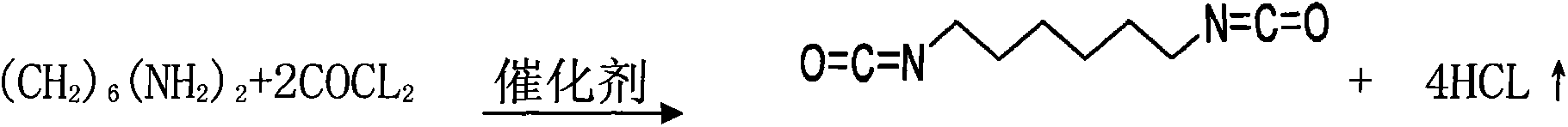

Device for refining hexamethylene diisocyanate and method thereof

A technology of hexamethylene diisocyanate and rectifying tower is applied in the field of production equipment for refining hexamethylene diisocyanate, and can solve the problems of reduced yield, HDI polymerization, inoperability of distillation tower and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

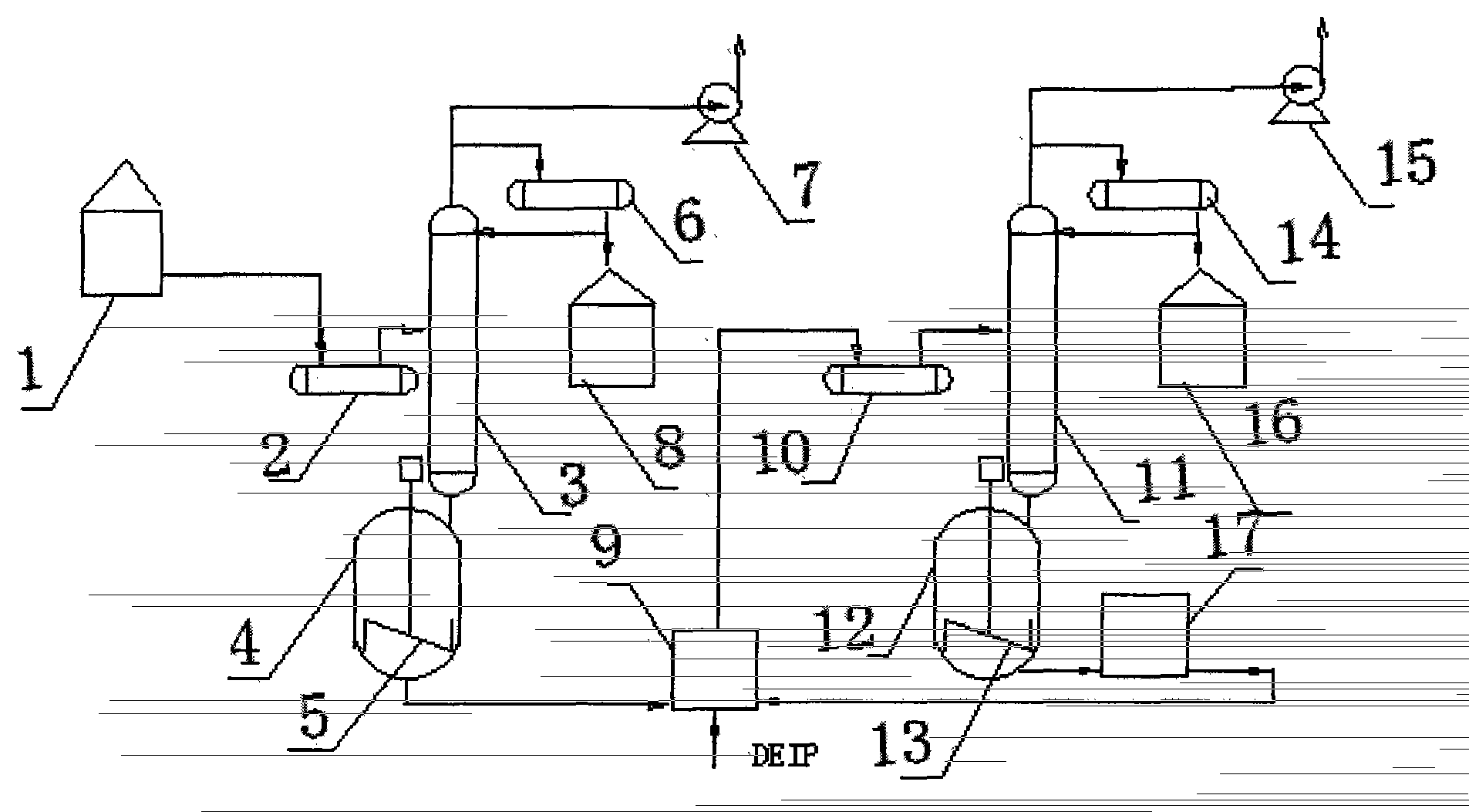

Method used

Image

Examples

Embodiment 1

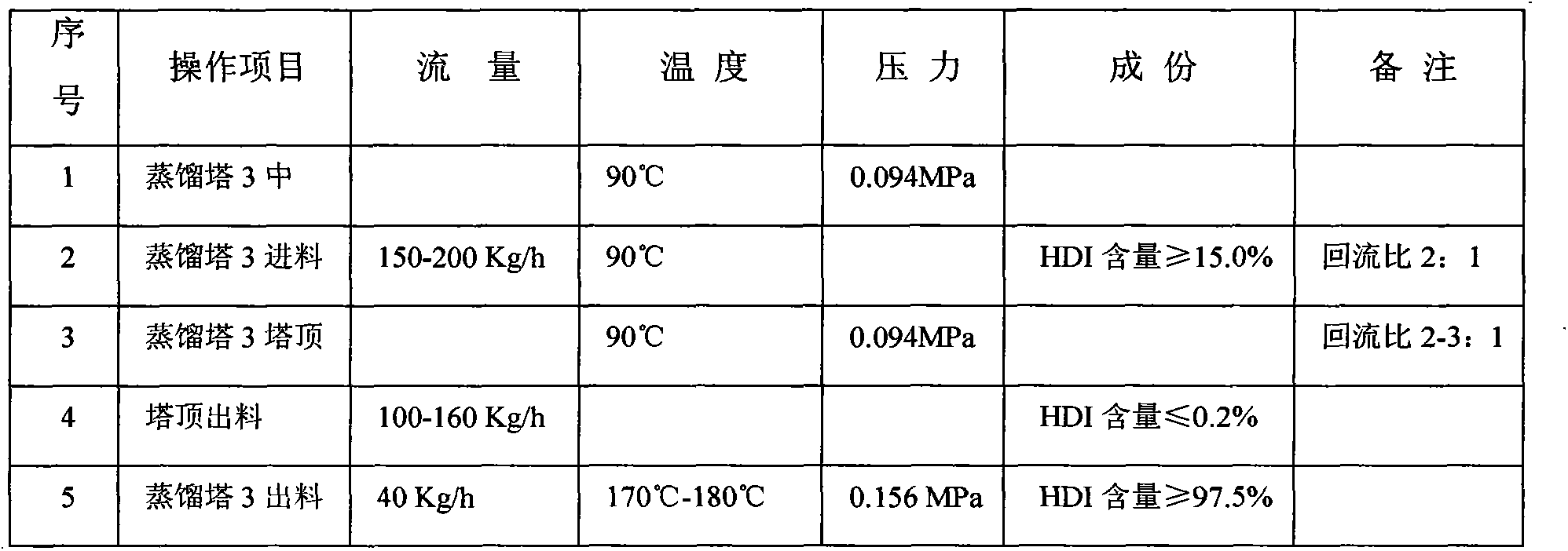

[0020] Embodiment 1: process condition control is as follows table:

[0021]

[0022] Distillation steps

[0023] a Turn on the heat conduction oil furnace through the on-site control cabinet to make the temperature reach 205°C, and make a record.

[0024] b Close the valves on the top of the tower and the extraction pipeline of the tower kettle.

[0025] c. Open the feed valve of the first preheater 2. When the temperature reaches 90° C. and the jacket oil temperature of the distillation column (3) is higher than 95° C. and rises linearly, open the feed valve of the top of the tower and the automatic control of the tower.

[0026] d Open the circulating water valve of the first condenser 6 at the top of the tower.

[0027] e Start the first vacuum pump 7, control the vacuum degree to be 0.094Mpa, and make a record.

[0028] f Open the heat transfer oil flow regulating valve in the 3rd kettle of the distillation tower, start the heat transfer oil furnace oil pump, and co...

Embodiment 2

[0045] Embodiment 2: process condition control is as follows table:

[0046]

[0047] Operational steps according to the above conditions include:

[0048] a) Open the outlet valve of the crude product tank 1, open the feed valve of the first preheater 2, and start feeding when the temperature reaches 160-170°C, and the crude 1,6-hexamethylene diisocyanate solution enters the middle part of the distillation tower 3, the tower still 4 After the temperature is higher than 195°C, open the first condenser 6, start the first vacuum pump 7, and control the vacuum degree to 0.070-0.089Mpa; start to control the full reflux operation of the distillation tower 3 for half an hour, when the temperature at the top of the tower reaches the temperature required by the process, Sampling and analysis, when it meets the process requirements, start to slowly adjust to the specified reflux flow, sampling and analysis at the top of the tower, when the HDI content contained in the o-dichlorobenz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com