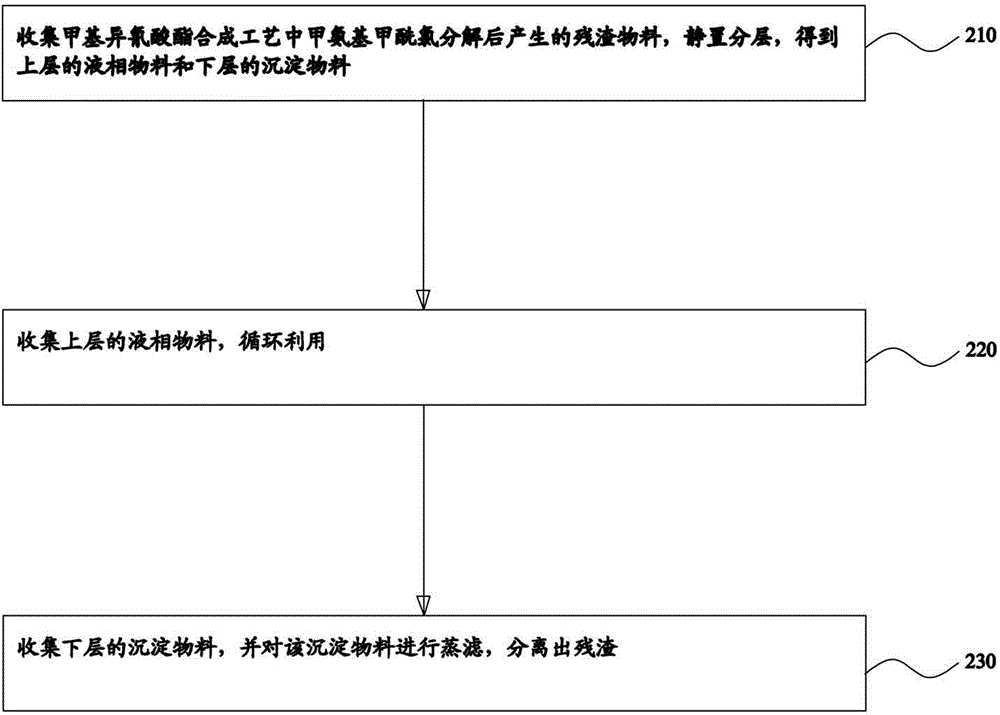

[0067] Collect 1000L of residue material produced after the decomposition of carbamoyl chloride in the synthesis process of methyl isocyanate, put it in the residue isolation tank for stratification, and the precipitated material will naturally settle to the lower layer of the residue isolation tank. The phase material is automatically discharged into the mixing tank through the overflow port, and the liquid phase material is measured to be 955L. The liquid phase material is translucent after sampling and observation, and it is sent to the methyl isocyanate synthesis system for circulation without blocking the rectification tower packing.

Embodiment 2

[0069] Collect 1500L of residue material produced after the decomposition of carbamoyl chloride in the synthesis process of methyl isocyanate, put it in the residue isolation tank for stratification, and the precipitated material will naturally settle to the lower layer of the residue isolation tank. The phase material is automatically discharged into the mixing tank through the overflow port, and the liquid phase material is measured to be 1420L. The liquid phase material is translucent after sampling and observation, and is sent to the methyl isocyanate synthesis system for circulation without blocking the rectification tower packing.

Embodiment 3

[0071] Collect 2000L of residue material produced after the decomposition of carbamoyl chloride in the synthesis process of methyl isocyanate, put it in the residue isolation tank for stratification, and the precipitated material will naturally settle to the lower layer of the residue isolation tank. The phase material is automatically discharged into the mixing tank through the overflow port, and the liquid phase material is measured to 1930L. The liquid phase material is transparent and sent to the methyl isocyanate synthesis system for circulation without blocking the rectification tower packing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com