Patents

Literature

322results about "Isocyanic acid derivatives purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

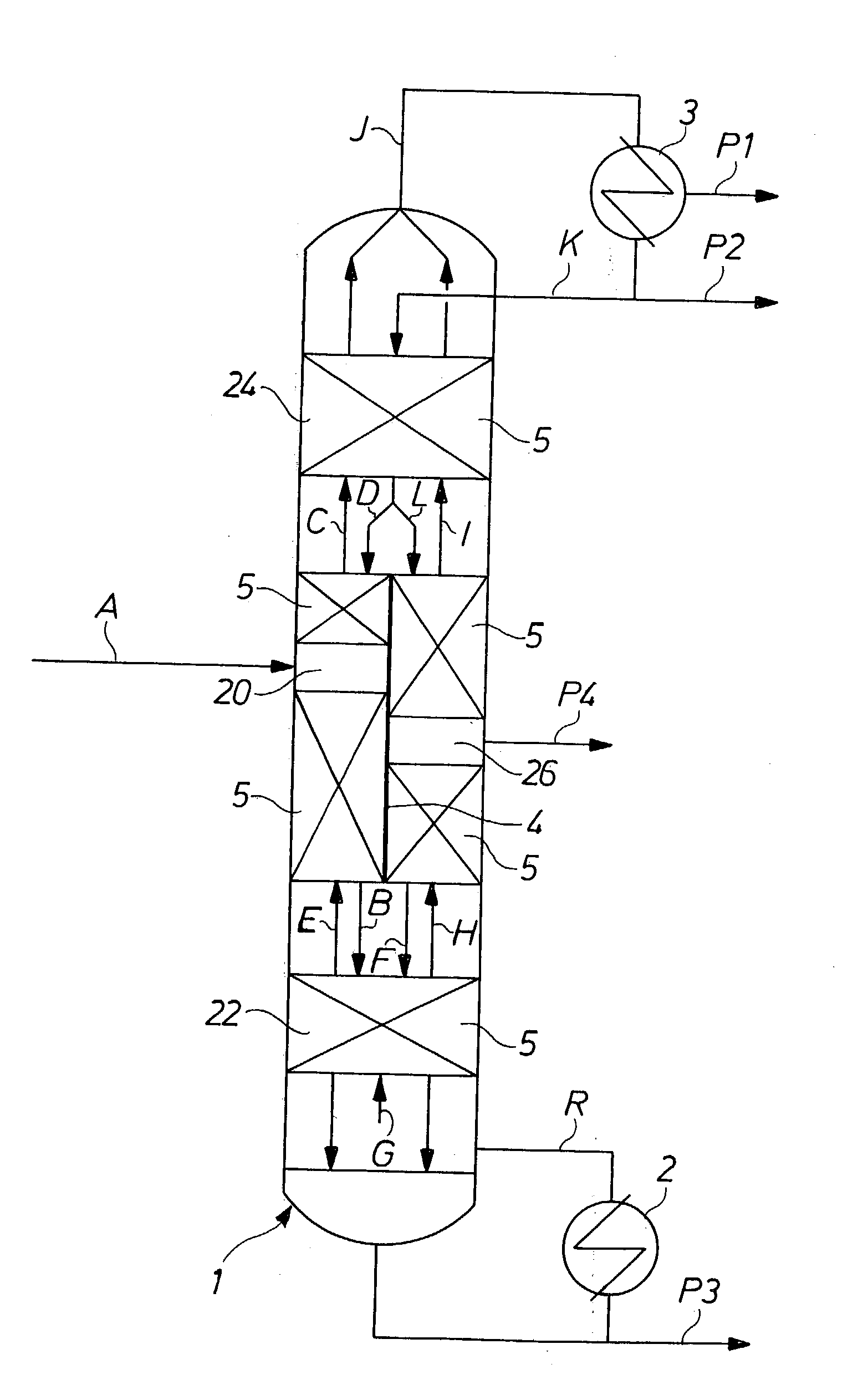

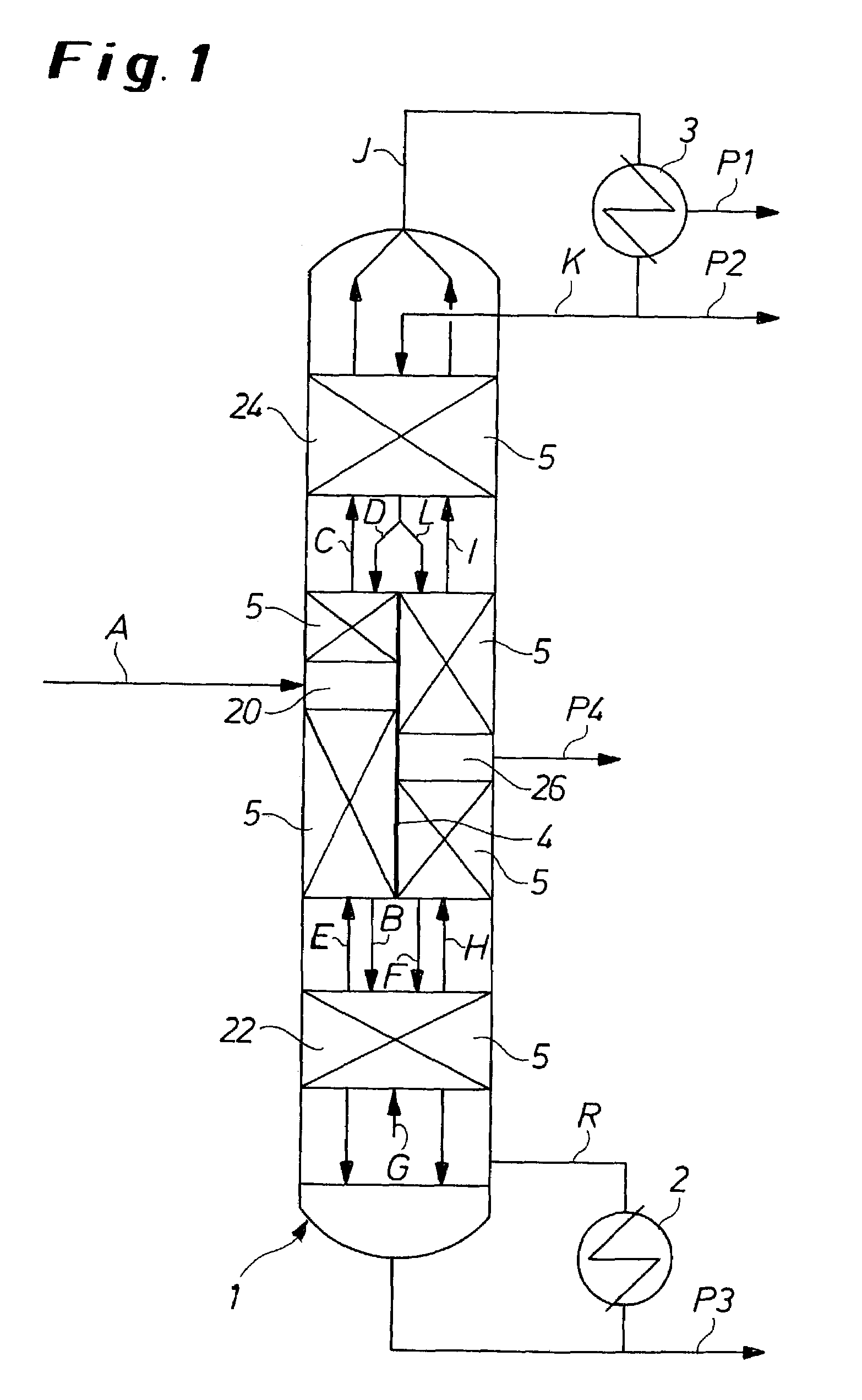

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS20030230476A1Weaken energyLow investment costThermal non-catalytic crackingOrganic compound preparationPurification methodsOrganic solvent

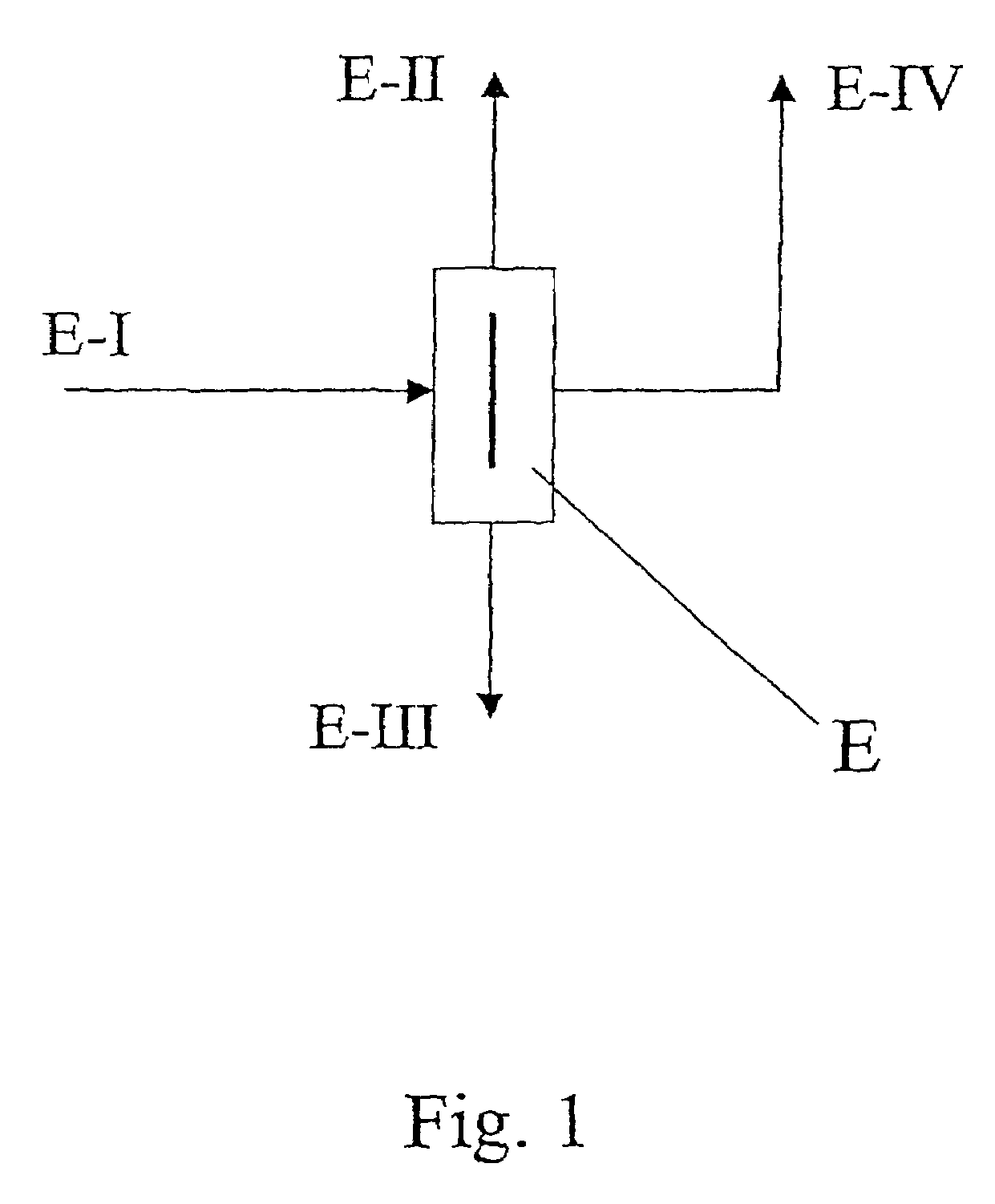

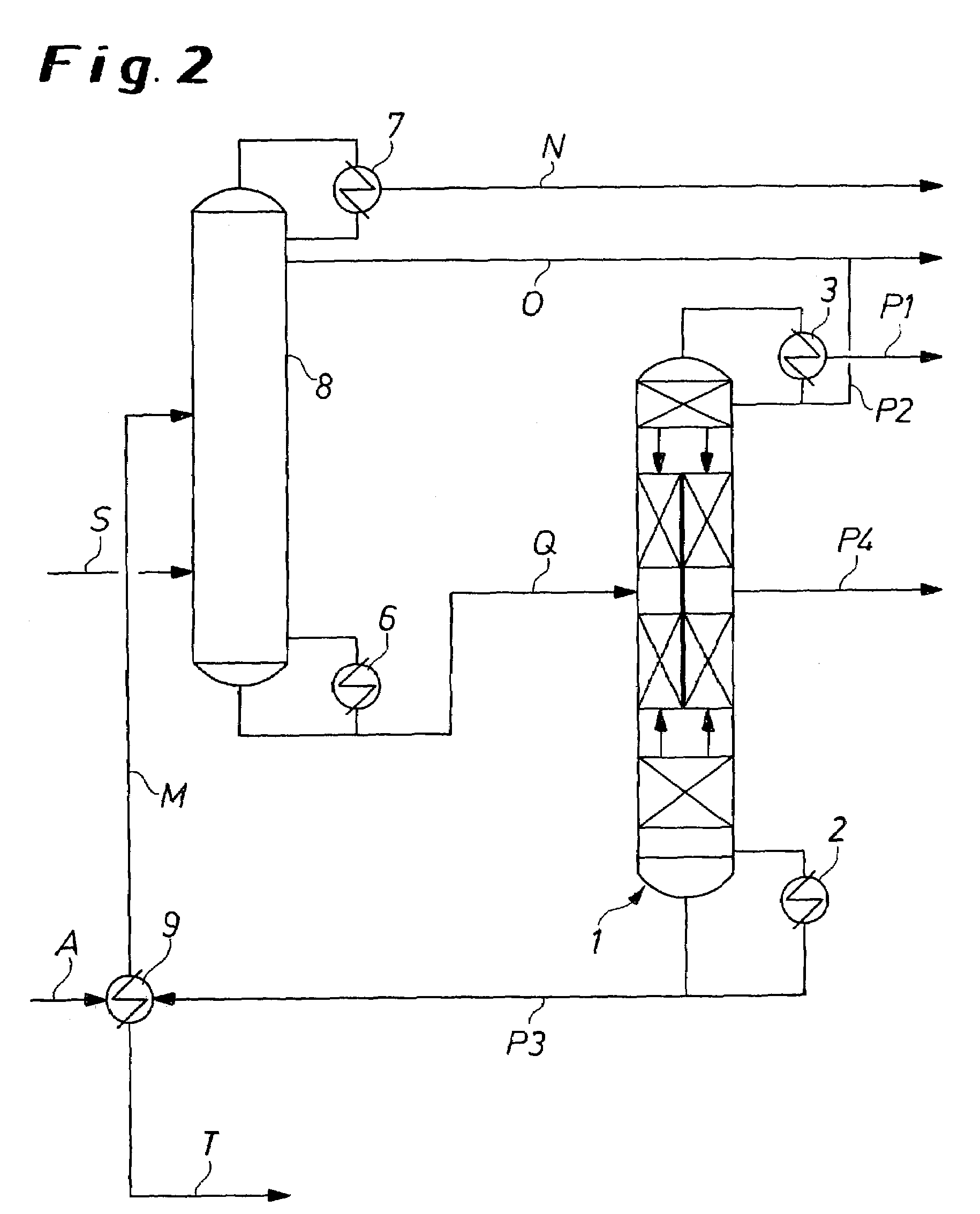

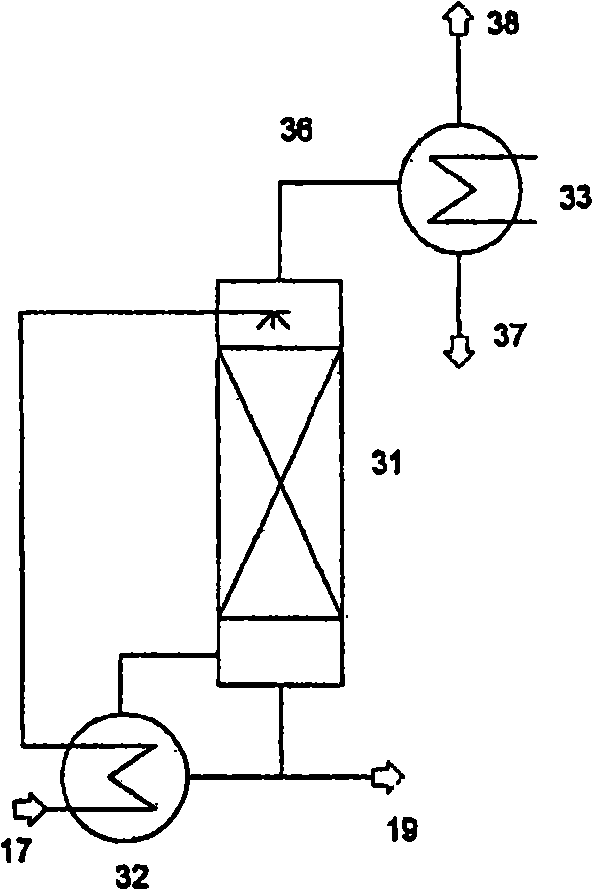

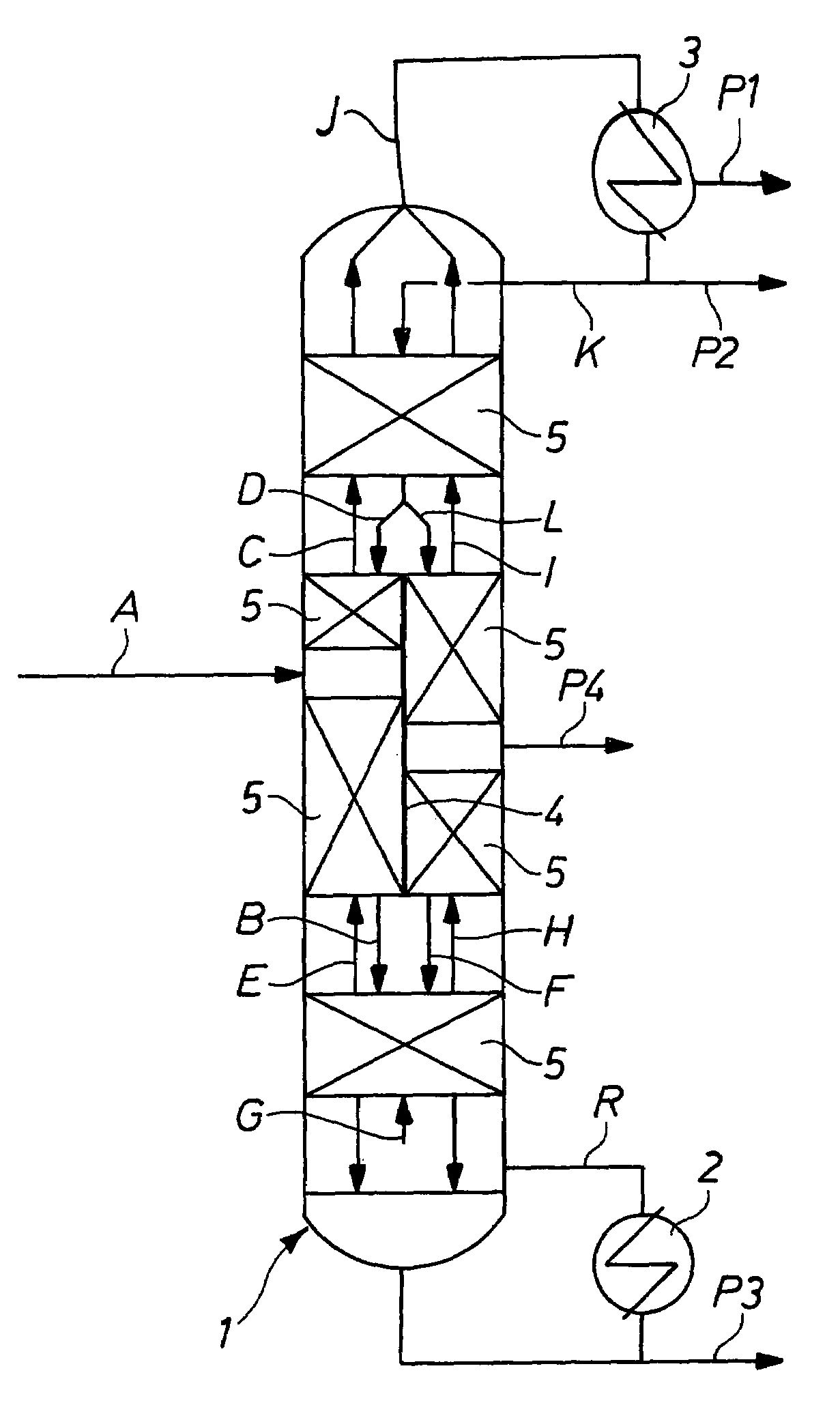

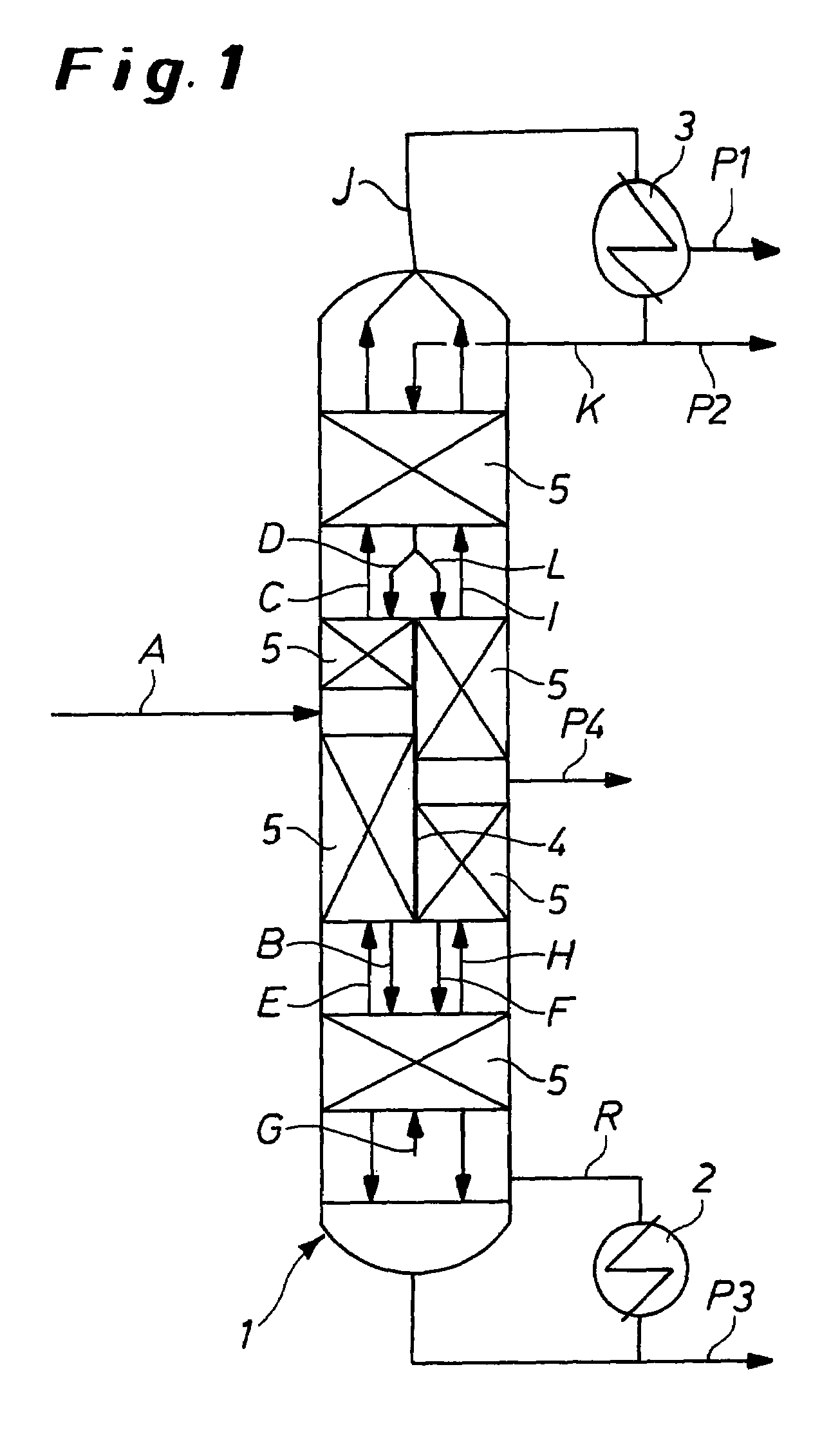

Process for the purification of toluenediisocyanate from a crude distillation feed comprising toluenediisocyanate, an organic solvent and less than 2% by weight phosgene by separating the crude distillation feed in a dividing-wall distillation column into at least four product fractions P1-P4. P1 is a phosgene enriched low-boiler product, P2 is a solvent-enriched product, P3 is a high boiler enriched bottoms and P4 is a toluenediisocyanate product stream.

Owner:COVESTRO DEUTSCHLAND AG

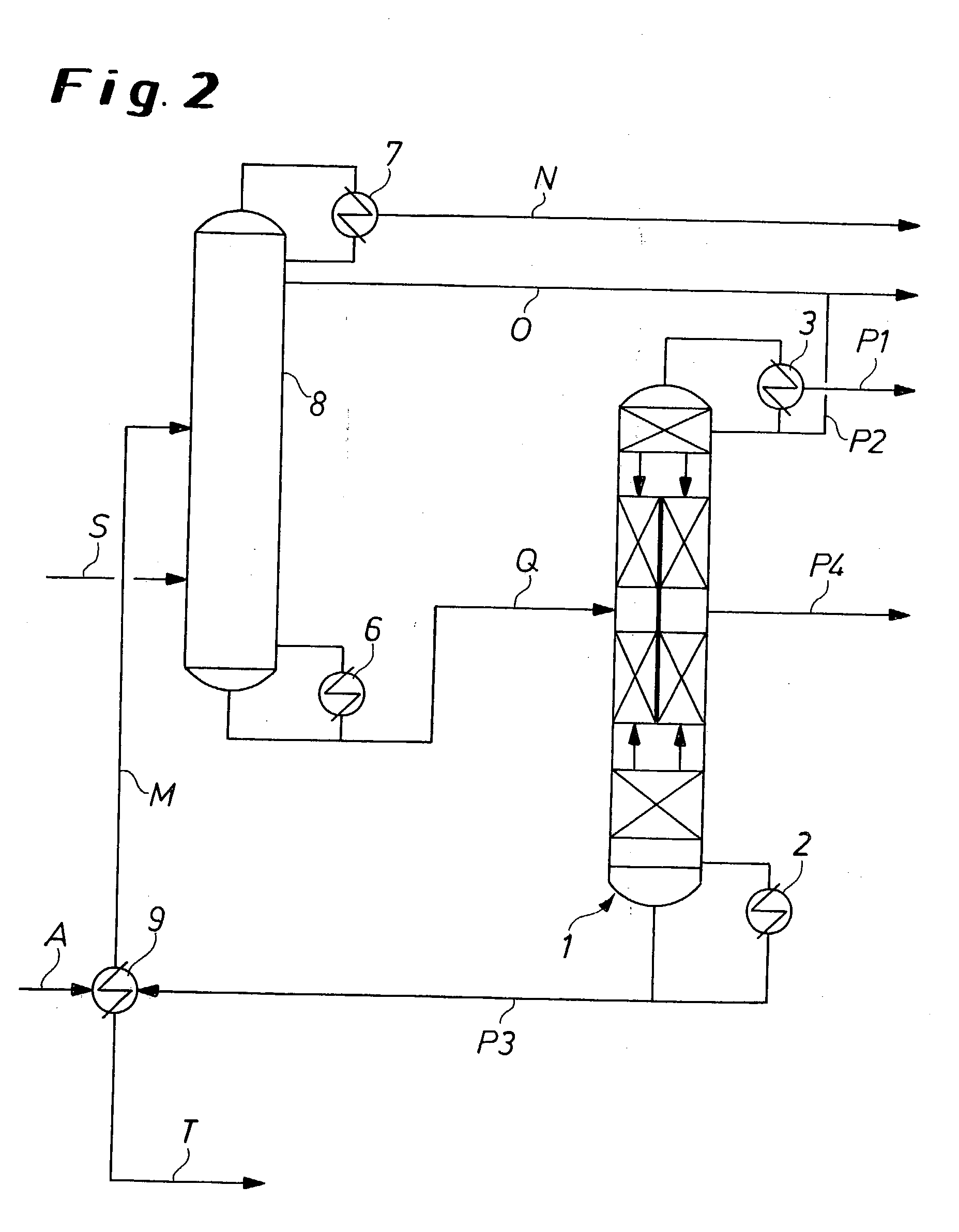

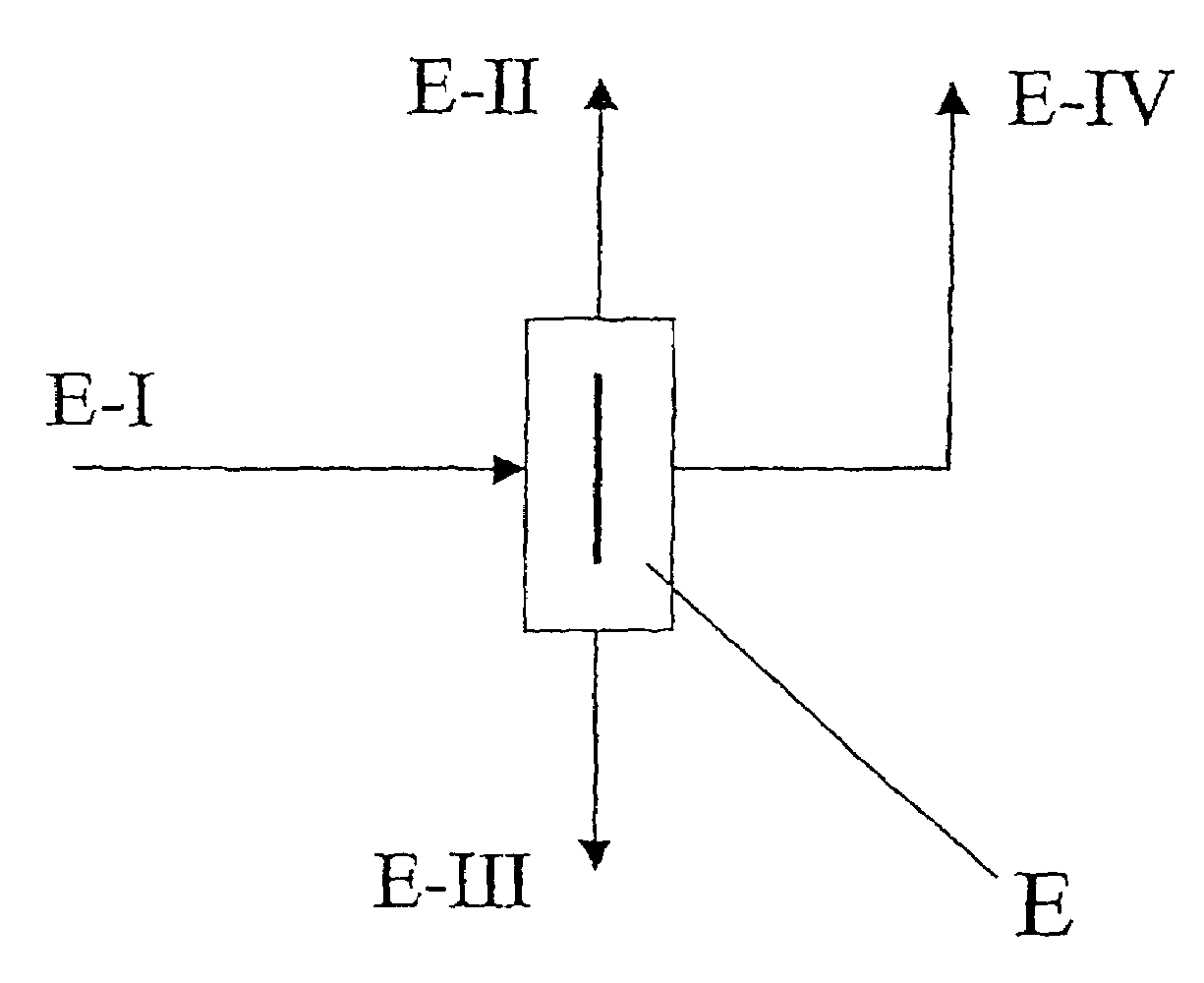

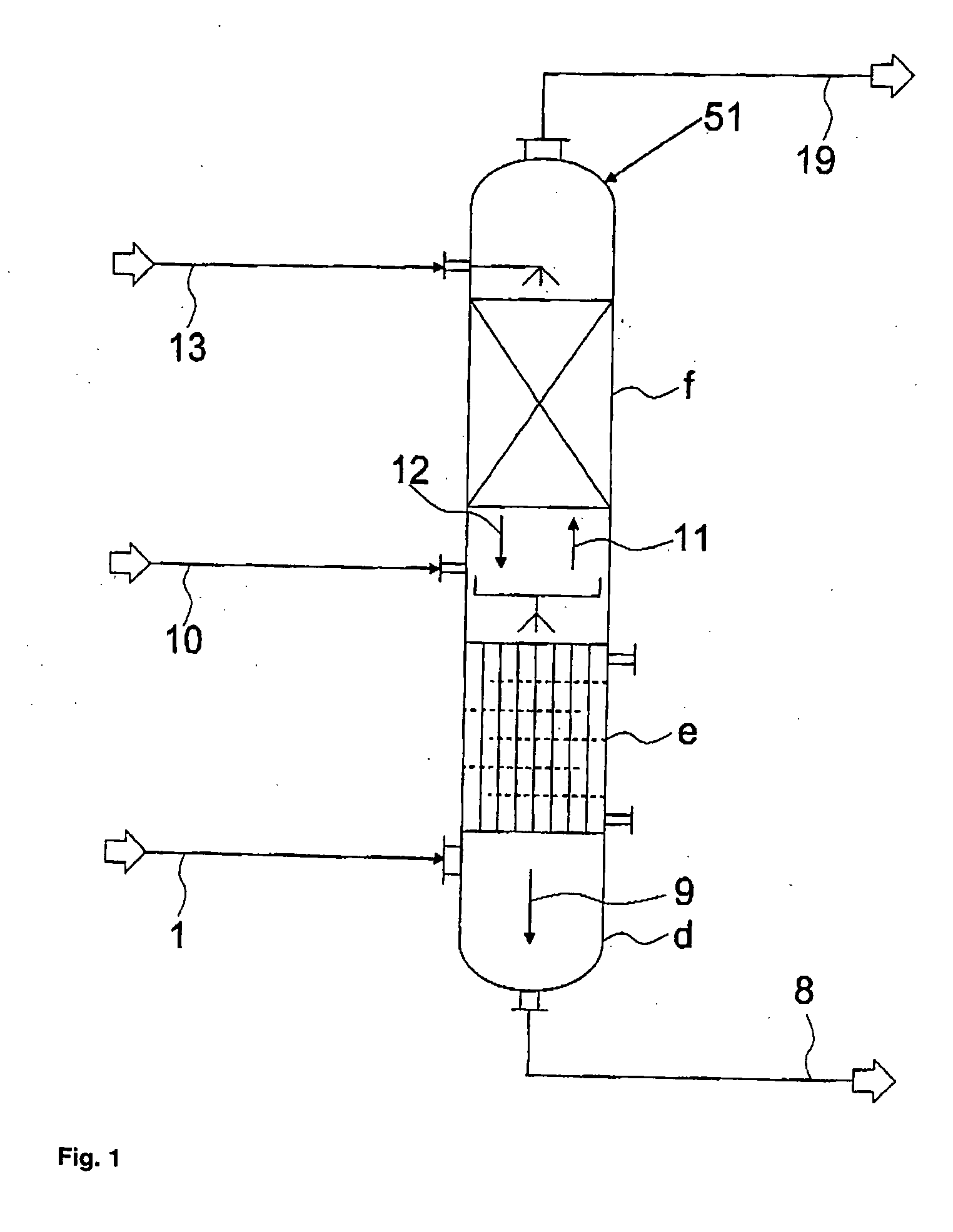

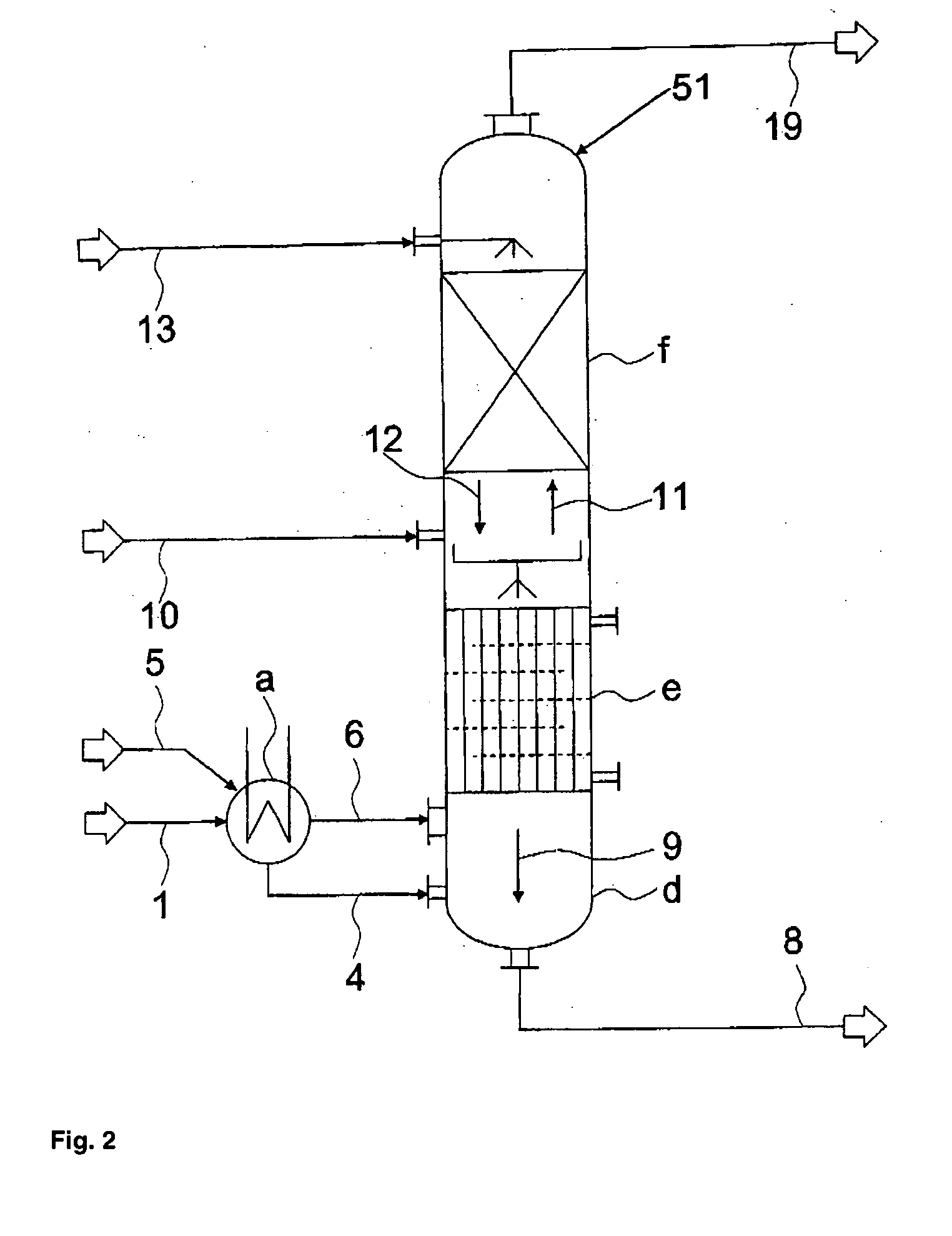

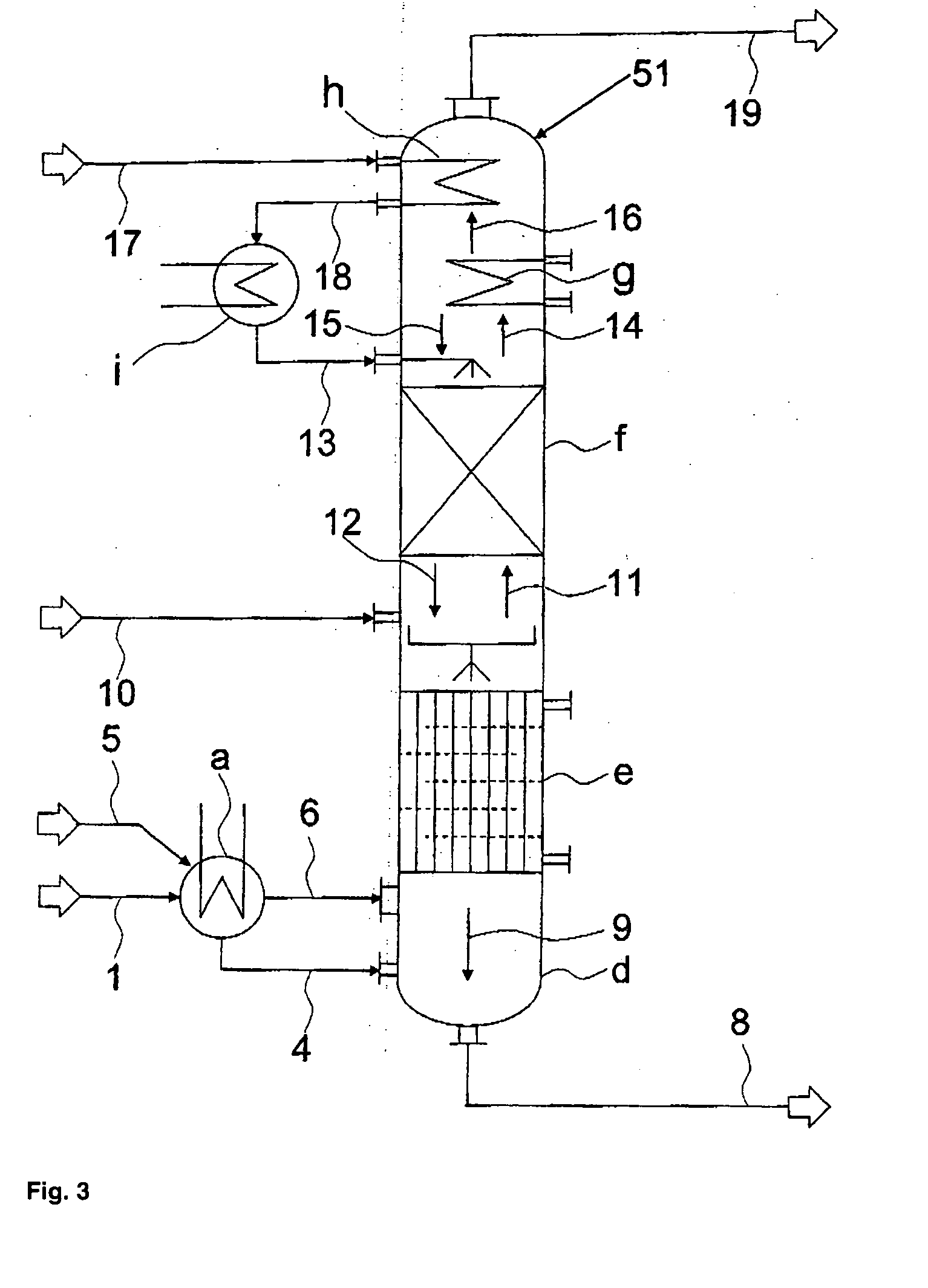

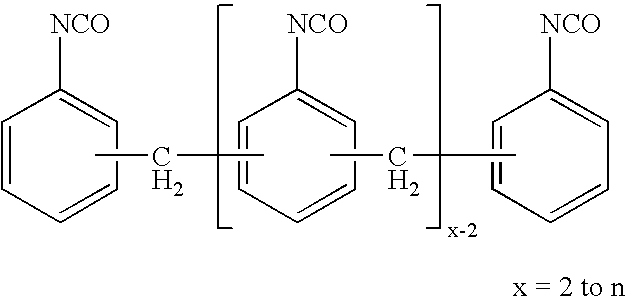

Process for the distillation of a mixture of isomeric diisocyanatodiphenylmethanes

InactiveUS7649108B2Reduce spendingReduce energy inputOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

A mixture of isomeric diisocyanatodiphenylmethanes composed of at least 2,2′-diisocyanato-diphenylmethane, 2,4′-diisocyanatodiphenylmethane and 4,4′-diisocyanatodiphenyl-methane is distilled in at least one stage and a divided-wall column is used in at least one distillation stage.

Owner:BAYER MATERIALSCIENCE AG

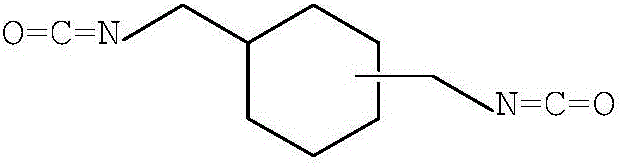

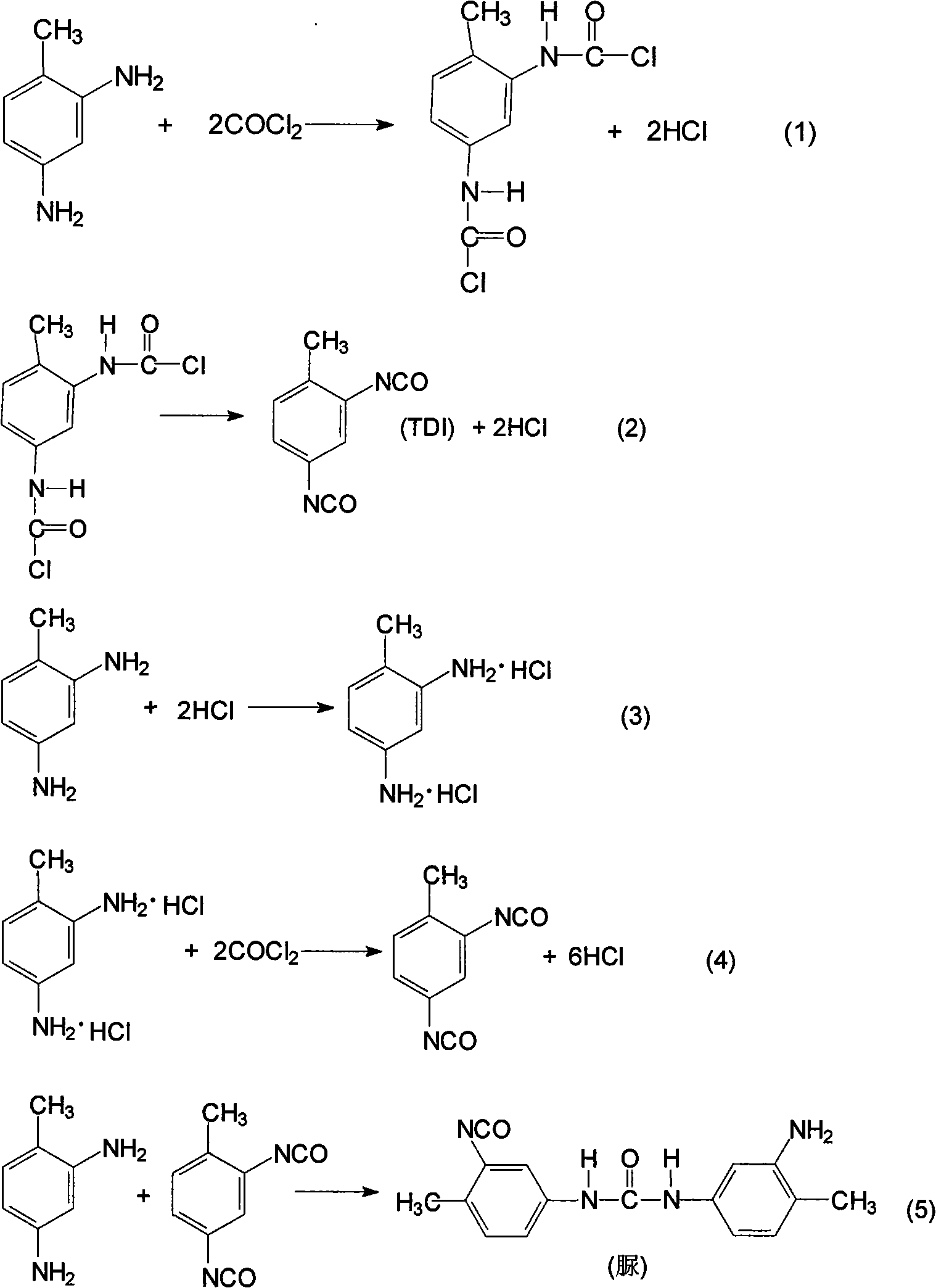

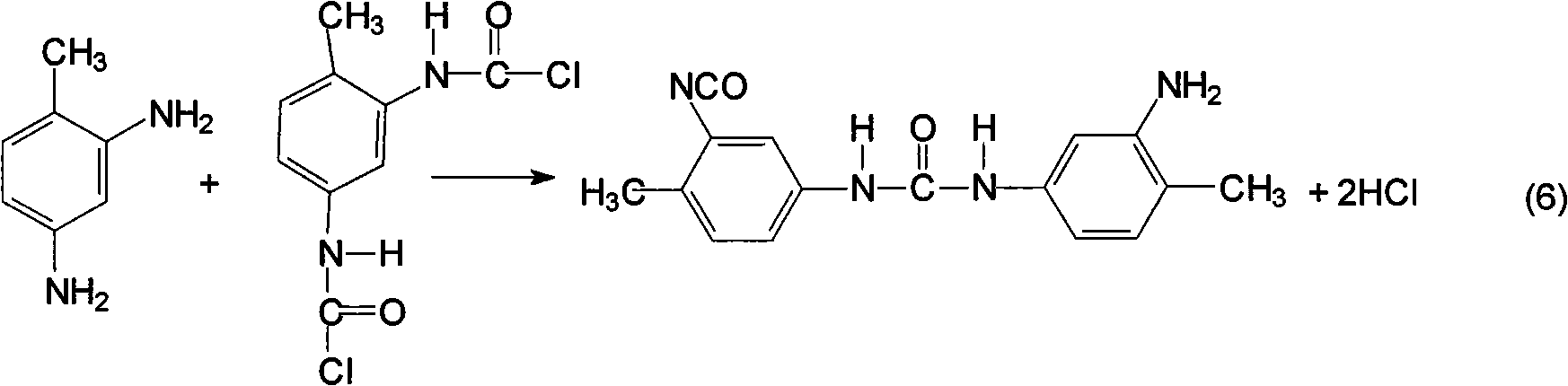

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

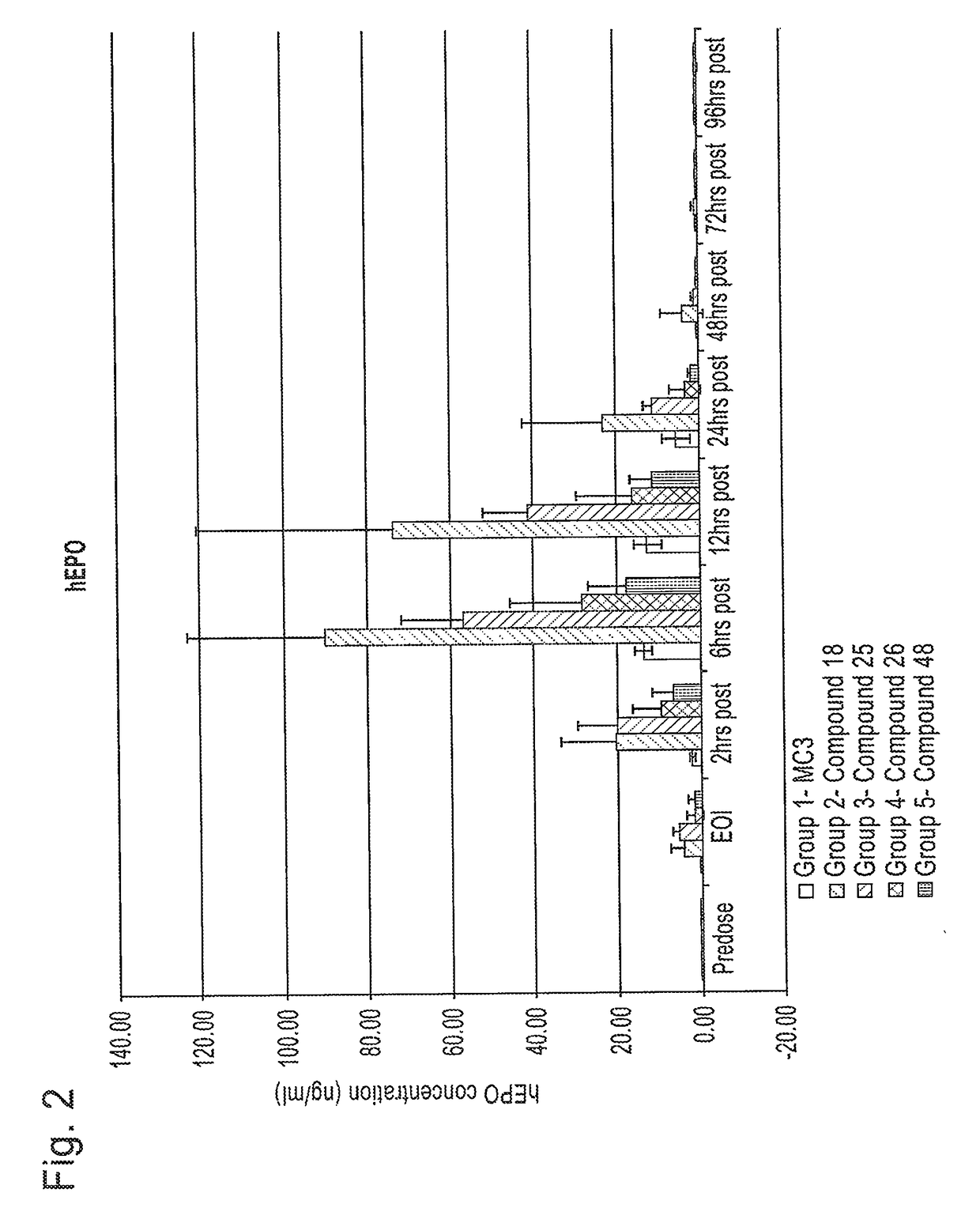

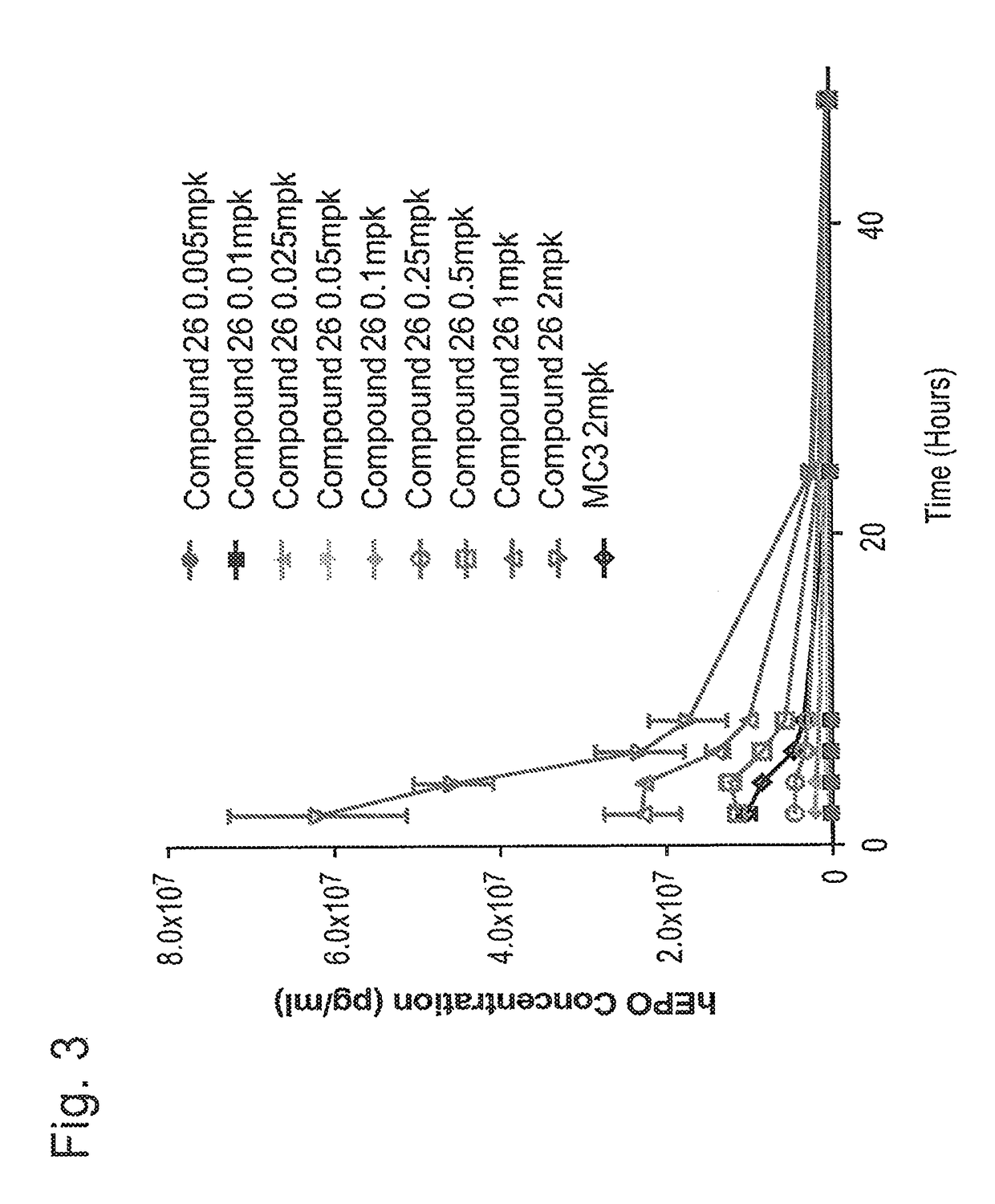

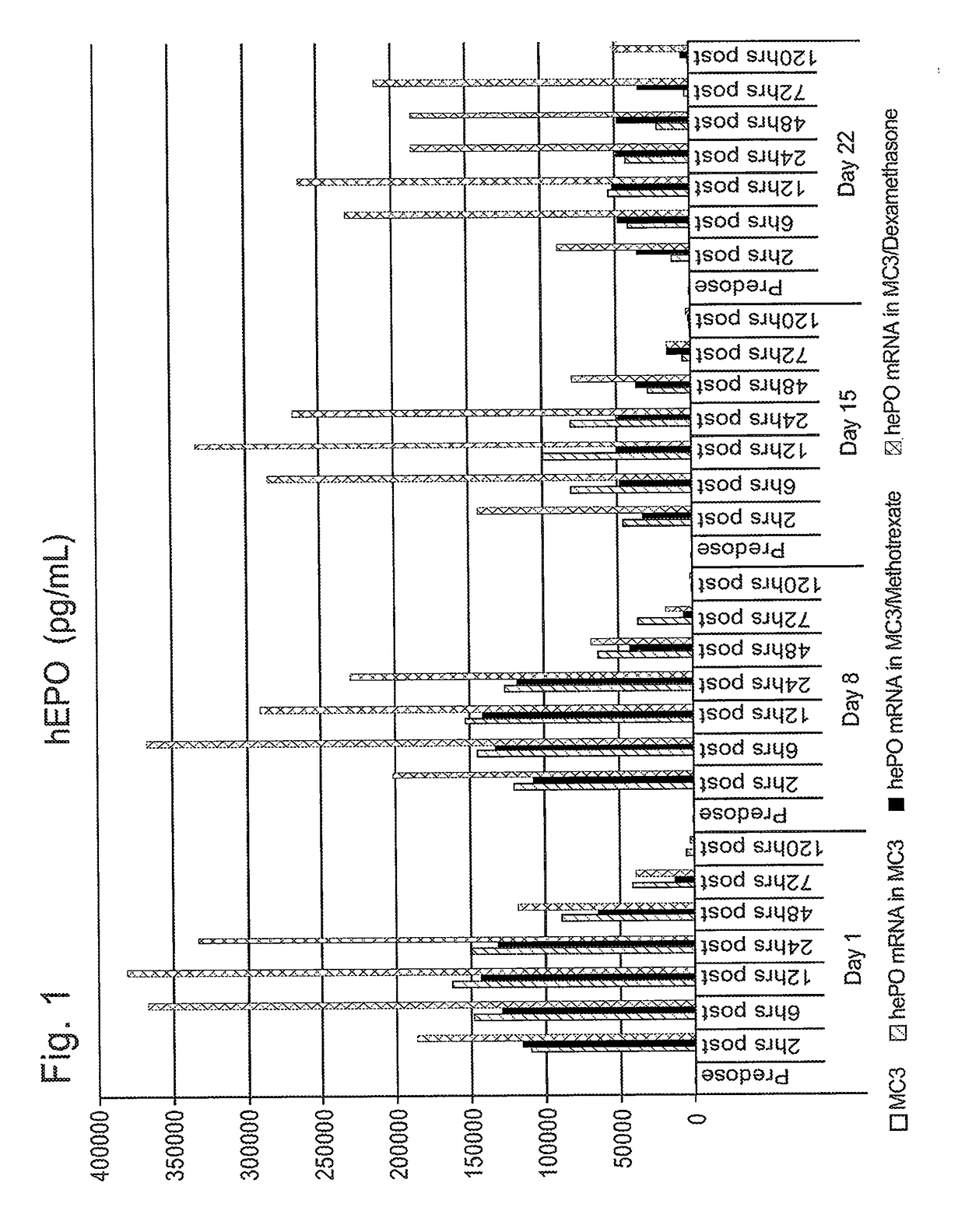

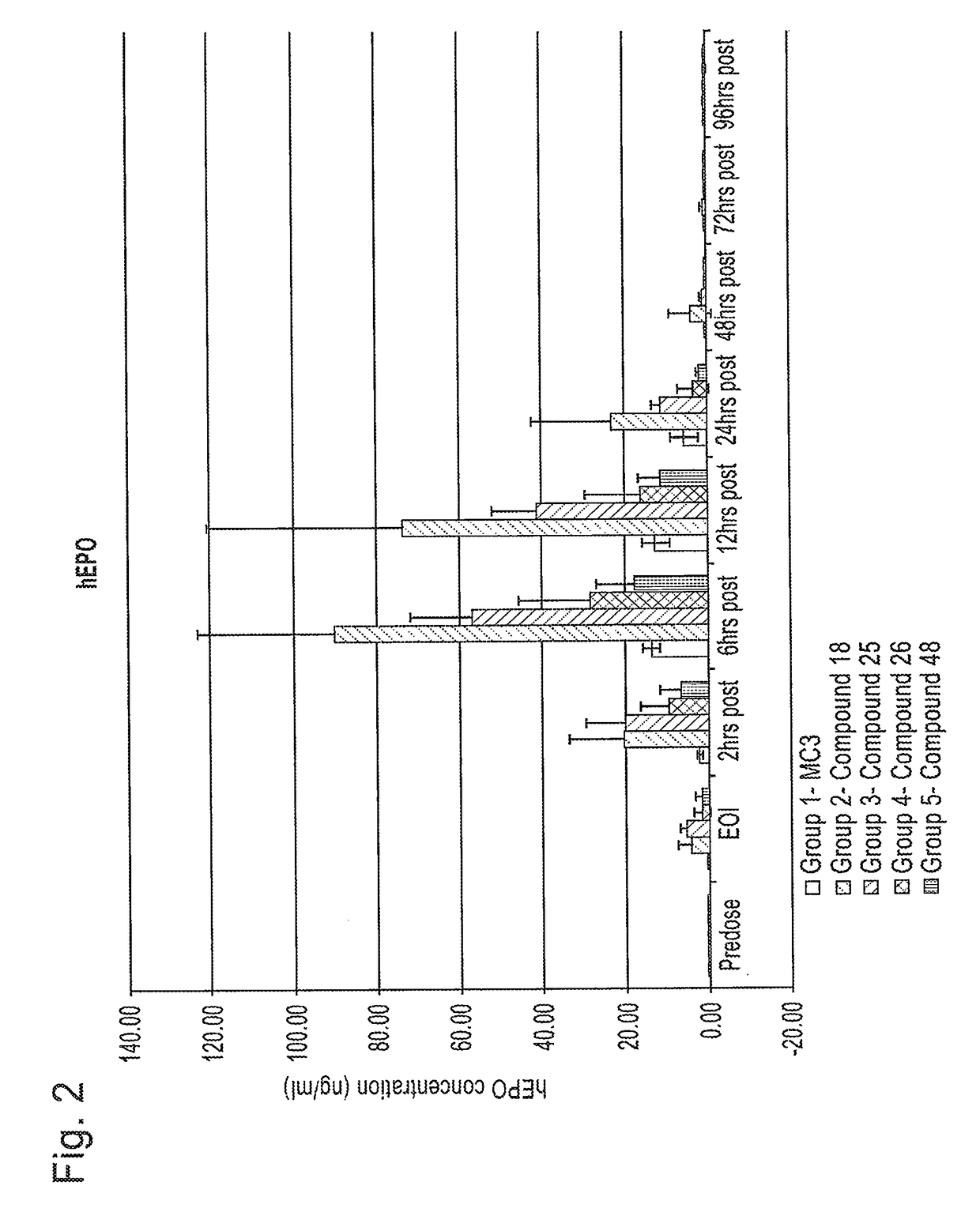

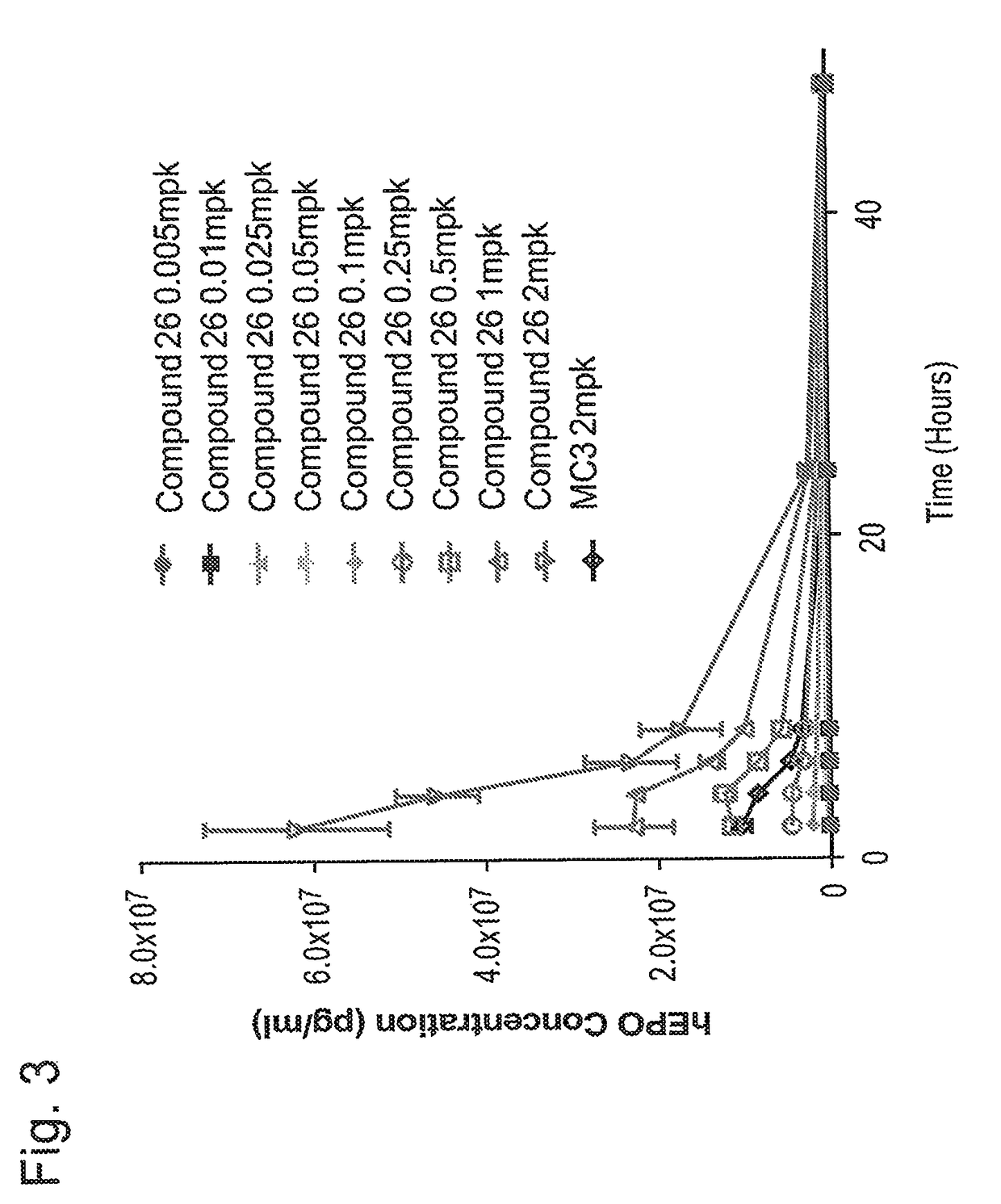

Compounds and compositions for intracellular delivery of therapeutic agents

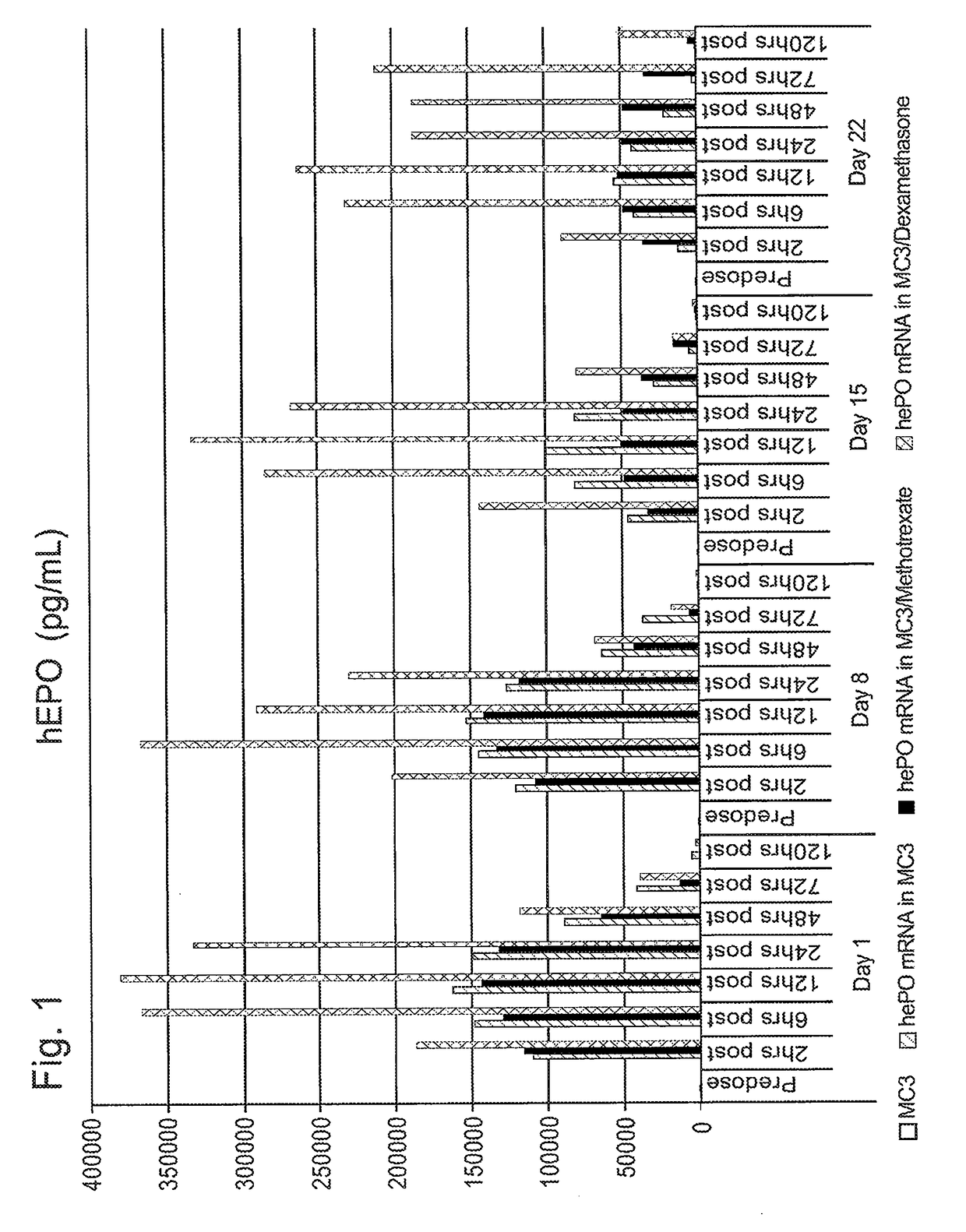

ActiveUS20170210697A1Low immunogenicityReduce inductionPowder deliveryOrganic active ingredientsNanoparticlePhospholipid

The disclosure features novel lipids and compositions involving the same. Nanoparticle compositions include a novel lipid as well as additional lipids such as phospholipids, structural lipids, and PEG lipids. Nanoparticle compositions further including therapeutic and / or prophylactics such as RNA are useful in the delivery of therapeutic and / or prophylactics to mammalian cells or organs to, for example, regulate polypeptide, protein, or gene expression.

Owner:MODERNATX INC

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS7118653B2Lower energy requirementsLow investment costOrganic compound preparationIsocyanic acid derivatives purification/separationOrganic solventToluene diisocyanate

Owner:COVESTRO DEUTSCHLAND AG

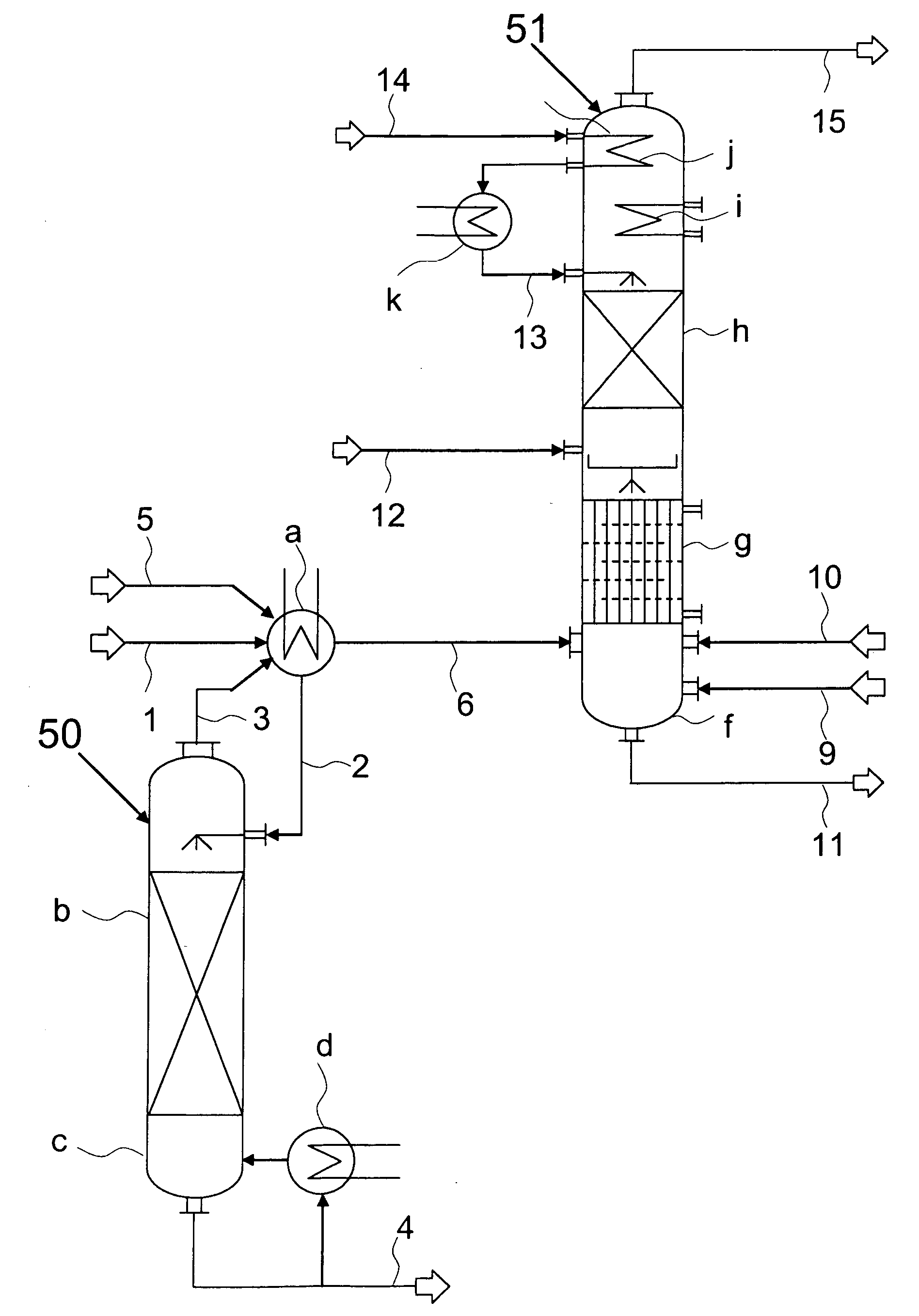

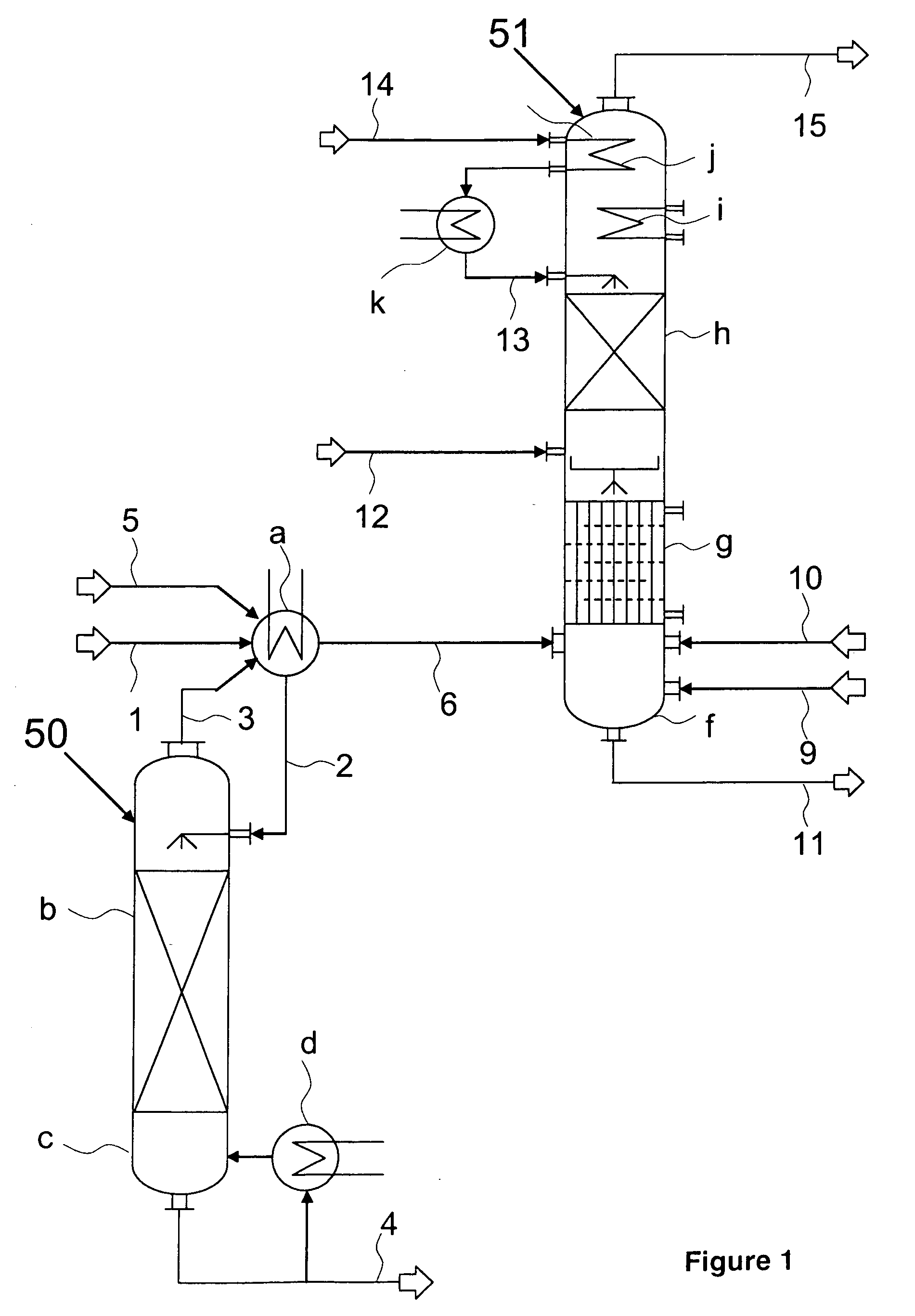

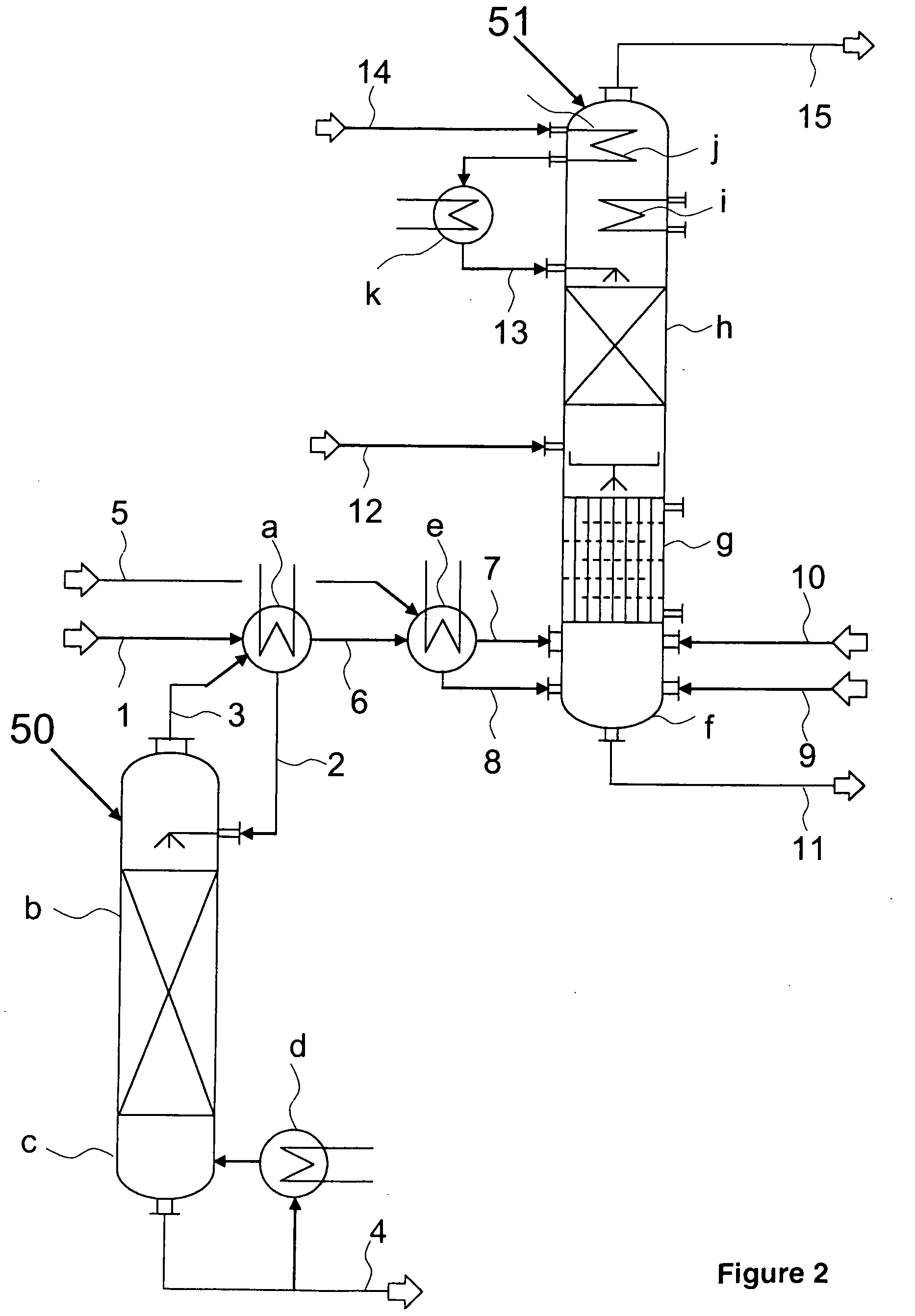

Process for the continuous preparation of isocyanates

ActiveUS20070299279A1High chemical yieldIncreased space-time yieldOrganic compound preparationIsocyanic acid derivatives purification/separationProcess engineeringPhosgene

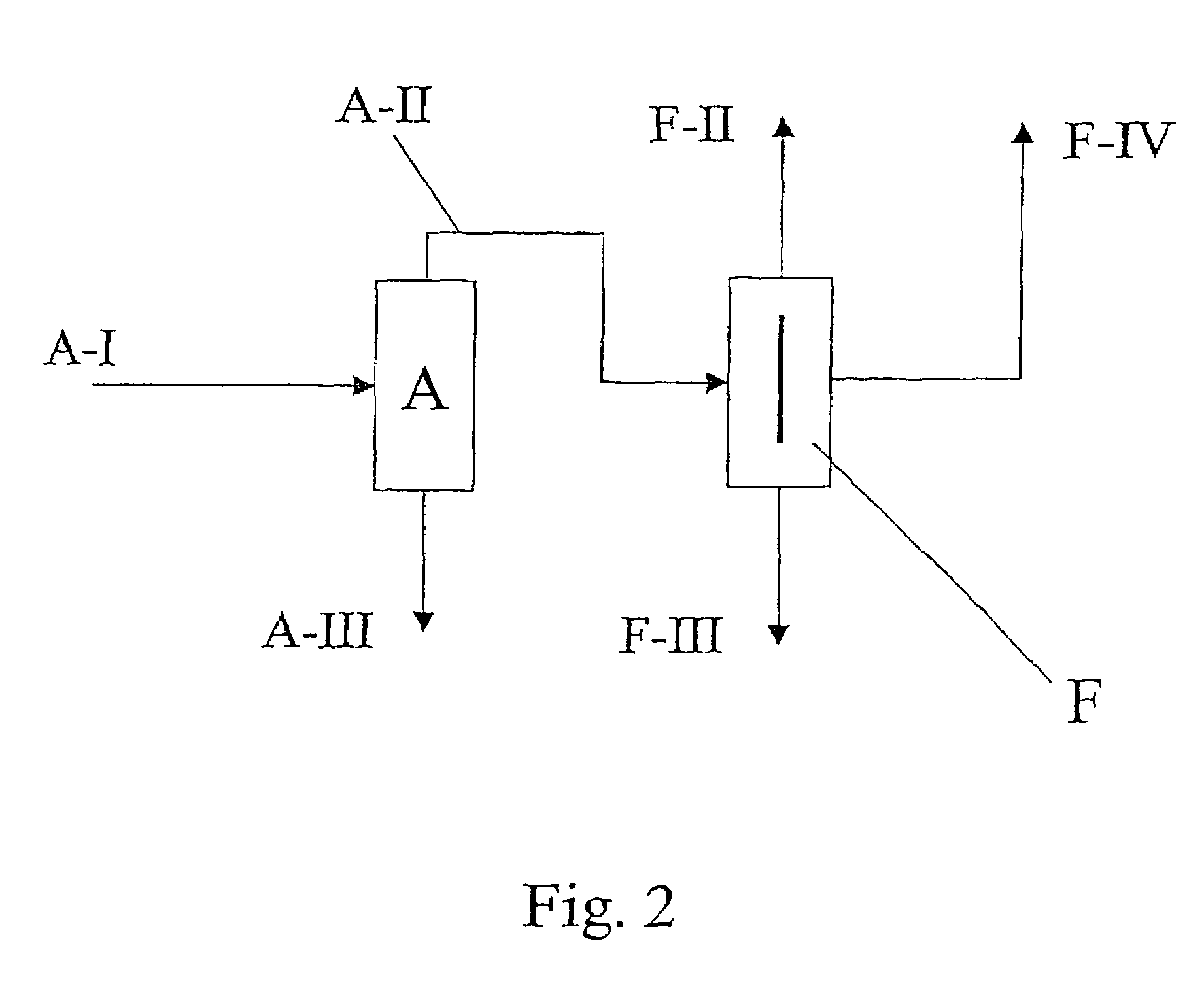

Isocyanates are produced by reacting an organic amine with phosgene in process which includes at least three stages. The first stage is carried out in a dynamic mixer. The second stage is carried out in at least one reactor. The third stage is carried out in at least one material separating apparatus. The pressure in the reactor of the second stage must be greater than or equal to the pressure in the dynamic mixer. The pressure in the third stage material separating apparatus must be lower than the pressure in the second stage reactor.

Owner:COVESTRO DEUTSCHLAND AG

Distillation for processing admixture of isomeric compound of diphenylmethane diisocyanate

ActiveCN101003497AEasy to operateEasy to manufactureIsocyanic acid derivatives purification/separationDistillation methodDiphenylmethane diisocyanate

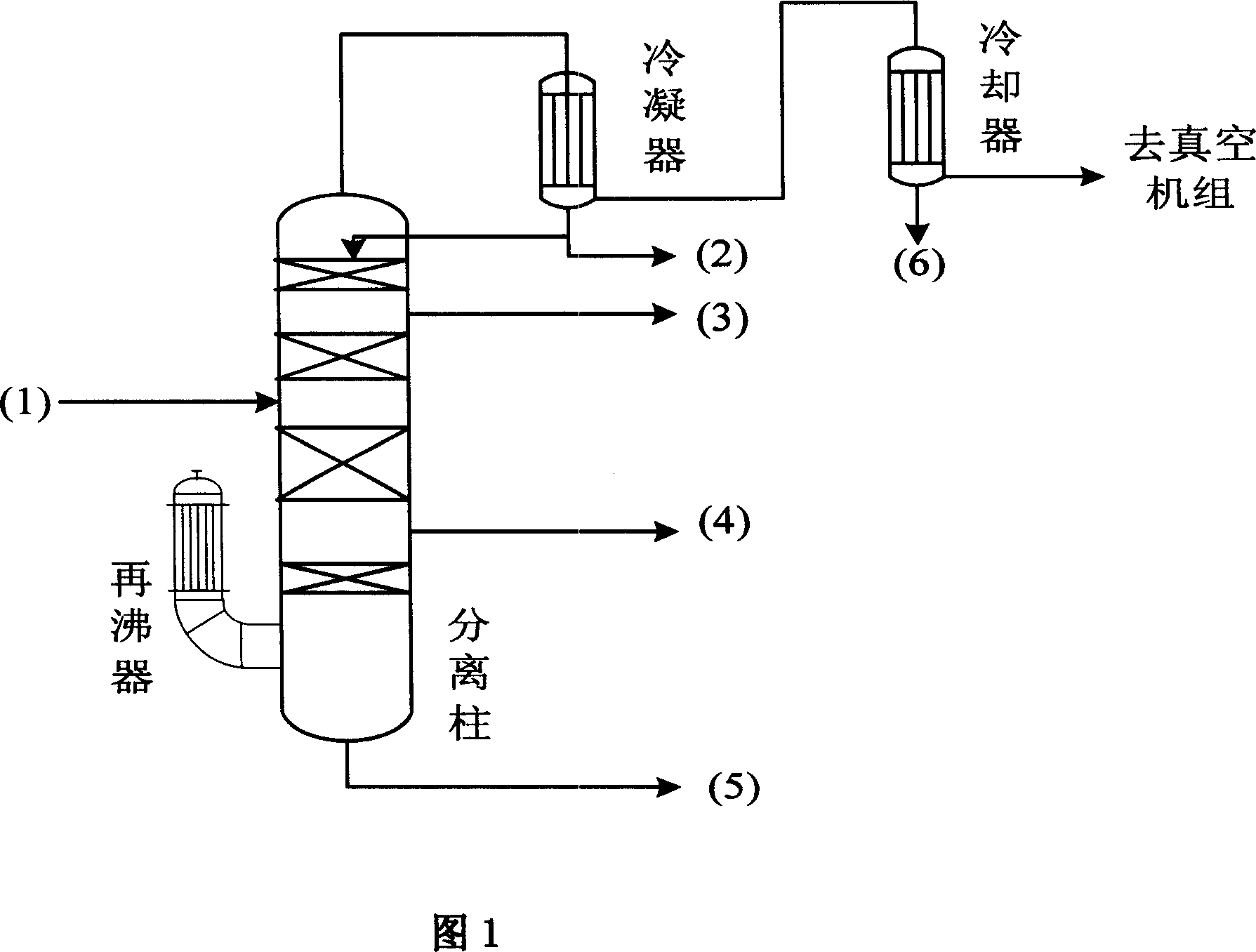

This invention relates to a method for distilling an isomer mixture of isocyanate. The method comprises: adding an isomer mixture of diphenylmethane diisocyanate into a separator, and distilling to obtain at least one product mixture, which comprises: 2,4'-MDI 50-60 wt.%, 4,4'-MDI 40-50 wt.%, 2,2'-MDI less than 1.5 wt.%, 2,4'-MDI less than 1 wt.%, and 4,4'-MDI greater than 99 wt.%. Compared with present distillation methods, the method has such advantages as saved distillation steps, reduced distillation column number, saved energy input, reduced isocyanate loss, and high 4,4'-MDI purity in the product mixture.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

Compounds and compositions for intracellular delivery of therapeutic agents

ActiveUS20170210698A1Low immunogenicityReduce inductionPowder deliveryOrganic active ingredientsNanoparticlePhospholipid

The disclosure features novel lipids and compositions involving the same. Nanoparticle compositions include a novel lipid as well as additional lipids such as phospholipids, structural lipids, and PEG lipids. Nanoparticle compositions further including therapeutic and / or prophylactics such as RNA are useful in the delivery of therapeutic and / or prophylactics to mammalian cells or organs to, for example, regulate polypeptide, protein, or gene expression.

Owner:MODERNATX INC

Method for synthesizing hexamethylene diisocyanate (HDI) biuret

InactiveCN101475680AReduce HDI contentReduce use toxicityIsocyanic acid derivatives purification/separationDissolutionHigh pressure

The invention relates to a method for synthesizing hexamethylene diisocyanate (HDI) biuret through a spray method. The method comprises the following steps: adopting the high pressure to inject water in the form of fog drops into an HDI contained reaction kettle, setting the temperature to be between 60 and 130 DEG C, setting the mol ratio of HDI to water 2 to 15, setting the water spraying time to be between 0.5 and 8 hours, carrying out heat preservation at a temperature of between 80 and 150 DEG C for 0 to 5 hours, and then carrying out the separation through a separating device; setting the separation temperature to be between 70 and 200 DEG C and the pressure to be between 0.5 and 50,000Pa; and pumping the separated steaming residue into a dilution container with a stirrer for dissolution, adding a metered solvent into the dilution container in advance, continuously adding the metered solvent into the dilution container with the pumping of the steaming residue, and carrying out the dilution to obtain an HDI biuret product with 25 to 100 percent of solid content. The method improves the reaction efficiency for producing the HDI biuret product, reduces the generation of polyurea, reduces the HDI content in the HDI biuret, and reduces the use toxicity of the HDI biuret. In addition, the production process is economical and has environmental protection.

Owner:JIANGMEN YIYUAN BIOCHEM ENG

Process for the preparation of isocyanates in the gas phase

ActiveUS20080146834A1Increase the number ofShorten the timeOrganic compound preparationIsocyanic acid derivatives purification/separationGas phaseContact time

An isocyanate is produced by reacting a primary amine with phosgene in the gas phase above the boiling point of the amine over an average contact time of 0.05 to 15 seconds under adiabatic conditions.

Owner:COVESTRO DEUTSCHLAND AG

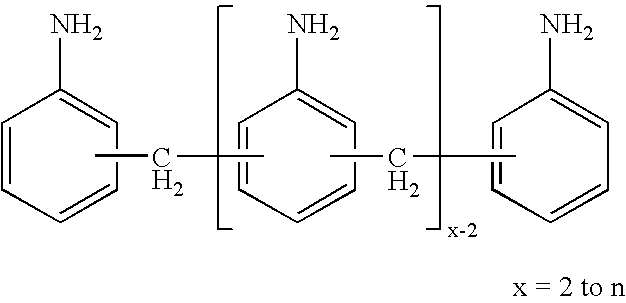

Process for the production of 4,4'-diphenylmethane diisocyanate

InactiveUS20070117997A1Simple processOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

The present invention relates to a process for the production of 4,4′-diphenylmethane diisocyanate (4,4′-MDI) by acid-catalyzed condensation of aniline with formaldehyde, reaction of the mixtures of di- and polyamines obtained with phosgene to form the corresponding mixture of MDI isomers and homologues (di- and polyisocyanates of the diphenylmethane series) and subsequent separation of the mixture by distillation to form 4,4′-MDI and polymeric MDI.

Owner:BAYER MATERIALSCIENCE AG

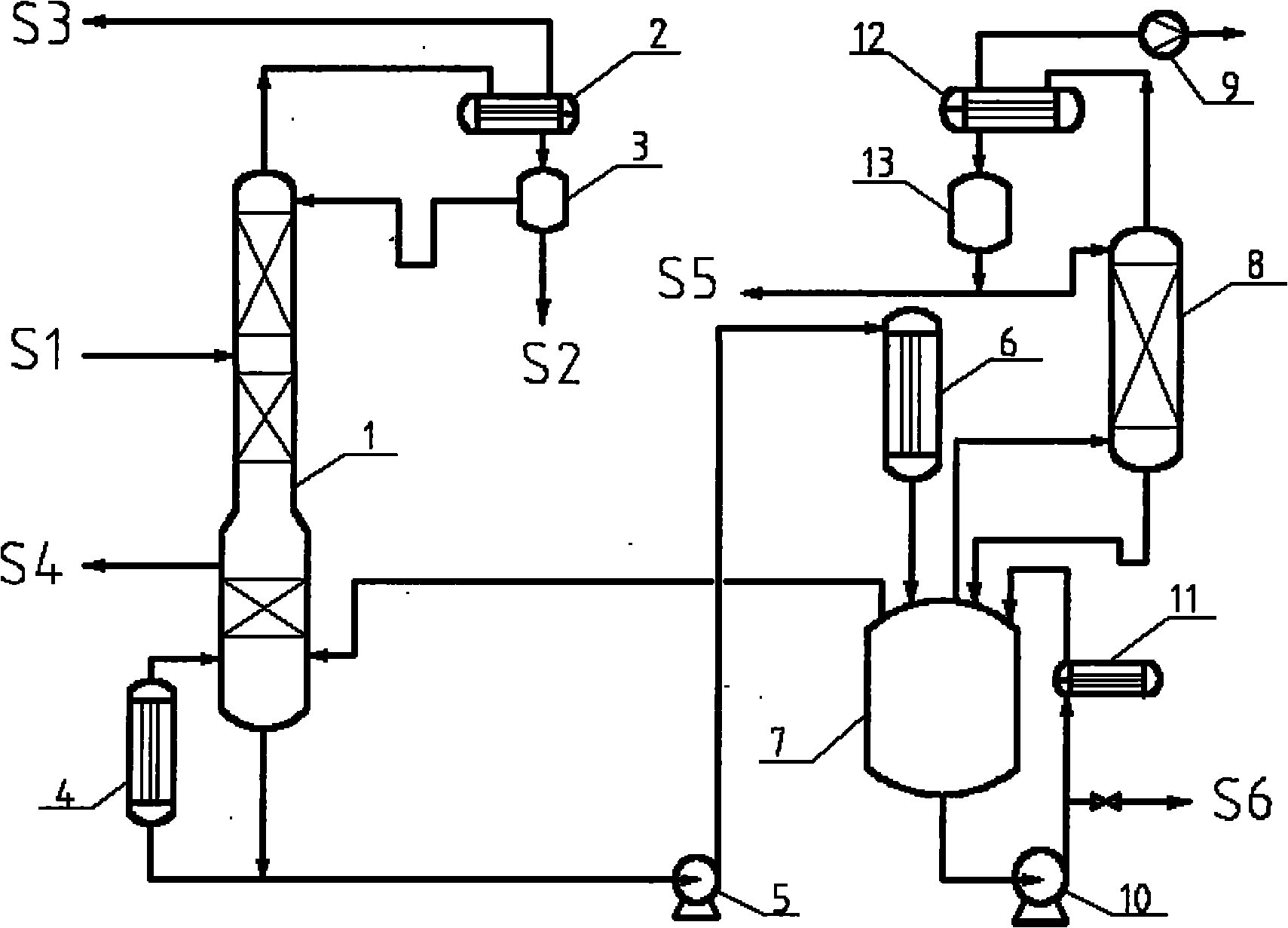

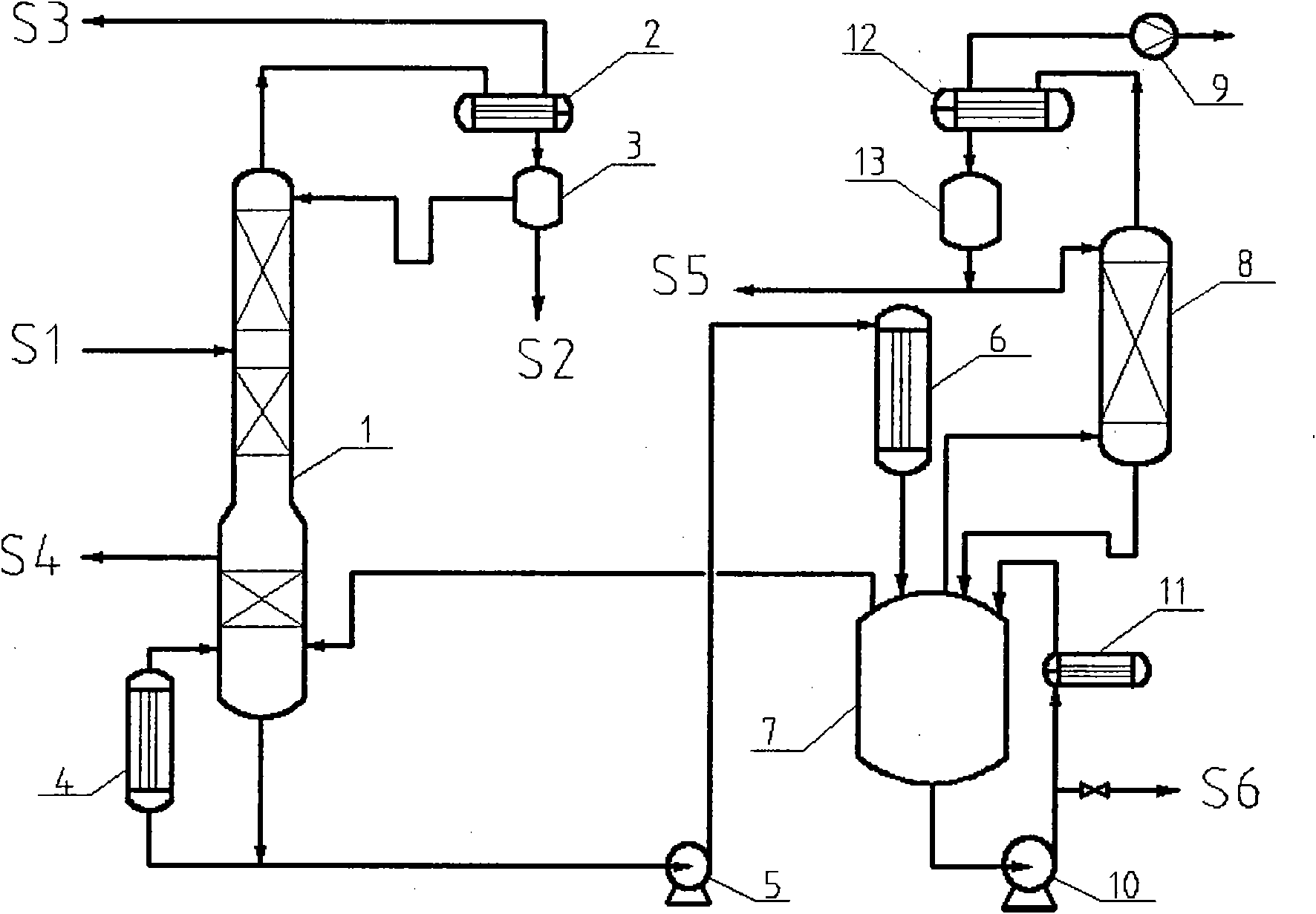

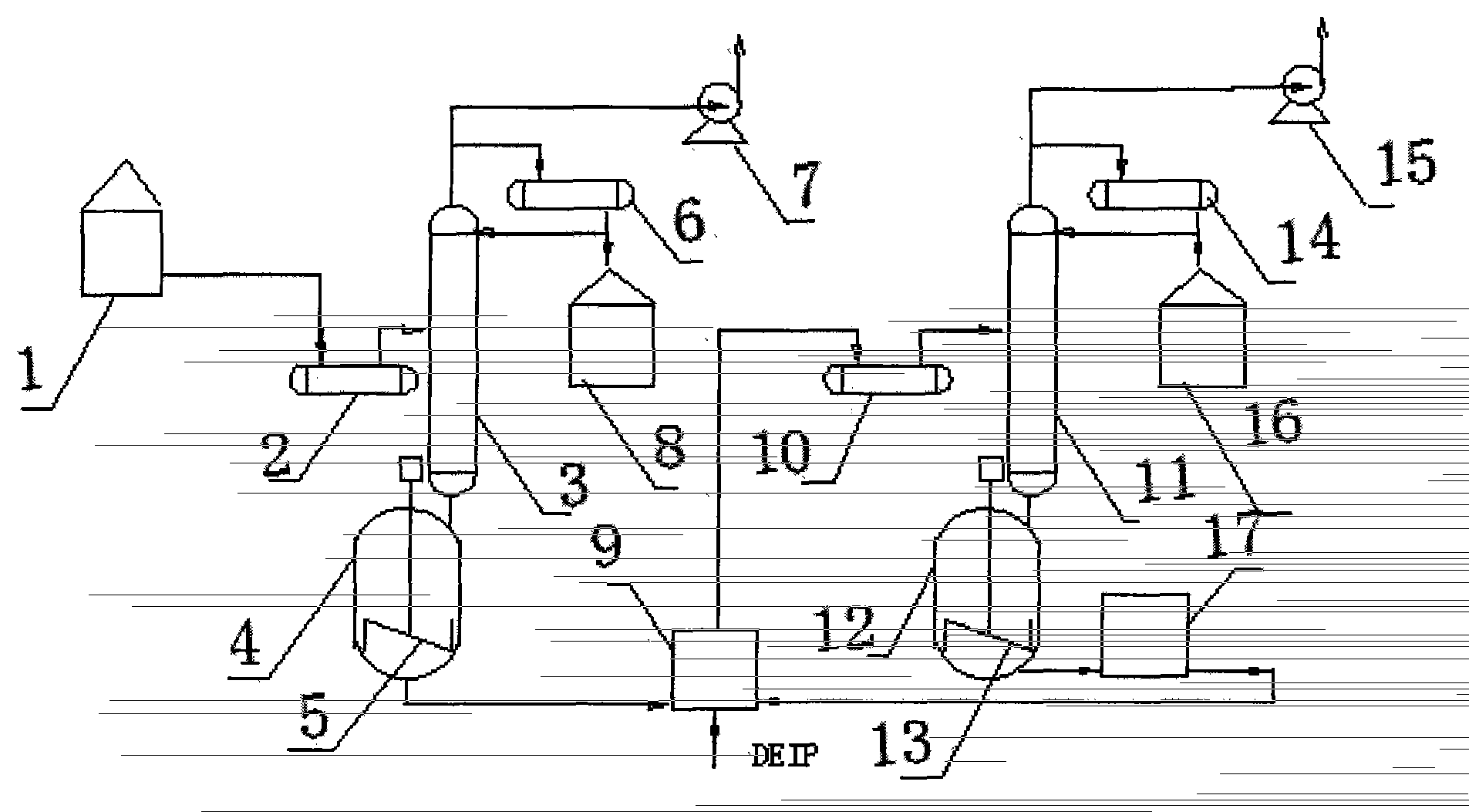

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666AContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

The invention relates to a refining and reclaiming technology of a tail gas absorption solvent in the production of toluene diisocyanate (TDI). The solvent containing little phosgene, toluene diisocyanate and di-Et-1,3-benzenedicarboxylate (DEIP) performs two-stage refinement in an atmospheric refining tower and a vacuum refining tower, and a falling-film evaporator and a storage tank are arranged between the two towers. The overhead non-condensable gas phase of the atmospheric refining tower is returned to a phosgene absorption tower to recycle phosgene, the refined solvent is drawn from theside of the atmospheric refining tower, the temperature of the tower bottom is controlled to be 3-8 DEG C higher than the boiling point of the solvent, the discharged material of the tower bottom enters the falling-film evaporator, the evaporating temperature is 20-30 DEG C higher than the boiling point of the solvent, the unevaporated material enters the storage tank for storage, the material inthe storage tank performs batch vacuum rectification under the absolute pressure of 0.1-0.25bar, and the unevaporated residual material enters the residue evaporator of a TDI device to recycle TDI and DEIP. By using the solvent refining technology provided by the invention, the useful components in the solvent can be completely recycled, and the technology has the advantages of simple and stable operation and lower cost and energy consumption.

Owner:QINGDAO UNIV OF SCI & TECH +1

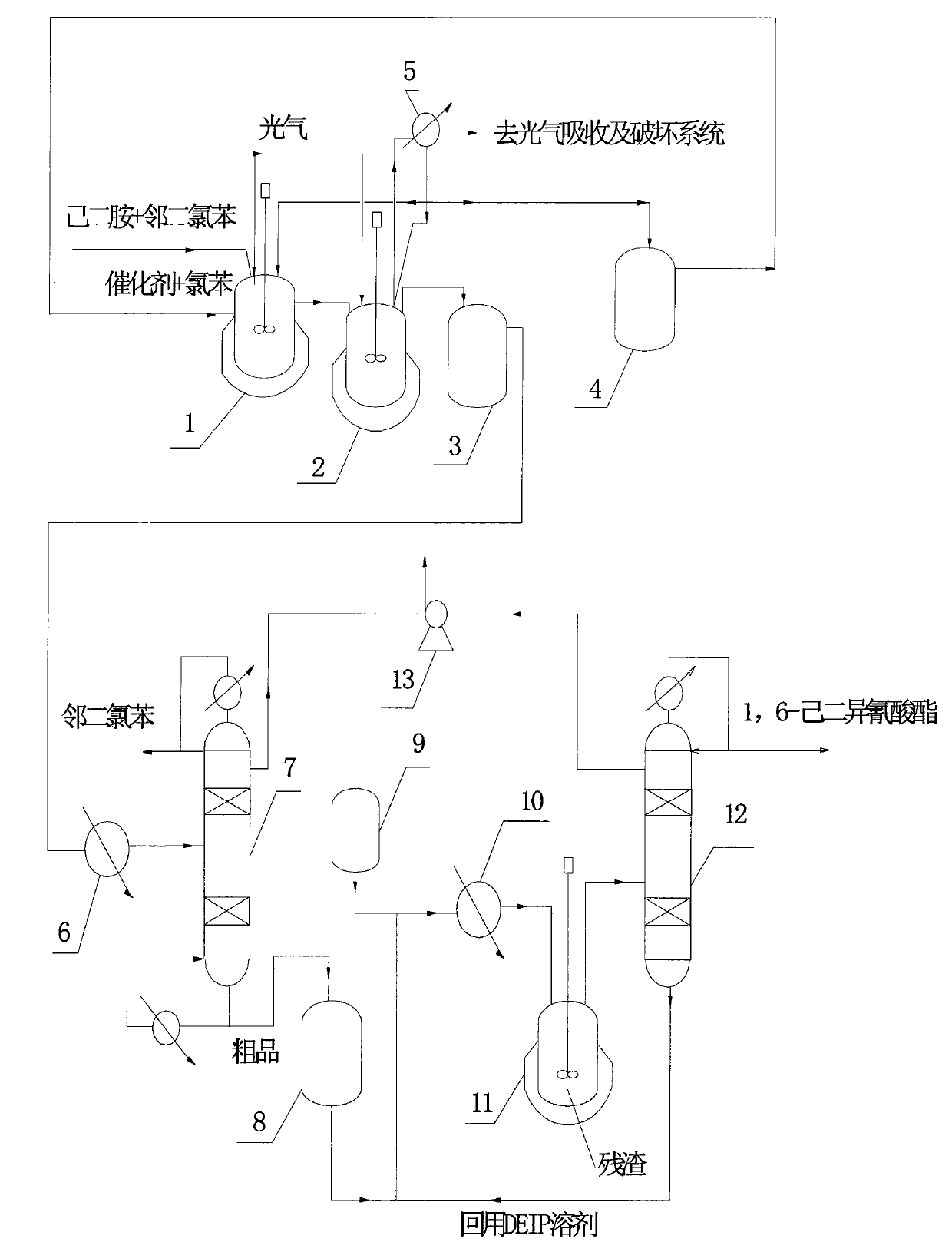

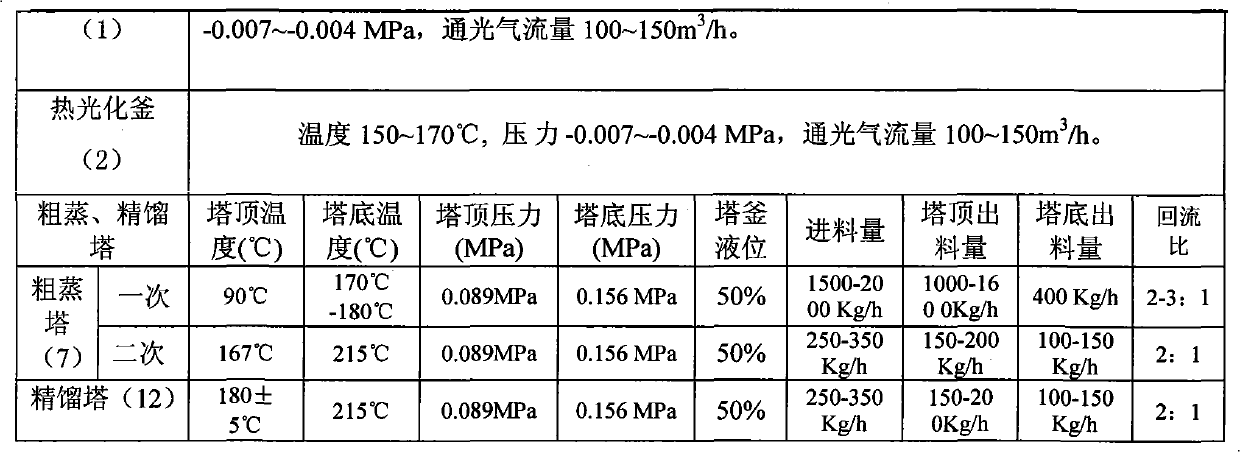

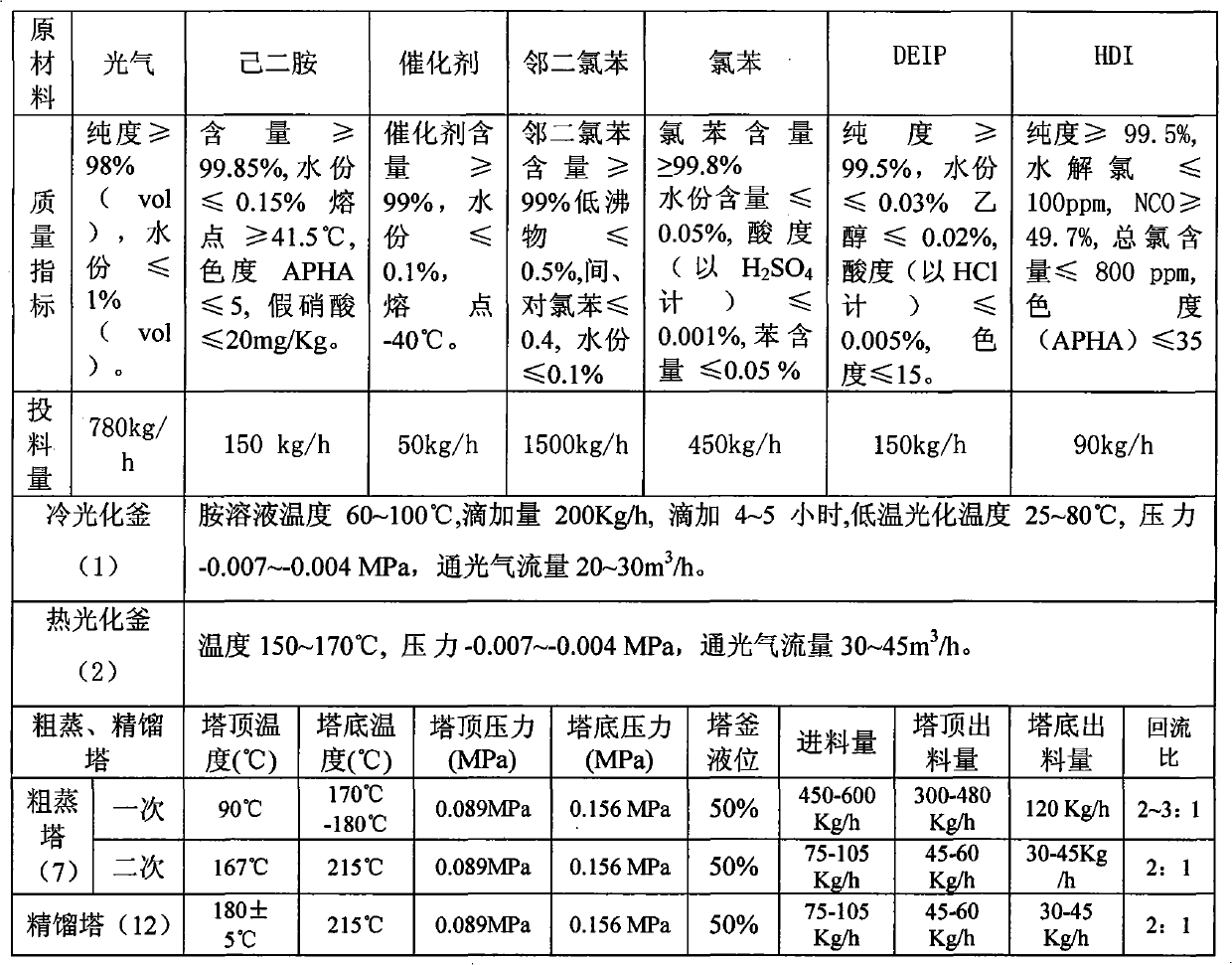

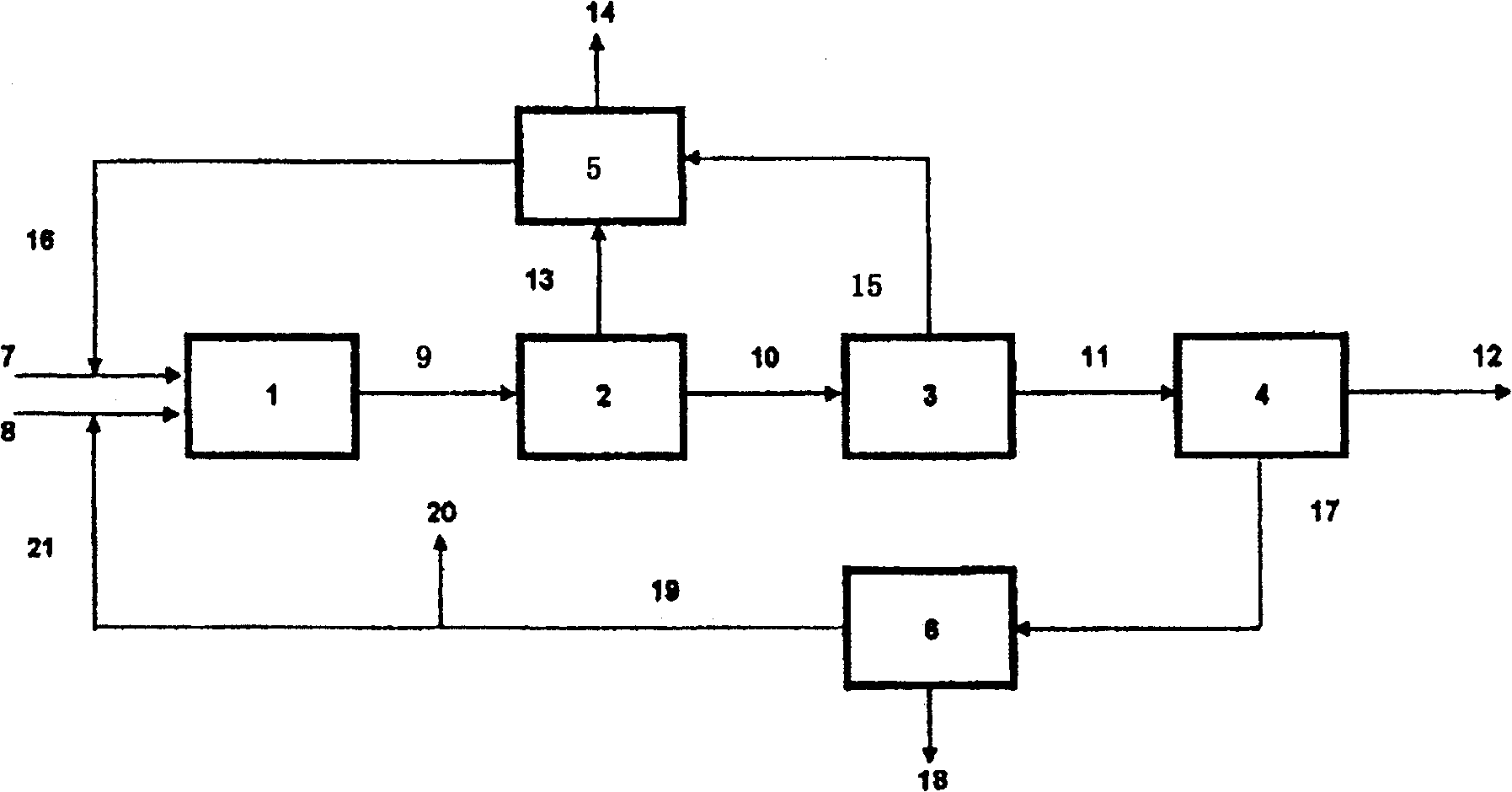

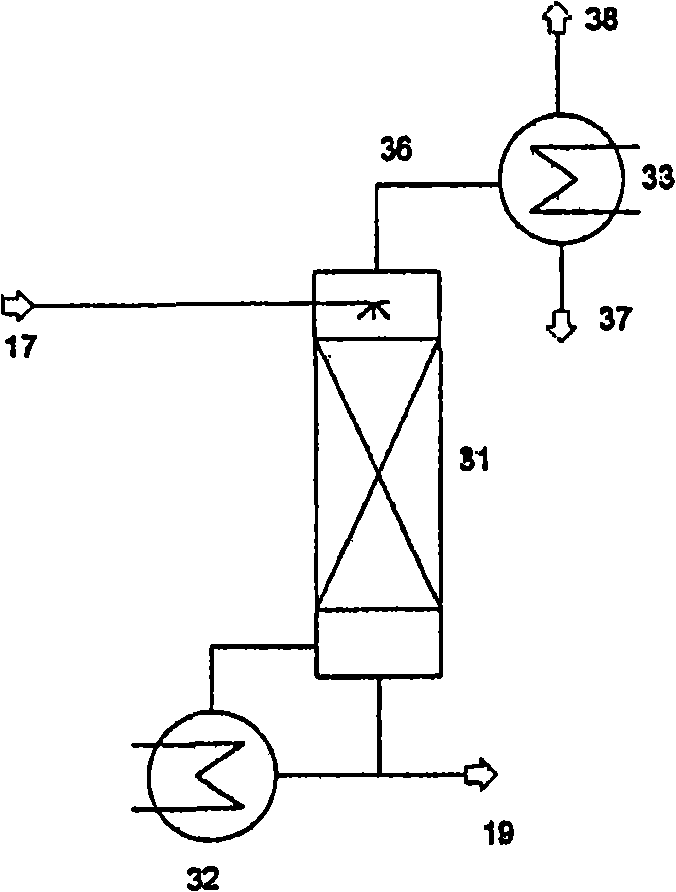

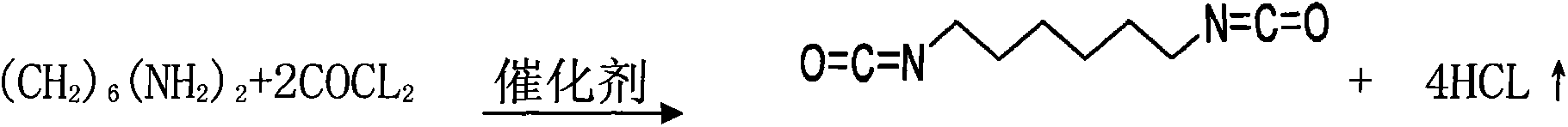

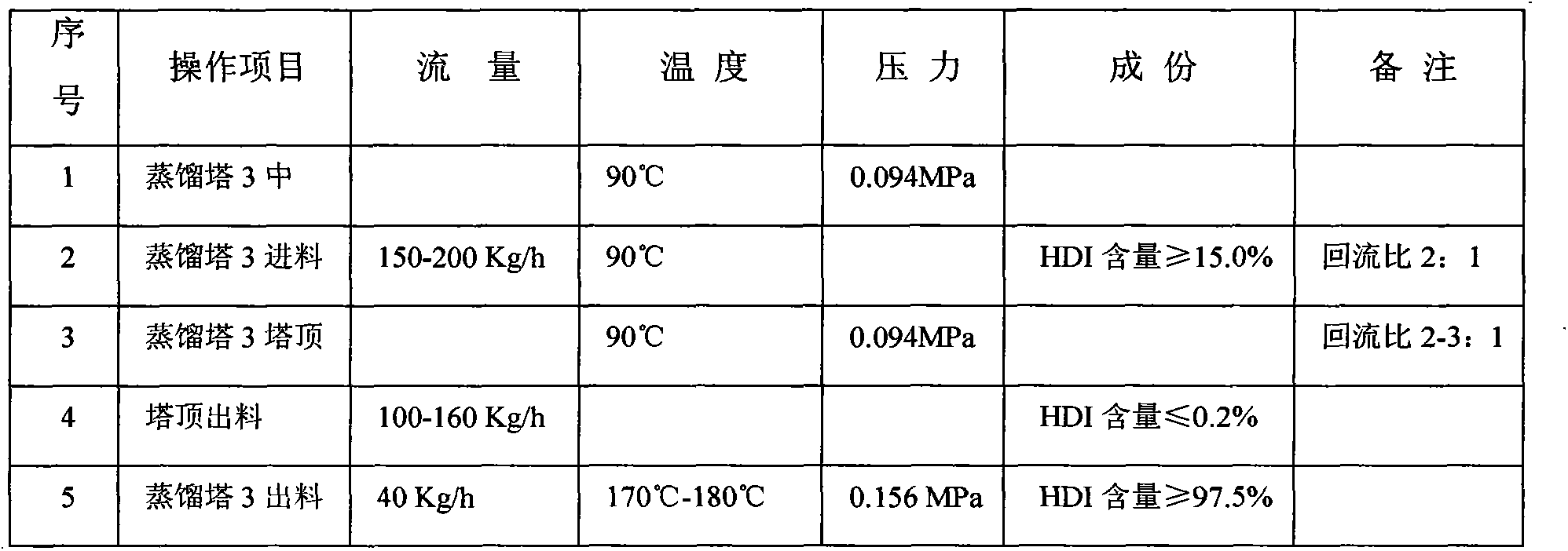

Method for continuously preparing 1,6-hexamethylene diisocyanate

InactiveCN101928235AOrganic compound preparationIsocyanic acid derivatives purification/separationChlorobenzeneBurn treatment

The invention relates to a method for preparing crude 1,6-hexamethylene diisocyanate through the phosgene method and separating pure 1,6-hexamethylene diisocyanate through rectification. The method uses o-dichlorobenzene and chlorobenzene as solvents and comprises the following steps: using hexanediamine and excessive phosgene to perform the two-step reaction of low temperature photochemical reaction and high temperature photochemical reaction under the action of catalyst and generate 1,6-hexamethylene diisocyanate (HDI), removing o-dichlorobenzene through distillation for reuse, continuously distilling to remove by-product chlorinated isocyanate, further mixing with DEIP solvent in a certain ratio through compulsory stirring, heating to perform flash evaporation and rectification, preparing the 1,6-hexamethylene diisocyanate product and DEIP through separation and purification, and regularly discharging the slagged tarry macromolecular compound to perform burning treatment.

Owner:甘肃银光聚银化工有限公司

Method for producing isocyanate

ActiveCN101302174AOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

Isocyanates, preferably diisocyanates and polyisocyanates of the diphenylmethane series (MDI), are produced by reaction of amines dissolved in a solvent with phosgene in the same solvent to form the corresponding isocyanates. Hydrogen chloride and excess phosgene are subsequently removed from the reaction mixture to obtain a crude isocyanate-containing solution. Subsequently, the crude isocyanate-containing solution is separated by distillation into isocyanates and solvent. The solvent is recycled and used for the production of solutions of the amines and of phosgene. The solvent being recycled is treated to reduce the phosgene and diisocyanate contents before being used for the production of the solution of the amine.

Owner:COVESTRO DEUTSCHLAND AG

Process for the preparation of isocyanates

ActiveUS20090209784A1Increased risk potentialPhosgenation processOrganic compound preparationIsocyanic acid derivatives purification/separationSolventPhosgene

The present invention relates to a process for the preparation of isocyanates by reacting the appropriate amines with phosgene, condensing the gas mixture thereby obtained, stripping the liquid phase thereby obtained and returning the solvent so retained in liquid form to the reaction stage. The gaseous constituents are then purified further in an absorption process.

Owner:COVESTRO DEUTSCHLAND AG

Method for manufacturing isocyanates in the gaseous phase

ActiveCN101205197AHigh operating hoursSolve temperature controlOrganic compound preparationIsocyanic acid derivatives purification/separationGas phaseContact time

Owner:COVESTRO DEUTSCHLAND AG

Process for the preparation of isocyanates in the gas phase

ActiveUS20080167490A1Minimal energy inputEasy to separateOrganic compound preparationIsocyanic acid derivatives purification/separationGas phasePhosgene

Isocyanates are produced by reaction of primary amines with phosgene in the gas phase. In this process, the reaction is terminated by guiding the reaction mixture from the reaction chamber through a cooling stretch into which liquids are injected. Direct cooling takes place in the cooling stretch in one stage in two or more cooling zones connected in series.

Owner:COVESTRO DEUTSCHLAND AG

Processes for the preparation of isocyanates

InactiveUS20070269365A1Guaranteed uptimeEasy to operateOrganic compound preparationIsocyanic acid derivatives purification/separationIsocyanateChemistry

Processes are described which comprise: (a) reacting chlorine with carbon monoxide to form phosgene; (b) reacting the phosgene with at least one organic amine to form at least one isocyanate and hydrogen chloride; (c) separating the hydrogen chloride; (d) oxidizing the hydrogen chloride with oxygen in a gas phase to form additional chlorine; and (e) recycling at least a portion of the additional chlorine to the reaction of the chlorine and the carbon monoxide; wherein the oxidation of the hydrogen chloride is initiated via a high energy source which may be selected from electron-exciting radiation, ionizing radiation, a gas discharge, a plasma, and combinations thereof.

Owner:BAYER MATERIALSCIENCE AG

Process for the production of isocyanates

ActiveUS20070249859A1Material minimizationReduce lossesOrganic compound preparationIsocyanic acid derivatives purification/separationPhysical chemistrySolvent

Isocyanates are produced by a) reacting at least one amine with phosgene, optionally in the presence of a solvent to produce the corresponding isocyanate and a stream containing hydrogen chloride, phosgene and optionally solvent, low-boiling compounds and inert substances is obtained, b) separating the stream containing hydrogen chloride, phosgene and optionally solvent, low-boiling compounds and inert substances in an at least two-stage sequence of absorption steps that includes (1) at least one isothermal absorption step and (2) at least one adiabatic absorption step, to obtain (i) a hydrogen chloride stream containing phosgene in concentrations of at most 0.5 wt. % (based on the weight of the hydrogen chloride stream) and (ii) a liquid phosgene stream, and c) recycling the liquid phosgene stream (ii) to the reaction of amine with phosgene.

Owner:COVESTRO DEUTSCHLAND AG

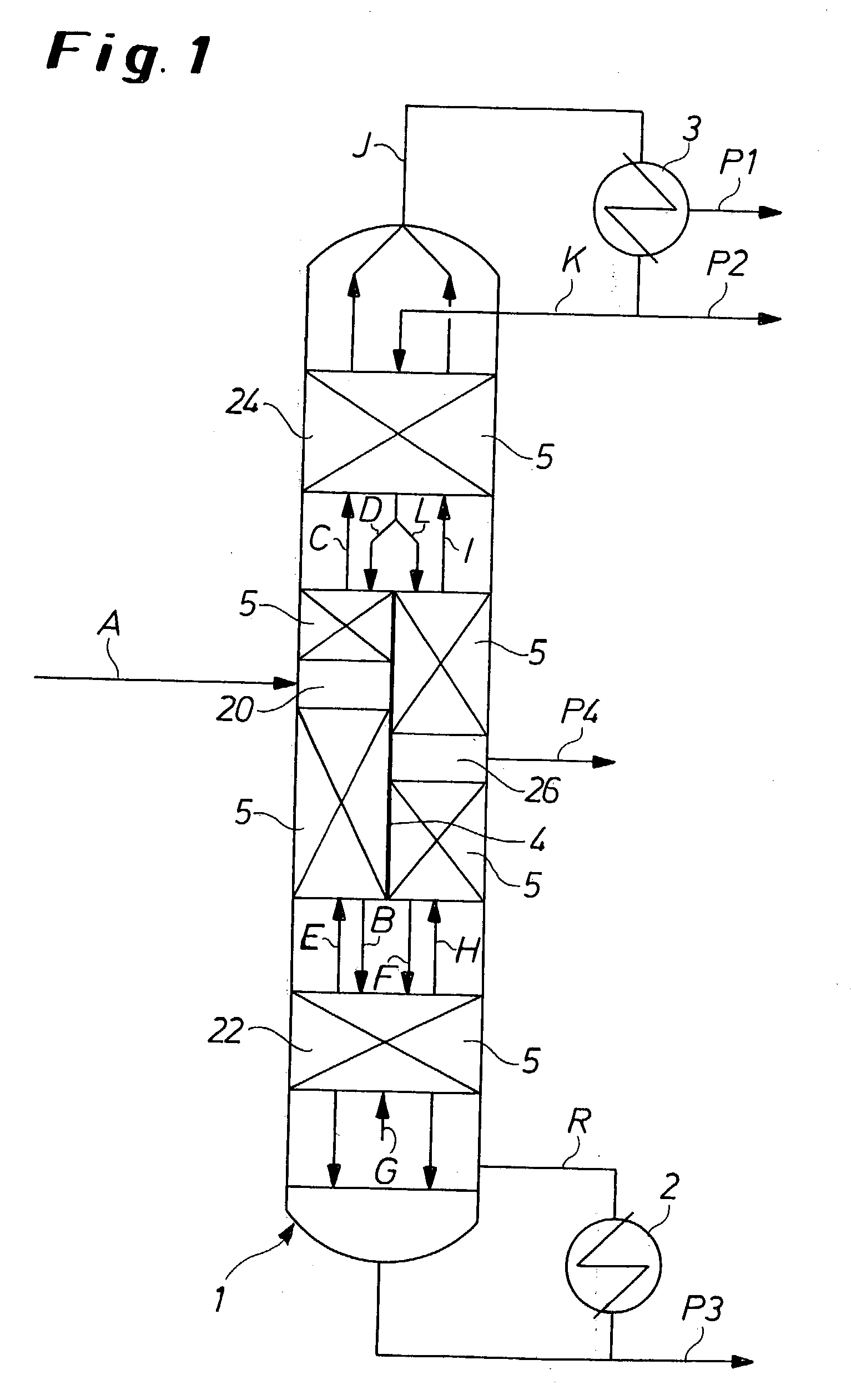

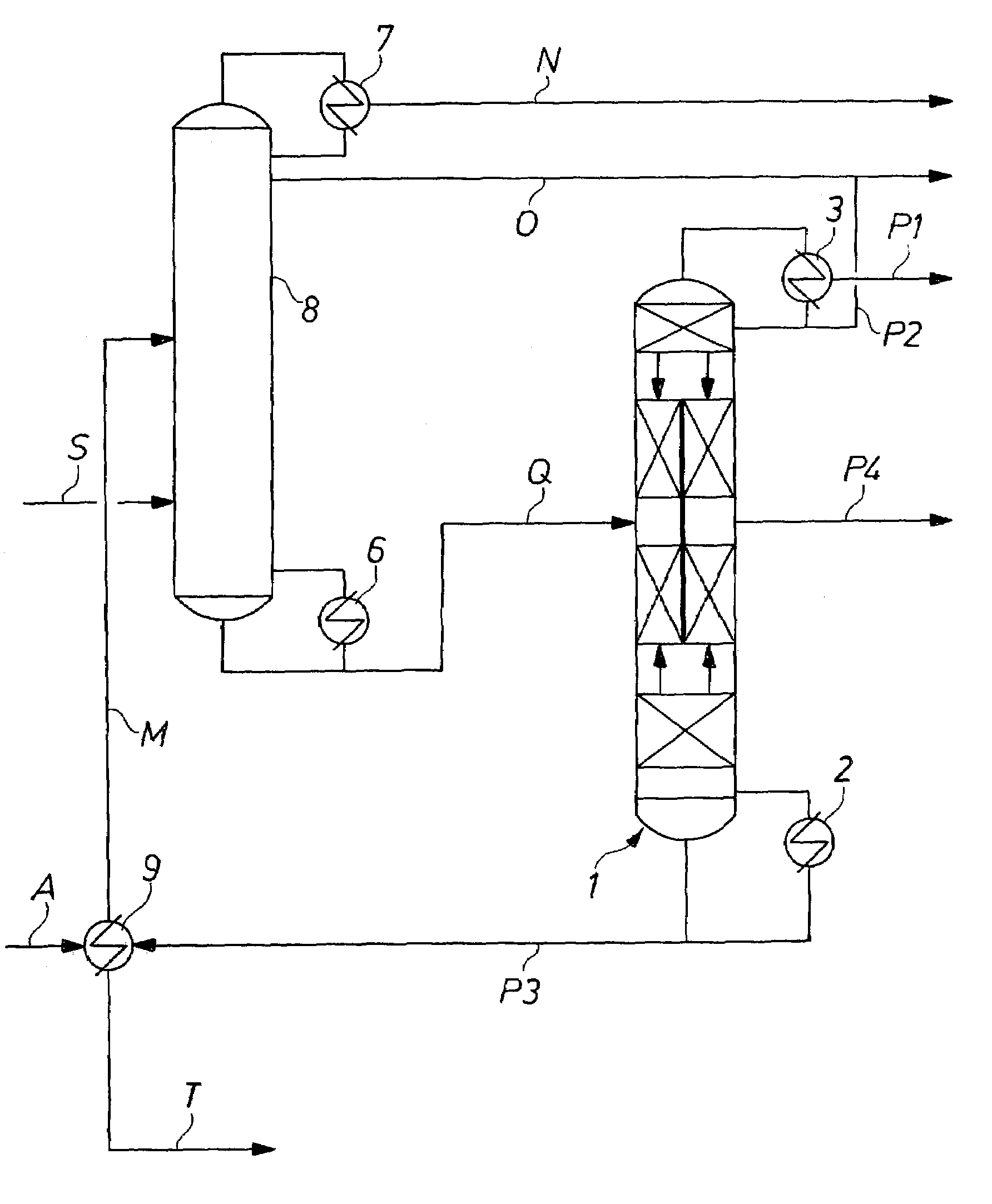

Process for the purification of toluene diisocyanate incorporating a dividing-wall distillation column for the final purification

InactiveUS7108770B2Improvement in TDI purityLower energy requirementsOrganic compound preparationIsocyanic acid derivatives purification/separationPurification methodsGas phase

Toluene diisocyanate is recovered from a crude distillation feed containing less than 2% by weight of phosgene by(a) fractionating the crude distillation feed containing less than 2% by weight of phosgene to remove the solvent and optionally the reaction residues to produce a crude toluene diisocyanate feed containing less than 20% by weight of solvent and(b) separating the crude toluene diisocyanate feed containing less than 20% by weight of solvent in a divided-wall distillation column into four product fractions P1–P4. P1 is a vapor phase low-boiler and solvent-enriched gas stream, P2 is a low-boiler and solvent-enriched product, P3 is a high boiler-enriched bottoms product containing toluene diisocyanate and P4 is a toluene diisocyanate product stream lean in low-boilers, high-boilers and reaction residues.

Owner:COVESTRO DEUTSCHLAND AG

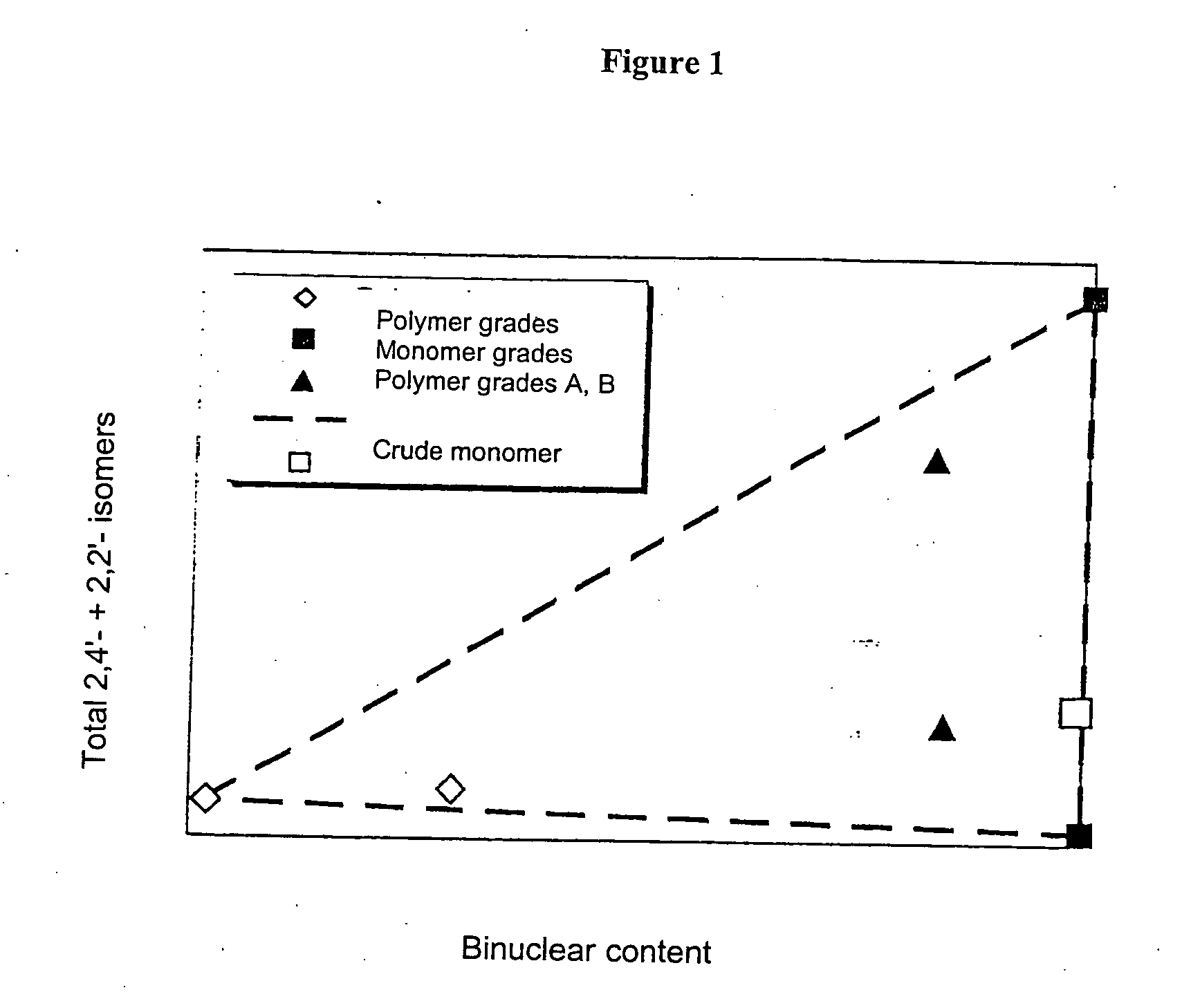

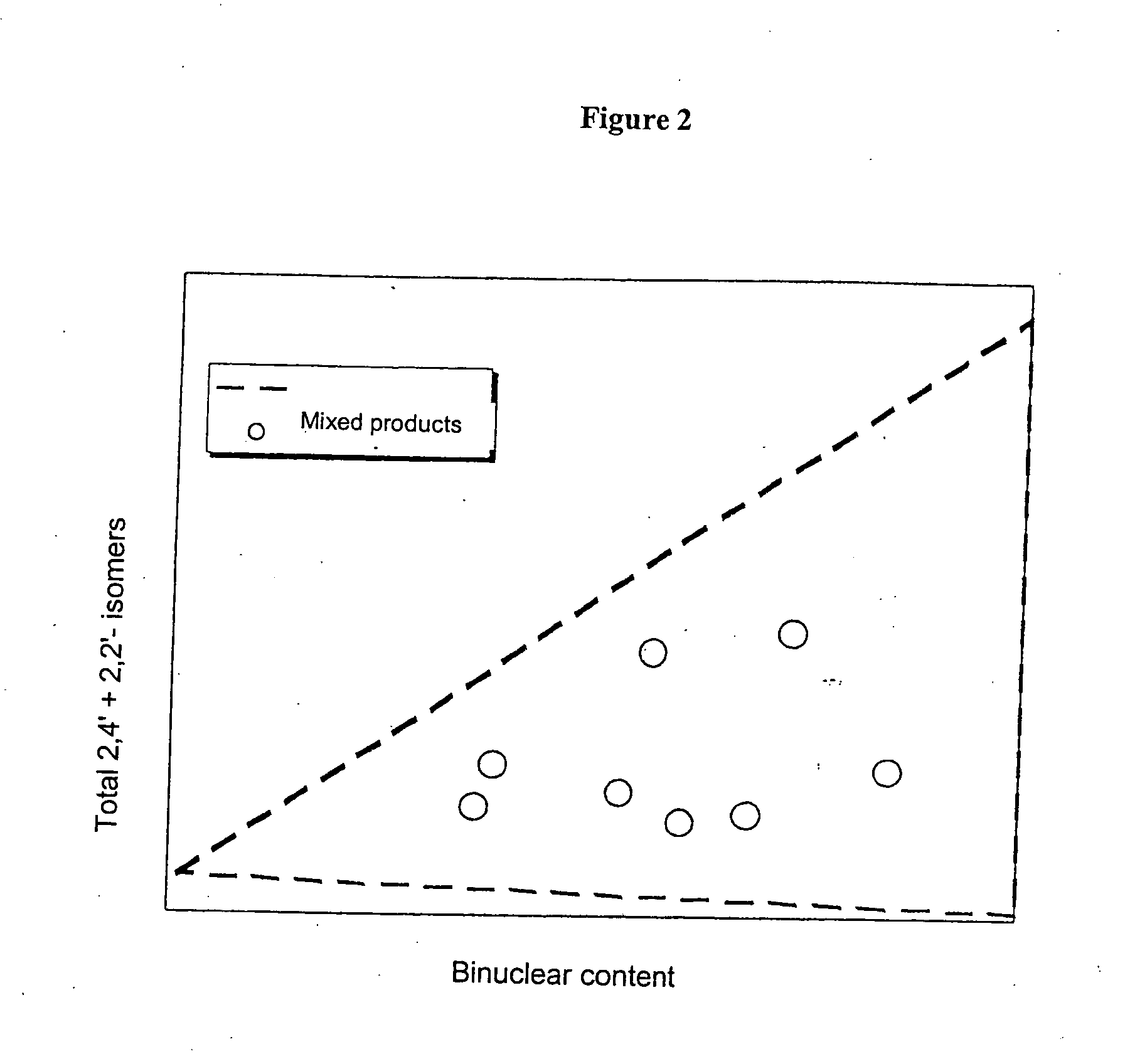

Production of mixtures of diisocyanates and polyisocyanates from the diphenylmethane series with high contents of 4,4'-methylenediphenyl diisocyanate and 2,4'-methylenediphenyl diisocyanate

ActiveUS20050020797A1Simple processLow component requirementsOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

A fraction of diisocyanates of the diphenylmethane series containing at least 95 wt. % binuclear methylenediphenyl diisocyanate is obtained by a) reacting aniline and formaldehyde in the presence of an acid catalyst to produce diamines and polyamines of the diphenylmethane series containing binuclear methylenediphenyl diamine, b) phosgenating the diamines and polyamines produced in a), optionally in the presence of a solvent, to produce a crude diisocyanate and polyisocyanate, and c) separating a fraction containing at least 95 wt. % binuclear methylenediphenyl diisocyanate with a 4,4′-MDI content of over 60 wt. %, a 2,4′-MDI content of 4 to 35 wt. % and a 2,2′-MDI content of 0.01 to 10 wt. %, relative to the mass of the fraction, and a maximum of 20 ppm phenyl isocyanate and optionally a maximum of 50 ppm solvent from the crude diisocyanate and polyisocyanate produced in b) in a single distillation step with optional upstream and / or downstream separation of low-boiling components.

Owner:COVESTRO DEUTSCHLAND AG

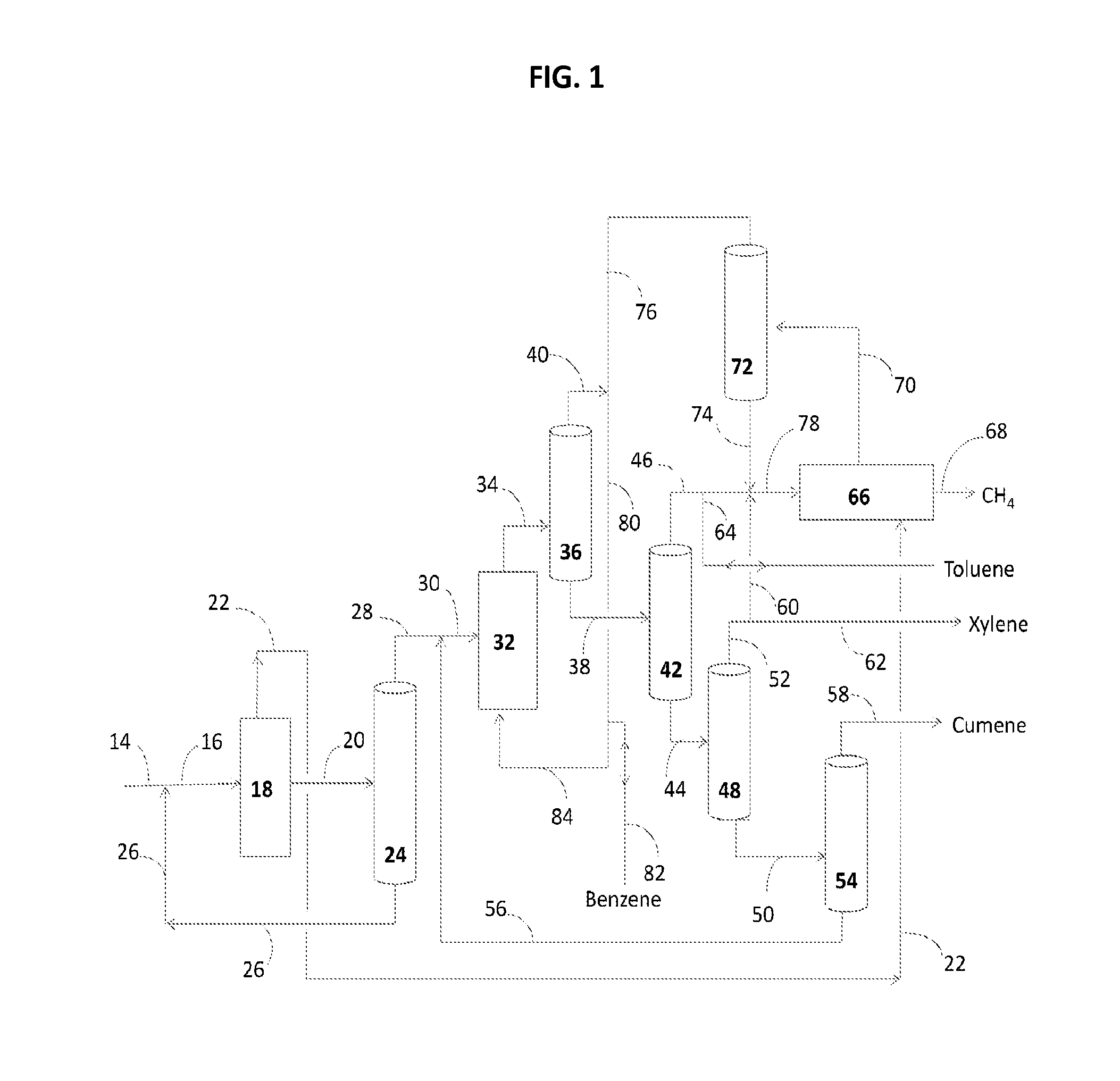

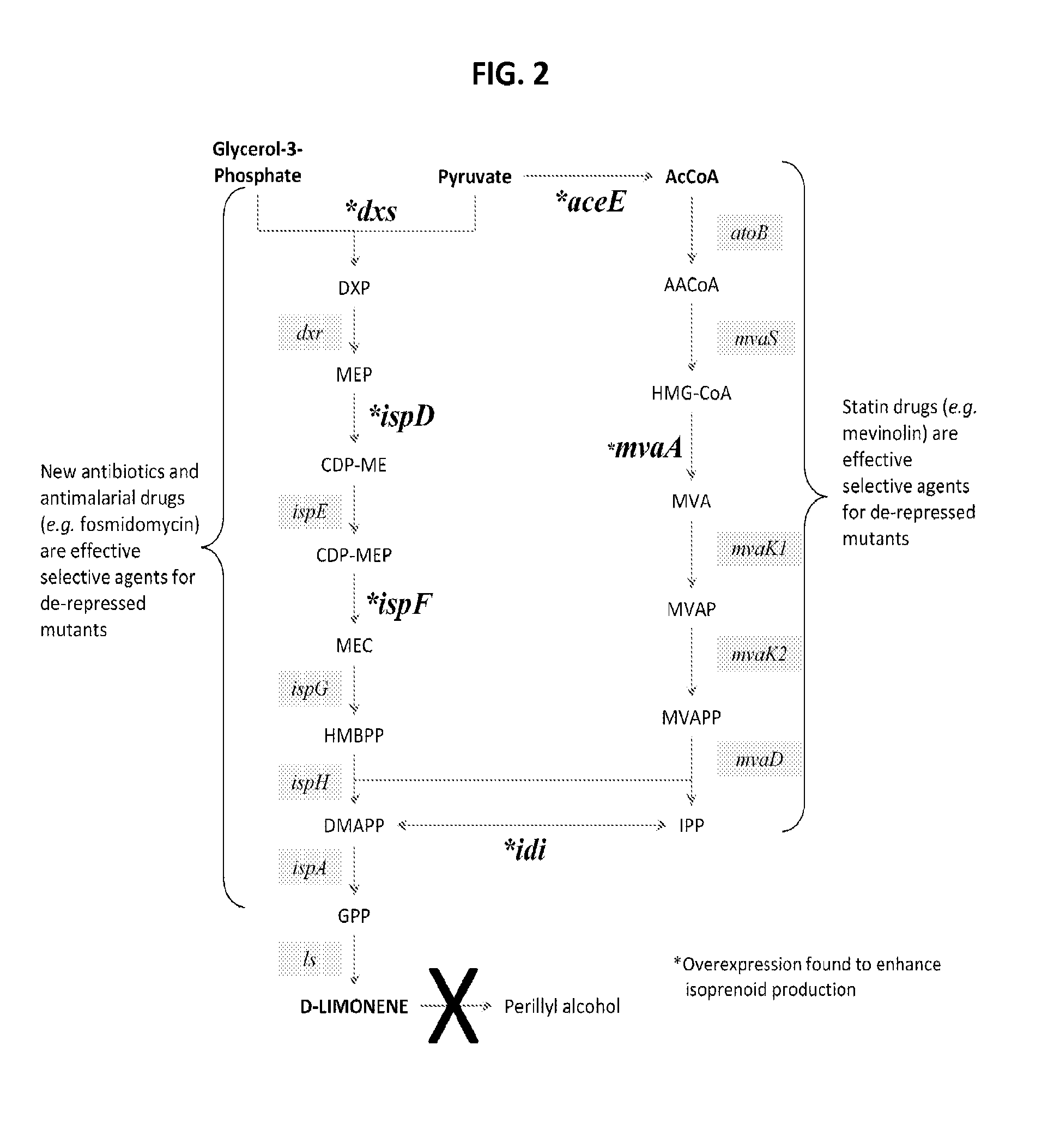

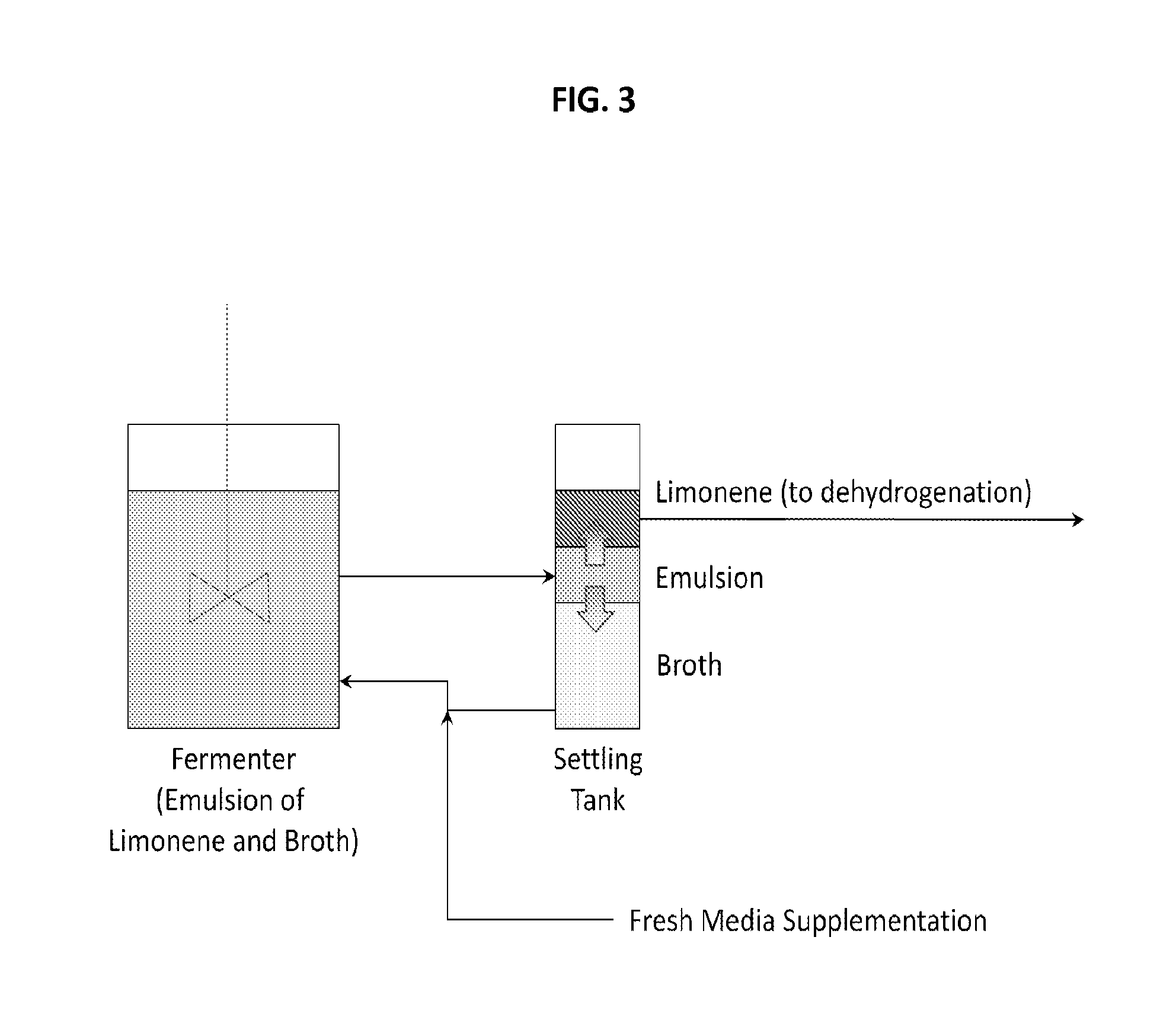

Production of renewable aromatic compounds

InactiveUS20130130345A1Hydrocarbon by isomerisationOrganic chemistry methodsBenzoic acidCyclohexanone

The invention provides a process for producing a variety renewable aromatic compounds such as benzene, toluene, xylenes, and cumene, as well as compounds derived from these including, for example, aniline, benzoic acid, cresol, cyclohexane, cyclohexanone, phenol and bisphenol A, toluene di-isocyanate, isophthalic acid, phthalic anhydride, terephthalic acid and dimethyl terephthalate. The invention also provides for renewable forms of these aromatic compounds.

Owner:JNF BIOCHEM

Device for refining hexamethylene diisocyanate and method thereof

The invention specifically relates to production equipment for refining hexamethylene diisocyanate and a method thereof. A stirrer is respectively arranged in the middle of the bottom of both a distillation column and a rectifying tower which are provided with a stirring device, and stirring wings are a frame type. The method for refining hexamethylene diisocyanate comprises the following steps: (1) letting an synthesized HDI solution enter a distillation column through a heat exchanger, starting a first vacuum pump, and starting a first stirrer in the column bottom while the agitation speed is less than or equal to 60rpm / min; Starting a first condenser on the tower top, evaporating all o-dichlorobenzene, continuously discharging by the distillation column and entering a mixing tank; and (ii) adding a DEIP solvent into the mixing tank, uniformly mixing crude HDI and the DEIP solvent according to the HDI-DEIP ratio of 1:1-1.5, sending the mixture into the rectifying tower to firstly evaporate mono-isocyanate chloride and continuously evaporate the HDI, drawing forth the DEIP for recycling, stirring high polymer residue in a heating vessel and discharging regularly, and carrying out burning treatment. The device and method provided by the invention can be applied in distillation separation and purification production technology which is easy to generate auto-agglutination phenomenon under the distillation condition.

Owner:甘肃银光聚银化工有限公司

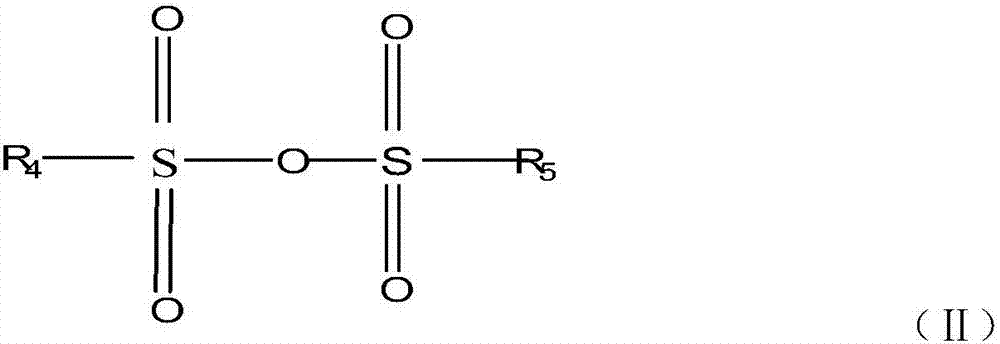

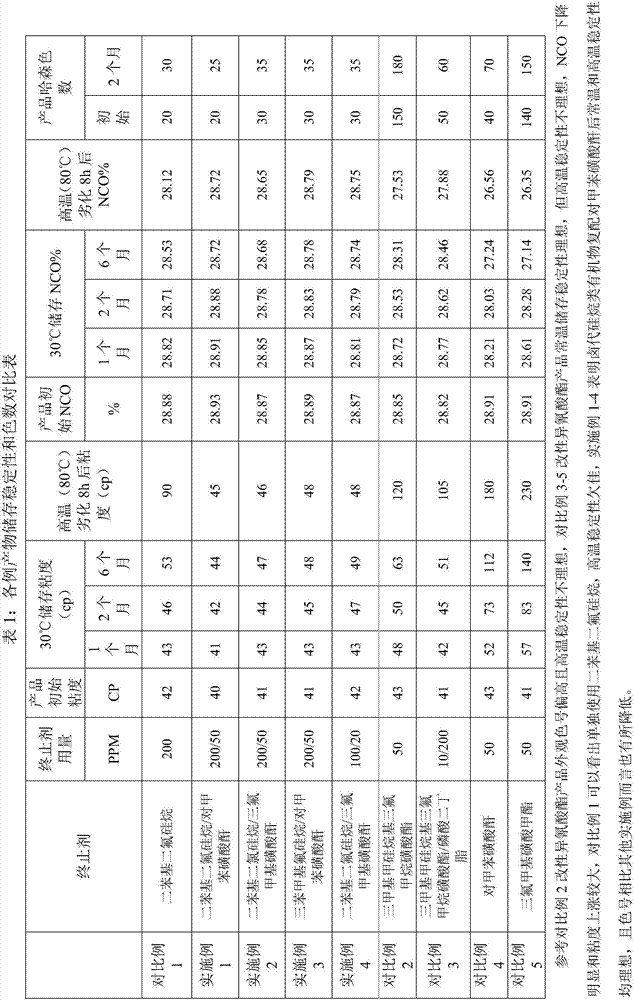

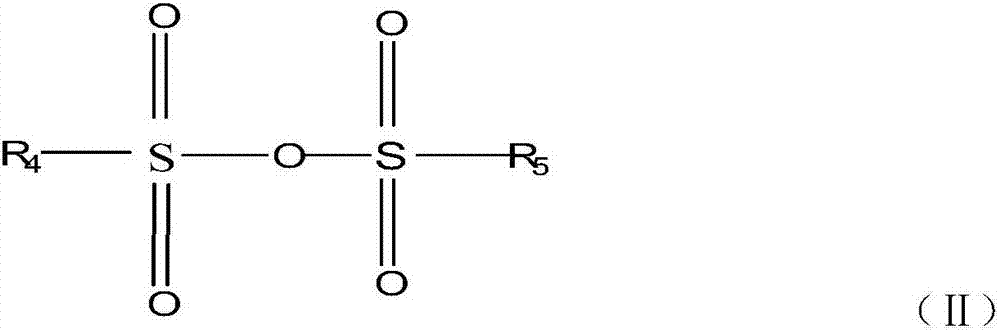

Light color modified isocyanate mixture and preparation method thereof

ActiveCN107879951AGood storage stability at room temperatureGroup content decreasedIsocyanic acid derivatives purification/separationHigh temperature storageSilanes

The invention relates to a light color modified isocyanate mixture and a preparation method thereof. The method comprises the following steps: (a) carrying out reaction on isocyanate groups of the rawmaterial isocyanate in the presence of phosphorus-heterocycle catalysts, and finally obtaining a modified isocyanate reaction solution containing carbodiimide and / or uretonimine derivatives; and (b)adding a terminating agent compounded from halogenated silane organic matters and sulfonic anhydrides into the reaction solution obtained in the step a so as to terminate the carbodiimide reaction. The modified isocyanate prepared by the method has the characteristics of normal-temperature liquid and normal temperature and high temperature storage stability and low color number.

Owner:WANHUA CHEM GRP CO LTD

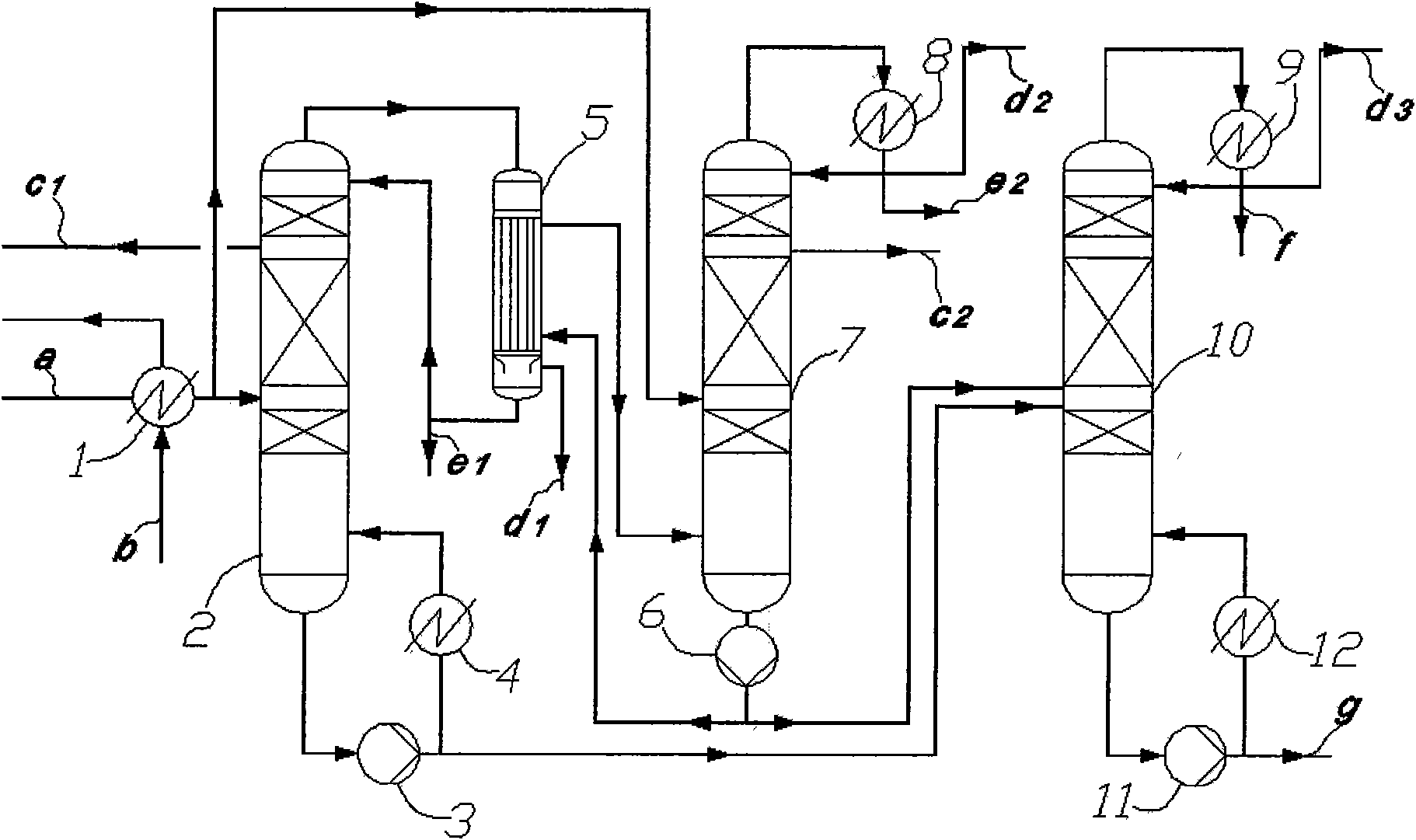

Method for recovering heat integrated solvent in continuous production of toluene di-isocyanate

ActiveCN101671277AReduce energy consumptionReduce manufacturing costChemical industryIsocyanic acid derivatives purification/separationOrganic solventDistillation

The invention discloses a method for recovering heat integrated solvent in the continuous production of toluene di-isocyanate, comprising the following steps: respectively importing materials to be distilled, which contains the toluene di-isocyanate and an inert organic solvent, to a first solvent eliminating tower with higher operation pressure and a second solvent eliminating tower with lower operation pressure to carry out distillation; leading steam from the top of the first solvent eliminating tower into a first condenser and leading part of tower bottom liquid in the second solvent eliminating tower into the first condenser to carry out heat transferring; and leading part of the tower bottom liquid from the first solvent eliminating tower and the second solvent eliminating tower intoa third solvent eliminating tower to carry out distillation. The method can obviously reduce the energy consumption in the production of the toluene di-isocyanate, thereby reducing the production cost of a unit toluene di-isocyanate product.

Owner:TIANJIN UNIV +1

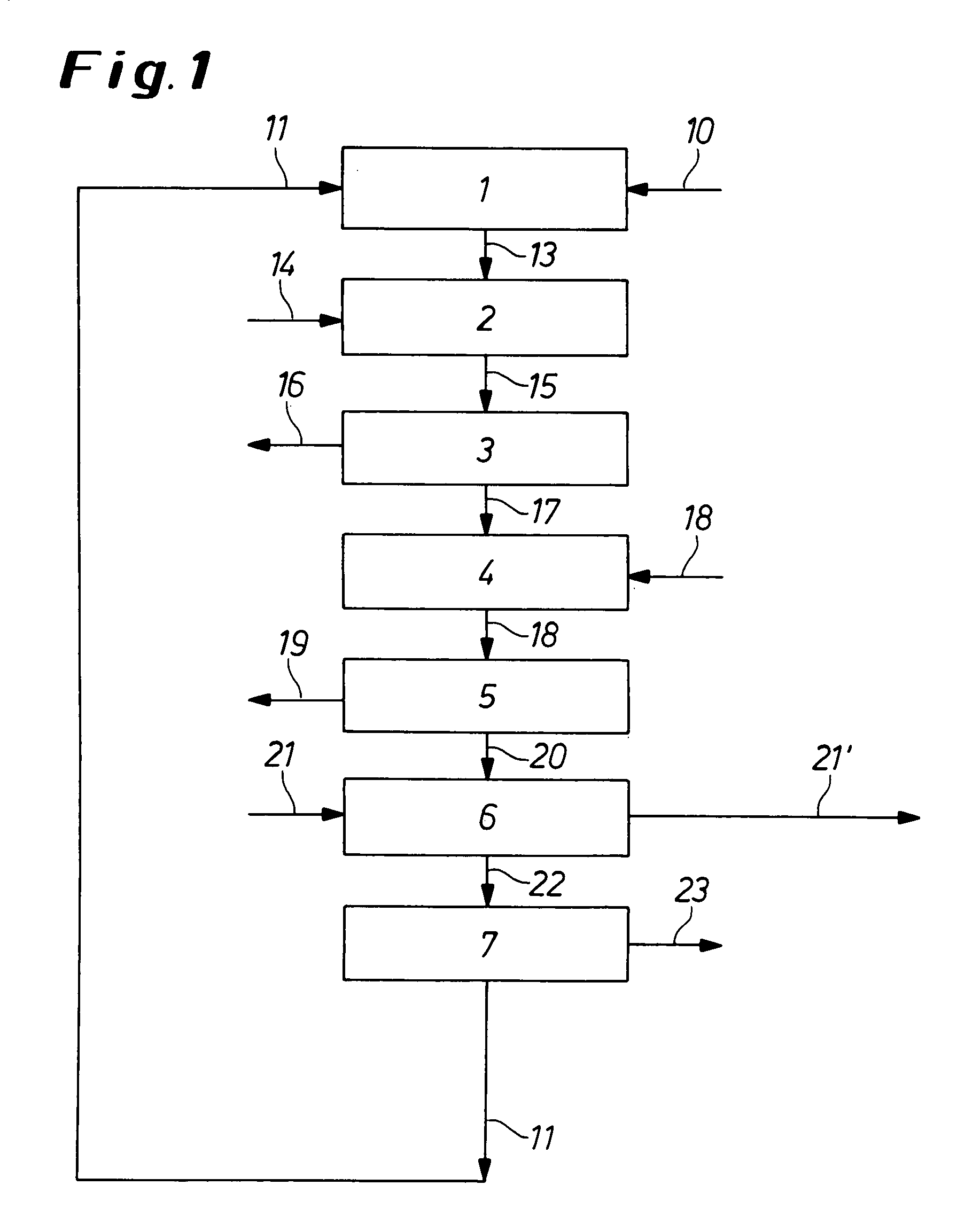

Multistage continuous preparation of cycloaliphatic diisocyanates

Cycloaliphatic diisocyanates can be prepared continuously and phosgene-free by reacting at least one cycloaliphatic diamine with at least one carbonic acid derivative and at least one alcohol to give a cycloaliphatic diurethane; freeing the cycloaliphatic diurethane of a low boiler, a medium boiler and mixtures thereof; thermally cleaving the cycloaliphatic diurethane in a cleavage apparatus to give a cycloaliphatic diisocyanate and a cleavage residue; continuously discharging a portion of the cleavage residue from the cleavage apparatus; removing the high boiler components from the discharge to obtain a purified discharge; reurethanizing the purified discharge with alcohol to obtain a reurethanized discharge; and recycling the reurethanized discharge into the process.

Owner:EVONIK DEGUSSA GMBH

Process for the preparation of isocyanates in the gas phase

ActiveUS7615662B2Minimal energy inputEasy to separateOrganic compound preparationIsocyanic acid derivatives purification/separationGas phasePhosgene

Isocyanates are produced by reaction of primary amines with phosgene in the gas phase. In this process, the reaction is terminated by guiding the reaction mixture from the reaction chamber through a cooling stretch into which liquids are injected. Direct cooling takes place in the cooling stretch in one stage in two or more cooling zones connected in series.

Owner:COVESTRO DEUTSCHLAND AG

Process for the production of very pure 2,4'-methylenediphenyl diisocyanate

ActiveUS20050222291A1Boiling pointEasy to useUmbrellasOrganic compound preparationOrganic chemistryMonomer

The present invention relates to a process for the production of MDI fractions containing 2,4′-MDI, and in which the 2,2′-MDI component from the MDA production is largely removed from the isomer mixture. Highly reactive monomeric MDI products can be produced in this way. These MDI products are characterised in their processing by significantly reduced emissions of MDI monomers.

Owner:COVESTRO DEUTSCHLAND AG

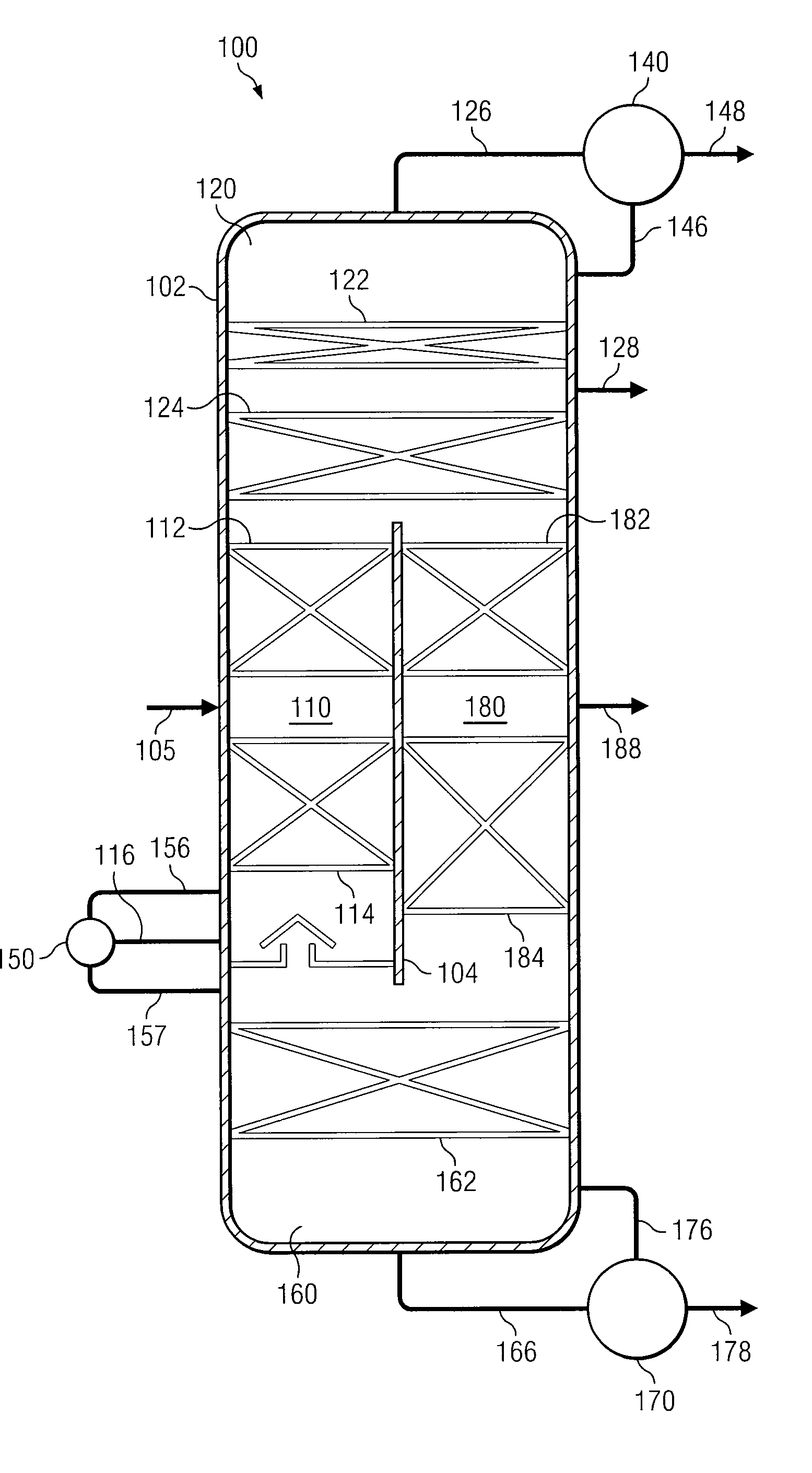

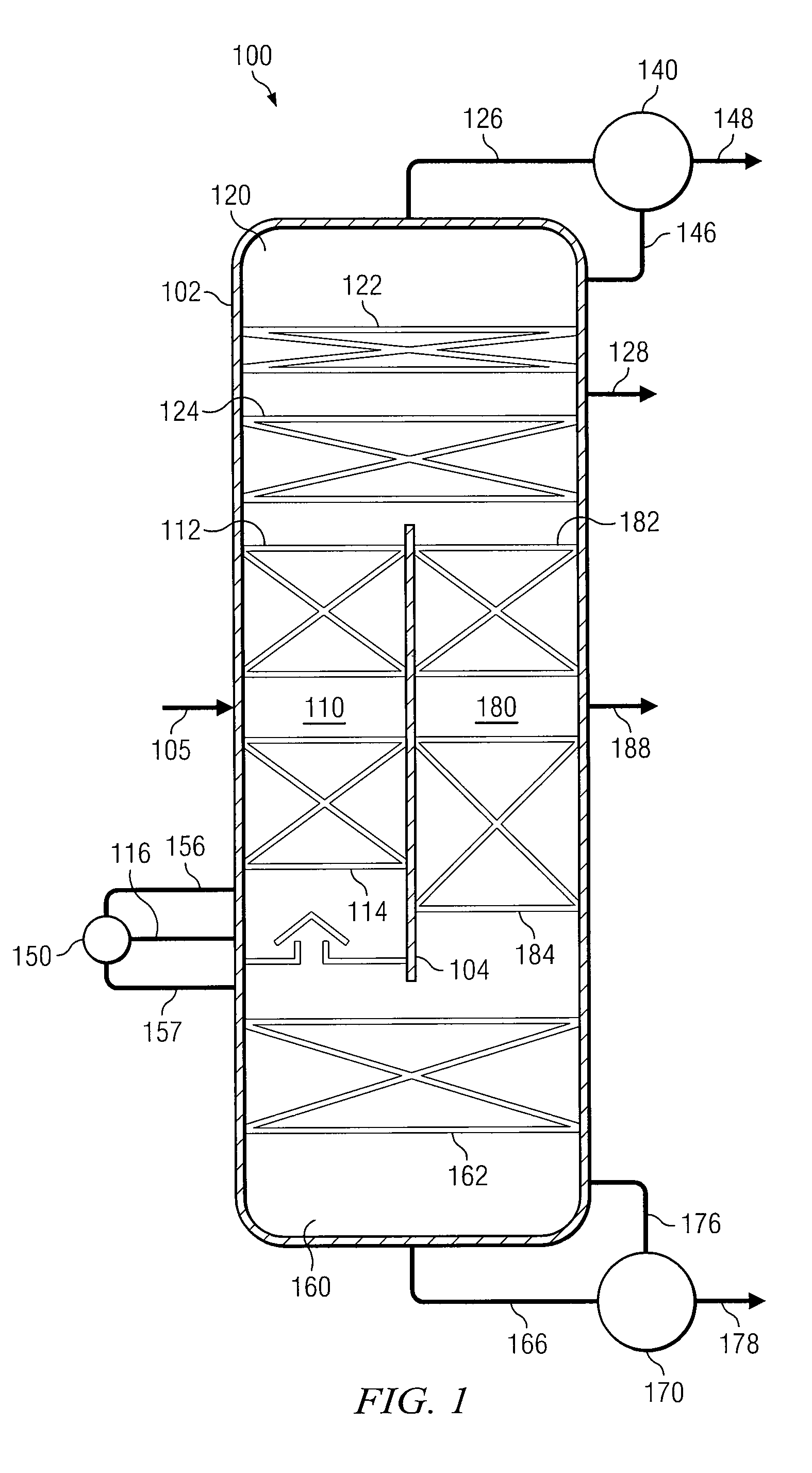

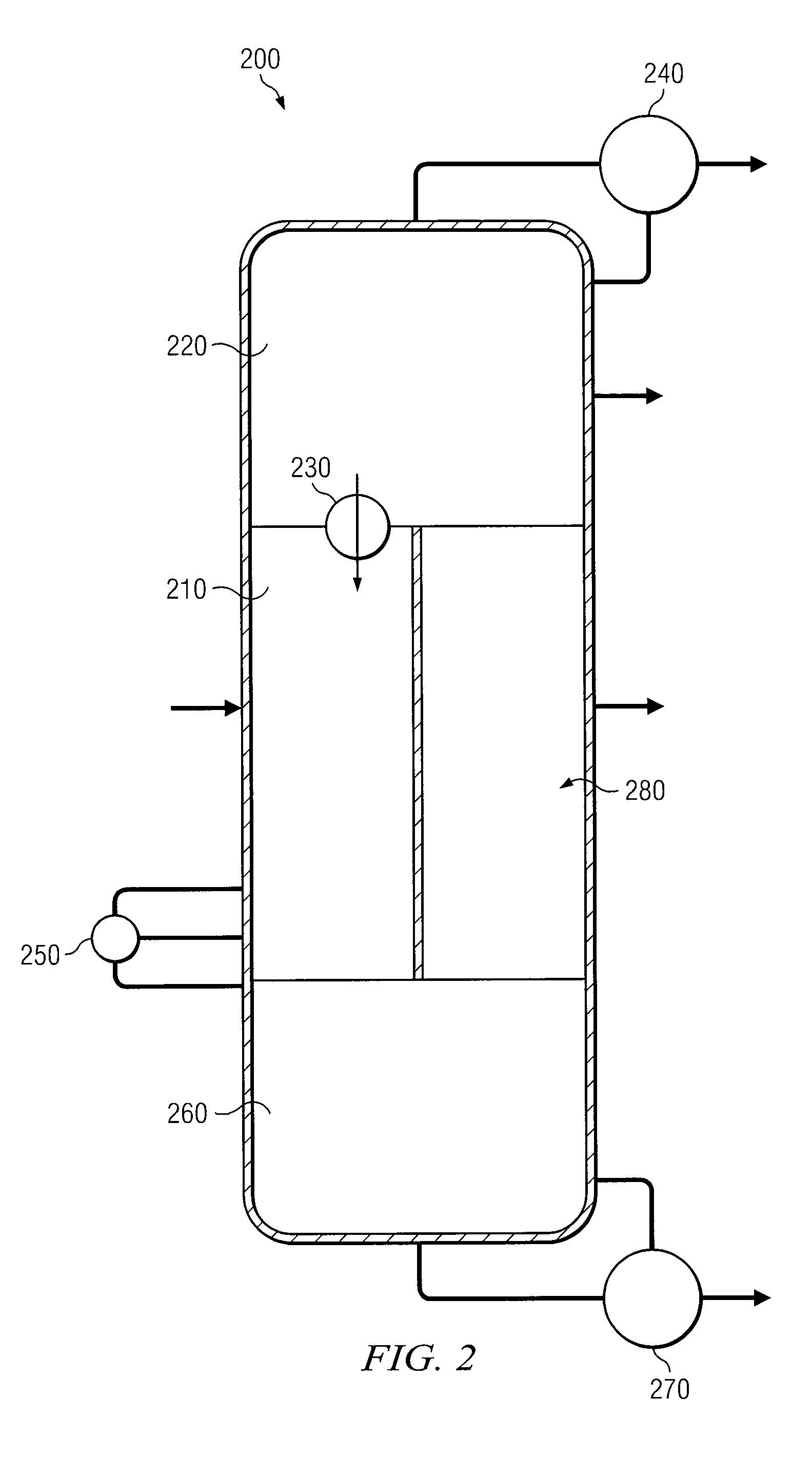

Apparatus, Systems, and Methods for Purification of Isocyanate Mixtures

ActiveUS20110178328A1Minimizing contentOrganic compound preparationIsocyanic acid derivatives purification/separationSolventChemistry

The present disclosure relates, according to some embodiments, to apparatus, systems, and / or methods for fractionating a feed mixture comprising, for example, one or more isocyanates, light components, solvents and / or heavier components. In some embodiments, fractionating an isocyanate feed mixture may comprise distilling the feed mixture in a non-adiabatic fractionating apparatus comprising a prefractionating section and / or column and a main section and / or column, which comprises a rectification section, a side section, and a stripping section. For example, isocyanates may be separated from light component(s), solvent(s) and / or heavier component(s). A fractionating apparatus may be configured and arranged, in some embodiments, as a dividing wall column. According to some embodiments of the disclosure, apparatus, systems, and / or methods may be energy efficient and / or may have a broad operating range.

Owner:THE DOW CHEM CO

Process for the continuous preparation of isocyanates

ActiveUS7547801B2High chemical yieldIncreased space-time yieldOrganic compound preparationIsocyanic acid derivatives purification/separationProcess engineeringPhosgene

Isocyanates are produced by reacting an organic amine with phosgene in process which includes at least three stages. The first stage is carried out in a dynamic mixer. The second stage is carried out in at least one reactor. The third stage is carried out in at least one material separating apparatus. The pressure in the reactor of the second stage must be greater than or equal to the pressure in the dynamic mixer. The pressure in the third stage material separating apparatus must be lower than the pressure in the second stage reactor.

Owner:COVESTRO DEUTSCHLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com