A low-residue, high-storage-stability solder paste for low-temperature aluminum and its preparation method

A technology with storage stability and low residue, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of severe corrosion, complex process, and the storage stability of solder paste cannot be well solved, and achieves low corrosiveness. , Less residue after welding, good storage stability at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

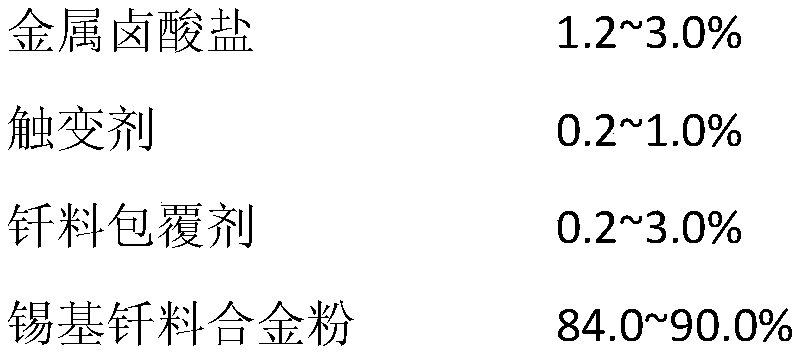

[0037] A solder paste for low-temperature aluminum with low residue and high storage stability, in terms of mass percentage, the composition of each raw material in the solder paste is as follows:

[0038]

[0039]

[0040] The preparation method is as follows:

[0041] 1) Weigh 80.0g triethanolamine, 4.0g zinc sulfate, 1.0g zinc oxide, 2.0g ferrous sulfate, 1.0g stannous oxide, 7.5g ethylene glycol phenyl ether and 5.0g propylene glycol phenyl ether into the reaction kettle, heat To 150°C, dissolve it completely into a uniform transparent solution, then cool the solution to 90°C, add 2.0g of 6500 thixotropic agent and 24.0g of zinc fluoride for homogeneous emulsification, then cool to room temperature and stand for 48h to obtain solder paste;

[0042] 2) Weigh 2.0g of PVPK15, 7.5g of ethylene glycol phenyl ether and 5.0g of propylene glycol phenyl ether into a stainless steel container and stir to completely dissolve PVPK15, then add 859.0g of Sn0.3Ag0.7Cu (Sn content is...

Embodiment 2

[0045] A low-temperature aluminum solder paste with low residue and high storage stability. The components in the solder paste are as follows according to mass percentage:

[0046]

[0047]

[0048] The preparation method is as follows:

[0049] 1) Weigh 30.0g of tetrahydroxypropylethylenediamine, 10.0g of hydroxyethylethylenediamine, 4.0g of zinc oxide, 20.0g of ethylene glycol phenyl ether and 10.0g of propylene glycol phenyl ether into the reaction kettle, and heat to 160°C , to make it all dissolve into a homogeneous transparent solution, then cool the solution to 70°C, add 5.0g of ethylene bisoleic acid amide, 10.0g of lithium fluoride and 2.0g of stannous bromide for homogeneous emulsification, and then cool to room temperature And after standing for 72 hours, the solder paste is obtained;

[0050] 2) Weigh 20.0g of PVPK30, 10.0g of PVPK60, 20.0g of ethylene glycol phenyl ether and 10.0g of propylene glycol phenyl ether into a stainless steel container and stir to...

Embodiment 3

[0053] A low-temperature aluminum solder paste with low residue and high storage stability. The components in the solder paste are as follows according to mass percentage:

[0054]

[0055] The preparation method is as follows:

[0056] 1) Weigh 100.0g dihydroxyethylethylenediamine, 3.0g ferrous sulfate, 3.0g ferrous oxide, 4.0g stannous oxide and 10.0g ethylene glycol phenyl ether into the reaction kettle, heat to 180 °C, make All of them were dissolved into a homogeneous transparent solution, then the solution was cooled to 60°C, 10.0g of calcium-based bentonite, 15.0g of stannous chloride and 15.0g of stannous fluoride were added for homogeneous emulsification, and then cooled to room temperature and allowed to stand for 72 hours After obtaining the solder paste;

[0057] 2) Weigh 10.0g of PVPK15, 5.0g of PVPK90, 10.0g of ethylene glycol phenyl ether into a stainless steel container and stir to completely dissolve PVPK15 and PVPK90, then add 815.0g of Sn9Zn (the content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com