Light color modified isocyanate mixture and preparation method thereof

一种异氰酸酯、混合物的技术,应用在浅色改性异氰酸酯混合物及其制备领域,达到色号降低明显、粘度变化小、稳定性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

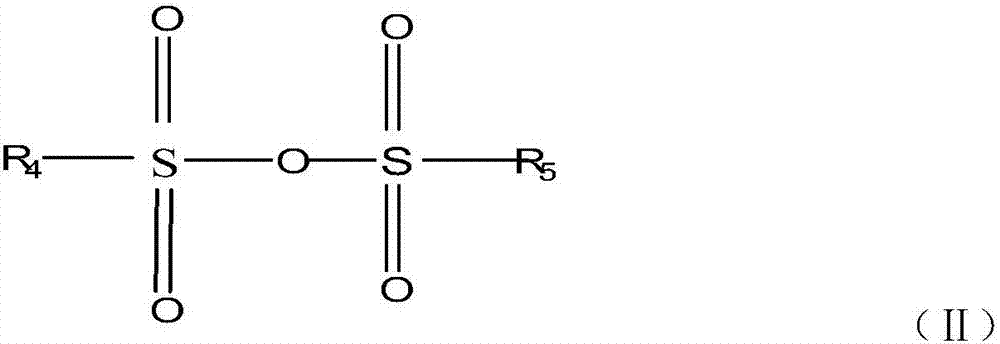

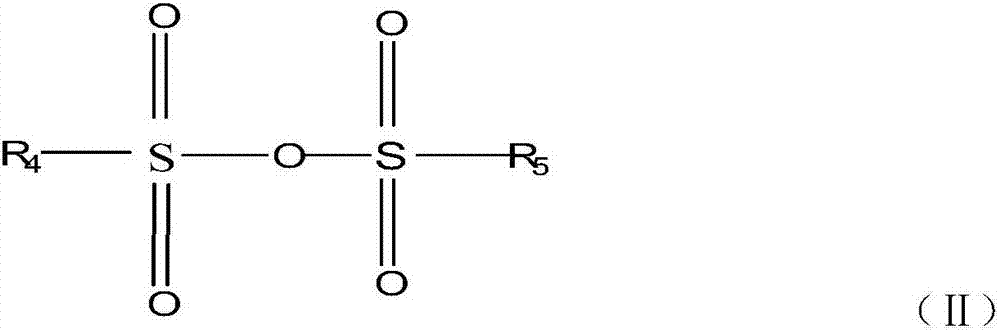

Method used

Image

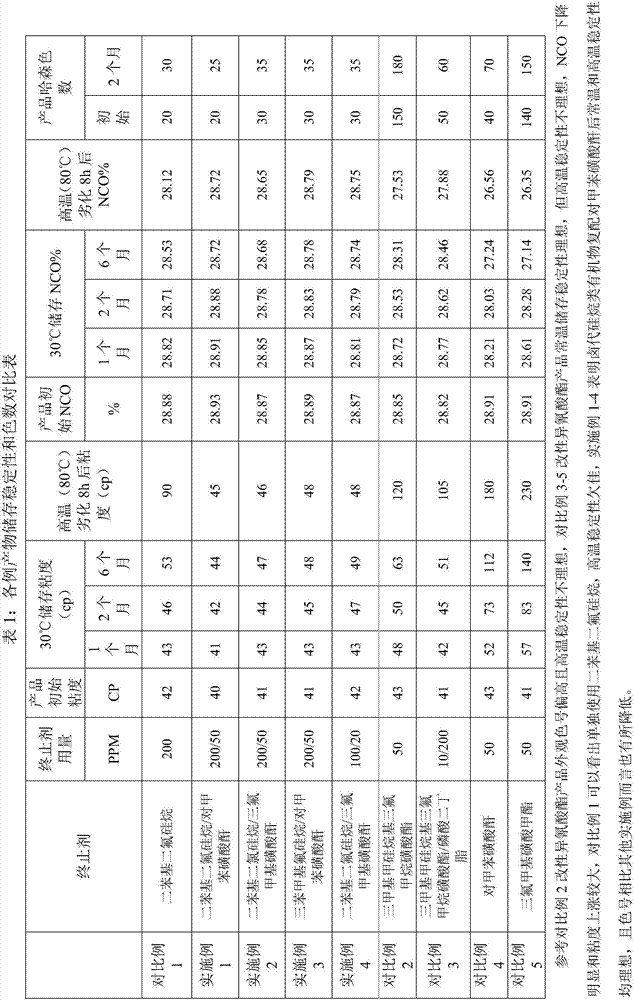

Examples

Embodiment 1

[0045] 500g diphenylmethane diisocyanate in N 2 Heat to about 50°C while stirring under protection, add 0.5ppm of 1-phenyl-3-methyl-3-phospholene high-efficiency catalyst, mix and quickly heat to 200°C, react for 90 minutes and reverse diphenyl After 200g of methane diisocyanate, add 200ppm of terminator diphenyldifluorosilane and 50ppm of terminator p-toluenesulfonic anhydride, rapidly cool the temperature down to 60°C, stir the mixture for 30 minutes, and then reverse 200g of diphenylmethane diisocyanate for the second time , followed by stirring at 70-80° C. for 120 minutes to obtain the final product.

Embodiment 2

[0047] 500g diphenylmethane diisocyanate in N 2 Heat to about 50°C while stirring under protection, add 0.5ppm of 1-phenyl-3-methyl-3-phospholene high-efficiency catalyst, mix and quickly heat to 200°C, react for 90 minutes and reverse diphenyl After 200g of methane diisocyanate, add 200ppm terminator diphenyl dichlorosilane and 50ppm terminator trifluoromethanesulfonic anhydride, quench the temperature down to 60°C, then stir the mixture for 30min, and then reverse 200g diphenylmethane for the second time diisocyanate, and then stirred at 70-80° C. for 120 minutes to obtain the final product.

Embodiment 3

[0049] 500g diphenylmethane diisocyanate in N 2 Heat to about 50°C while stirring under protection, add 1ppm of 1-methyl-3-methyl-3-phospholene-1-oxide high-efficiency catalyst, mix and quickly heat to 120°C, react after 200min After adding 200g of diphenylmethane diisocyanate, add 200ppm of terminator trityl fluorosilane and 50ppm of terminator p-toluenesulfonic anhydride, rapidly cool the temperature down to 60°C, stir the mixture for 30 minutes, and then reverse 200g of diphenyl methyl methane diisocyanate, and then stirred at 70-80°C for 120 minutes to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com