Method for recovering heat integrated solvent in continuous production of toluene di-isocyanate

A technology of toluene diisocyanate and recovery method, which is applied in the direction of purification/separation of isocyanic acid derivatives, climate sustainability, sustainable manufacturing/processing, etc., can solve the problem of a large amount of materials to be processed, reduce heat consumption, reduce Production cost and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

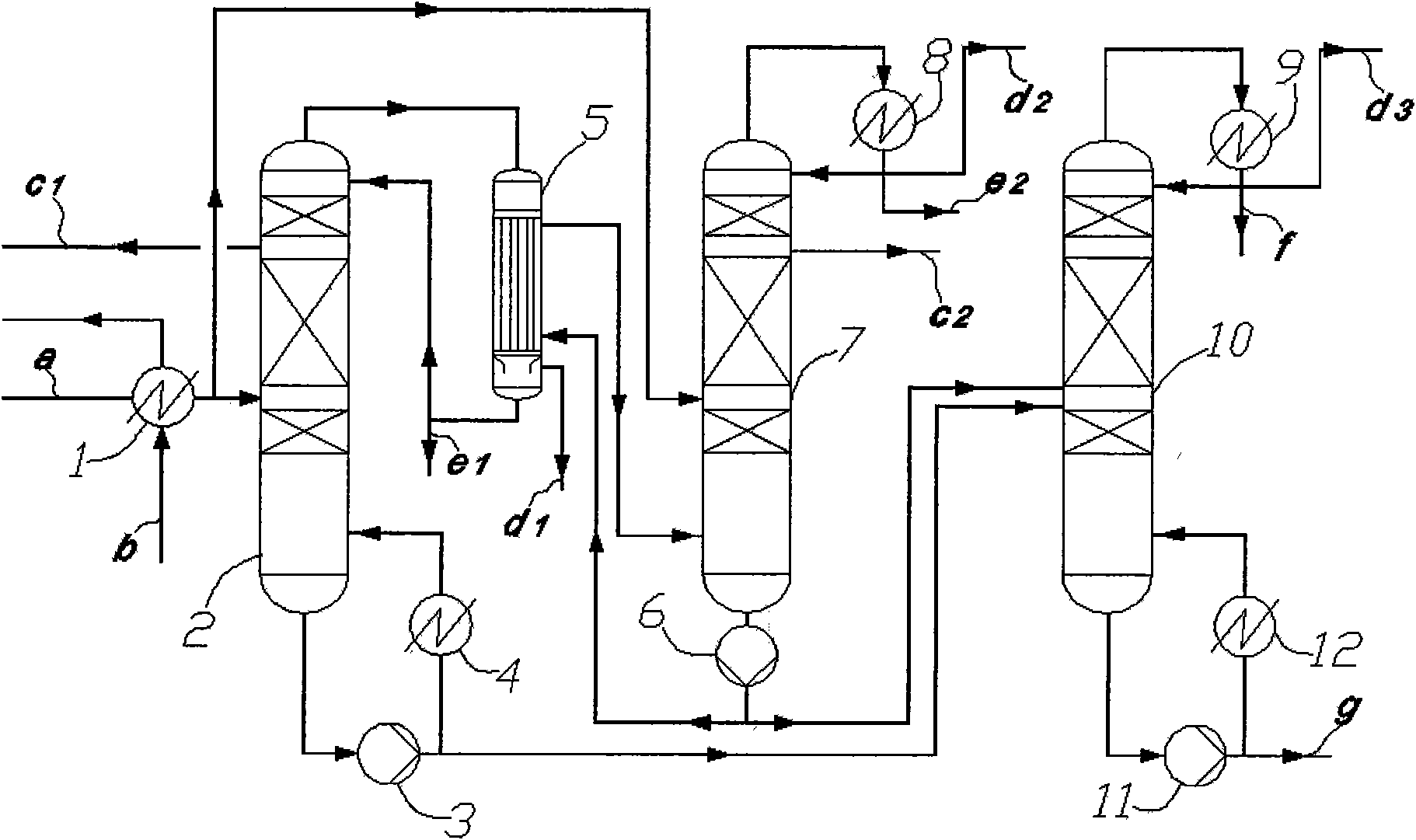

Method used

Image

Examples

Embodiment 1

[0052] Recovery method of solvent o-dichlorobenzene in the continuous production of toluene diisocyanate without heat integration:

[0053] The material to be distilled that comprises toluene diisocyanate and inert organic solvent comes from hydrogen chloride stripping section, and flow rate is 96100kg / hr, 180 ℃ of temperature, absolute pressure 380kPa, and wherein o-dichlorobenzene (ODCB) mass content is 91.6%, toluene diisocyanate ( TDI) mass content is 7.8%, also has a small amount of phosgene, carbon tetrachloride and tar in addition. The material to be distilled passes through a two-stage solvent removal tower to remove the solvent. The first solvent removal tower is a packed tower with a theoretical plate number of 30. It is operated at an absolute pressure of 18kPa at the top of the tower. The side line extracts pure ODCB at 76400kg / hr, wherein the TDI content is less than 27ppb (mass fraction), and the phosgene content is less than 2ppm (mass fraction). The steam at th...

Embodiment 2

[0057] Embodiment 2 is a heat-integrated solvent recovery method in the continuous production of toluene diisocyanate.

[0058] The material to be distilled comprising toluene diisocyanate and an inert organic solvent is the same as in Example 1.

[0059] The material to be distilled comprising toluene diisocyanate and an inert organic solvent is exchanged with the crude product at the outlet of the phosgenation reactor with a flow rate of 151906kg / hr, and the temperature of the material to be distilled after the heat exchange is reduced to 120°C. The ratio of % will divide the material to be distilled after the heat exchange into two parts, and distill as the feedstock of the first solvent removal tower (solvent is o-dichlorobenzene (ODCB)) and the second solvent removal tower respectively, and the first solvent removal tower The removal tower is a packed tower with a theoretical plate number of 30, operated at an absolute pressure of 21kPa at the top of the tower, and the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com