Method for continuously preparing 1,6-hexamethylene diisocyanate

A technology of hexamethylene diisocyanate and hexamethylene diamine, which is applied in the preparation of isocyanic acid derivatives, purification/separation of isocyanic acid derivatives, chemical instruments and methods, etc., and can solve the problem of mixing or back-mixing educts and prolonging the residence time of products , large investment, equipment corrosion and other issues

Inactive Publication Date: 2010-12-29

甘肃银光聚银化工有限公司

View PDF20 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the phosgene method is the main industrial route for preparing HDI, but there are many problems in the production process: because phosgene is a highly toxic gas, if the absorption treatment is not perfect, a large amount of by-product hydrogen chloride will leak in the phosgene method, causing Environmental pollution; and the by-product hydrogen chloride seriously corrodes the equipment in the production process, so the requirements for the material of the equipment are high, and the corresponding investment is large; the HDI product produced by the phosgene method contains hydrolyzed chlorine, which affects the application performance of the product

The disadvantage of many designs is that the pressure drop is too high, or some arrangement does not produce mixing or backmixing rapidly enough in the mixing zone itself or in the reaction chamber. The increase in pressure drop in the mixing element will inevitably require more effort to prepare the gaseous educt. , higher pressure is also associated with higher boiling temperature, which may cause thermal damage to educts and formation of secondary products during evaporation

Inadequate mixing or backmixing can result in a proportion of educts and prolonged residence time of the product, leading to undesired parallel or subsequent reactions

In some cases, another consequence of insufficient mixing is uneven temperature distribution in the reactor

As a result, overheating of certain zones in the reactor may occur, resulting in increased thermal decomposition of the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

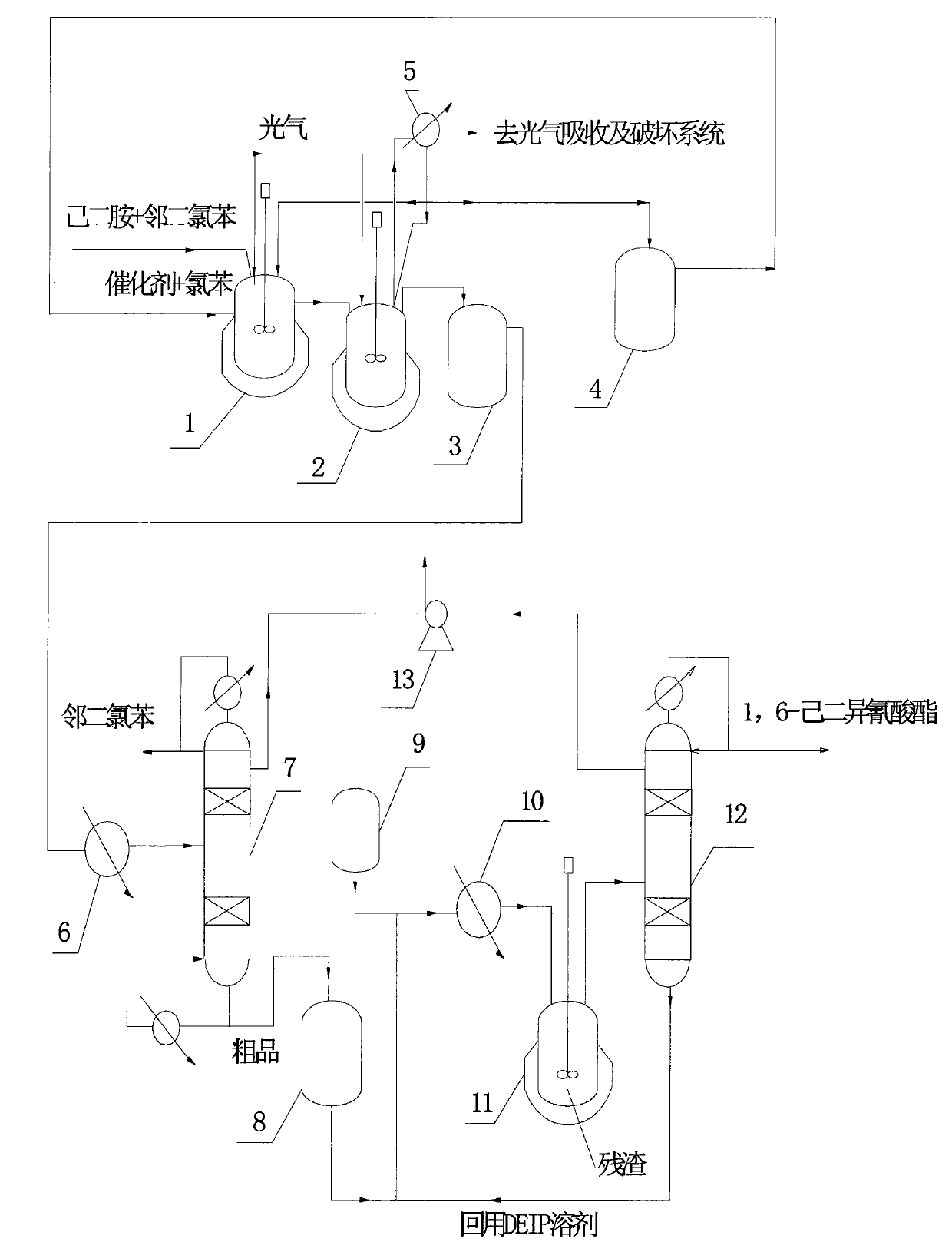

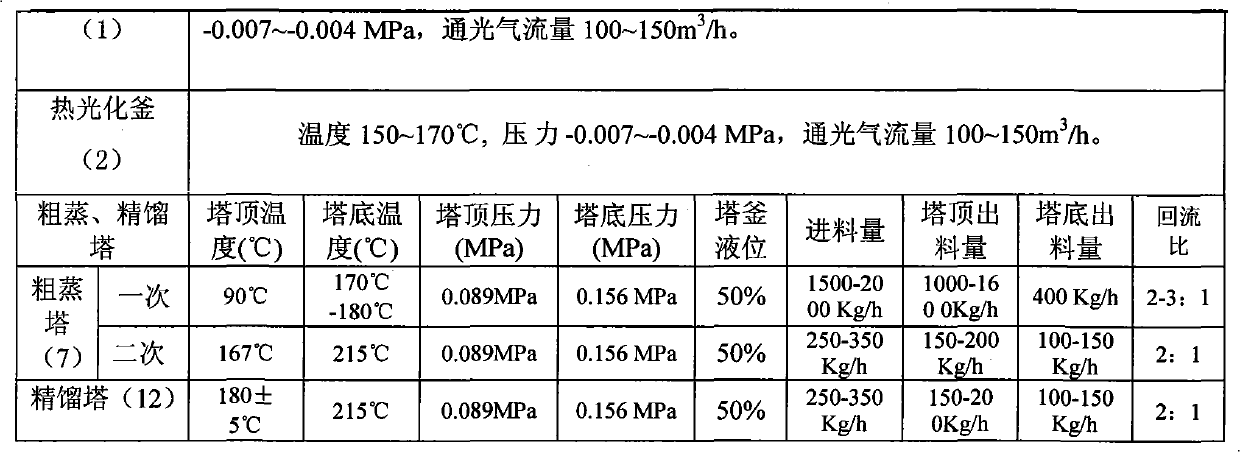

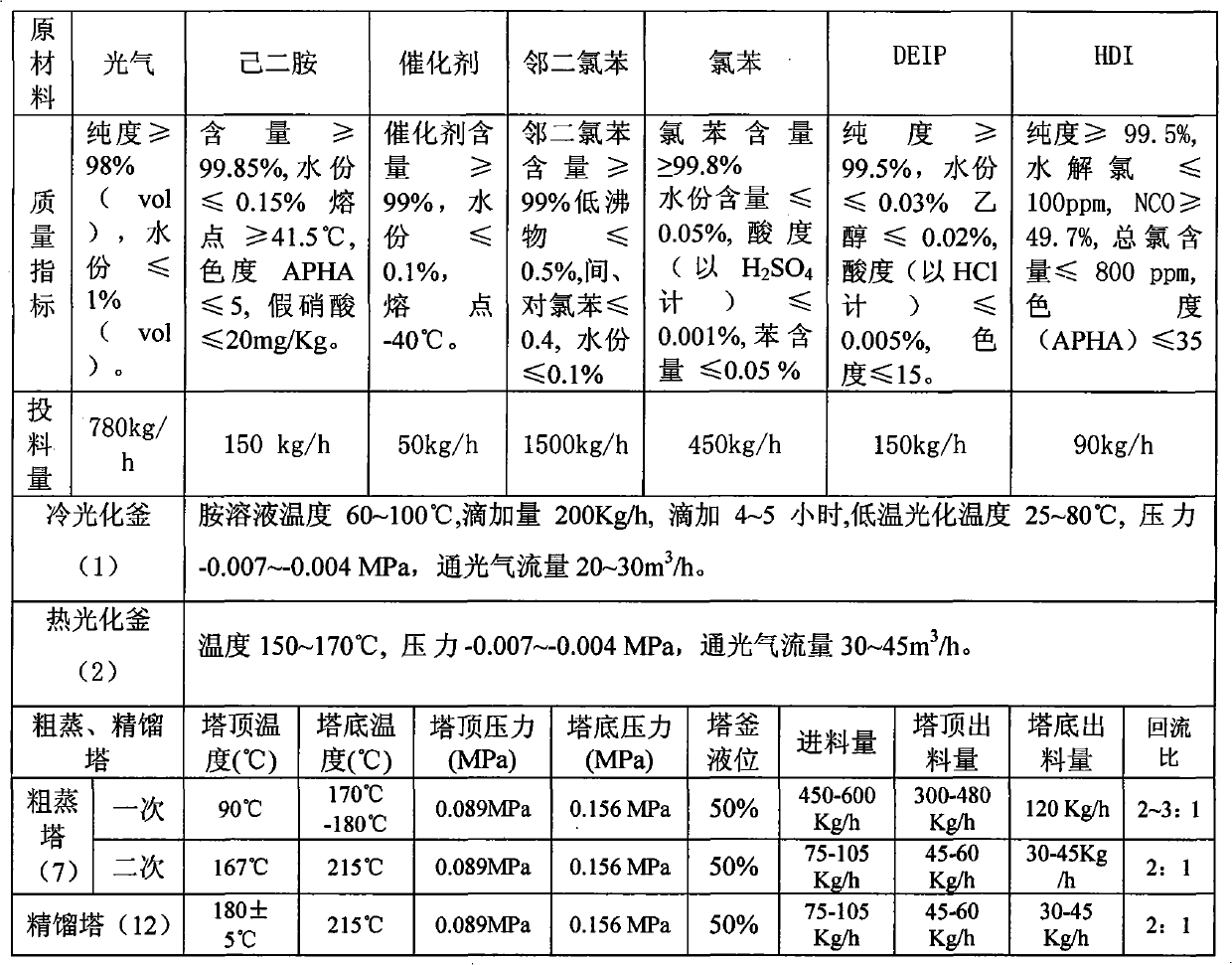

The invention relates to a method for preparing crude 1,6-hexamethylene diisocyanate through the phosgene method and separating pure 1,6-hexamethylene diisocyanate through rectification. The method uses o-dichlorobenzene and chlorobenzene as solvents and comprises the following steps: using hexanediamine and excessive phosgene to perform the two-step reaction of low temperature photochemical reaction and high temperature photochemical reaction under the action of catalyst and generate 1,6-hexamethylene diisocyanate (HDI), removing o-dichlorobenzene through distillation for reuse, continuously distilling to remove by-product chlorinated isocyanate, further mixing with DEIP solvent in a certain ratio through compulsory stirring, heating to perform flash evaporation and rectification, preparing the 1,6-hexamethylene diisocyanate product and DEIP through separation and purification, and regularly discharging the slagged tarry macromolecular compound to perform burning treatment.

Description

technical field The invention relates to a method for continuously preparing 1,6-hexamethylene diisocyanate, in particular to a method for preparing crude 1,6-hexamethylene diisocyanate by phosgene method and separating it into pure 1,6-hexamethylene diisocyanate by rectification. In this method, o-dichlorobenzene and chlorobenzene are used as solvents, and under the action of a catalyst, hexamethylenediamine (hexamethylenediamine, HDA) carries out a two-step reaction of low-temperature photochemical reaction and high-temperature photochemical reaction with excess phosgene, Thermal cracking reaction occurs simultaneously in the high-temperature photochemical section, and the intermediate product 1,6-hexamethylene dicarbamoyl chloride is further decomposed to generate 1,6-hexamethylene diisocyanate (1,6-hexamethylene diisocyanate, HDI), from the reaction The catalyst and chlorobenzene are evaporated from the liquid and reused, and the residual phosgene and by-product hydrogen ch...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C265/14C07C263/10C07C263/20

Inventor 赵伟华白卫兵陶春霞蒙鸿飞

Owner 甘肃银光聚银化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com